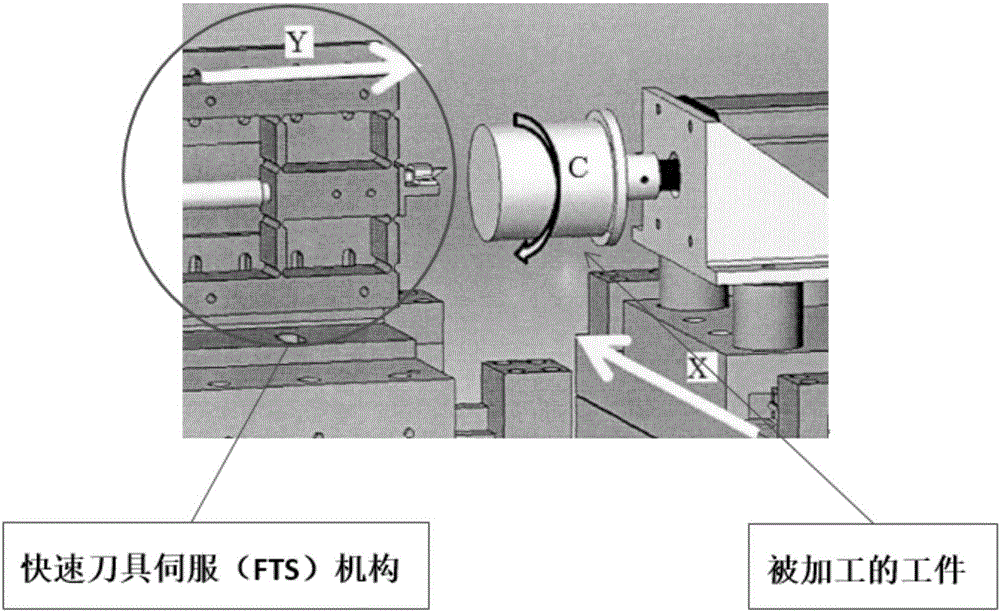

Parallel-connection translational three-dimensional rapid servo device of numerical control ultraprecision processing machine tool

A technology of ultra-precision machining and cutting tools, which is applied to metal processing machinery parts, feeding devices, manufacturing tools, etc. It can solve the problems of high processing cost, low processing efficiency, and difficulty in ensuring absolute rigidity, and achieve the effect of enhancing machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

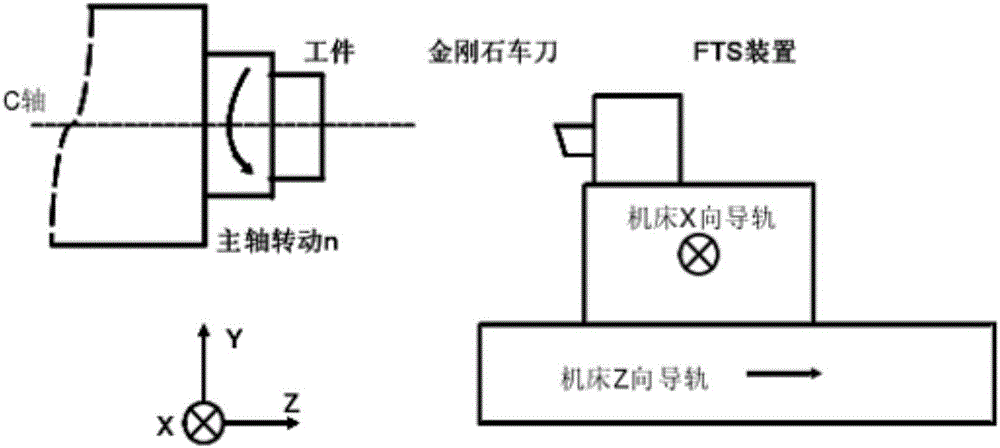

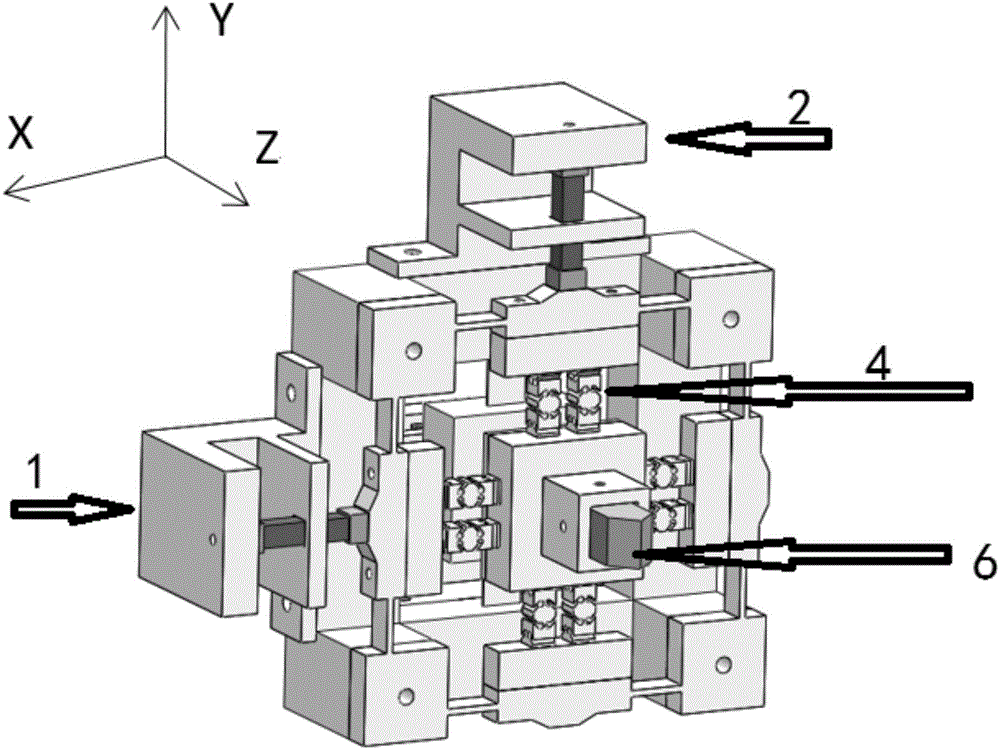

[0040] The embodiment of the present invention provides a parallel translational three-dimensional fast tool servo device for a numerically controlled ultra-precision processing machine tool, which is used to solve the high processing cost and low processing efficiency of the traditional FTS device, and cannot realize the displacement error compensation of multiple degrees of freedom, and it is difficult to ensure other Technical problem of absolute stiffness in direction.

[0041] In order to make the objectives, features, and advantages of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the following The described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com