Patents

Literature

31 results about "Rotational error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This ‘rotation error’ check is usually done in one of two ways: – by checking the element outlet pressure. – with phase sequency relay. If no pressure is built up after a few seconds of rotation, it means something is wrong, most probably, the element is rotating the wrong way. If your compressor uses this system,...

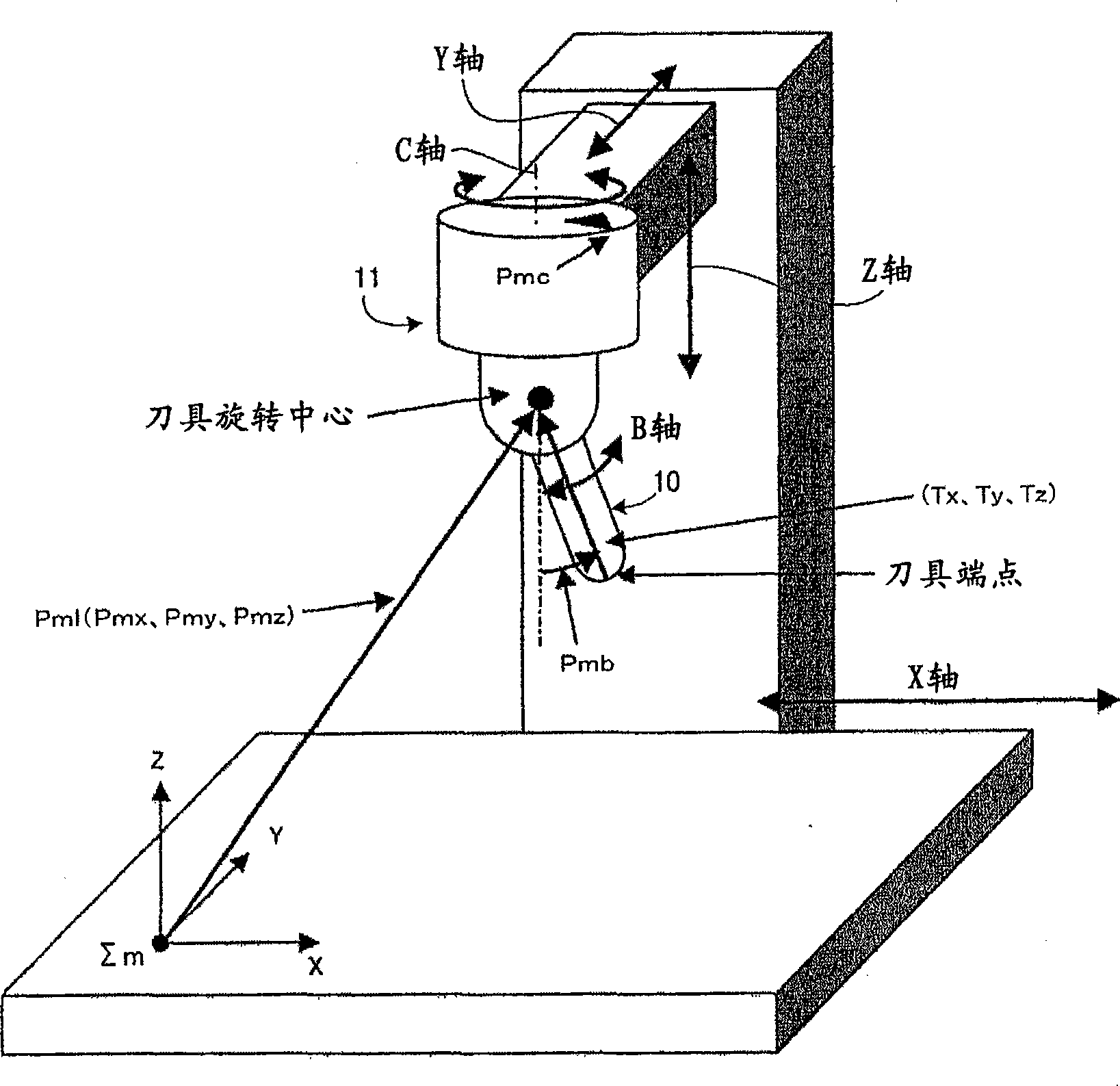

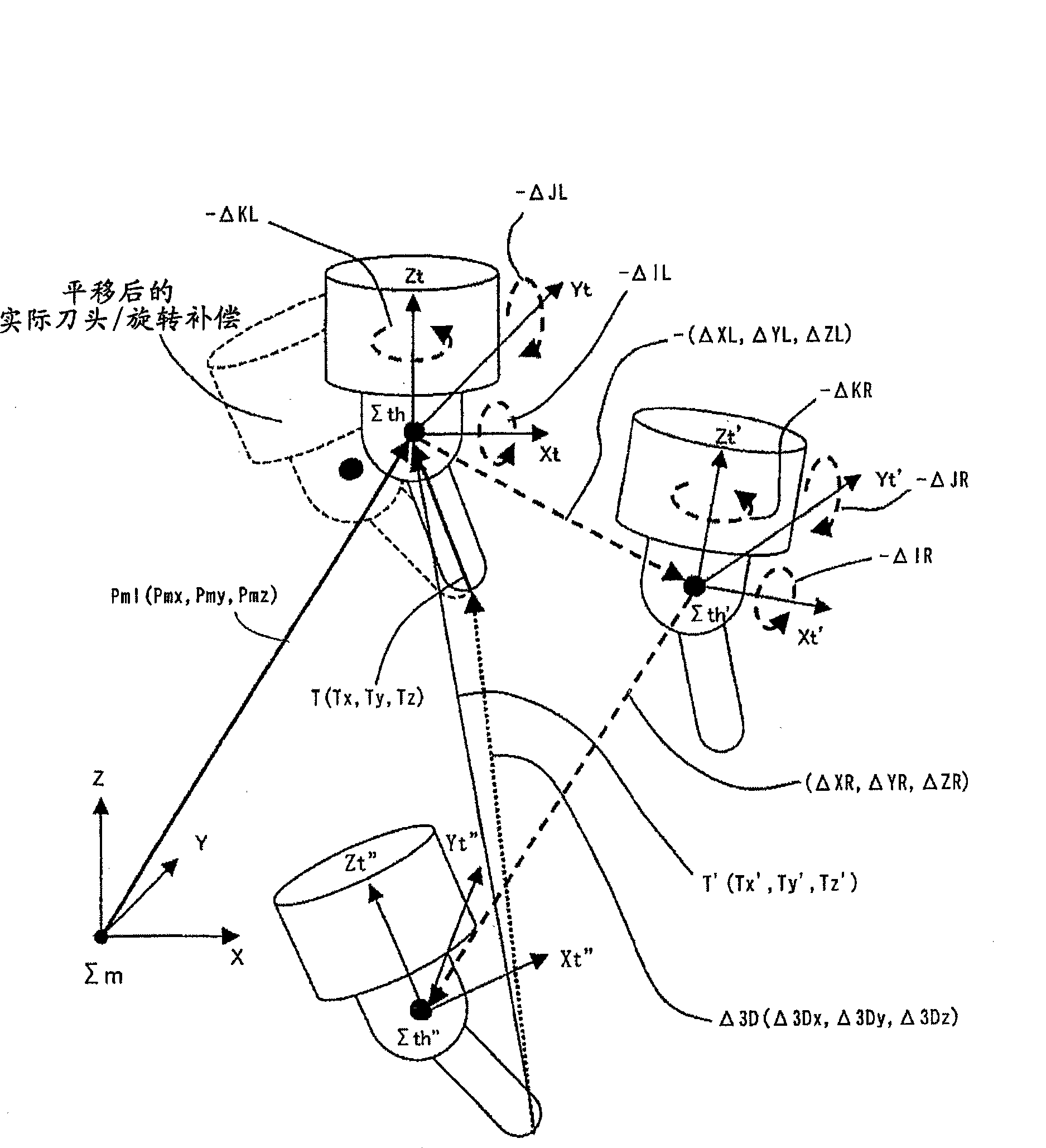

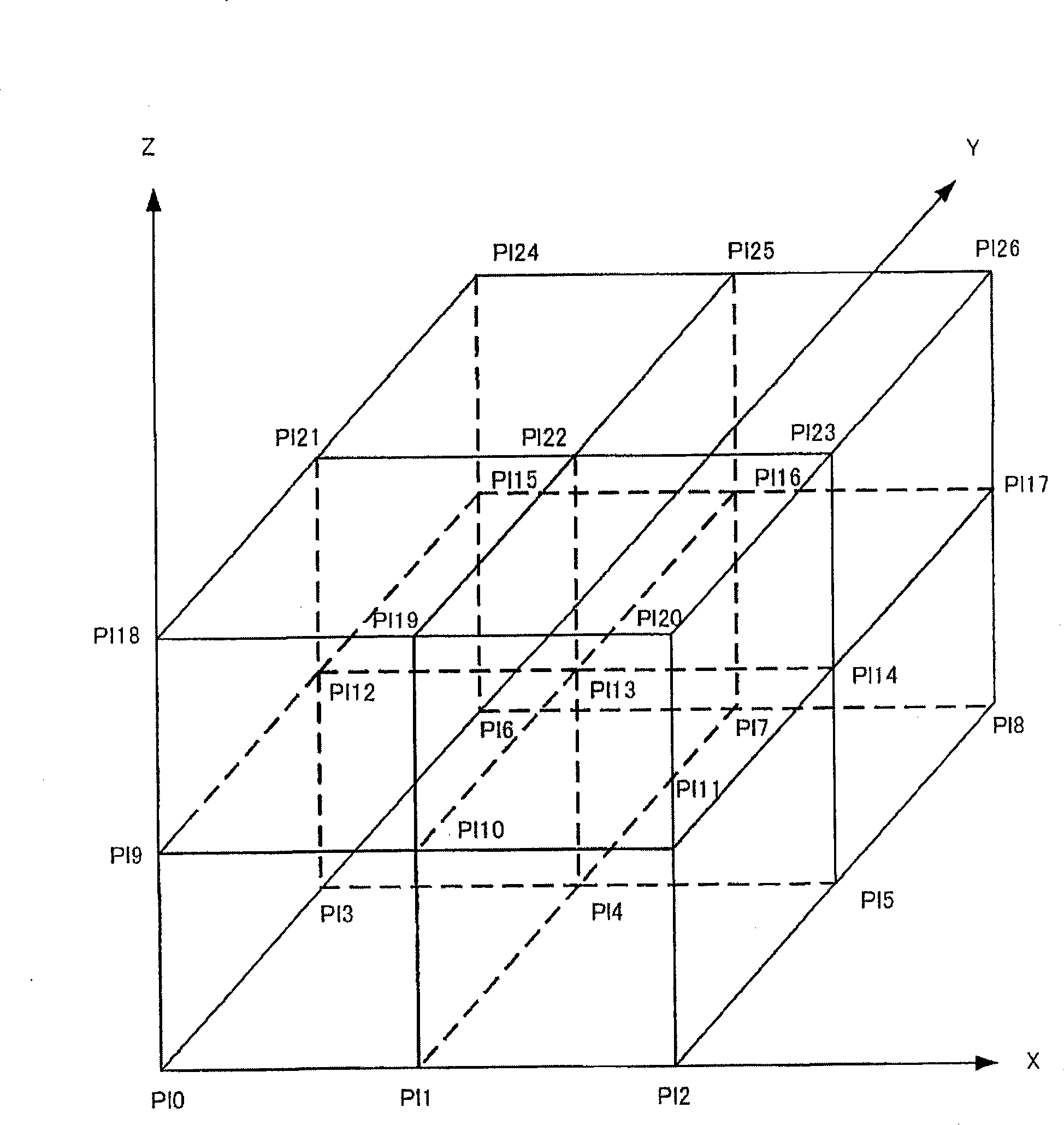

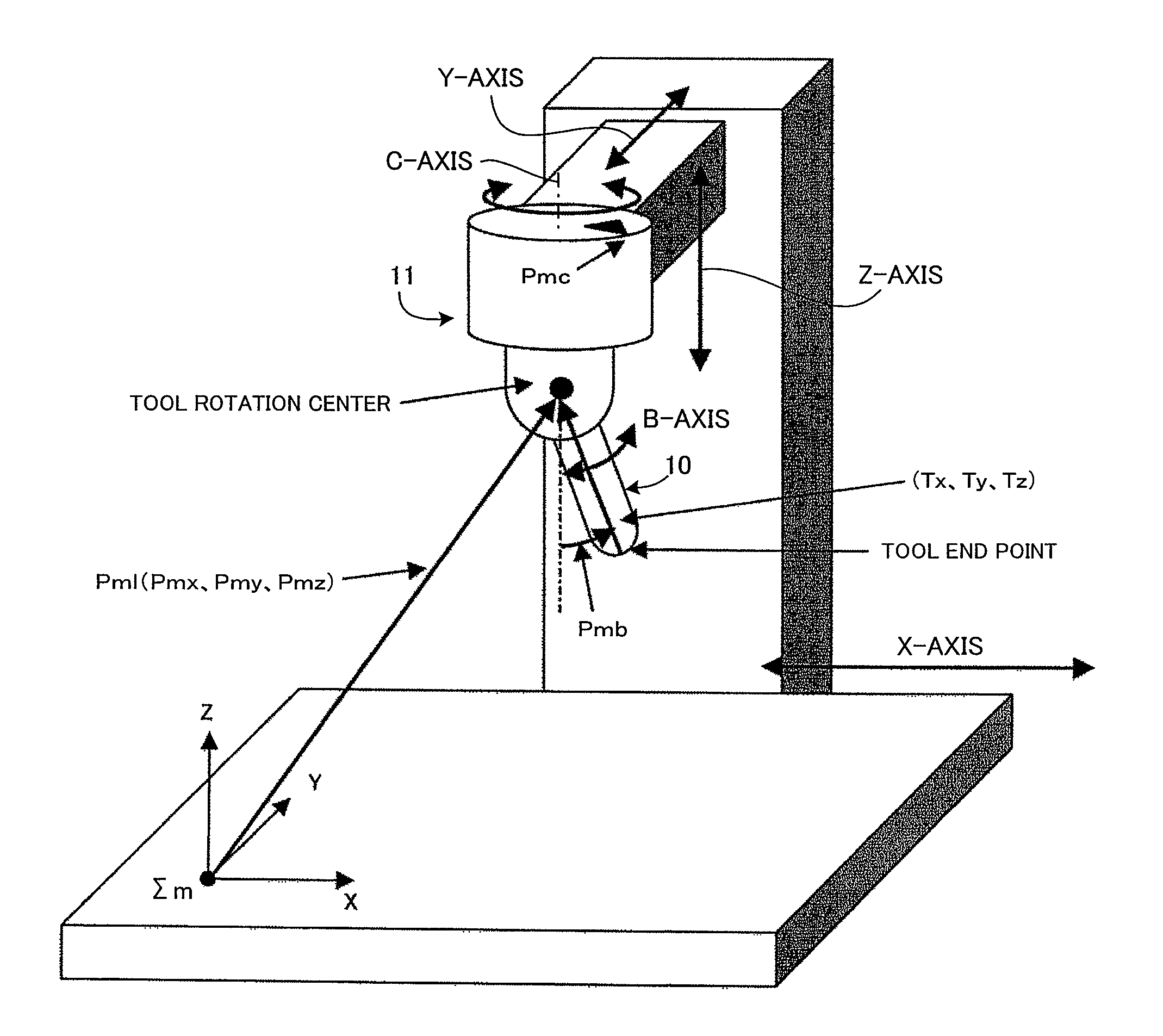

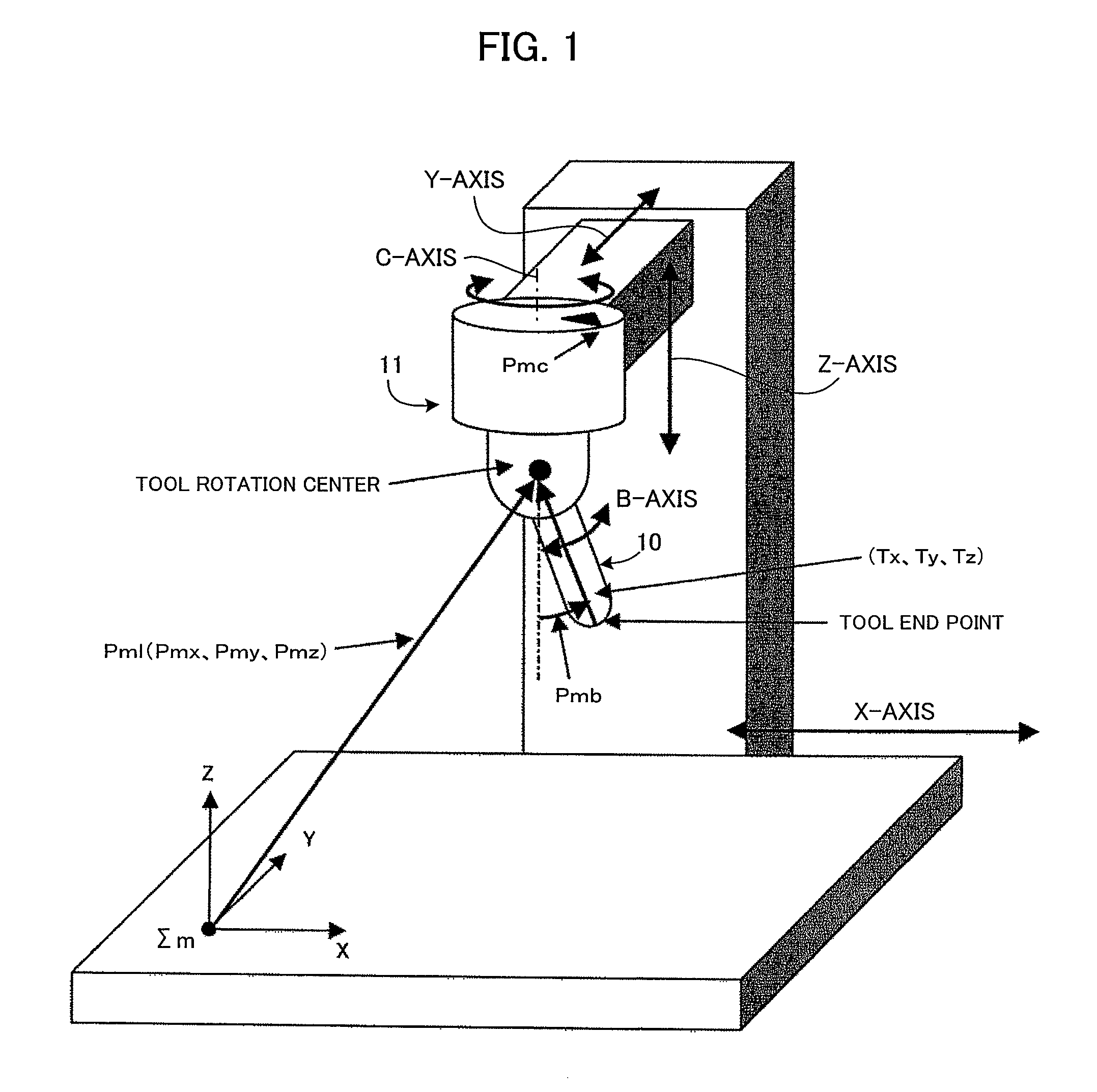

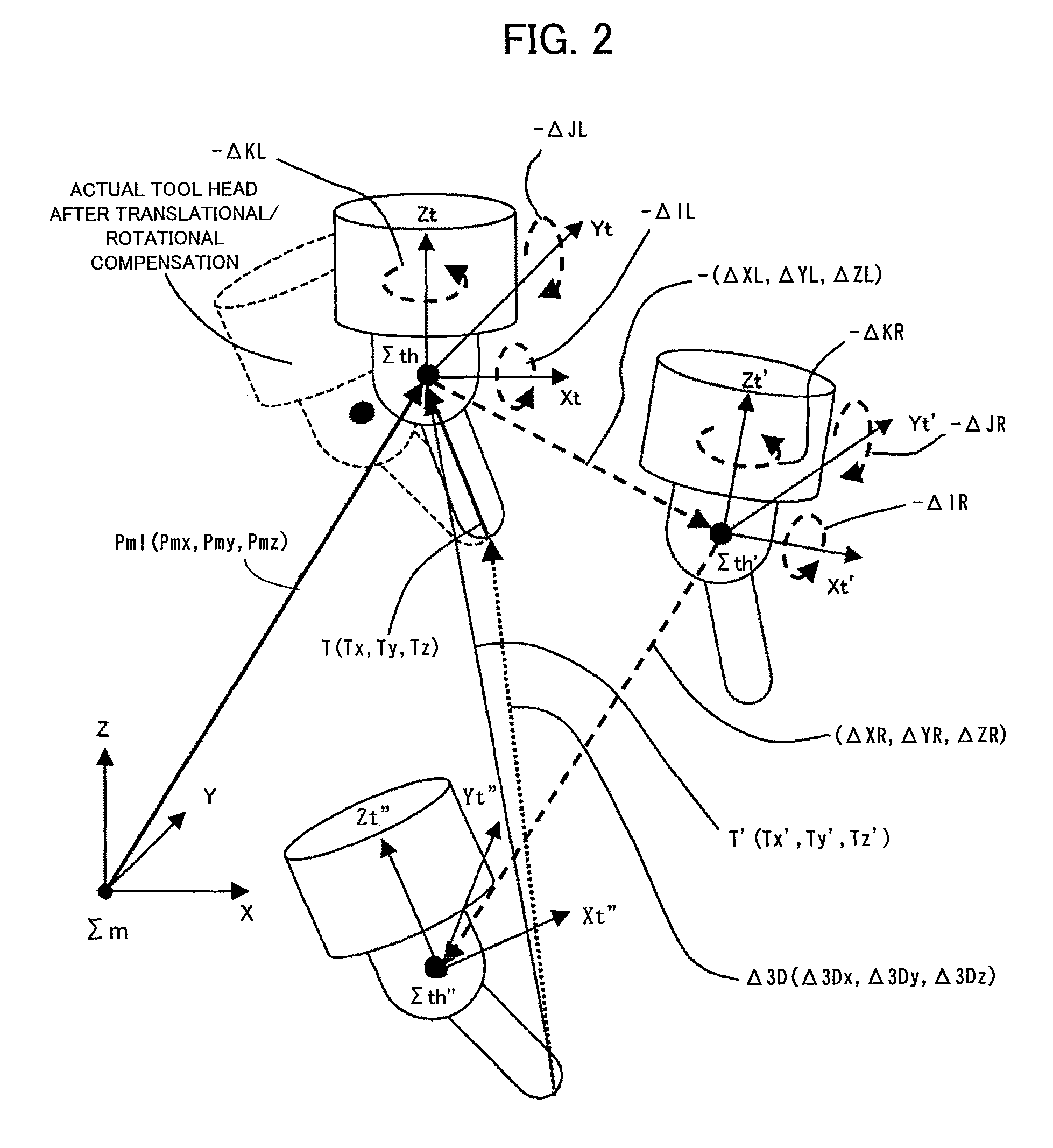

Numerical controller for controlling a five-axis machining apparatus

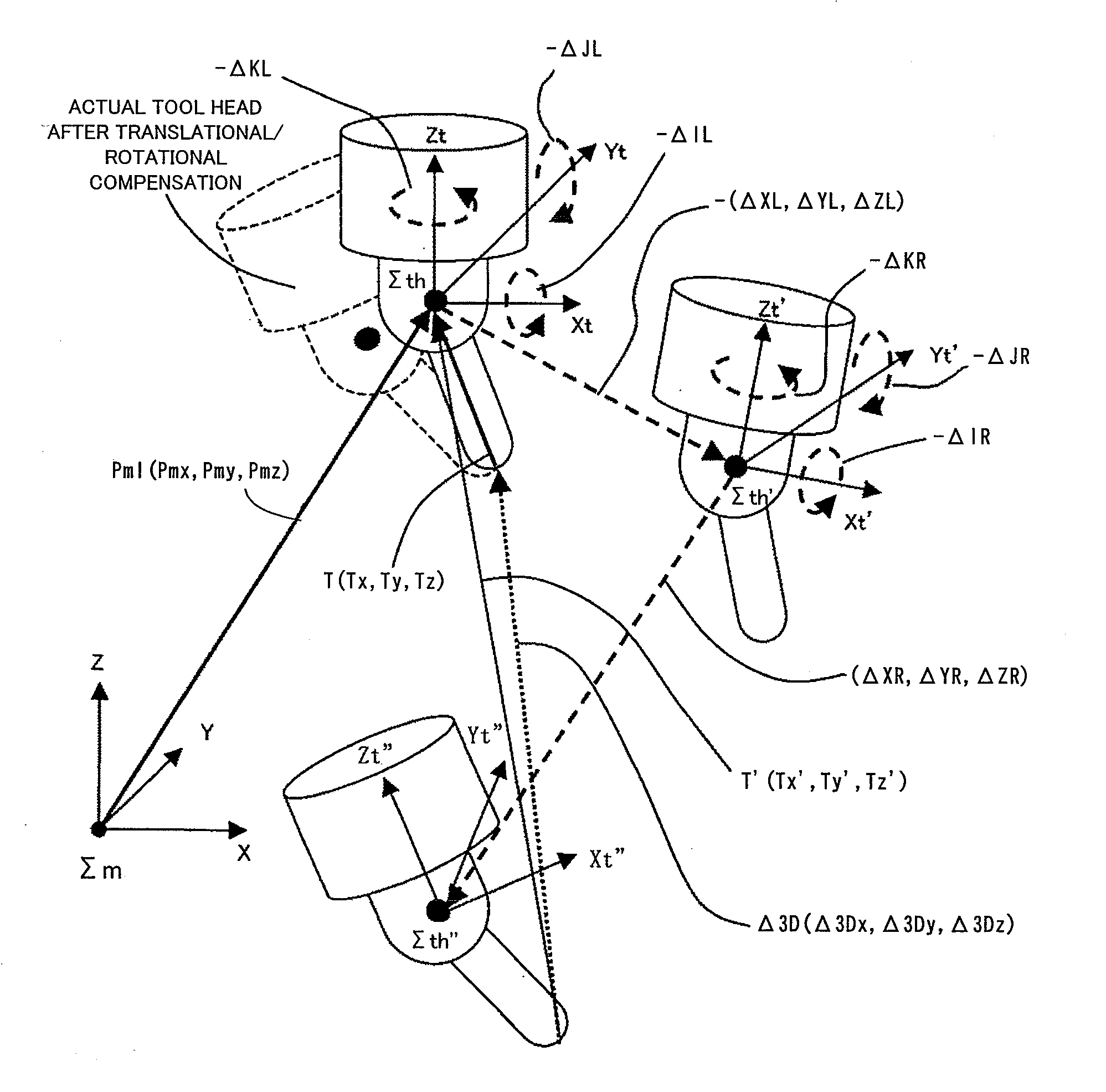

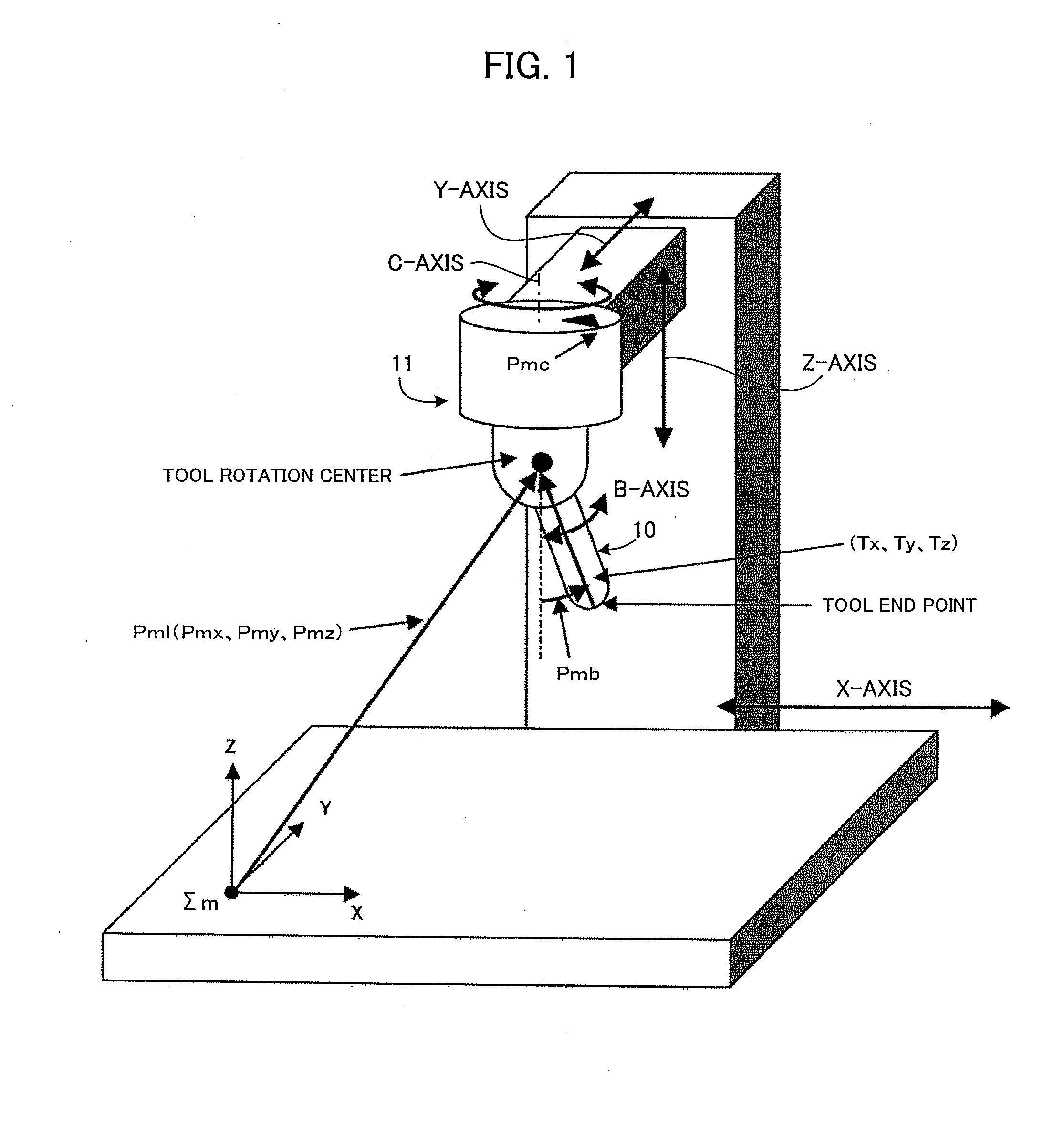

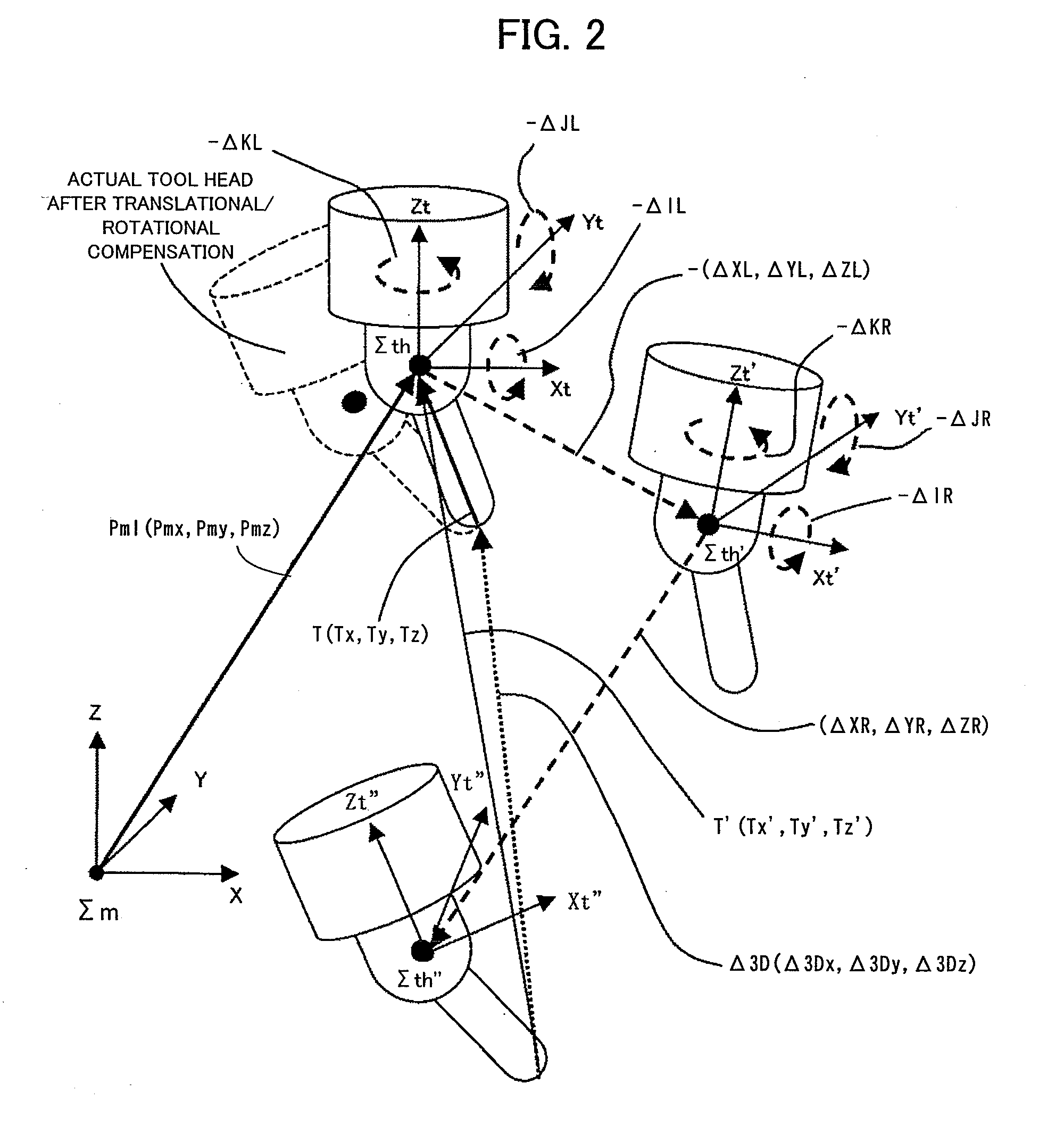

ActiveUS20090140684A1Compensation amount with easeComputer controlSimulator controlRotational axisRotational error

A numerical controller capable of moving a tool end point position to an accurate position in a five-axis machining apparatus. Compensation amounts are set, which correspond to respective ones of a linear axis-dependent translational error, a rotary axis-dependent translational error, a linear axis-dependent rotational error, and a rotary axis-dependent rotational error, which are produced in the five-axis machining apparatus. A translational / rotational compensation amount Δ3D is determined from these compensation amounts and added to a command linear axis position Pm. As the compensation amounts, there is used a corresponding one of six-dimensional lattice point compensation vectors, which are determined in advance as errors due to the use of a mechanical system and measured at lattice points of lattices into which the entire machine movable region is divided.

Owner:FANUC LTD

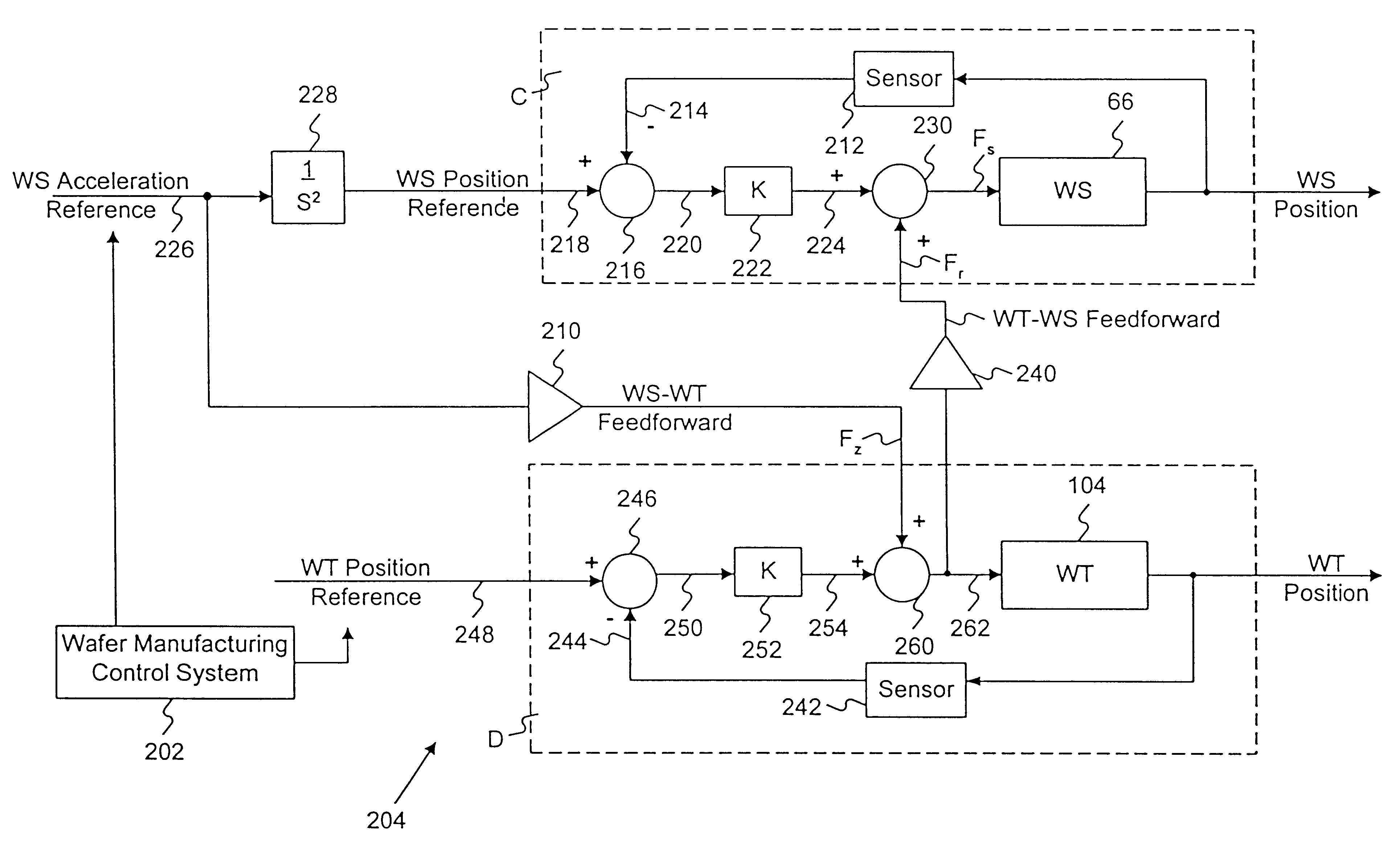

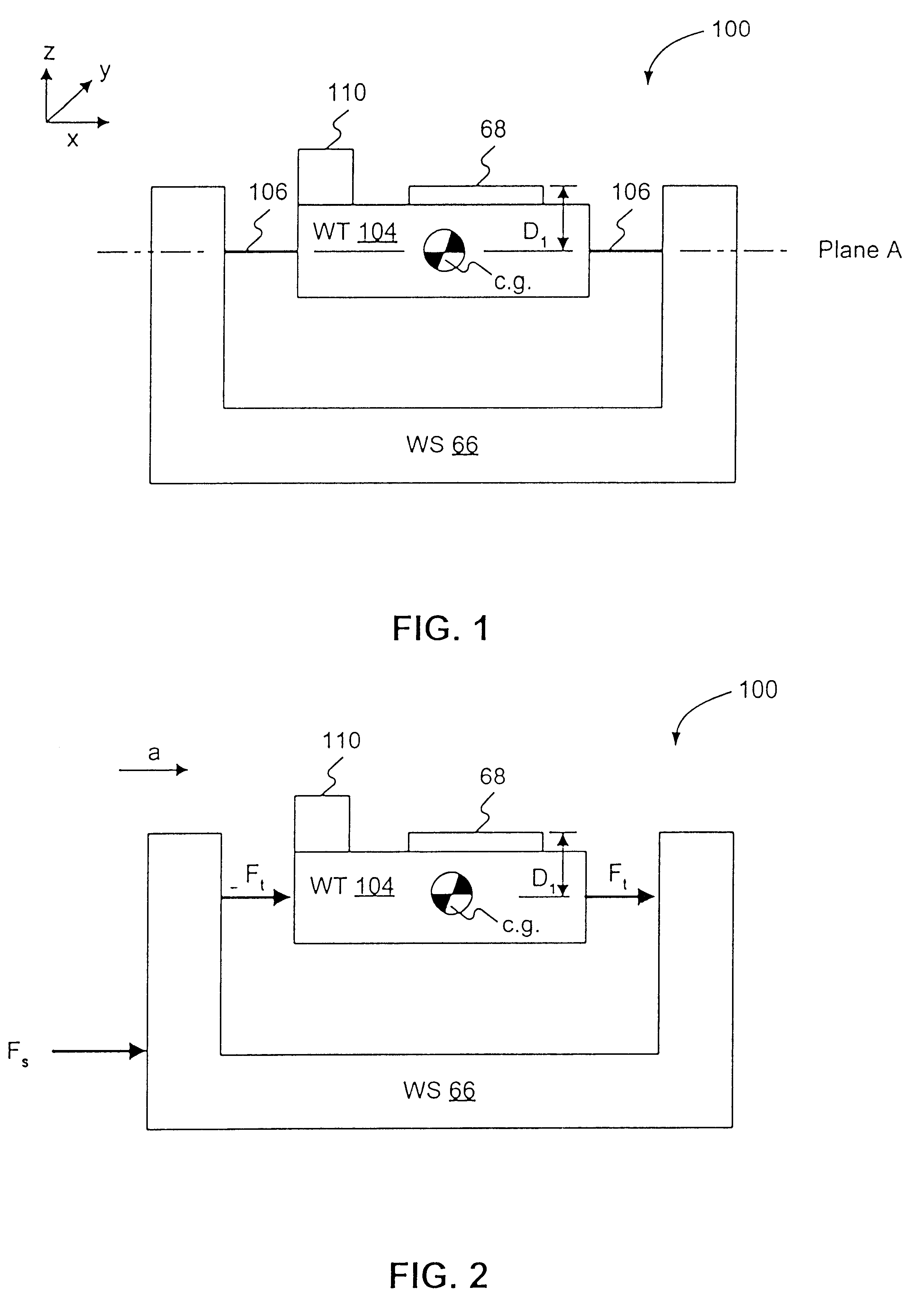

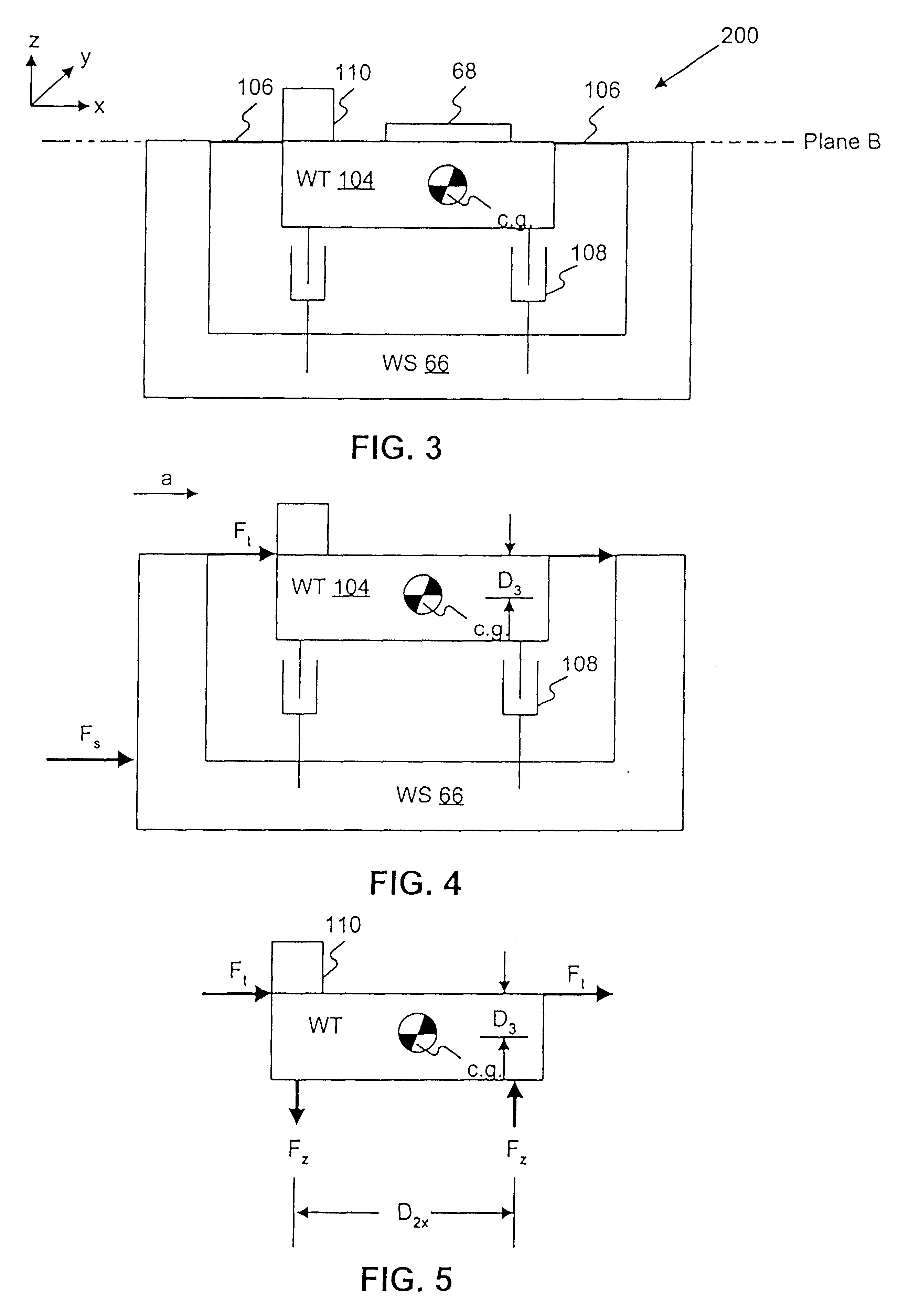

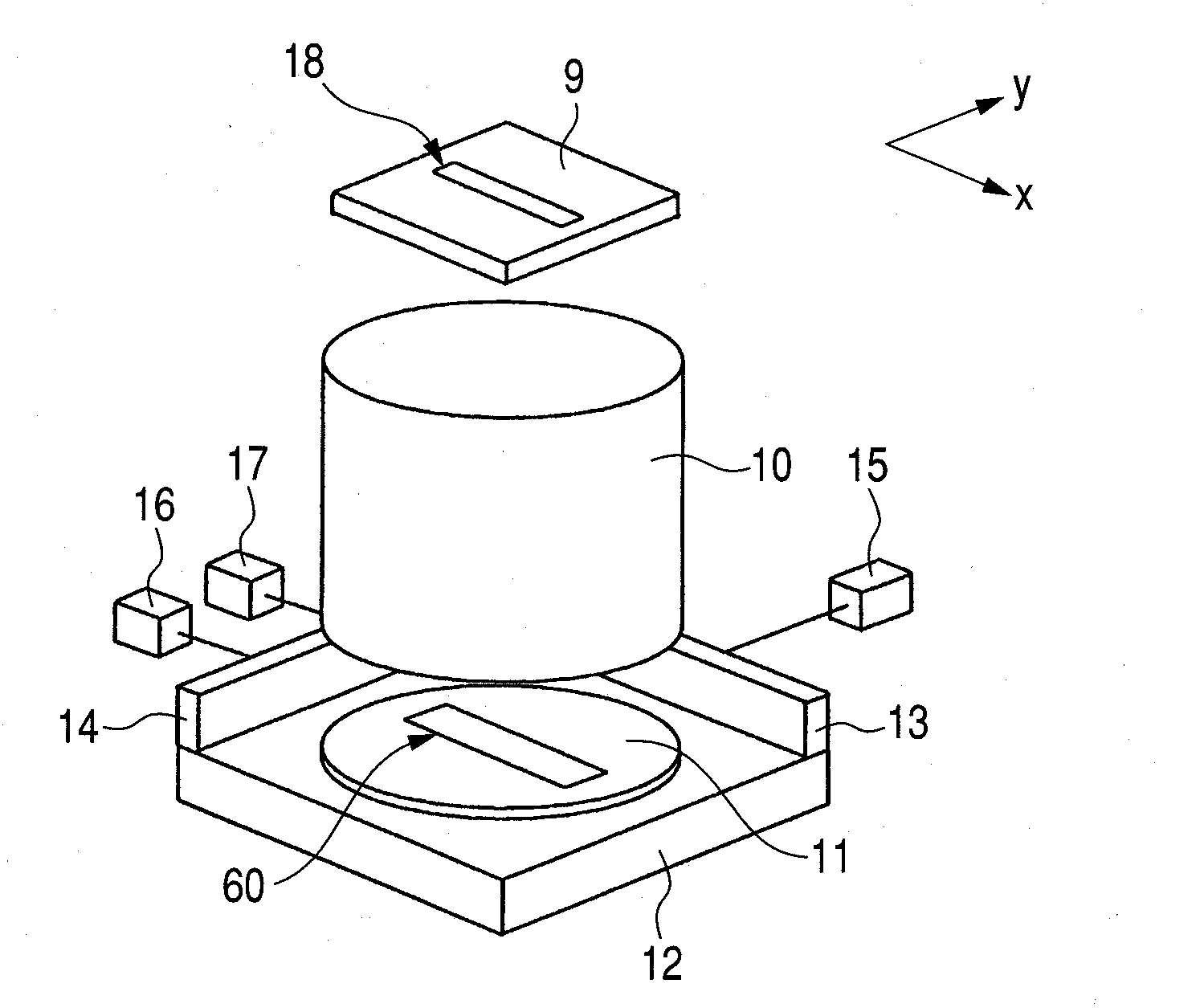

Stage device, control system, and method for stabilizing wafer stage and wafer table

InactiveUS6504162B1Electric discharge tubesPhotomechanical exposure apparatusRotational errorControl system

A wafer stage device and control system are provided to stabilize a wafer stage and a wafer table in a wafer manufacturing process. The wafer table supports the semiconductor wafer, while the wafer stage is accelerated in response to a wafer manufacturing control system to position the wafer table. The wafer stage device includes a set of flexures connecting the wafer table to the wafer stage. The flexures are positioned in a plane which is substantially in alignment with an upper surface of the wafer. The flexure's configuration causes a rotational error, such as pitching or rolling, of the wafer table as the wafer stage moves. The wafer stage device further includes a plurality of actuators to control the rotational error by exerting a stabilizing torque to the wafer table. The control system determines the stabilizing torque necessary to correct the pitching or rolling error of the wafer table.

Owner:NIKON CORP

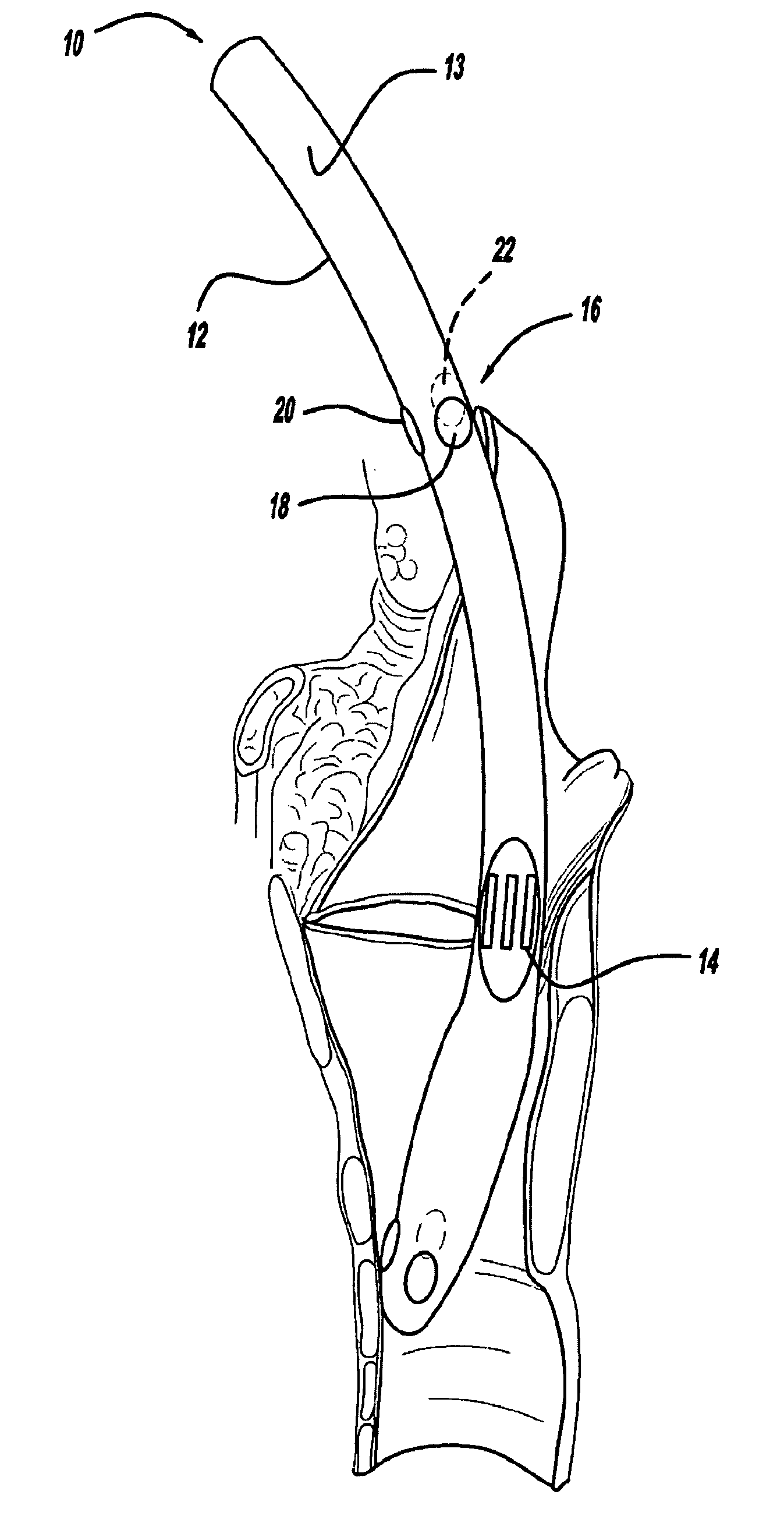

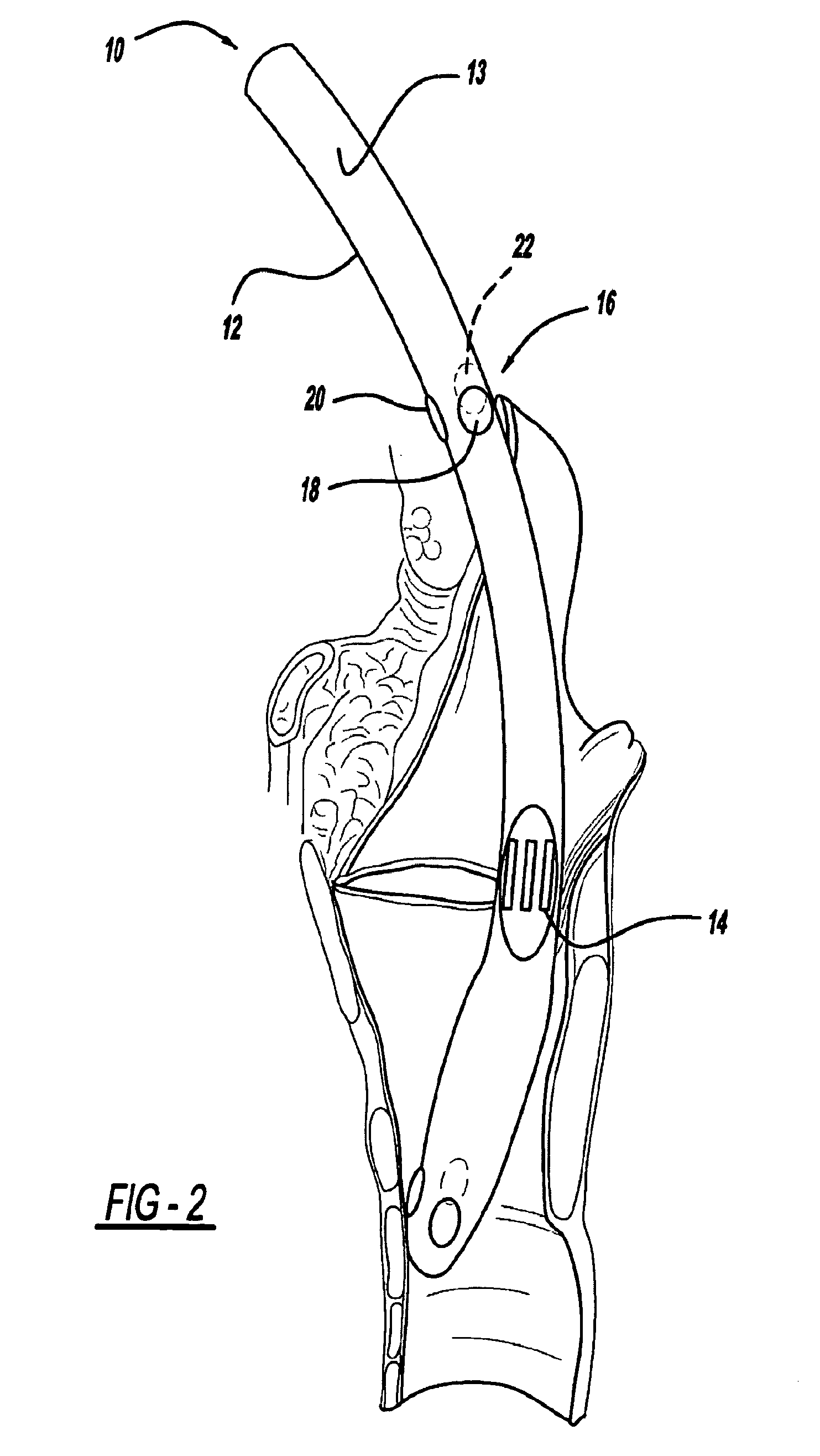

Nerve monitoring device

InactiveUS20100063376A1Rotational errorAccurate monitoringSensorsNeuroelectric signal measurementRotational errorMultielectrode array

The present invention provides a nerve monitoring device. The device includes a cannula, a sensor for monitoring the nerve and an alignment device. The cannula can be any surgical cannula, and is preferably an endotracheal tube. The sensor can be an electrode or other sensor that is capable of sensing nerve activity. The alignment device is a device that ensures that after insertion of the nerve sensor into a patient, the sensors are aligned to properly monitor the target nerve or muscle. The internal alignment device may communicate externally to surgeon by using electromagnetic energy as either a transmittor or a receiver. The mismatch of triangular laryngeal anatomy to circular cannula anatomy can be compensated for by a) altering the geometry (external shape) of the cannula and b) using soft, felt-like expandable electrodes. Rotational error can be compensated for by using a multi-electrode array wherein the optimized recording montage can be simply selected on the external recording device.

Owner:THE MAGSTIM

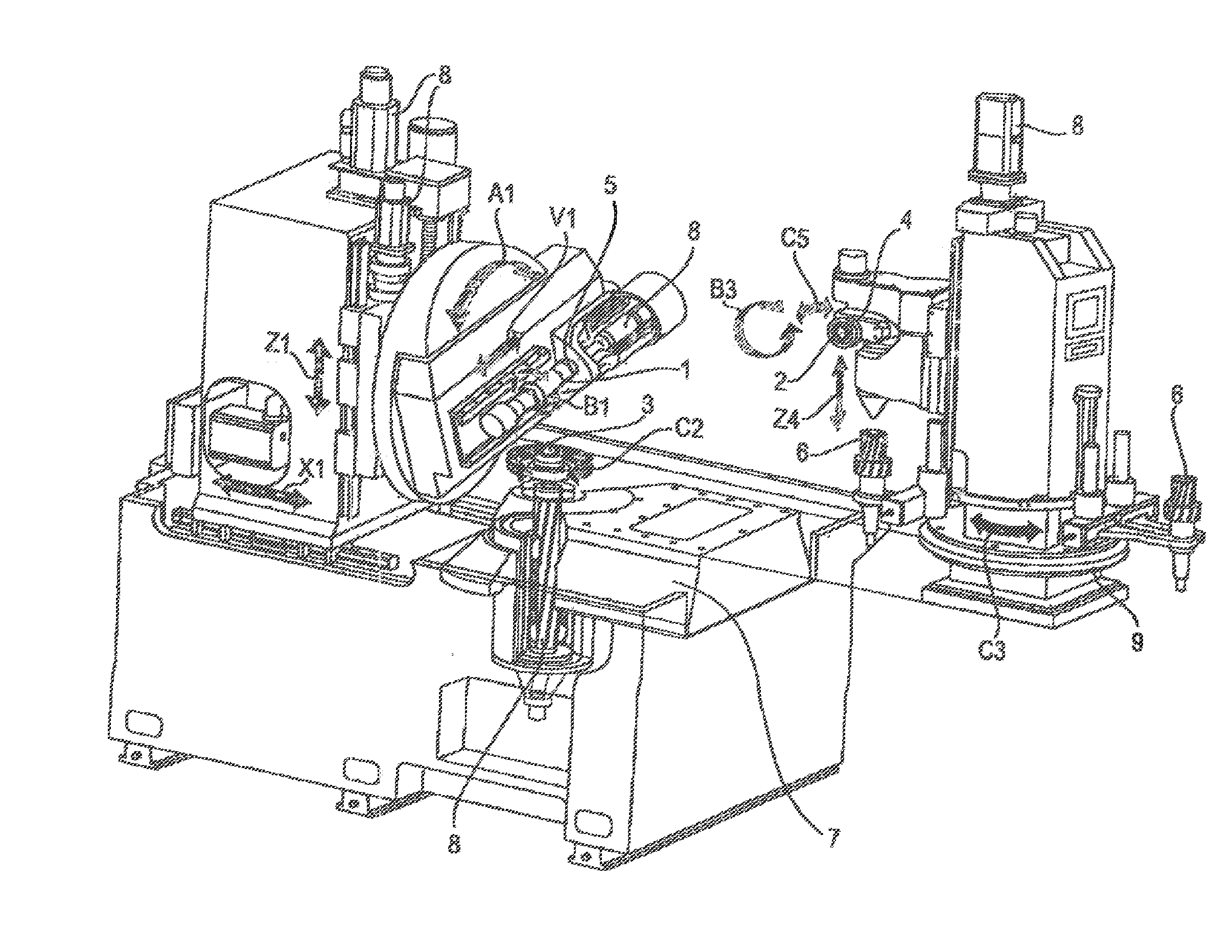

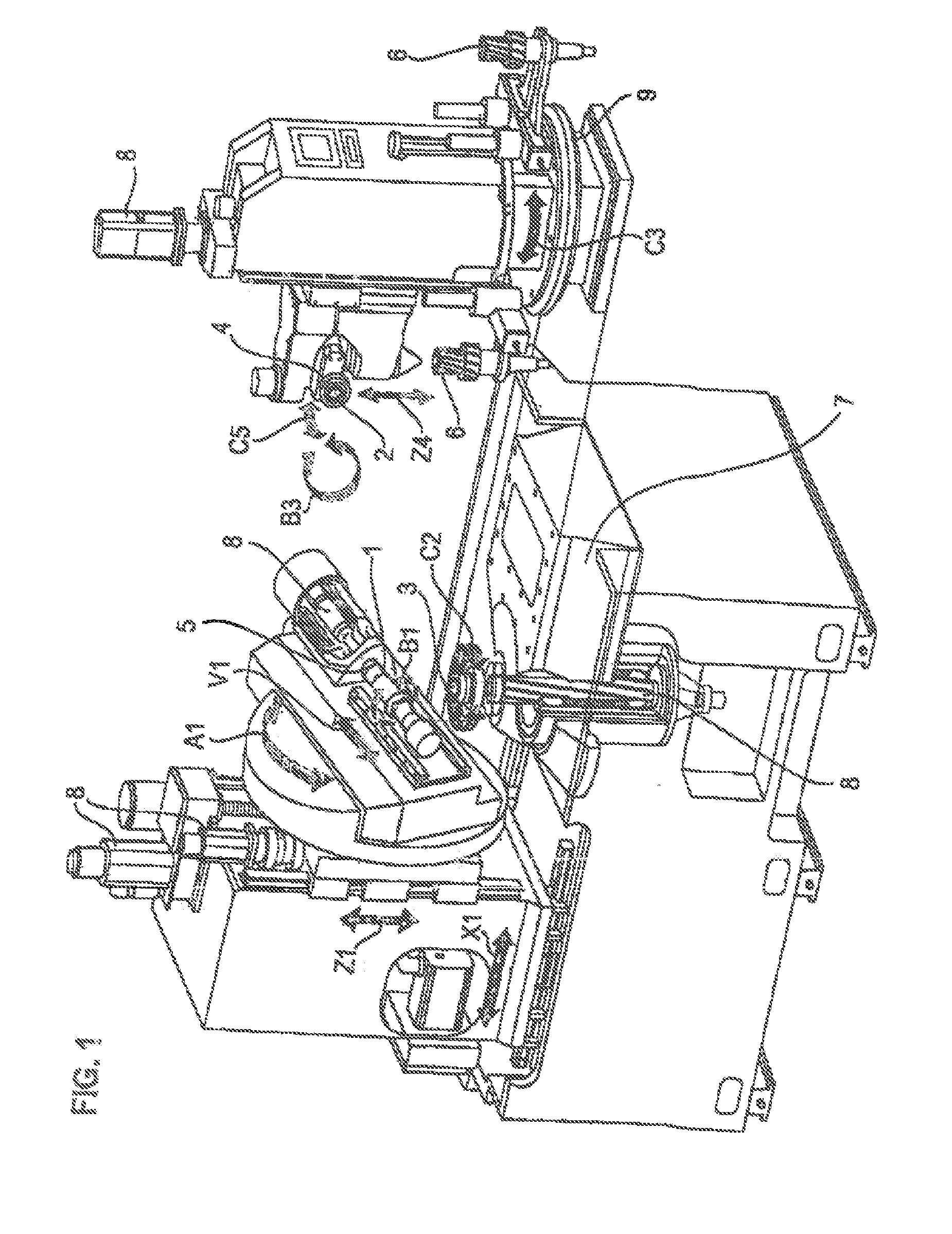

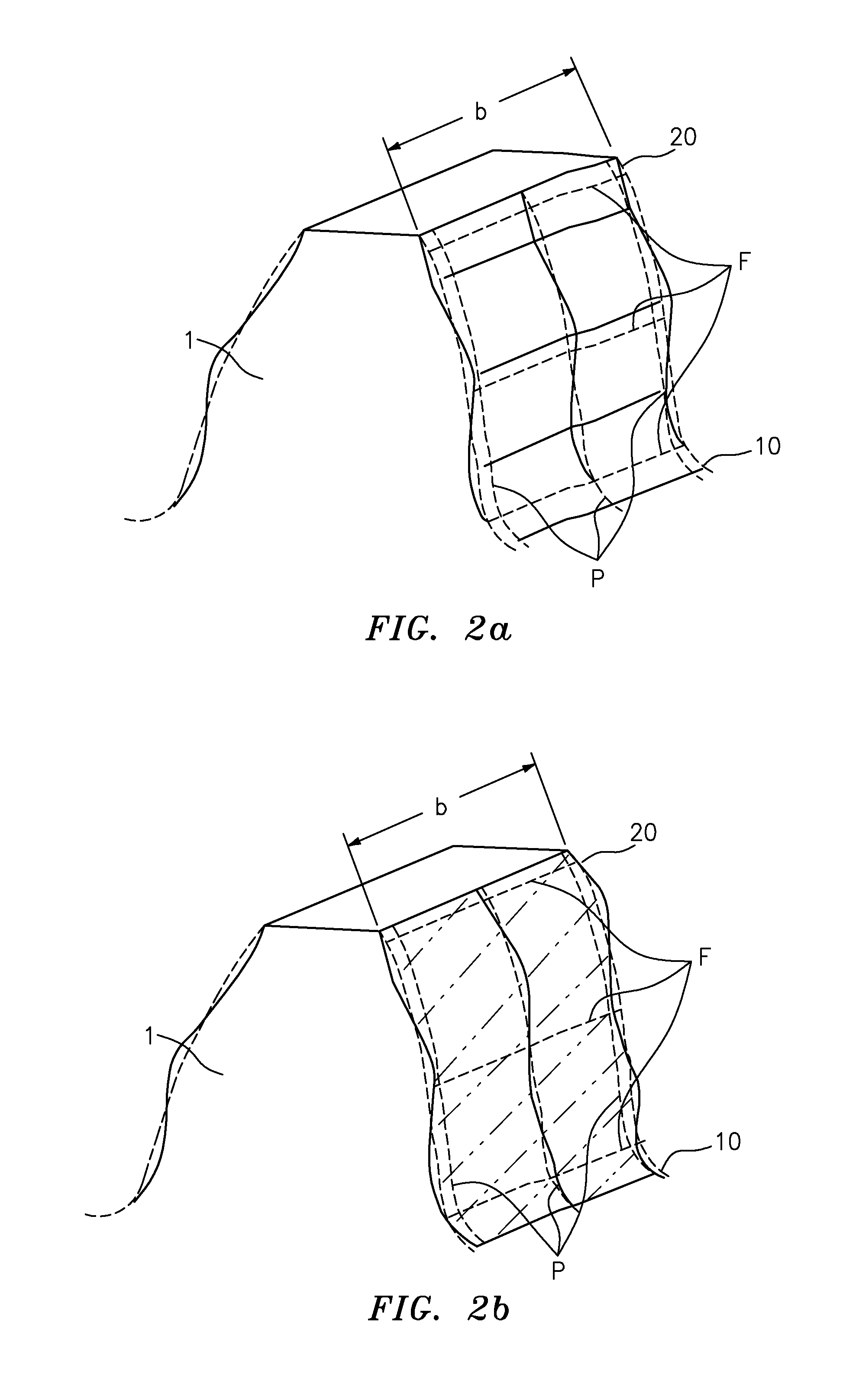

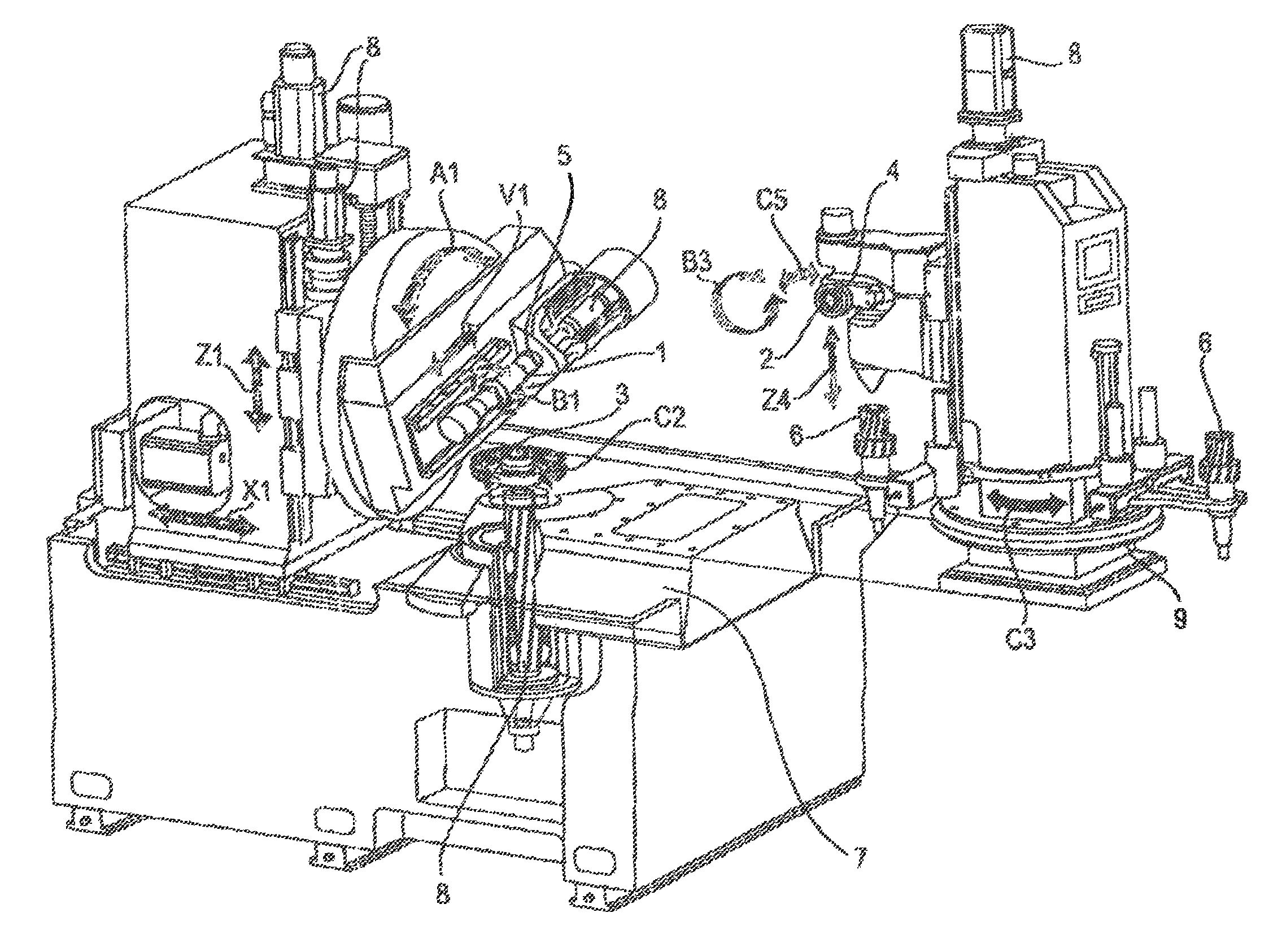

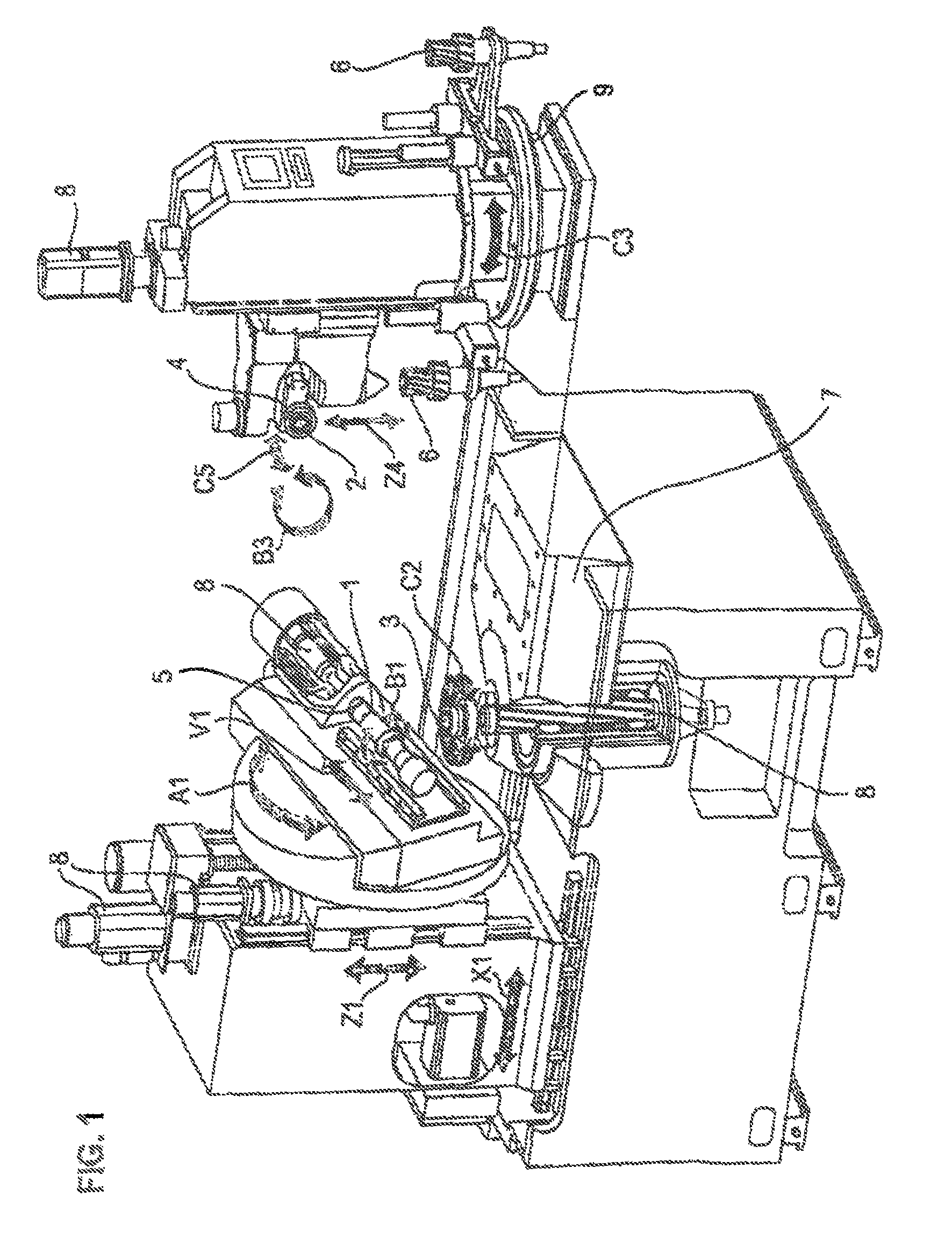

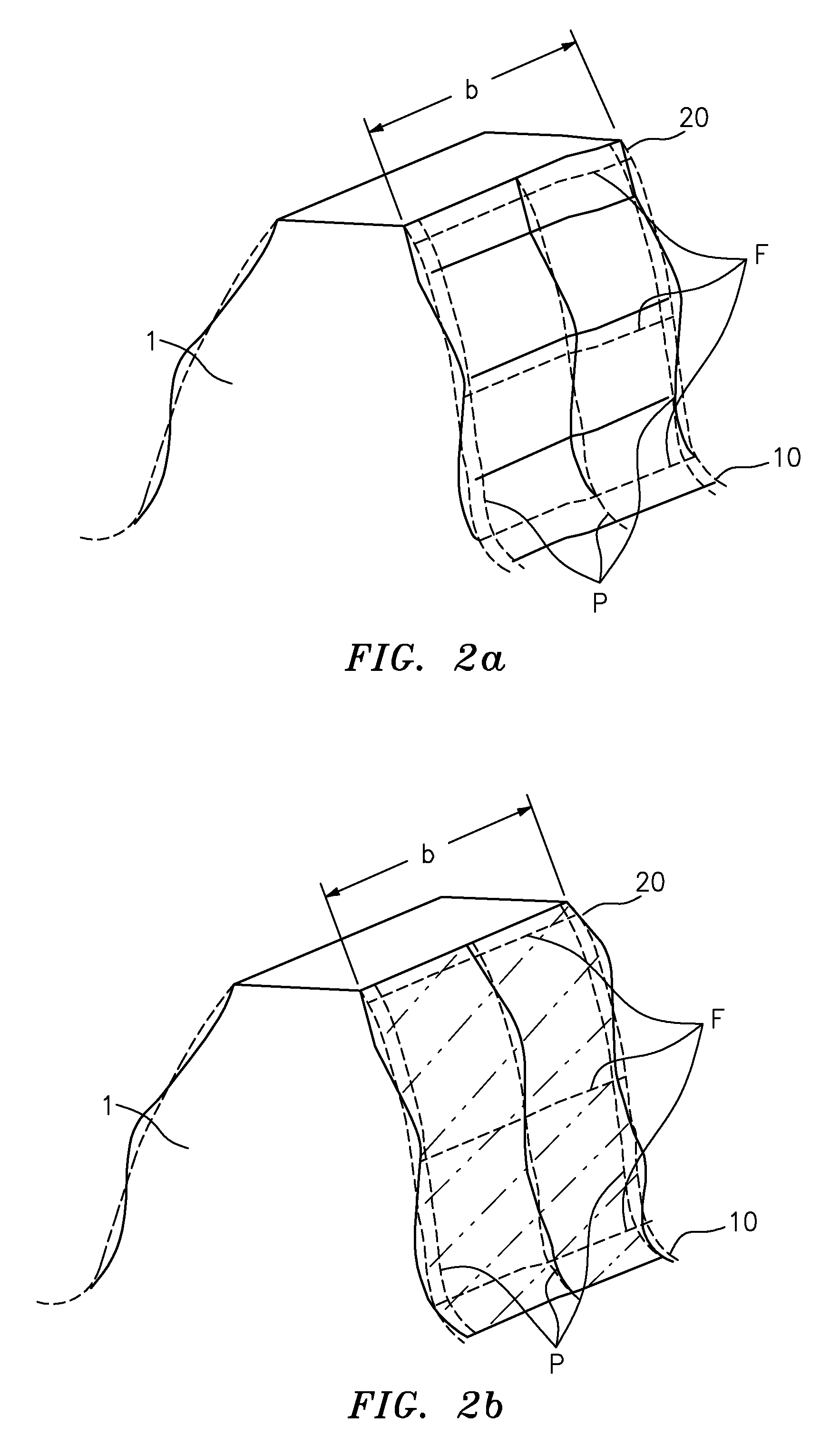

Machining Method for Hard-Fine Machining of Noise-Optimized Gears on a Gear-Cutting Machine

ActiveUS20140256223A1Improve uniformityAvoid and at least minimize vibration excitationAutomatic control devicesGrinding feed controlRotational errorEngineering

The present invention relates to a method for hard-fine machining of tooth flanks with corrections and / or modifications on a gear-cutting machine, wherein respective toothed wheel pairings which mesh with one another within a transmission or a test device are machined while taking account of the respective mating flanks, and wherein the tooth flanks of the relevant workpieces are provided with periodic waviness corrections or waviness modifications. In accordance with the invention, the rotational error extent is determined by means of rotational distance error measurement of the toothed wheel pairs in a gear measuring device and / or transmission. This measurement result serves as an input value for defining the amplitude, frequency and phase position for the periodic flank waviness corrections on the tooth flanks of the toothed wheel pairings for production in the gear-cutting machine.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

Numerical controller for controlling a five-axis machining apparatus

The invention provides a numerical controller for controlling a five-axis machining apparatus. The numerical controller capable of moving a tool end point position to an accurate position in a five-axis machining apparatus. Compensation amounts are set, which correspond to respective ones of a linear axis-dependent translational error, a rotary axis-dependent translational error, a linear axis-dependent rotational error, and a rotary axis-dependent rotational error, which are produced in the five-axis machining apparatus. A translational / rotational compensation amount 3D is determined from these compensation amounts and added to a command linear axis position Pm. As the compensation amounts, there is used a corresponding one of six-dimensional lattice point compensation vectors, which are determined in advance as errors due to the use of a mechanical system and measured at lattice points of lattices into which the entire machine movable region is divided.

Owner:FANUC LTD

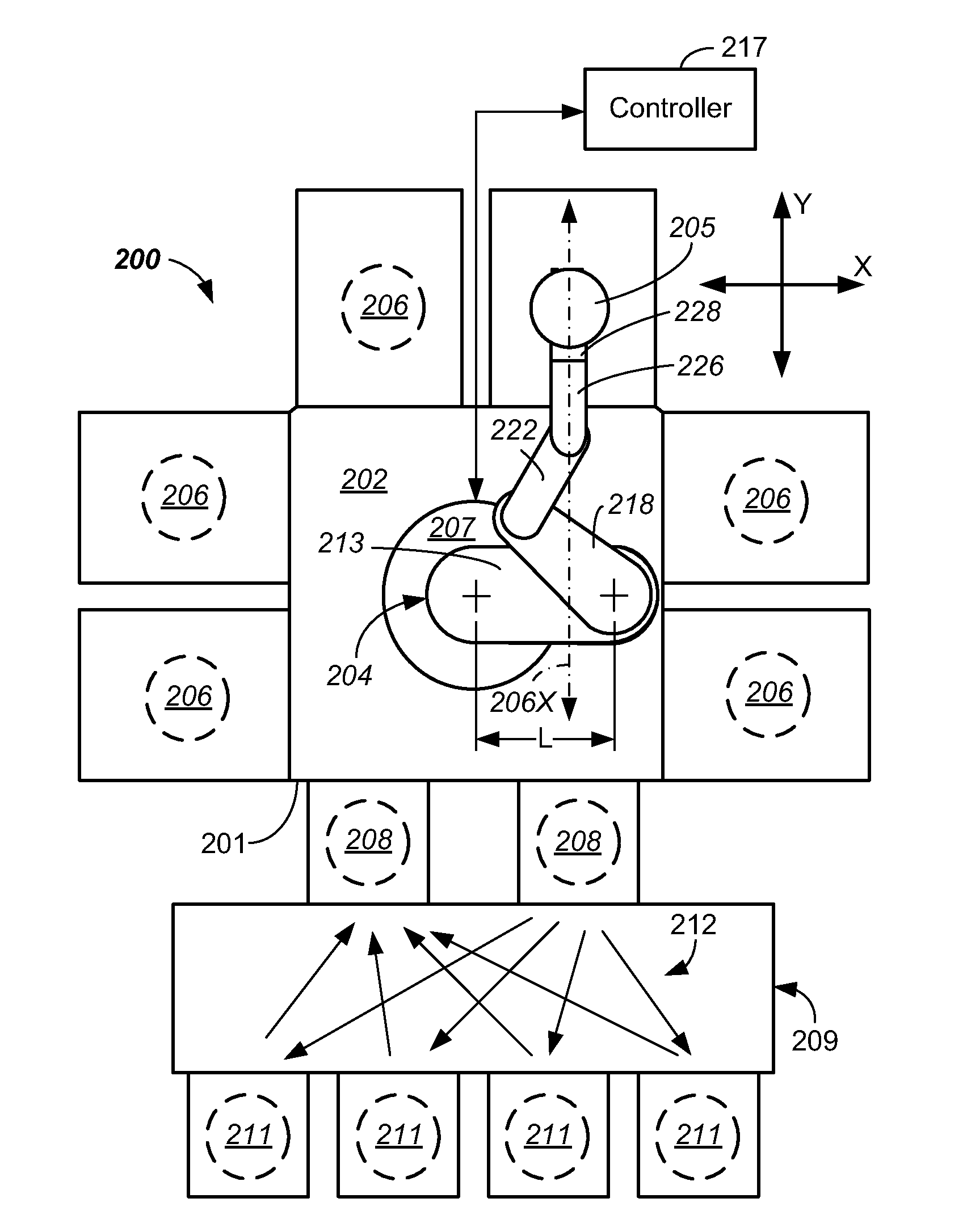

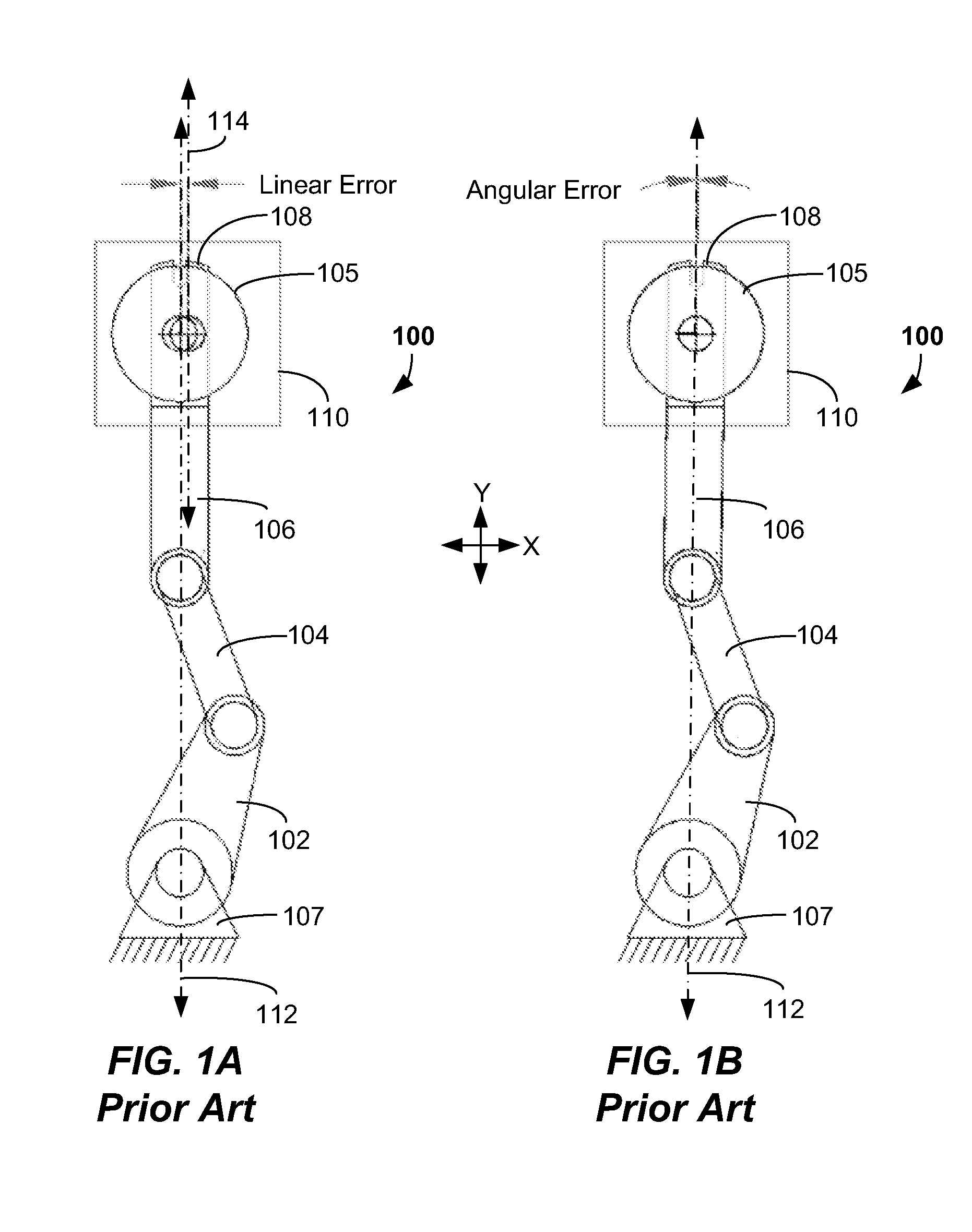

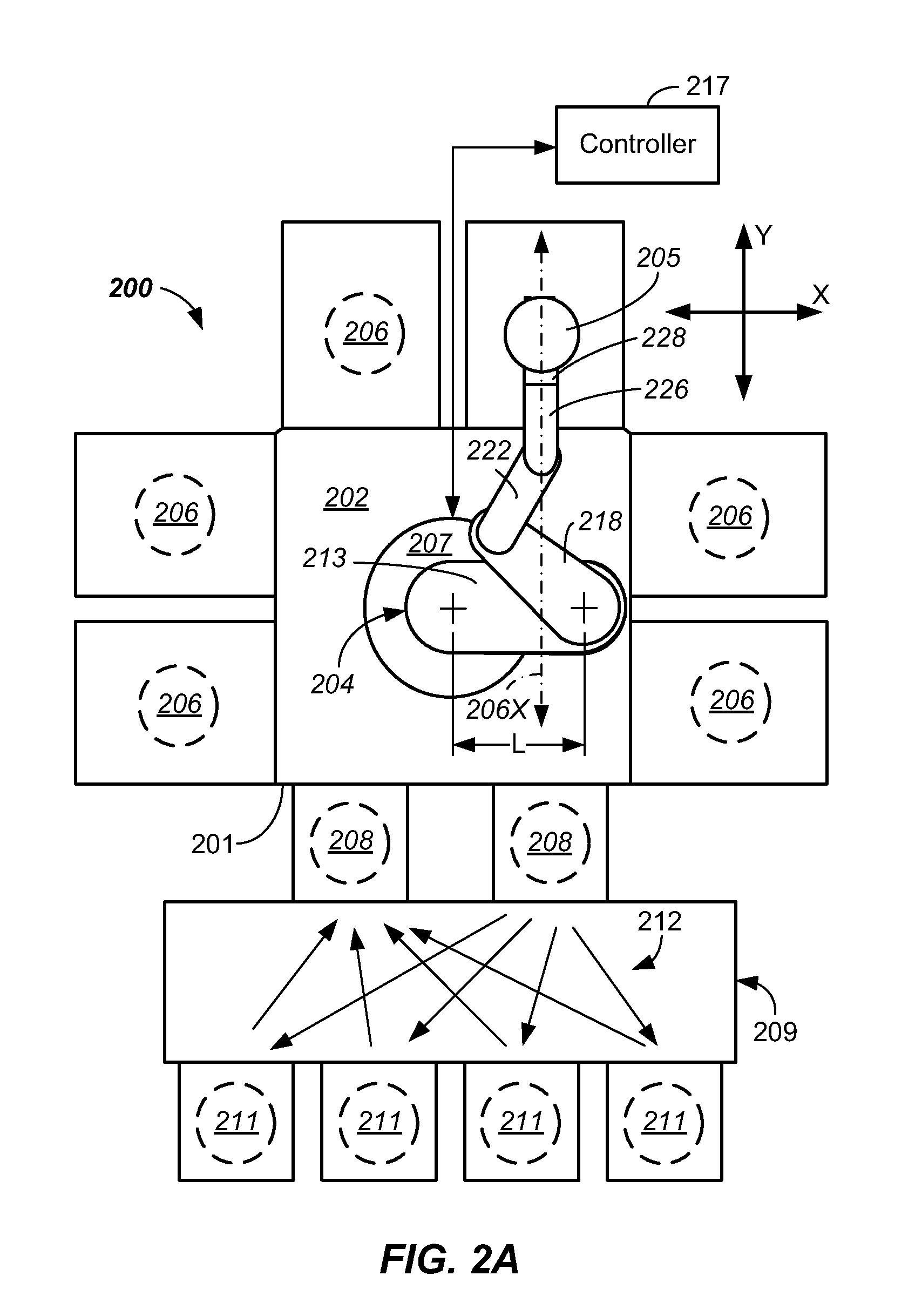

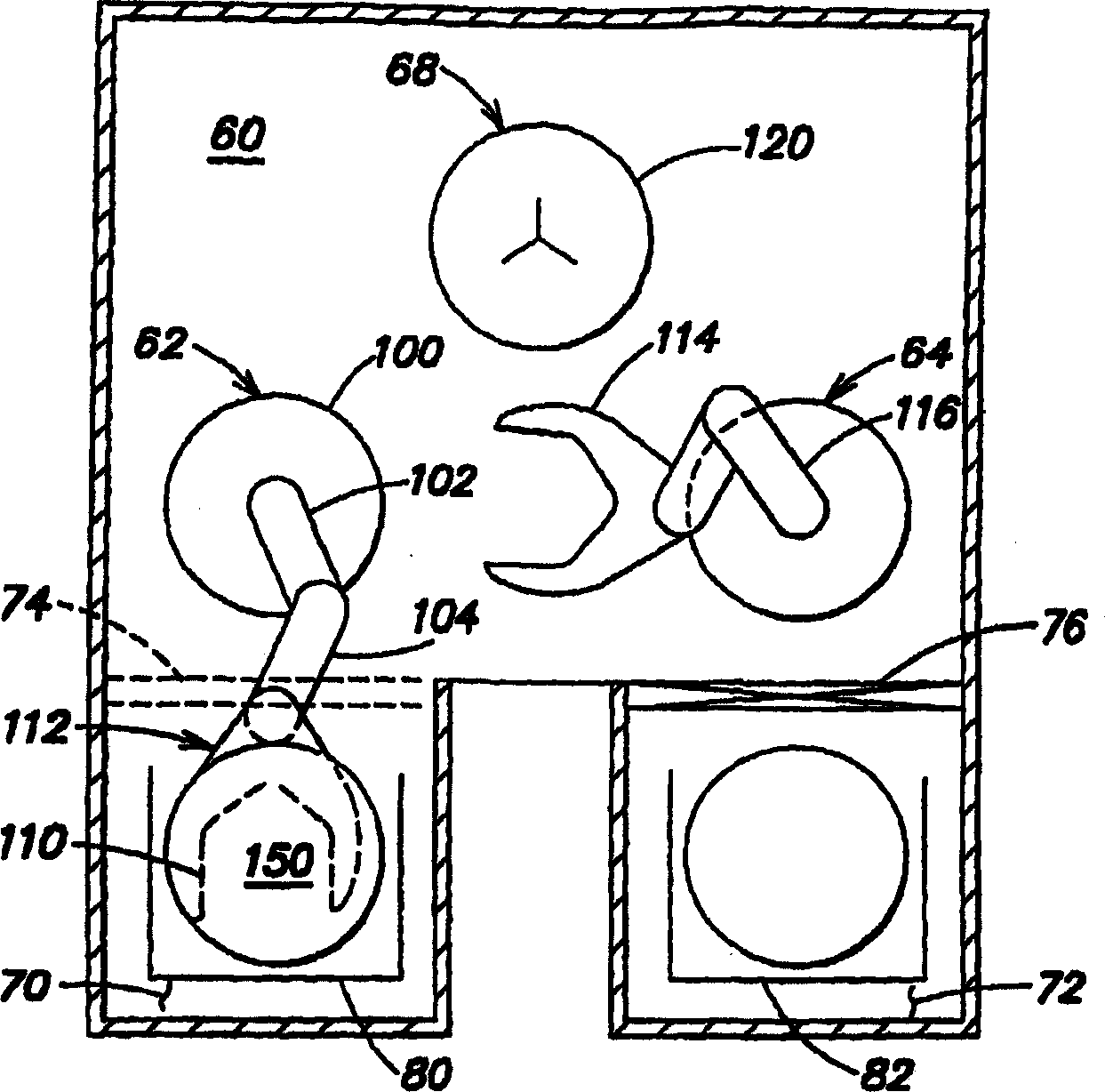

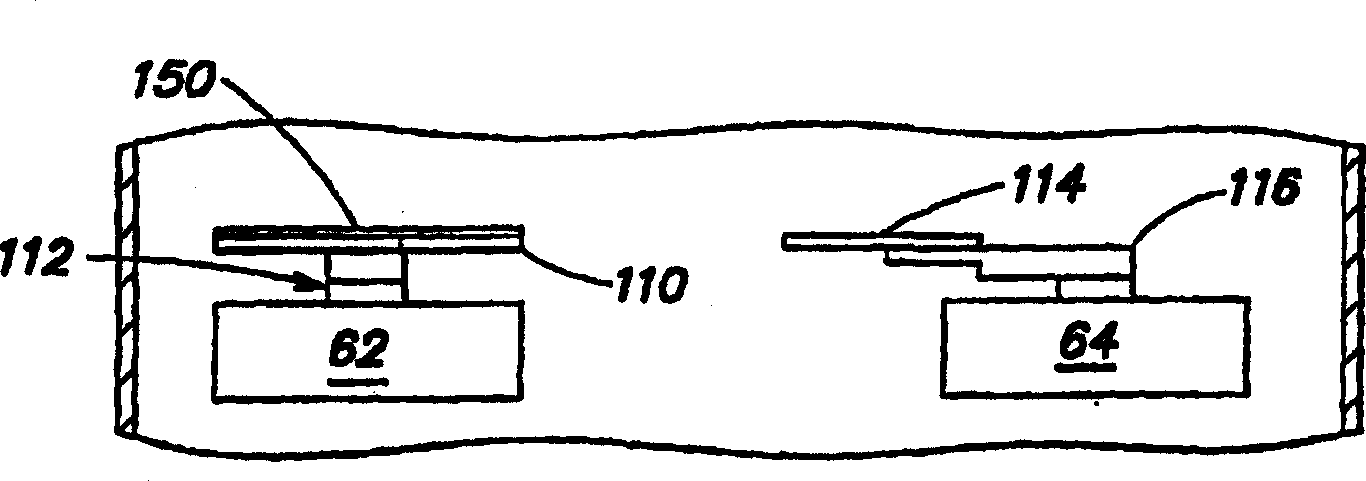

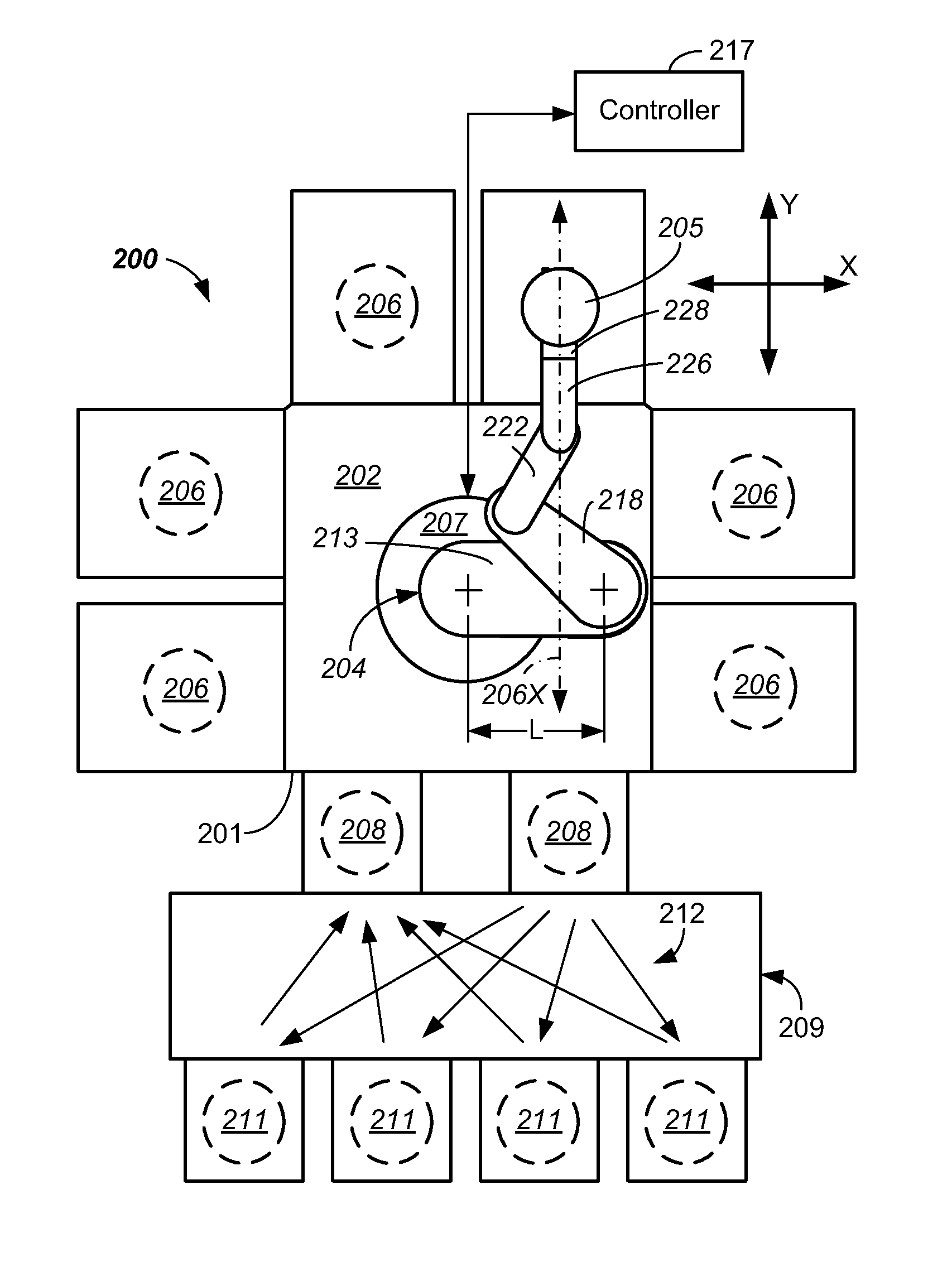

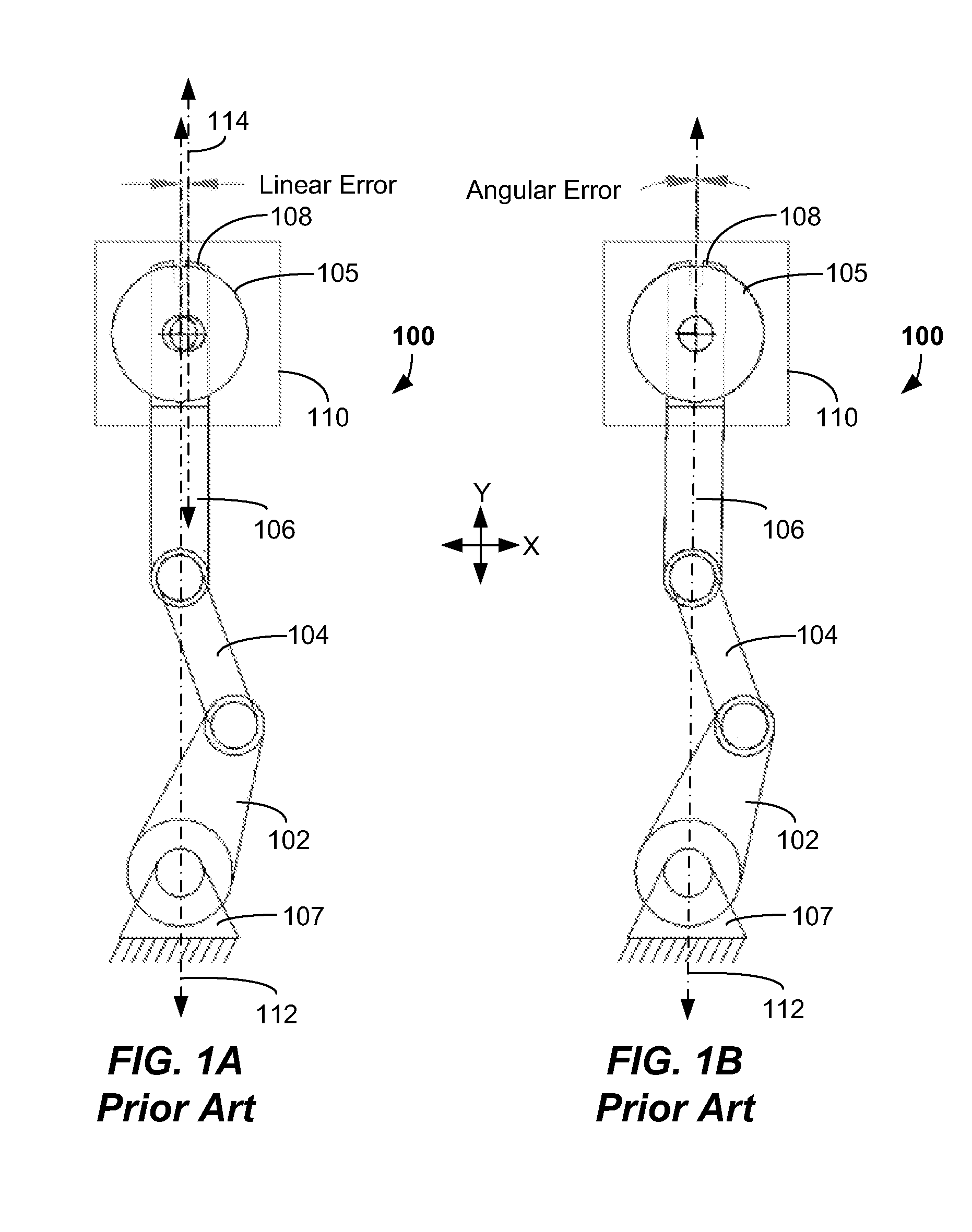

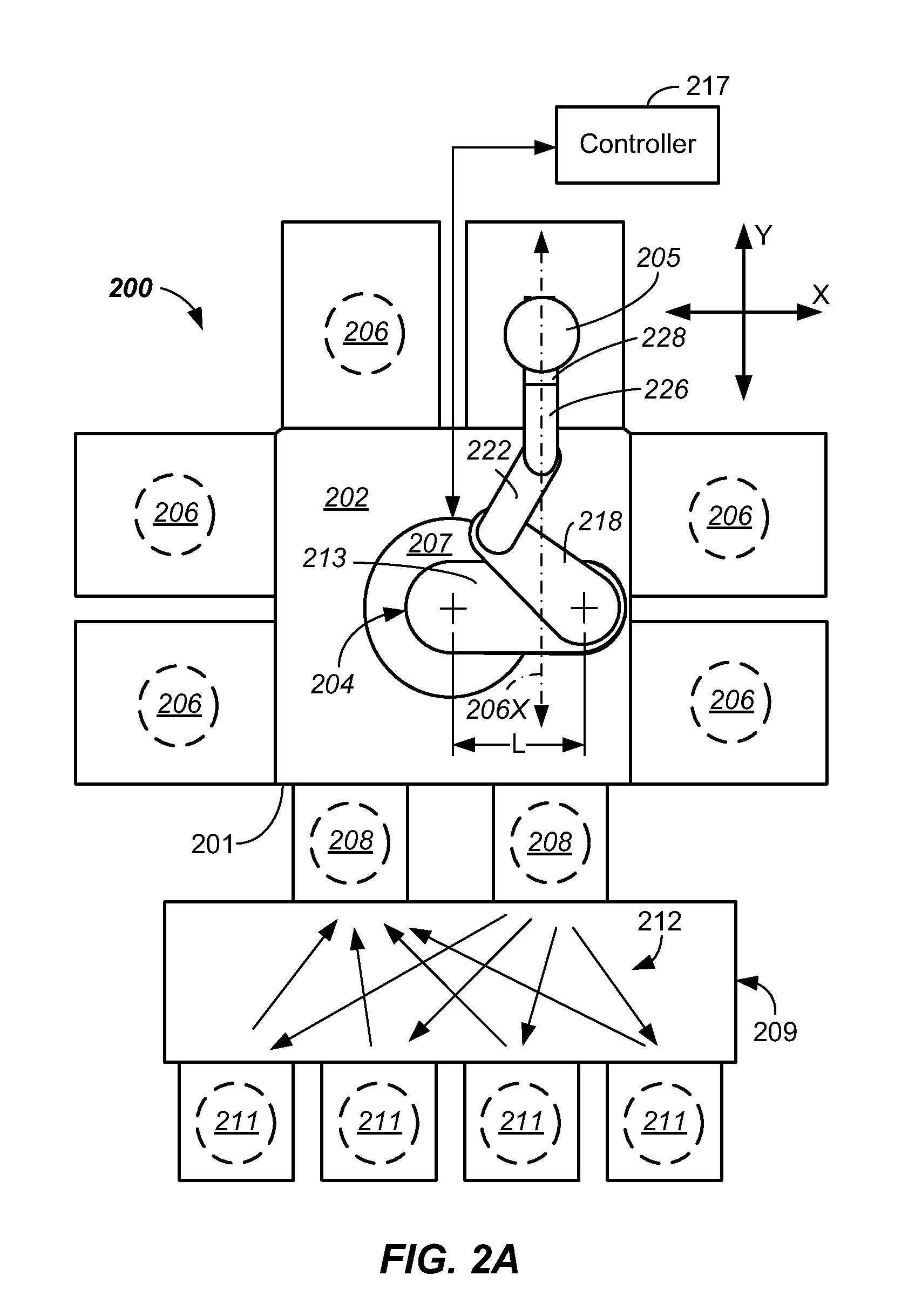

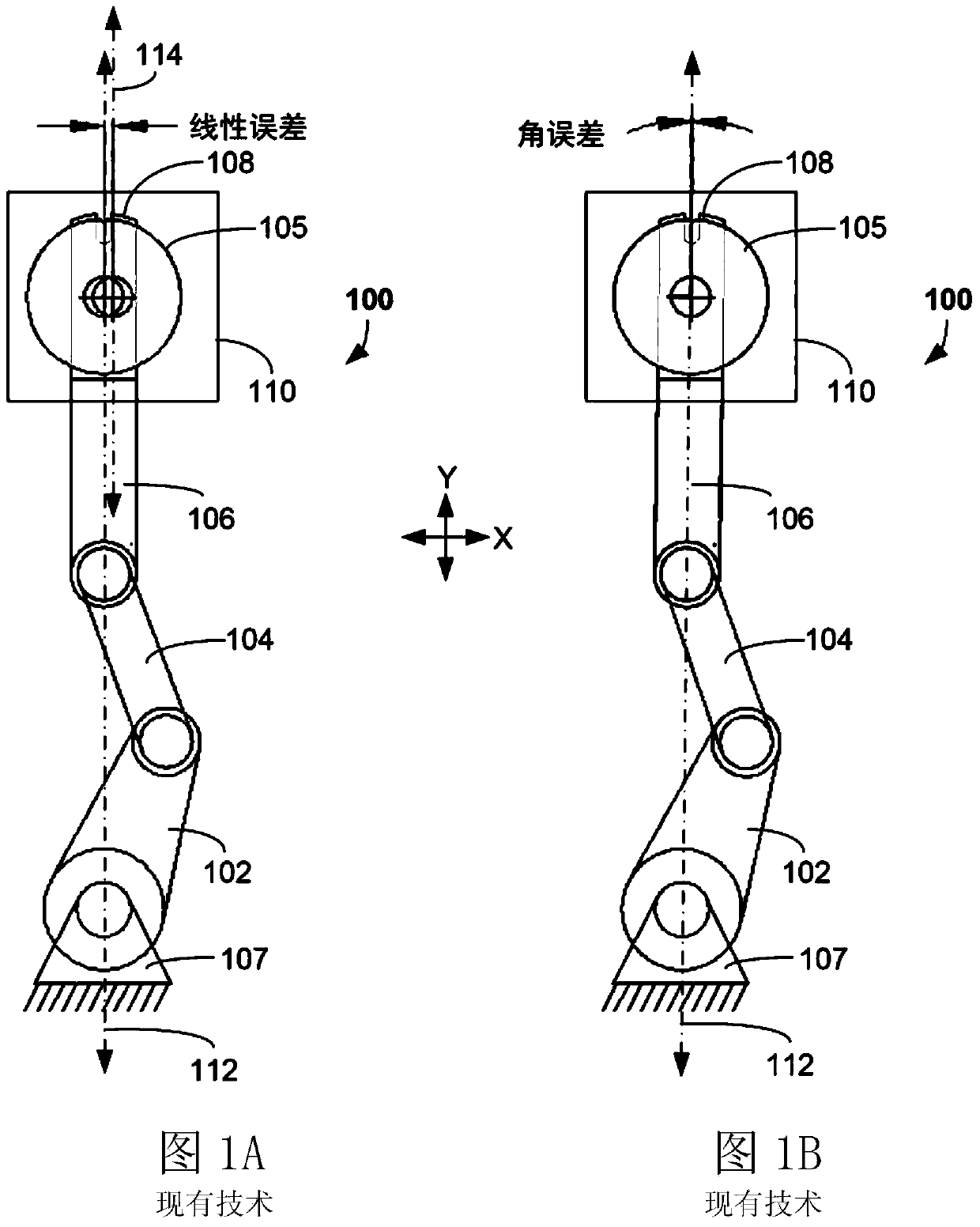

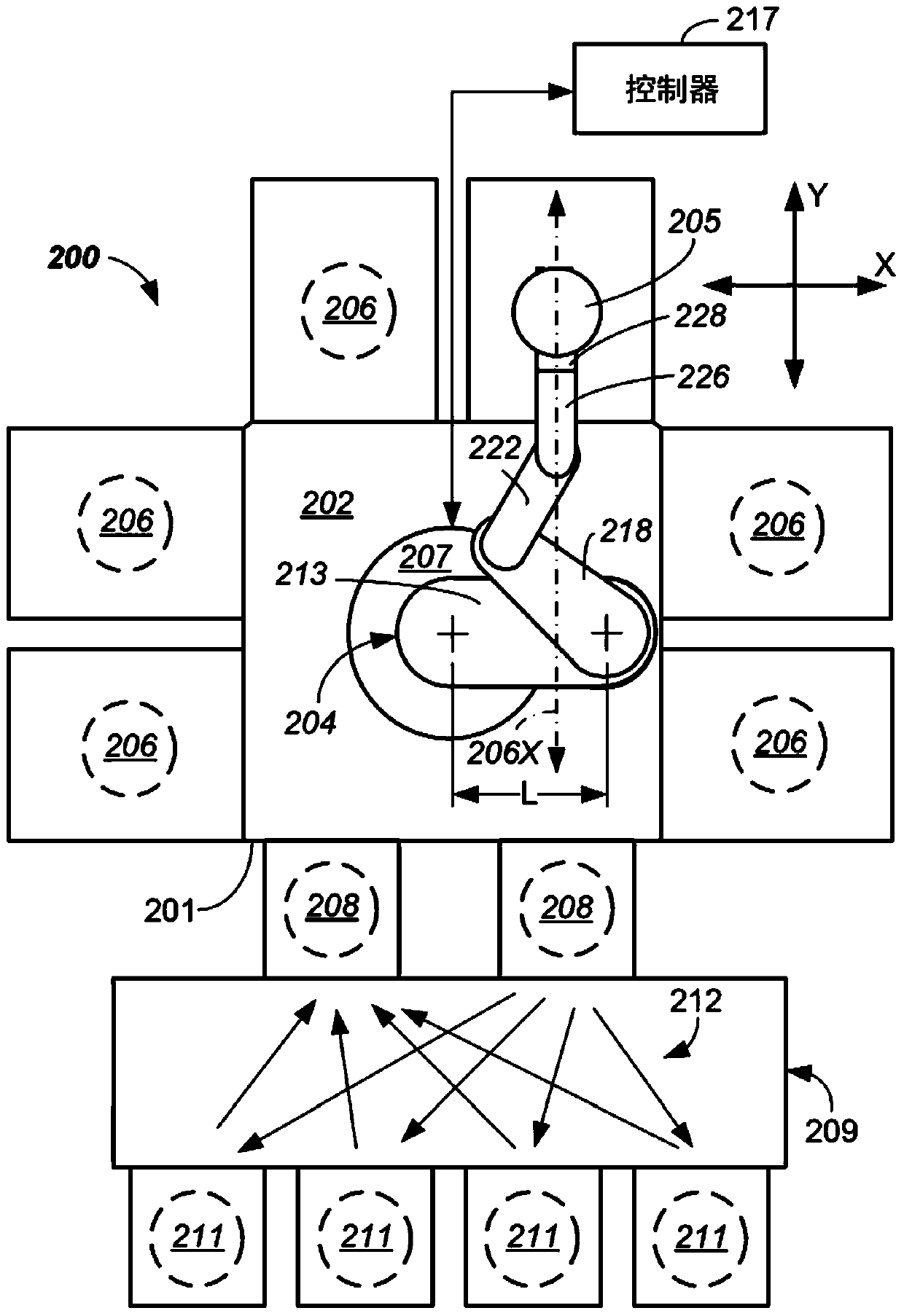

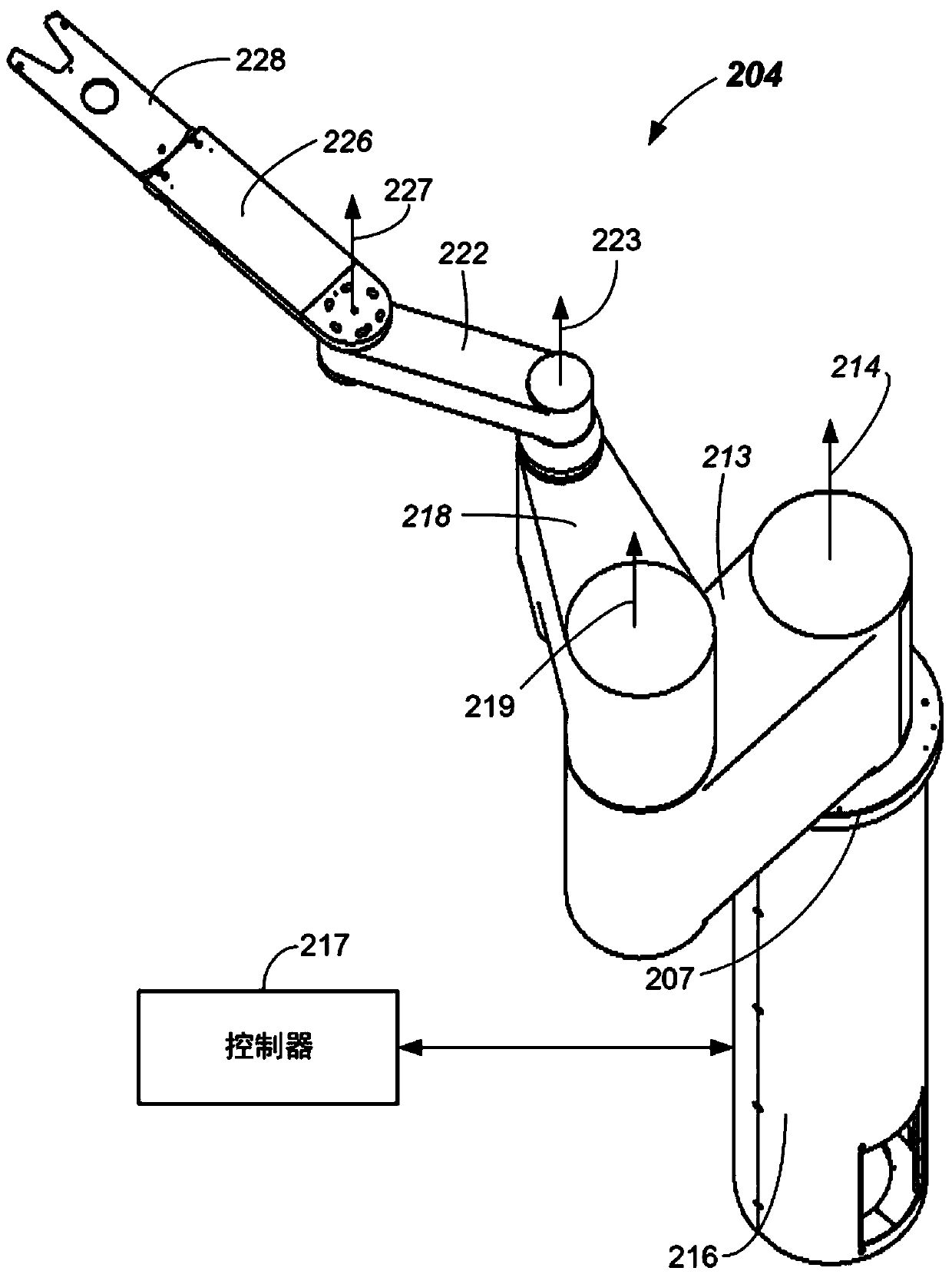

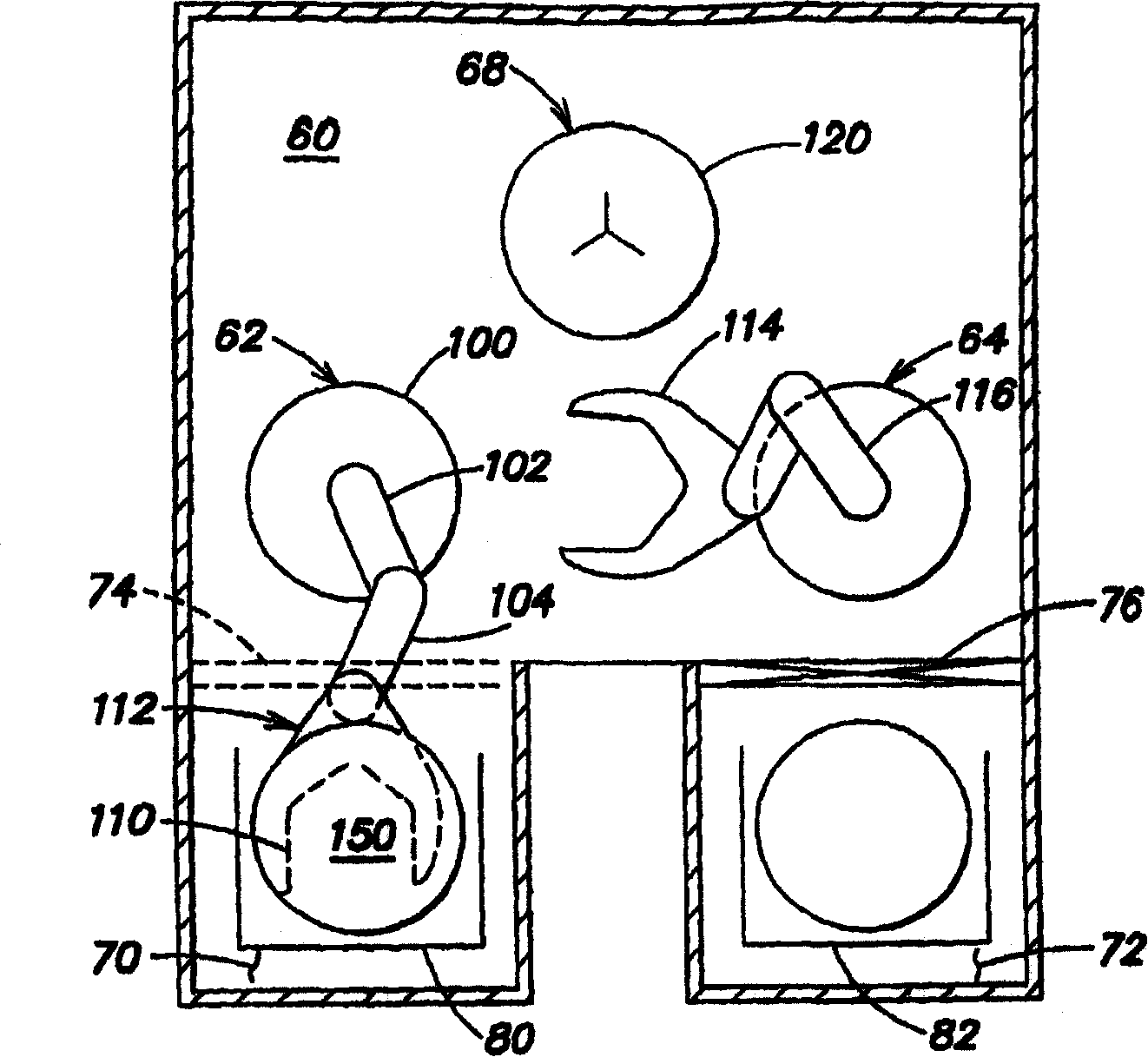

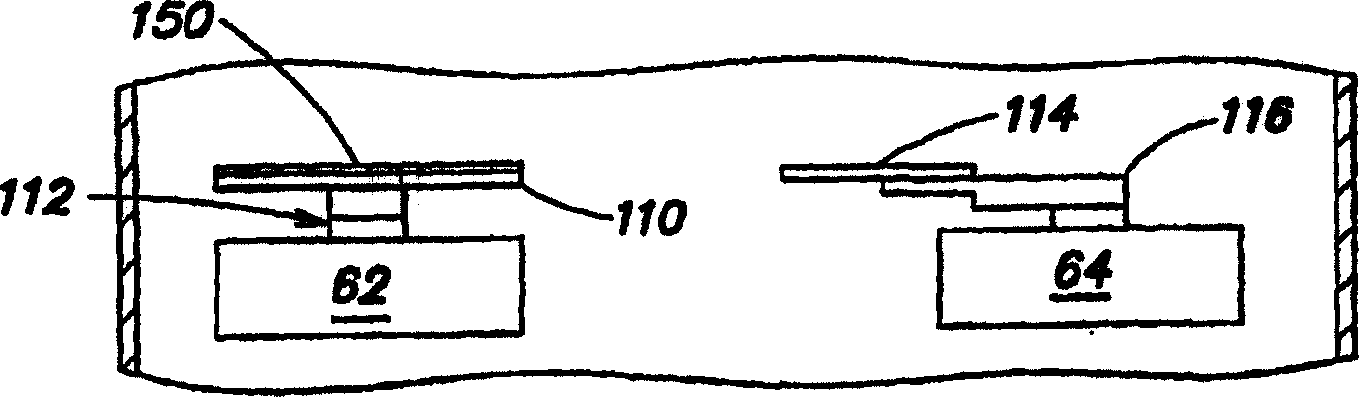

Systems having multi-linkage robots and methods to correct positional and rotational alignment in multi-linkage robots

Methods of correction of rotational and linear misalignment in multi-link robots are provided. The method allows for precise orientation of an end effector to put or pick substrates at a target destination by correcting for both positional and rotational orientation errors. The method rotates a boom linkage to a position adjacent to the target destination, corrects for linear and rotational error by rotating a boom linkage as well as an upper arm link as well as extending or retracting a wrist member. Systems including long boom linkages are disclosed. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

Numerical controller for controlling a five-axis machining apparatus

ActiveUS7969111B2Compensation amount with easeComputer controlSimulator controlRotational axisRotational error

A numerical controller capable of moving a tool end point position to an accurate position in a five-axis machining apparatus. Compensation amounts are set, which correspond to respective ones of a linear axis-dependent translational error, a rotary axis-dependent translational error, a linear axis-dependent rotational error, and a rotary axis-dependent rotational error, which are produced in the five-axis machining apparatus. A translational / rotational compensation amount Δ3D is determined from these compensation amounts and added to a command linear axis position Pm. As the compensation amounts, there is used a corresponding one of six-dimensional lattice point compensation vectors, which are determined in advance as errors due to the use of a mechanical system and measured at lattice points of lattices into which the entire machine movable region is divided.

Owner:FANUC LTD

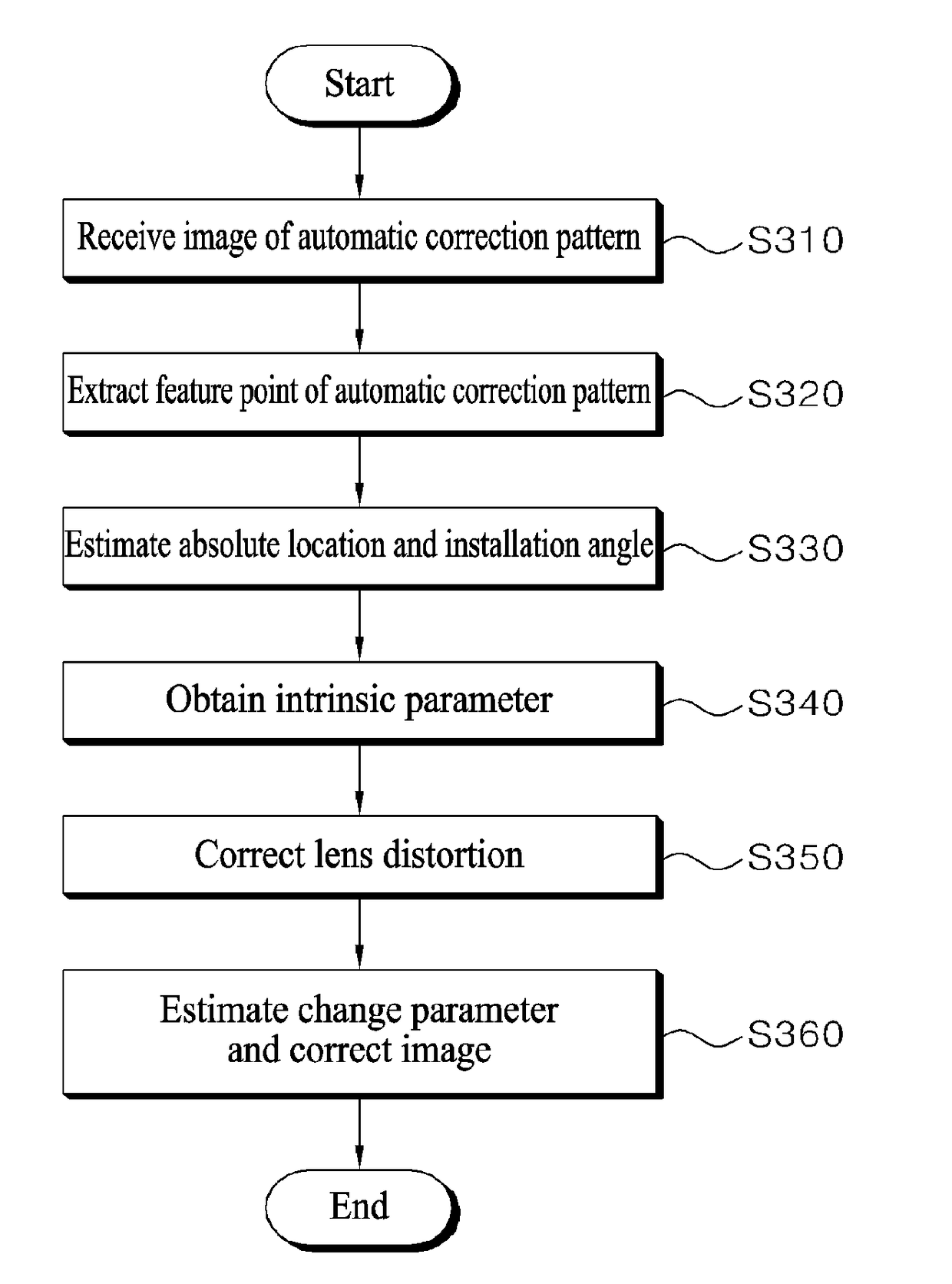

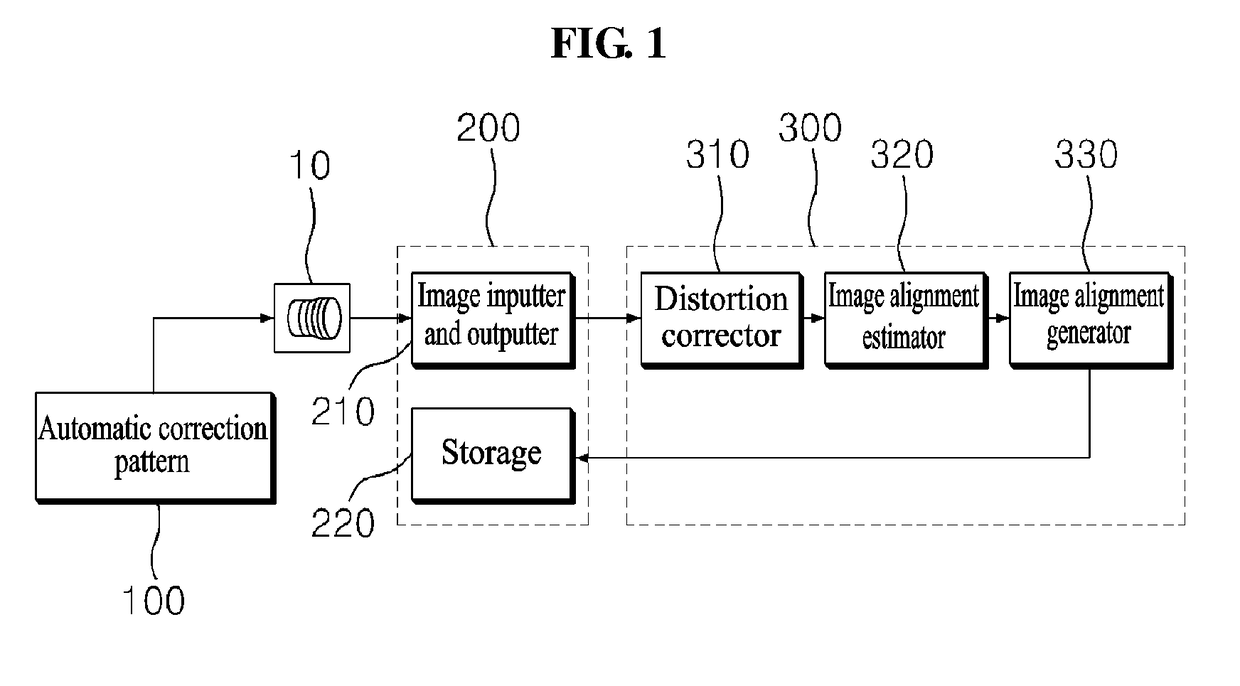

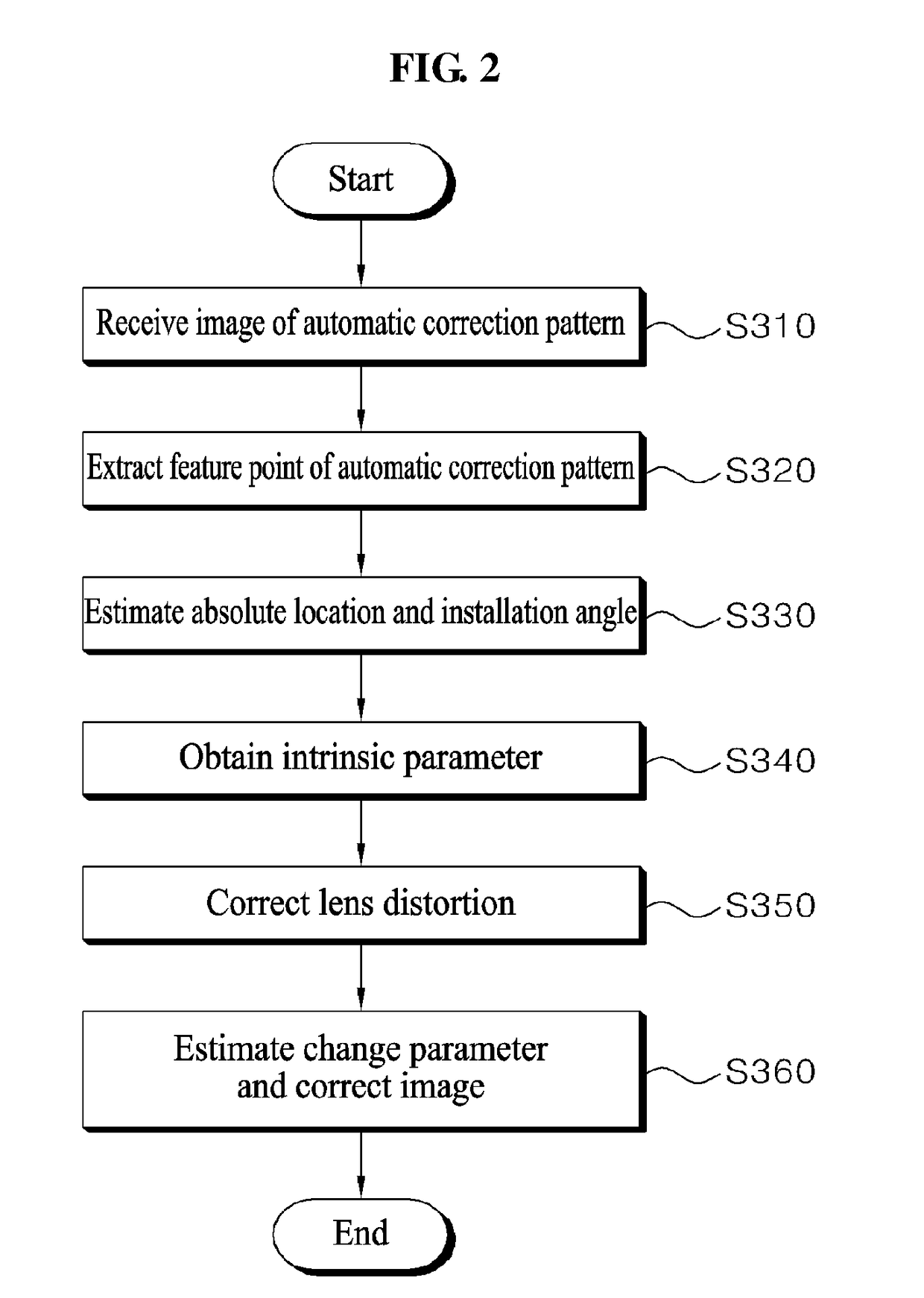

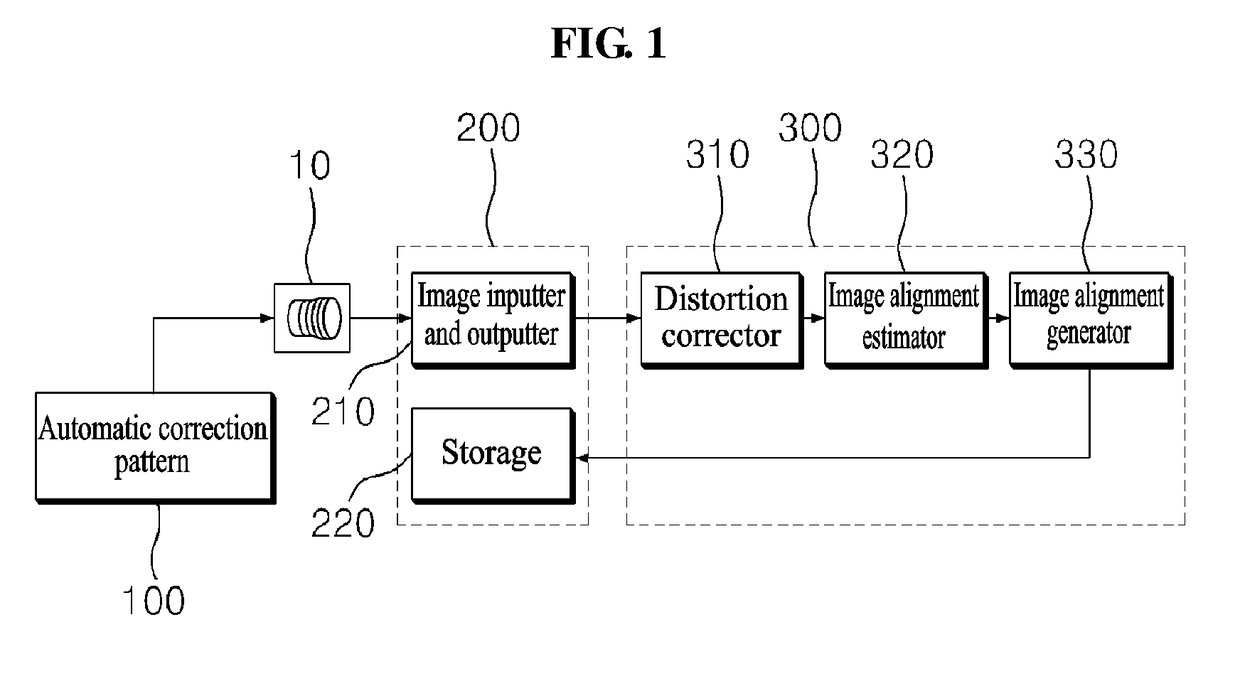

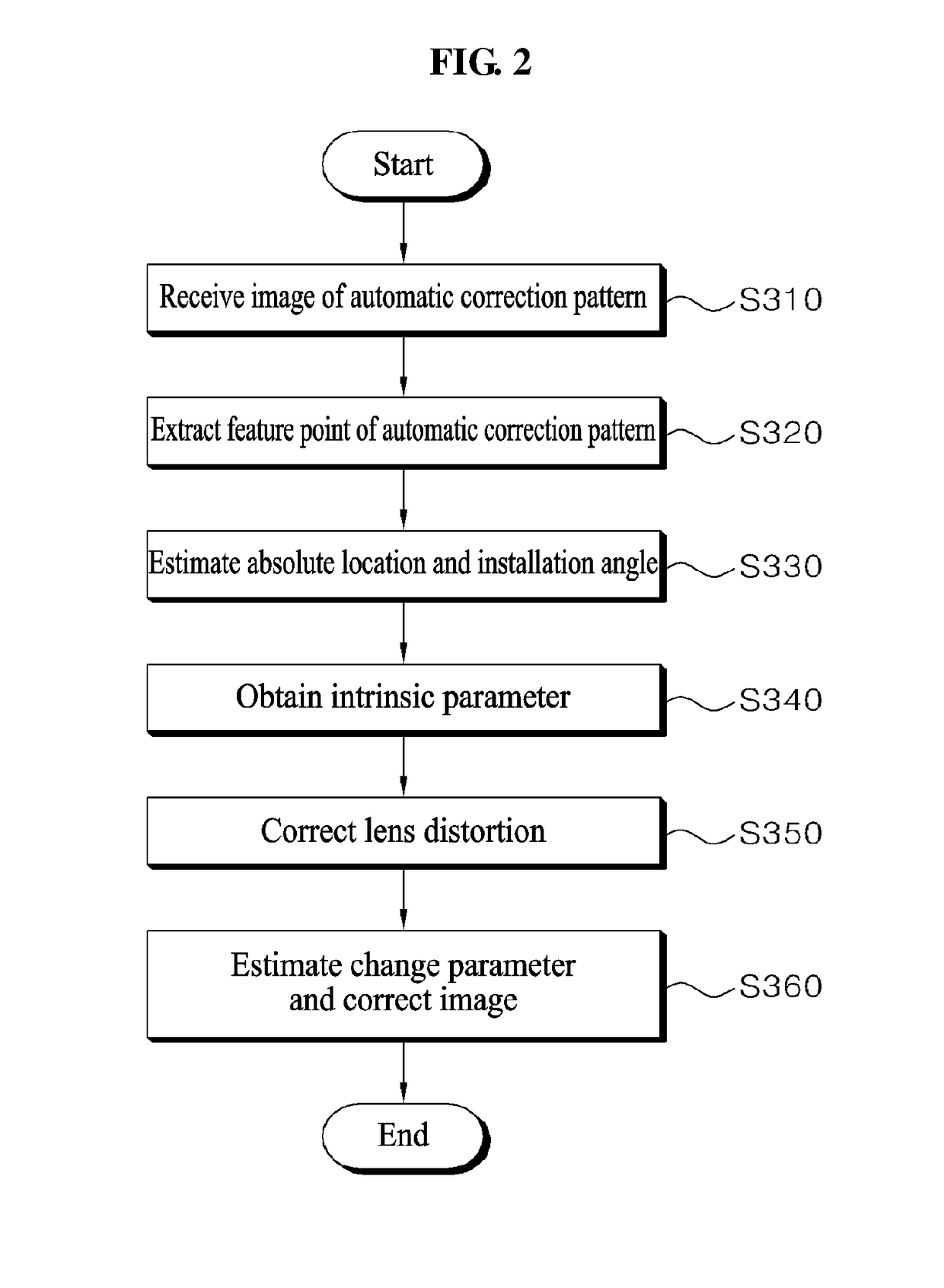

Image processing apparatus having automatic compensation function for image obtained from camera, and method thereof

ActiveUS20180122099A1Corrected simply and readilyImage enhancementTelevision system detailsRotational errorImaging processing

The present invention relates to an image processing apparatus having an automatic compensation function for an image obtained from a camera, and a method thereof, and provides an image processing apparatus having an automatic compensation function for an image obtained from a camera, the apparatus comprising: an automatic compensation pattern of which one or more can be provided in an arbitrary place near a camera; an input / output module which receives an image as an input from the camera and transmits the same to the image processing apparatus; and an image processing module which is a processing unit containing an algorithm for compensating for distortion of the image obtained from the camera, wherein the input / output module comprises an image input / output unit for transmitting / receiving data in between the camera and the image processing module, and a storage unit for storing information processed by the image processing module, and the image processing module comprises a distortion compensation unit, an image alignment estimation unit, and an image alignment generation unit, the distortion compensation unit extracting, from the received image, characteristic points of the automatic compensation pattern, estimating the absolute location and installation angle of the camera by using the information based on the extracted characteristic points, and performing lens distortion compensation by using an inner parameter stored in the storage unit, the image alignment estimation unit estimating, in the image, the camera installation location and rotational error as a change parameter by using information on the absolute location and installation angle of the camera estimated in the distortion compensation unit, and the image alignment generation unit compensating for the three-dimensional location and size of the image by using the change parameter estimated in the image alignment estimation unit.

Owner:NC& CO LTD

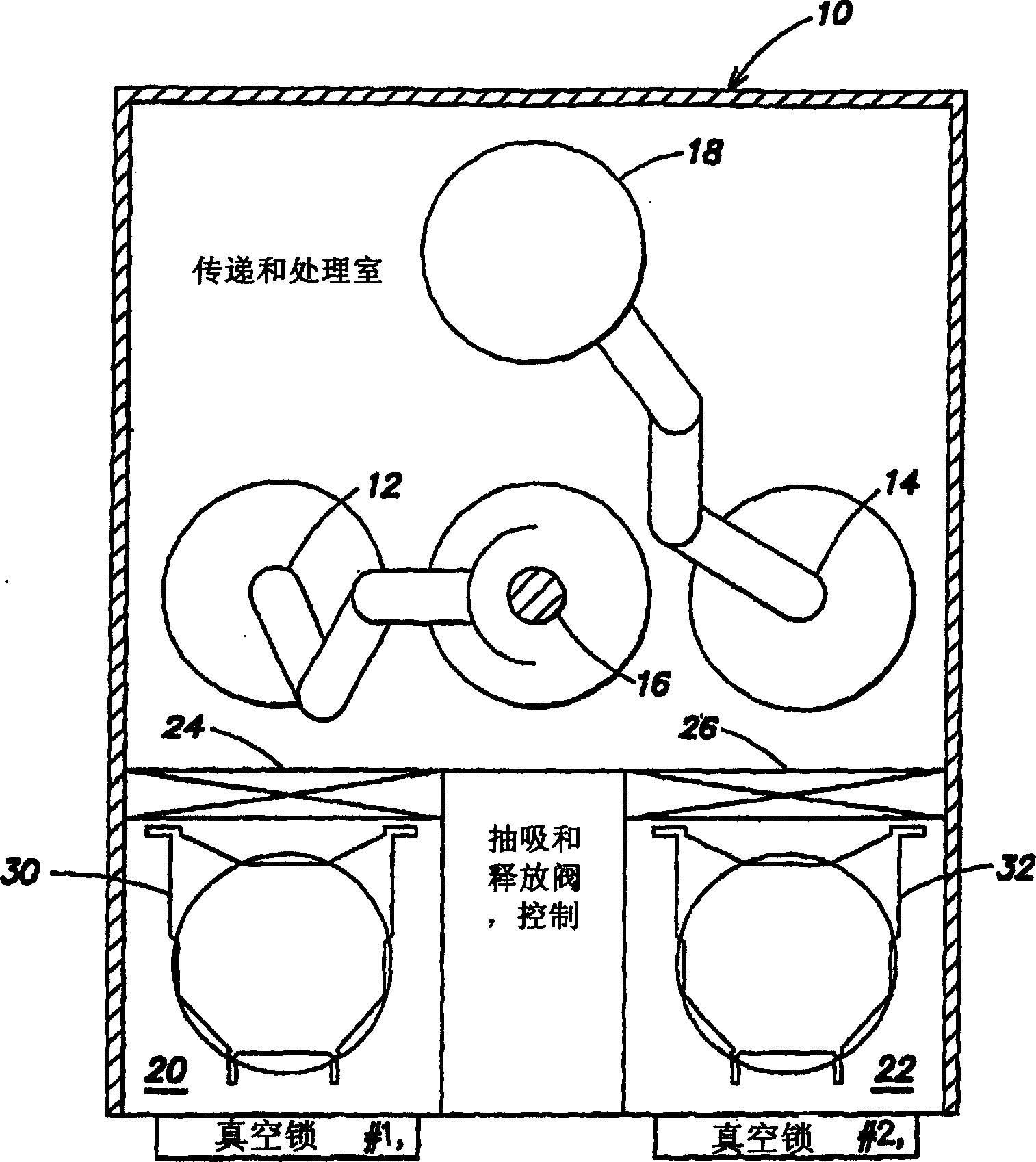

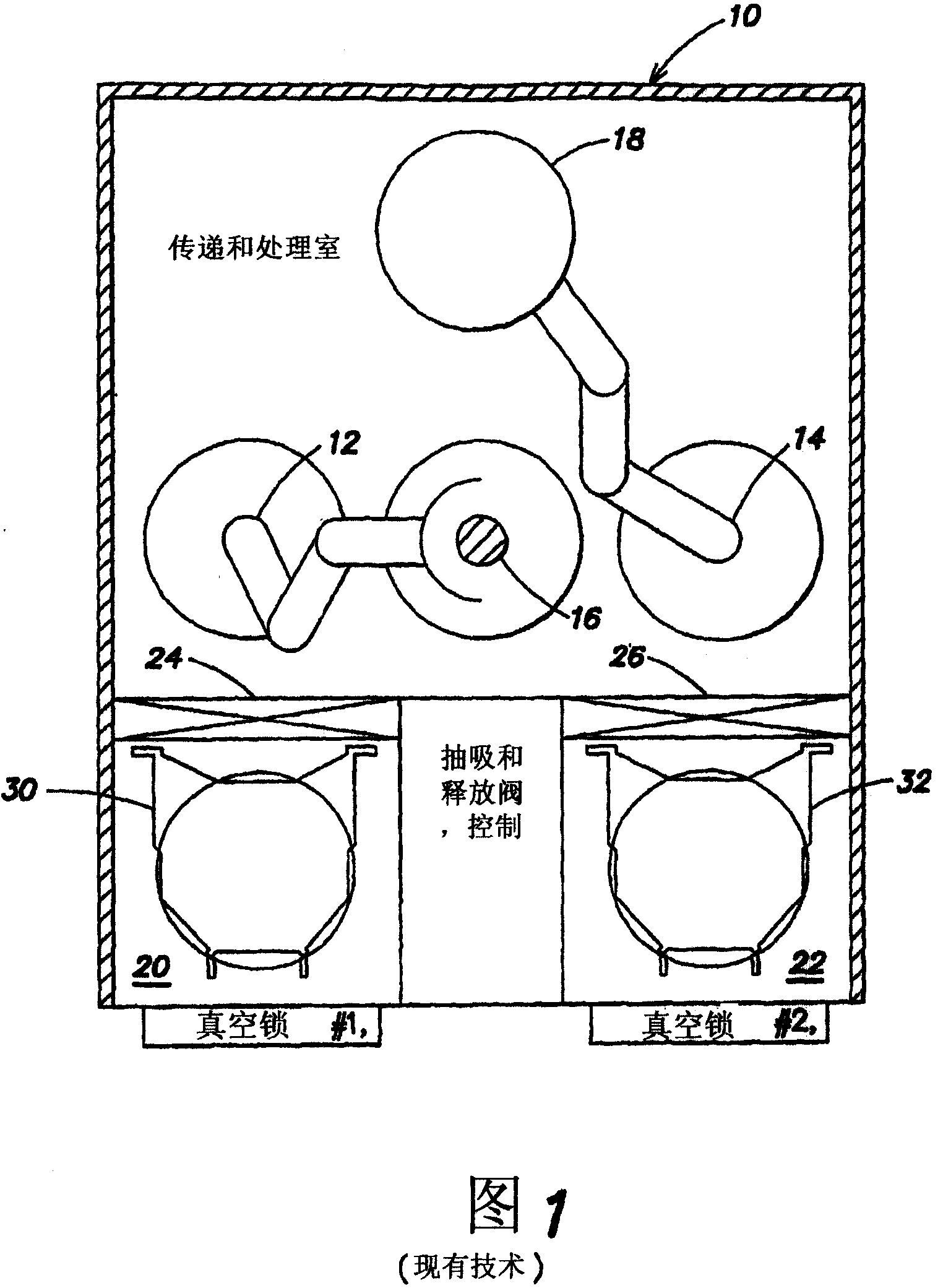

Methods and apparatus for high speed object handling

InactiveCN1765004ADigital data processing detailsSemiconductor/solid-state device manufacturingObject handlingRotational error

Methods and apparatus for high speed workpiece handling are provided. A method for workpiece handling includes: utilizing a first robot to remove a workpiece from a first magazine; transferring the workpiece from the first robot directly to a second robot without transferring the workpiece to a transfer station; utilizing the A second robot places the workpiece on a workpiece holder at a processing station; and transfers the workpiece from the workpiece holder to the first cassette with the first robot after processing. The end effectors of the first and second robots may each have a plurality of vertical positions for efficient workpiece handling. The displacement and rotation errors of the workpiece can be sensed and corrected without using a transfer station. The method and apparatus are useful for handling semiconductor wafers.

Owner:VARIAN SEMICON EQUIP ASSOC INC

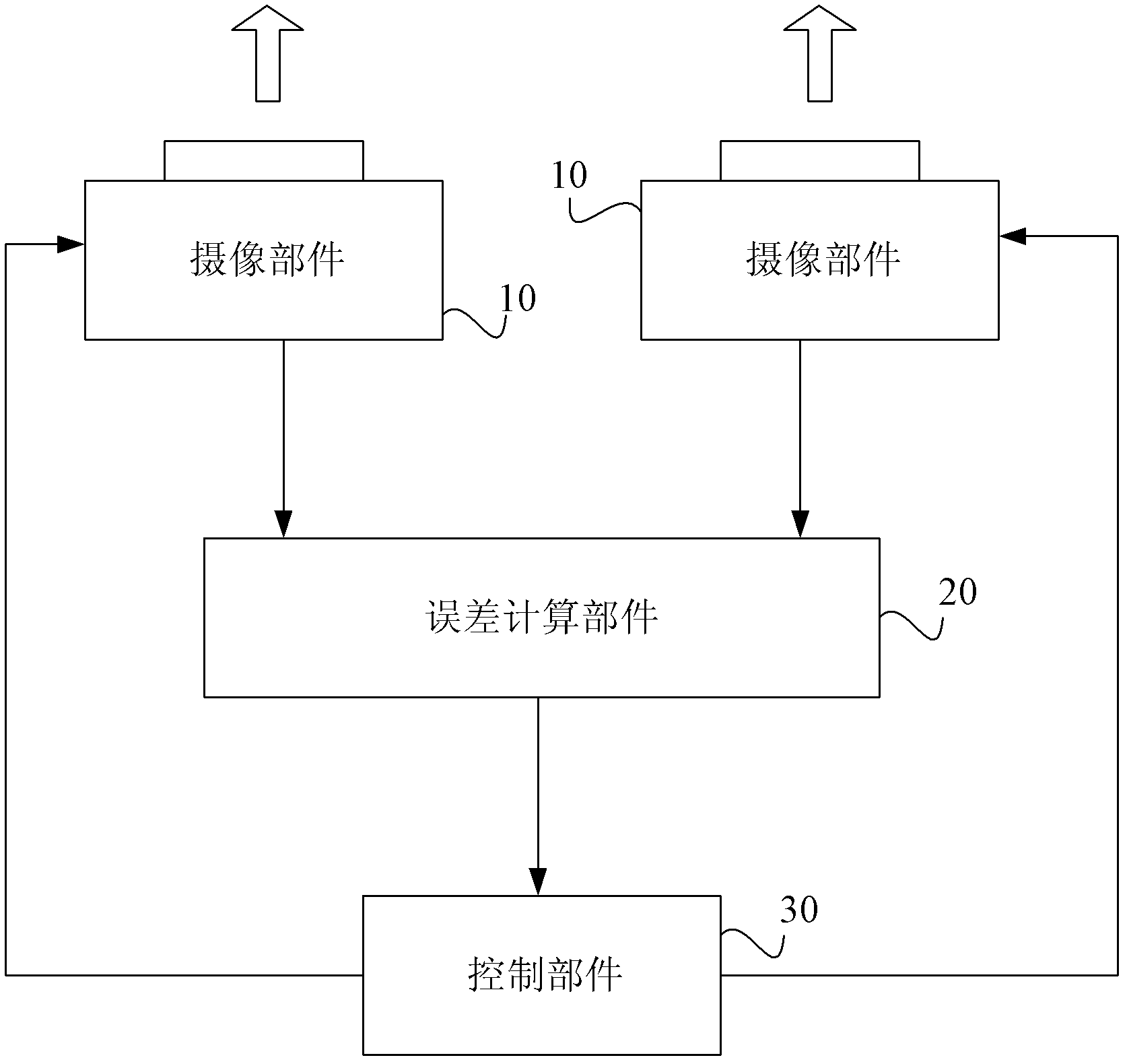

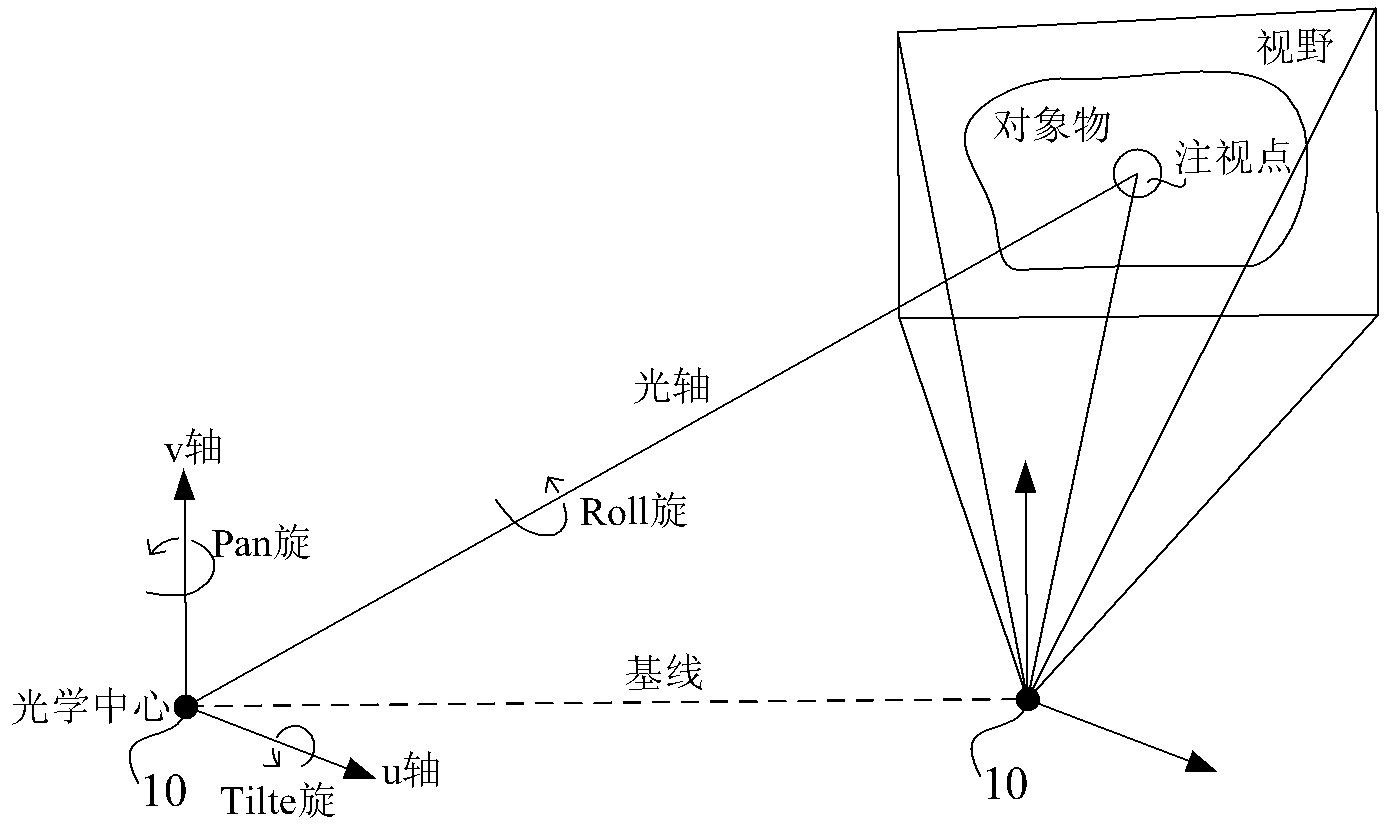

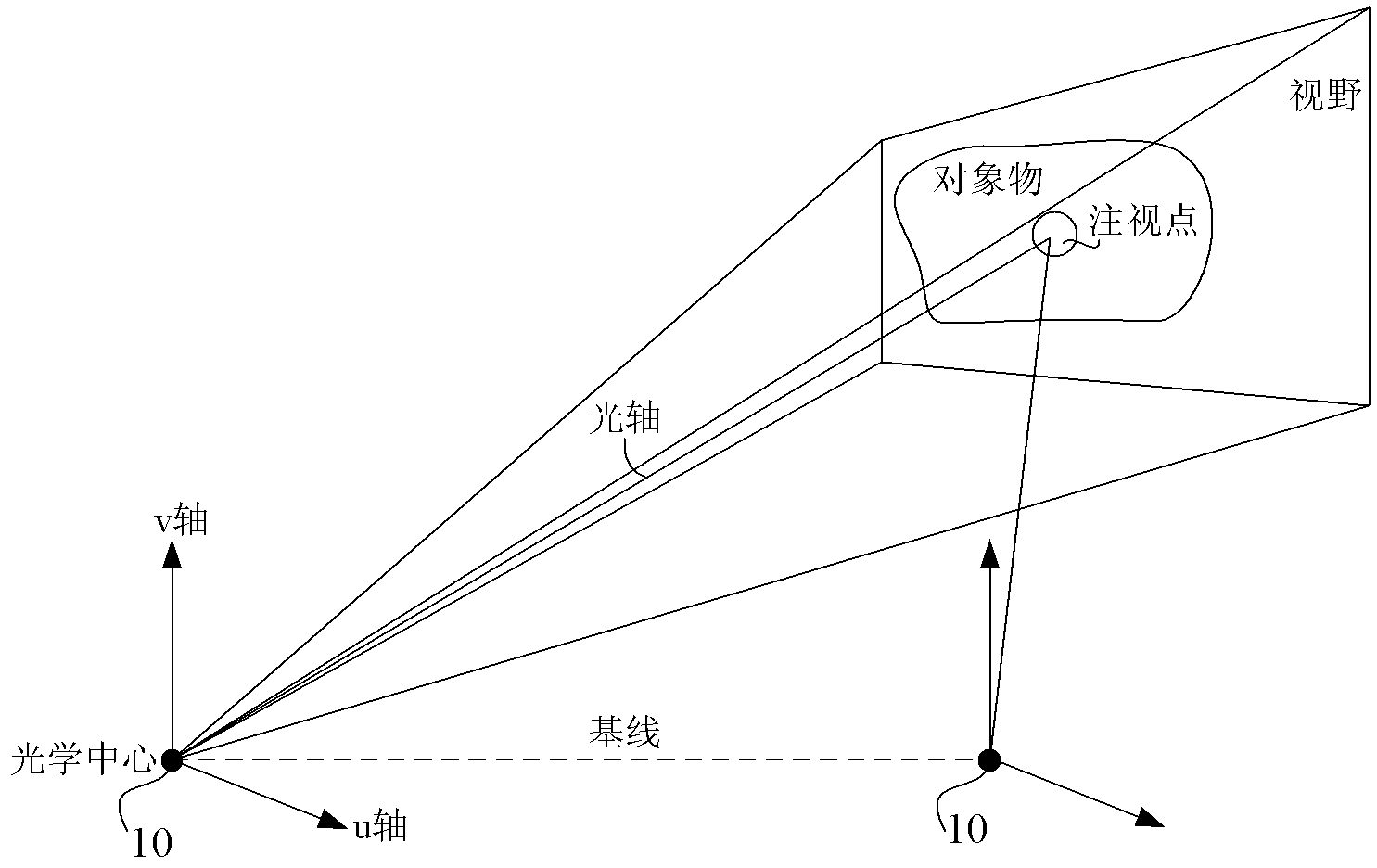

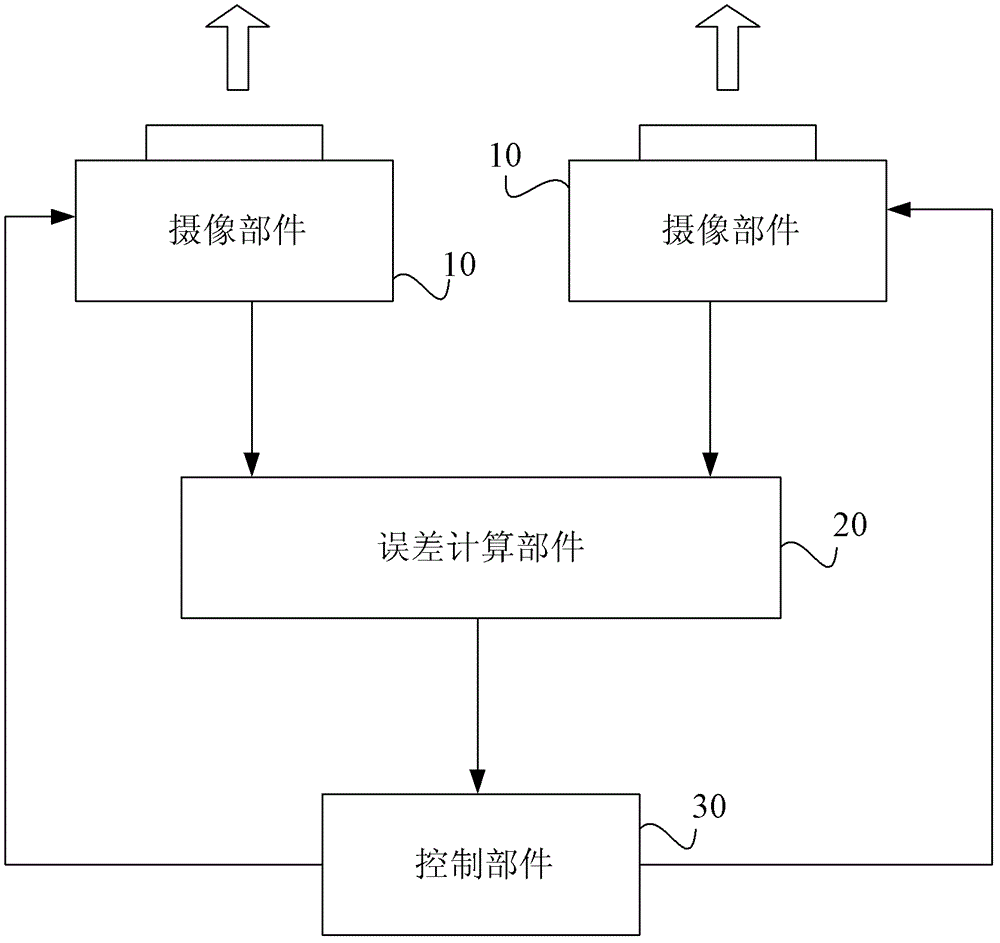

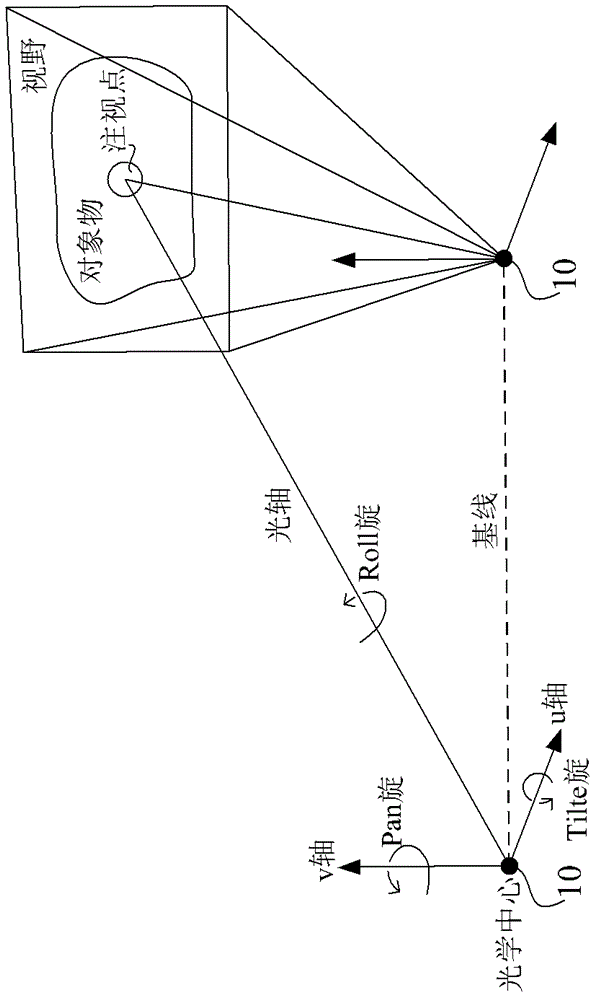

Control system for stereo video camera

The invention provides a control system for a stereo video camera. The control system can obtain stereo images with stereo visual effects even under the condition of unknown relative position relationship between two shooting parts. The control system for the stereo video camera comprises the two shooting parts, an error computing part and a control part, wherein the two shooting parts at least have one controllable digital or analogue degree of freedom for any parameter of Yaw, Pitch, Roll and a zoom rate, and can shoot continuous images by own shooting elements; the error computing part computes a rotating error and a zoom error between the shooting parts by comparing each image shot by the two shooting parts with a preset standard convergence model of each shooting part; and the control part controls the rotating angle and zoom rate of each shooting part by utilizing the rotating error and the zoom error computed by the error computing part.

Owner:比比威株式会社

Machining method for hard-fine machining of noise-optimized gears on a gear-cutting machine

ActiveUS9409244B2Improve uniformityAvoid orAutomatic control devicesFeeding apparatusRotational errorGear wheel

Owner:LIEBHERR VERZAHNTECHNIK GMBH

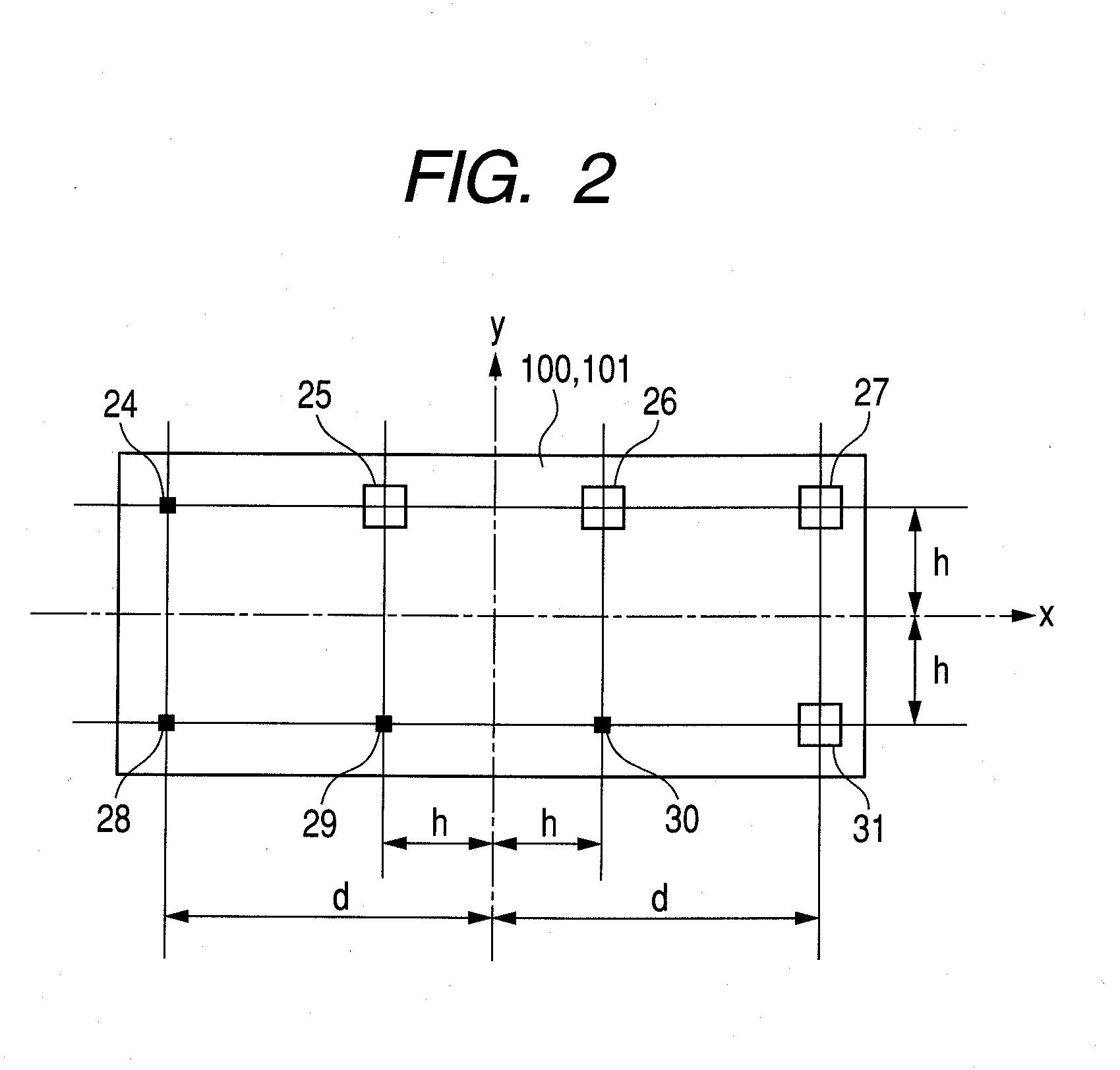

Measuring method, adjustment method for stage movement characteristics, exposure method, and device manufacturing method

InactiveUS20090257045A1Short timePrecise arrangementPhotomechanical apparatusDigital computer detailsCamera lensRotational error

Provided is a measuring method including: transferring a measuring mark disposed on an original to a substrate at a plurality of locations; moving a substrate stage for holding the substrate so that the substrate is rotated by 90 degrees about a rotation axis parallel to an optical axis of a projection optical system; then transferring the measuring mark to the substrate at a plurality of locations so that the measuring mark overlaps the transfer region; measuring positional deviations among the transferred measuring marks and a first overlap mark in a region where the transfer regions overlap each other; and calculating at least one of a positional error of a shot on the substrate, a rotational error of the same, and an orthogonality in shot arrangement based on a result of the measurement.

Owner:CANON KK

Systems having multi-linkage robots and methods to correct positional and rotational alignment in multi-linkage robots

Methods of correction of rotational and linear misalignment in multi-link robots are provided. The method allows for precise orientation of an end effector to put or pick substrates at a target destination by correcting for both positional and rotational orientation errors. The method rotates a boom linkage to a position adjacent to the target destination, corrects for linear and rotational error by rotating a boom linkage as well as an upper arm link as well as extending or retracting a wrist member. Systems including long boom linkages are disclosed. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

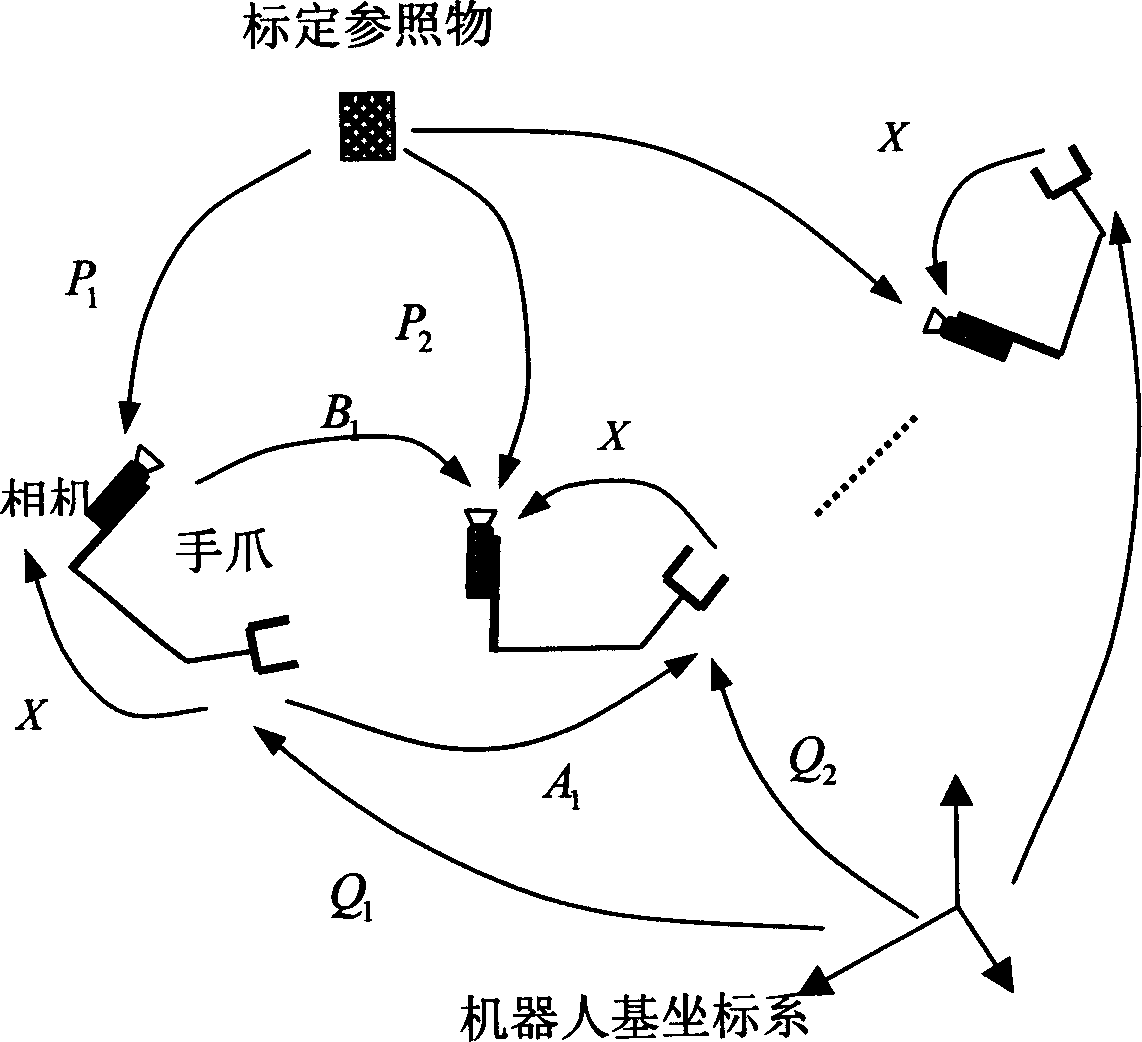

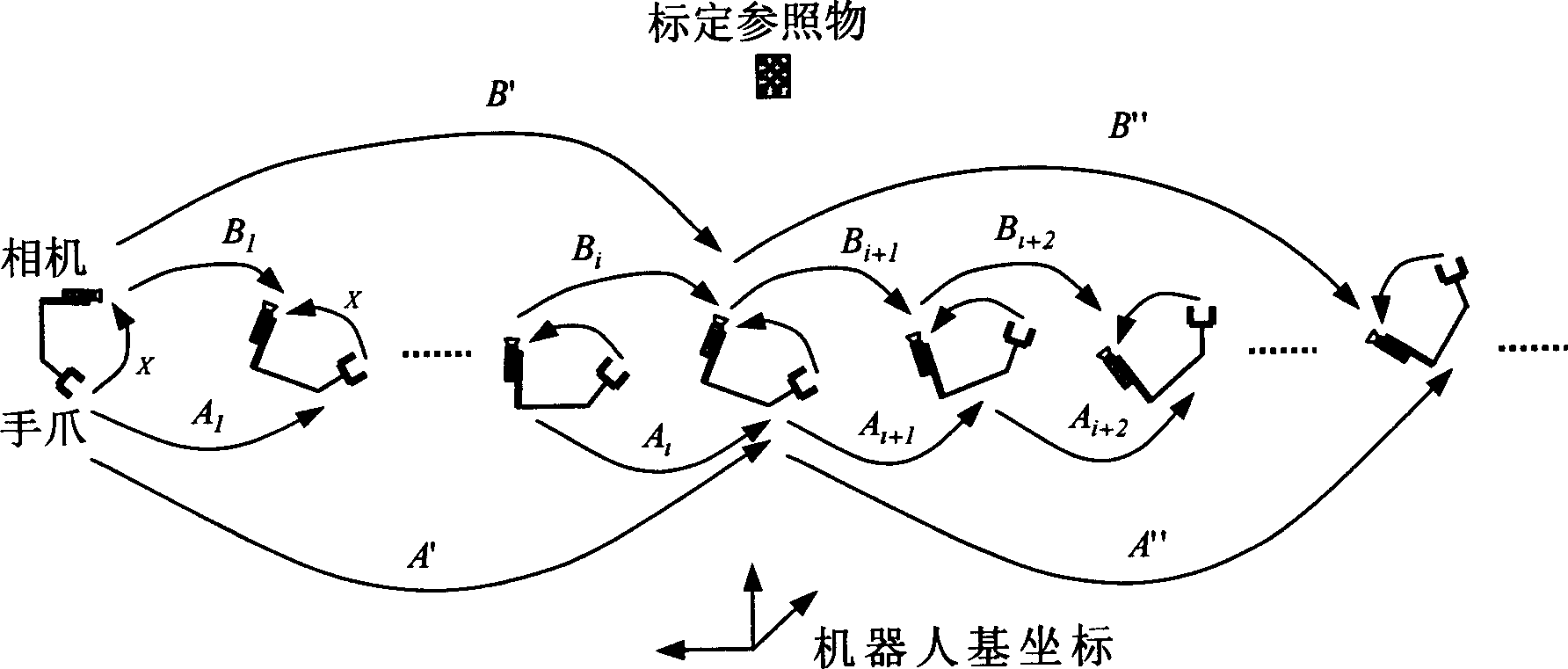

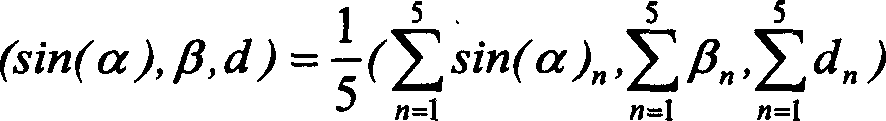

Adaptive motion selection method used for robot on line hand eye calibration

InactiveCN1686682AIncrease the number of calibrationsImprove calibration accuracyProgramme-controlled manipulatorRotational errorHand eye calibration

An adaptive movement selection method for in-line calibration of robot's hand and eyes includes using the previous 5 movement parameters of the hands of robot to calculate the inertial values of 3 thresholds for movement selection, in-line calibration of hands and eyes on the basis of movement selection, calculating rotational error and traslation error, adaptively changing said 3 thresholds, performing movement selection and calibration of hands and eyes again, and cyclically repeating above-said steps.

Owner:SHANGHAI JIAO TONG UNIV

Systems having multi-linkage robots and methods to correct positional and rotational alignment in multi-linkage robots

Methods of correction of rotational and linear misalignment in multi-link robots are provided. The method allows for precise orientation of an end effector to put or pick substrates at a target destination by correcting for both positional and rotational orientation errors. The method rotates a boom linkage to a position adjacent to the target destination, corrects for linear and rotational error by rotating a boom linkage as well as an upper arm link as well as extending or retracting a wrist member. Systems including long boom linkages are disclosed. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

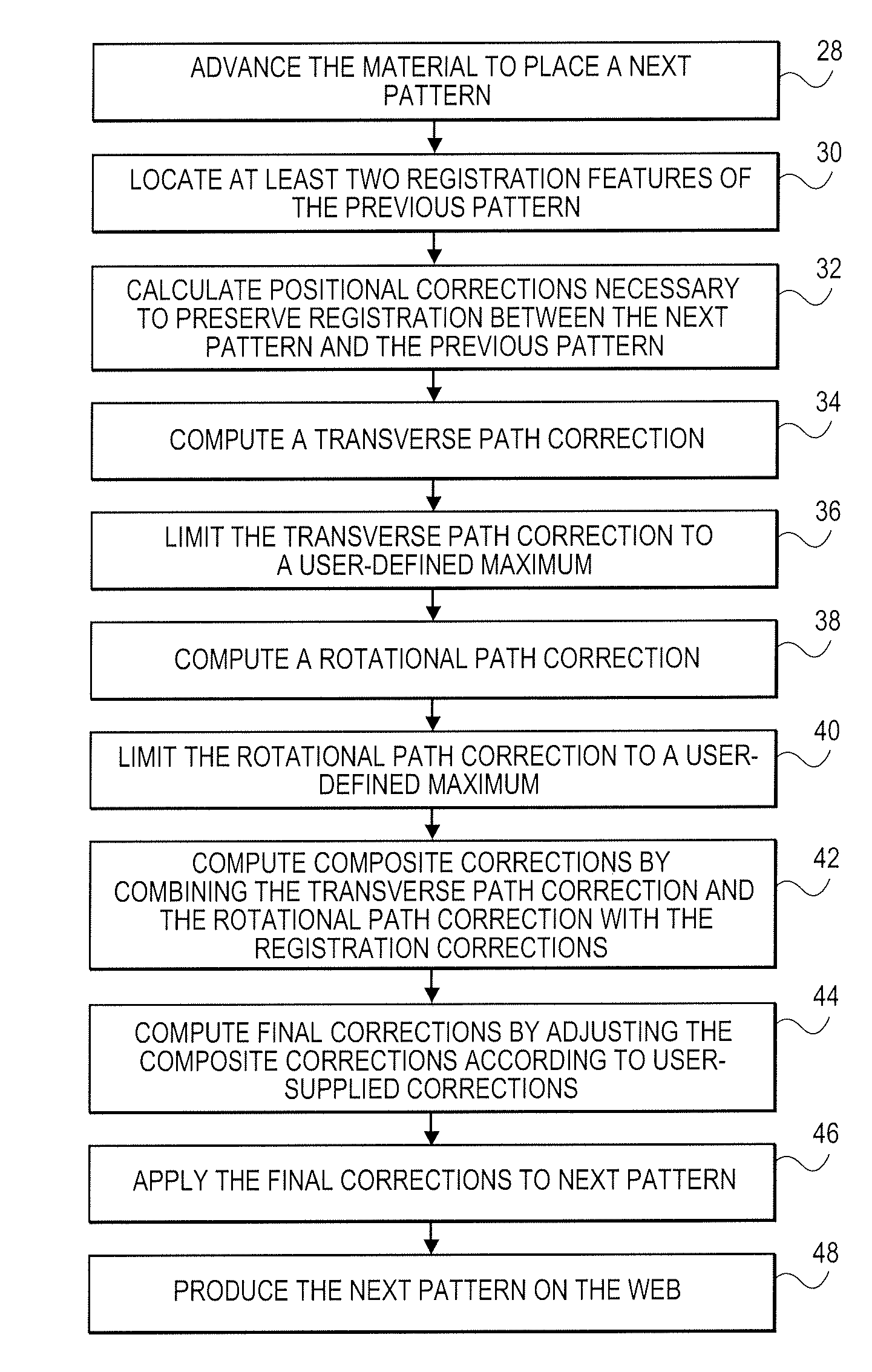

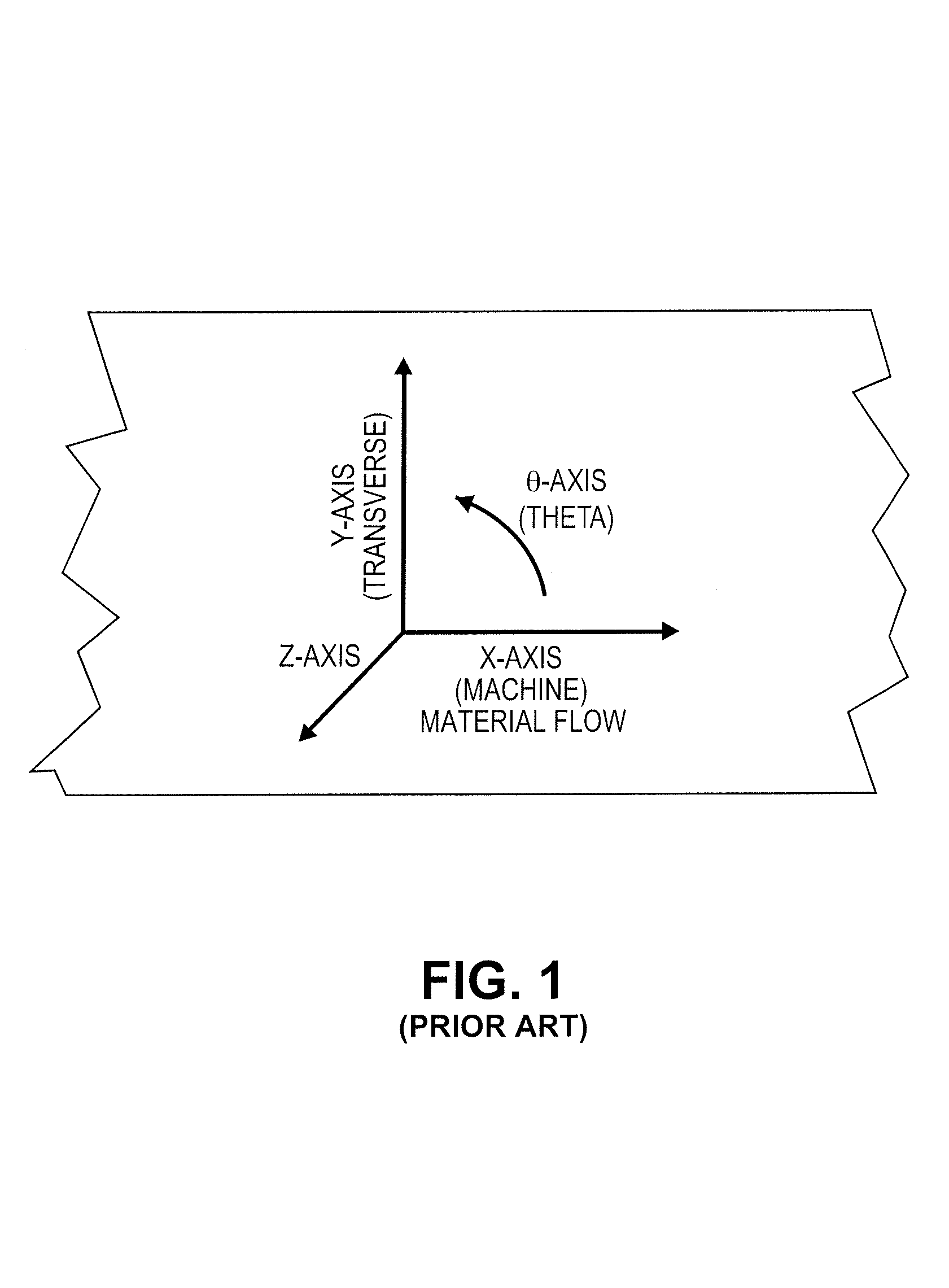

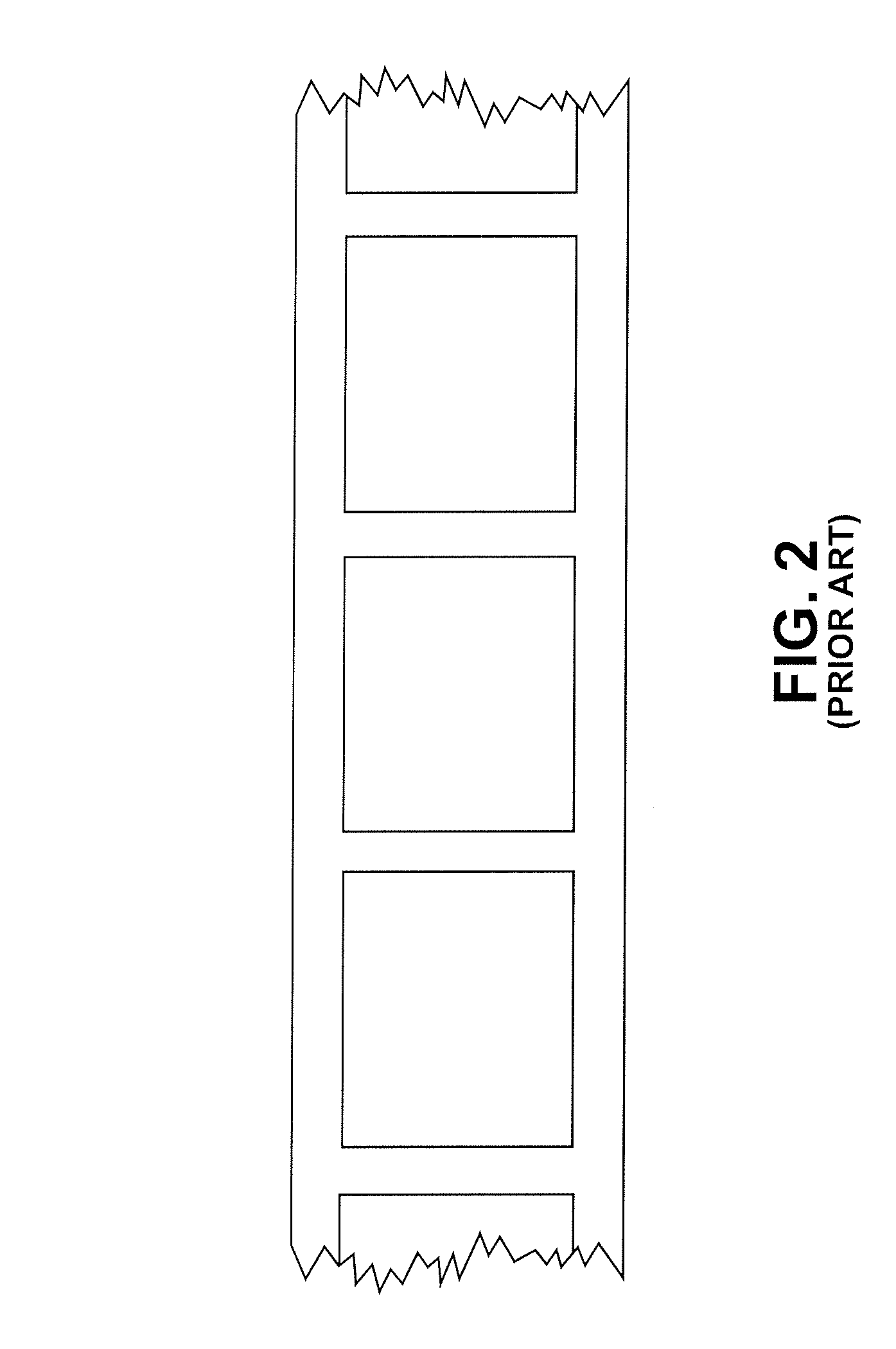

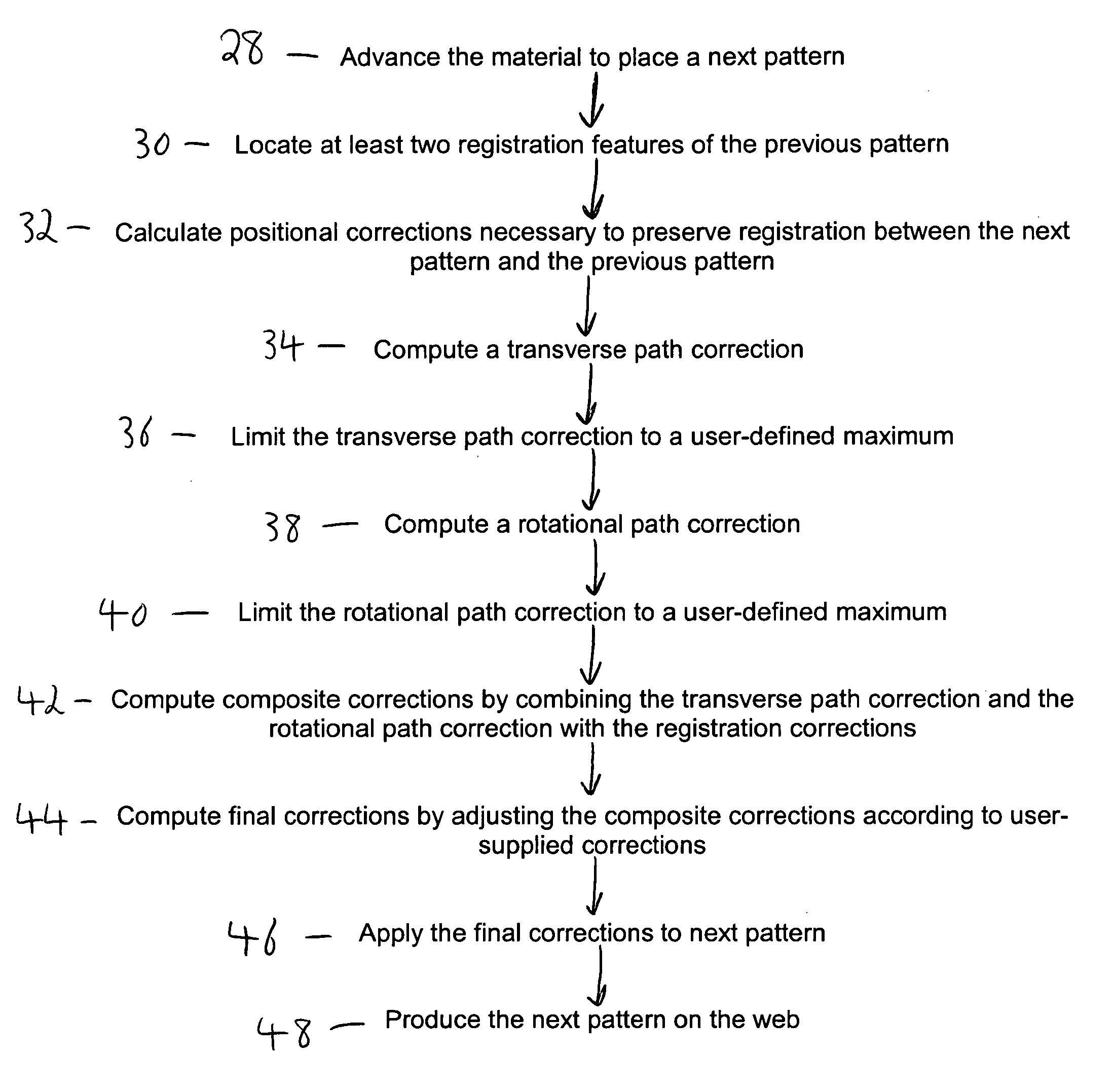

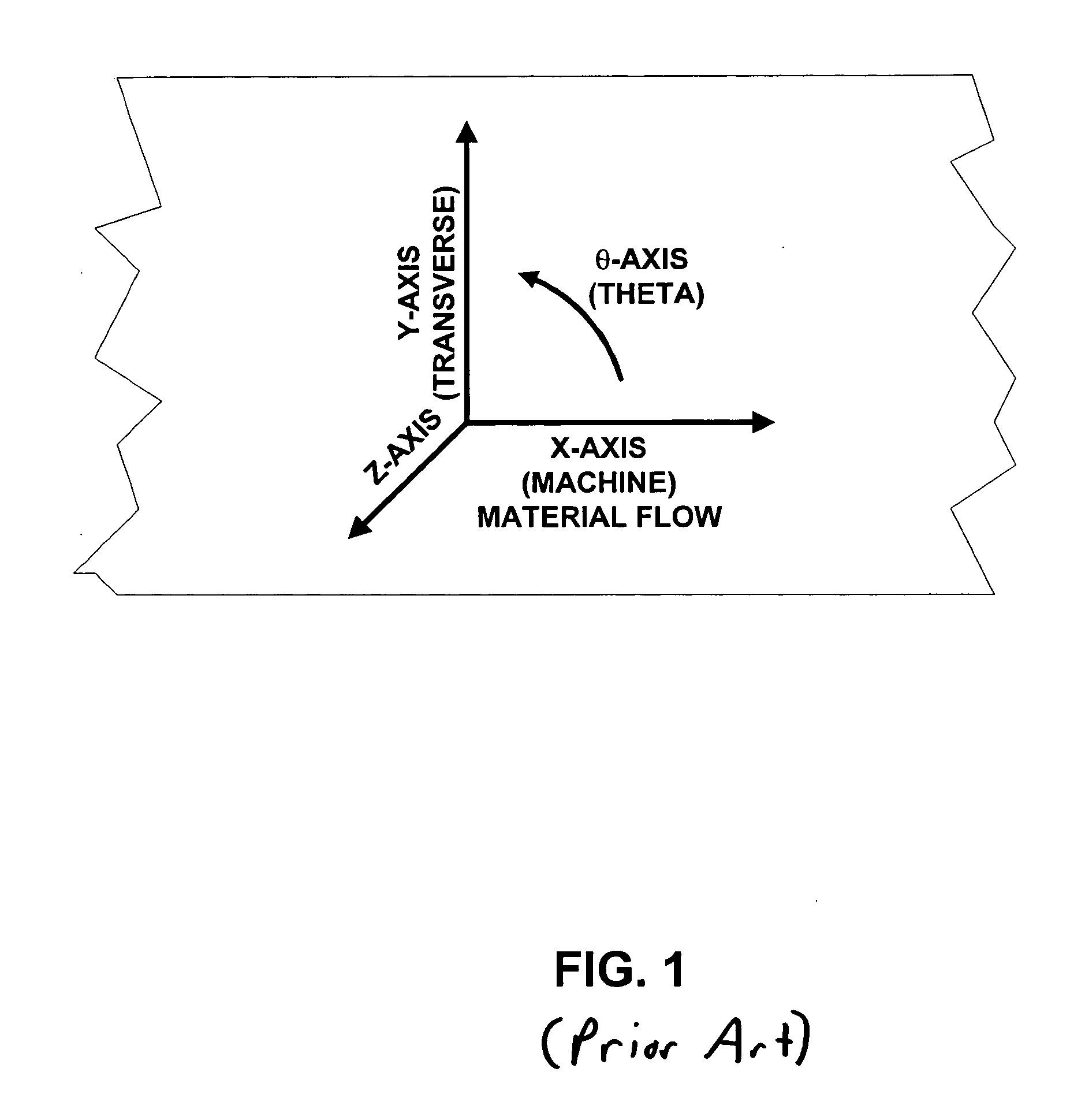

Method for tracking a registered pattern to a continuous web

A method of applying a registered pattern to a continuous web of material involves determining a position of a next pattern such that the next pattern is in registration with a previous pattern, adjusting the position to maintain a transverse location relative to the web, and adjusting a rotation of the pattern so that the pattern is substantially aligned with a longitudinal axis of the web. Registration features of the web and registration features of the next pattern are used to determine longitudinal, transverse, and rotational errors between the registered position of the next pattern and the path of the web. The registered position of the next pattern is adjusted along a transverse axis of the web according to a transverse error to maintain the transverse location. A rotation of the registered position is adjusted according to an angle that is determined using the transverse error and a distance from a registration feature to a center of the pattern along a longitudinal axis of the pattern.

Owner:PRECO ACQUISITION LLC

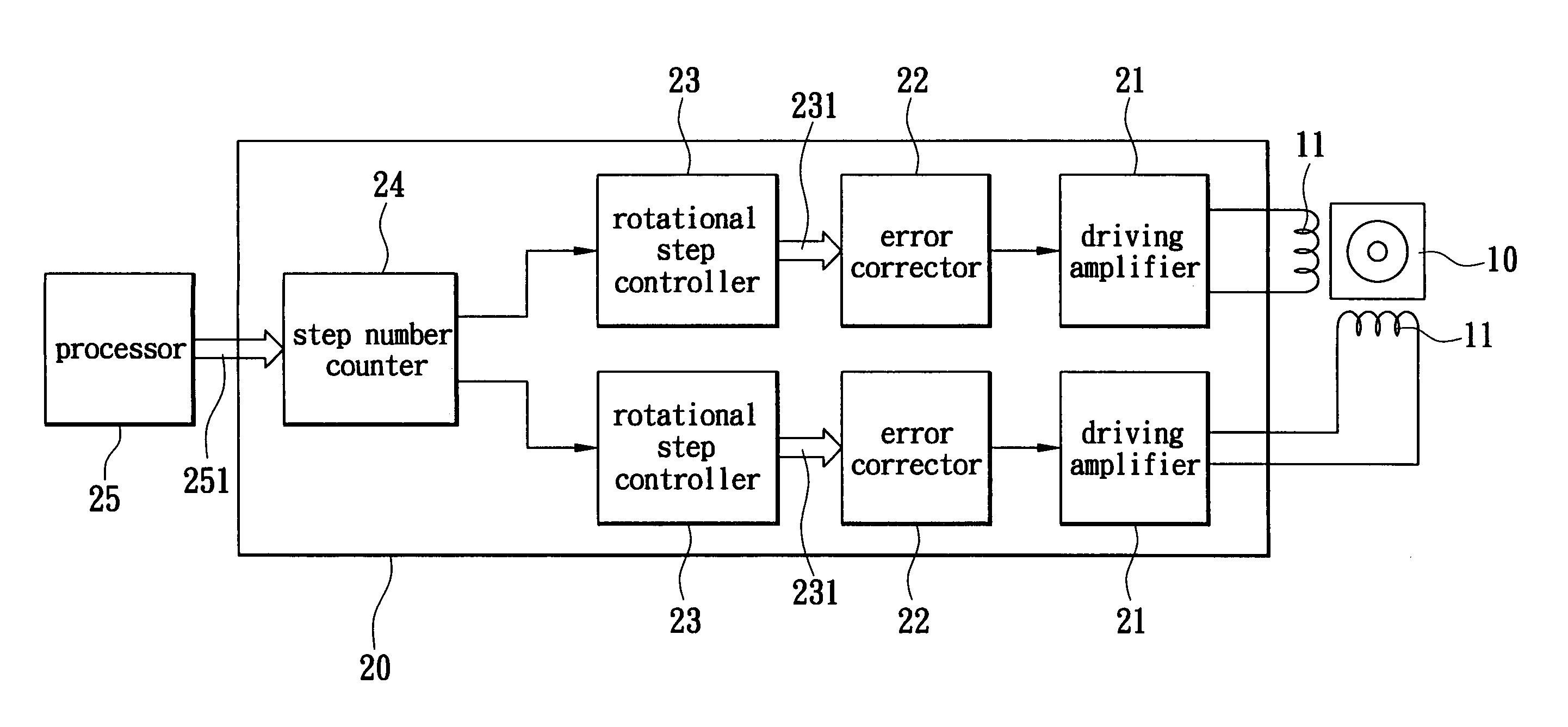

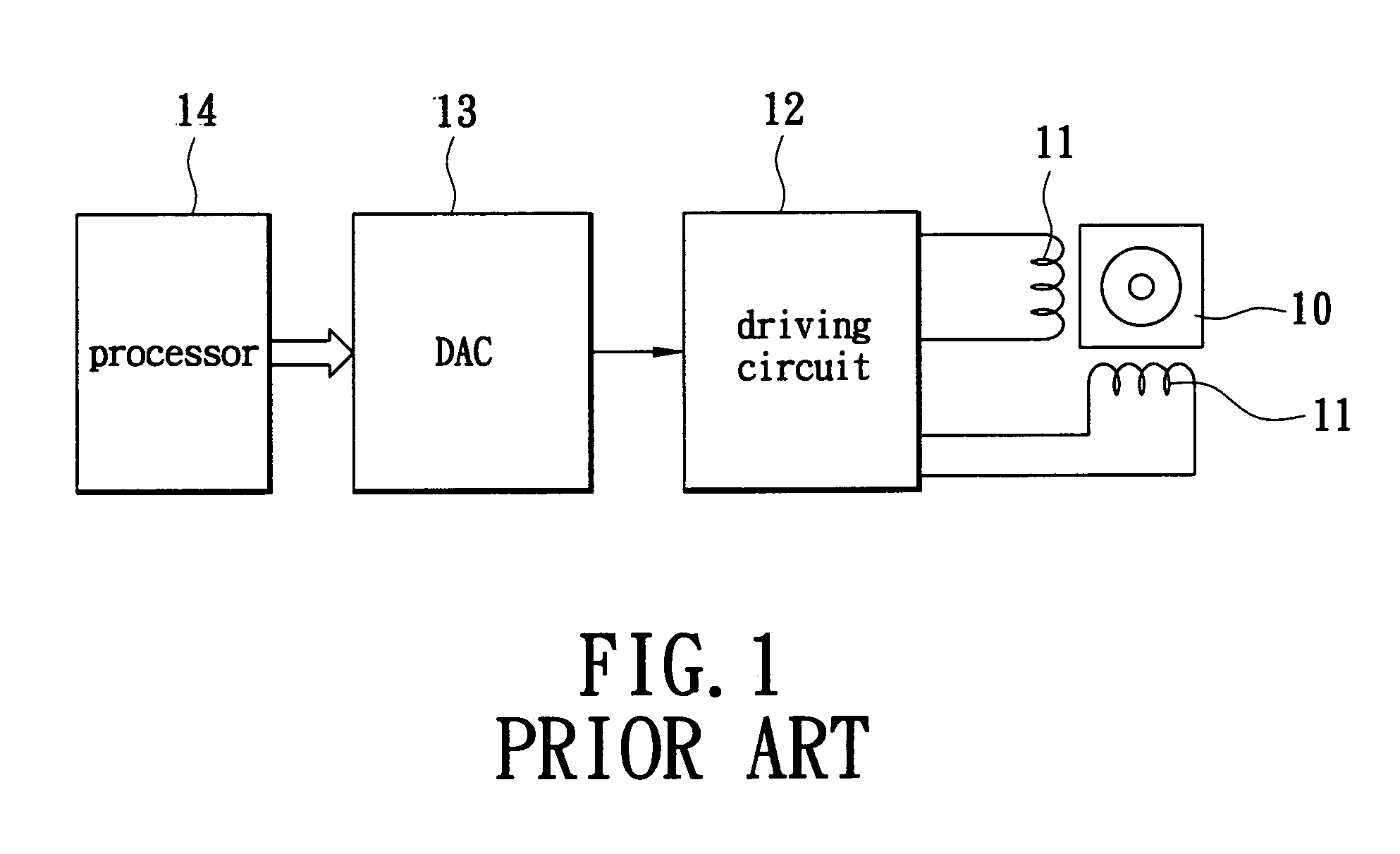

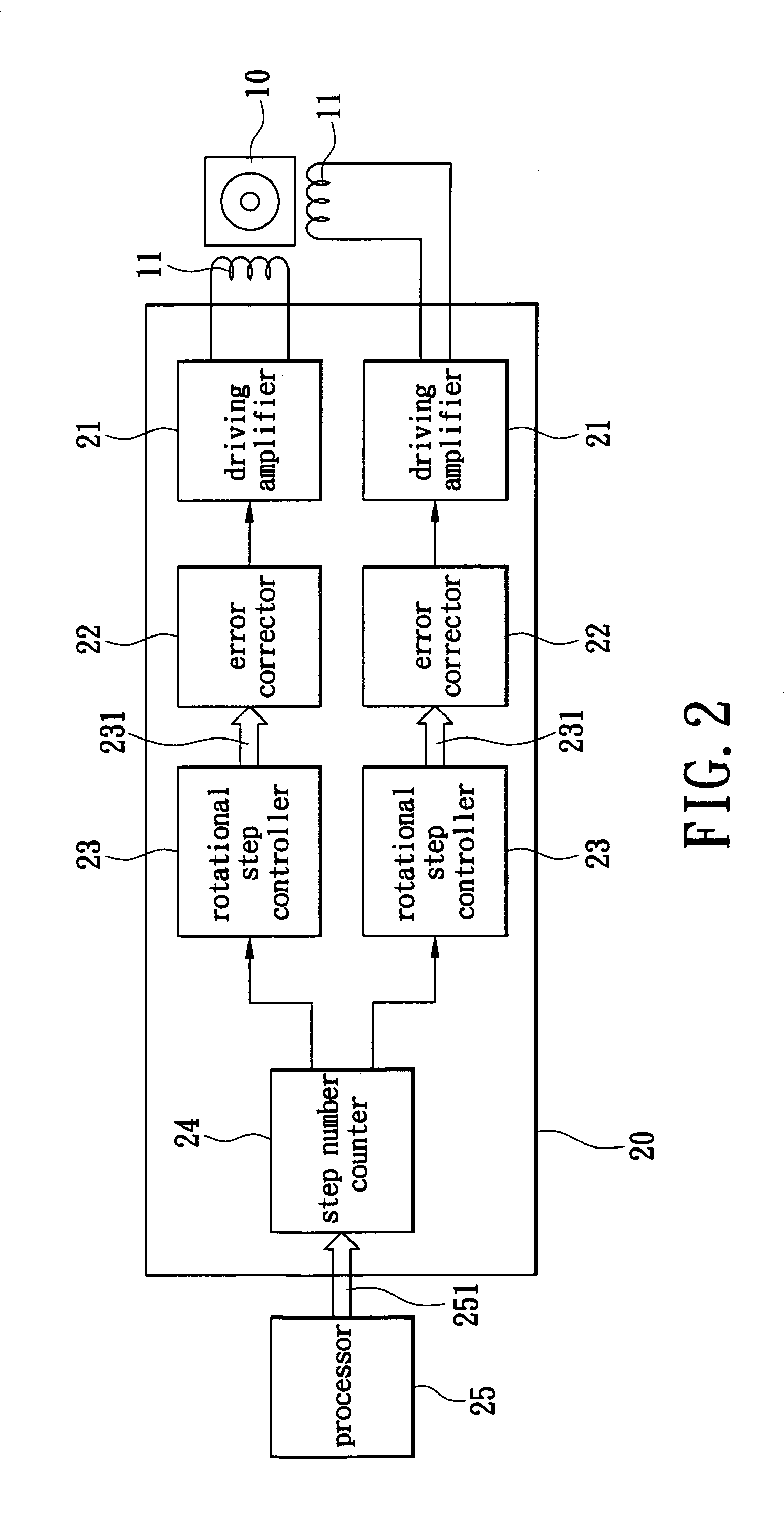

Error-correction apparatus for step-motor transmission system and a method for the same

InactiveUS6967460B1Improve the accuracy of operationEasy to operateComputer controlSimulator controlRotational errorEngineering

An error-correction method and apparatus are used for a step motor transmission system. The step motor has a plurality of inductor coils therein for rotating an internal shaft thereof. A rotational error gamma table is established by measuring an error value for each rotational step of the step motor. The error-correction apparatus receives an external digital displacement signal for producing a rotational step signal. A compensation current is produced according to the rotational step signal and an error value in the rotational error gamma table. The inductor coils are driven by the compensation current to rotate the internal shaft precisely.

Owner:SERVICE & QUALITY TECHNOLOGY CO LTD

Method for tracking a registered pattern to a continuous web

A method of applying a registered pattern to a continuous web of material involves determining a position of a next pattern such that the next pattern is in registration with a previous pattern, adjusting the position to maintain a transverse location relative to the web, and adjusting a rotation of the pattern so that the pattern is substantially aligned with a longitudinal axis of the web. Registration features of the web and registration features of the next pattern are used to determine longitudinal, transverse, and rotational errors between the registered position of the next pattern and the path of the web. The registered position of the next pattern is adjusted along a transverse axis of the web according to a transverse error to maintain the transverse location. A rotation of the registered position is adjusted according to an angle that is determined using the transverse error and a distance from a registration feature to a center of the pattern along a longitudinal axis of the pattern.

Owner:PRECO ACQUISITION LLC

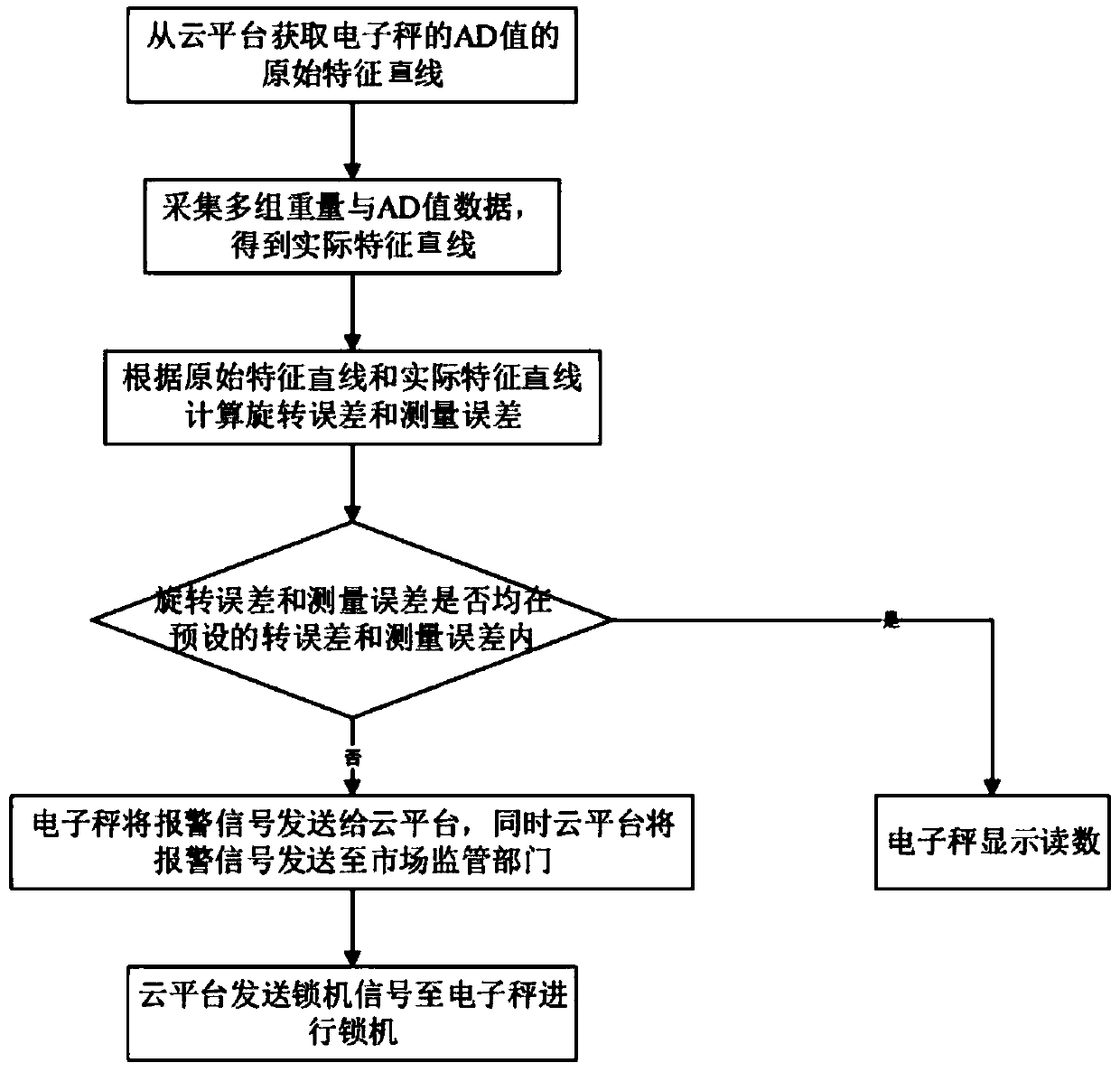

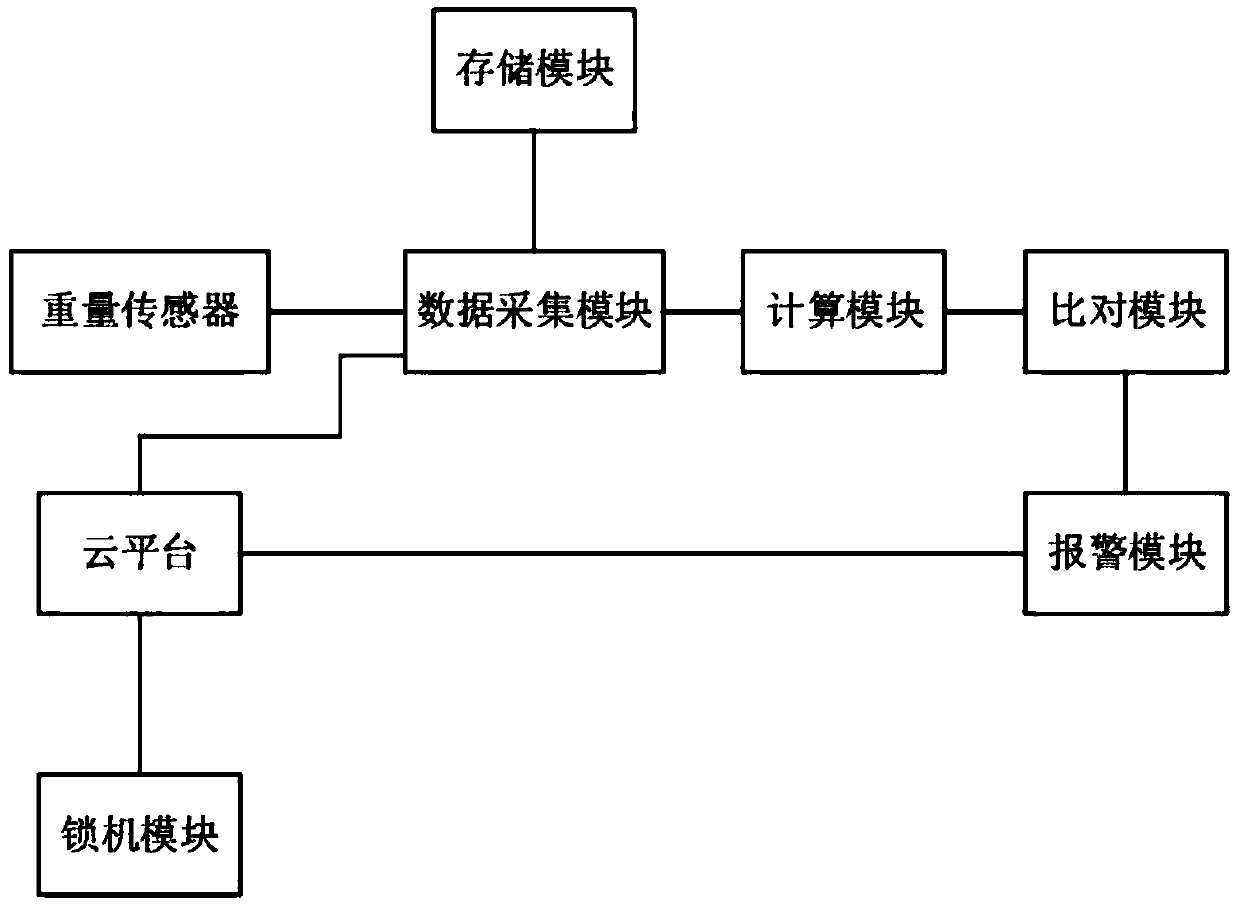

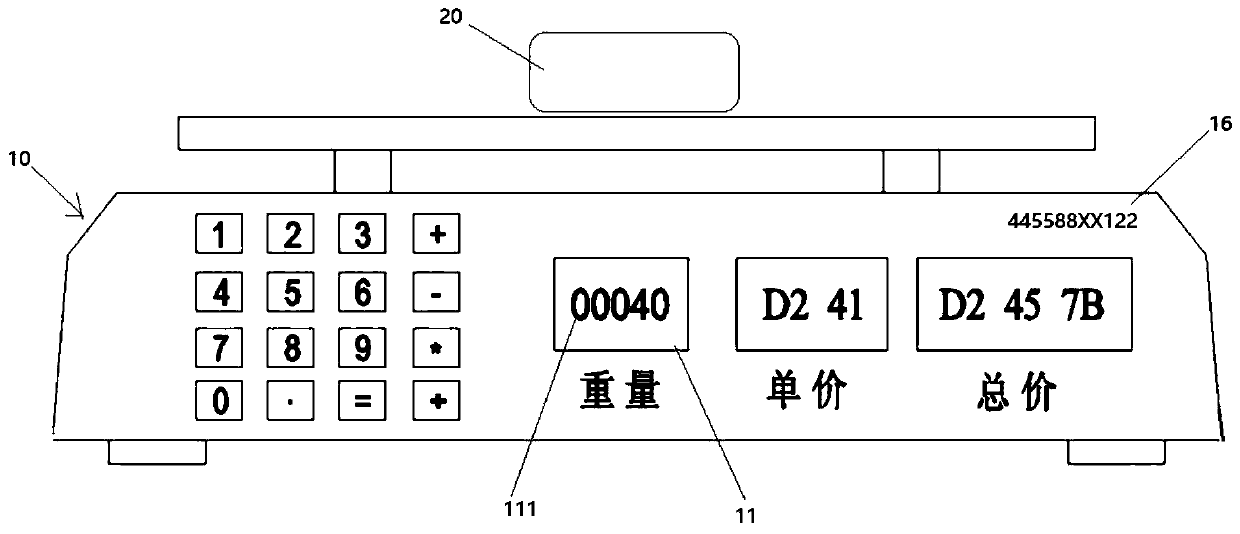

Electronic scale anti-cheating method and electronic scale with anti-cheating function

InactiveCN109655147APrevent cheatingTo achieve the purpose of monitoringWeighing apparatus testing/calibrationObservational errorRotational error

The invention discloses an electronic scale anti-cheating method and an electronic scale with an anti-cheating function. The electronic scale anti-cheating method comprises the steps of acquiring original feature line y1=a1x and actual feature line y2=a2x of AD value of an electronic scale; calculating and judging whether a rotational error and a measurement error are within a preset error range according to the original feature line and the actual feature line; if not, sending a warning signal to a cloud platform. The reasonable preset error is given herein; the actual errors are calculated according to multiple acquired actual weights; if the actual errors exceed the reasonable preset error, it is indicated that the electronic scale cheats; the warning information is reported to the cloud platform so as to monitor the electronic scale in real time and avoid cheating; the electronic scale can be locked via the cloud platform to stop operating, and cheating behaviors can be delivered to a market supervision department.

Owner:深圳市计量质量检测研究院(国家高新技术计量站国家数字电子产品质量监督检验中心)

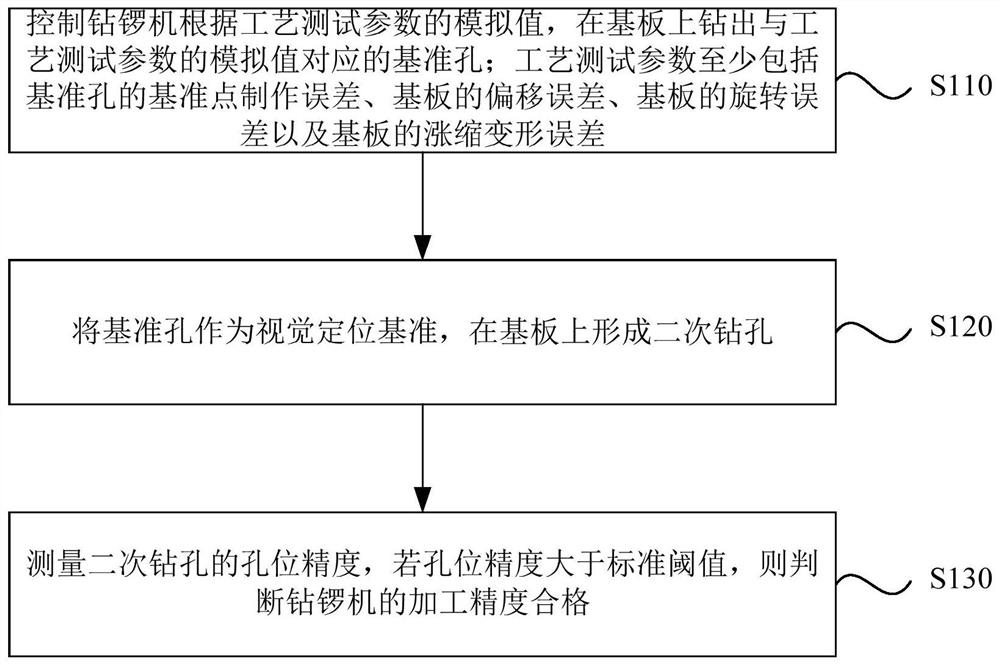

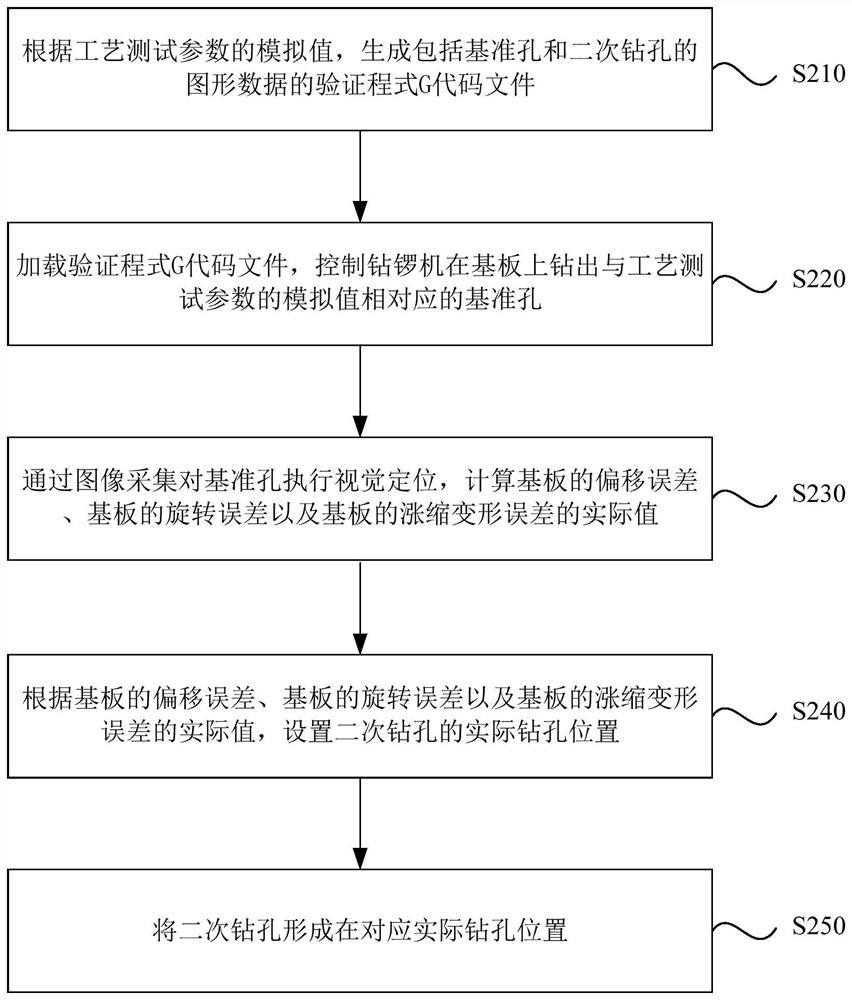

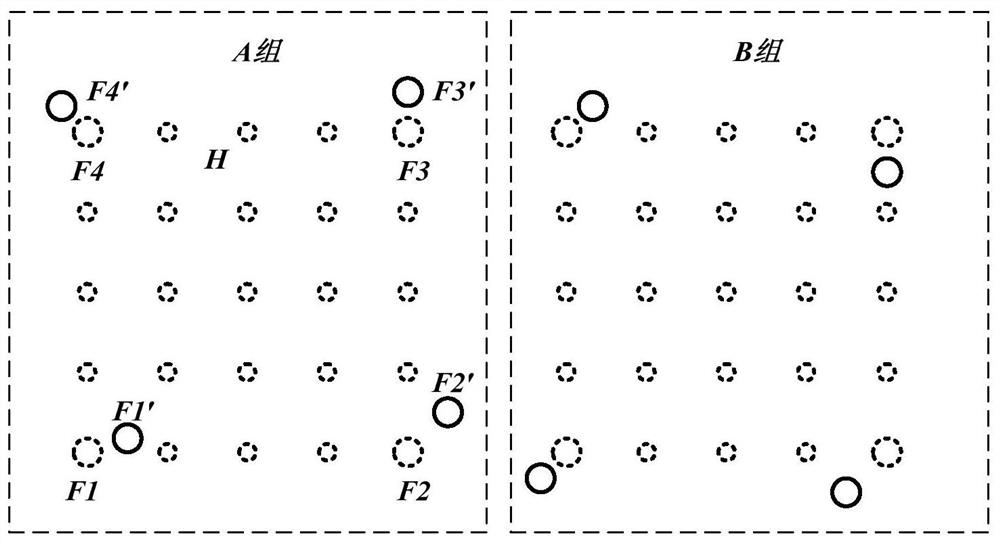

Verification method and device for machining precision of drilling and milling machine, drilling and milling machine and storage medium

ActiveCN112466001AImprove verification efficiencyMeet needsRegistering/indicating quality control systemsRegistering/indicating during manufacturing processRotational errorProcess engineering

The embodiment of the invention discloses a verification method and device for machining precision of a drilling and milling machine, the drilling and milling machine and a storage medium. The methodcomprises the following steps: controlling a drilling and milling machine to drill a reference hole corresponding to an analog value of a process test parameter on a substrate according to the analogvalue of the process test parameter, wherein the process test parameters at least comprise a reference point manufacturing error of the reference hole, an offset error of the substrate, a rotation error of the substrate and an expansion deformation error of the substrate; taking the reference hole as a visual positioning reference, and forming a secondary drill hole in the substrate; and measuringthe hole position precision of the secondary drilling, and if the hole position precision is larger than a standard threshold value, judging that the machining precision of the drilling and milling machine is qualified. According to the technical scheme provided by the embodiment of the invention, low-cost, high-efficiency and high-automation verification of the machining precision of the drilling and milling machine can be achieved.

Owner:SUZHOU VEGA TECH CO LTD

Image processing apparatus having automatic compensation function for image obtained from camera, and method thereof

ActiveUS10176595B2Corrected simply and readilyImage enhancementTelevision system detailsRotational errorImaging processing

The present invention relates to an image processing apparatus having an automatic compensation function for an image obtained from a camera, and a method thereof, and provides an image processing apparatus having an automatic compensation function for an image obtained from a camera, the apparatus comprising: an automatic compensation pattern of which one or more can be provided in an arbitrary place near a camera; an input / output module which receives an image as an input from the camera and transmits the same to the image processing apparatus; and an image processing module which is a processing unit containing an algorithm for compensating for distortion of the image obtained from the camera, wherein the input / output module comprises an image input / output unit for transmitting / receiving data in between the camera and the image processing module, and a storage unit for storing information processed by the image processing module, and the image processing module comprises a distortion compensation unit, an image alignment estimation unit, and an image alignment generation unit, the distortion compensation unit extracting, from the received image, characteristic points of the automatic compensation pattern, estimating the absolute location and installation angle of the camera by using the information based on the extracted characteristic points, and performing lens distortion compensation by using an inner parameter stored in the storage unit, the image alignment estimation unit estimating, in the image, the camera installation location and rotational error as a change parameter by using information on the absolute location and installation angle of the camera estimated in the distortion compensation unit, and the image alignment generation unit compensating for the three-dimensional location and size of the image by using the change parameter estimated in the image alignment estimation unit.

Owner:NC& CO LTD

Stereo camera control system

Owner:比比威株式会社

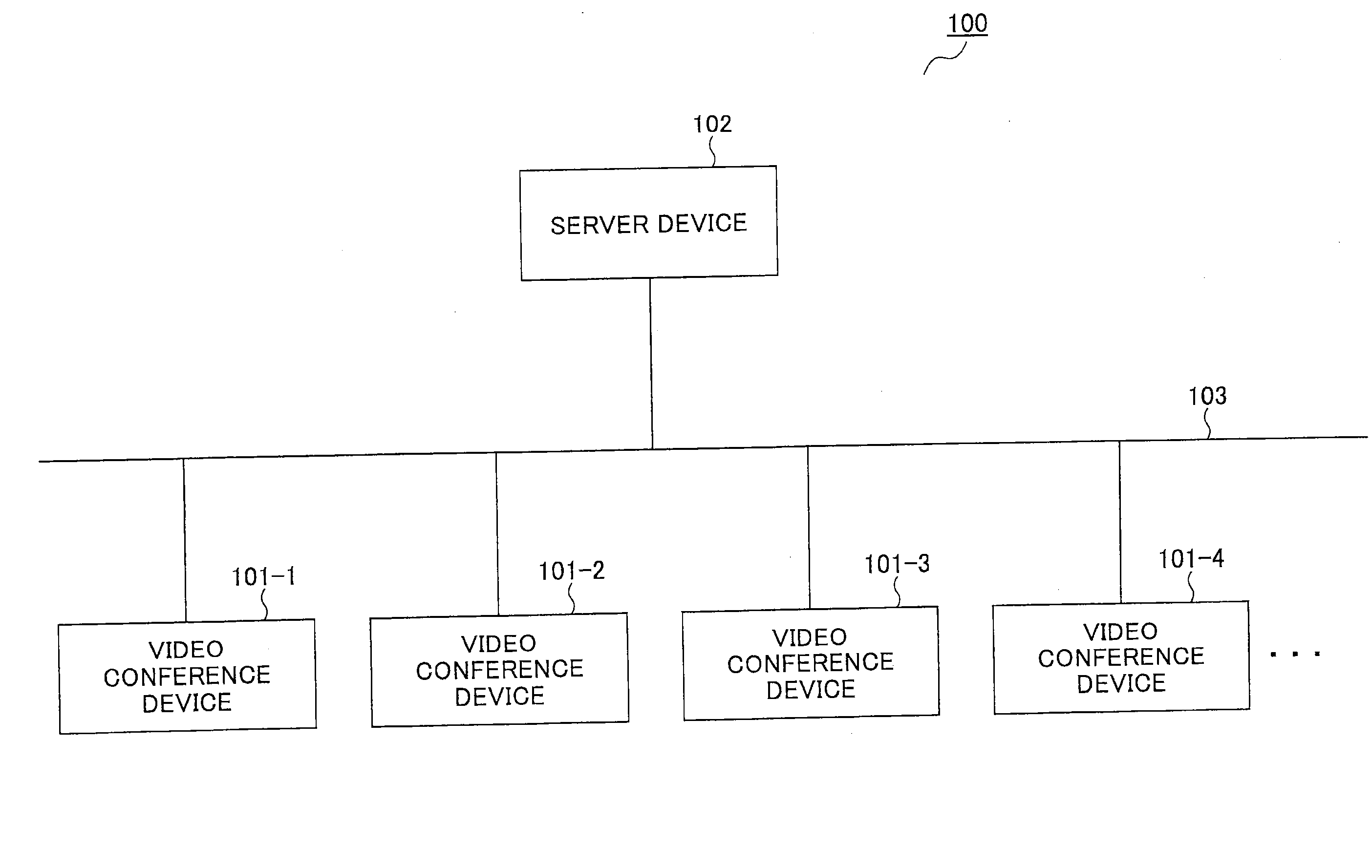

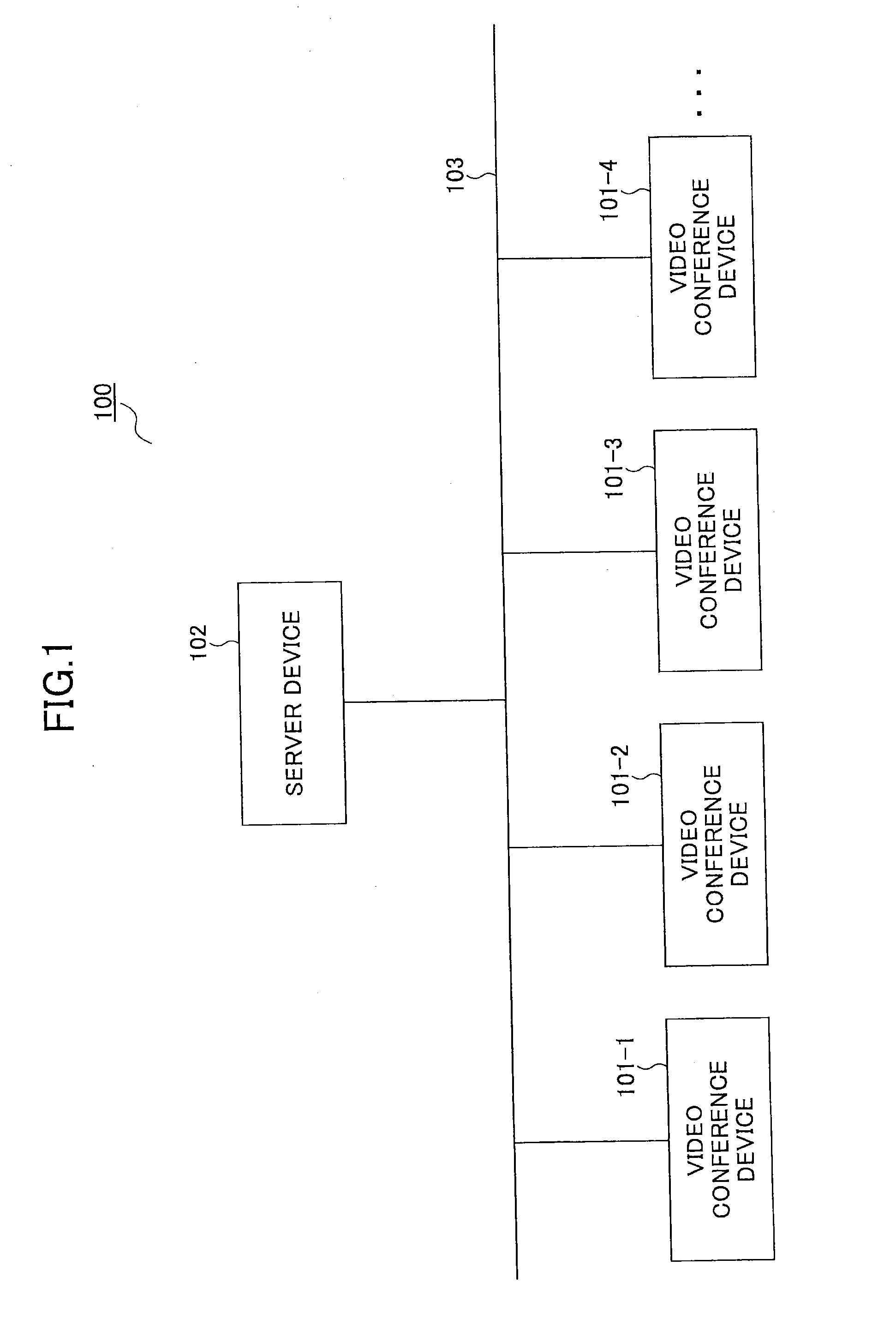

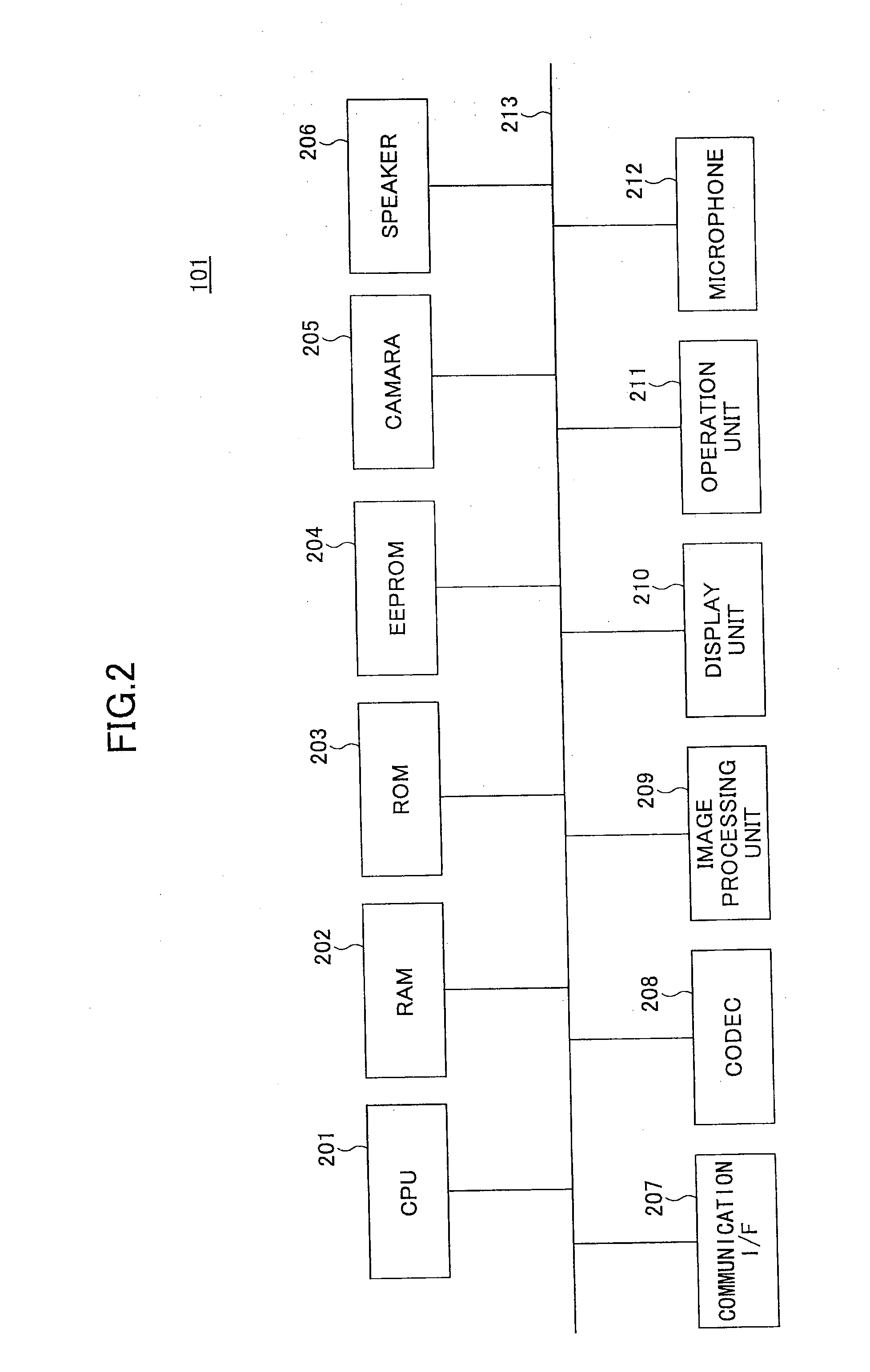

Communication device and communication system

InactiveUS20150264274A1Easy to correctTelevision system detailsTelevision conference systemsInformation processingCommunications system

A communication device includes a display unit for displaying a display image based on an image that is captured by a capture unit, a retrieval unit for selectively retrieving one correction information item from an information processing device that stores, in advance, a plurality of the correction information items corresponding to rotational errors or tilts of the capture unit, and a correction unit for correcting the display image based on the retrieved correction information item.

Owner:RICOH KK

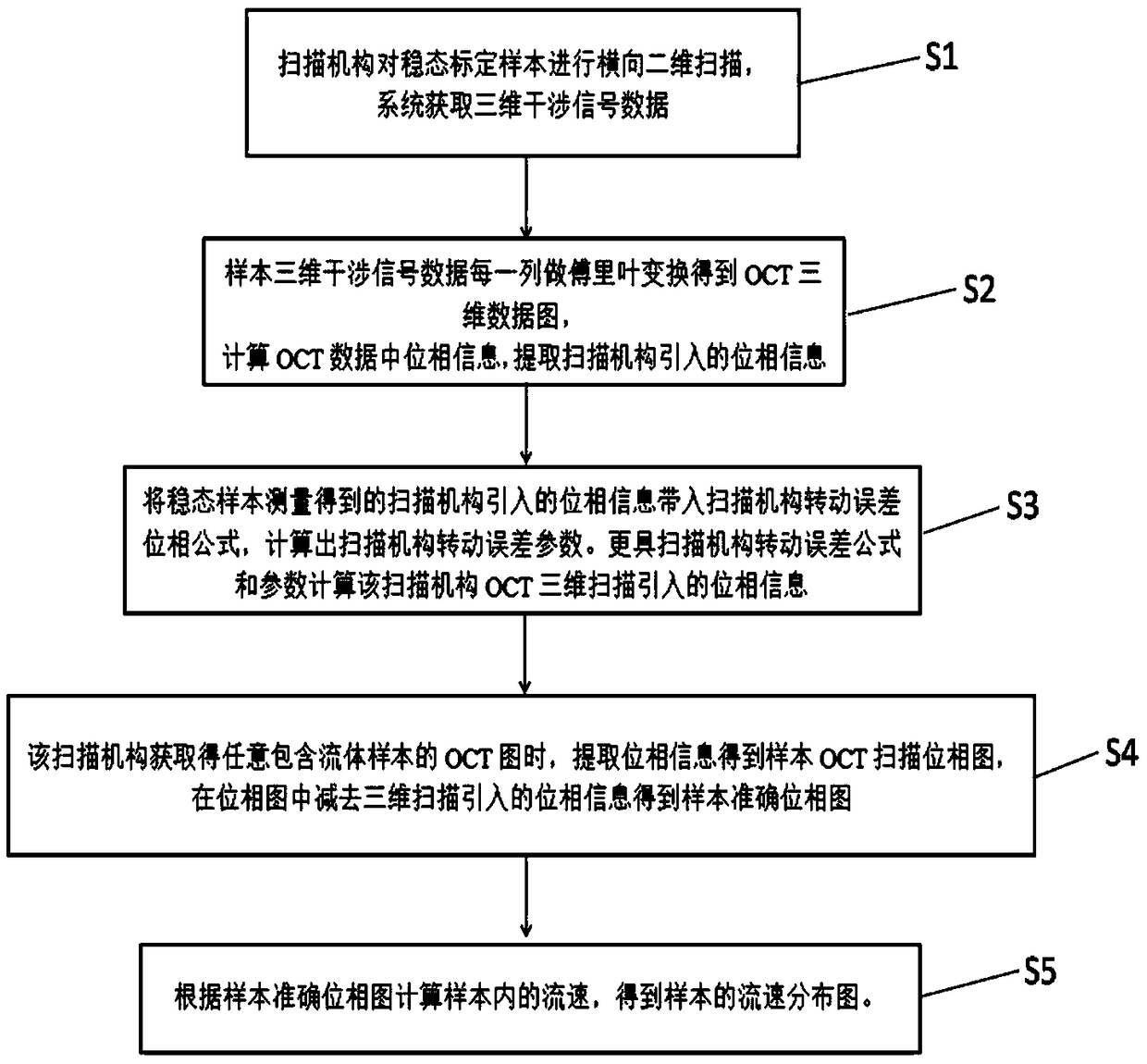

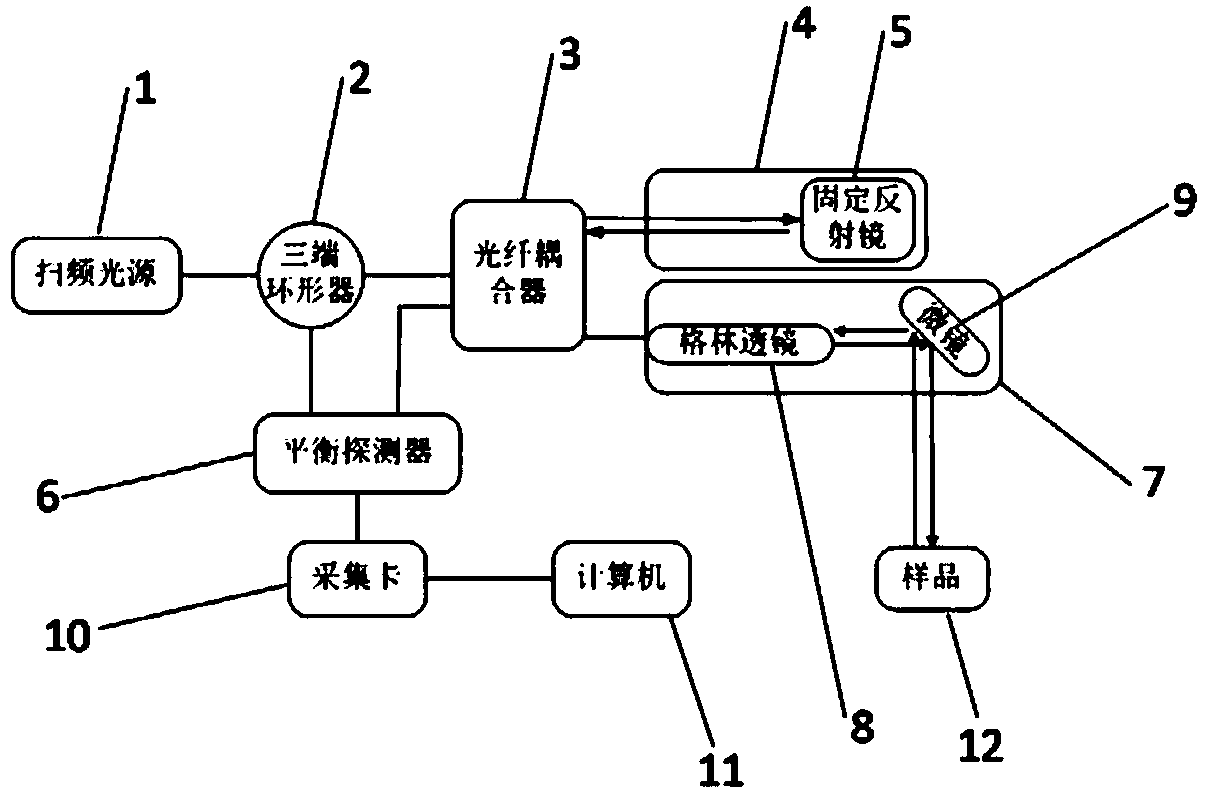

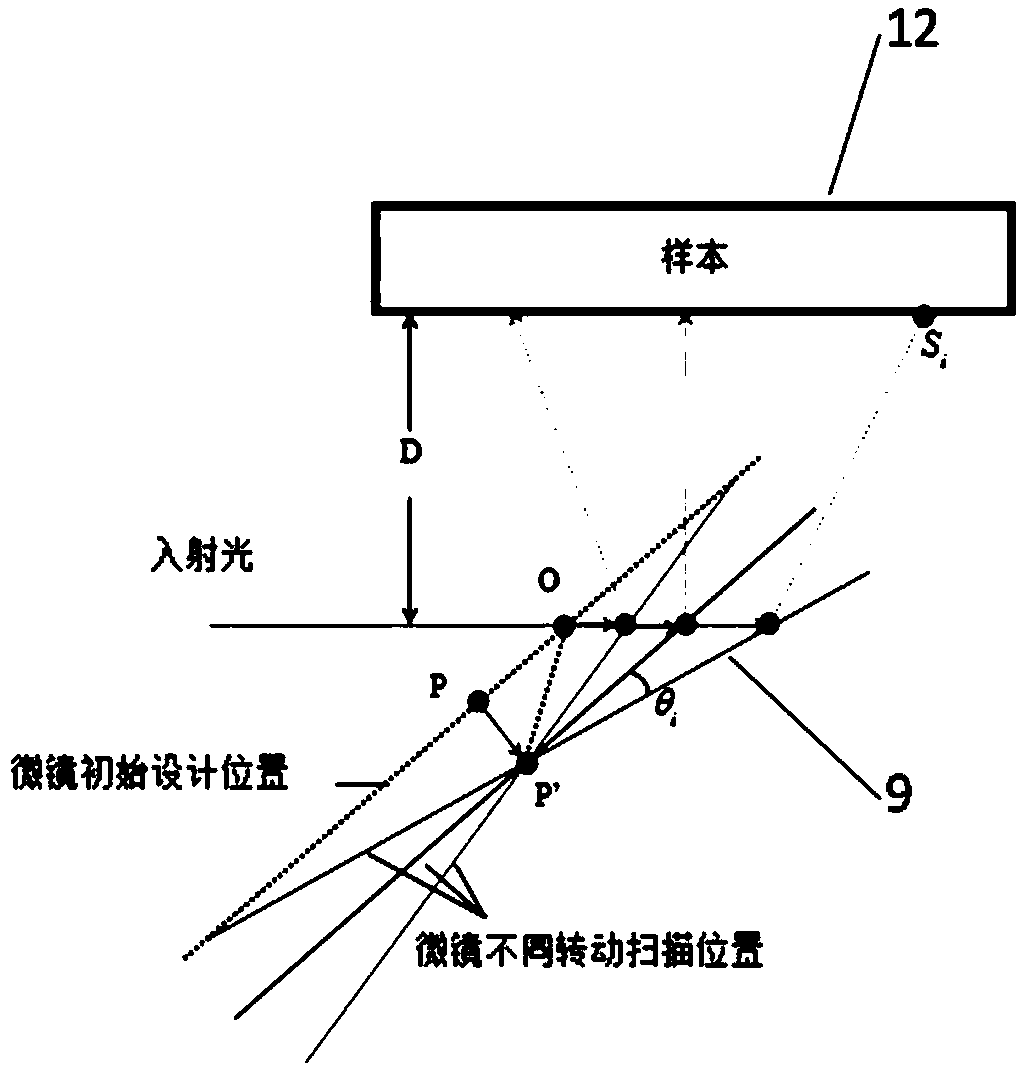

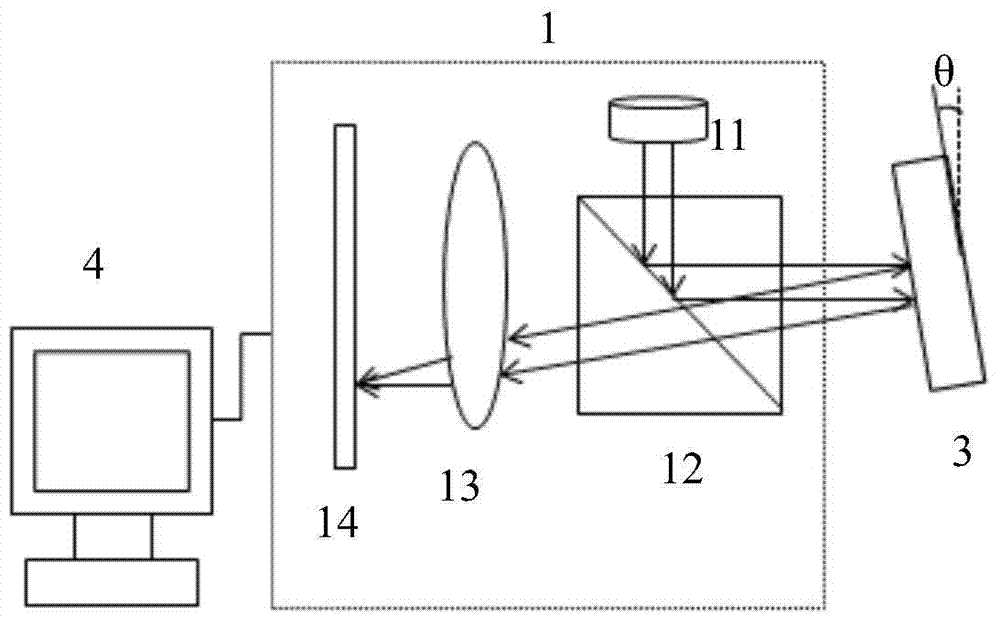

Doppler flow velocity detection method for optical coherence tomography system

ActiveCN109223044ABlood flow measurement devicesInfrasonic diagnosticsRotational errorComputational physics

The invention discloses a Doppler flow velocity detection method for an optical coherence tomography system, which includes the following steps: A scan mechanism performs transverse two-dimensional scanning on a steady-state calibration sample, the acquisition of three-dimensional interference signal data, Fourier transform is performed on each column of that sample three-dimensional interferencesignal data to obtain an OCT three-dimensional data map, the phase information in the OCT three-dimensional data is calculated, the phase information introduced by the scanning mechanism is extracted,according to the phase information introduced by the scanning mechanism, the rotational error parameters of the scanning mechanism are calculated, The phase information introduced by the OCT three-dimensional scanning is calculated, and the phase information is extracted to obtain the phase data map of the sample OCT scanning. The accurate phase map of the sample is obtained by subtracting the phase information introduced by the three-dimensional scanning from the phase data map, and the velocity distribution map of the sample is obtained by calculating the velocity of the sample according tothe accurate phase map of the sample. The invention can obtain the actual error of the scanning mechanism, and further obtain the accurate value of the phase error introduced by the scanning mechanism to the OCT imaging.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

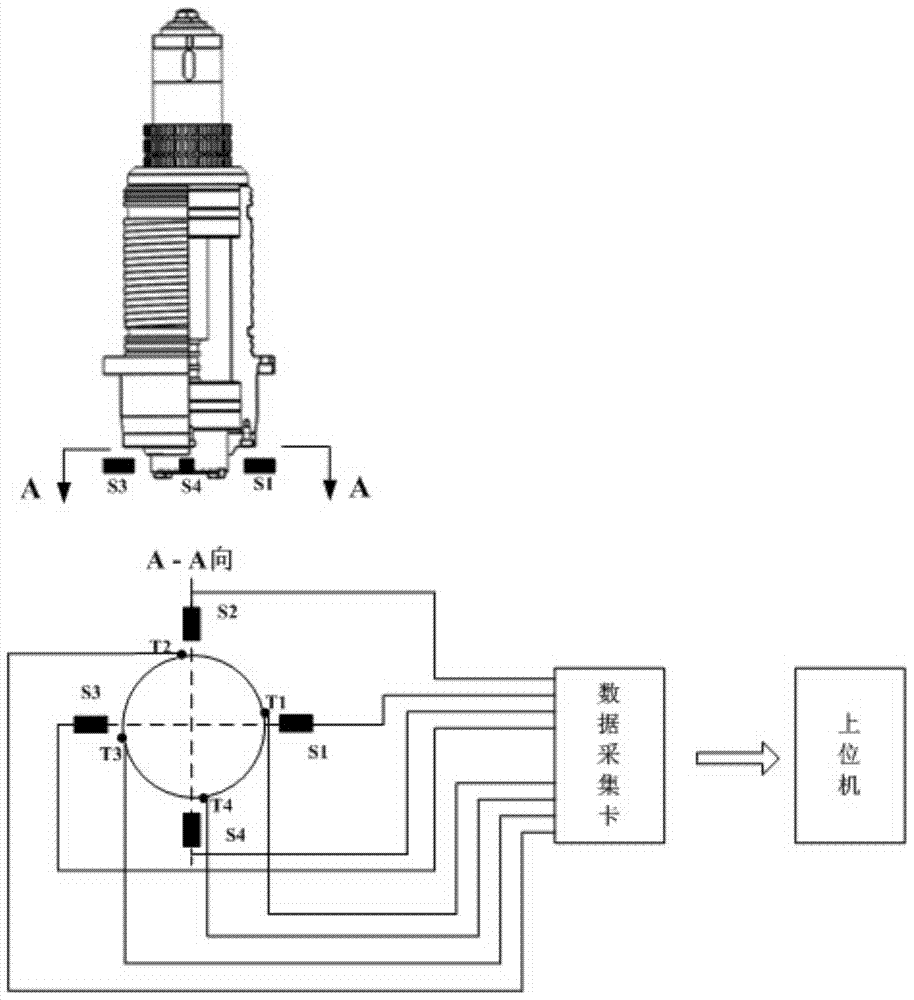

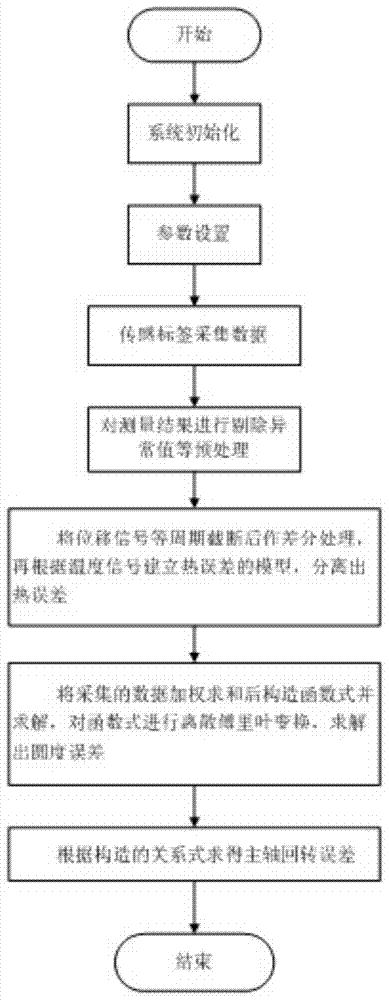

Separation and Treatment of Thermal Error, Roundness Error and Rotational Error of Machine Tool Spindle

ActiveCN105234745BAchieve separationHigh precisionMeasurement/indication equipmentsRotational errorControl engineering

Owner:NANTONG GUOSHENG INTELLIGENCE TECH GRP CO LTD

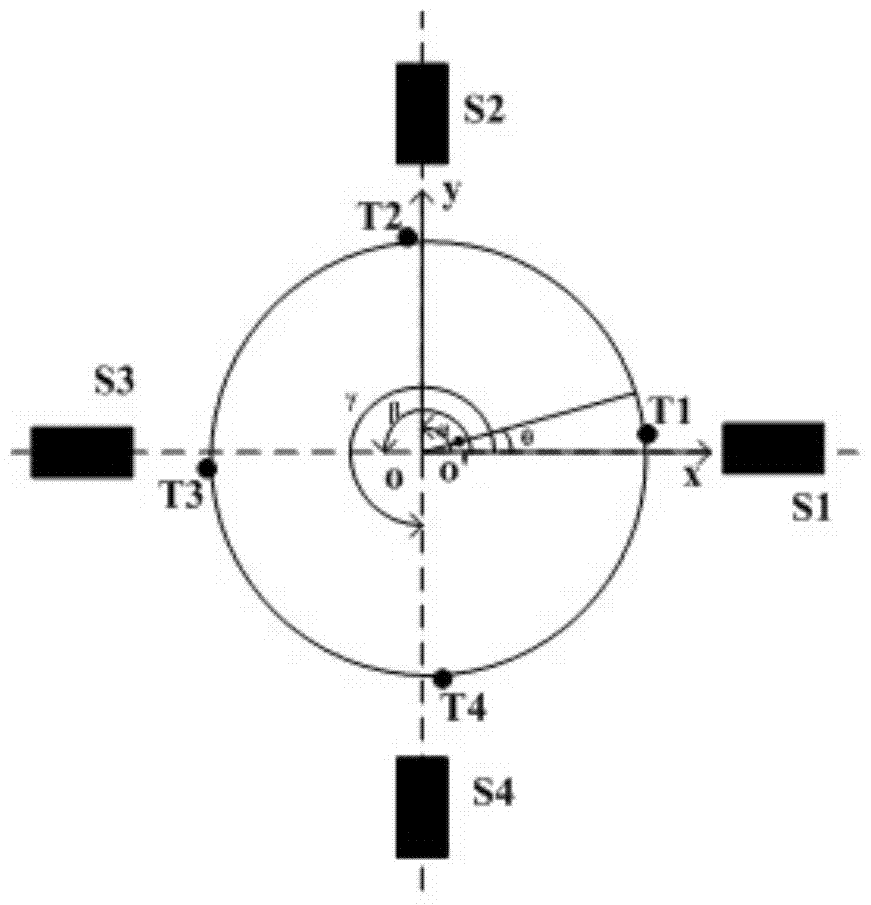

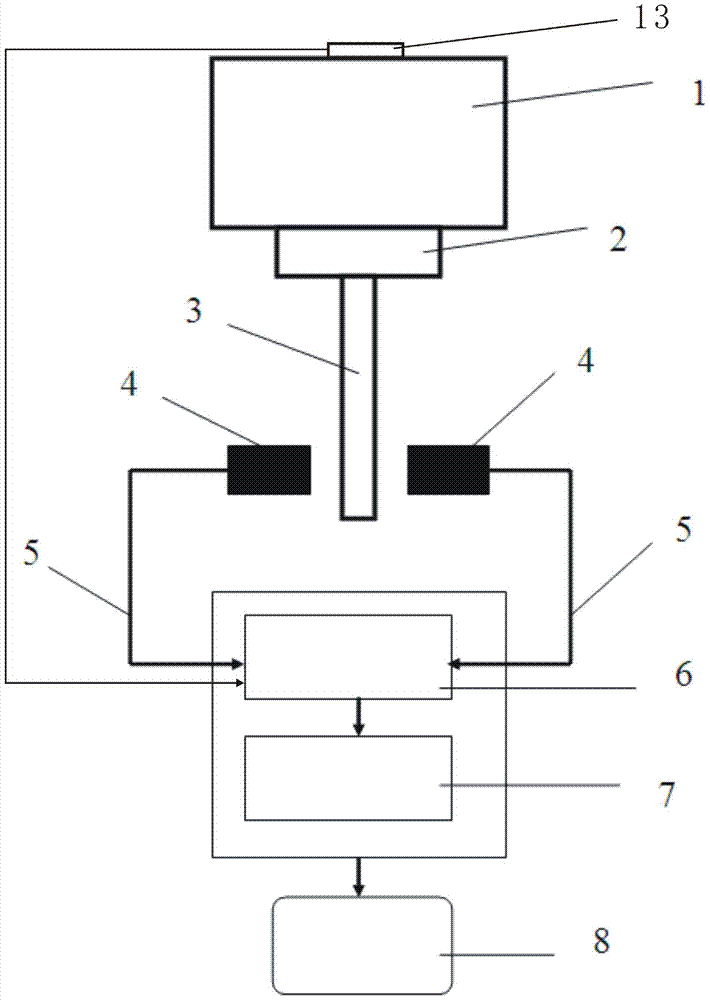

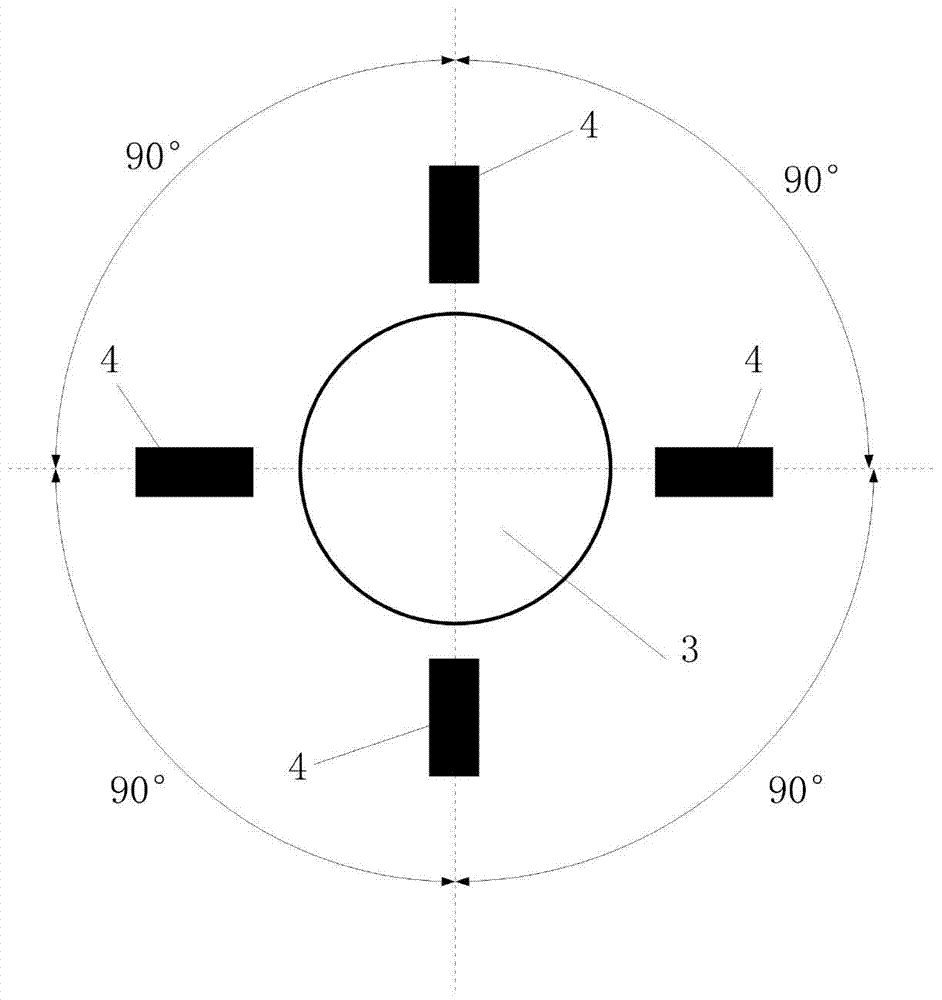

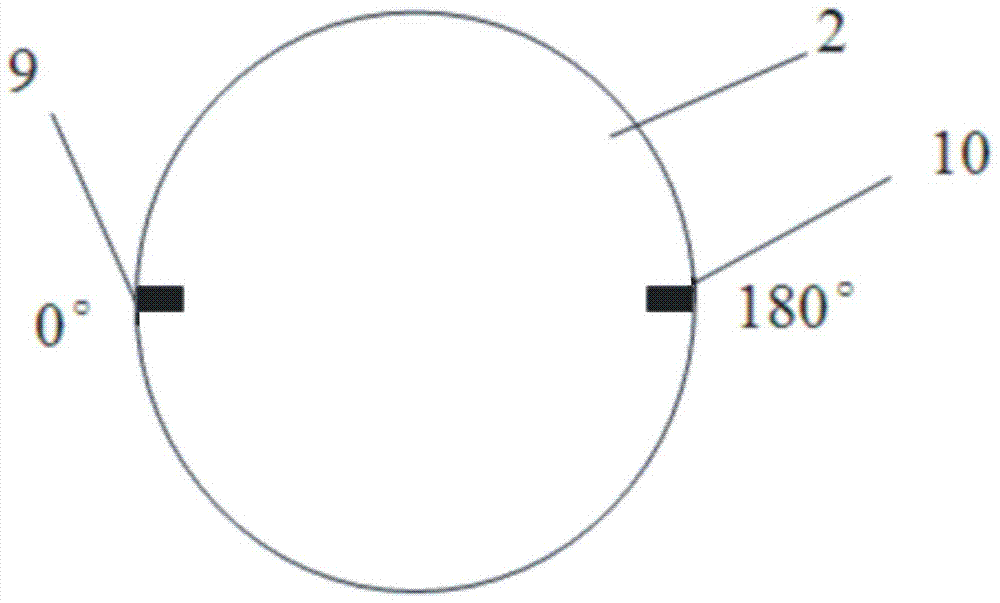

Measuring device and method for dynamic rotary error of main shaft of complete rotary equipment

ActiveCN105043317BSimple error separationError separation and controllableMeasurement devicesRotational errorMeasurement device

The invention discloses a device for measuring the dynamic revolution error of a main shaft of a set of revolution equipment. A connecting reference column is mounted between a reference rod and the main shaft, the measuring ends of four displacement sensors are arranged in the circumference of the standard rod and used to detect displacement of the reference rod, the signal output end of each displacement sensor is connected with a data collector, a signal conditioner and a host computer, and the end surface of the connecting reference column and the end surface, connected to the end surface of the connecting reference column, of the reference rod are provided with two symmetrical marks respectively. The invention also discloses a method for measuring the dynamic revolution error of the main shaft of the set of revolution equipment. The method comprises that the main shaft is rotated, and the displacement sensors record numbers; the main shaft is rotated again after the reference rod rotates for 180 degrees, and the displacement sensors record numbers; Fourier transform is carried out on data; and the radial revolution error of the main shaft is calculated according to the data. The error separating technology in the courter-rotating method is improved to measure the dynamic revolution error of the main shaft of the set of equipment, the measuring precision is substantially improved, and the device and method can be widely popularized and applied.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

Methods and apparatus for high speed object handling

InactiveCN100385614CDigital data processing detailsSemiconductor/solid-state device manufacturingObject handlingRotational error

Methods and apparatus for high speed workpiece handling are provided. The method for workpiece handling includes removing a workpiece from a first cassette with a first robot, transferring the workpiece from the first robot directly to a second robot without transferring the workpiece to a transfer station, placing the workpiece on a workpiece holder at a processing station with the second robot, and transferring the workpiece from the workpiece holder to the first cassette with the first robot following processing. End effectors of the first and second robots may each have a plurality of vertical positions for efficient workpiece handling. Displacement error and rotational error of the workpiece may be sensed and corrected without use of a transfer station. The methods and apparatus may be used for handling semiconductor wafers.

Owner:VARIAN SEMICON EQUIP ASSOC INC

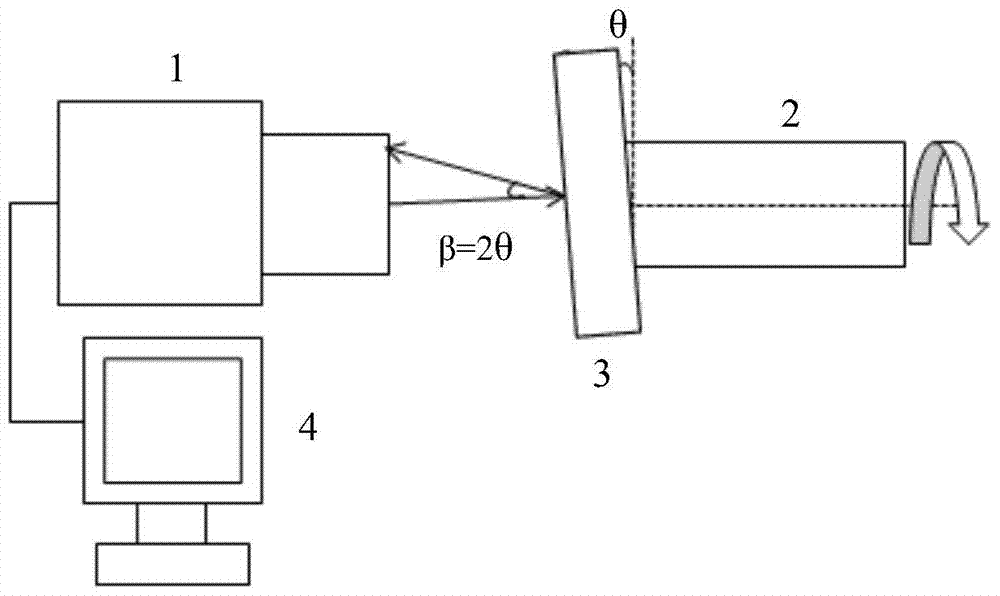

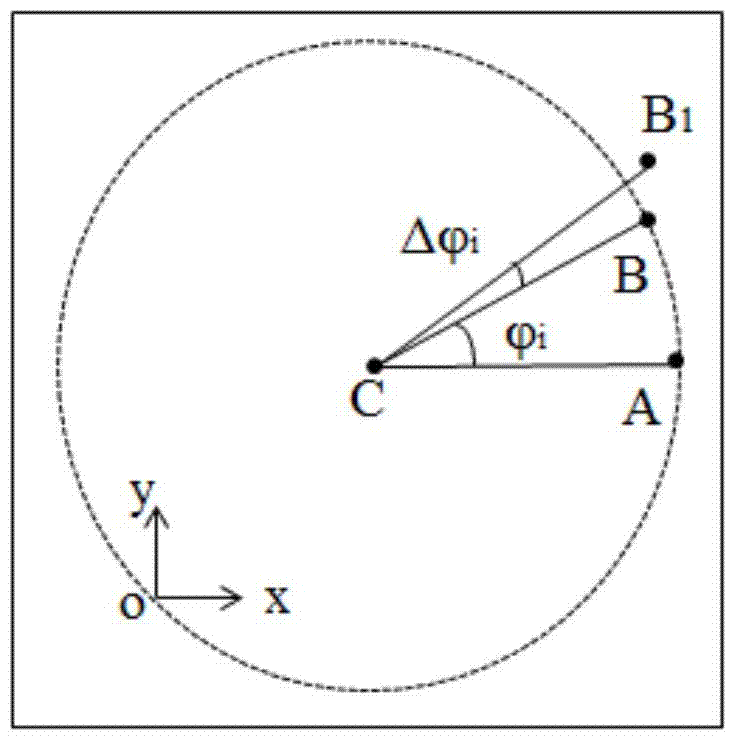

A method for measuring the rotation angle of a rotating shaft to suppress the rotation error of the shafting inclination angle

InactiveCN105423957BInhibition effectHigh measurement accuracyUsing optical meansRotational errorLight spot

The invention belongs to the field of optical measurement, and is a method for measuring the rotation angle of a rotating shaft that can suppress the influence of the inclination angle rotation error of a shaft system. The measurement principle system of the present invention is shown in FIG. 1 , the rotating shaft 2 with the optical wedge 5 is placed between the autocollimator 1 and the reflector 3 . Due to the refraction effect of the optical wedge 5, the beam emitted by the autocollimator 1 is reflected by the reflector 3, forms a deflection angle β with the outgoing beam, returns to the autocollimator 1, and converges into a light point image; when the rotating shaft 2 and the light When the wedge 5 rotates integrally, the reflected light beam rotates around the axis of the rotating shaft 2, and the light spot image in the autocollimator 1 moves along a circular trajectory; the computer 4 records the centroid coordinates of the light spot image on the circumference, and fits the trajectory circle The coordinates of the center of the circle, and then specify the starting point A and the end point B on the circumference, and use the coordinate values of A and B to calculate the corresponding circle center opening angle, which is the rotation angle of the rotation axis 2 to be measured from A to B. In the present invention, the rotation error of the inclination angle of the shaft system hardly affects the measurement accuracy of the rotation angle.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

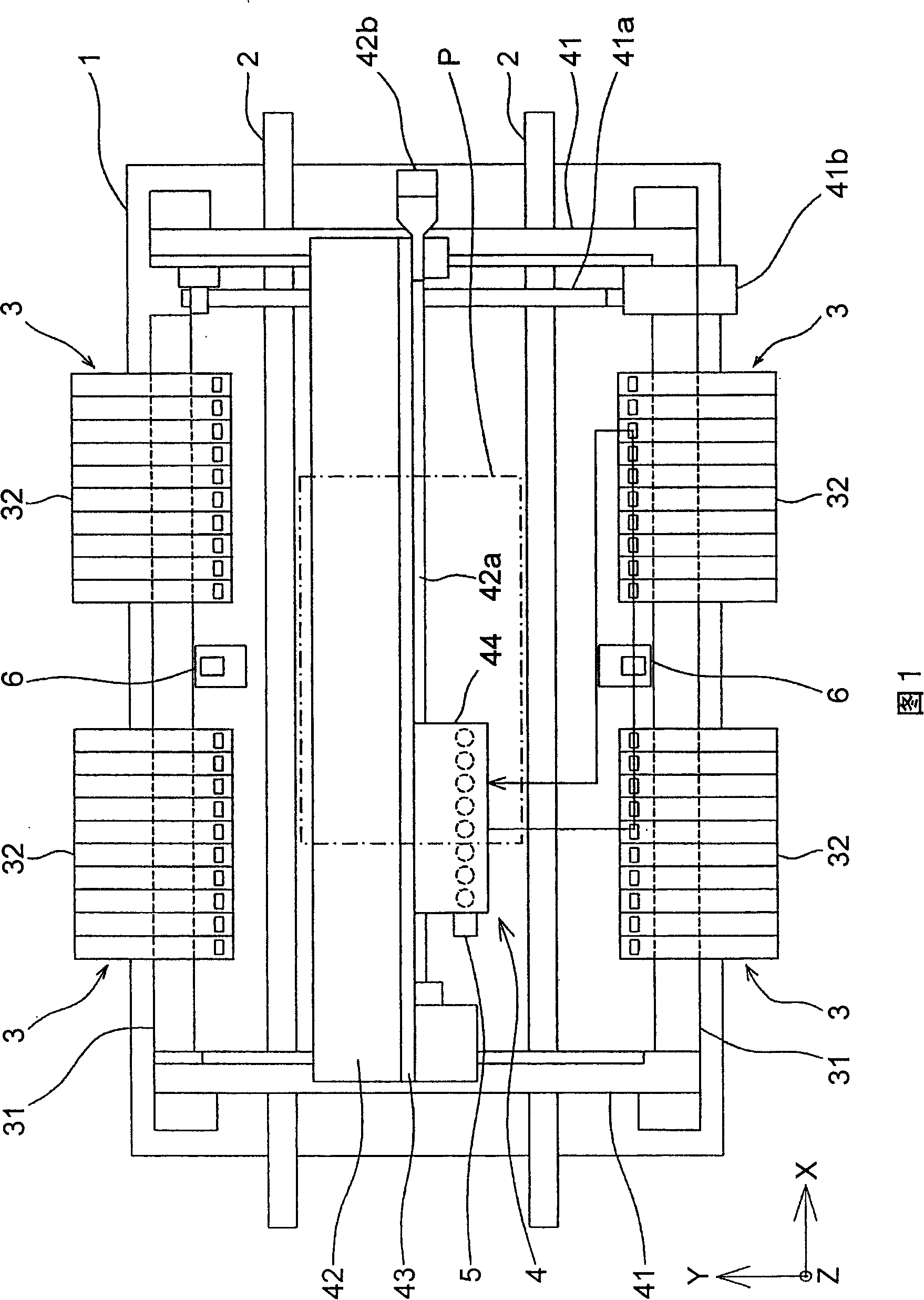

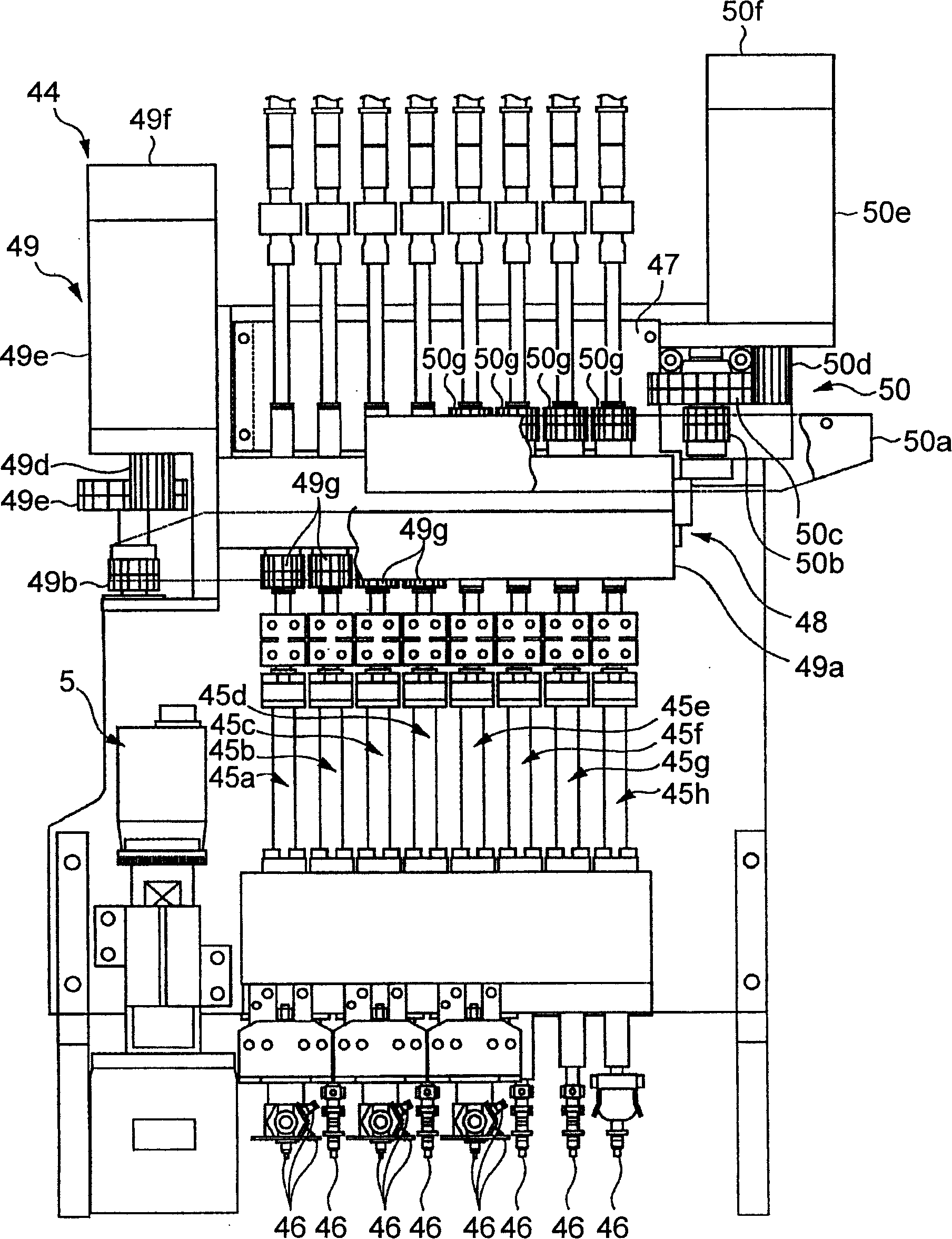

Shifting device, surface installation apparatus, error list generating method

The present invention provides a transfer device which can position with high accuracy, a surface mounting device, a method for producing an error table, programs, and a storing medium. Before electronic components are mounted on a printed board P, an operation control unit 77a adjusts mounting positions, by taking into account chucking positional offset of electronic components which is calculated by an image processor 73, based on the fetched image of a part recognition camera 6, and also, corrects rotational errors around a Z axis of each head based on an error table 74c.

Owner:YAMAHA MOTOR CO LTD

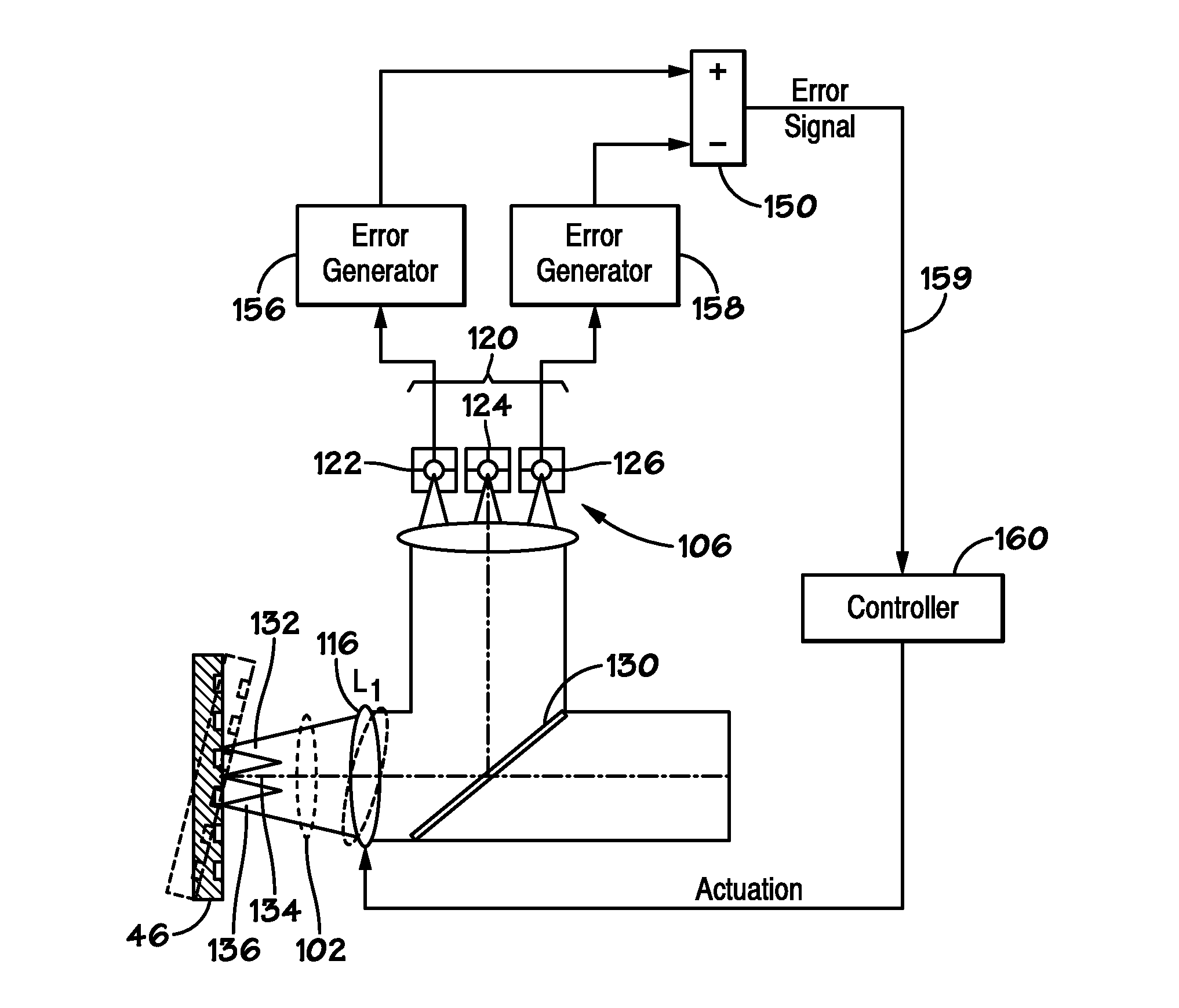

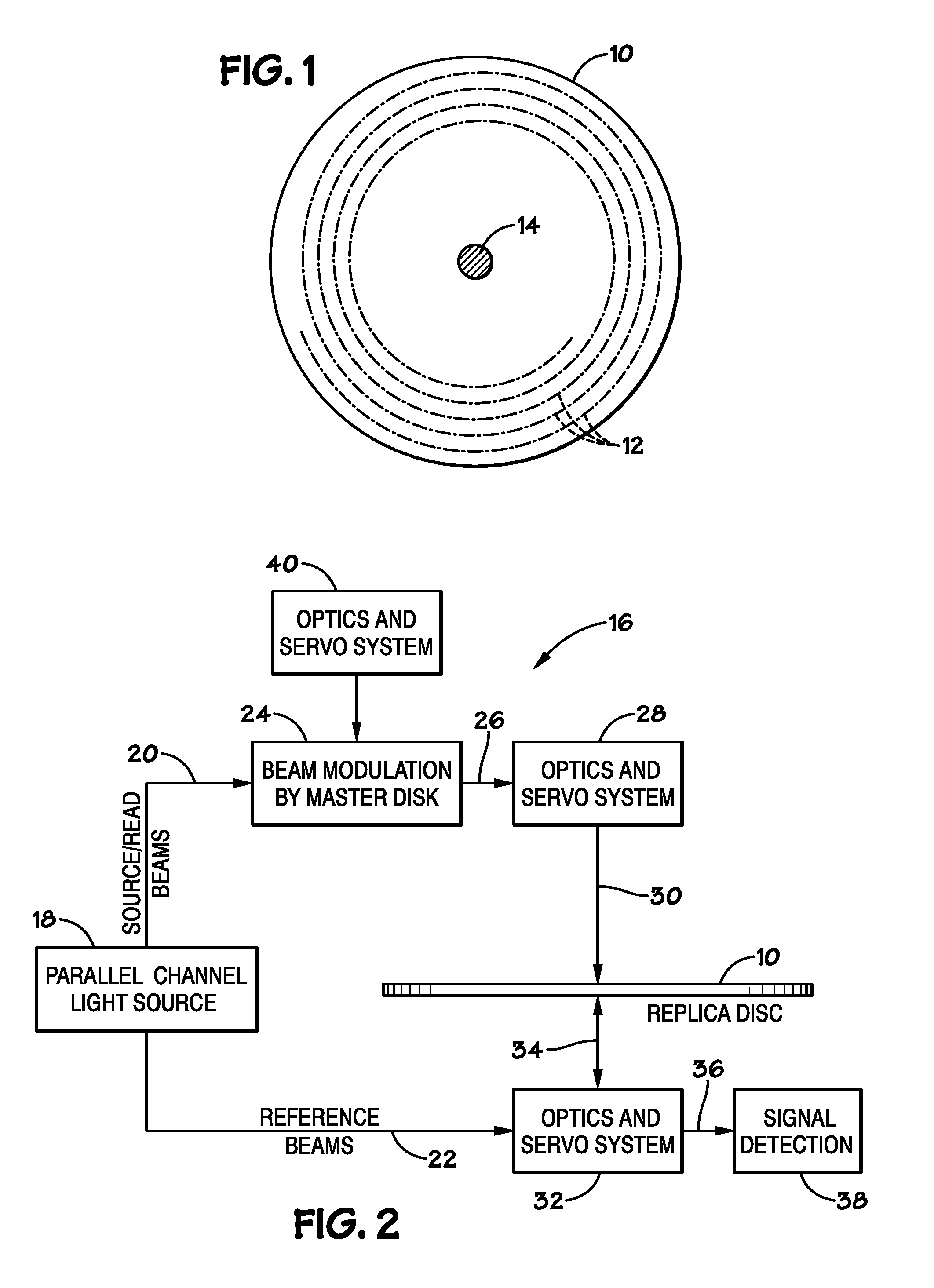

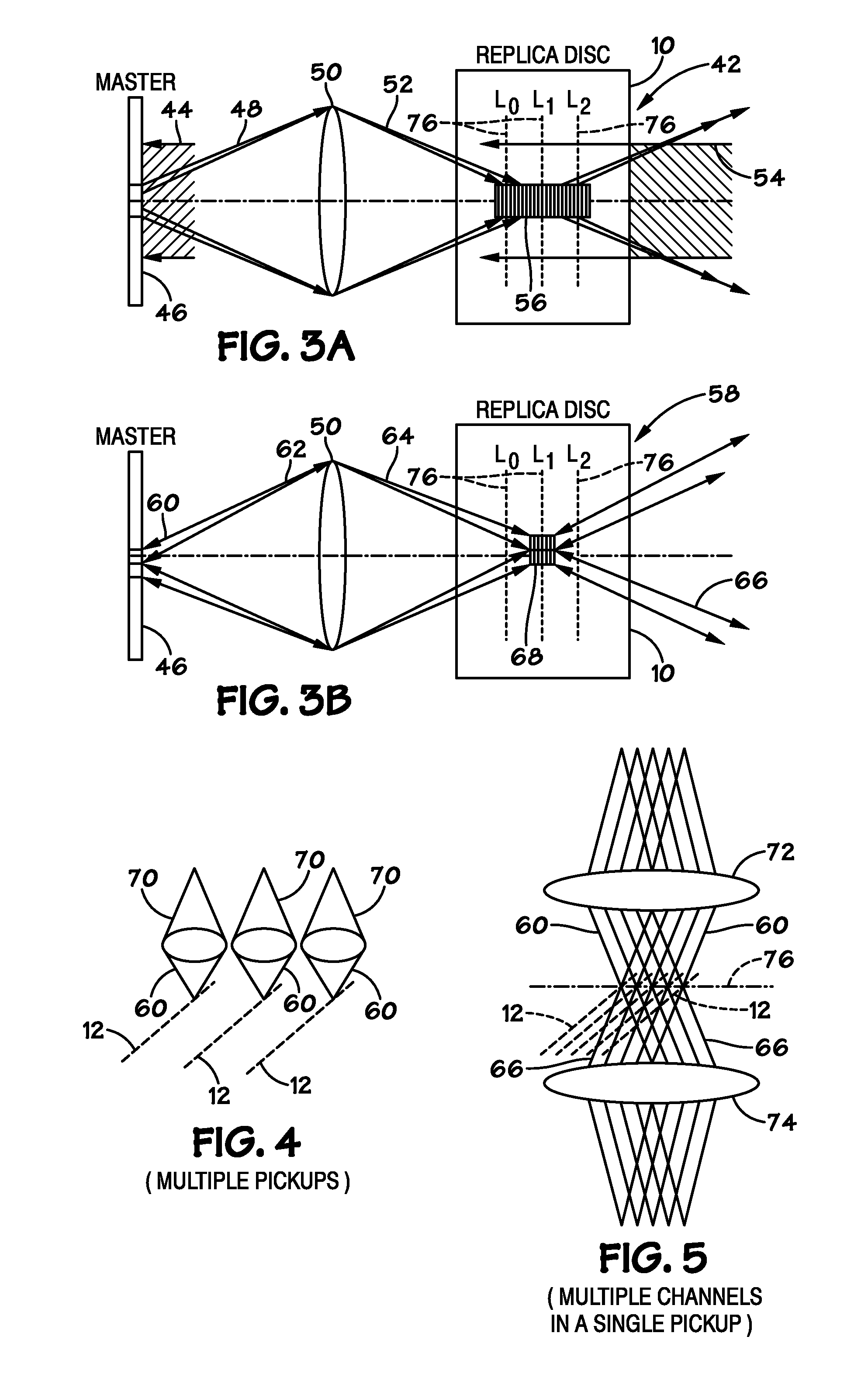

Servoing system for master with parallel tracks in a holographic replication system

Techniques are provided for controlling the reading of optical data from a master disk in a holographic replication system. Imperfections in the master disk or movement of the disk during a recording process may cause source beams to deviate from target data tracks. In some embodiments, a detector system is used to determine the focus and alignment of the source beams on the master disk, as well as the tilt and rotation of the disk with respect to the holographic replication system. The detector system may detect deviations in the intensity distribution of the reflections of the source beams and generate an error signal corresponding to focusing, tracking, tilt, and / or rotational errors. Servo-mechanical devices may actuate optical components to compensate for such errors.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com