Verification method and device for machining precision of drilling and milling machine, drilling and milling machine and storage medium

A verification method and machining technology, which is applied in the direction of registration/instruction machine work, registration/instruction quality control system, registration/instruction, etc., can solve complex problems such as complex processing accuracy, and achieve enhanced reliability and high-efficiency automation. , The effect of improving the verification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

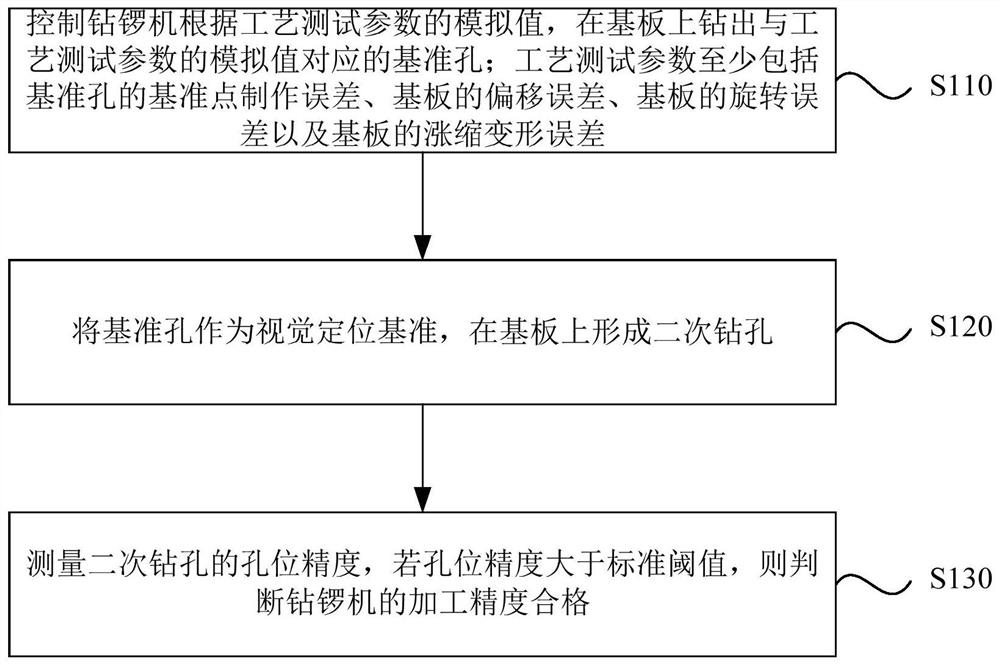

[0031] figure 1 It is a flow chart of the verification method of the machining accuracy of the gong drilling machine provided by Embodiment 1 of the present invention. This embodiment is applicable to the verification of the machining accuracy of the gong drilling machine. The method can be executed by the verification device for the machining accuracy of the gong drilling machine provided in the embodiment of the present invention. The device can be implemented by means of hardware and / or software. And can be integrated in PCB processing equipment. Such as figure 1 As shown, it specifically includes the following steps:

[0032] Step S110, controlling the drilling machine to drill a reference hole corresponding to the simulated value of the process test parameter on the substrate according to the simulated value of the process test parameter; the process test parameter includes at least the manufacturing error of the reference point of the reference hole and the offset erro...

Embodiment 2

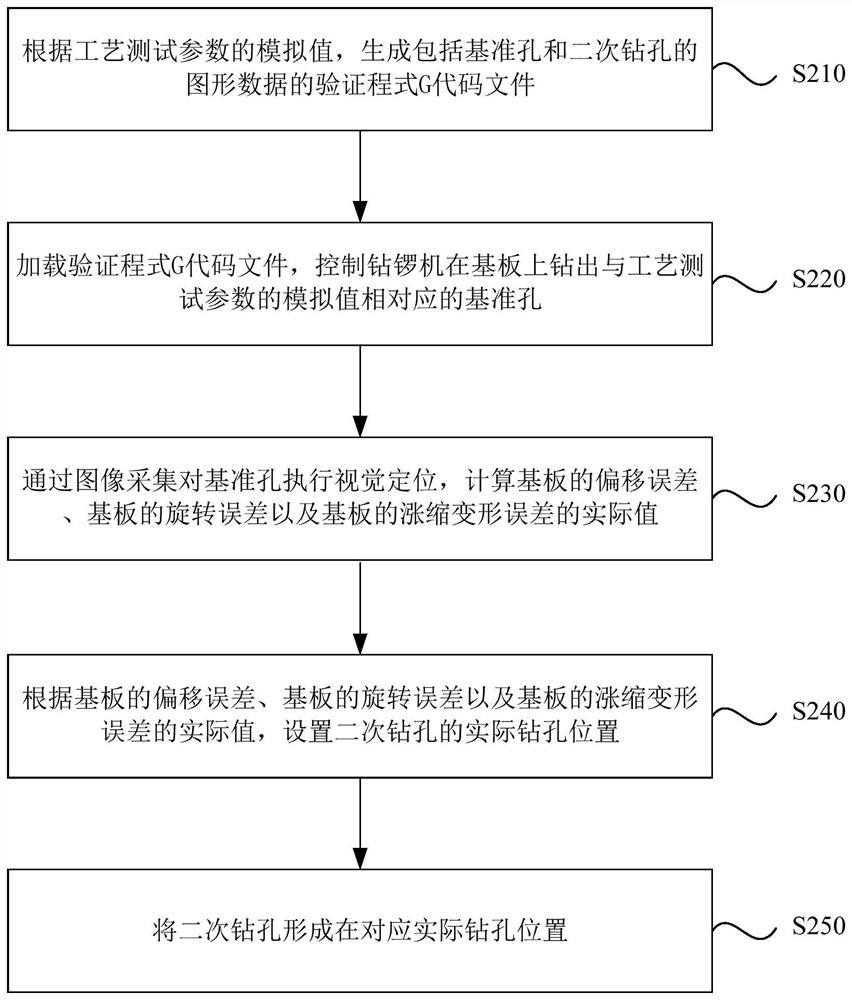

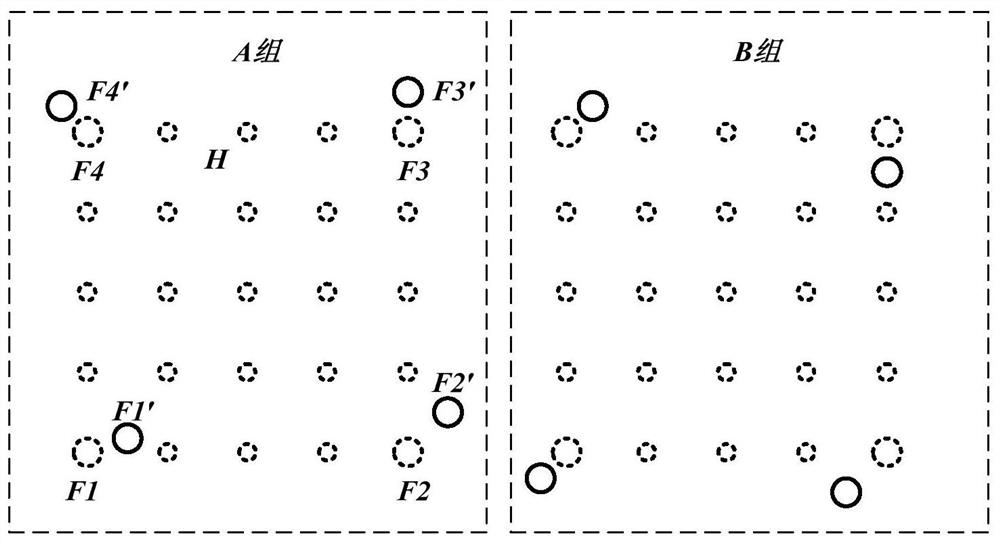

[0047] figure 2 It is a flow chart of the verification method for the machining accuracy of the gong drilling machine provided by the second embodiment of the present invention. The technical solution of this embodiment is further refined on the basis of the above-mentioned technical solution. Specifically, the drilling machine is controlled to drill a reference hole corresponding to the simulated value of the process test parameter on the substrate according to the simulated value of the process test parameter. Including: According to the simulated value of the process test parameters, the verification program G code file including the graphic data of the reference hole and the secondary drilling is generated; the verification program G code file is loaded to control the drilling of the drilling machine on the substrate and the process test parameters. The reference hole to which the simulated value corresponds. Such as figure 2 As shown, the calibration method of the vis...

Embodiment 3

[0063] Figure 4 It is a flow chart of the verification method of the machining accuracy of the gong drilling machine provided by the third embodiment of the present invention. The technical solution of this embodiment is further refined on the basis of the above-mentioned technical solution, such as Figure 4 As shown, the calibration method of the vision system of the gong drilling machine includes the following steps:

[0064] Step S310, controlling the drilling machine to drill a reference hole corresponding to the simulated value of the process test parameter on the substrate according to the simulated value of the process test parameter; the process test parameter includes at least the manufacturing error of the reference point of the reference hole and the offset error of the substrate , the rotation error of the substrate and the expansion and contraction deformation error of the substrate.

[0065] Step S320 , using the reference hole as a visual positioning referen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com