Patents

Literature

309results about "Registering/indicating quality control systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

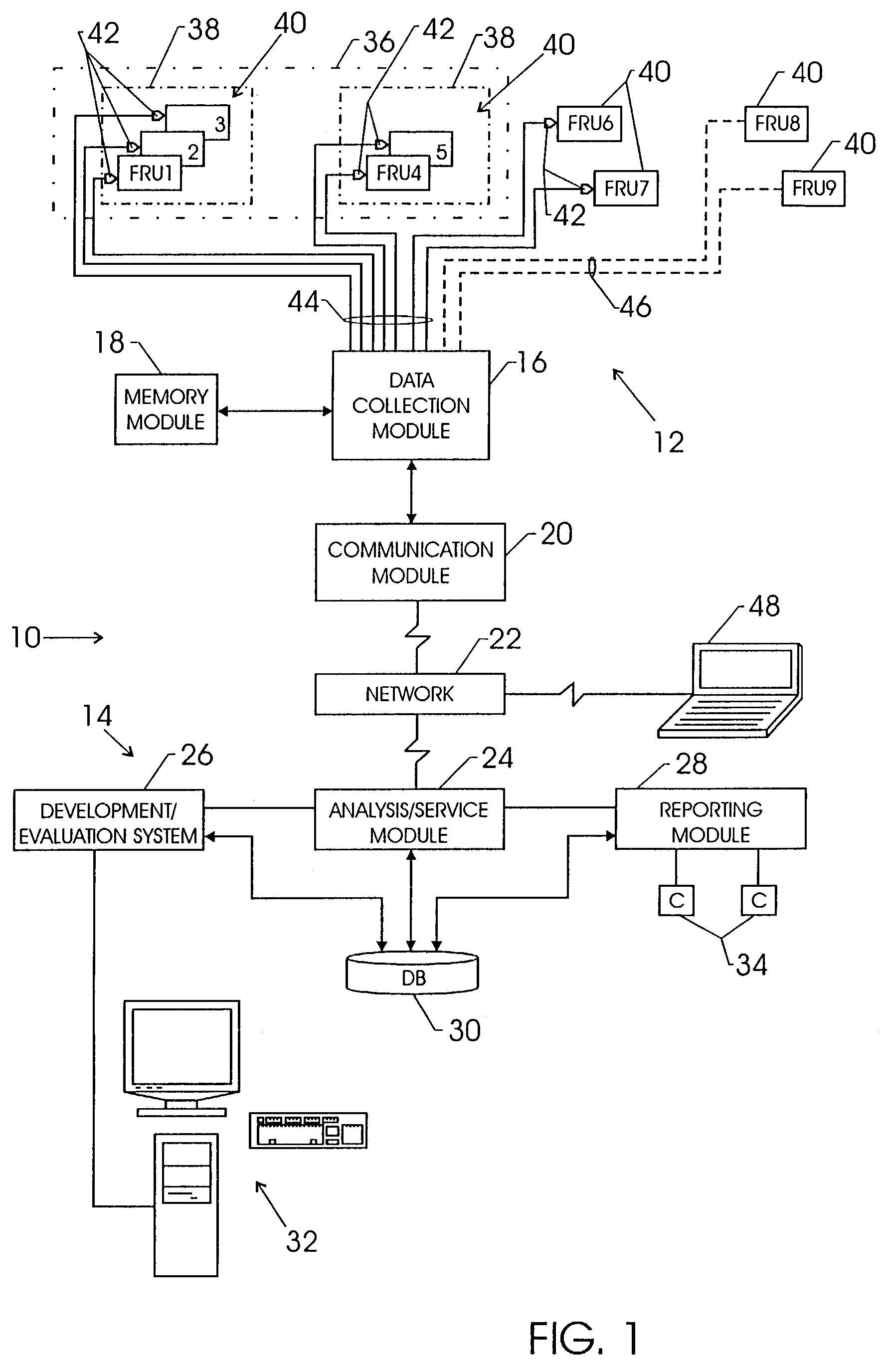

Complex system serviceability design evaluation method and apparatus

InactiveUS7249284B2Facilitate establishingEase of evaluationFault responseRegistering/indicating quality control systemsService modelField replaceable unit

A technique is provided for designing and evaluating service models for components, functions, subsystems and field replaceable units in a complex machine system. At a component or item level, each model identifies various items, failure modes, and so forth which may be the root cause of anticipated serviceable events or faults. The design tools permit numerous interfaces to be used in the design of service models, and in the evaluation of the degree to which the models address detectability and isolation capabilities for the root causes of serviceable events and faults.

Owner:GE MEDICAL SYSTEMS INC

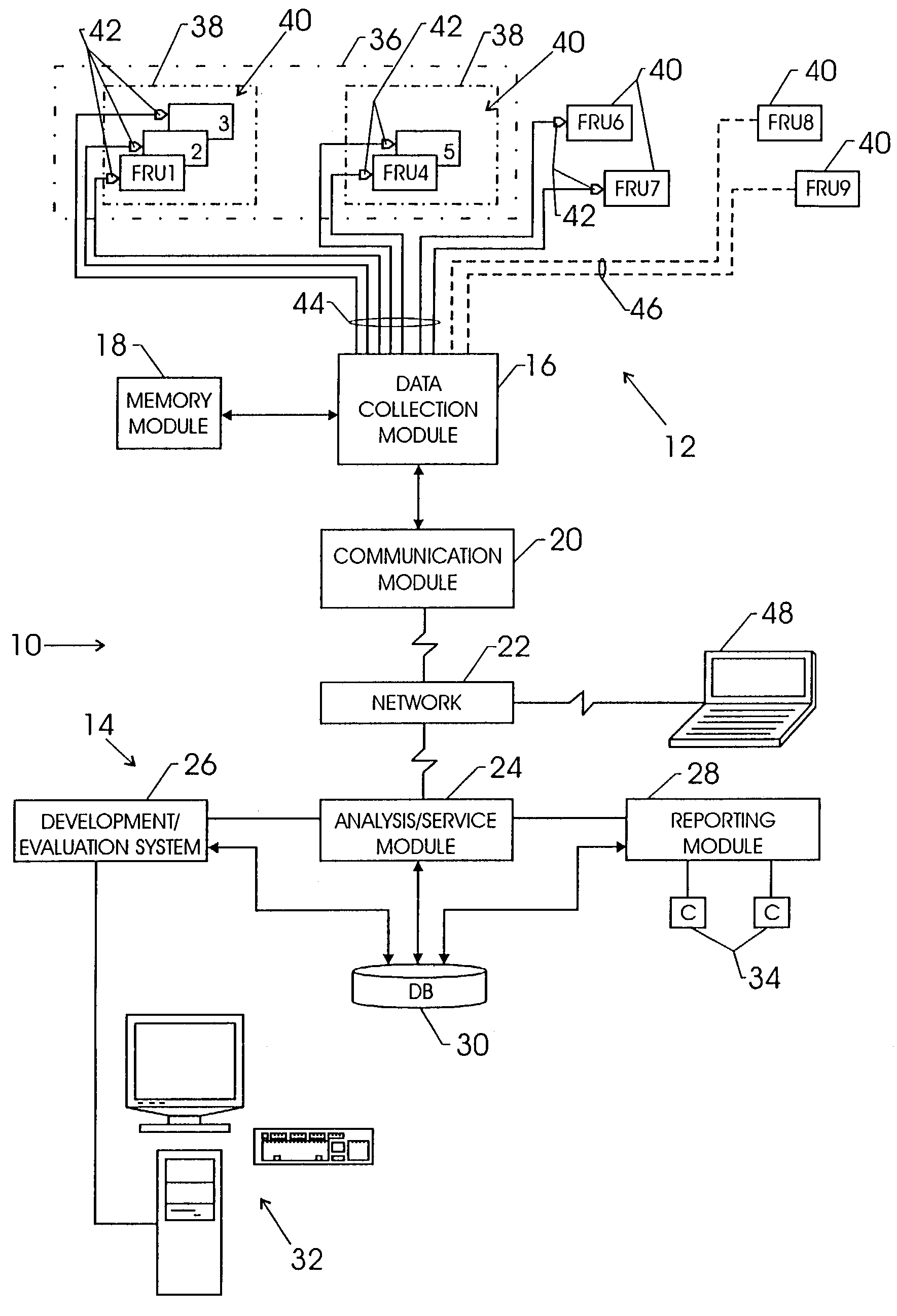

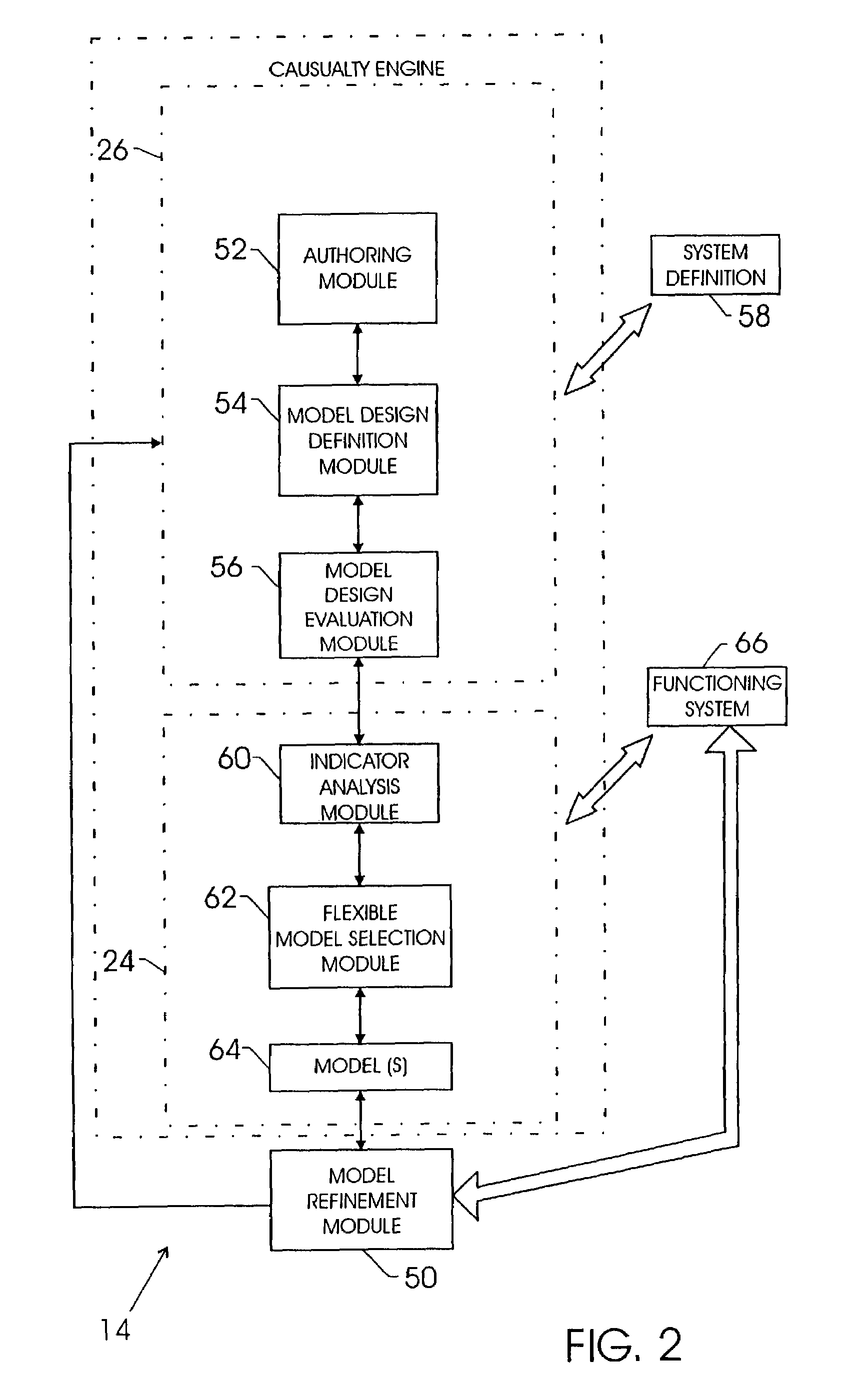

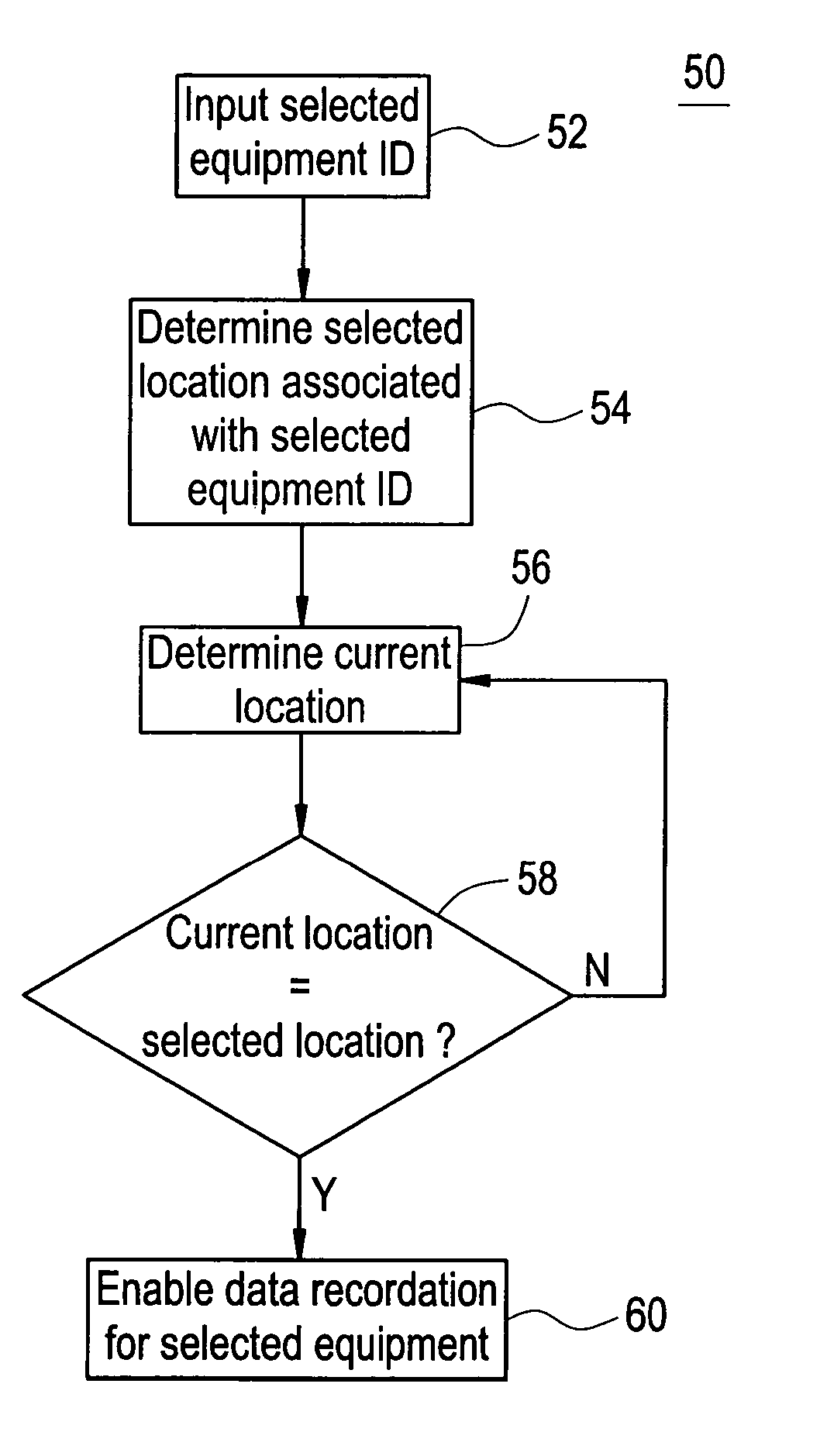

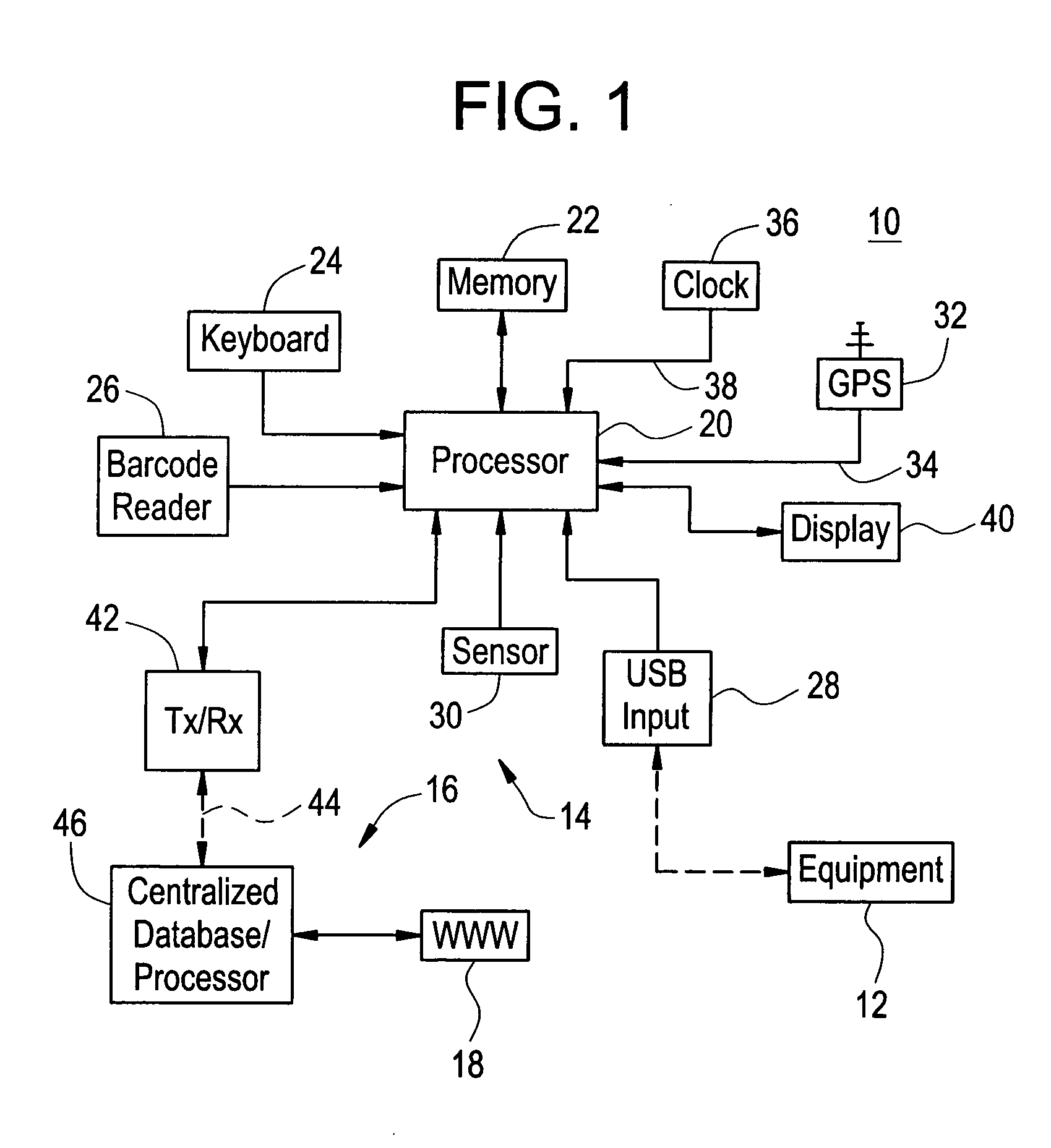

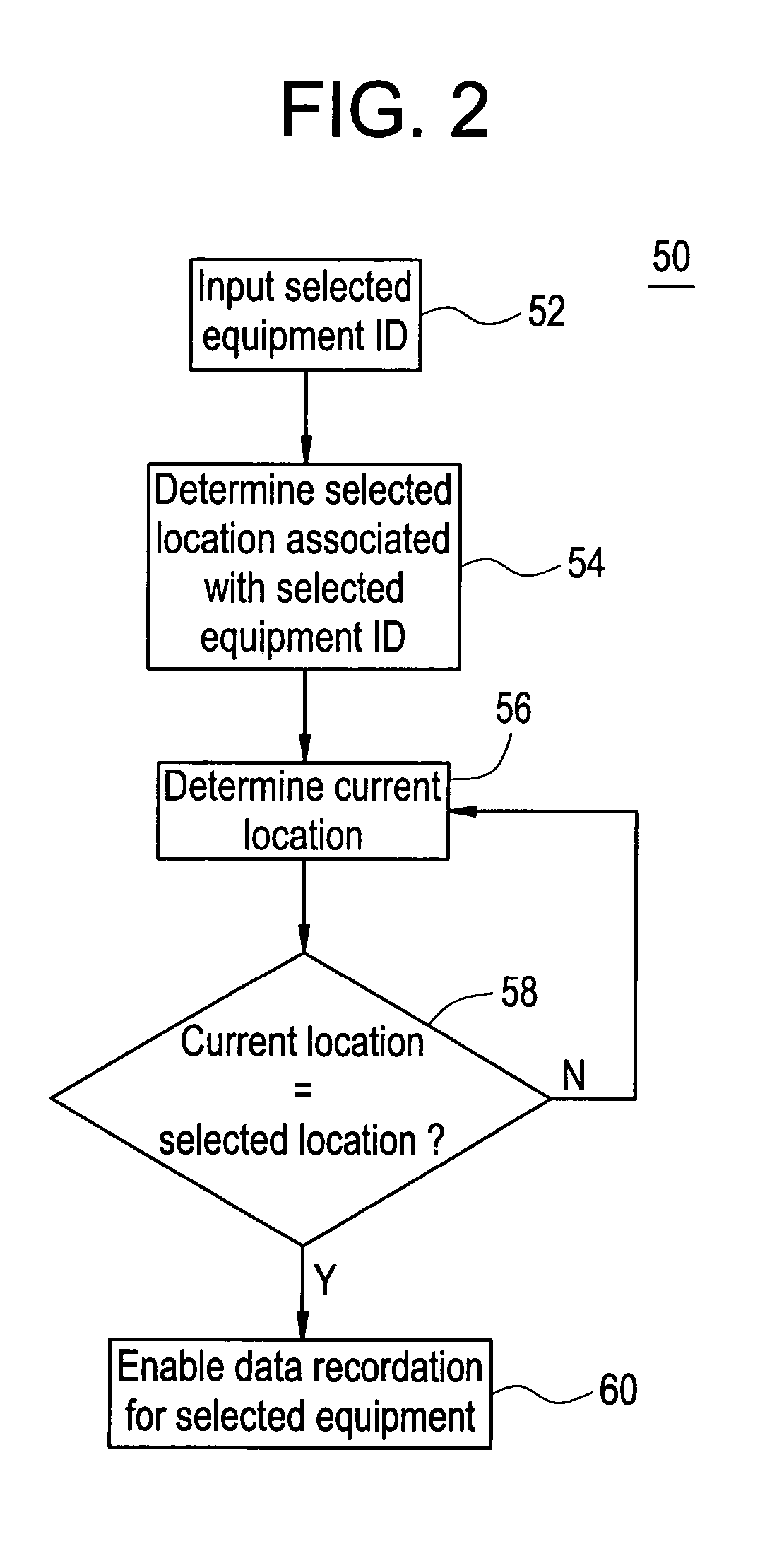

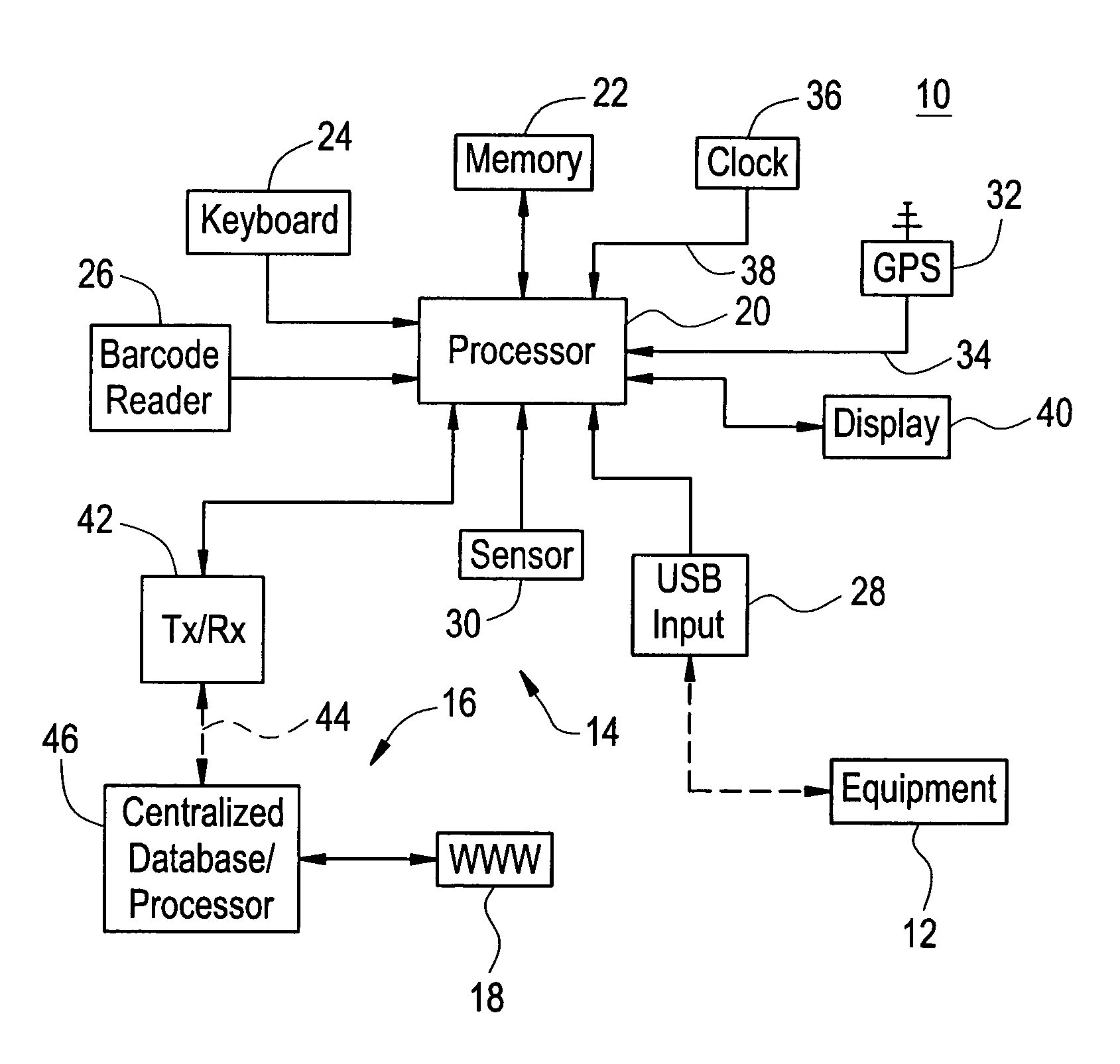

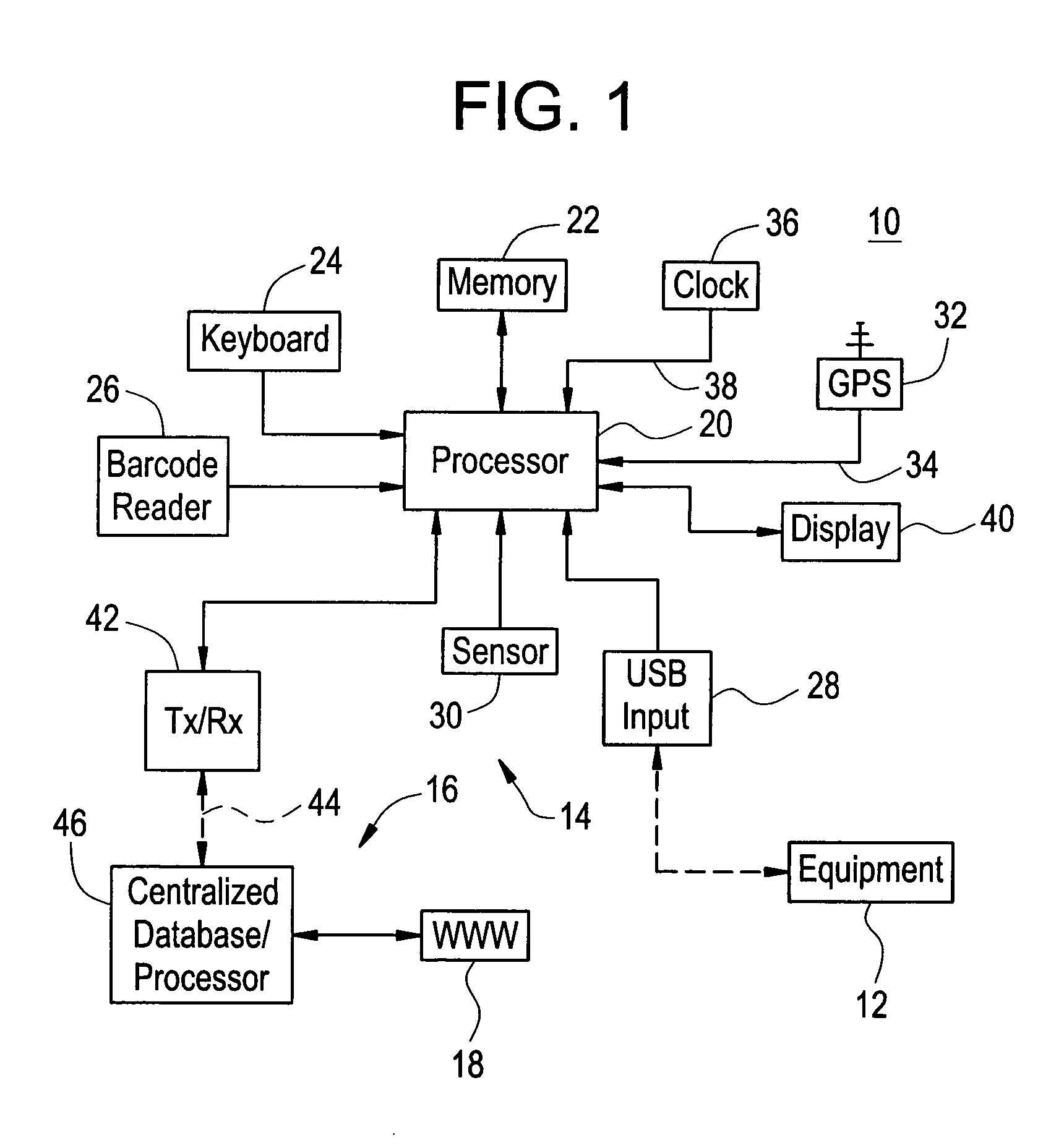

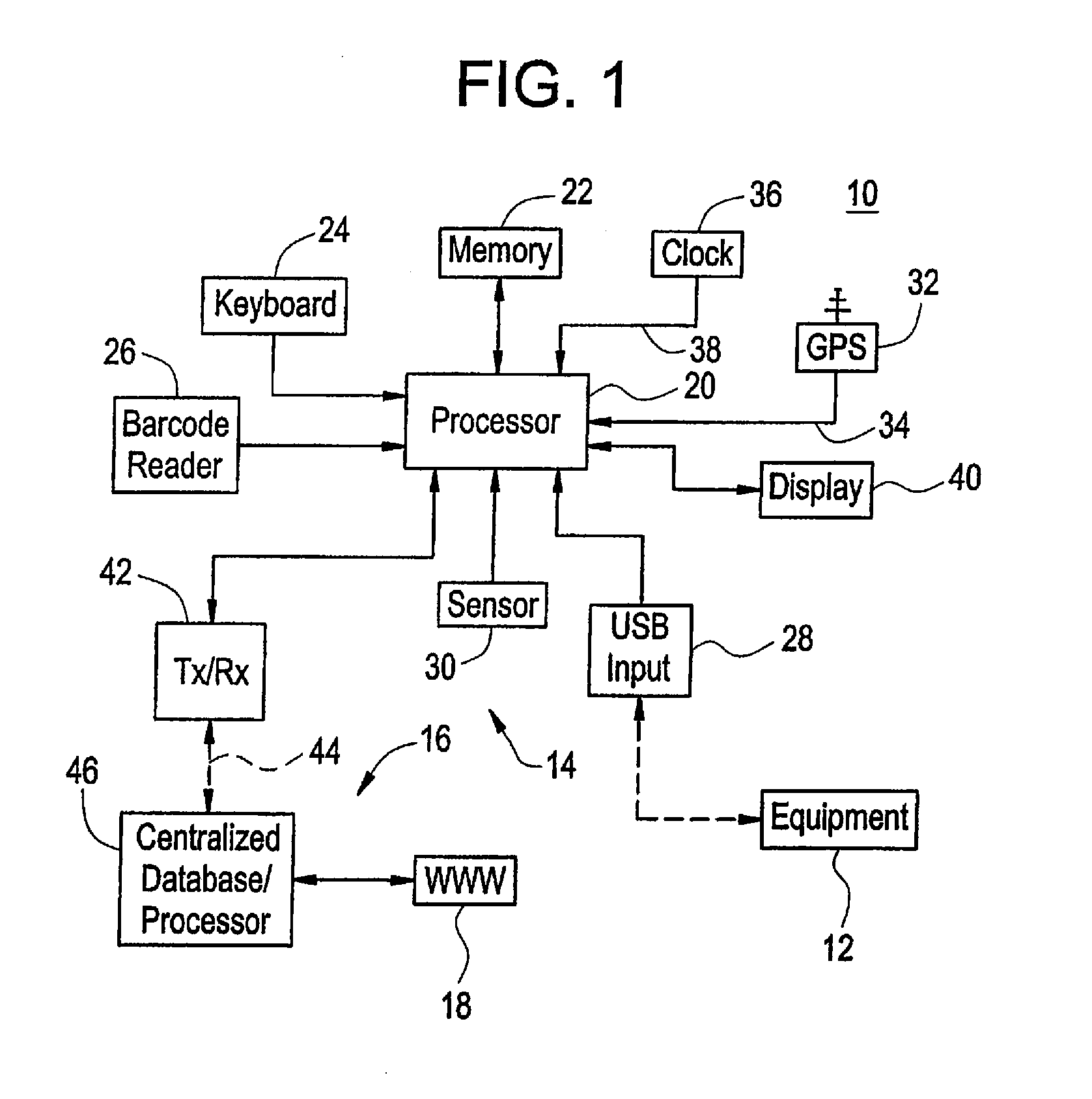

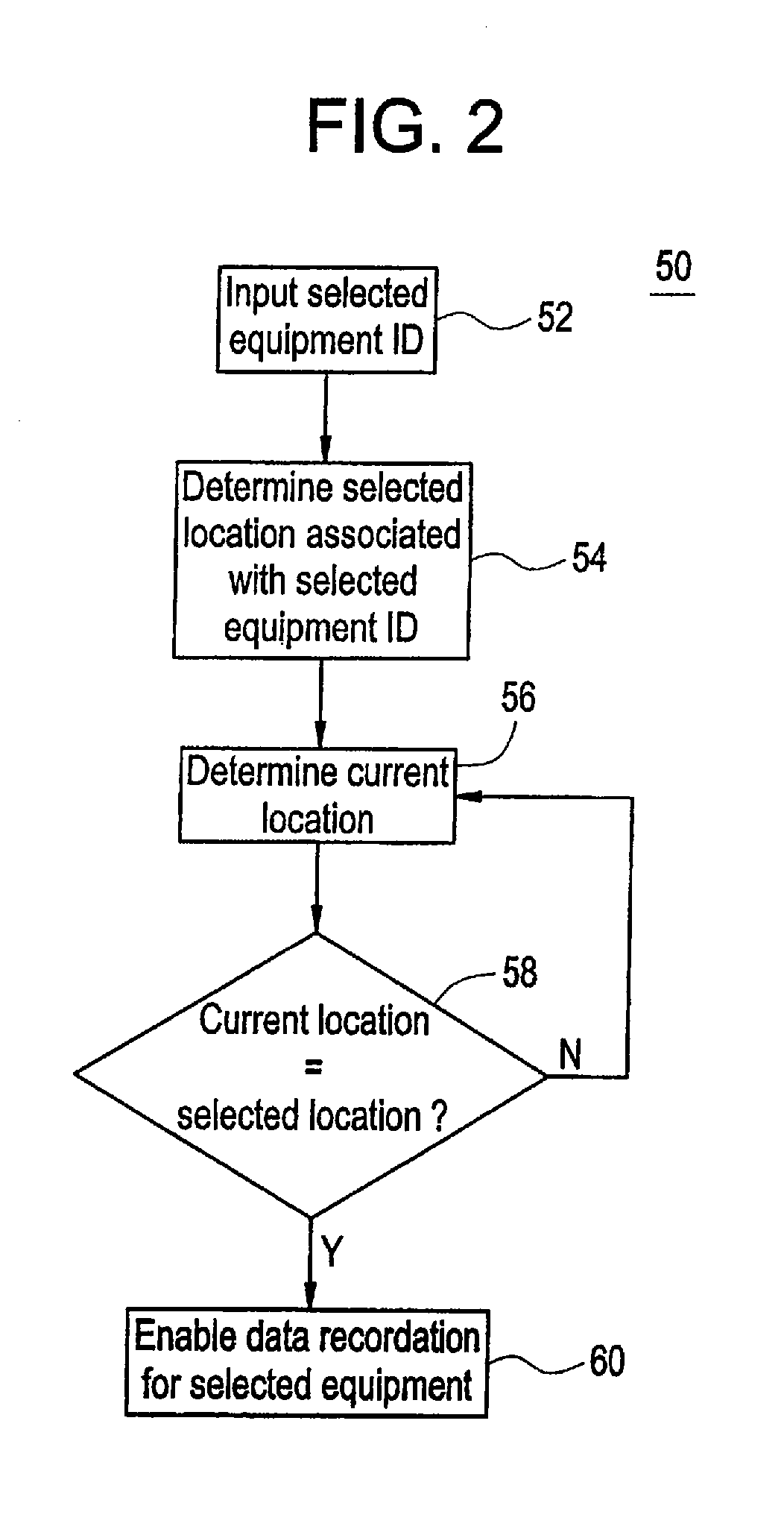

Inspection data recording apparatus and method

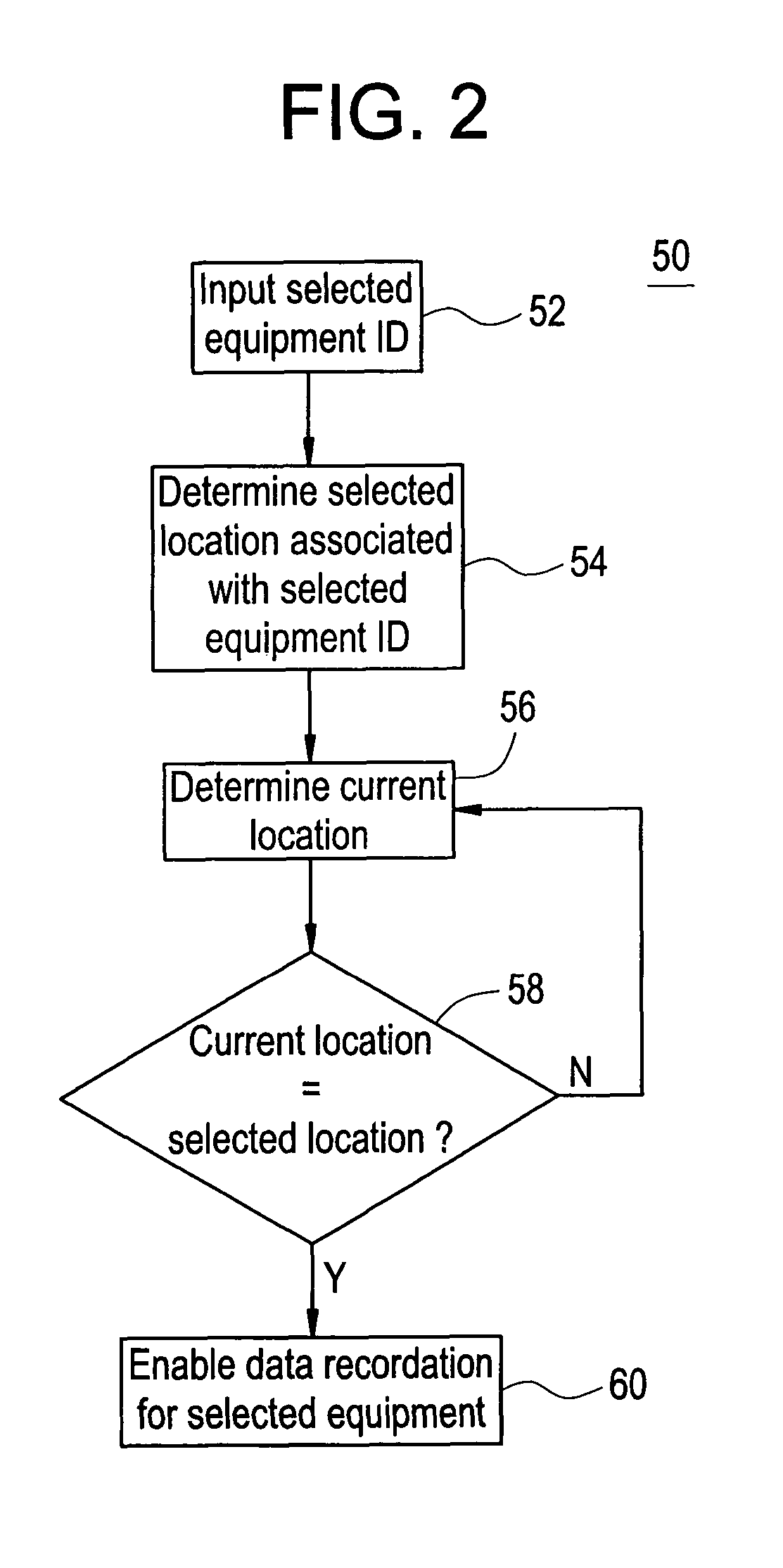

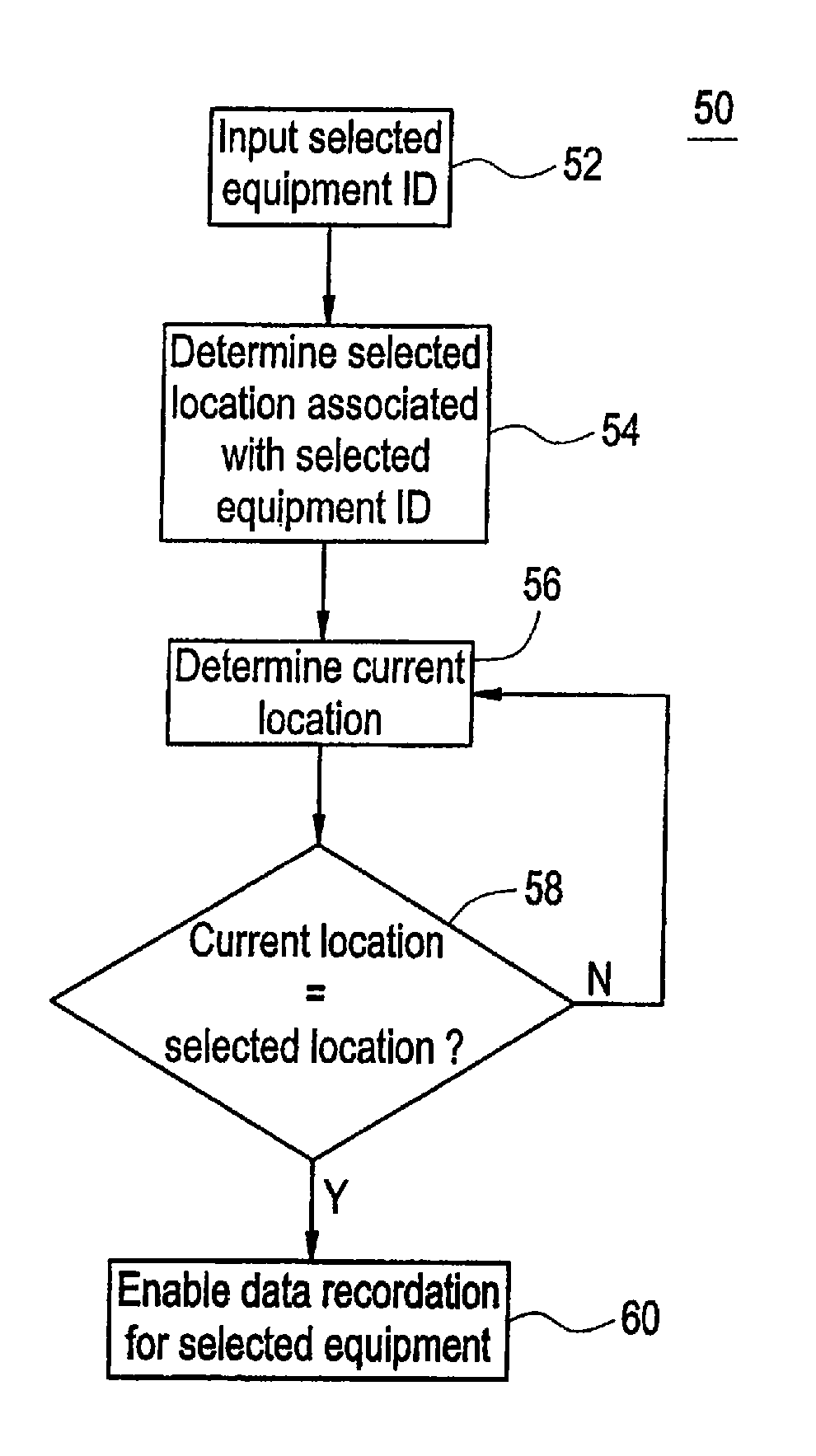

InactiveUS20050023347A1Checking time patrolsRegistering/indicating quality control systemsLocation detectionUnique device identifier

A system (10) and method for recording inspection data for geographically remote equipment assets. A portable inspection data recording device (14) is transported by a mobile inspector to a plurality of locations of equipment (12) to be inspected. The data recording device includes a location detection device (32), and a unique equipment identifier is associated with each remote equipment location, so that travel instructions may be displayed for directing the inspector to the location of selected equipment. Recordation of inspection data for selected equipment is enabled only when the portable inspection data recording device is located proximate the selected equipment. Data recordation may be enabled by displaying an equipment-specific data recordation form on input / output display (40) having selected data field automatically populated in response to the selected unique equipment identifier.

Owner:GE GLOBAL SOURCING LLC

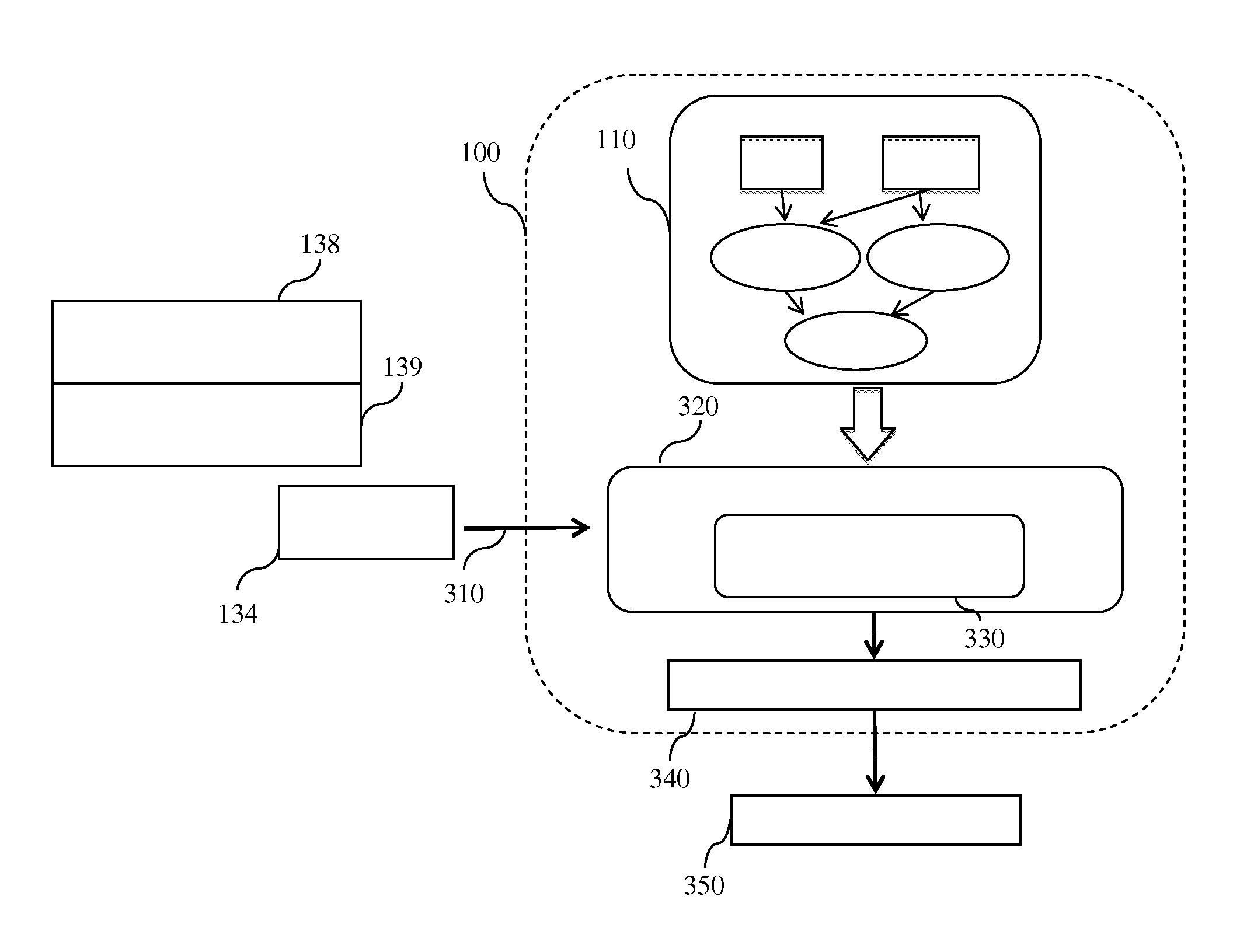

Method and system for root cause analysis and quality monitoring of system-level faults

ActiveUS20130159240A1Registering/indicating working of vehiclesRoad vehicles traffic controlGraphicsRoot cause analysis

System fault codes, component fault codes, and failure modes may be received at a system. A first level model comprising first level causal relationships and first level causal weights between the system fault codes and the component fault codes may be generated. A second level model comprising second level causal relationships and second level causal weights between the component fault codes and the failure modes may be generated. The first level model and the second level model may be combined to generate a model such as graphical model. One or more causal probabilities may be determined using the graphical model.

Owner:GM GLOBAL TECH OPERATIONS LLC

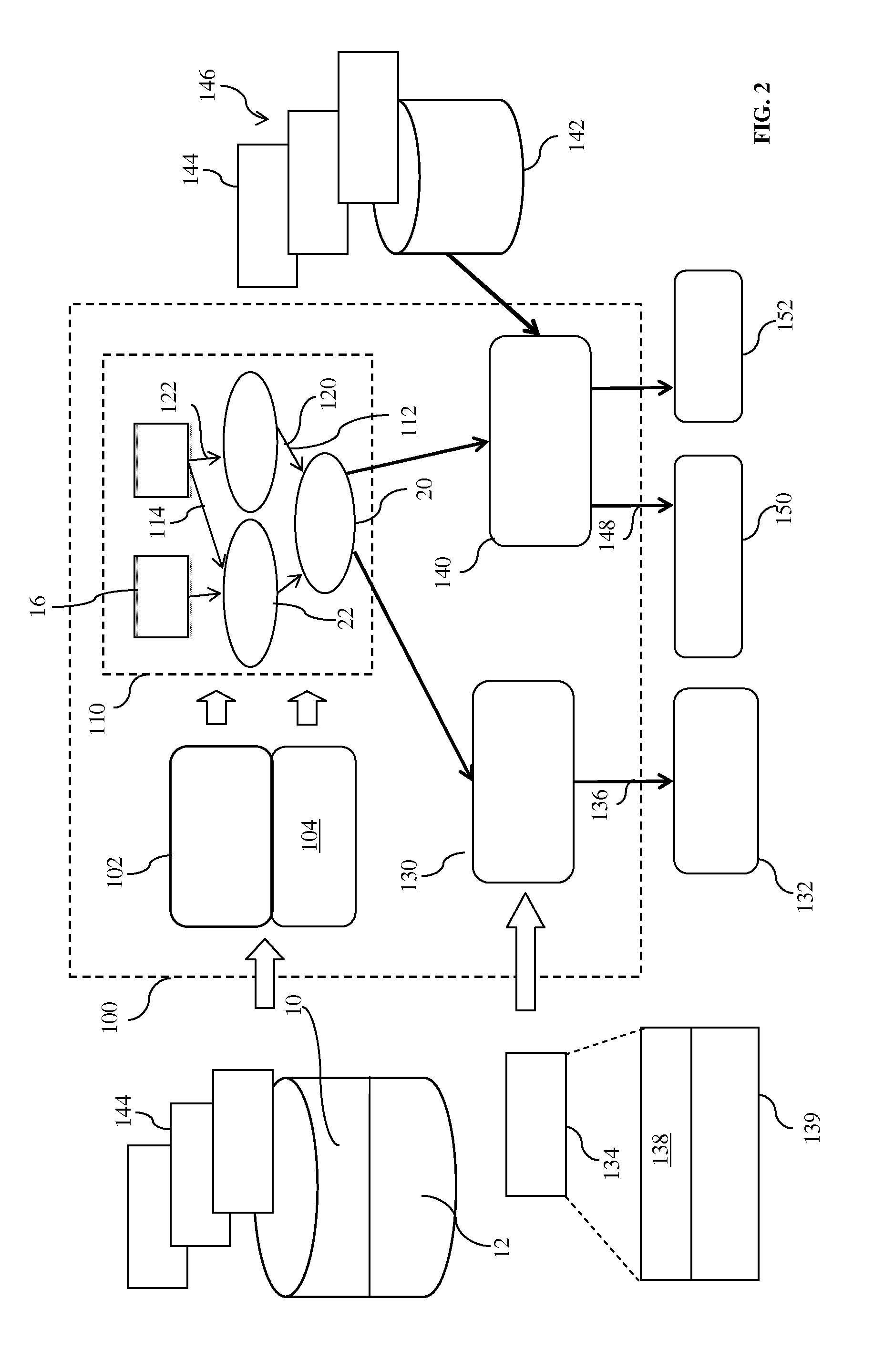

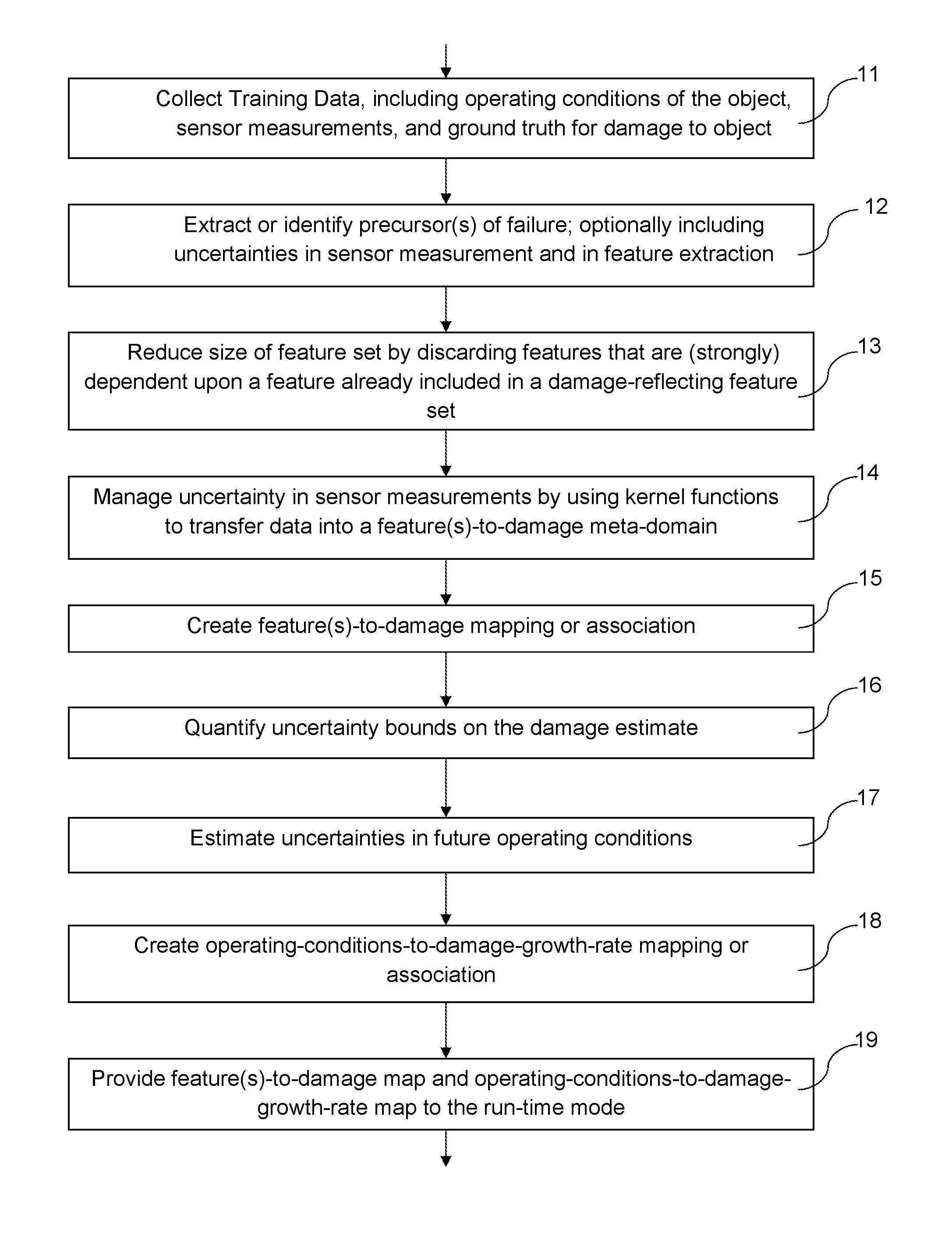

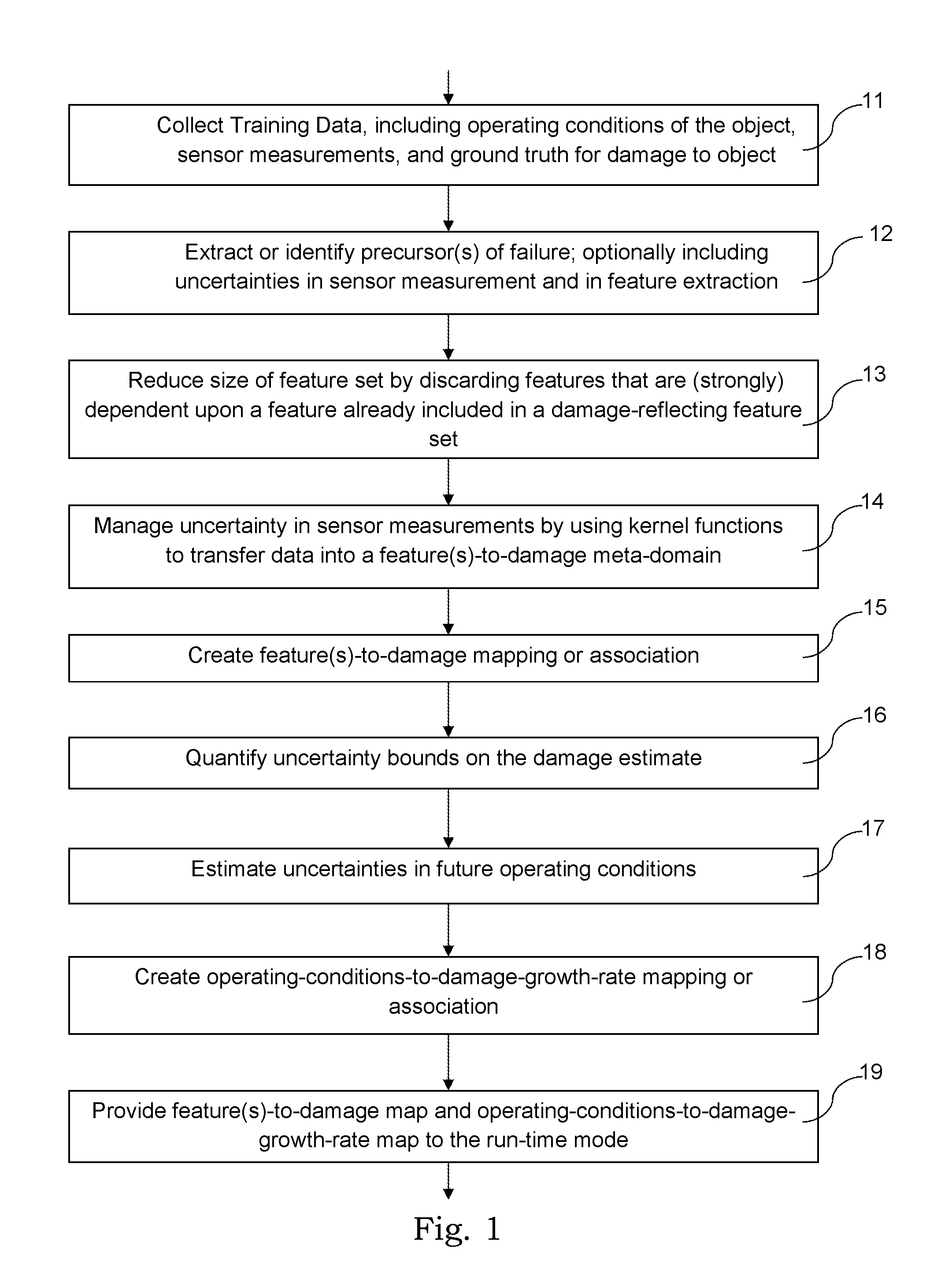

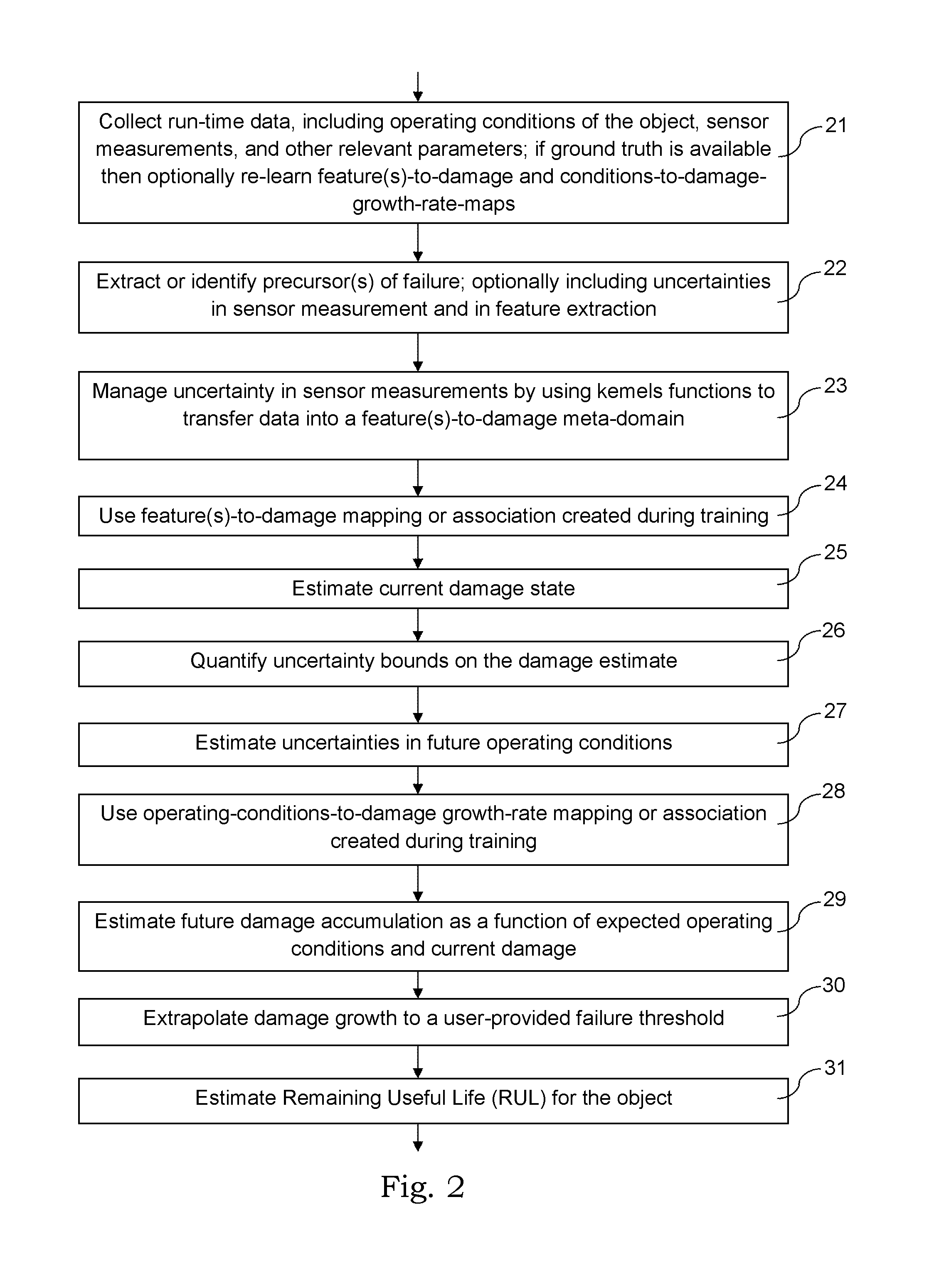

Decomposition technique for remaining useful life prediction

InactiveUS8725456B1Enhanced informationDecrease domain sizePlug gaugesTesting/monitoring control systemsGround truthDecomposition

The prognostic tool disclosed here decomposes the problem of estimating the remaining useful life (RUL) of a component or sub-system into two separate regression problems: the feature-to-damage mapping and the operational conditions-to-damage-rate mapping. These maps are initially generated in off-line mode. One or more regression algorithms are used to generate each of these maps from measurements (and features derived from these), operational conditions, and ground truth information. This decomposition technique allows for the explicit quantification and management of different sources of uncertainty present in the process. Next, the maps are used in an on-line mode where run-time data (sensor measurements and operational conditions) are used in conjunction with the maps generated in off-line mode to estimate both current damage state as well as future damage accumulation. Remaining life is computed by subtracting the instance when the extrapolated damage reaches the failure threshold from the instance when the prediction is made.

Owner:NASA

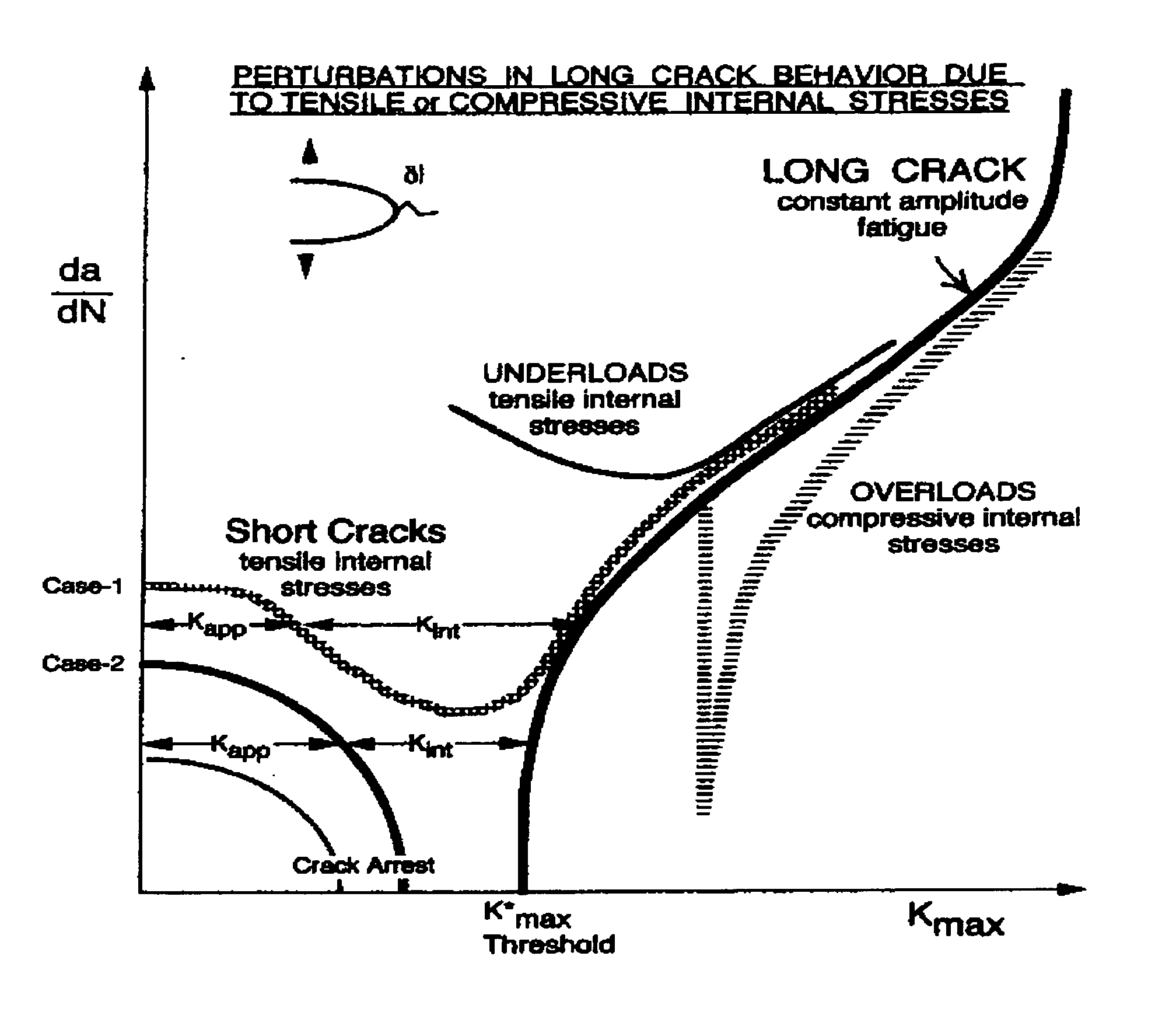

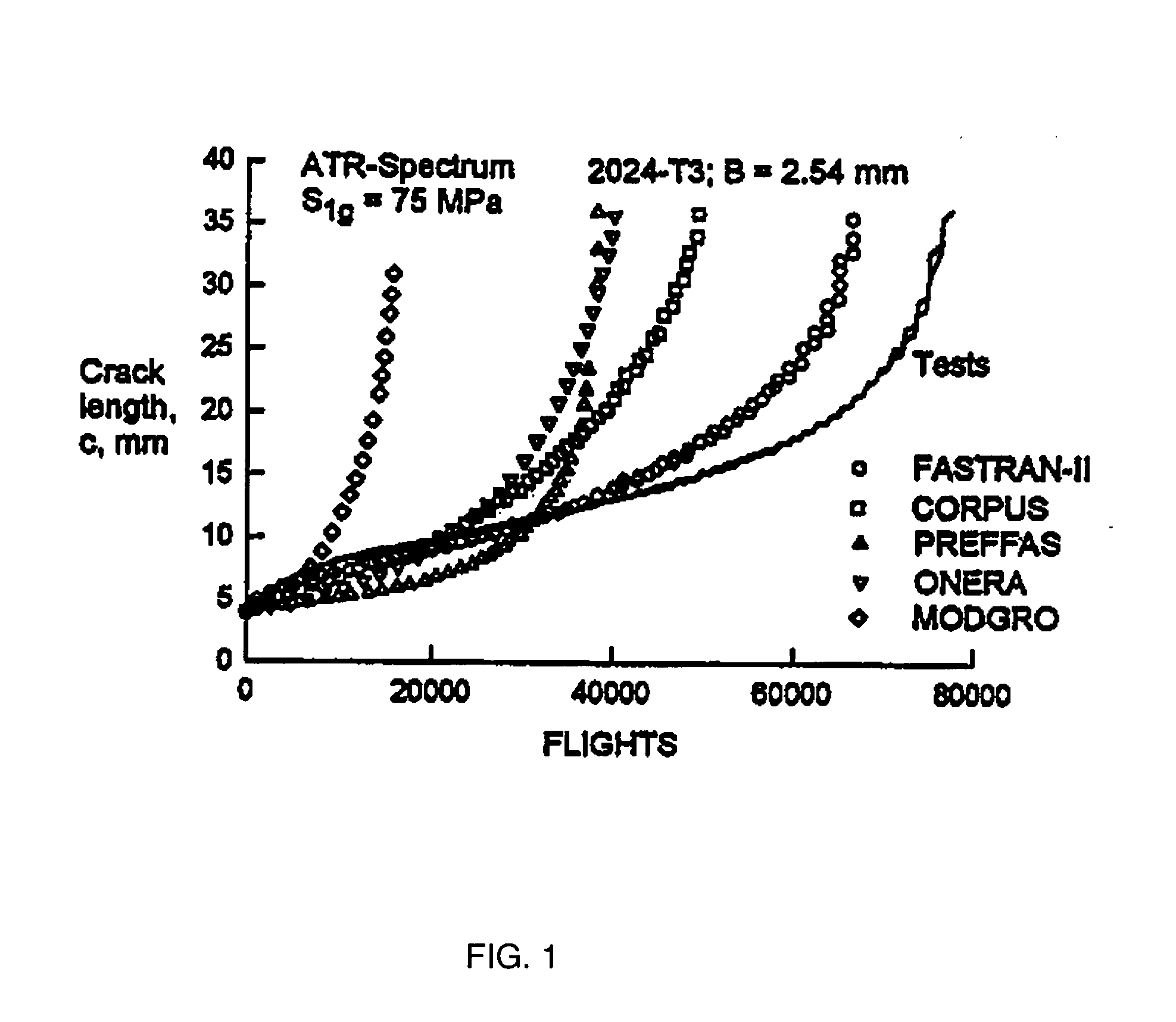

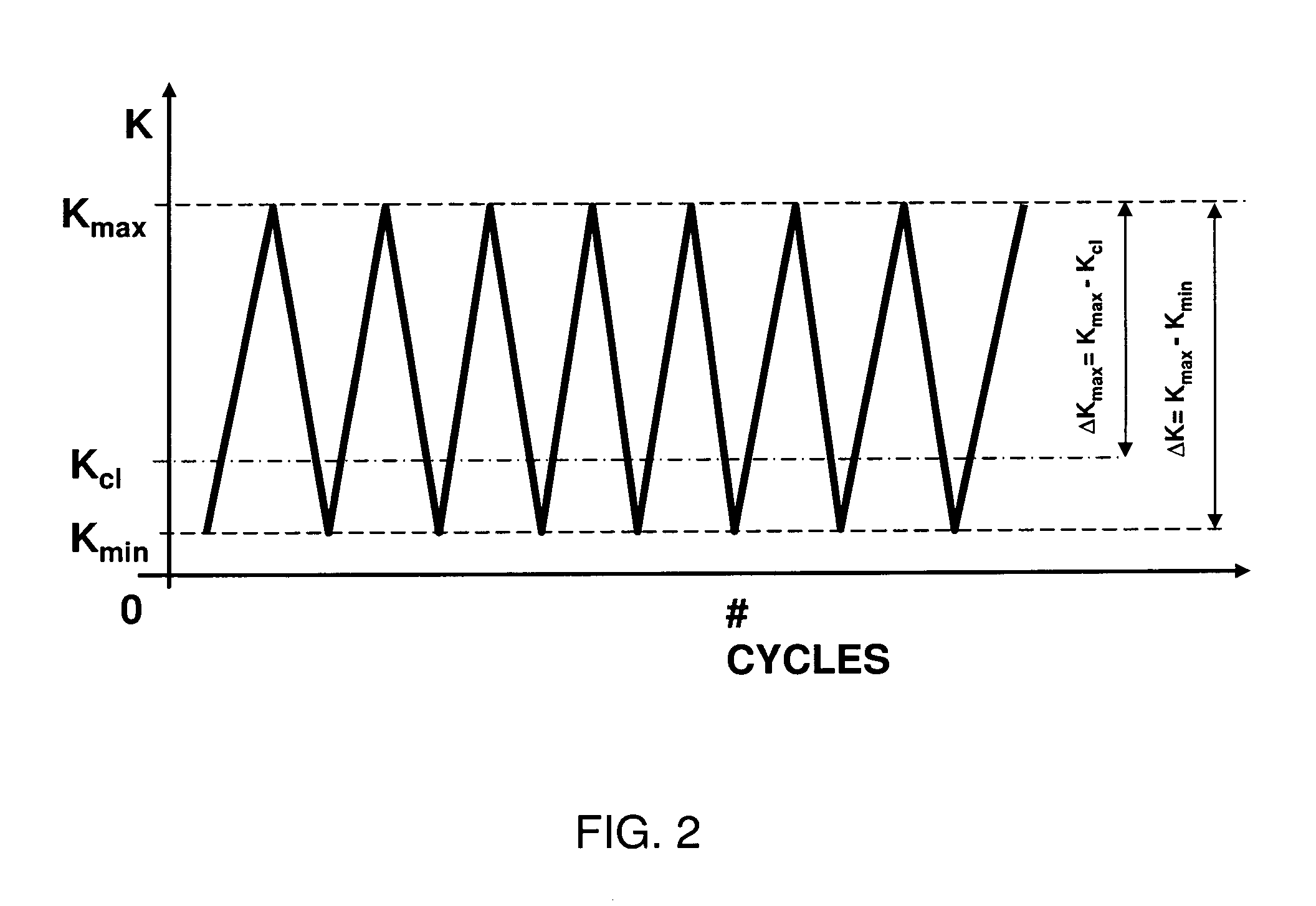

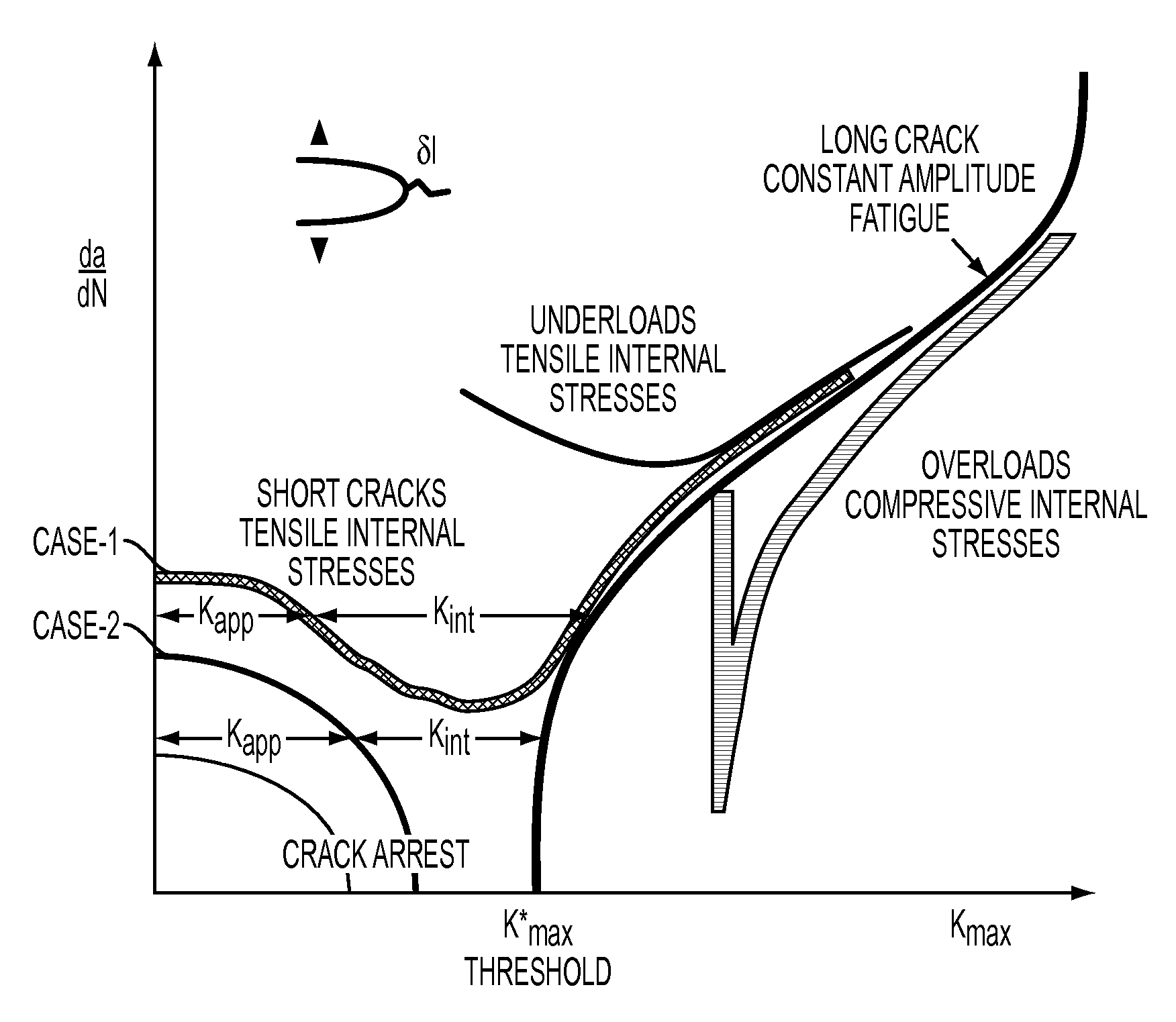

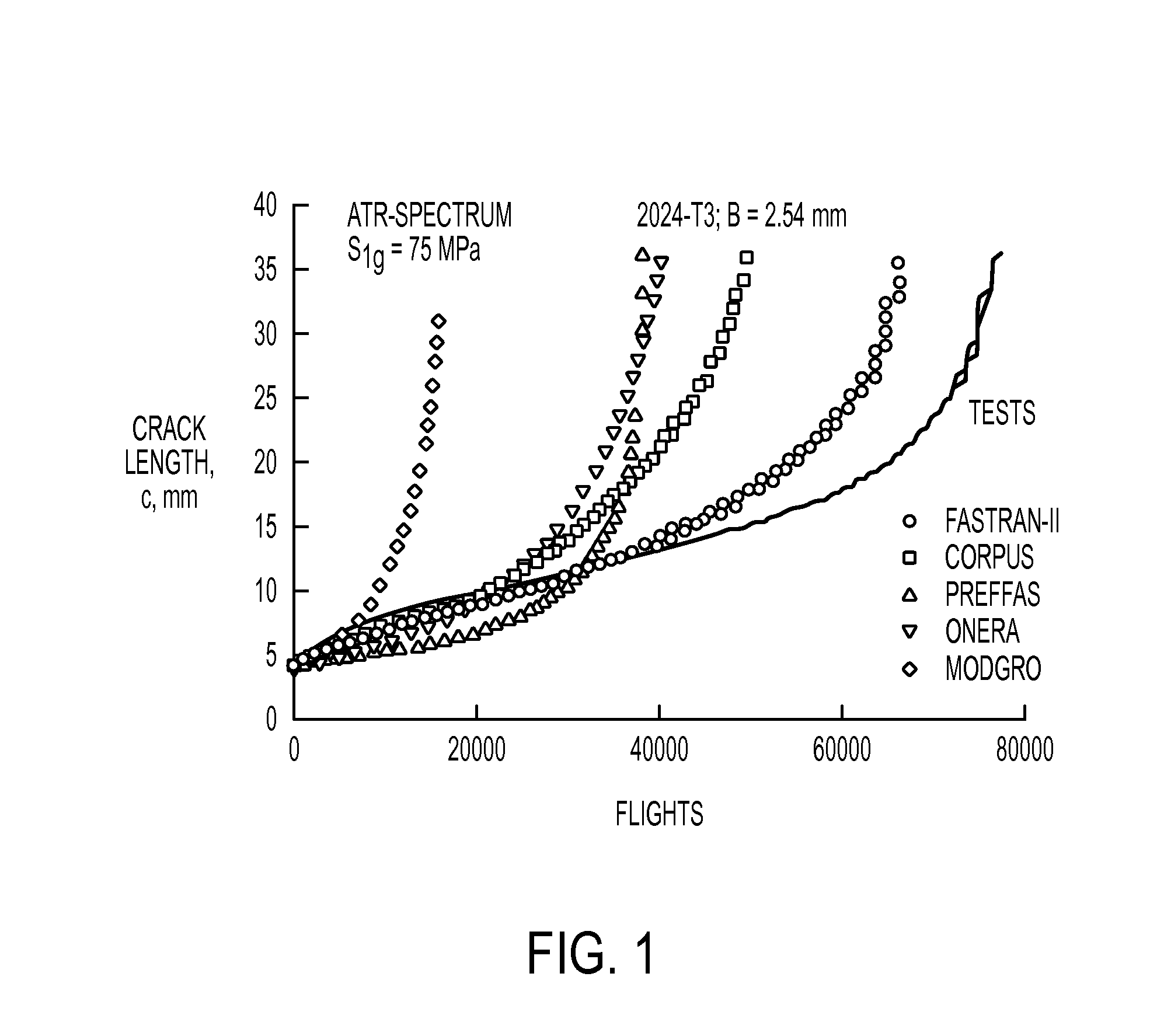

System and Method for predicting Material Fatigue and Damage

InactiveUS20080177516A1Registering/indicating quality control systemsDigital computer detailsReliability engineeringMaterial fatigue

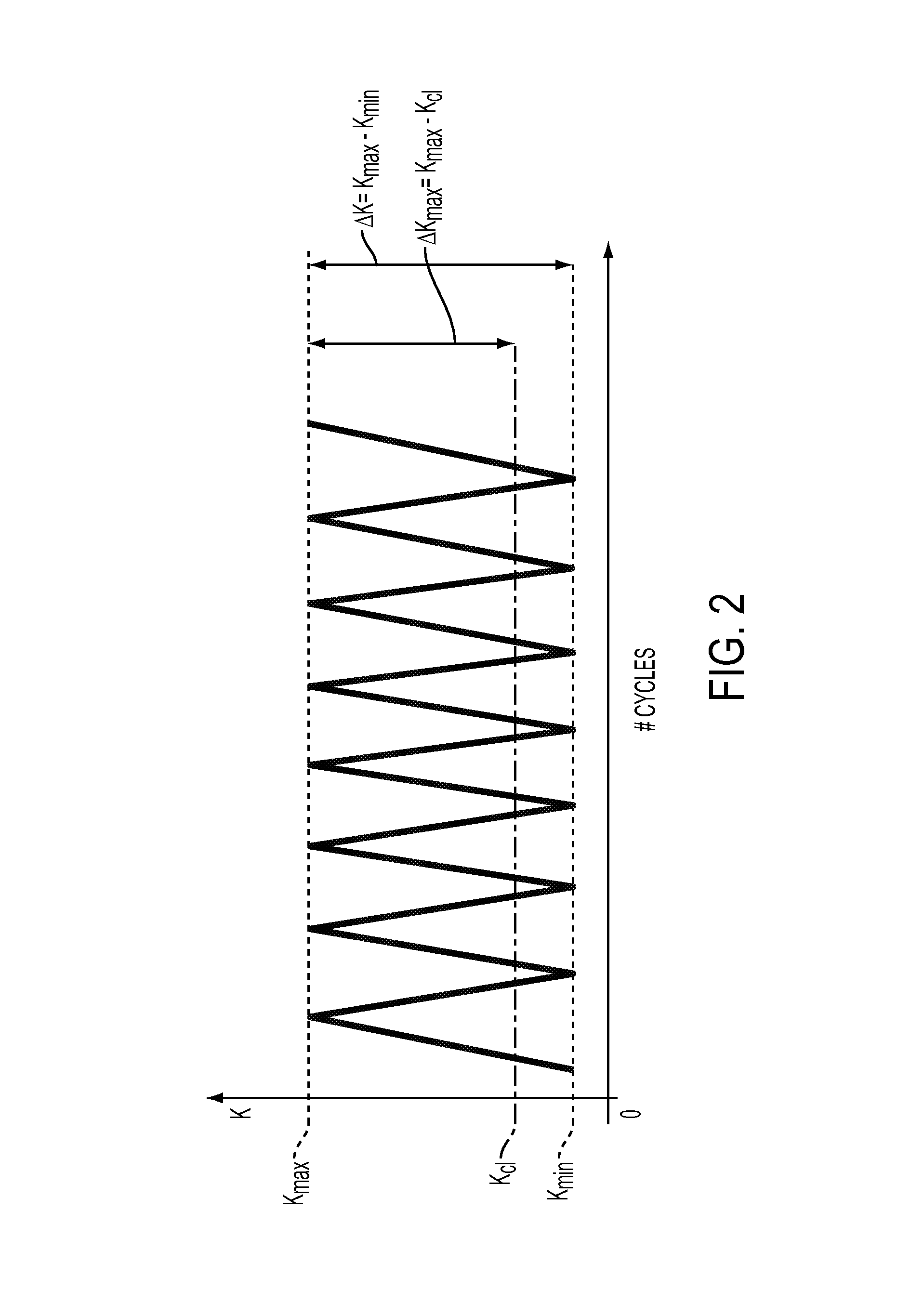

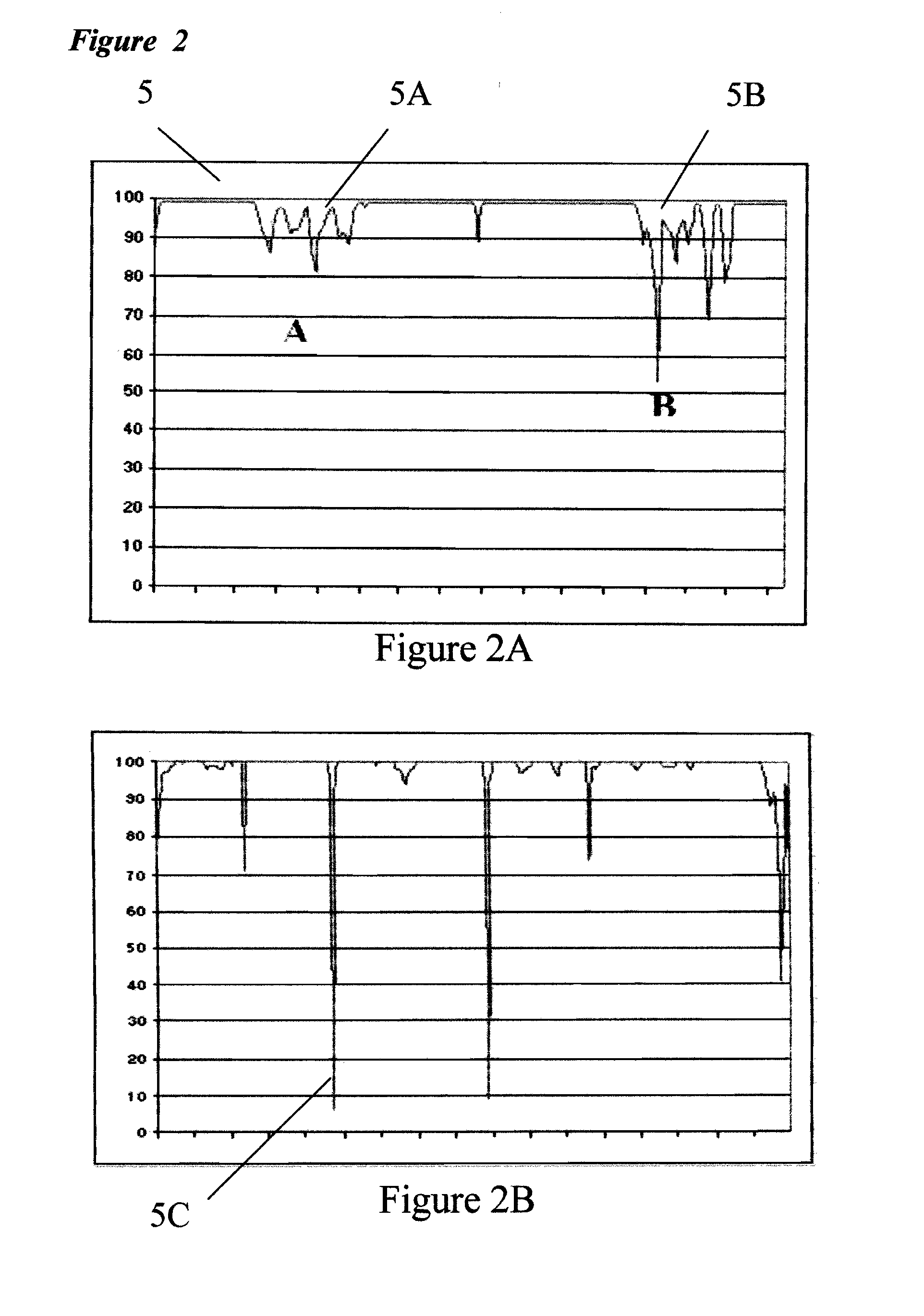

A method and system for determining damage prediction of a component. The component may be critical component used in an aircraft or other vehicle experiencing cyclic loading. The method and system determines the ΔK, Kmax and Kinternal values for the component and utilizes these values in order to predict damage and / or failure of the component.

Owner:NAVY SEC OF THE THE USA AS REPRESENTED BY THE

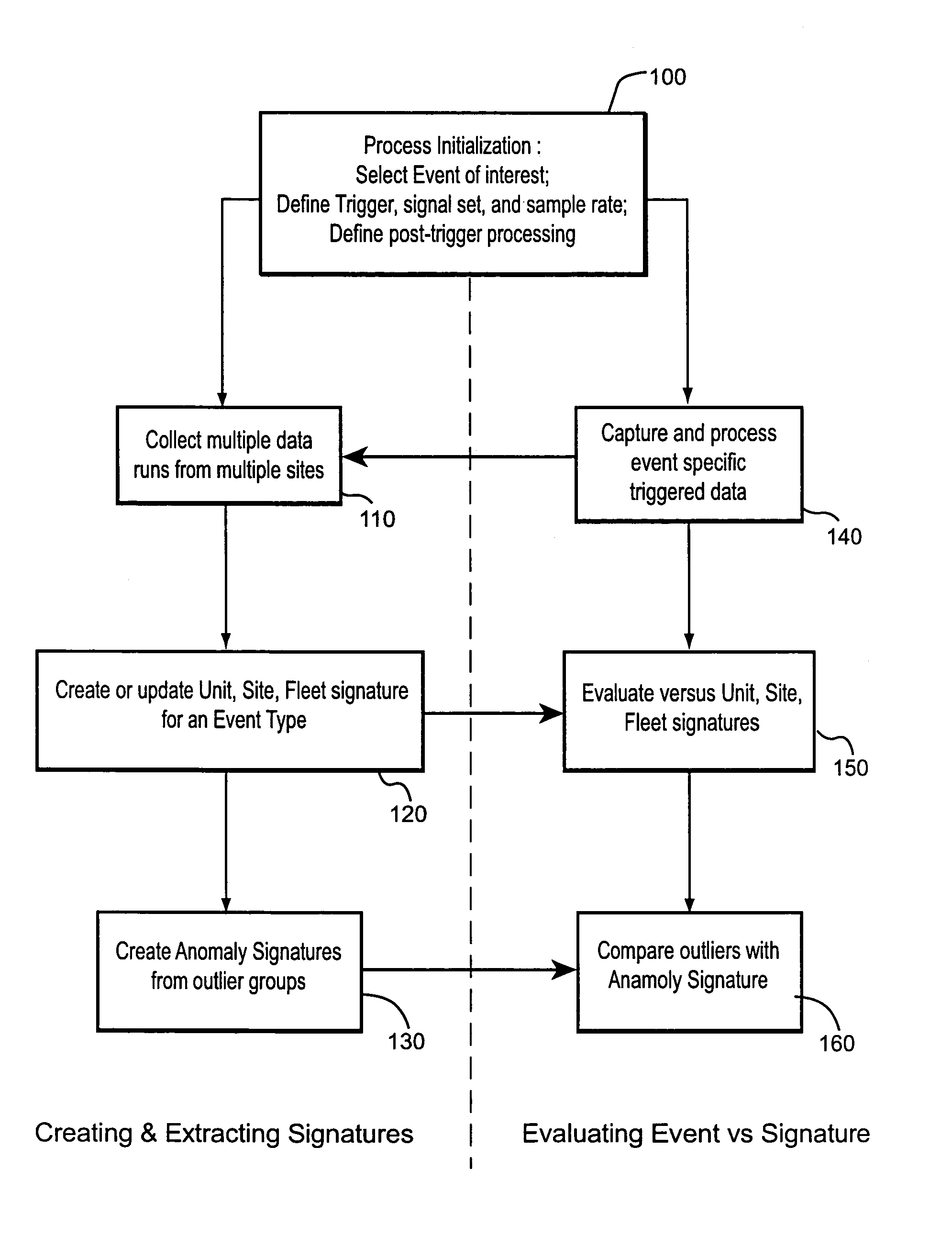

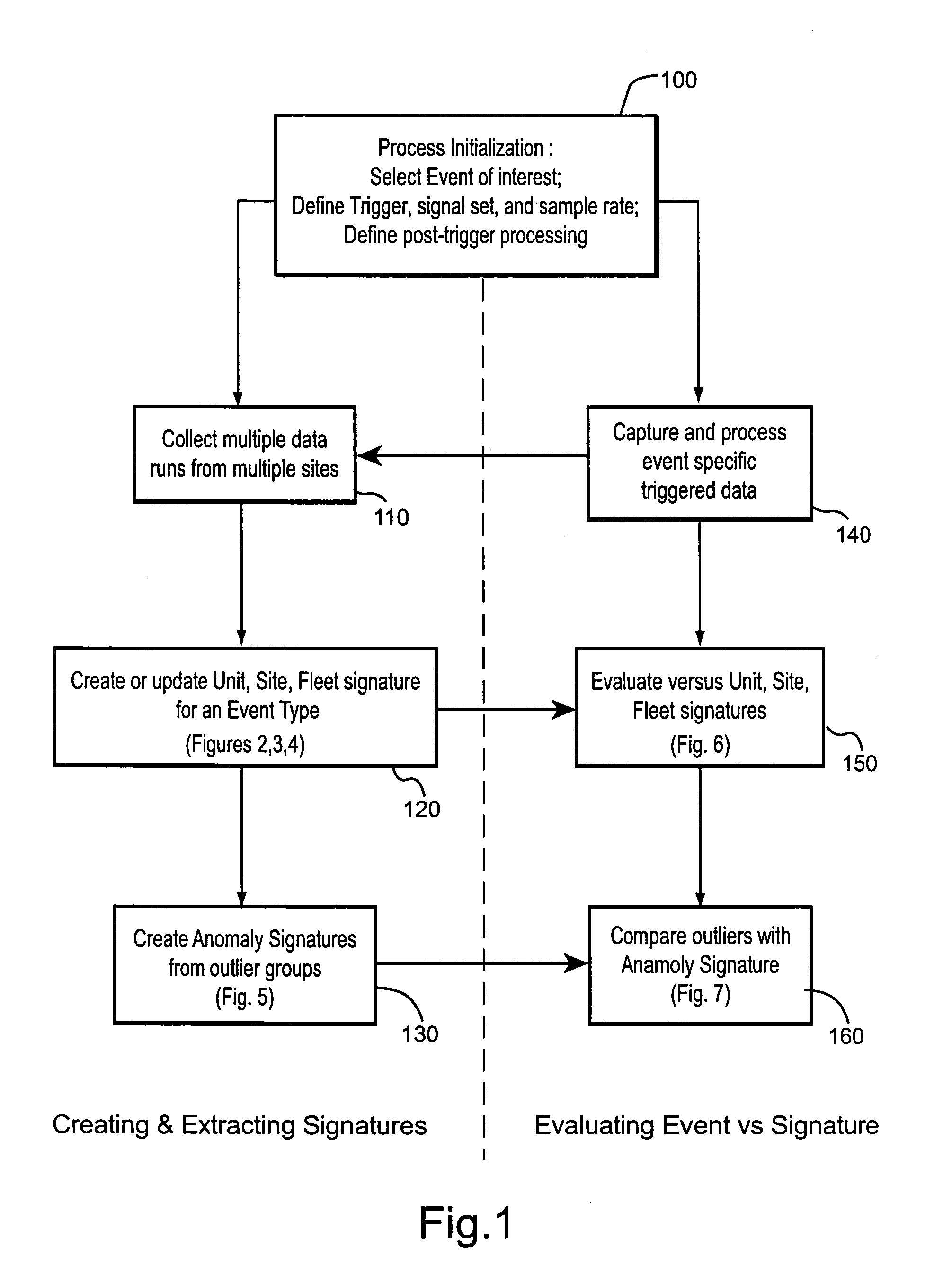

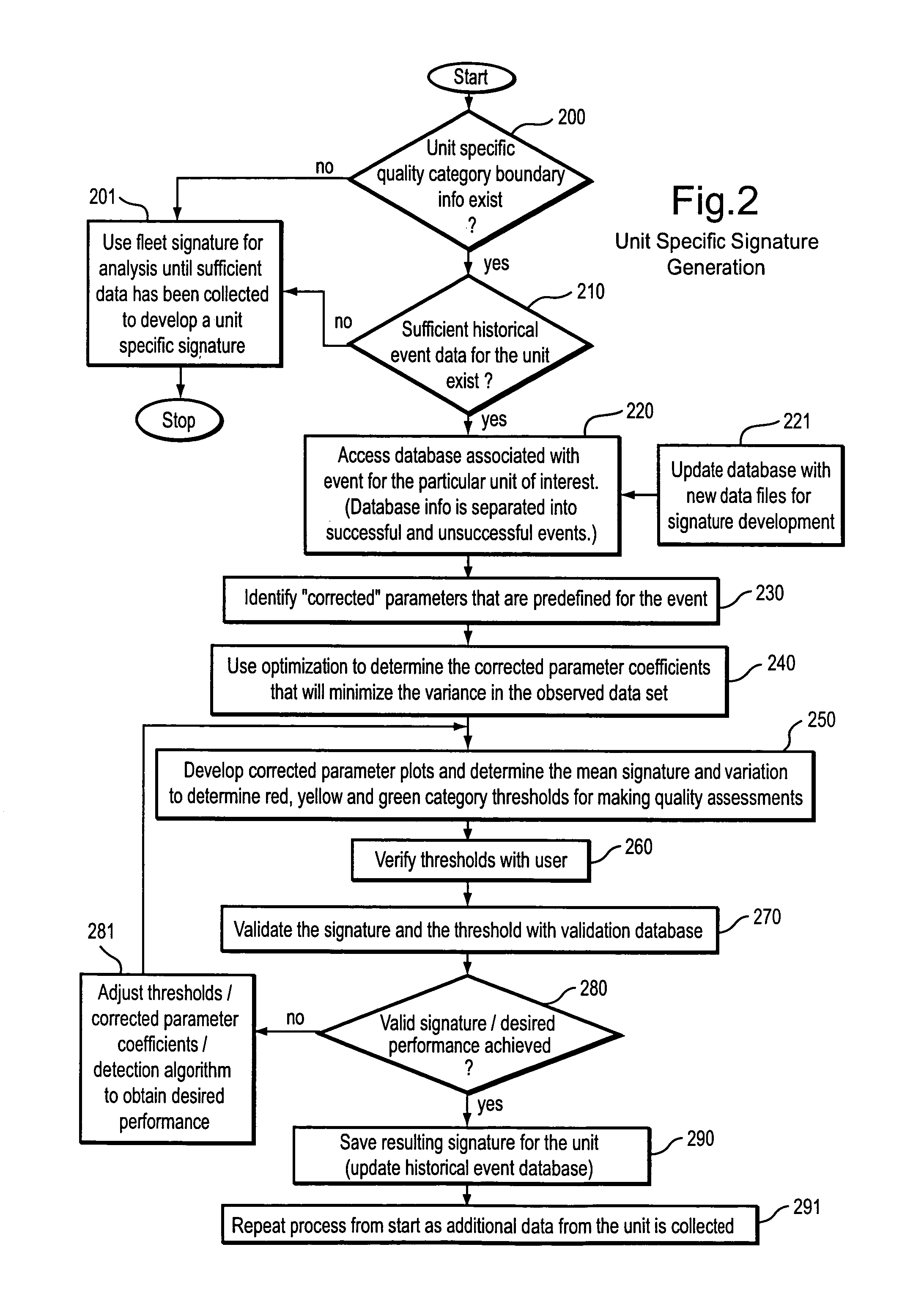

Method for developing a unified quality assessment and providing an automated fault diagnostic tool for turbine machine systems and the like

InactiveUS6973396B1Accurate analysisAccurate assessmentVibration measurement in solidsMachine part testingFuel qualityMachining system

A computer implemented process is provided for assessing and characterizing the degree of success or failure of an operational event of a machine system such as a fluid compressor machine or turbine machine or the like on a continuous numerical scale. The computer implemented process develops and tracks machine unit signatures, machine site signatures and machine fleet signatures to evaluate various operational events and provide fault detection. At least some sensor data acquired from the machine system during an operational event is transformed to correct or at least reduce variabilities in the data caused by ambient conditions and fuel quality. The transformed data is then analyzed using statistical methods to determine how closely the operational event conforms to an expected normal behavior and the information is used to develop a single comprehensive quality assessment of the event. By saving, tracking and updating operational event assessments over time, machine / component degradation may be recognized at any early stage and corrective action may be initiated in advance of a catastrophic failure.

Owner:GENERAL ELECTRIC CO

System and method for predicting material fatigue and damage

InactiveUS7889840B2Registering/indicating quality control systemsDigital computer detailsReliability engineeringMaterial fatigue

A method and system for determining damage prediction of a component. The component may be critical component used in an aircraft or other vehicle experiencing cyclic loading. The method and system determines the ΔK, Kmax and Kinternal values for the component and utilizes these values in order to predict damage and / or failure of the component.

Owner:NAVY SEC OF THE THE USA AS REPRESENTED BY THE

Autonomous remaining useful life estimation

ActiveUS20130060487A1Plug gaugesRegistering/indicating quality control systemsComputer scienceLongevity

The equipment comprises at least one computer and a material features acquisition system operable to detect a plurality of material features. The features are then evaluated according to rules that capture the multidiscipline knowledge of experts and are already inputted into the computer. The computer iterations are processed until an acceptable conclusion is made regarding the condition of the material under evaluation, thus alleviating the need for multidiscipline experts to examine and analyze all the material data manually.

Owner:STYLWAN IP HLDG LLC

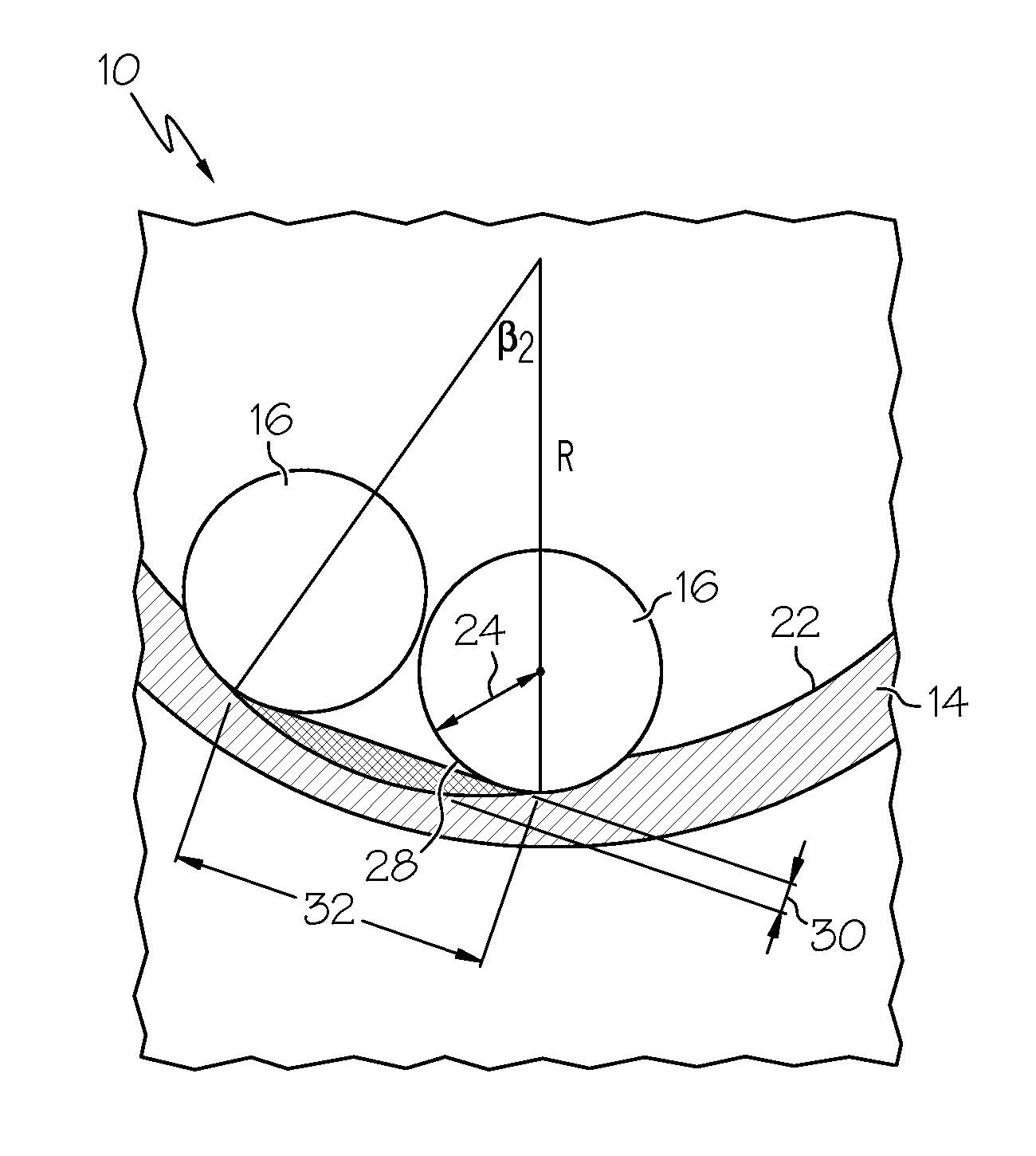

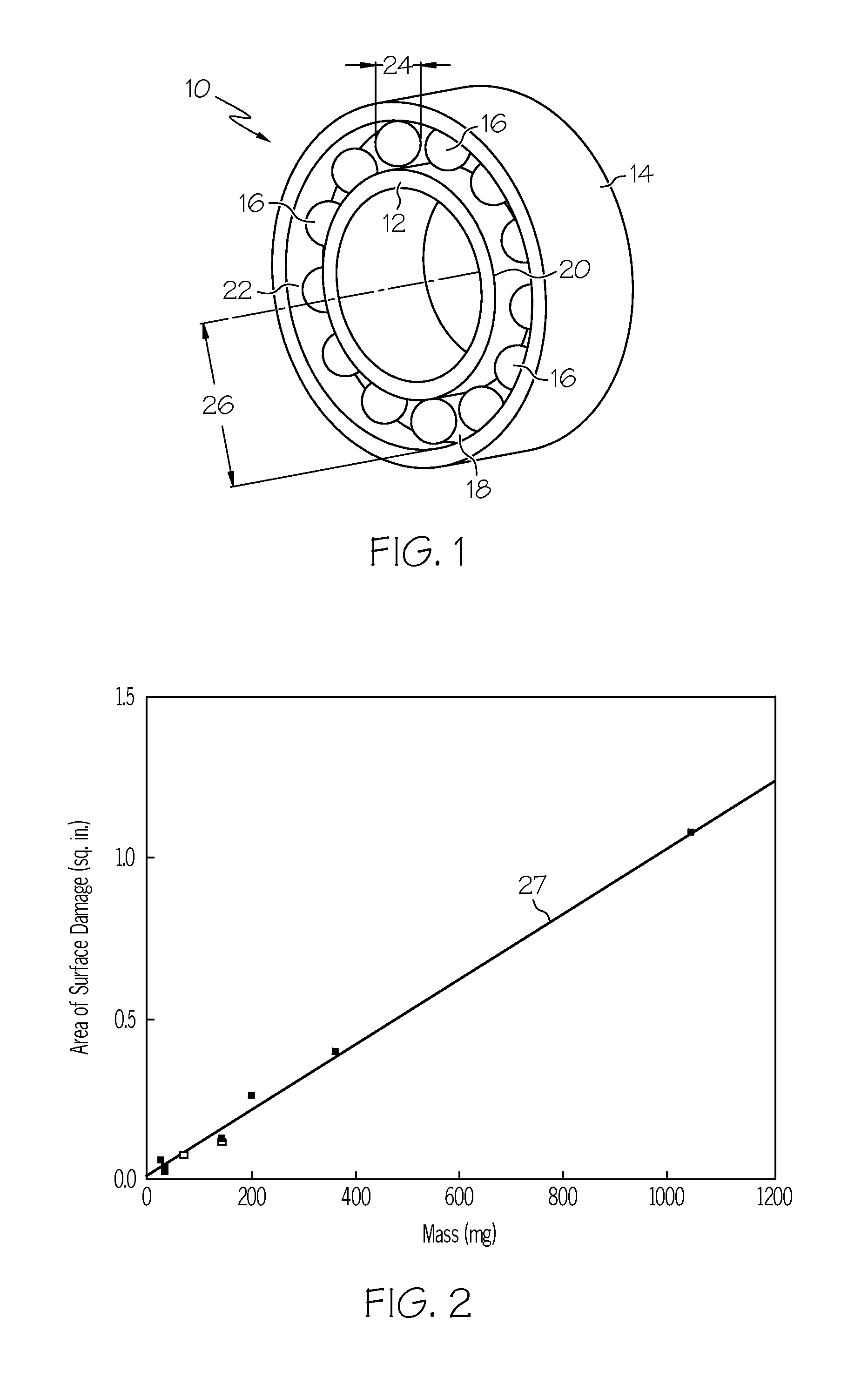

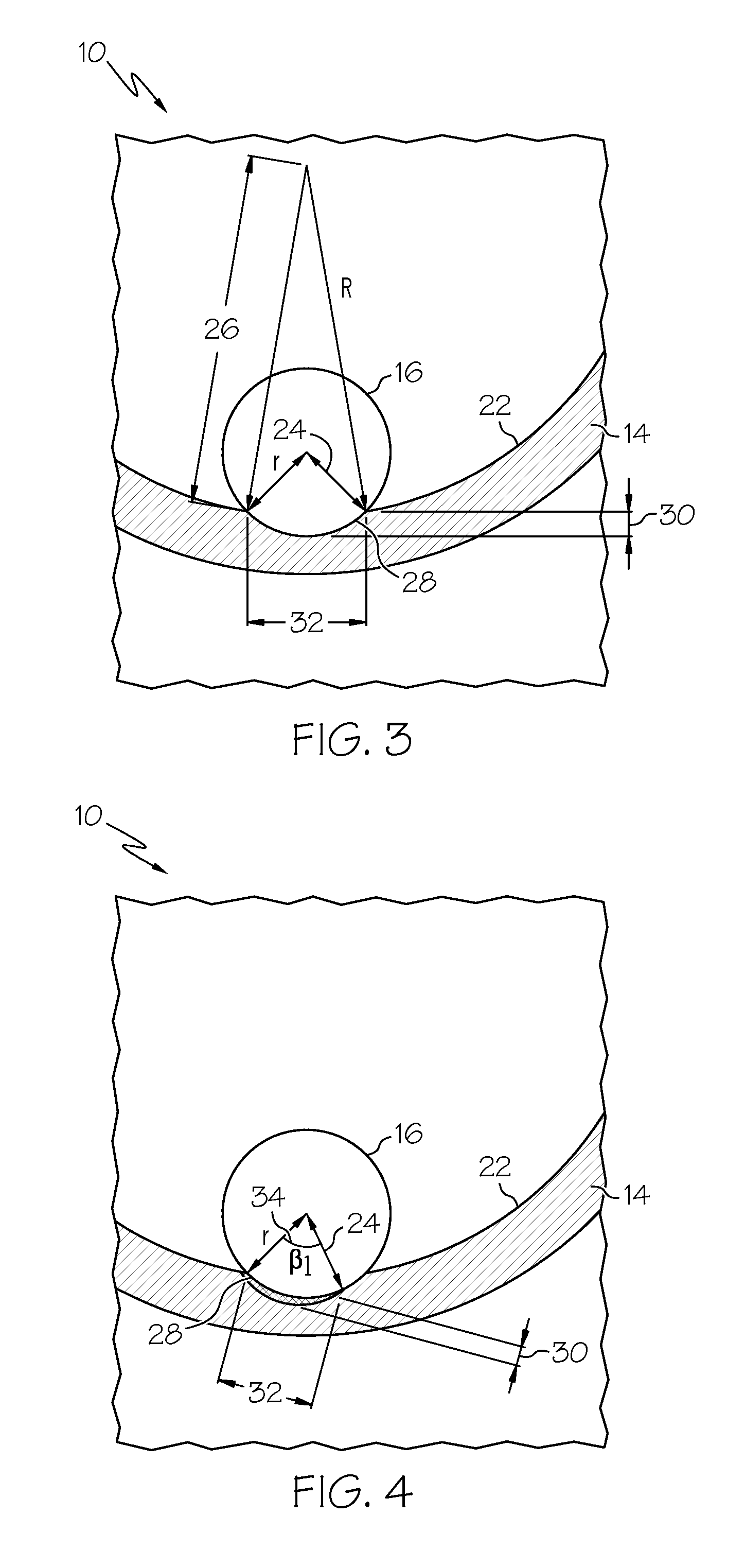

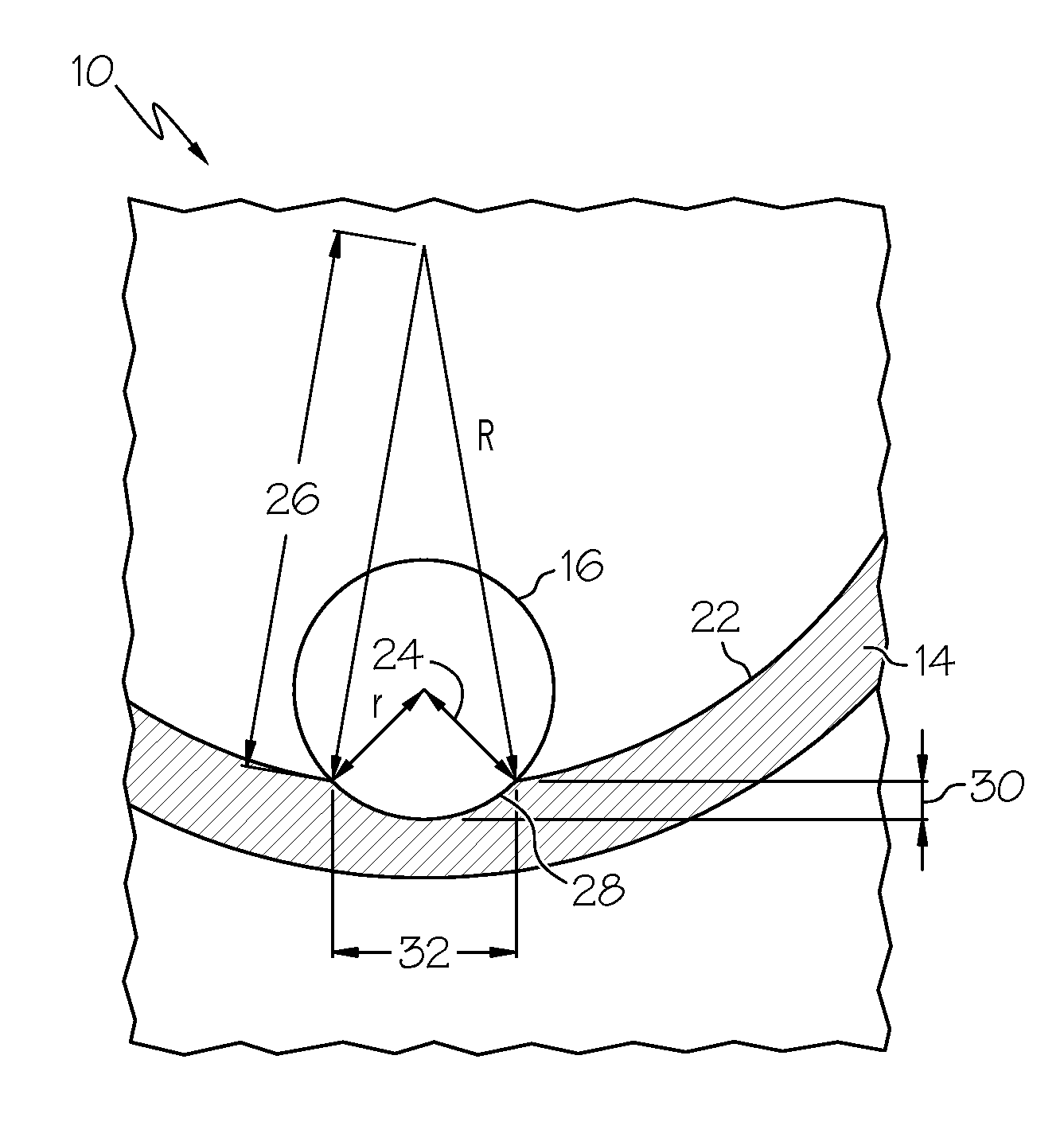

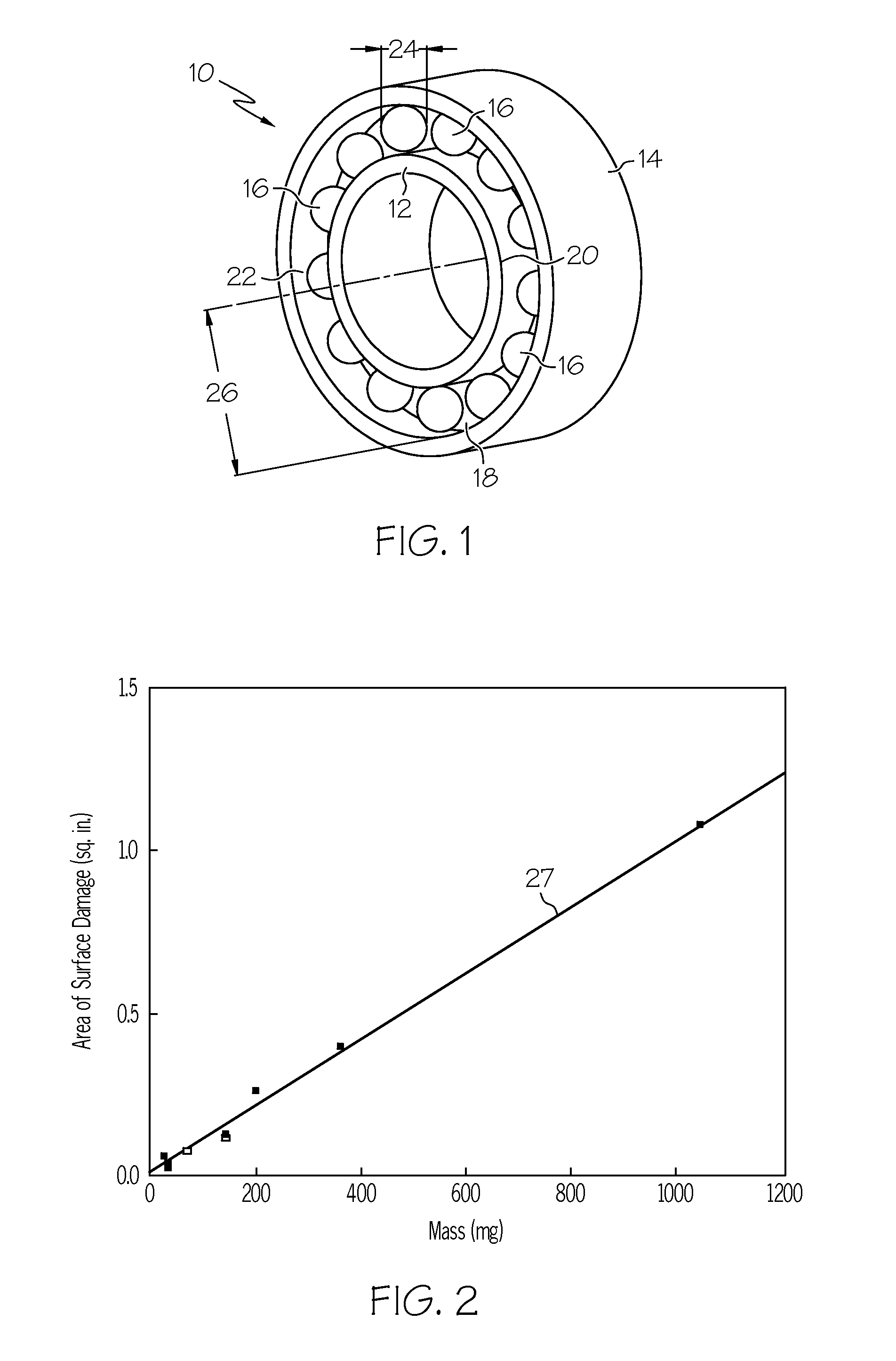

Method and system for detecting incipient bearing failures

Methods and systems for estimating wear damage of a rolling-element bearing system including at least one rolling-element bearing are provided. A first number of first condition indicators representative of the wear damage of the at least one rolling-element bearing are generated. A second number of second condition indicators are generated based on the first plurality of first condition indicators. The second number is less than the first number an indication of the wear damage of the at least one rolling-element bearing is generated based on the second number of second condition indicators.

Owner:HONEYWELL INT INC

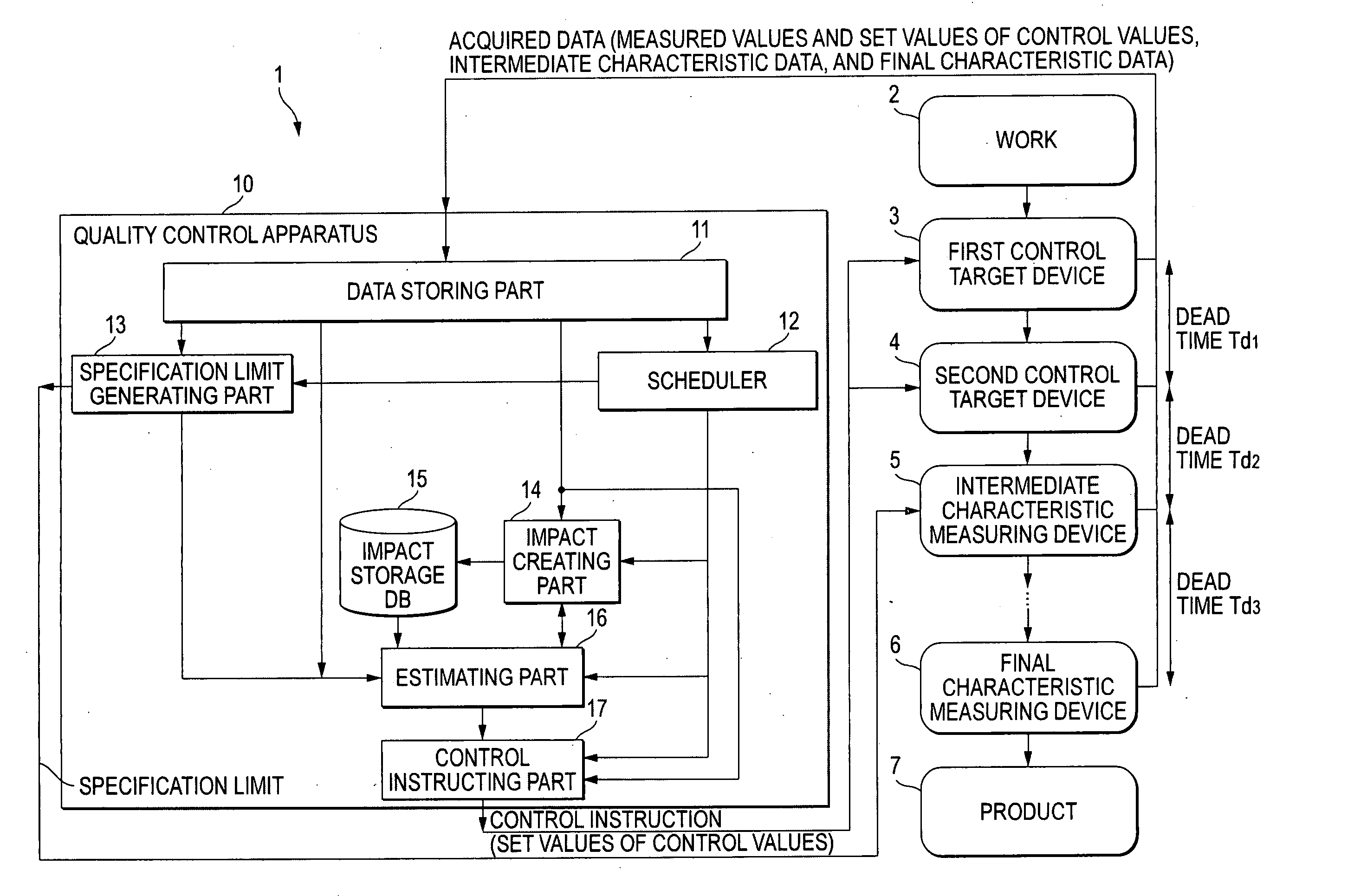

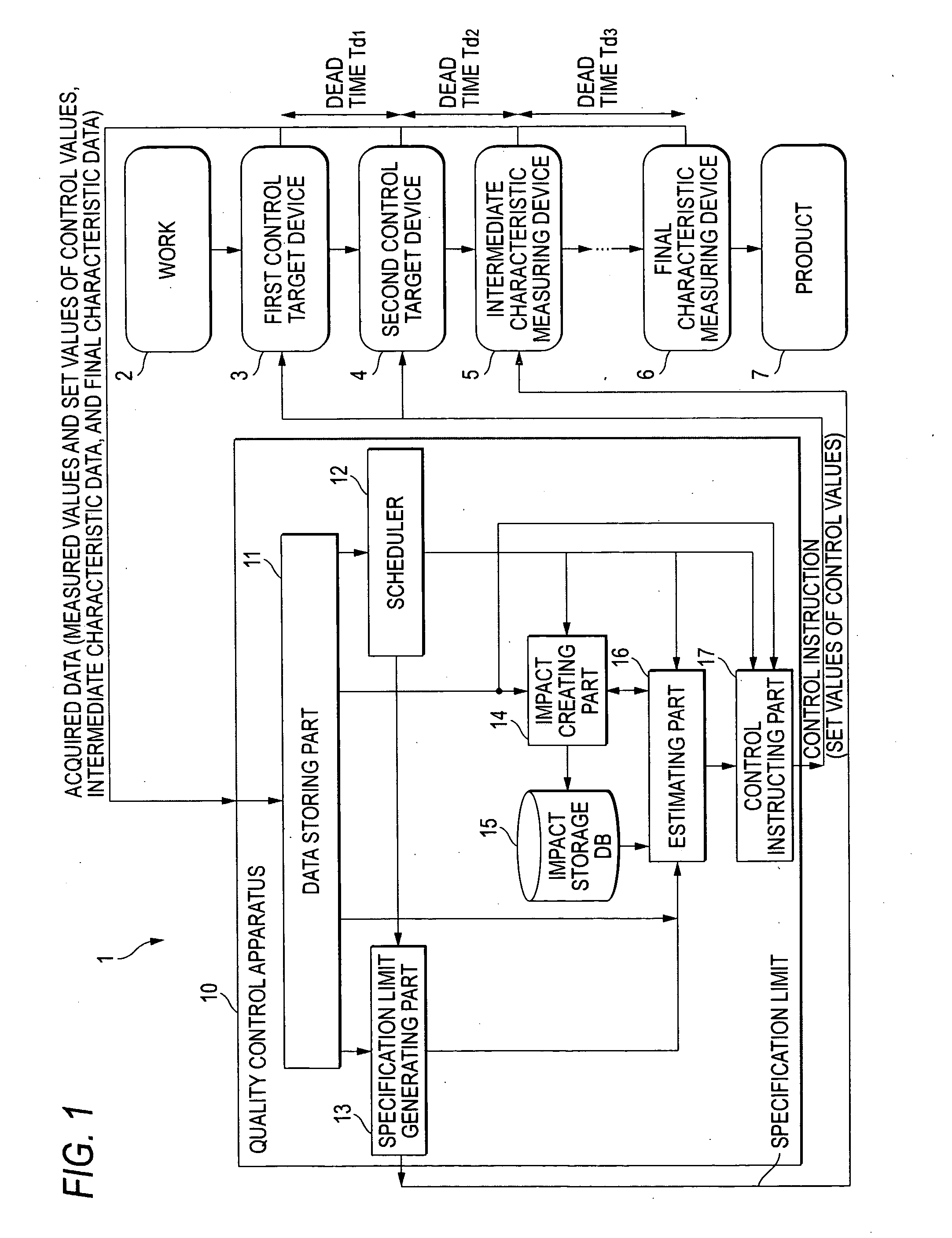

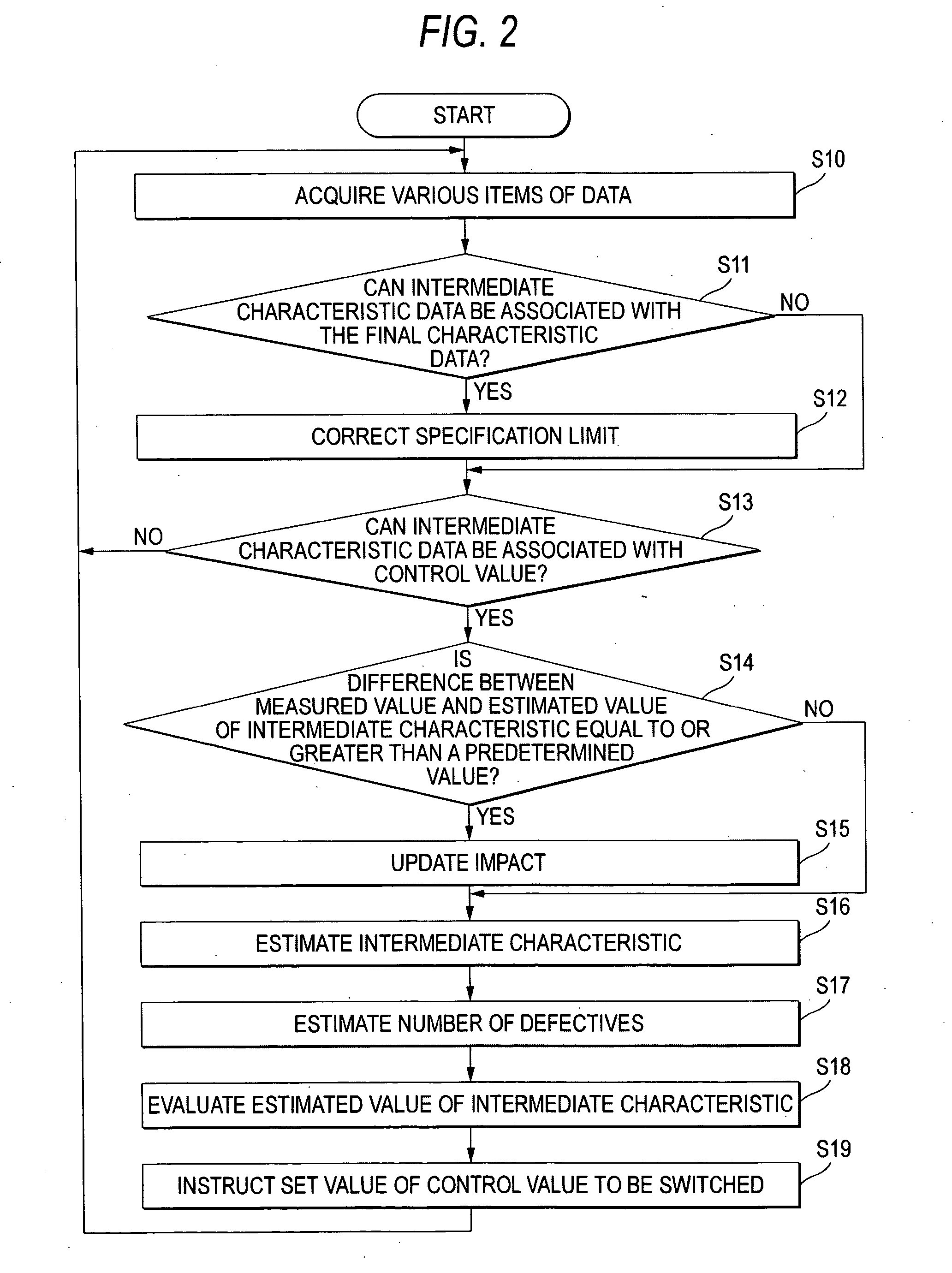

Quality control apparatus and control method of the same, and recording medium recorded with quality control program

ActiveUS20050246045A1Exact numberMinimal numberElectric signal transmission systemsRegistering/indicating quality control systemsDead timeQuality control

Various items of data collected at different process steps are associated on production sites where traceability is hard to conduct. A quality control apparatus controls a manufacturing process in order to manufacture products of predetermined quality, including a data storing part which collects measurement data measured by multiple devices disposed in a manufacturing process and stores the collected measurement data along with measured time or collected time; and a scheduler which associates the measurement data of the devices with each other in consideration of dead time generated between the devices at measured time or collected time.

Owner:ORMON CORP

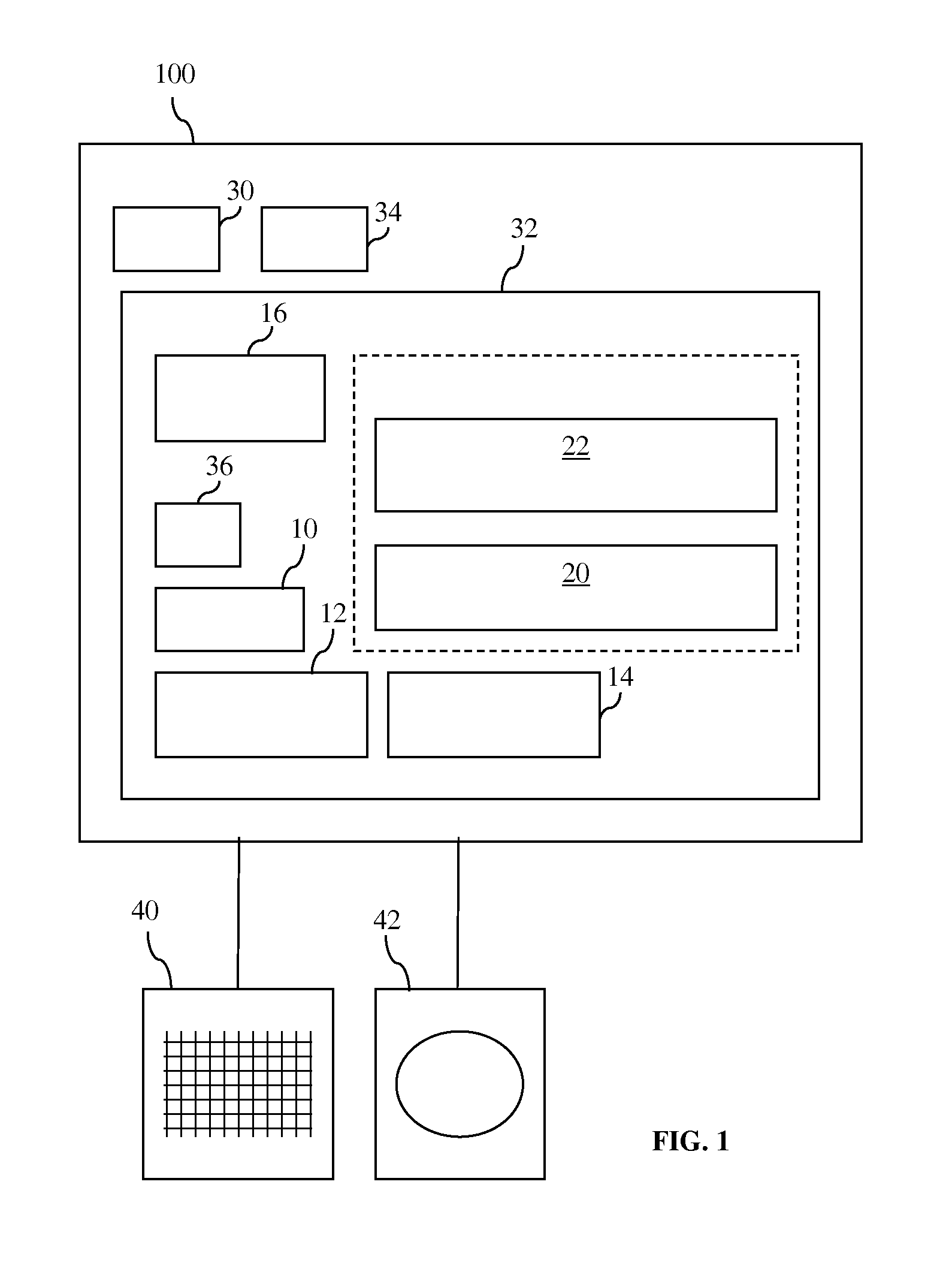

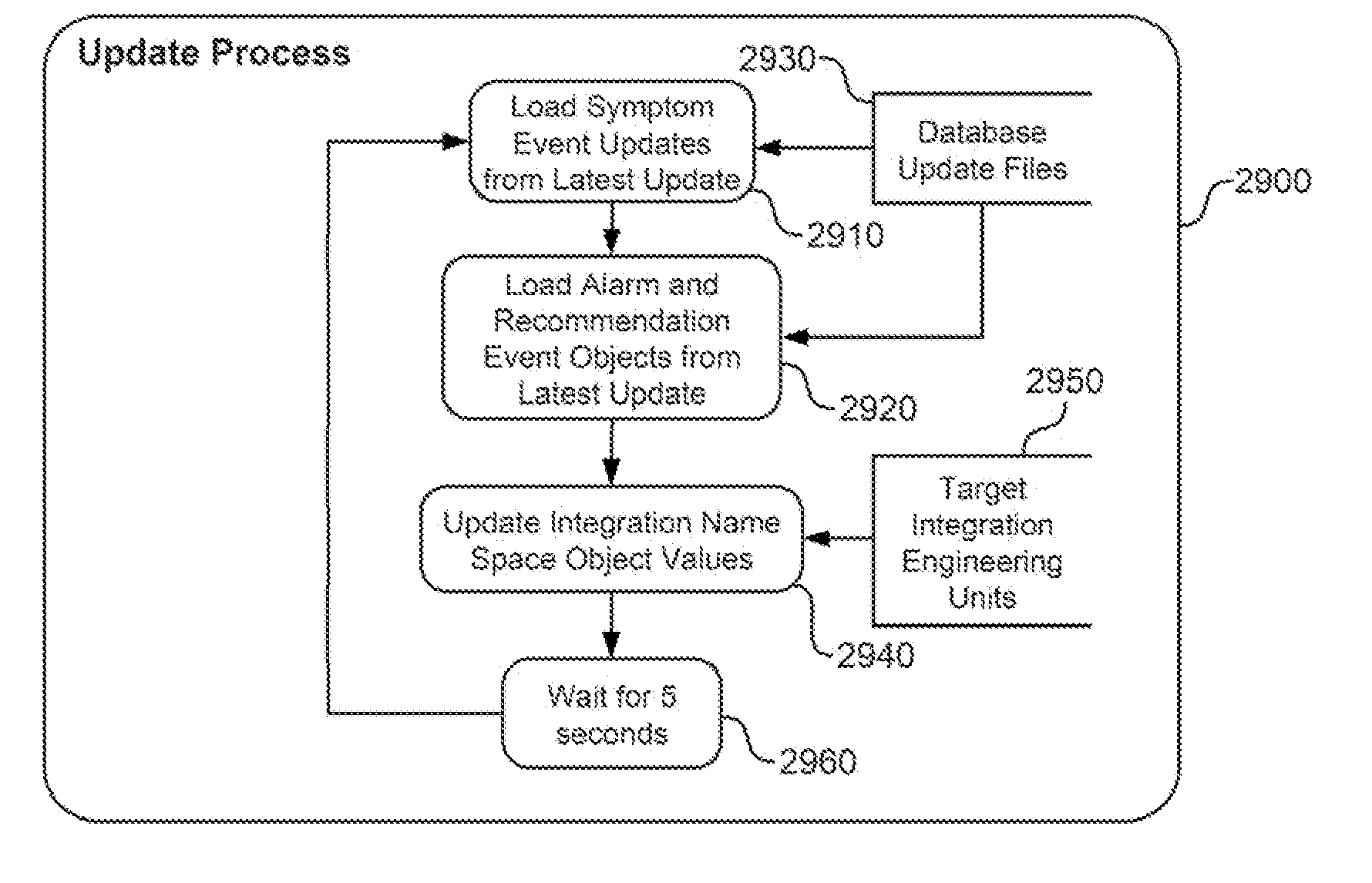

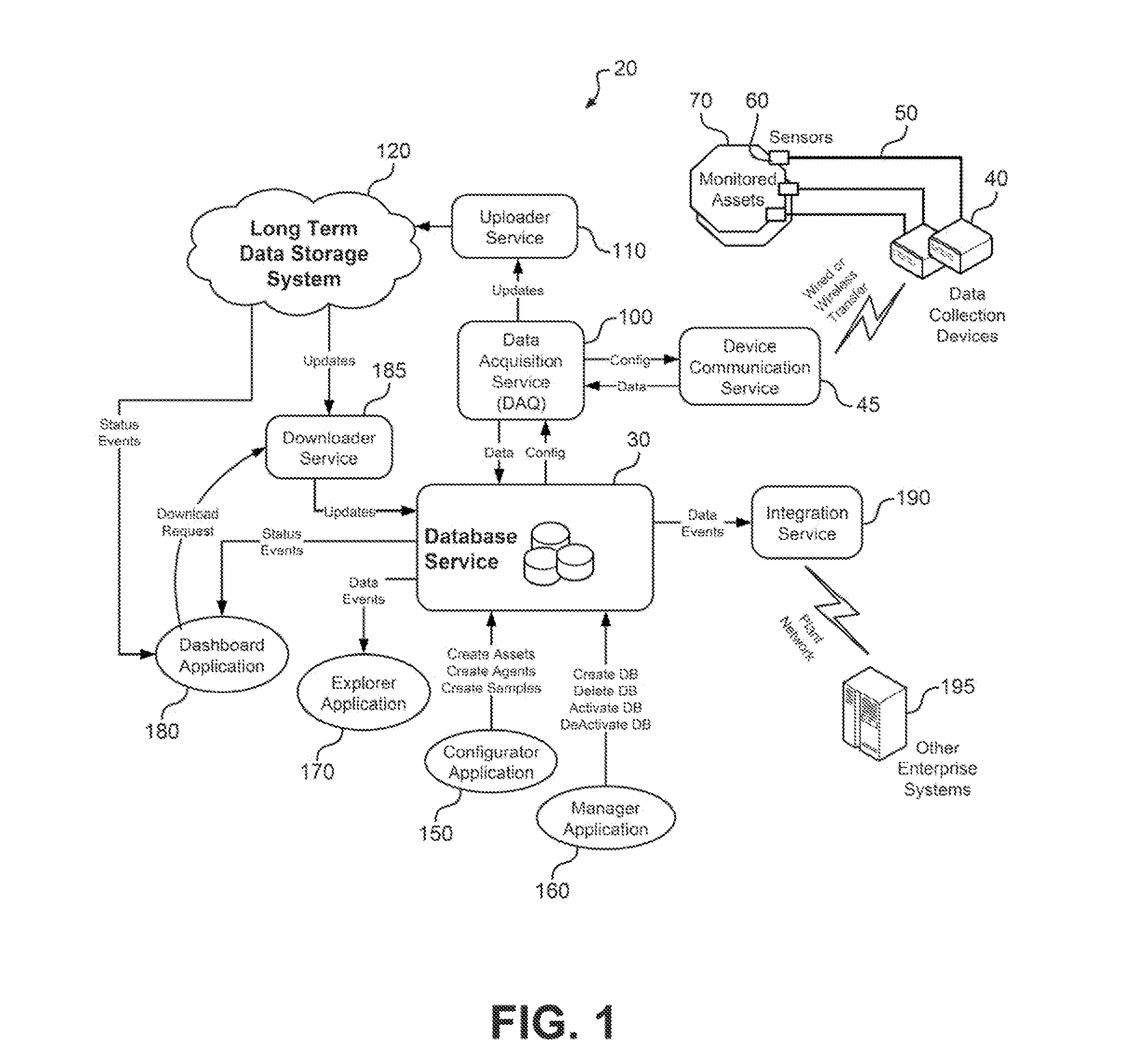

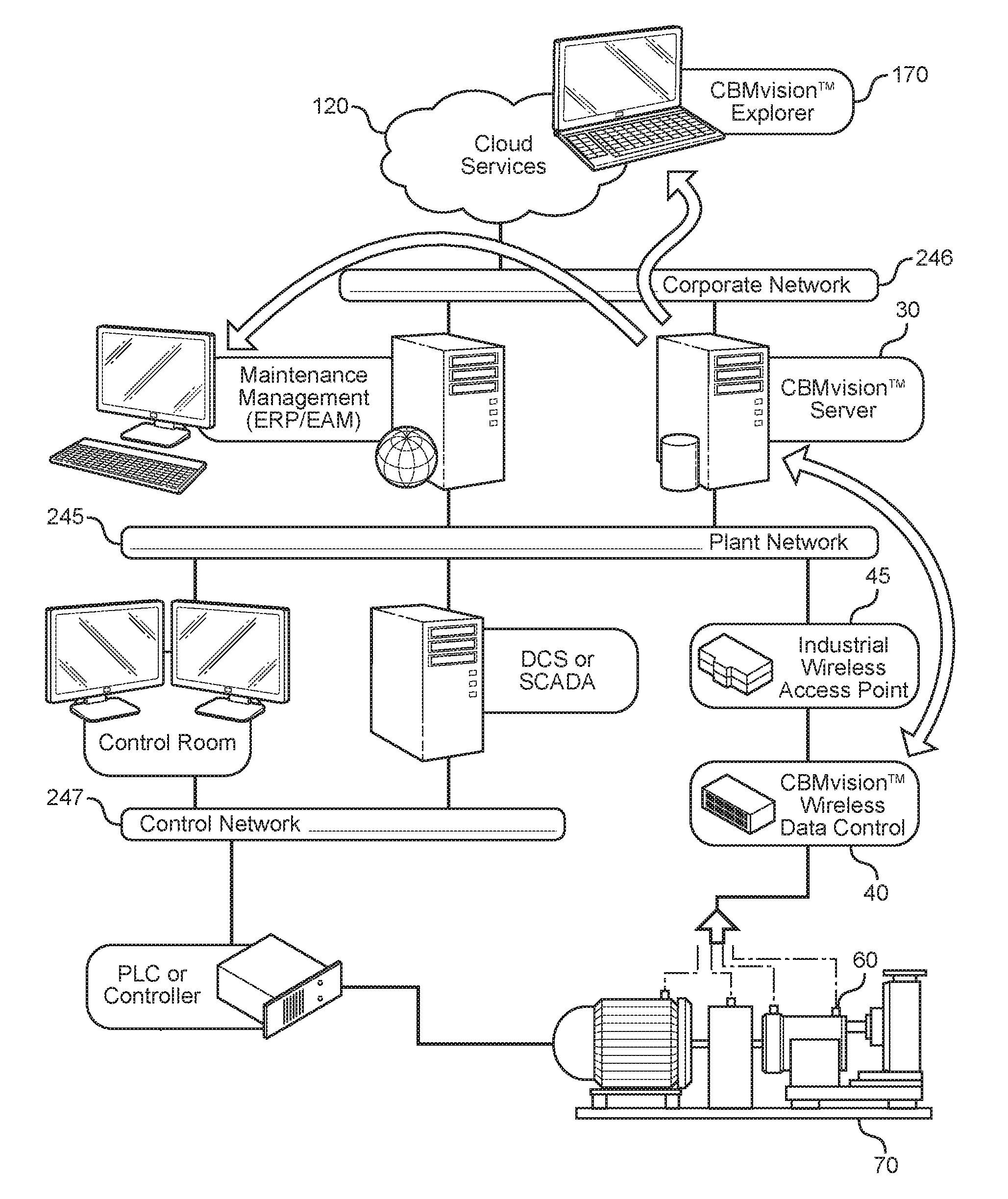

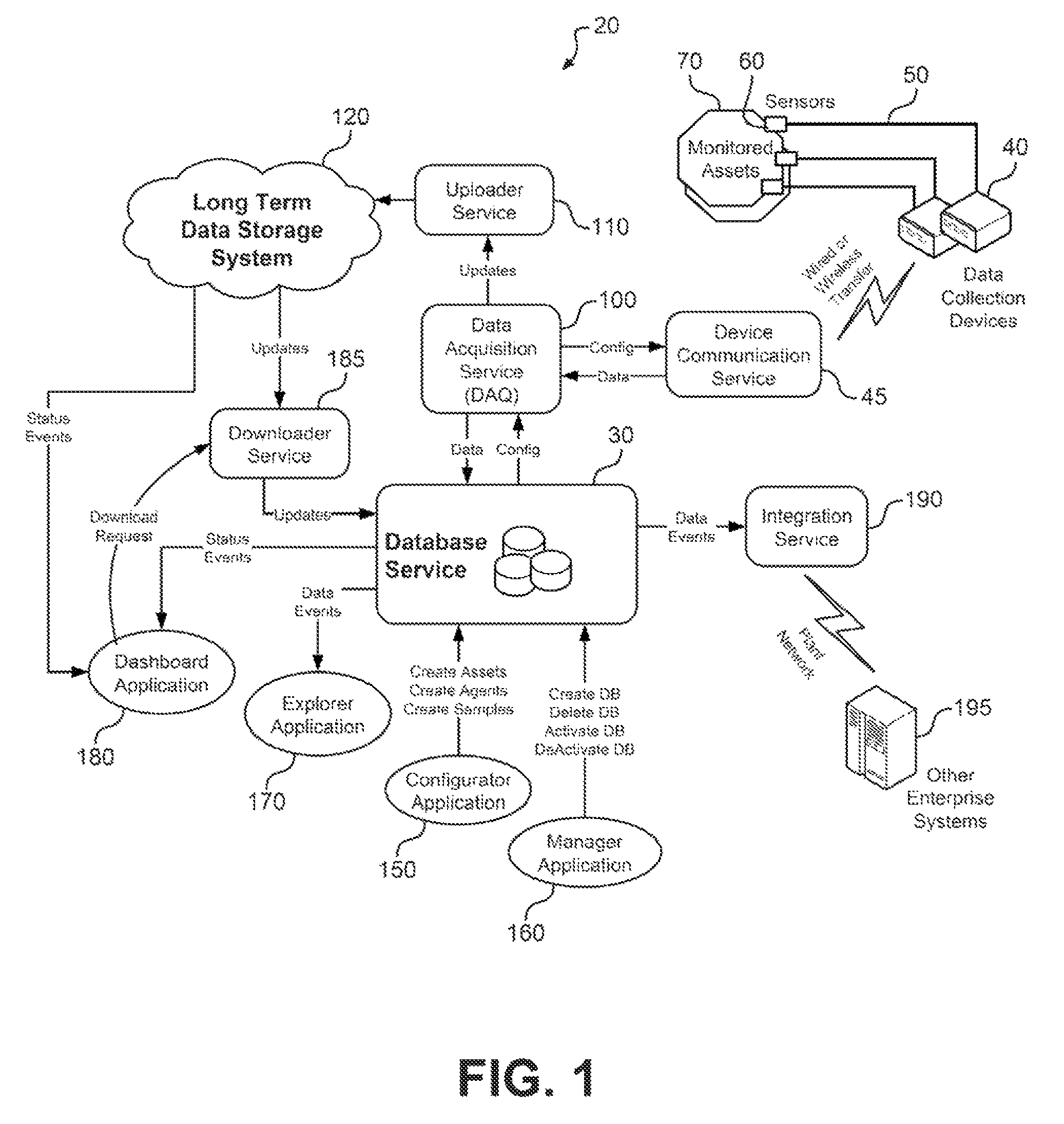

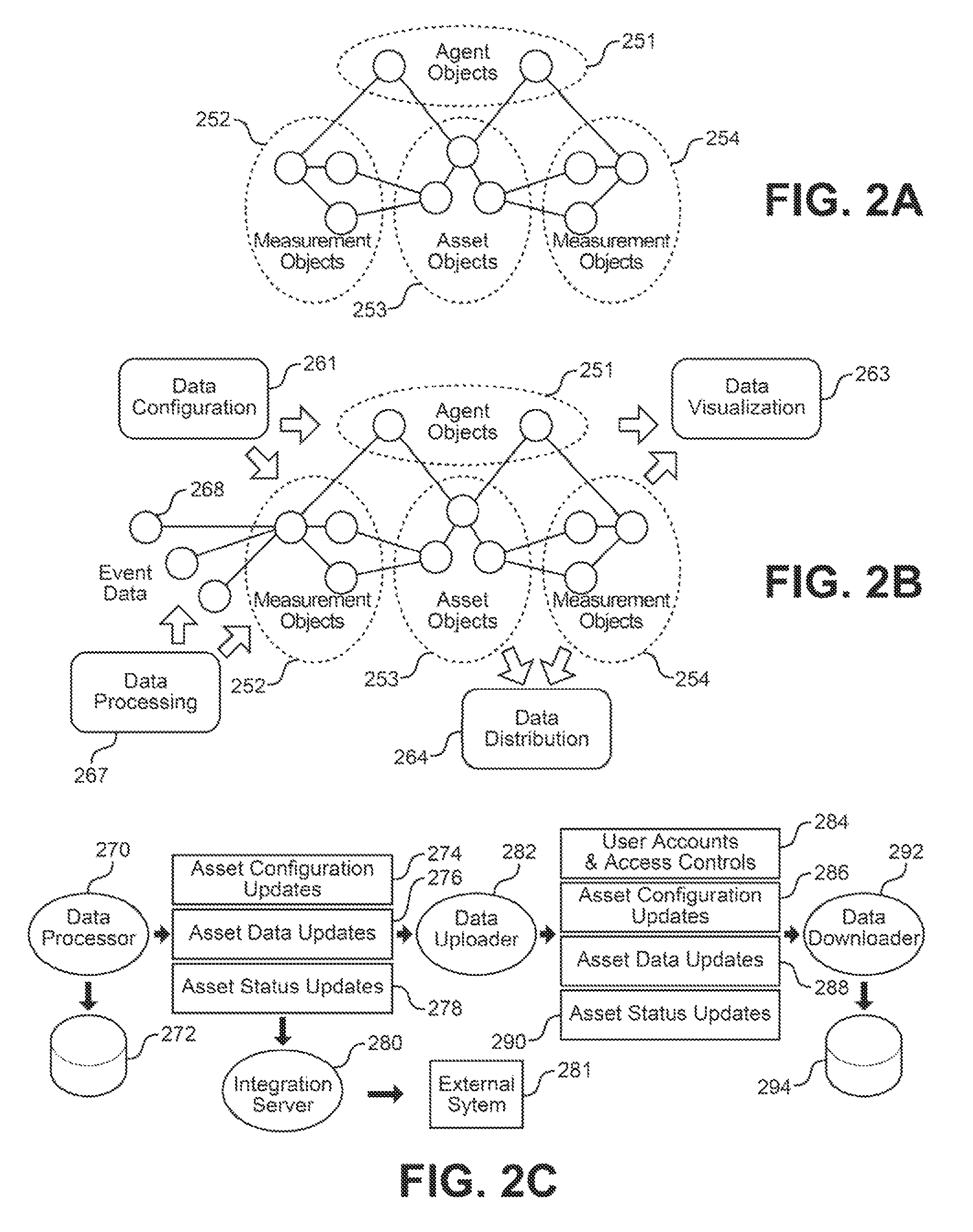

Method and System for Monitoring and Reporting Equipment Operating Conditions and Diagnostic Information

InactiveUS20140074409A1Provide real-timeProvide methodProgramme controlError detection/correctionAnalysis dataNetwork packet

A method and system (20) is provided for condition based monitoring reliability maintenance capabilities for an asset (70), such as one or more machines, by establishing a network including of a sensor (60) or a plurality of sensors installed, temporarily or in generally fixed locations, on asset (70), wherein sensor (60) provides time sequenced operational information in the form of data based on vibrations, temperature, electrical signals, or other operating conditions. Sensors (60) are connected to a local controller (40) which transmits the data via a local or wide area network (45), either through wired or wireless communication paths, in data packets, each containing divided portions of the operational information. The data packets are mapped and stored into multiple, dedicated databases for ease of retrieving and analyzing the data. Preferably, a cloud-based storage arrangement (120) is employed to storing the mapped data.

Owner:CBM ENTERPRISE SOLUTIONS

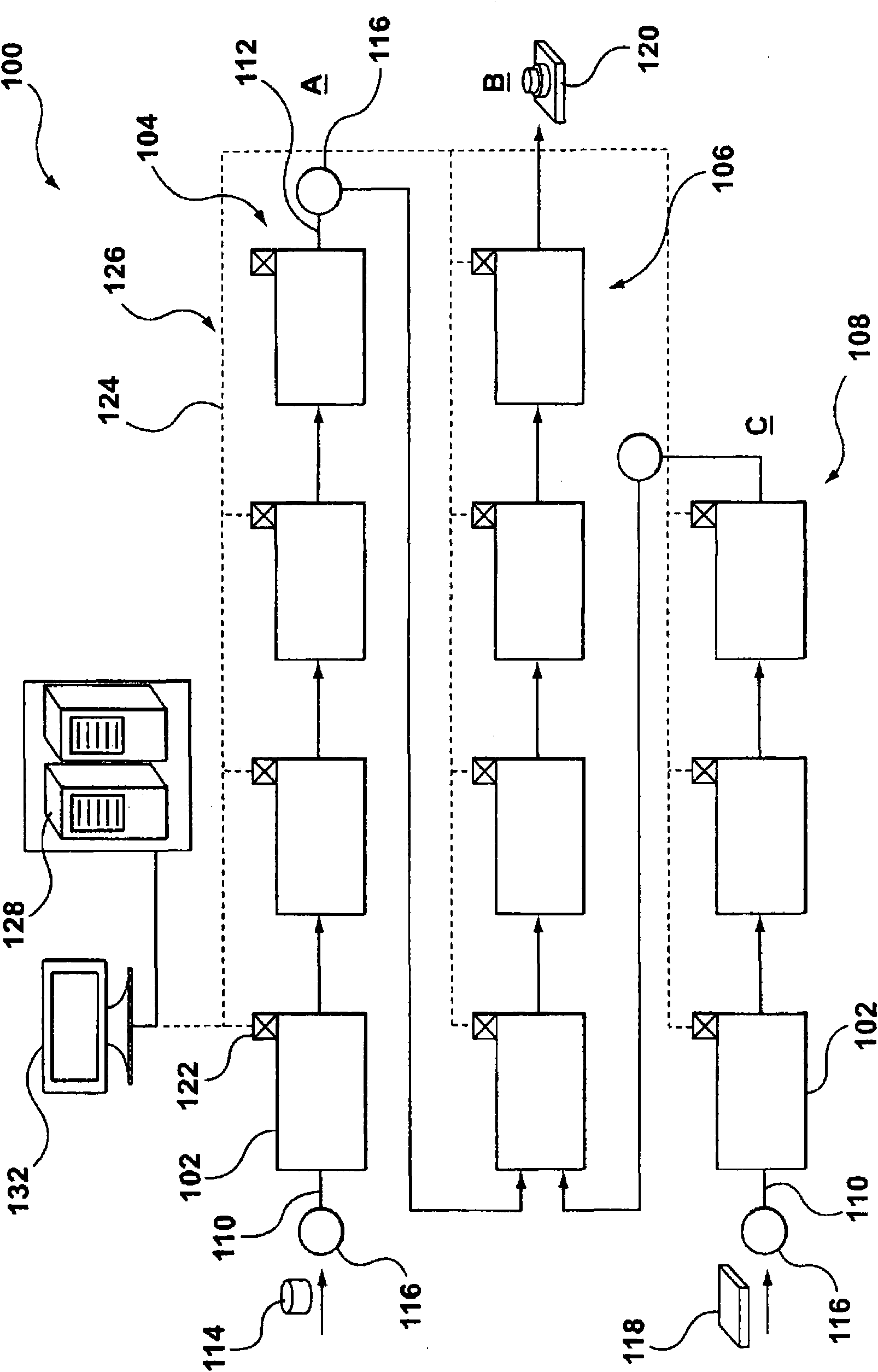

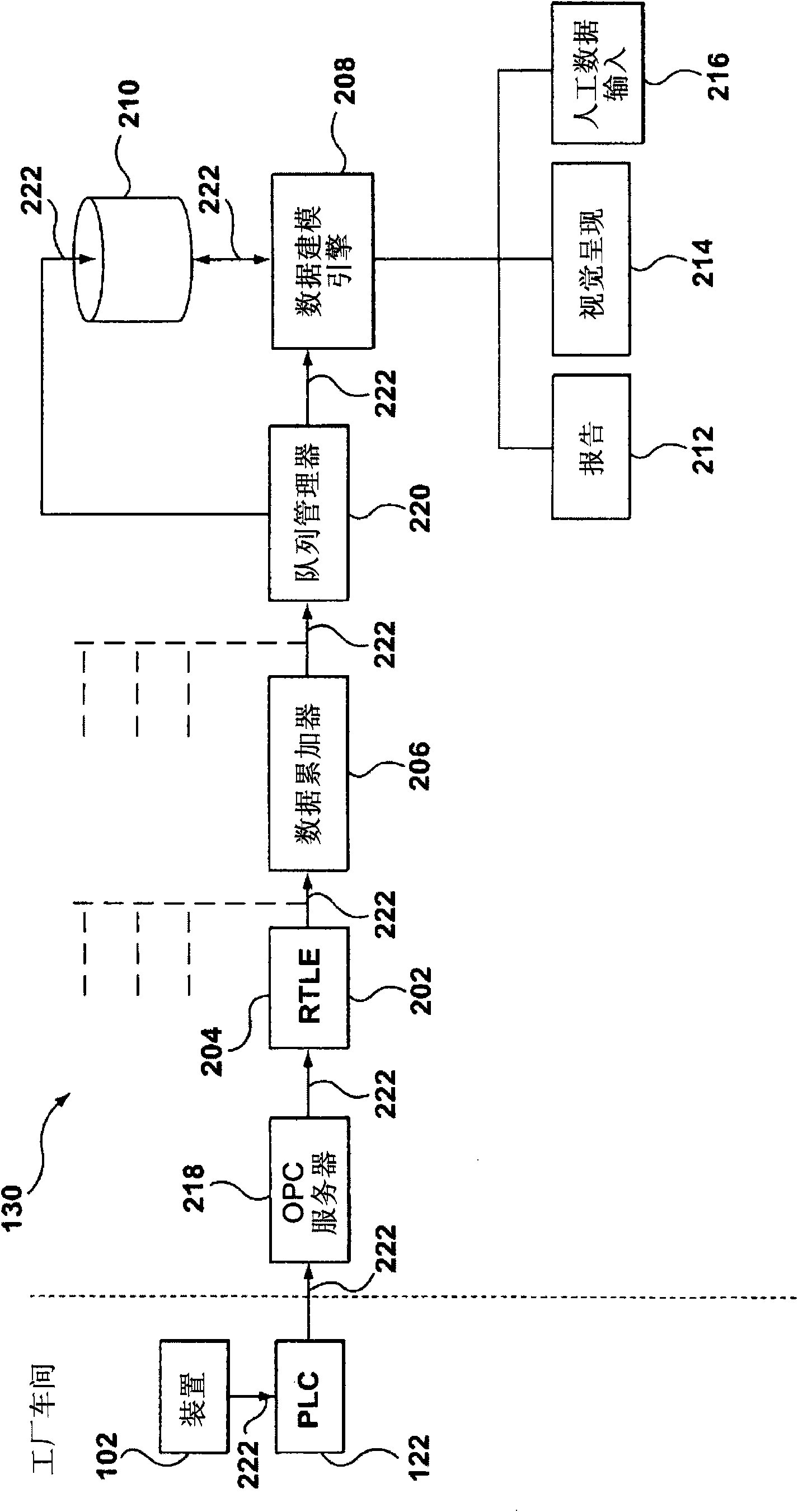

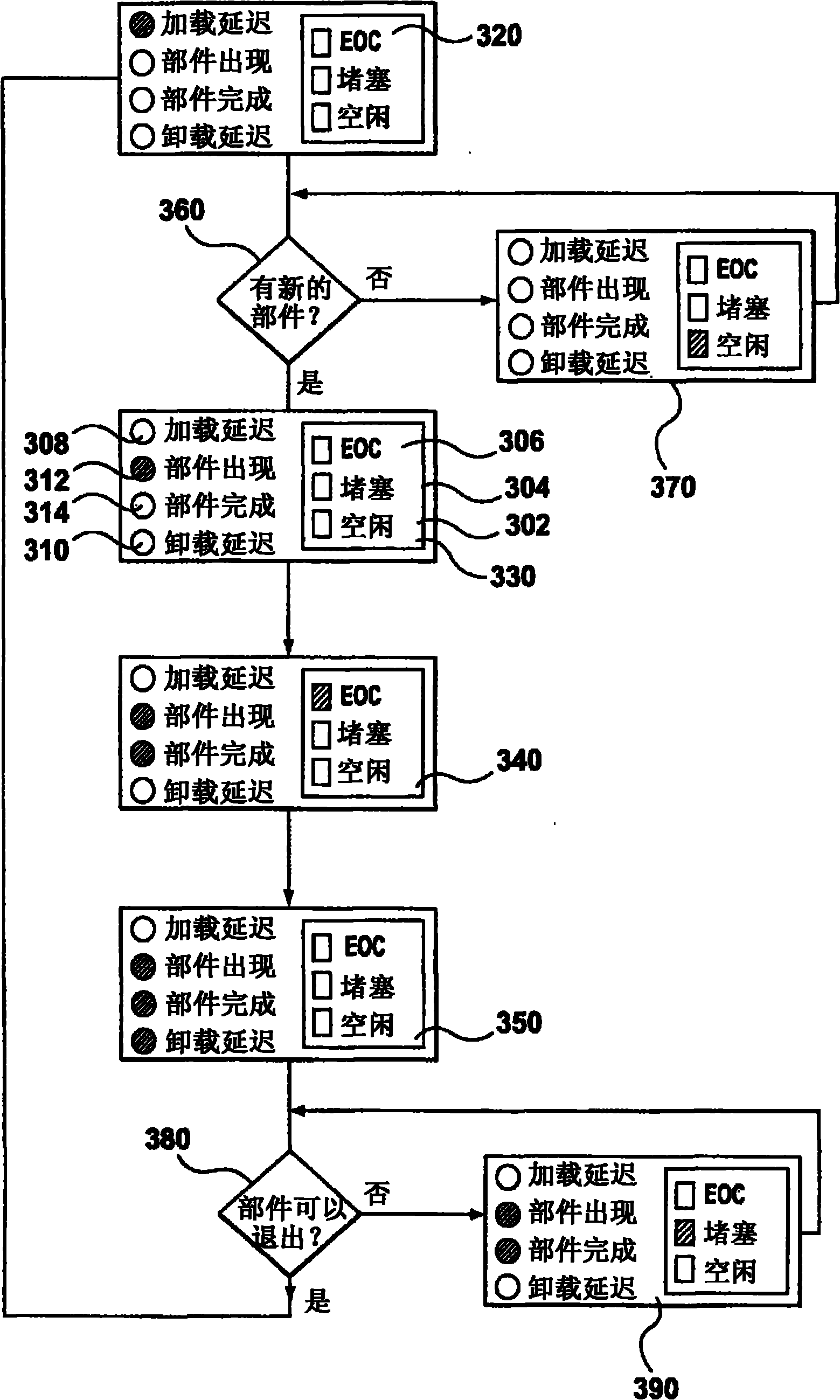

System and method of monitoring and quantifying performance of an automated manufacturing facility

The present invention is directed to a method and system for identifying, quantifying and presenting to a user constraints in an automated manufacturing or processing facility. A data processing system continuously receives basic status signals and state signals from automation equipment in the facility and evaluates and processes these signals to derive a throughput capability measure (a measure of constraint) of each given manufacturing workstation in the process. The throughput capability measure is expressed as a ratio of an ideal cycle time to an accumulated overcycled time. The accumulated overcycled time includes only delays and excludes any speed-up of a workstation. A constraint is identified as the workstation that has the lowest throughput capability measure as compared with all other workstations in a production line. Preferably, throughput capability measures for all workstations are presented to users graphically. Further drill-down can be provided for obtaining more detailed information about the constraint and capacity loss as well as entering information relevant to the constraint, such as a stoppage or slow-down.

Owner:ACTIVPLANT CORP

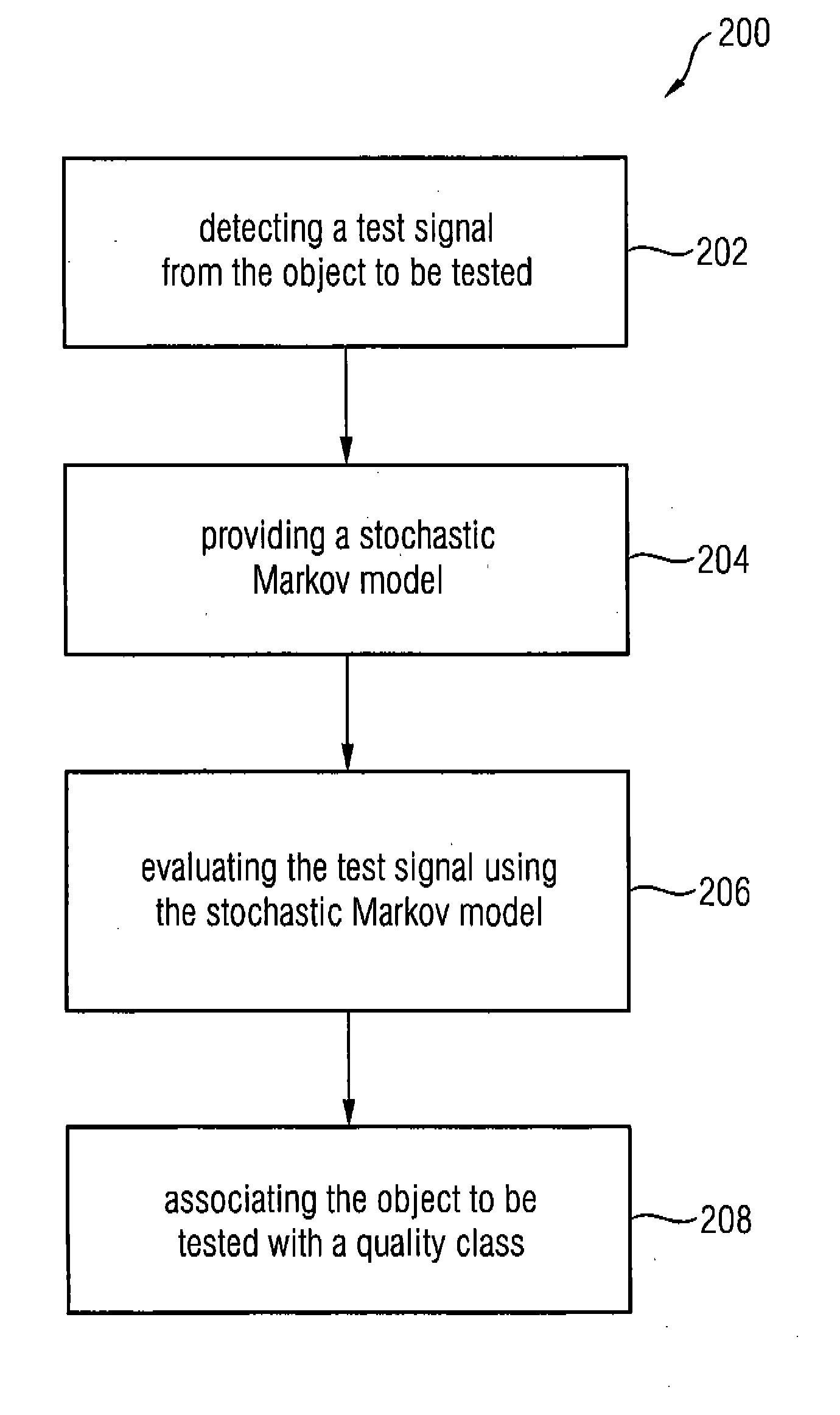

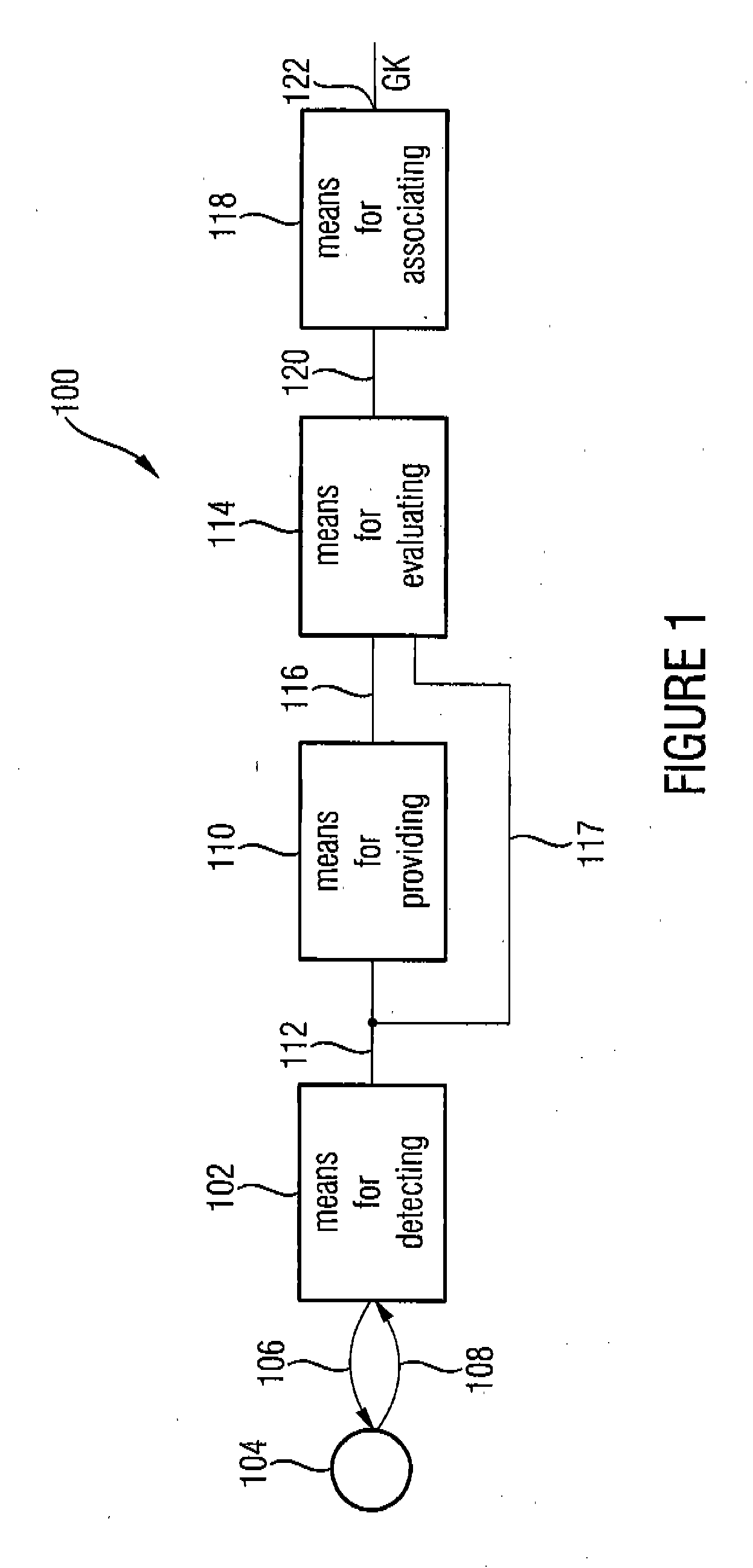

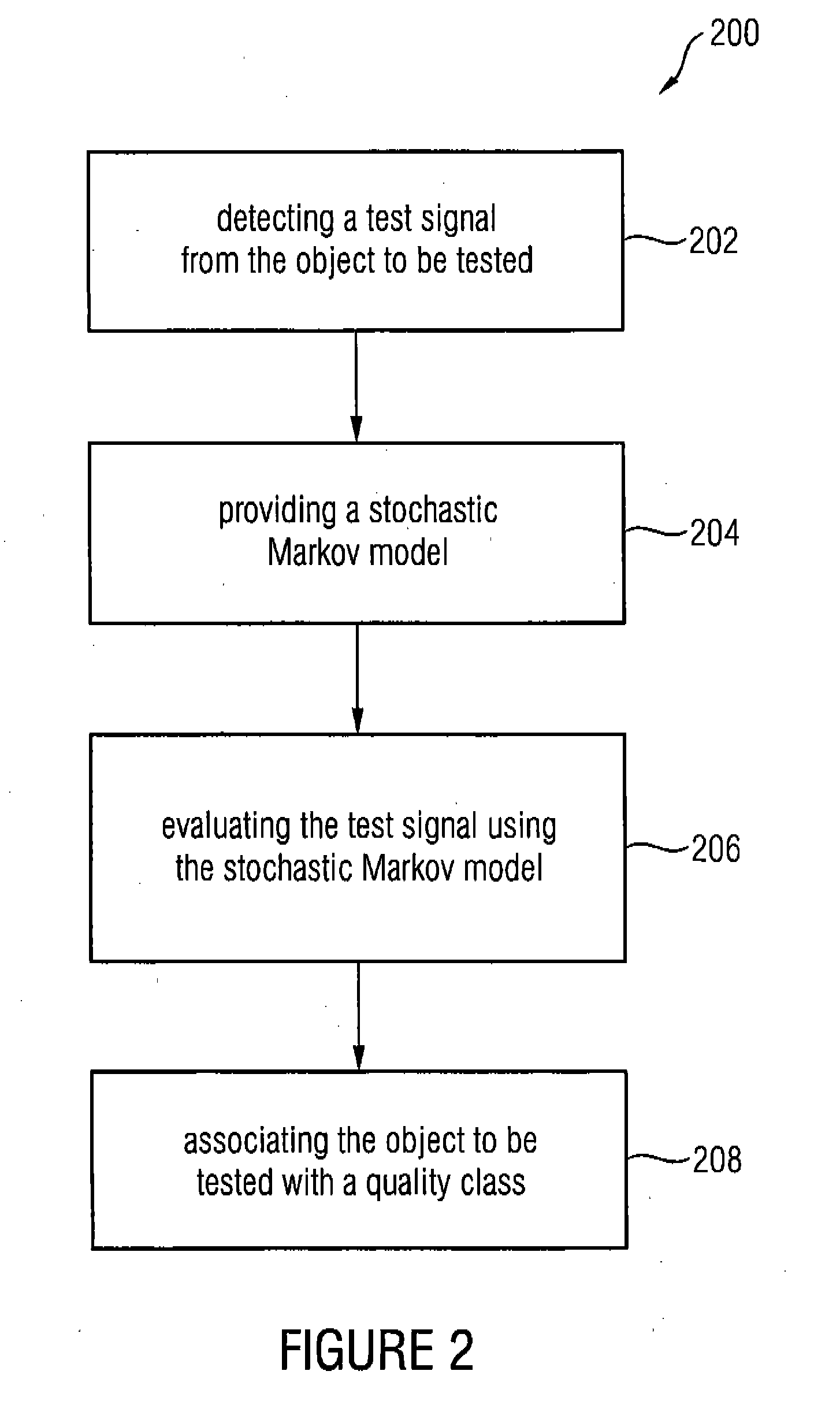

Device and Method for Assessing a Quality Class of an Object to be Tested

InactiveUS20070100623A1High selectivityLess failure-proneAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using acoustic emission techniquesTest objectComputer science

A device for assessing a quality class of an object to be tested includes a unit for detecting a test signal from the object to be tested. Furthermore, the device for assessing includes a unit for providing a stochastic Markov model including states and transitions between states on the basis of reference measurements of objects of known quality classes, and a unit for evaluating the test signal using the stochastic Markov model. In addition, the device for assessing includes a unit for associating the object to be tested with a quality class based on the evaluation of the test signal. Such a device has the advantage to be able to perform a more precise association of an object to be tested with a quality class as compared to prior art.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

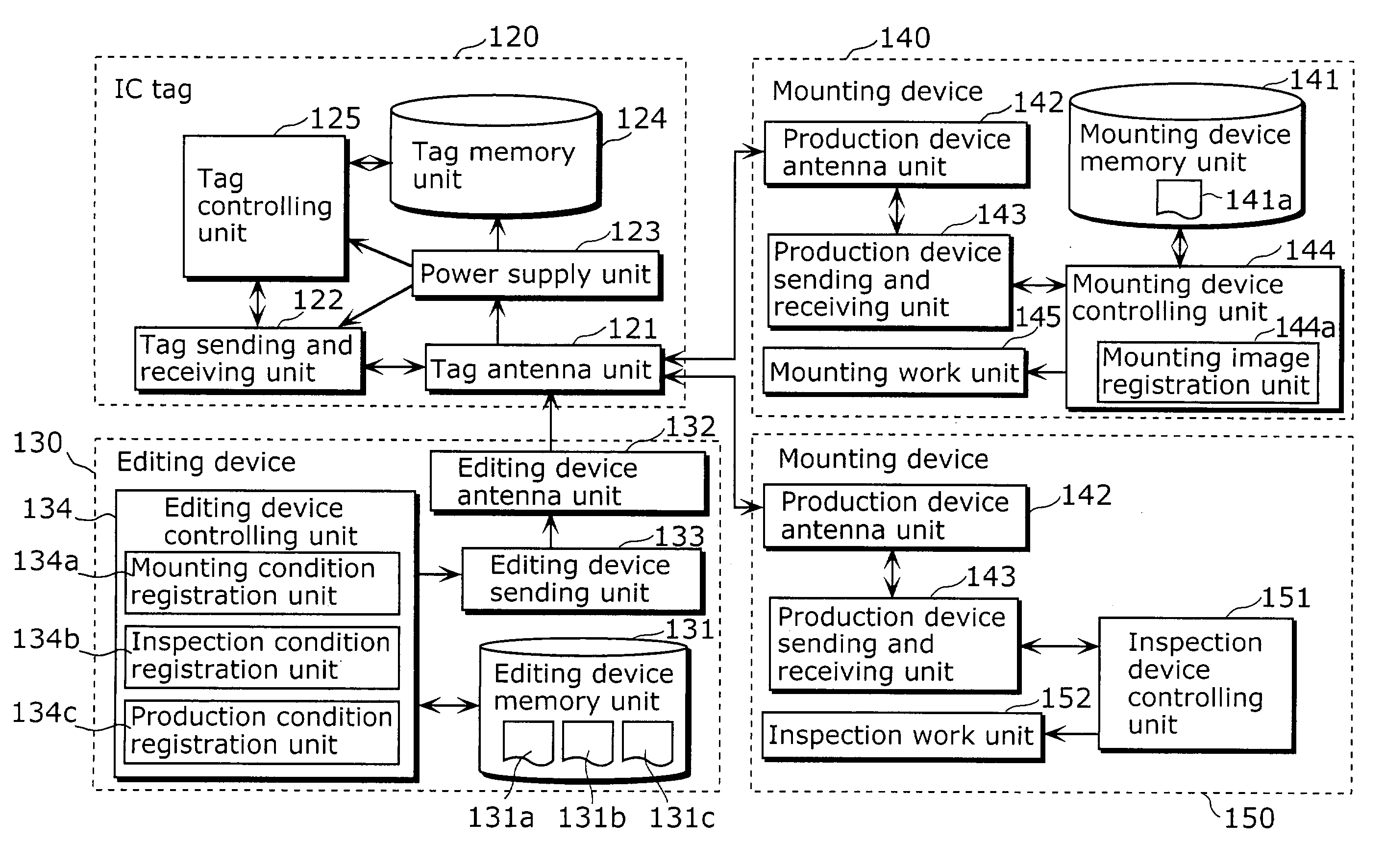

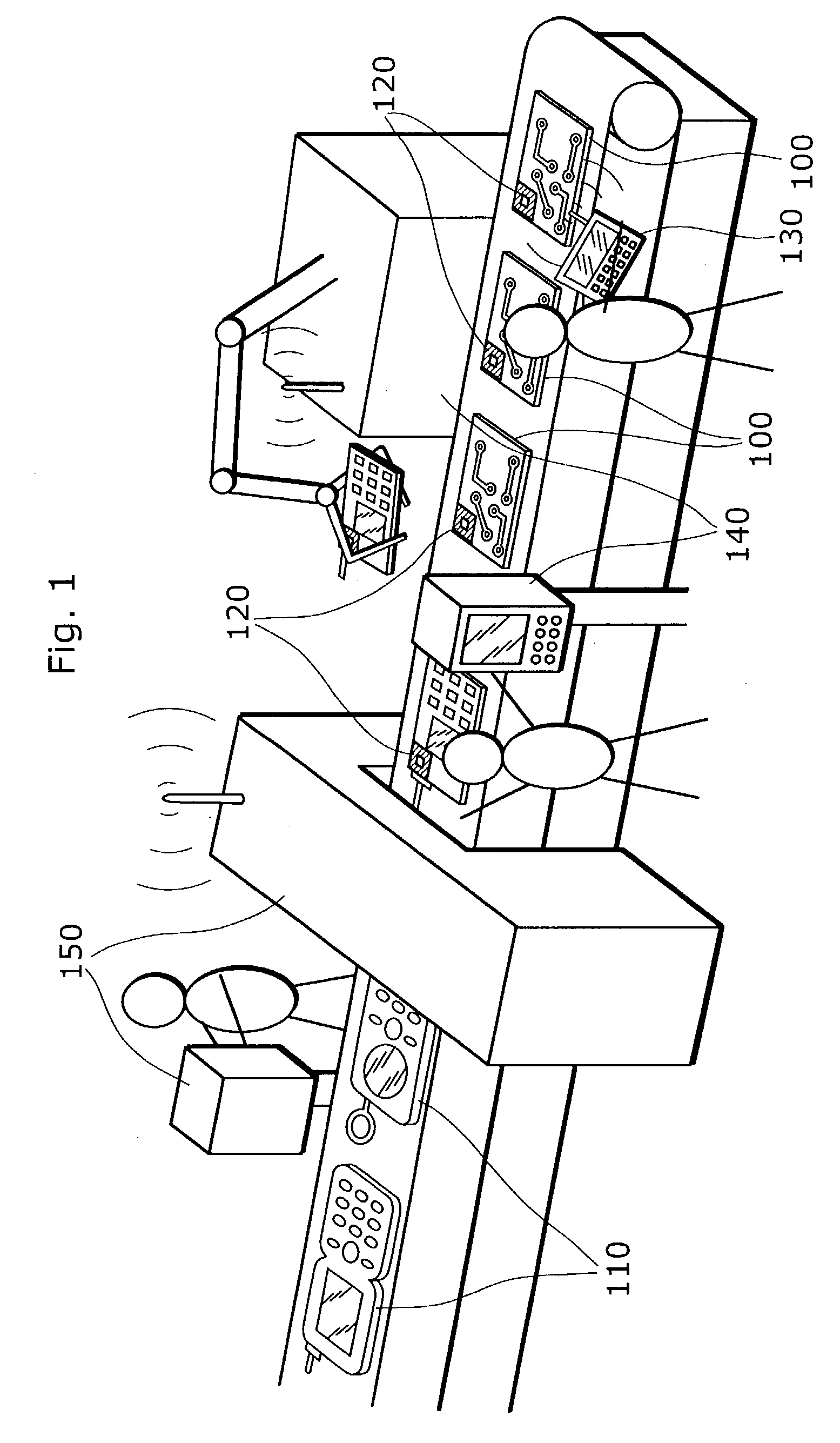

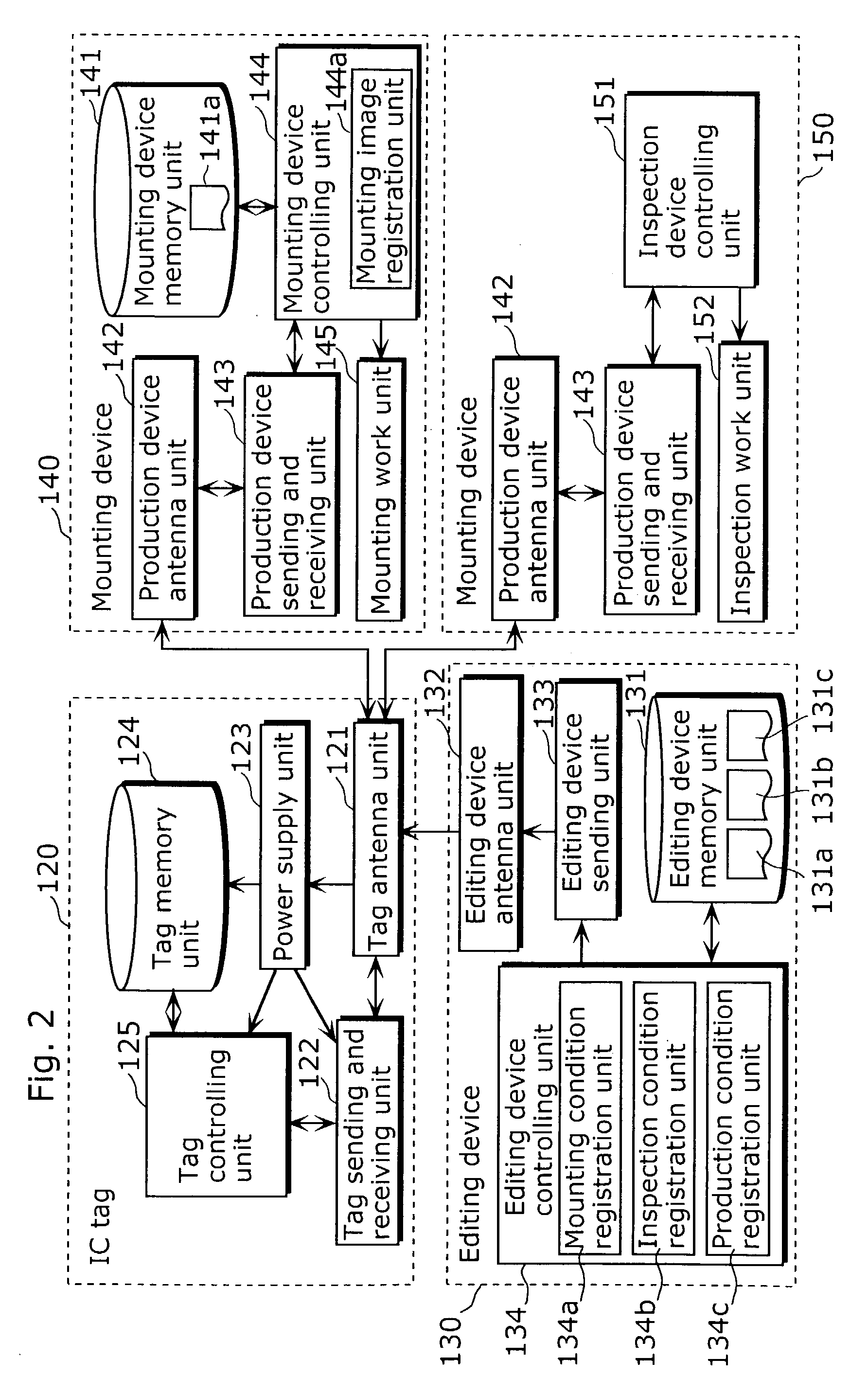

Production system and production method

InactiveUS20040162628A1Easy to producePrecision productionOther printing matterDigital data processing detailsWork in processMethods of production

Comprising: an IC tag 120 that is attached to a work in process 100 of a portable telephone 110 and memorizes information related to a production condition of the portable telephone 110; a mounting device 140 that reads out the information related to the production condition of the portable telephone 110 from the IC tag 120 and mounts components of the portable telephone 110, based on the readout information related to the production condition of the portable telephone 110, on the work in process 100 with the IC tag 120 attached; an inspection device 150 that reads out the information related to the production condition of the portable telephone 110 from the IC tag 120, and inspects the work in process 100, which the IC tag 120 is attached and the components of the portable telephone 110 are mounted, based on the readout information related to the production condition of the portable telephone 110; and an editing device 130 that writes the information related to production of the portable telephone 110 into the IC tag 120.

Owner:SHIGEMATSU +2

Inspection data recording apparatus and method

InactiveUS7832638B2Checking time patrolsRegistering/indicating quality control systemsLocation detectionUnique device identifier

Owner:GE GLOBAL SOURCING LLC

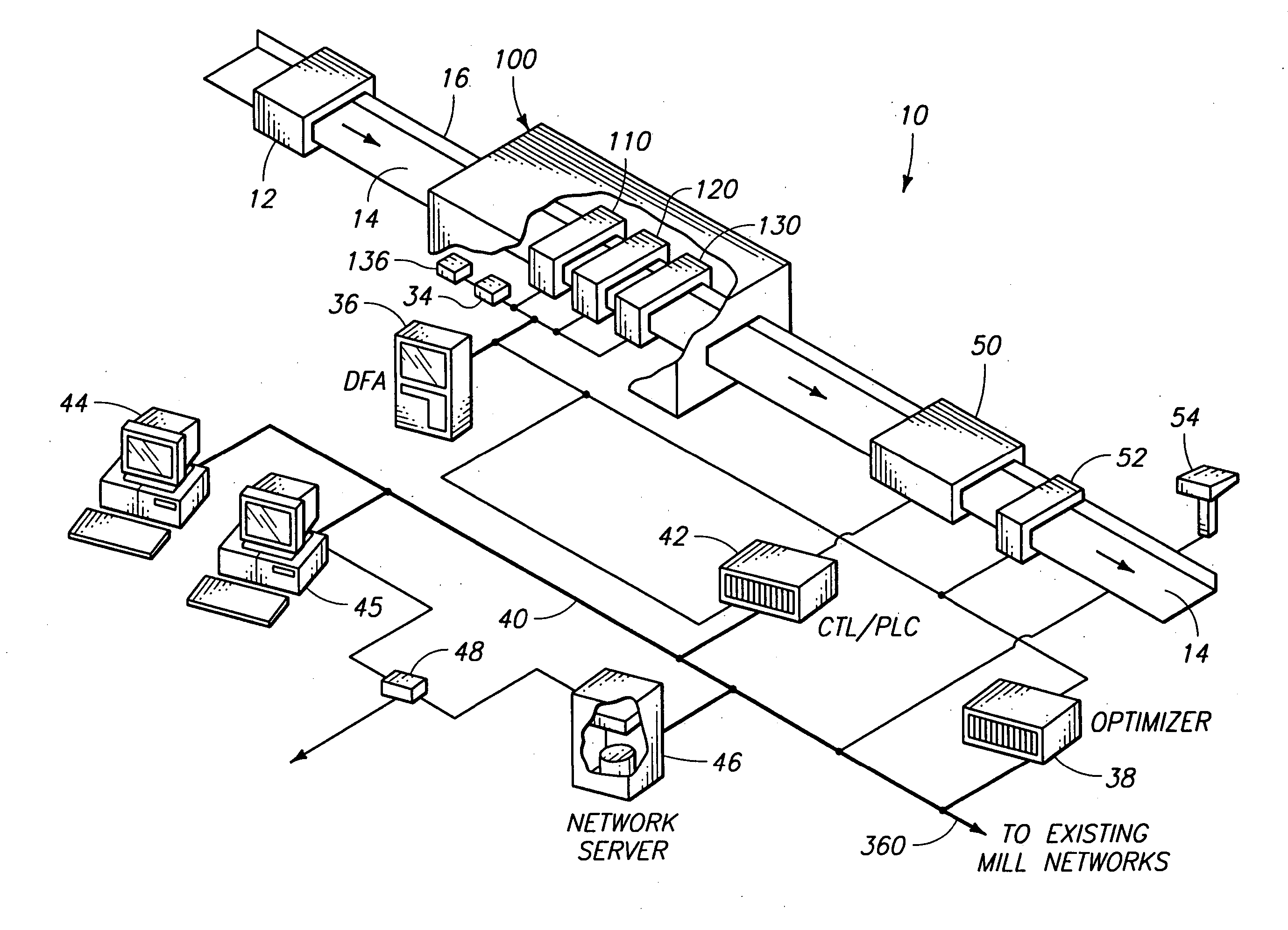

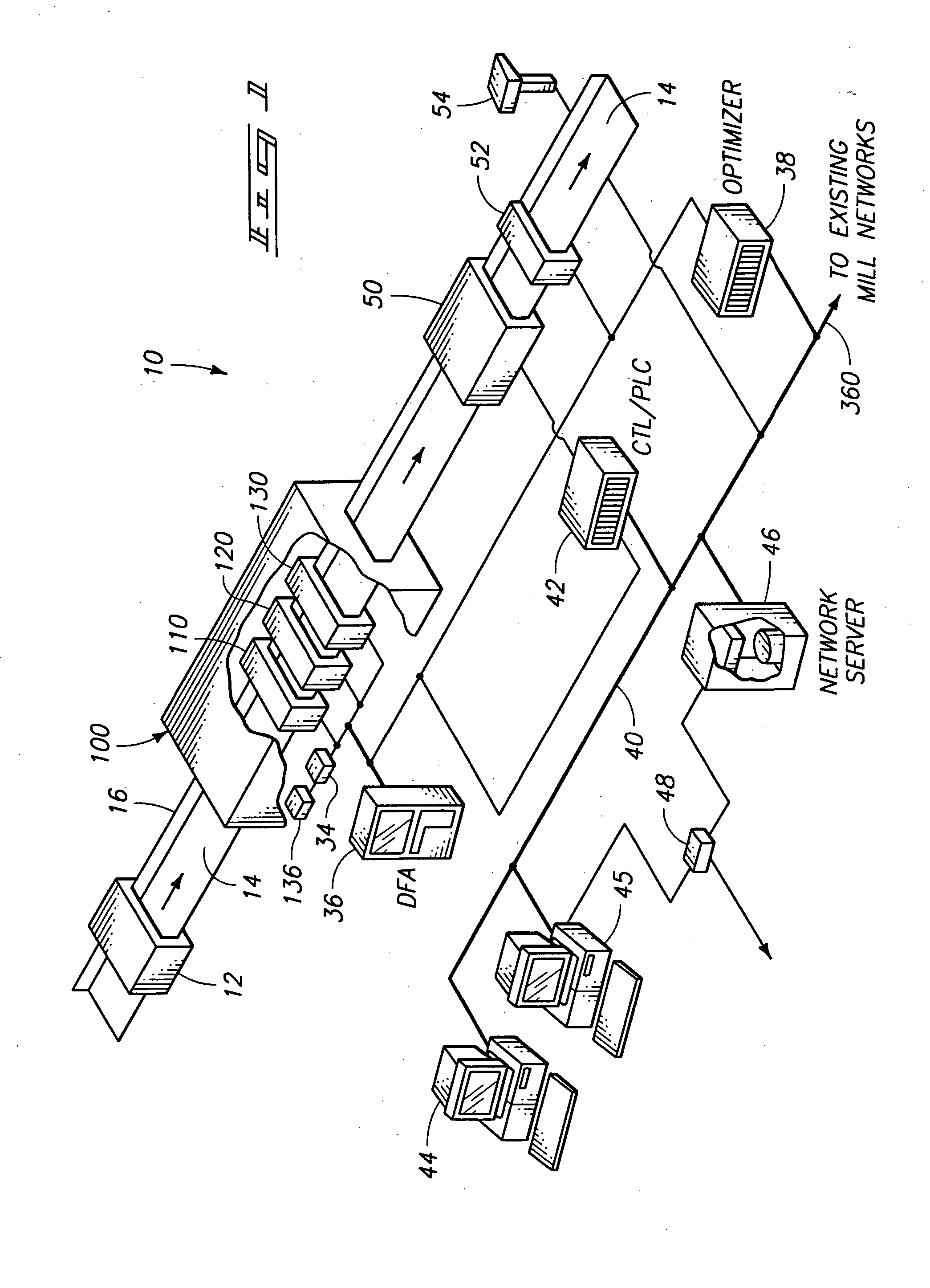

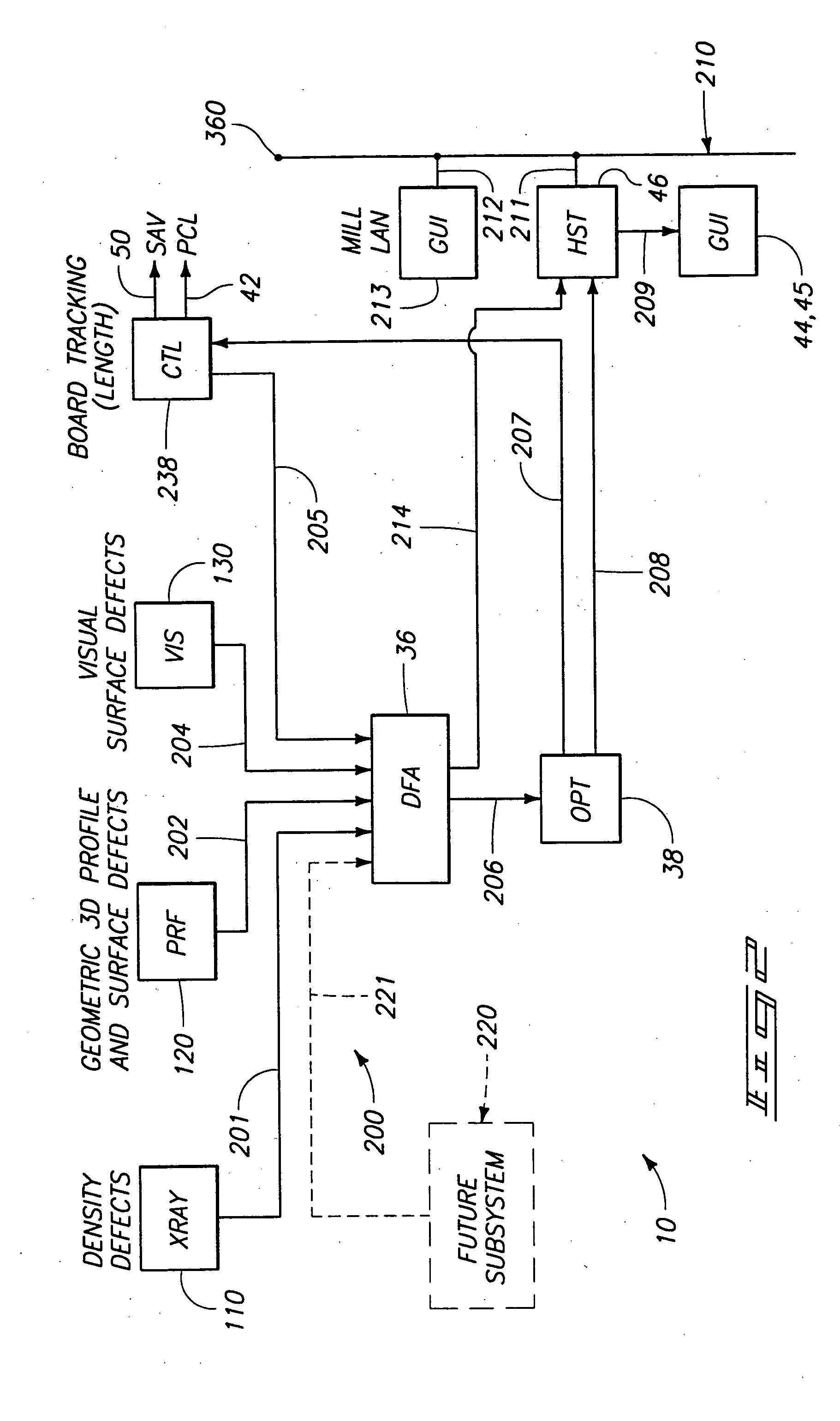

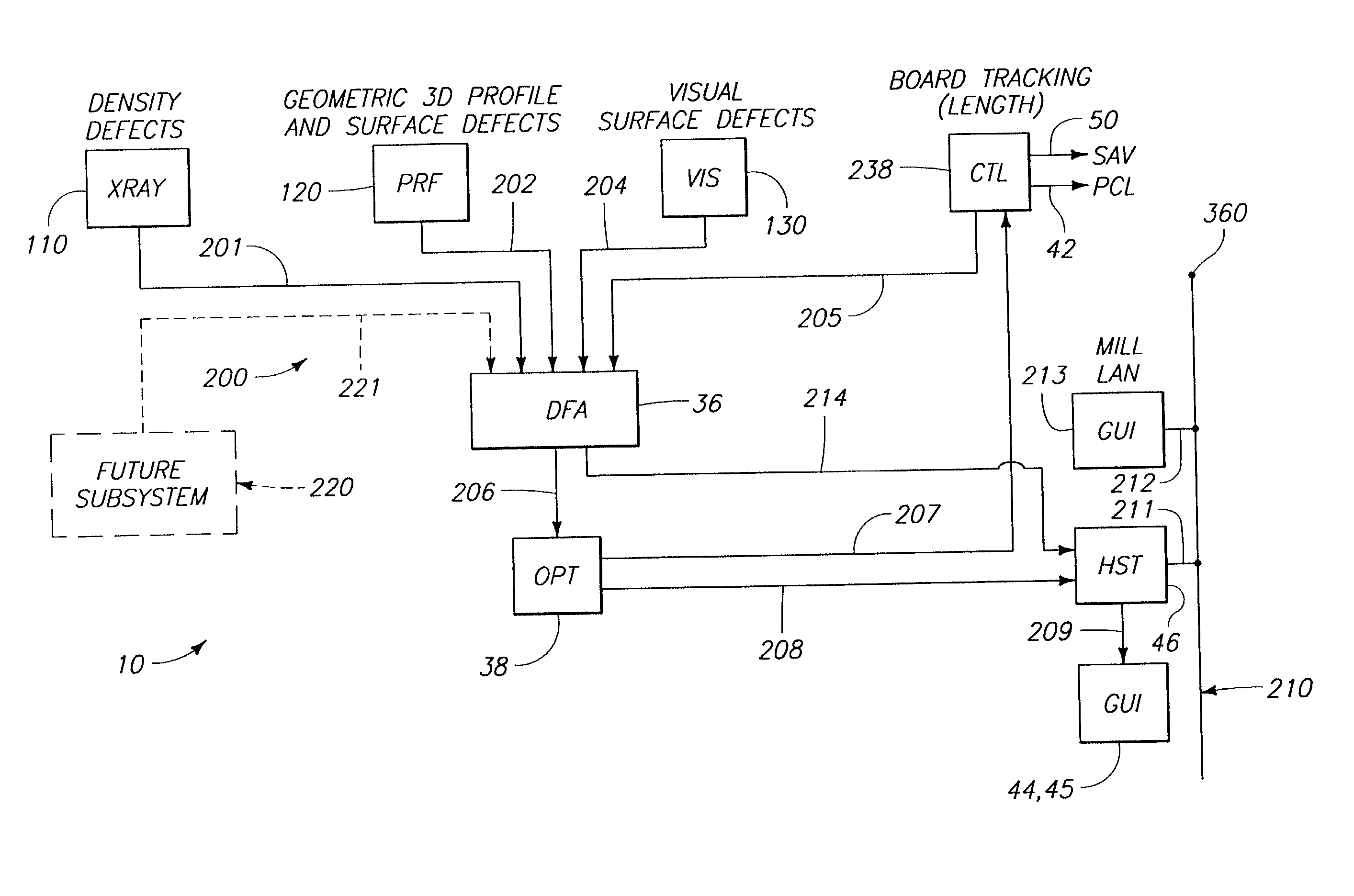

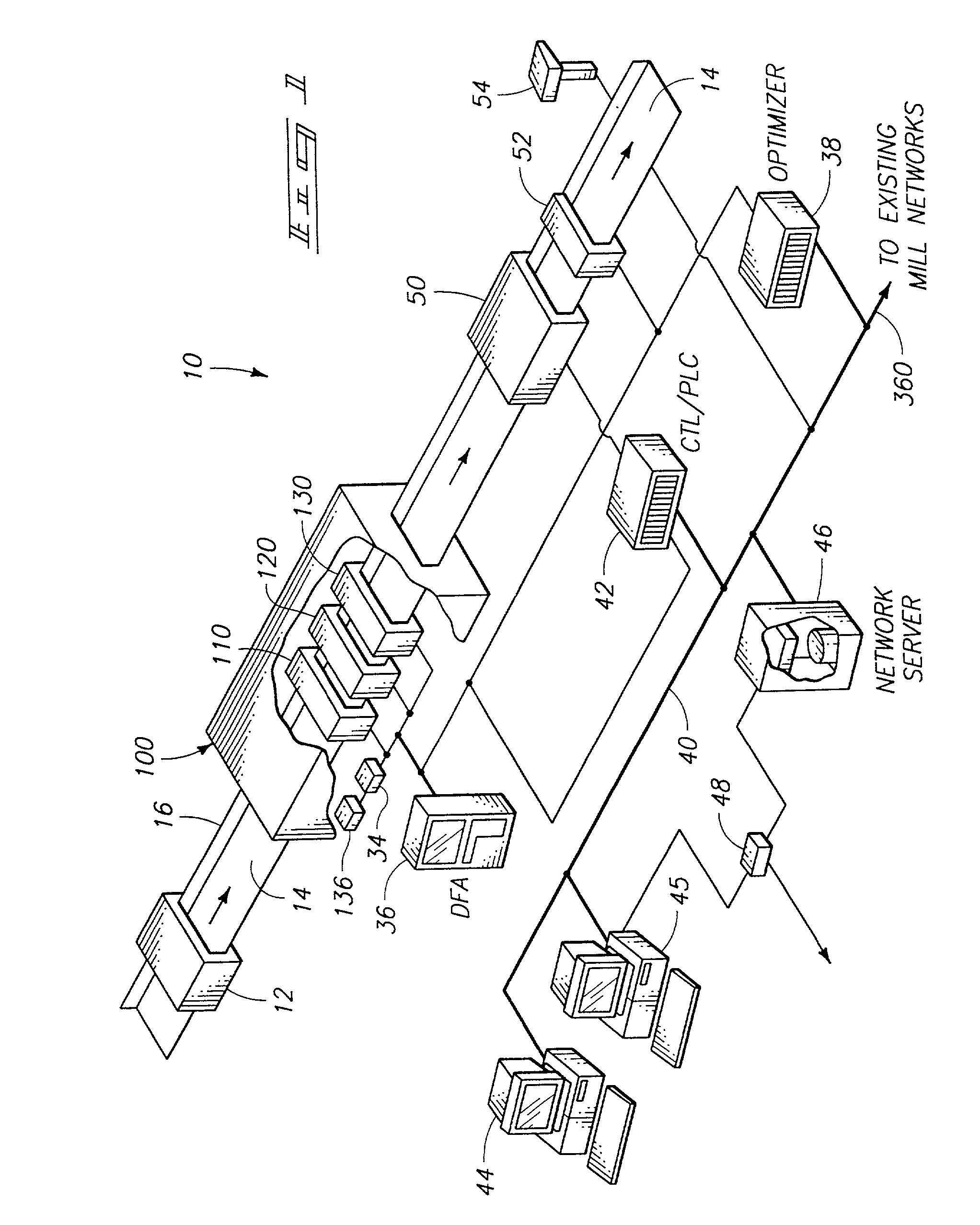

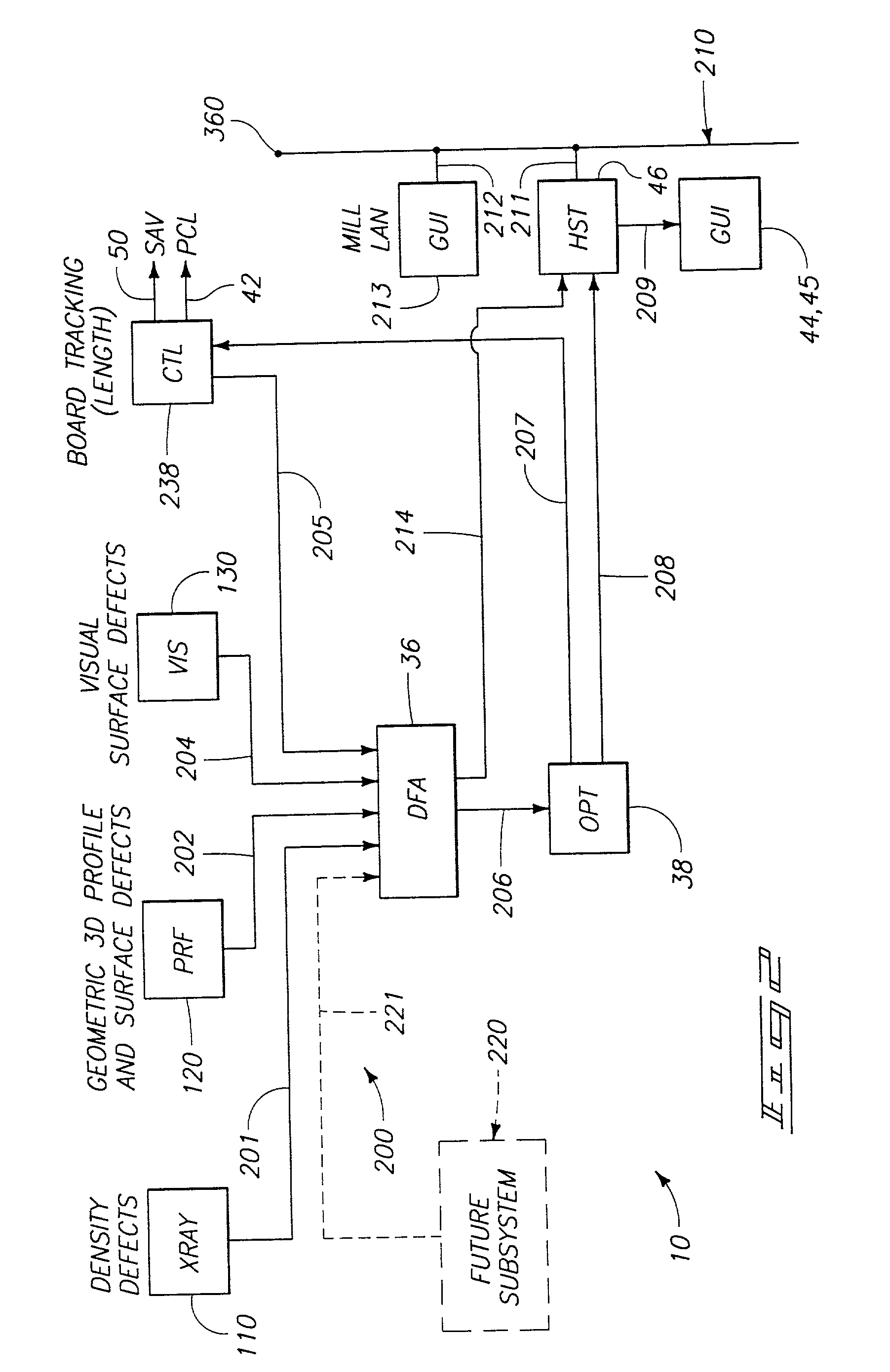

Method and apparatus for improved inspection classification of attributes of a workpiece

InactiveUS20050021280A1Linear/angular speed measurementFluid speed measurementKinematicsAngular velocity

An apparatus for detecting the probable existence, location, and type of defects in a workpiece is described. The apparatus includes a sensor subsystem, an optimizer, a control subsystem, and a computer system having a processor and computer readable memory. Sensor subsystem senses a first section of the workpiece and produces signals corresponding to a physical characteristic of the workpiece. The computer system is configured to generate a workpiece model based on the signals produced by the sensor subsystem. In an alternate embodiment, a defect assembler can be provided to merge signals from a plurality of sensor subsystems. The defect assembler can also be configured to generate the workpiece data model. The optimizer is configured to generate workpiece segmentation recommendations based on the workpiece data model. The processor is configured with a first producer thread program which, in response to the receipt of a first set of signals by the computer system, receives a data subscription request from a subsystem which uses data and transmits the signals from the computer readable memory to the generator of the data subscription request. The processor is further configured to generate a second producer thread in response to storage of a second set of signals in the computer readable memory. The second producer thread is configured to receive one of the data subscription requests and selectively send the second set of signals to the generator of the data subscription request. A tracking device for tracking selective kinematics of a workpiece moving through a plant is also disclosed. The tracking device includes an encoder wheel configured to tangentially contact a workpiece and rotate at an angular velocity coincident with the linear velocity of the workpiece. The tracking apparatus further includes a drive mechanism for driving the encoder wheel at a first angular velocity approaching the angular velocity of the encoder wheel which is coincident with the linear velocity of the workpiece. The tracking device also includes a signal generator configured to interact with the encoder wheel and generate a signal in response to the angular velocity of the encoder wheel. The tracking apparatus can be incorporated into the apparatus for detecting defects within a workpiece by providing the signal from the signal generator to the control subsystem.

Owner:USNRKOCKUMS CANCAR

Traditional Chinese medicine production process knowledge system

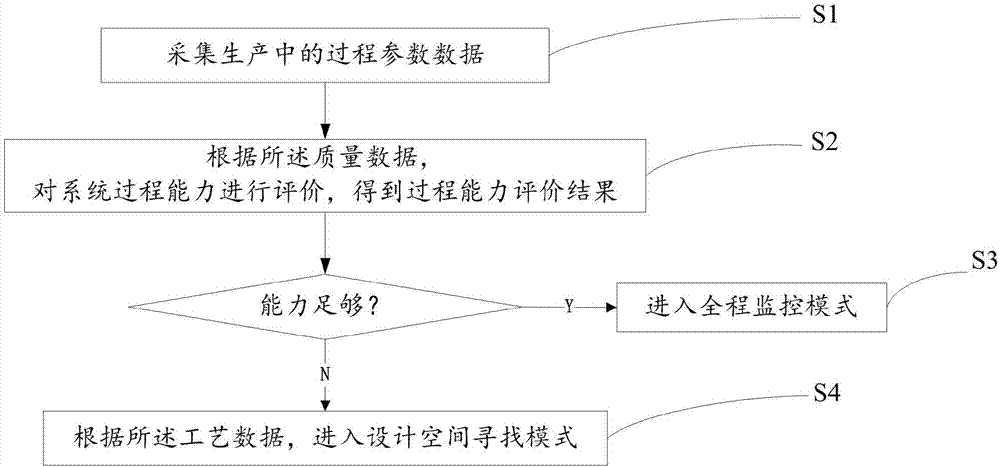

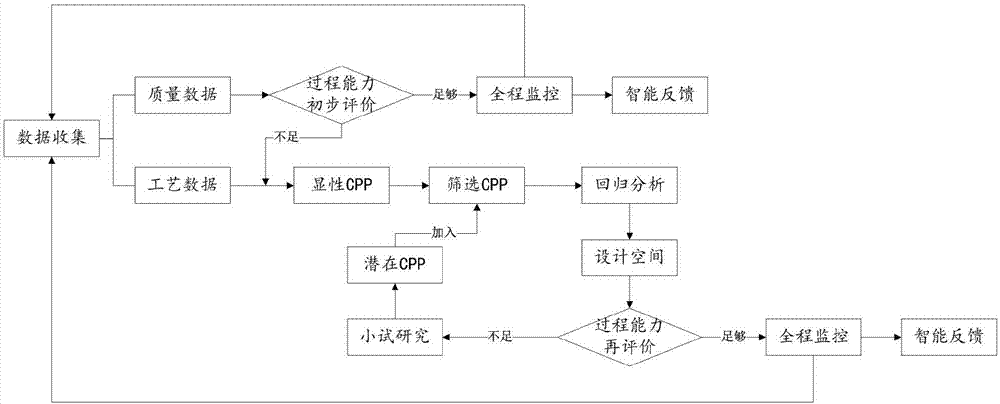

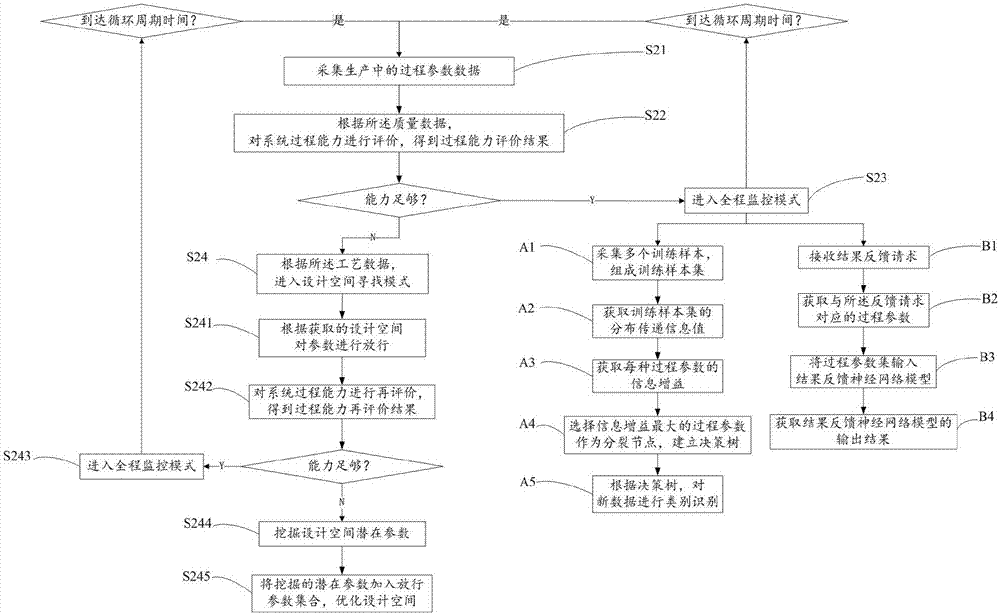

ActiveCN107578104AImprove reliabilityAvoid the effects of multicollinearityAlternative medicinesRegistering/indicating quality control systemsQuality dataDesign space

The invention discloses a traditional Chinese medicine production process knowledge system which comprises a database module, a competency assessment module, a monitoring feedback module and a designspace looking-for module. The database module comprises a production data collection unit and a storage unit, the production data collection unit is used for collecting process parameter data in production, process parameters include quality data and process data, and the storage unit is used for storing the collected process parameter data; the competency assessment module is used for assessing system process capability according to the quality data to acquire process capability assessment results; the monitoring feedback module is used for entering a whole-process monitoring mode when the process capability assessment results are responded adequately; the design space looking-for module is used for entering a design space looking-for module according to the process data when the processcapability assessment results are responded inadequately. The parameters are released or design space is looked for through the process capability assessment, so that the production process knowledgesystem is allowed to gradually returns to the process knowledge system with the traditional Chinese medicine production process adjusted and fed back intelligently.

Owner:JIANGSU KANION PHARMA CO LTD +1

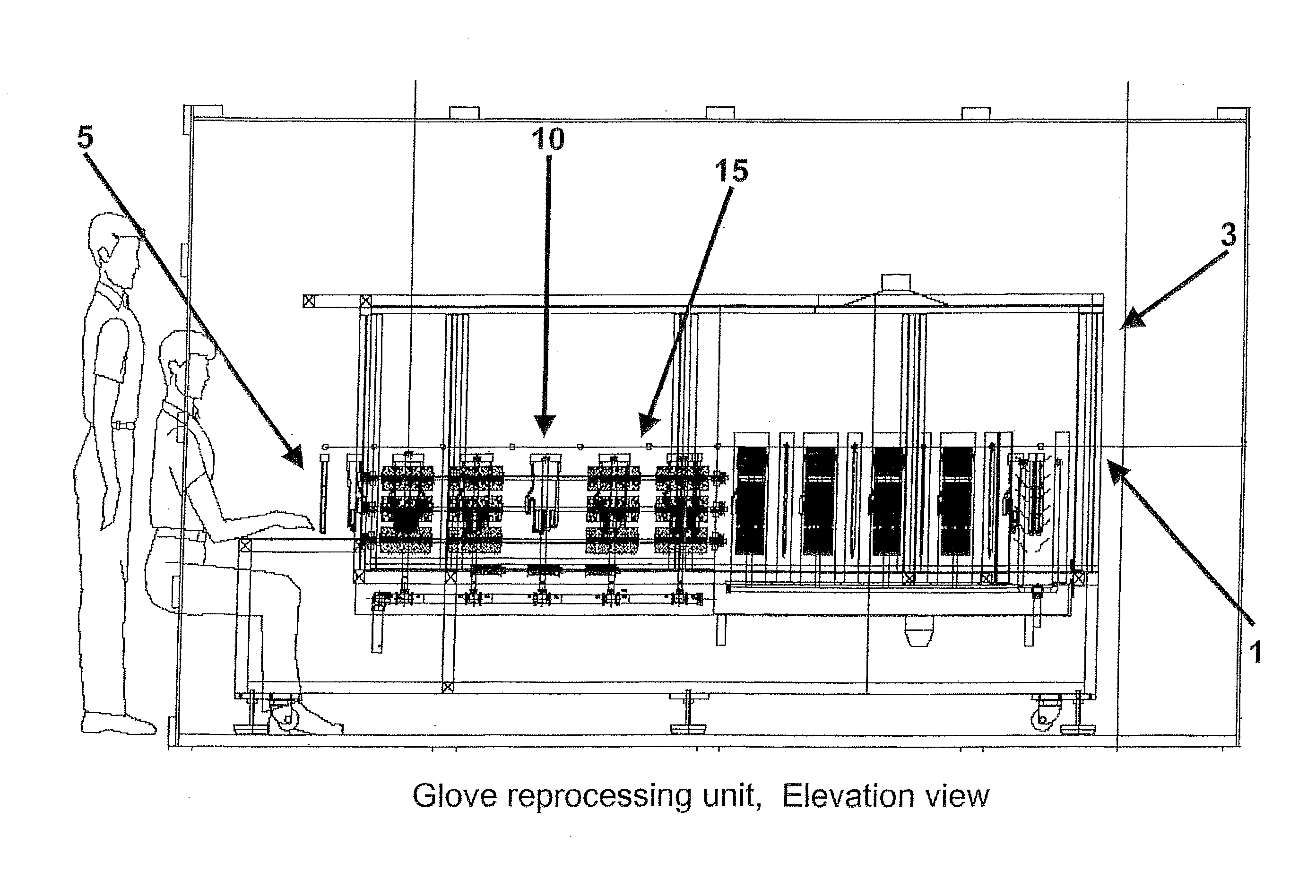

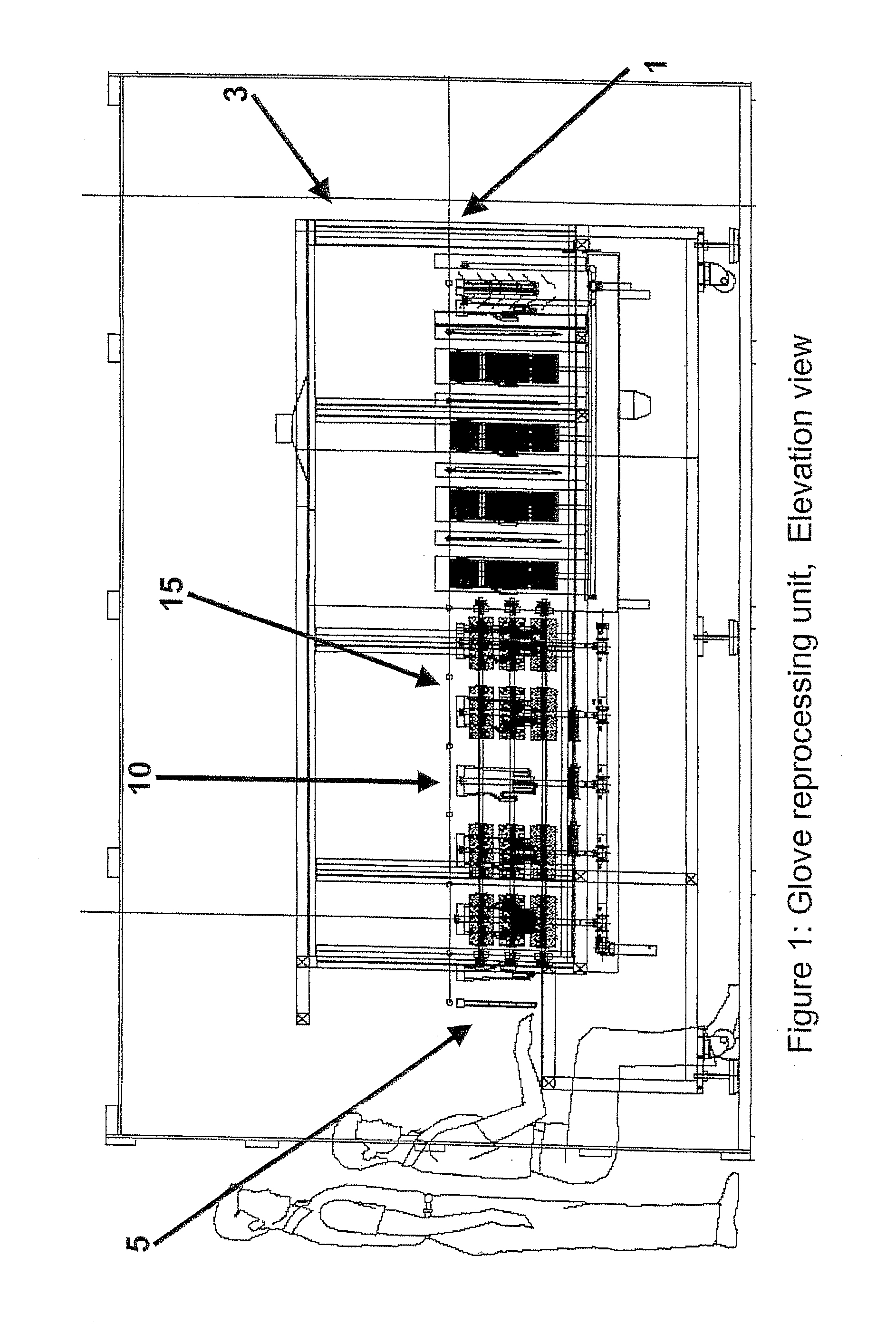

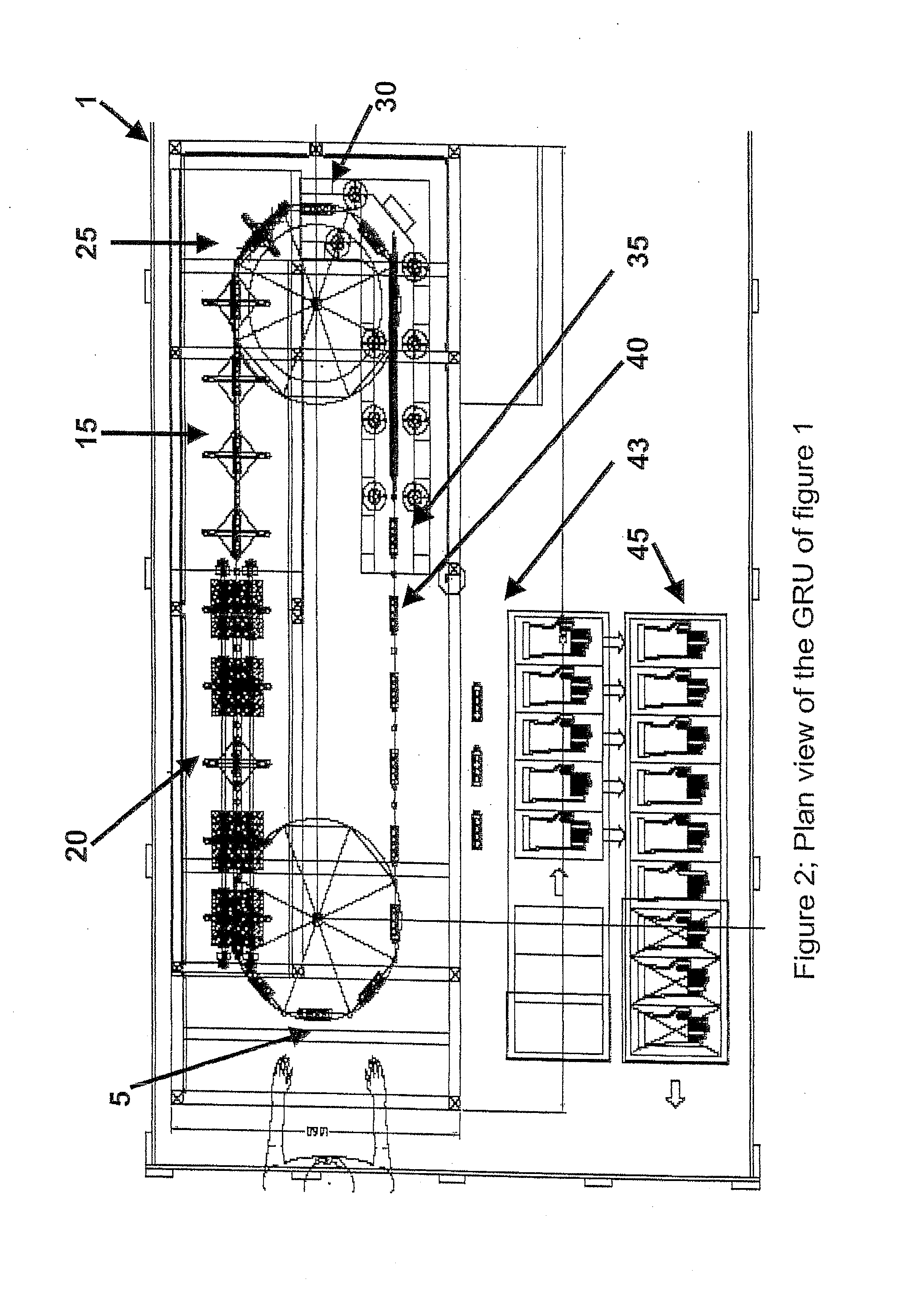

System for the processing of reusable gloves

InactiveUS20100263695A1Increase the cost of useWaste disposal volumeResistance/reactance/impedenceRegistering/indicating quality control systemsIdentification deviceEmbedded system

A system for processing reusable gloves comprising a conveyor means (15) to convey a plurality of the reusable gloves to a plurality of processing stations (3); said processing stations including; a loading station for mounting the gloves to the conveyor means; an inspection station for inspecting the gloves for pre-determined criteria; a washing station for washing the gloves; an interrogation station for interrogating identification means of the gloves so as to receive data from said identification means; a testing station for testing the integrity of the gloves; an unloading station for unloading the gloves.

Owner:TGT ENTERPRISE LTD

Method and system for detecting incipient bearing failures

Methods and systems for estimating wear damage of a rolling-element bearing system including at least one rolling-element bearing are provided. A first number of first condition indicators representative of the wear damage of the at least one rolling-element bearing are generated. A second number of second condition indicators are generated based on the first plurality of first condition indicators. The second number is less than the first number an indication of the wear damage of the at least one rolling-element bearing is generated based on the second number of second condition indicators.

Owner:HONEYWELL INT INC

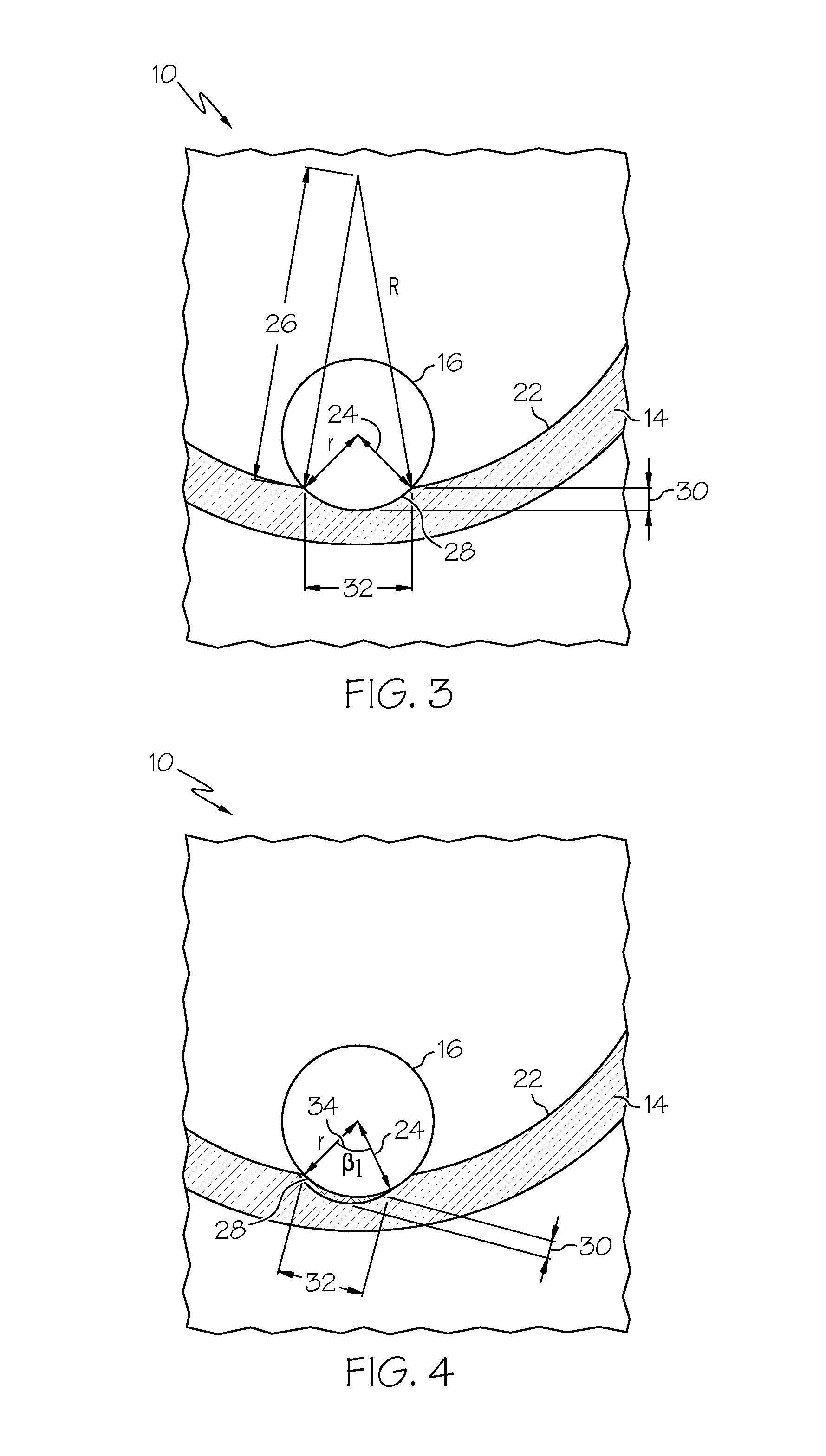

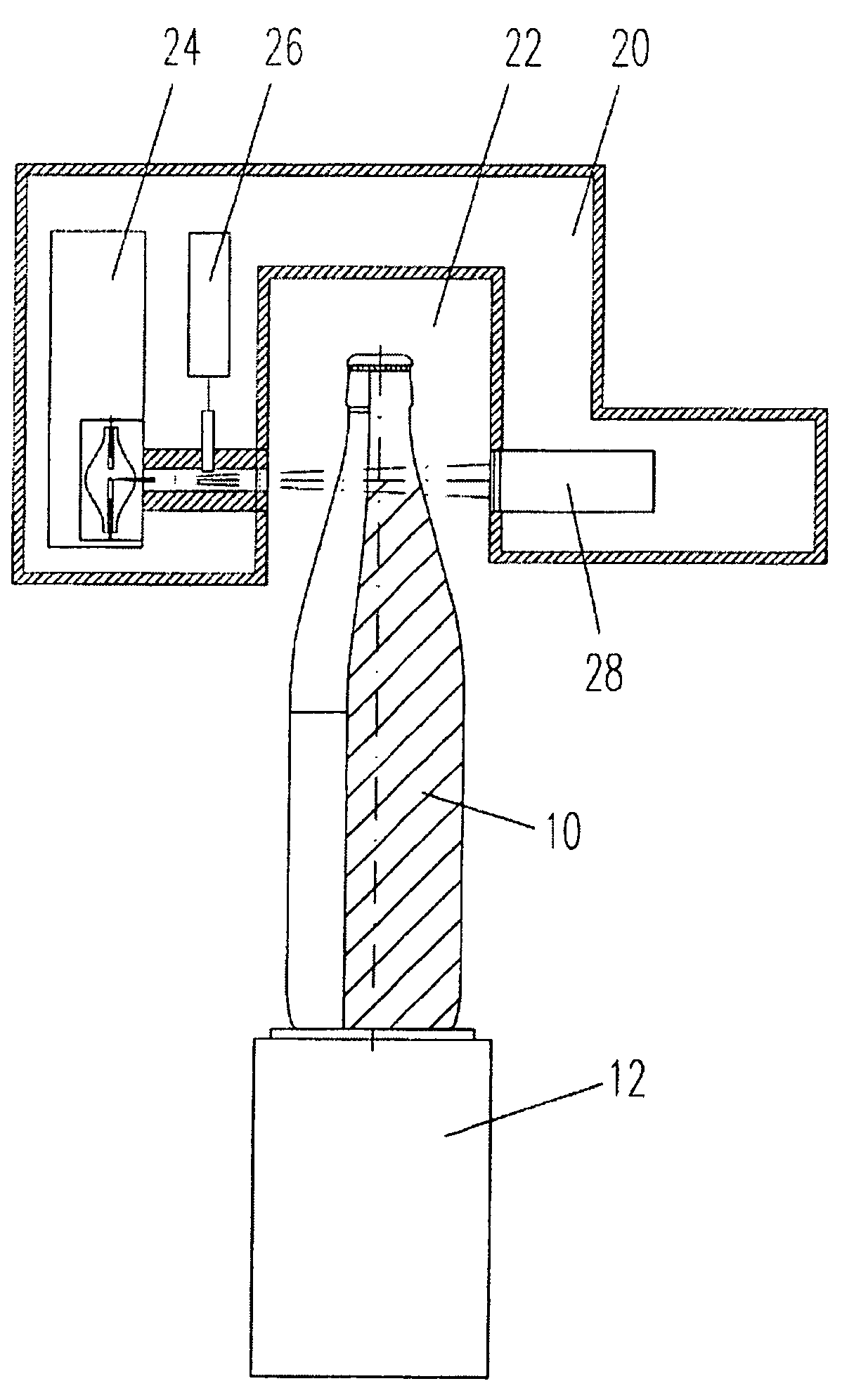

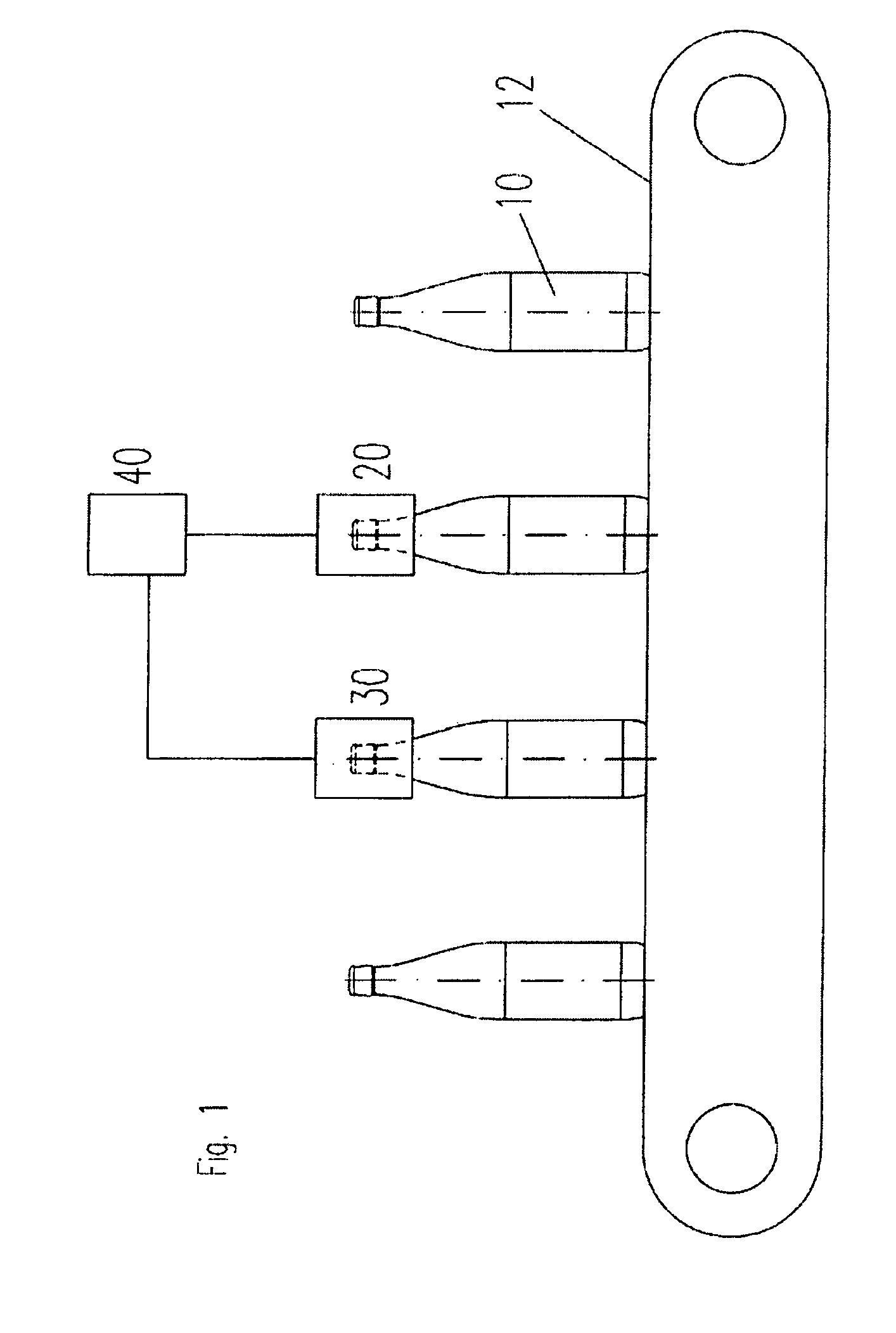

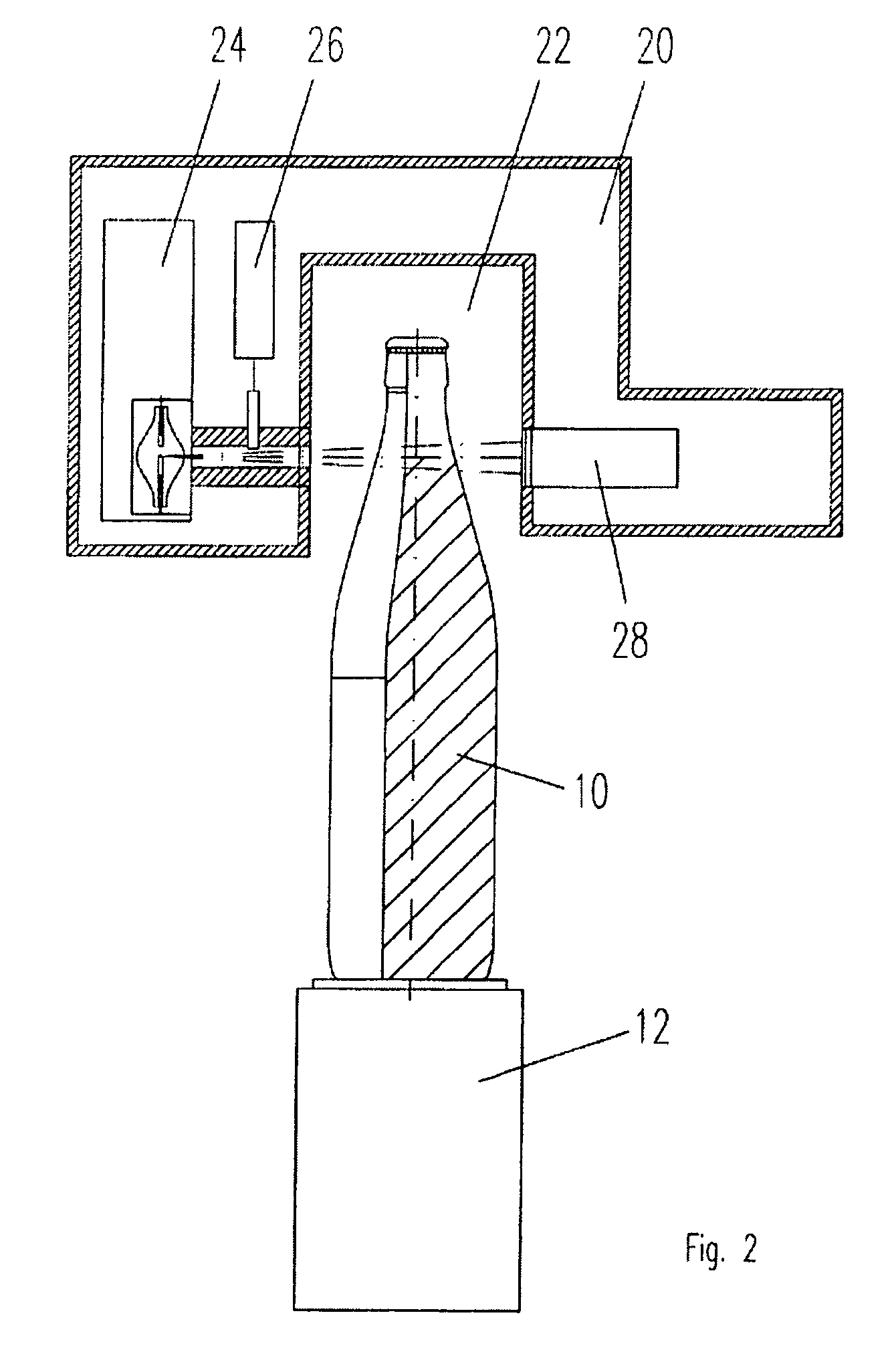

Method of establishing the integrity of a product located in a container

ActiveUS7727567B2Clear determinationAccurate measurementDough treatmentTesting/calibration apparatusEngineeringBottle

To establish the integrity of a product located in a container a given feature of the product in the container is determined by means of a first measurement method in which a first physical property of the product is ascertained, the given feature is additionally ascertained at least directly or by means of a second measurement method which is based on a second physical property which is different from the first physical property, and the values obtained by means of the two measurement methods of the given feature are compared. If the product is a drink in a bottle and if the given feature is the fill level, the first measurement method can consist of the fill level being measured by means of absorption of an X-ray beam, and the second measurement method can consist of the change effected by the bottle in the resonant frequency of a high-frequency oscillating circuit being measured.

Owner:HEUFT SYSTTECHN GMBH

Systems and Methods for Gas Turbine Operational Impact Modeling Using Statistical and Physics-Based Methodologies

ActiveUS20160026739A1Registering/indicating quality control systemsComputation using non-denominational number representationOperational impactGas turbines

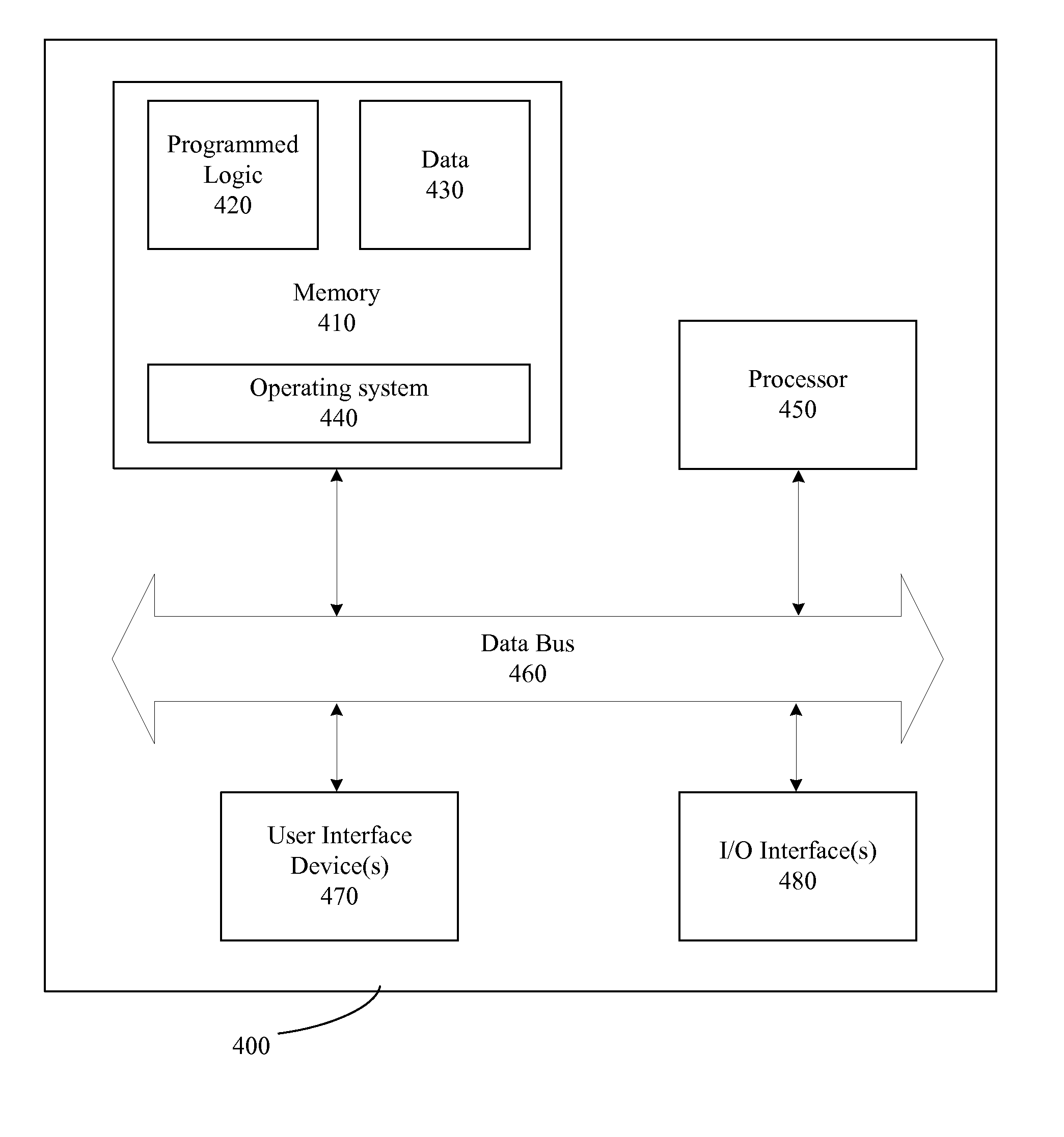

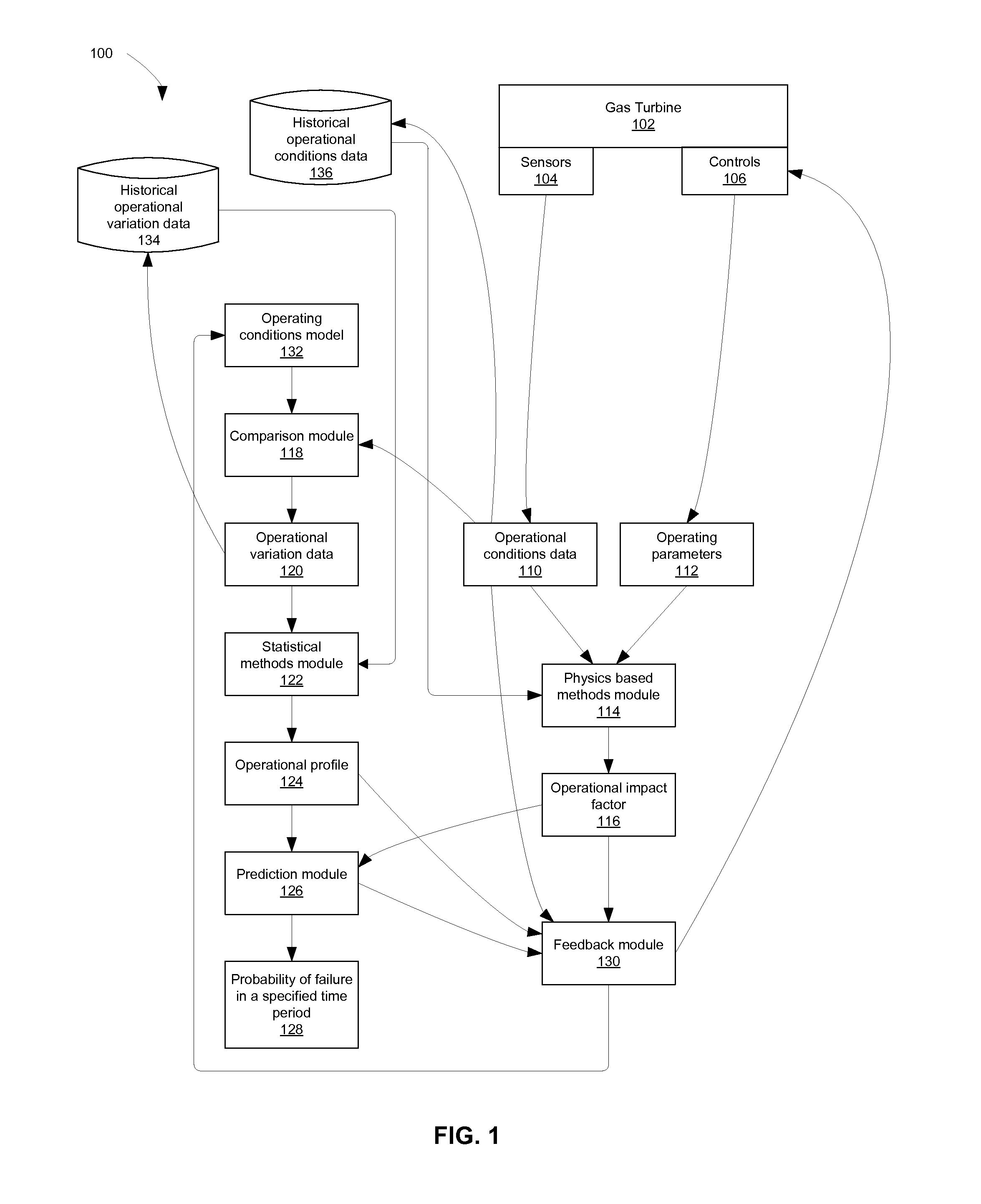

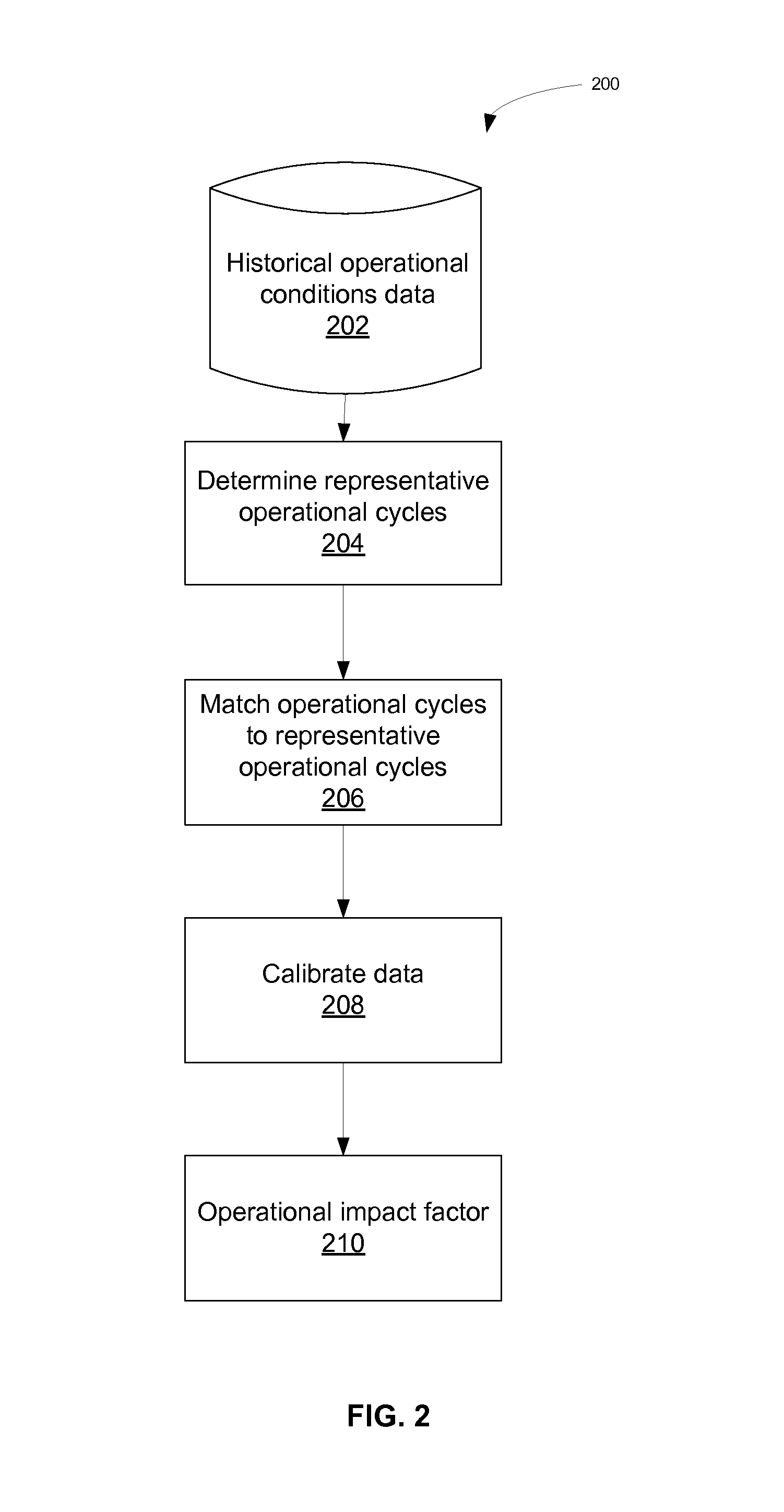

Systems and methods for gas turbine operational impact modeling using statistical and physics-based methodologies are disclosed. According to one embodiment of the disclosure, a method can include receiving, by one or more processors, operational conditions data associated with a hardware component of a gas turbine; based at least in part on the operational variation data, applying, by one or more processors, statistical methods to establish an operational profile of the hardware component; receiving, by one or more processors, operating parameters and operational conditions data associated with the hardware component; based at least in part on the operating parameters and the operational conditions data, applying, by one or more processors, physics-based methods to establish an operational impact factor of the hardware component; and based at least in part on the operational profile and the operational impact factor determining, by one or more processors, a probability of a failure of the hardware component within a time period.

Owner:GENERAL ELECTRIC CO

Method and apparatus for controlling site-specific operations

A method and apparatus for controlling a site-specific activity at a plurality of remote locations, for example, the inspection of geographically remote equipment or the gathering of data for a census. A mobile operator transports a portable tool (14) to a plurality of locations where a site-specific activity is to be conducted. The portable tool includes a location detection device (32). Processing of data using the portable tool is enabled only when the portable tool is located proximate a designated site, as determined by the location detection device. In various embodiments, the enabled site-specific activity may include data recordation, data transmission, data reception, data processing, and / or the display of a data entry form.

Owner:GE GLOBAL SOURCING LLC

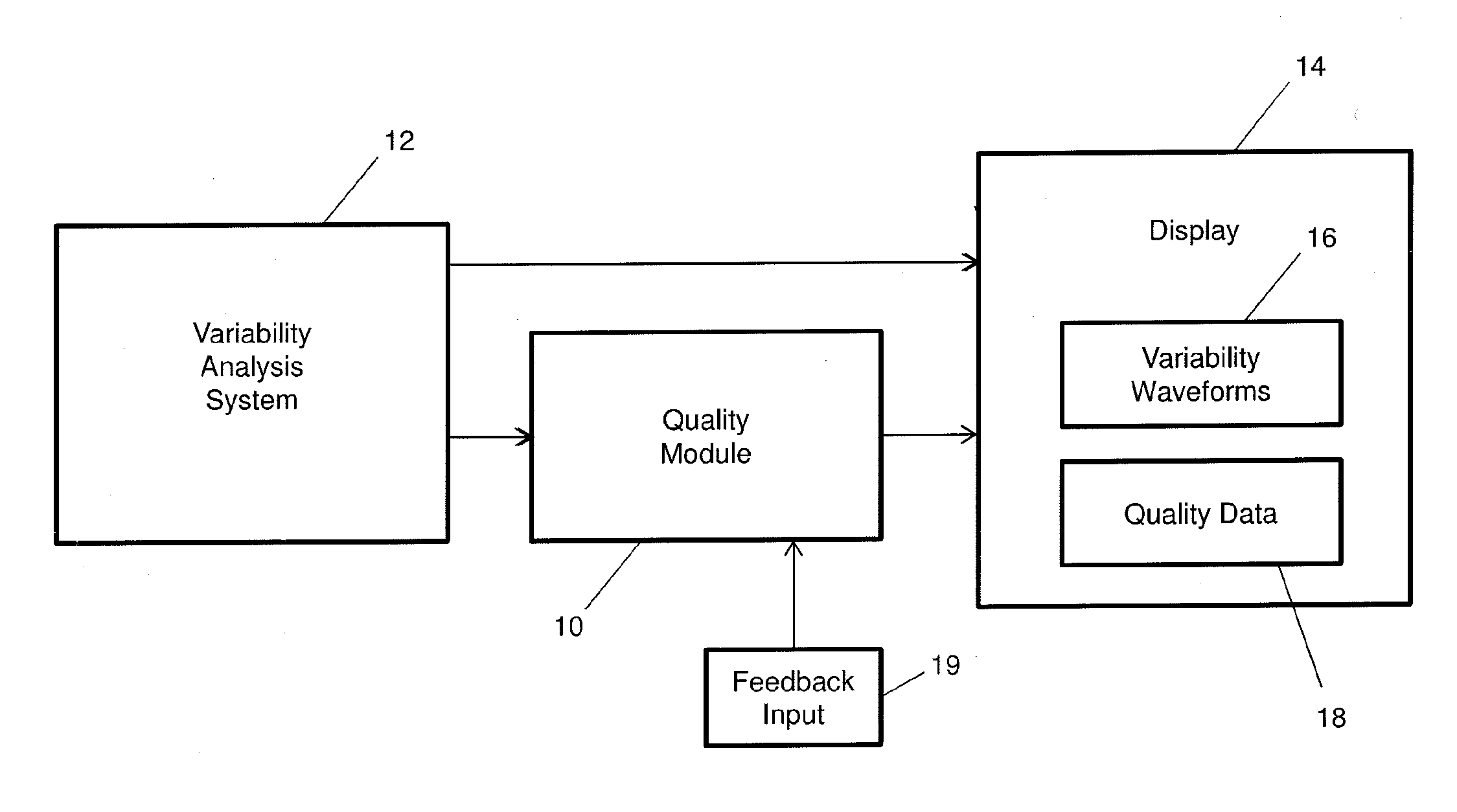

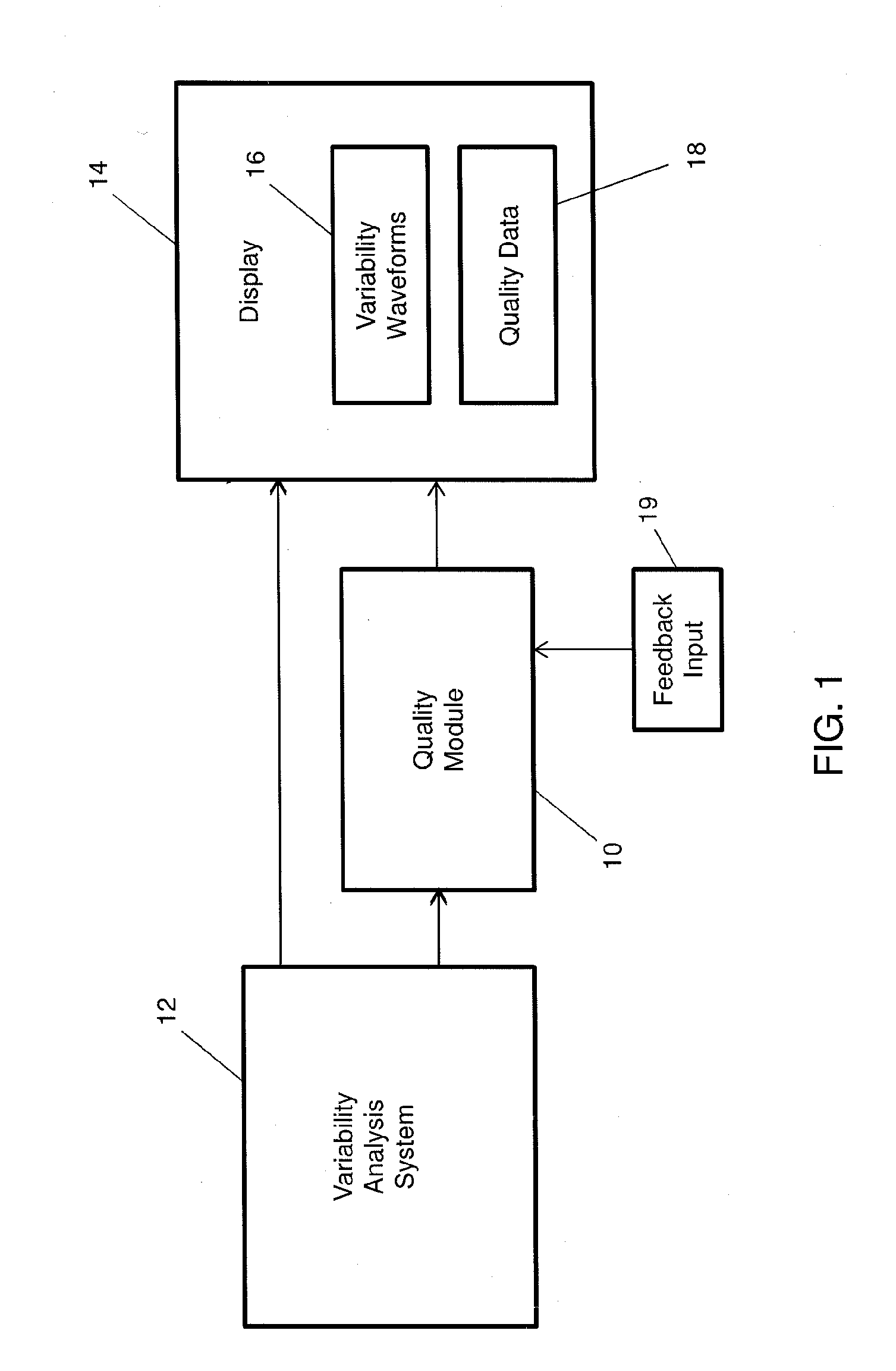

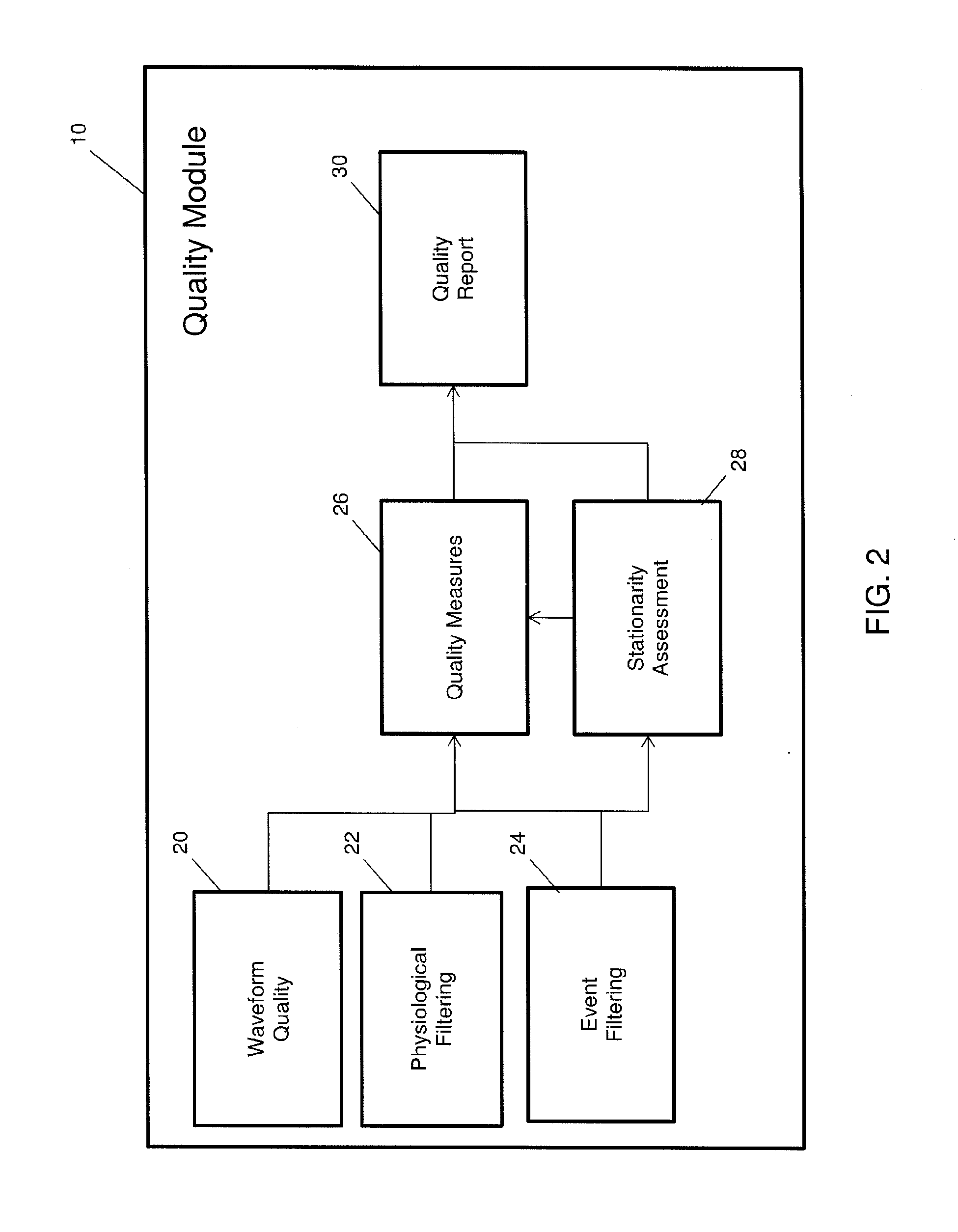

Method for Multi-Scale Quality Assessment for Variability Analysis

InactiveUS20150164428A1ElectrocardiographyNoise figure or signal-to-noise ratio measurementQuality assessmentReal-time computing

A system and method are provided for assessing quality for a variability analysis. The method comprises: obtaining at least one waveform corresponding to a corresponding physiological measurement; determining at least one measure of waveform quality of the at least one waveform; extracting from a waveform, at least one event time series; determining a measure of event time series quality of the at least one event time series; determining at least one measure of stationarity of the at least one event time series; computing a quality measure using the at least one measure of waveform quality and the at least one measure of stationarity; and displaying the quality measure.

Owner:OTTAWA HOSPITAL RES INST +2

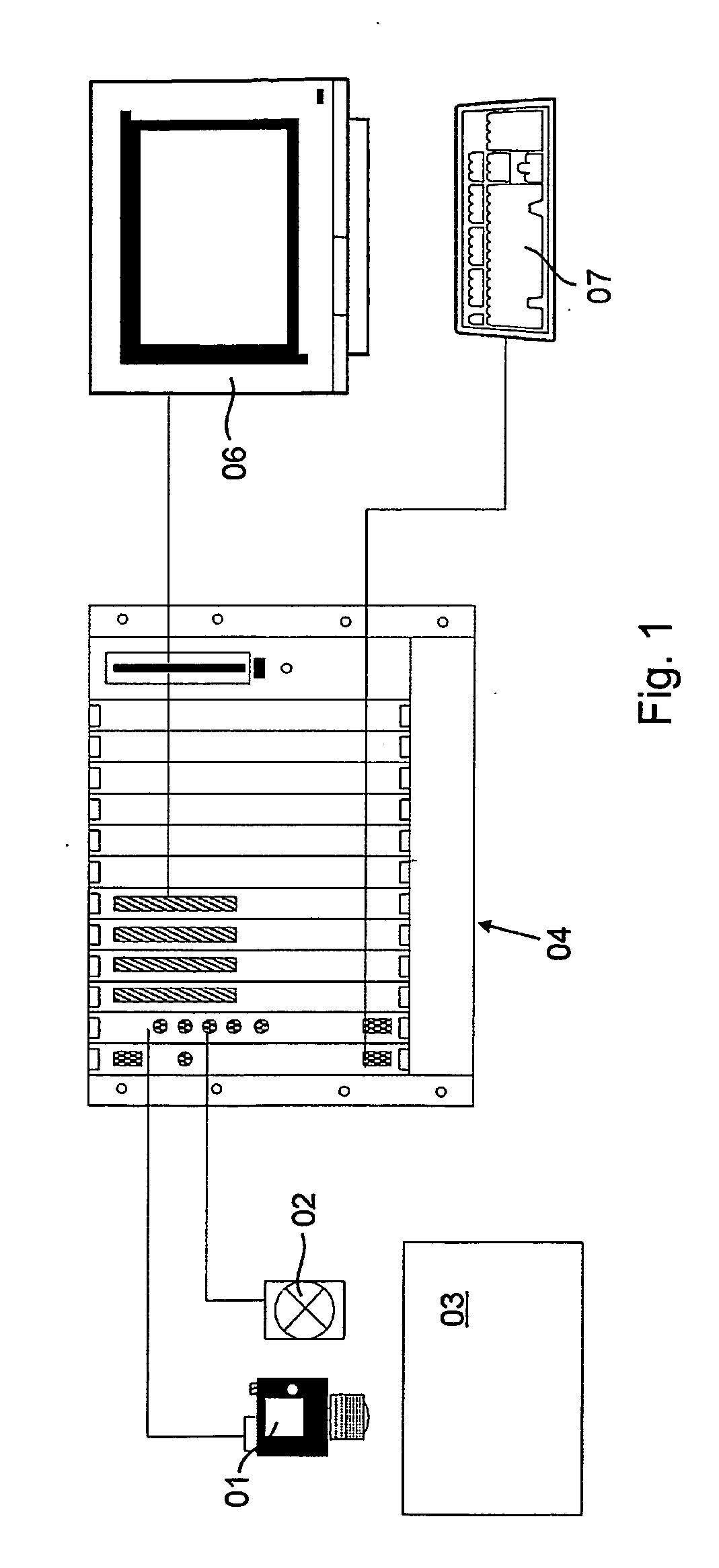

Method and apparatus for improved inspection and classification of attributes of a workpiece

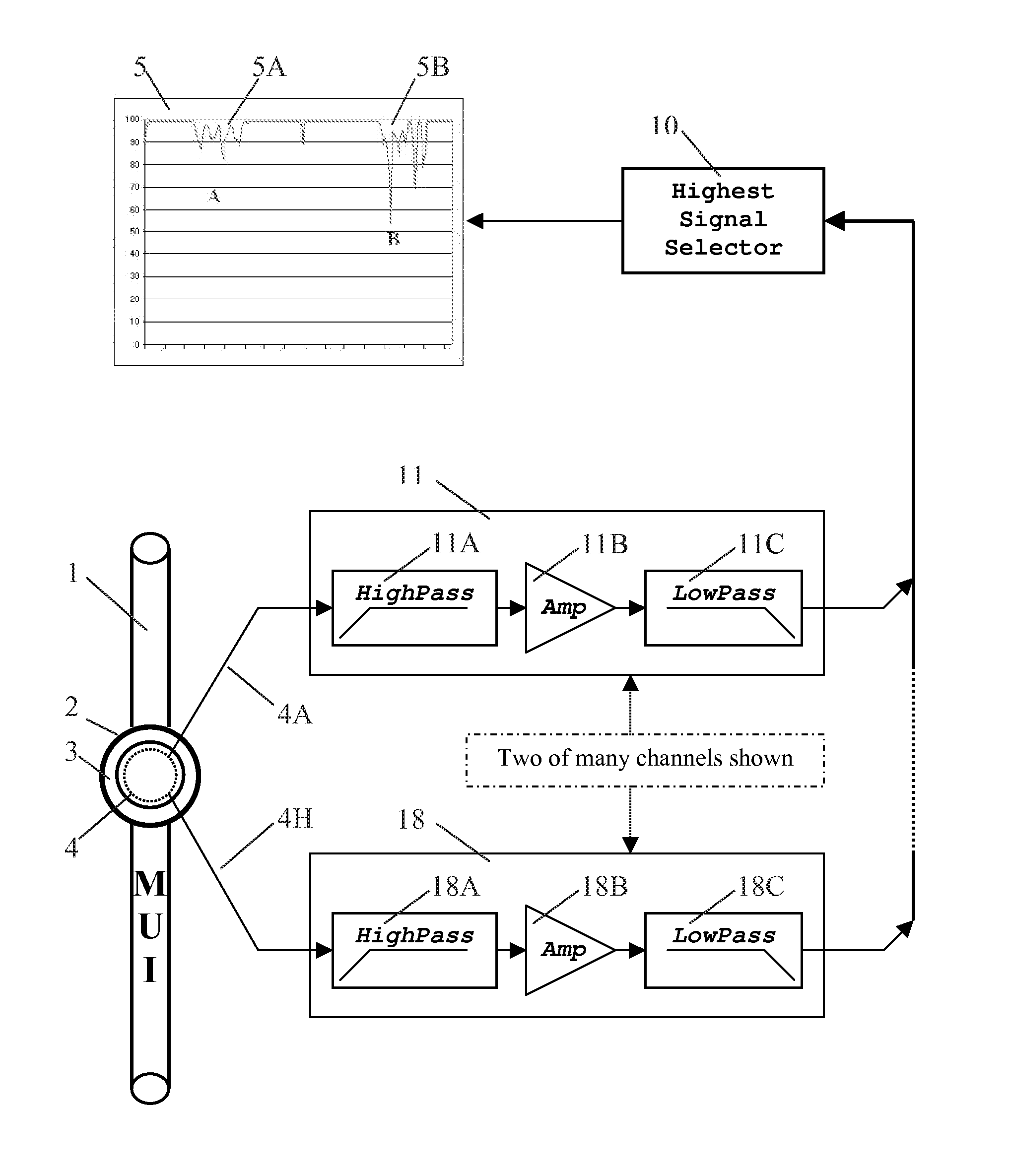

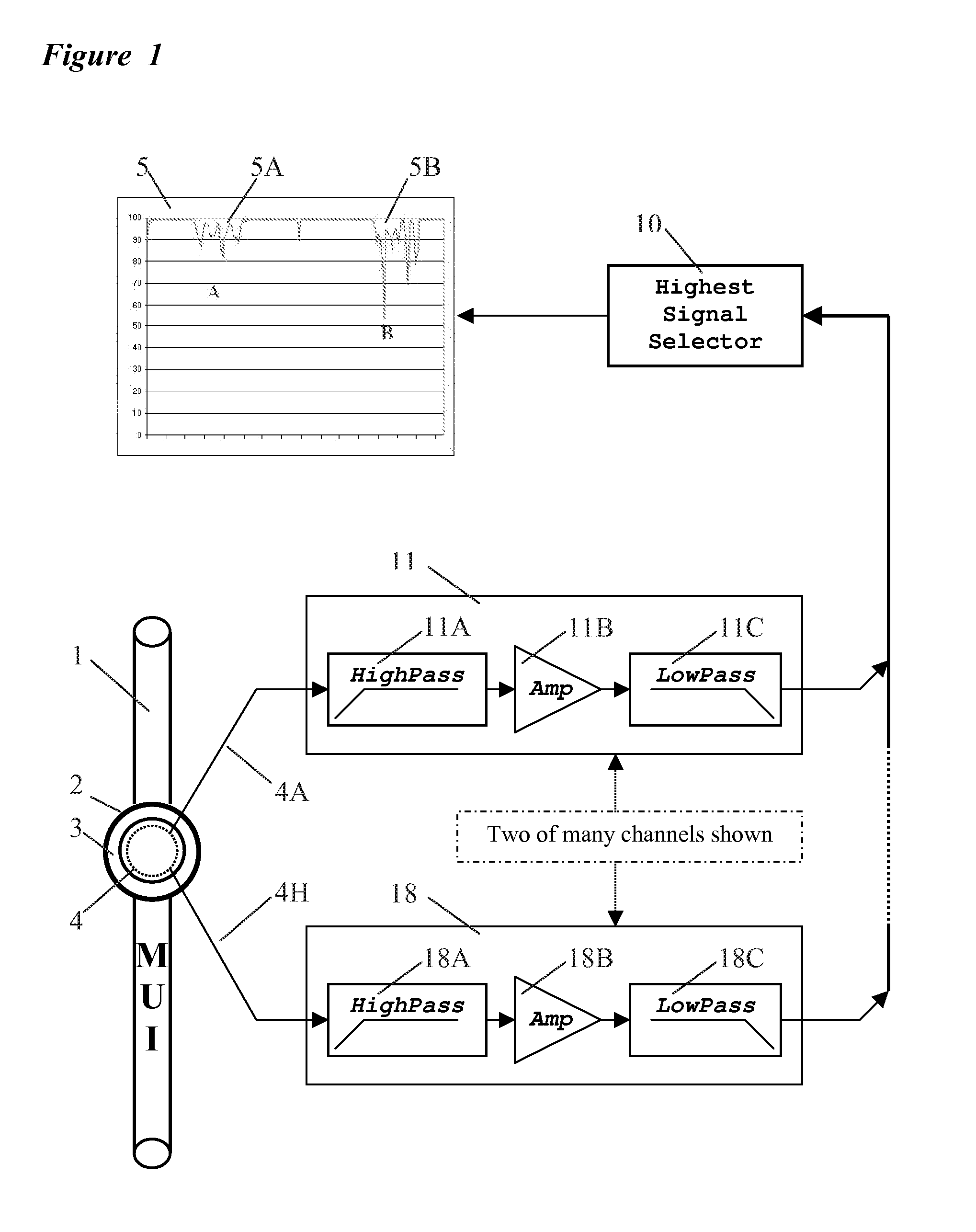

InactiveUS20020040283A1Amplifier modifications to reduce noise influenceRegistering/indicating quality control systemsComputerized systemComputer science

An apparatus for detecting the probable existence, location, and type of defects in a workpiece is described. The apparatus includes a sensor subsystem, an optimizer, a control subsystem, and a computer system having a processor and computer readable memory The sensor subsystem senses a first section of the workpiece and produces signals corresponding to a physical characteristic of the workpiece. The computer system is configured to generate a workpiece model based on the signals produced by the sensor subsystem. In an alternate embodiment, a defect assembler can be provided to merge signals front a plurality of sensor subsystems. The defect assembler can also be configured to generate the workpiece data model. The optimizer is configured to generate workpiece segmentation recommendations based on the workpiece data model.

Owner:USNRKOCKUMS CANCAR

Method and system for monitoring and reporting equipment operating conditions and diagnostic information

InactiveUS9400867B2Provide real-timeRegistering/indicating quality control systemsElectric testing/monitoringElectricityAnalysis data

A method and system (20) is provided for condition based monitoring reliability maintenance capabilities for an asset (70), such as one or more machines, by establishing a network including of a sensor (60) or a plurality of sensors installed, temporarily or in generally fixed locations, on asset (70), wherein sensor (60) provides time sequenced operational information in the form of data based on vibrations, temperature, electrical signals, or other operating conditions. Sensors (60) are connected to a local controller (40) which transmits the data via a local or wide area network (45), either through wired or wireless communication paths, in data packets, each containing divided portions of the operational information. The data packets are mapped and stored into multiple, dedicated databases for ease of retrieving and analyzing the data. Preferably, a cloud-based storage arrangement (120) is employed to storing the mapped data.

Owner:CBM ENTERPRISE SOLUTIONS

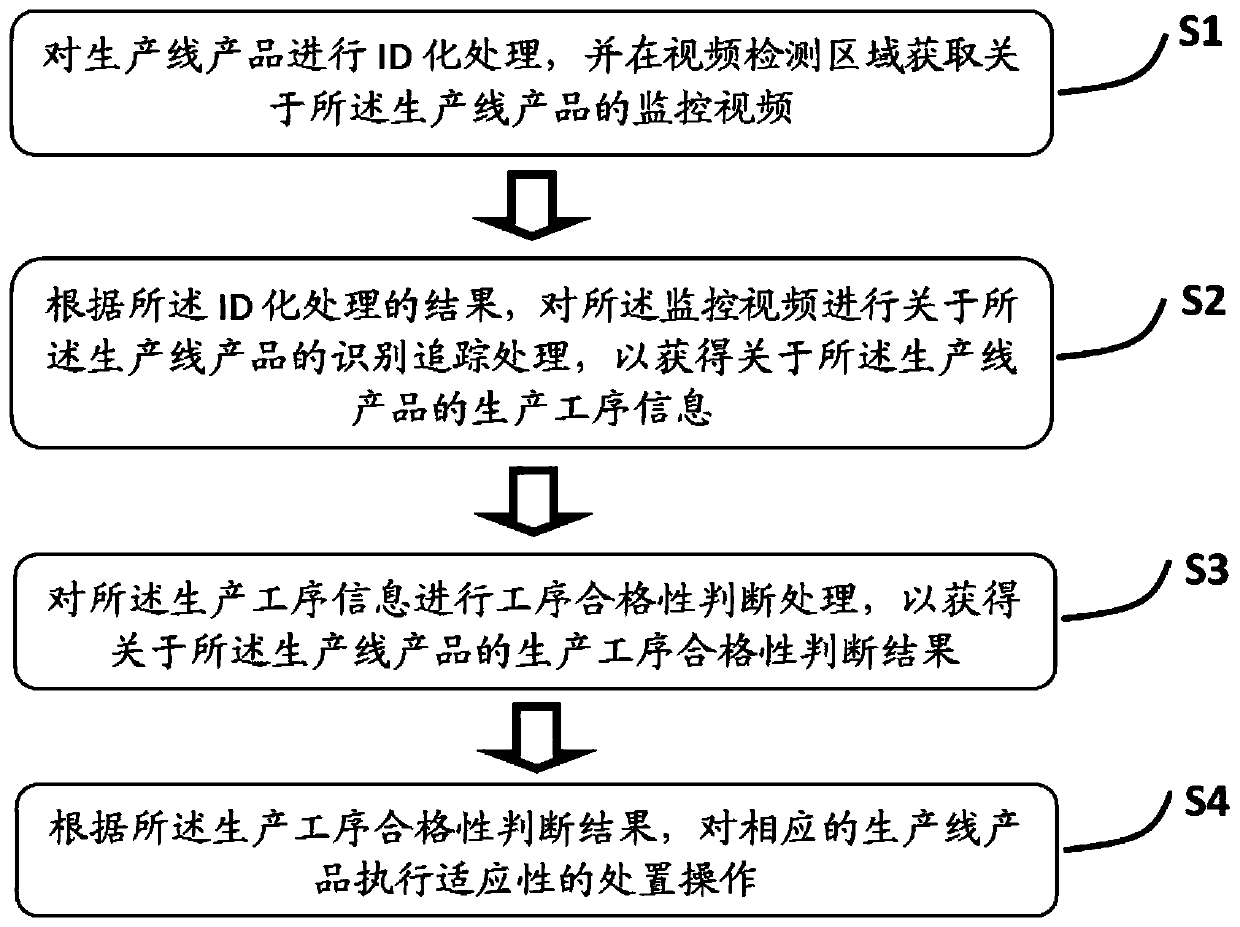

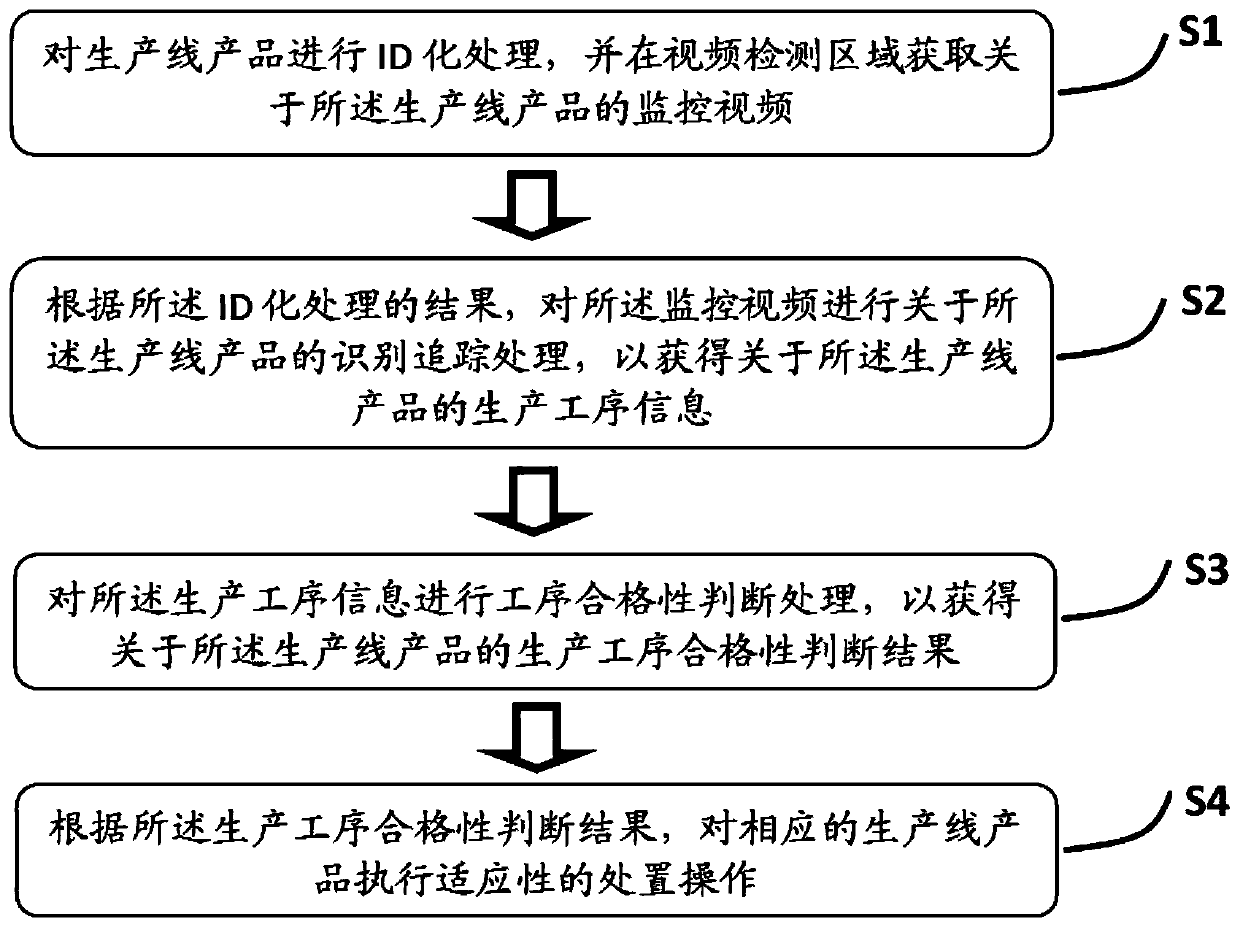

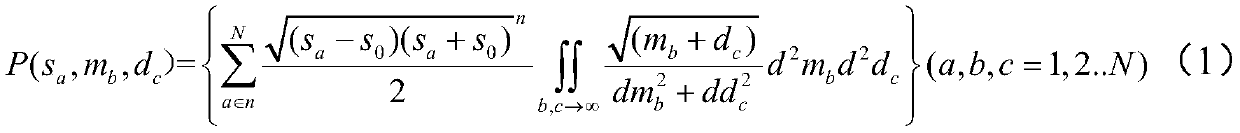

Production line product positioning method based on monitoring video

ActiveCN111127517AEasy to traceEasy to handleImage enhancementImage analysisProduction lineProcess engineering

The invention provides a production line product positioning method based on a monitoring video. According to the production line product positioning method based on the monitoring video, visual ID processing is carried out on a production line product; and the defective products are subjected to ID identification in the monitoring video, so that all the defective products can be traced and processed in a centralized manner in a certain link of production, and therefore, huge waste of manpower and material resources caused by emergency stop of the assembly line can be avoided, and the operation efficiency of the assembly line and the qualification rate of product quality can be improved.

Owner:BEIJING RONGLIAN YITONG INFORMATION TECH CO LTD

Coffee drink order processing apparatus using unmanned coffee drink making machine, and operating method therefor

InactiveCN109328370AReservationsRegistering/indicating quality control systemsEngineeringArrival time

Owner:주식회사비트코퍼레이션

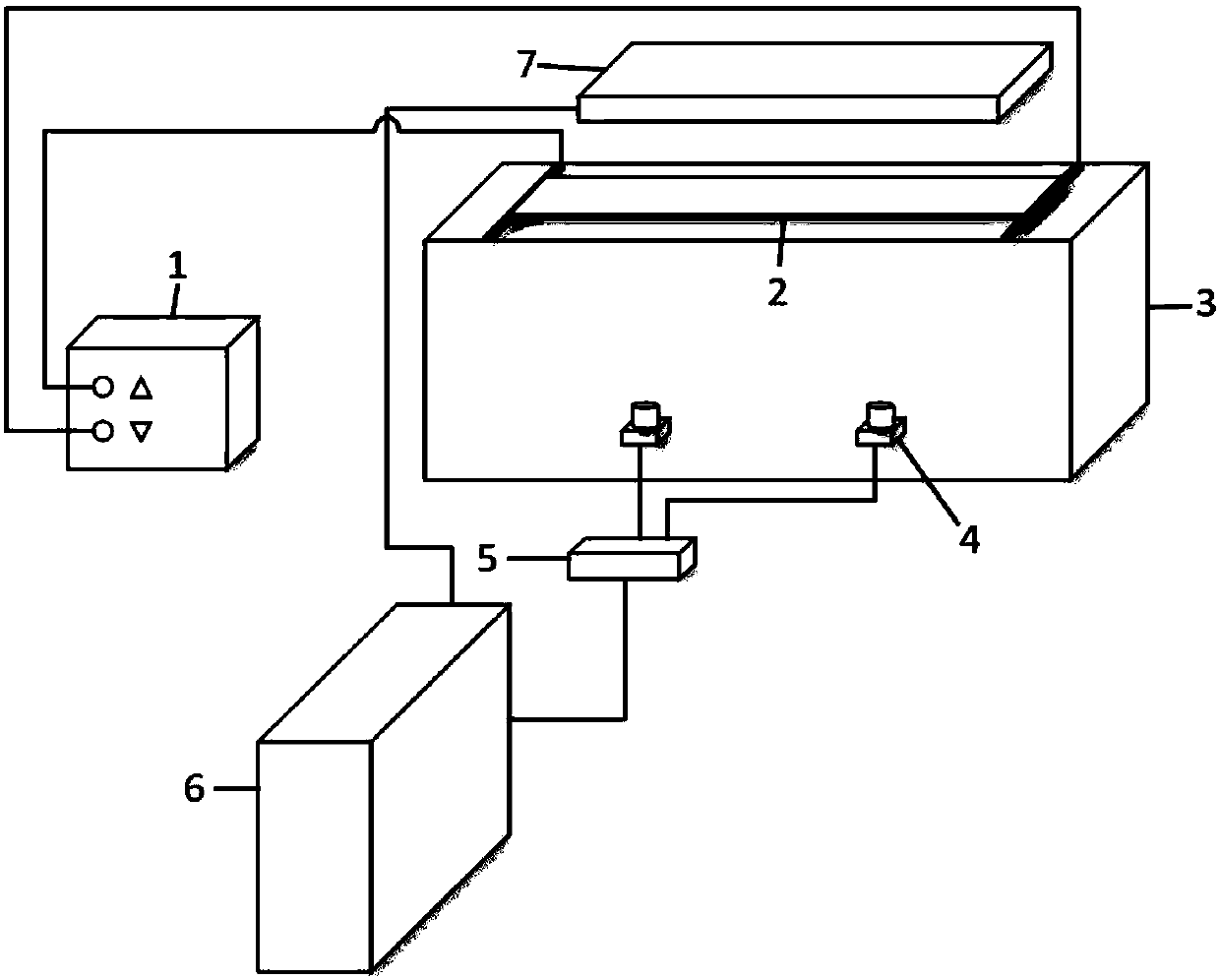

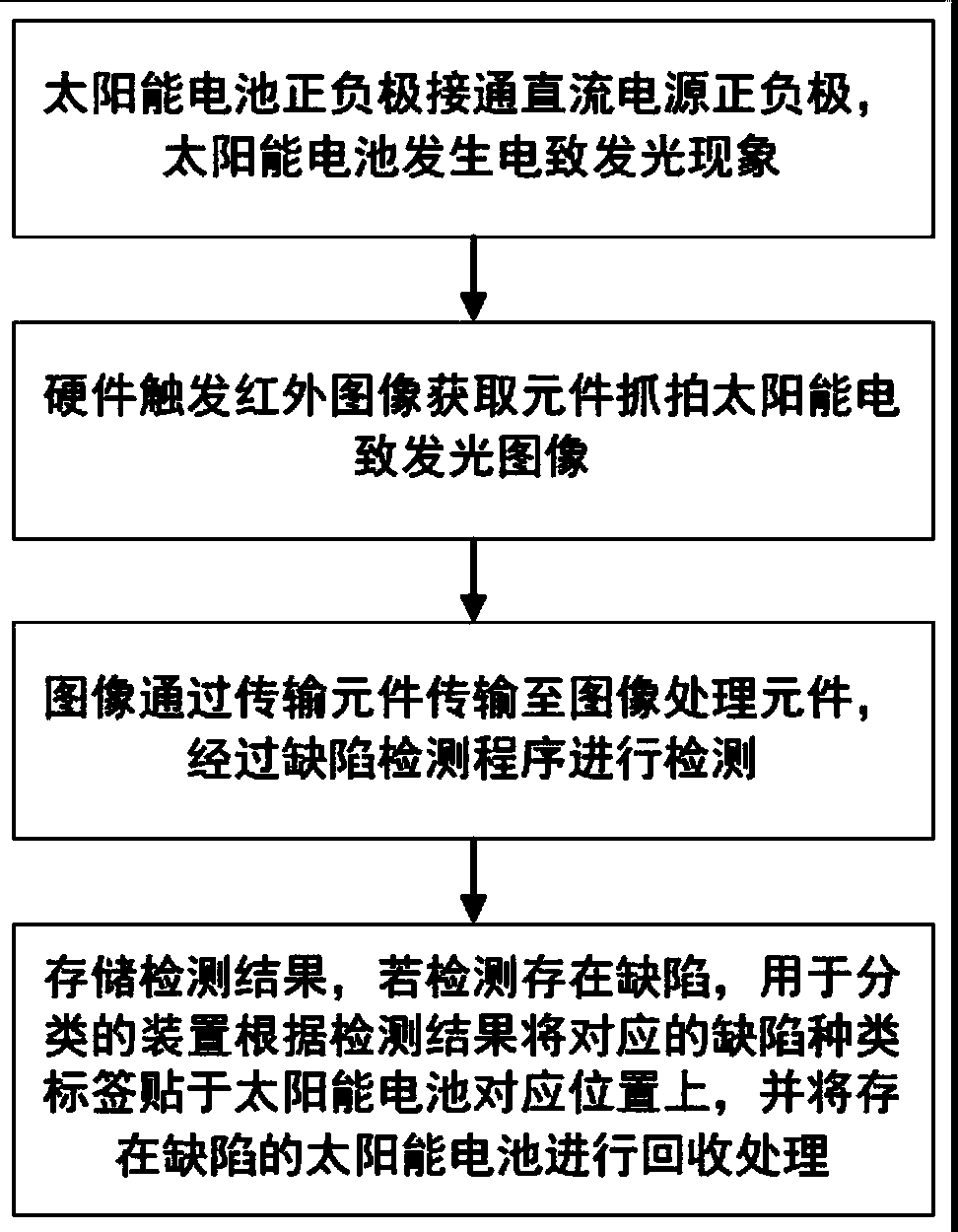

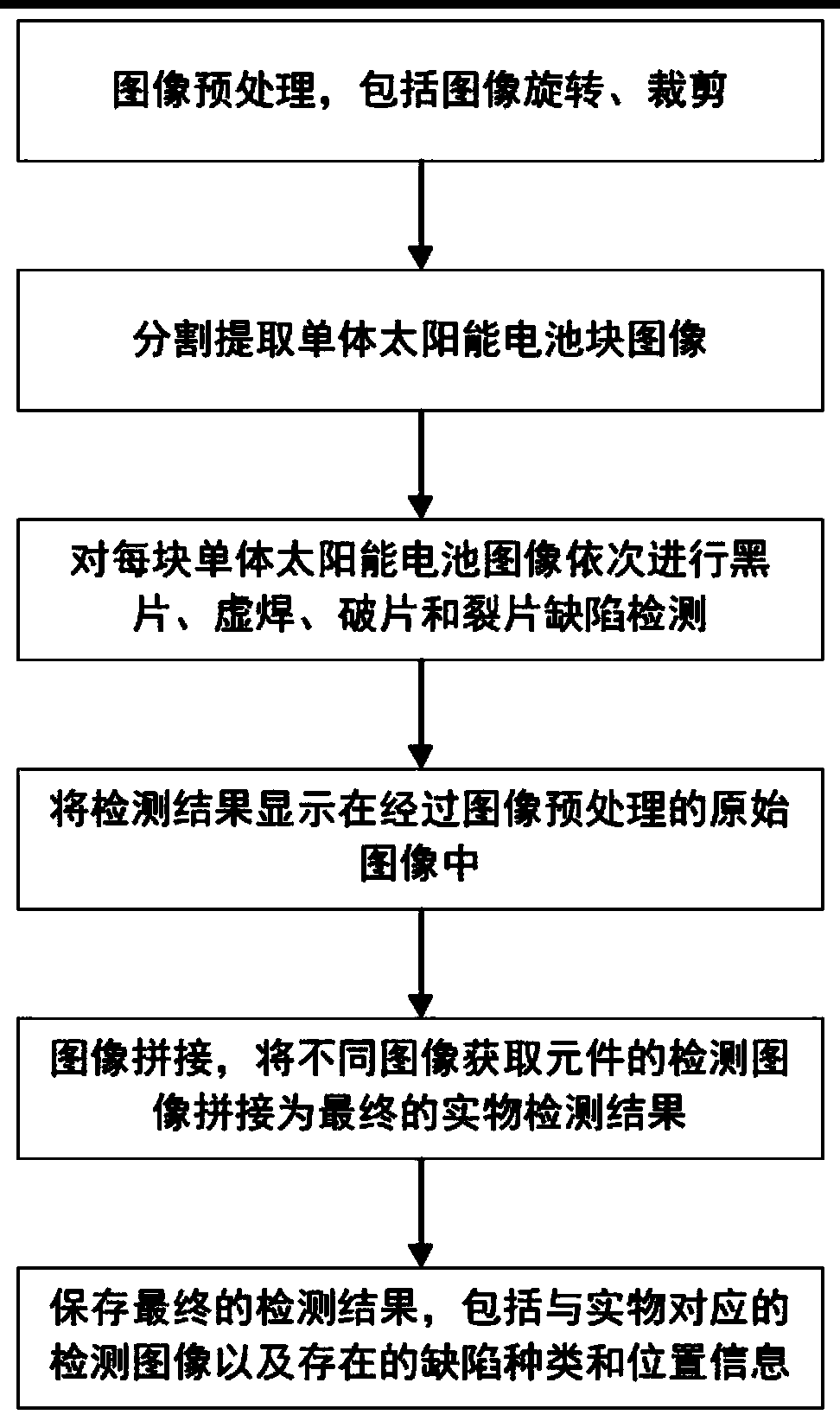

Image-based solar cell defect detection system and method

ActiveCN111275679ARealize real-time detectionImage enhancementImage analysisNerve networkImaging processing

The invention relates to the technical field of image detection, in particular to the field of solar cell defect detection, particularly relates to an image-based solar cell defect detection system and method, and comprises a device for detecting solar cell defects and a solar cell defect detection method. According to the device provided by the invention, the electroluminescence test image of thesolar cell can be obtained; after image preprocessing and image segmentation, a single solar cell block image is extracted; performing image segmentation on the segmented single solar cell; the defects of black pieces, pseudo soldering and broken pieces are detected and recognized based on a traditional image processing mode, the defects of broken pieces are detected and recognized based on a convolutional neural network mode, the solar cells are classified in real time by the detection device according to detection results, and real-time detection of the defects in the production and manufacturing process of the solar cells is achieved.

Owner:TONGJI UNIV

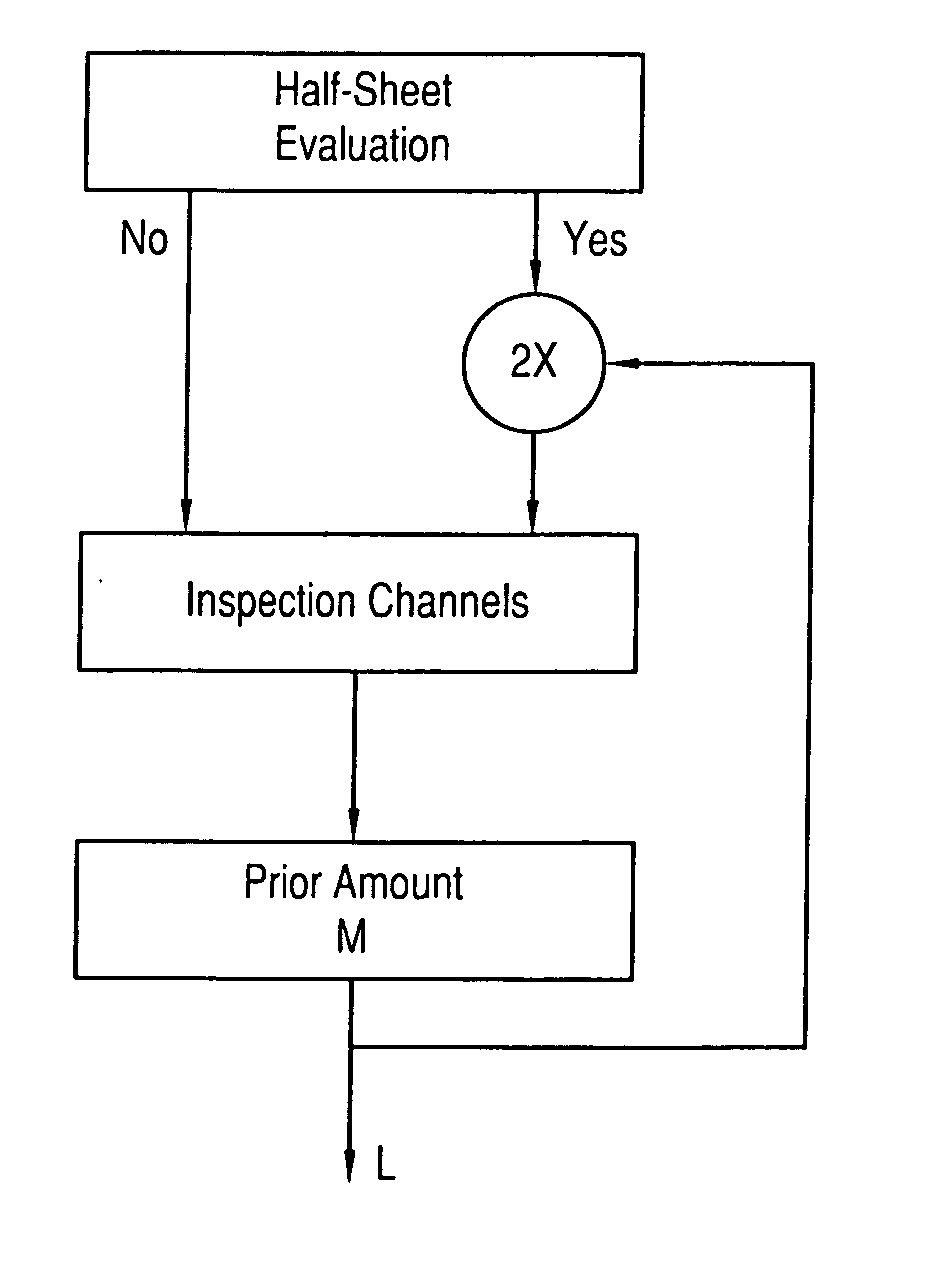

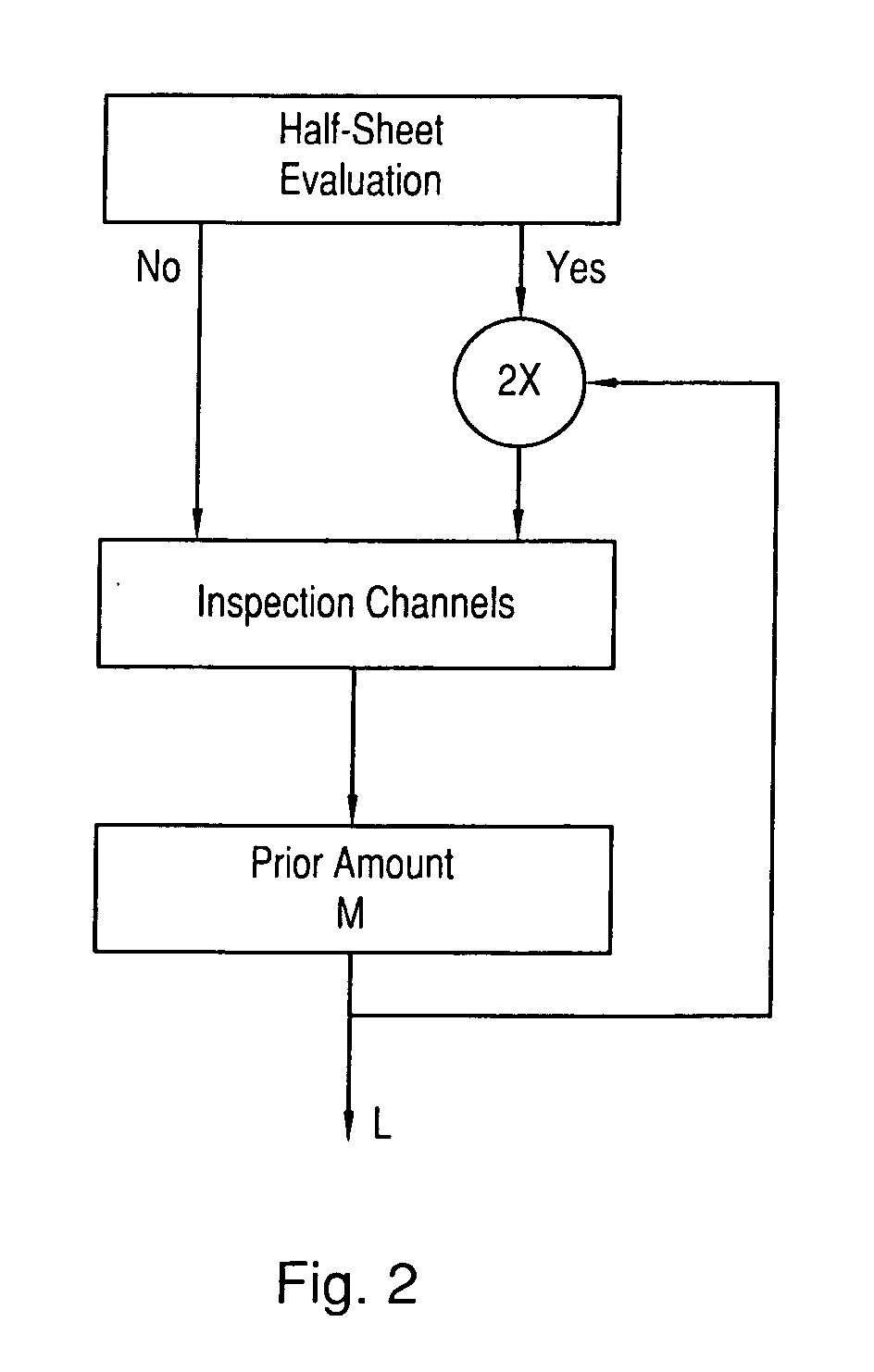

Method for Evaluating the Quality of a Printed Matter, Provided by a Printing Machine

InactiveUS20070223789A1Increase productivityImprove economyImage analysisRegistering/indicating quality control systemsEngineeringImaging data

The quality of printed matter, which is one of several copies of the same printed matter produced by a printing machine, is evaluated. An amount of copies of the printed matter is selected from the total production of this printed matter. The selected amount of these copies are evaluated with regard to at least one error type which belongs to an amount of different error types or with regard to at least one feature of the error. Within the selected amount of copies, an error of a defined error type or of a defined feature, which is detected on at least one of the copies, is evaluated in relation to at least one error of another type or feature detected on the same copy, or another copy of the selected amount. The printed matter is classified as having good or bad quality based on that evaluation. A common reading, producing image data, is obtained by an image sensor from the selected copies. All of the errors to be evaluated in relation to each other are detected from image data gathered during the same common recording.

Owner:KOENIG & BAUER AG

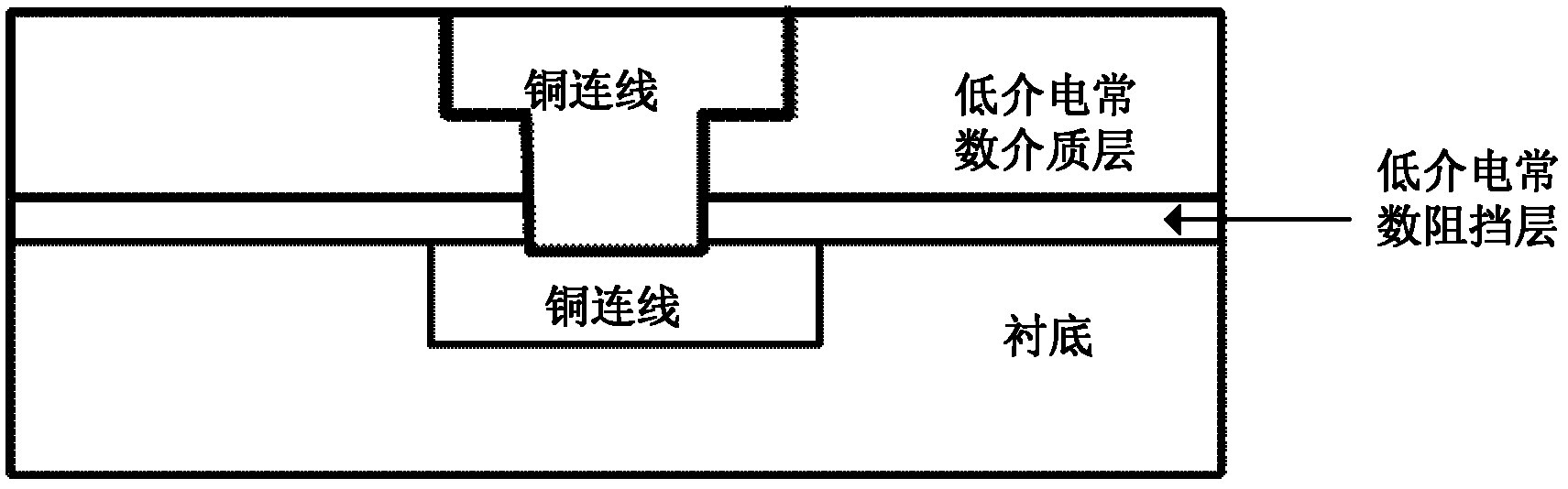

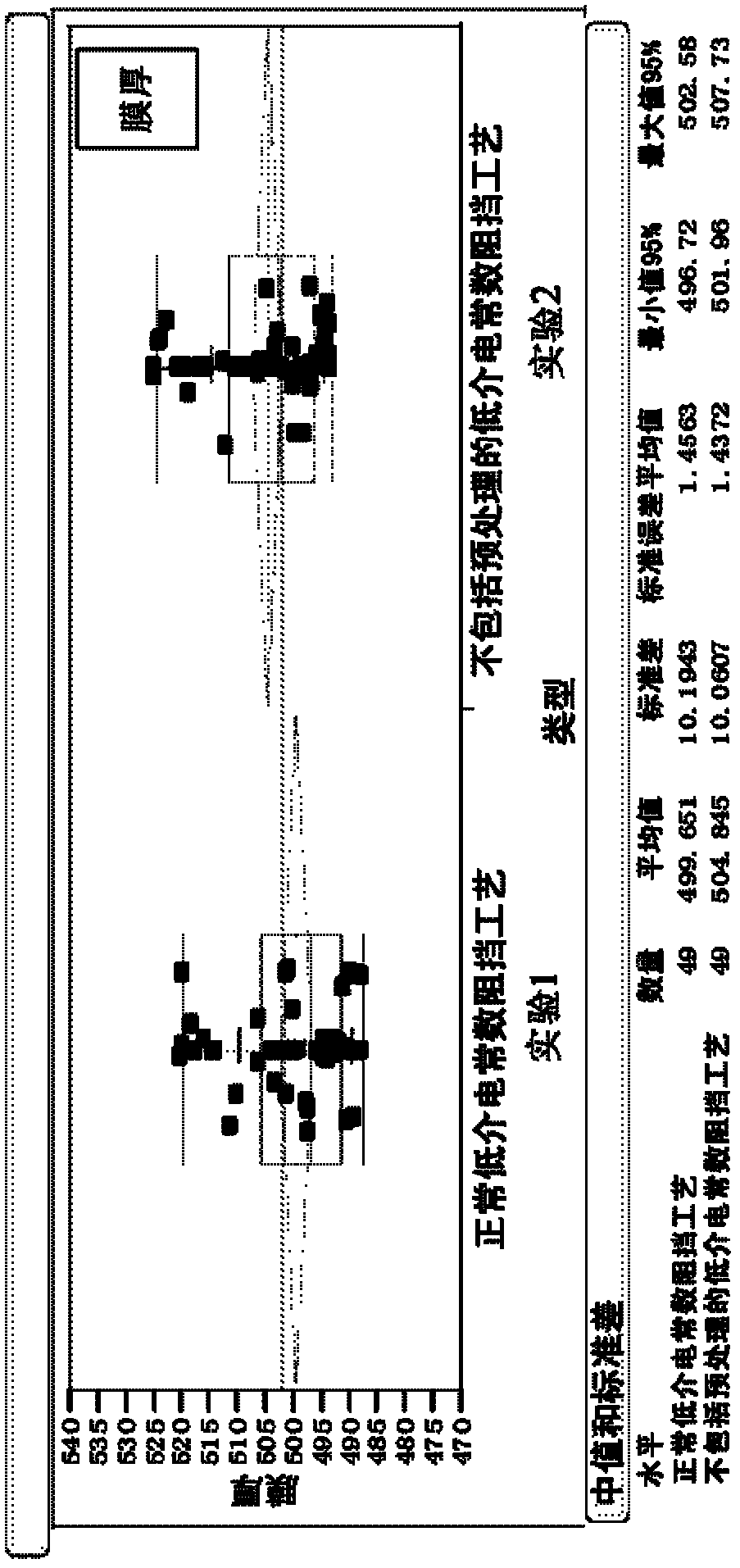

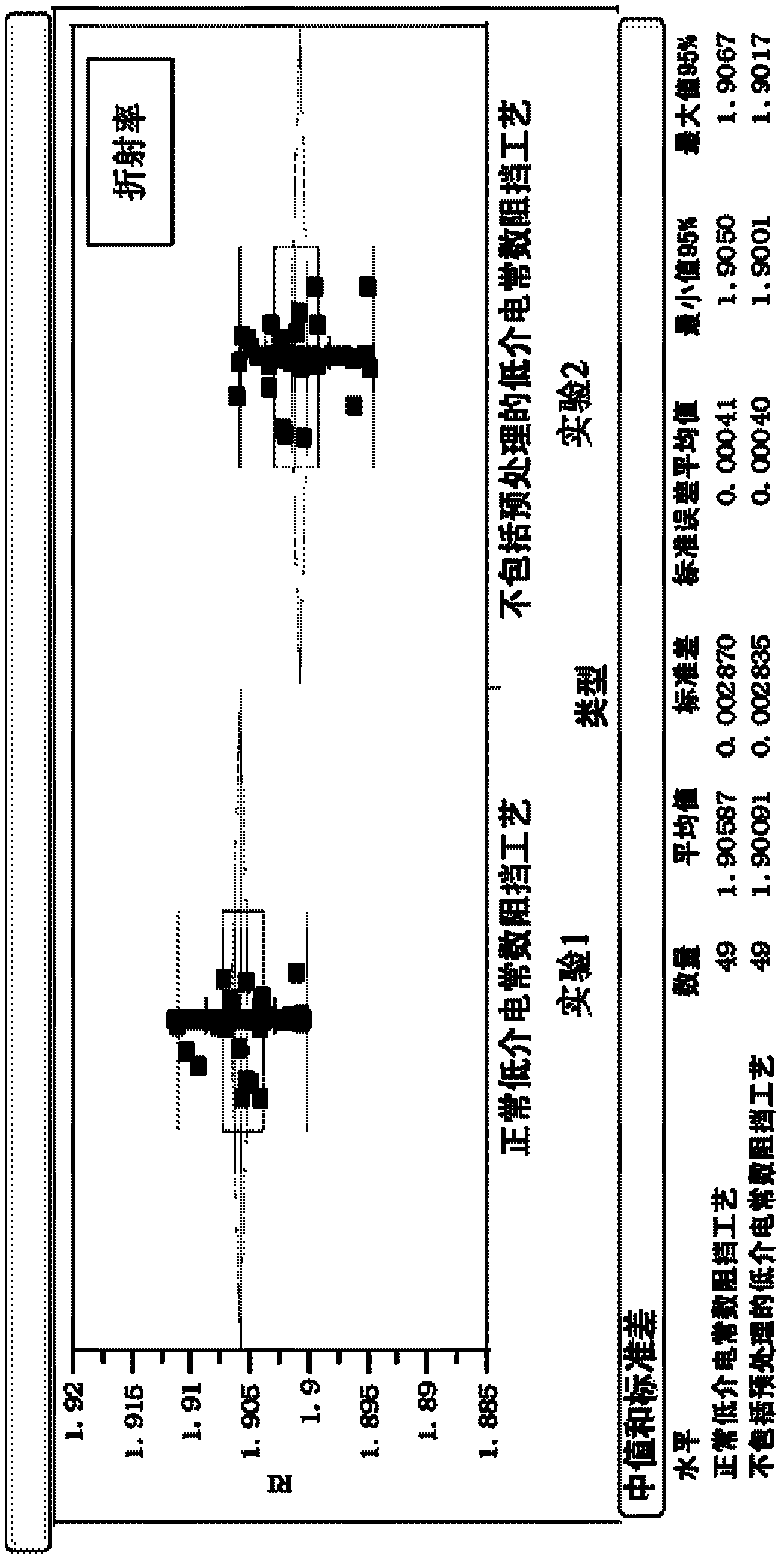

Method and device for monitoring pretreatment in low-dielectric-constant barrier layer process

ActiveCN102437069AAvoid failureImprove reliabilitySemiconductor/solid-state device testing/measurementRegistering/indicating quality control systemsControl lineEngineering

The invention provides a method and a device monitoring pretreatment in a low-dielectric-constant barrier layer process. The method comprises the following steps of: detecting a plurality of film parameters of a silicon substrate which is subjected to pretreatment at different times; establishing a statistic process control curve according to the plurality of film parameters; setting a control line with a preset threshold value; if the range of the statistic process control curve is within the threshold value, judging that the pretreatment is normal; and if the range of the statistic process control curve exceeds the threshold value, judging that the pretreatment is abnormal. The method and the device can be used for effectively preventing invalidation of a pretreatment process so as to improve the reliability and the stability of a product.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com