System and method of monitoring and quantifying performance of an automated manufacturing facility

A technology of production equipment and production capacity, applied in general control systems, control/regulation systems, registration/indication quality control systems, etc., can solve problems such as expensive, difficult, and time-consuming data solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following description and the embodiments illustrated therein are provided by way of illustration of one or more specific embodiments, illustrating the principles of the invention. These examples are provided for purposes of explanation, and similar components are designated with the same reference numerals throughout the specification and drawings.

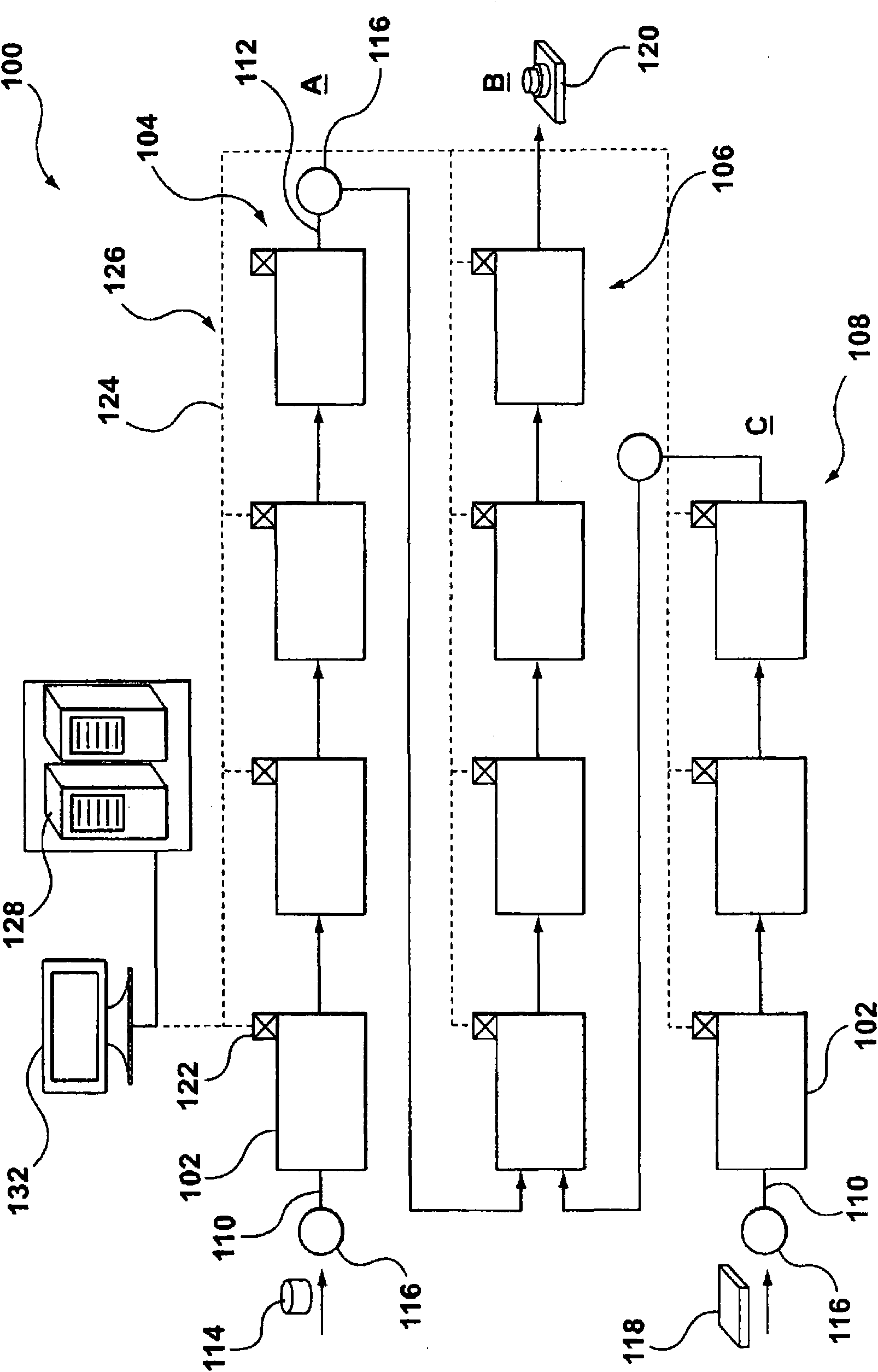

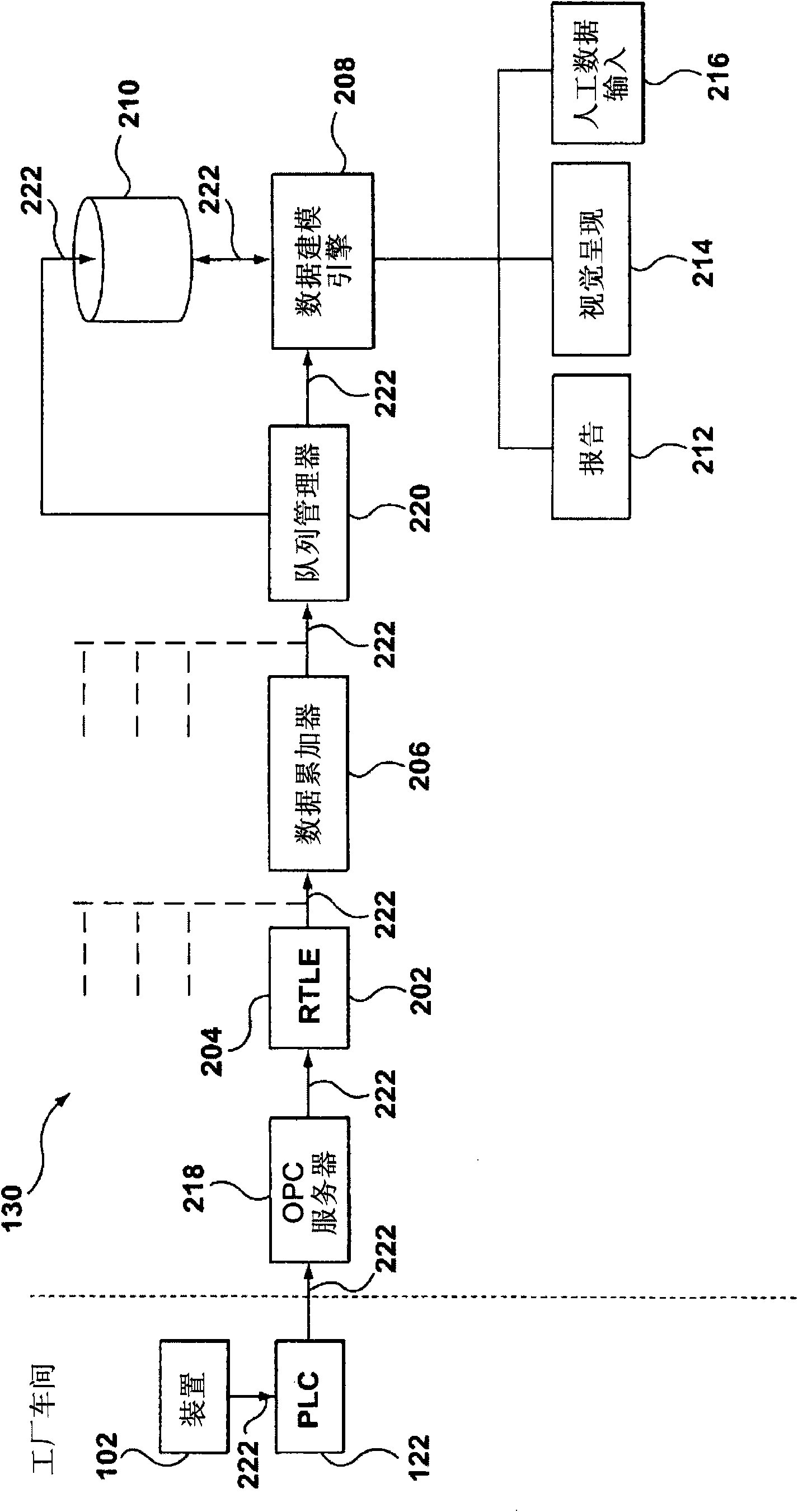

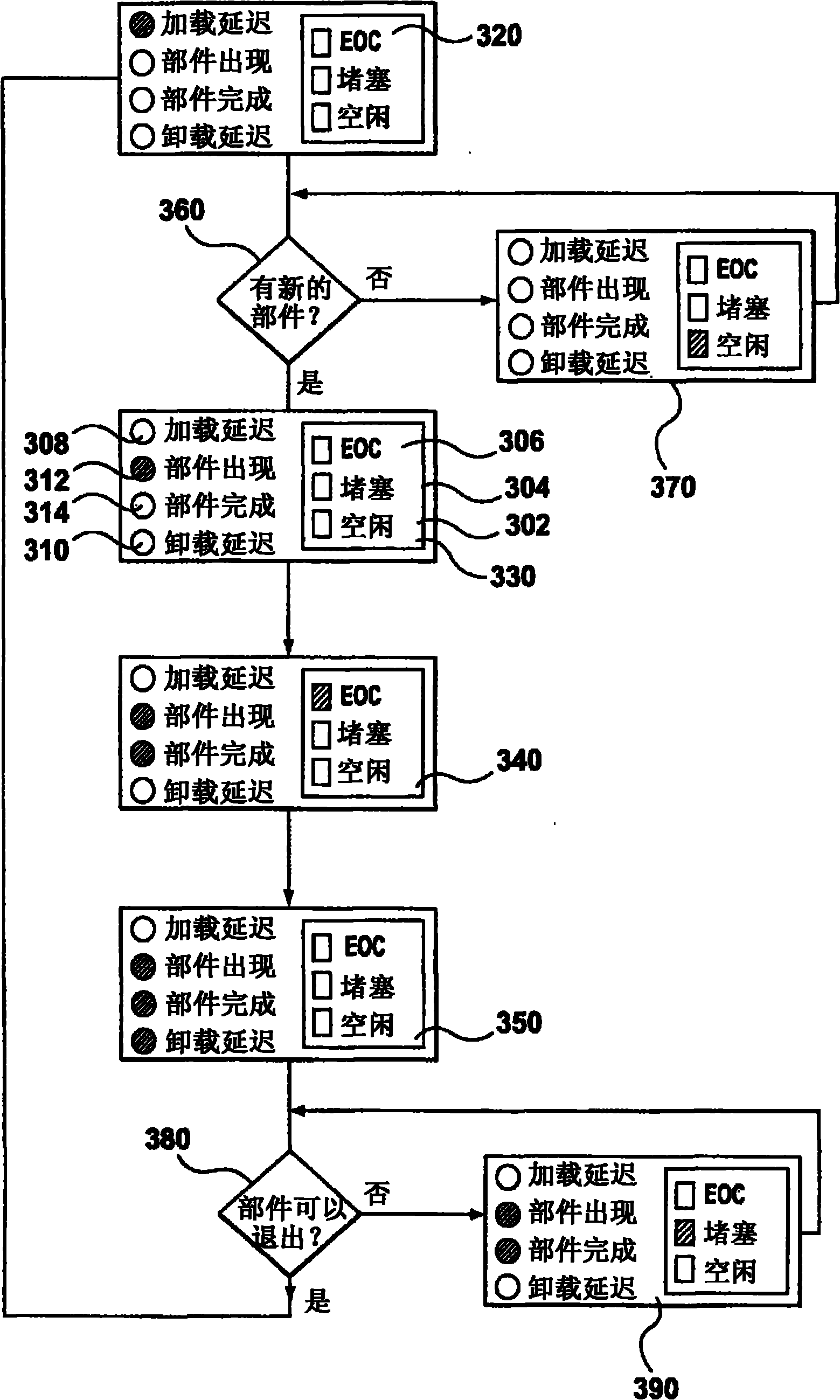

[0033] The present invention relates to systems and methods for determining and quantifying constraints in automated production or processing equipment. The equipment has multiple automation stations. In one embodiment, the system takes event and status signals automatically collected from each station and processes these signals to derive a measure of throughput for each station. The automatic acquisition of signals is further enhanced by providing an input device which allows a user to manually enter information relating to the performance of the workstation. Rather than collecting a large number of signals, the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com