Traditional Chinese medicine production process knowledge system

A production process control, traditional Chinese medicine technology, applied in the field of process knowledge system, can solve problems such as simple functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

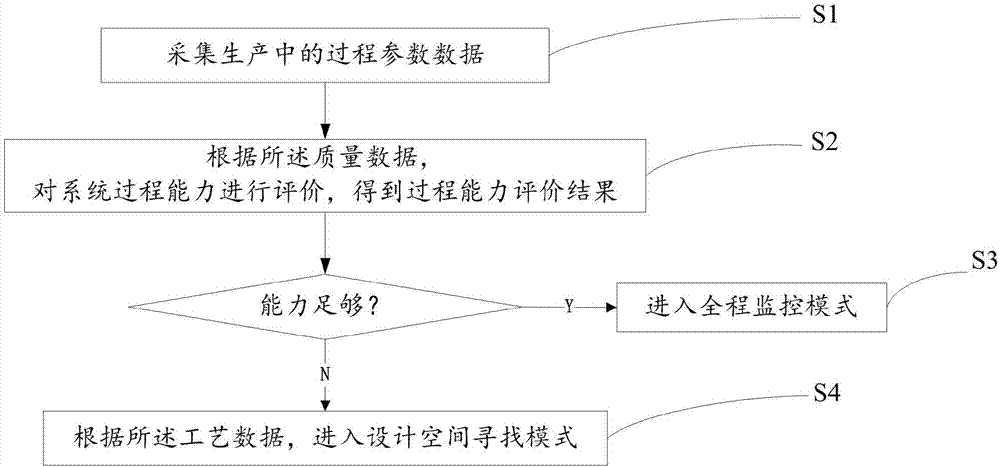

[0111] In one embodiment of the present invention, a kind of traditional Chinese medicine production process control method is provided, see figure 1 , the method includes the following processes:

[0112] S1. Collect process parameter data in production, where the process parameter includes quality data and process data.

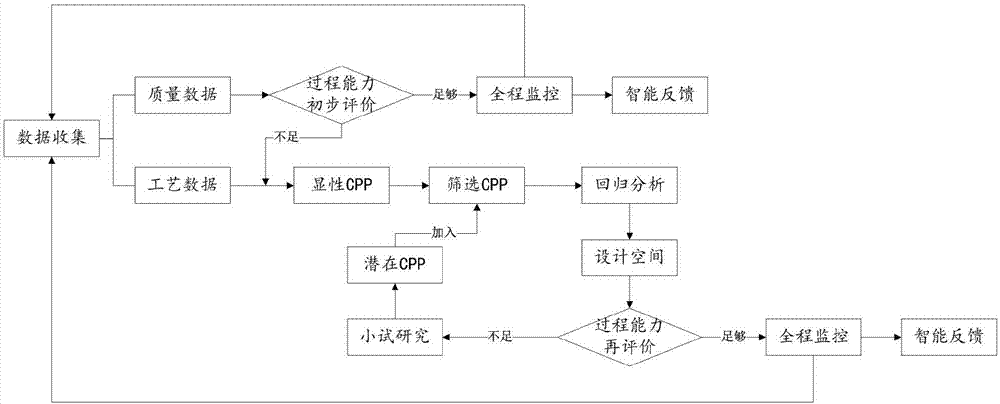

[0113] Specifically, the quality data is used as the data basis for system process capability evaluation, and the process data is used as the data basis for assisting in finding the design space, see figure 2 .

[0114] Wherein, the quality data is the performance parameter of the intermediate in the manufacturing process, and the type includes the content, transfer rate, purity, etc. of the index components of the intermediate.

[0115] S2. Evaluate the process capability of the system according to the quality data, and obtain a process capability evaluation result. If the process capability evaluation result is sufficient, execute S3; otherwise, execut...

Embodiment 2

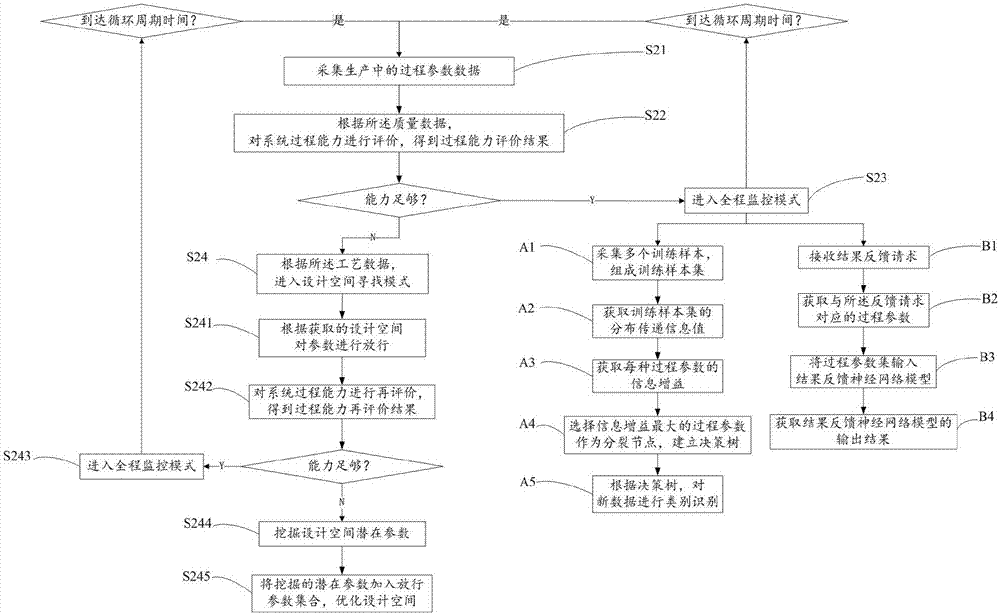

[0123] In one embodiment of the present invention, a kind of complete production control method of traditional Chinese medicine production process is provided, see figure 2 with image 3 , the method includes the following processes:

[0124]S21. Collect process parameter data in production, where the process parameter includes quality data and process data.

[0125] S22. Evaluate the process capability of the system according to the quality data, and obtain the process capability evaluation result. If the process capability evaluation result is sufficient, execute S23; otherwise, execute S24, which is the same as the first embodiment above.

[0126] S23. Enter the whole process monitoring mode.

[0127] On the one hand, as described in Embodiment 1, after entering the whole-process monitoring mode, real-time monitoring can be realized, including the following process:

[0128] A1. Collect multiple training samples to form a training sample set;

[0129] A2. Obtain the di...

Embodiment 3

[0196] In one embodiment of the present invention, a method for finding a design space is provided, see Figure 5 , the method includes the following processes:

[0197] S31. Obtain process data, the process data including the quality parameters of the intermediate in the previous section;

[0198] S32. Select the type of key quality attribute according to the production situation of the workshop;

[0199] S33. Screening process data related to the key quality attribute as a key process parameter;

[0200] S34. Establish a relationship model between the key process parameters and key quality attributes;

[0201] S35. Acquire a design space according to the relationship model, where the design space is a specific interval corresponding to the critical quality attribute.

[0202] Among them, the process of screening key process parameters is as follows:

[0203] In actual production, not all process parameters have analytical value, because in the actual production process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com