Method and device for monitoring pretreatment in low-dielectric-constant barrier layer process

A low dielectric constant, pretreatment technology, applied in circuits, electrical components, complex mathematical operations, etc., can solve the problems affecting the adhesion of the dielectric layer and the copper connection, affecting the reliability and stability of the product, and improve reliability. Effects on stability, failure prevention, and adhesion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments described here are for illustration only, and are not intended to limit the present invention.

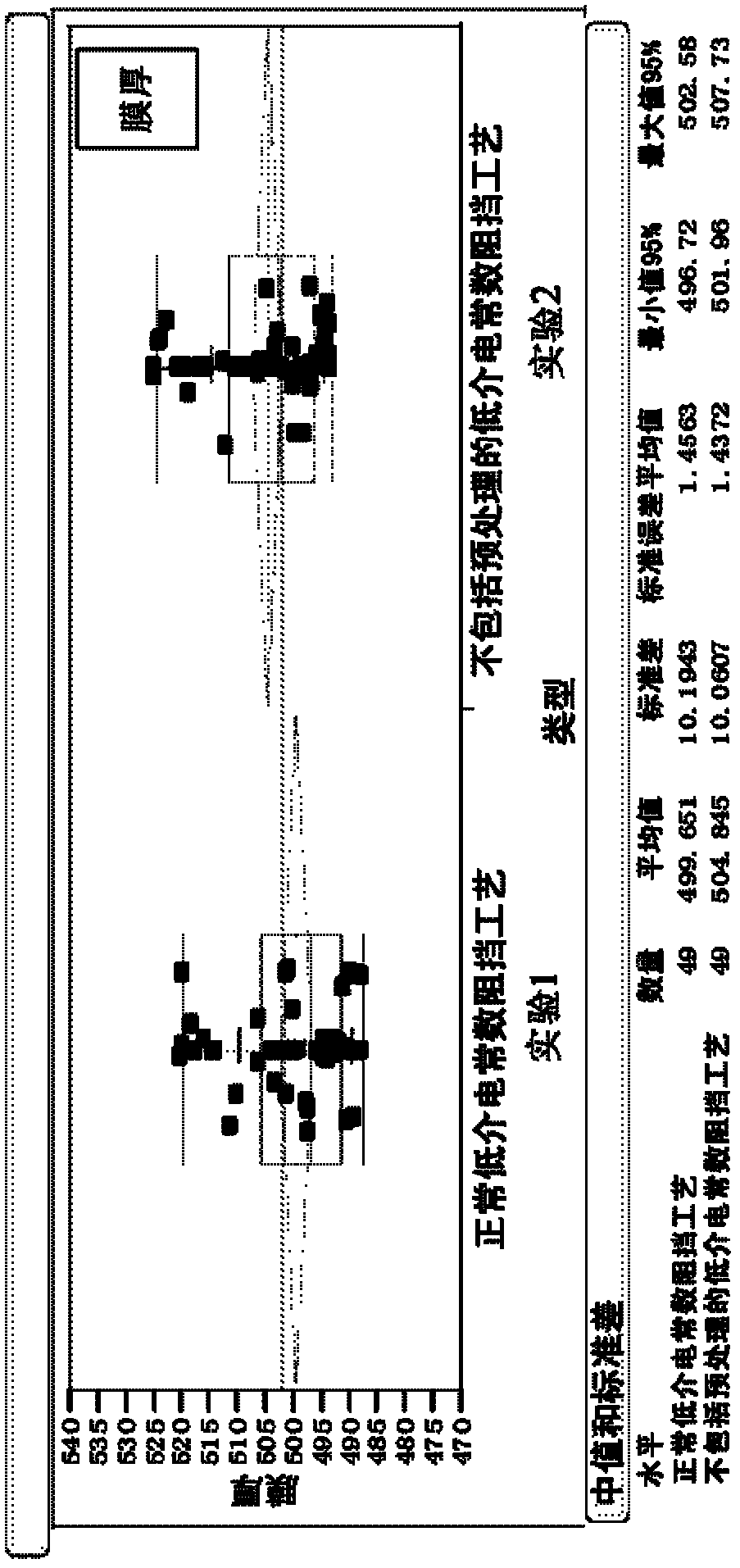

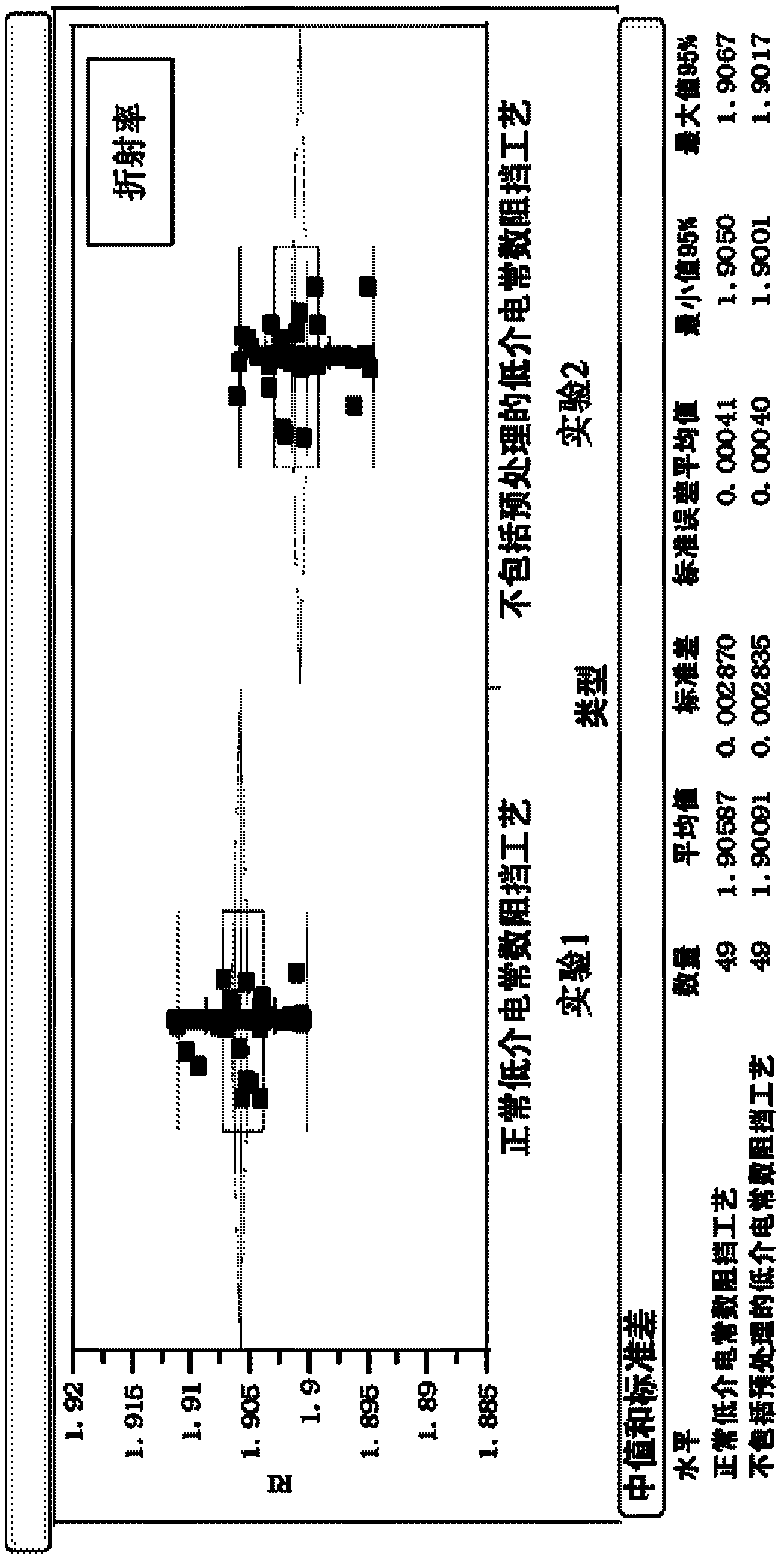

[0016] For traditional monitoring methods, see Table 1 below:

[0017]

[0018] Table 1

[0019] The monitoring method of the present invention has increased the monitoring of an independent pretreatment than traditional monitoring method, see following table 2:

[0020]

[0021] Table 2

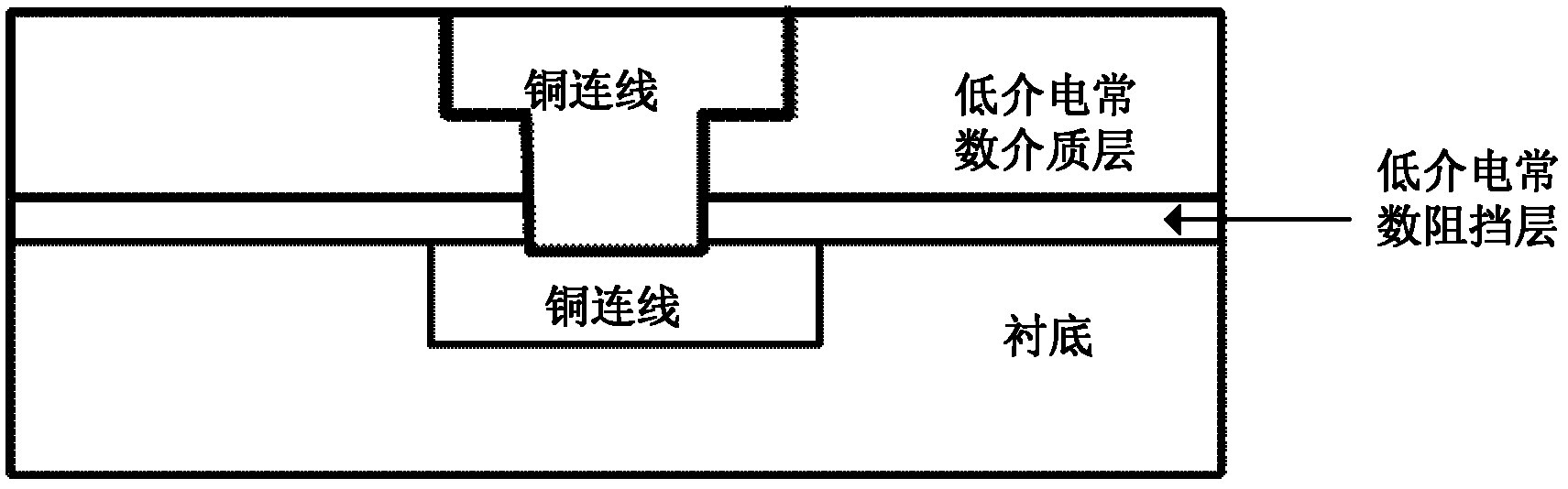

[0022] Comparing the present invention with the traditional monitoring method, the present invention provides a pretreatment monitoring method in the low dielectric constant barrier layer process. In detail, the present invention manufactures products (such as figure 1 In-process timing (e.g., 24 hours as a cycle) of the product shown) performs a separate pretreatment process on the wafer (silicon substrate) in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com