Patents

Literature

848results about "Gauges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

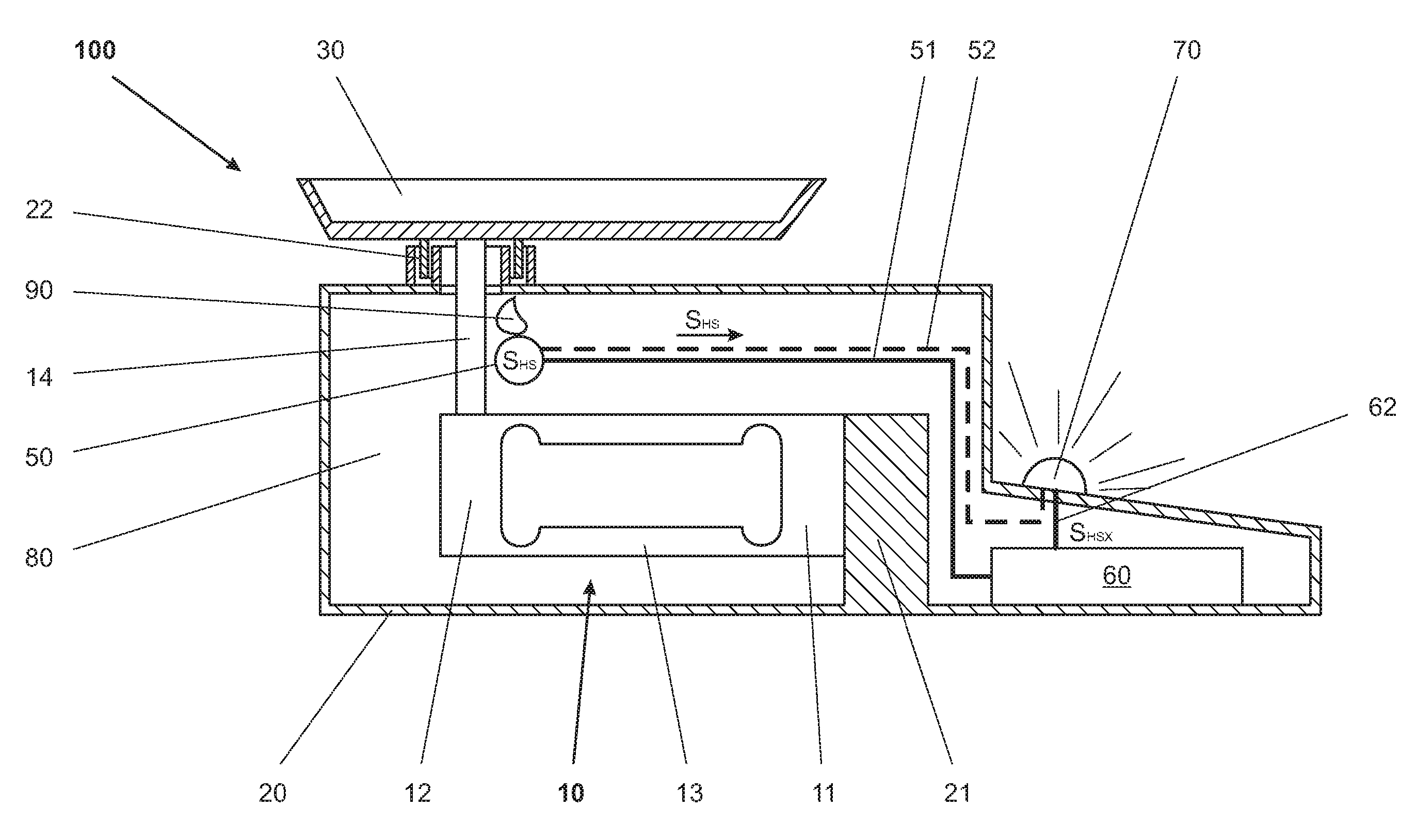

Method of monitoring and/or determining the condition of a force-measuring device, and force-measuring device

ActiveUS7497137B2Accurate calculationPlug gaugesWeighing apparatus testing/calibrationInterior spaceMeasurement device

In a method for monitoring and / or determining the condition of a force-measuring device with at least one housing that has an interior space and with at least one force-measuring cell installed in the interior space of the at least one housing, at least one parameter of the atmospheric climate of the interior space is measured with at least one sensor that is arranged in the interior space of the housing or with at least one sensor that is arranged at the housing, wherein said parameter is of a kind that has an influence on the operating lifetime of the force-measuring cell; and a sensor signal corresponding to the measured parameter of the atmospheric climate of the interior space is transmitted to a computing unit and / or to a data output device.

Owner:METTLER TOLEDO GMBH

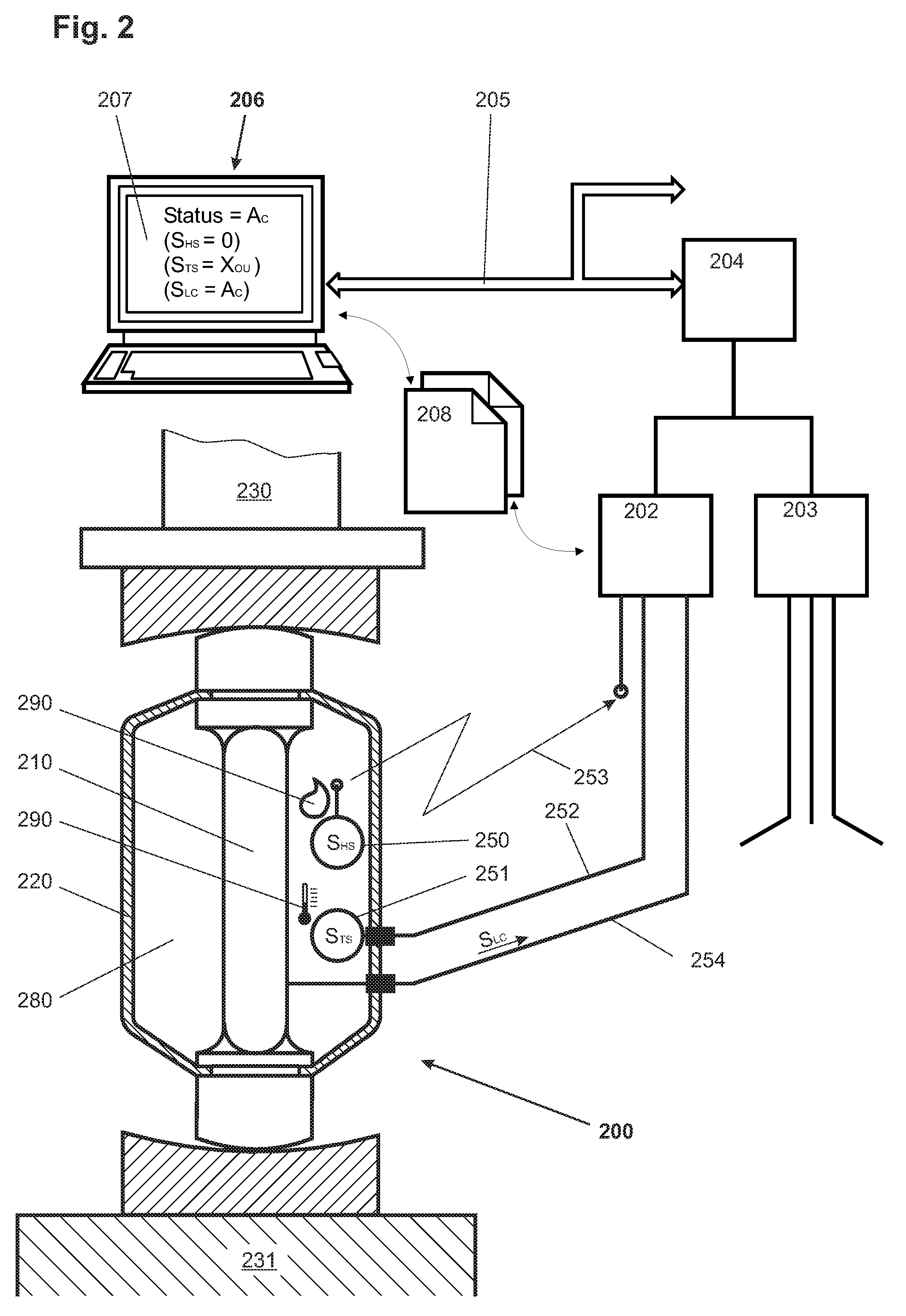

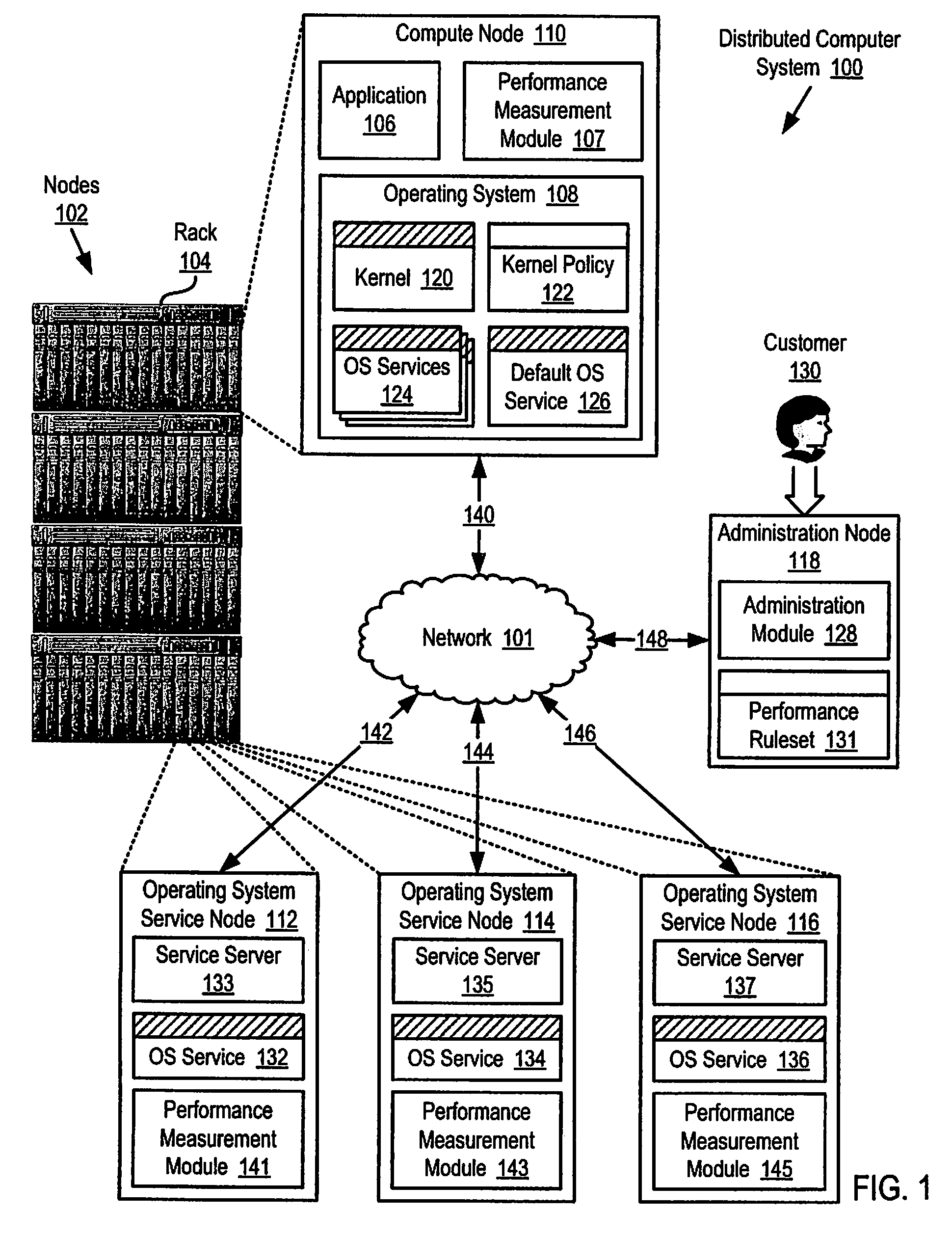

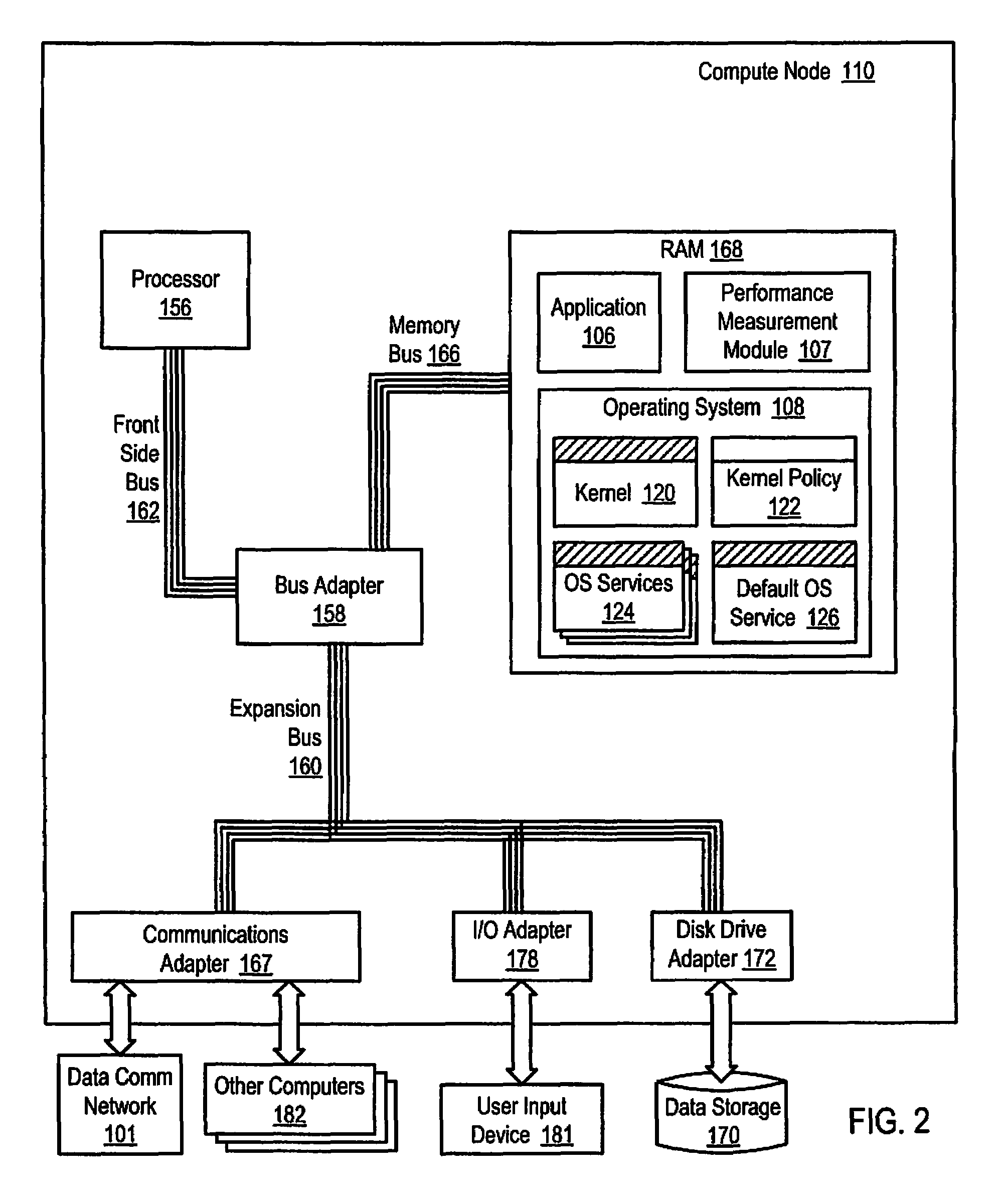

Providing policy-based operating system services in an operating system on a computing system

InactiveUS7634388B2Plug gaugesMeasurement arrangements for variableOperational systemOperating system

Methods, apparatus, products are disclosed for providing policy-based operating system services in an operating system on a computing system. The computing system includes at least one compute node. The compute node includes an operating system. The operating system includes a kernel and a plurality of operating system services of a service type. Providing policy-based operating system services in an operating system on a computing system includes establishing, on the compute node, a kernel policy specifying one of the operating system services of the service type for use by the kernel in the operating system, establishing a performance ruleset, the performance ruleset specifying rules for analyzing the performance of the computing system, measuring performance of the computing system, and adjusting the kernel policy in dependence upon the performance ruleset and the measured performance.

Owner:IBM CORP

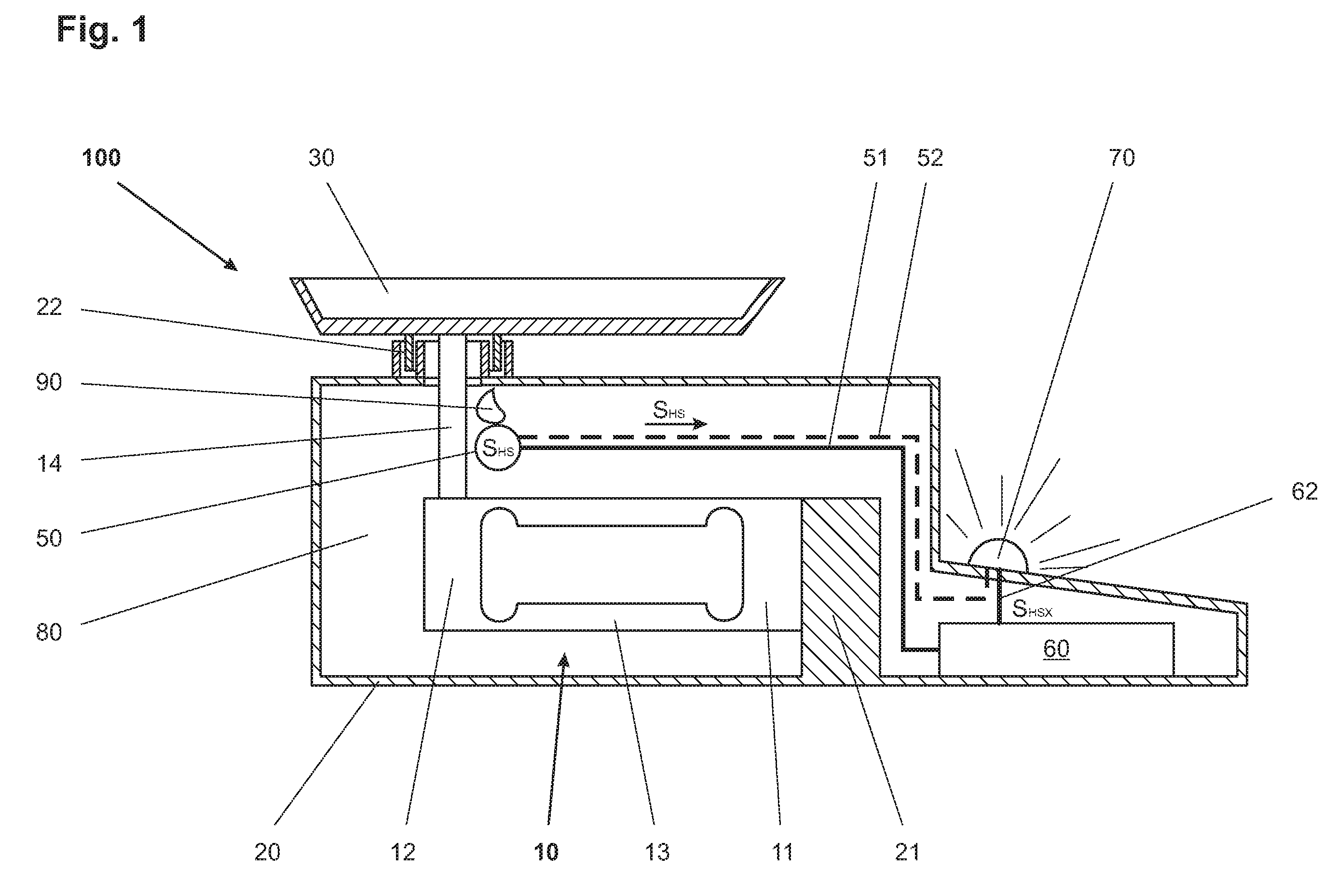

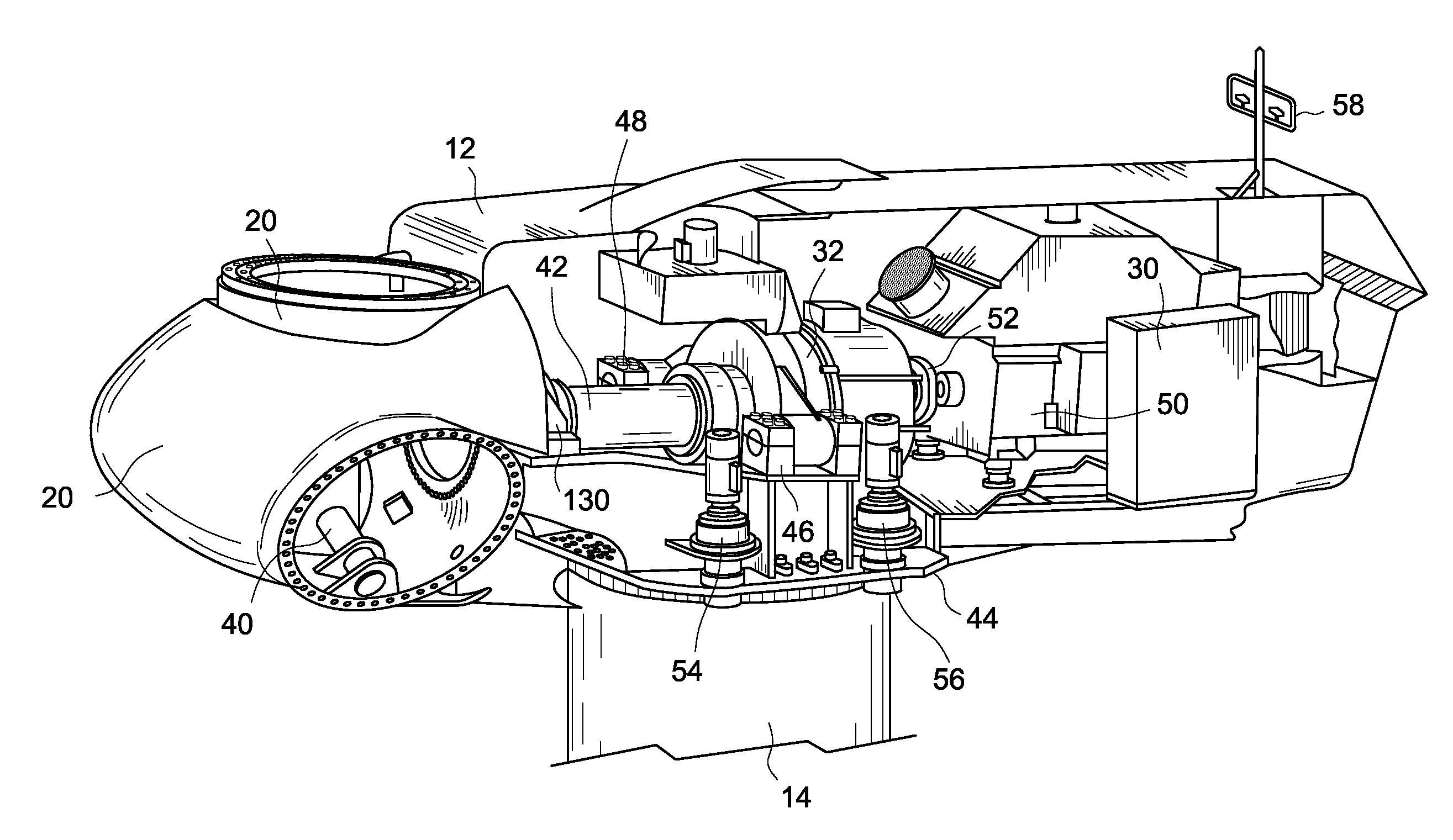

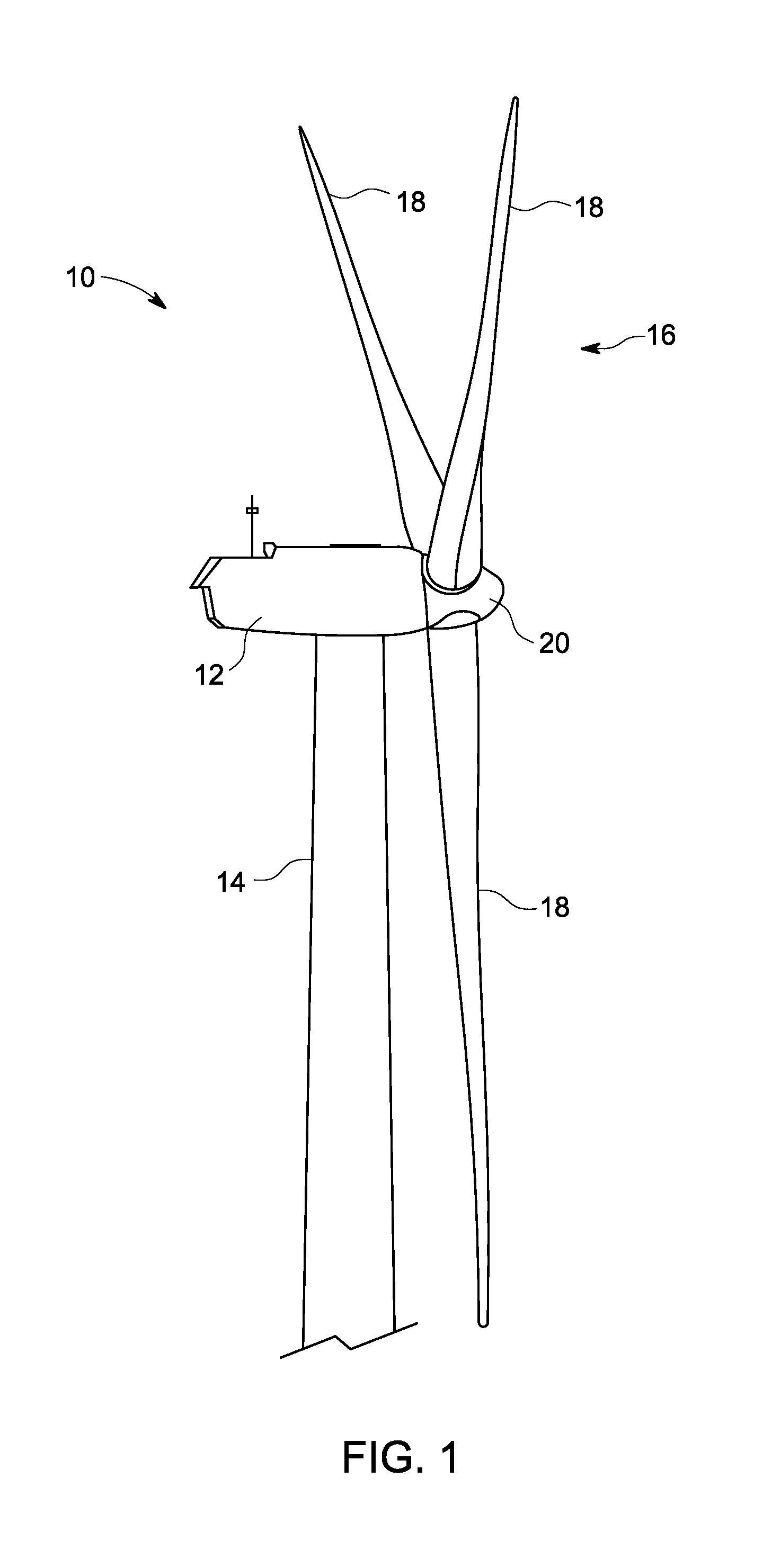

System and method for monitoring wind turbine gearbox health and performance

A system and method are provided to monitor the health and performance of a wind turbine gearbox. A plurality of sensors coupled to the wind turbine gearbox provide input to a controller. The controller generates output information that includes performance and health information of the wind turbine gearbox based on the input received from each of the sensors.

Owner:GENERAL ELECTRIC CO

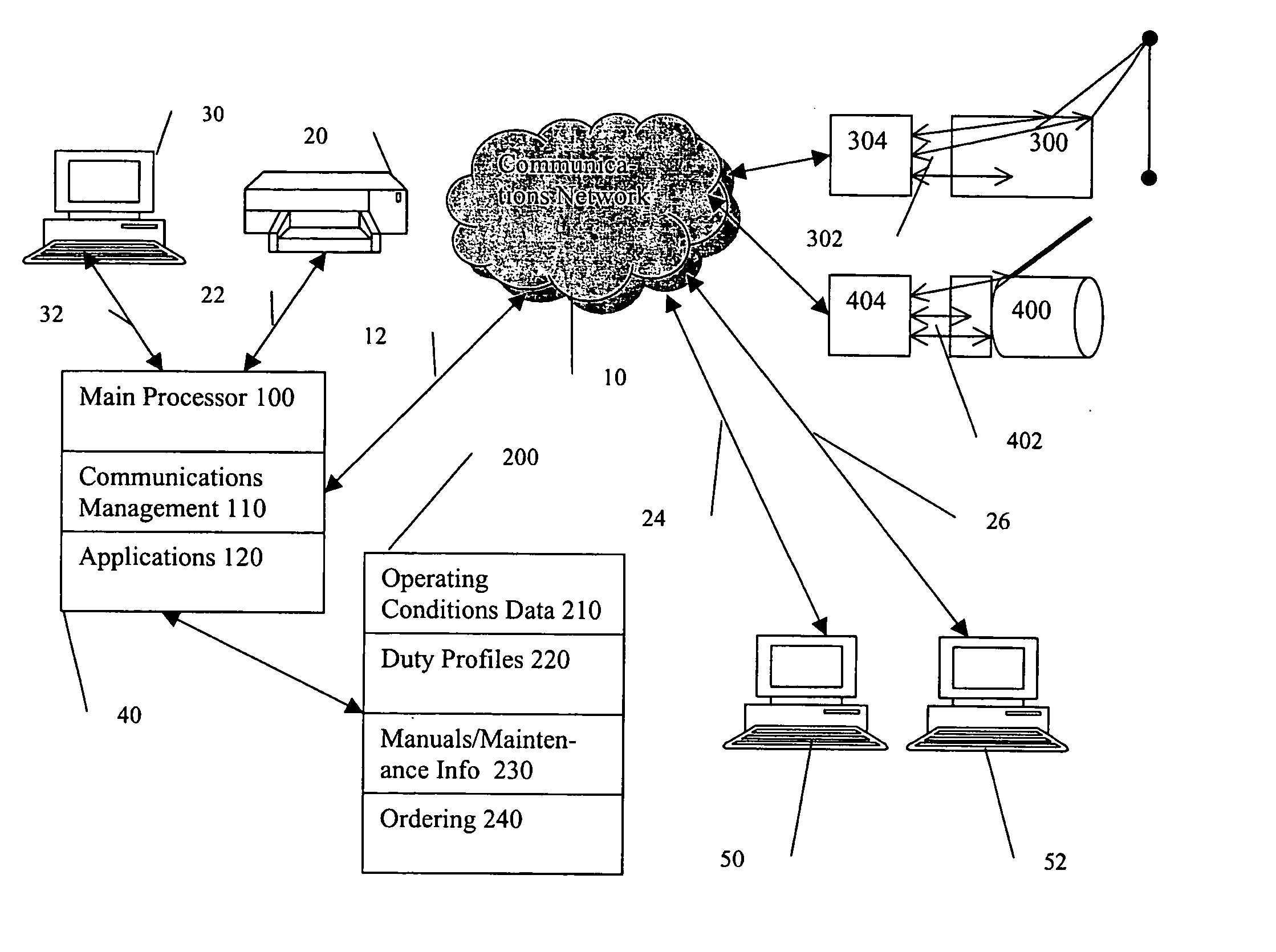

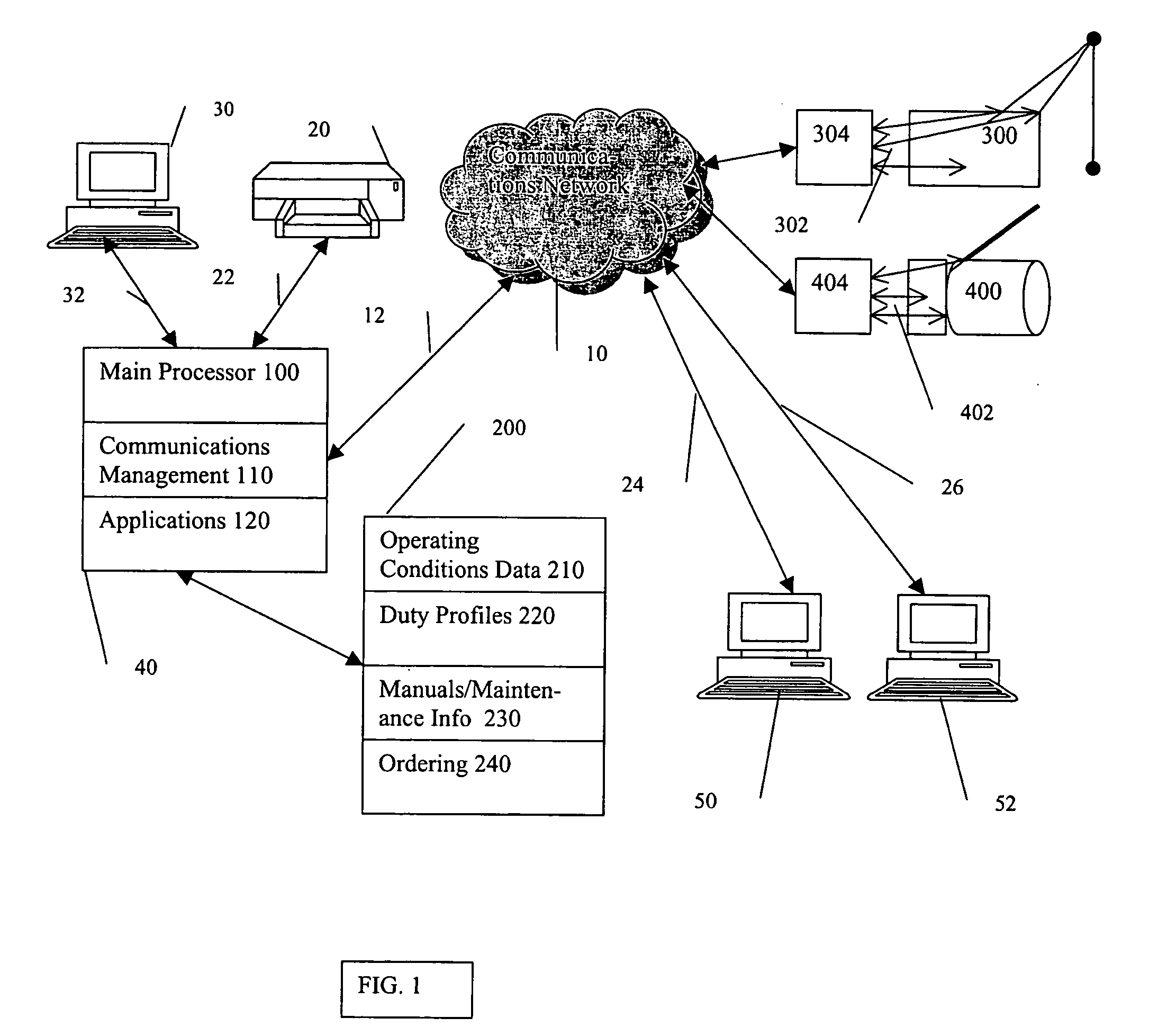

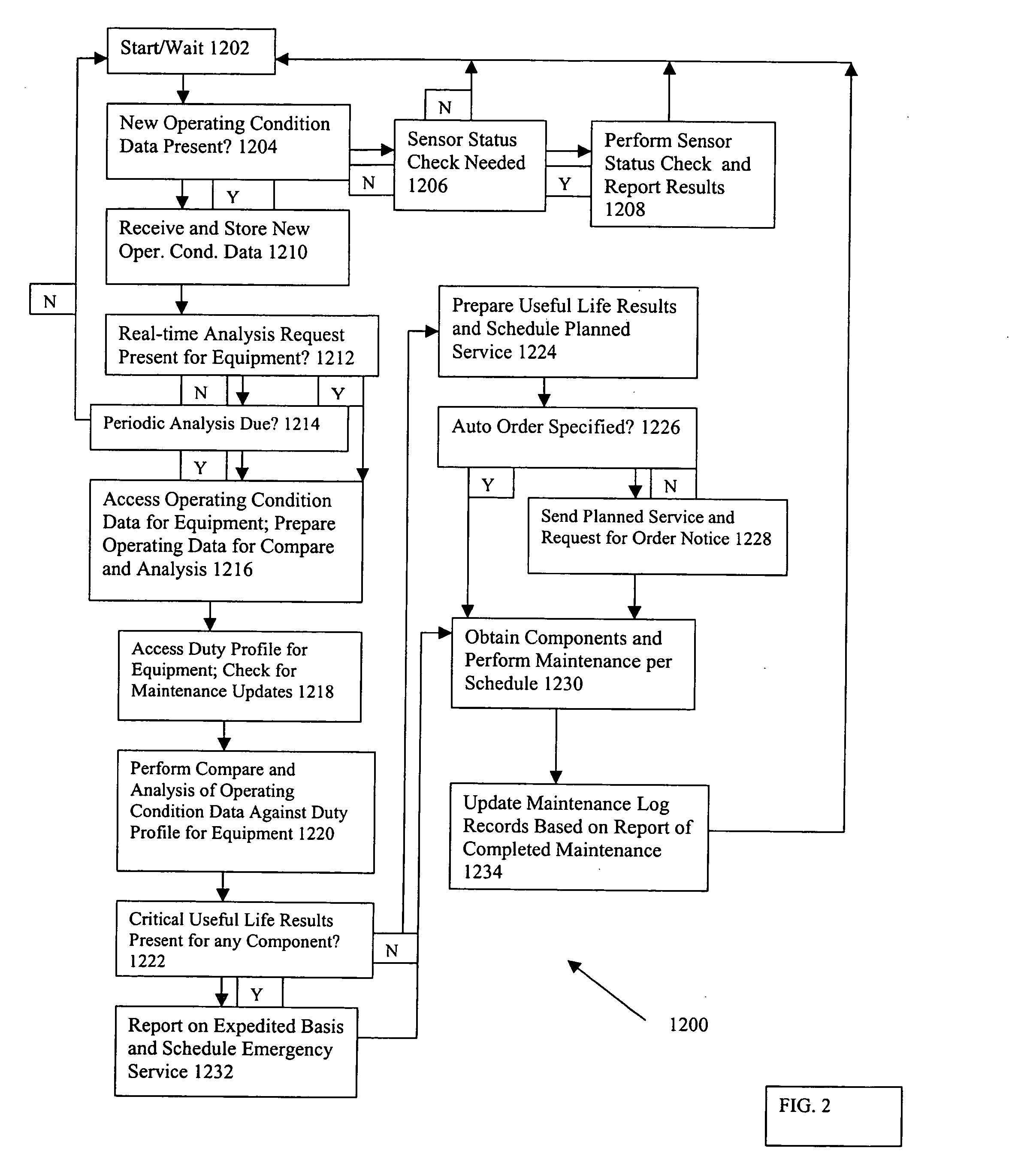

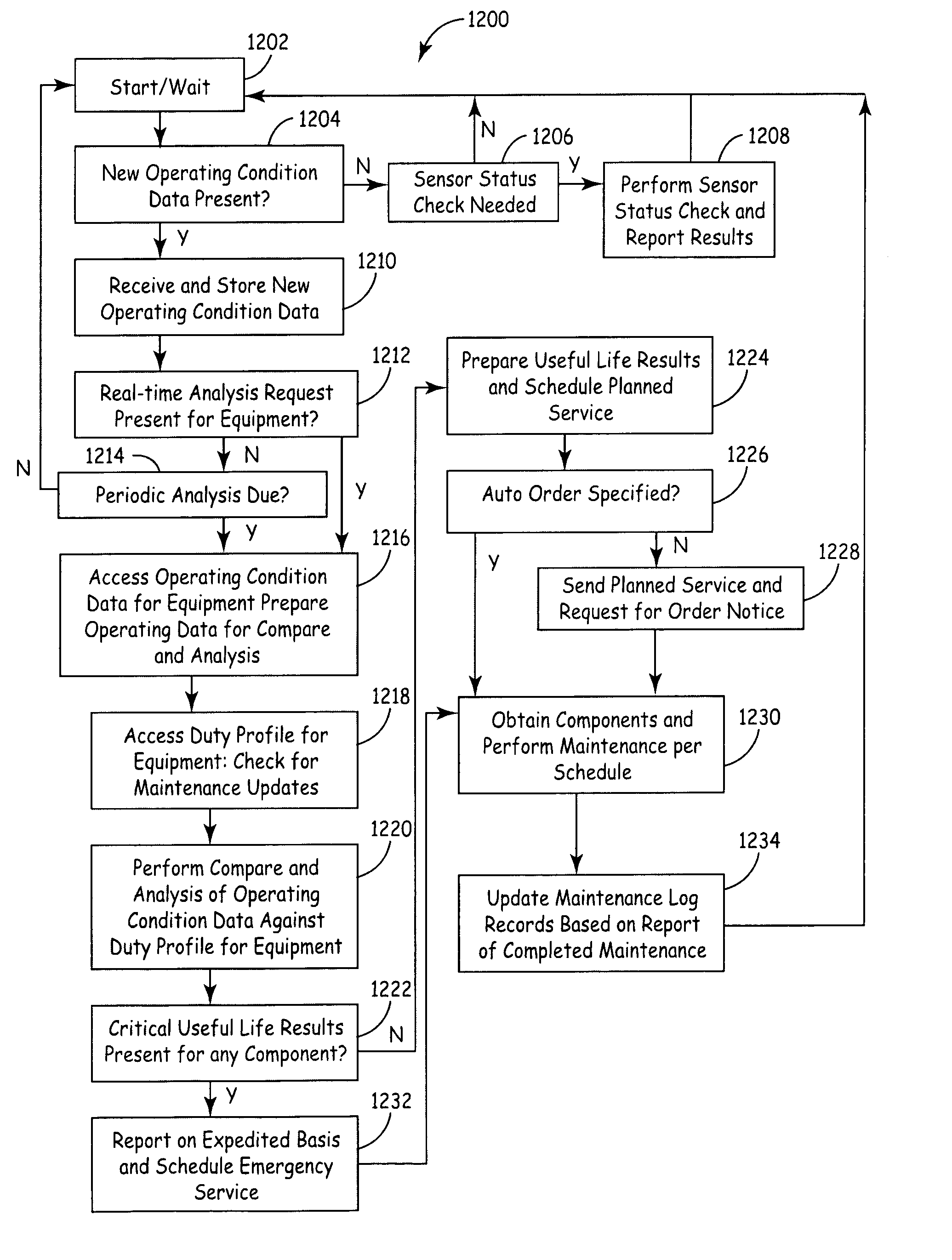

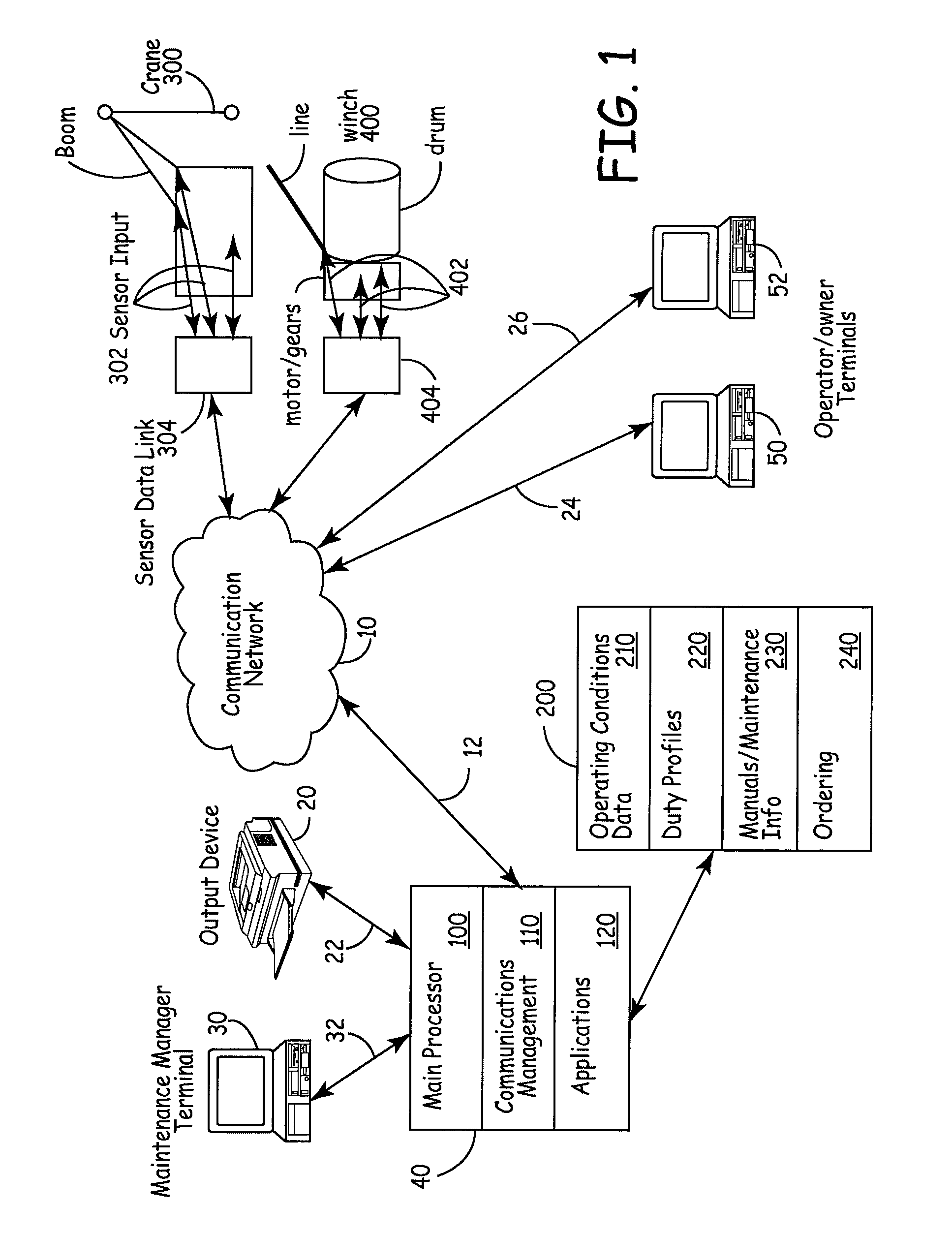

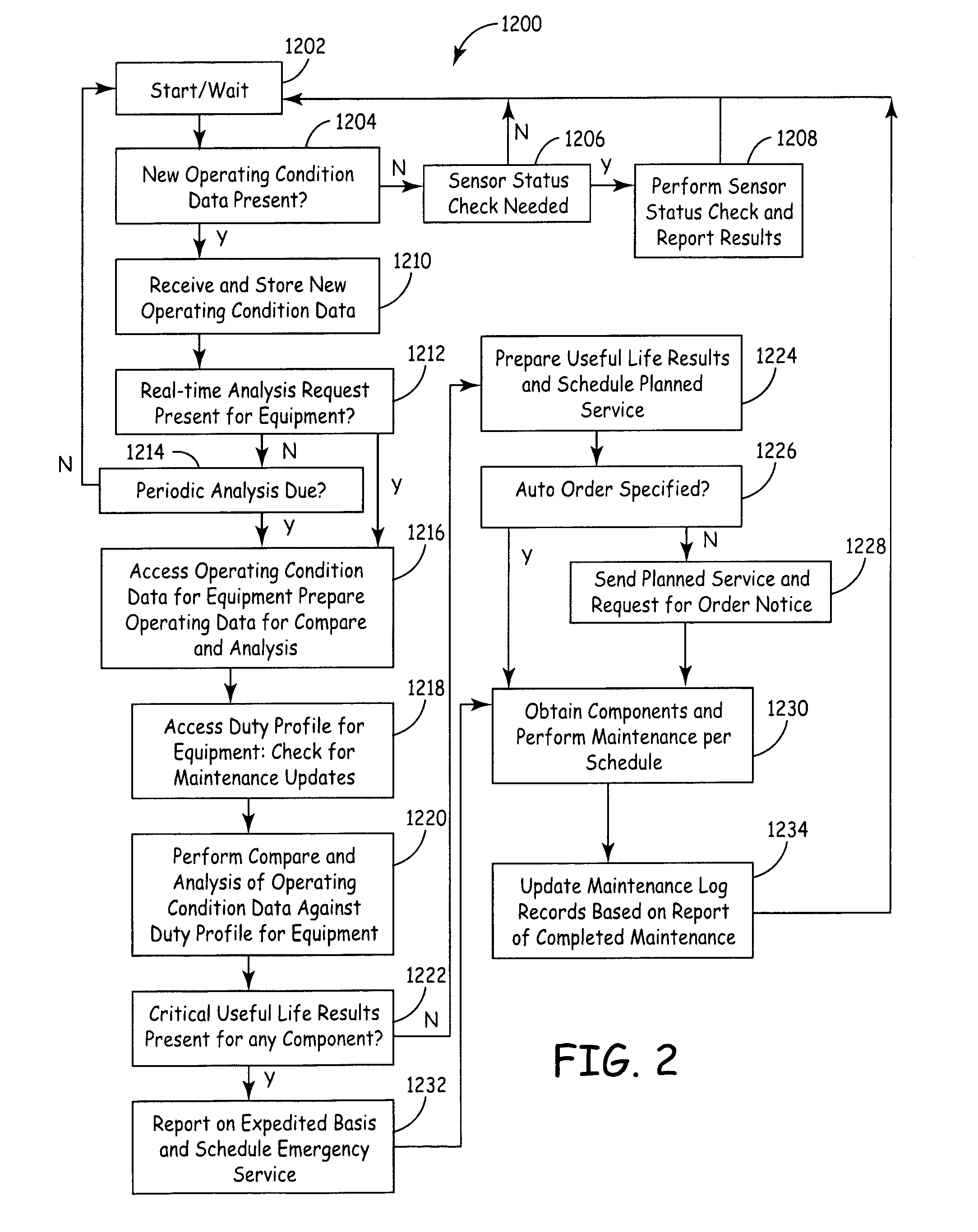

Equipment component monitoring and replacement management system

ActiveUS20050143956A1Improve performanceGood interpretationPlug gaugesMachine part testingComputer scienceOperant conditioning

A system for managing replacement components for equipment having a plurality of components each with a limited useful life has a computer with a processor. The system includes a computer program module for defining a duty profile comprising a plurality of usage cases for the equipment, each usage case involving two or more of the plurality of components and specified operating conditions assumed to be experienced by the involved components during the execution of each of the usage cases. There are also a computer program module for determining a theoretical useful life for each component involved in a duty profile, the theoretical useful life being based on component useful life data under the specified operating conditions; and sensors for determining and monitoring the occurrence of equipment operation corresponding to a usage case and measuring the actual operating conditions experienced in the operation and the number of such operations. A further computer program module computes an adjusted theoretical useful life for a component that has experienced one or more operations, based on a comparison of actual operating conditions to operating conditions assumed to be experienced in the operation of the usage case.

Owner:HYDRALIFT AMCLYDE INC

Component Adaptive Life Management

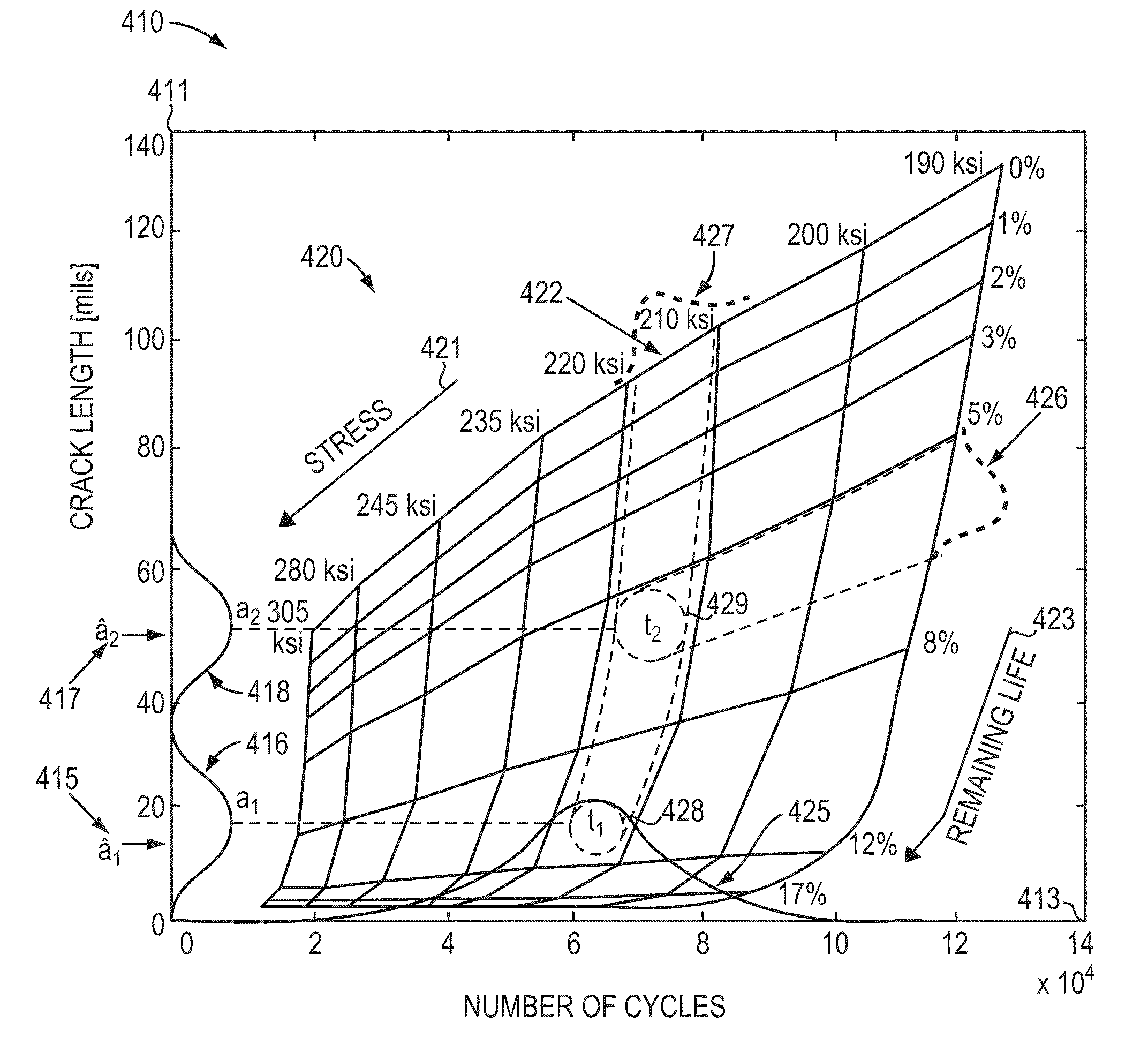

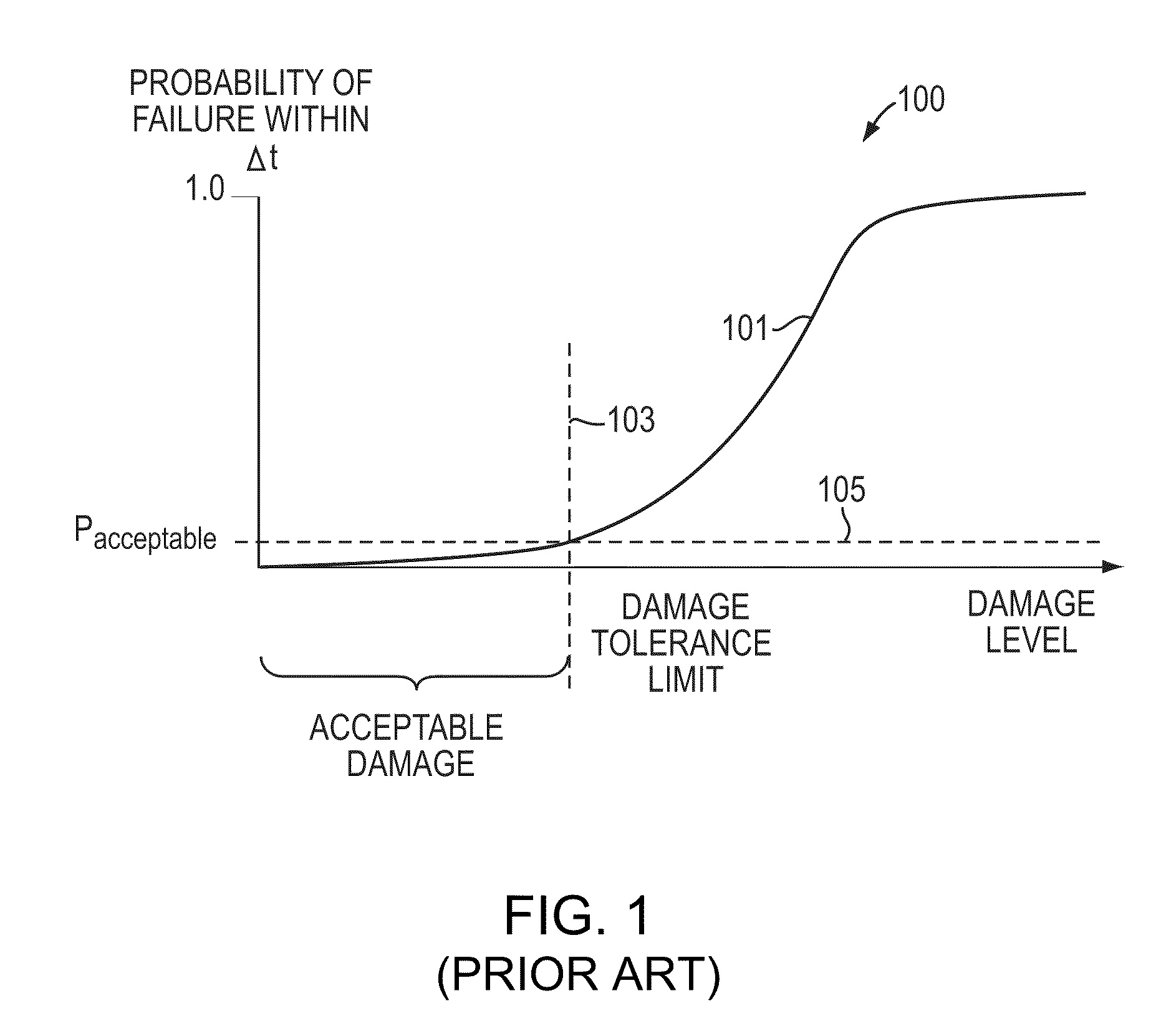

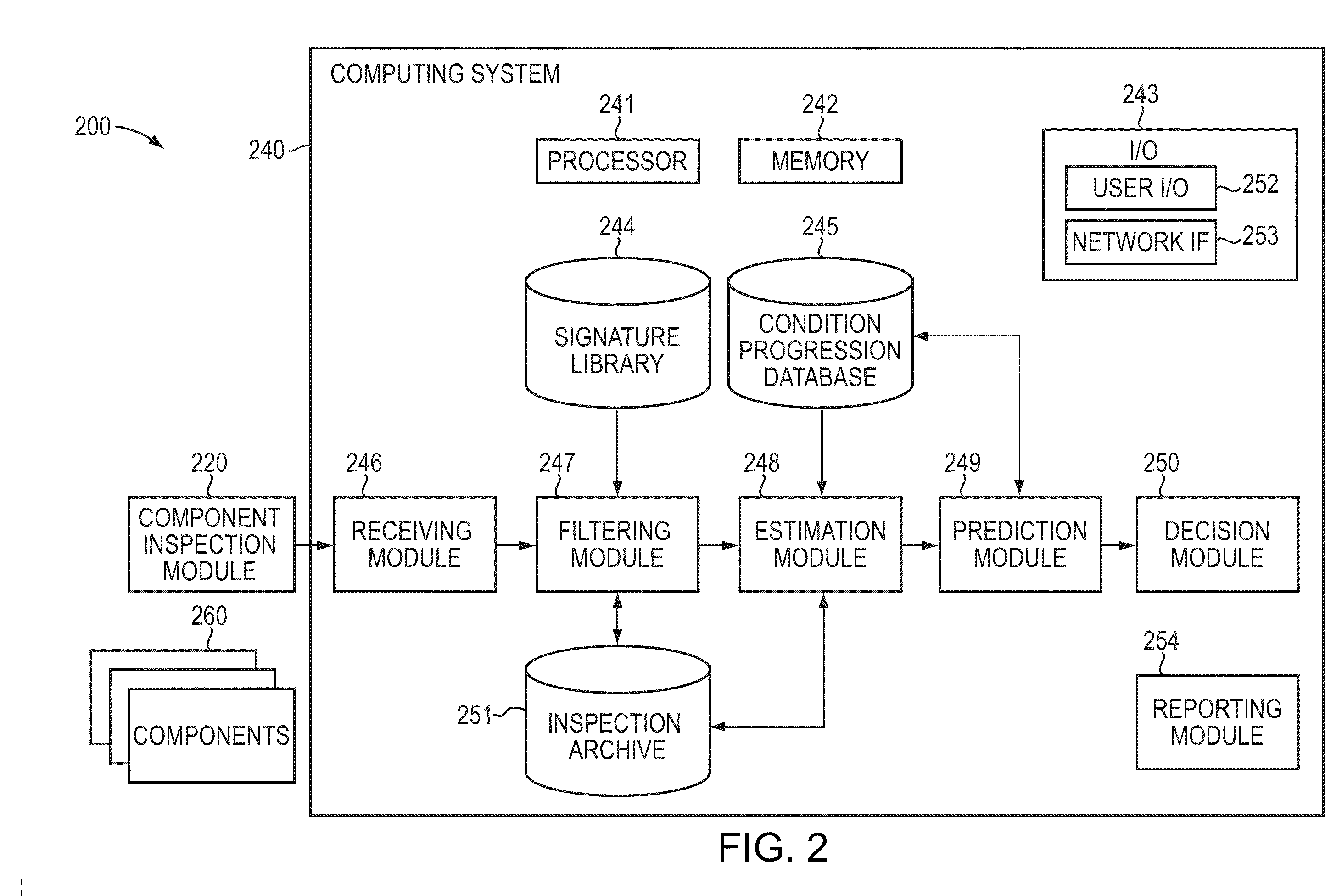

ActiveUS20110060568A1Plug gaugesRegistering/indicating working of machinesNon destructiveStress level

A framework for adaptively managing the life of components. A sensor provides non-destructive test data obtained from inspecting a component. The inspection data may be filtered using reference signatures and by subtracting a baseline. The filtered inspection data and other inspection data for the component is analyzed to locate flaws and estimate the current condition of the component. The current condition may then be used to predict the component's condition at a future time or to predict a future time at which the component's condition will have deteriorated to a certain level. A current condition may be input to a precomputed database to look up the future condition or time. The future condition or time is described by a probability distribution which may be used to assess the risk of component failure. The assessed risk may be used to determine whether the part should continue in service, be replaced or repaired. A hyperlattice database is used with a rapid searching method to estimate at least one material condition and one usage parameter, such as stress level for the component. The hyperlattice is also used to rapidly predict future condition, associated uncertainty and risk of failure.

Owner:JENTEK SENSORS

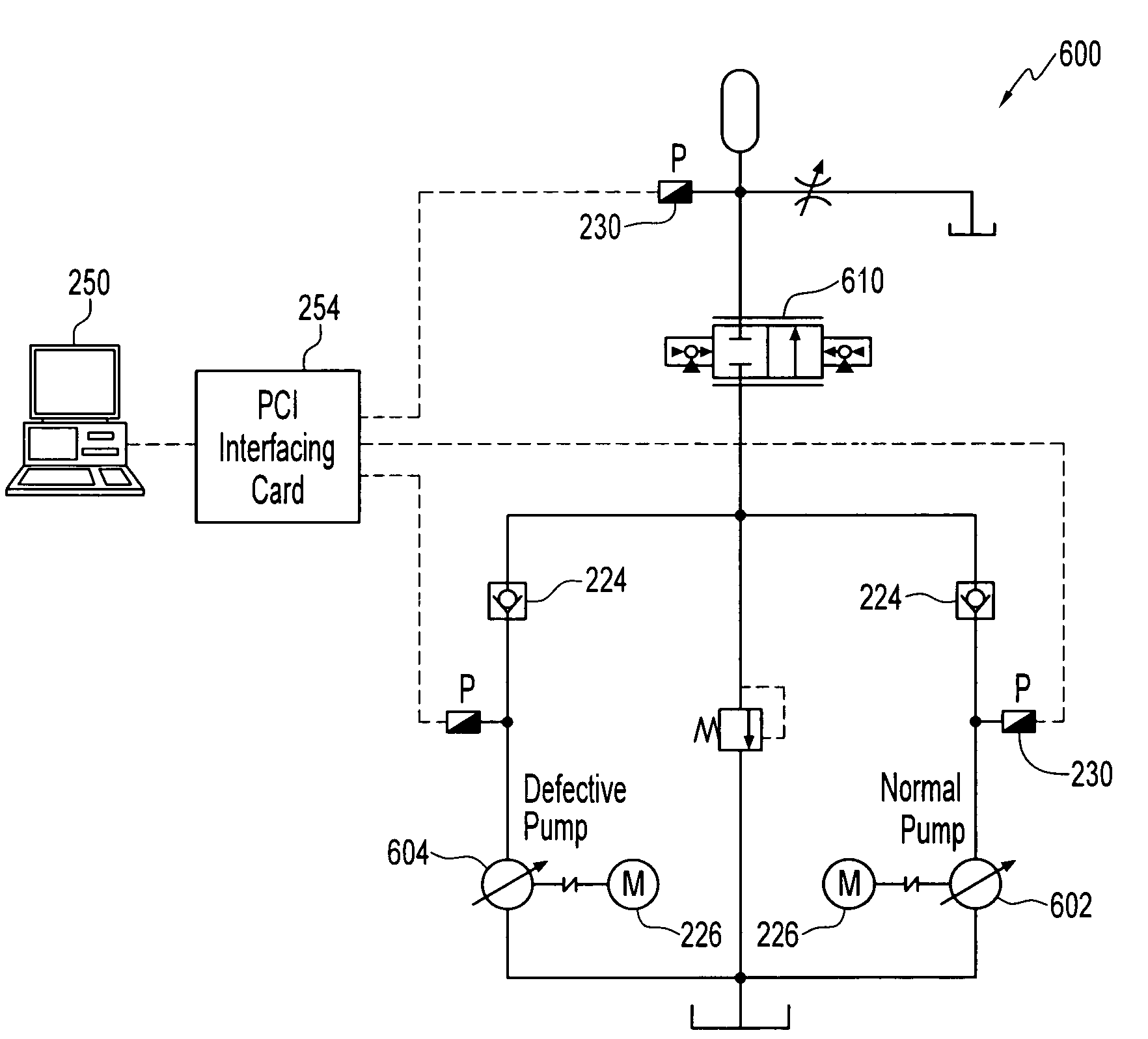

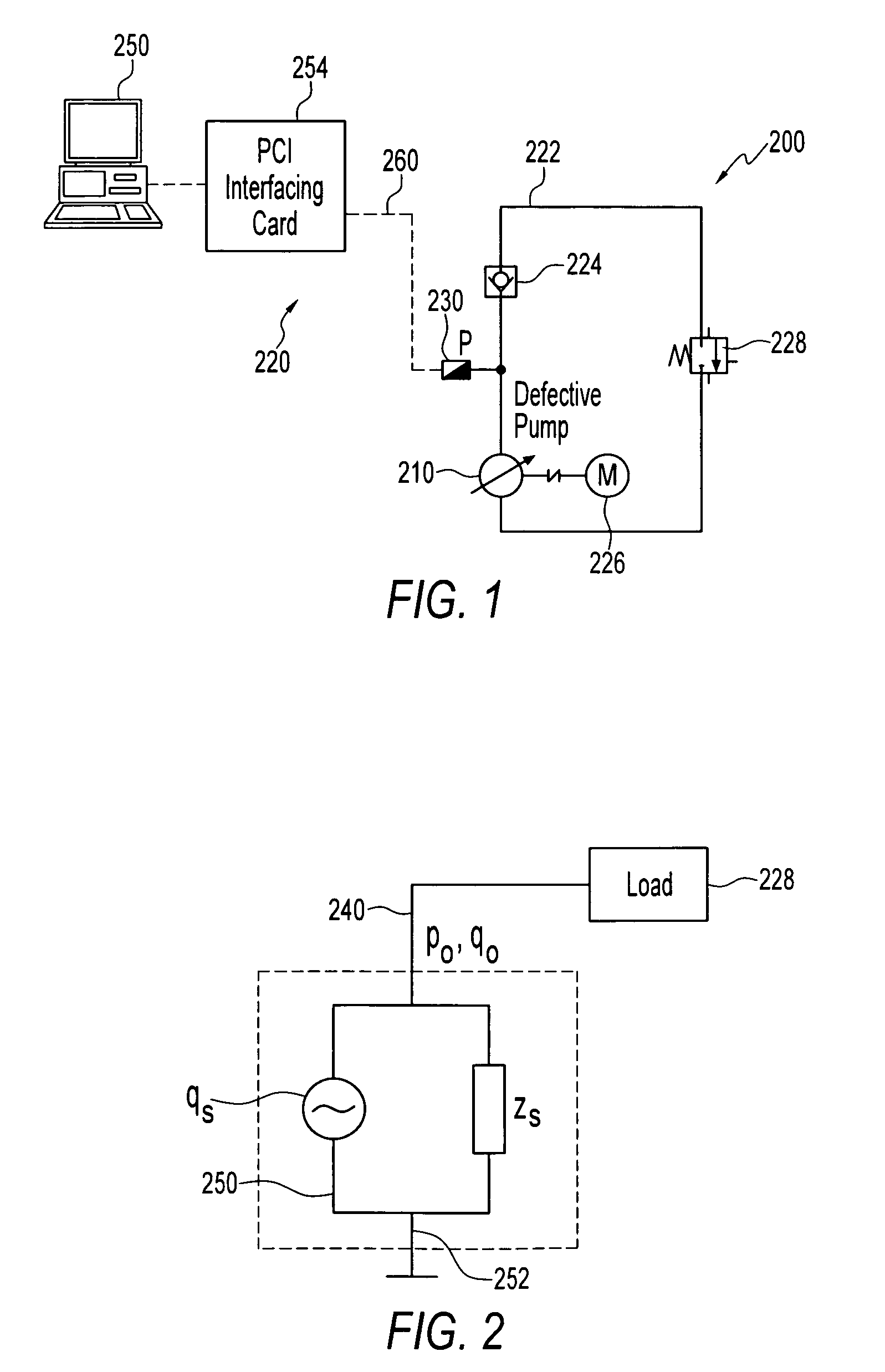

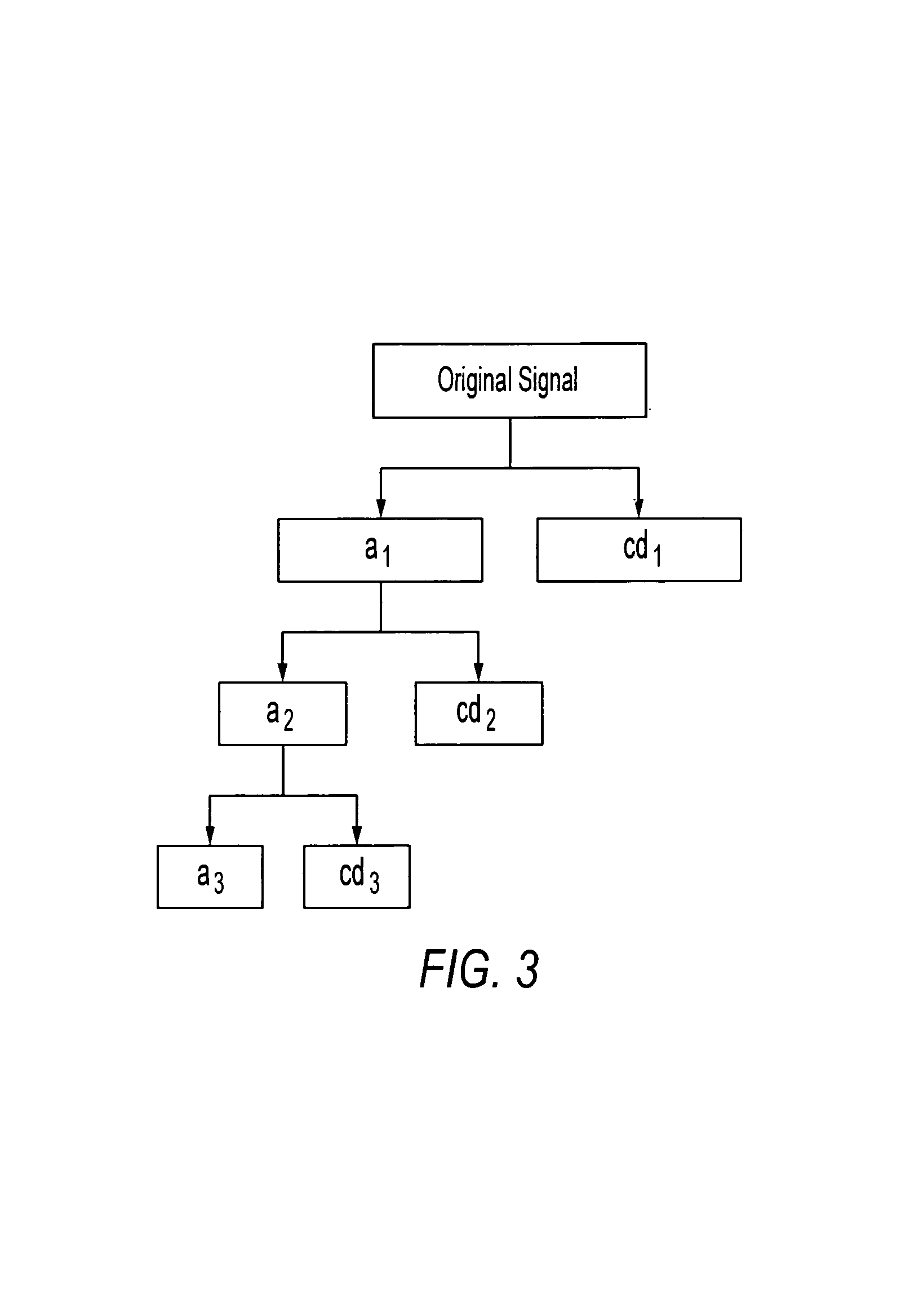

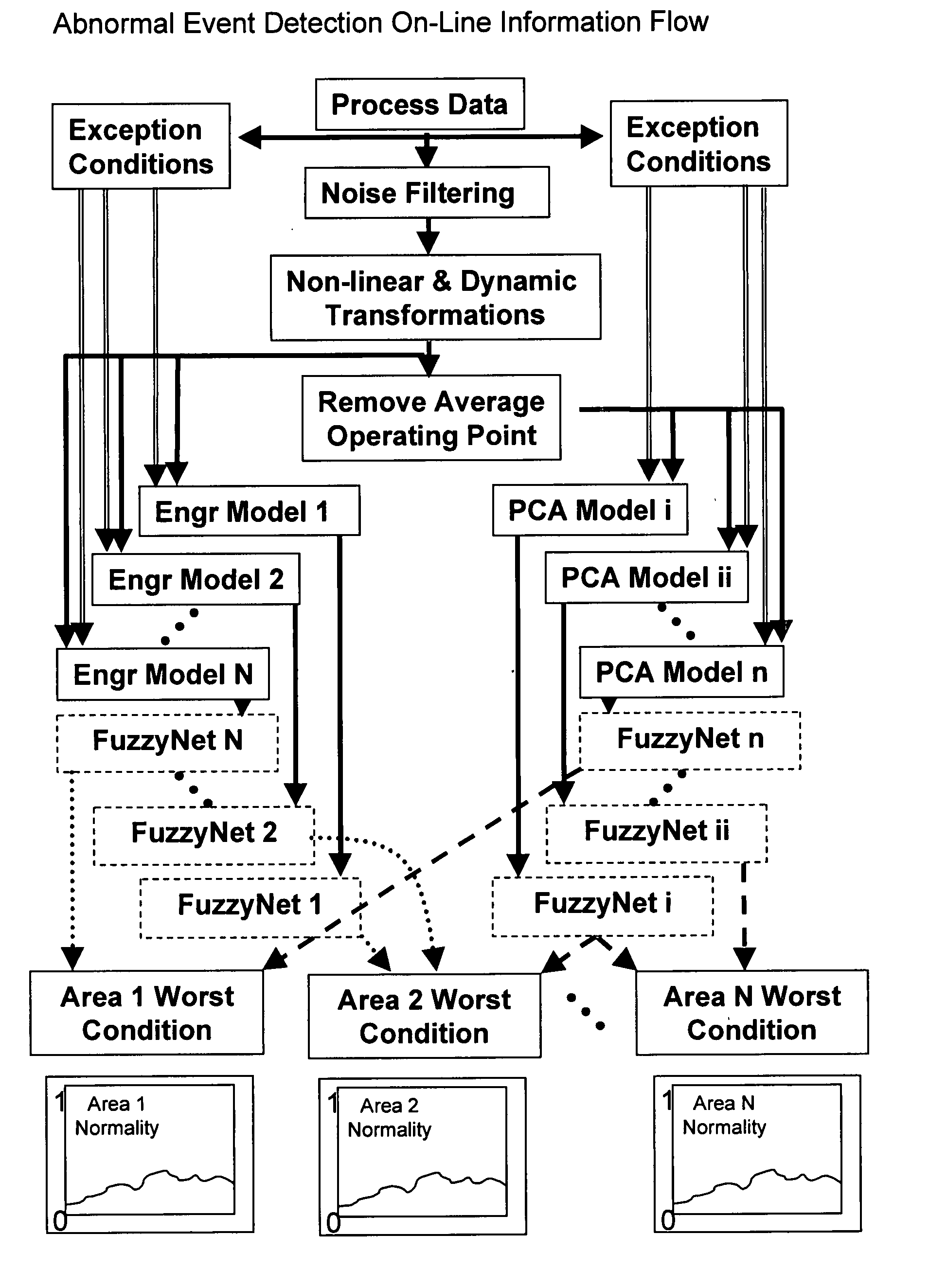

Method and apparatus for analyzing performance of a hydraulic pump

A method and apparatus for analyzing a hydraulic pump in real-time. A pressure signal is provided representing a discharge pressure of the hydraulic pump, and the pressure signal is decomposed into a plurality of levels. Each of the plurality of levels has at least one frequency band. A feature pressure signal is located in at least one of the frequency bands and compared to a reference wavelet to determine if a fault exists in the hydraulic pump and / or a type of defect in the hydraulic pump.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

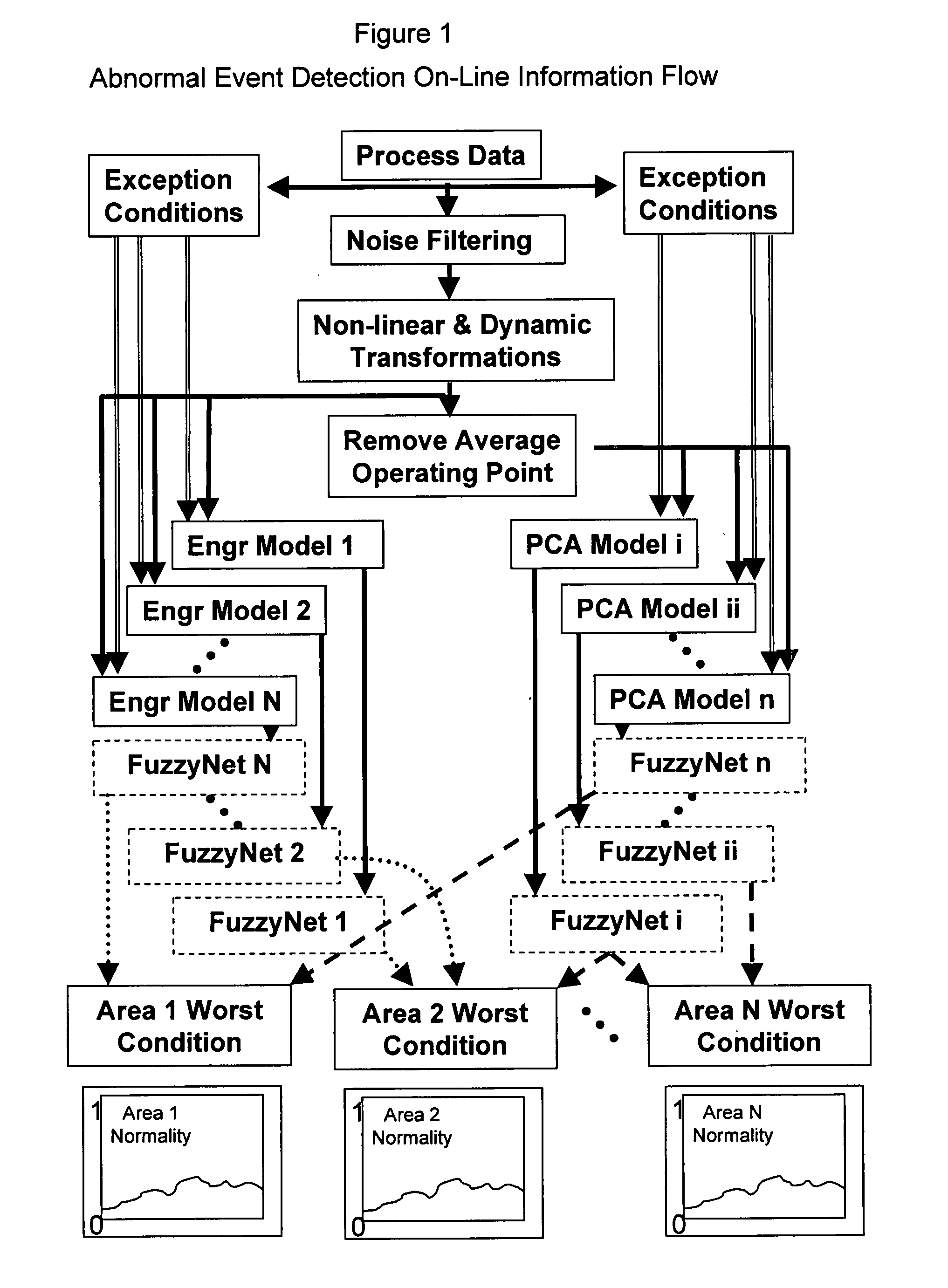

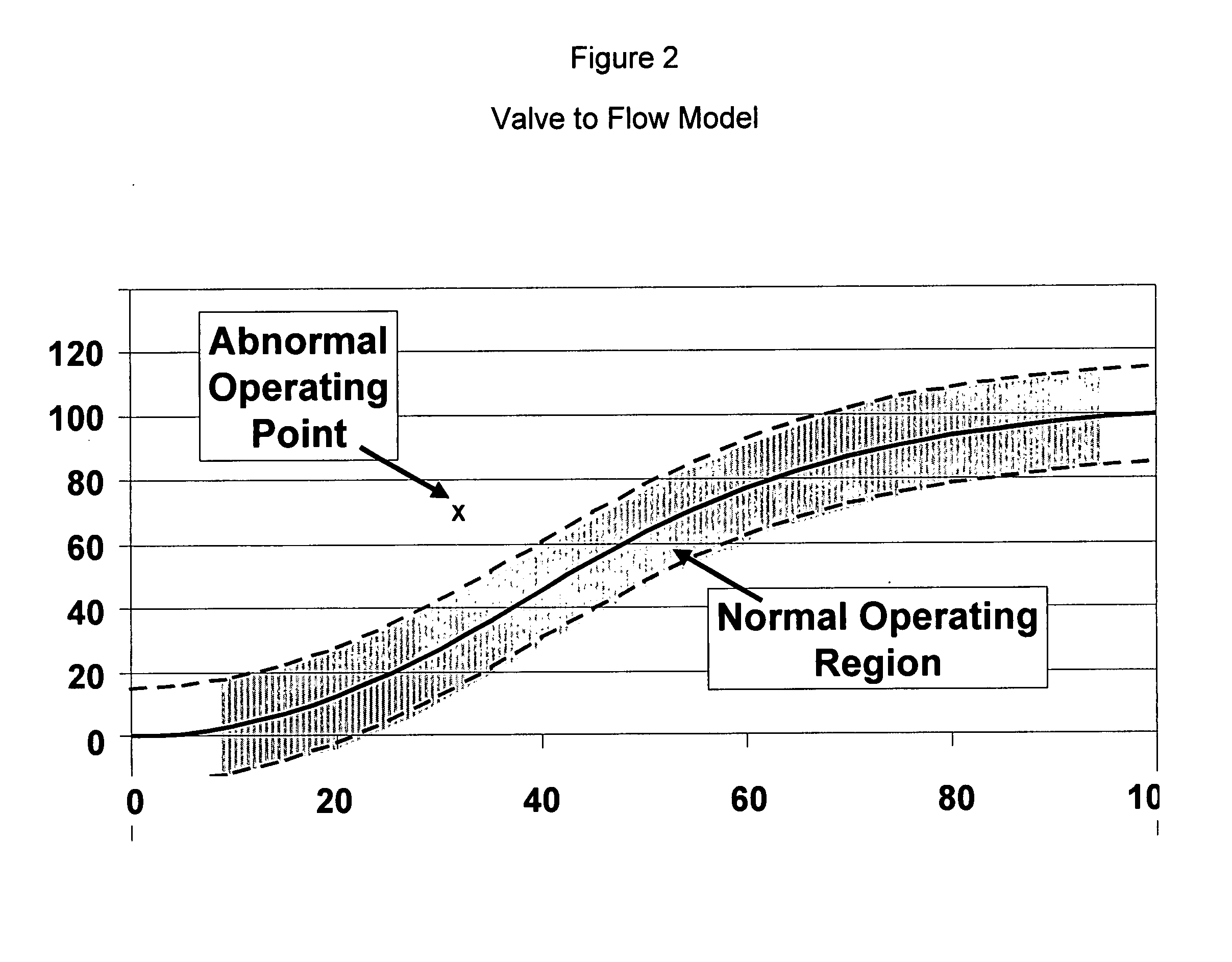

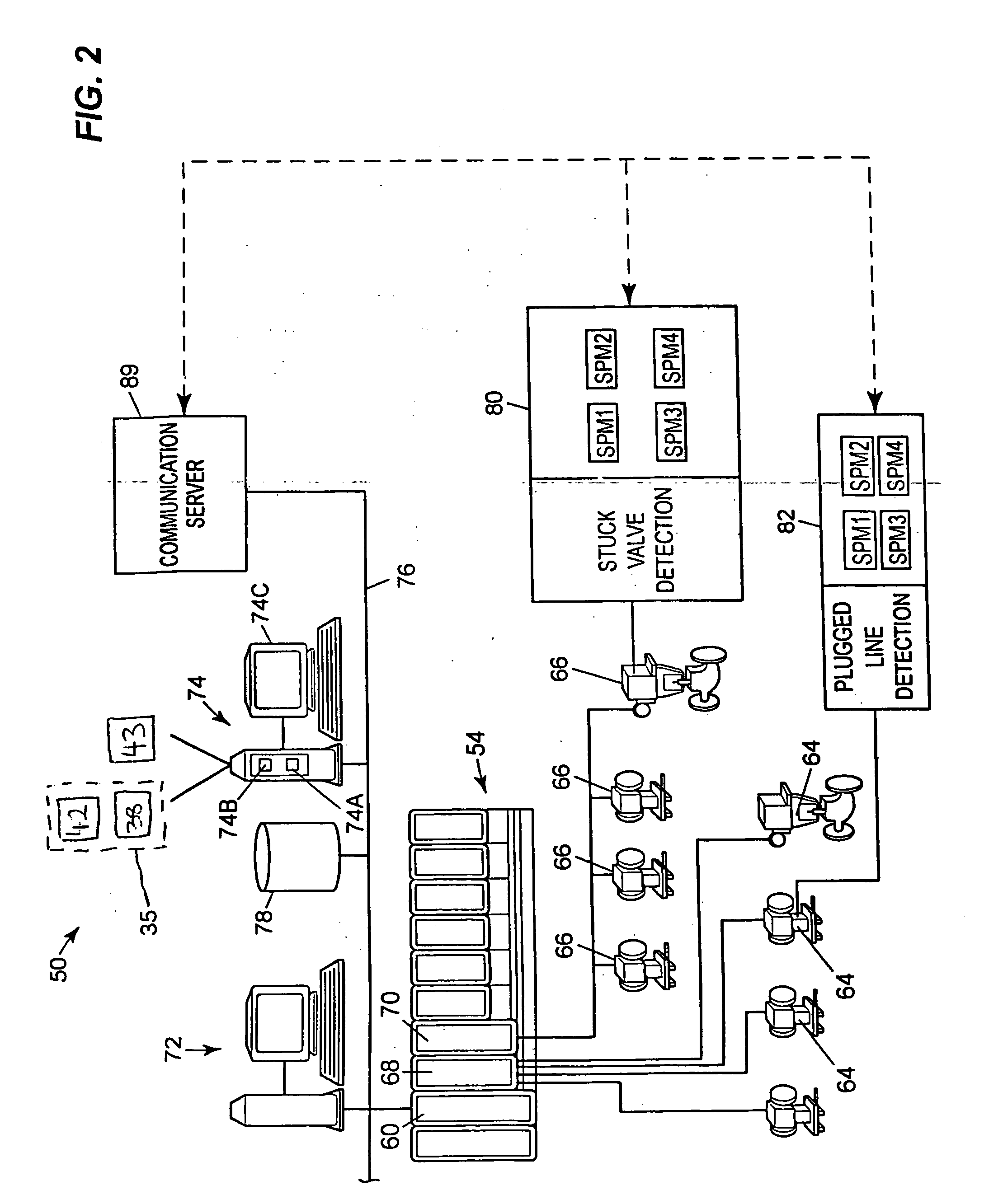

Application of abnormal event detection technology to delayed coking unit

ActiveUS20070250292A1Efficiently presentedPlug gaugesMeasurement arrangements for variablePrincipal component analysisCorrelation analysis

The present invention is a method for detecting an abnormal event for process units of a Delayed Coking Unit. The method compares the operation of the process units to statistical and engineering models. The statistical models are developed by principal components analysis of the normal operation for these units. The engineering models are based statistical and correlation analysis between variables. If the difference between the operation of a process unit and the normal model result indicates an abnormal condition, then the cause of the abnormal condition is determined and corrected.

Owner:EXXON RES & ENG CO

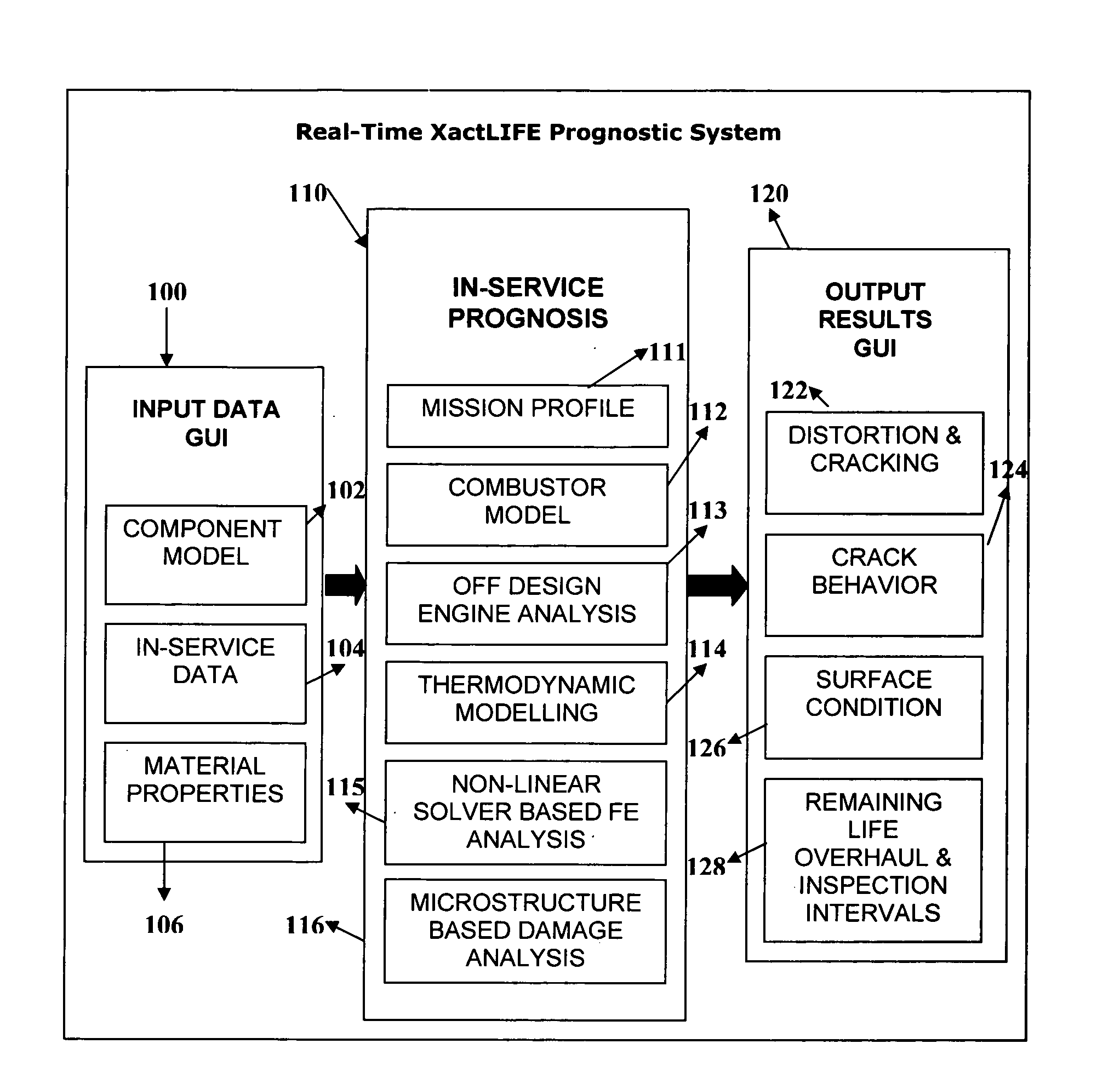

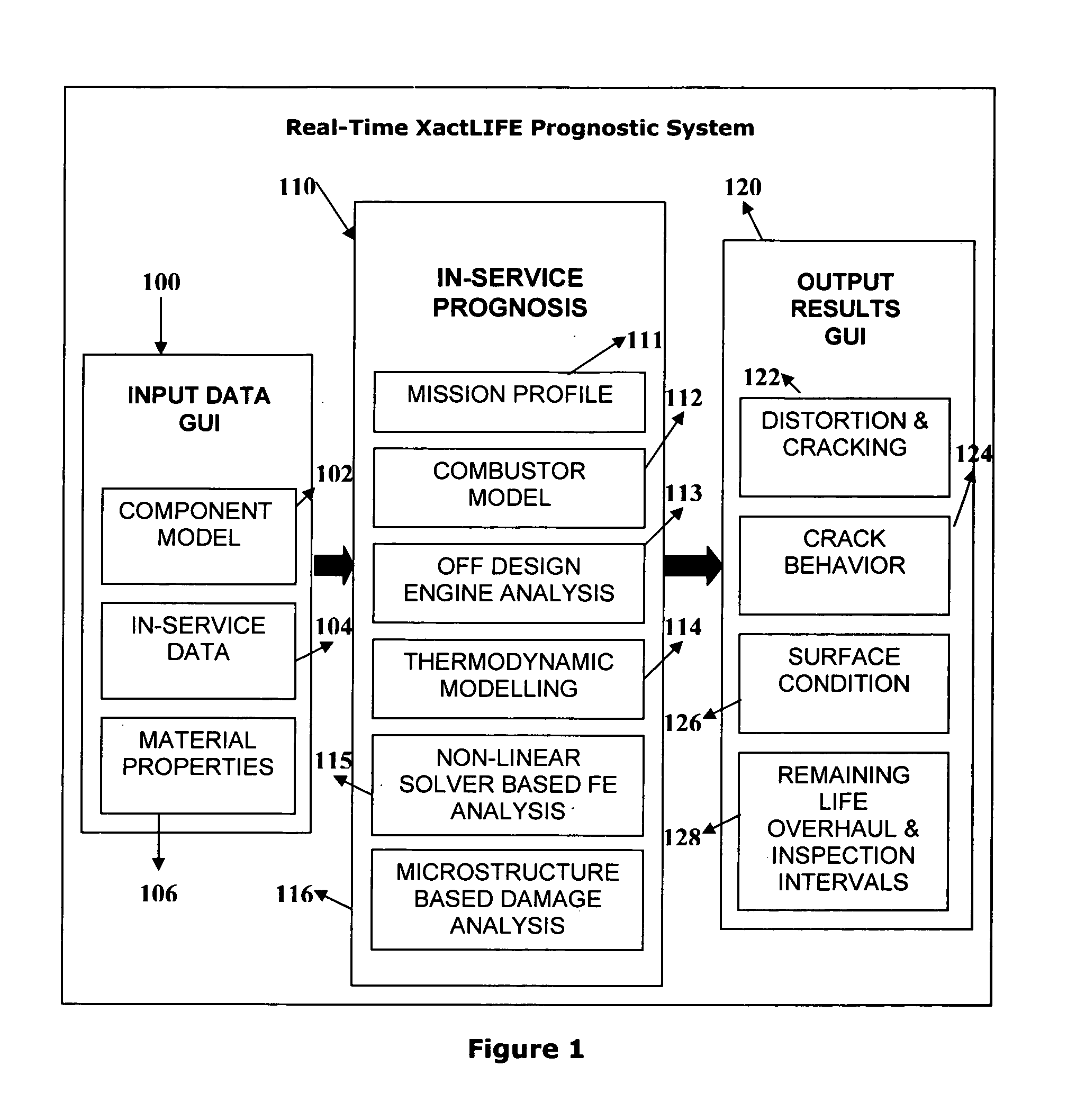

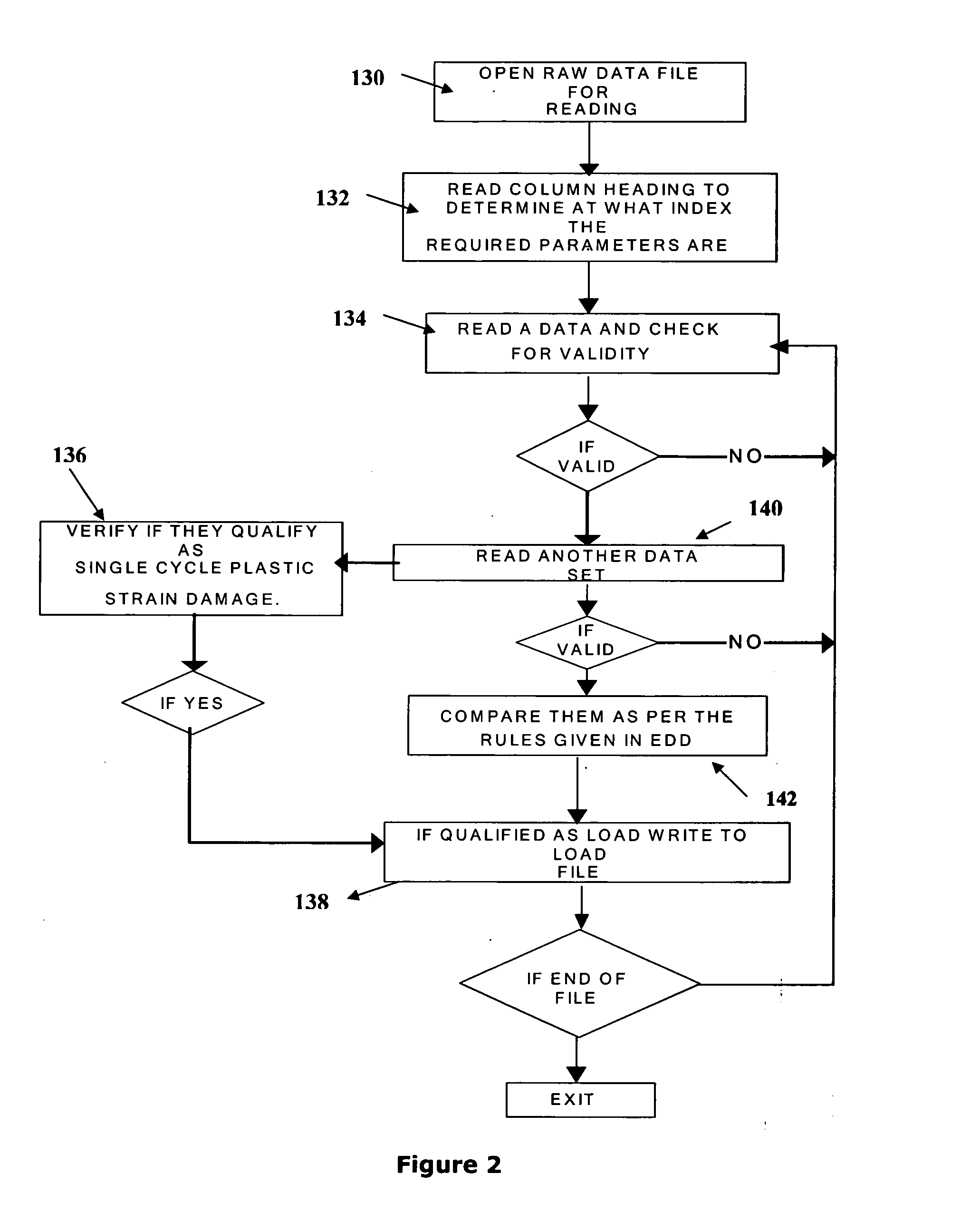

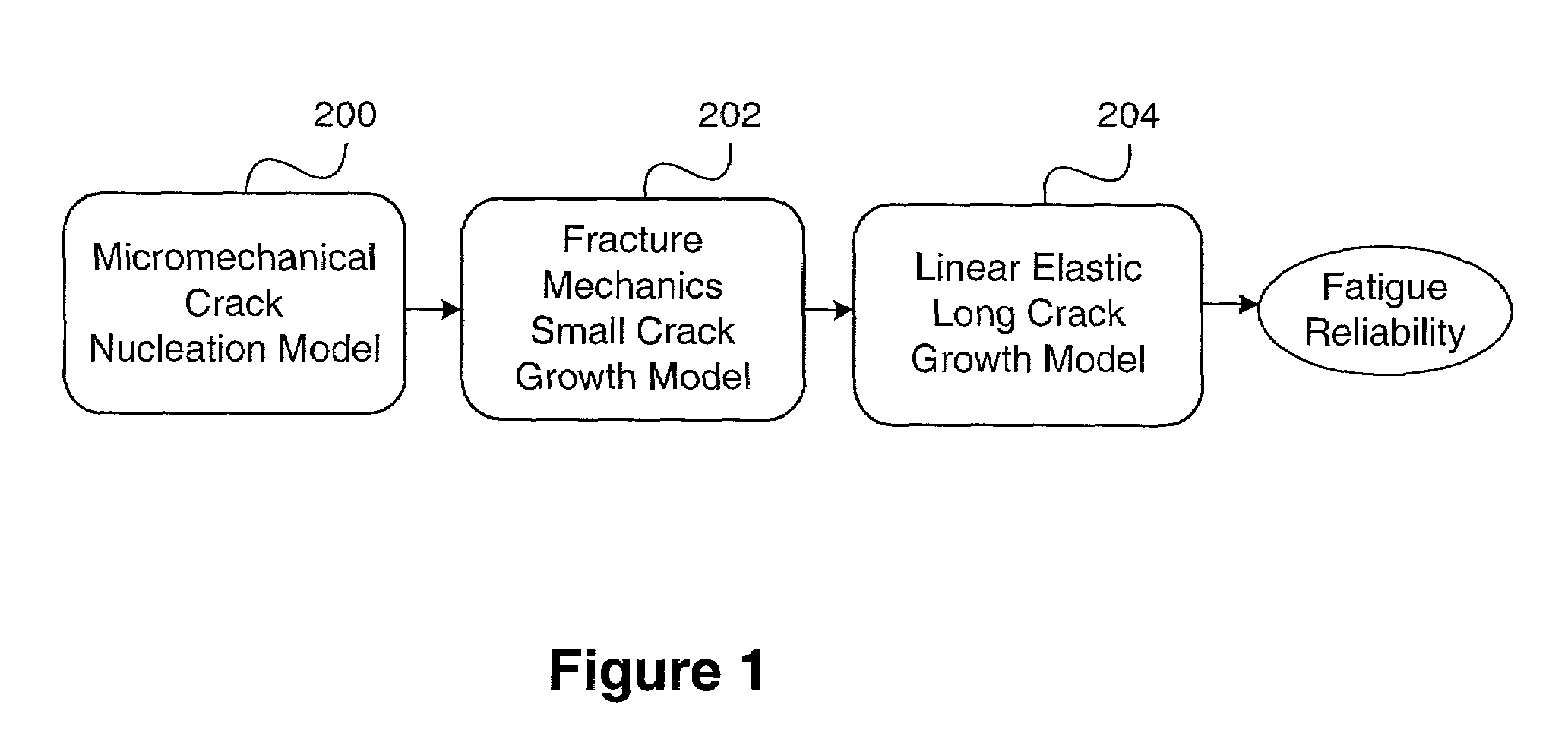

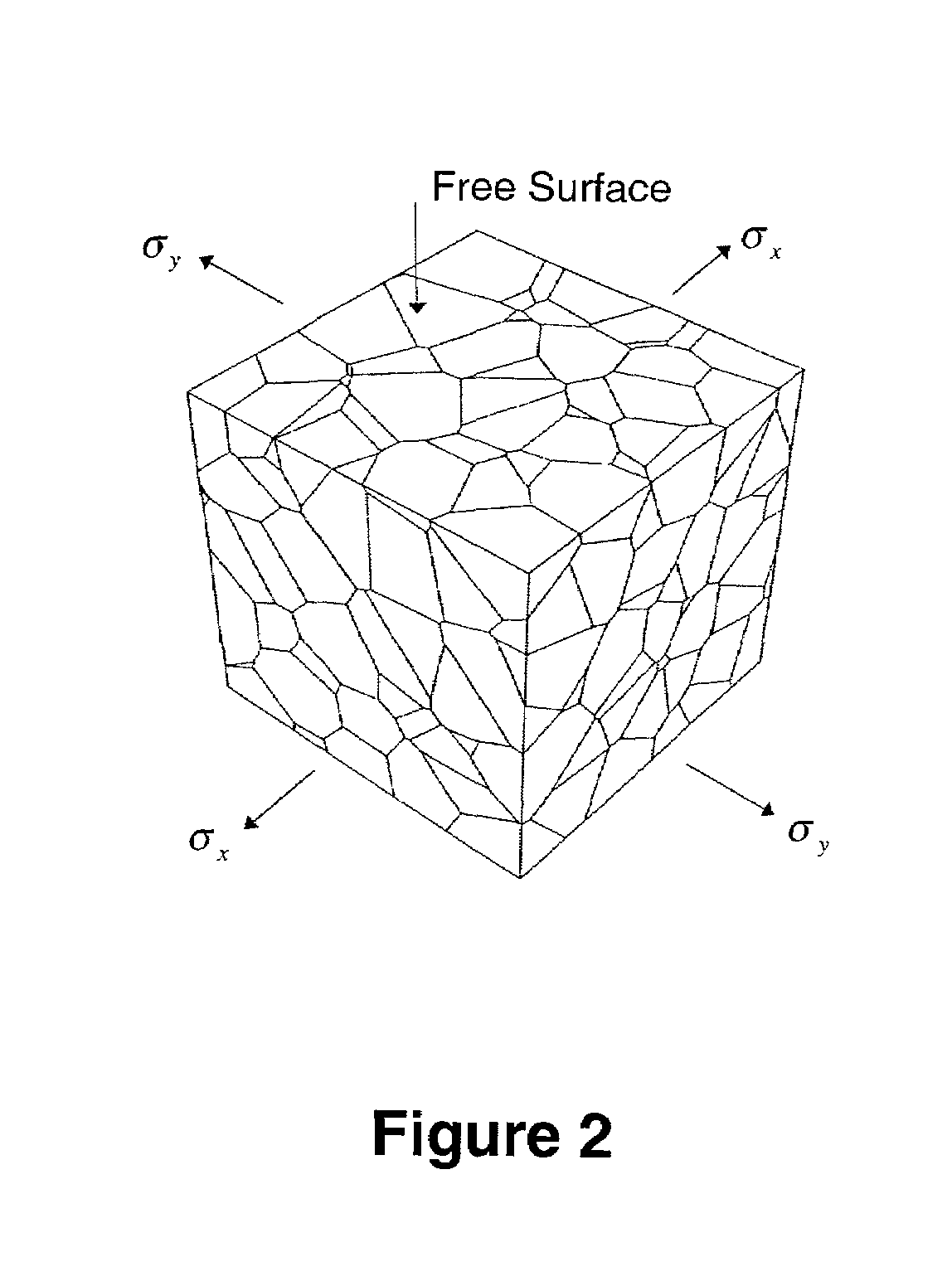

Method and system for real-time prognosis analysis and usage based residual life assessment of turbine engine components and display

ActiveUS20110137575A1Low costFacilitate decisionsPlug gaugesTesting dielectric strengthCombustion chamberOff design

A method and system for performing continuous (real-time) physics based prognostics analysis as a function of actual engine usage and changing operating environment. A rule-based mission profile analysis is conducted to determine the mission variability which yields variability in the type of thermal-mechanical loads that an engine is subjected to during use. This is followed by combustor modeling to predict combustion liner temperatures and combustion nozzle plane temperature distributions as a function of engine usage which is followed by off-design engine modeling to determine the pitch-line temperatures in hot gas path components and thermodynamic modeling to compute the component temperature profiles of the components for different stages of the turbine. This is automatically followed by finite element(FE) based non-linear stress-strain analysis using an real-time FE solver and physics based damage accumulation, life consumption and residual life prediction analyses using microstructural modeling based damage and fracture analysis techniques.

Owner:KOUL ASHOK

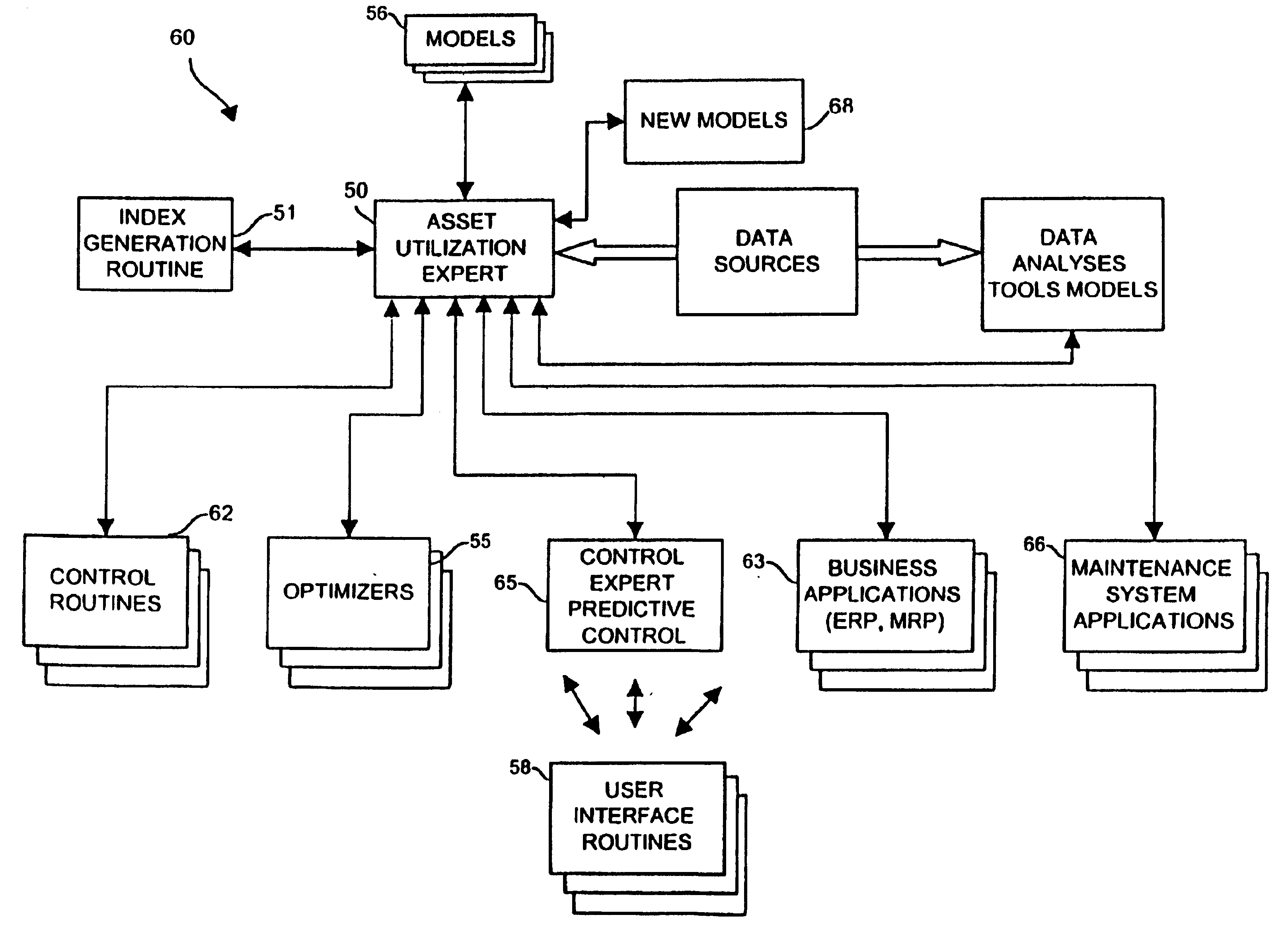

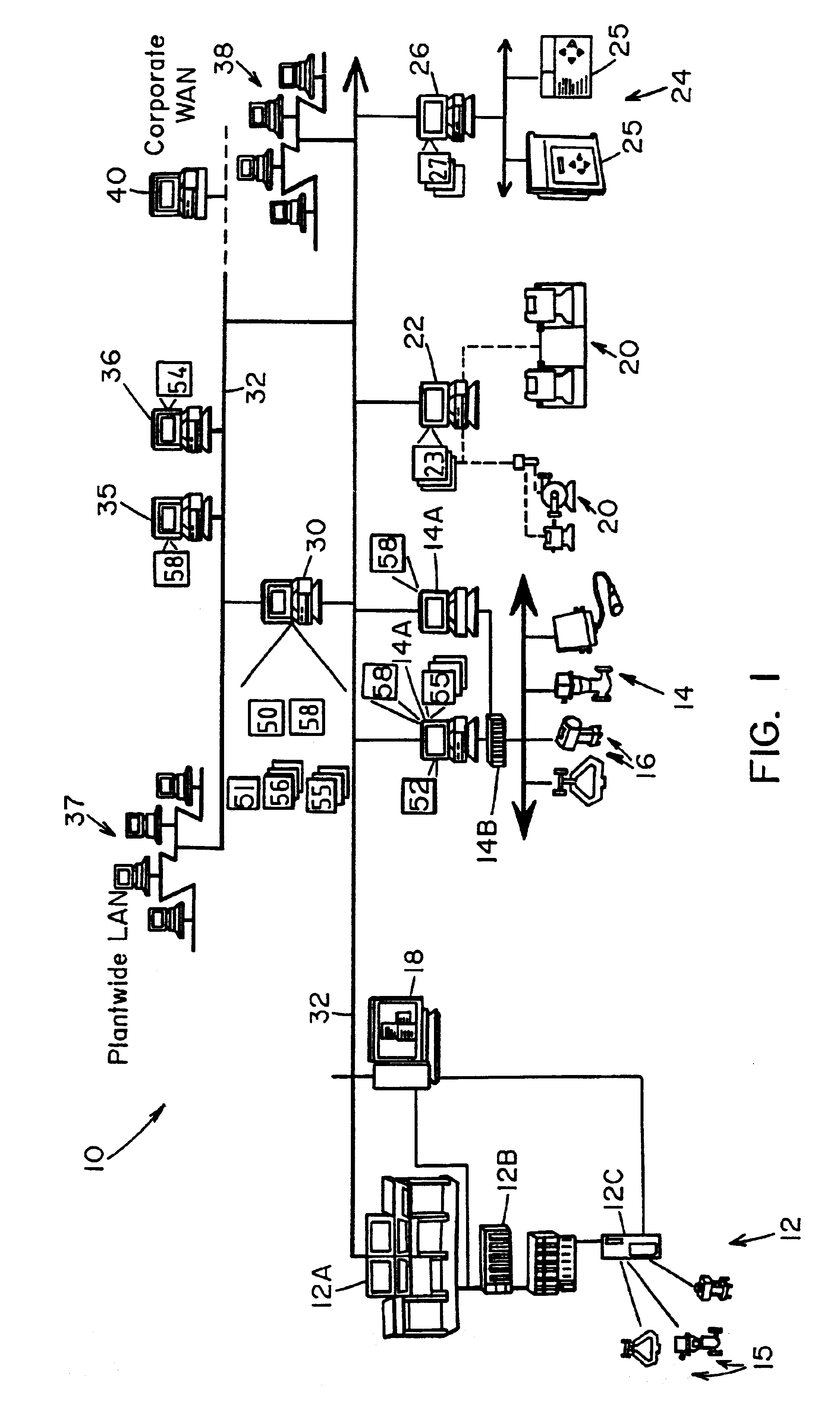

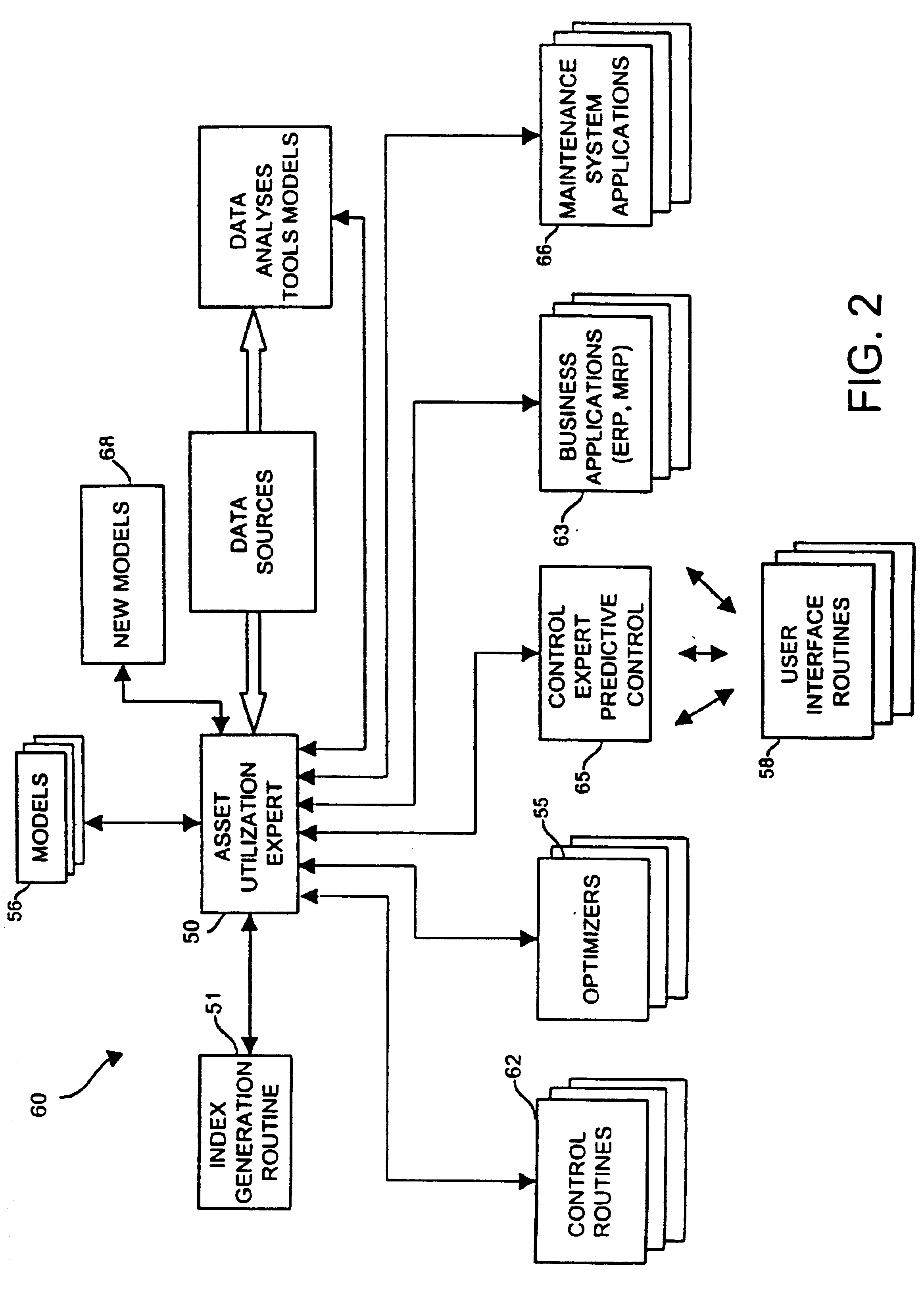

Fiducial technique for estimating and using degradation levels in a process plant

A process plant uses an asset utilization expert to collect data or information pertaining to the assets of the process plant from various sources or functional areas of the plant including, for example, the process control functional areas, the maintenance functional areas and the business systems functional areas. Some of this data, such as data indicative of one or more process parameters associated with a process entity like a furnace, may be used to estimate a degradation level, such as a coking level, of the process entity at a first time. The estimated level of the degradation of the process entity at the first time may then be compared to a predetermined desired level of degradation of the process entity at the first time and the operation of the process entity may be altered based on the comparison to drive the estimated amount of degradation of the process entity at a second time to be approximately equal to a predetermined desired level of degradation at the second time.

Owner:FISHER-ROSEMOUNT SYST INC

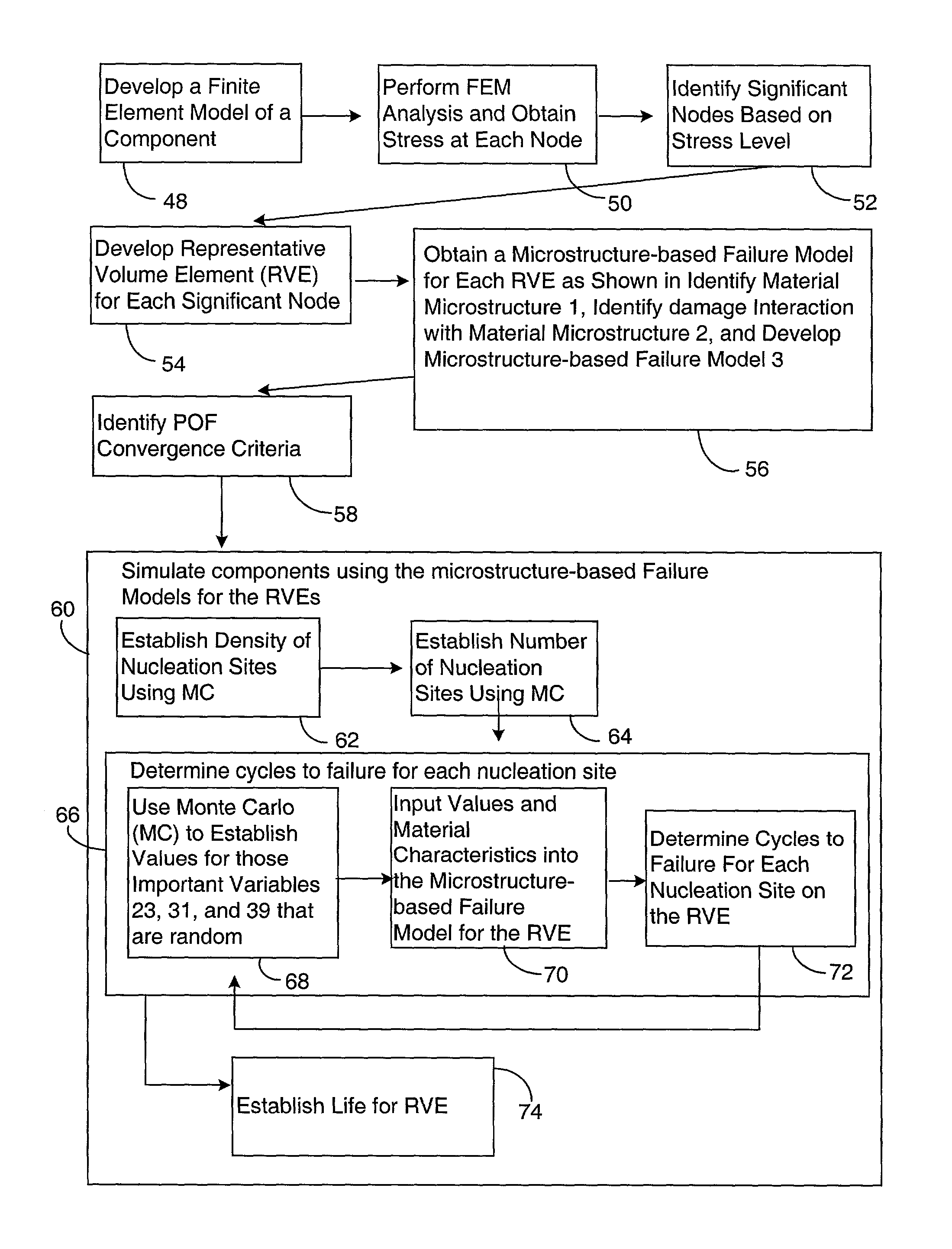

Method and apparatus for predicting the failure of a component

ActiveUS7016825B1Plug gaugesComputation using non-contact making devicesProbit modelComputer science

The invention provides a method and apparatus for predicting the failure of a component using a probabilistic model of a material's microstructural-based response to fatigue. The method predicts the component failure by a computer simulation of multiple incarnations of real material behavior, or virtual prototyping. The virtual prototyping simulates the effects of characteristics that include grain size, grain orientation, micro-applied stress and micro-yield strength that are difficult to simulate with real specimens. The invention provides an apparatus for predicting the response of a component to fatigue using the method.

Owner:VEXTEC CORP

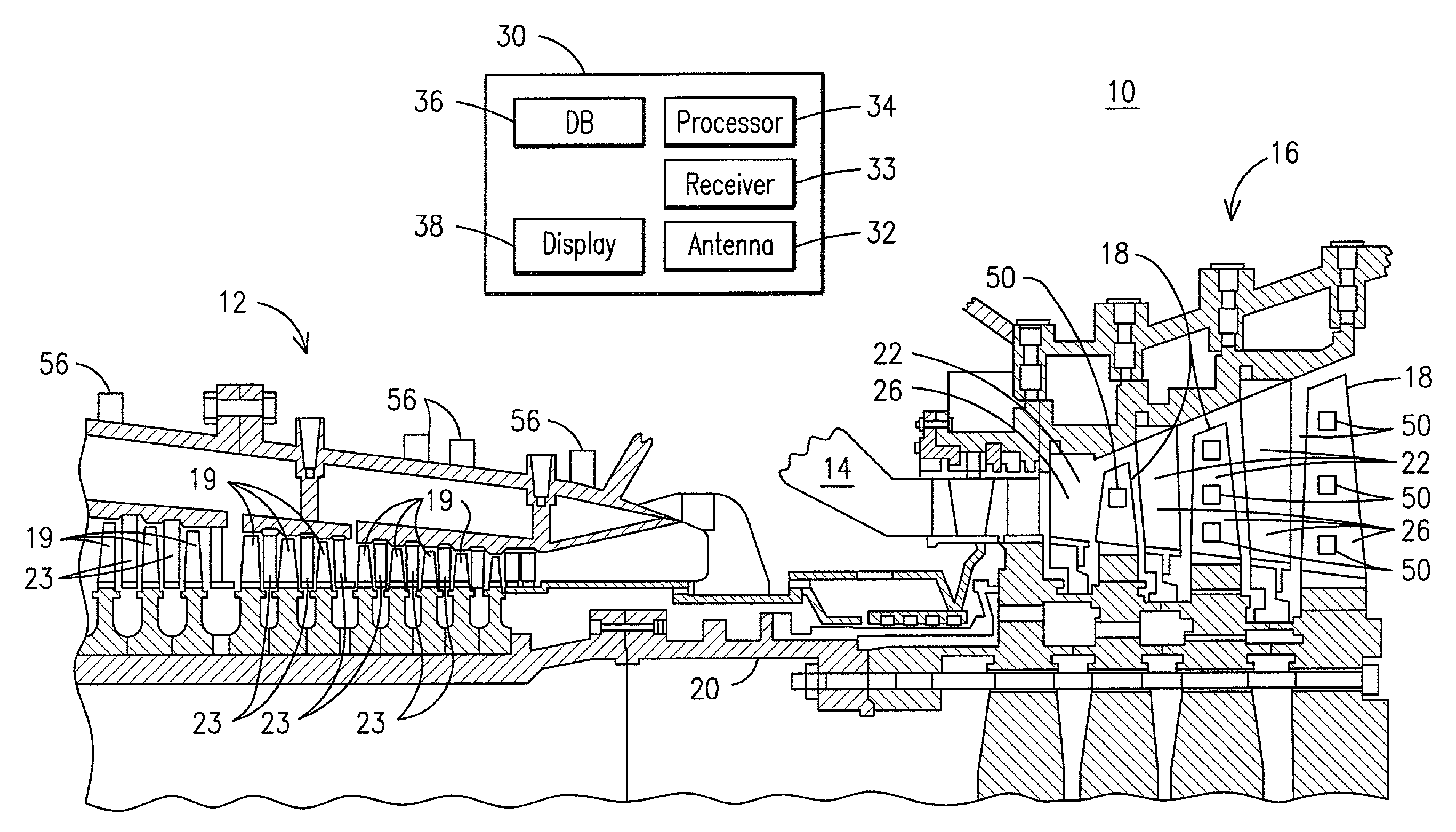

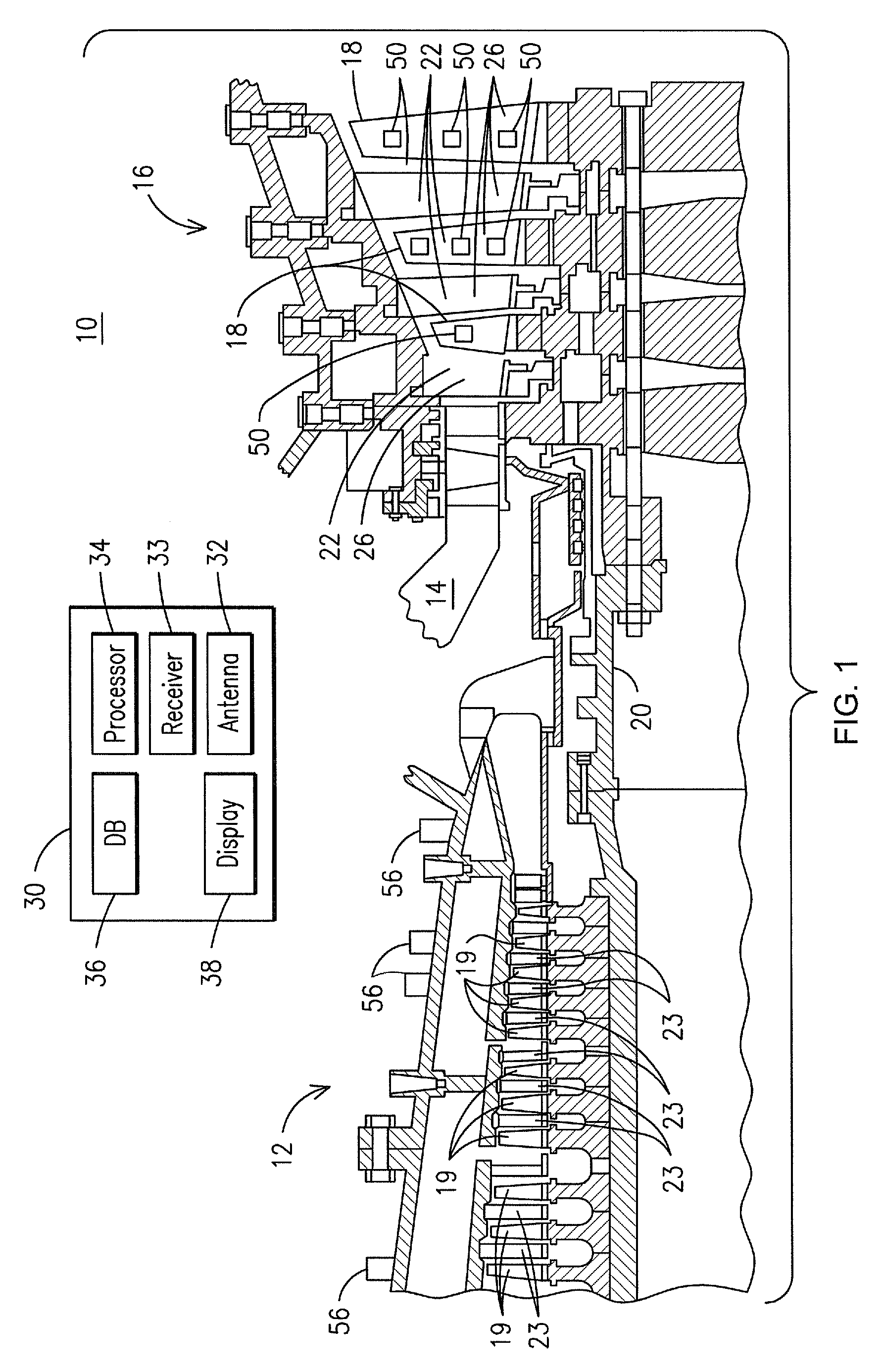

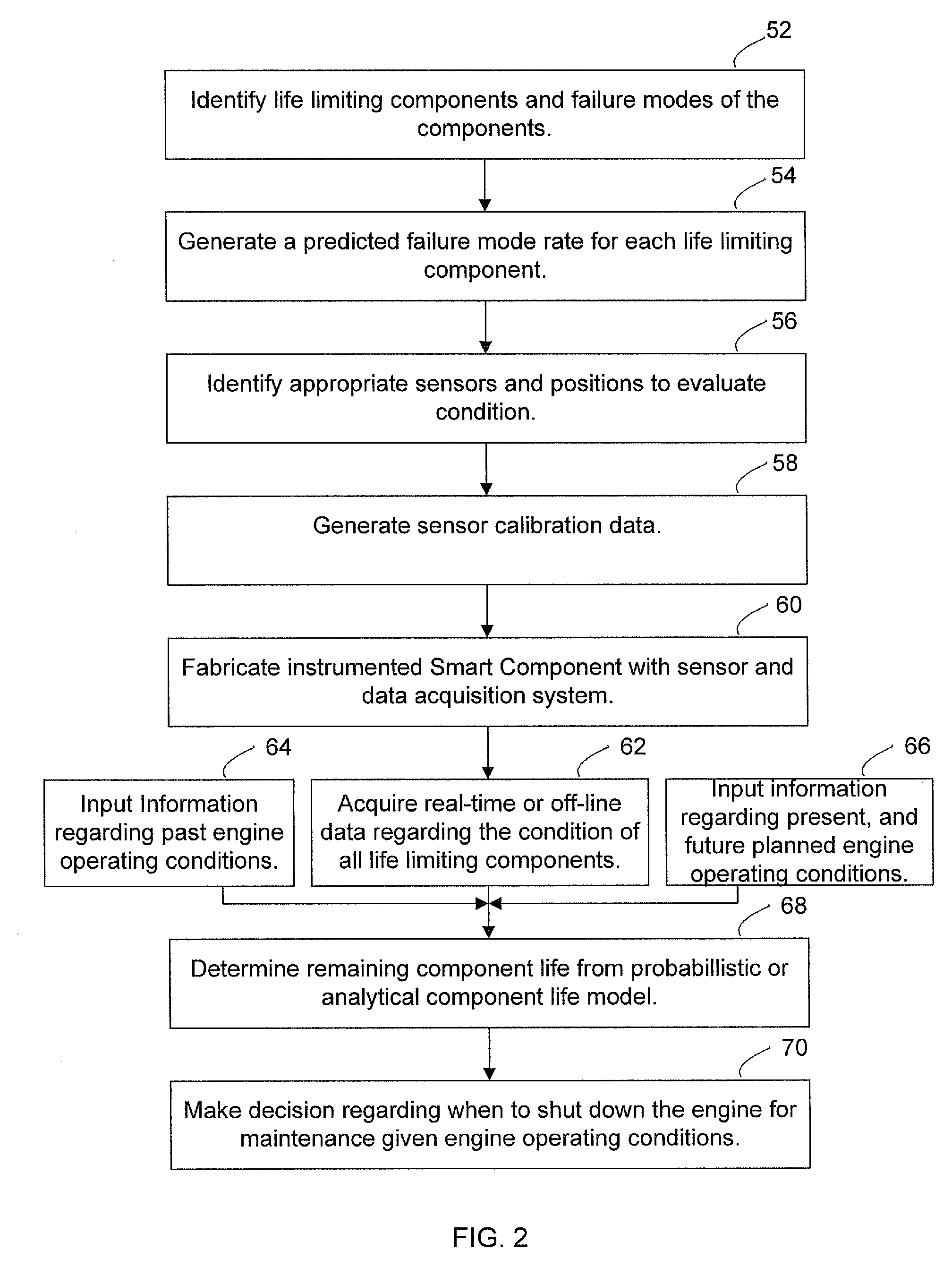

Method for predicting a remaining useful life of an engine and components thereof

A method for predicting the remaining useful life of an engine (10) having components (18, 19, 22, 23) that are instrumented with sensors (50) that generate electronic data signals indicative of an operating condition of the component comprises identifying (52) one or more components and at least one failure mode for each component that limit an operating life of the components and engine (10). The method further comprises acquiring (62) and storing data relative to current operating conditions of the components associated with the identified failure mode; and, then determining (68) a remaining useful life of the component based on the data relative to current operating condition of the components, the data relative to historical data of the operating condition associated with the failure mode and a predicted failure mode rate.

Owner:SIEMENS ENERGY INC

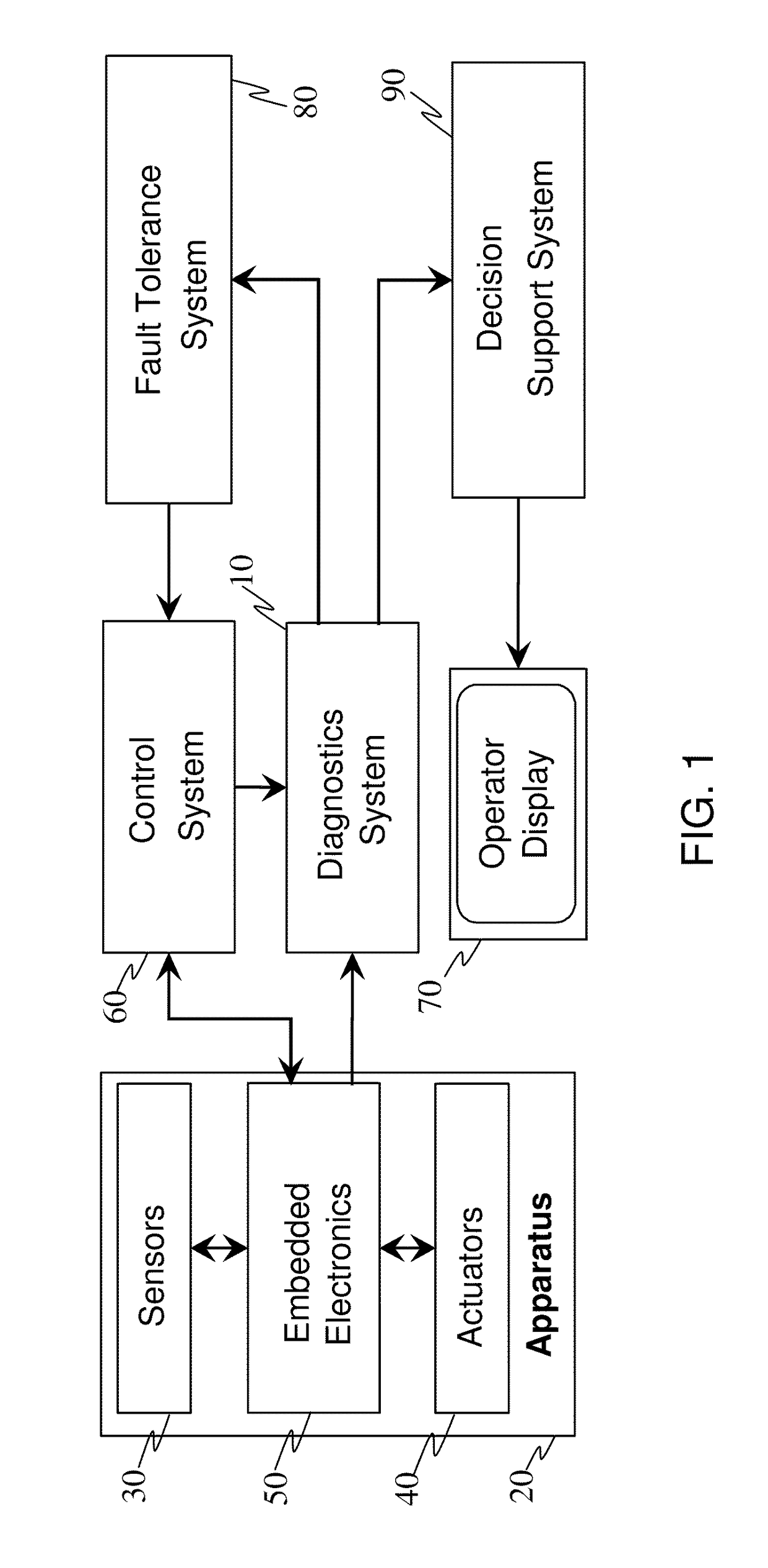

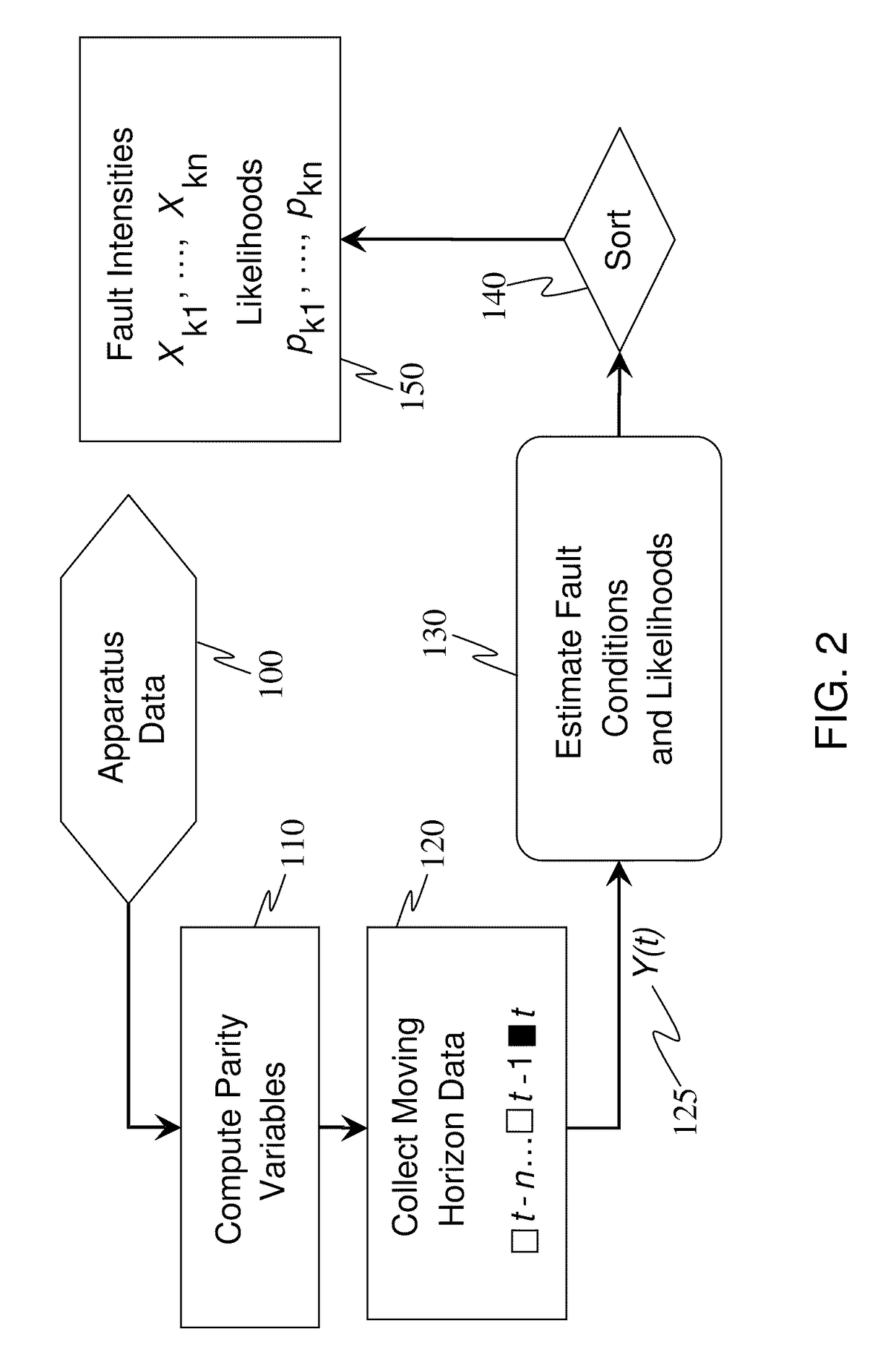

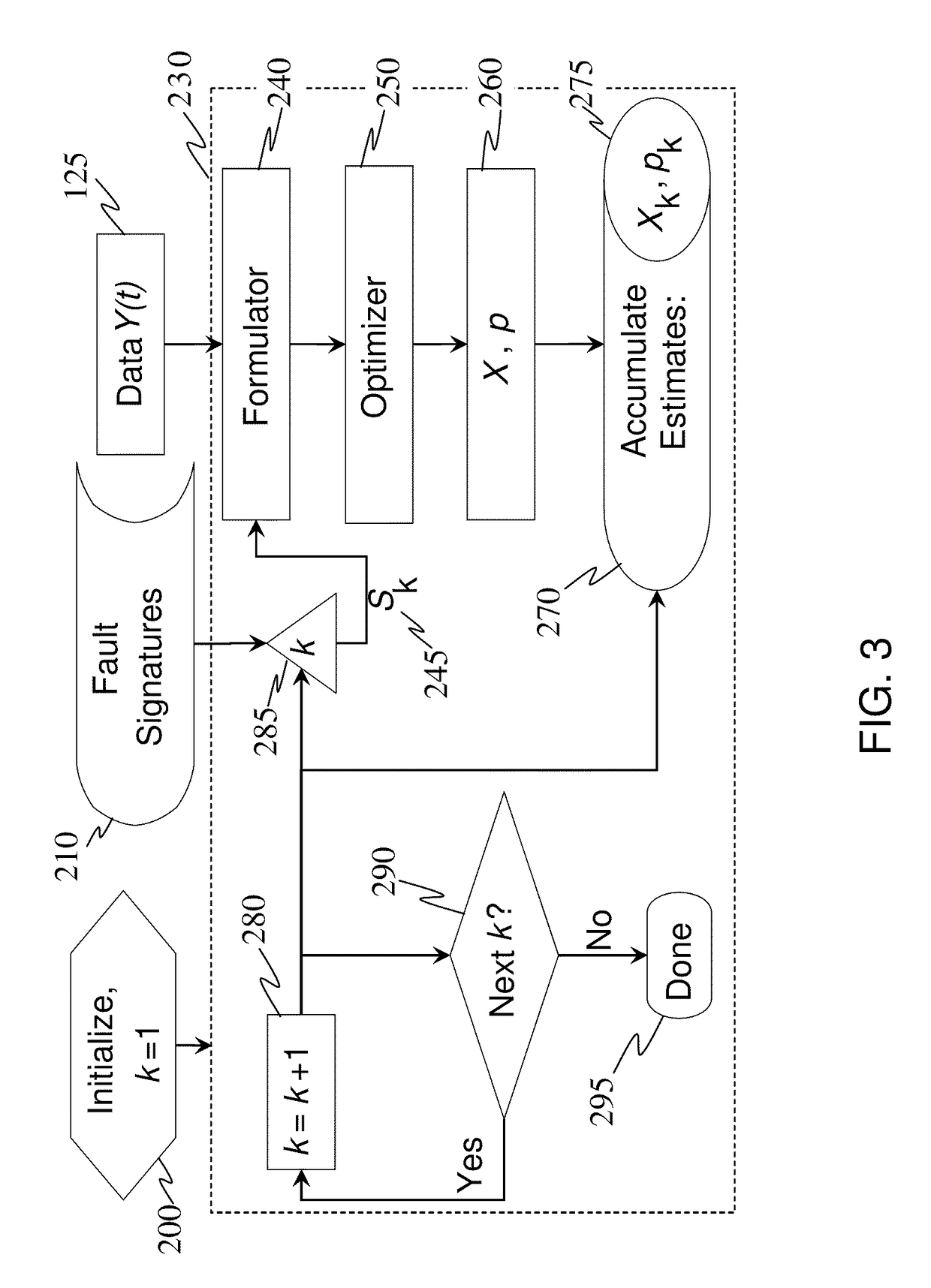

Method and system for diagnostics of apparatus

ActiveUS8121818B2Improve accuracyImprove performancePlug gaugesAmplifier modifications to reduce noise influenceControl systemEstimation methods

Proposed is a method, implemented in software, for estimating fault state of an apparatus outfitted with sensors. At each execution period the method processes sensor data from the apparatus to obtain a set of parity parameters, which are further used for estimating fault state. The estimation method formulates a convex optimization problem for each fault hypothesis and employs a convex solver to compute fault parameter estimates and fault likelihoods for each fault hypothesis. The highest likelihoods and corresponding parameter estimates are transmitted to a display device or an automated decision and control system. The obtained accurate estimate of fault state can be used to improve safety, performance, or maintenance processes for the apparatus.

Owner:MITEK ANALYTICS

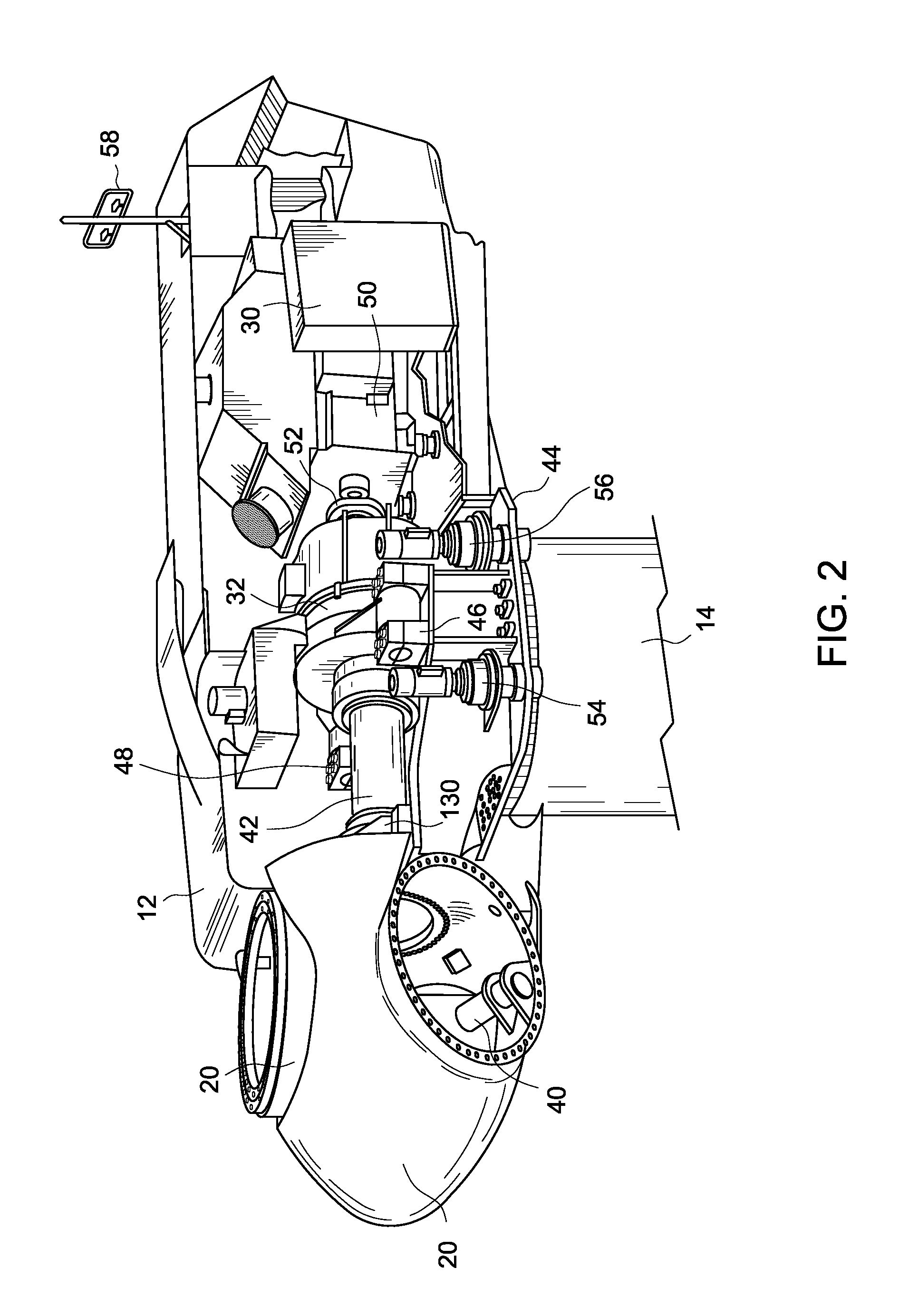

Equipment component monitoring and replacement management system

A computer system for managing replacement components for equipment having a plurality of components, each component having a limited useful life, has a computer program module defining a duty profile comprising a plurality of usage cases for the equipment, each usage case involving two or more of the components and specified operating conditions for the involved components during execution of the usage cases. A further program module determines a theoretical useful life for each component involved in a duty profile, based on component useful life data under specified operating conditions; and sensors determine and monitor the occurrence of equipment operation corresponding to a usage case and measur actual operating conditions and number of operations. A further program module computes an adjusted theoretical useful life for a component experiencing operations, based on a comparison of actual operating conditions to those assumed for the usage case.

Owner:HYDRALIFT AMCLYDE INC

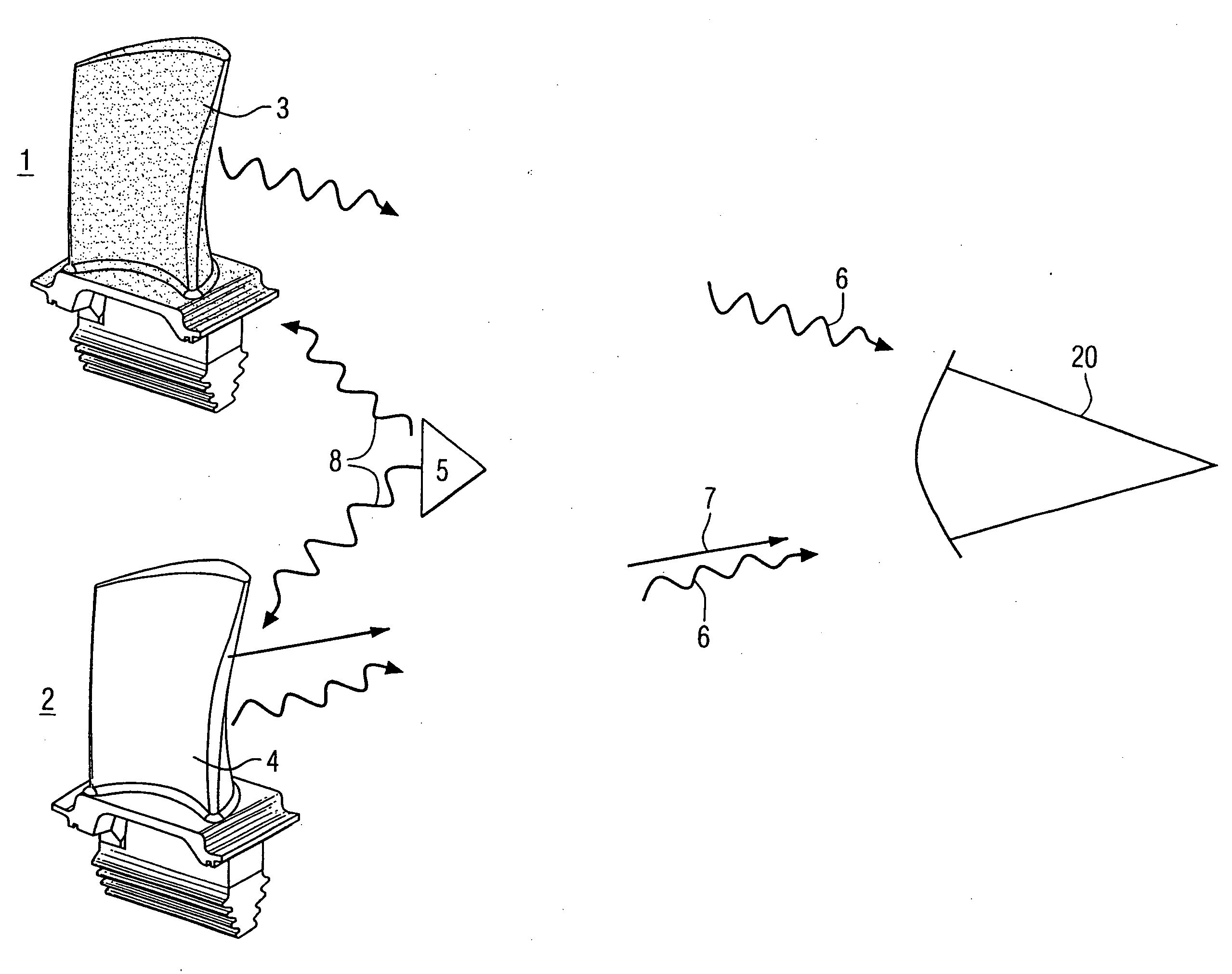

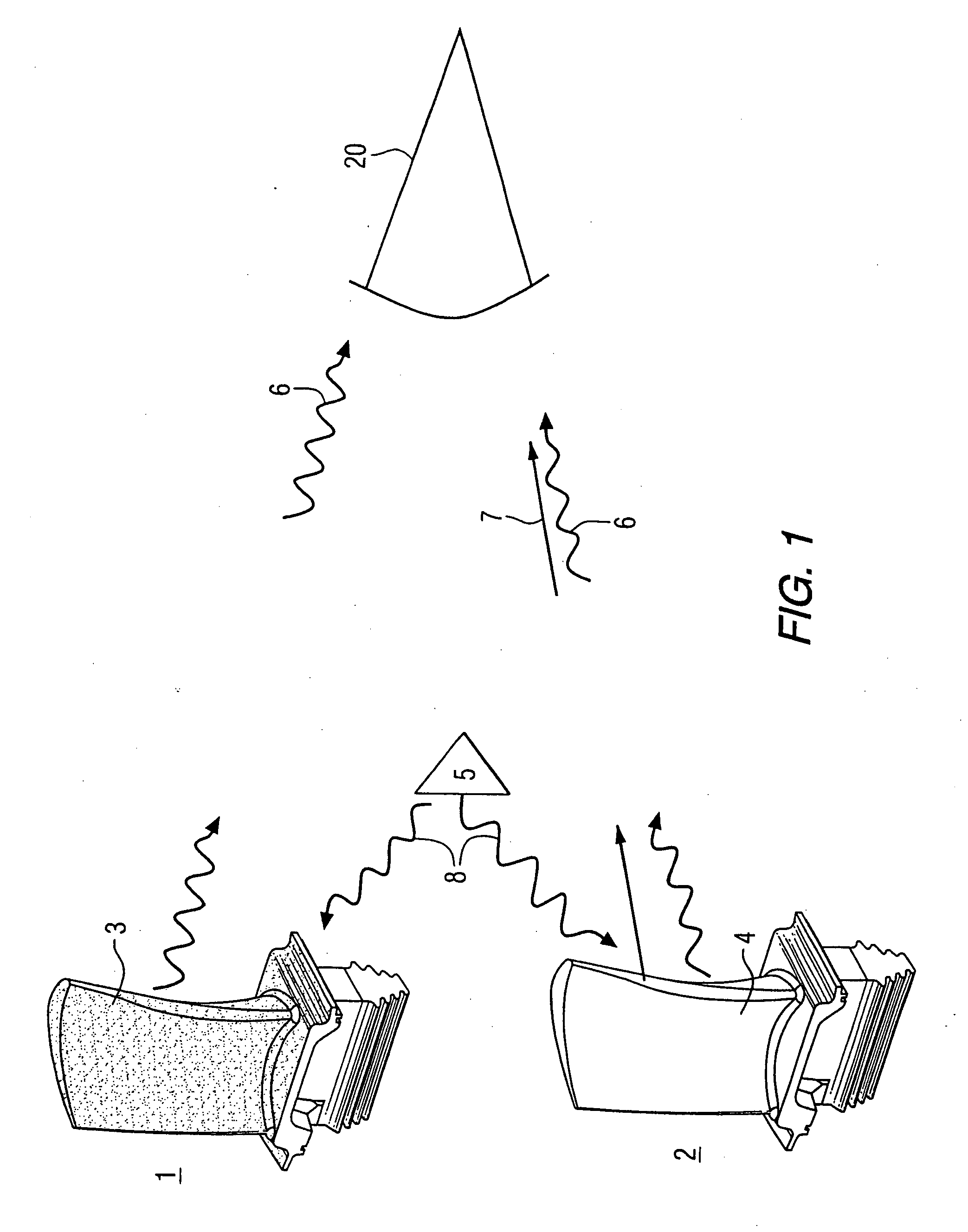

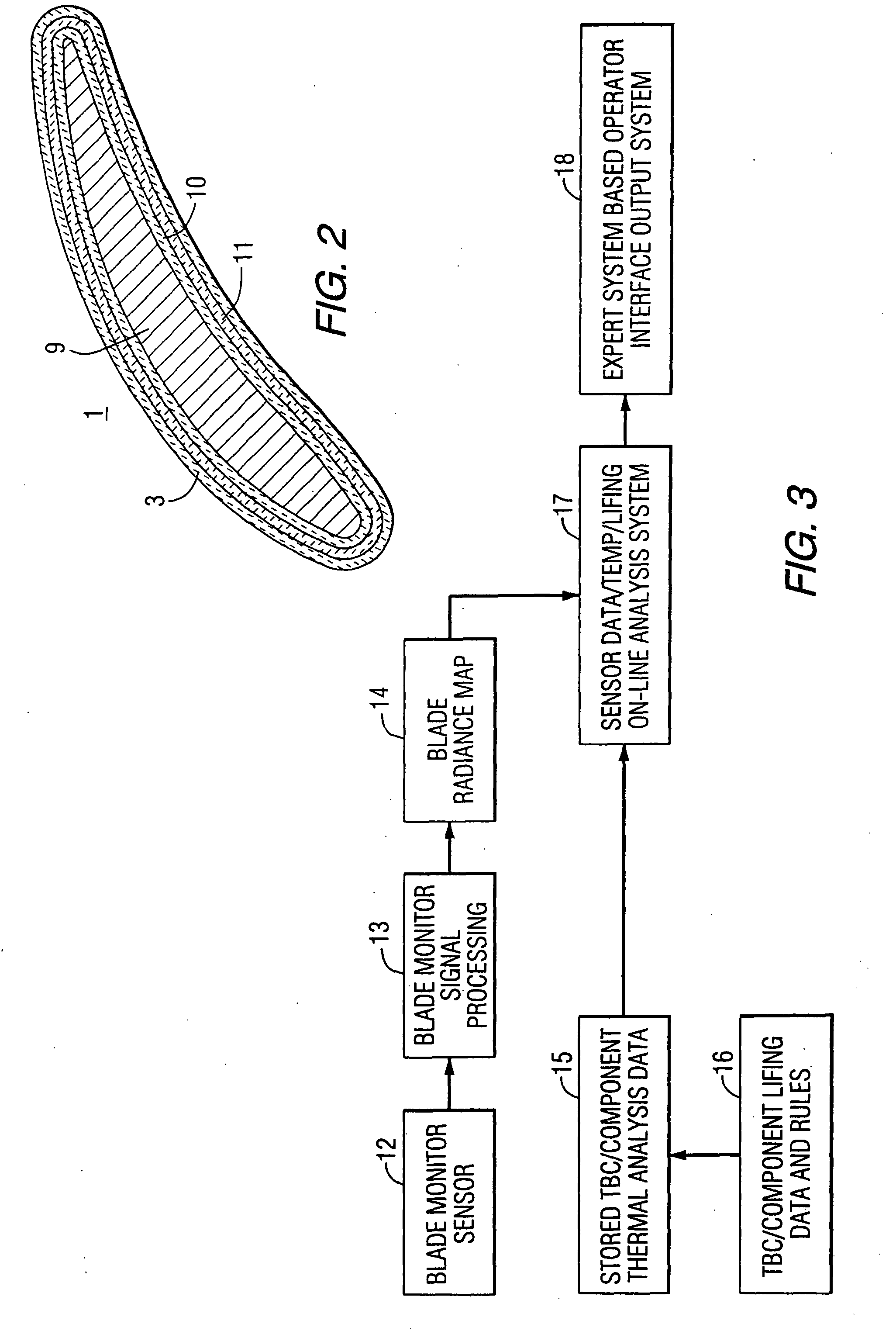

Method and apparatus for measuring on-line failure of turbine thermal barrier coatings

InactiveUS20090312956A1Detect degradationAvoid severe repairThermometer detailsPlug gaugesTurbine bladeEngineering

A method of remotely monitoring the radiant energy (6) emitted from a turbine component such as a turbine blade (1) having a low-reflective surface coating (3) which may be undergoing potential degradation is used to determine whether erosion, spallation, delamination, or the like, of the coating (3) is occurring.

Owner:SIEMENS ENERGY INC

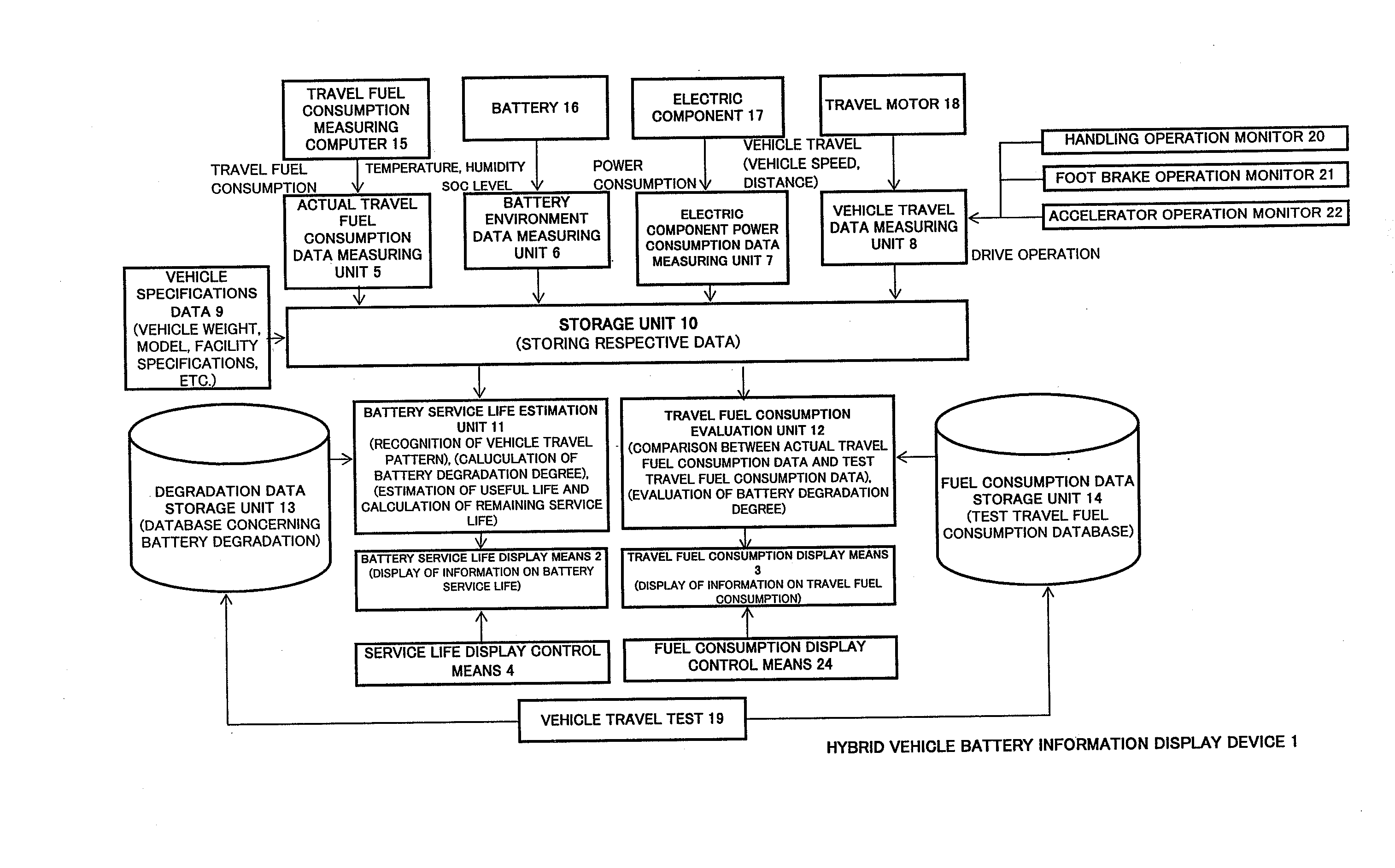

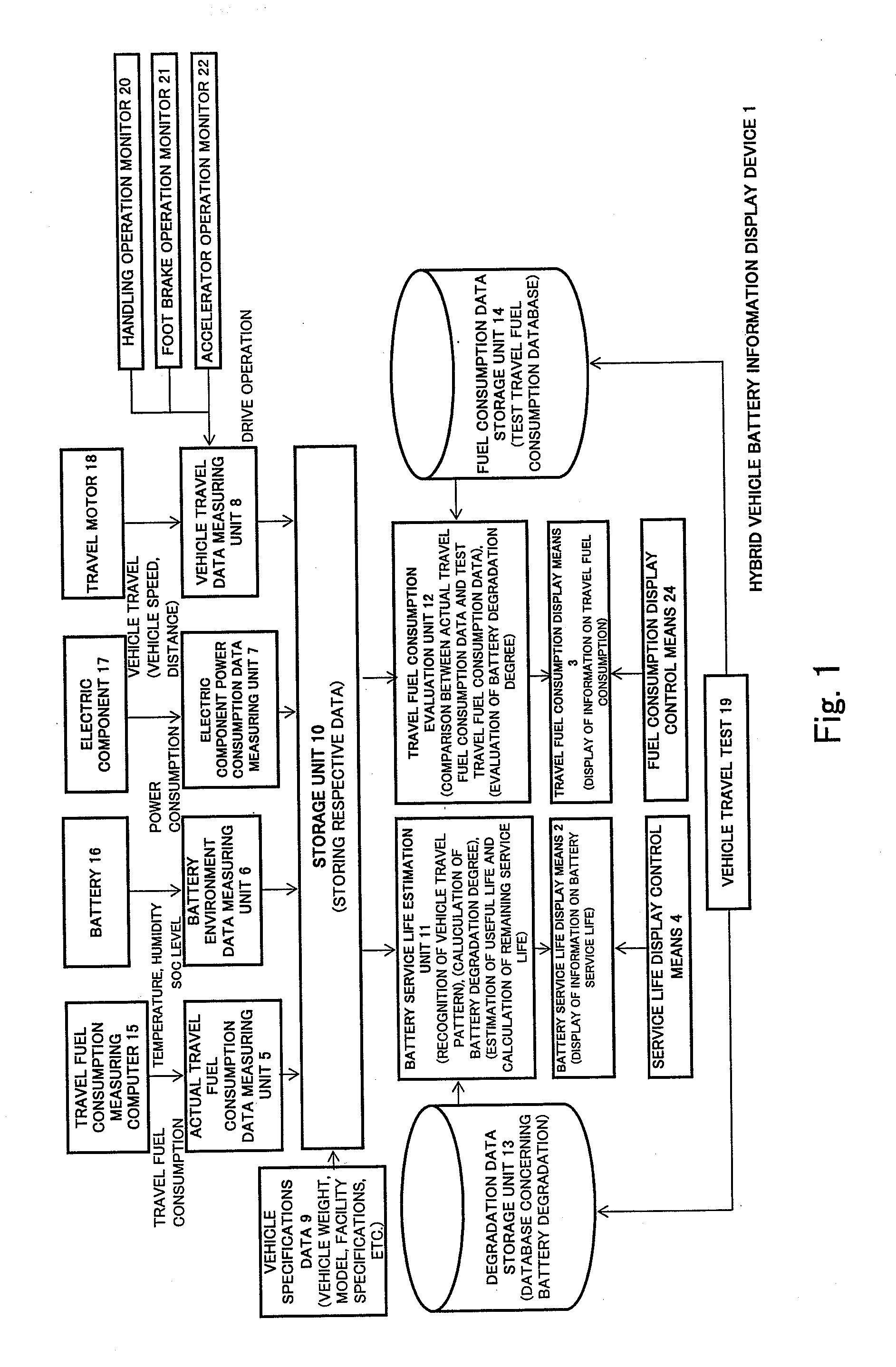

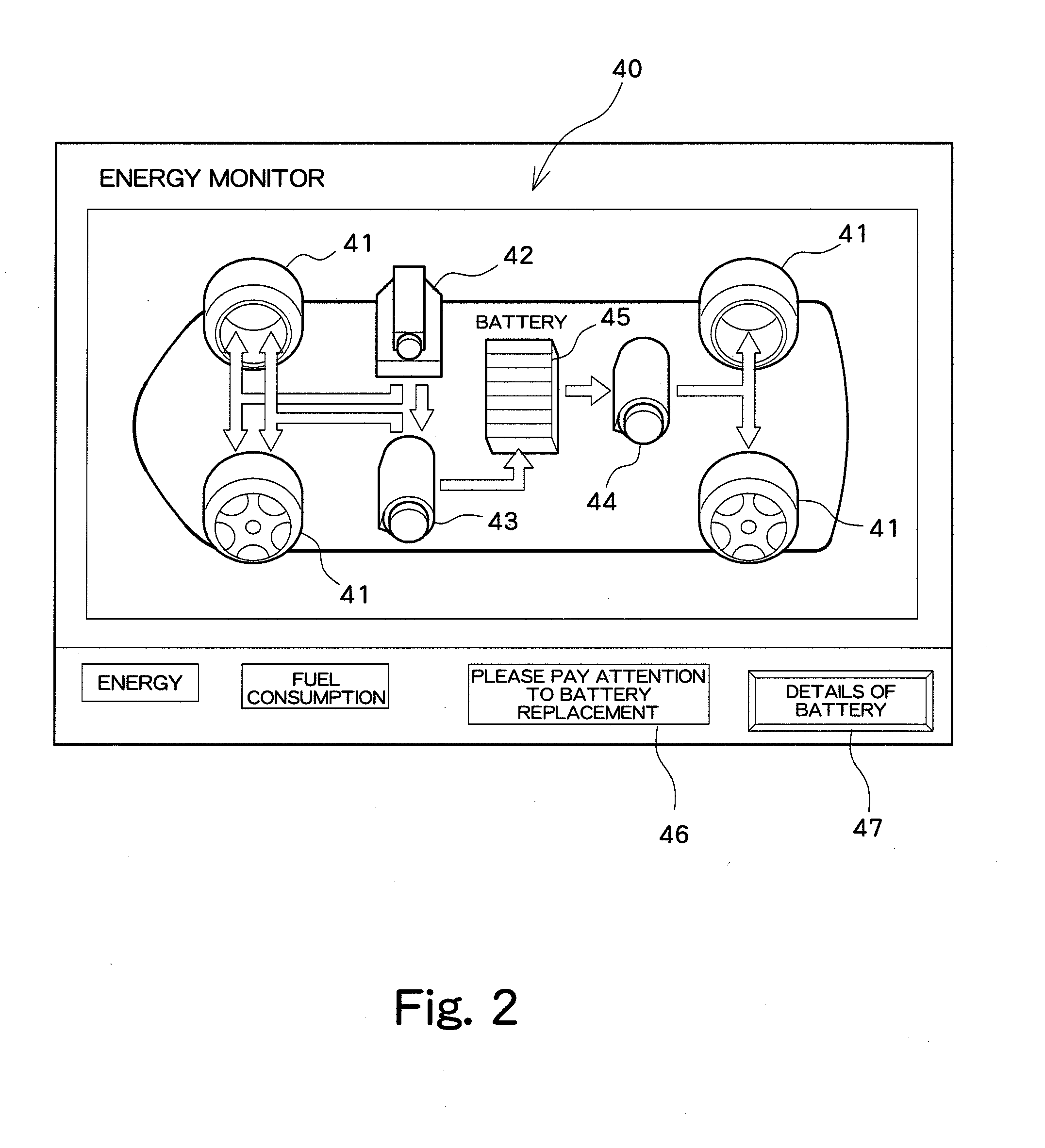

Hybrid vehicle battery information display device

A hybrid vehicle battery information display device 1 includes a battery service life display unit 2 which estimates a degree of battery degradation with respect to a useful life of a battery 16 from data on vehicle travel and the like based on battery degradation data measured from a vehicle travel test 19, to display information on a battery service life; a travel fuel consumption display unit 3 which evaluates, from the vehicle travel test 19, a degradation degree of actual travel fuel consumption data due to the battery degradation for each drive pattern based on test travel fuel consumption data set for each drive pattern, to display information on a travel fuel consumption; and a display control unit 4 which controls the display of information on the battery service life.

Owner:TOYOTA JIDOSHA KK

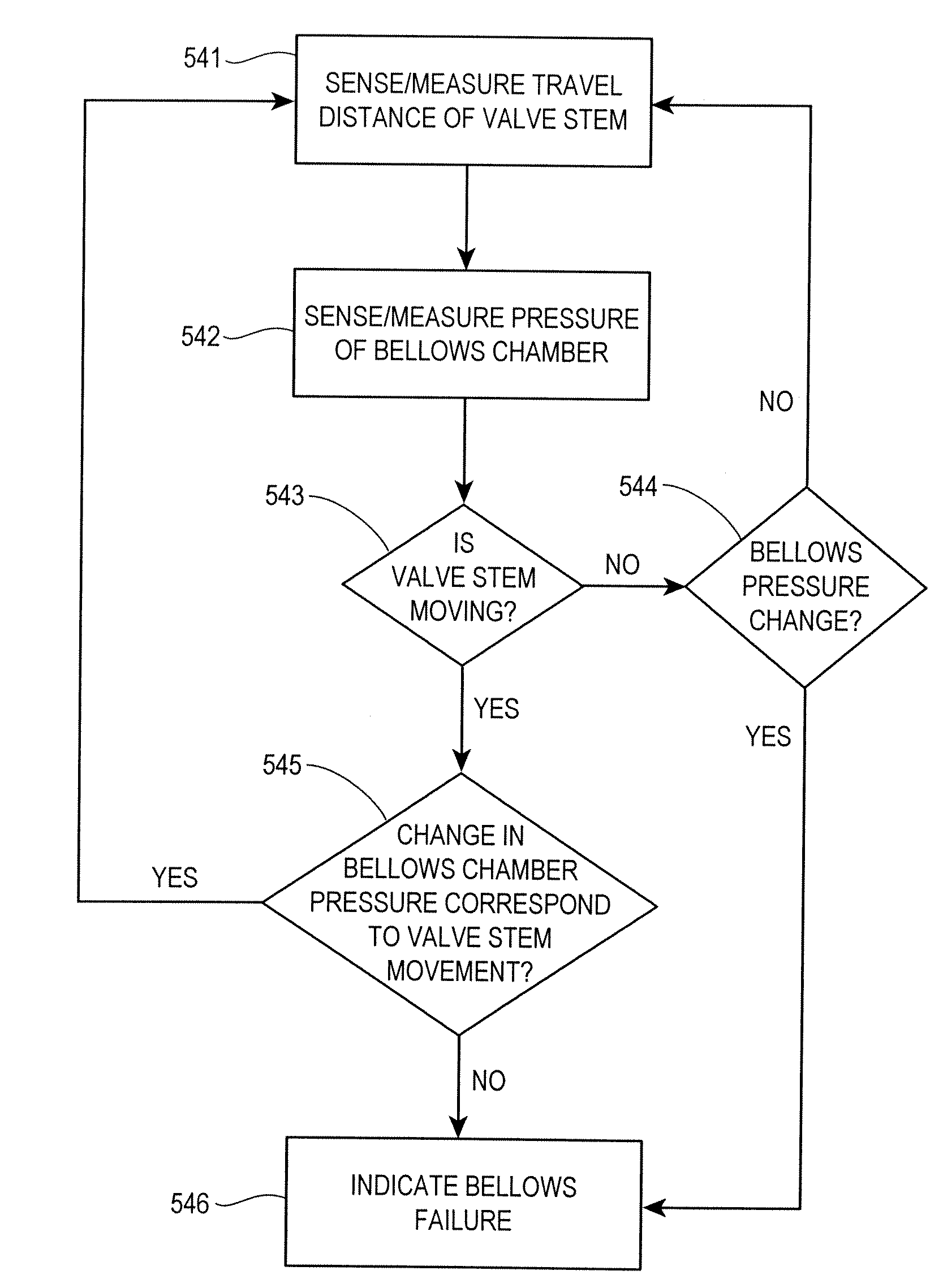

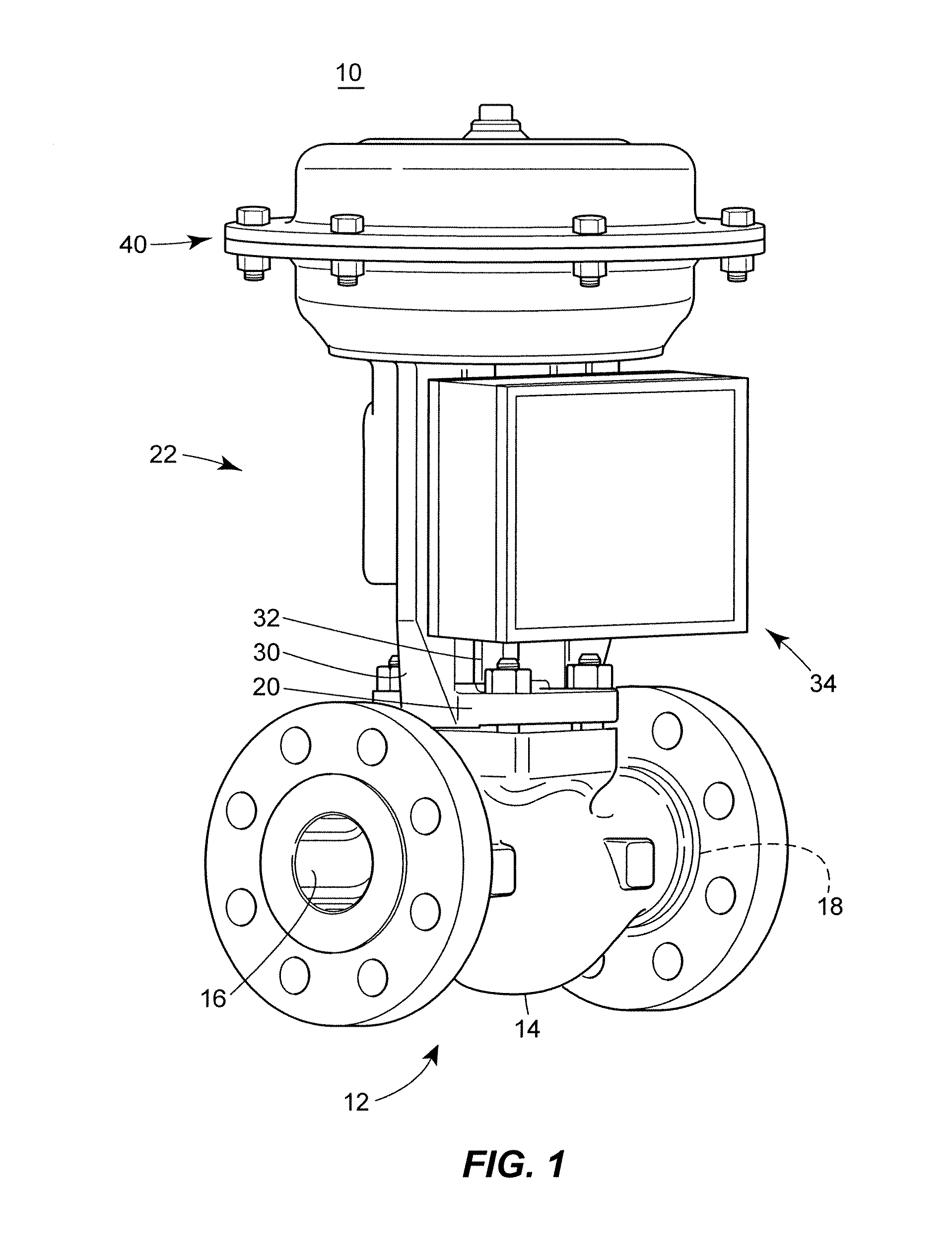

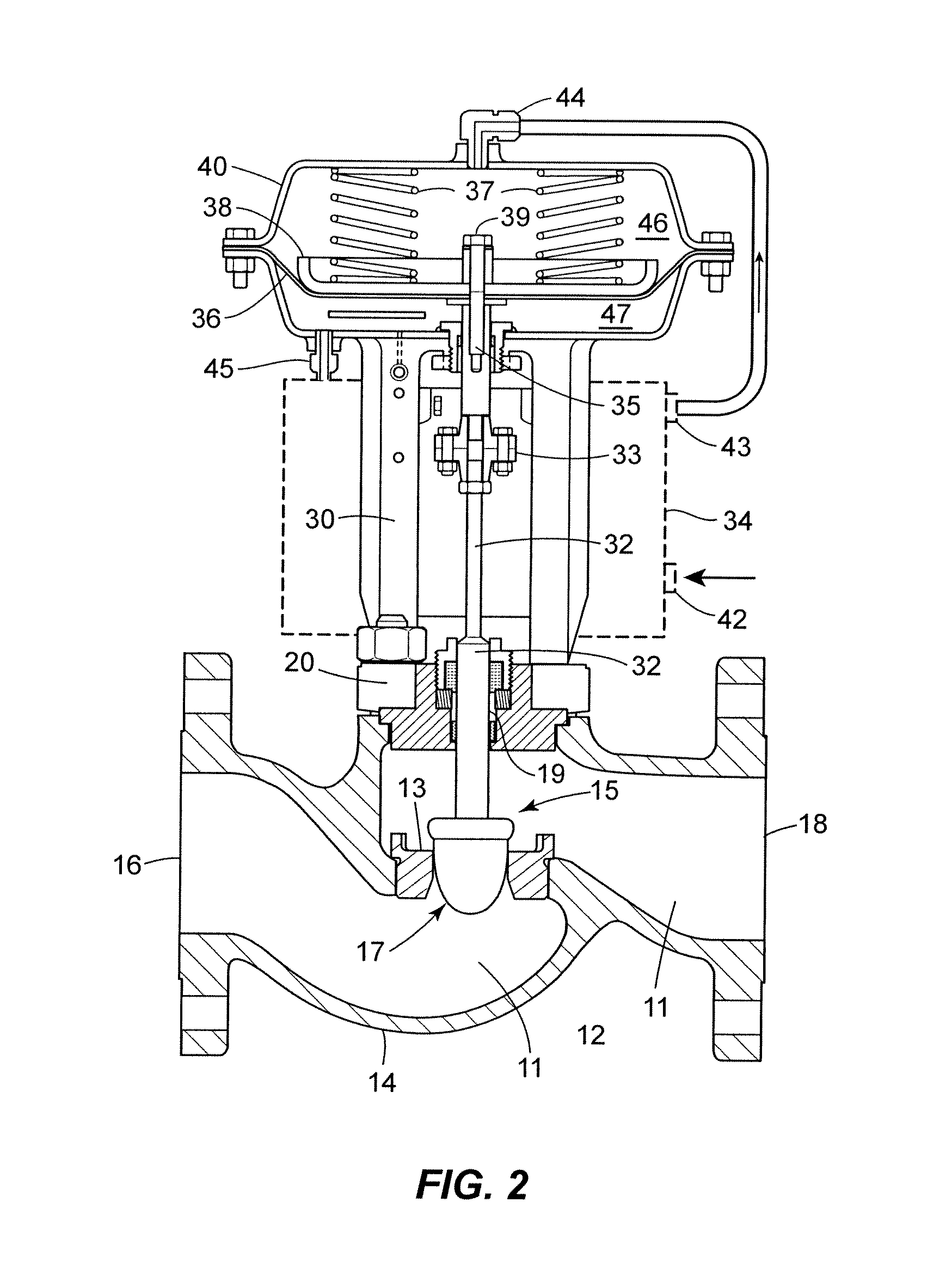

Diagnostic method for detecting control valve component failure

The claimed method and system identifies faults and / or deterioration of components in a process control valve. The system may use different sensor combinations to provide the necessary data to compute irregular component integrity. Alerts may be generated to indicate potential component integrity problems. In particular, the system may detect potential deterioration and / or faults in actuator springs, pneumatic tubing and piping, and bellows seals. The claimed system may be communicatively coupled to a process control network to provide a more elaborate alarm system. Moreover, additional statistical methods may be used to refine the detection accuracy of the system.

Owner:FISHER CONTROLS INT LLC

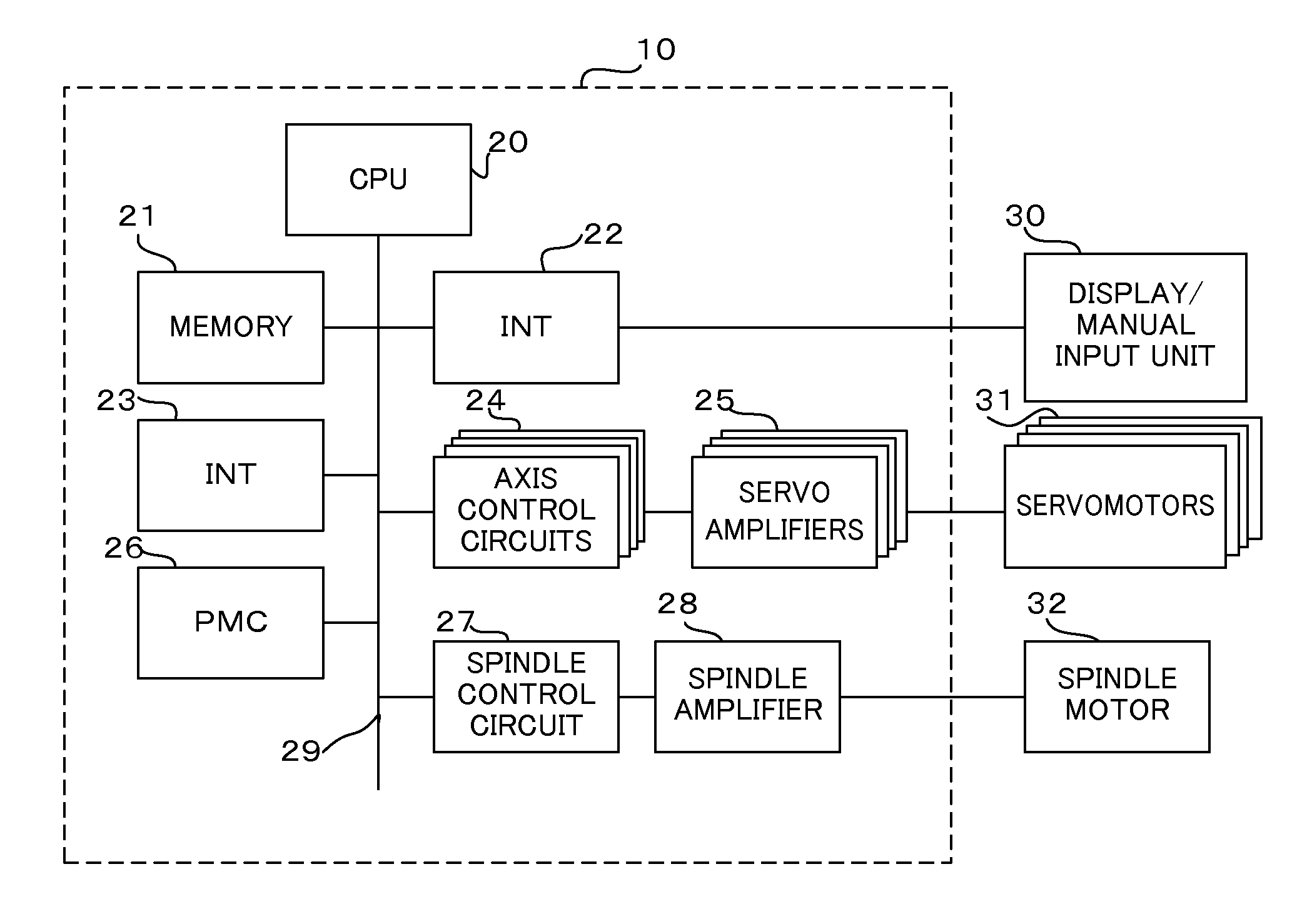

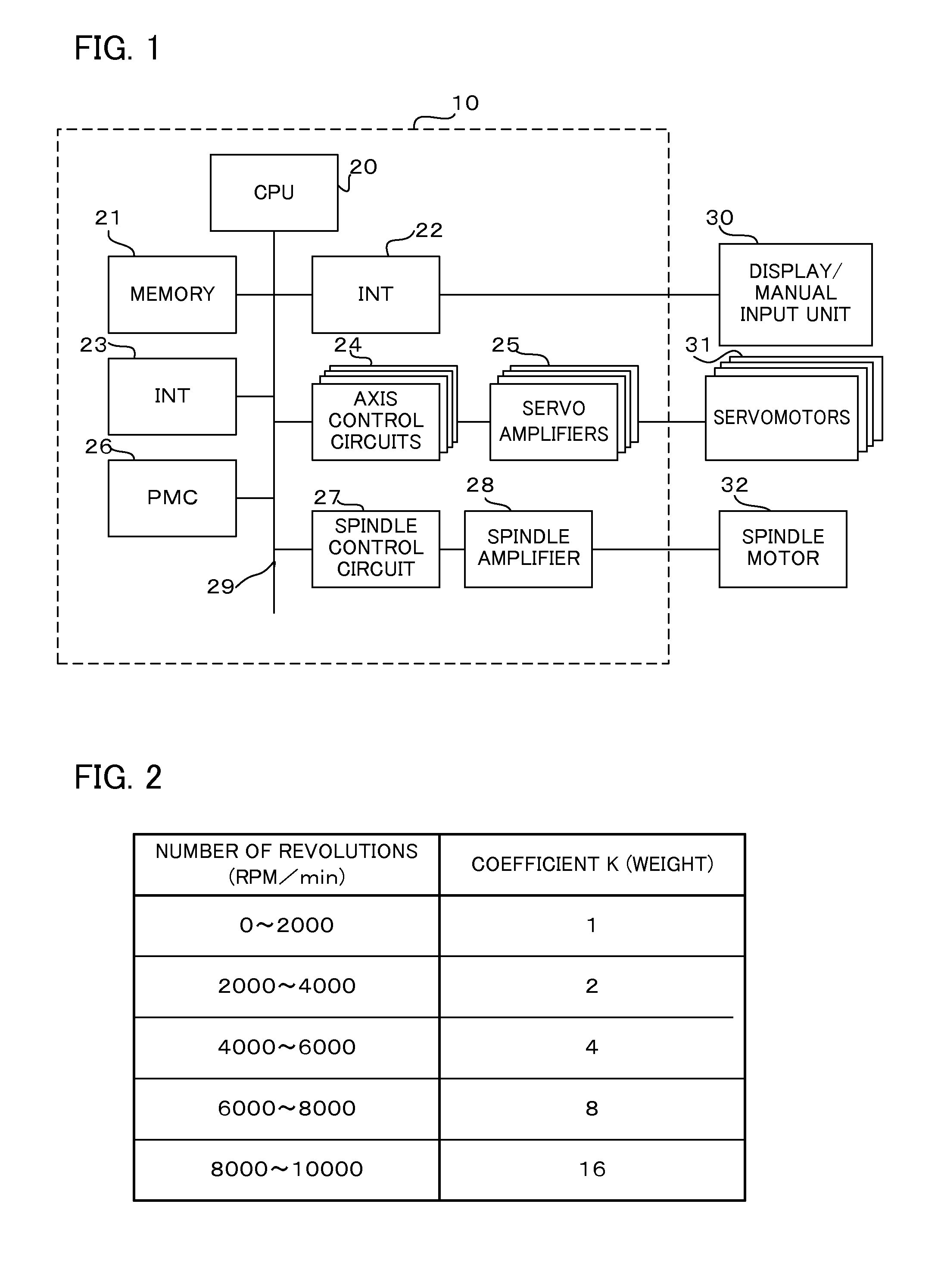

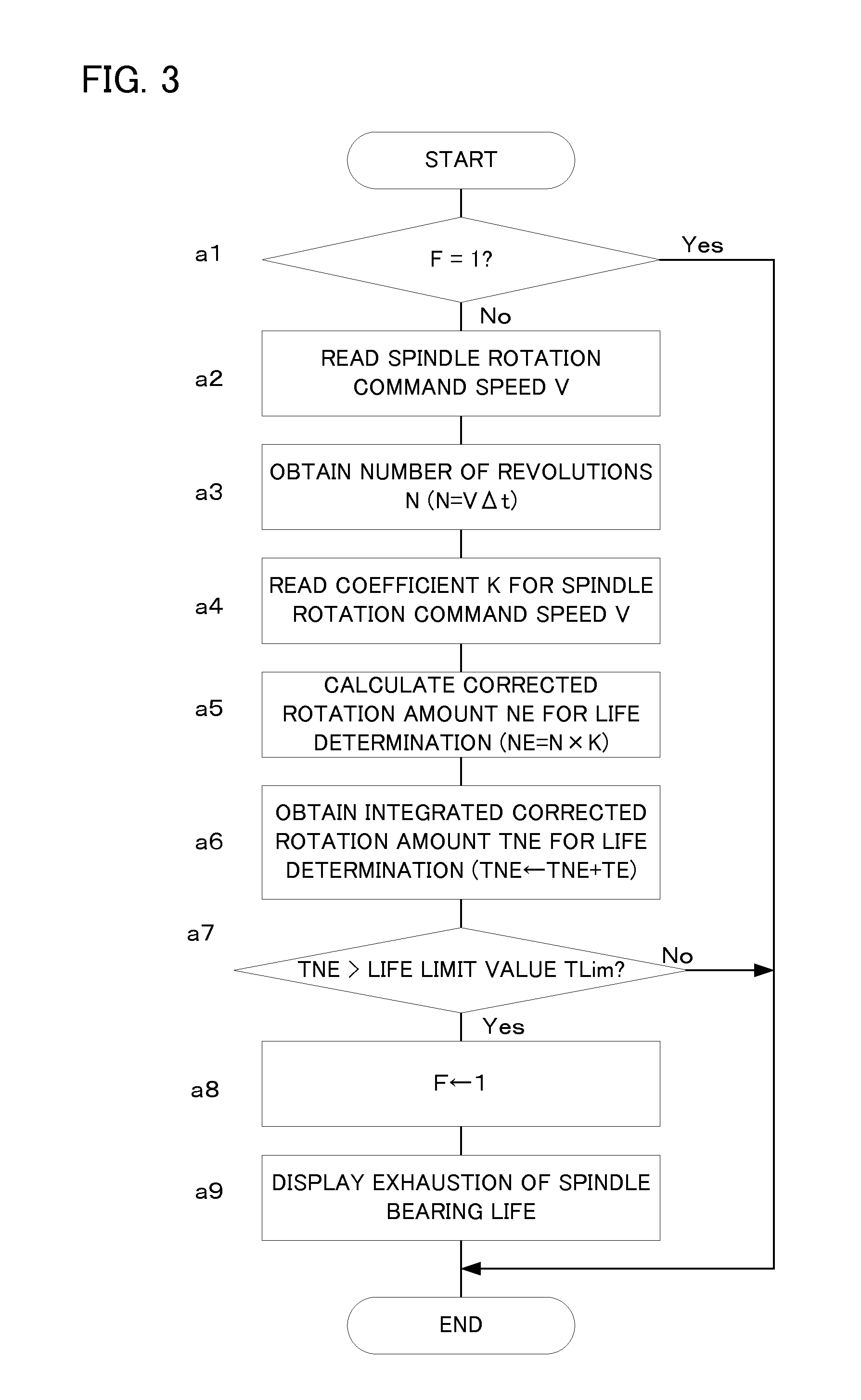

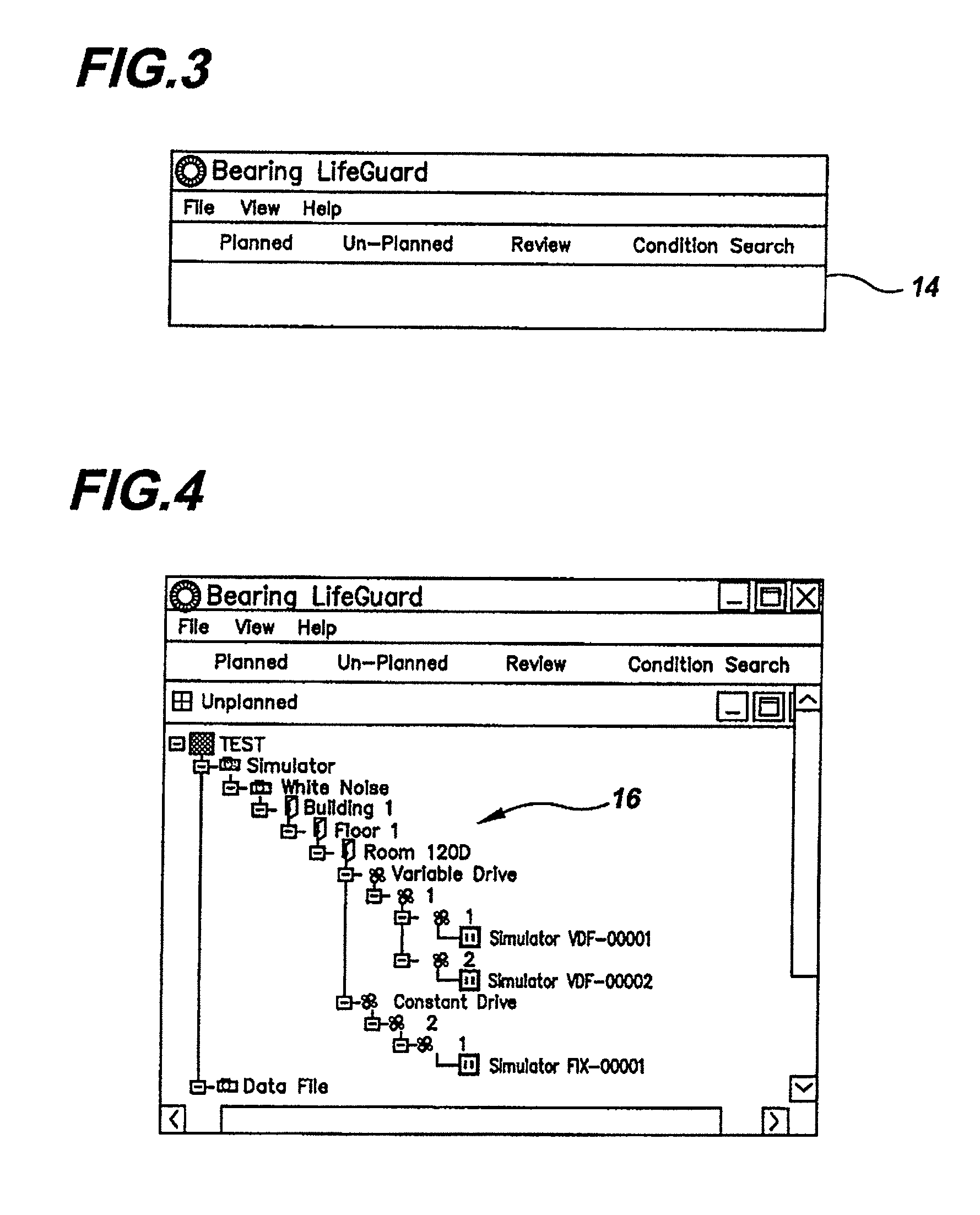

Bearing life determination device

A corrected rotation amount, based on conversion to a rotation amount at a reference rotational speed, is obtained by multiplying a command speed read in each period by a period time and a coefficient value corresponding to the rotational speed. An integrated corrected rotation amount is obtained by integrating the corrected rotation amount. If this integrated corrected rotation amount exceeds a life limit value, the life of a bearing is determined to be exhausted.

Owner:FANUC CORP

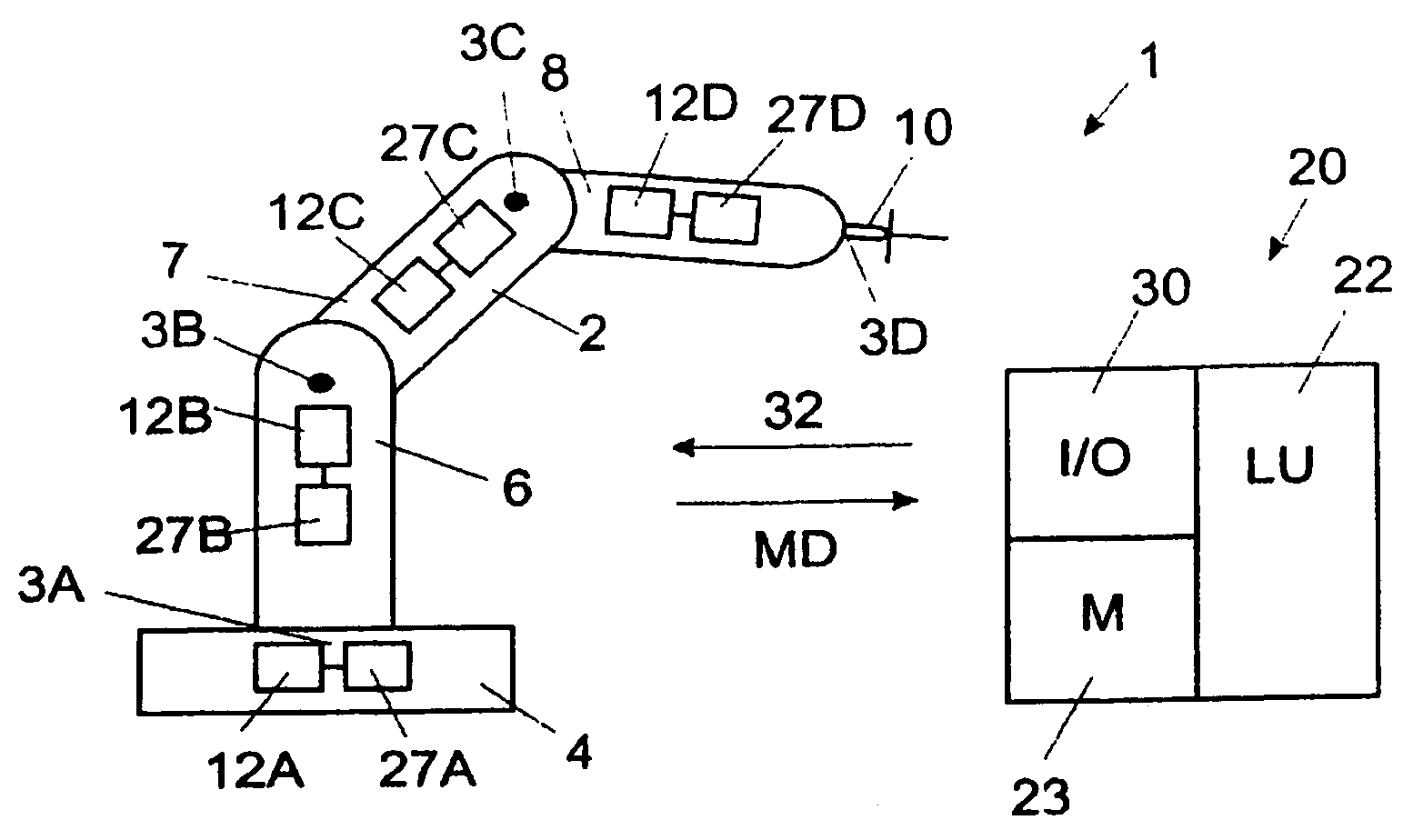

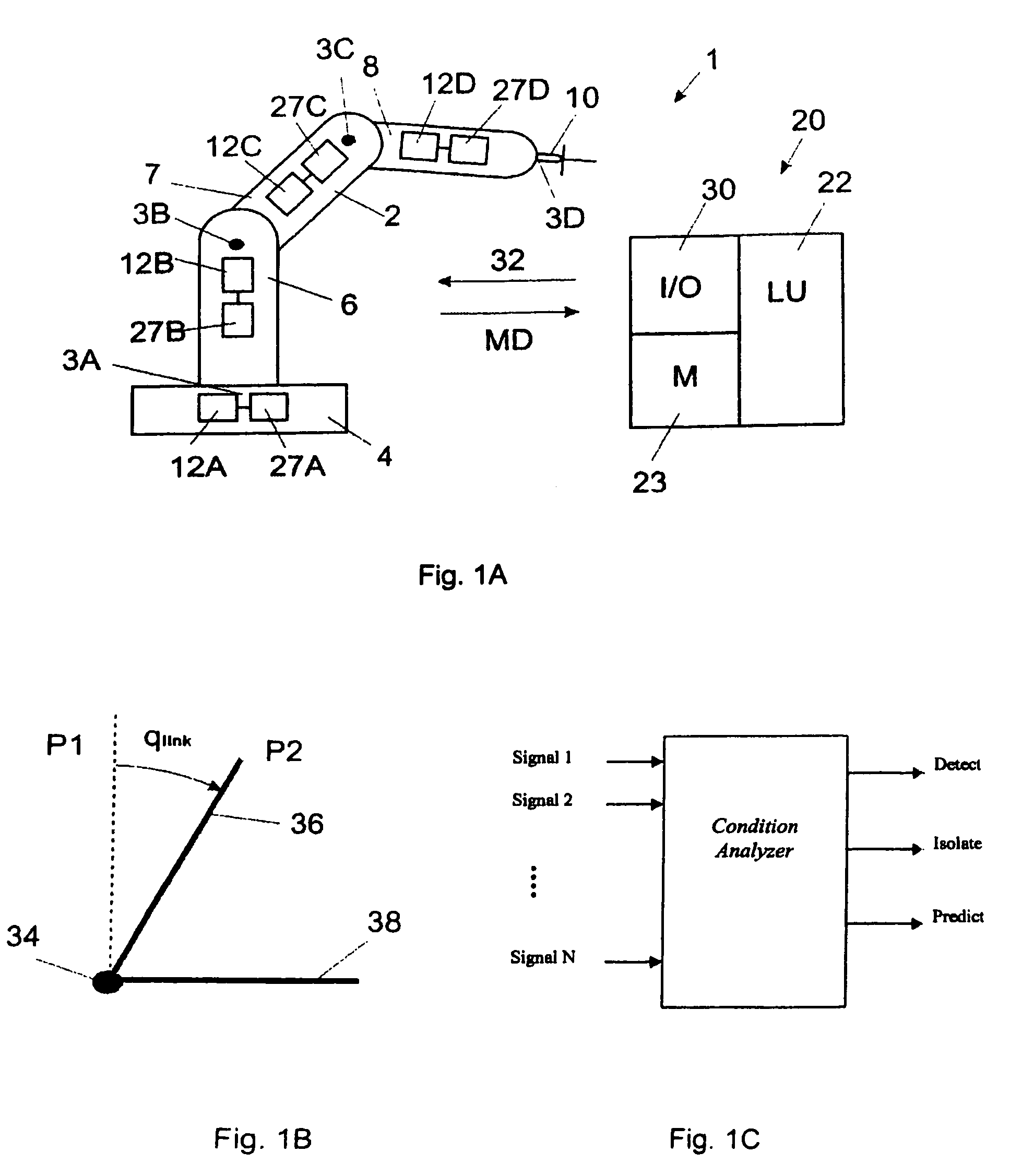

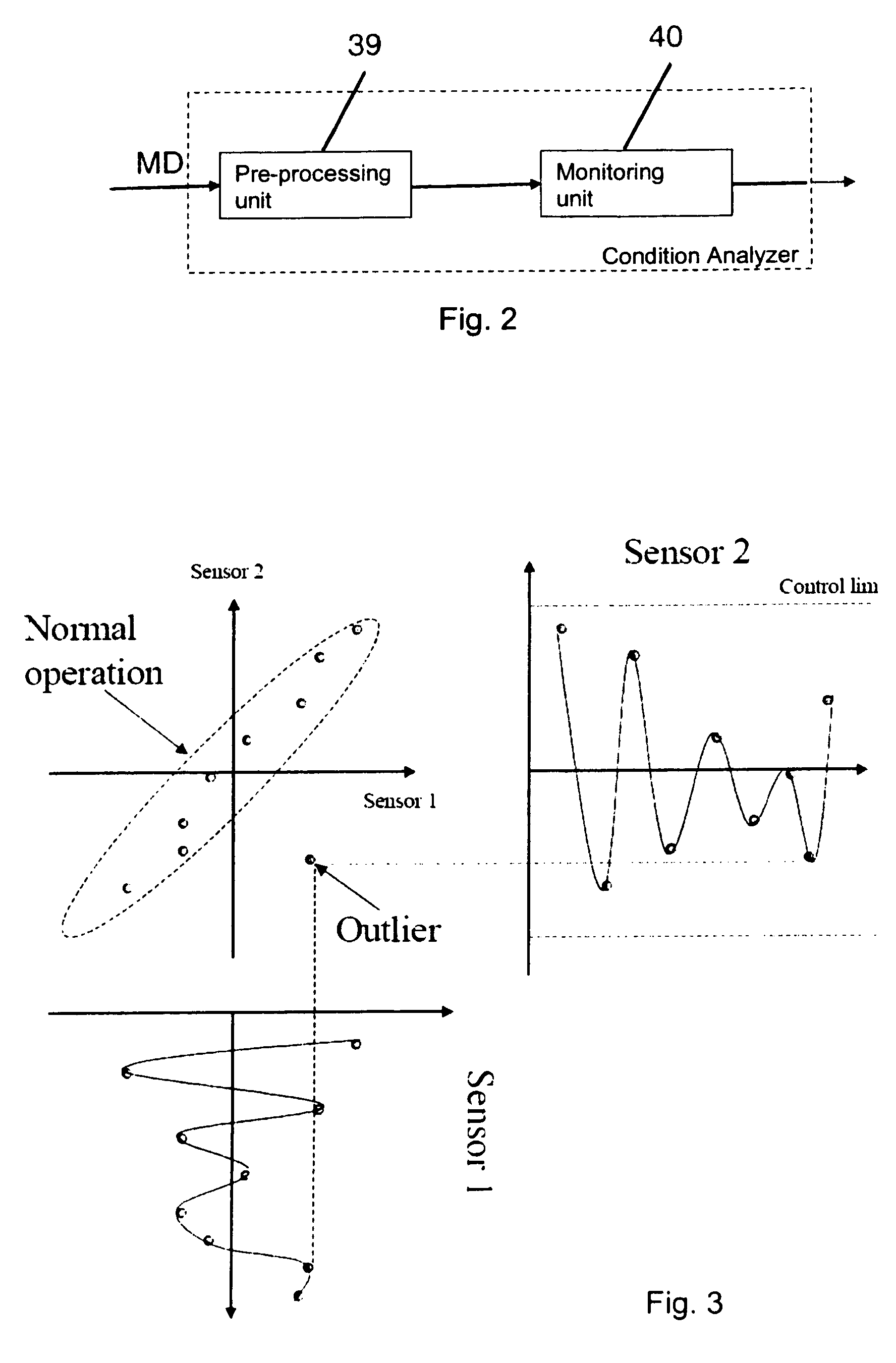

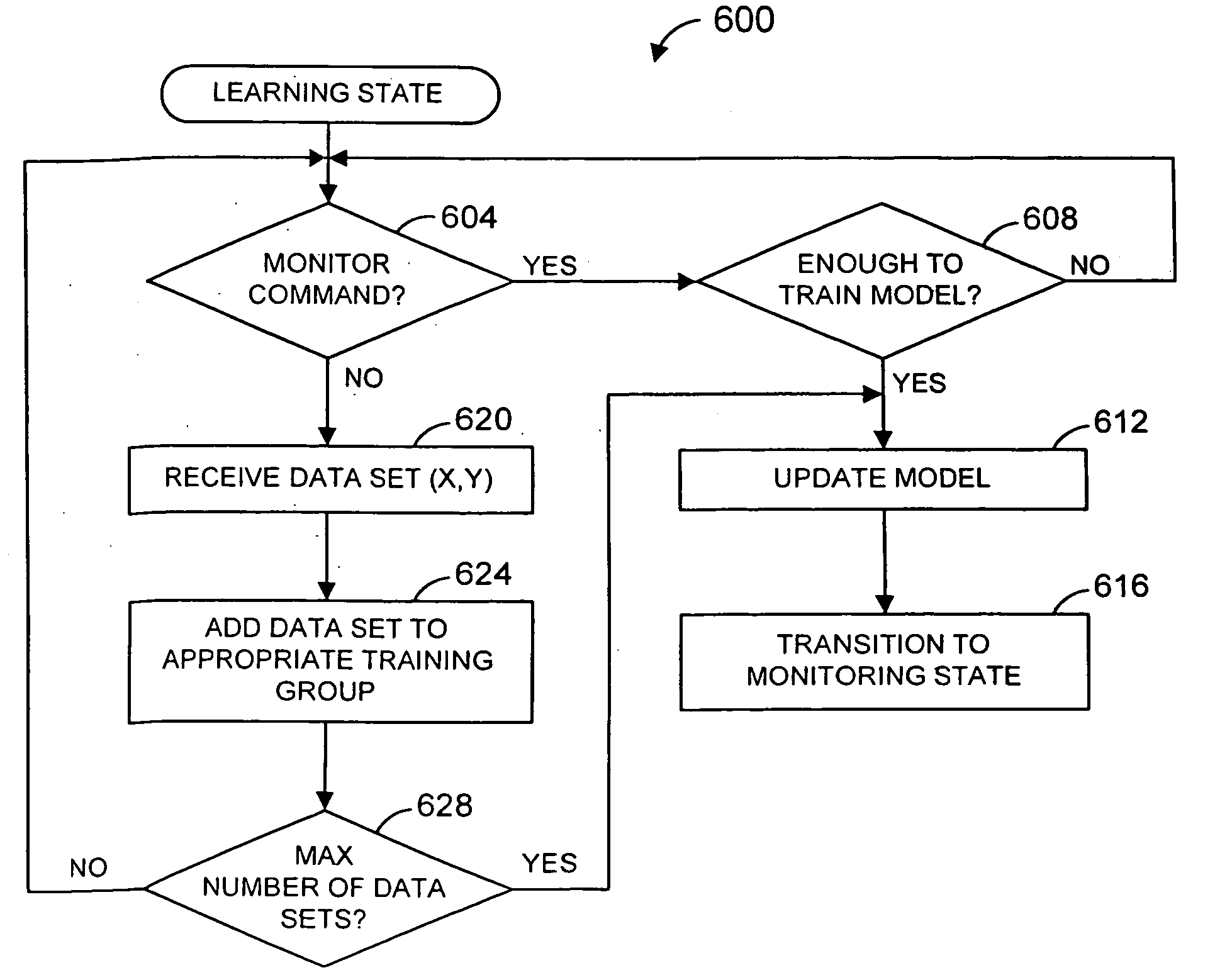

Method and a control system for monitoring the condition of an industrial robot

ActiveUS7826984B2Overcomes drawbackAutomatically conditionProgramme controlProgramme-controlled manipulatorRobotic systemsControl system

An industrial robot diagnostic method including performing a condition analysis utilizing at least two selected input signals, wherein each selected input signal indicates a condition related to a property of the industrial robot, performing an analysis of any combination of the selected input signals utilizing a signal modeling of the signals and outputting from the condition analyzer a result being at least one of: a detection of a malfunction of the robot system, an identification of a root cause failure in the robot system and prediction of a potential malfunction in the robot system. Also an industrial robot system utilizing the method.

Owner:ABB (SCHWEIZ) AG +1

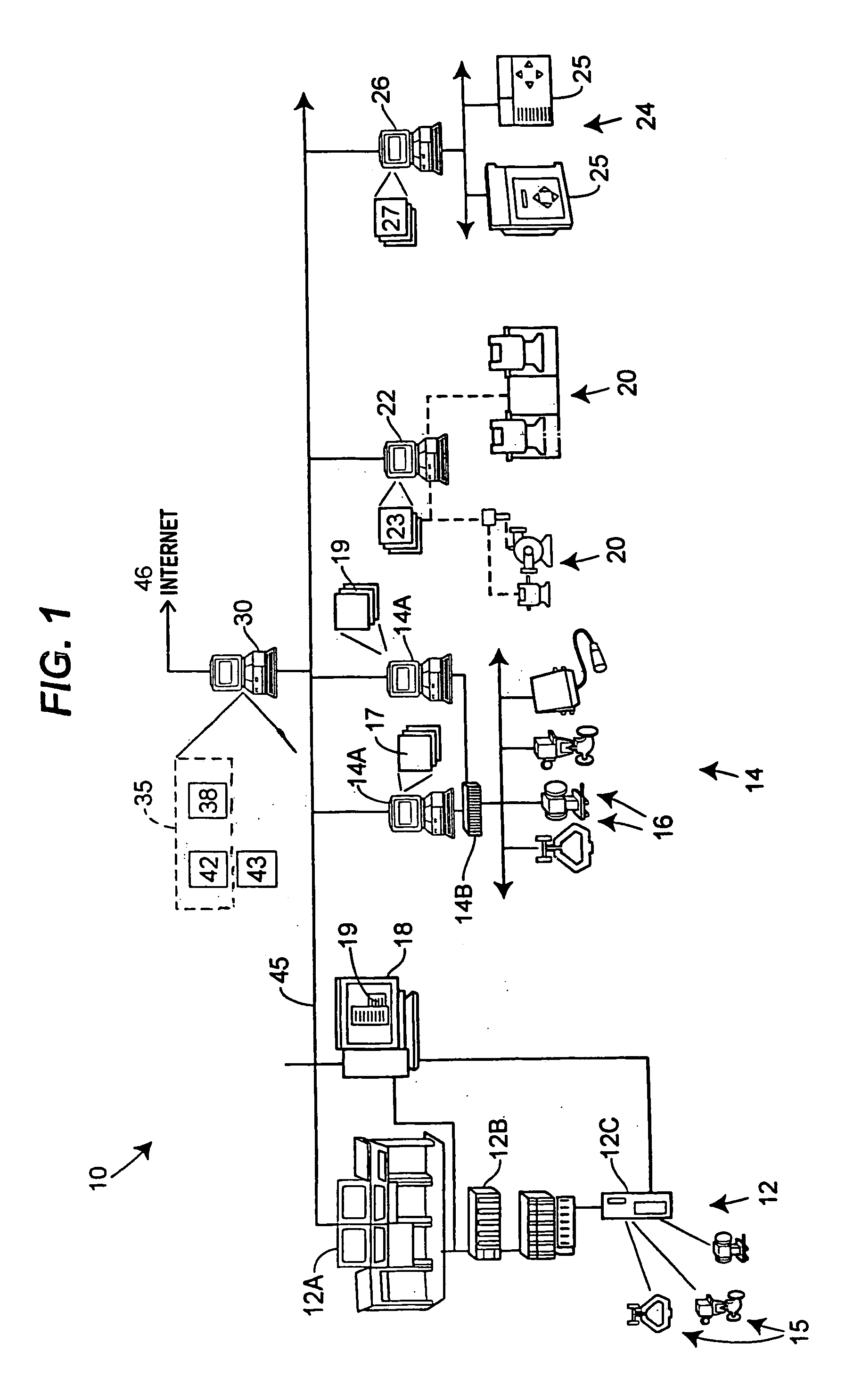

Method and system for detecting abnormal operation in a process plant

ActiveUS20080027678A1Easy to detectPlug gaugesMeasurement arrangements for variableProcess engineeringProcess plant

A system for detecting abnormal operation of at least a portion of a process plant includes a model to model at least the portion of the process plant. The model may be configurable to include multiple regression models corresponding to multiple different operating regions of the portion of the process plant. The system may also include a deviation detector configured to determine if the actual operation of the portion of the process plant deviates significantly from the operation predicted by the model. If there is a significant deviation, this may indicate an abnormal operation.

Owner:FISHER-ROSEMOUNT SYST INC

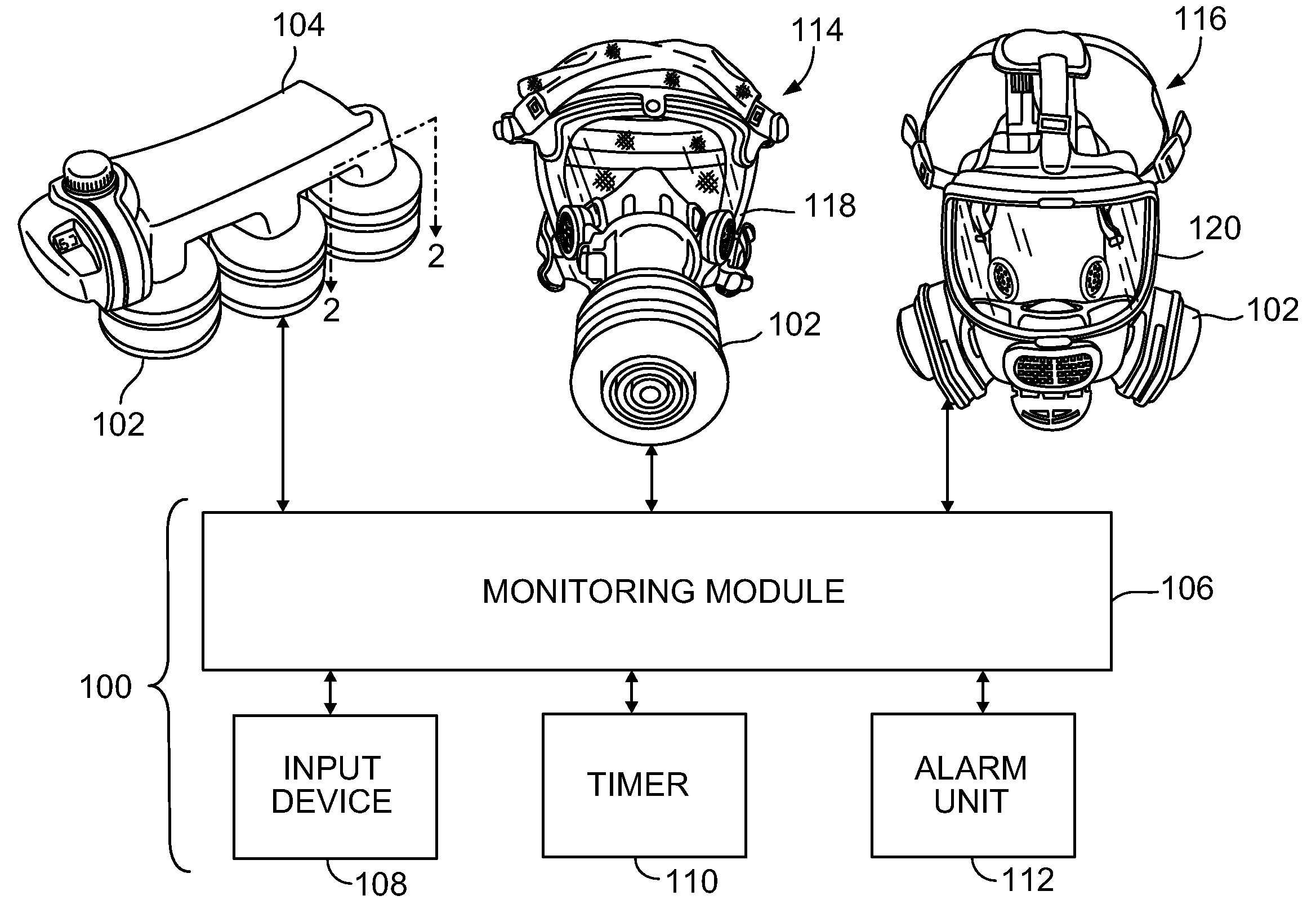

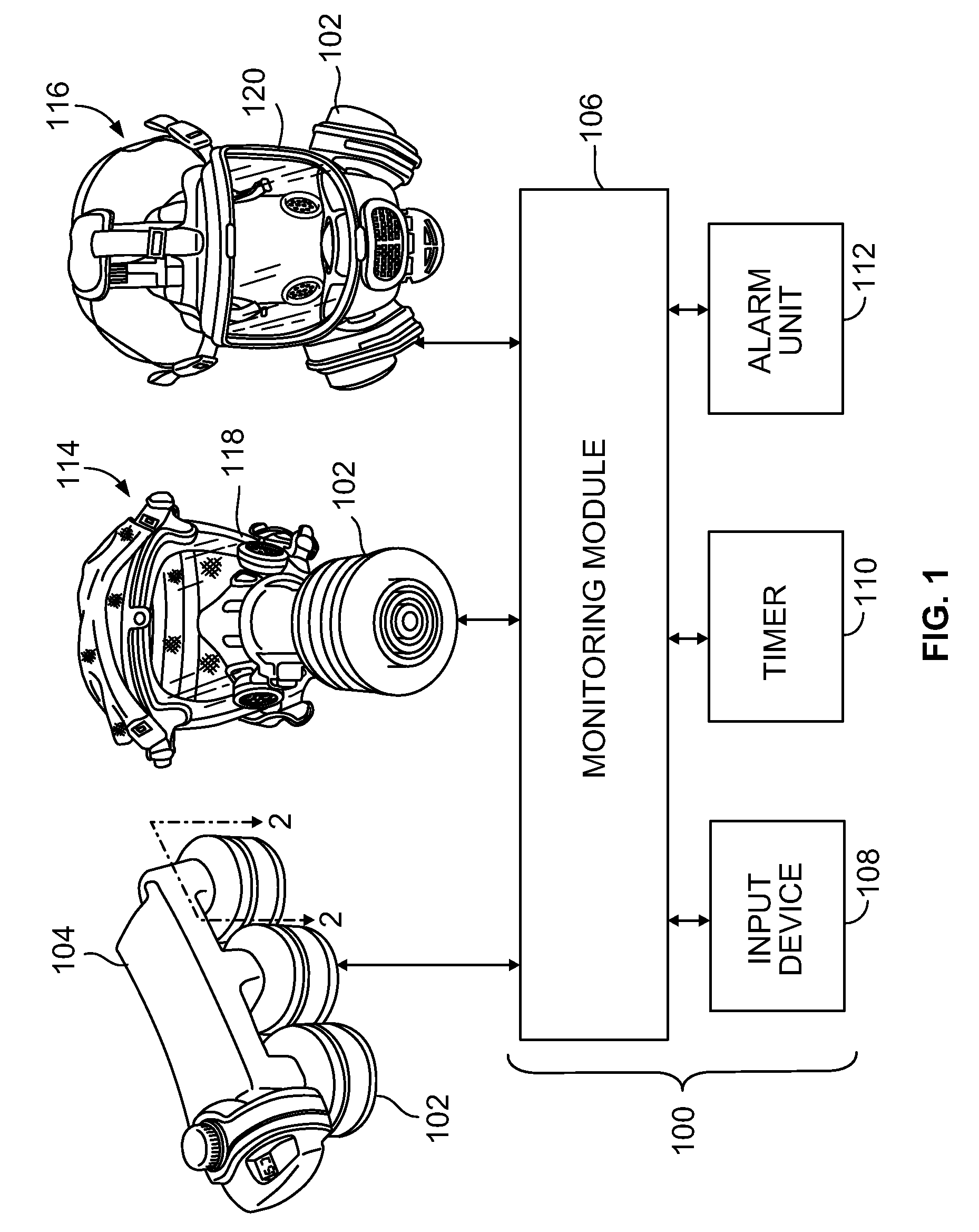

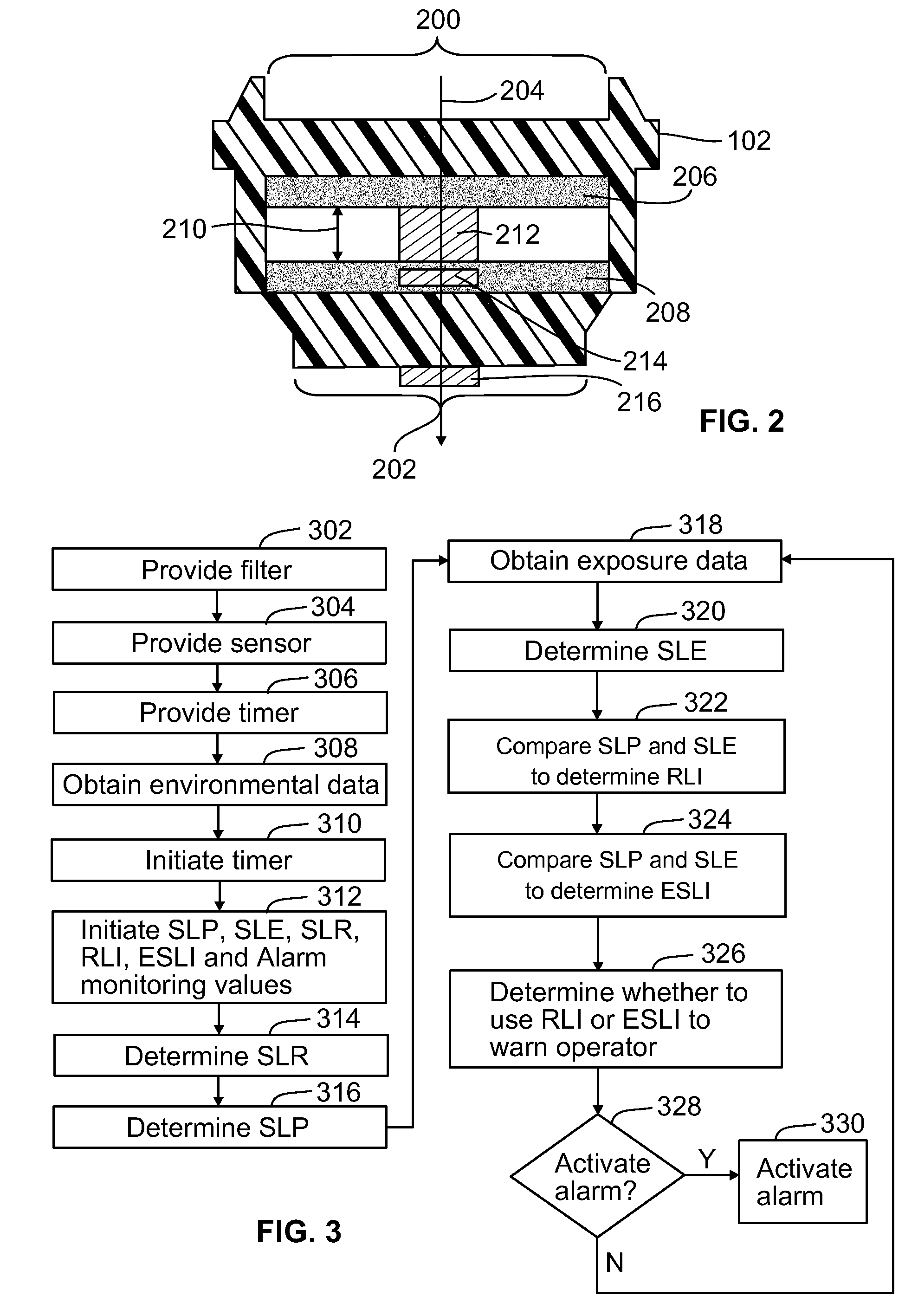

Systems and methods for determining filter service lives

A method for determining a service life for a filter includes measuring exposure data and calculating a service life estimate based on the exposure data. The service life estimate is representative of an estimated exposure time that the filter is exposed to ambient conditions represented by the exposure data before the contaminant passes through the filter at a breakthrough concentration. The method also includes obtaining environmental data and establishing a predicted service life based on the environmental data. The predicted service life is representative of a predicted exposure time that the filter is exposed to the ambient conditions represented by the environmental data before the contaminant passes through the filter at the breakthrough concentration. The method further includes determining the service life for the filter based on a comparison of the estimated and predicted service lives.

Owner:SCOTT TECH INC

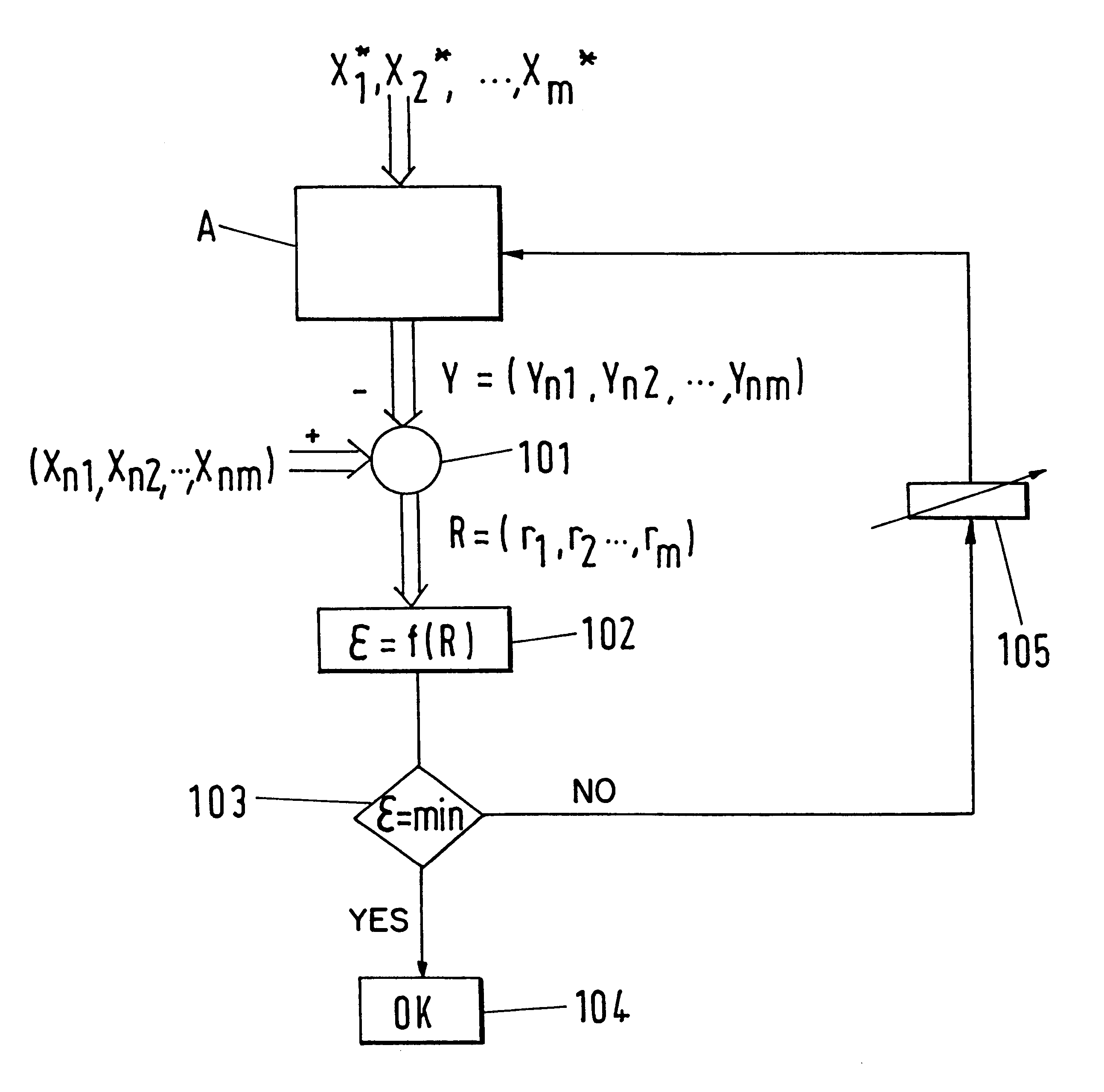

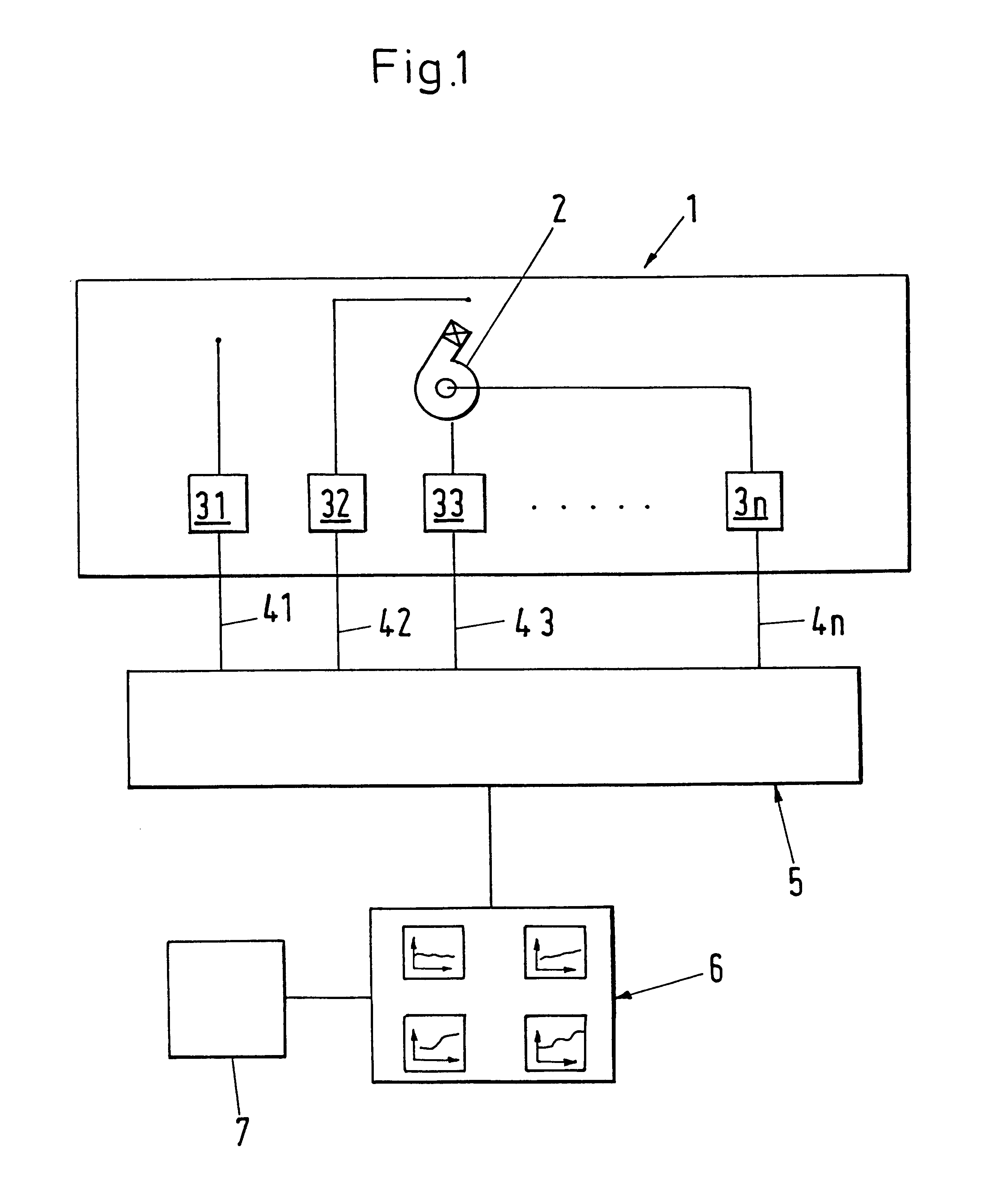

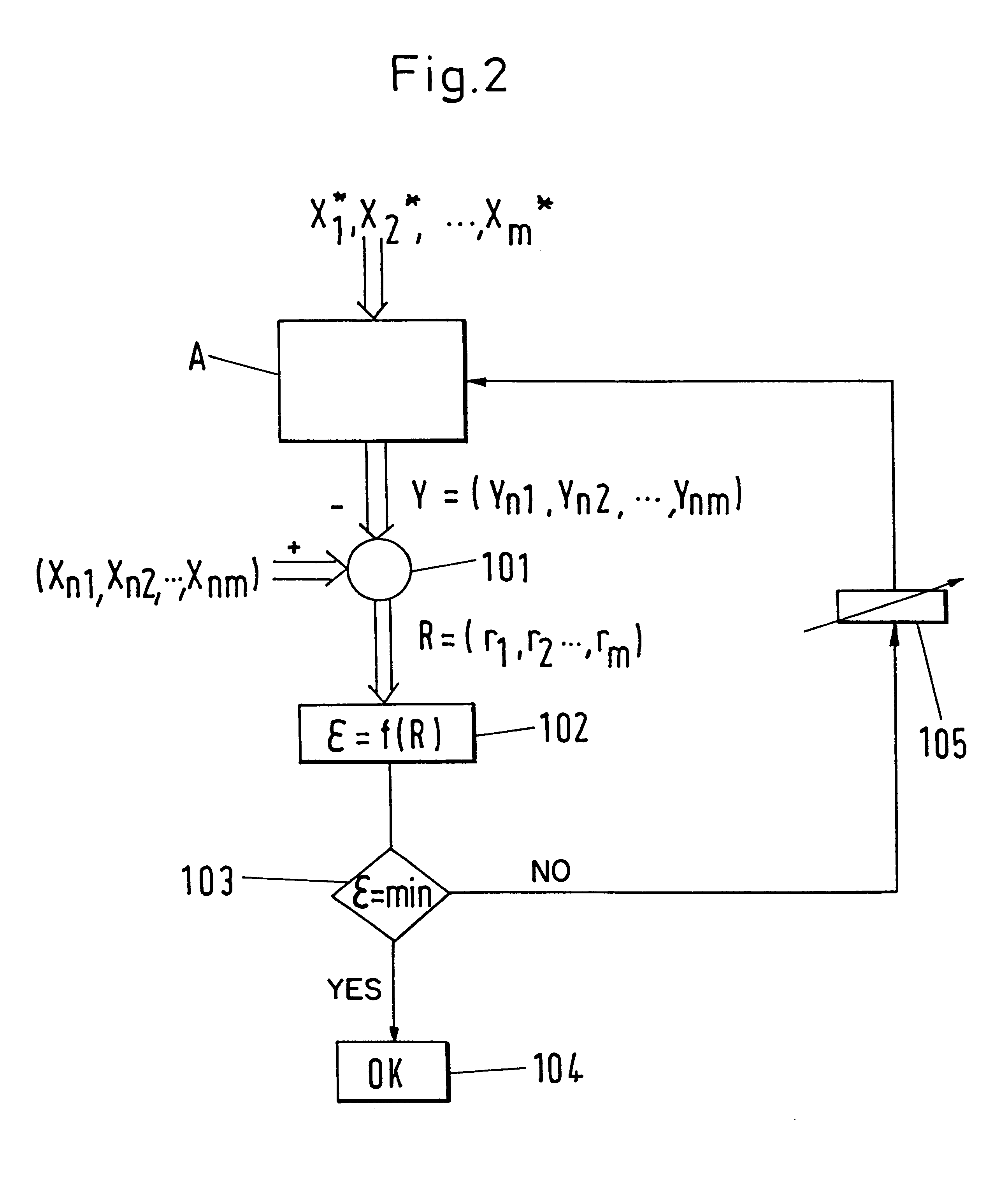

Method for monitoring plants with mechanical components

InactiveUS6208953B1Unnecessary standstill timeReduce maintenance costsPlug gaugesRegistering/indicating working of machinesMechanical componentsOperational behavior

In a method for monitoring plants with mechanical components, measured values (xiT; xiu) are determined at predeterminable time intervals for a fixed set of parameters (xi). The measured values (xiT) which are determined for various working points during a modelling phase are used for the generation of a model for the operating behavior of the components. With the help of the model for the operating behavior at least one monitoring value (r; snu) is derived at predeterminable time intervals which is independent of the respective current working point. The temporal behavior of the monitoring value (r; snu) is used for estimating the wear in the components and / or for the detection of operating disturbances.

Owner:SULZER INNOTEC

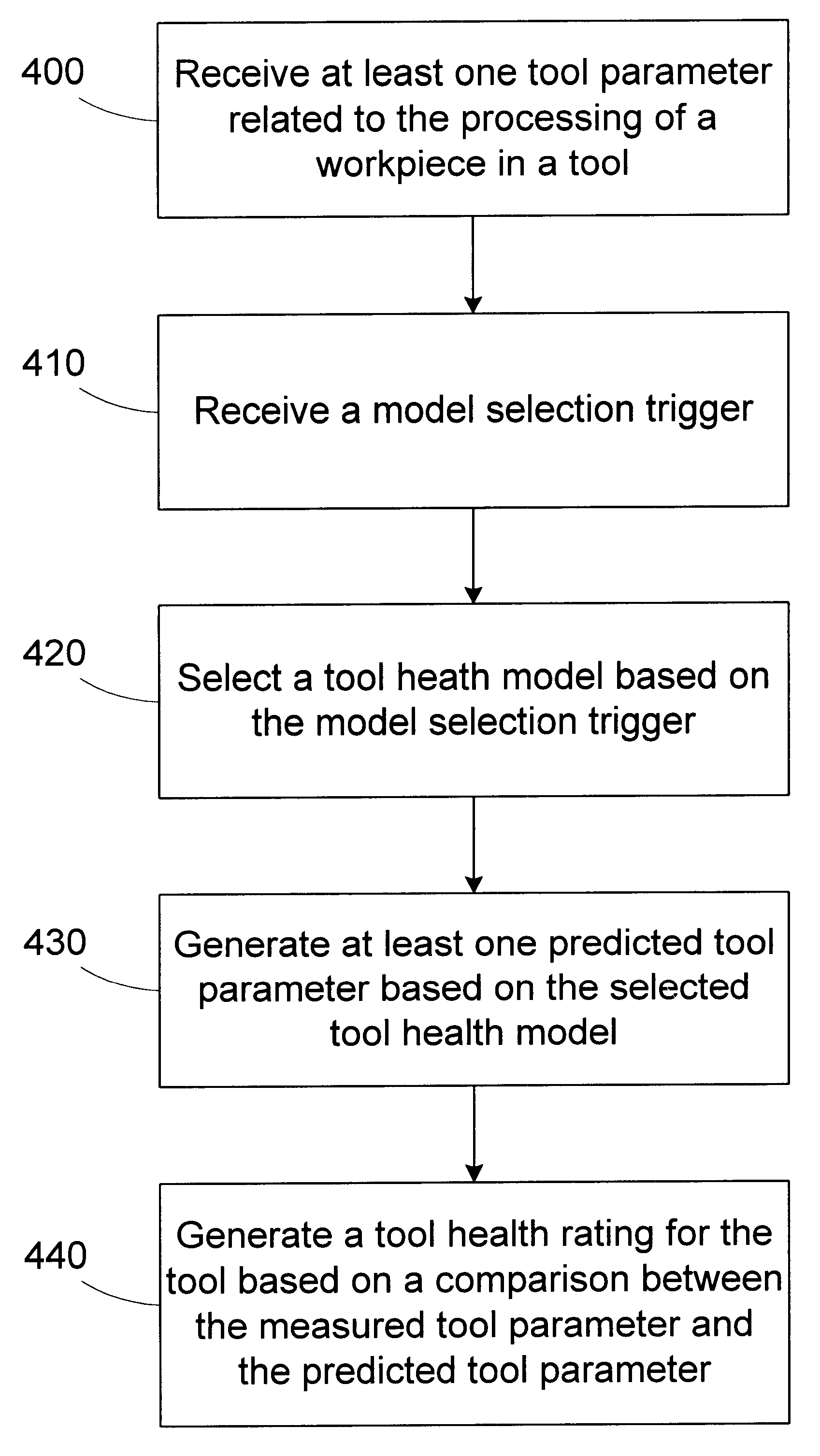

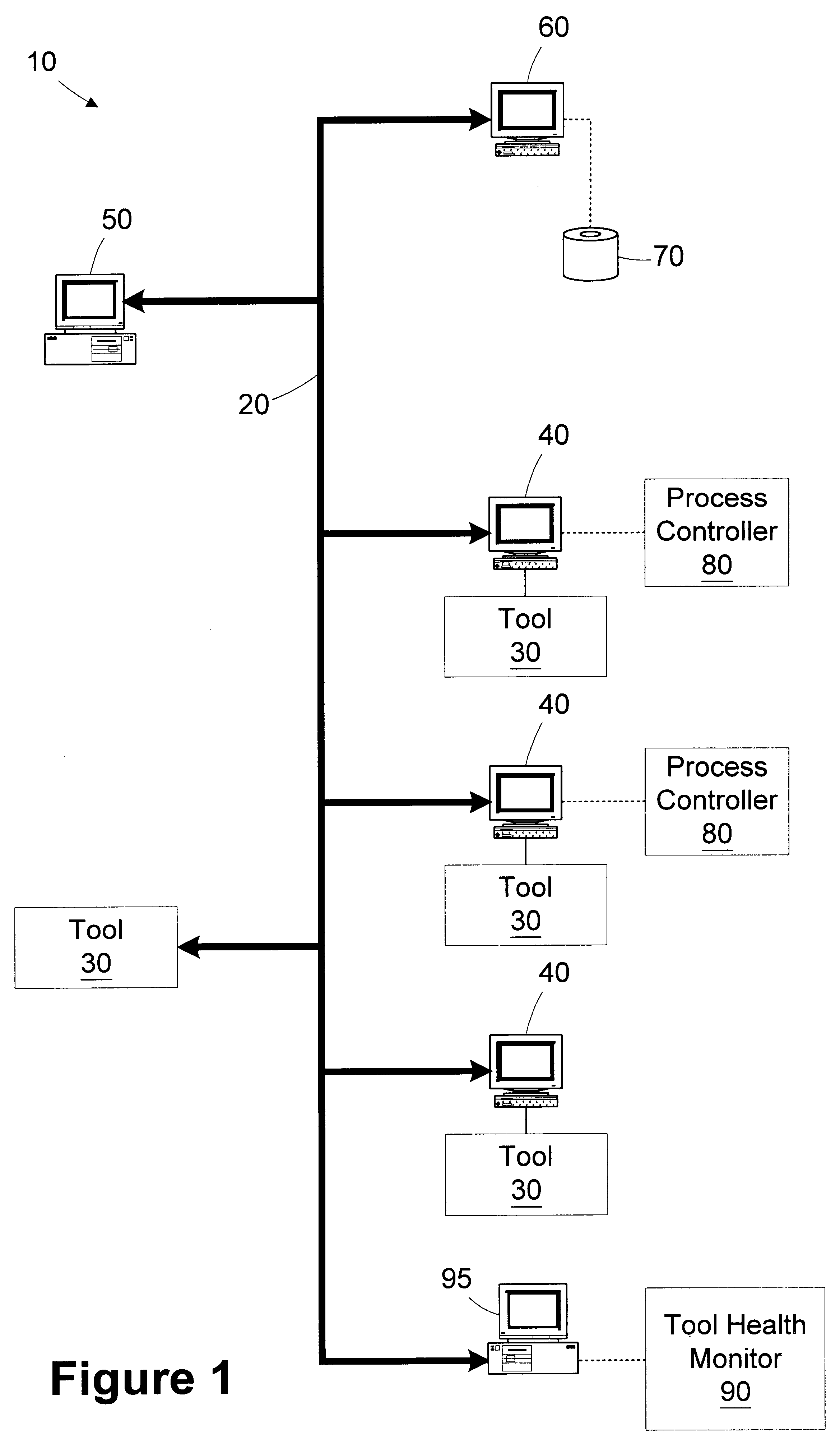

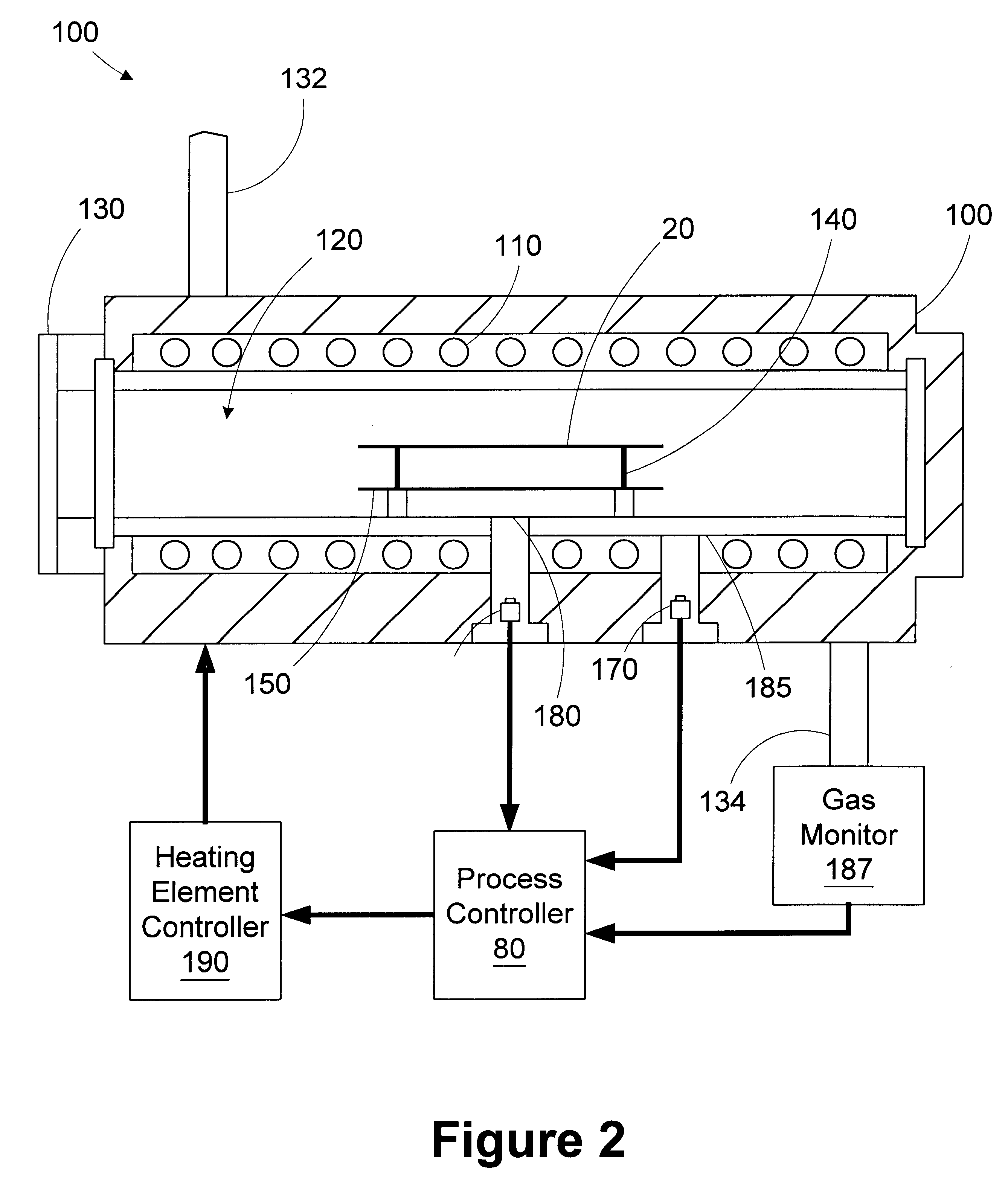

Method and apparatus for monitoring tool health

A method for monitoring health of a tool includes receiving at least one tool parameter related to the processing of a workpiece in a tool; receiving a model selection trigger; selecting a tool health model based on the model selection trigger; generating at least one predicted tool parameter based on the selected tool health model; and generating a tool health rating for the tool based on a comparison between the measured tool parameter and the predicted tool parameter. A tool health monitor includes a library of tool health models, a model selector, and a fault detection and classification unit. The model selector is adapted to receive a model selection trigger and select a tool health model based on the model selection trigger. The fault detection and classification unit is adapted to receive at least one tool parameter related to the processing of a workpiece in a tool, generate at least one predicted tool parameter based on the selected tool health model, and generate a tool health rating for the tool based on a comparison between the received tool parameter and the predicted tool parameter.

Owner:ADVANCED MICRO DEVICES INC

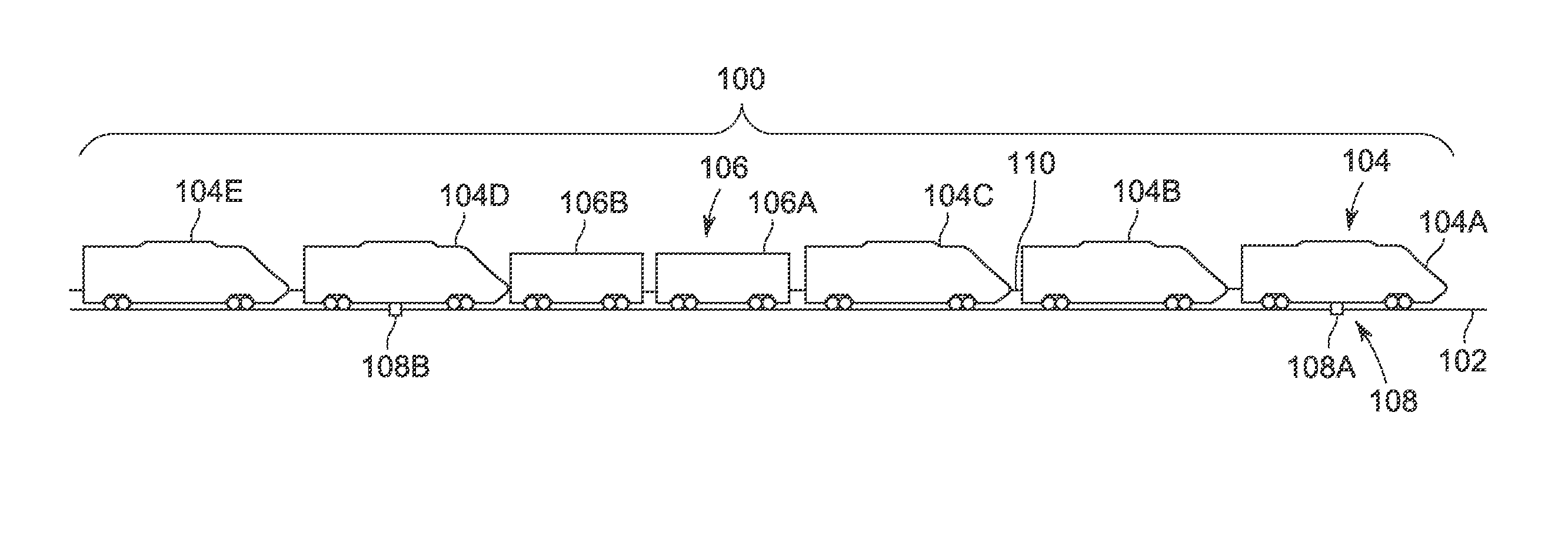

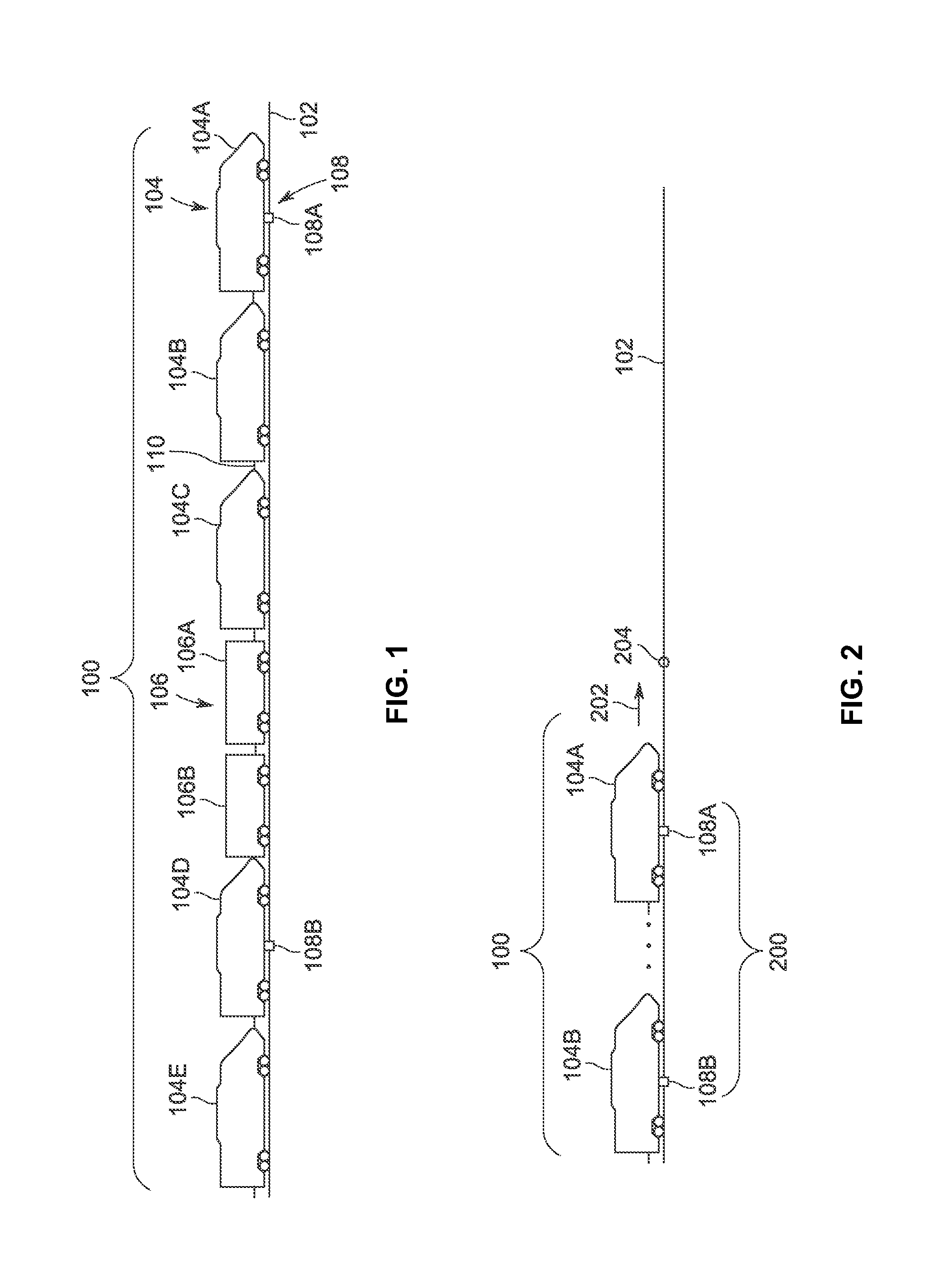

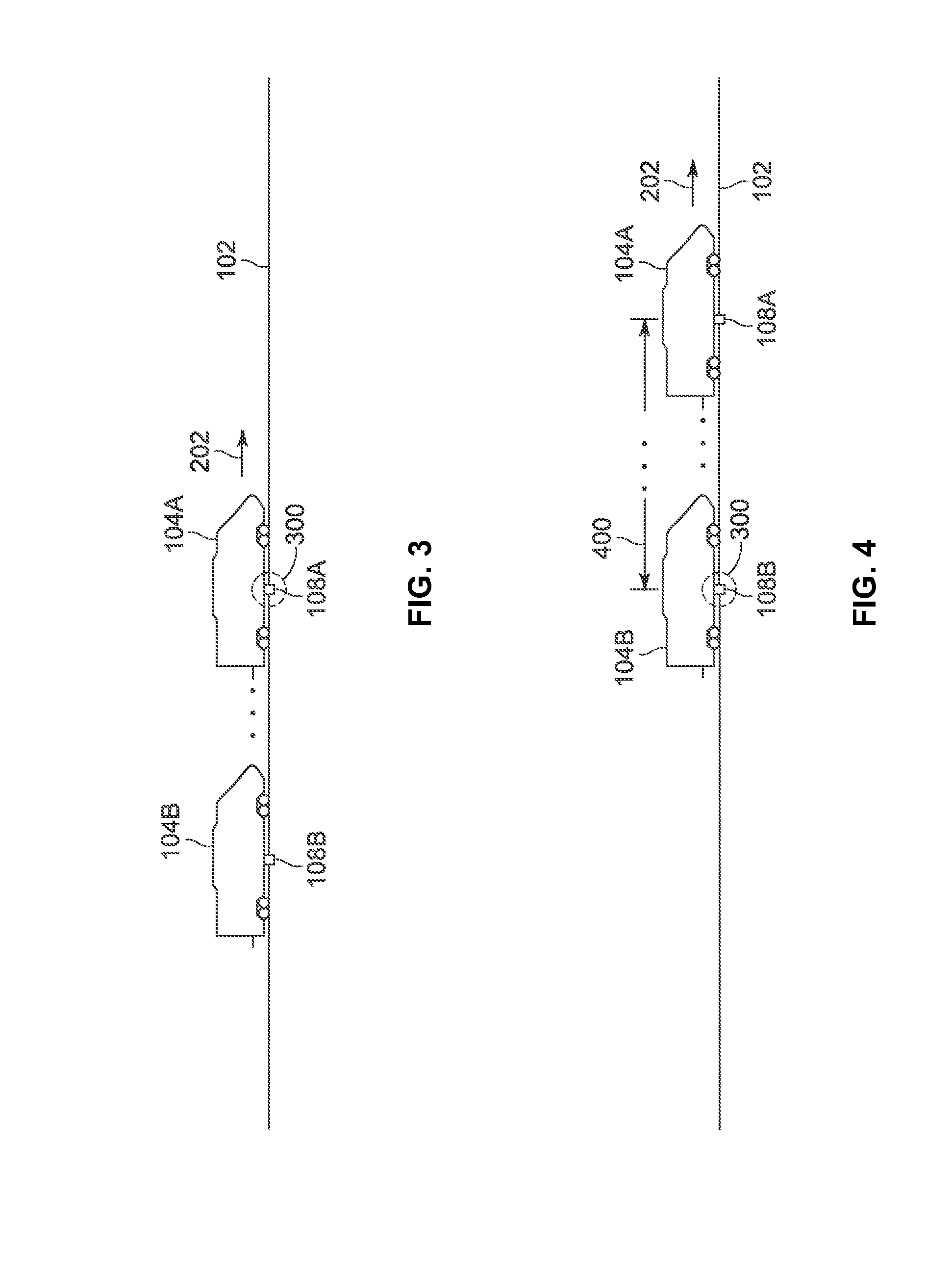

System and method for inspecting a route during movement of a vehicle system over the route

A sensing system includes a leading sensor, a trailing sensor, and a route examining unit. The leading sensor is onboard a first vehicle of a vehicle system that is traveling along a route. The leading sensor measures first characteristics of the route as the vehicle system moves along the route. The trailing sensor is disposed onboard a second vehicle of the vehicle system. The trailing sensor measures second characteristics of the route as the vehicle system moves along the route. The route examining unit is disposed onboard the vehicle system and receives the first characteristics of the route and the second characteristics of the route to compare the first characteristics with the second characteristics. The route examining unit also identifies a segment of the route as being damaged based on a comparison of the first characteristics with the second characteristics.

Owner:GE GLOBAL SOURCING LLC

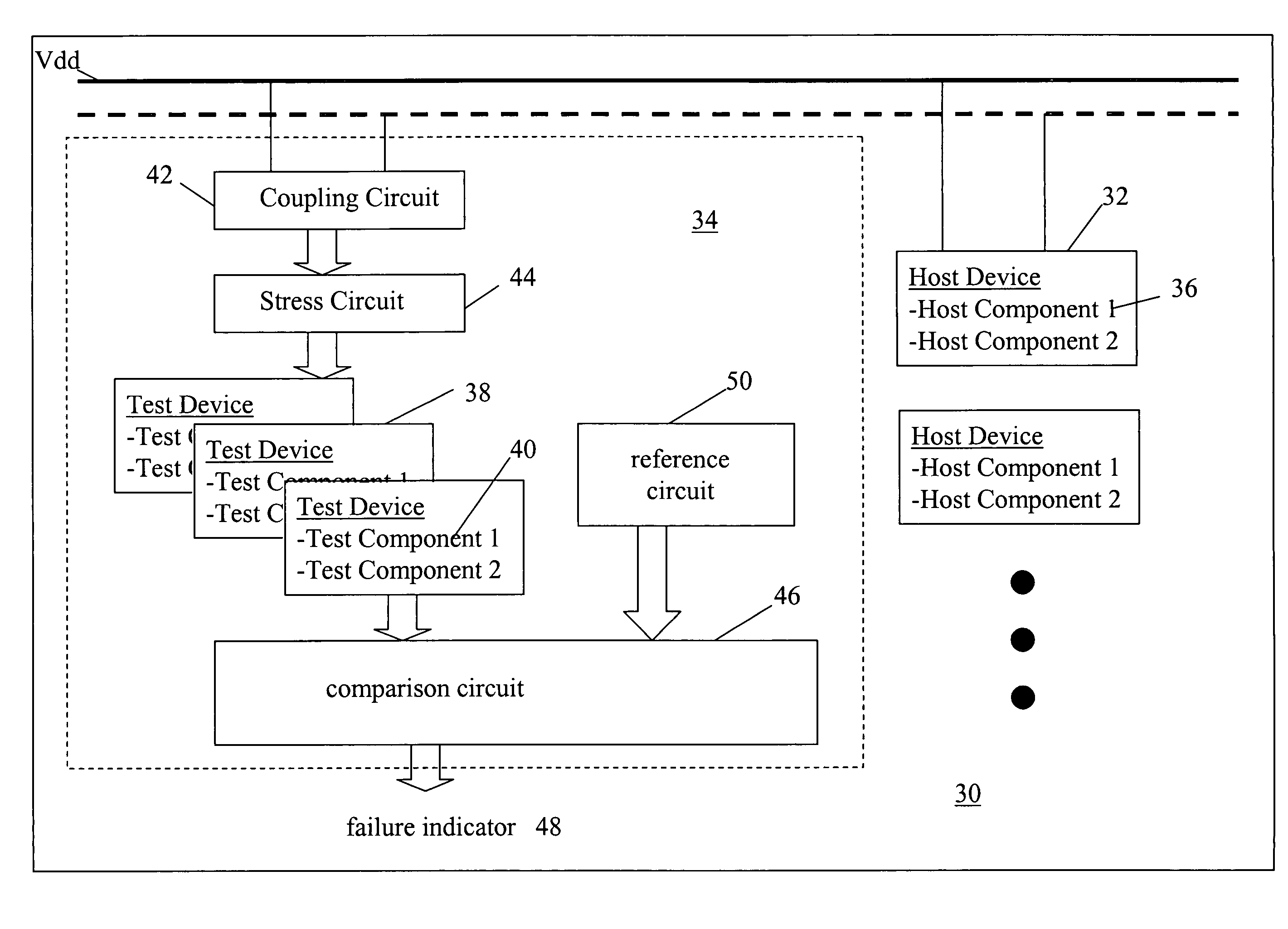

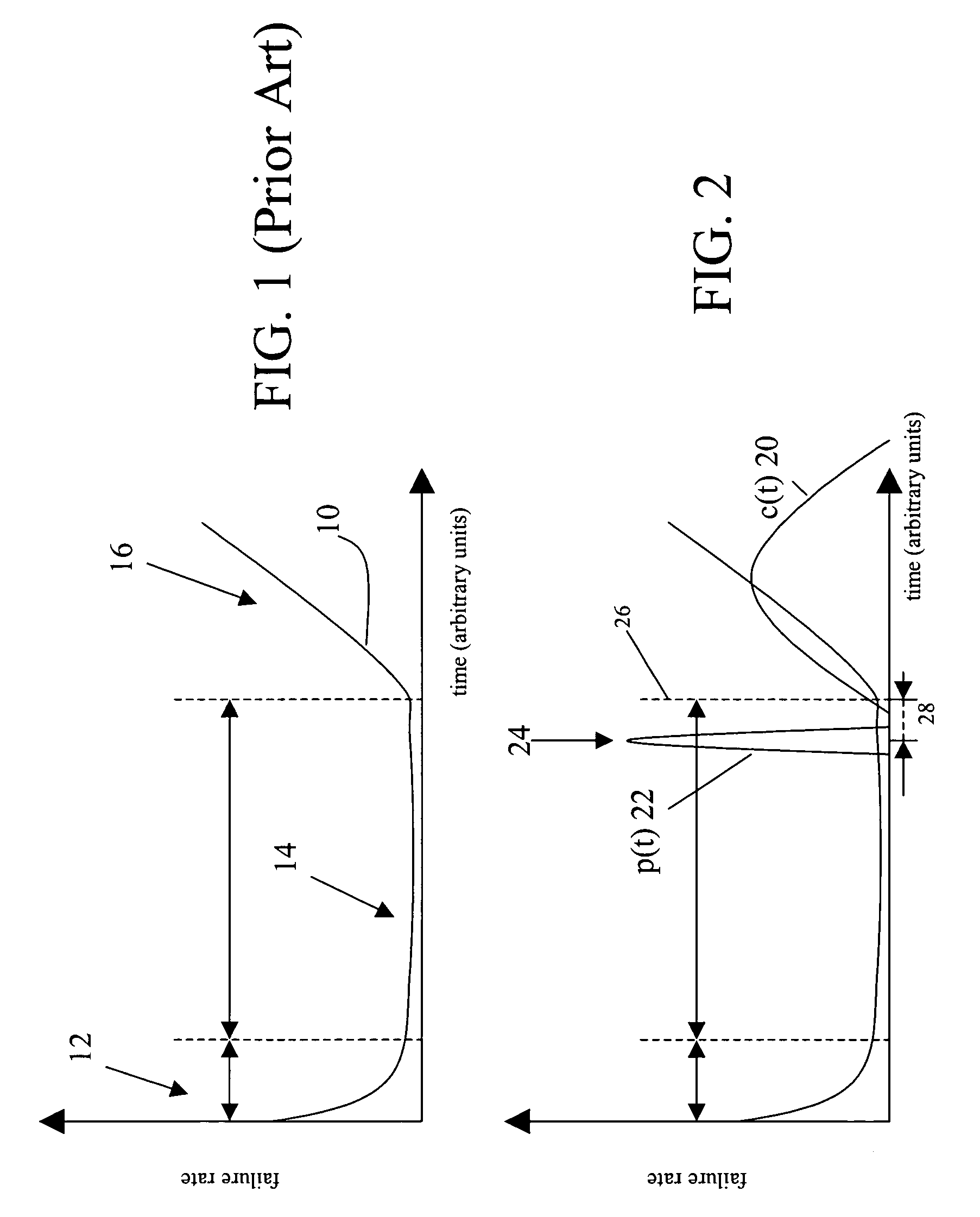

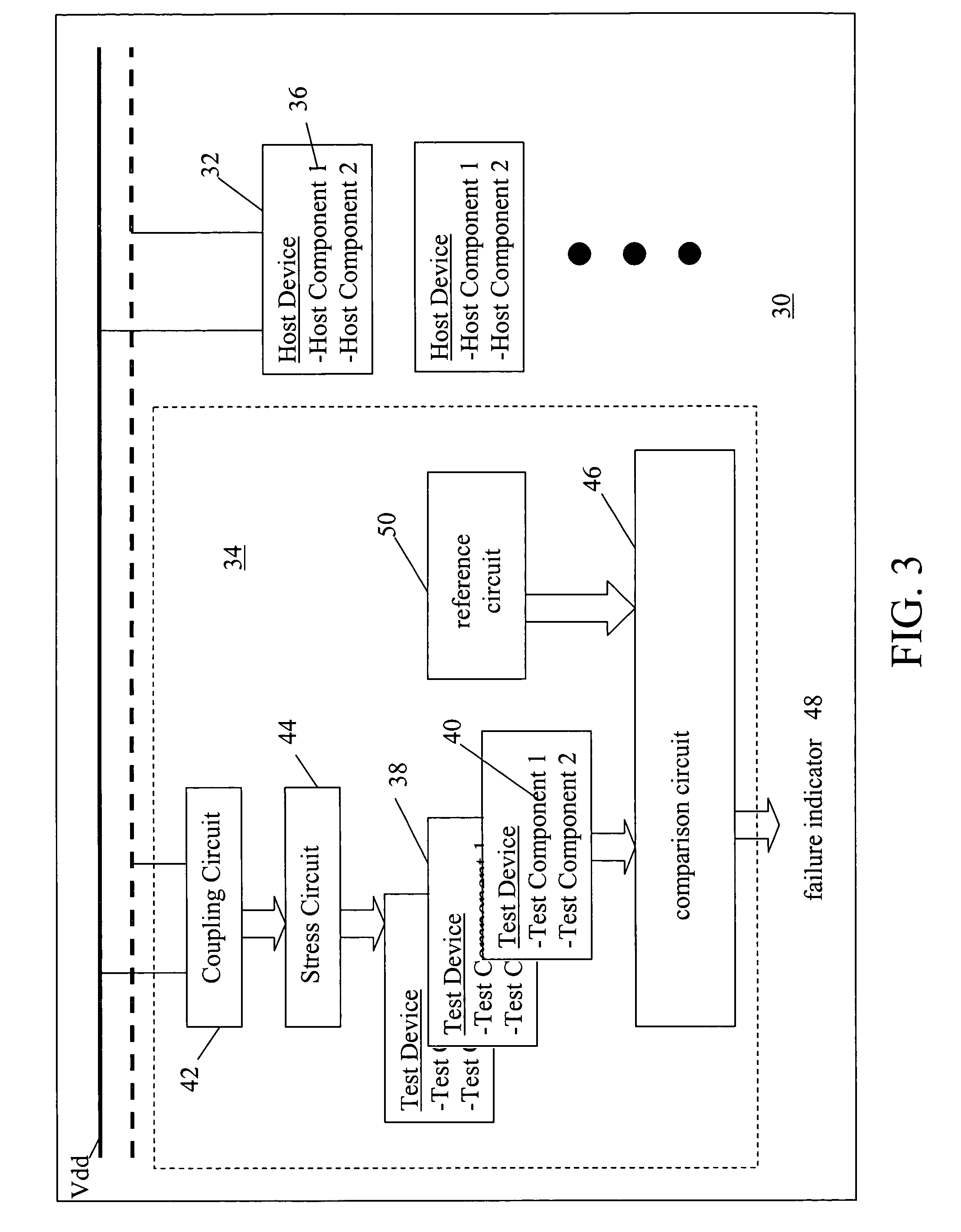

Prognostic cell for predicting failure of integrated circuits

InactiveUS7271608B1Improve deteriorationLow operating pressurePlug gaugesAlarmsRelative timesIntegrated circuit

A prognostic cell is used to predict impending failure of a useful circuit or circuits in a host IC. Increasing the stress on the prognostic cell relative to the useful circuit shifts the failure distribution of the cell along the time axis. The relative amount of time between the useful circuit failure and prognostic cell trigger point is the “prognostic distance”. The prognostic distance is controlled by designing in the excess stress applied in test device(s), by setting the threshold for triggering in the comparison circuit or by both. Prediction accuracy is enhanced by using multiple test devices to oversample the underlying failure distribution and triggering the failure indicator when a certain fraction fail.

Owner:RIDGETOP GROUP

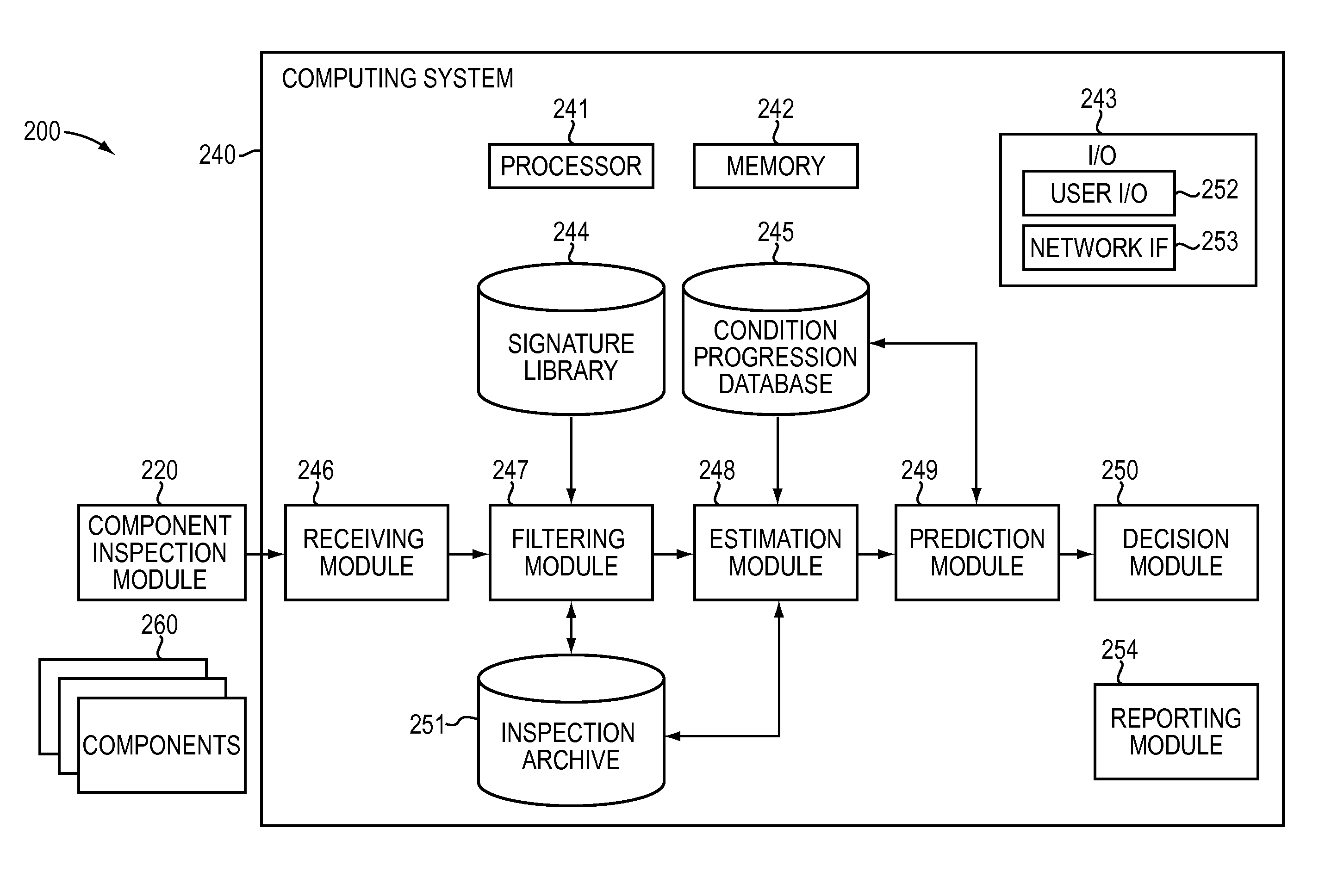

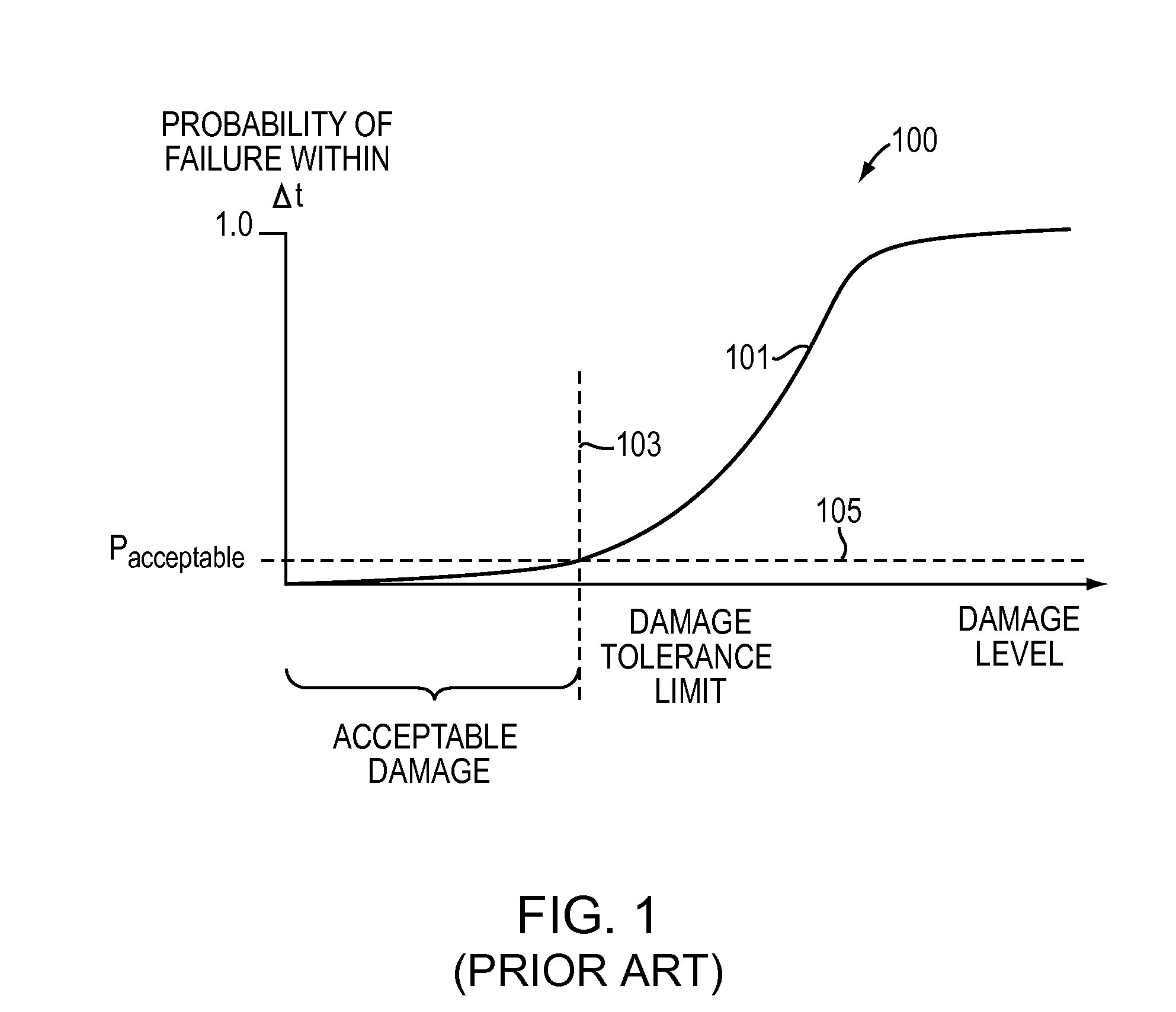

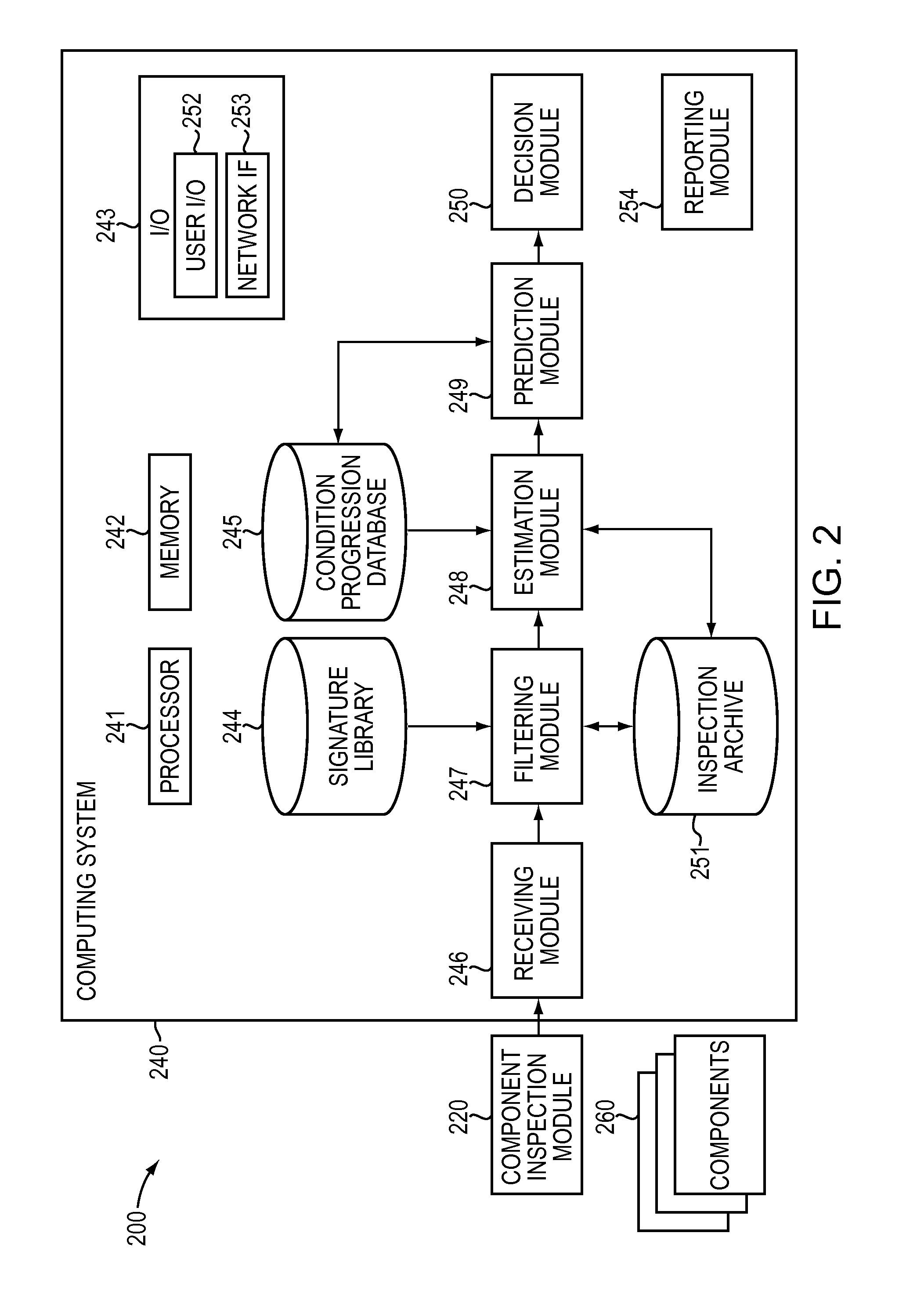

Component Adaptive Life Management

InactiveUS20110054806A1Improve responsePlug gaugesRegistering/indicating working of machinesNon destructiveStress level

A framework for adaptively managing the life of components. A sensor provides non-destructive test data obtained from inspecting a component. The inspection data may be filtered using reference signatures and by subtracting a baseline. The filtered inspection data and other inspection data for the component is analyzed to locate flaws and estimate the current condition of the component. The current condition may then be used to predict the component's condition at a future time or to predict a future time at which the component's condition will have deteriorated to a certain level. A current condition may be input to a precomputed database to look up the future condition or time. The future condition or time is described by a probability distribution which may be used to assess the risk of component failure. The assessed risk may be used to determine whether the part should continue in service, be replaced or repaired. A hyperlattice database is used with a rapid searching method to estimate at least one material condition and one usage parameter, such as stress level for the component. The hyperlattice is also used to rapidly predict future condition, associated uncertainty and risk of failure.

Owner:JENTEK SENSORS

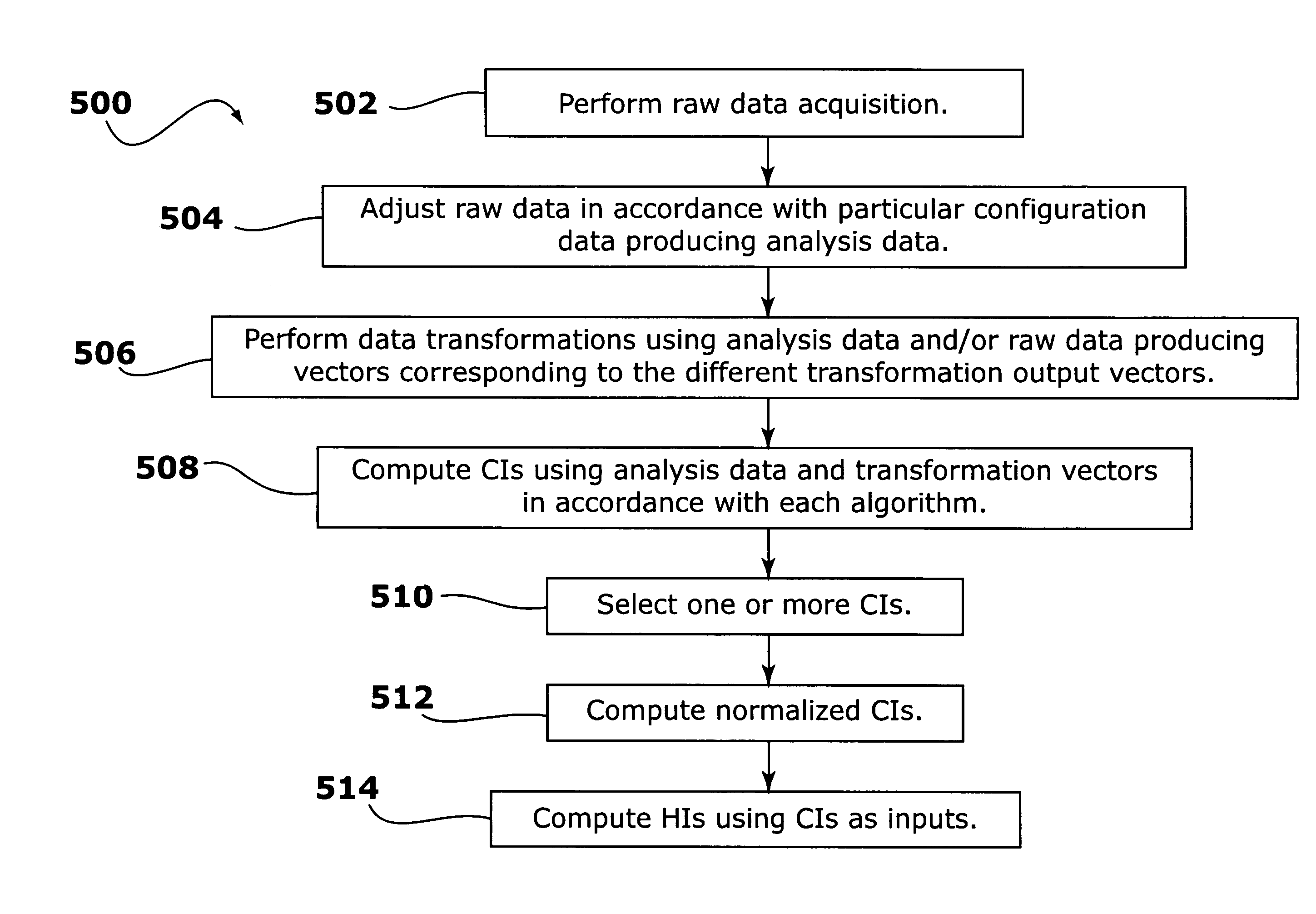

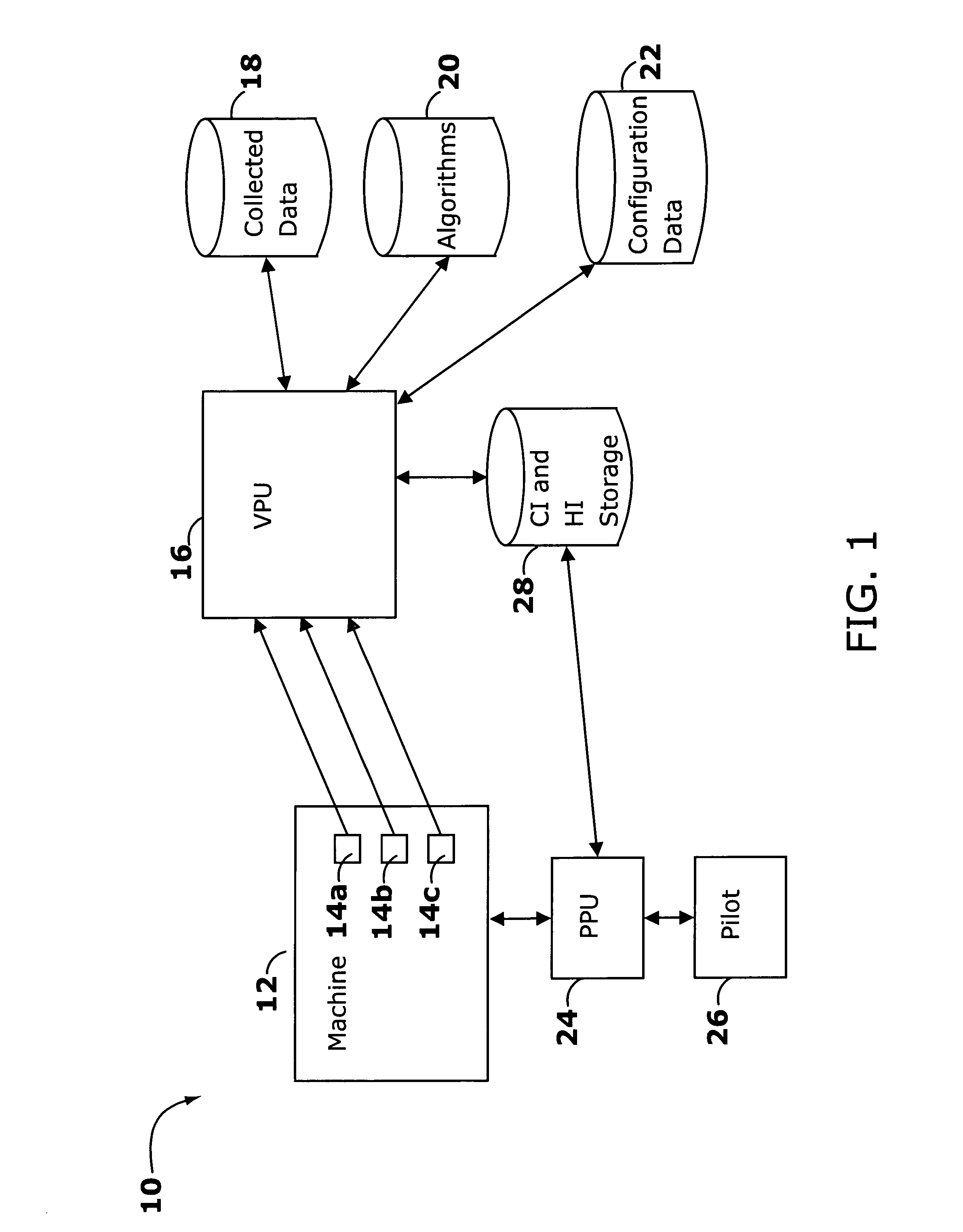

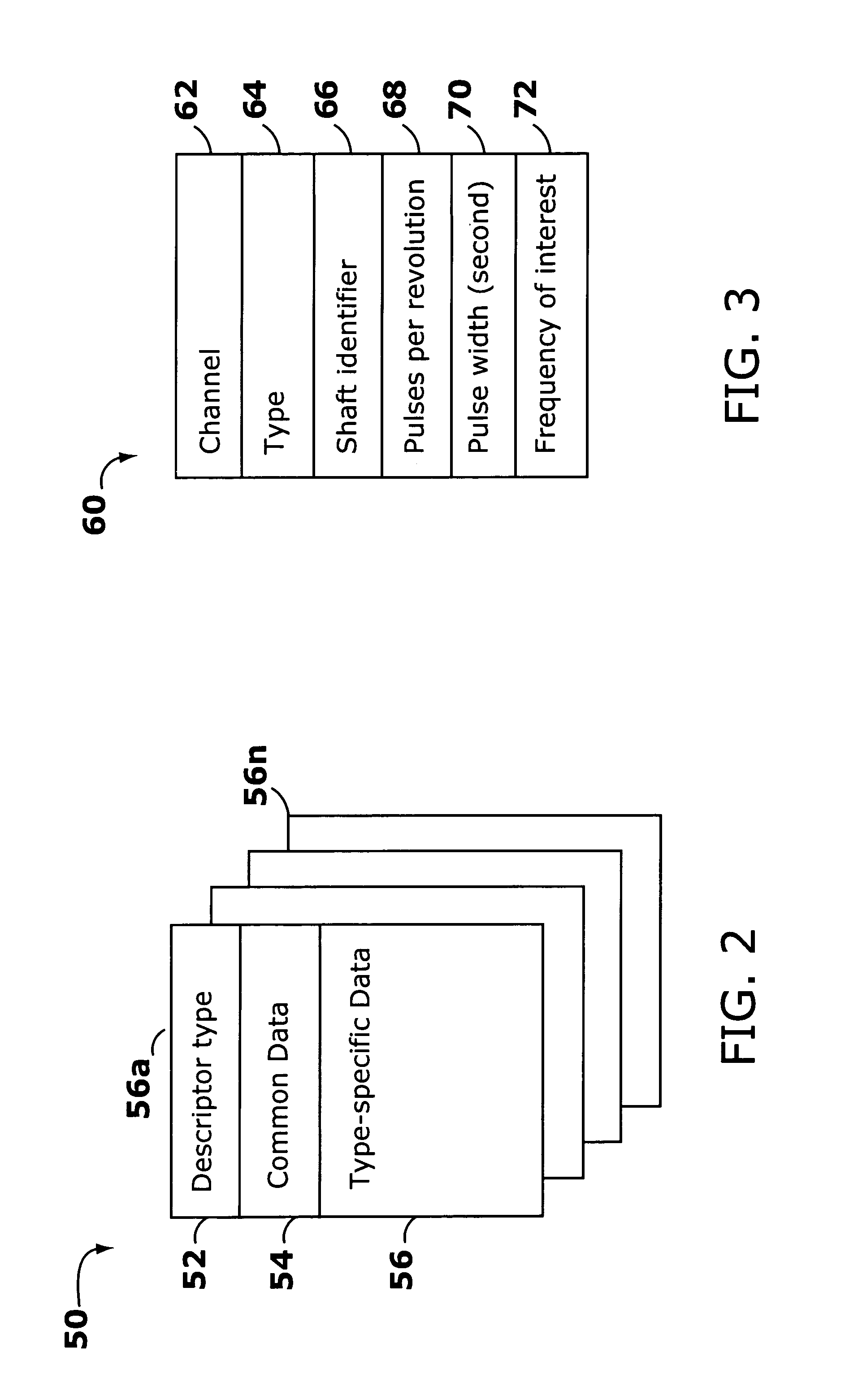

Method and apparatus for estimating values for condition indicators

Disclosed are techniques used in connection with determining a health indicator (HI) of a component, such as that of an aircraft component. The HI is determined using condition indicators (CIs) which parameterize characteristics about a component minimizing possibility of a false alarm. Different algorithms are disclosed which may be used in determining one or more CIs. The HI may be determined using a normalized CI value. Techniques are also described in connection with selecting particular CIs that provide for maximizing separation between HI classifications. Given a particular HI at a point in time for a component, techniques are described for predicting a future state or health of the component using the Kalmán filter. Techniques are described for estimating data values as an alternative to performing data acquisitions, as may be used when there is no pre-existing data.

Owner:SIMMONDS PRECISION PRODS

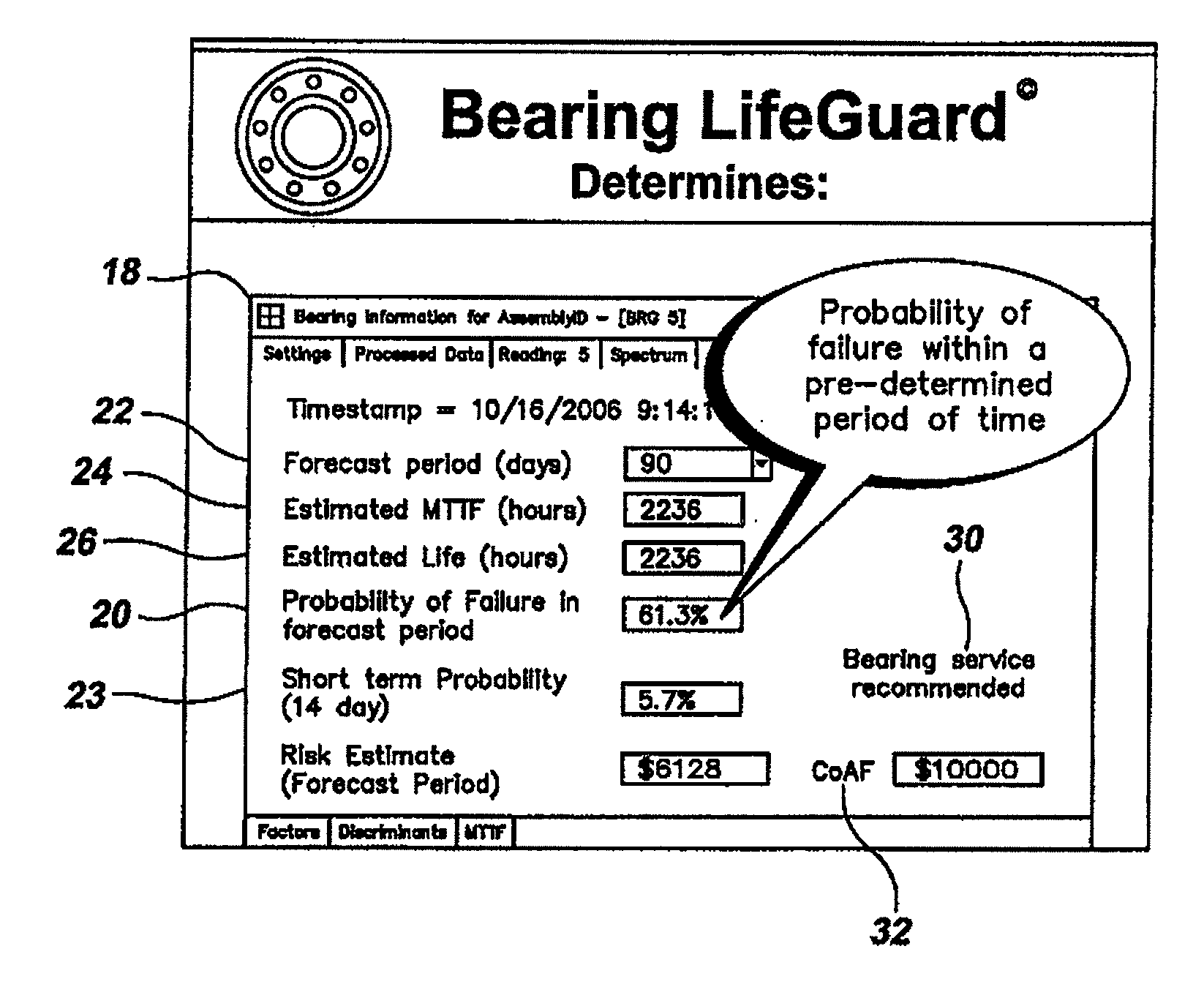

Rotating bearing analysis and monitoring system

A method of analyzing vibrations of a rolling element bearing installed in a rotating machine includes accessing vibration data corresponding to the bearing to be analyzed, determining a degraded condition factor BD for the bearing, selecting an expected designer-determined mean-time-to-failure MTTF of the bearing operating under a design load in the operating environment of the rotating machine, selecting a forecast time period, calculating a reduced mean-time-to-failure RMTTF of the bearing using the expected designer-determined mean-time-to-failure MTTF and the degraded condition factor BD, calculating a probability of failure of the bearing in the forecast time period using the reduced mean time to failure RMTTF, accessing cost data corresponding to a cost of failure of the bearing in the rotating machine, calculating a financial risk from the calculated probability of failure in the forecast time period and the cost data, and displaying the financial risk for the selected time period.

Owner:DYNAMIC MEASUREMENT CONSULTANTS

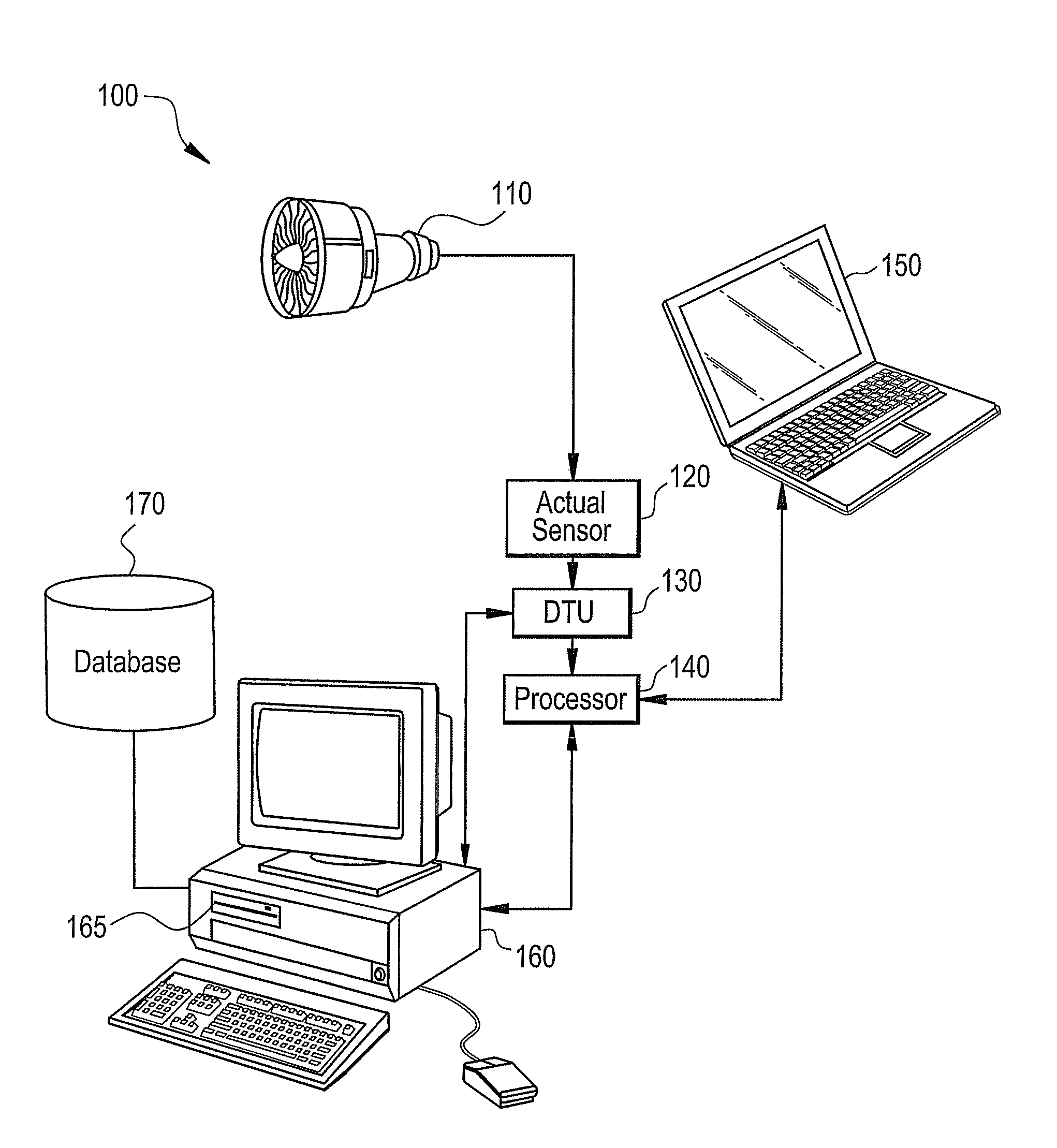

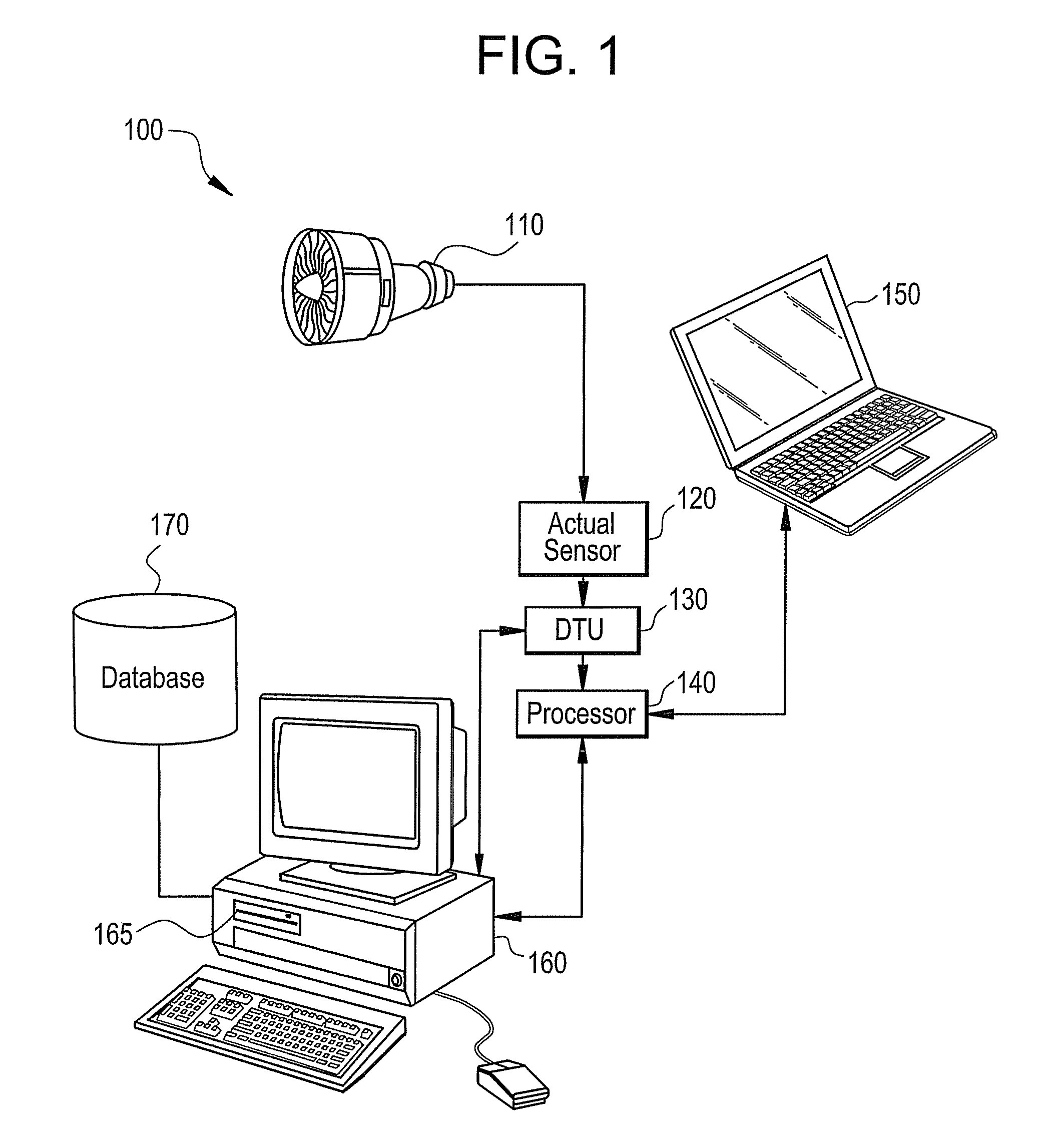

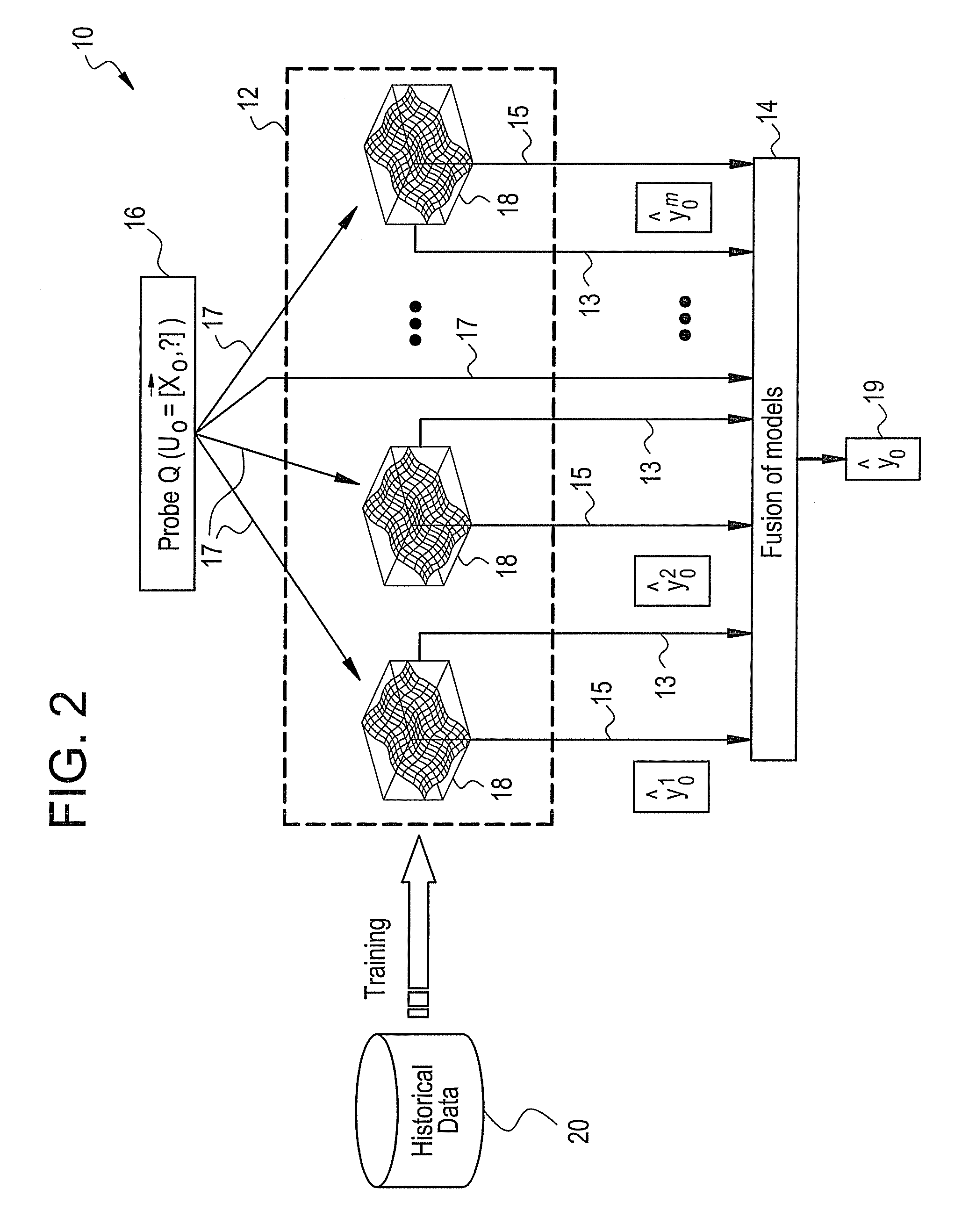

System and method for equipment remaining life estimation

A method to reduce uncertainty bounds of predicting a remaining life of a probe using a set of diverse models is disclosed. The method includes generating an estimated remaining life output by each model of the set of diverse models, aggregating each of the respective estimated remaining life outputs via a fusion model, and in response to the aggregating, predicting the remaining life, the predicting having reduced uncertainty bounds based on the aggregating. The method further includes generating a signal corresponding to the predicted remaining life of the probe.

Owner:GENERAL ELECTRIC CO

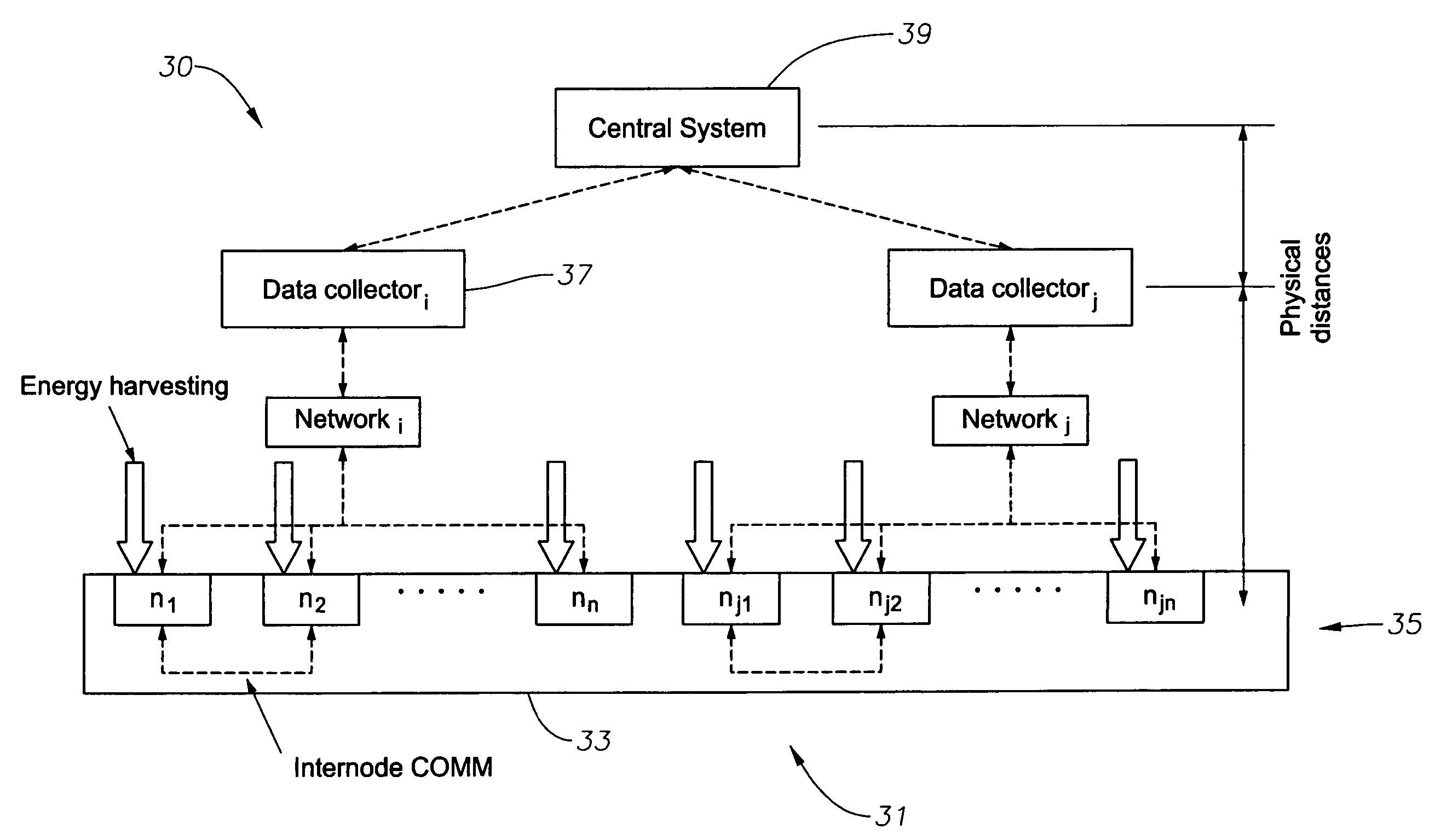

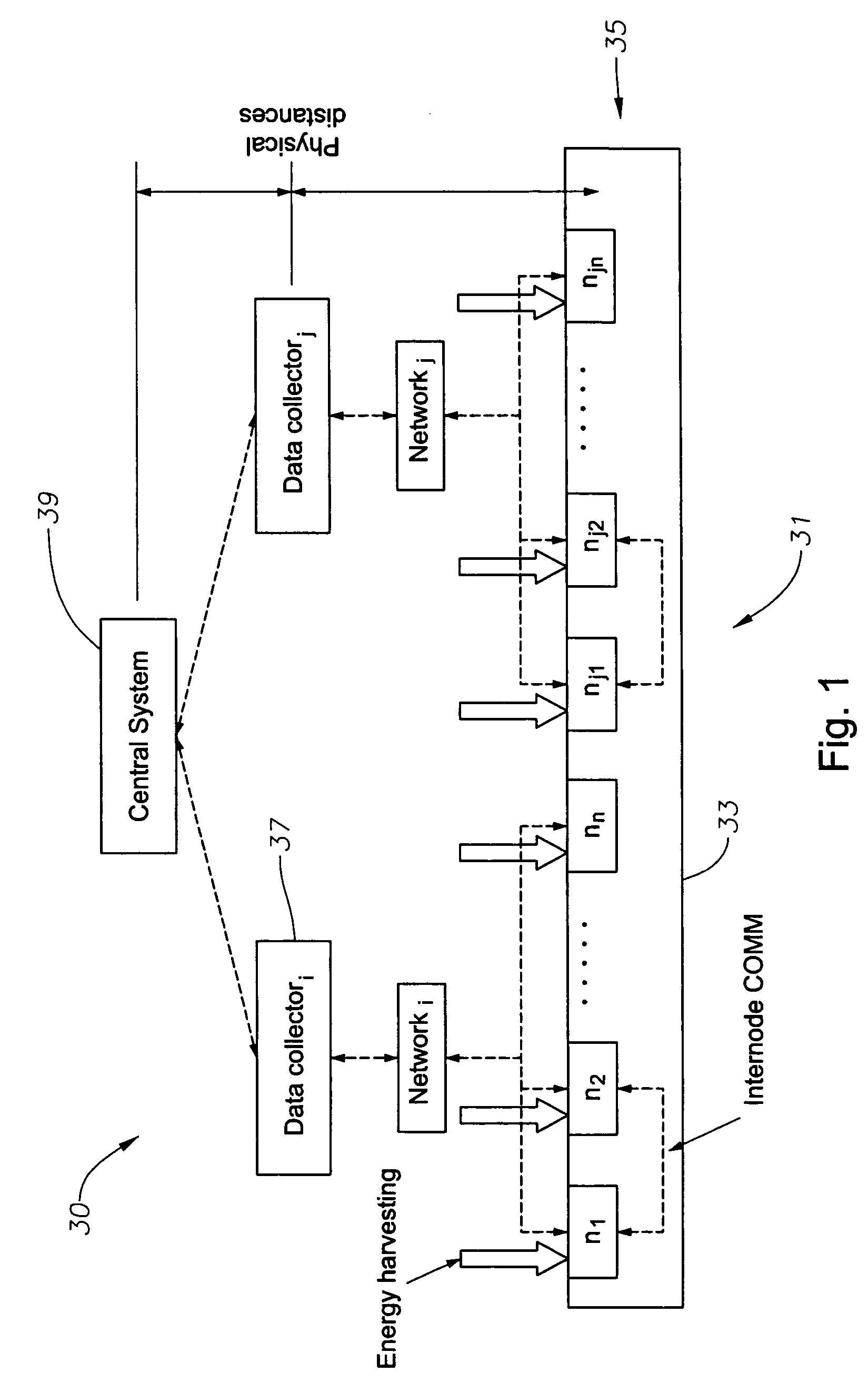

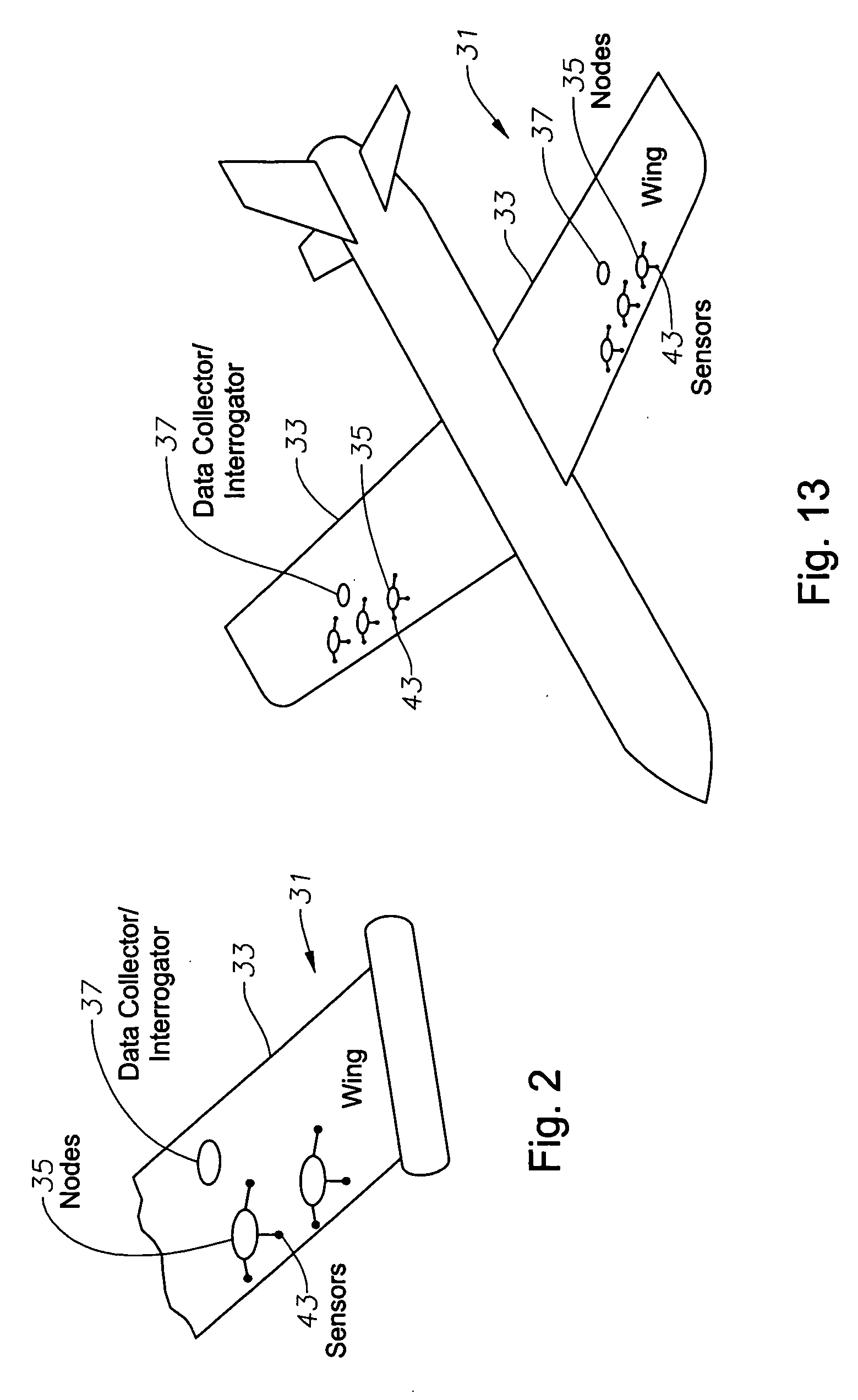

System to monitor the health of a structure, sensor nodes, program product, and related methods

ActiveUS20070118335A1Low powerLess complexPlug gaugesError detection/correctionEngineeringSensor node

A system to monitor the health of a structure, health monitoring sensor nodes, program product, and associated methods are provided. The system includes an array of health monitoring sensor nodes connected to or embedded within a structure to monitor the health of the structure. Each health monitoring sensor node includes sensor elements positioned to sense parameters of the structure and to provide data related to the parameters to a health monitoring sensor node interrogator. Each health monitoring sensor node has a tunable antenna arrangement individually tunable to minimize data collisions between each other of the health monitoring sensor nodes. Each health monitoring sensor node also includes a processor and memory in communication with the processor storing a parameter processing program product adapted to control tuning the antenna arrangement and providing data to the health monitoring sensor node interrogator.

Owner:LOCKHEED MARTIN CORP

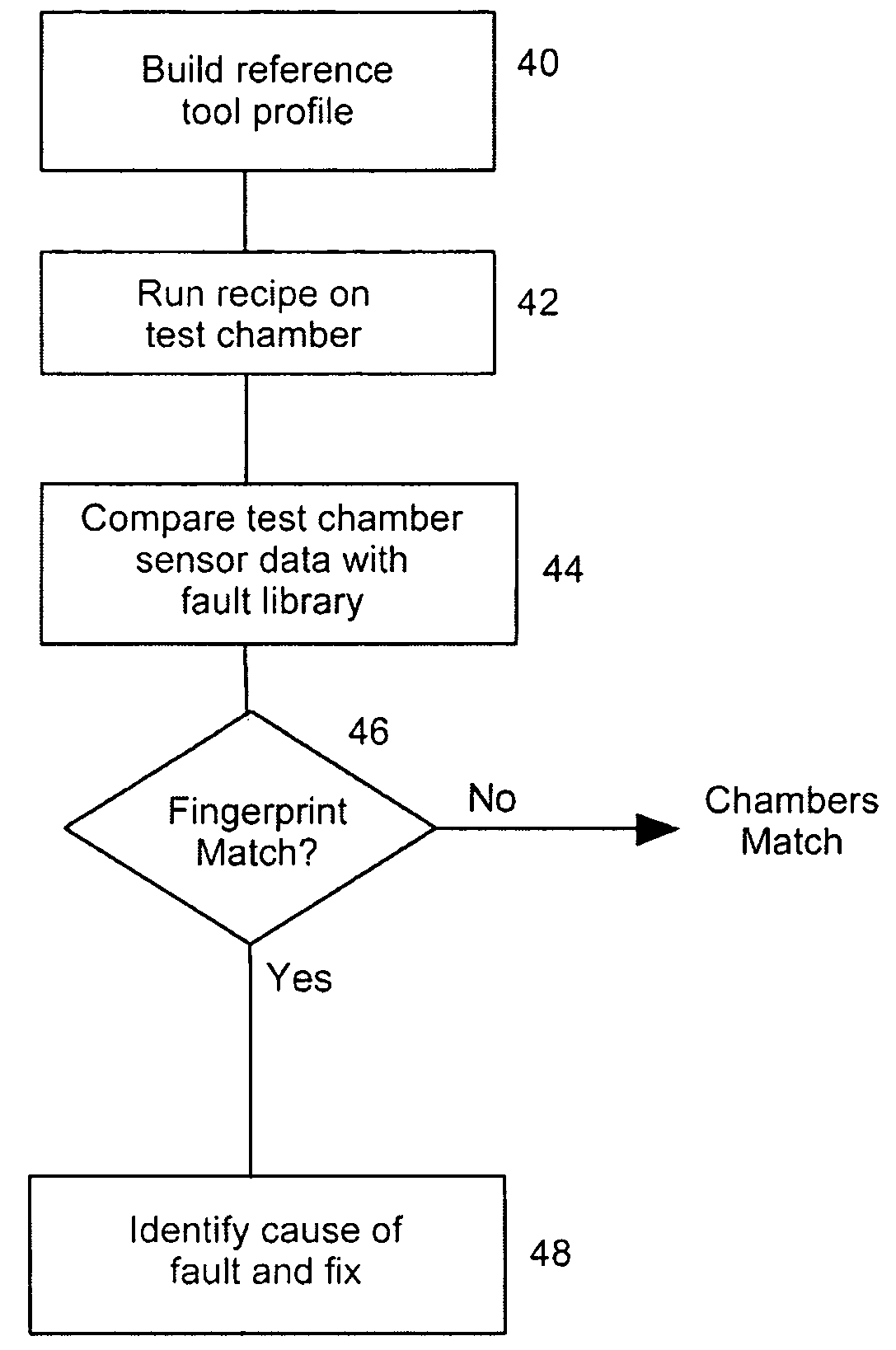

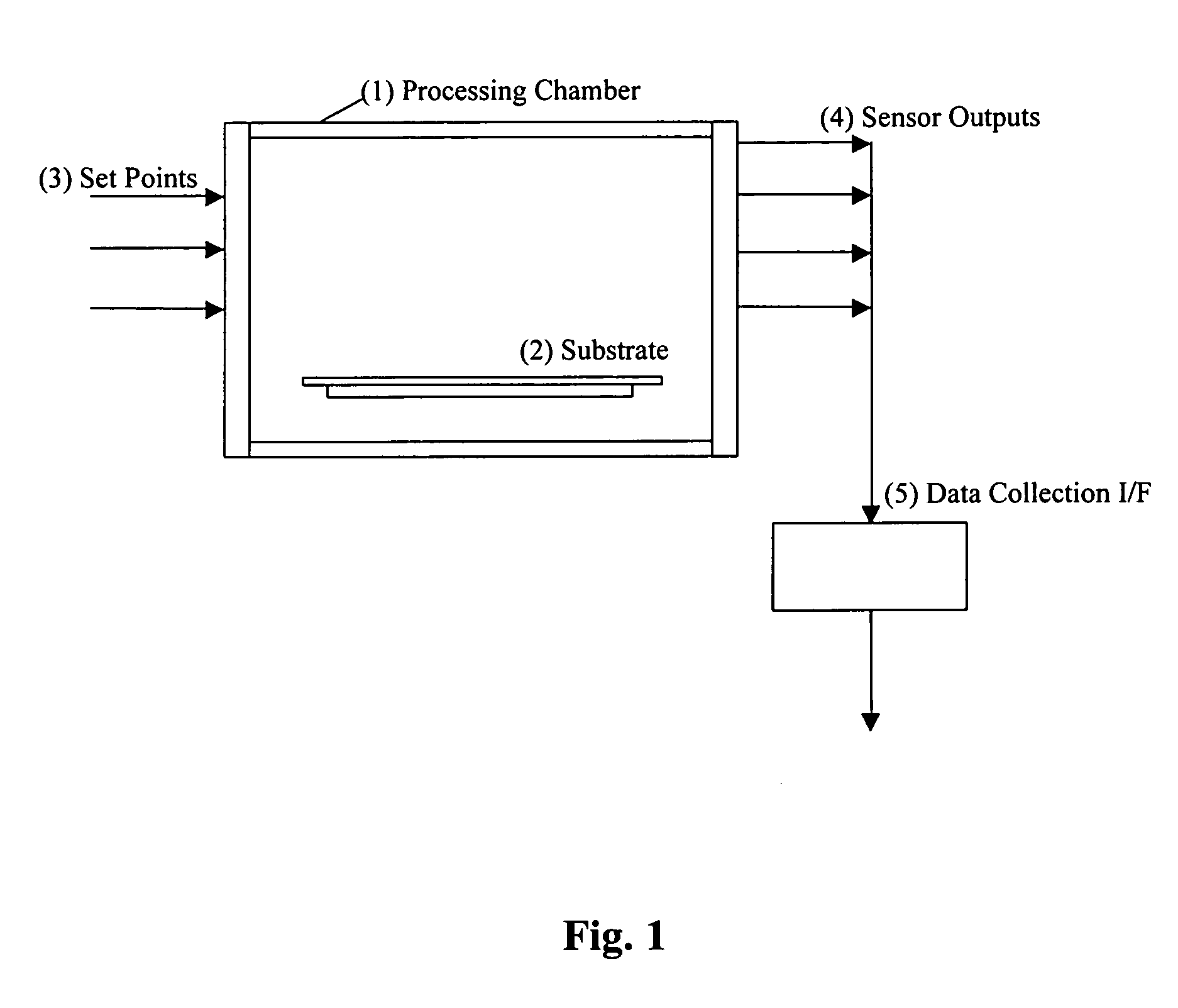

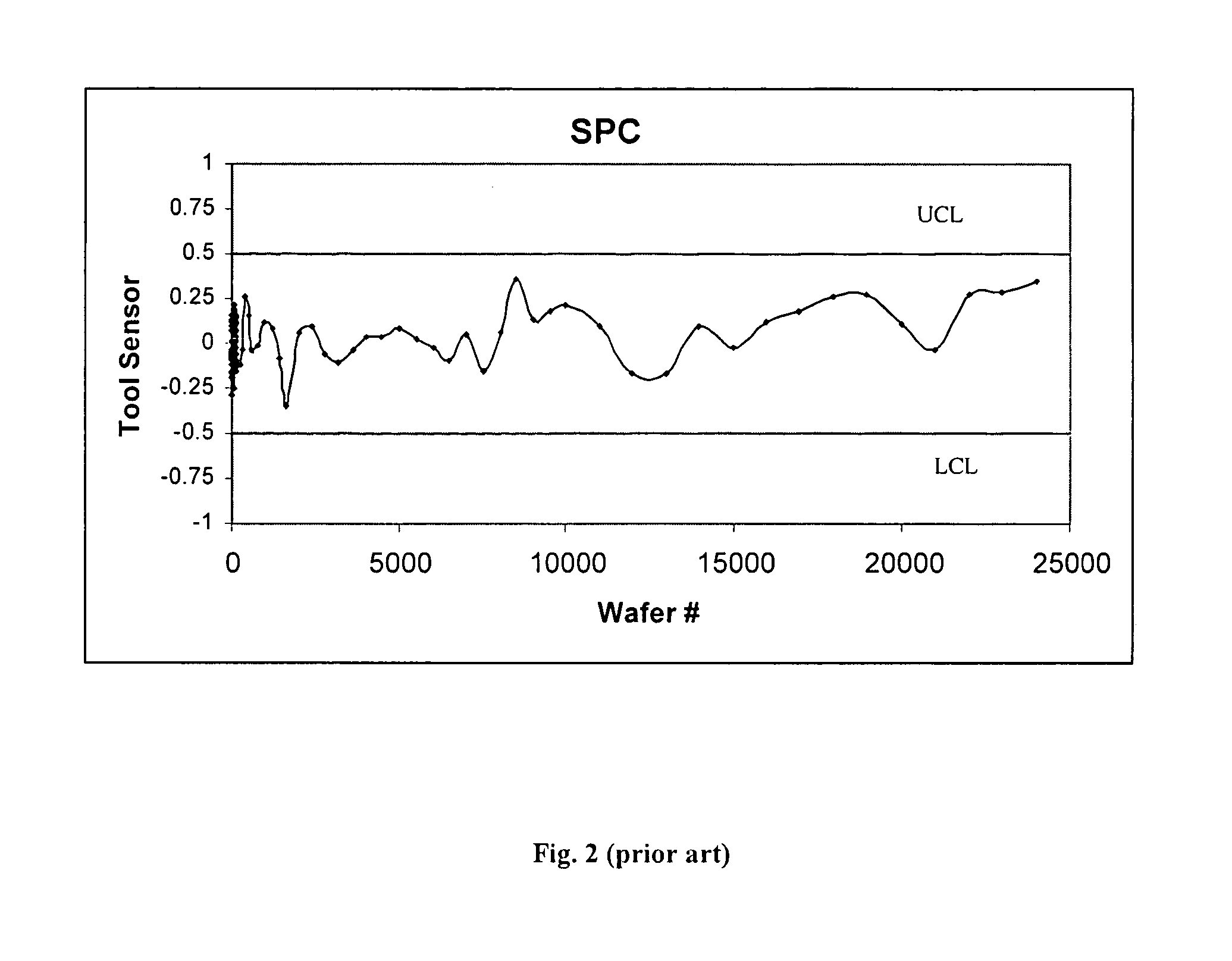

Method for process control of semiconductor manufacturing equipment

ActiveUS7062411B2Plug gaugesSemiconductor/solid-state device testing/measurementFault recognitionSemiconductor

A method of fault identification on a semiconductor manufacturing tool includes monitoring tool sensor output, establishing a fingerprint of tool states based on the plurality of sensors outputs, capturing sensor data indicative of fault conditions, building a library of such fault fingerprints, comparing present tool fingerprint with fault fingerprints to identify a fault condition and estimating the effect of such a fault condition on process output. The fault library is constructed by inducing faults in a systematic way or by adding fingerprints of known faults after they occur.

Owner:LAM RES CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com