Patents

Literature

240 results about "Relative times" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

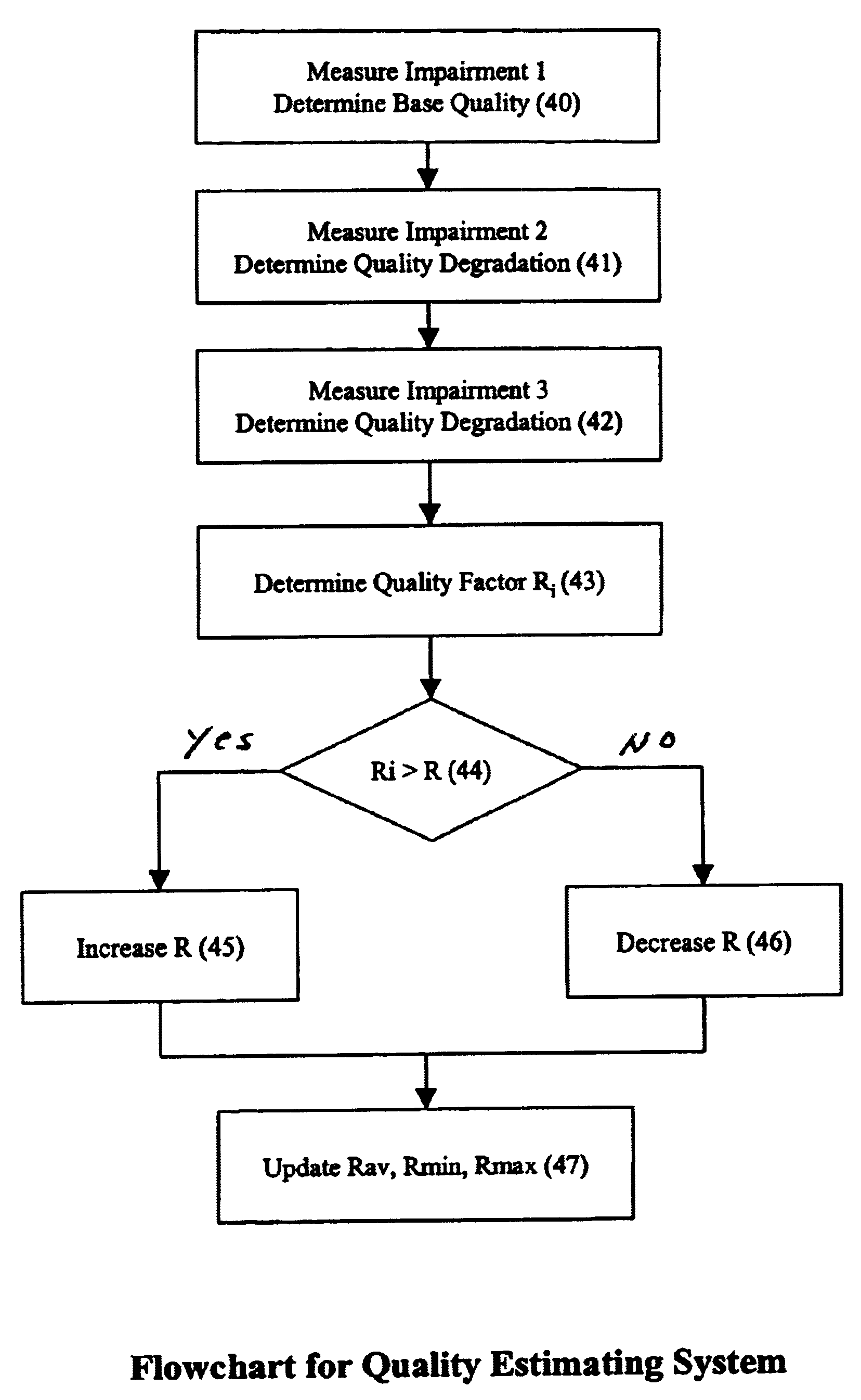

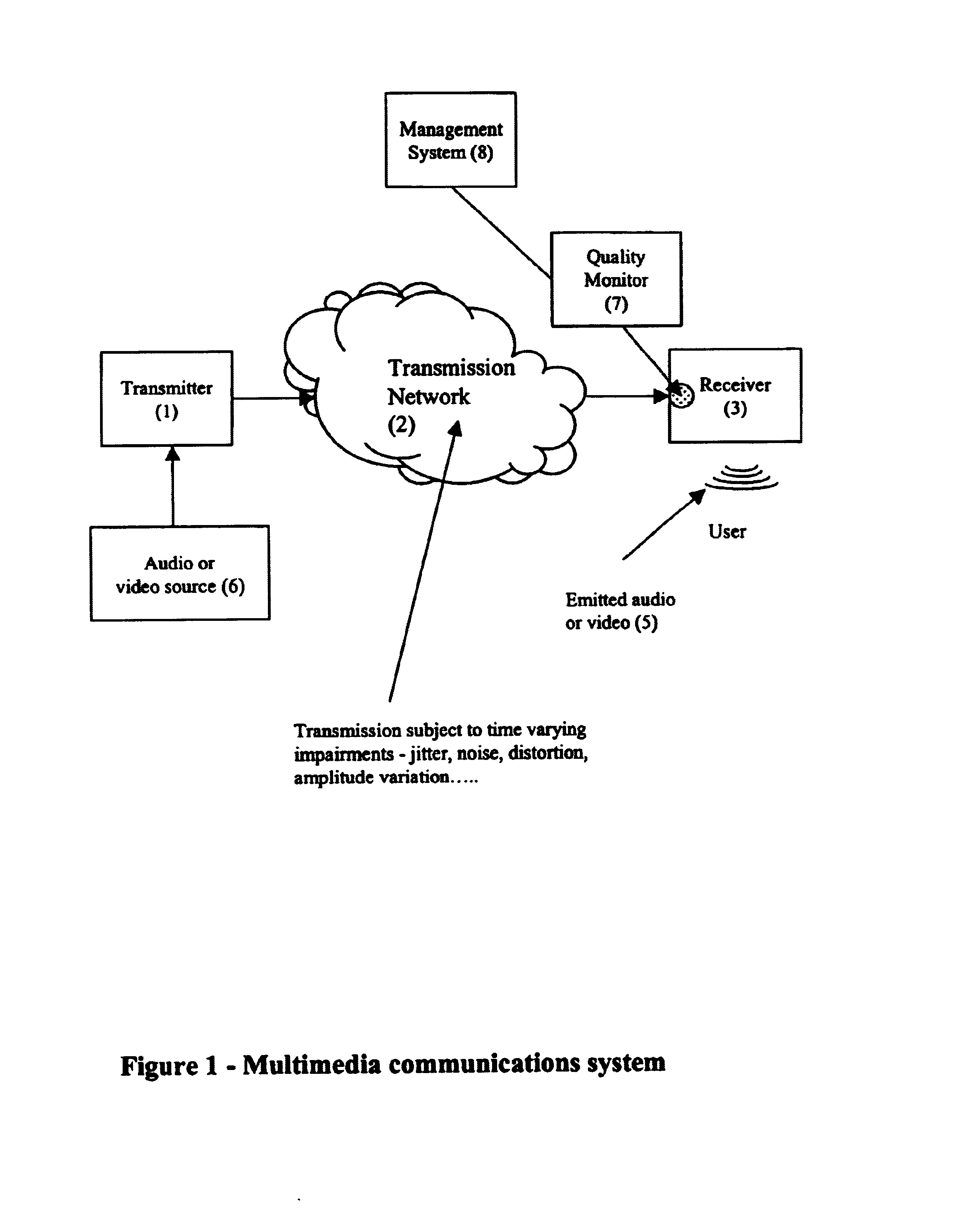

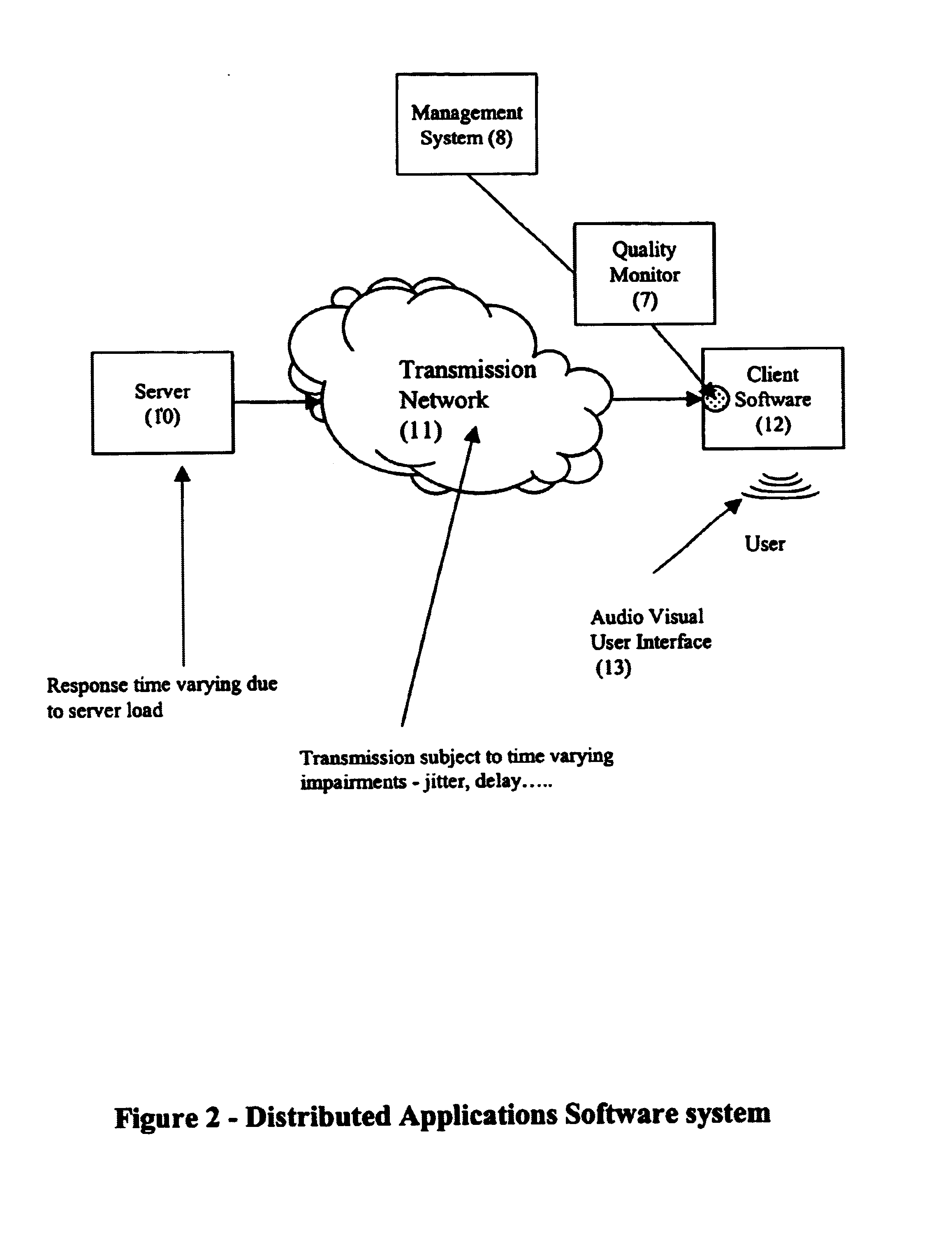

Dynamic quality of service monitor

InactiveUS7075981B1Error detection/prevention using signal quality detectorTransmission systemsQuality of serviceSoftware system

A subjective quality monitoring system for multimedia signal transmission systems or distributed applications software systems employs a counter which is increased if subjective quality is high and decreased if subjective quality is low in order to represent the effects of the relative temporal location of transmission impairments or system loading.

Owner:TELCHEMY

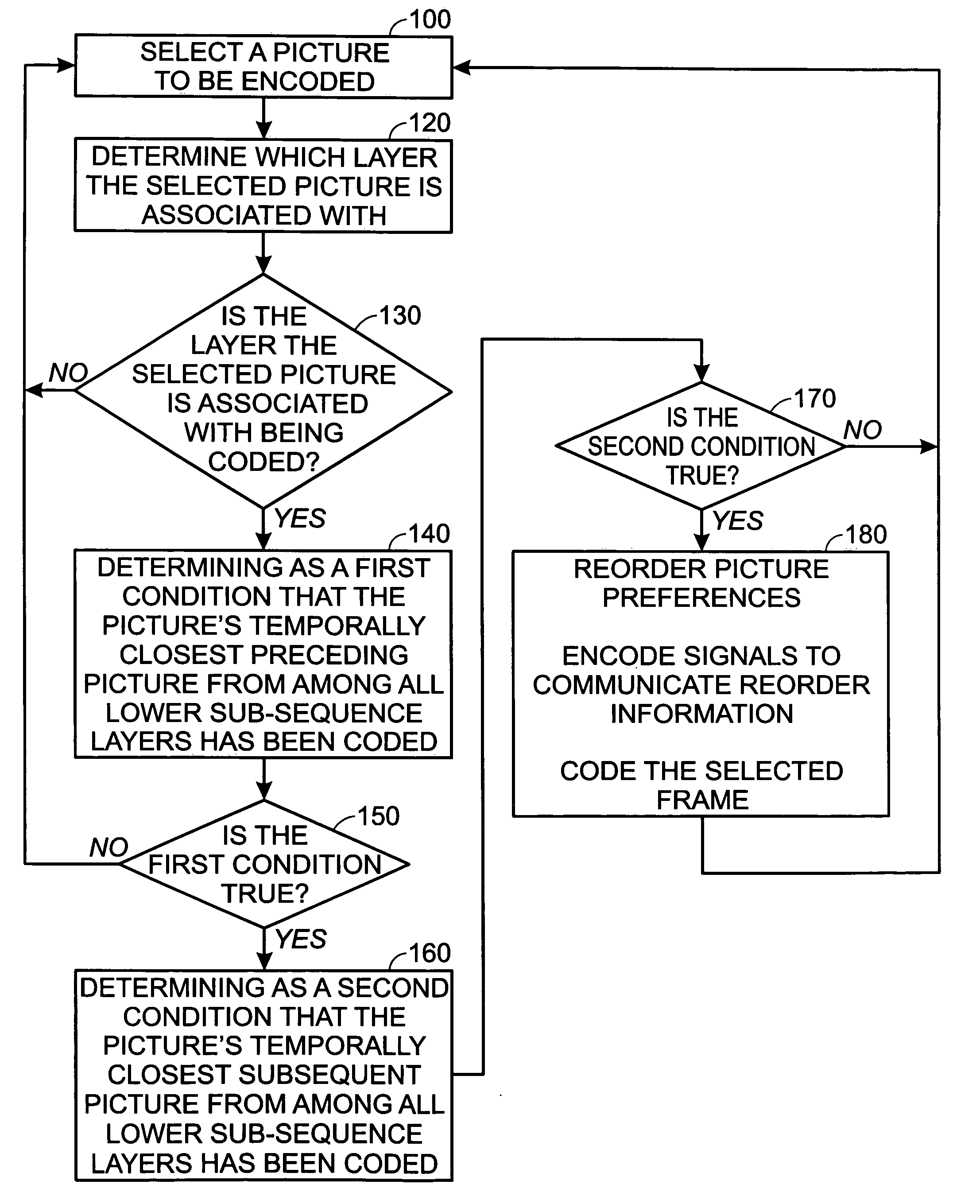

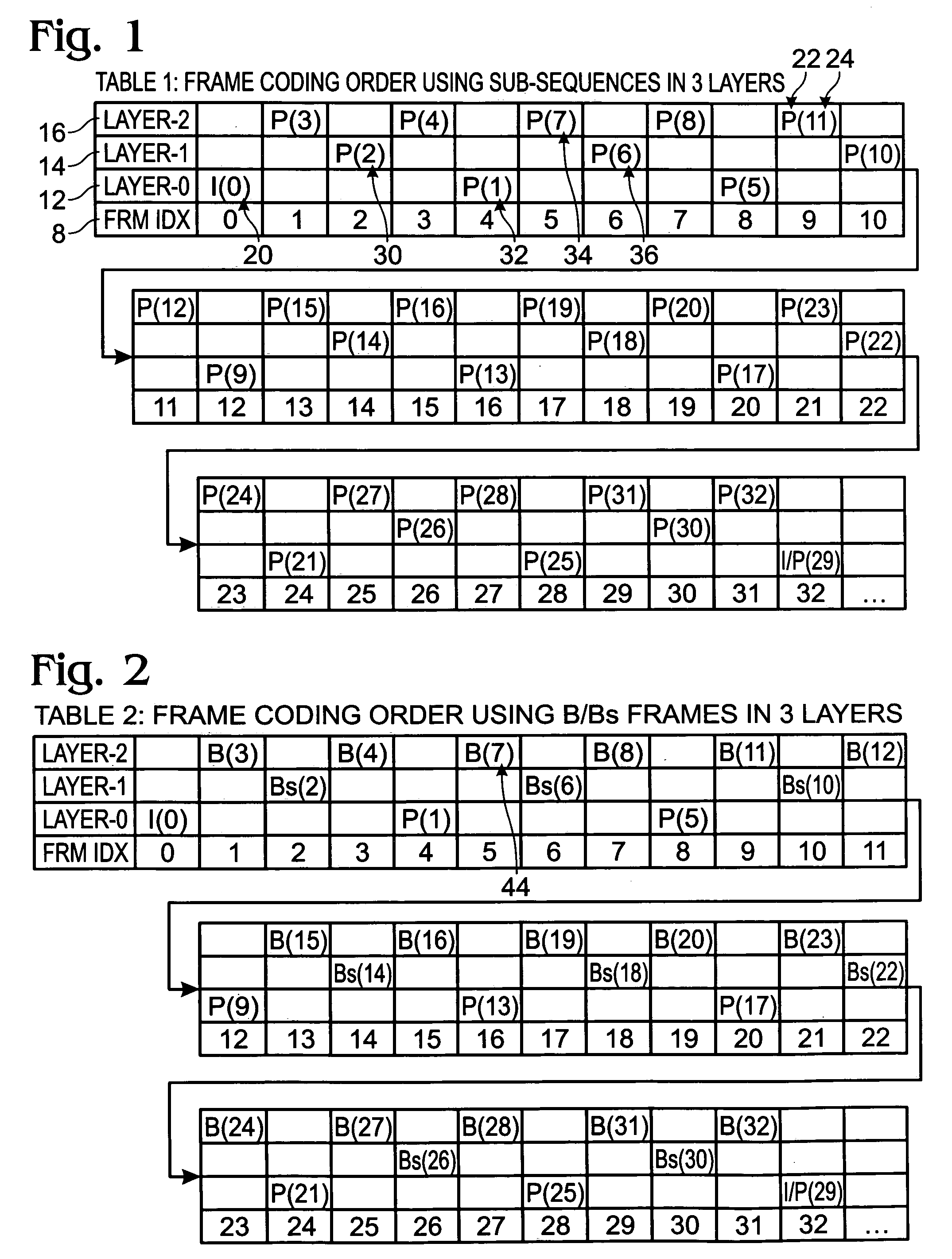

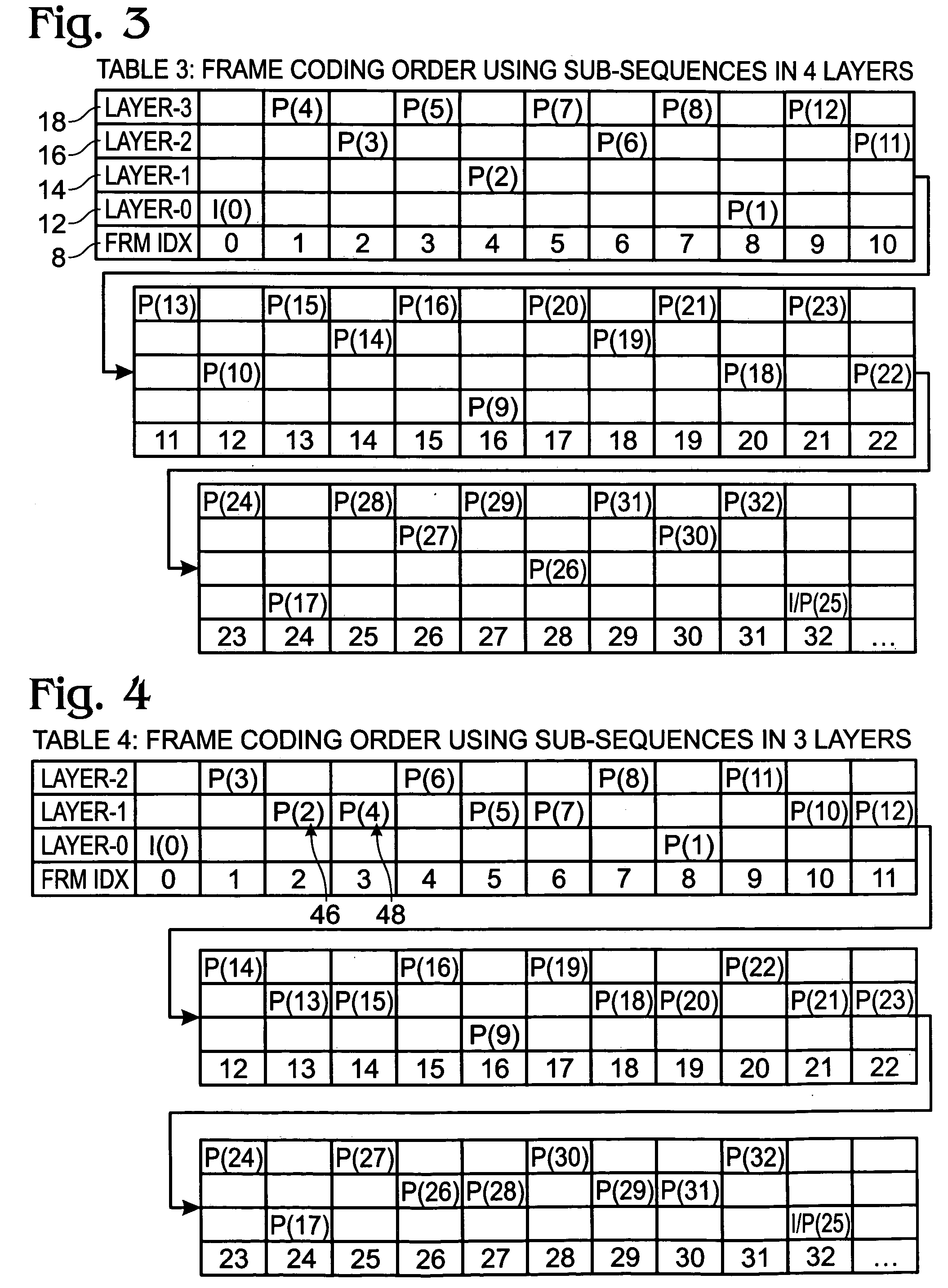

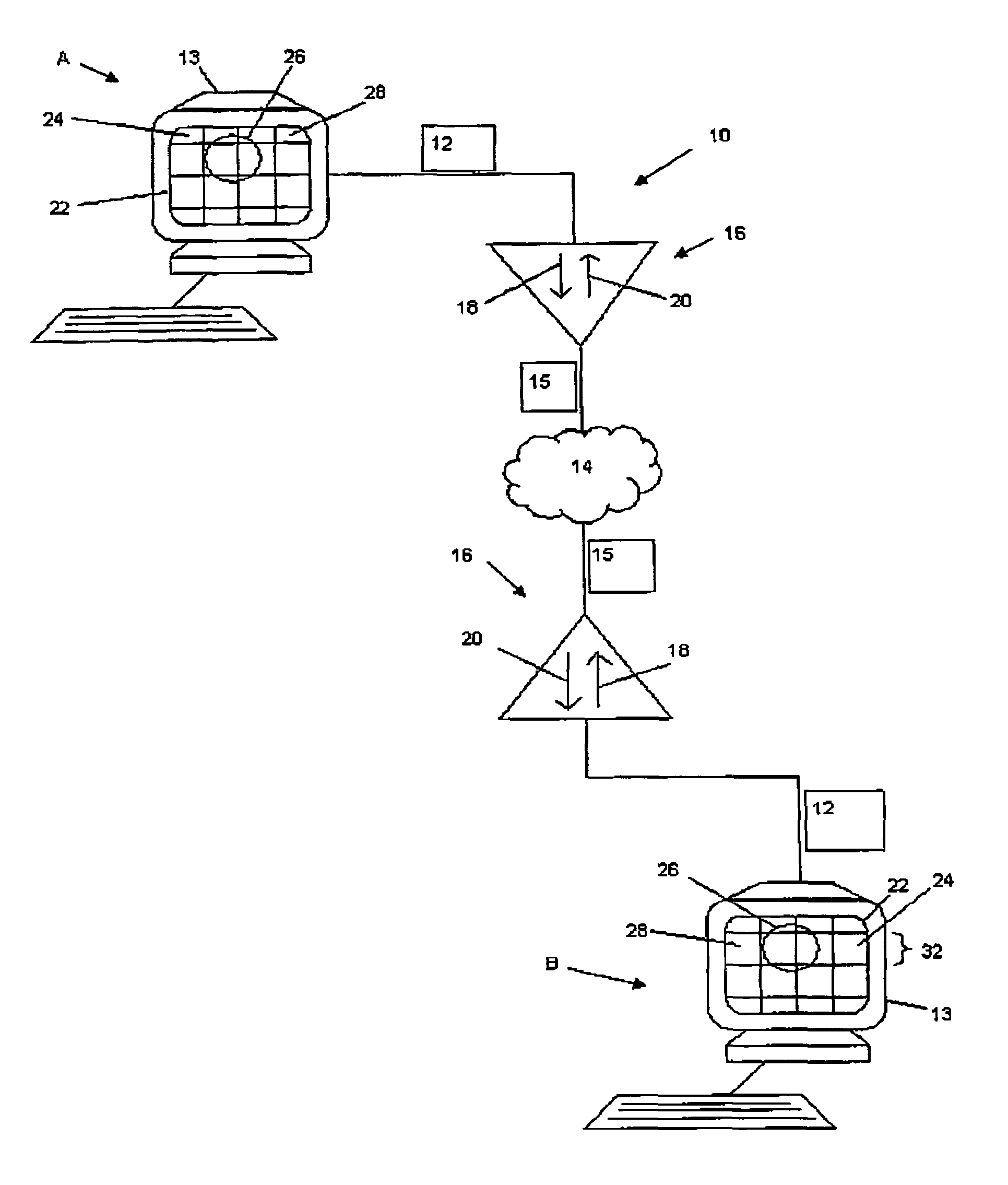

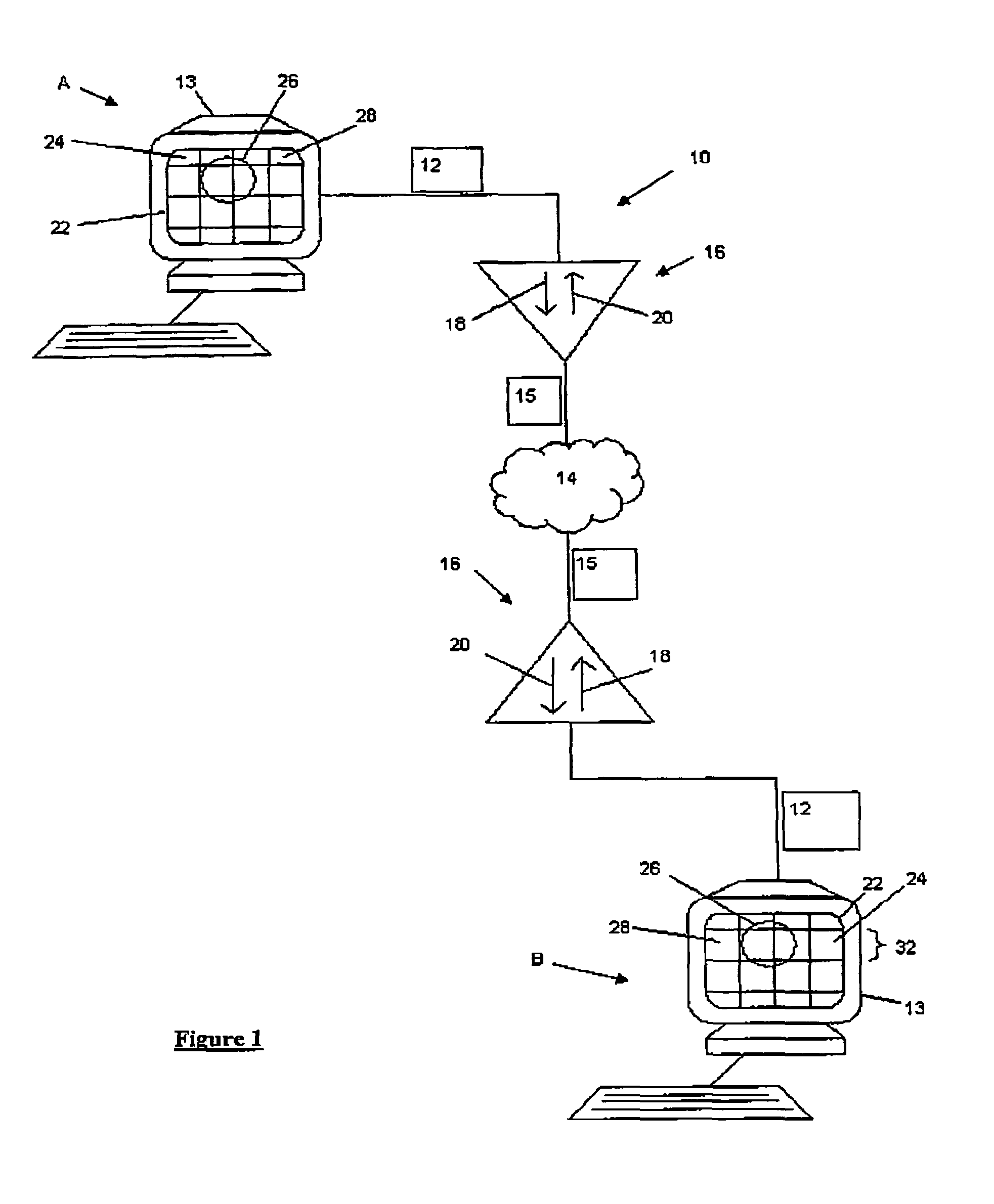

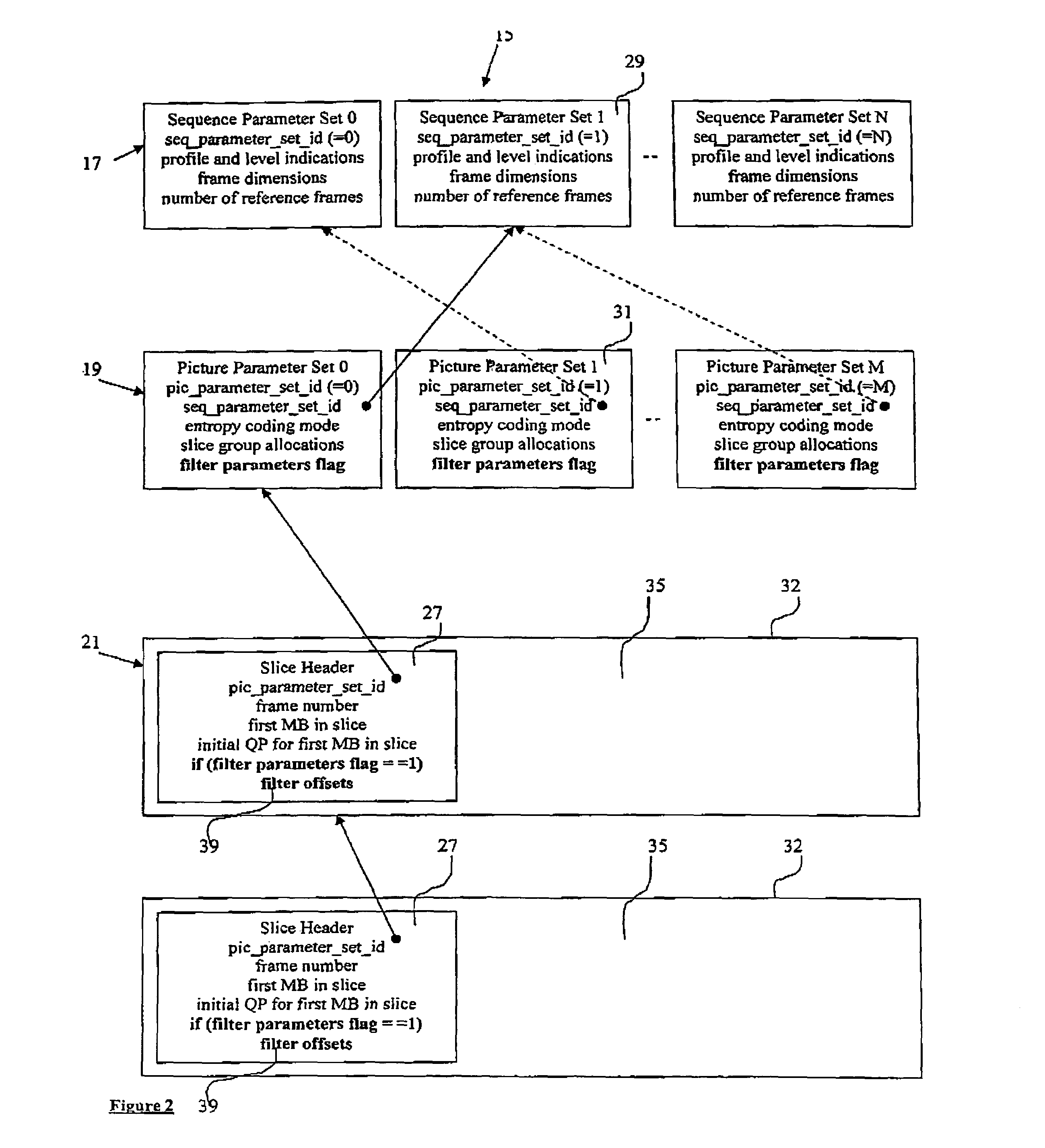

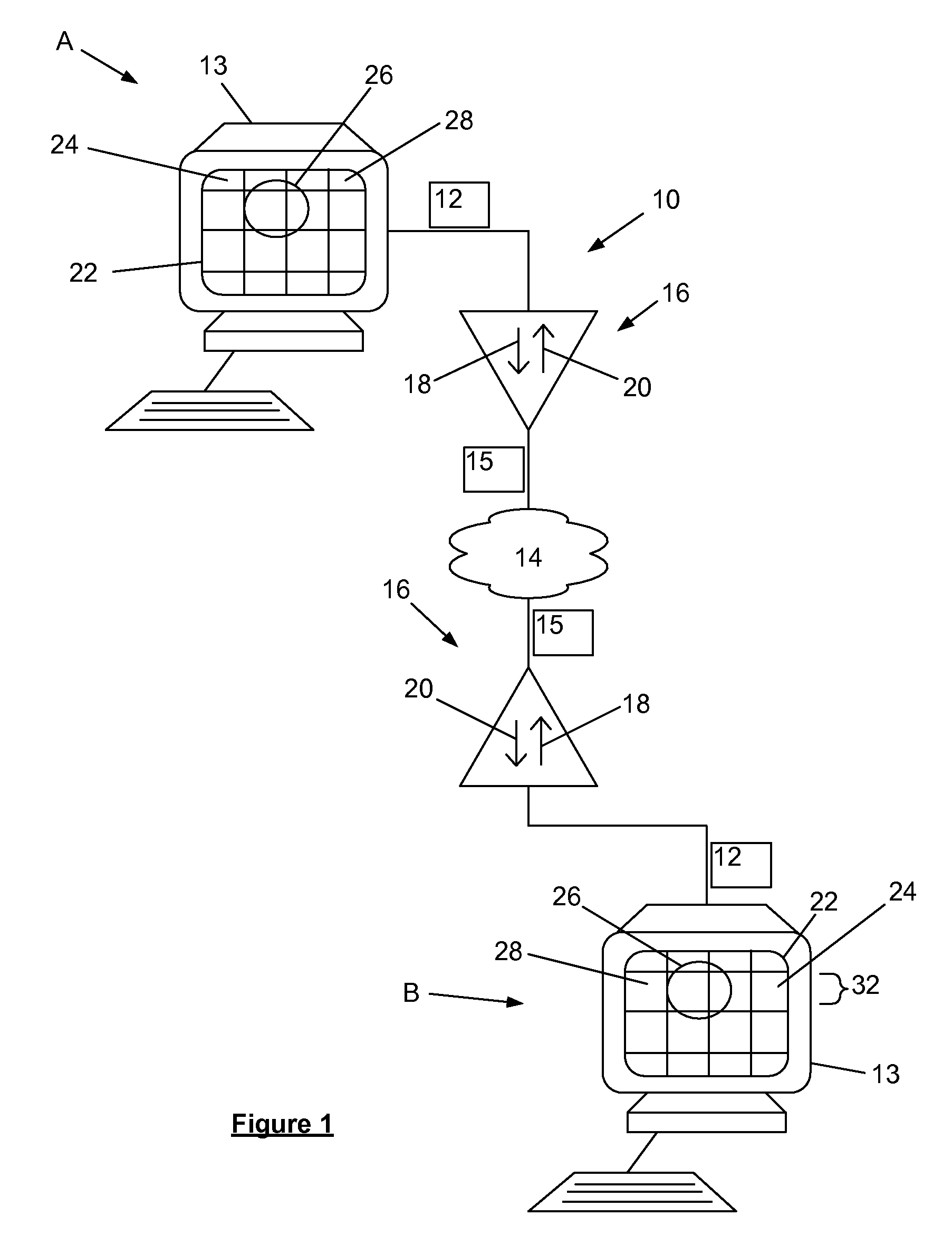

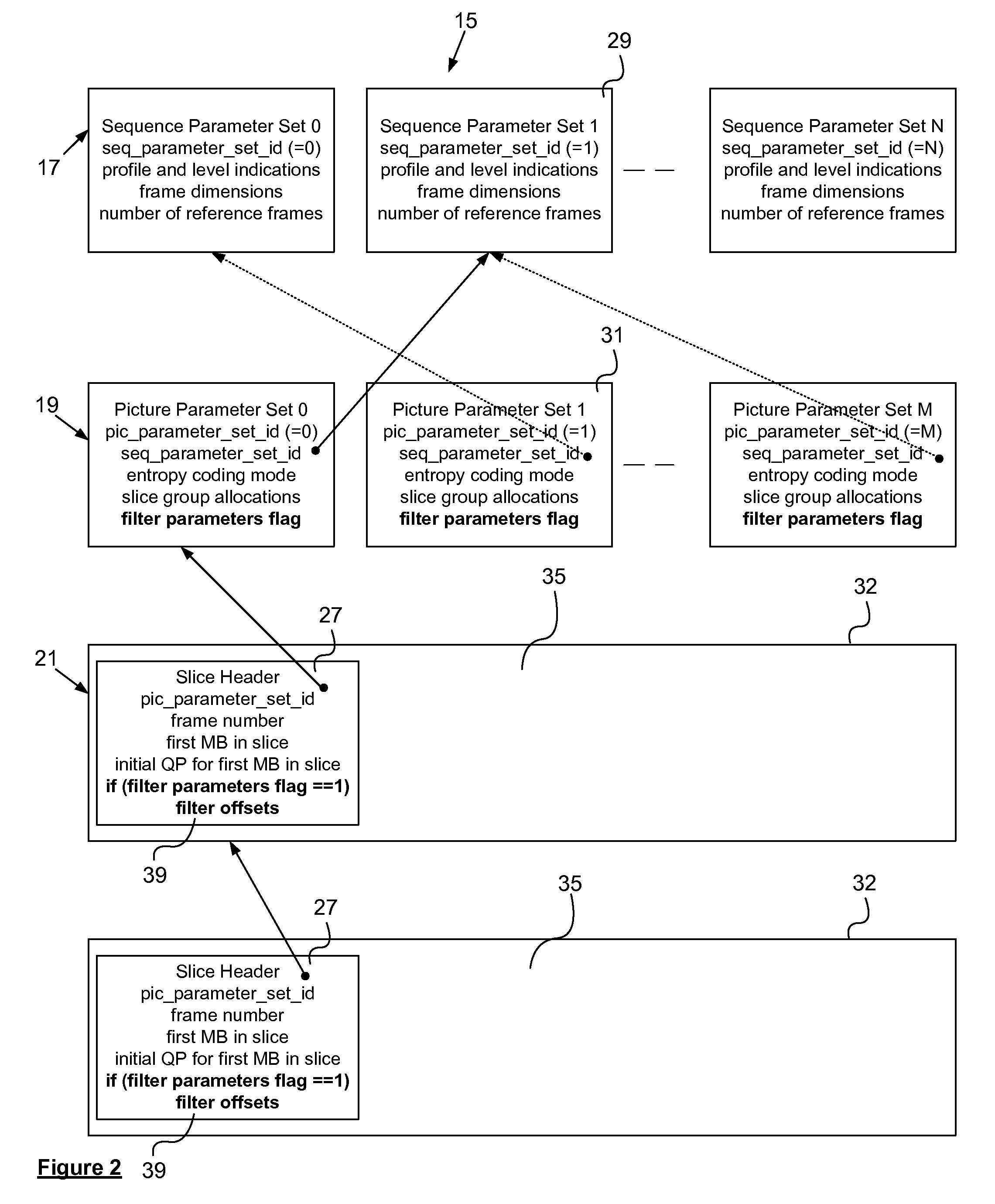

Temporal scalable coding using AVC coding tools

InactiveUS20060013305A1Efficient temporal scalable codingReasonable coding efficiencyColor television with pulse code modulationColor television with bandwidth reductionComputer architectureVideo encoding

A temporally scalable video coding method is provided to interleave pictures from all layers of a video sequence including video sub-sequences organized using enhancement layers following a set of rules: (1) pictures in each layer are to be coded sequentially within the layer; (2) a picture from an upper layer should be coded when its temporally closest neighboring pictures among all lower layers (in both forward and backward directions if available) have been already coded; in other words, coding of an upper-layer picture requires the temporally closest neighboring pictures among all lower layers (in both forward and backward directions if available) be coded before hand. To ensure a reasonable coding efficiency, for each picture, its qualified reference pictures may be reordered so that the reference pictures are ordered using their relative temporal distance from the current picture instead of the default picture coding order.

Owner:SHARP LAB OF AMERICA INC

Low-complexity motion vector prediction for video codec with two lists of reference pictures

ActiveUS7400681B2Color television with pulse code modulationColor television with bandwidth reductionMotion vectorVideo encoding

A method of motion vector prediction for use in differential motion vector coding within a block motion-compensation-based video coder. The video coder employs a generalized multiple reference picture buffer which may contain multiple reference pictures in both the forward and backward temporal direction from the current picture. For the purpose of coding selections of reference pictures within the buffer, the pictures are organized into two, potentially overlapping, lists of reference pictures. The prediction of a motion vector that selects a reference picture using a given reference picture list is not dependent upon any motion vectors that select their reference pictures using the other reference picture list. The values of spatially neighbouring motion vectors that use the same list of reference pictures as the notion vector being predicted are used for prediction, regardless of the relative temporal direction of the current and neighbouring motion vectors.

Owner:CISCO SYST CANADA

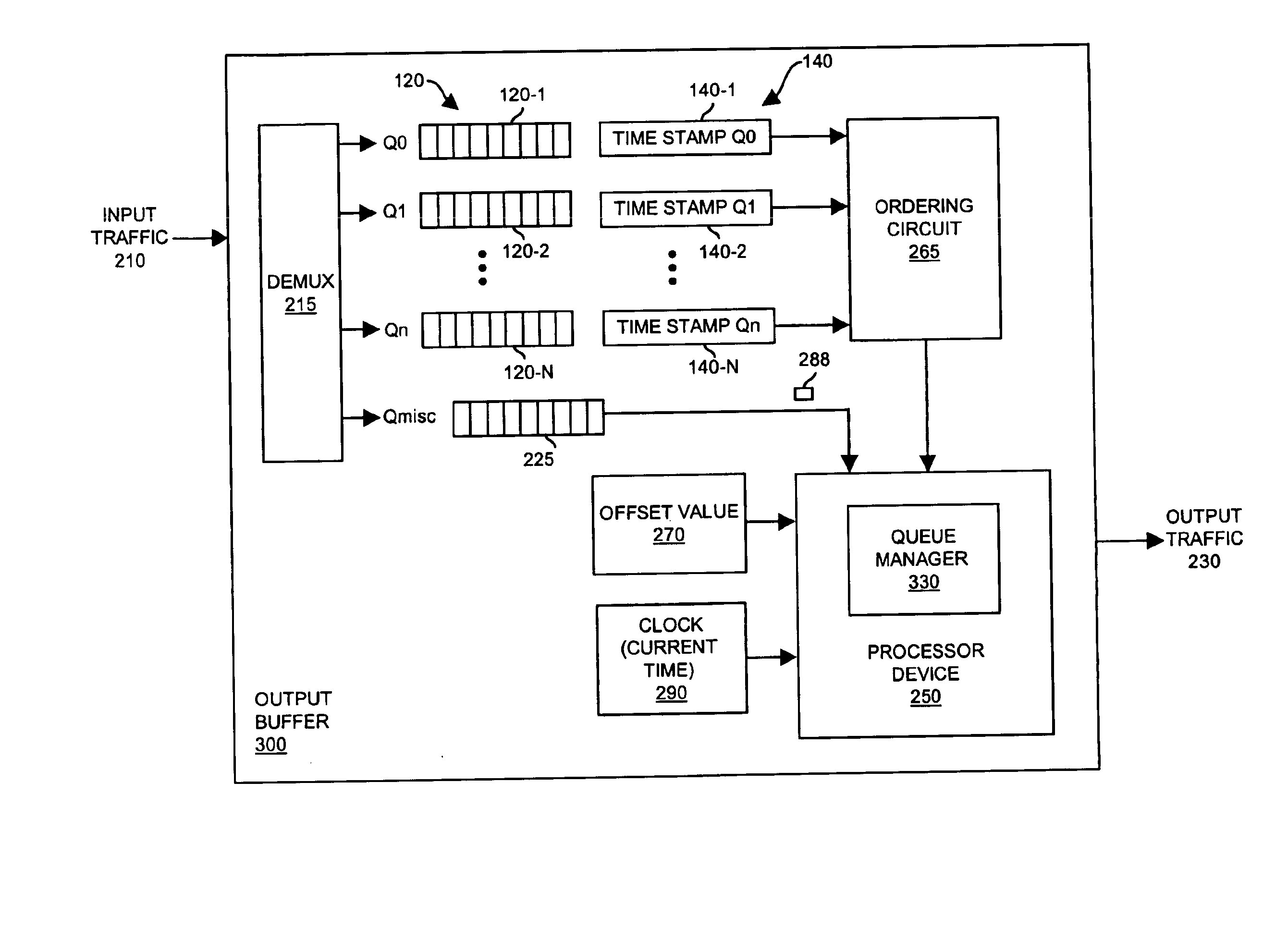

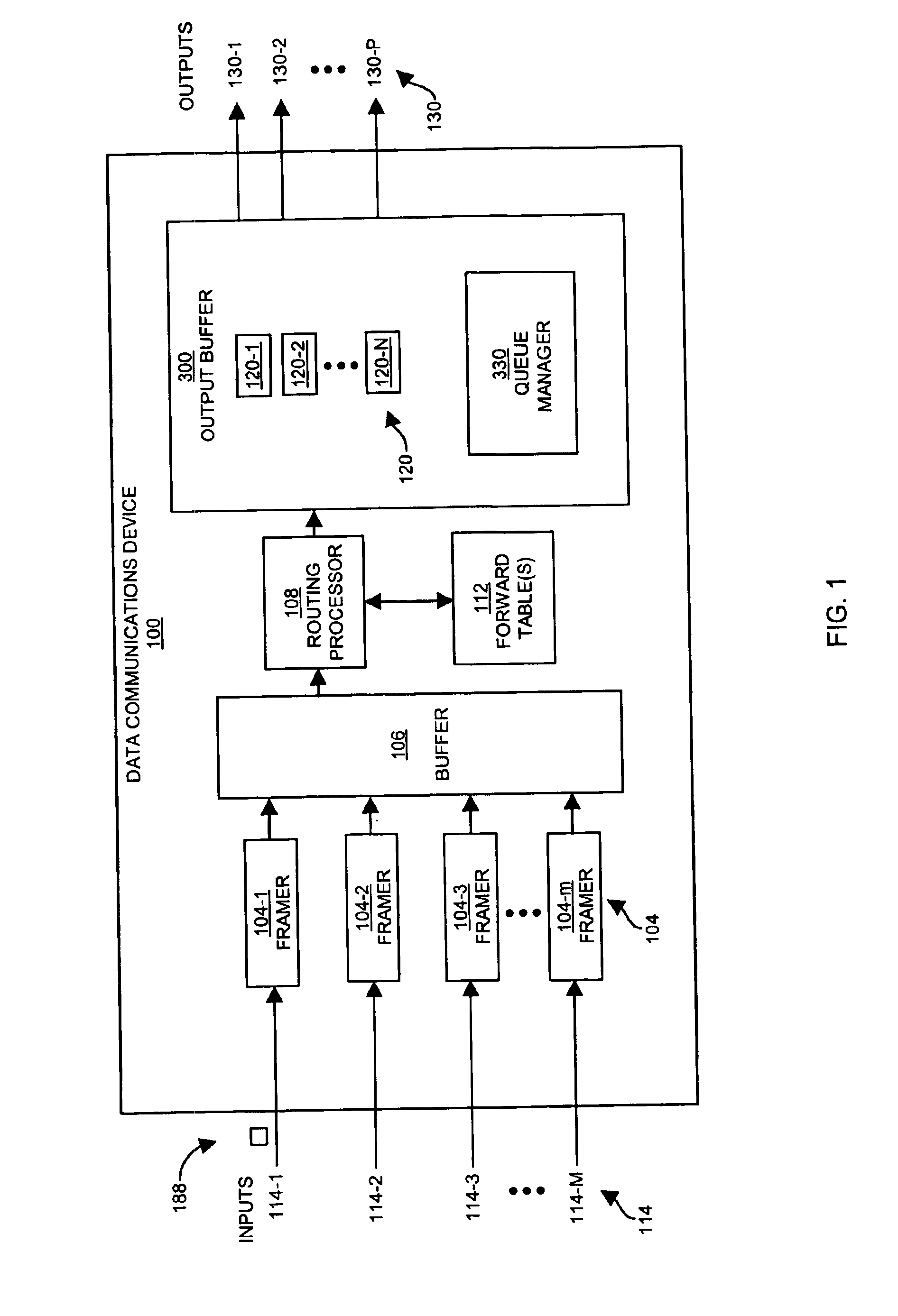

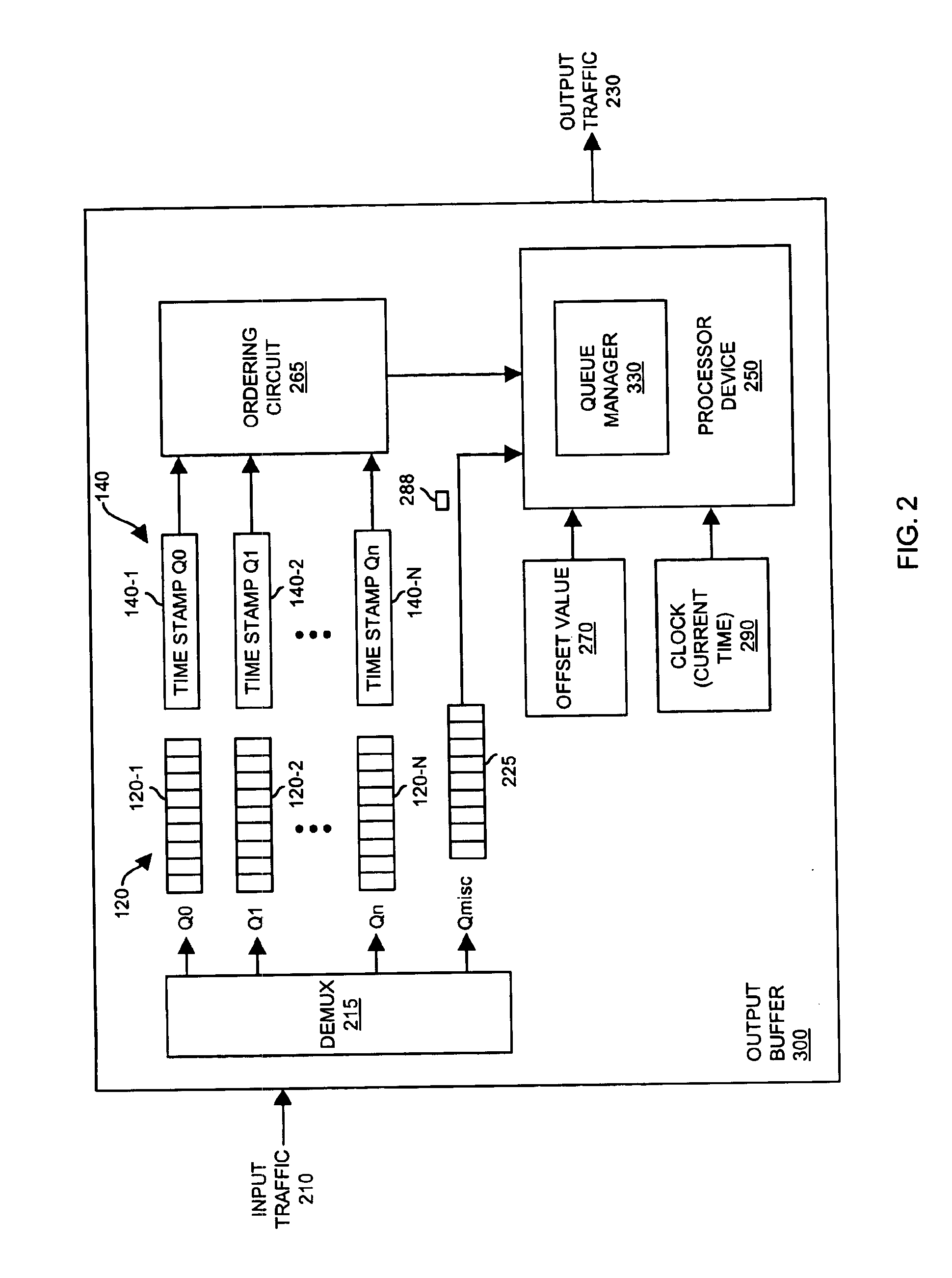

Methods and apparatus for maintaining queues

InactiveUS6876952B1Reduce circuit complexityTime indicationError preventionReal-time clockData stream

One or more queues store data information such as packets or data flows for later transmission to downstream communication devices. A real-time clock tracks current time and an advancement of a moving time reference, which is displaced with respect to the current time of the clock by an offset value. Thus, as current time advances, the moving time reference also advances in time. Upon servicing a queue, a time stamp associated with the serviced queue is also advanced in time. To monitor a rate of outputting data from the one or more queues, a processor device at least occasionally adjusts the offset value so that the moving time reference and values of the time stamps advance in relation to each other. Consequently, by tracking a relative time difference between current time of the real-time clock and a relative advancement of time stamps, a rate of outputting data information from the queue is monitored over time.

Owner:CISCO TECH INC

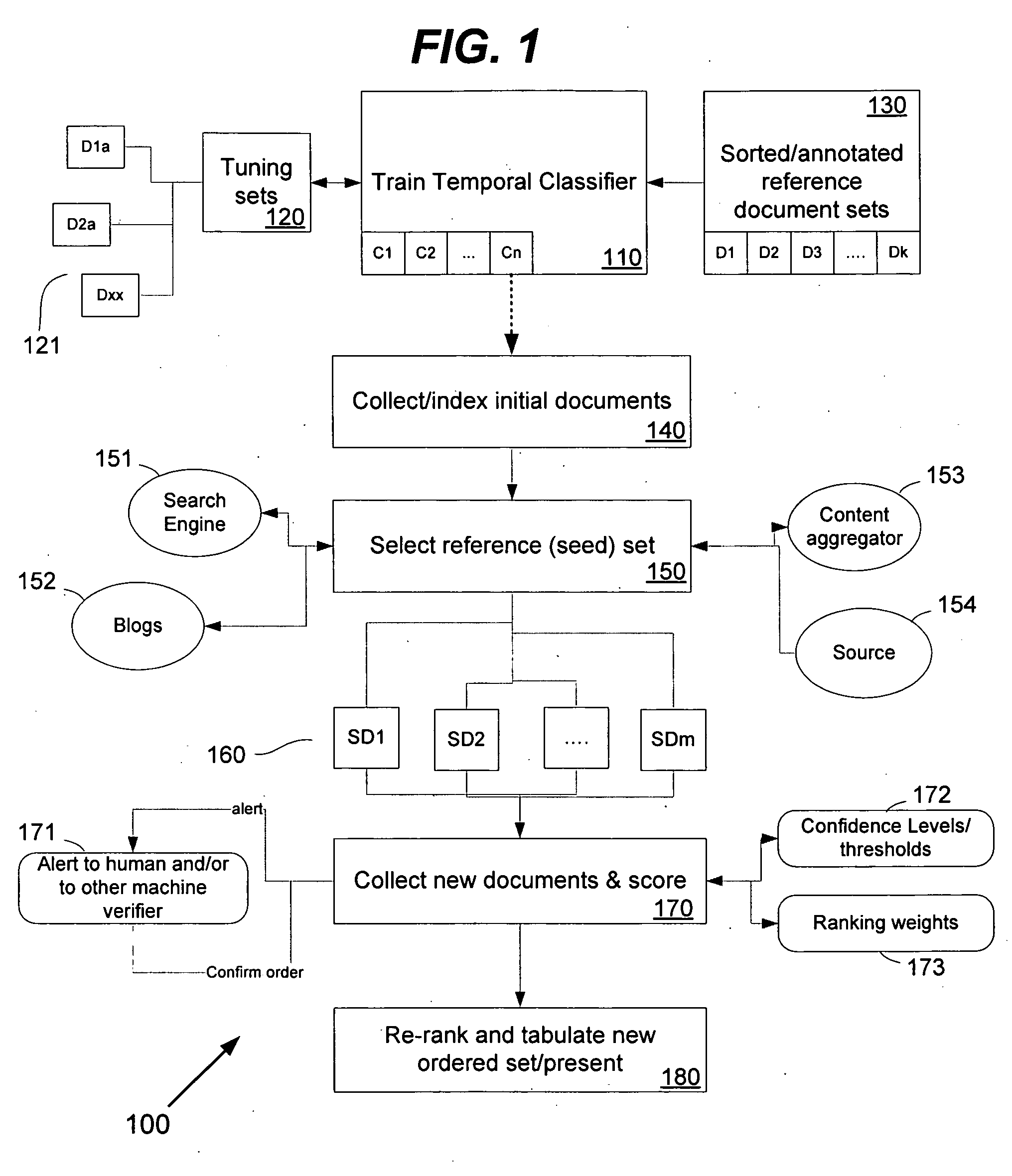

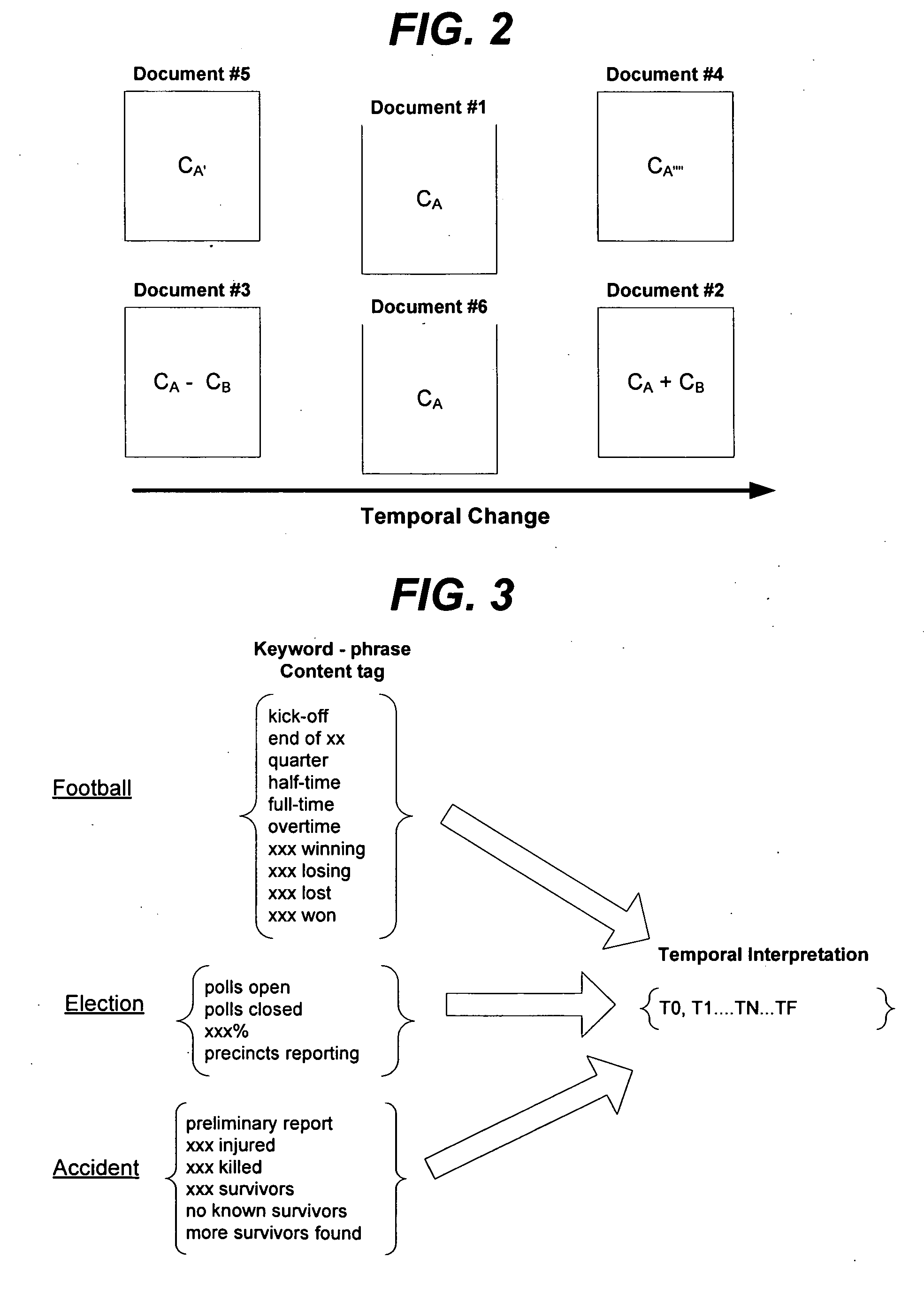

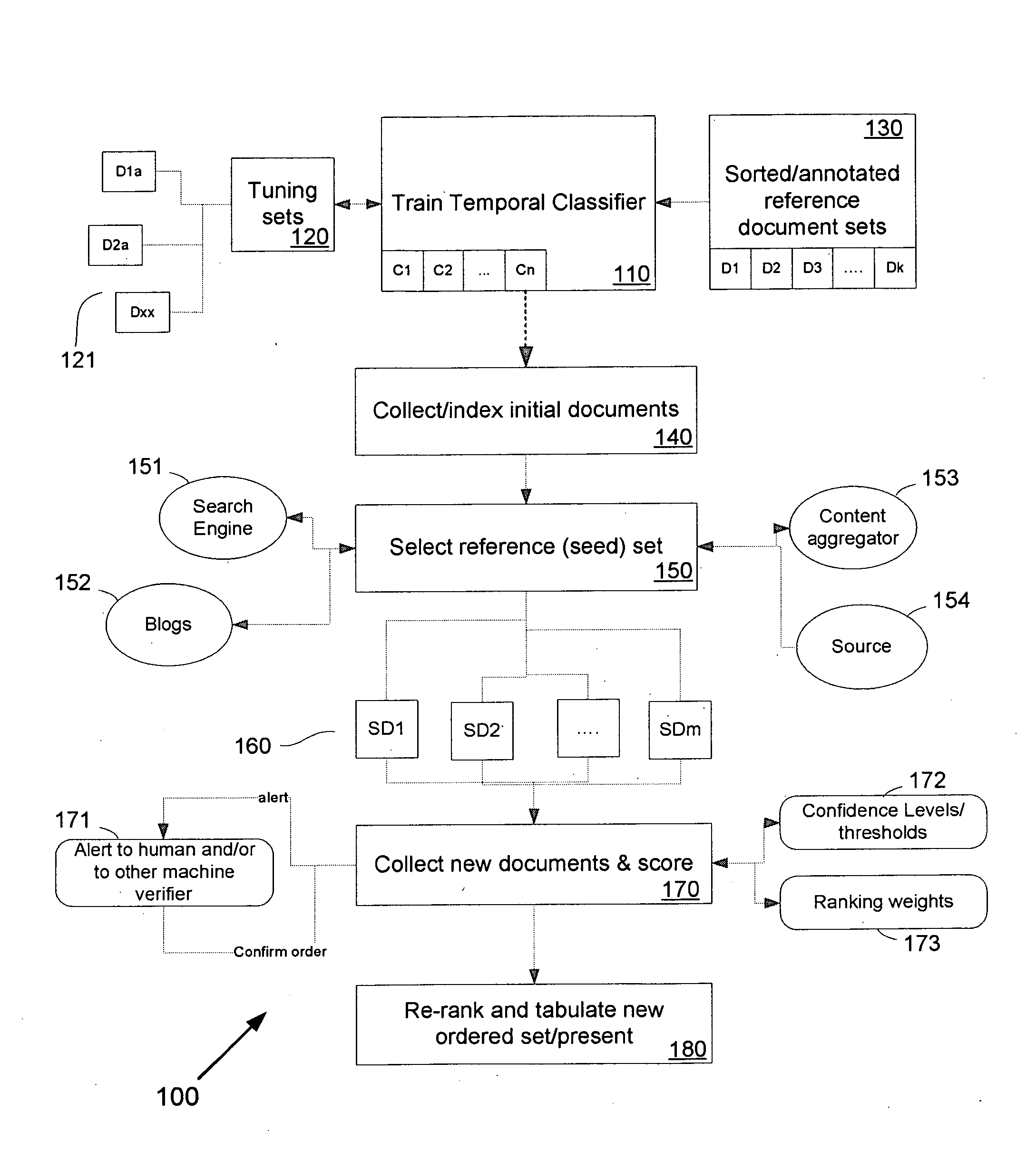

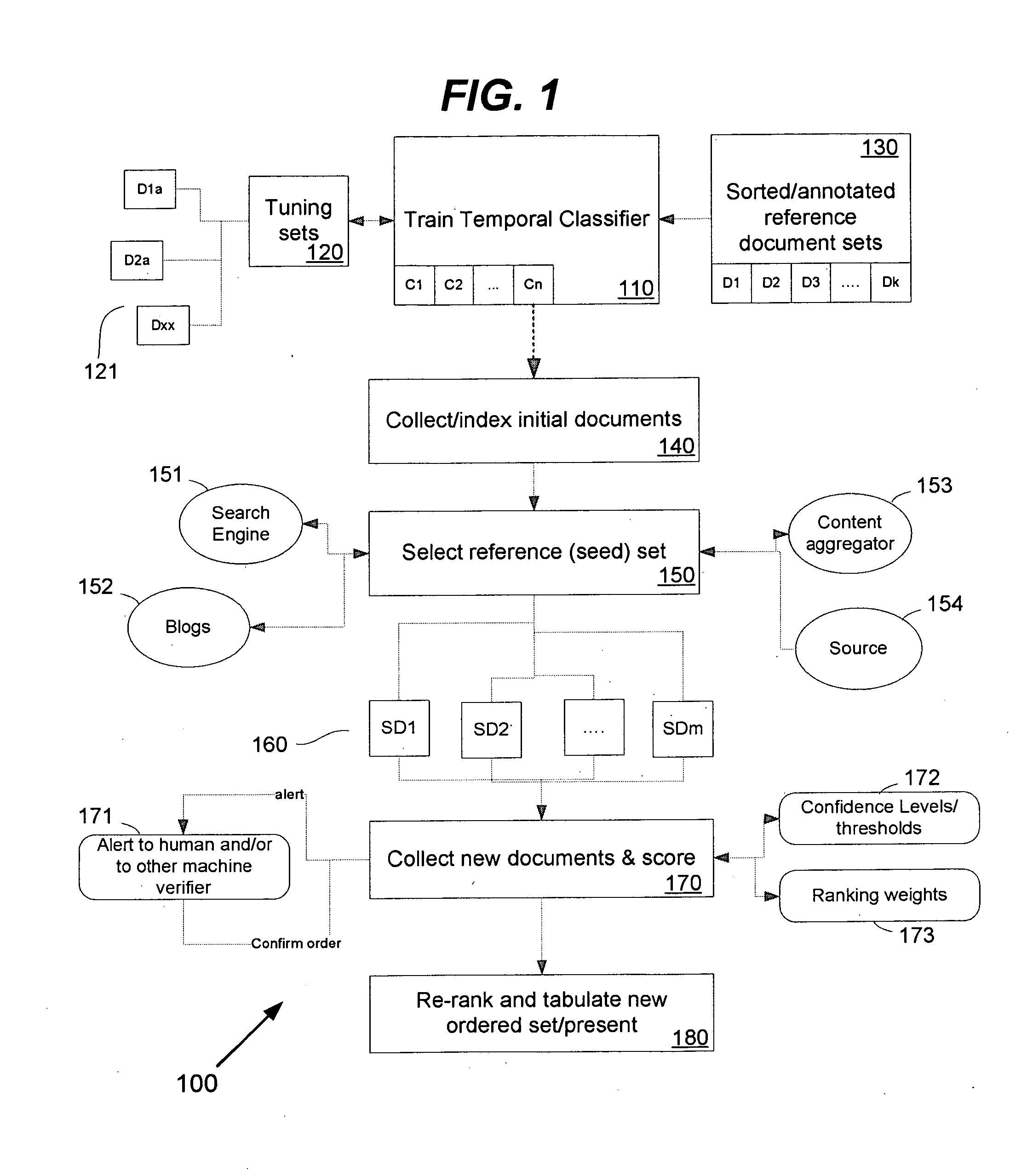

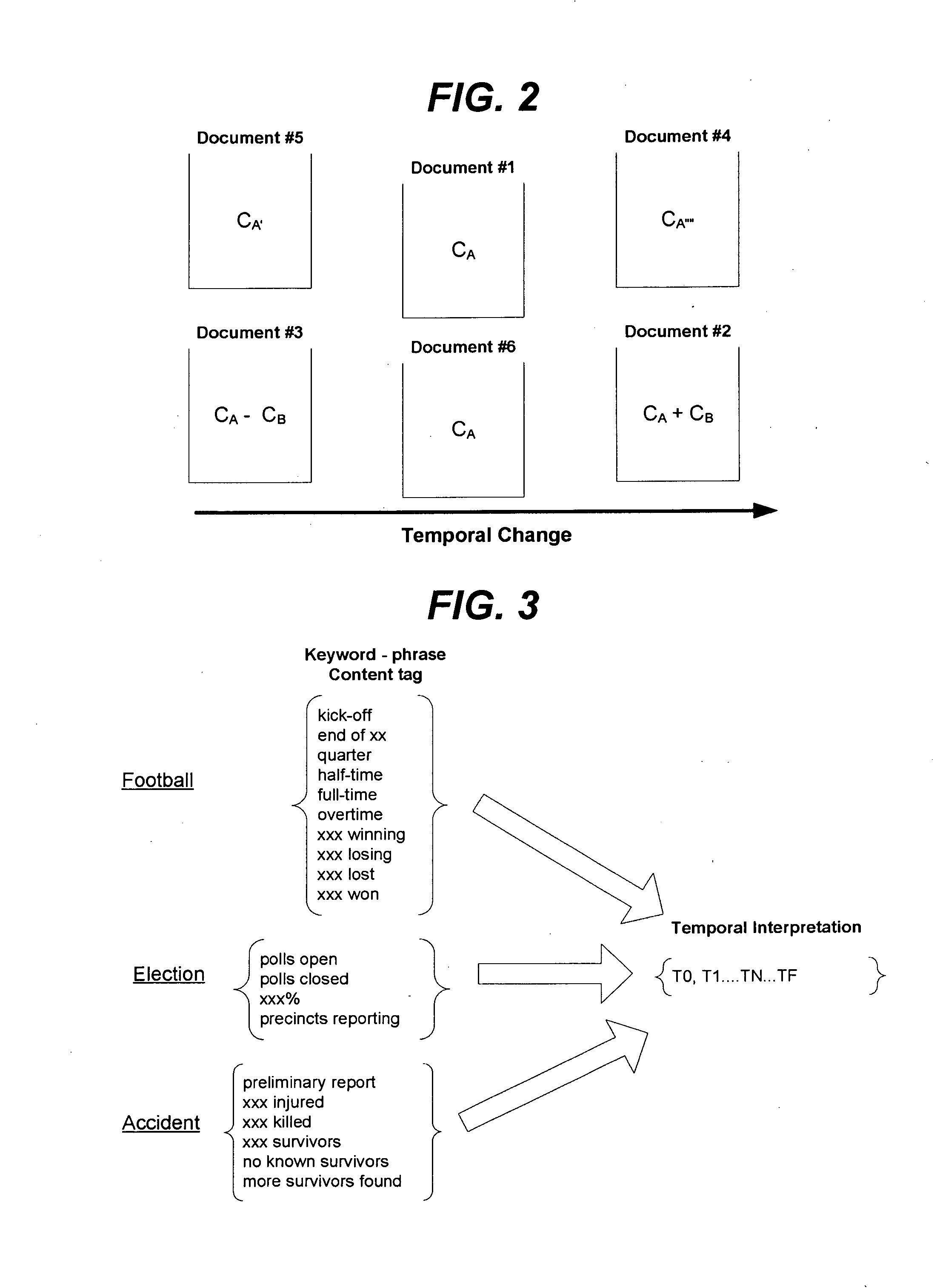

Event Based Document Sorter and Method

Events and / or topics are studied and classified according to their temporal qualities to determine their relative state. The content of a document relating to such event / topic is analyzed to identify temporal components. These components can be compared with corresponding counterparts in other documents to identify a relative temporal order. The invention can be used in environments such as automated news aggregators, search engines, and other electronic systems which compile information having temporal qualities.

Owner:JOHN NICHOLAS & KRISTIN GROSS

Low-Complexity Motion Vector Prediction Systems and Methods

ActiveUS20090034621A1Color television with pulse code modulationColor television with bandwidth reductionMotion vectorPrediction system

Owner:CISCO TECH INC

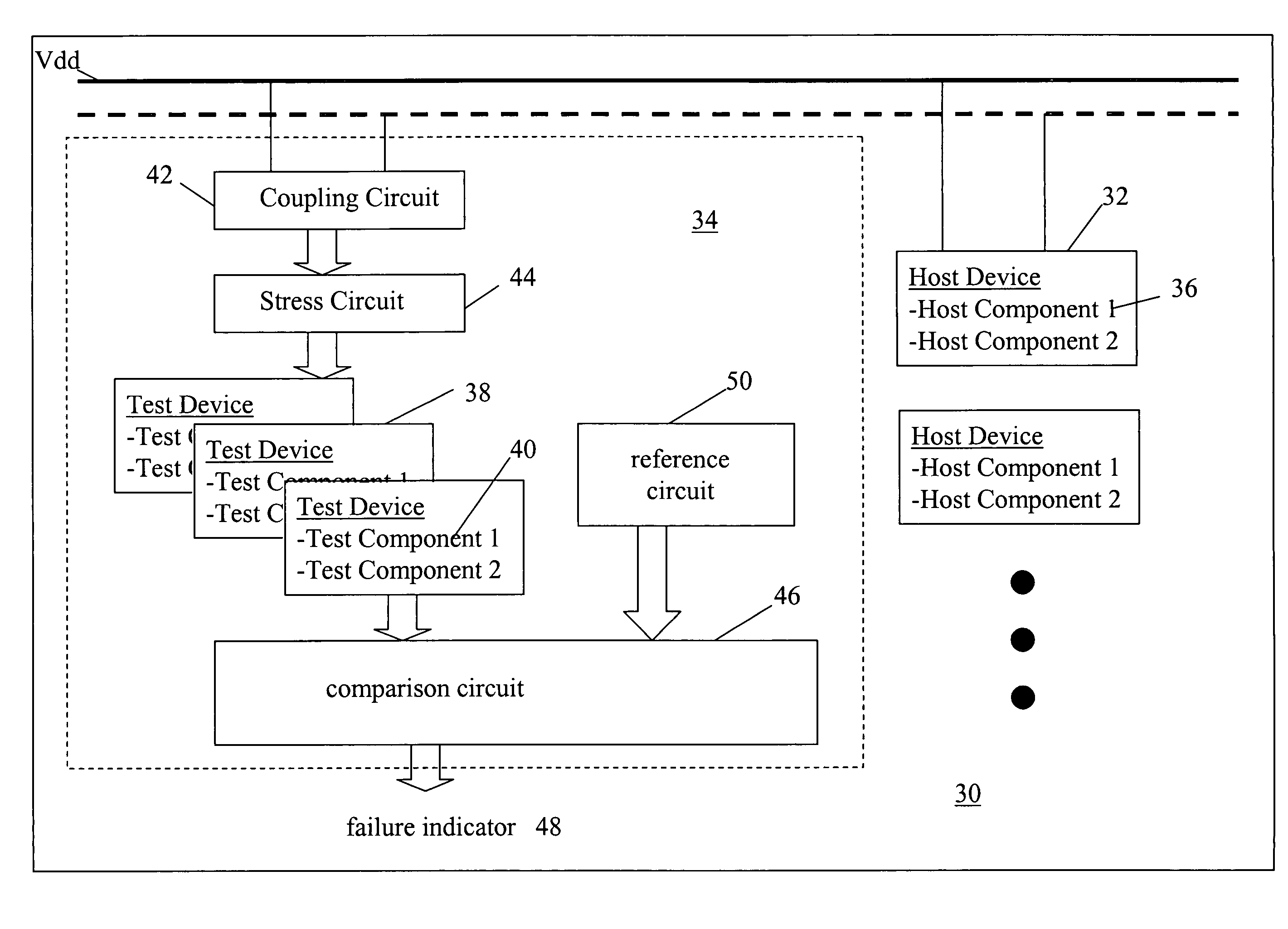

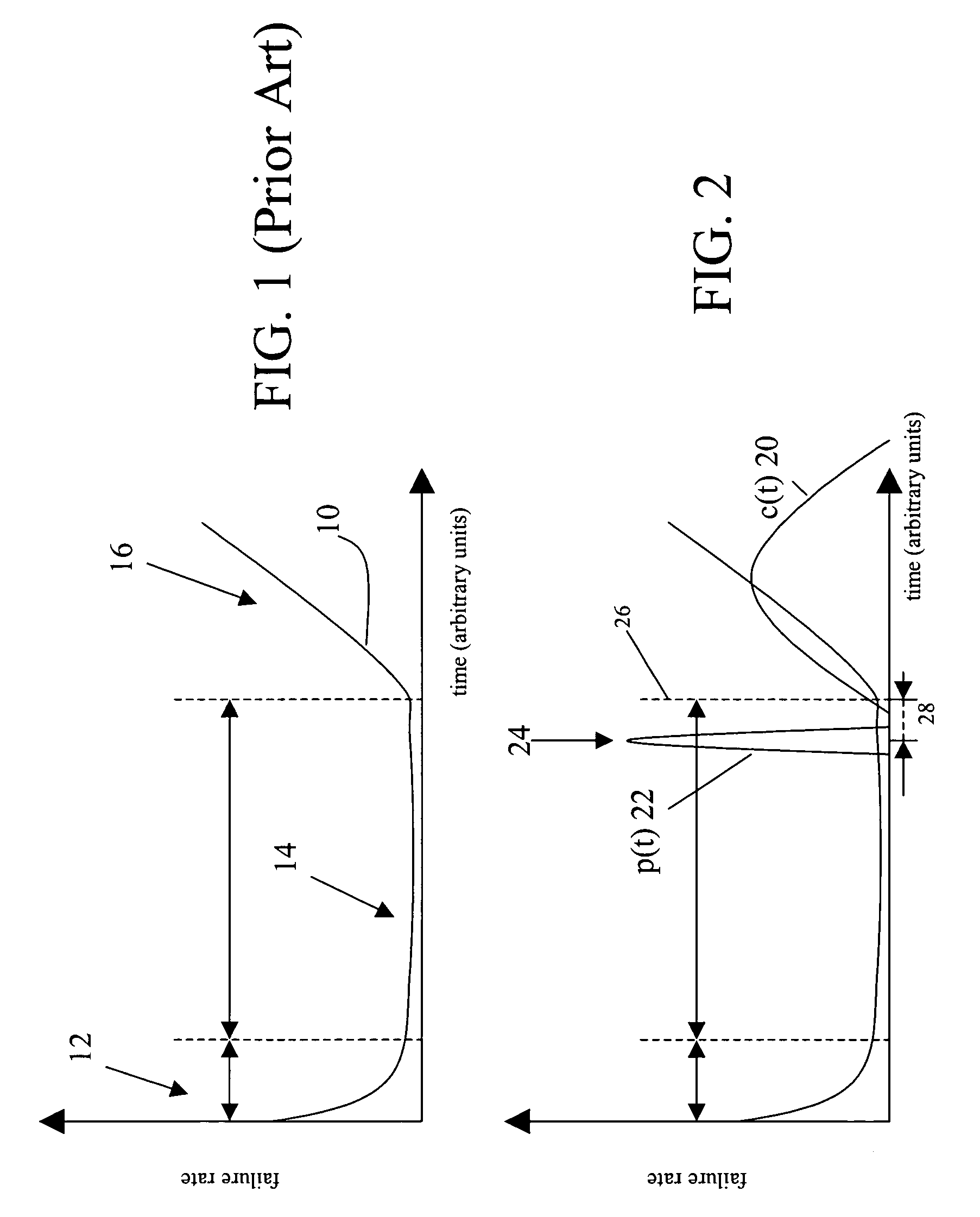

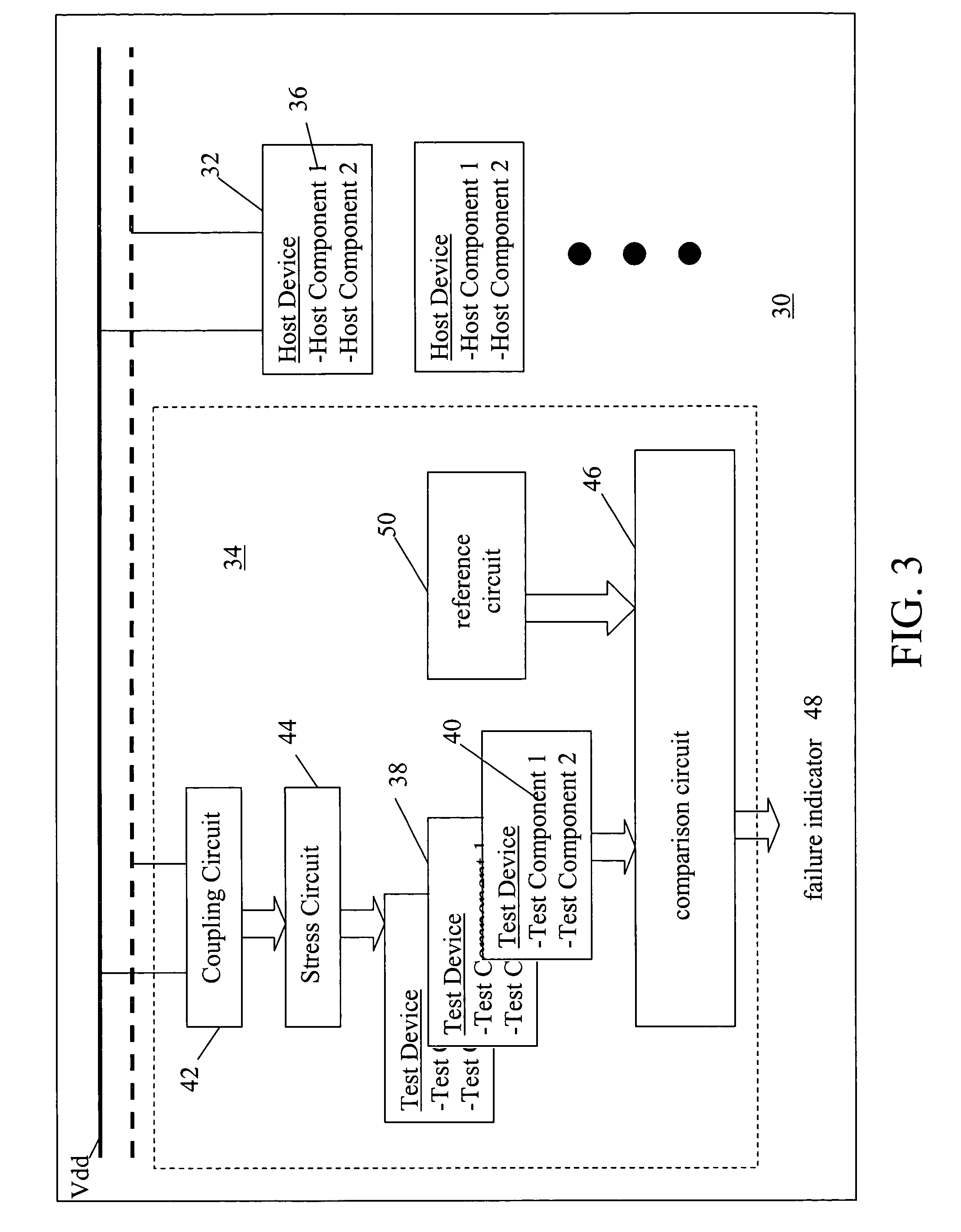

Prognostic cell for predicting failure of integrated circuits

InactiveUS7271608B1Improve deteriorationLow operating pressurePlug gaugesAlarmsRelative timesIntegrated circuit

A prognostic cell is used to predict impending failure of a useful circuit or circuits in a host IC. Increasing the stress on the prognostic cell relative to the useful circuit shifts the failure distribution of the cell along the time axis. The relative amount of time between the useful circuit failure and prognostic cell trigger point is the “prognostic distance”. The prognostic distance is controlled by designing in the excess stress applied in test device(s), by setting the threshold for triggering in the comparison circuit or by both. Prediction accuracy is enhanced by using multiple test devices to oversample the underlying failure distribution and triggering the failure indicator when a certain fraction fail.

Owner:RIDGETOP GROUP

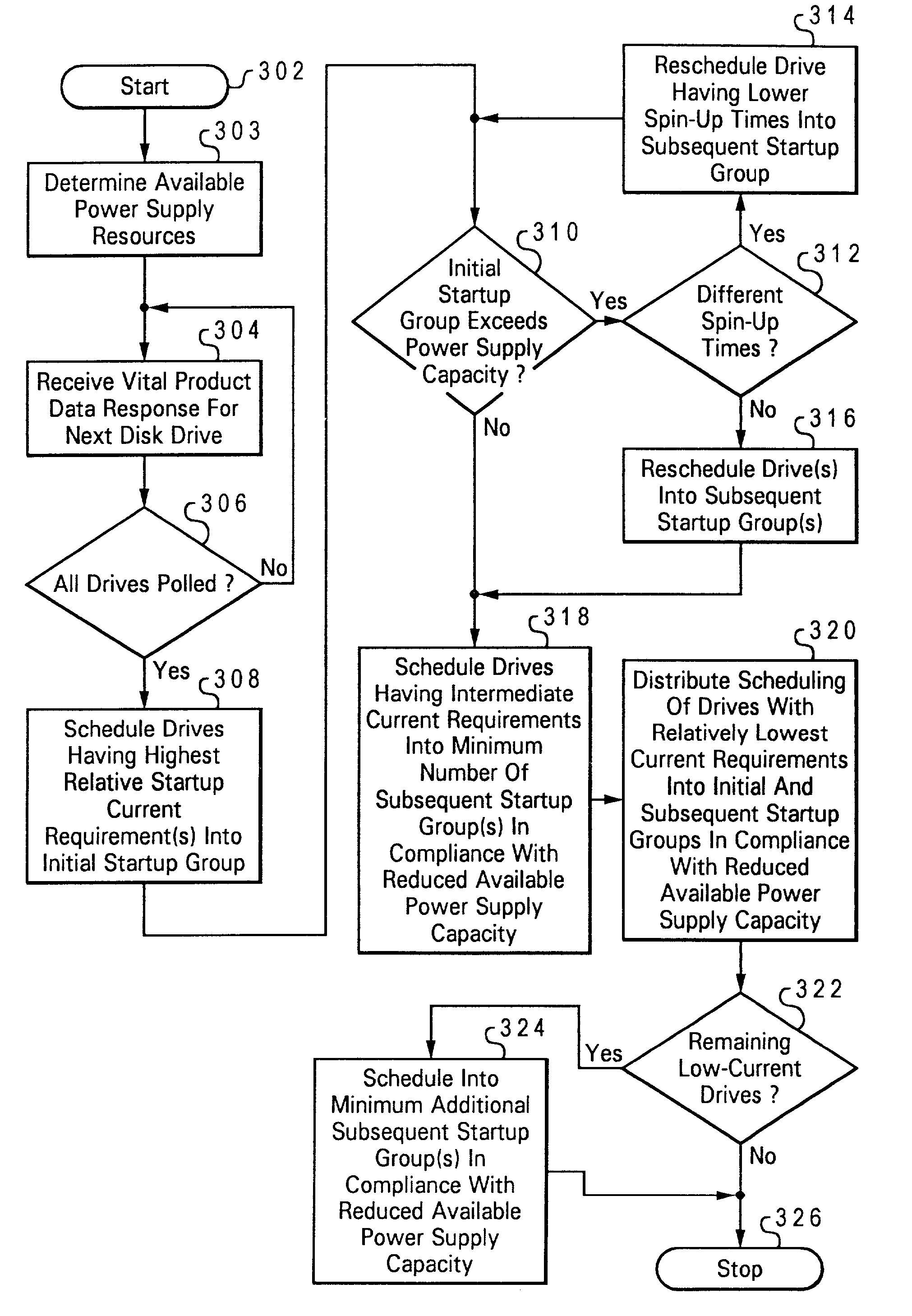

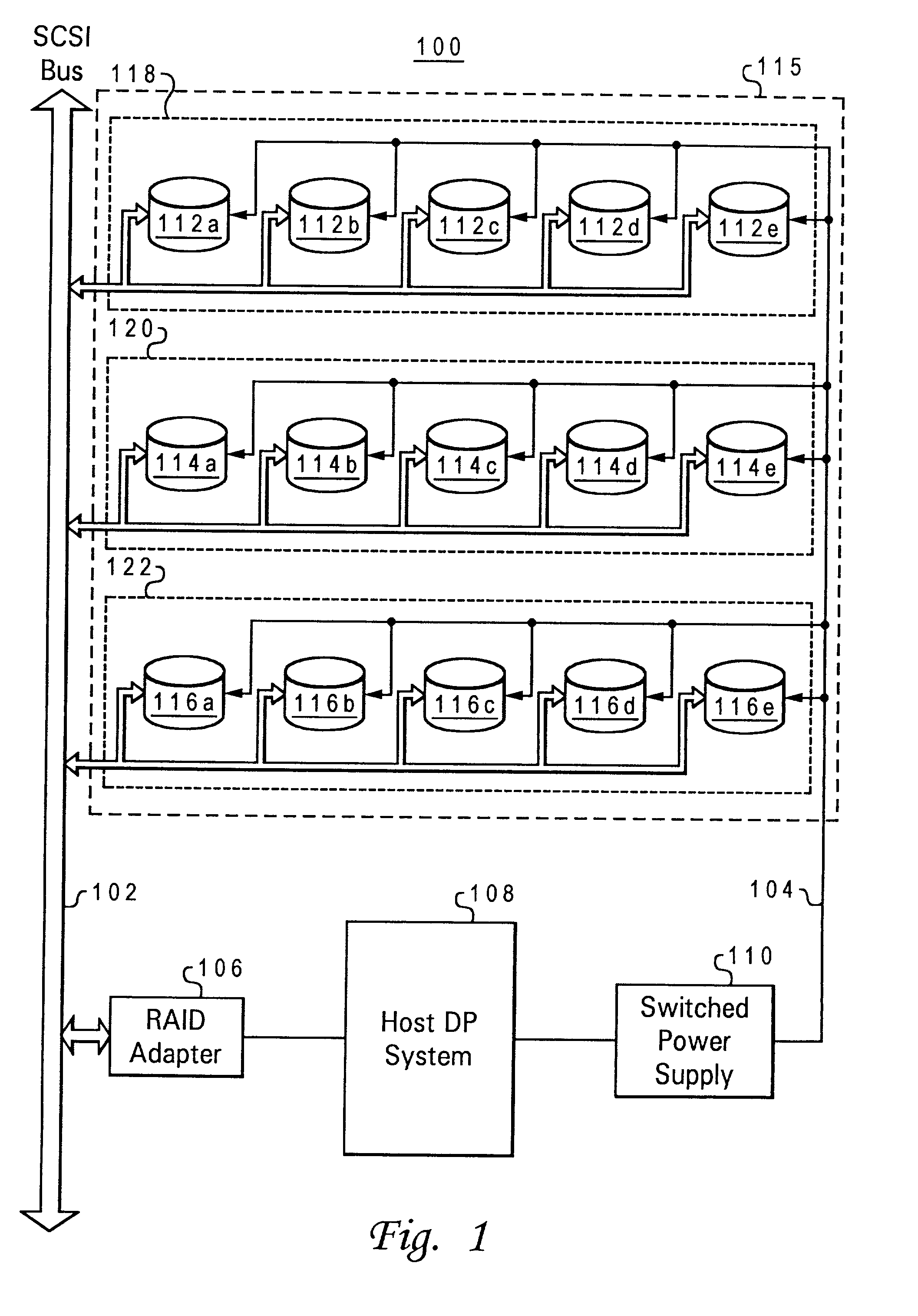

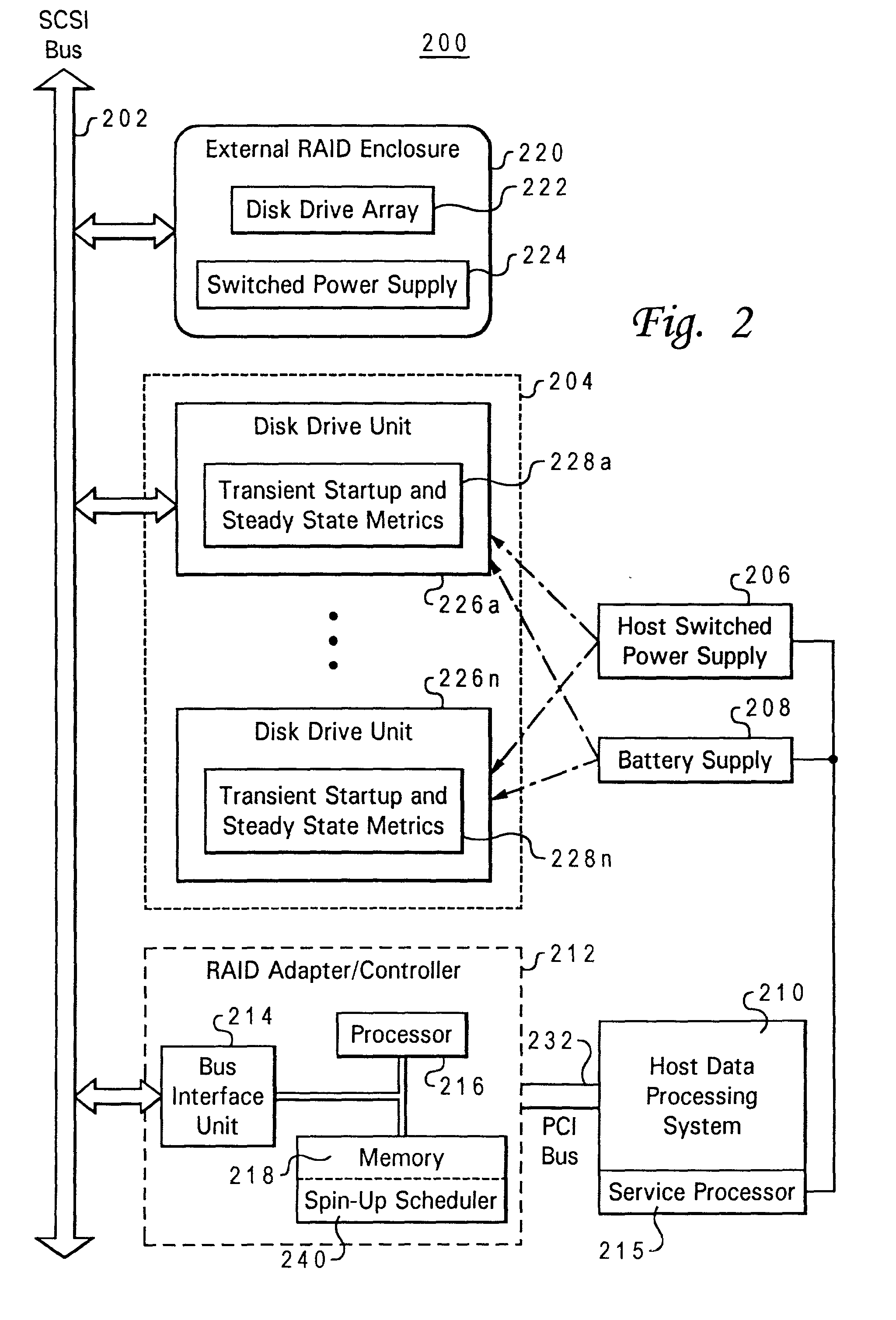

Adaptive startup policy for accelerating multi-disk array spin-up

A method and system for adaptively implementing a disk drive startup sequence for a disk drive array. Prior to a next disk drive spin-up sequence a currently available power supply resource capacity and a startup metric of each of the array disk drives are determined. Each of the disk drives are scheduled into designated startup groups as a function of both the determined currently available power supply resource capacity and the determined startup metric. The scheduling of disk drives into designated startup groups includes determining an activation sequence timing schedule for each of the disk drives. The activation sequence timing schedule determines the relative times at which spindle motors for each of said plurality of disk drives will be activated as a function of the determined startup metric for each of the disk drives and the available power supply resource capacity as reduced by the steady state power requirements of each of the startup groups.

Owner:LENOVO GLOBAL TECH INT LTD

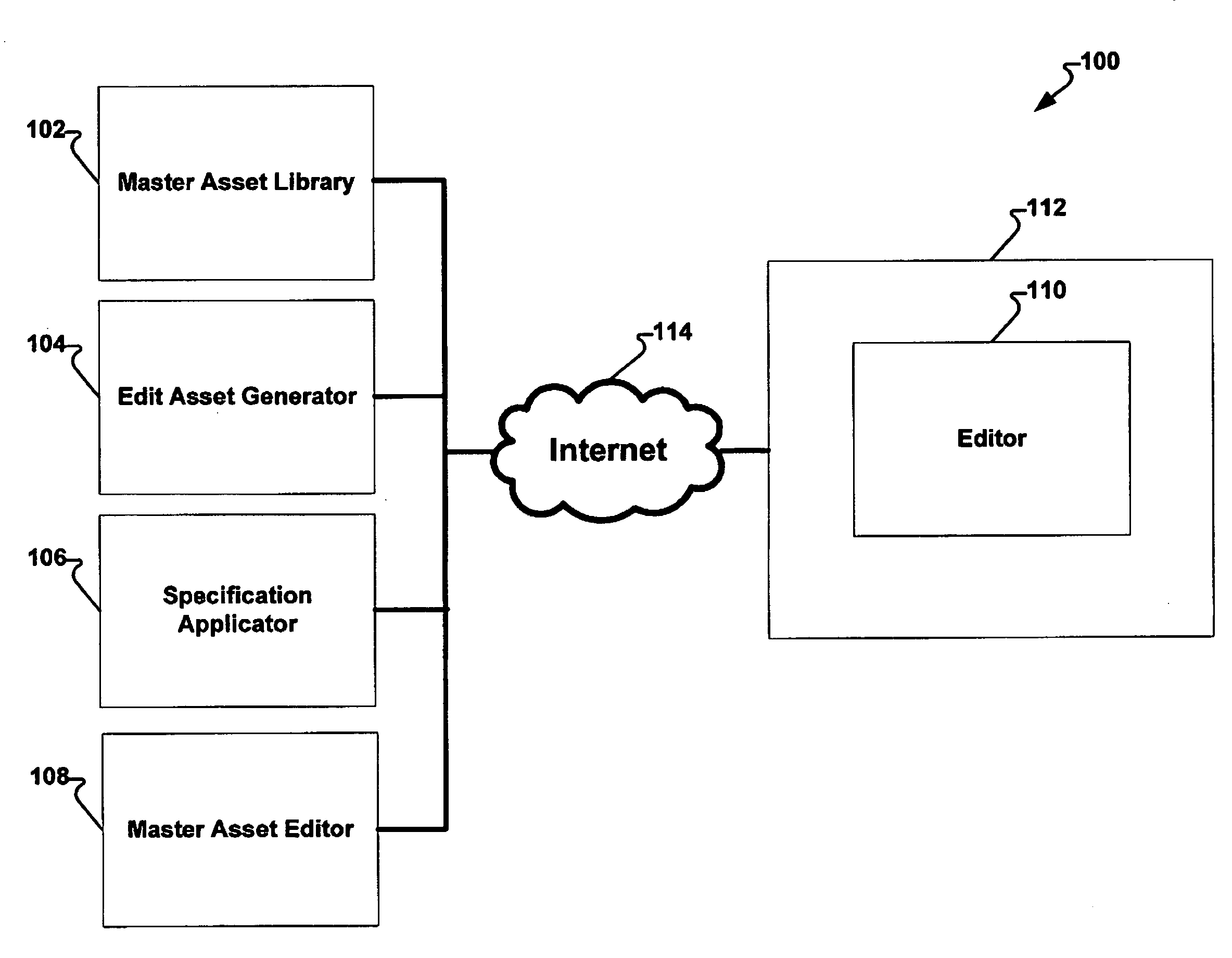

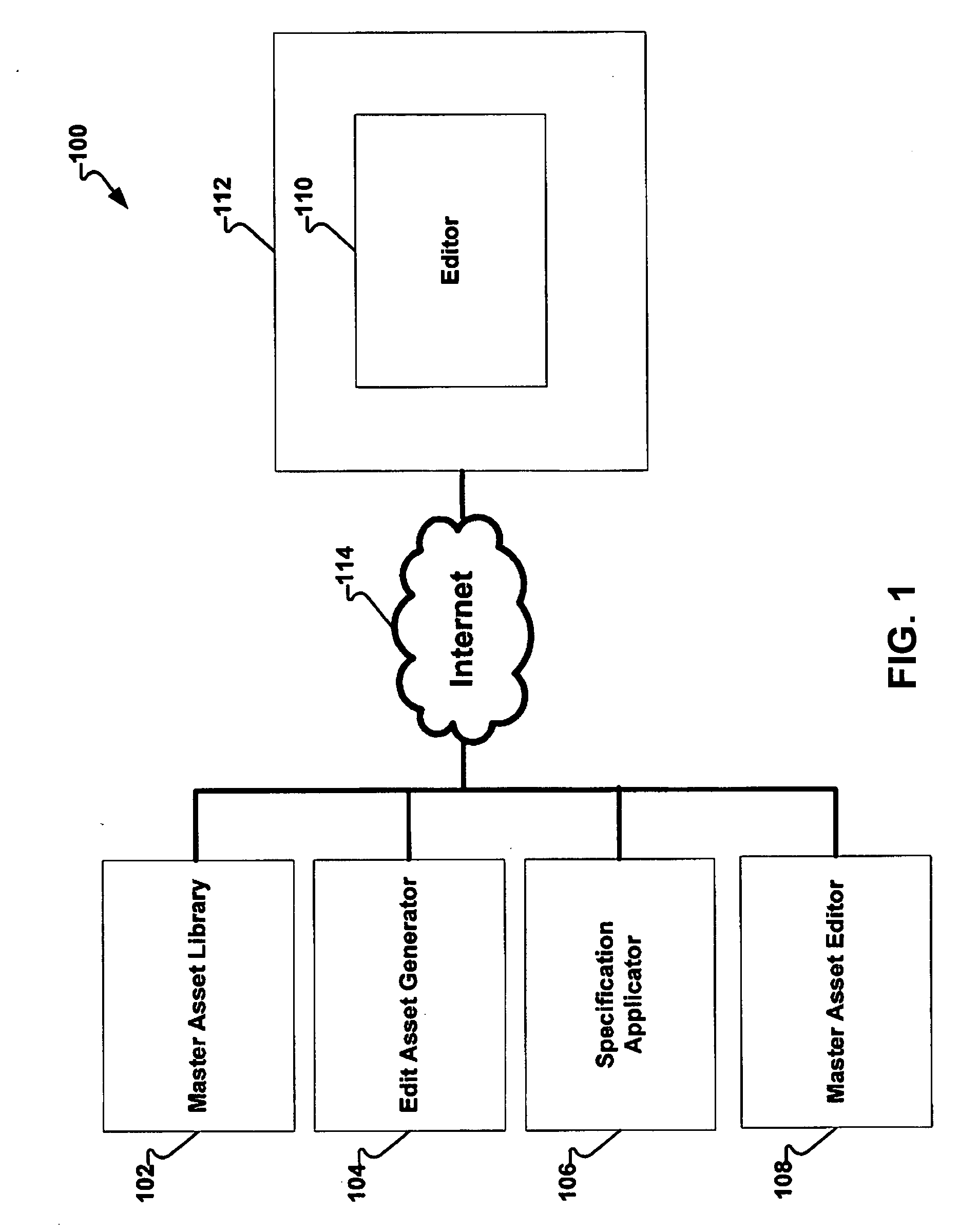

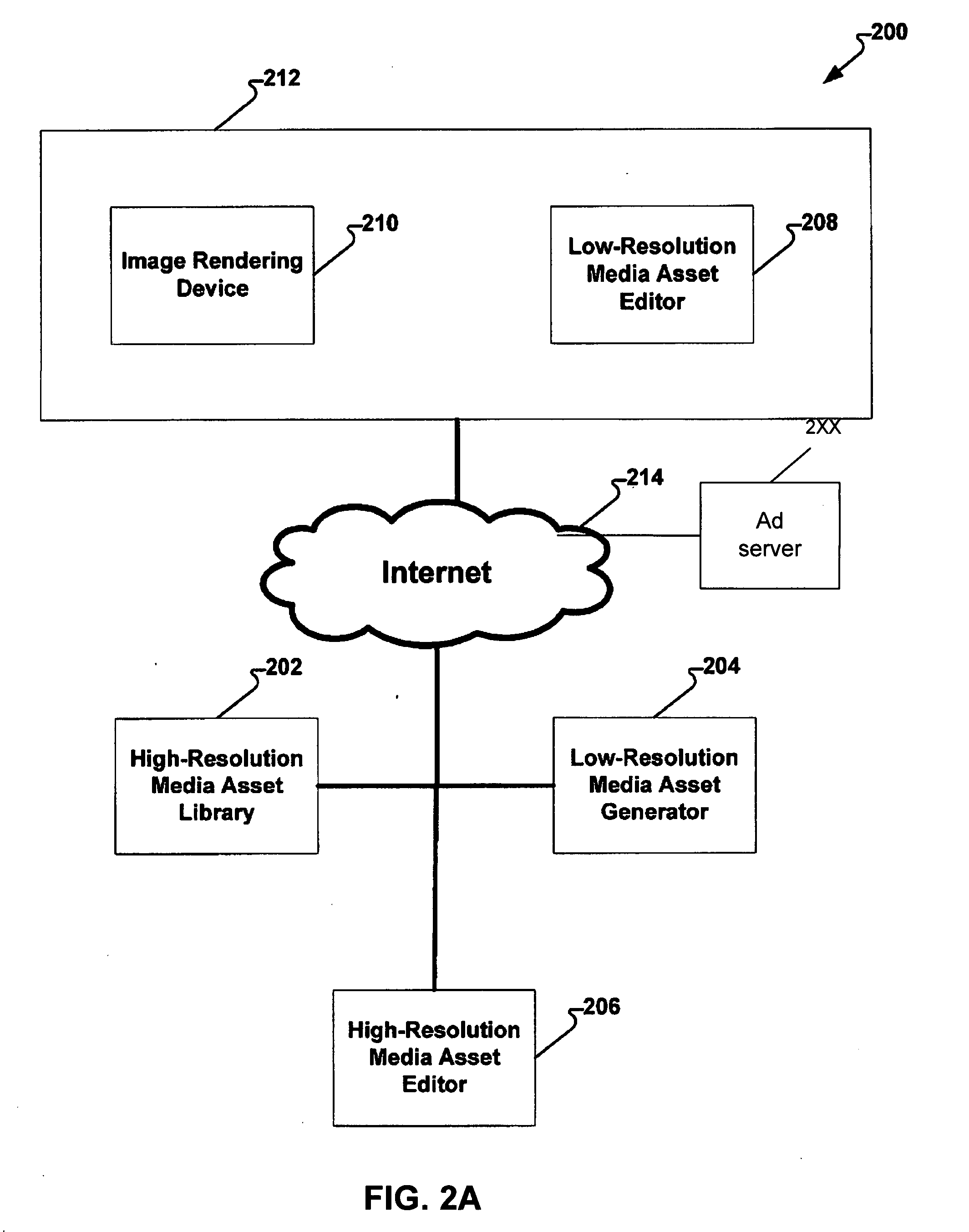

User interface for editing media assests

InactiveUS20070240072A1Facilitate editing medium assetData processing applicationsElectronic editing digitised analogue information signalsDisplay deviceRelative times

An interface for editing media assets is provided. The interface includes a display for displaying a plurality of tiles, each tile associated with a media asset, and a timeline for displaying relative times of each of the plurality of media assets as edited by a user for an aggregate media asset. The timeline display automatically adjusts in response to edits to the media assets; in one example, the timeline concatenating in response to an edit or change in the media assets selected for the aggregate media asset (e.g., in response to the addition, deletion, or edit of a selected media asset). Additionally, in some examples, the timeline maintains a fixed length when adjusting in response to edits to the media assets. In another example, the interface includes a search interface for searching for media assets from remote or local sources.

Owner:OATH INC

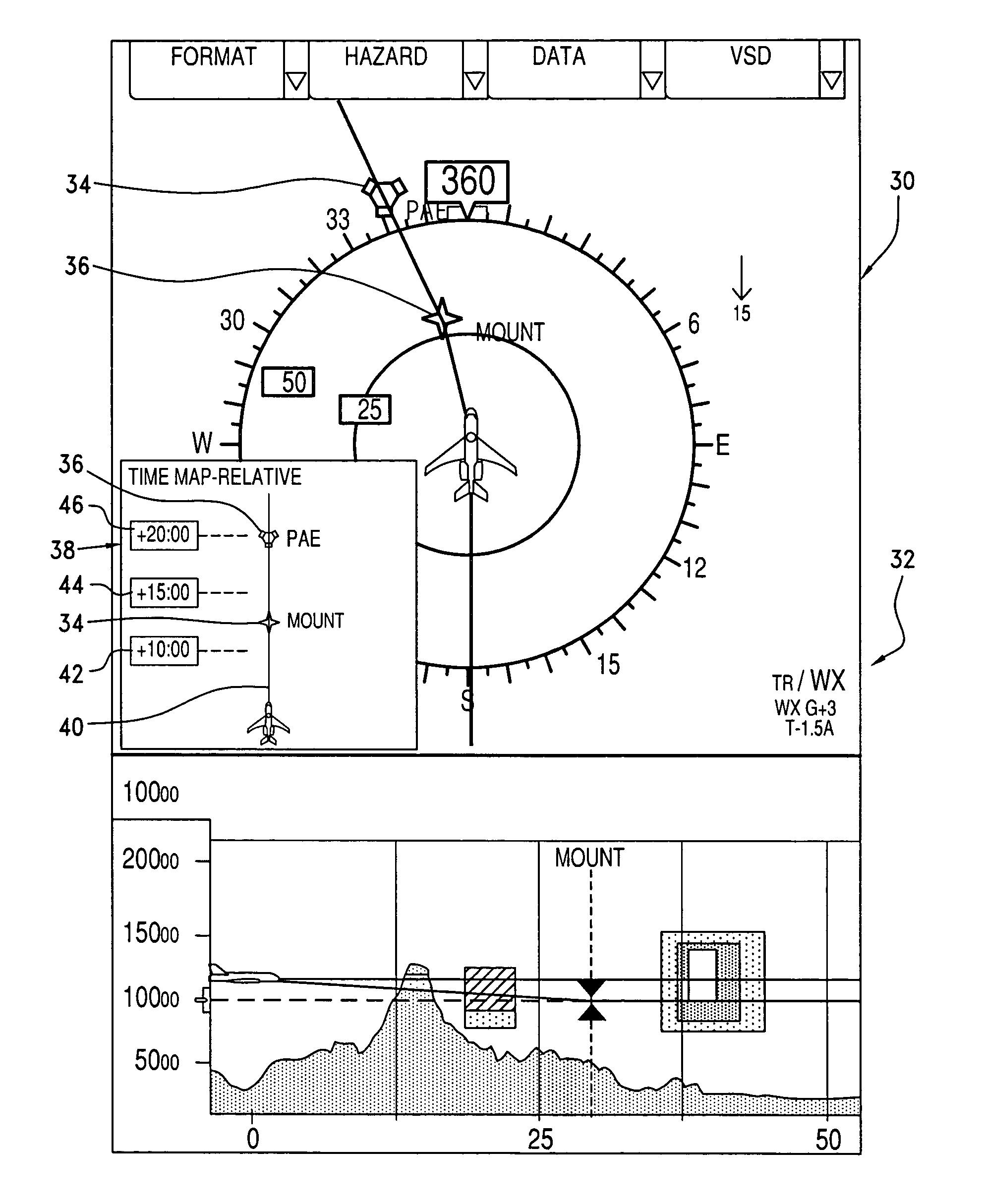

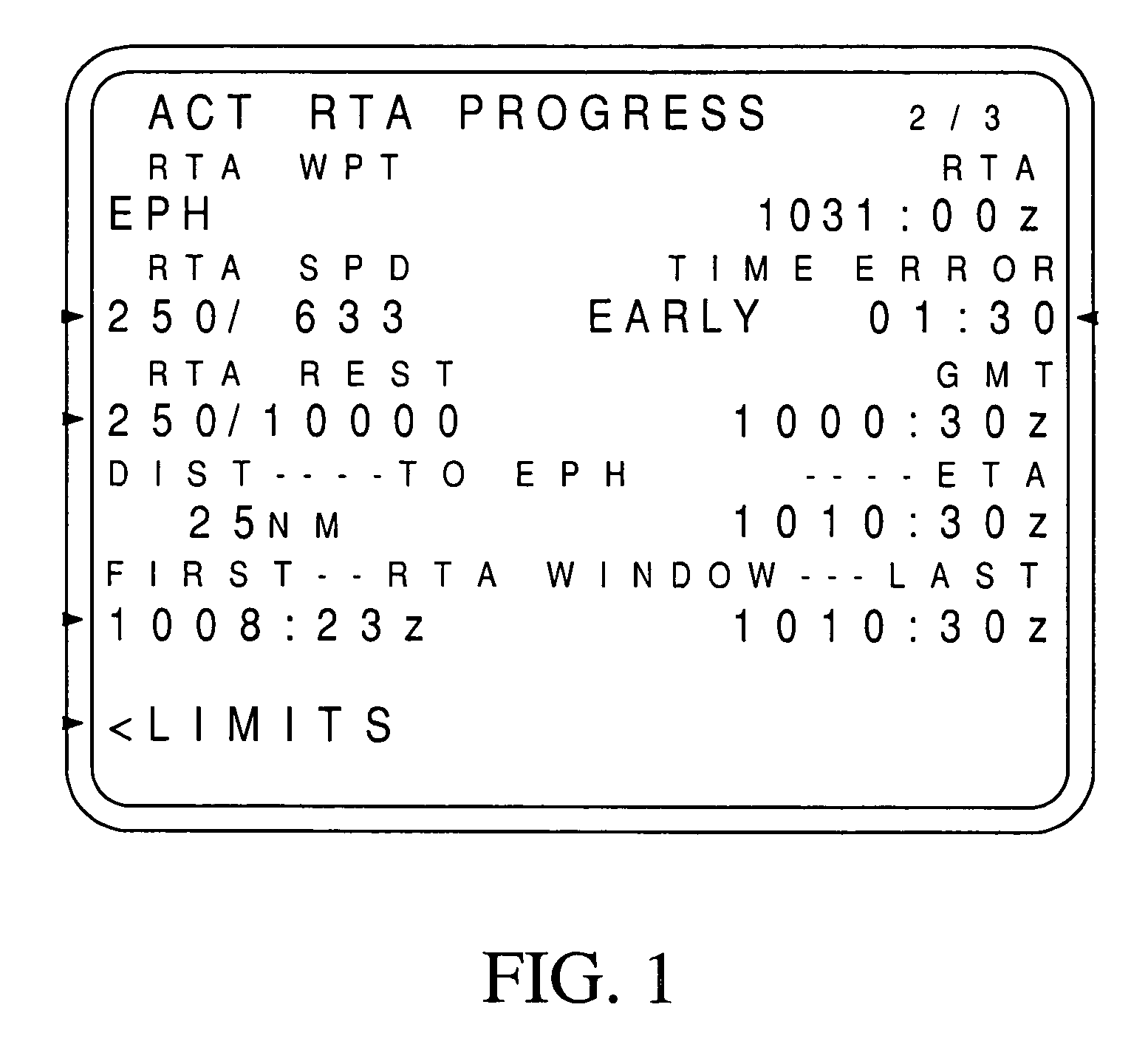

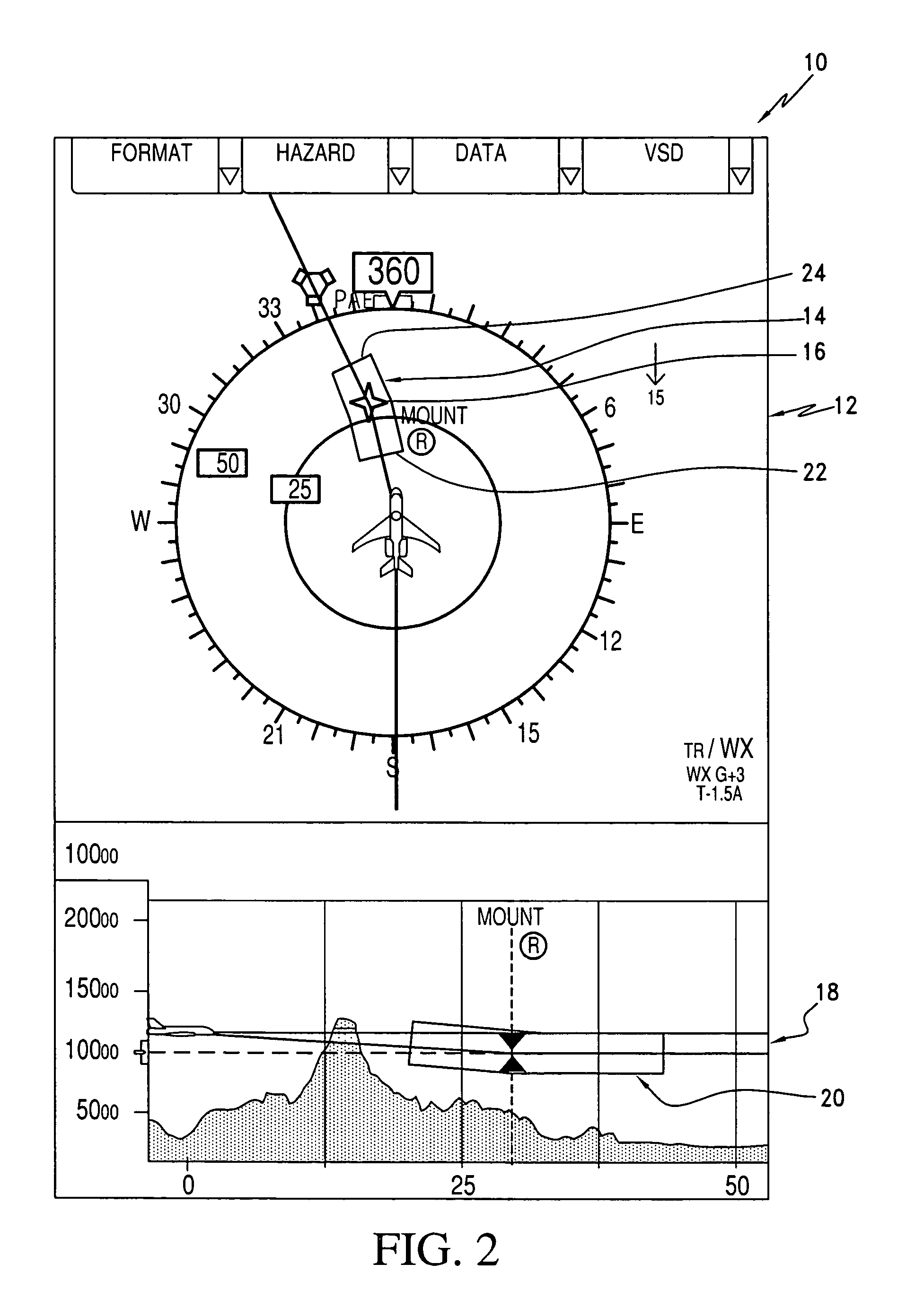

Flight display system with enhanced temporal depiction of navigation information

ActiveUS7765061B1Instruments for road network navigationRoad vehicles traffic controlJet aeroplaneLow speed

In one aspect, the flight display system comprises a navigation map that includes a time window for a required time of arrival (RTA) waypoint. The time window has a proximal end indicating the aircraft's position at the RTA using a defined lowest speed and a distal end indicating the aircraft's position at the RTA using a defined highest speed. In another aspect, a pop-up time map displays flight plan waypoints mapped out along a time line adjacent to a plurality of time markers. The waypoint scrolls along the time line during flight. In another aspect, the flight display system includes a full format time map for displaying at least one flight plan waypoint mapped out along a time line adjacent to a plurality of time markers. In another broad aspect, a time / bearing map includes a plurality of concentric “range” rings corresponding to selected times in the future; a plurality of radially spaced bearing ticks positioned at selected locations about the concentric rings; and, a relative time ring presentable about a central axis of, and internal to, the concentric rings. The relative time ring represents a fixed increment in time. Selected waypoints are presentable at their relative bearing to the airplane and at their range (in time) from the airplane.

Owner:ROCKWELL COLLINS INC

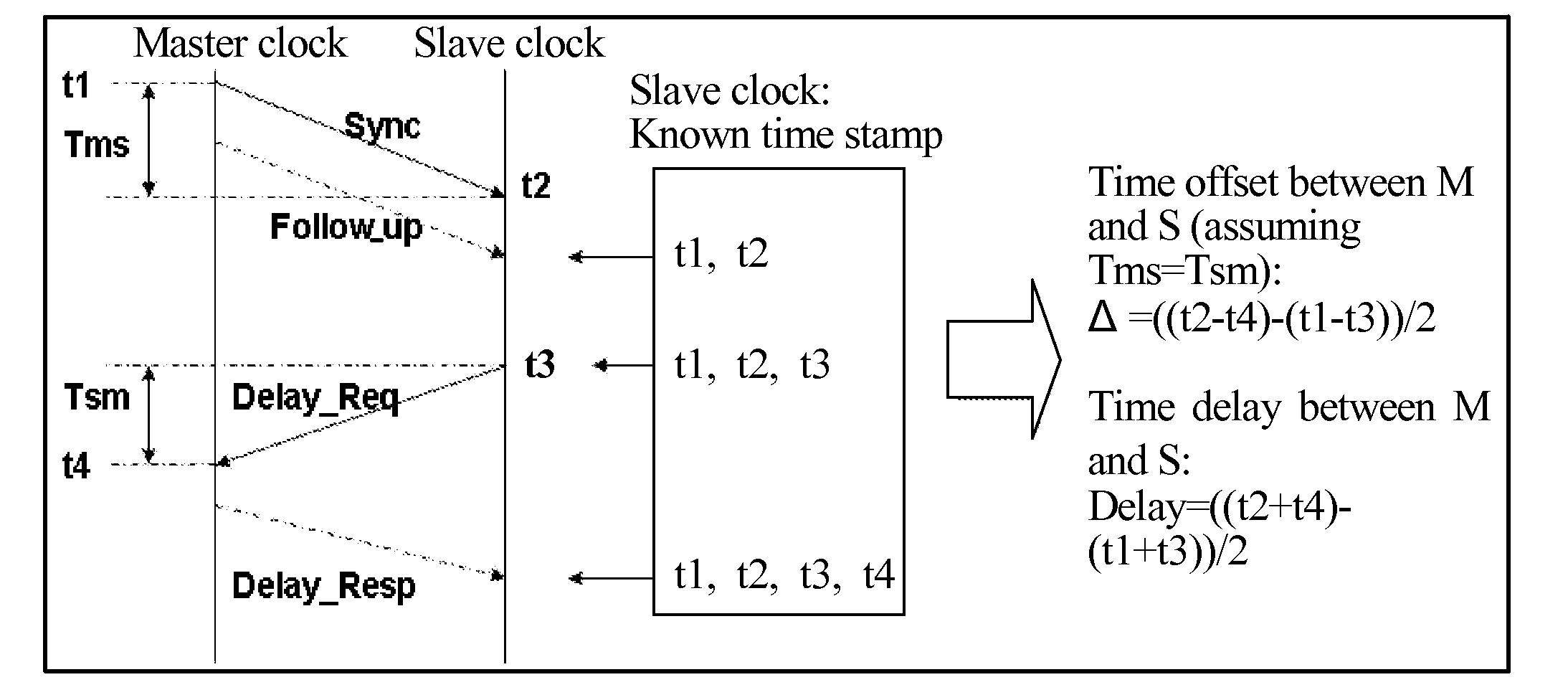

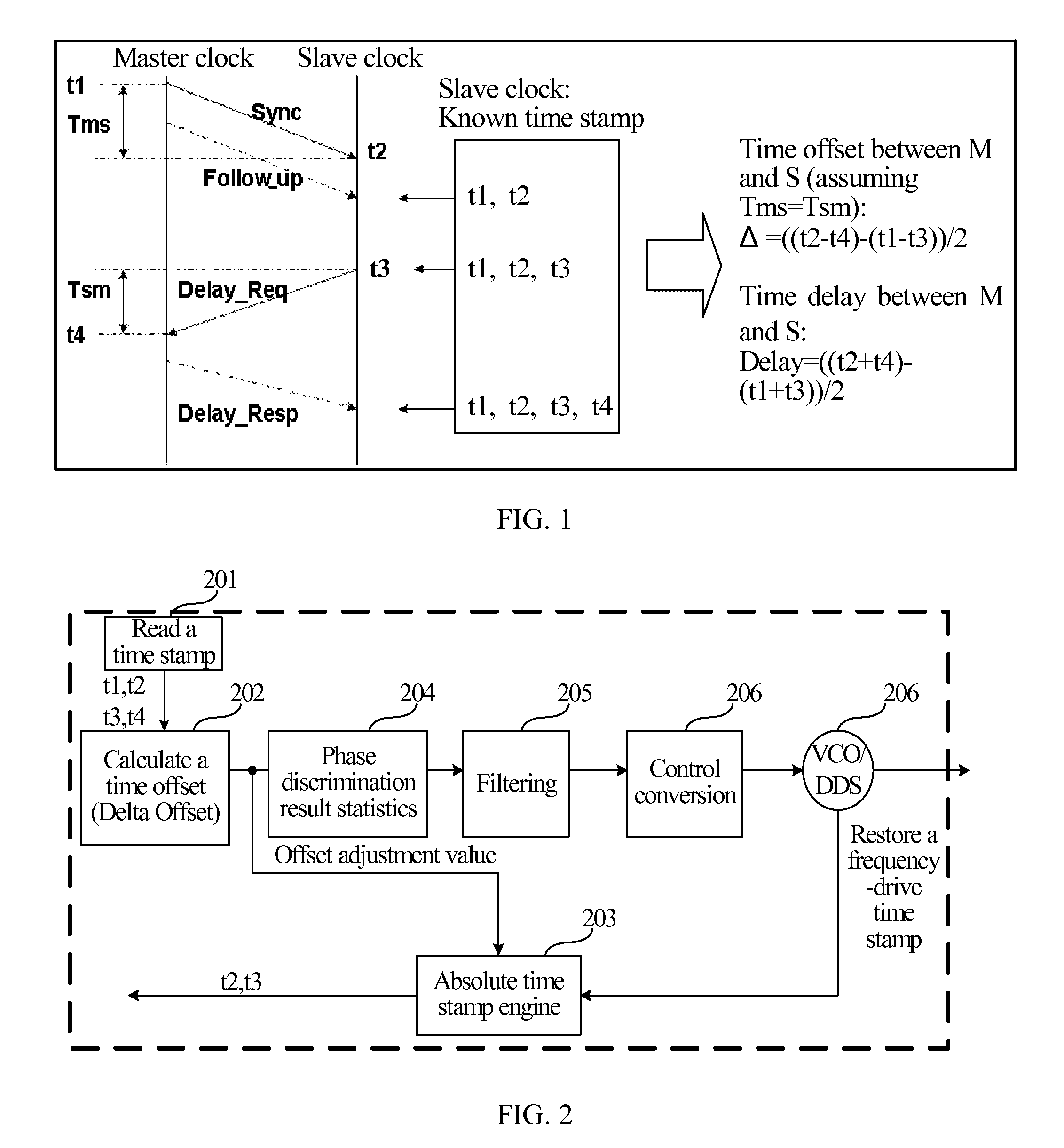

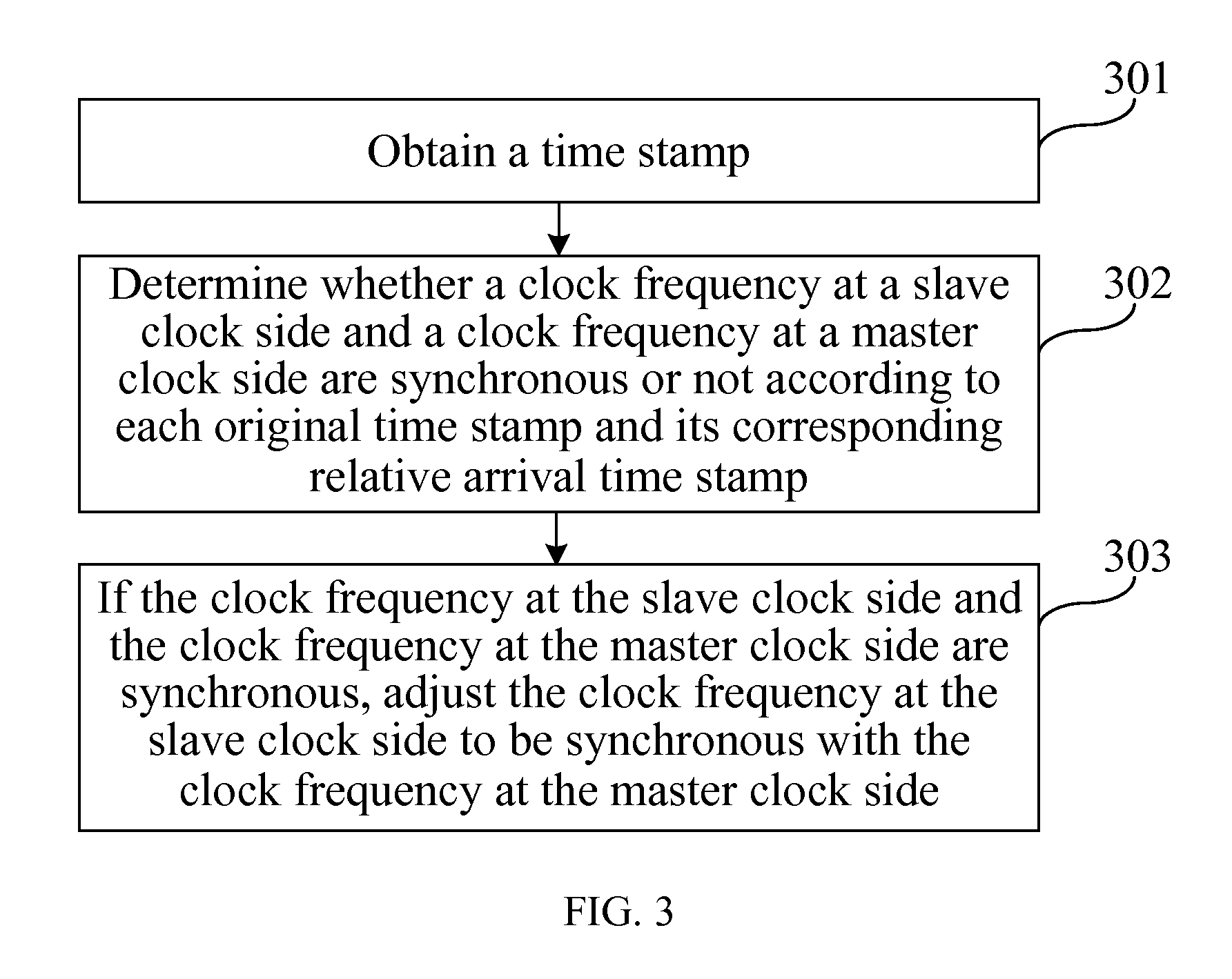

Method and system for precise-clock synchronization, and device for precise-clock frequency/time synchronization

InactiveUS20100098111A1Occupied link bandwidth resources are greatly reducedPulse automatic controlTime-division multiplexData synchronizationSlave clock

A precise-clock synchronization method and system and a precise-clock frequency / time synchronization device are provided. In the embodiments of the present invention, two time stamp engines are provided at a slave clock side. A relative time stamp engine provides a relative arrival time stamp. An absolute time stamp engine provides an absolute arrival time stamp. The frequency / time synchronization is calculated by using different time stamps obtained from different time stamp engines, so the frequency synchronization and time synchronization of master clock and the slave clock may be separately accomplished, and one synchronization function may be enabled or disabled. Therefore, the frequency synchronization and time synchronization of the master clock and the slave clock do not interfere with each other, thus greatly reducing the occupied link bandwidth resources.

Owner:HUAWEI TECH CO LTD

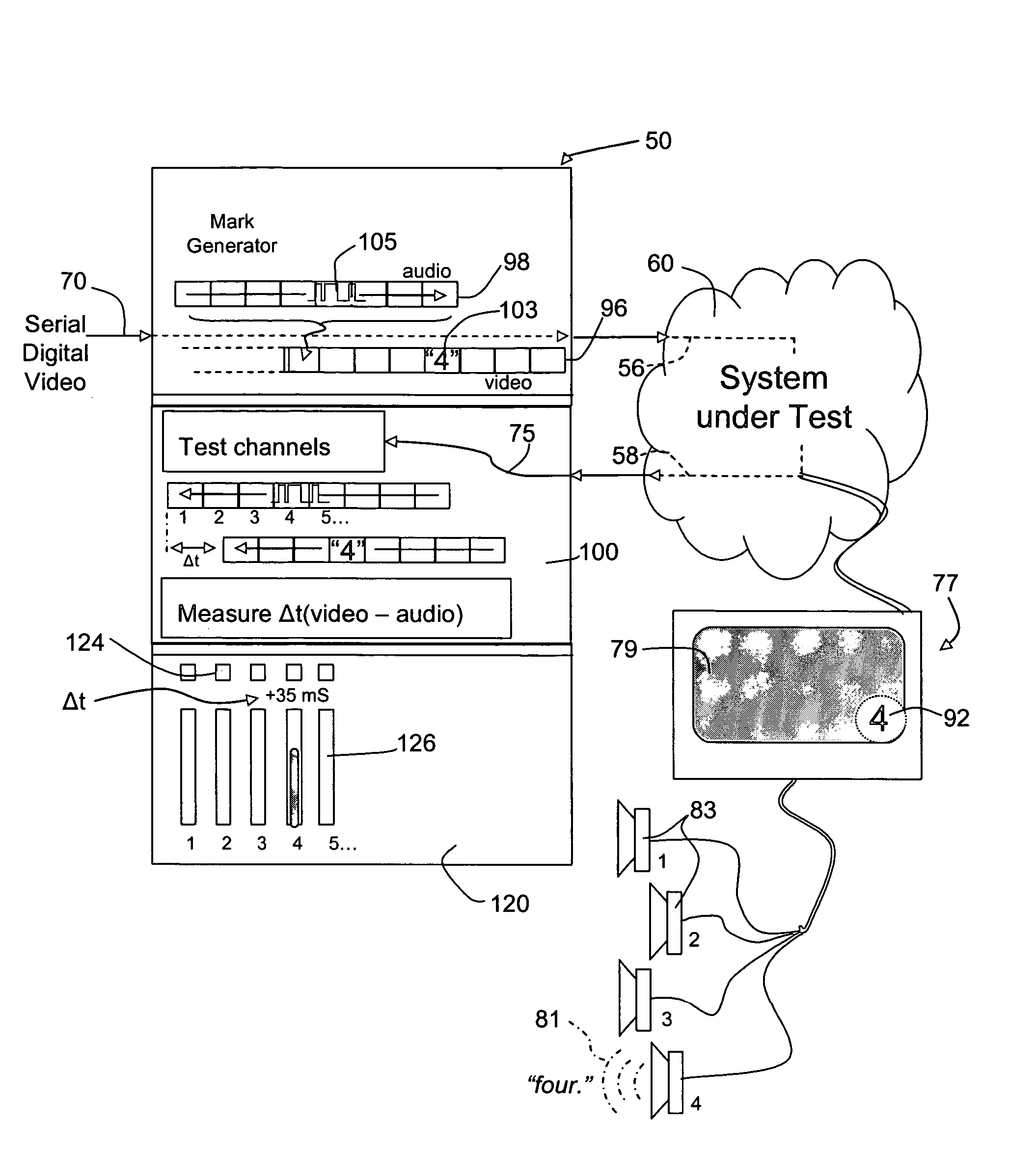

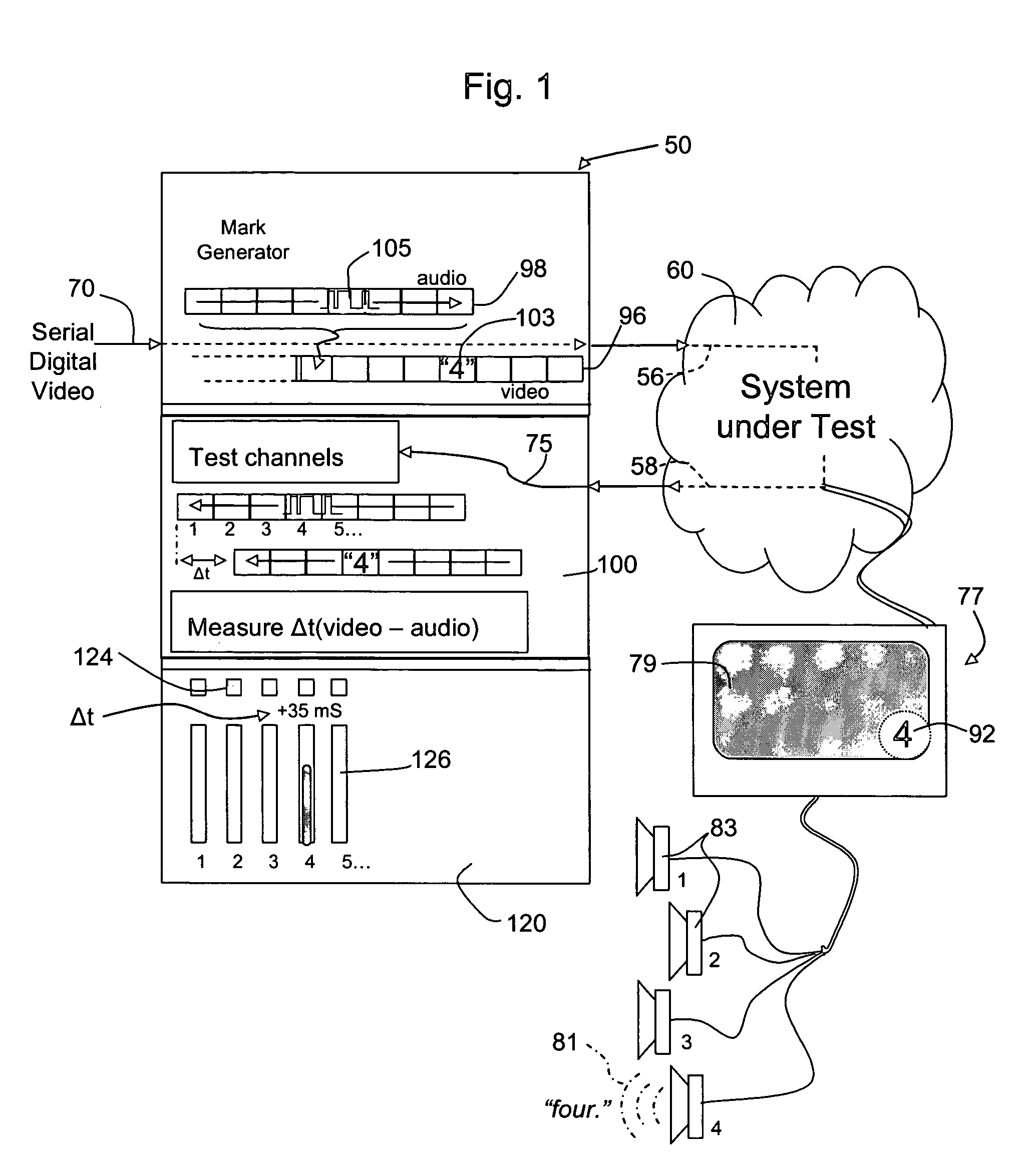

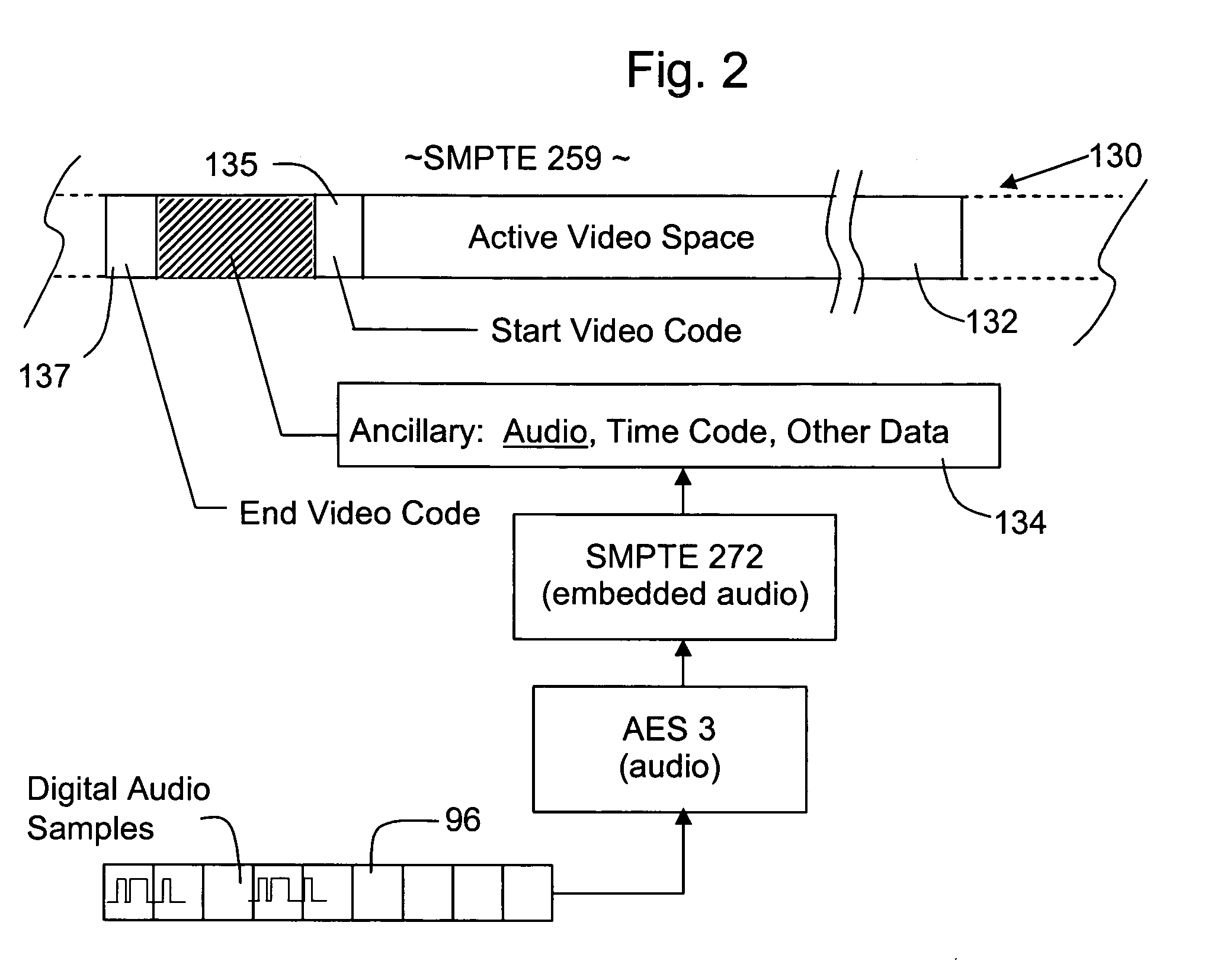

Digital audio-video differential delay and channel analyzer

InactiveUS20050219366A1Sufficient variationClear instructionsTelevision system detailsColor television detailsDigital signal processingDigital video

A testing device and method for a digital video processing system is coupleable to an input and output of the processing system, and inserts video and audio marking information into the input to test system operation. The test device inserts a video marker and an audio marker data code for a single audio channel, preferably in the same digital input frame. The device then monitors the same audio channel and also all the other audio channels at the output, while monitoring for the video marker. The device indicates the occurrence and timing of results that appear at the outputs, the relative timing of the output audio mark(s) versus the video mark, an alarm in the event that an output mark is not found or found on an unexpected channel, etc. The test device successively exercises the audio and video portions of the processing system while also providing numeric timing measurements that are useful for proper setup and operation.

Owner:VIDETEK

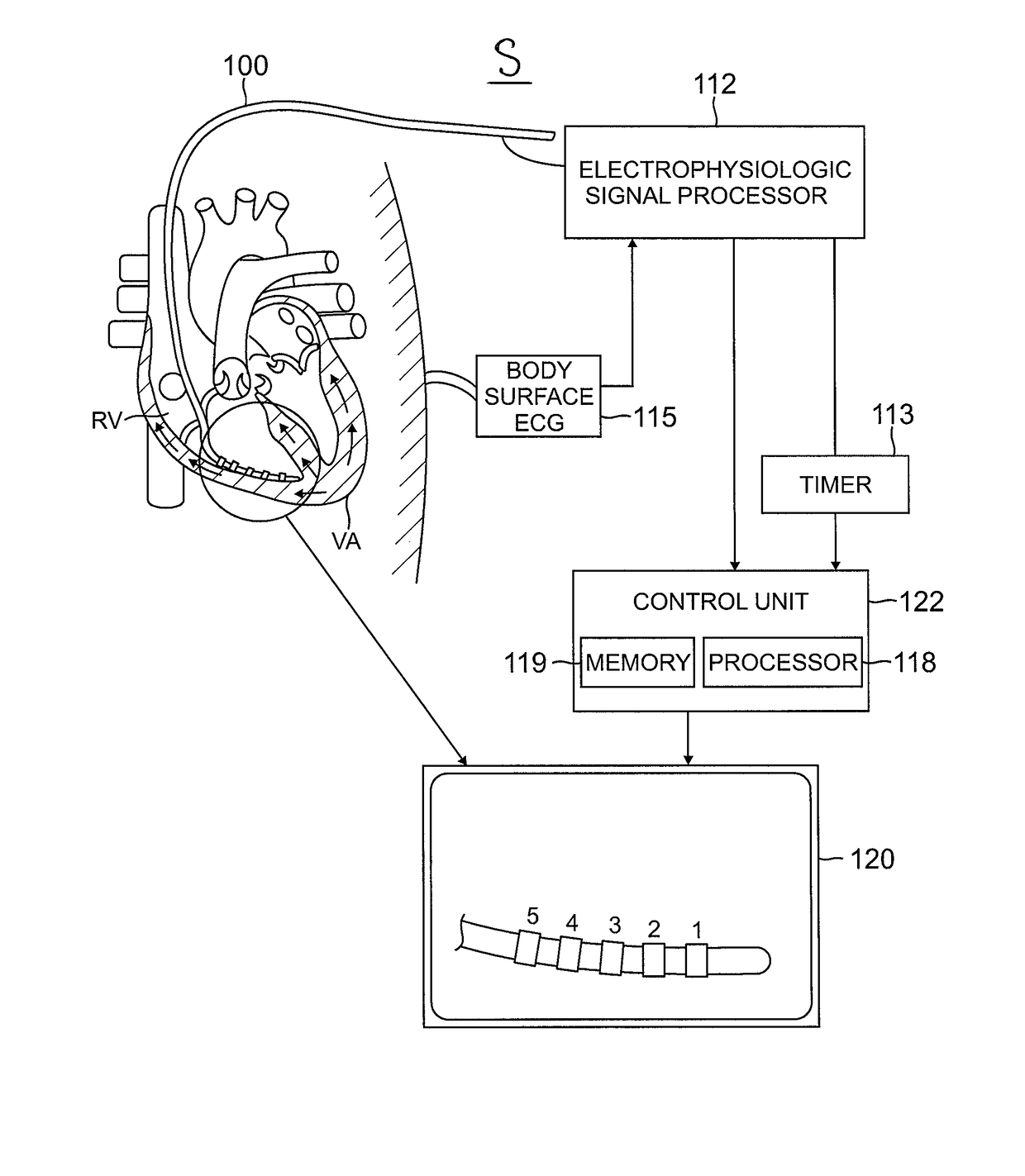

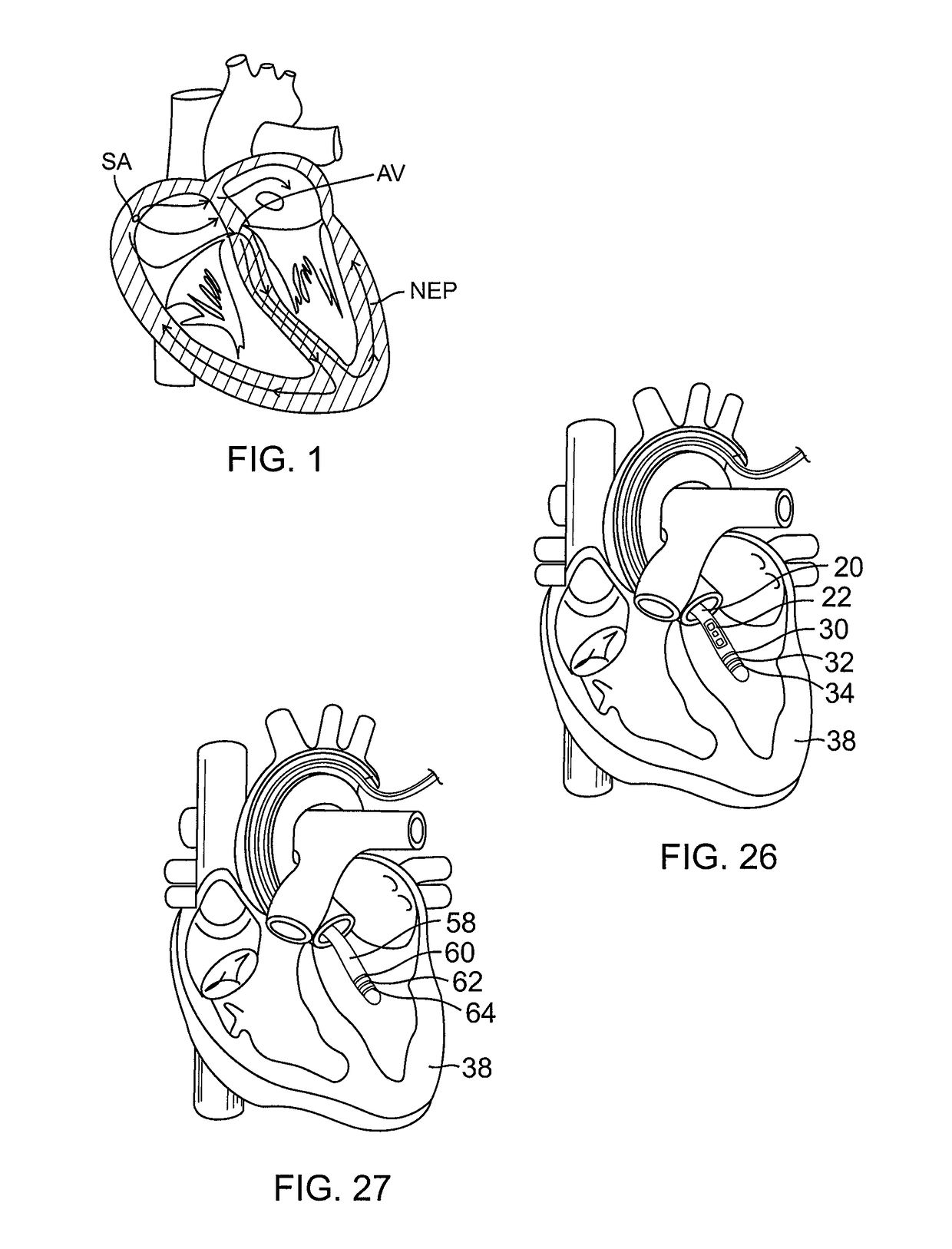

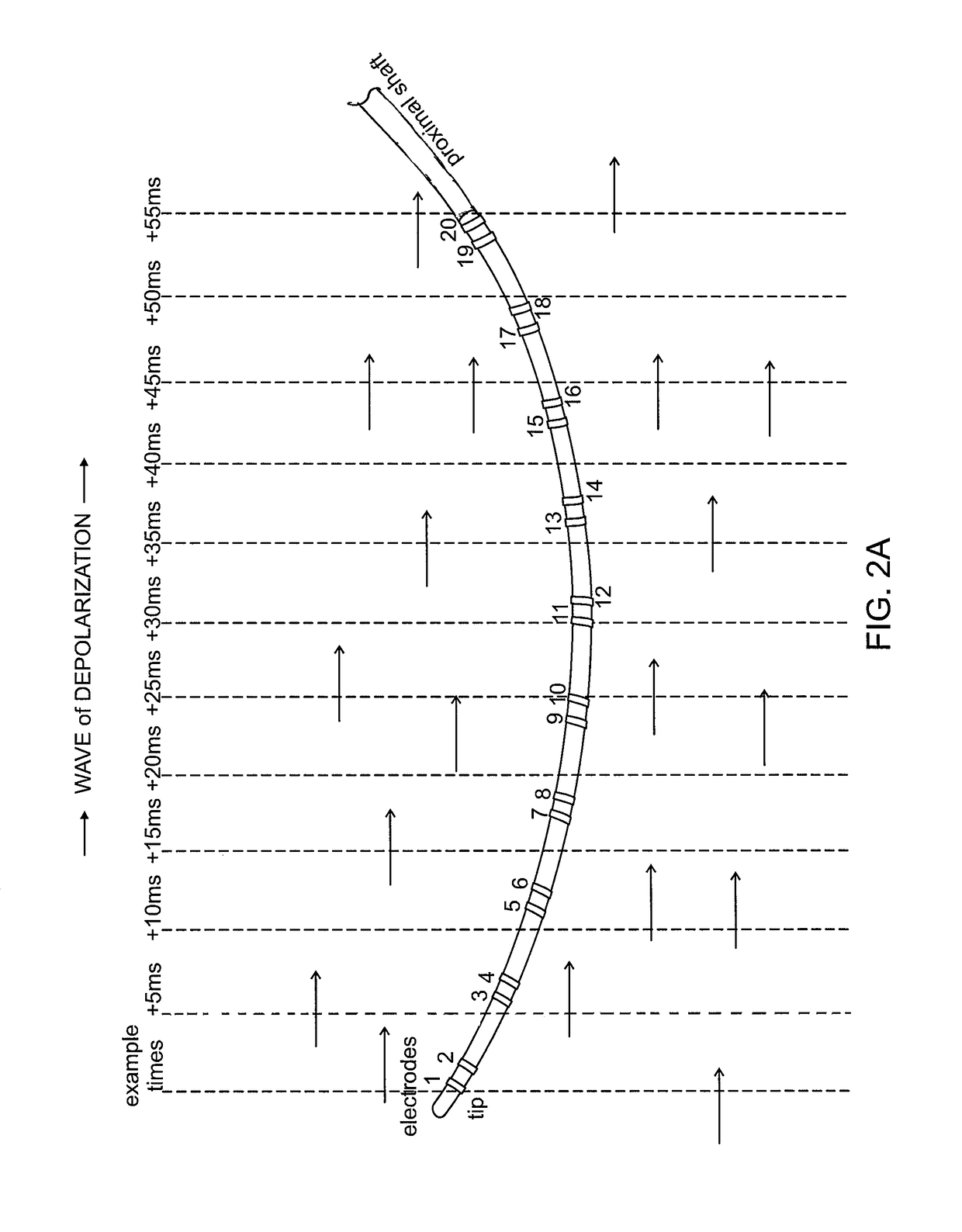

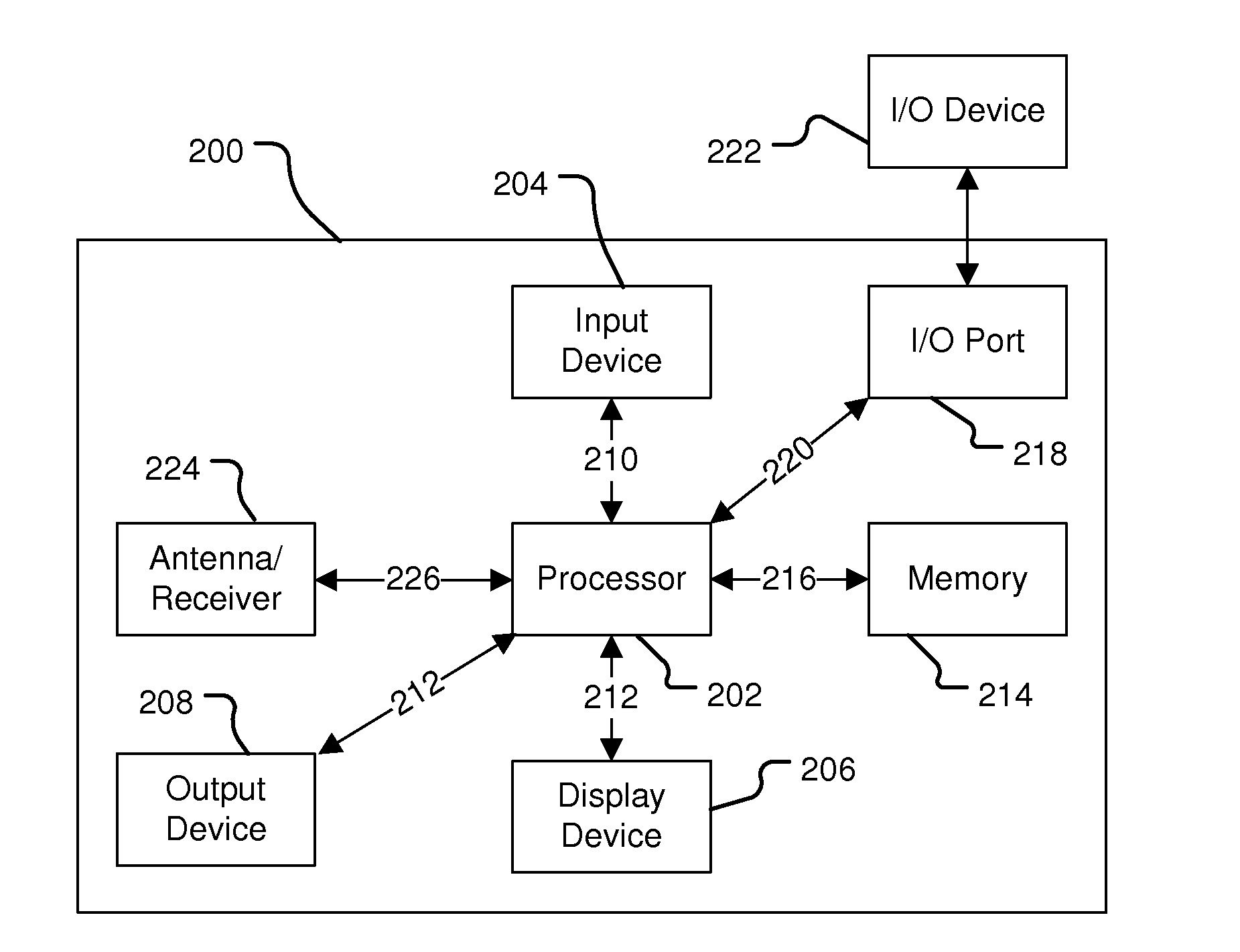

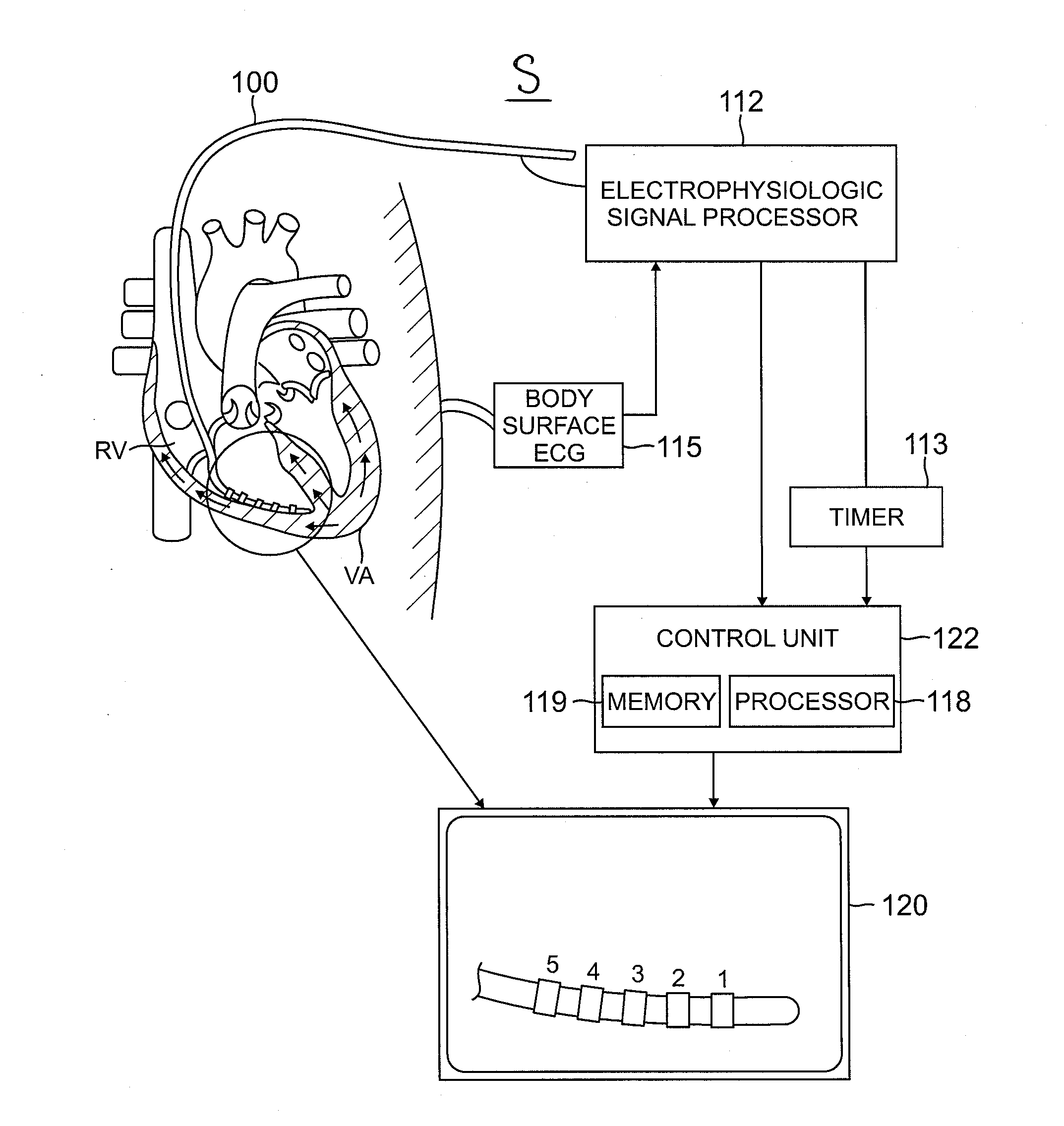

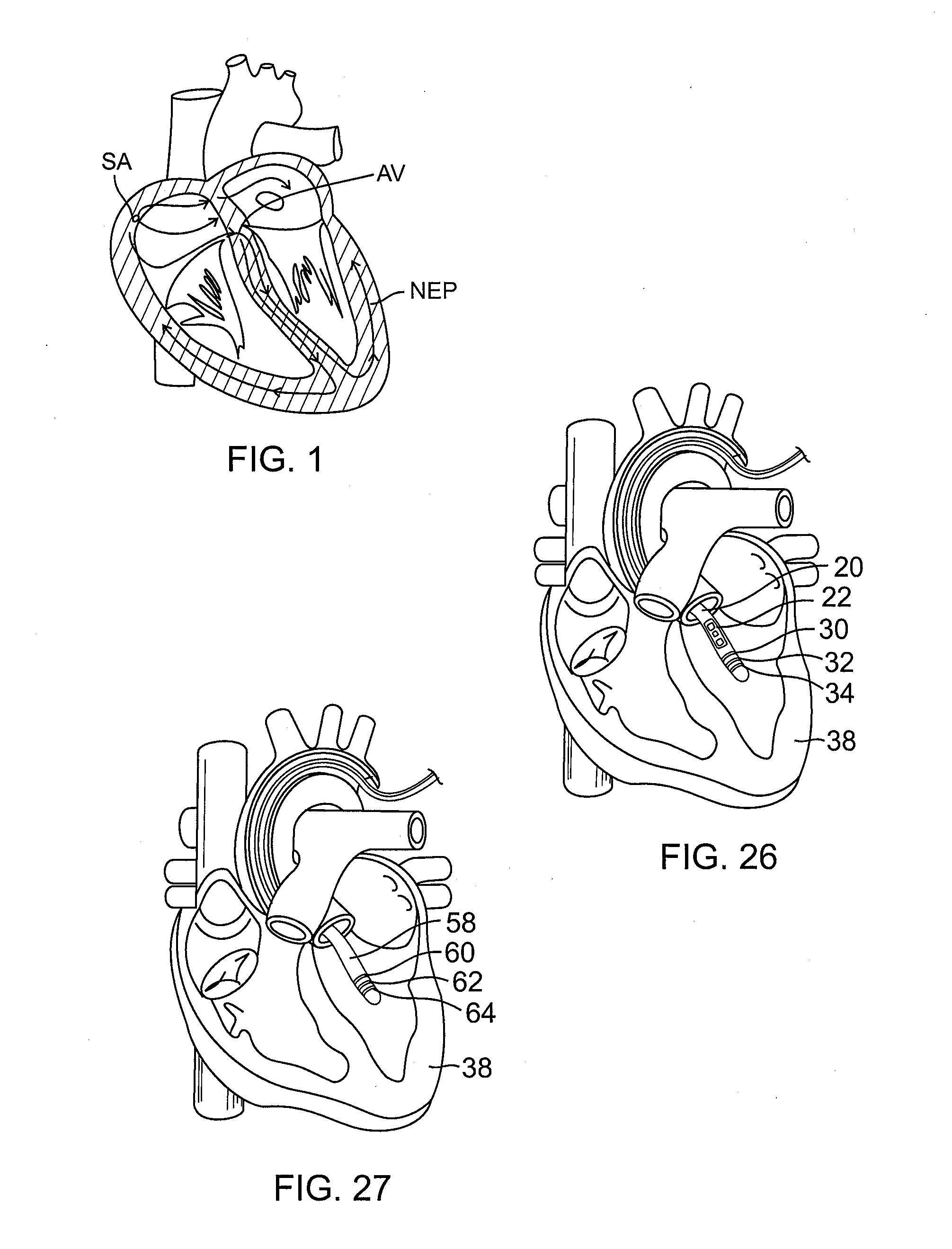

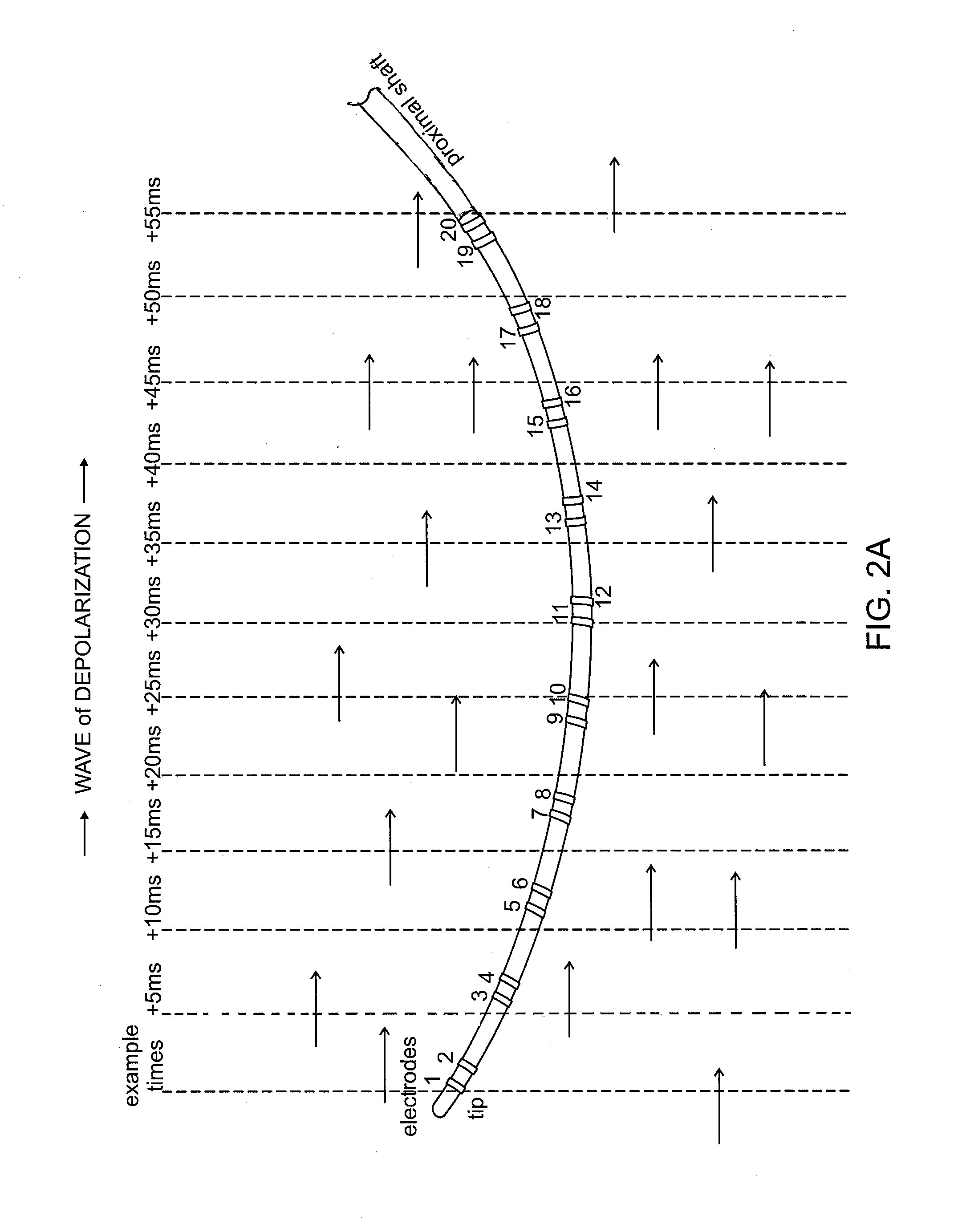

System and method for visualizing electrophysiology data

A method and system for visualization of electrophysiology information sensed by electrodes on a catheter, includes recording times of electrode signal acquisition, designating a reference electrode signal acquisition, assigning a relative time to each recorded time of electrode signal acquisition relative to the reference electrode signal acquisition, identifying the electrodes with signal acquisition, correlating assigned relative times to identified electrodes to generate a sequence of electrode signal acquisitions, and generating a visual representation of the sequence of electrode signal acquisitions generating a visual representation with a graphical image of the electrodes, wherein individual electrodes are visually marked to represent the sequence of electrode signal acquisitions.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

Method and apparatus for phase detection in digital signals

InactiveUS6151356APulse automatic controlDc level restoring means or bias distort correctionDigital dataPropagation delay

The invention provides an improved method and apparatus for detecting the phase difference between a digital data signal and a clock signal. By ensuring that no pulse in the output phase signal is narrow enough to introduce a non-linearity, the present invention avoids a source of non-linearity exhibited in existing phase detectors. In addition, by ensuring that critical timing paths through the circuit contain similar circuit blocks, with similar propagation delays, relative time relationships are preserved from clock and data inputs to XOR inputs. The circuit is therefore largely insensitive to changes in the characteristics of the components so long as they all move together, as they would in an integrated circuit implementation.

Owner:RPX CLEARINGHOUSE

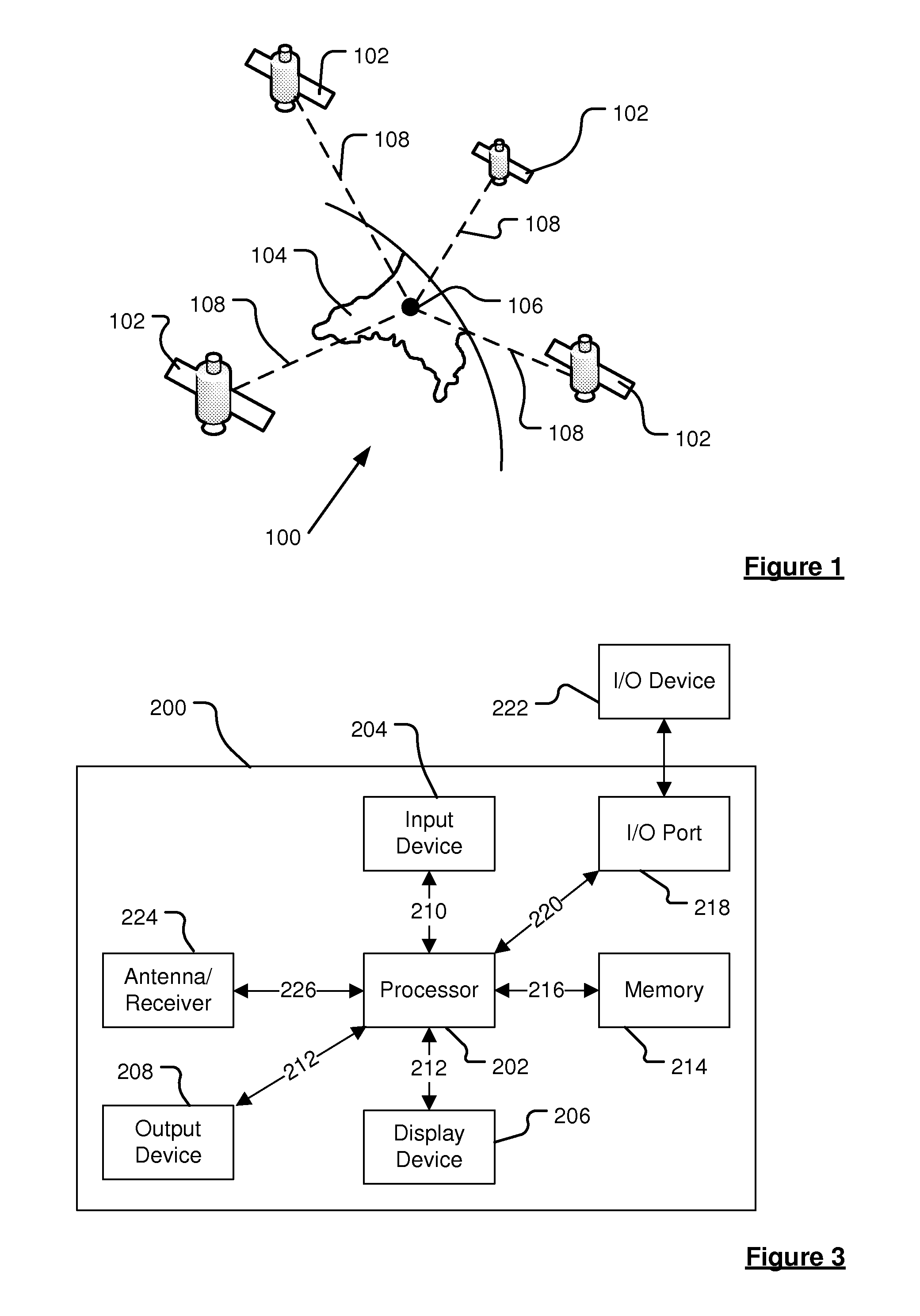

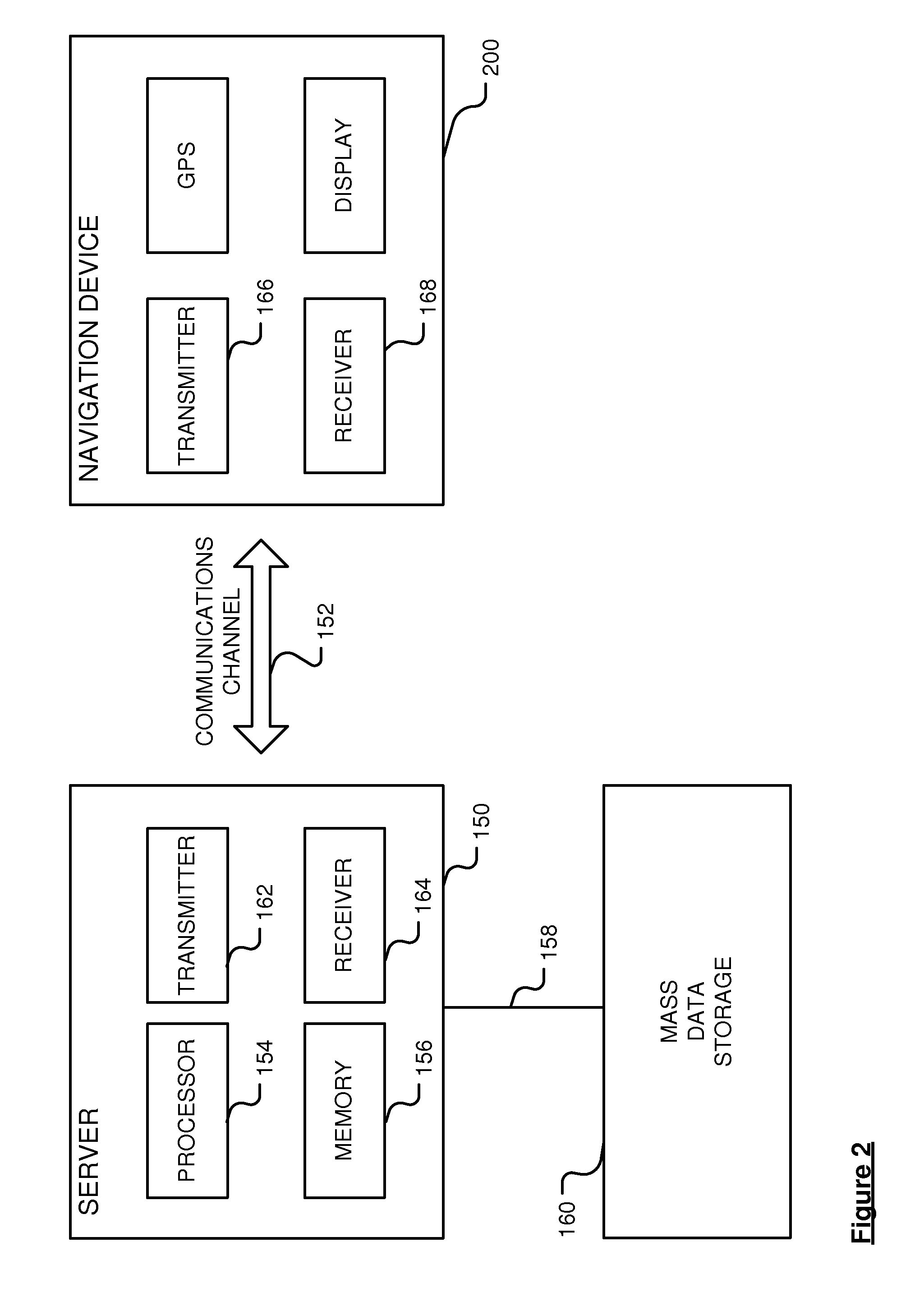

Navigation apparatus, server apparatus and method of providing point of interest data

InactiveUS20110125398A1Improve accuracyImprove the usefulnessInstruments for road network navigationMultiple digital computer combinationsCommunication interfaceRelative times

A navigation apparatus includes a communications interface for communicating data via a communications network and a processing resource coupled to the interface and arranged to receive a request for point of interest information, and to communicate via the communications interface a message constituting a point of interest data request for receipt by a remote server. In at least one embodiment, the processing resource is capable of receiving via the communications interface POI data identifying a first POI and a second POI, the POI data being in response to the message and arranged to provide an indication of relative temporal proximity of the first and second POIs. The processing resource is also arranged to respond to the request for POI information by identifying the first POI and the second POI and relative temporal proximity information relating thereto, the relative temporal proximity information being based upon the indication of relative temporal proximity received.

Owner:TOMTOM INT BV

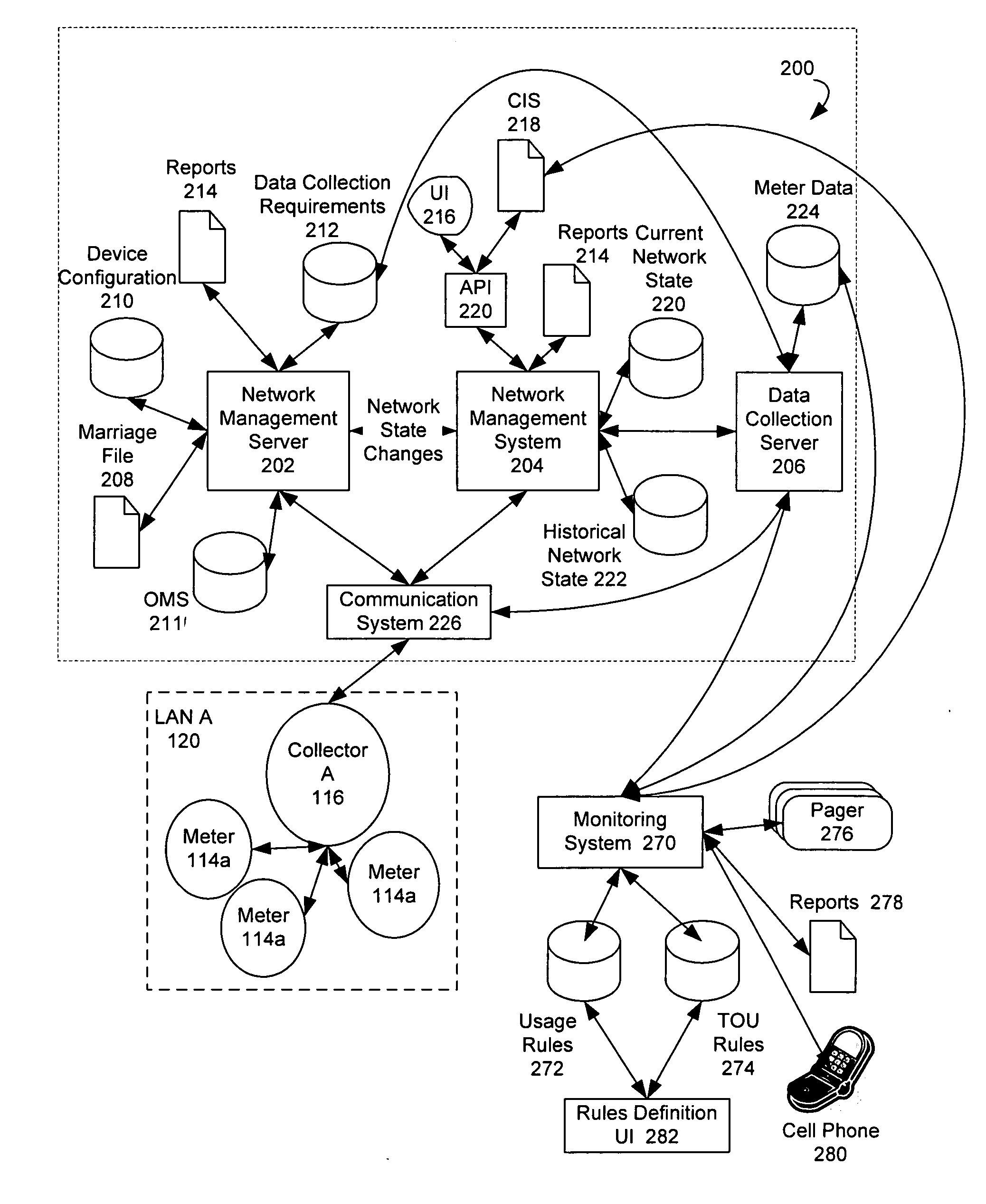

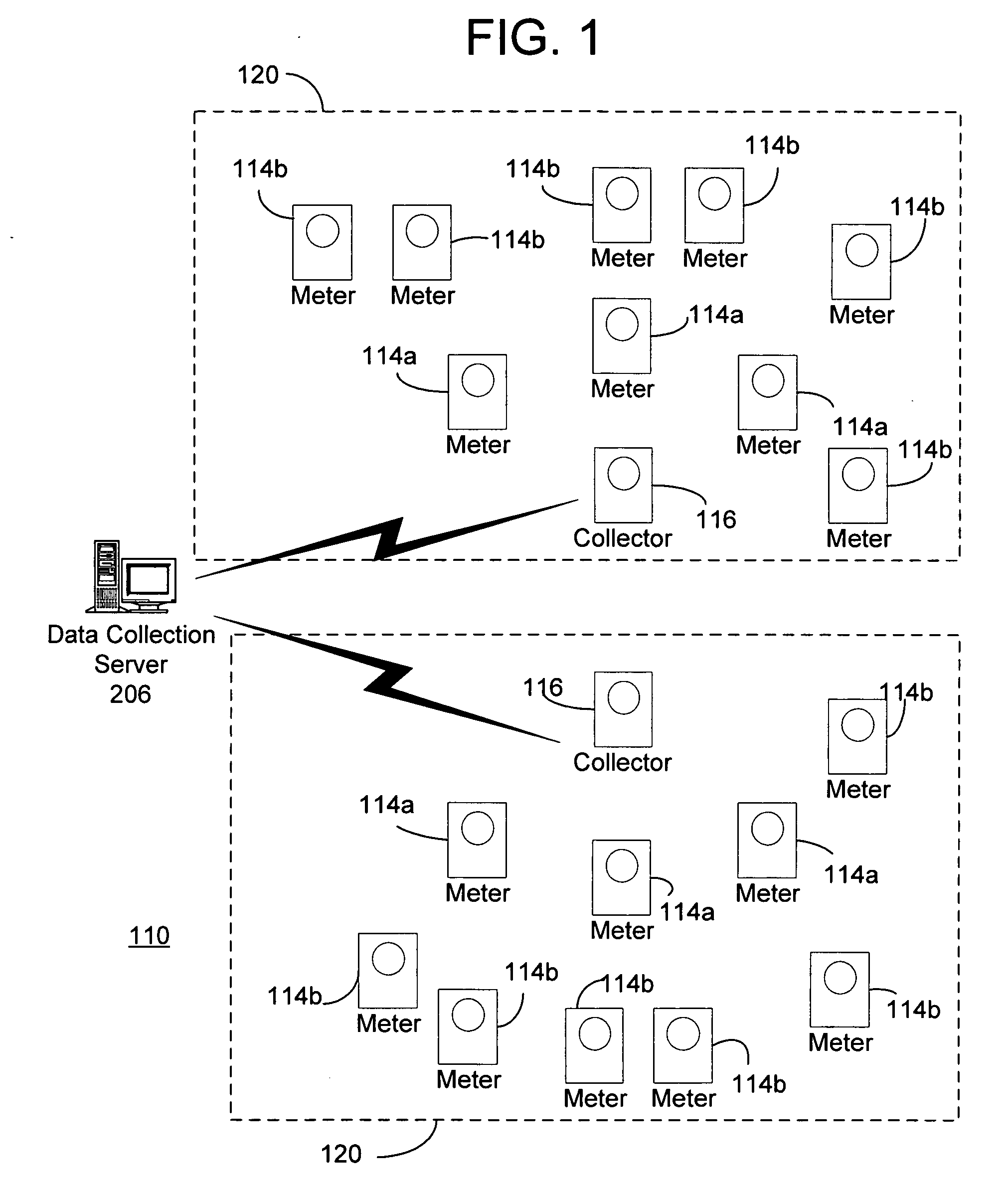

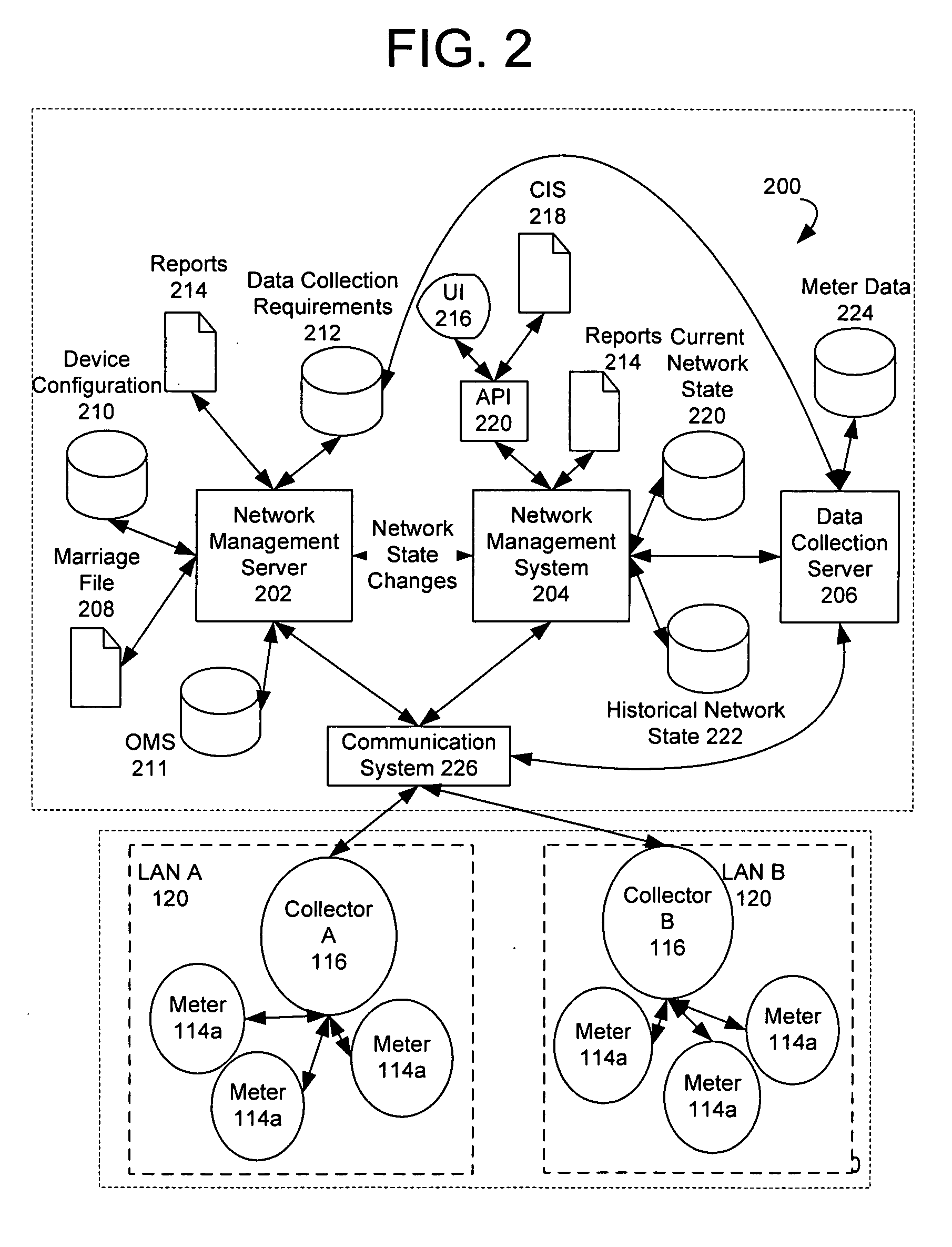

Fuzzy time-of-use metering and consumption monitoring using load profile data from relative time transmit-only devices

Systems and methods for providing Time-of-Use (TOU) rate schedules to relative-time meters (e.g., water and gas meters) in a utility metering network. The system may also be used to determine usage based on filtering interval data received from the relative-time meters. The TOU rate schedules are bound by windows of time, i.e., a type of fuzzy switch time, which is bounded on both sides, rather than instantaneous switch times. The fuzzy TOU schedule defines the time of a tier switch as the end time of the first completed interval recorded after the start of some window of time. A monitoring system may be included that implements configurable usage filters that allow for the classification of usage in terms of interval data. Usage filters can be defined so that they are applied against individual interval readings, various aggregations of interval readings, and / or the statistical products of interval readings, etc. A filtering algorithm allows for the comparison of incoming and / or historical interval data against defined usage and schedule filters to determine if usage is abnormal and should be investigated further.

Owner:ELSTER ELECTRICTY LLC

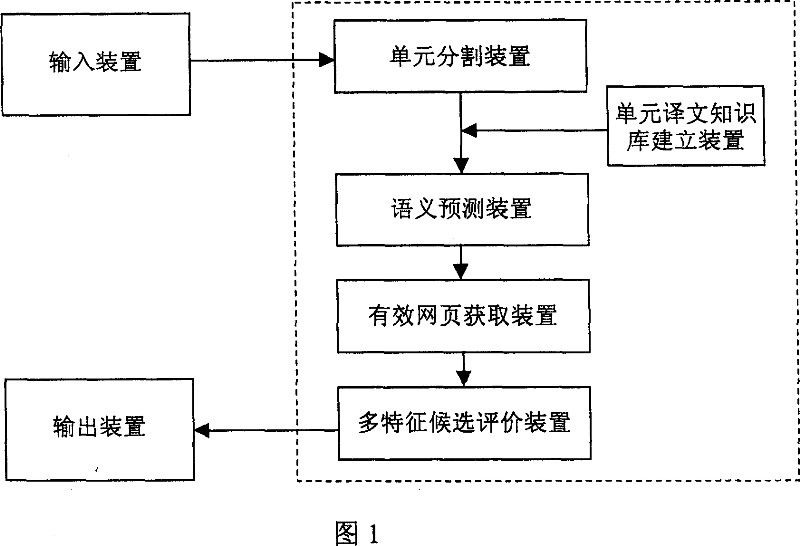

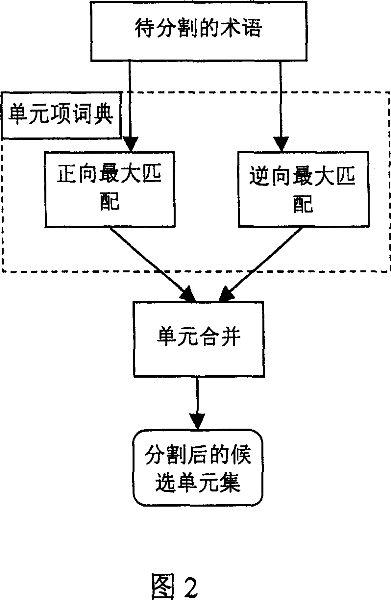

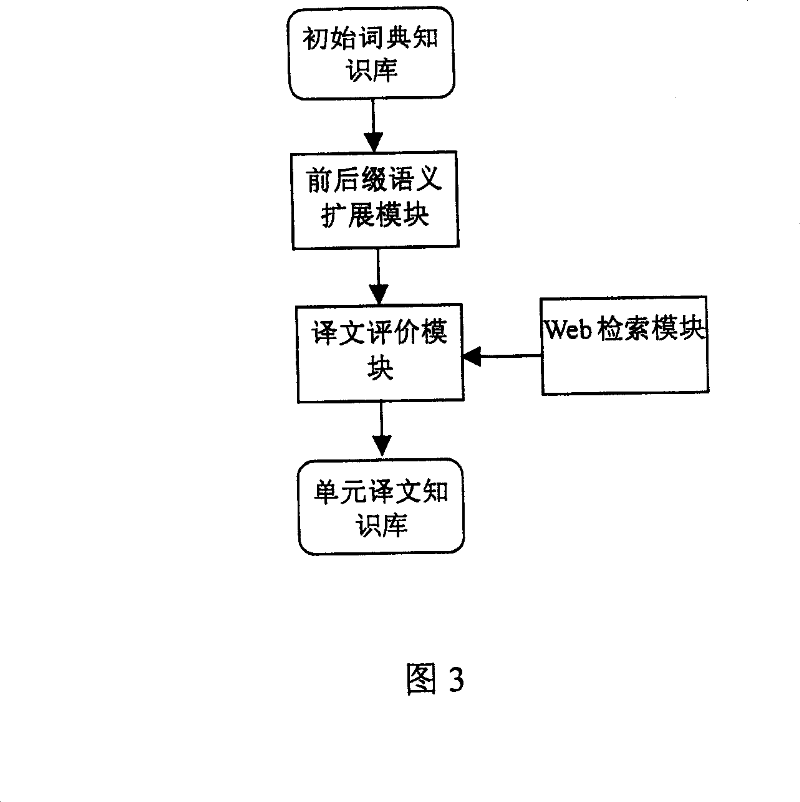

Translation obtaining method and apparatus based on semantic forecast

InactiveCN101042692AImprove performanceHigh translation accuracySpecial data processing applicationsTheoretical computer scienceRelative times

This invention relates to one code message get method and device based on means prediction, which comprises the following steps: unit cutting step to divide the input requires into meanings prepare units set; unit codes knowledge database establishing to expend the prepare units in original common dictionary and to form unit code knowledge database; meaning prediction based on the prediction method to get relative times of the inquire meanings; effective page getting step to get the relative inquire items set by use of the combination times and to get effective page through index; prepare evaluating to get effective page to get prepare file list on codes.

Owner:FUJITSU LTD

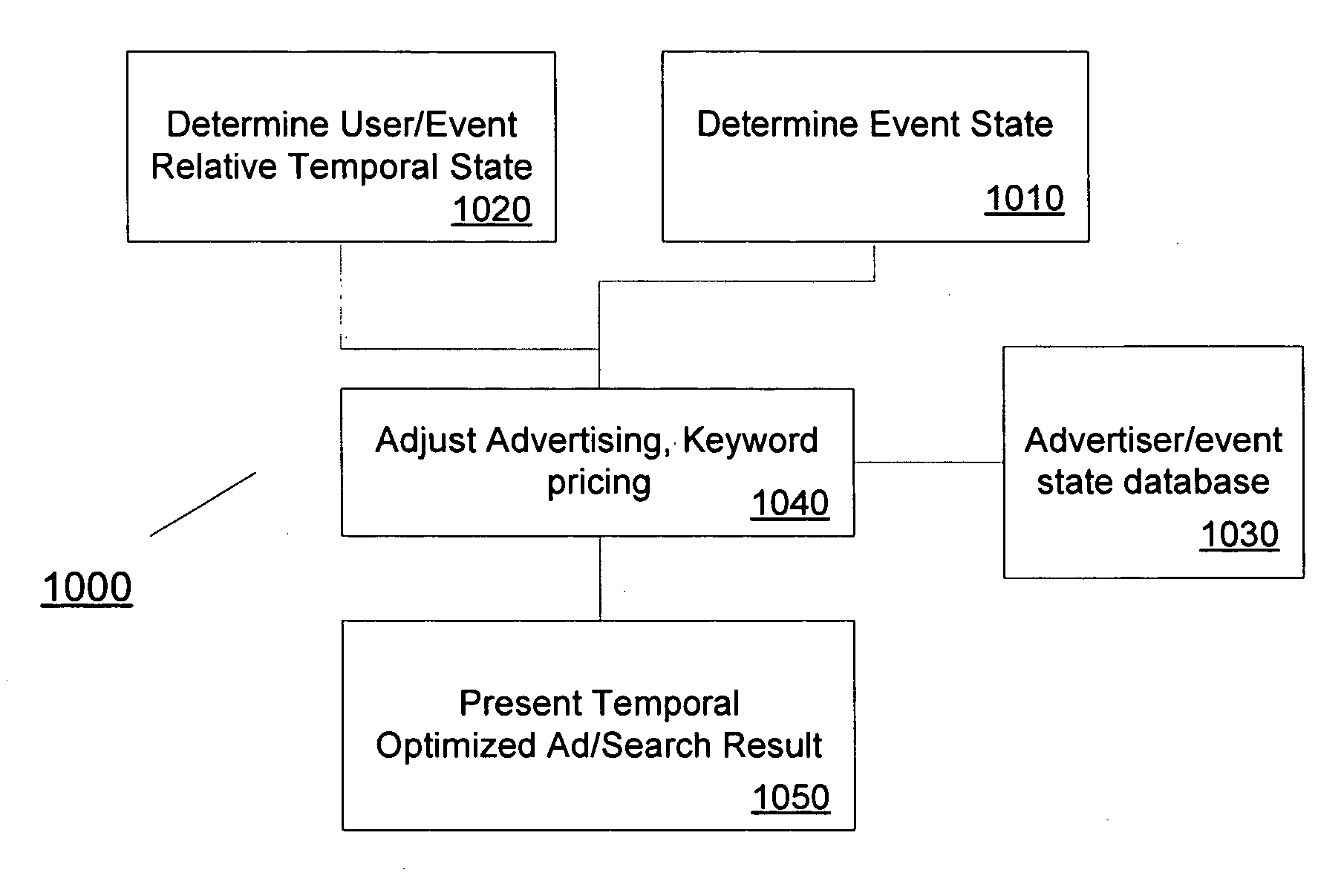

Temporal Document Sorter and Method Using Semantic Decoding and Prediction

Electronic documents are classified and compared according to their temporal qualities. The content of a document relating to an event is analyzed to identify temporal components, including semantic counterparts. These components can be compared with corresponding counterparts in other documents to identify a relative temporal order, and / or to generate predictions of future news stories. The invention can be used in environments such as automated news aggregators, search engines, and other electronic systems which compile information having temporal qualities.

Owner:JOHN NICHOLAS & KRISTIN GROSS

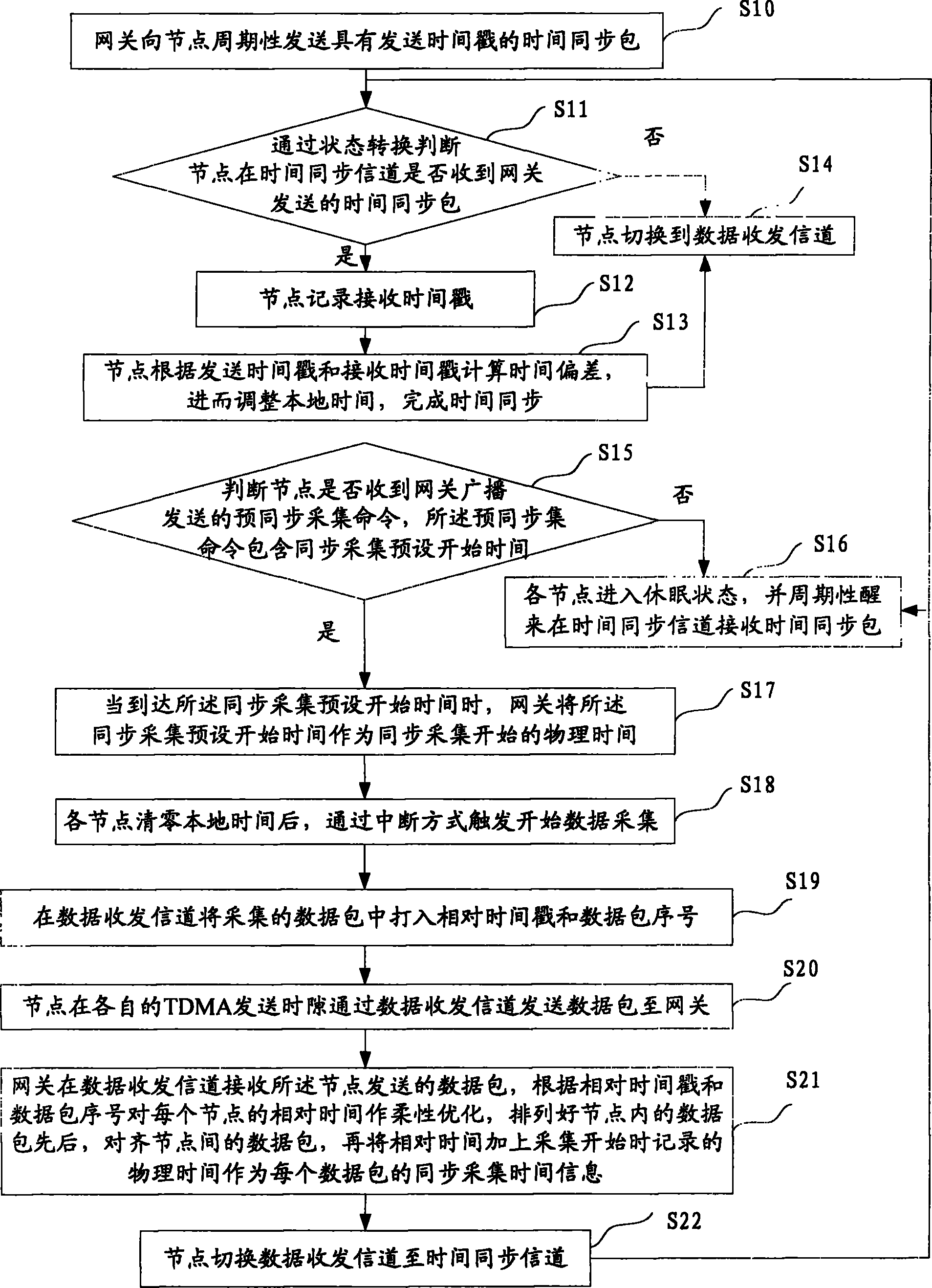

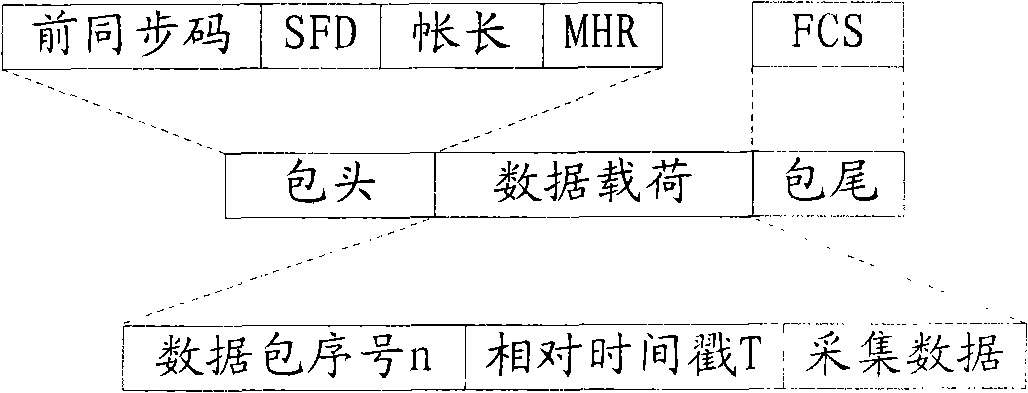

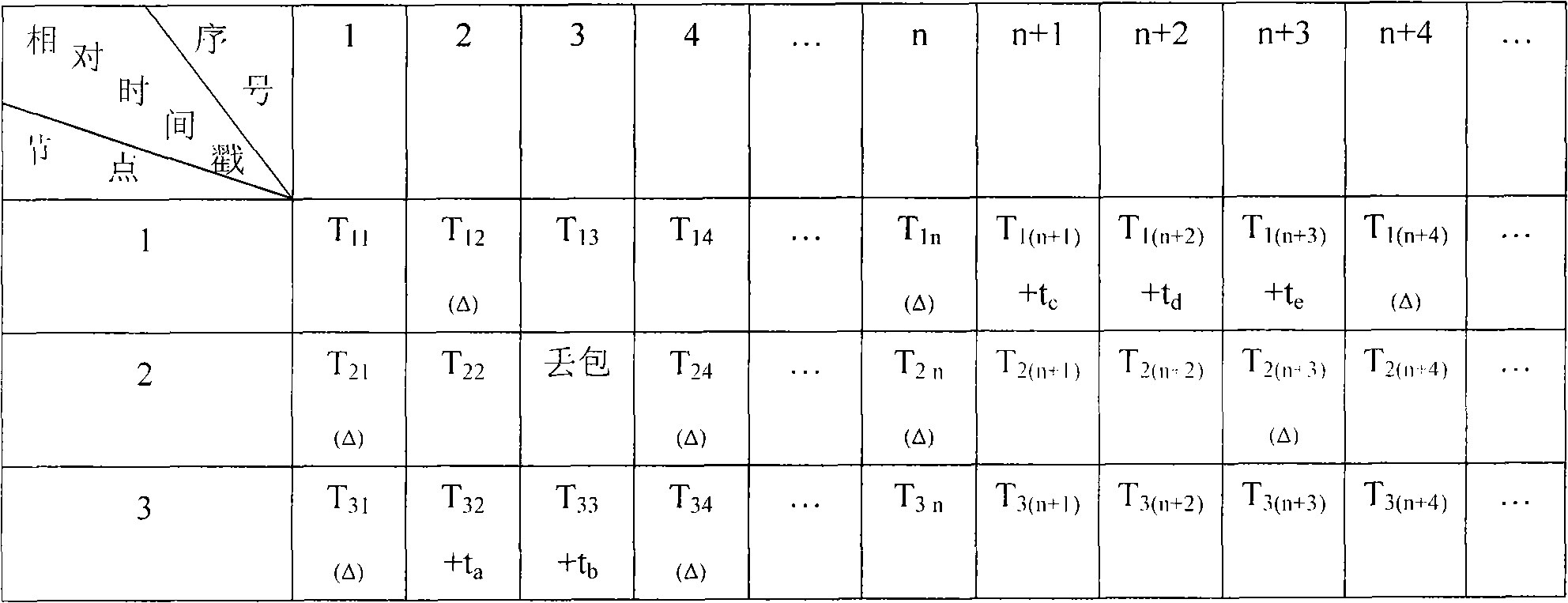

Method and system for synchronous acquisition of wireless sensor network for structural health monitoring

InactiveCN101778405AHigh time synchronization efficiencyImproving Synchronized Acquisition AccuracySynchronisation arrangementNetwork topologiesStart timeTimestamp

The invention discloses a method and a system for the synchronous acquisition of a wireless sensor network for structural health monitoring. The method comprises the following steps: when a time synchronization packet sent by a gateway is received, adjusting local time by nodes according to sending timestamp and receiving timestamp to complete time synchronization; when the nodes receive pre-synchronous acquisition instructions broadcasted and sent by the gateway and reach the preset start time of the synchronous acquisition, taking the preset start time of the synchronous acquisition as the physical time of the starting of the synchronous acquisition by the gateway, performing zero clearing on the local time by each node to start acquiring data, marking the relative timestamp and the serial number of data packets in the acquired data packet, and sending the data packet to the gateway; and performing flexible optimization on the relative time of each node by the gateway according to relative timestamp and the serial number of the data packets, and adding the relative time to the physical time as synchronous acquisition time information of each data packet. The method can realize time synchronization and the synchronous acquisition in the process of acquisition, ensure that the time of sampling points is accurate, avoid packet loss and ensure the reliability of global diagnosisin the process of the structural health monitoring. The invention simultaneously discloses a system for the synchronous acquisition of the wireless sensor network for the structural health monitoring.

Owner:WUHAN UNIV OF TECH

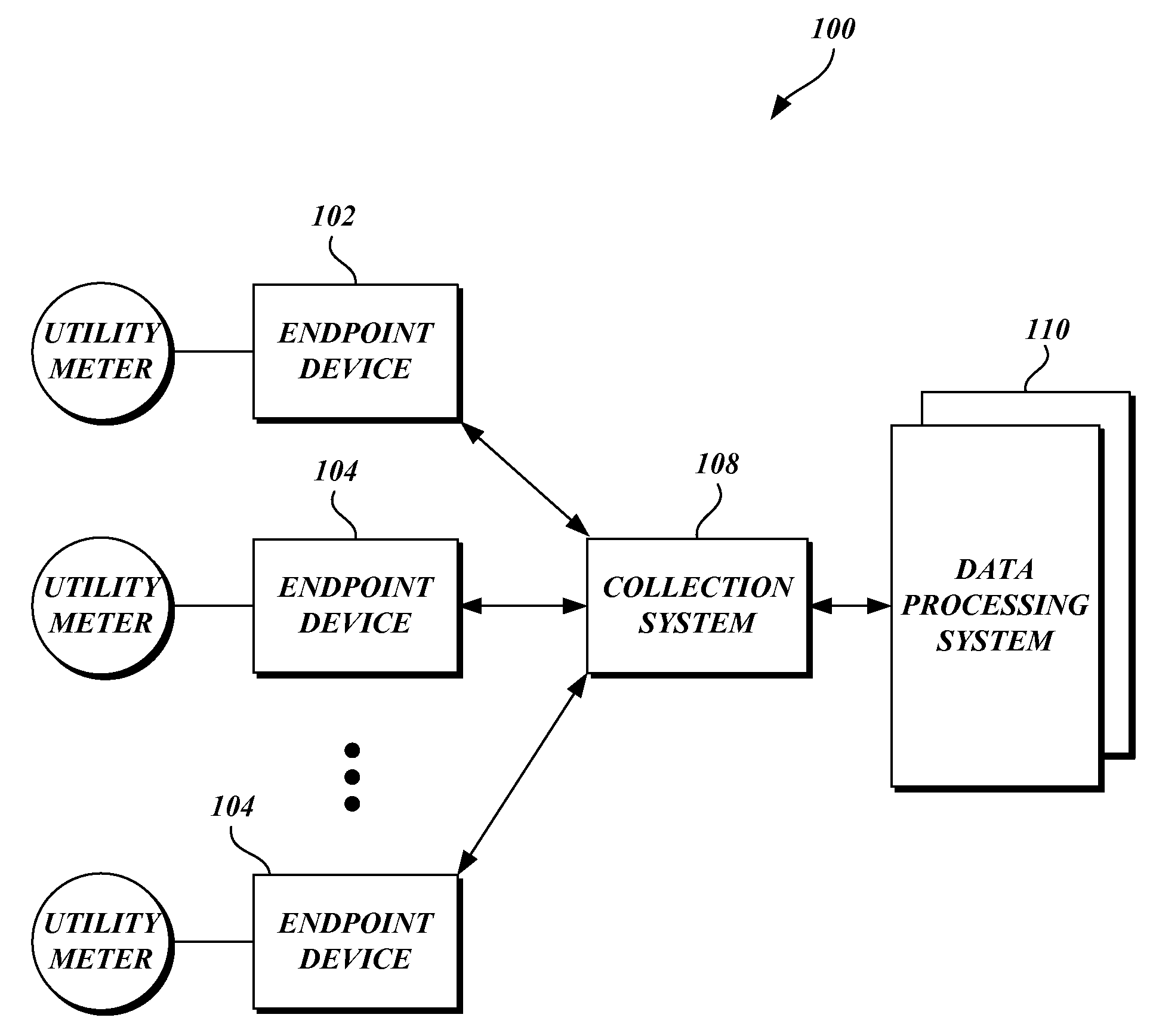

Relative time system

ActiveUS20100188255A1Simple logicSimple inexpensiveTime indicationElectric signal transmission systemsReal-time clockCollection system

A system, method and device are provided for obtaining, from each endpoint device, meter reading data where the meter reading data are recorded and managed based on a relative time clock in each endpoint device. The relative time clock may be a simple inexpensive clock that tracks minutes and triggers recording of meter reading data for a particular hour at the end of that hour. In that embodiment, a collection system sends an endpoint device a request that includes a requested time that is converted into a relative time so that the endpoint device can understand the request. Since each recorded interval is generated based on a relative time maintained by the clock in the endpoint device rather than an absolute (real) time, the endpoint device does not need to maintain accurate date / time or to read meter reading data from the utility meter based on a real date / time.

Owner:ITRON

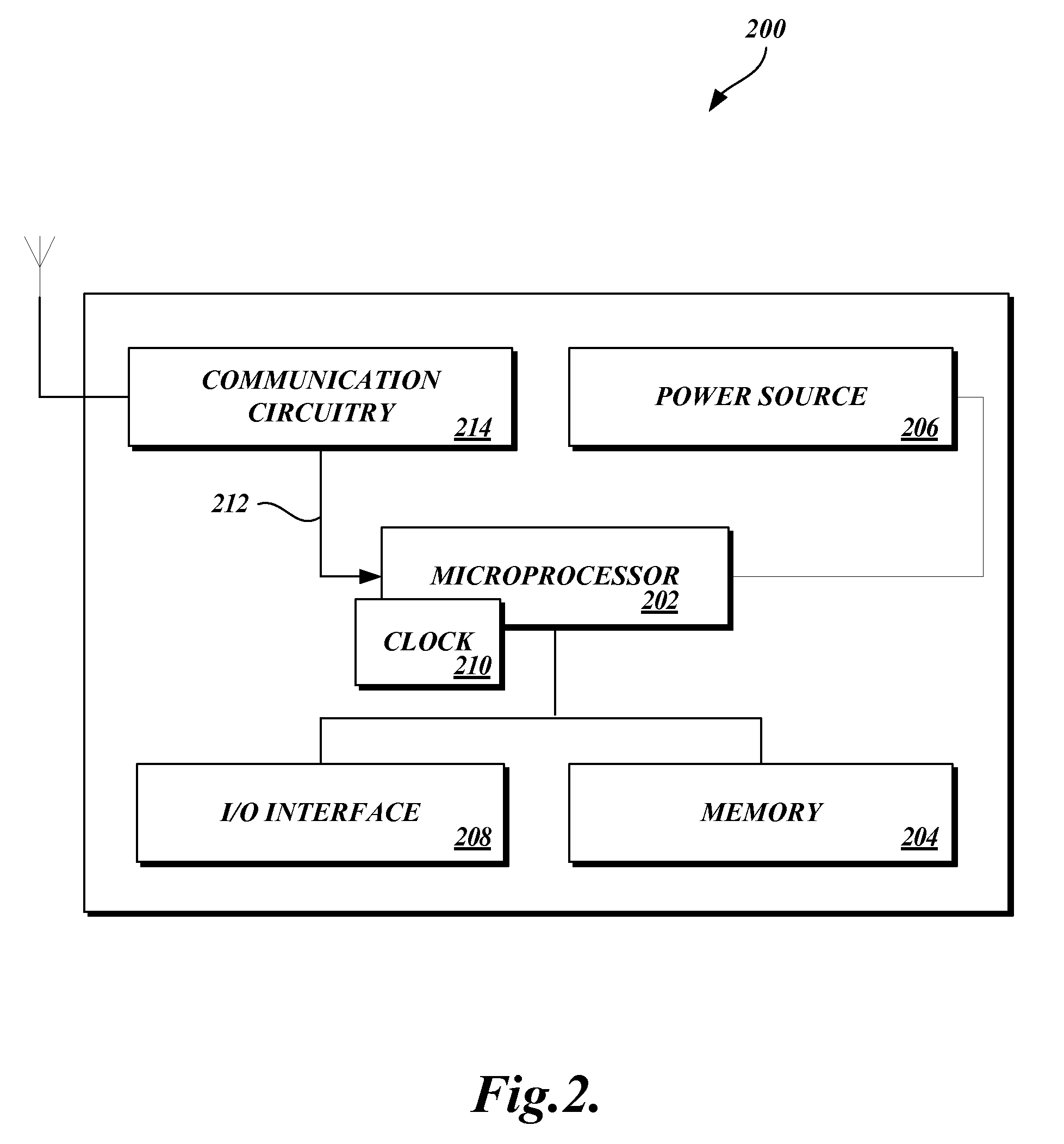

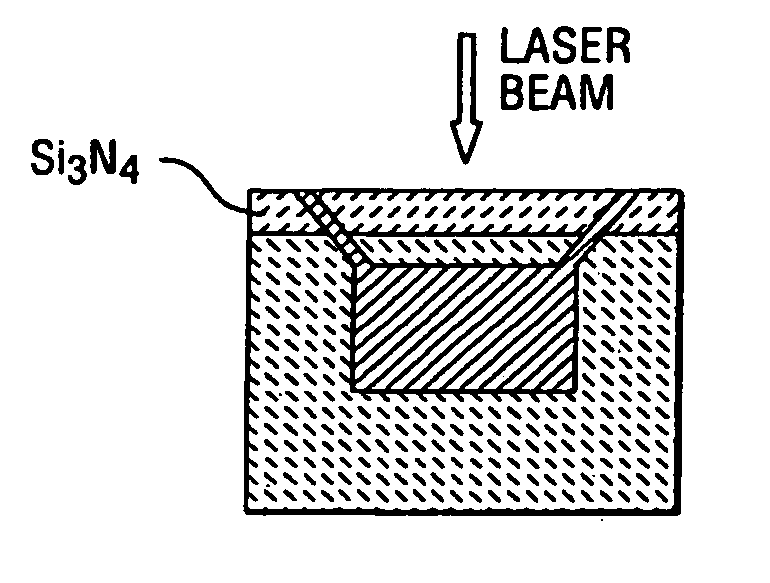

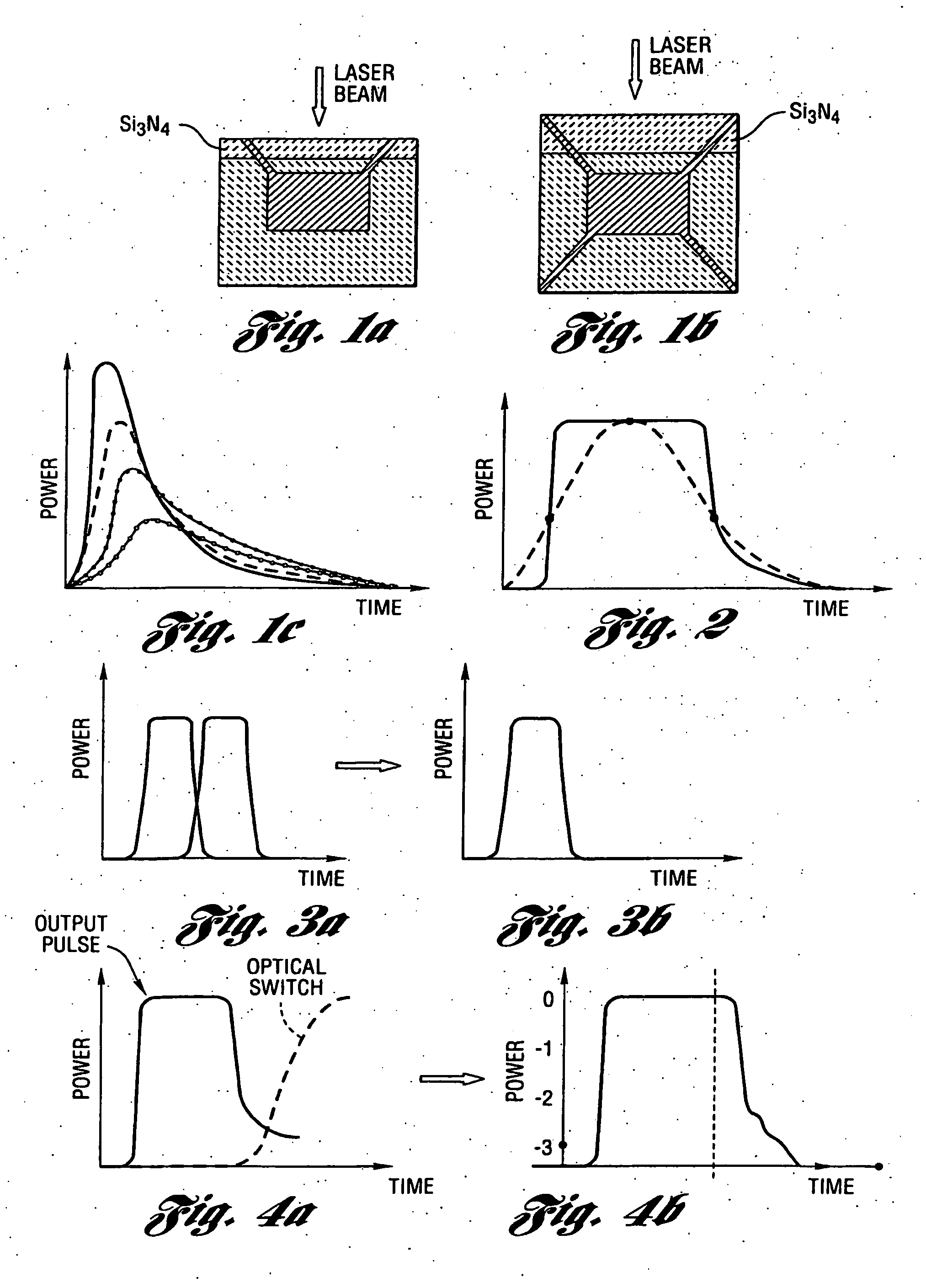

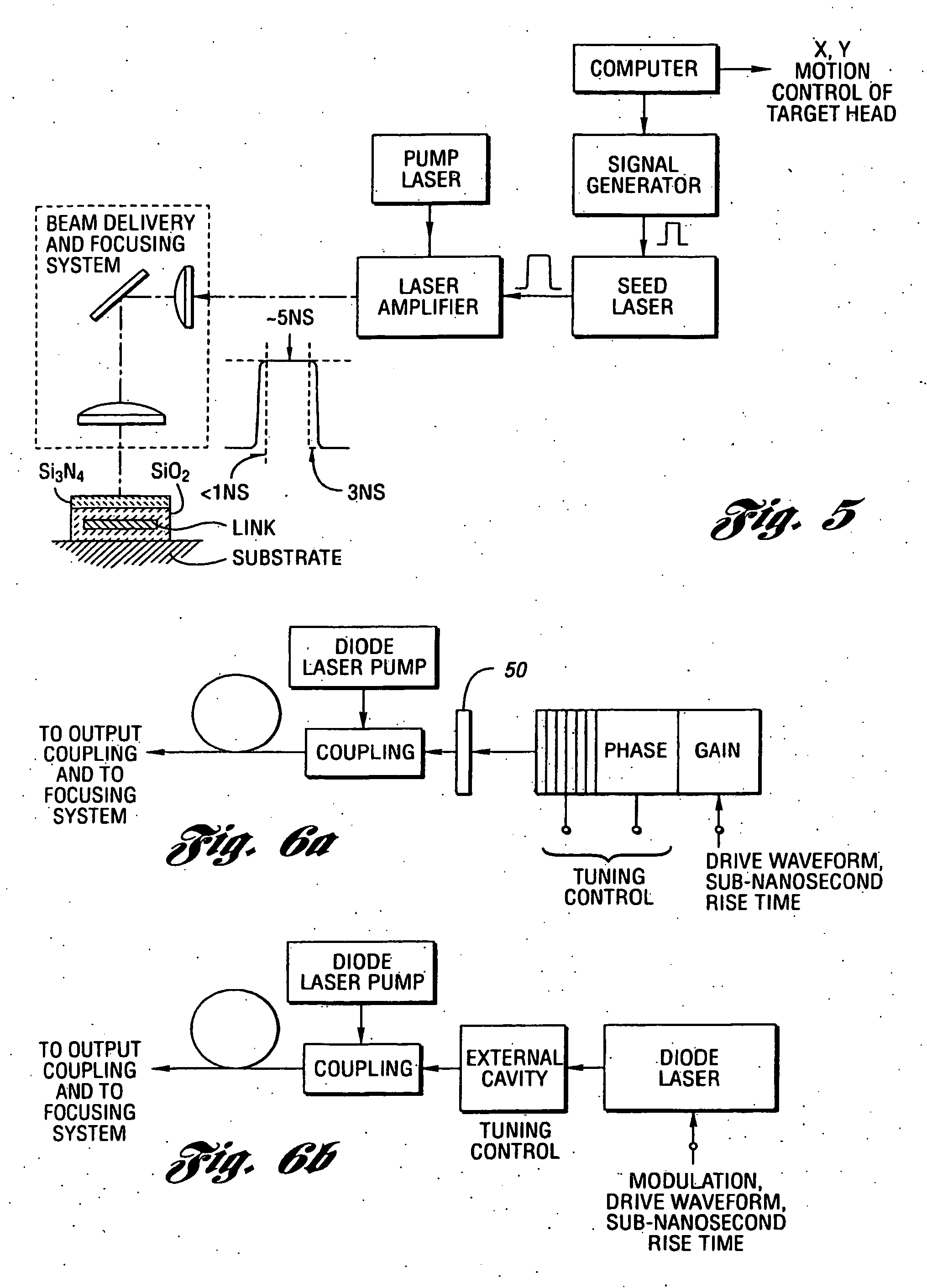

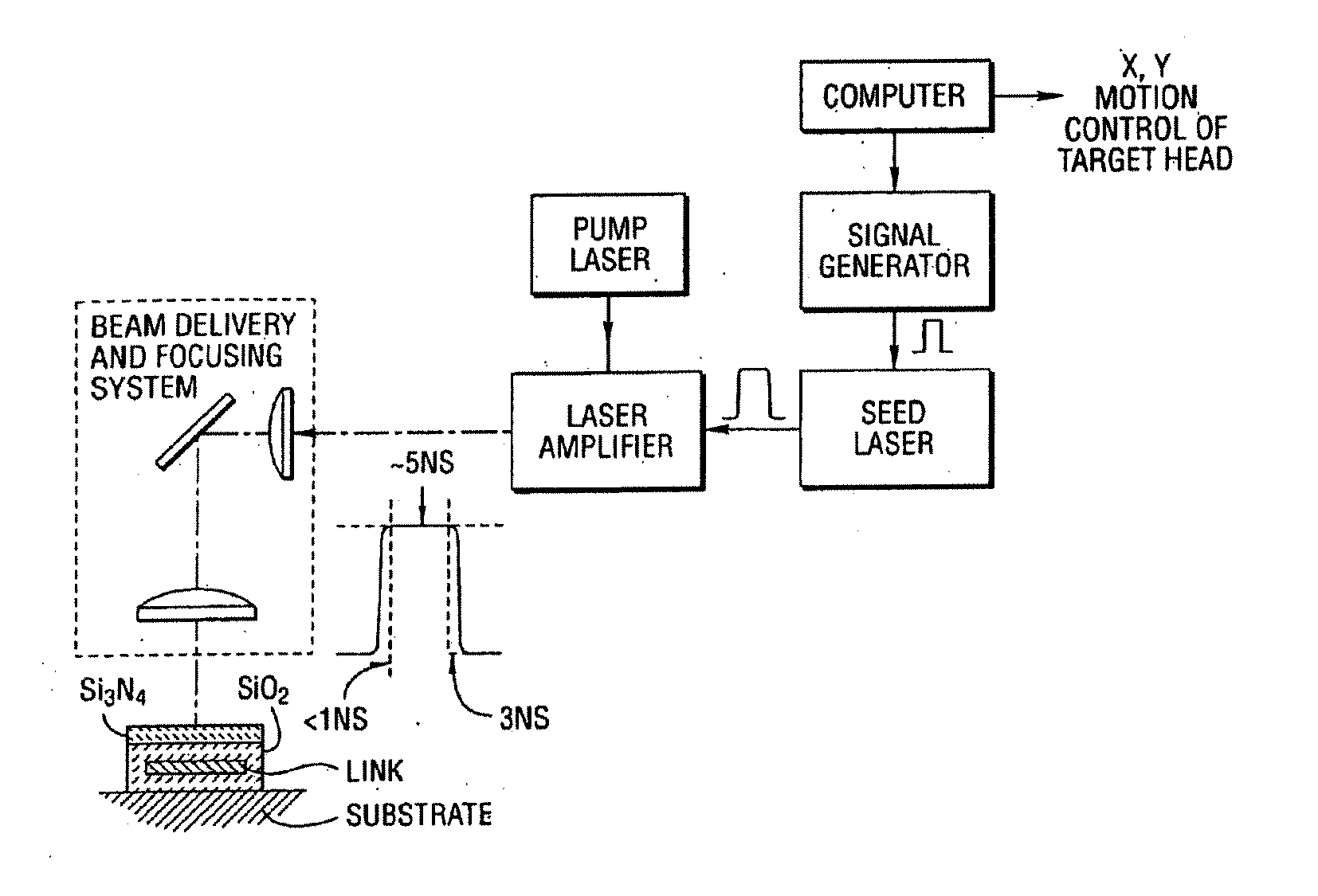

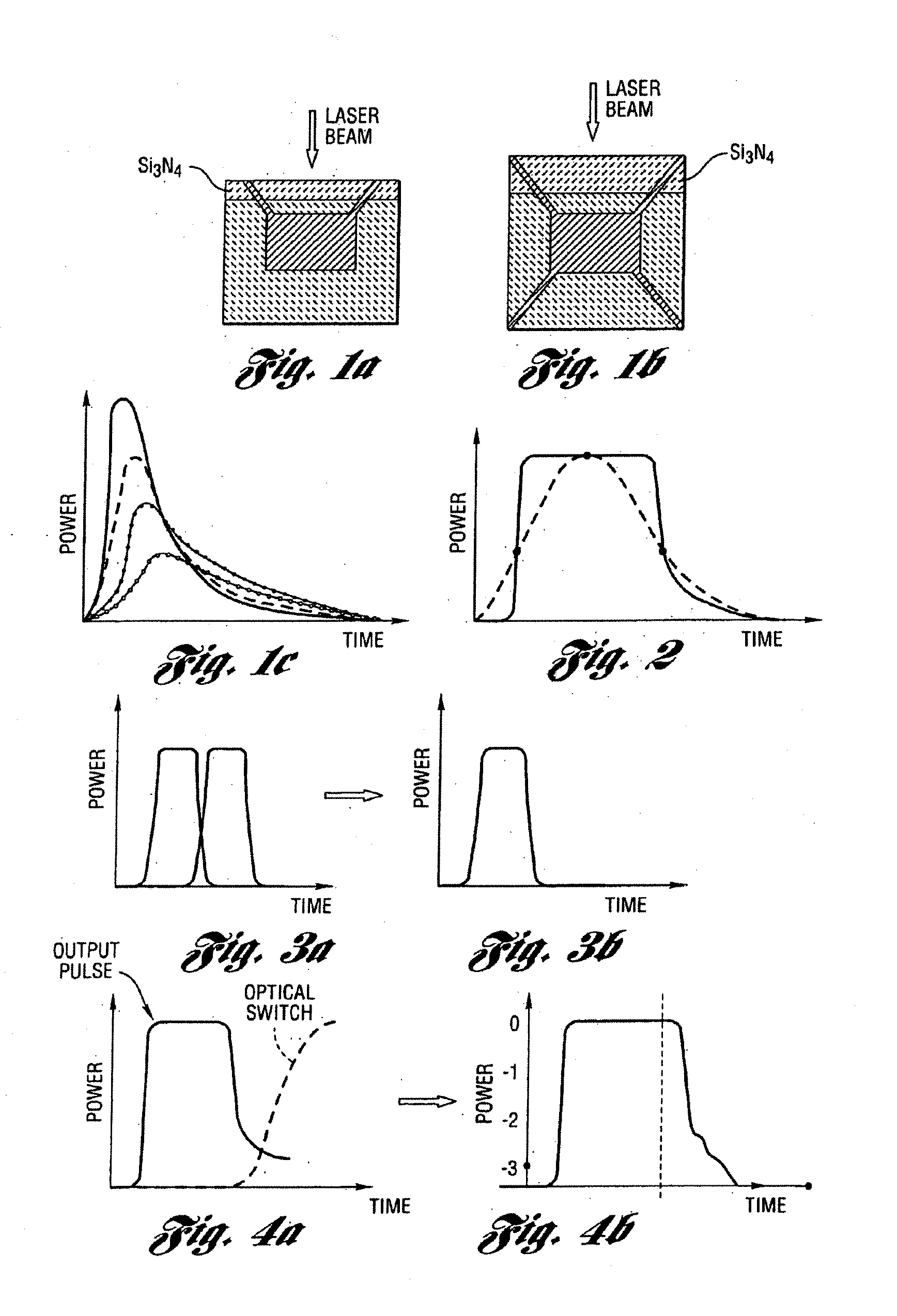

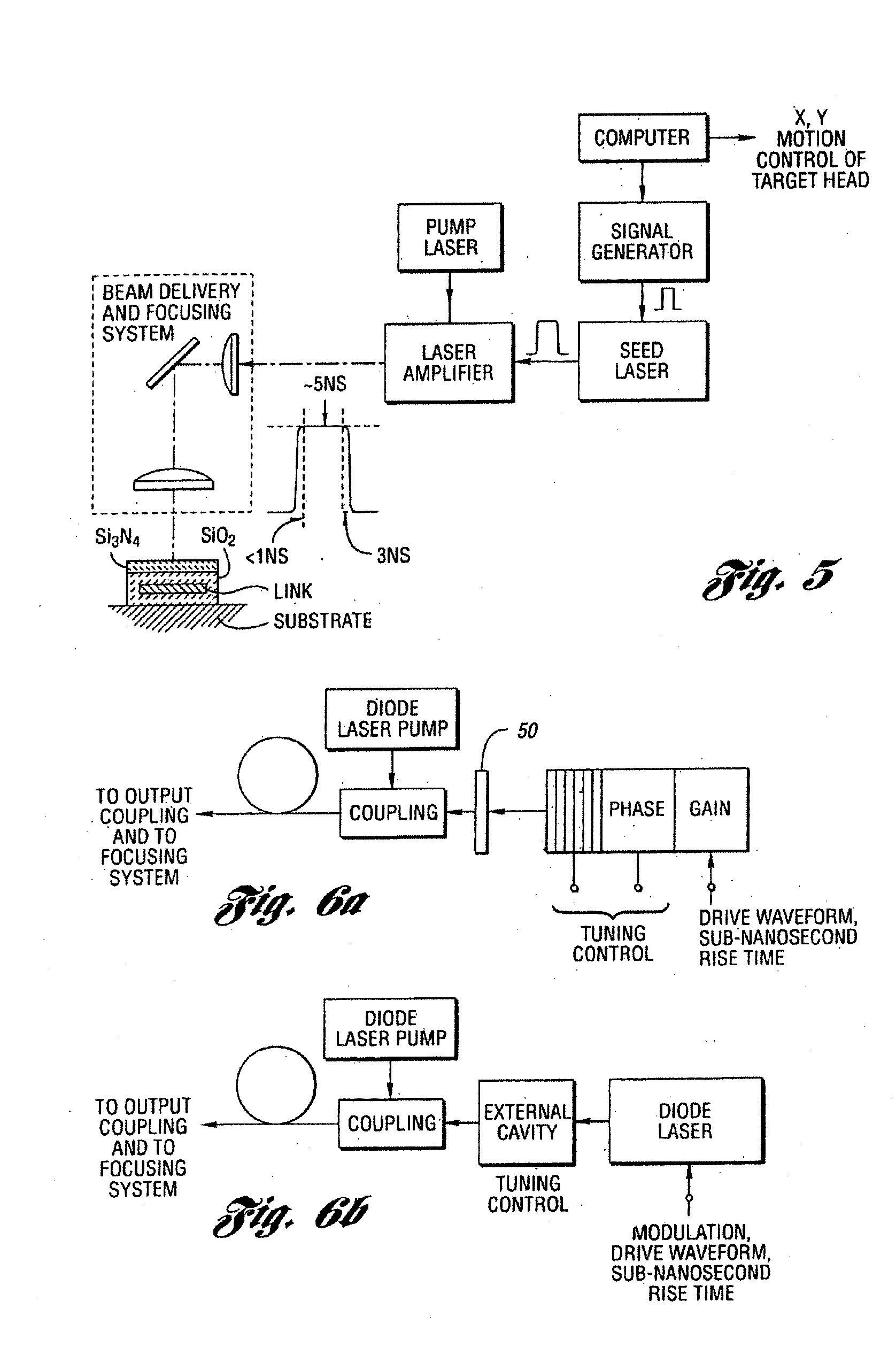

Energy-efficient, laser-based method and system for processing target material

InactiveUS20060086702A1Guaranteed uptimeRule out the possibilityLaser detailsSemiconductor/solid-state device detailsControl signalEngineering

An energy-efficient method and system for processing target material such as microstructures in a microscopic region without causing undesirable changes in electrical and / or physical characteristics of material surrounding the target material is provided. The system includes a controller for generating a processing control signal and a signal generator for generating a modulated drive waveform based on the processing control signal. The waveform has a sub-nanosecond rise time. The system also includes a gain-switched, pulsed semiconductor seed laser for generating a laser pulse train at a repetition rate. The drive waveform pumps the laser so that each pulse of the pulse train has a predetermined shape. Further, the system includes a laser amplifier for optically amplifying the pulse train to obtain an amplified pulse train without significantly changing the predetermined shape of the pulses. The amplified pulses have little distortion and have substantially the same relative temporal power distribution as the original pulse train from the laser. Each of the amplified pulses has a substantially square temporal power density distribution, a sharp rise time, a pulse duration and a fall time. The system further includes a beam delivery and focusing subsystem for delivering and focusing at least a portion of the amplified pulse train onto the target material. The rise time (less than about 1 ns) is fast enough to efficiently couple laser energy to the target material, the pulse duration (typically 2-10 ns) is sufficient to process the target material, and the fall time (a few ns) is rapid enough to prevent the undesirable changes to the material surrounding the target material.

Owner:ELECTRO SCI IND INC

Systems and methods for minimizing security logs

InactiveUS20050273673A1Error detection/correctionComputer security arrangementsTemporal informationTime segment

A method and system for consolidating a computer security log includes providing a security log including information pertaining to security events on a computer system, the log including entries specifying at least information identifying a relative time each event occurred and information identifying a type of each event, determining from the log a number of times a particular type of event occurred during a specified time period and creating a consolidated log including for each entry at least information identifying a first time that the particular type of event occurred during the specified time period, information identifying the type of the particular event and information indicating a number of times the particular type of event occurred during the specified time period.

Owner:COMP ASSOC THINK INC

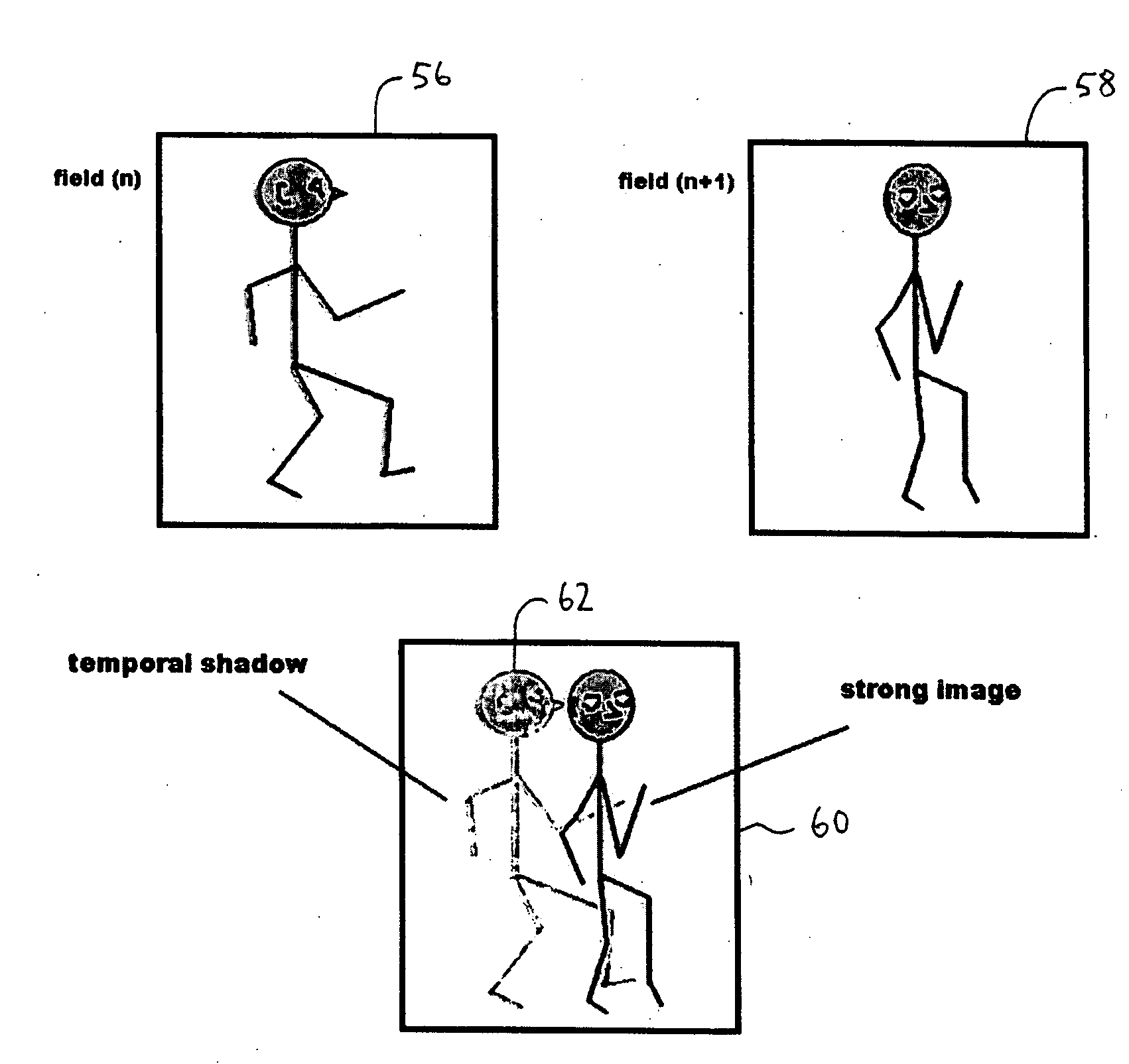

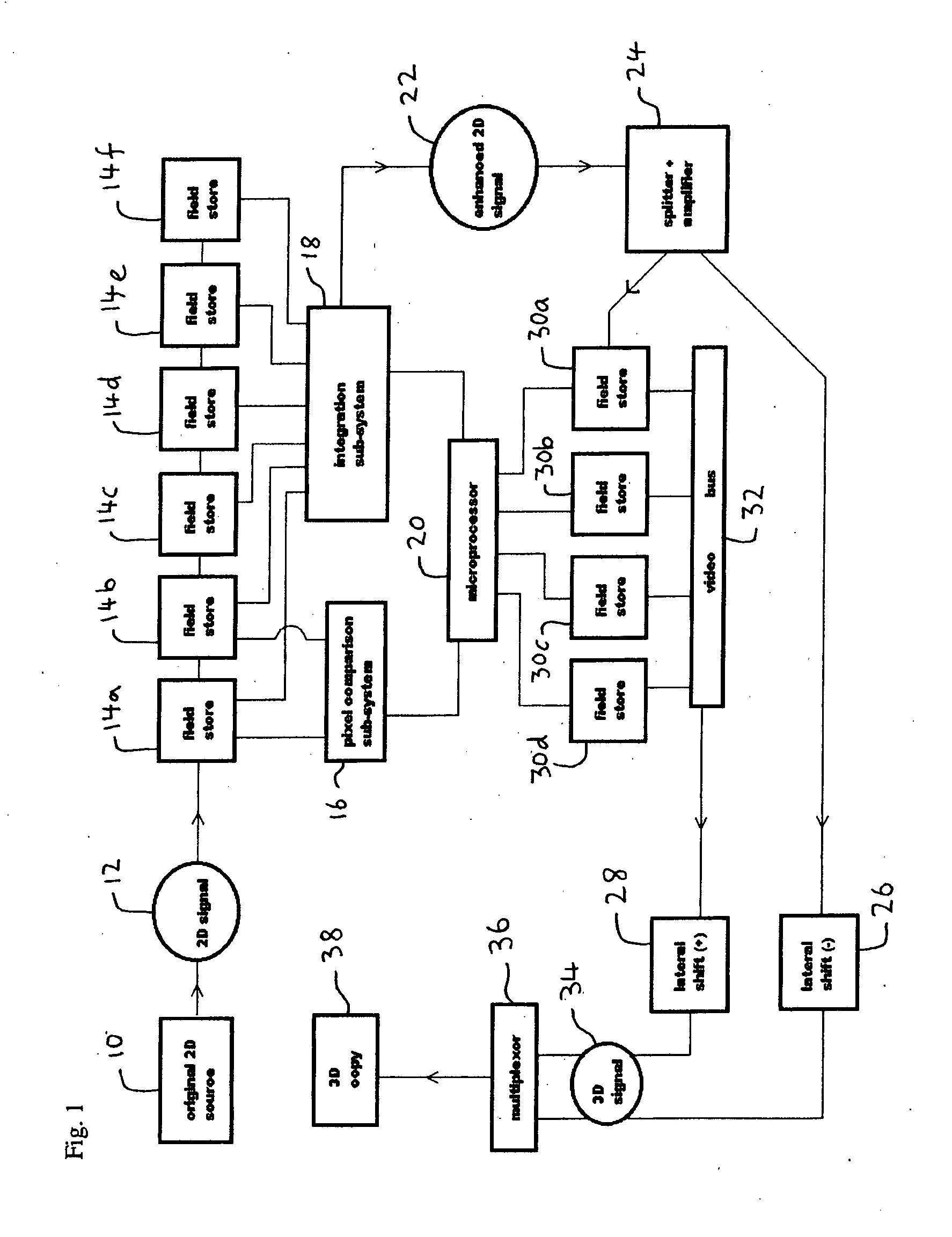

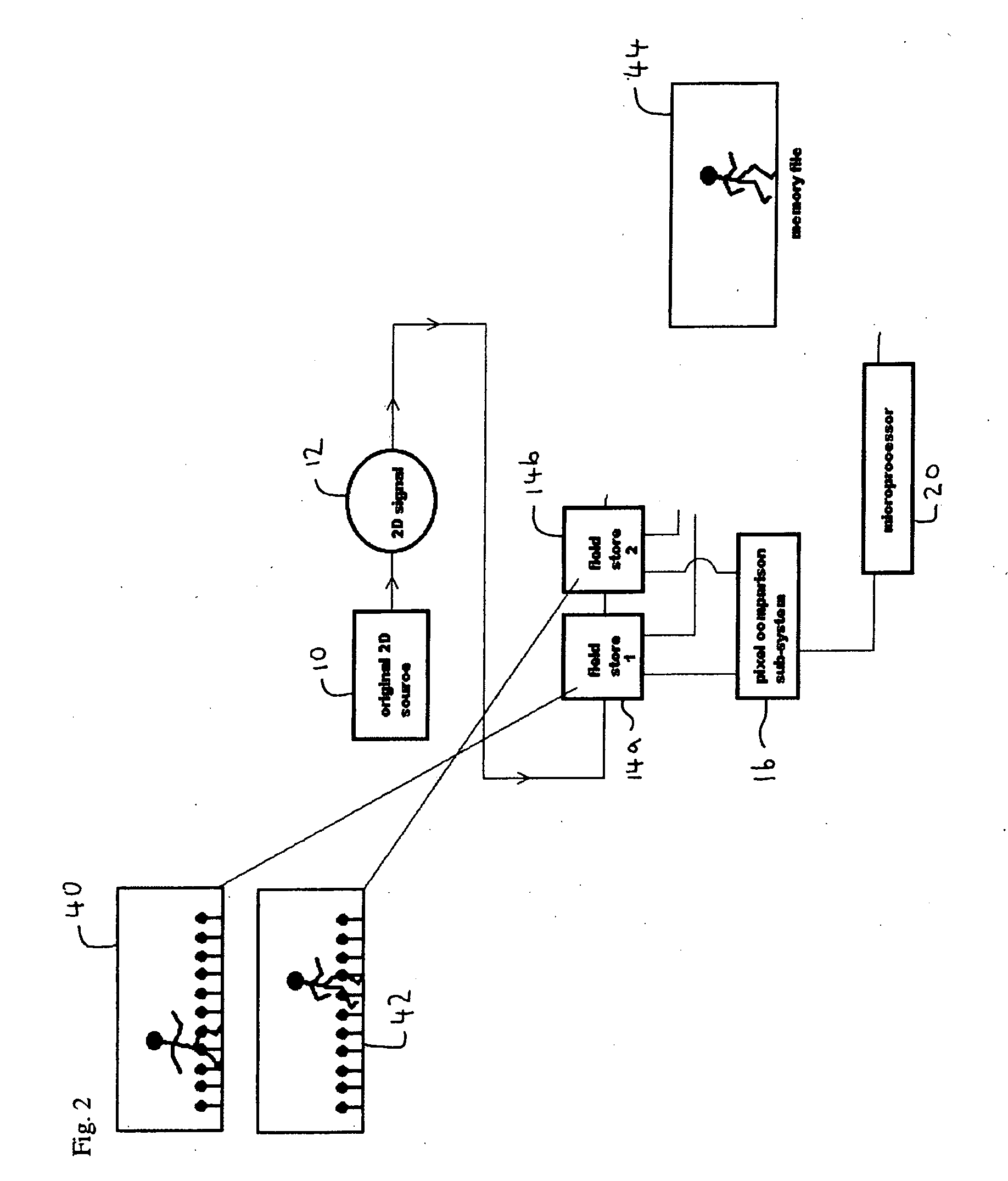

Stereoscopic Motion Picture

A stereoscopic motion picture sequence comprises a first channel of sequential images intended for viewing by one of a viewer's left and right eyes and a second channel of sequential images intended for viewing by the other one of the viewer's left and right eyes. Each image in each channel comprises primary image content representing a scene consisting of a plurality of elements and ‘temporal shadow’ image content. The temporal shadow image content in a first image comprises a degraded and / or partially transparent image of at least one element of the primary image content corresponding to a view of said at least one element as seen in the primary image content of a second image from the first or second channel. The temporal shadow images provide additional cognitive cues assisting the viewer's perception of the stereoscopic image sequence as having 3D depth. The temporal shadows may be used to augment conventional stereoscopic motion pictures and are particularly useful in relation to pseudo-stereoscopic ‘time parallax’ motion pictures derived from a 2D motion picture sequence by duplicating the original motion picture sequence in two (left and right) channels and applying a relative lateral displacement and relative time delay to the duplicated channels. Methods and systems for producing such motion picture sequences are also described, together with a modified display screen (or motion picture sequence) having a border pattern incorporating irregular protruding edge details:

Owner:ASHBEY JAMES AMACHI

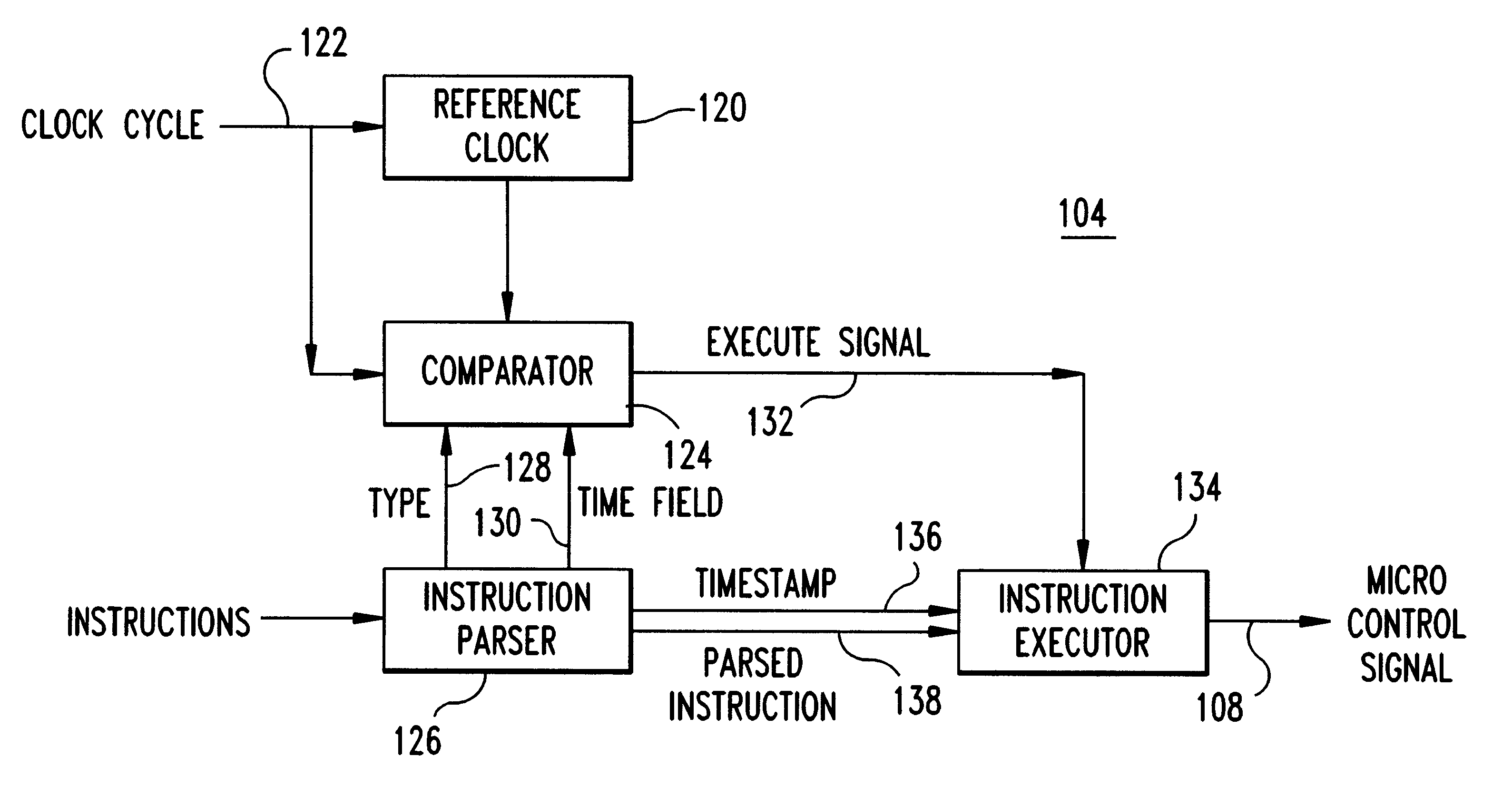

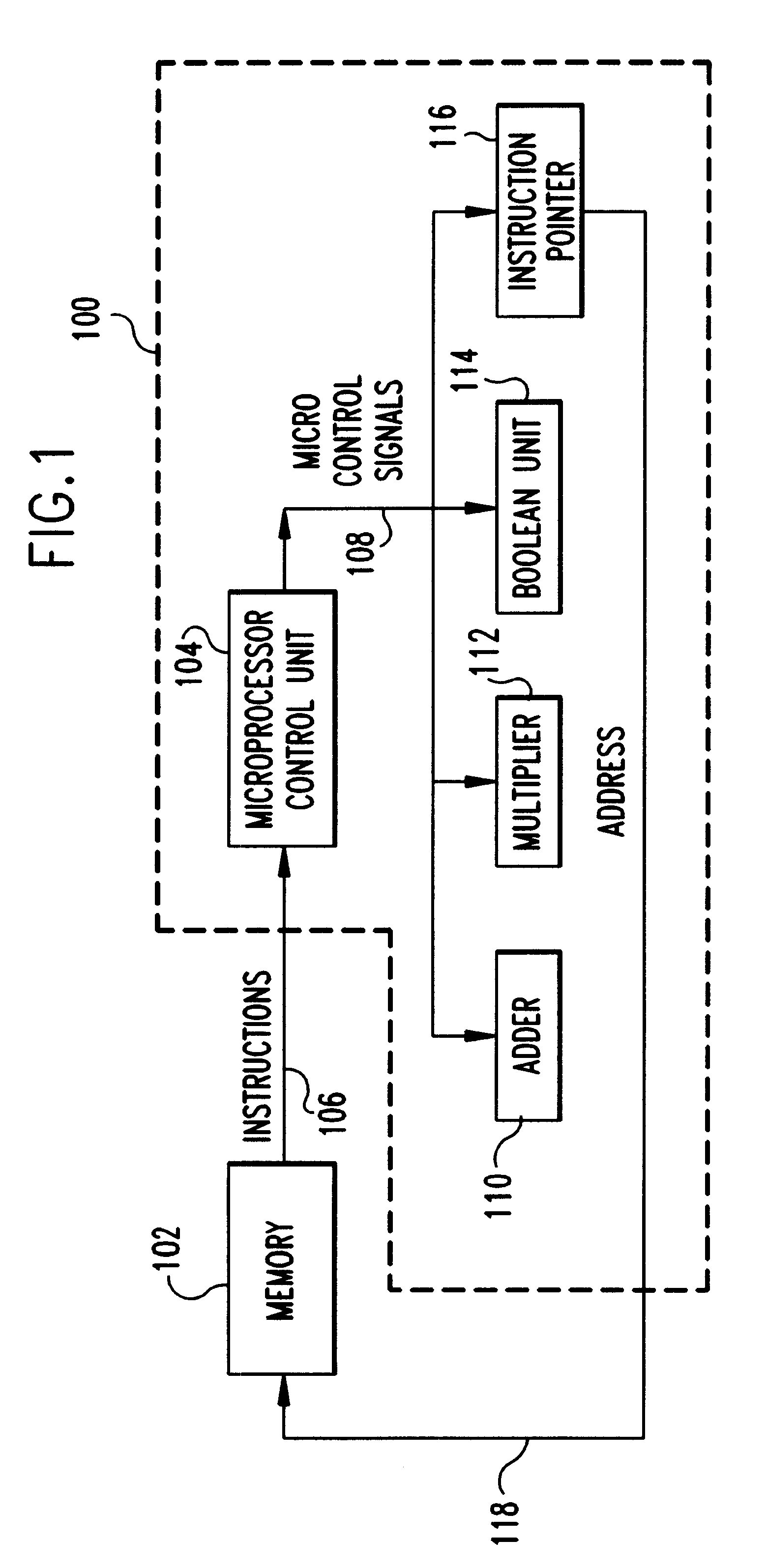

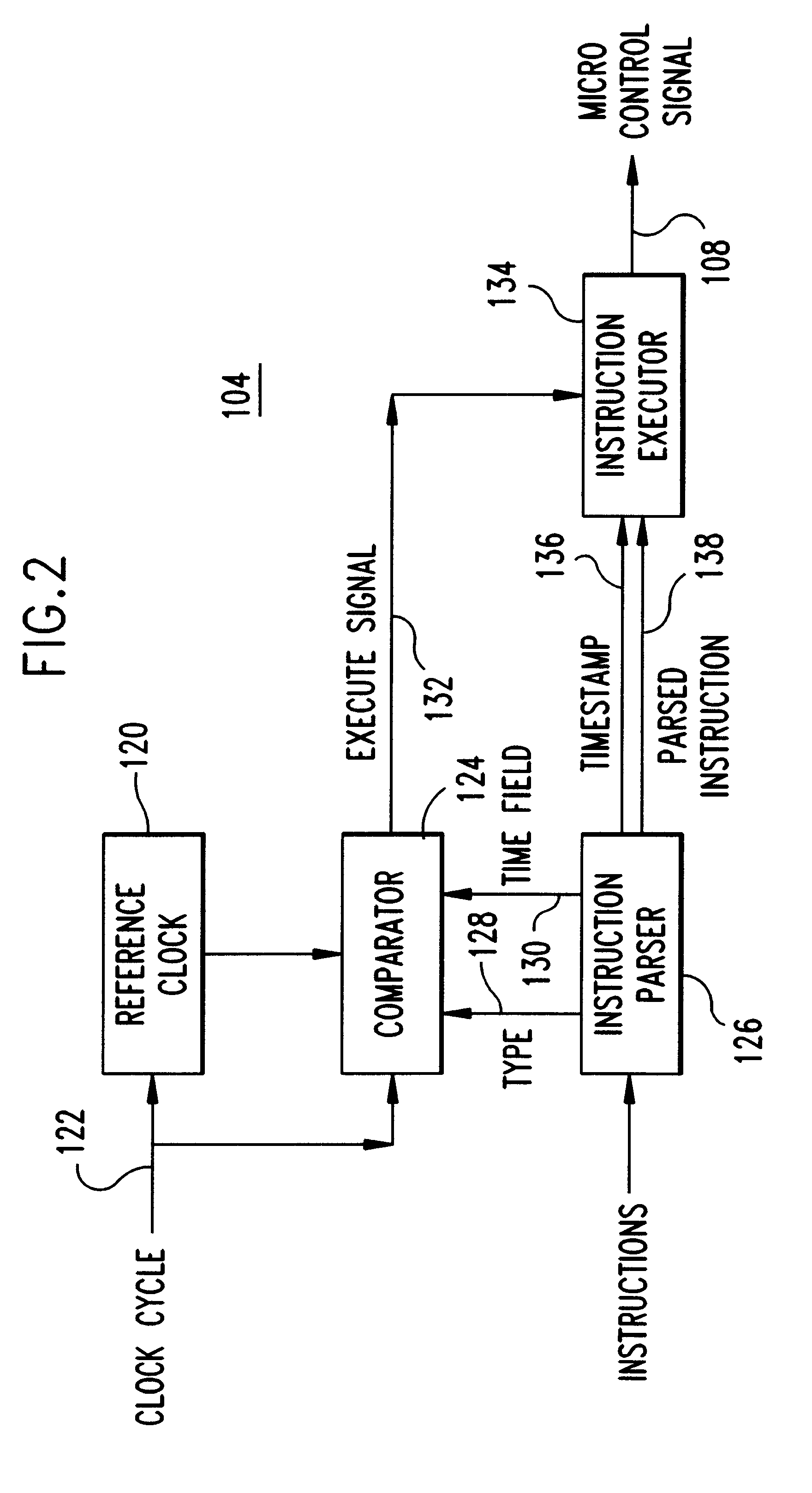

System and method for temporally controlling instruction execution

An apparatus and method of controlling instruction execution in the apparatus with a precise temporal execution arrangement. The apparatus may be a processor or microprocessor capable of executing a function specific wait state that is dependant upon a type specified by an instruction field. The processor includes a reference clock counter that maintains the wait count, an instruction parser that strips the wait type and count from instructions and passes the stripped information to a comparator. The comparator compares the stripped information against the wait count. The wait types include: a relative timestamp type indicating execution at some time subsequent to the present cycle; a direct timestamp type indicating an absolute time for execution; and a timestamp range indicating a time period when execution is valid.

Owner:IBM CORP

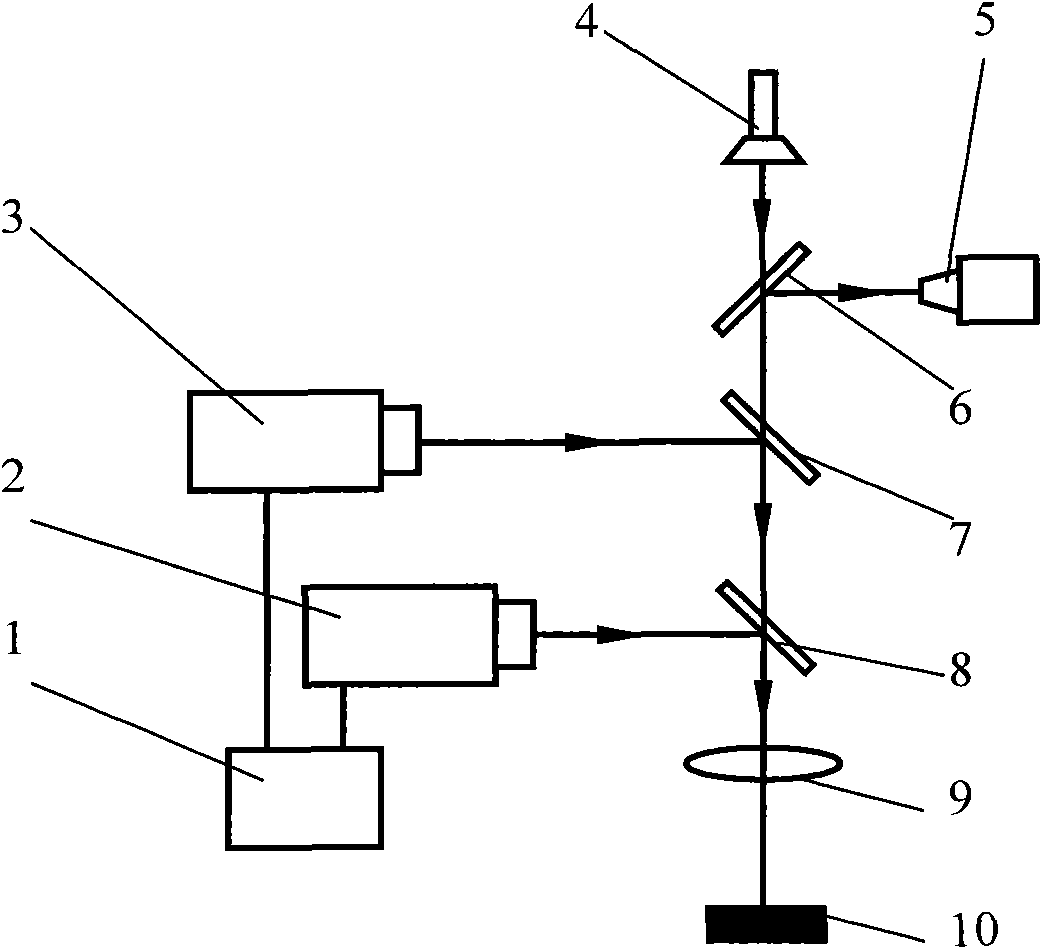

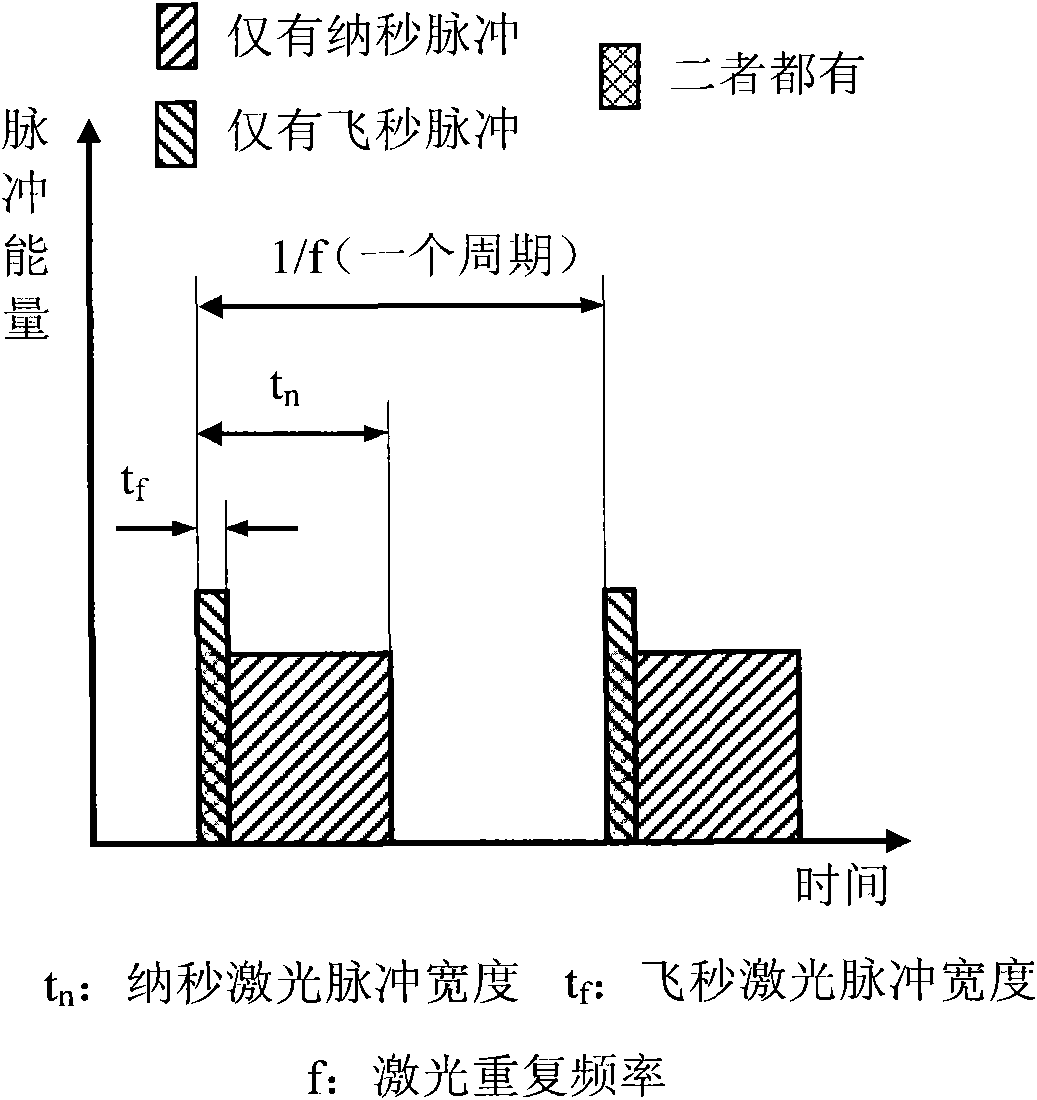

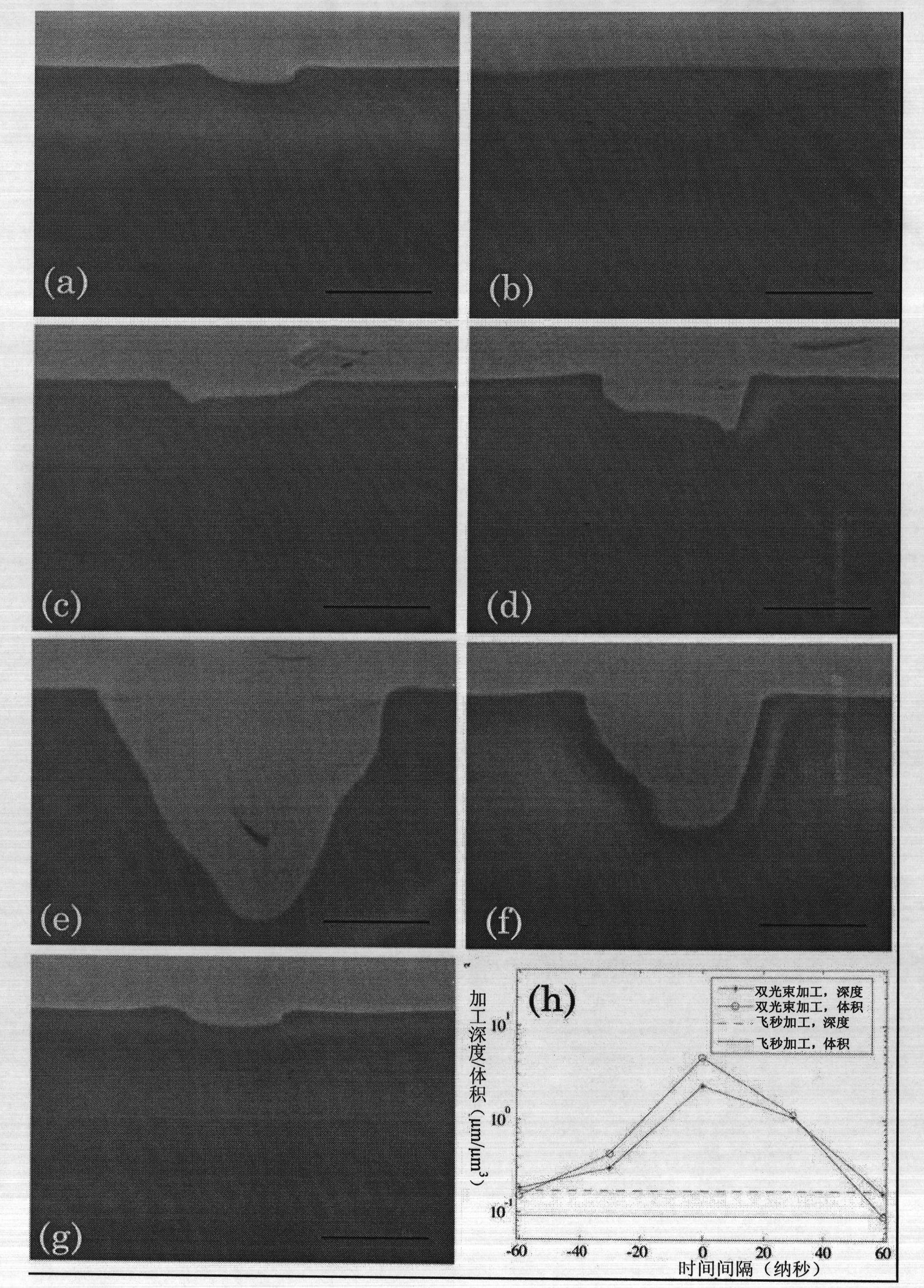

Nano-femtosecond dual-laser composite machining system

InactiveCN102059451AHigh precisionHigh nanosecond laser processing efficiencyLaser beam welding apparatusOptical elementsMicro nanoNuclear fusion

The invention relates to a nano-femtosecond dual-laser composite machining system. The system comprises a femtosecond laser, a nanosecond laser, a synchronous control circuit, an illuminating light source, a semi-transparent semi-reflecting mirror, a first dichroscope, a second dichroscope, a focusing lens and a charge coupled device (CCD) image detector, wherein the synchronous control circuit controls laser pulse output of the femtosecond laser and the nanosecond laser, and accurately adjusts relative time of nanosecond pulse and femtosecond pulse in the aspect of time to synchronize leading edges of the two pulses; the illuminating light source is positioned on one side of the semi-transparent semi-reflecting mirror, and the second dichroscope, the first dichroscope and the focusing lens are coaxially arranged on the other side of the semi-transparent semi-reflecting mirror in turn and are positioned on a straight line together with the illuminating light source; and the CCD image detector is positioned at the tail end of a reflecting light path of the semi-transparent semi-reflecting mirror. Through the system, the advantages of high femtosecond laser machining accuracy and high nanosecond laser machining efficiency are simultaneously integrated, and high-accuracy and high-efficiency micro-nano machining is realized; and the system can be widely applied to the fields such as high-accuracy machining of aviation and aerospace key parts, microstructure machining of a laser fusion ignition target, microstructure machining of a microsensor and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Energy efficient, laser-based method and system for processing target material

InactiveUS20080035614A1Rule out the possibilityPromote resultsLaser detailsSemiconductor/solid-state device detailsControl signalEngineering

Owner:ELECTRO SCI IND INC

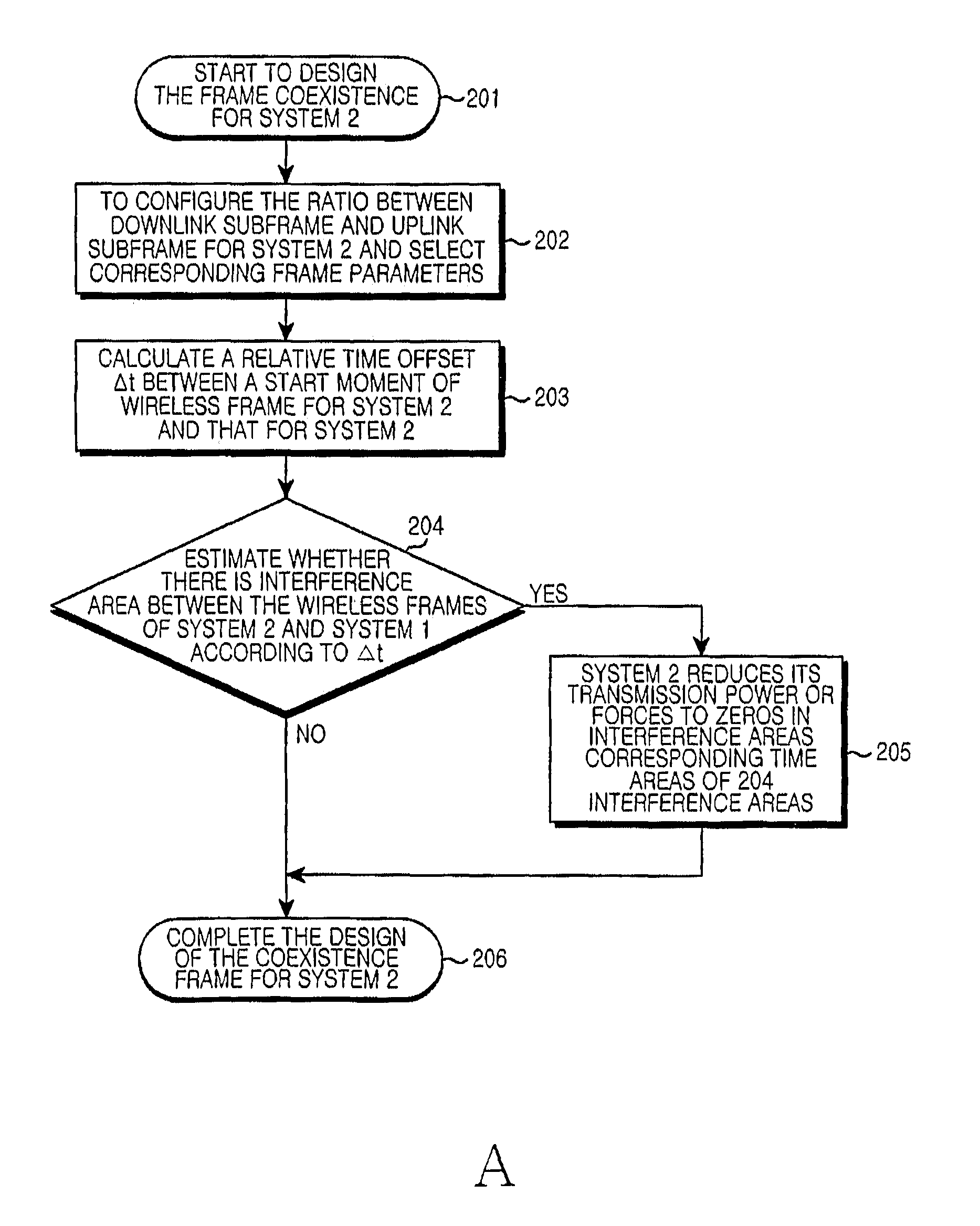

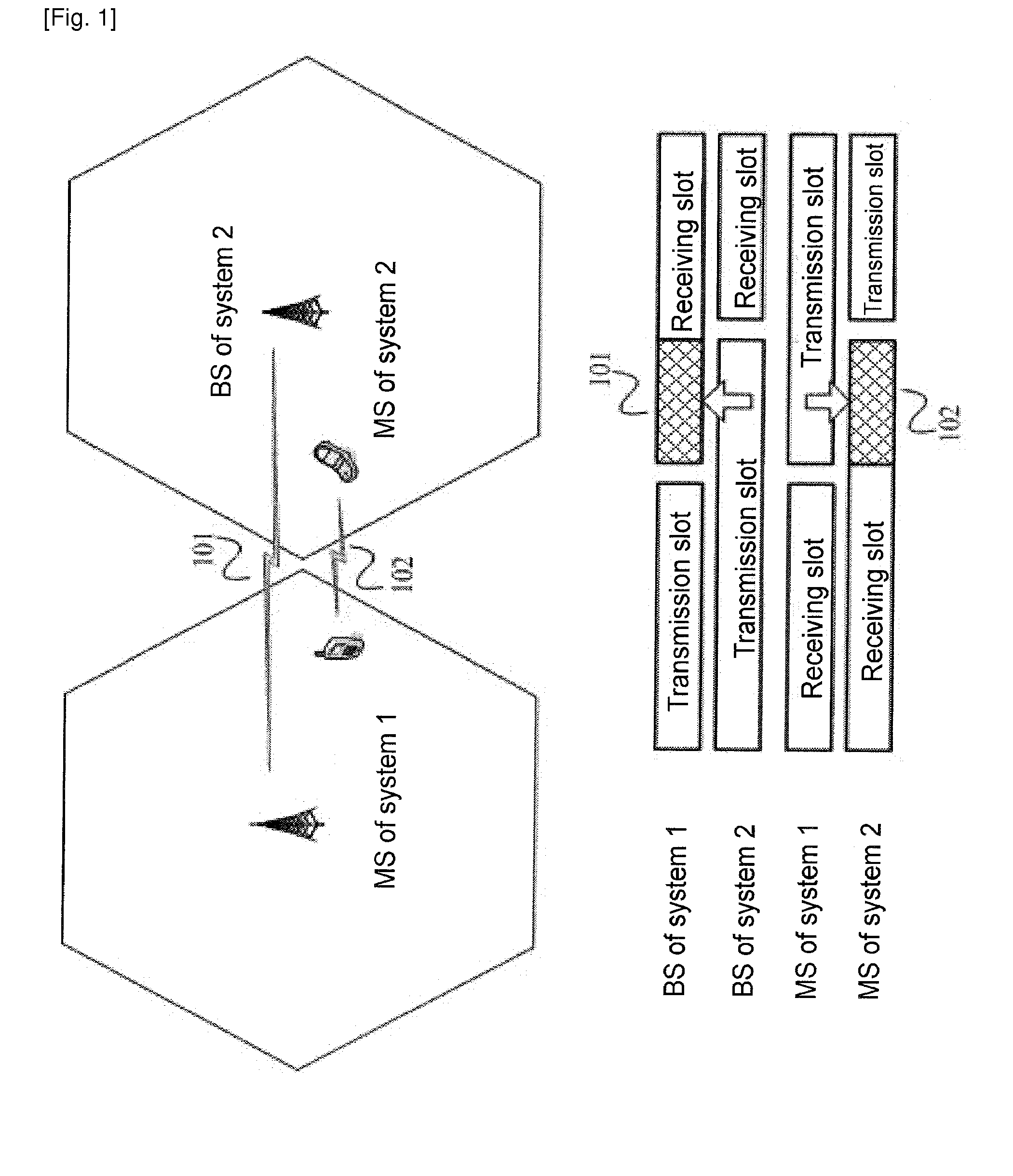

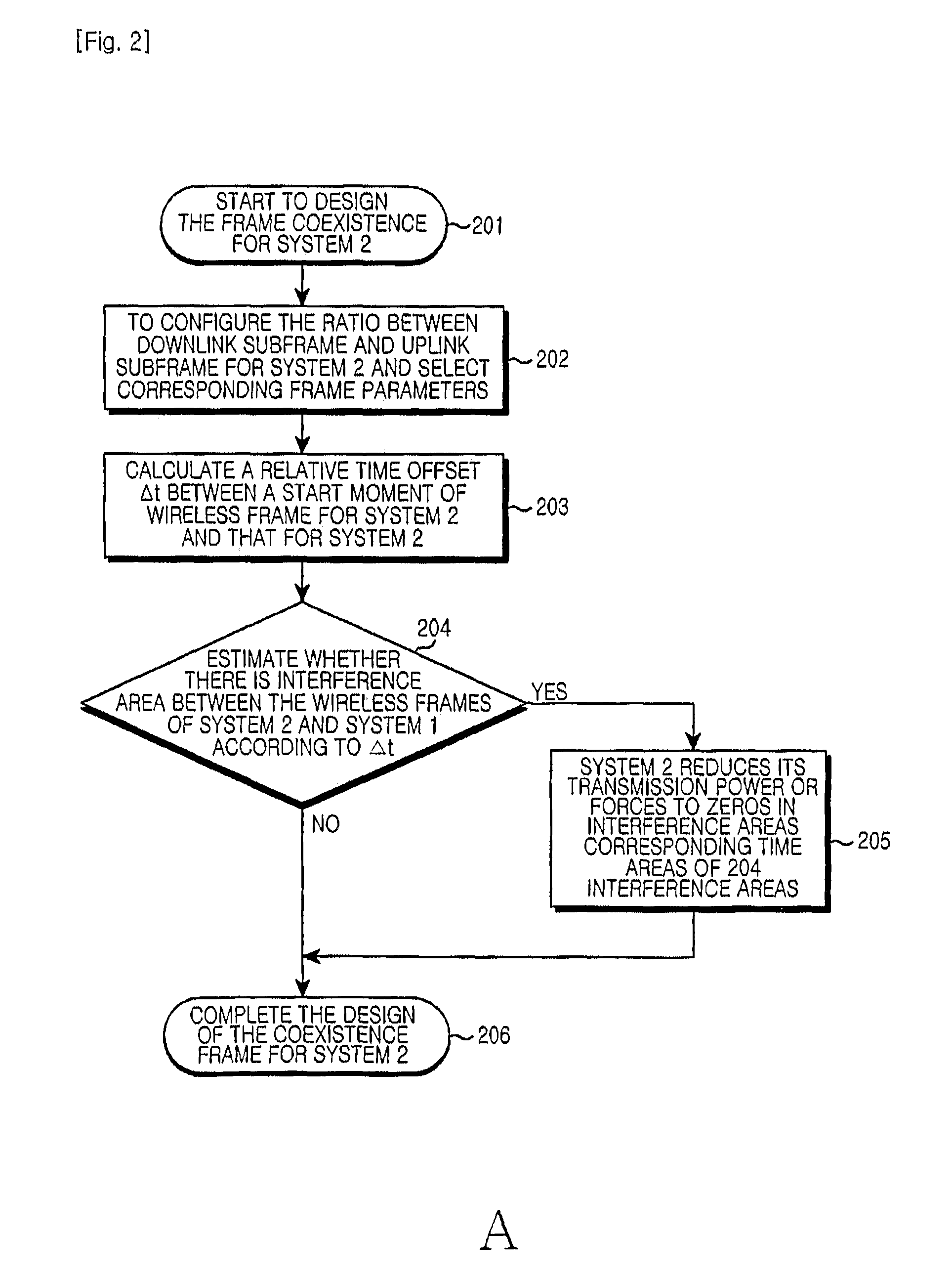

Method for multiple TDD systems coexistence

InactiveUS20100290372A1Interference in frequency bandTransmission time can be guaranteedSynchronisation arrangementTime-division multiplexCarrier signalRelative times

The method for multiple TDD systems coexistence comprising steps of: a newly deployed system calculating a relative time offset Δt for a corresponding frame; the newly deployed system transmitting uplink and downlink signals based on a time reference information obtained by a summation of the relative time offset Δt and a time reference of an existing system. With the method proposed in present invention, uplink and downlink interference from adjacent frequency bands and from adjacent carriers in the same frequency band can be greatly reduced and a transmission time utility can be guaranteed for a newly deployed system.

Owner:SAMSUNG ELECTRONICS CO LTD

System and method for visualizing electrophysiology data

ActiveUS20160183824A1Facilitate easeAvoid sequenceElectrocardiographySensorsRecording durationGraphics

A method and system for visualization of electrophysiology information sensed by electrodes on a catheter, includes recording times of electrode signal acquisition, designating a reference electrode signal acquisition, assigning a relative time to each recorded time of electrode signal acquisition relative to the reference electrode signal acquisition, identifying the electrodes with signal acquisition, correlating assigned relative times to identified electrodes to generate a sequence of electrode signal acquisitions, and generating a visual representation of the sequence of electrode signal acquisitions generating a visual representation with a graphical image of the electrodes, wherein individual electrodes are visually marked to represent the sequence of electrode signal acquisitions.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

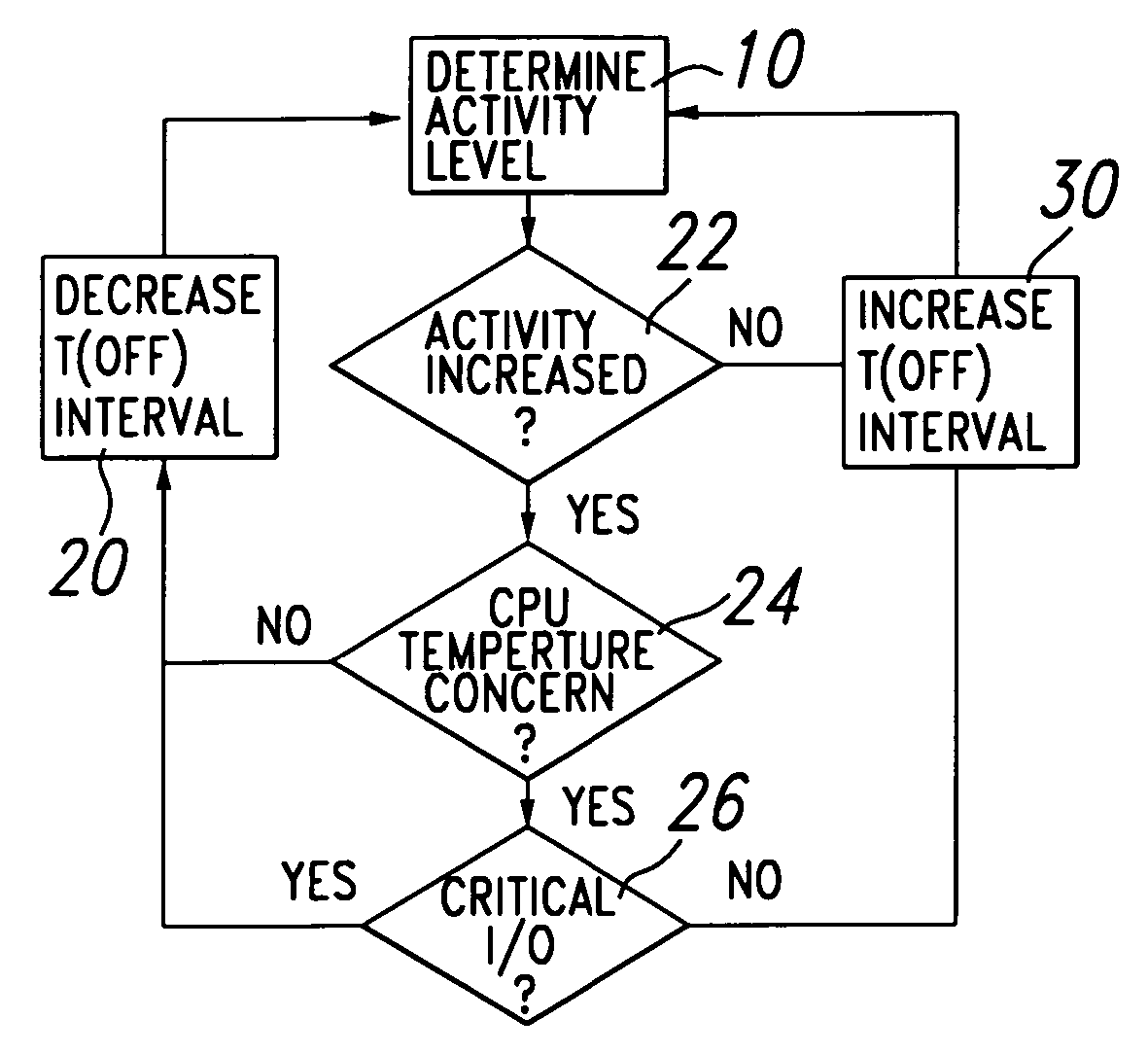

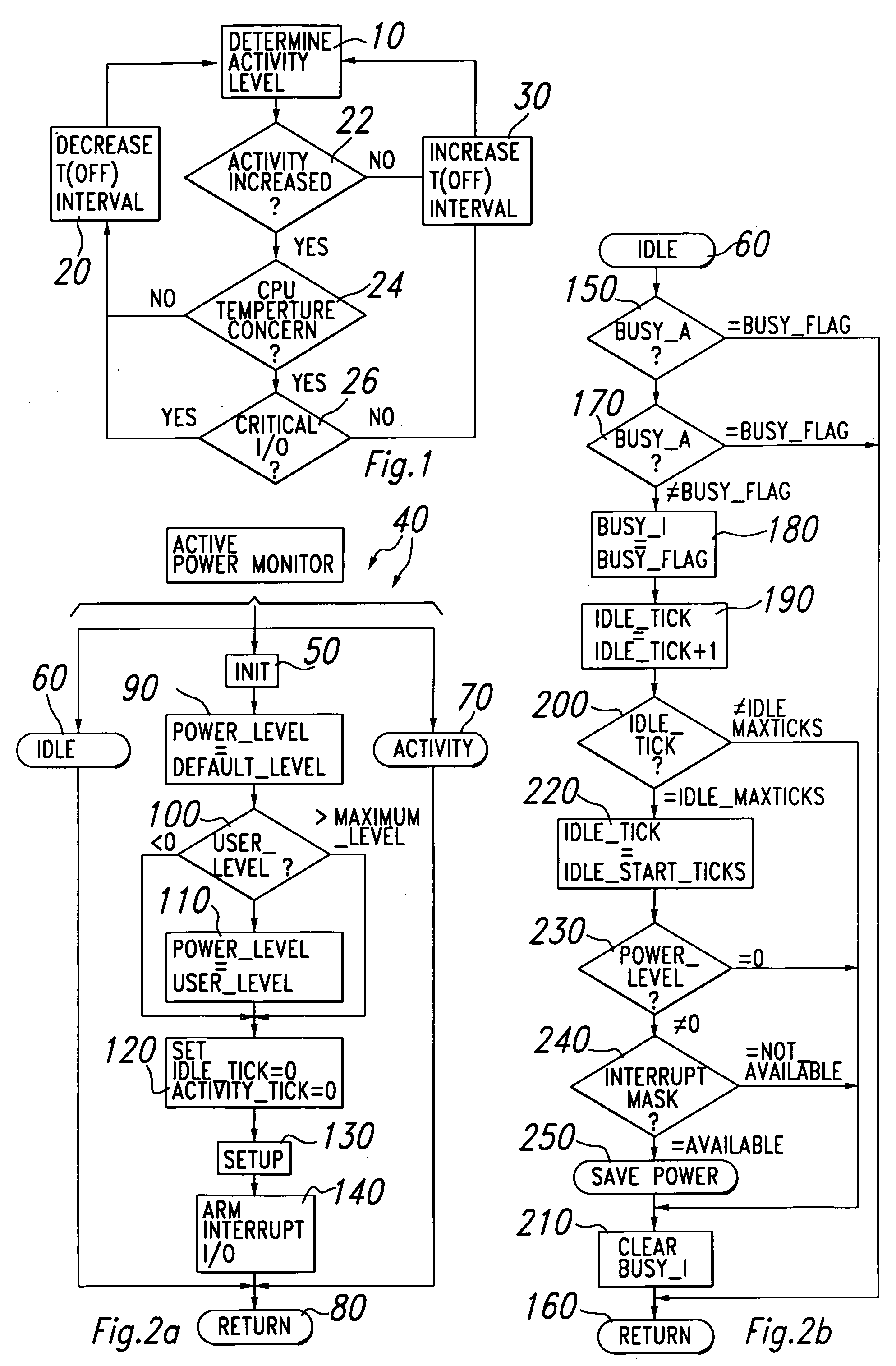

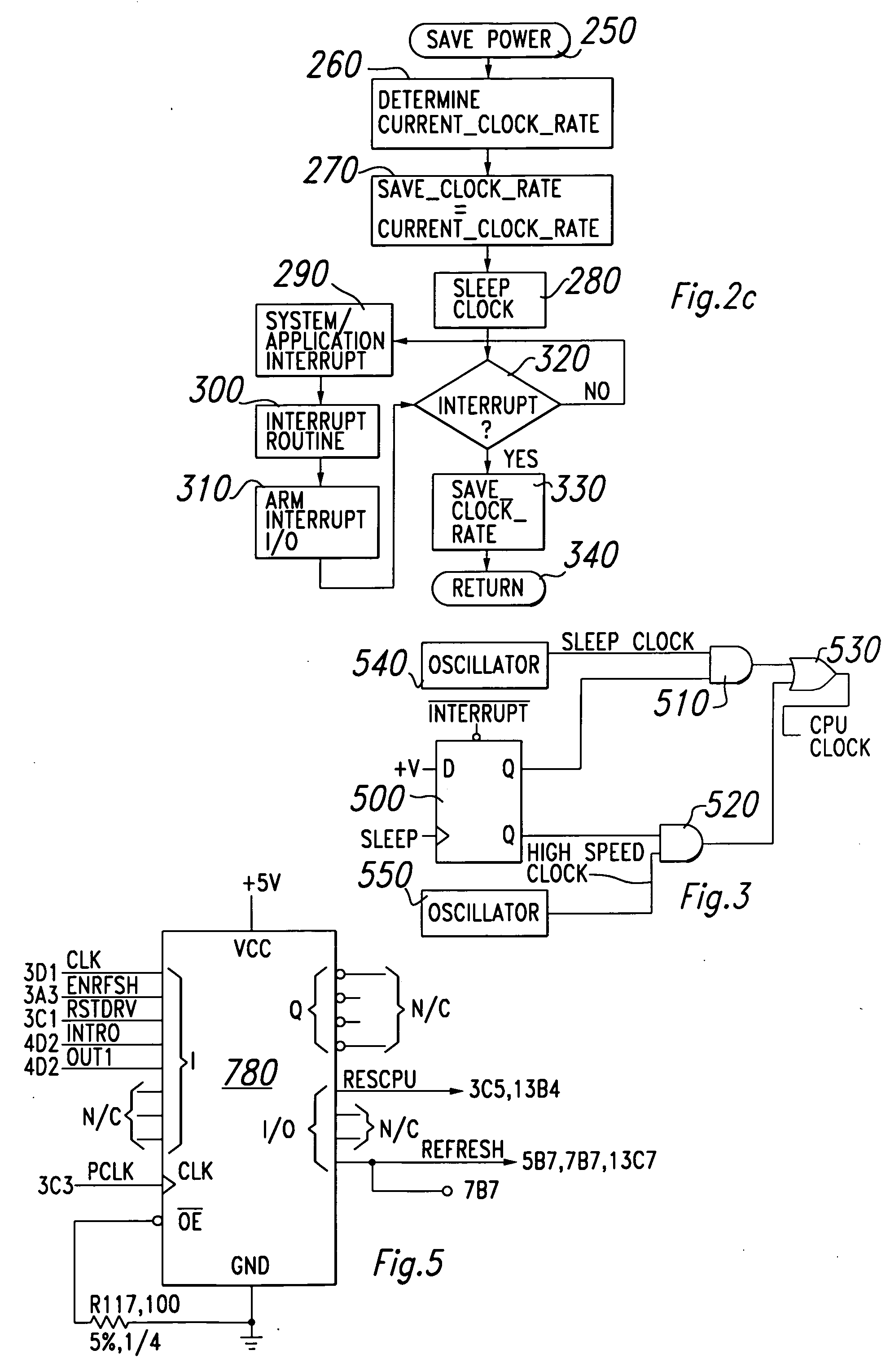

Apparatus employing real-time power conservation and thermal management

InactiveUS20050223258A1Power supply for data processingGenerating/distributing signalsControl powerIdle time

An apparatus employing a monitor for detecting temperature associated with a processor and, depending on the respective embodiment, detecting an amount of idle time, activity time, or idle time and activity time associated with the processor, results of detecting being used for controlling a clock speed. Yet other embodiments disclose, depending upon the respective embodiment, a processor and / or apparatus employing the same, comprising a monitor for detecting temperature and for determining an amount of Input / Output (I / O), relative importance of Input / Output (I / O), and / or relative amount of time between Input / Output (I / O), associated with the processor, results of the detecting and measuring being used to control power dissipation associated with the processor.

Owner:WATTS LA VAUGHN F JR

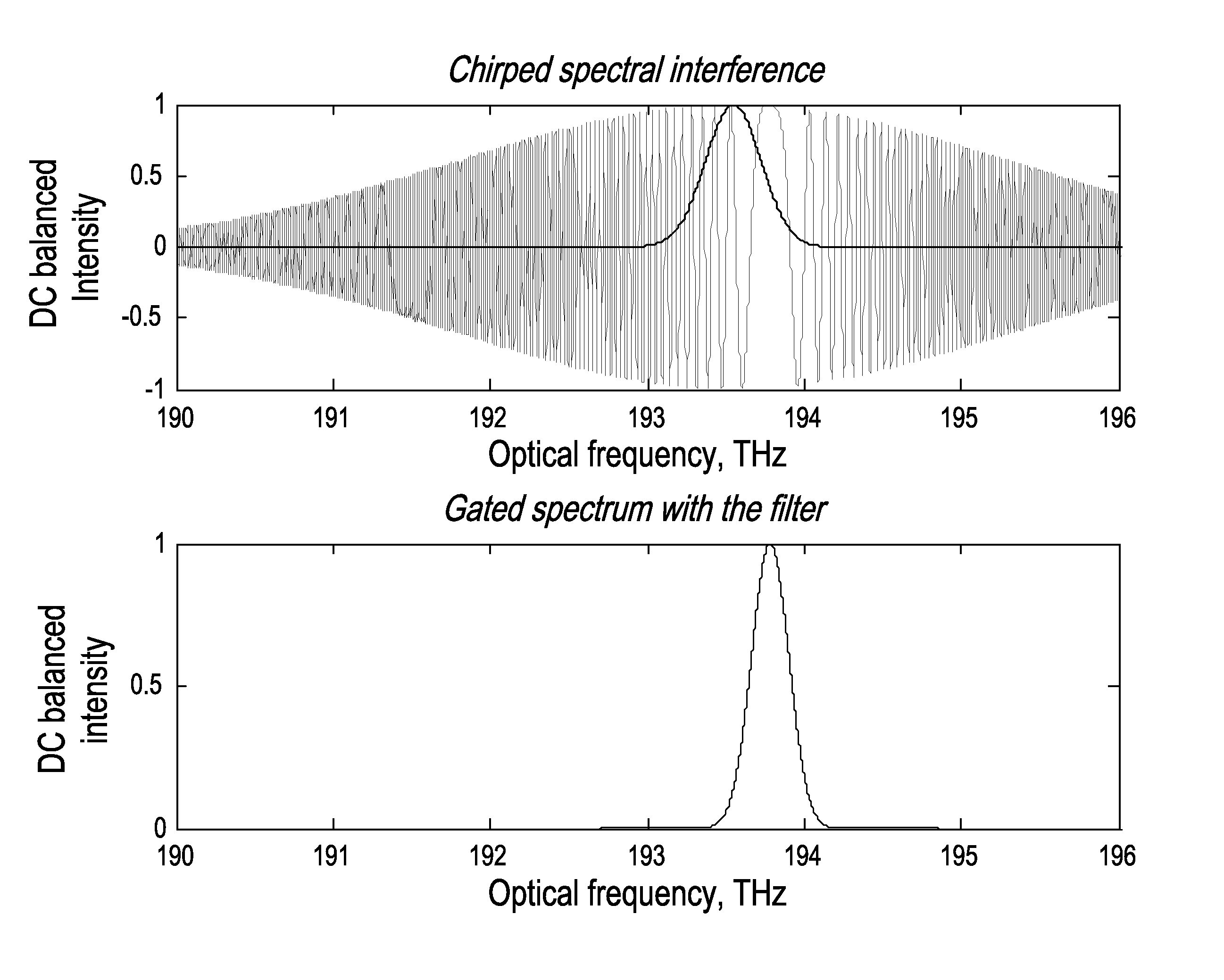

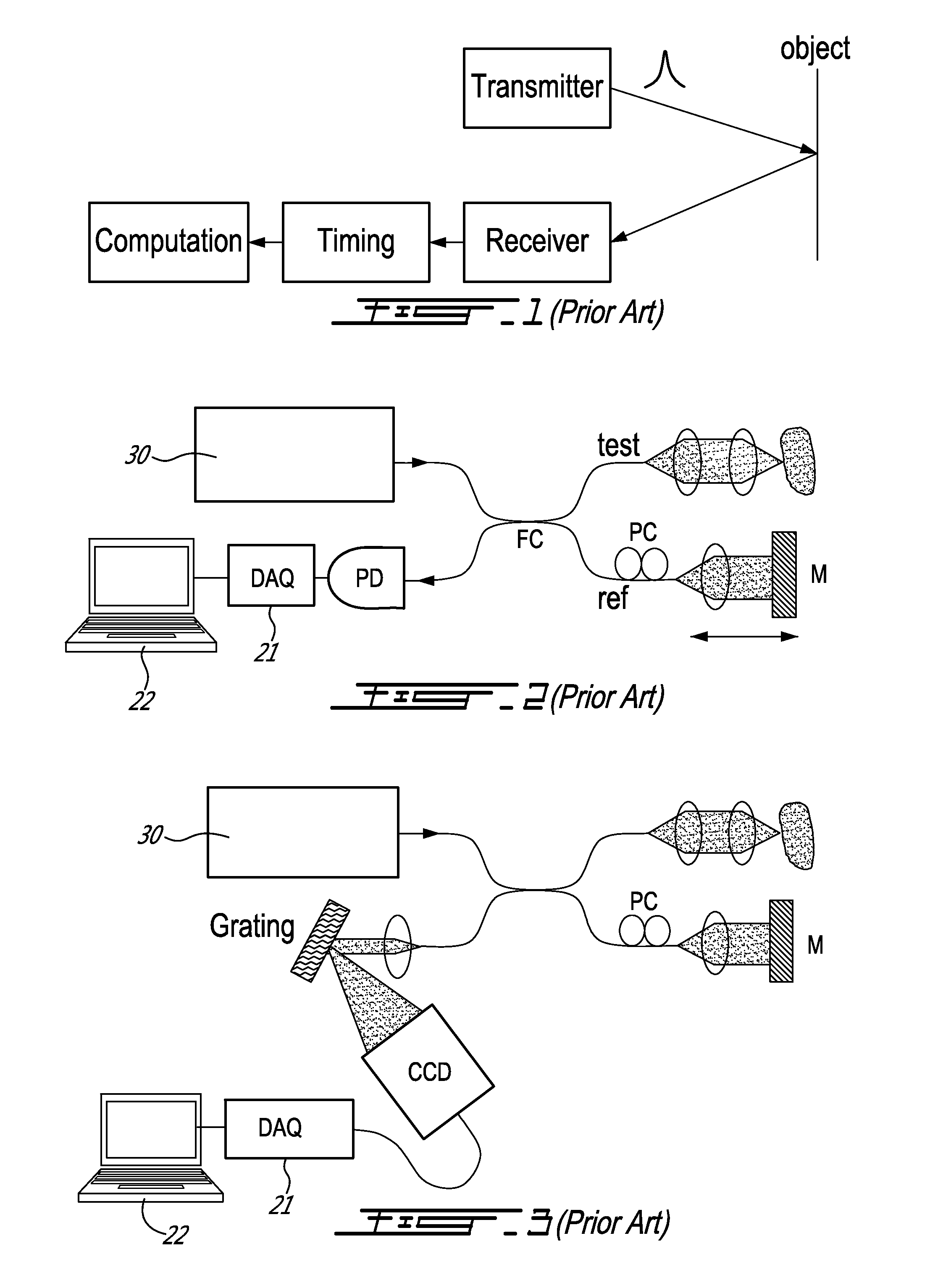

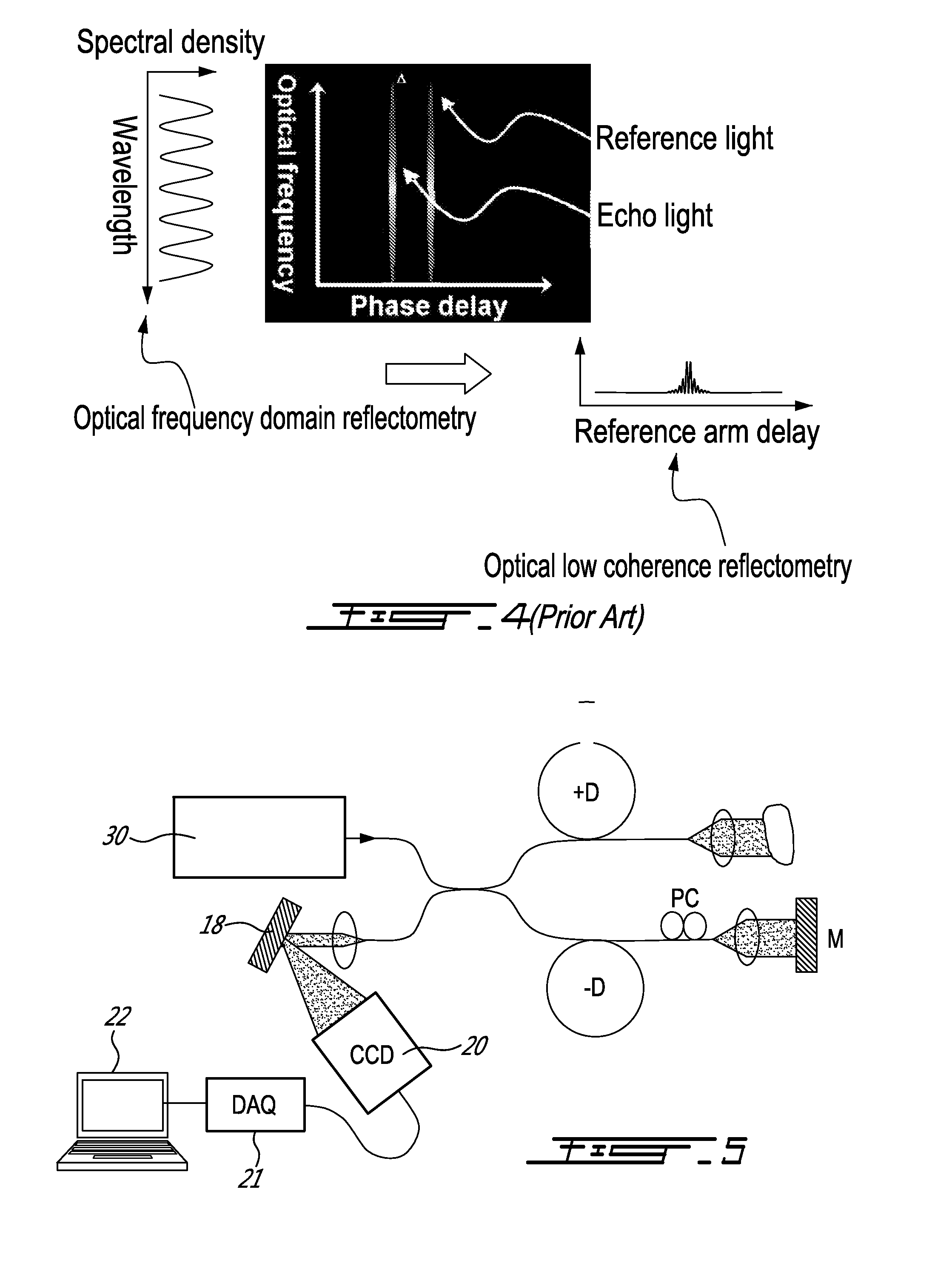

Cross-chirped interferometry system and method for light detection and ranging

ActiveUS20100118292A1Radiation pyrometryOptical rangefindersFrequency spectrumFull width at half maximum

An interferometric method and system enabling light echoes-to-spectrum mapping, applicable for laser rangefinder, biomedical imaging including surface 3D mapping and tomography, vehicle position identification, and spectrum analysis. The direct mapping into spectrum allows a time-of-flight detection without using any timing pulse modulation. The sensitivity of the detection can be as high as that of the conventional low coherence interferometry, thereby an eye-safe and low-cost solution not compromising performance. In a practical implementation, high accurate range detection can be easily achievable with the level of accuracy equivalent to the laser rangefinder using a 20 ps Full-Width-at-Half-Maximum (FWHM) timing pulse. The system and method comprise applying dispersion-unbalanced interference (referred to as ‘cross-chirp interference’) and gating a phase matched spectral component. The dispersion unbalance used to induce linear one-to-one correspondence between the relative time delay and the spectral component, the performances in terms of range and resolution of the system and method increase with the increase in dispersion unbalance

Owner:INSTITUT NATIONAL DE LA RECHERCHE SCIENTIFIQUE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com