Nano-femtosecond dual-laser composite machining system

A compound processing and femtosecond laser technology, which is applied in laser welding equipment, metal processing equipment, optics, etc., can solve the problems of not being able to take into account both processing accuracy and efficiency at the same time, and achieve the effect of high processing accuracy and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

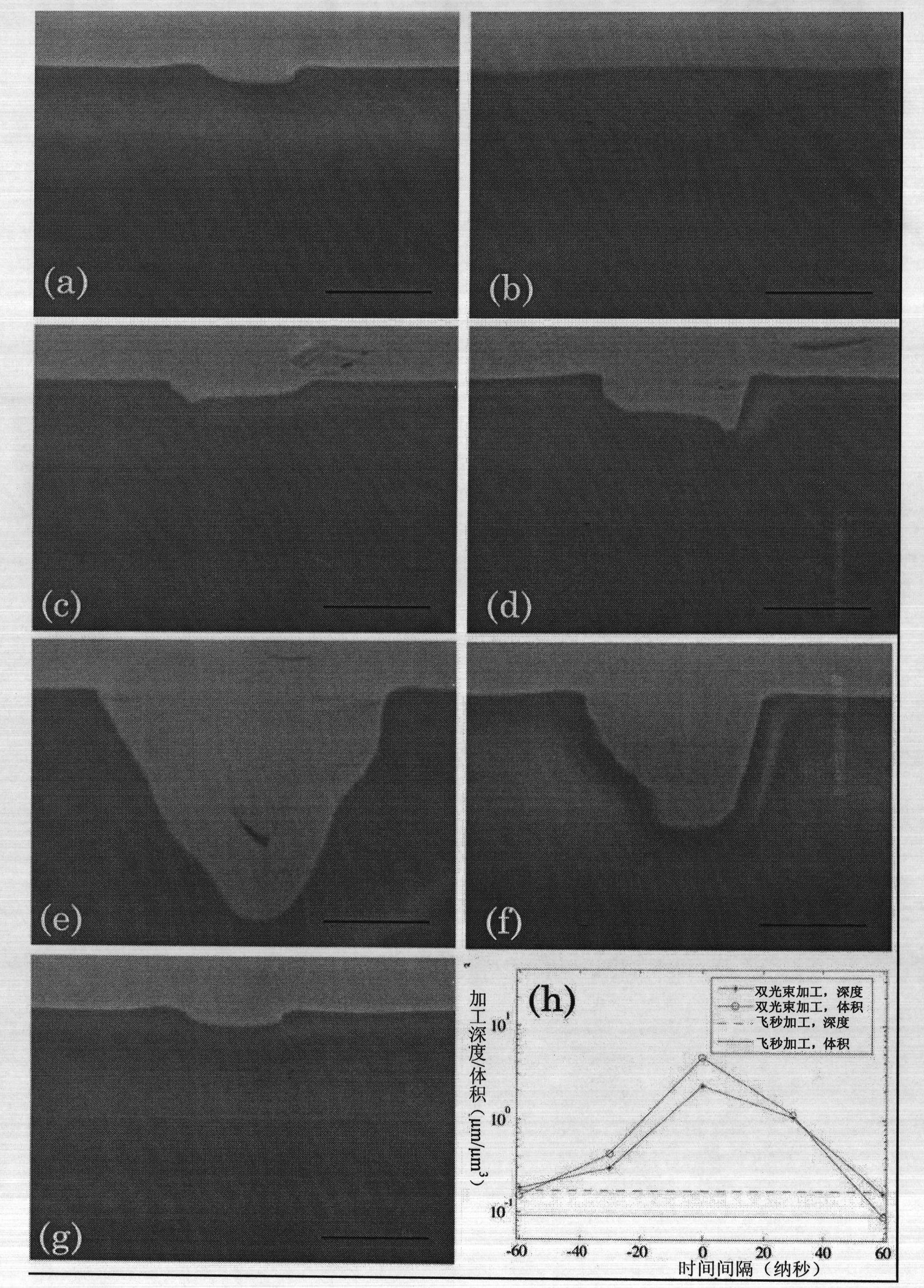

[0025] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

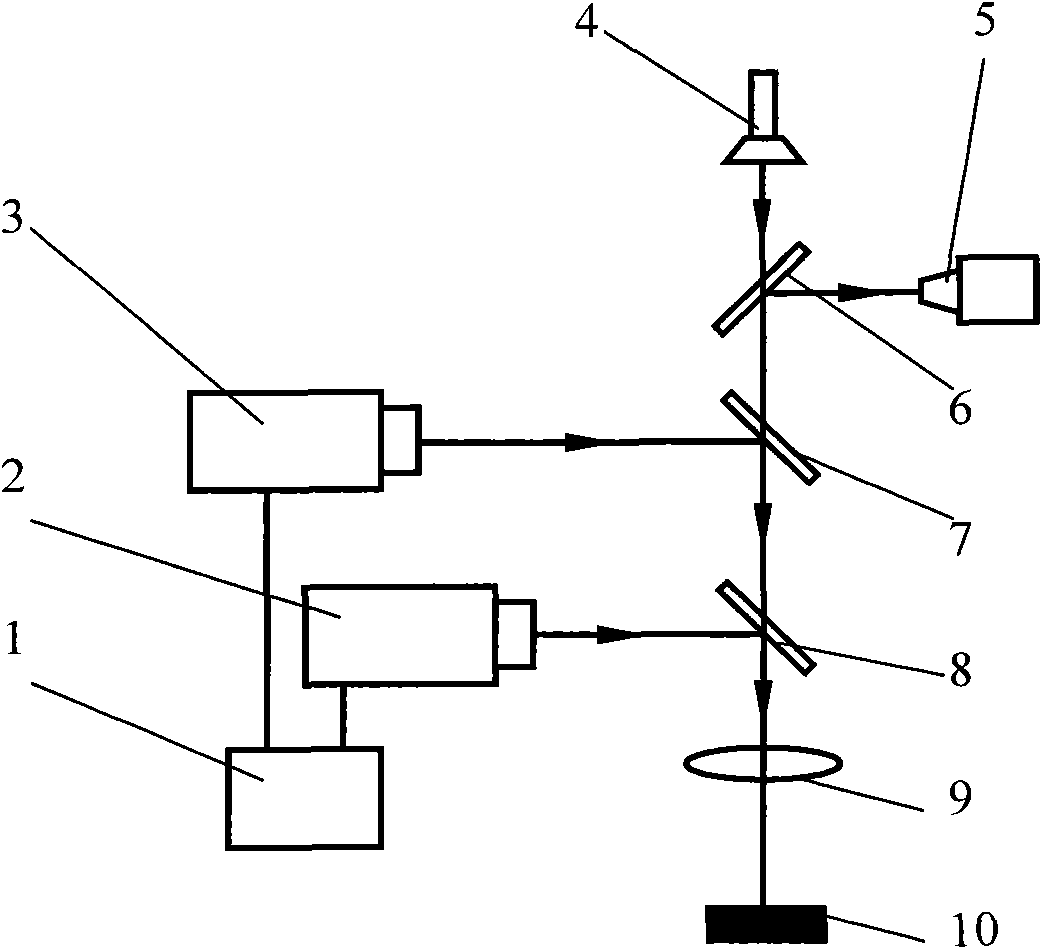

[0026] The nanofemtosecond dual-laser composite processing system of the present invention is as figure 1 As shown, the femtosecond laser 2 and the nanosecond laser 3 are respectively connected to the synchronous control circuit 1 through signal control lines; the illumination light source 4 is located on one side of the half mirror 6, and the other side is the second dichroic mirror 7, The first dichroic mirror 8 and the focusing lens 9 are coaxially placed successively, and are positioned on a straight line with the illumination source 4; The axes of the dichroic mirror 8, the second dichroic mirror 7 and the focusing lens 9 are vertical.

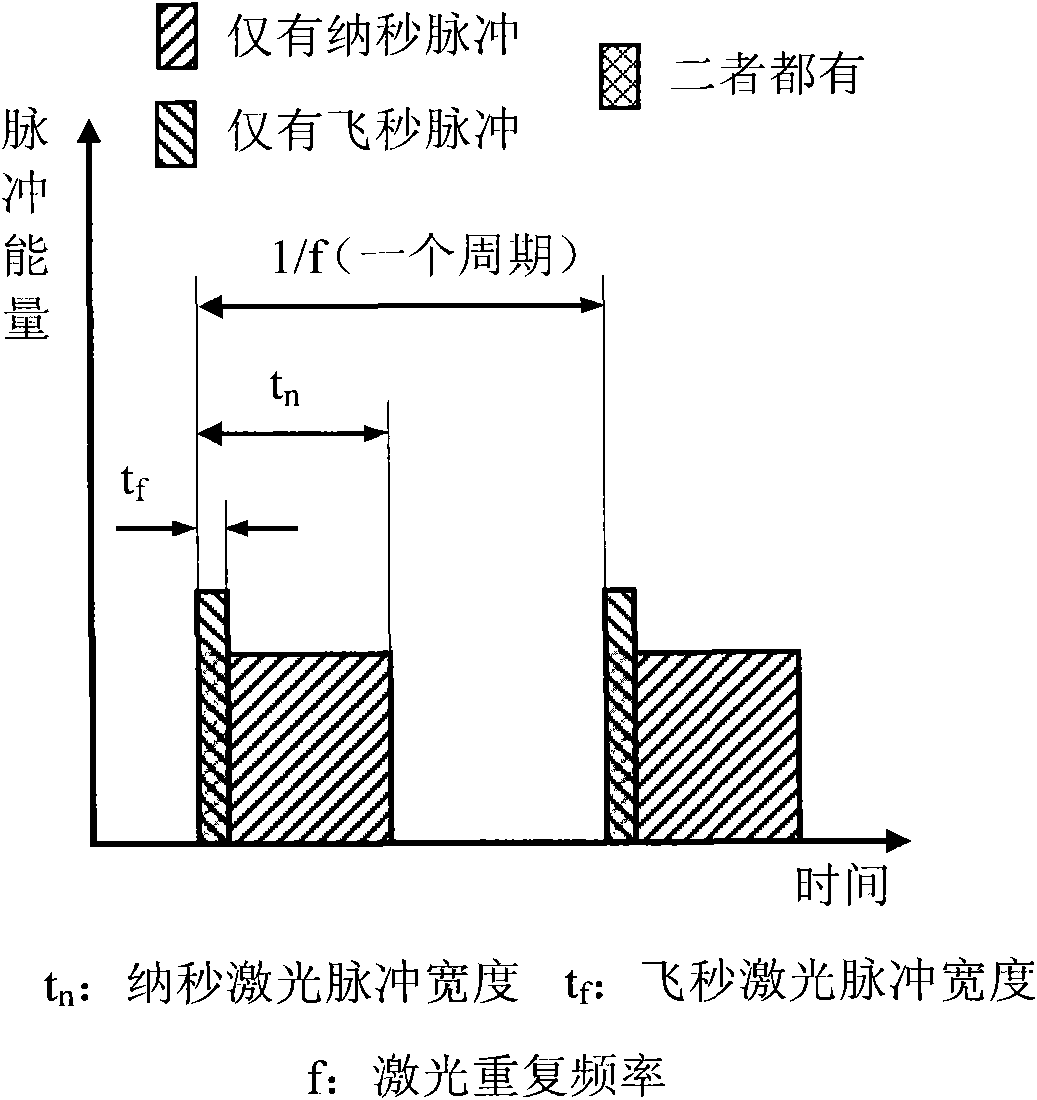

[0027] In this embodiment, a titanium-sapphire femtosecond laser is selected, with a central wavelength of 800nm and a pulse wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com