Patents

Literature

427results about "Registering/indicating during manufacturing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

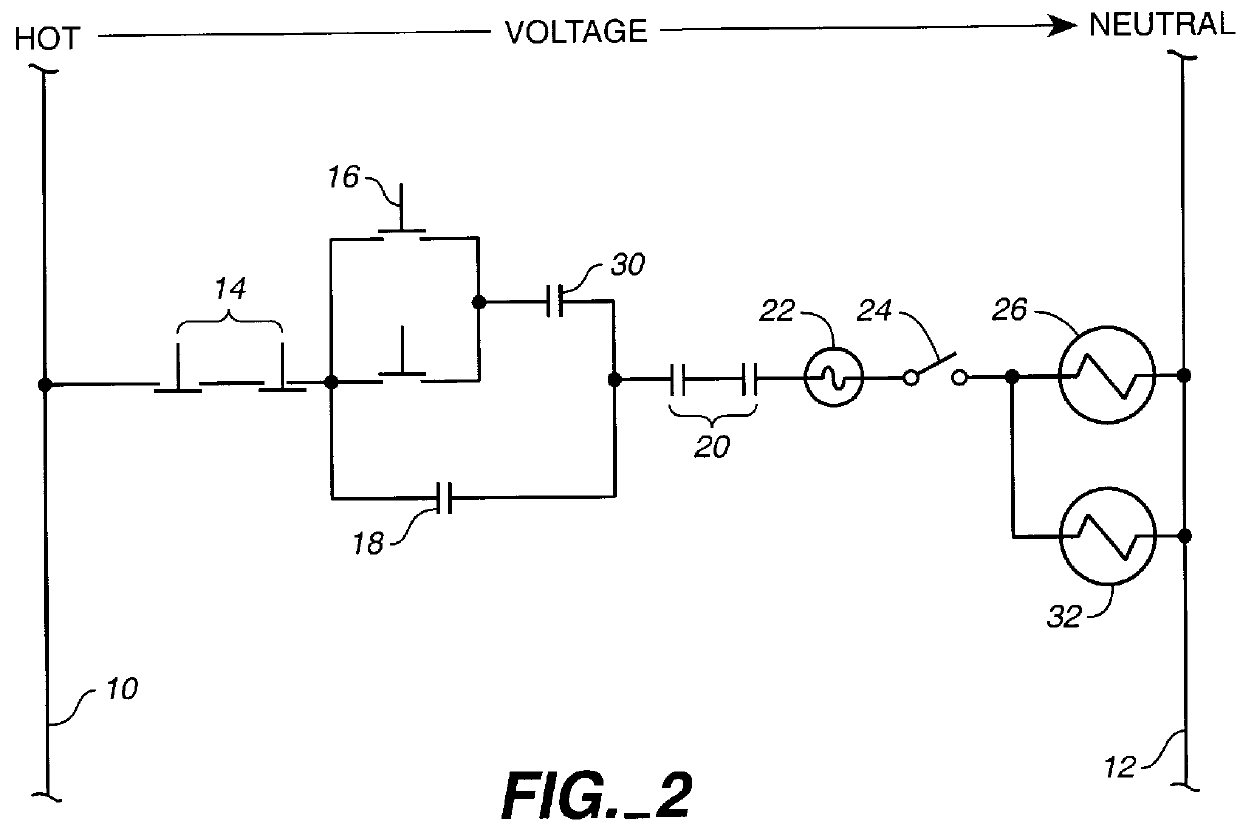

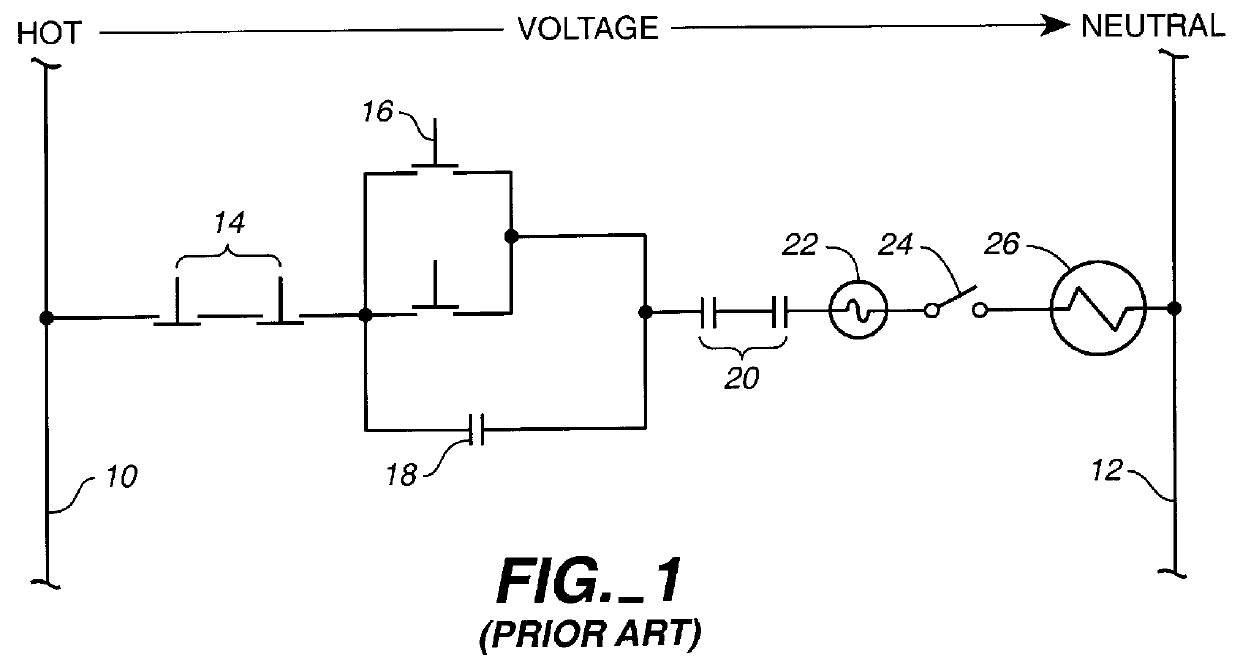

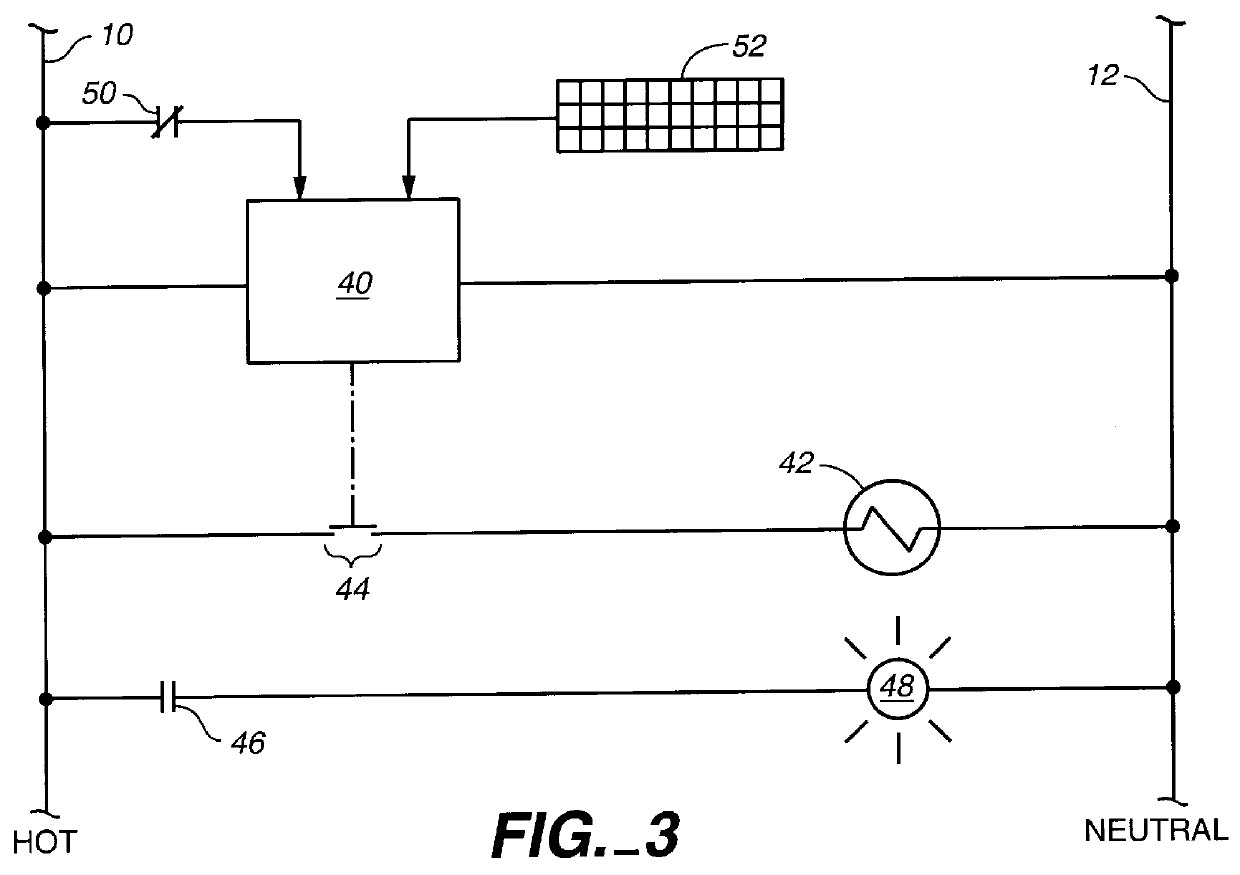

Method and apparatus for collecting manufacturing equipment downtime data

InactiveUS6128543AAccurate qualityFaster rateSafety arrangmentsTechnology managementDowntimeRunning time

A method and apparatus for collecting manufacturing equipment downtime data which electrically blocks stopped equipment (production) from restarting until an acceptable reason (either by code or direct identification) has been entered and recognized by an electronic logic system. Locking out the restart capability until the downtime cause has been entered ensures that the causes for all downtimes are recorded in a timely fashion. This data is gathered and recorded to measure and define explanations for lost equipment running time. Other related data may also be gathered.

Owner:HITCHNER JIM

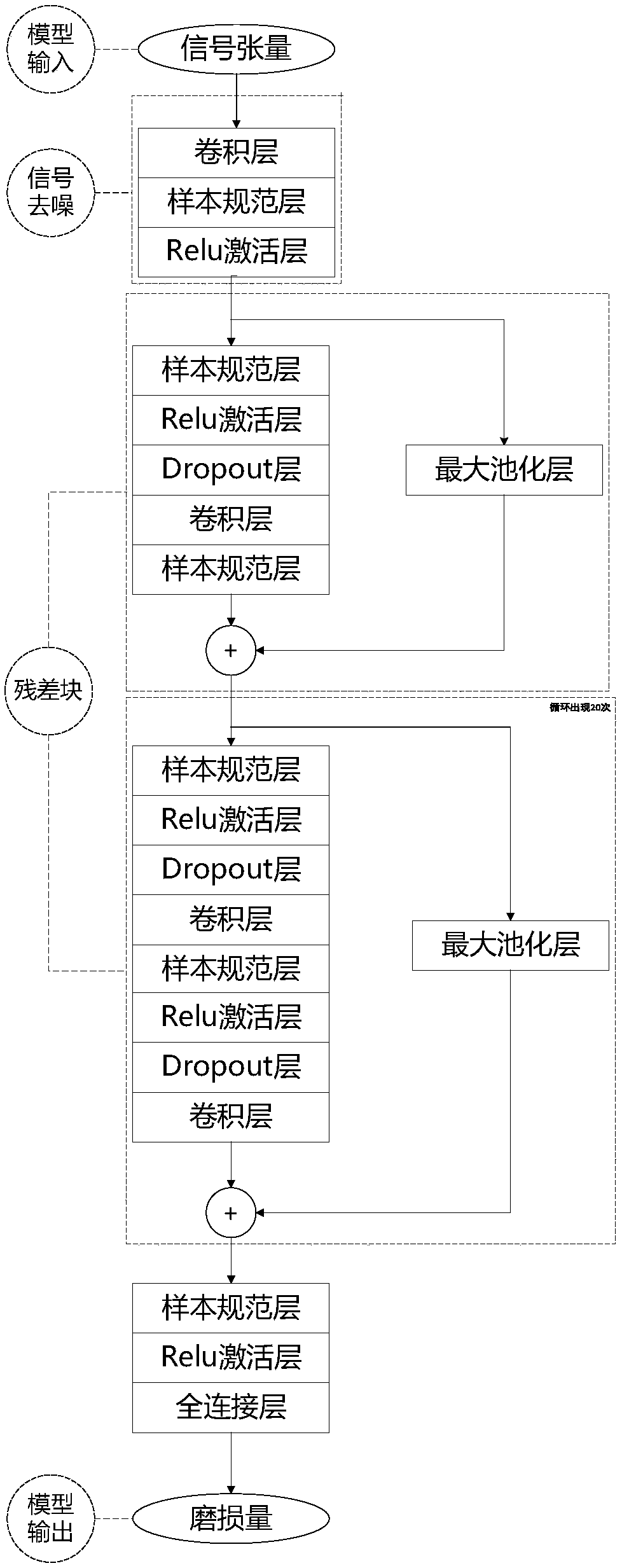

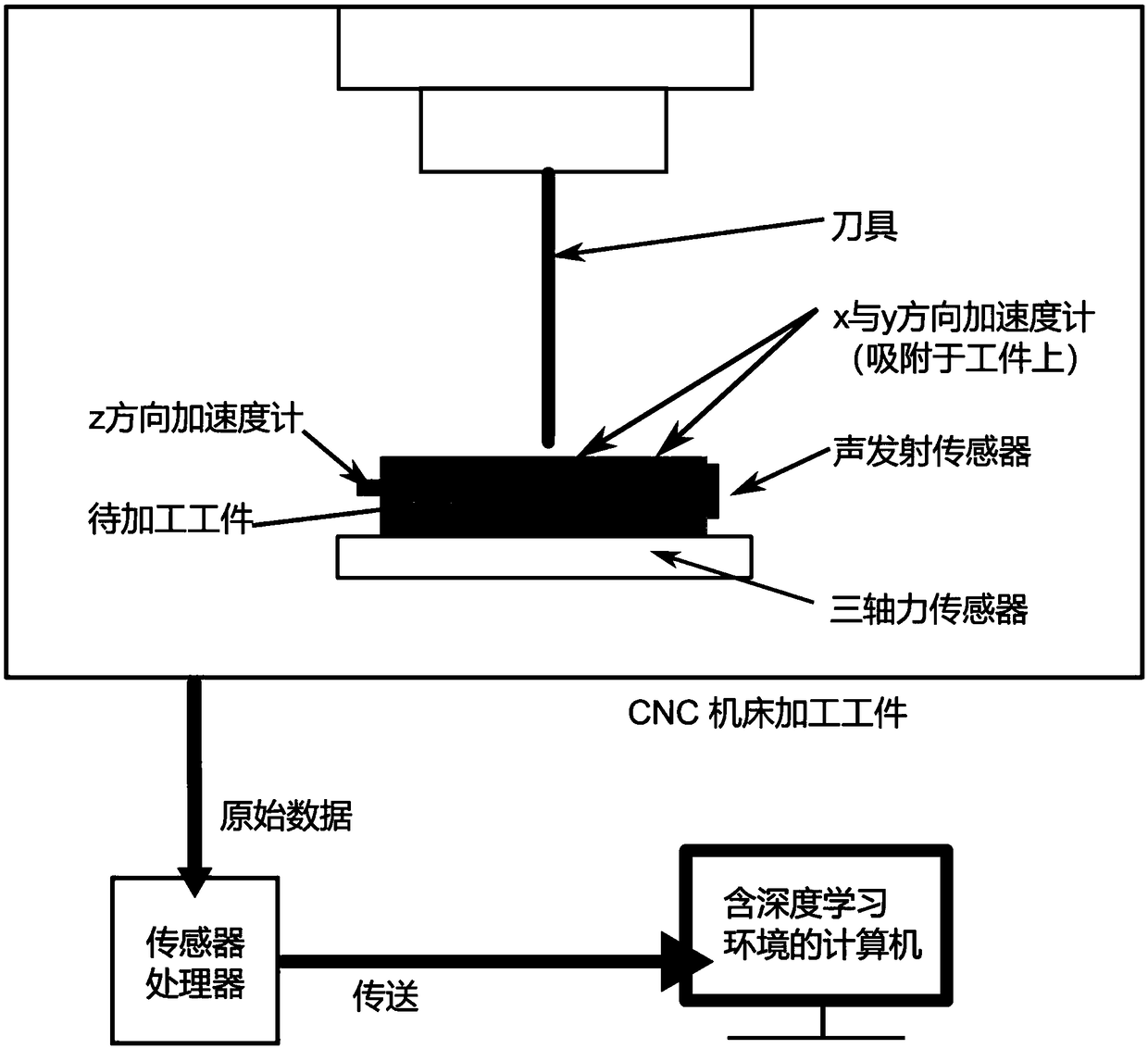

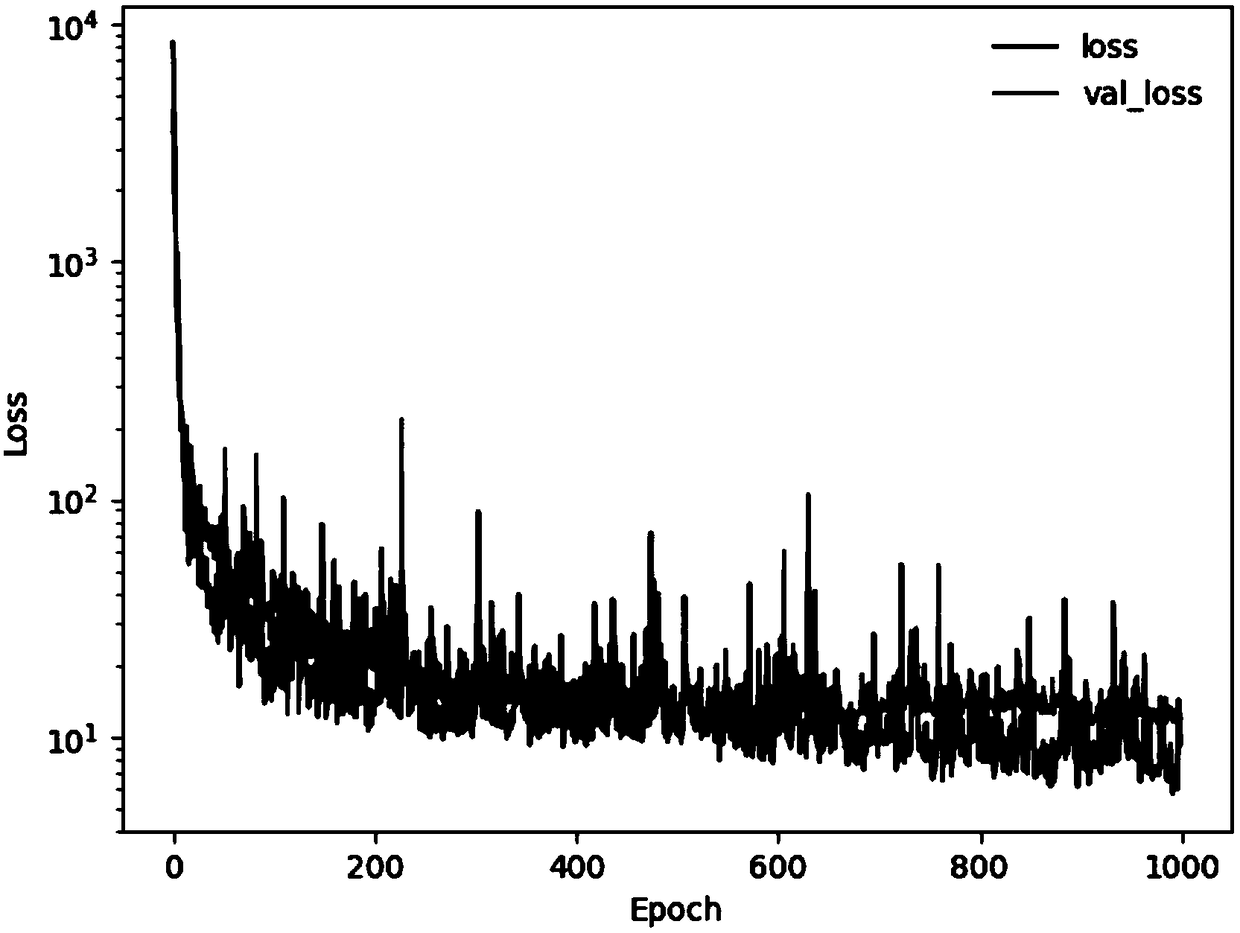

Modeling and monitoring method of cutter abrasion loss on basis of residual error convolutional neural network

ActiveCN108942409AThe result is accuratePromote migrationMeasurement/indication equipmentsRegistering/indicating during manufacturing processTime domainSupervised learning

The invention provides a modeling and monitoring method of cutter abrasion loss on the basis of a residual error convolutional neural network. A residual error convolutional network is used as a self-adaptive model, adjustment of parameters of the model is performed on this basis, and finally a model of the cutter abrasion loss is established. The model adopts time-domain signals of different sensors as input, the cutter abrasion loss is used as output, and meanwhile in consideration of uncertainty in a machining process, the signal features in the machining process are extracted through the convolutional neural network theory; then the signal features of the different dimensions are used as input of full-joint neural network, and the influence weight of the feature components on the cutter abrasion loss is obtained automatically through an adam algorithm; and finally a model from signals to the abrasion loss is established according to a supervised learning method, and the predictionof the cutter abrasion loss is achieved. The self-adaptive modeling method provided by the invention has the characteristics that the measurement process is simple and convenient, data processing is fast, and the results are accurate.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

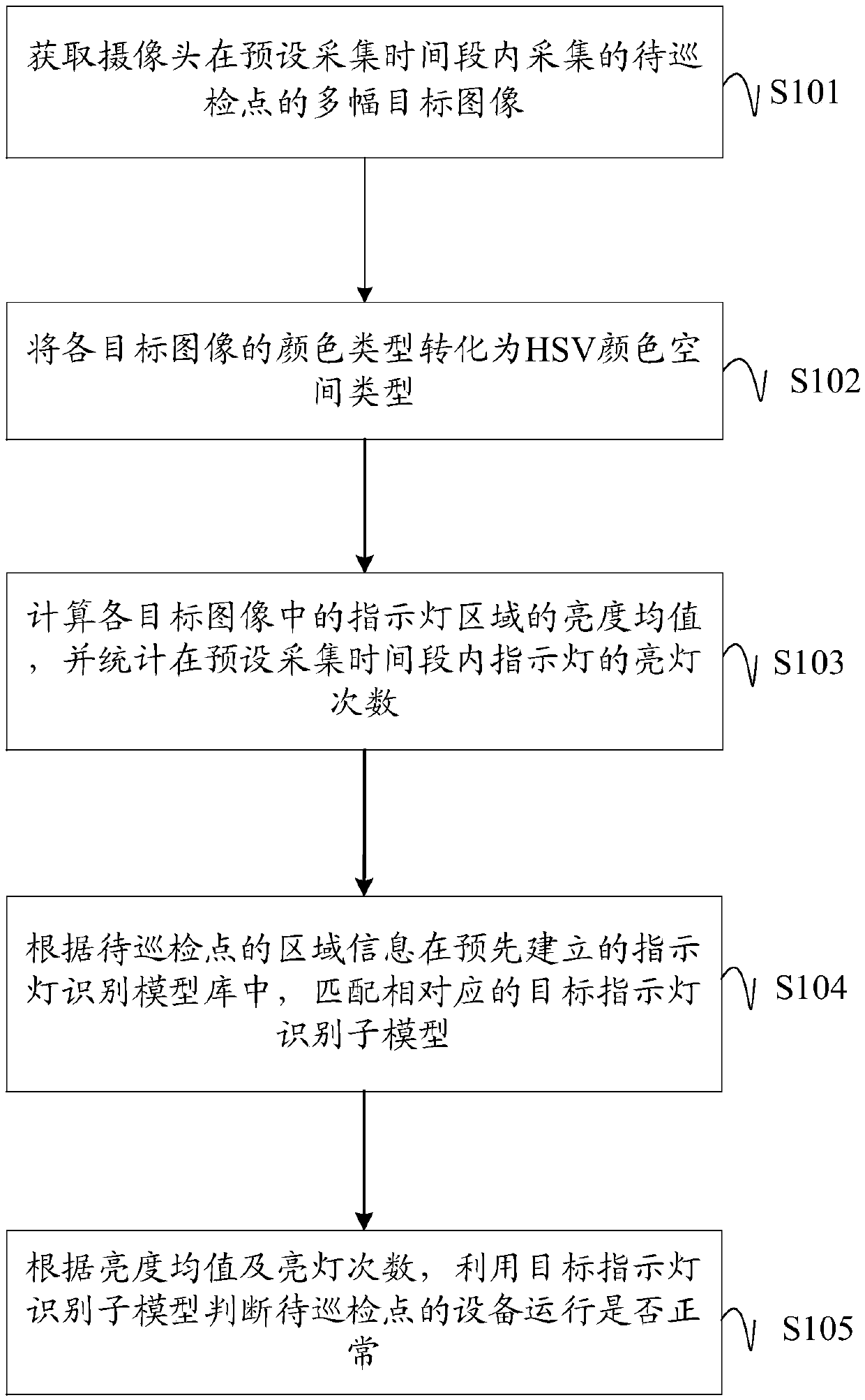

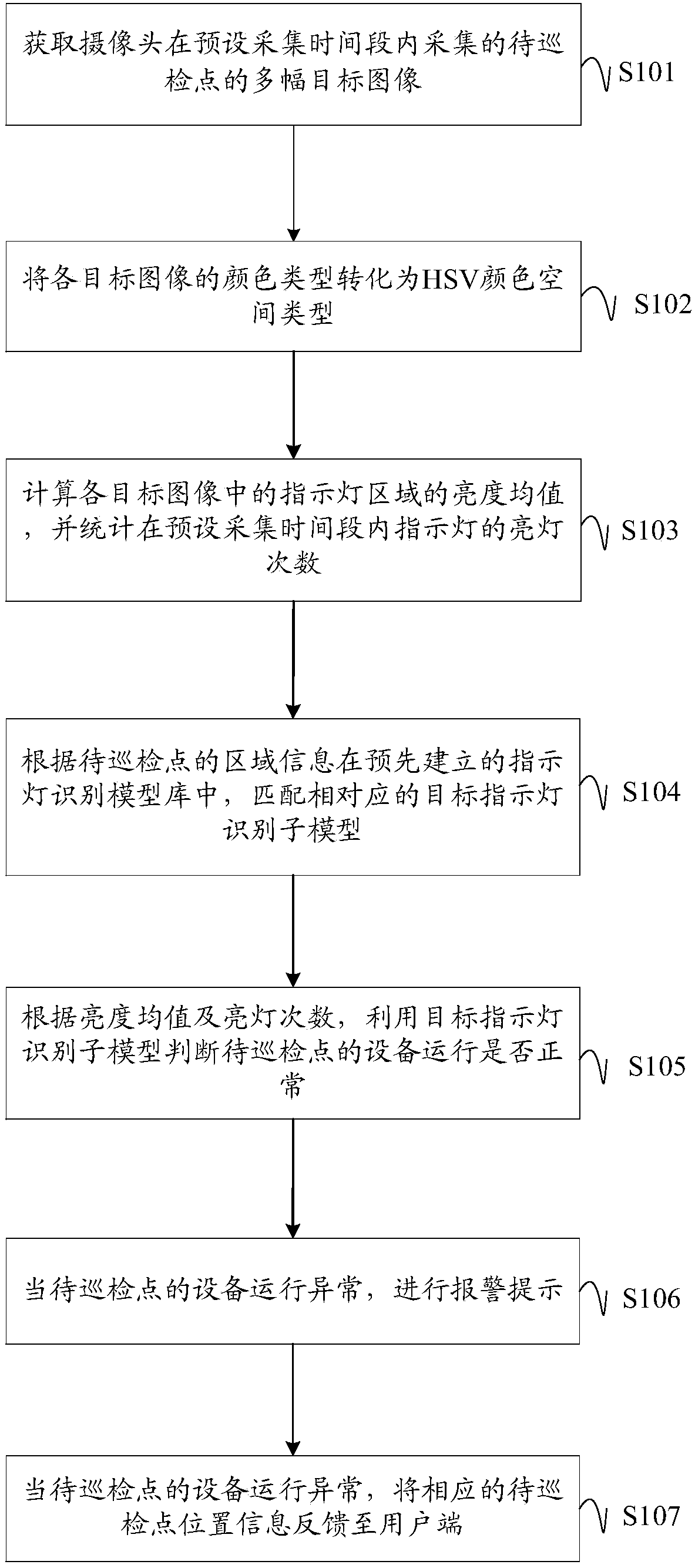

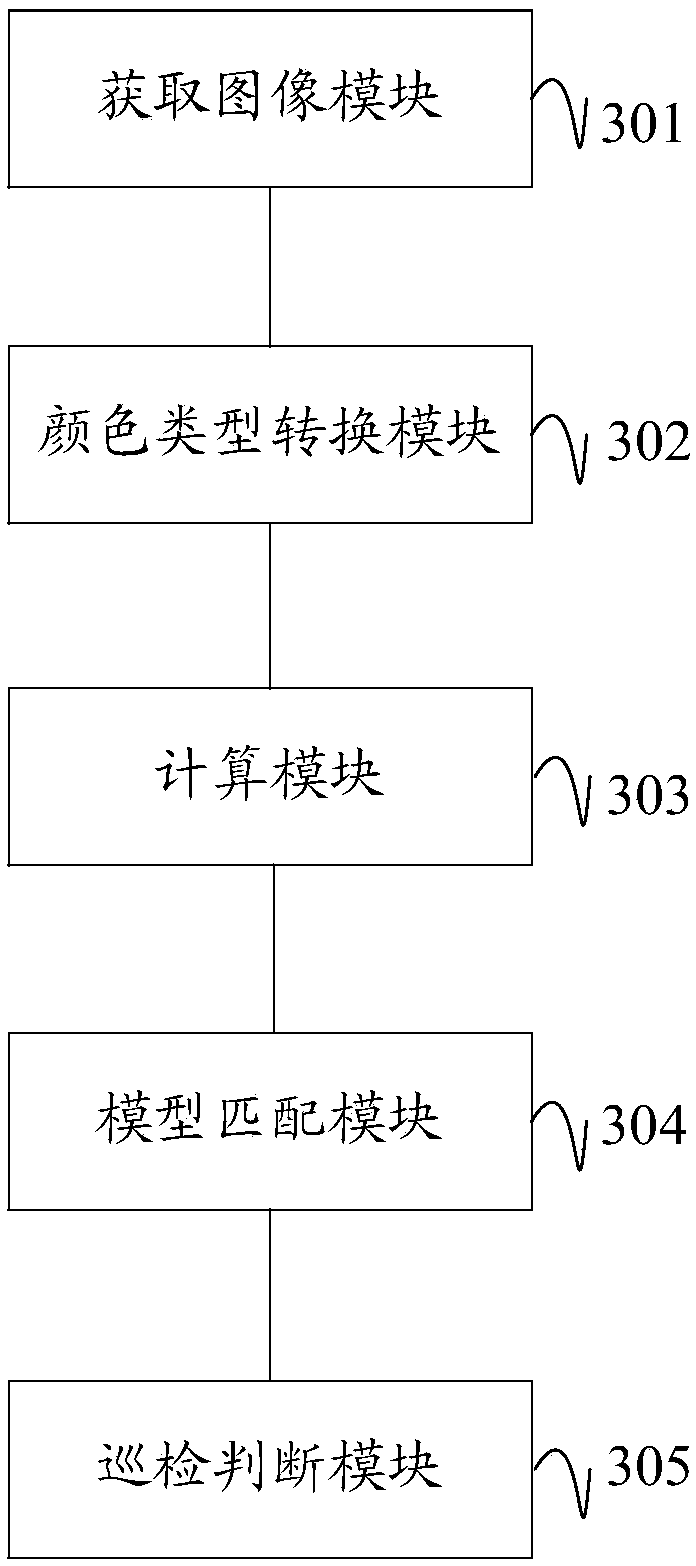

Device inspection method, device and system, computer readable storage medium and tour inspection robot

ActiveCN107832770AGuaranteed uptimeImprove stabilityCharacter and pattern recognitionRegistering/indicating during manufacturing processTime segmentAcquisition time

The embodiment of the invention discloses a device inspection method, device and system, a computer readable storage medium and an indoor hanging rail intelligent tour inspection robot. The method comprises the steps of acquiring a plurality of target images of a to-be-inspected point collected by a camera of the robot in a preset acquisition time period; converting the color types of the target images into HSV color space types; calculating the brightness mean value of indicator light areas in each target image, counting the lighting times of indicator lights in a preset acquisition time period, matching corresponding target indicator light identification sub-model in a pre-established indicator light identification model library according to the area information of the to-be-inspected point, and determining whether the equipment operation of the to-be-inspected point is normal or not by using the target indicator light identification sub-model according to the brightness mean value and the lighting frequency. According to the technical scheme, the equipment running condition of the current inspection point can be judged quickly and accurately, so that the equipment which is abnormal in operation can be fed back in time, and relatively high stability and accuracy are ensured.

Owner:ZHEJIANG GUOZI ROBOT TECH

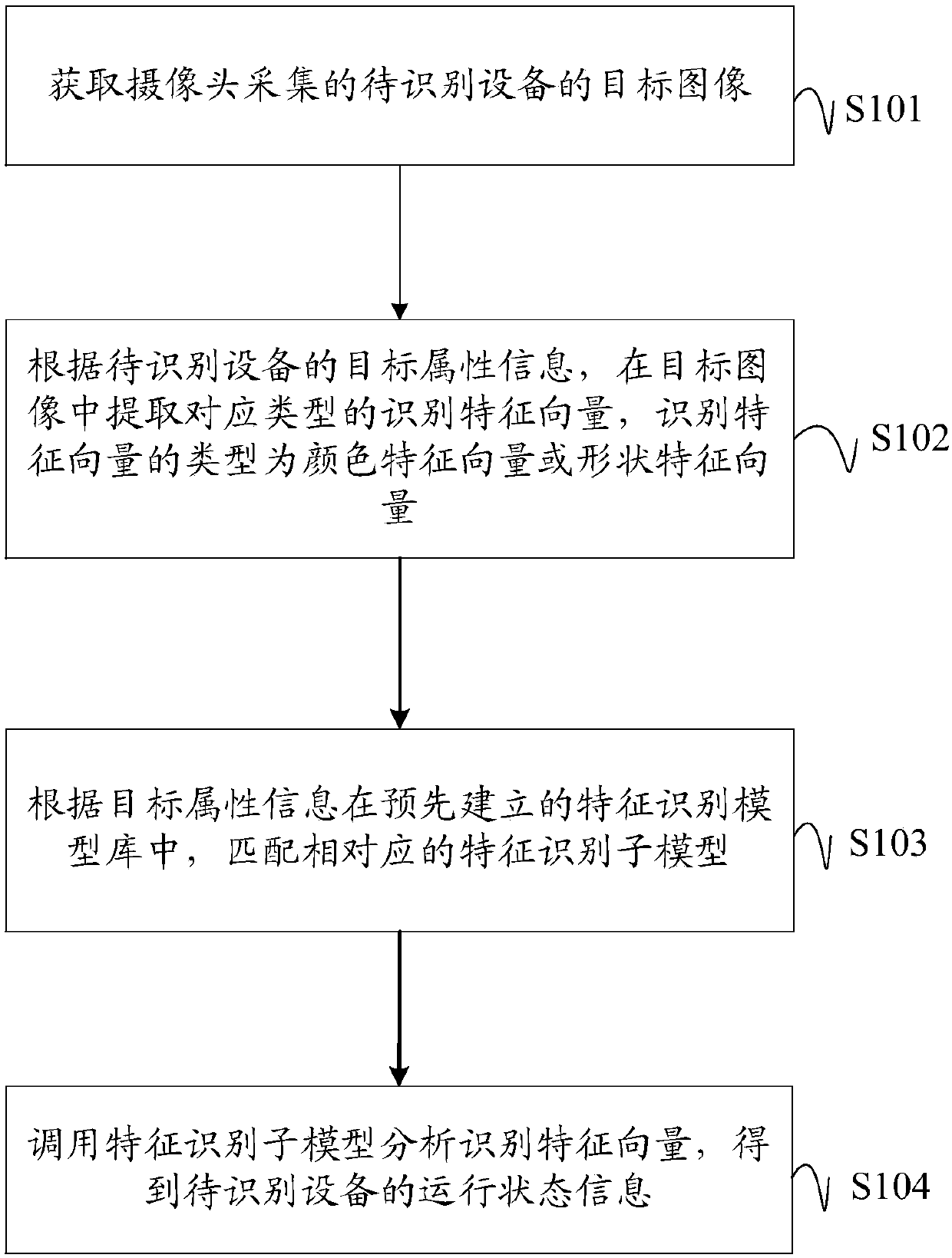

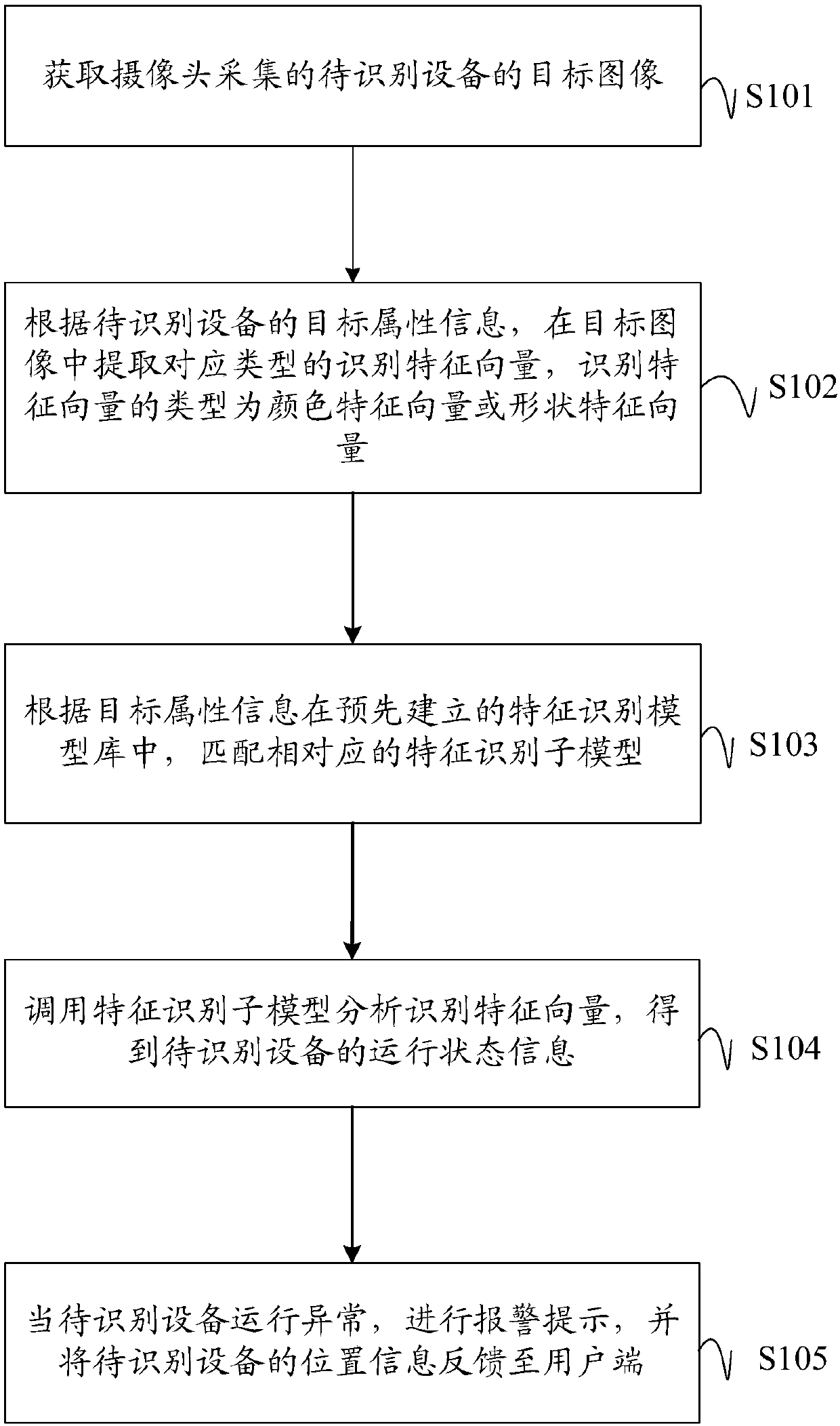

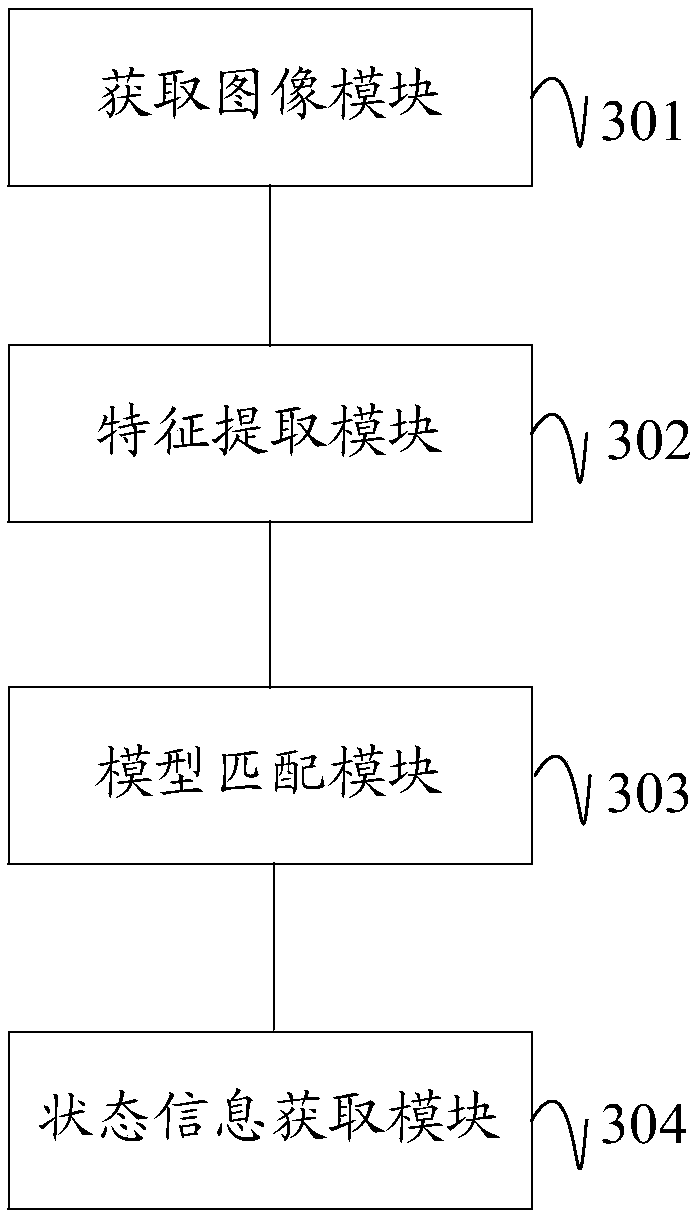

Equipment state information acquisition method, device, system and storage medium and robot

ActiveCN107784310AEasy accessAccurate acquisitionCharacter and pattern recognitionRegistering/indicating during manufacturing processFeature vectorFeature recognition

The embodiment of the invention discloses an equipment state information acquisition method, a device, a system and a storage medium and as well as an indoor rail-hung intelligent patrol robot. The method comprises the following steps: acquiring a target image of to-be-recognized equipment collected by a camera of the robot; extracting recognition characteristic vectors of corresponding types in the target image according to target attribute information of the to-be-recognized equipment; matching corresponding characteristic recognition sub modules in a pre-established characteristic recognition model library according to the target attribute information; and invoking the characteristic recognition sub modules to analyze extracted recognition characteristic vector to obtain operating stateinformation of the to-be-recognized equipment. According to the technical scheme provided by the invention, the operating state information of current equipment can be acquired, so that equipment which operates abnormally is fed back immediately; the system solves the problems that the manual patrol efficiency is low and the oversight is likely to happen effectively and has relatively high stability and accuracy.

Owner:ZHEJIANG GUOZI ROBOT TECH

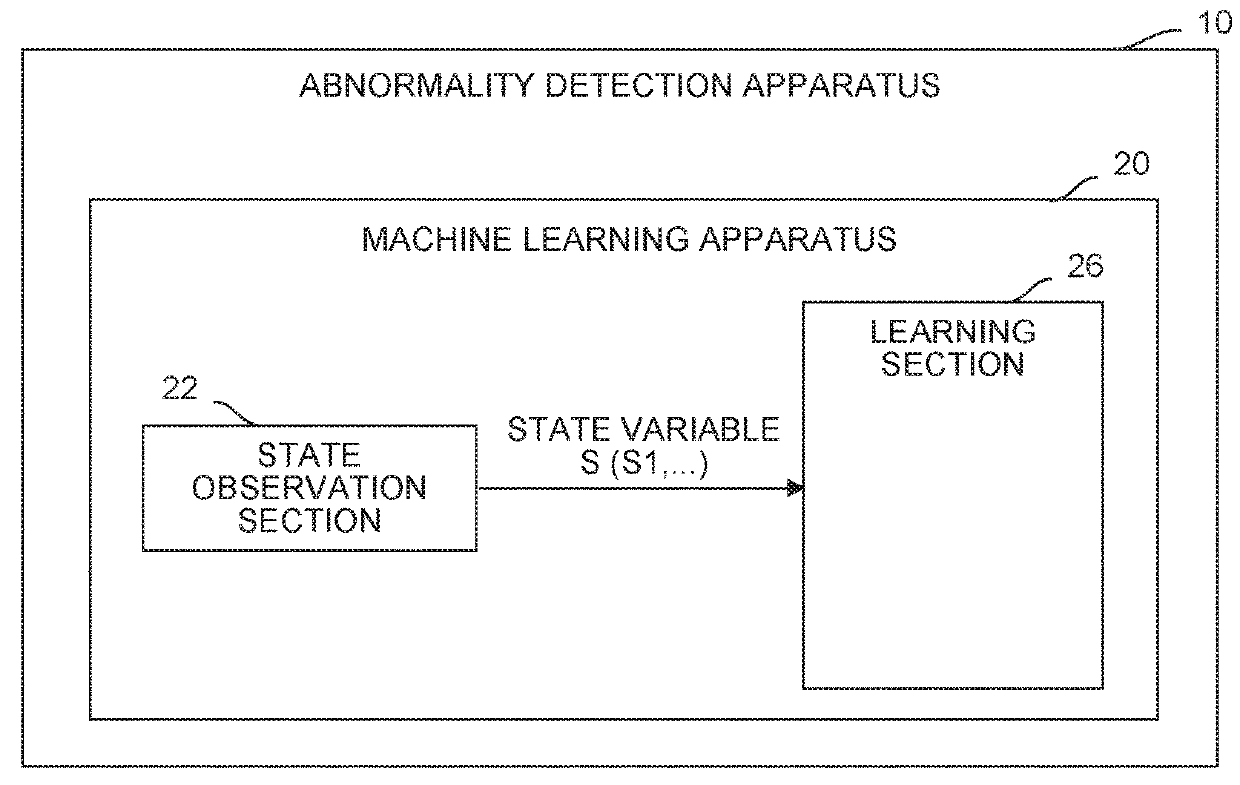

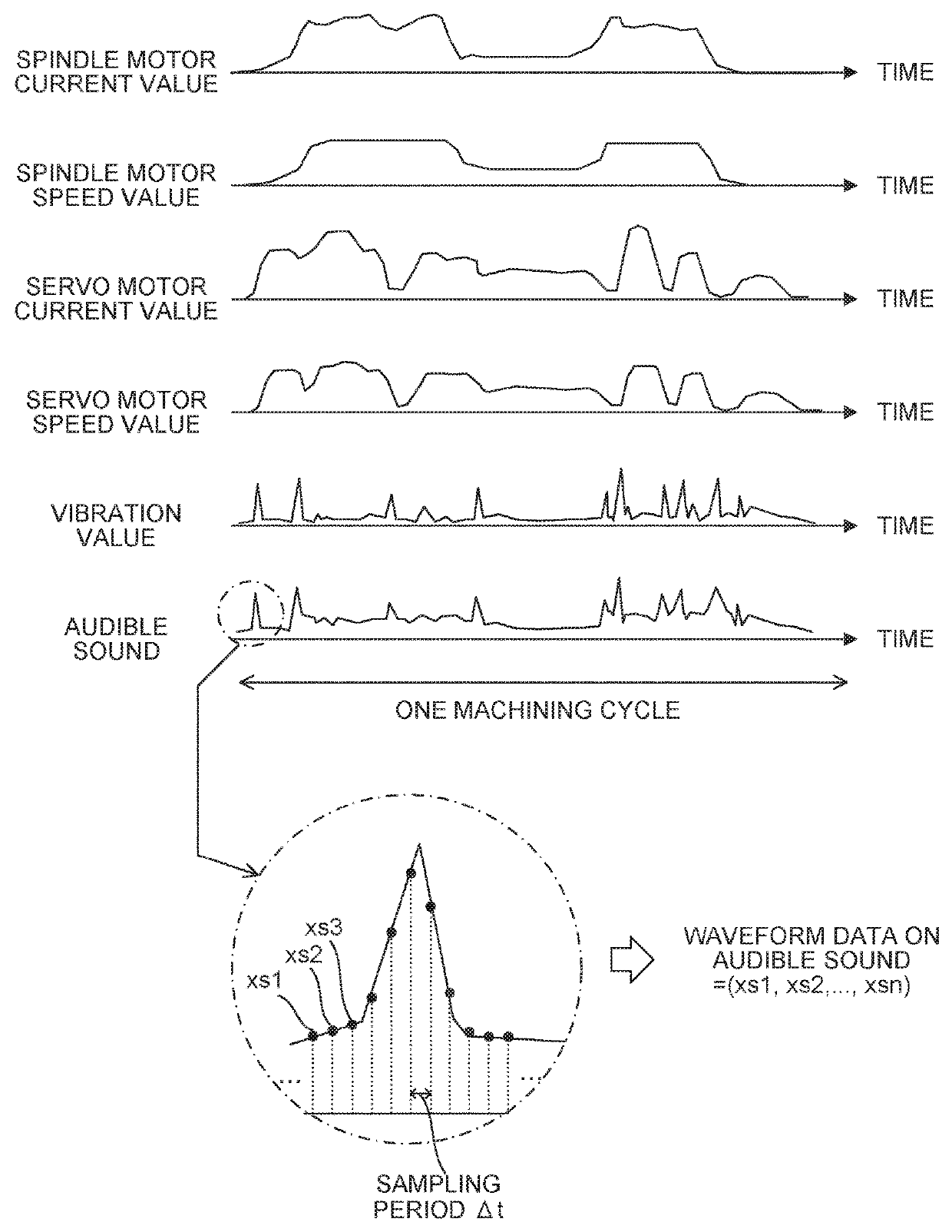

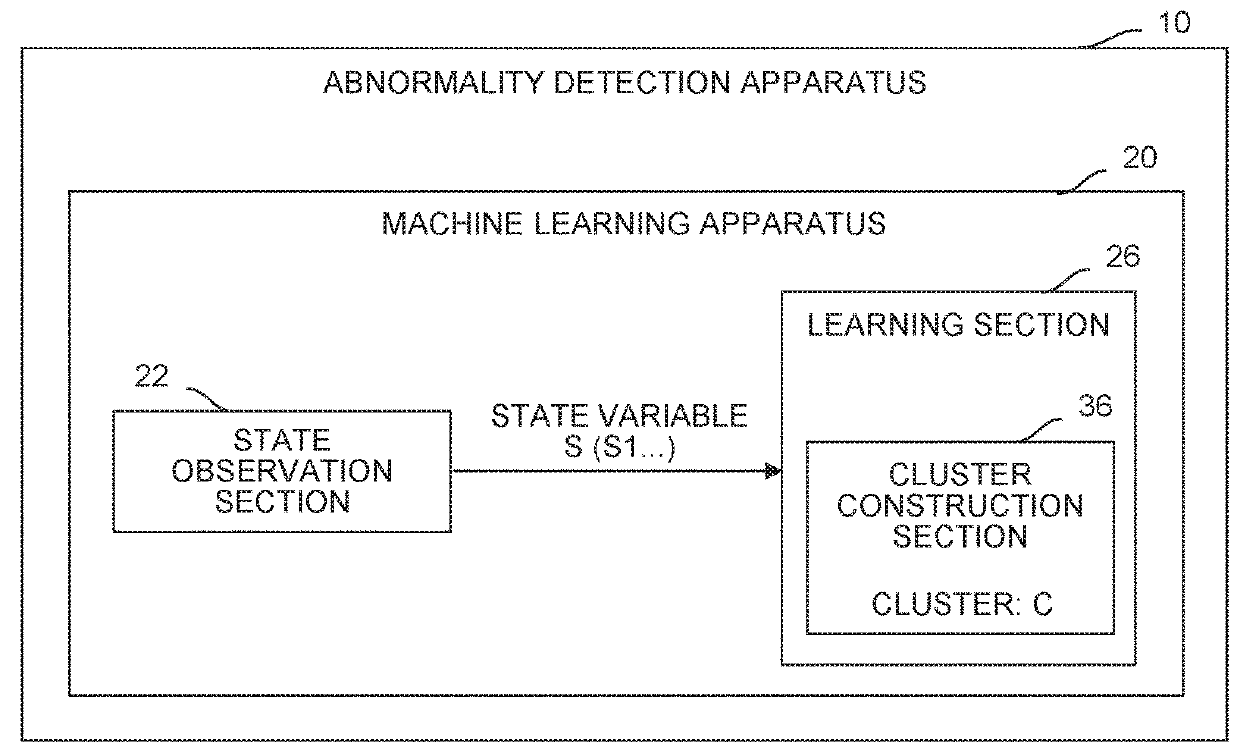

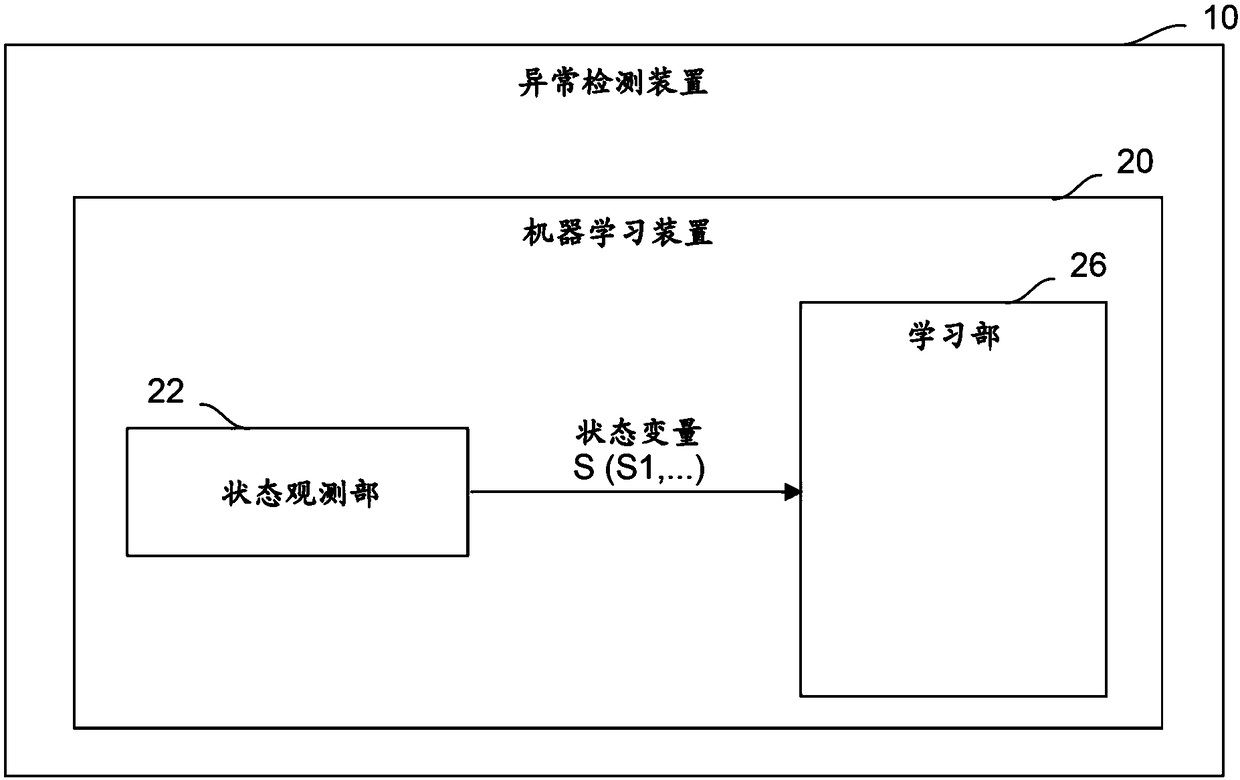

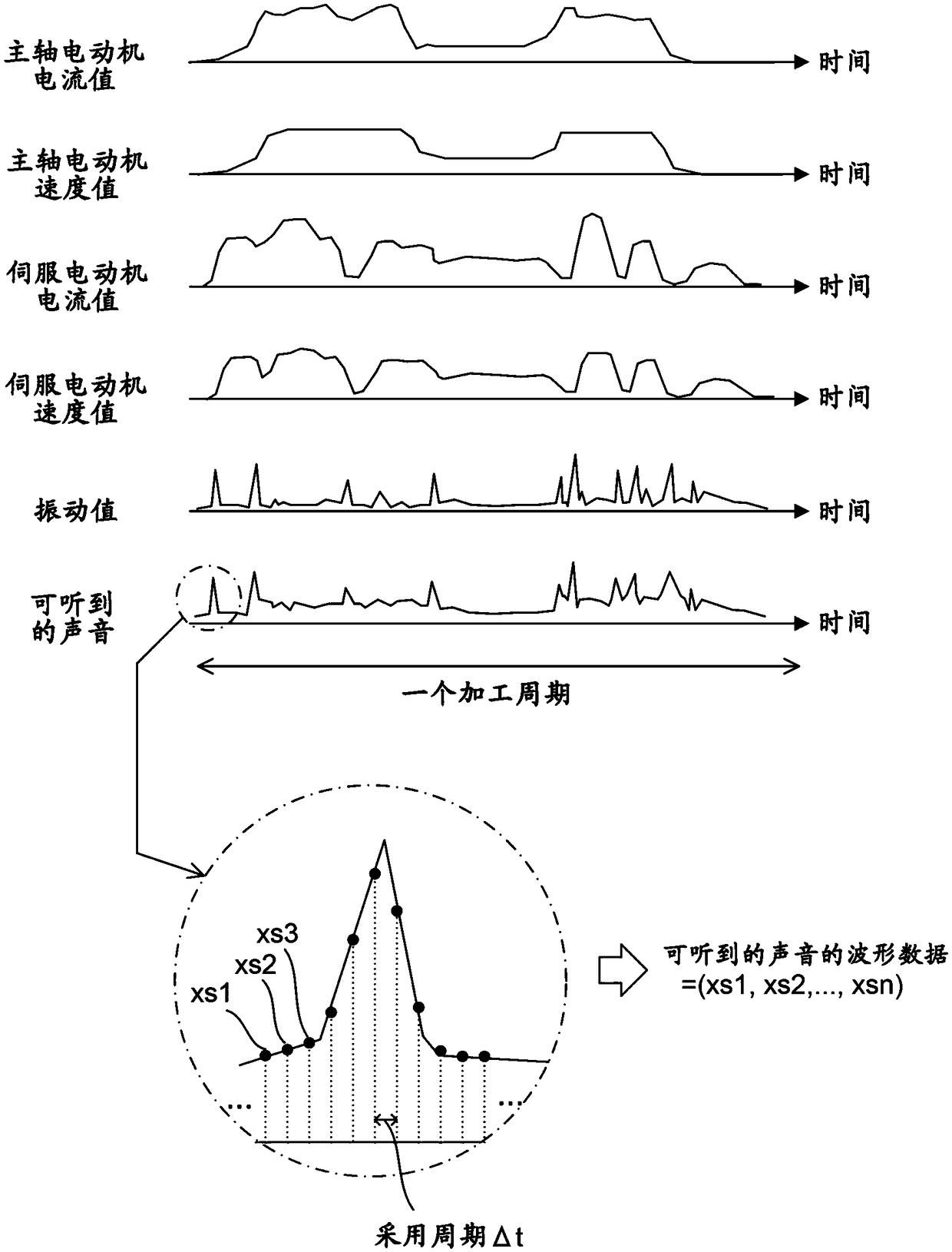

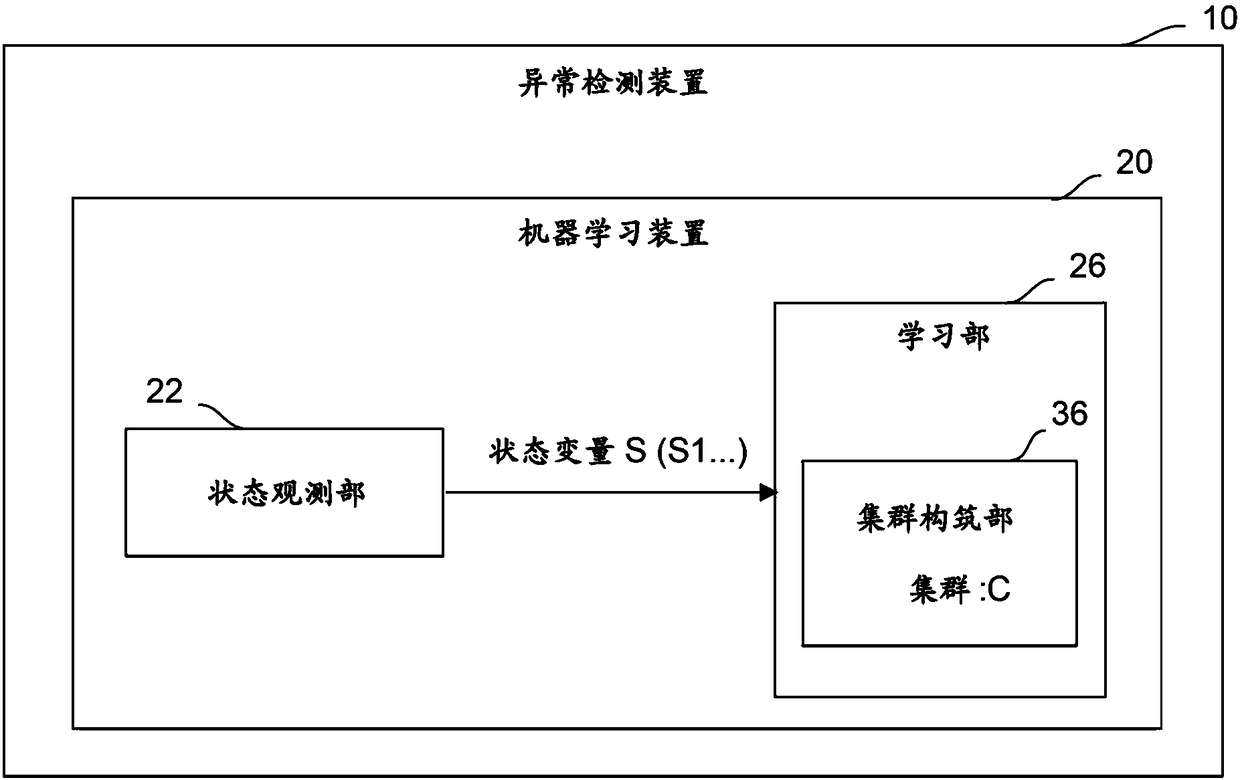

Abnormality detection apparatus and machine learning apparatus

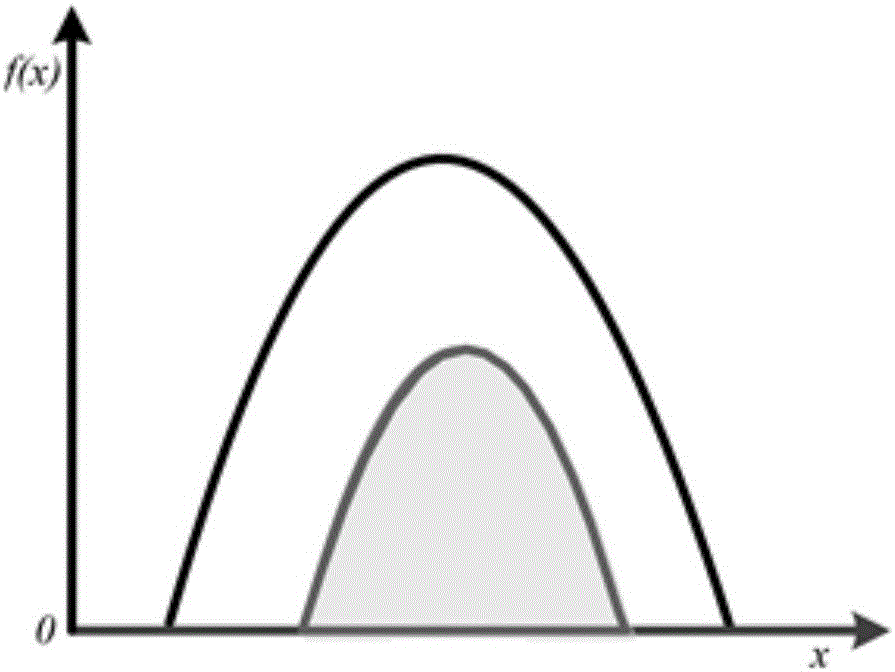

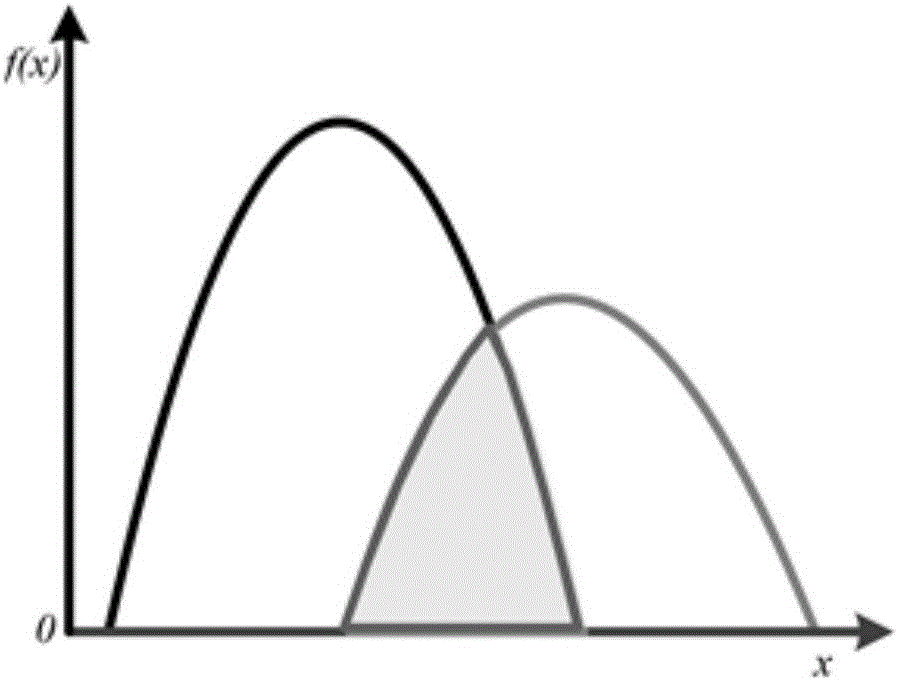

InactiveUS20180264613A1Abnormal stateProgramme controlMeasurement devicesState variableAnomaly detection

An abnormality detection apparatus includes a machine learning apparatus for learning waveform data concerning a physical quantity detected when a machine tool is normally operating. The machine learning apparatus observes the waveform data concerning the physical quantity detected when the machine tool is normally operating, as a state variable indicating a current environmental state, and learns a feature of the waveform data concerning the physical quantity detected when the machine tool is normally operating, using the observed state variable.

Owner:FANUC LTD

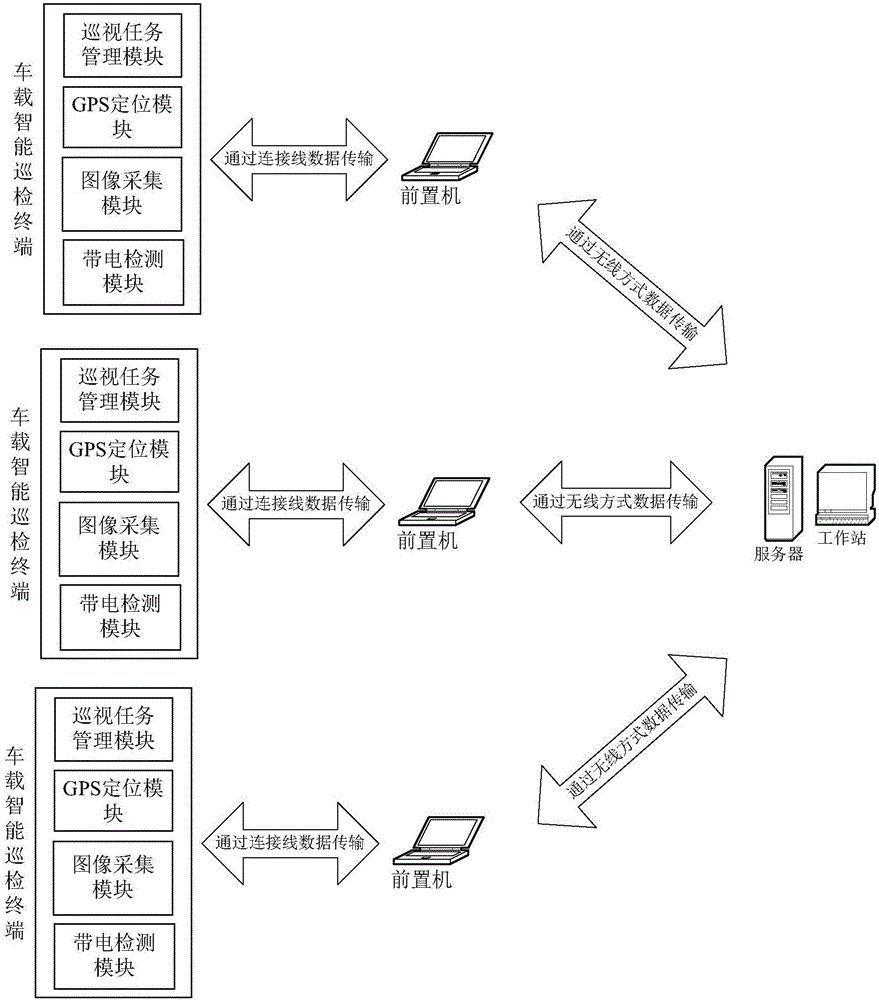

Smart inspection system for distributing line based on vehicle-mounted mobile terminal and inspection method

InactiveCN106296864AImprove inspection efficiencyImprove power supply reliabilityData processing applicationsRegistering/indicating during manufacturing processInformatizationMaster station

The invention discloses a smart inspection system for a distributing line based on a vehicle-mounted mobile terminal and an inspection method. The system comprises a vehicle-mounted smart inspection terminal, wherein the vehicle-mounted smart inspection terminal is arranged on the top of a vehicle and mutually communicates with a master station server; the vehicle-mounted smart inspection terminal is configured to generate inspection result data according to received data and uploads the inspection result data to the master station server; the master station server is configured to receive and store the inspection result data uploaded by the vehicle-mounted smart inspection terminal, and analyzes and early warns distributing line faults according to the received data. According to the smart inspection system and the inspection method disclosed by the invention, intelligentization and informatization of distributing line inspection are realized by adopting a smart control and information communication technology, the working efficiency of inspection of the distributing line can be effectively improved, labor force is saved, inspection times are increased, potential hazards of equipment are found in time, and the reliability of power supply is improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

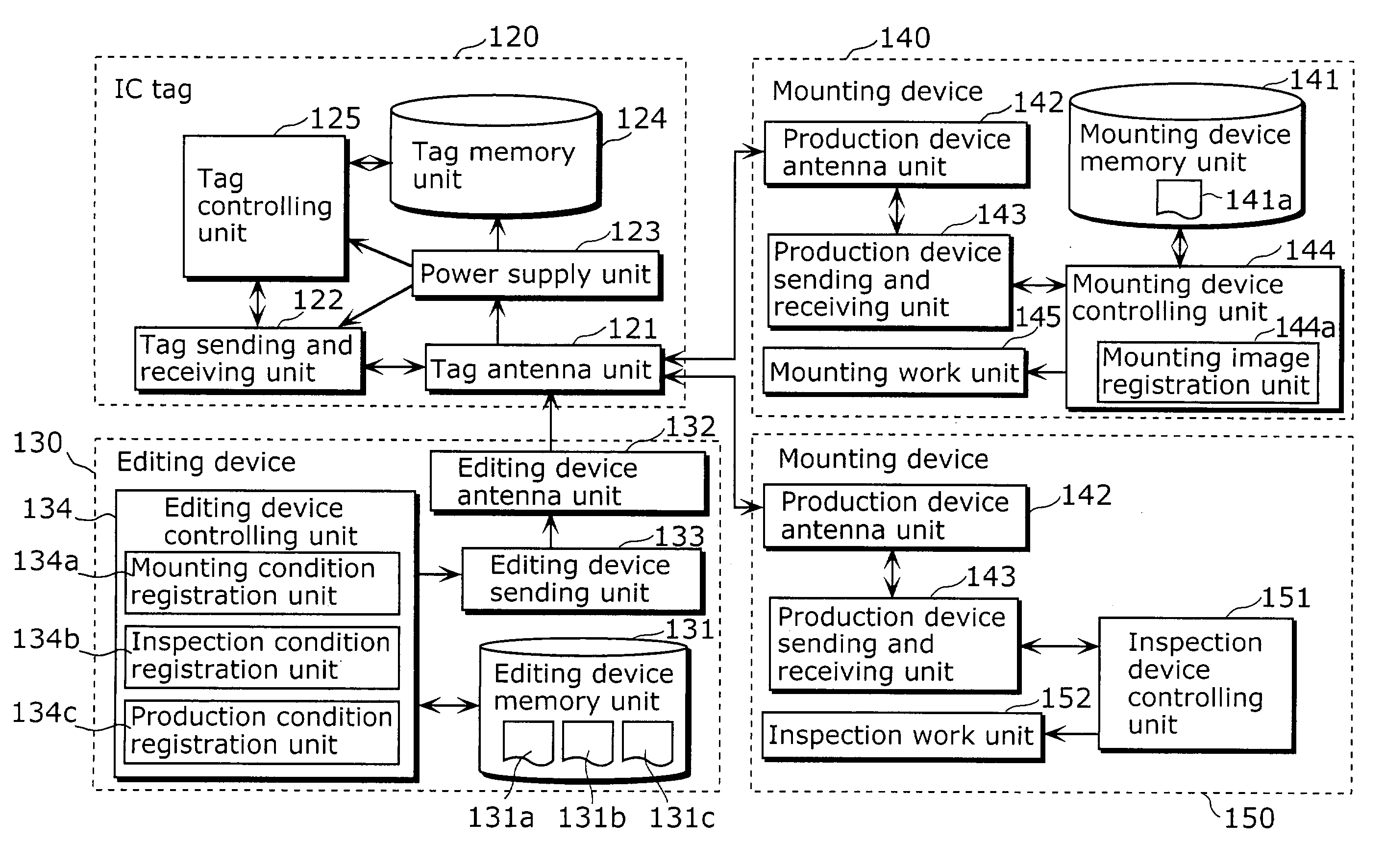

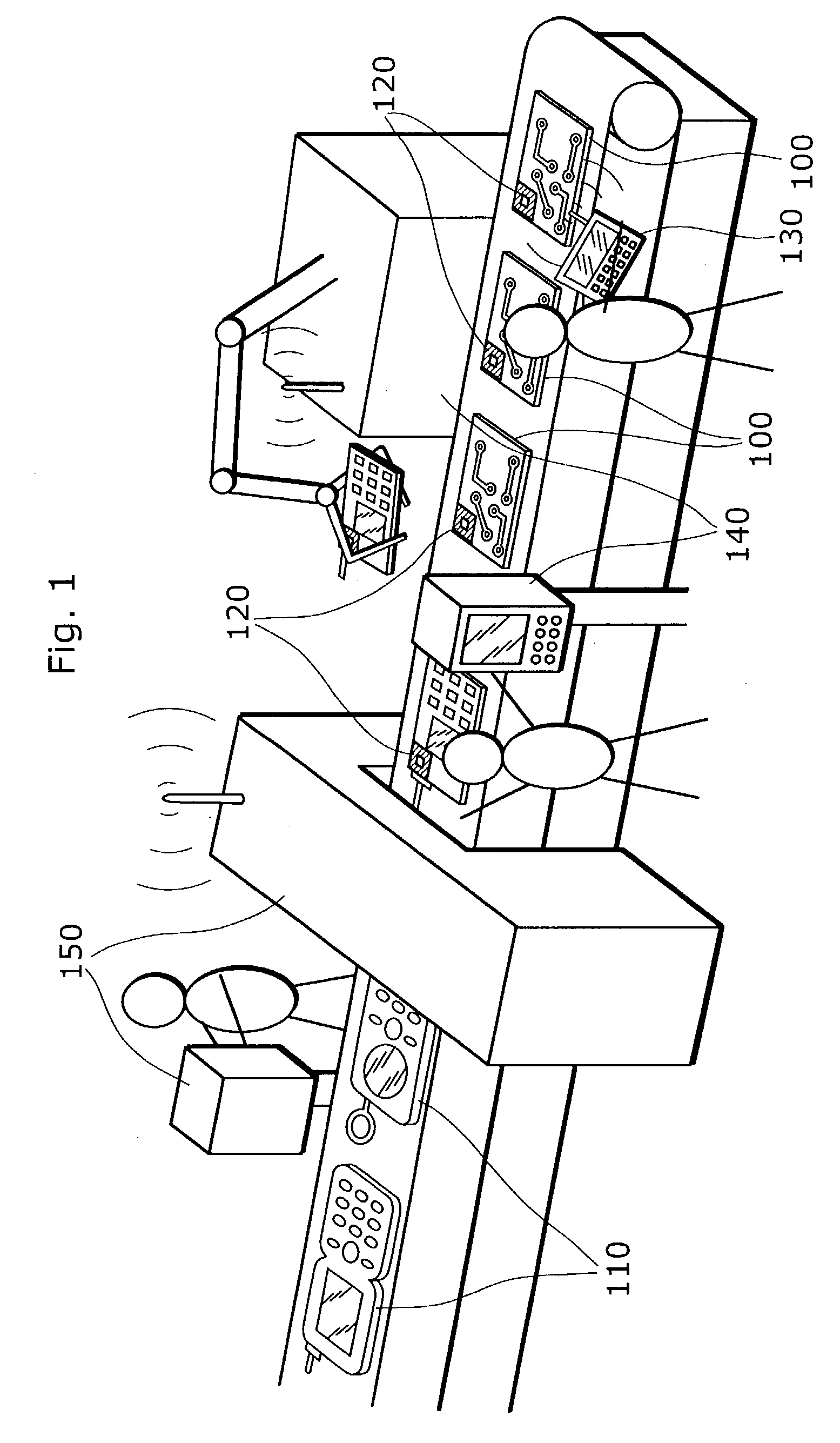

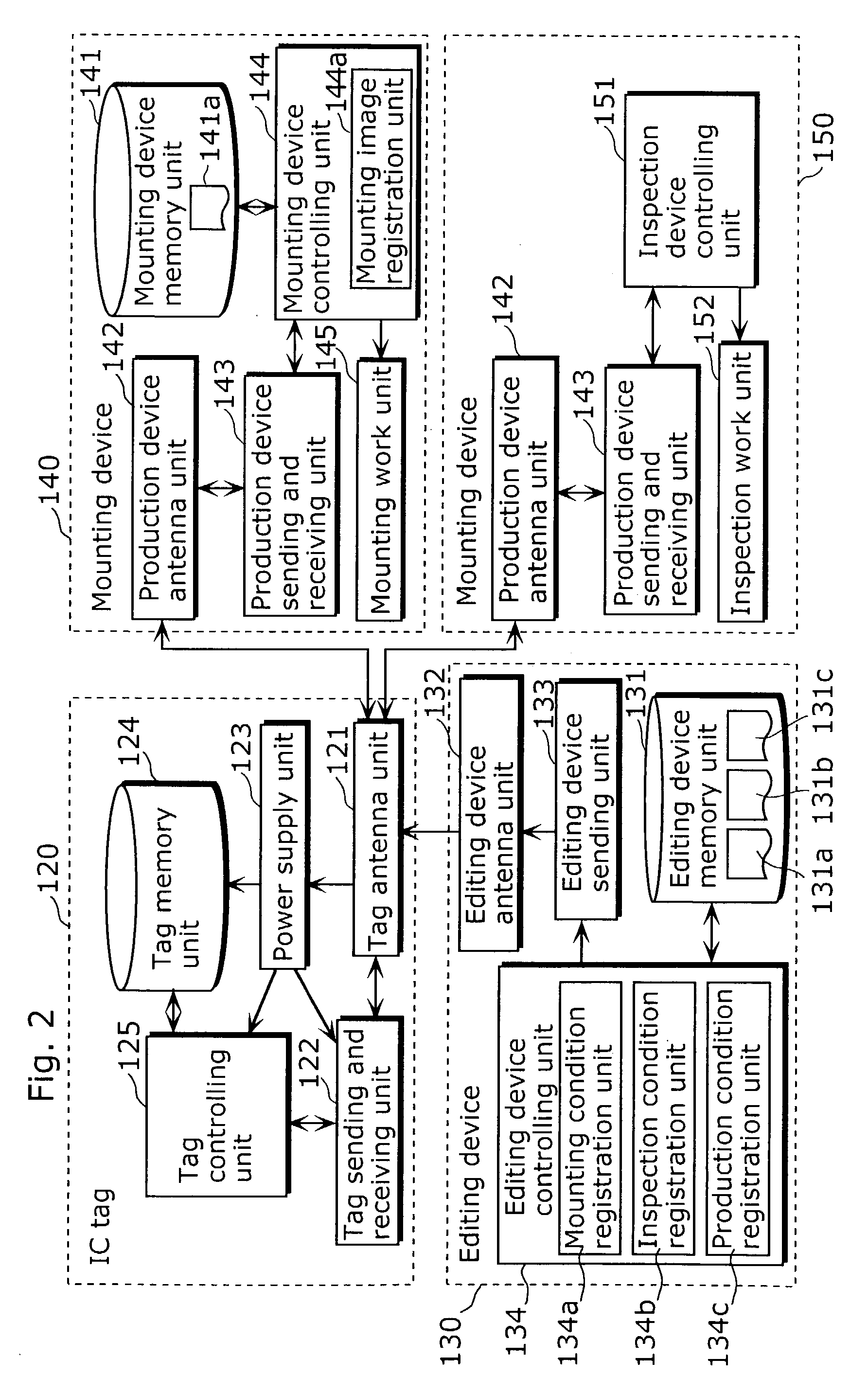

Production system and production method

InactiveUS20040162628A1Easy to producePrecision productionOther printing matterDigital data processing detailsWork in processMethods of production

Comprising: an IC tag 120 that is attached to a work in process 100 of a portable telephone 110 and memorizes information related to a production condition of the portable telephone 110; a mounting device 140 that reads out the information related to the production condition of the portable telephone 110 from the IC tag 120 and mounts components of the portable telephone 110, based on the readout information related to the production condition of the portable telephone 110, on the work in process 100 with the IC tag 120 attached; an inspection device 150 that reads out the information related to the production condition of the portable telephone 110 from the IC tag 120, and inspects the work in process 100, which the IC tag 120 is attached and the components of the portable telephone 110 are mounted, based on the readout information related to the production condition of the portable telephone 110; and an editing device 130 that writes the information related to production of the portable telephone 110 into the IC tag 120.

Owner:SHIGEMATSU +2

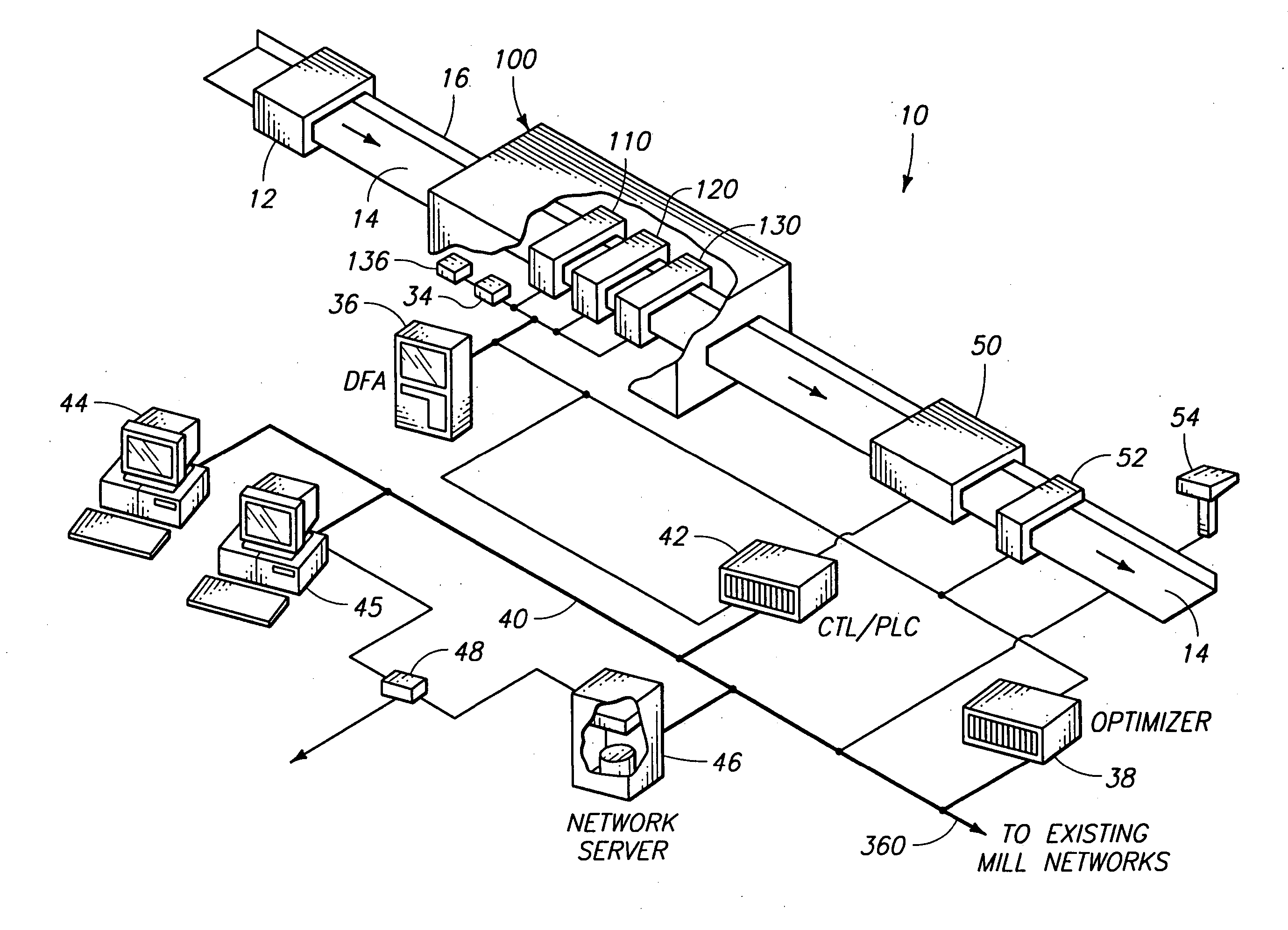

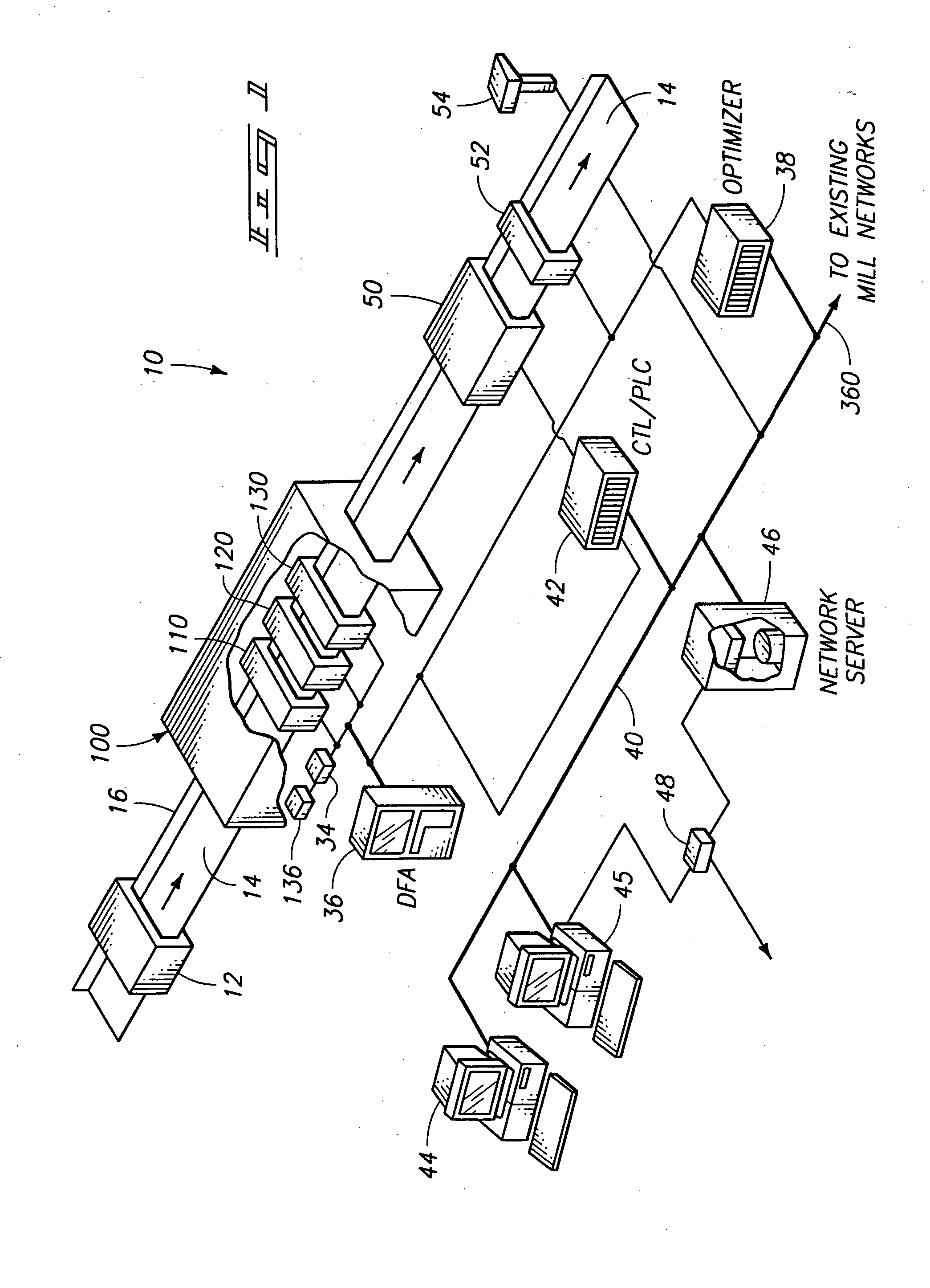

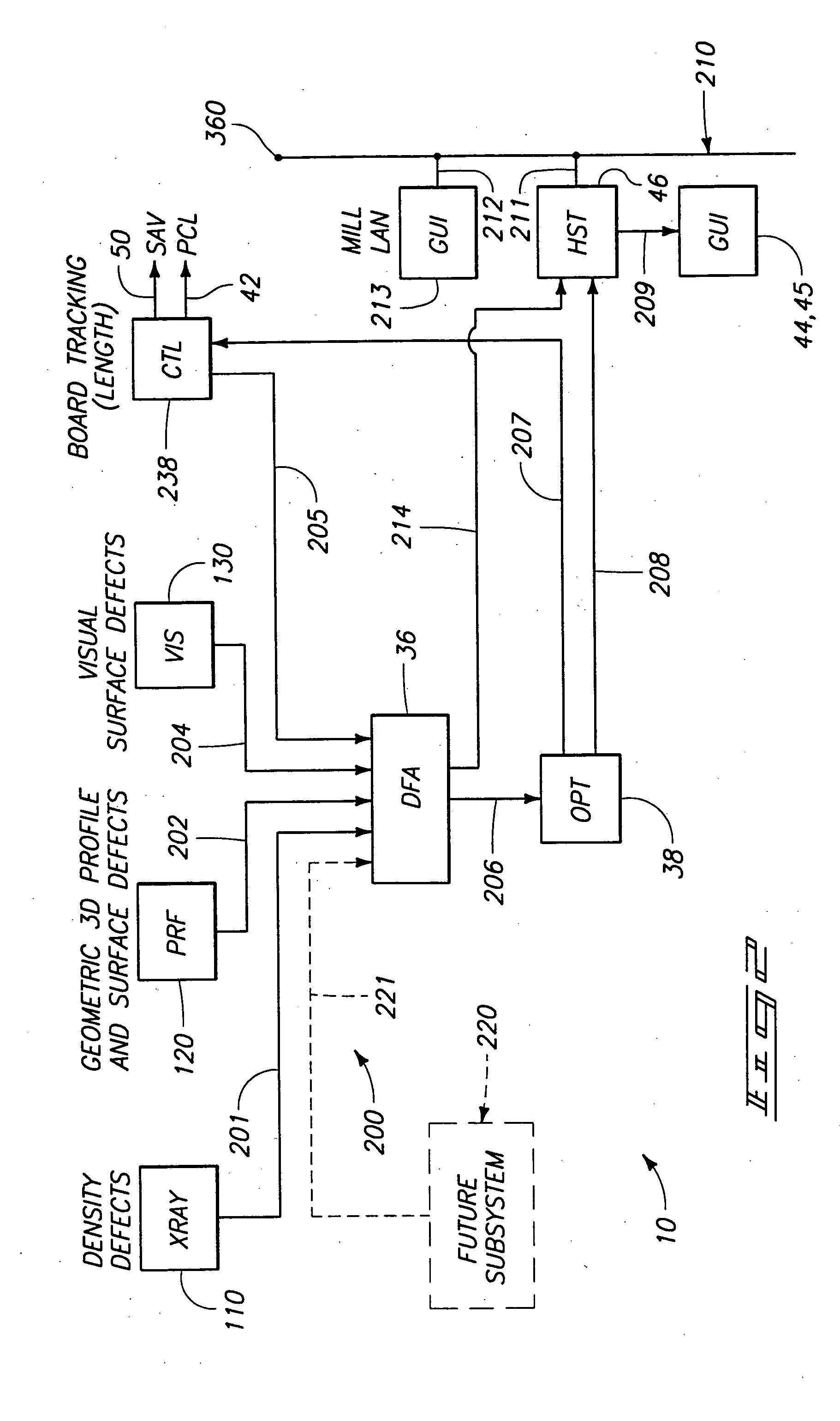

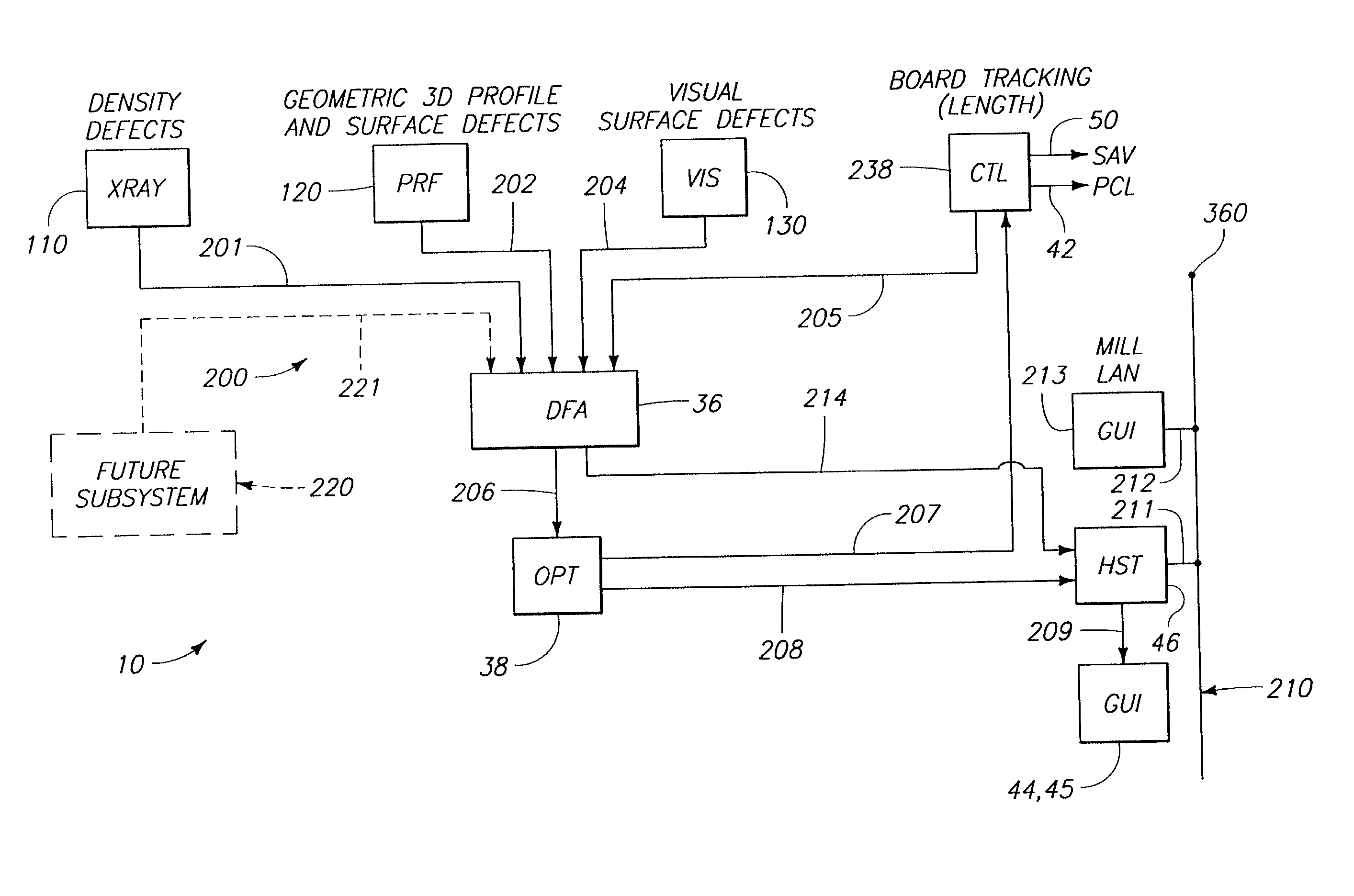

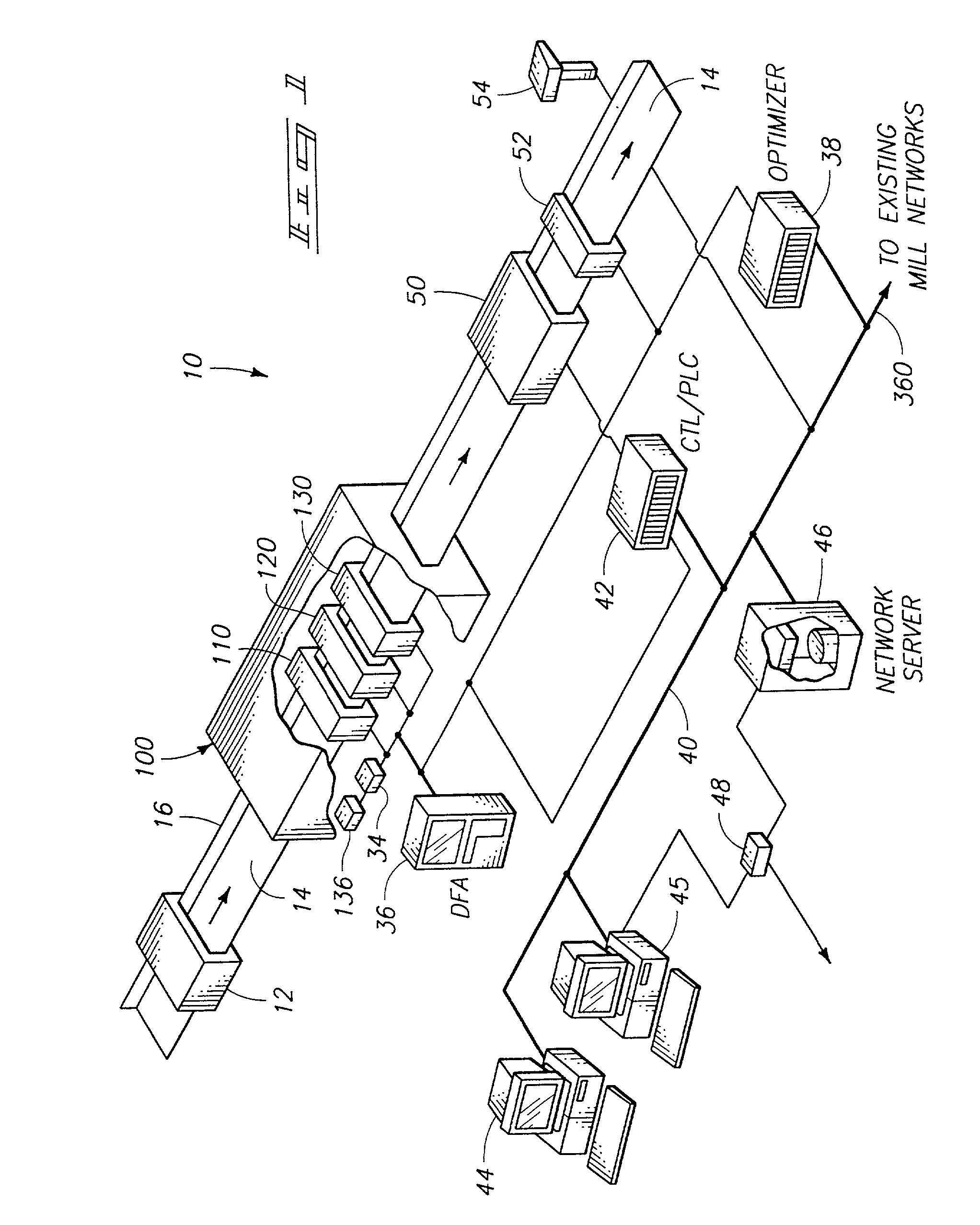

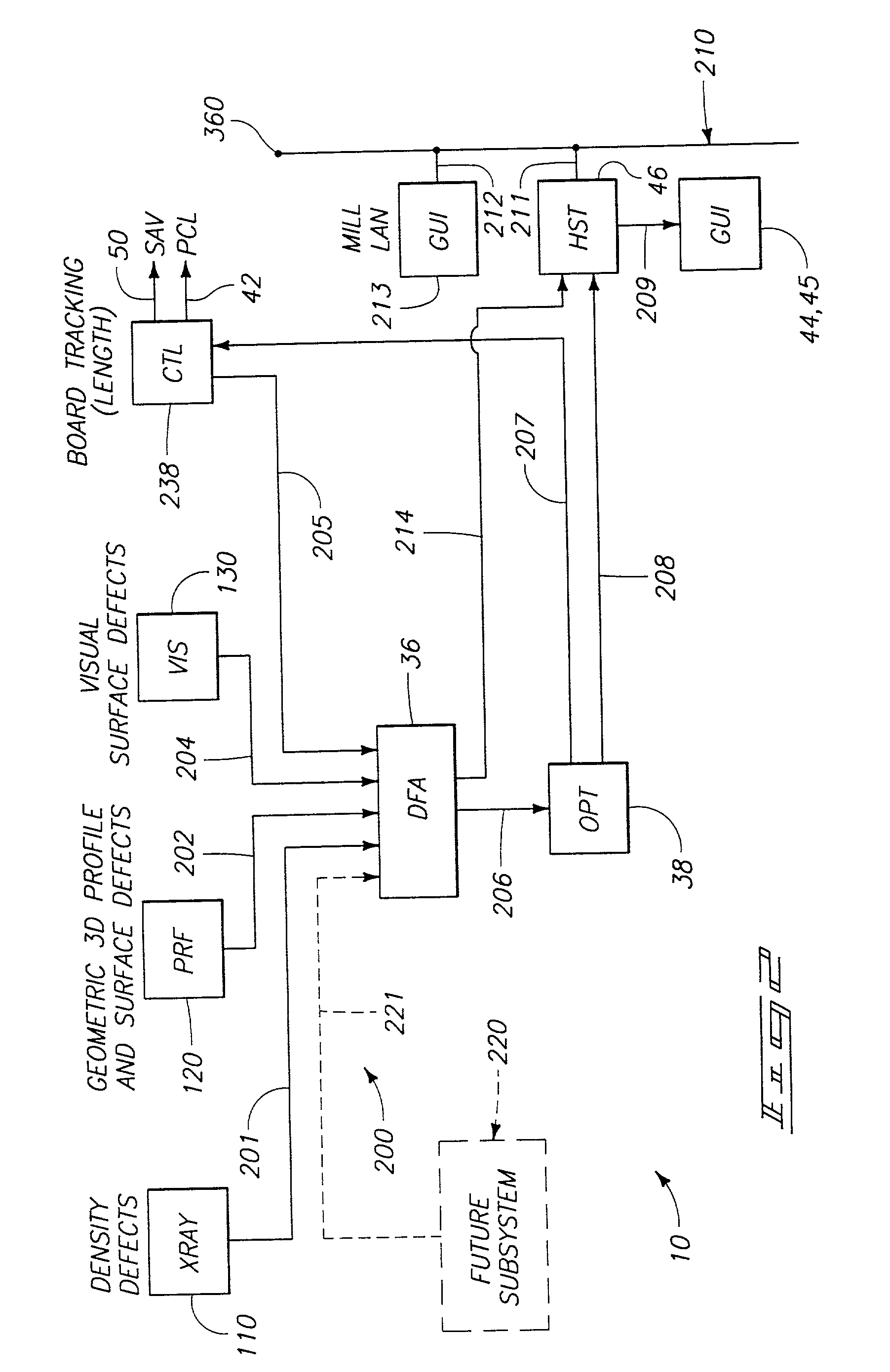

Method and apparatus for improved inspection classification of attributes of a workpiece

InactiveUS20050021280A1Linear/angular speed measurementFluid speed measurementKinematicsAngular velocity

An apparatus for detecting the probable existence, location, and type of defects in a workpiece is described. The apparatus includes a sensor subsystem, an optimizer, a control subsystem, and a computer system having a processor and computer readable memory. Sensor subsystem senses a first section of the workpiece and produces signals corresponding to a physical characteristic of the workpiece. The computer system is configured to generate a workpiece model based on the signals produced by the sensor subsystem. In an alternate embodiment, a defect assembler can be provided to merge signals from a plurality of sensor subsystems. The defect assembler can also be configured to generate the workpiece data model. The optimizer is configured to generate workpiece segmentation recommendations based on the workpiece data model. The processor is configured with a first producer thread program which, in response to the receipt of a first set of signals by the computer system, receives a data subscription request from a subsystem which uses data and transmits the signals from the computer readable memory to the generator of the data subscription request. The processor is further configured to generate a second producer thread in response to storage of a second set of signals in the computer readable memory. The second producer thread is configured to receive one of the data subscription requests and selectively send the second set of signals to the generator of the data subscription request. A tracking device for tracking selective kinematics of a workpiece moving through a plant is also disclosed. The tracking device includes an encoder wheel configured to tangentially contact a workpiece and rotate at an angular velocity coincident with the linear velocity of the workpiece. The tracking apparatus further includes a drive mechanism for driving the encoder wheel at a first angular velocity approaching the angular velocity of the encoder wheel which is coincident with the linear velocity of the workpiece. The tracking device also includes a signal generator configured to interact with the encoder wheel and generate a signal in response to the angular velocity of the encoder wheel. The tracking apparatus can be incorporated into the apparatus for detecting defects within a workpiece by providing the signal from the signal generator to the control subsystem.

Owner:USNRKOCKUMS CANCAR

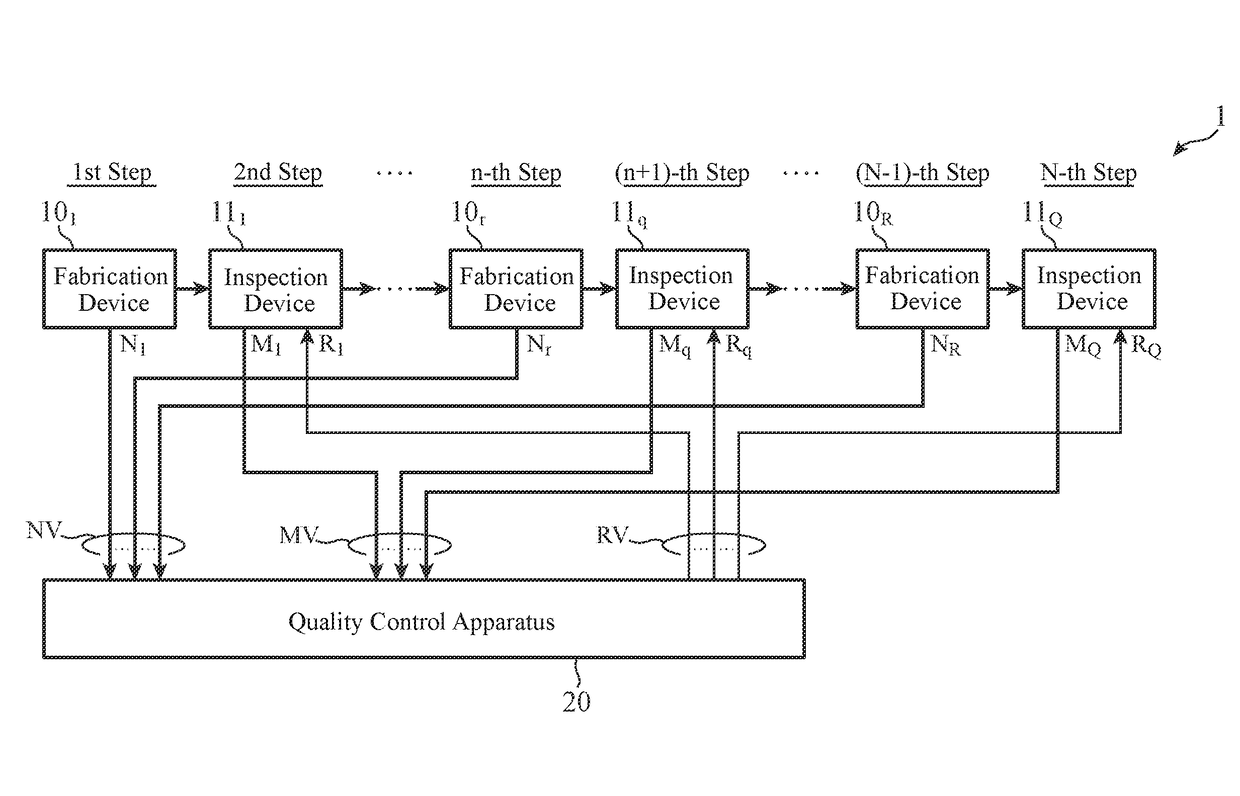

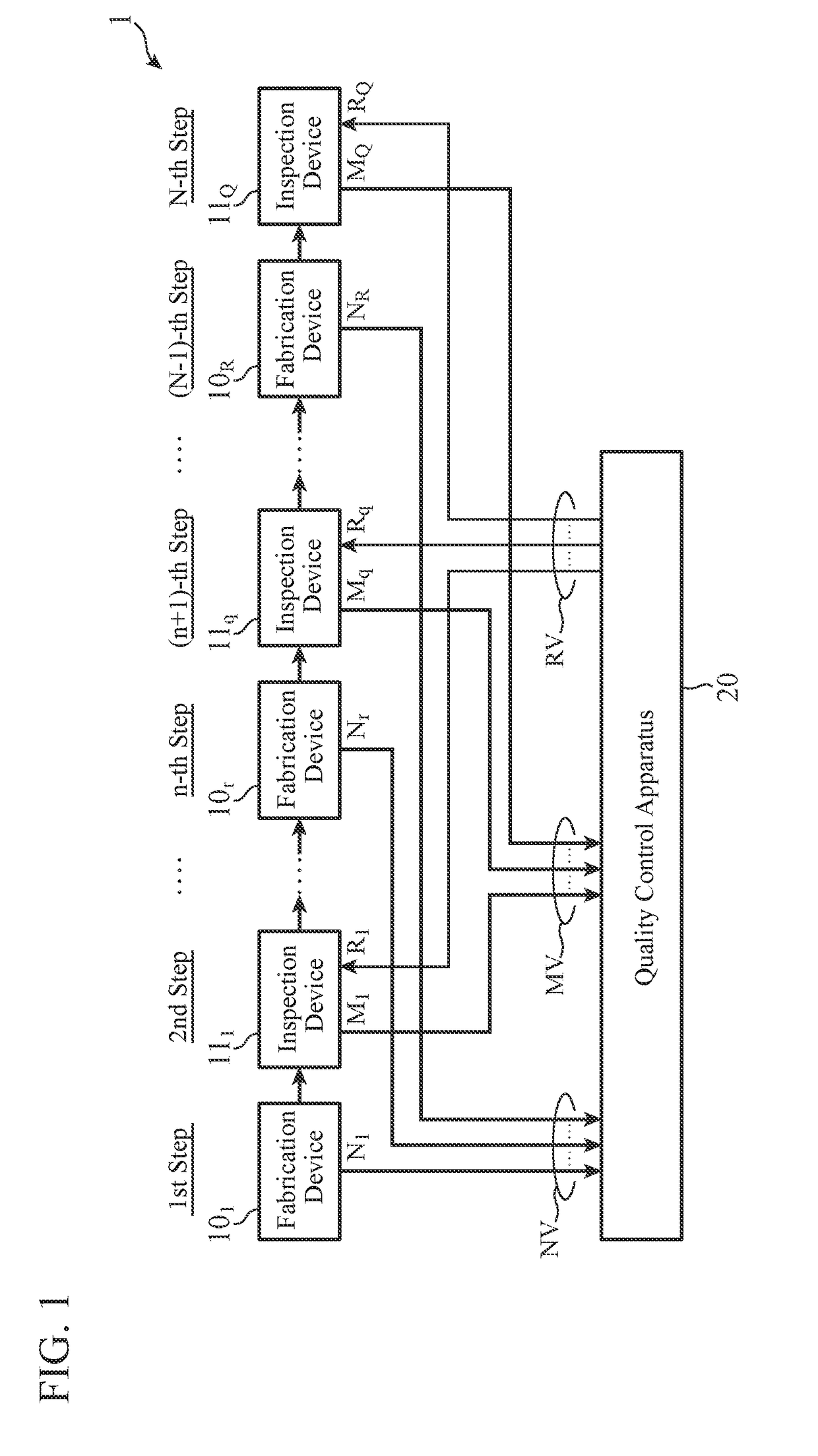

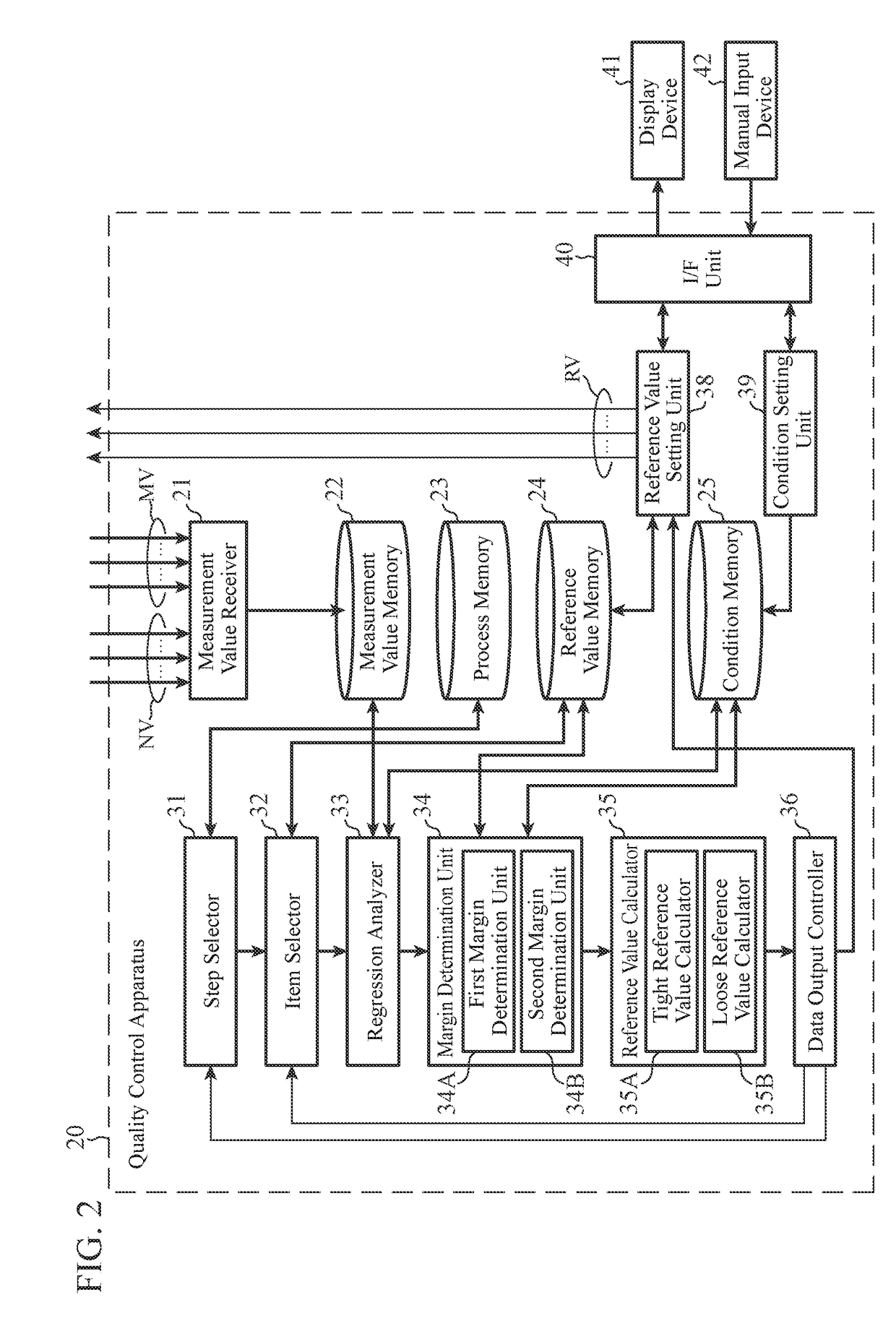

Quality control apparatus, quality control method, and quality control program

InactiveUS20180284739A1Increase productionImage analysisTesting/monitoring control systemsRegression analysisQuality control

A quality control apparatus (20) includes: a regression analyzer (33) for calculating a regression formula on the basis of measurement values acquired from an upstream step and comparative measurement values acquired from a downstream step; a margin determination unit (34) for calculating a prediction value by substituting a determination reference value defining a determination reference range in the upstream step for an explanatory variable of the regression formula, comparing the prediction value with a comparative determination reference range in a downstream step, and determining whether the measurement values are accepted; and a reference value calculator (35) for calculating a new determination reference value to replace the determination reference value in accordance with the determination result.

Owner:MITSUBISHI ELECTRIC CORP

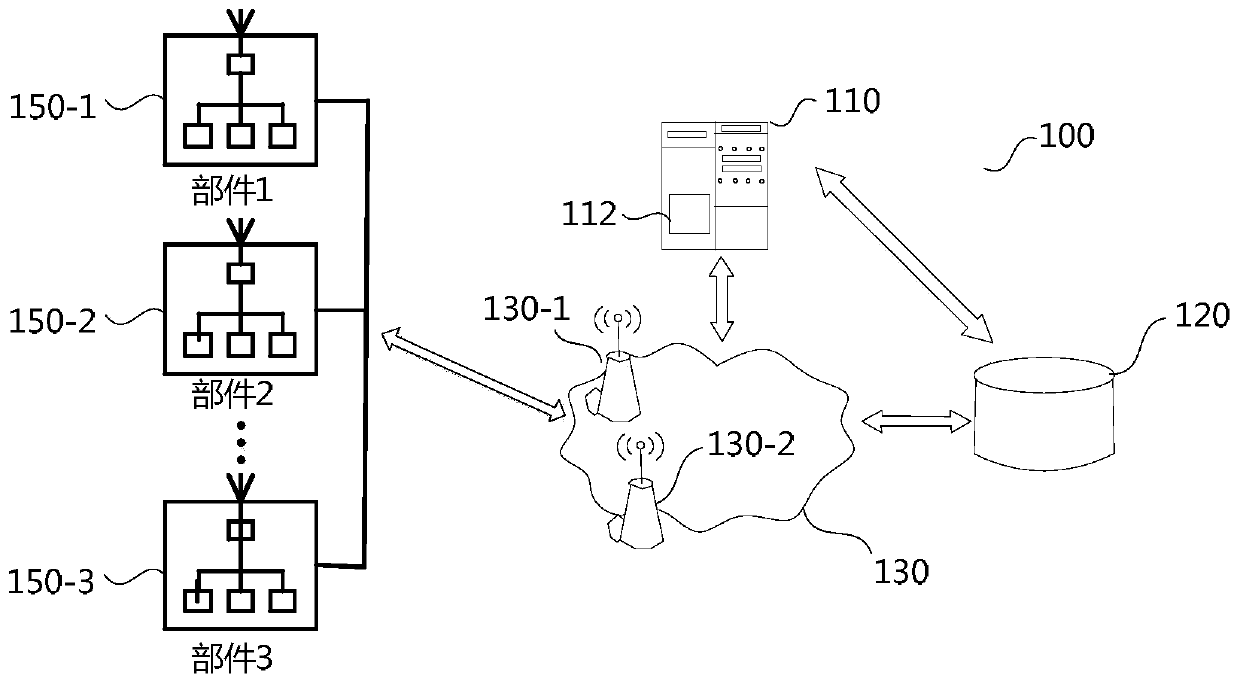

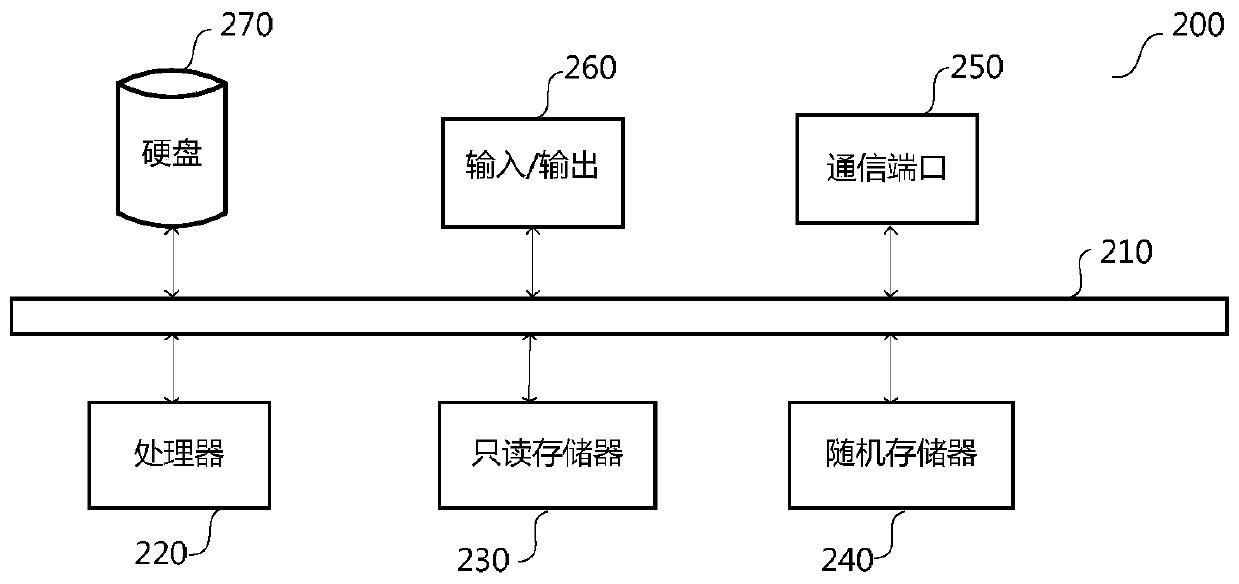

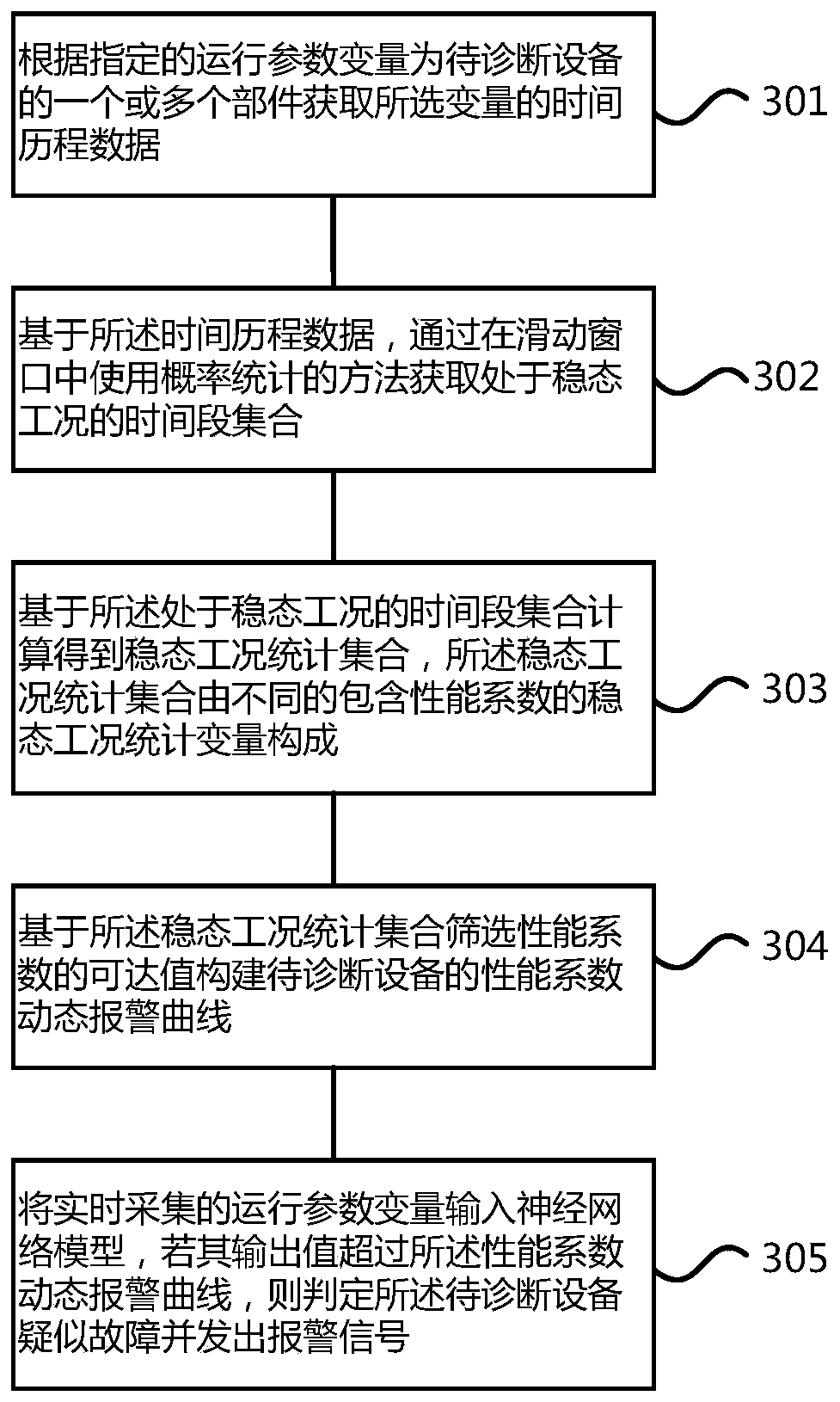

Equipment abnormality diagnosis method and device based on energy consumption model and data interaction

ActiveCN111047732ARegistering/indicating during manufacturing processAlarmsNetwork modelComputer data processing

The invention relates to the technical field of computer data processing, in particular to an equipment exception diagnosis method and device based on an energy consumption model and data interaction.The invention provides an equipment exception diagnosis method based on an energy consumption model and data interaction. The method comprises the following steps: acquiring time history data of a selected variable for one or more components of to-be-diagnosed equipment according to a specified operating parameter variable, then obtaining a time period set in a steady-state working condition by using a probability statistics method in a sliding window, further calculating to obtain a steady-state working condition statistics set, screening reachable values of performance coefficients based onthe steady-state working condition statistics set, and constructing a performance coefficient dynamic alarm curve of to-be-diagnosed equipment through a neural network model; and inputting operationparameter variables collected in real time into a neural network model, and if the output value of the operation parameter variables exceeds the performance coefficient dynamic alarm curve, judging that the to-be-diagnosed equipment is suspected to have a fault and sending out an alarm signal.

Owner:QINGDAO HISENSE TRANS TECH

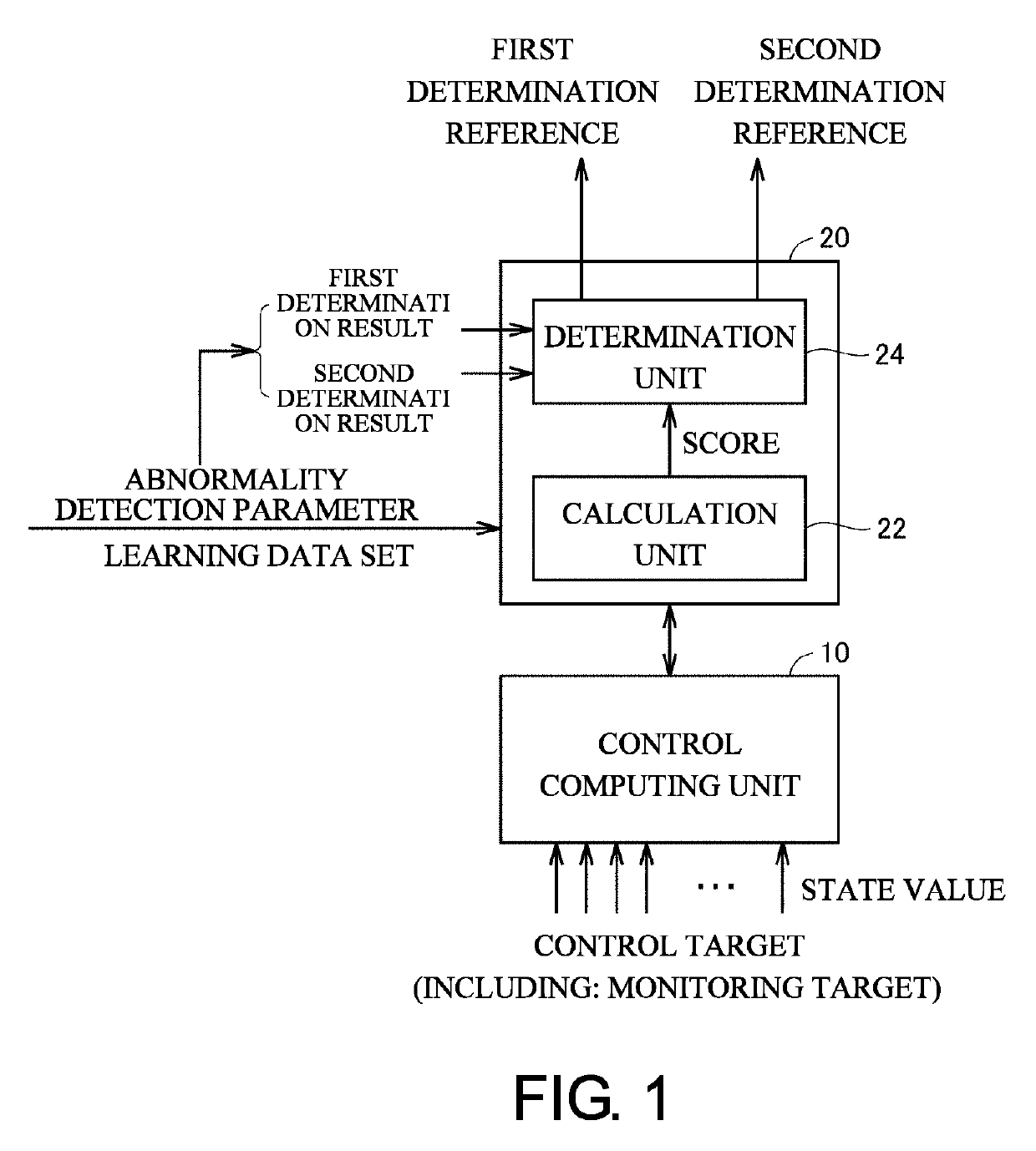

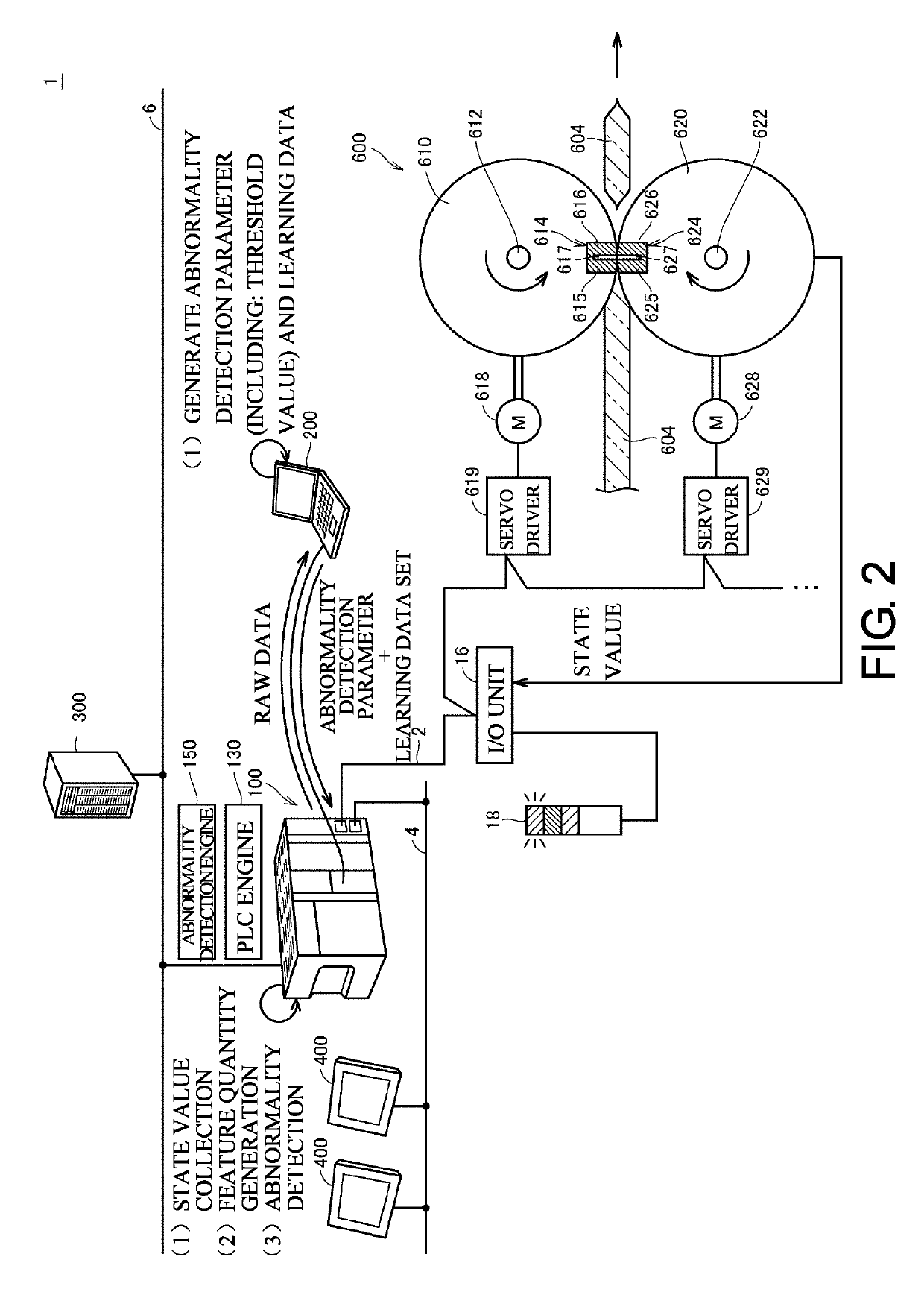

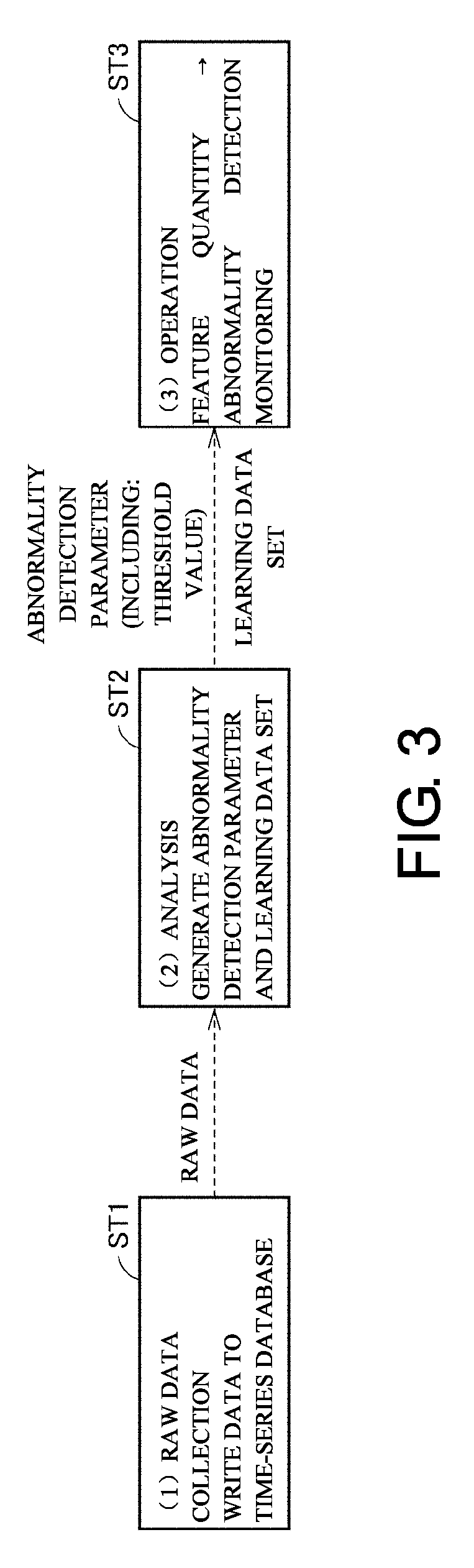

Abnormality detection system, support device, and abnormality detection method

InactiveUS20190301979A1Flexible settingsMeet actual needsTesting/monitoring control systemsStructural/machines measurementPredictive maintenanceComputer science

There is a need to flexibly set a determination reference suitable for application of predictive maintenance to an actual production site. A first abnormality detection unit includes a calculation unit that calculates a score using a feature quantity that is calculated from a state value related to a monitoring target according to an abnormality detection parameter, and a determination unit that performs a determination using the score calculated by the calculation unit and a first determination reference and a second determination reference included in the abnormality detection parameter, outputs a first determination result when the score matches the first determination reference, and outputs a second determination result when the score matches the second determination reference.

Owner:ORMON CORP

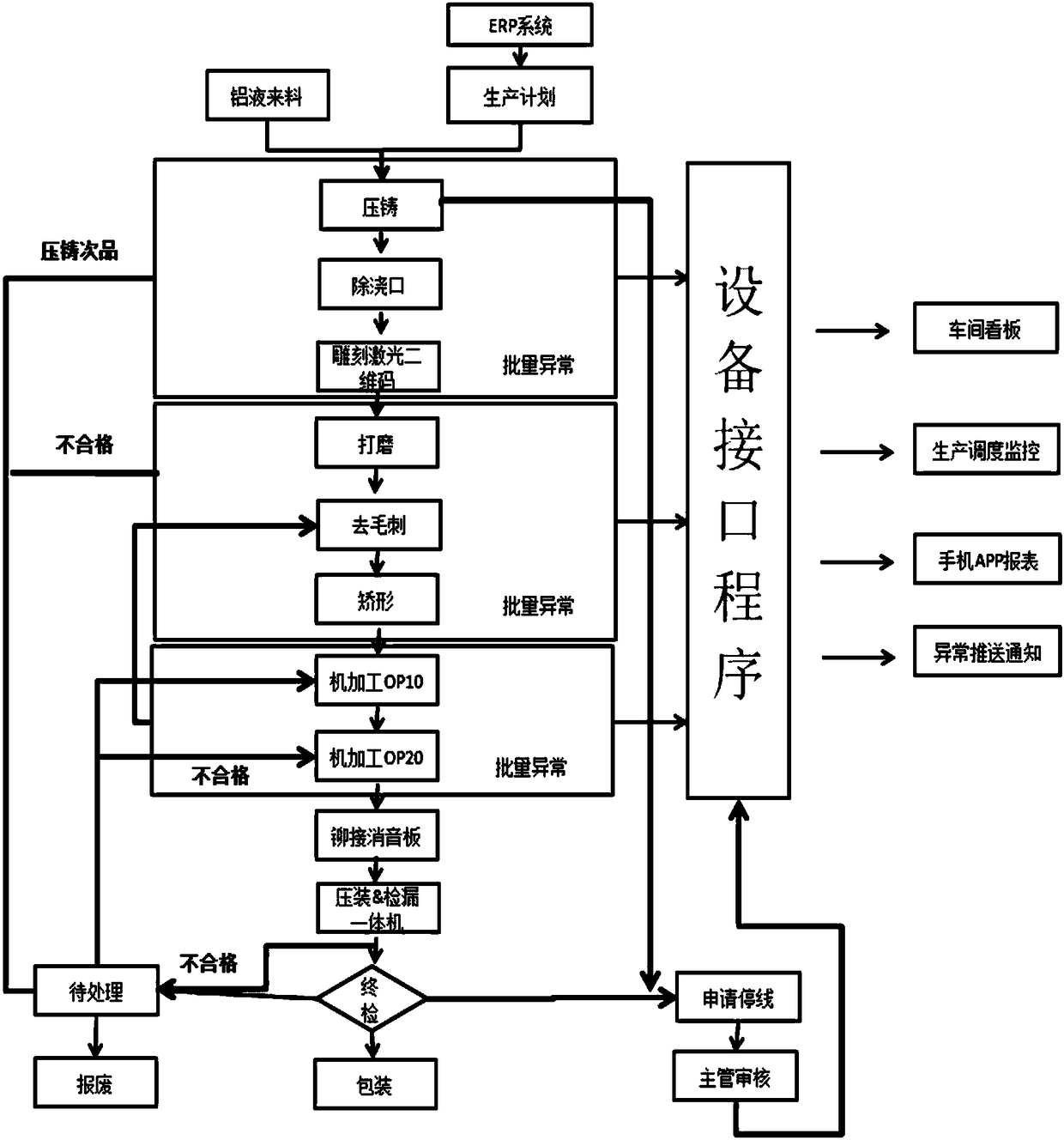

Full operation process accurate tracing method for aluminum alloy die casting product

ActiveCN108537301AQuick restoreEasy to handleCo-operative working arrangementsRegistering/indicating during manufacturing processDie castingProduct processing

The invention discloses a full operation process accurate tracing method for an aluminum alloy die casting product. In a full operation process of the aluminum alloy die casting product, various itemsof production data can be monitored and collected in real time through two-dimensional code recording and scanning, a large quantity of complicated and error-prone human labor is replaced, a whole processing procedure can be restored, production processes can be visualized, detected abnormal problems can be quantitatively analyzed, a tracing range can be narrowed, product processing can be locked, ability of rapidly processing abnormal events can be improved, and production costs can be effectively reduced.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

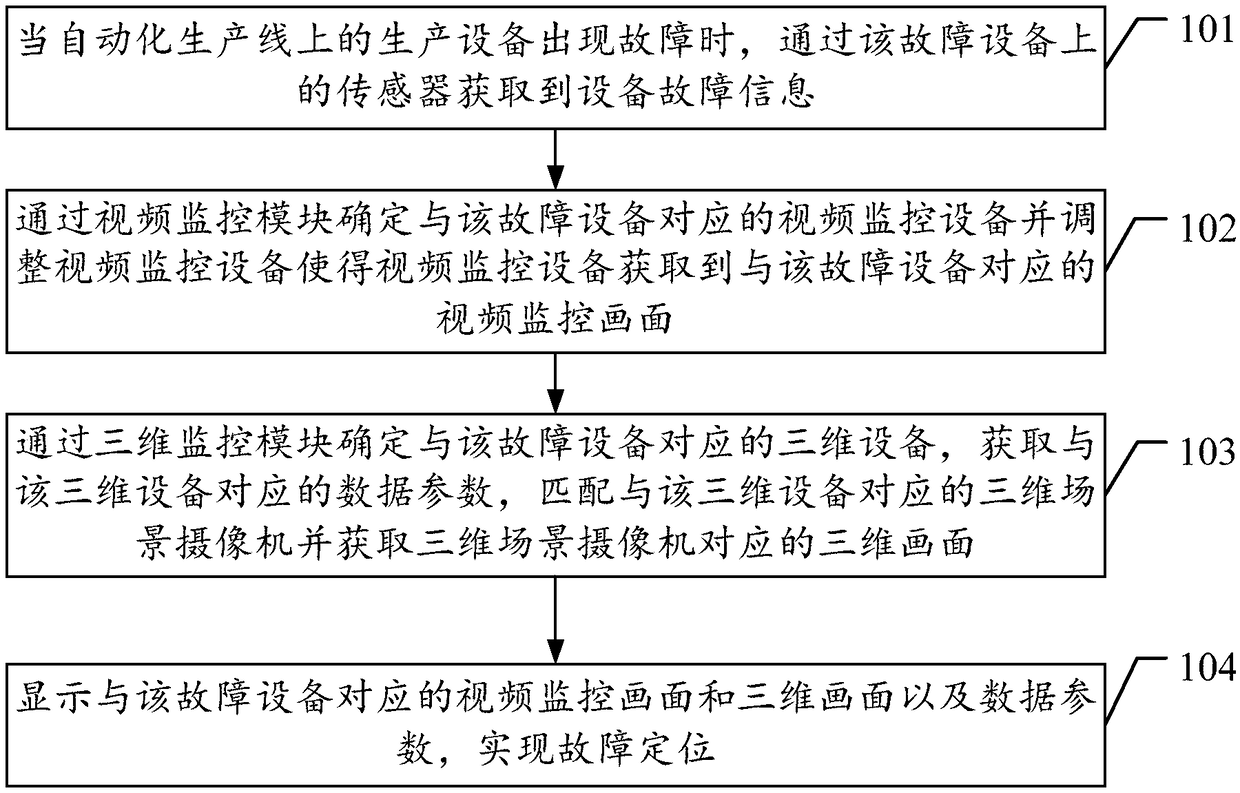

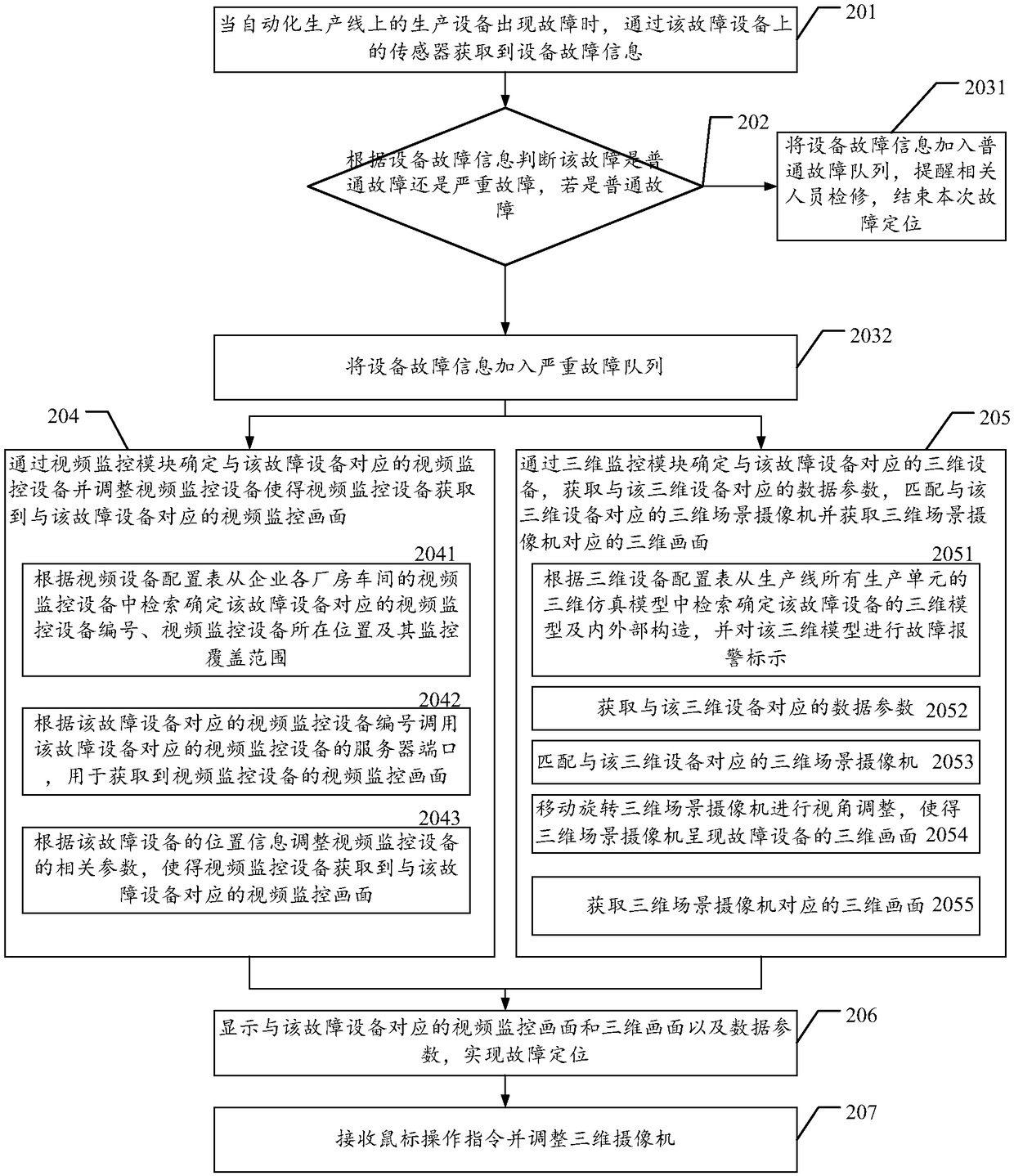

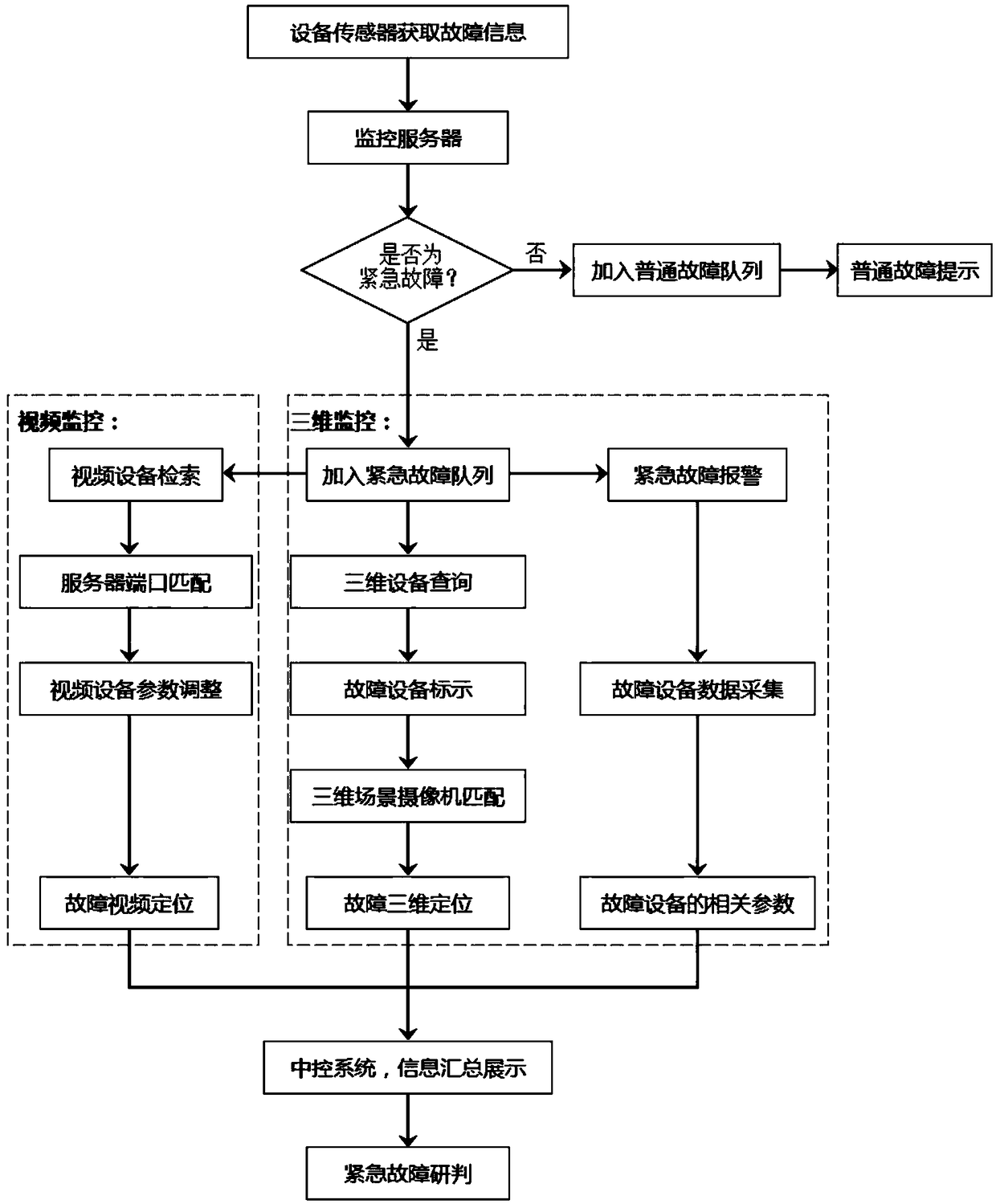

Device fault location method based on 3D virtual simulation and video monitoring linkage

InactiveCN109246390AAchieve positioningAchieve depthData processing applicationsRegistering/indicating during manufacturing processVideo monitoringThree dimensional simulation

The invention provides a device fault location method based on 3D virtual simulation and video monitoring linkage. Through building a multi-dimensional linkage mode of a three-dimensional simulation image, a video signal and fault data for a production unit and combining the three-dimensional virtual simulation and video monitoring, the method can achieve the fault-simulation-video linkage positioning and deep data presentation. When a fault happens, a central control system will instantly give an alarm and indicates a fault device and an alarm condition, and simultaneously switches a monitoring image to the fault position of a workshop. Through the combination of a video image of the onsite scene with the free and flexible browsing and deep data presentation of the three-dimensional monitoring, a user can quickly locate the fault, visually understands the onsite environment and operation parameters of the fault device deeply, estimates the severity of the fault based on the real-timedata and analyzes the cause of the fault, thereby greatly reducing the fault checking time, improving the maintenance efficiency, and reducing the economic loss of an enterprise. The invention also provides a corresponding system.

Owner:GUANGDONG POWER GRID CO LTD +1

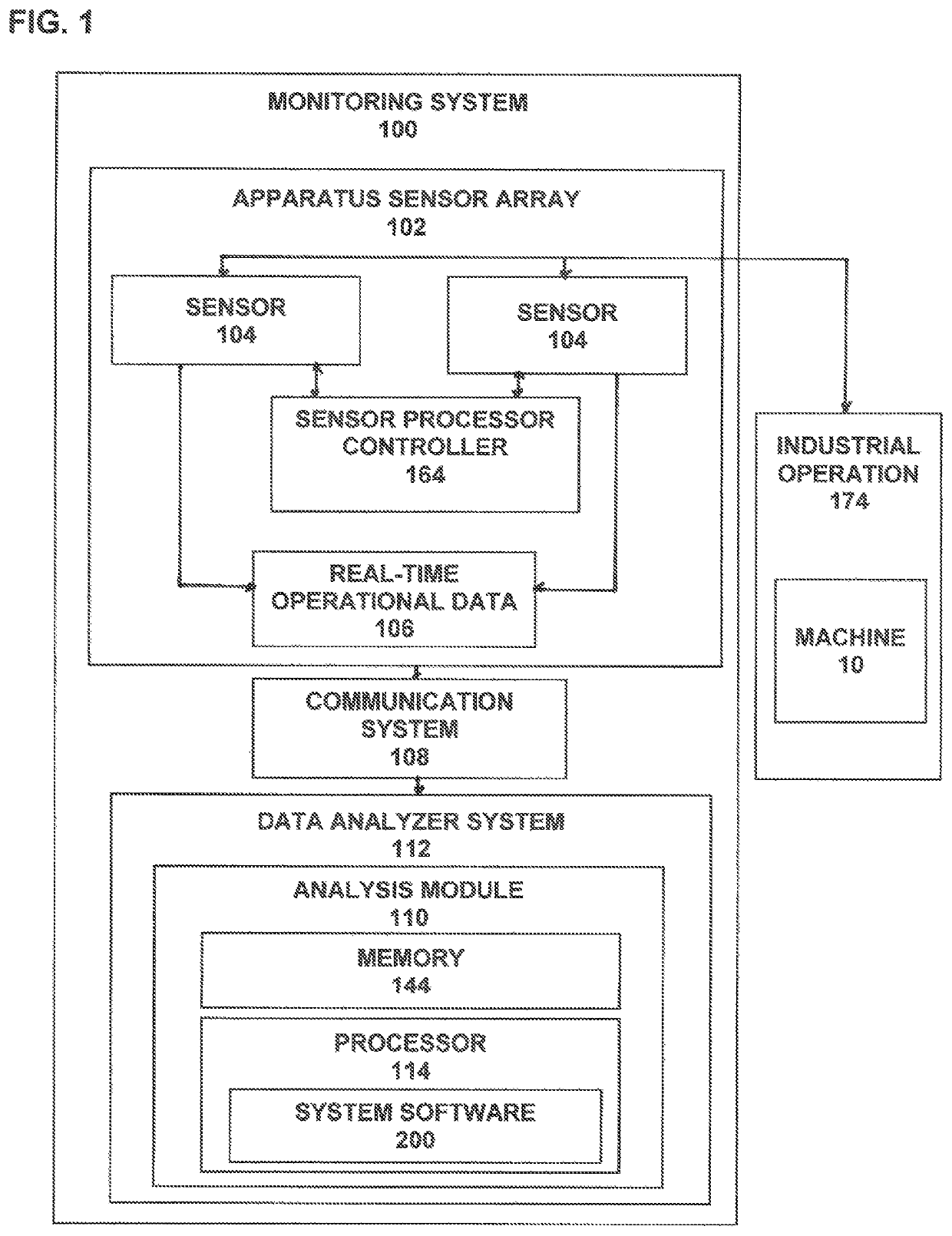

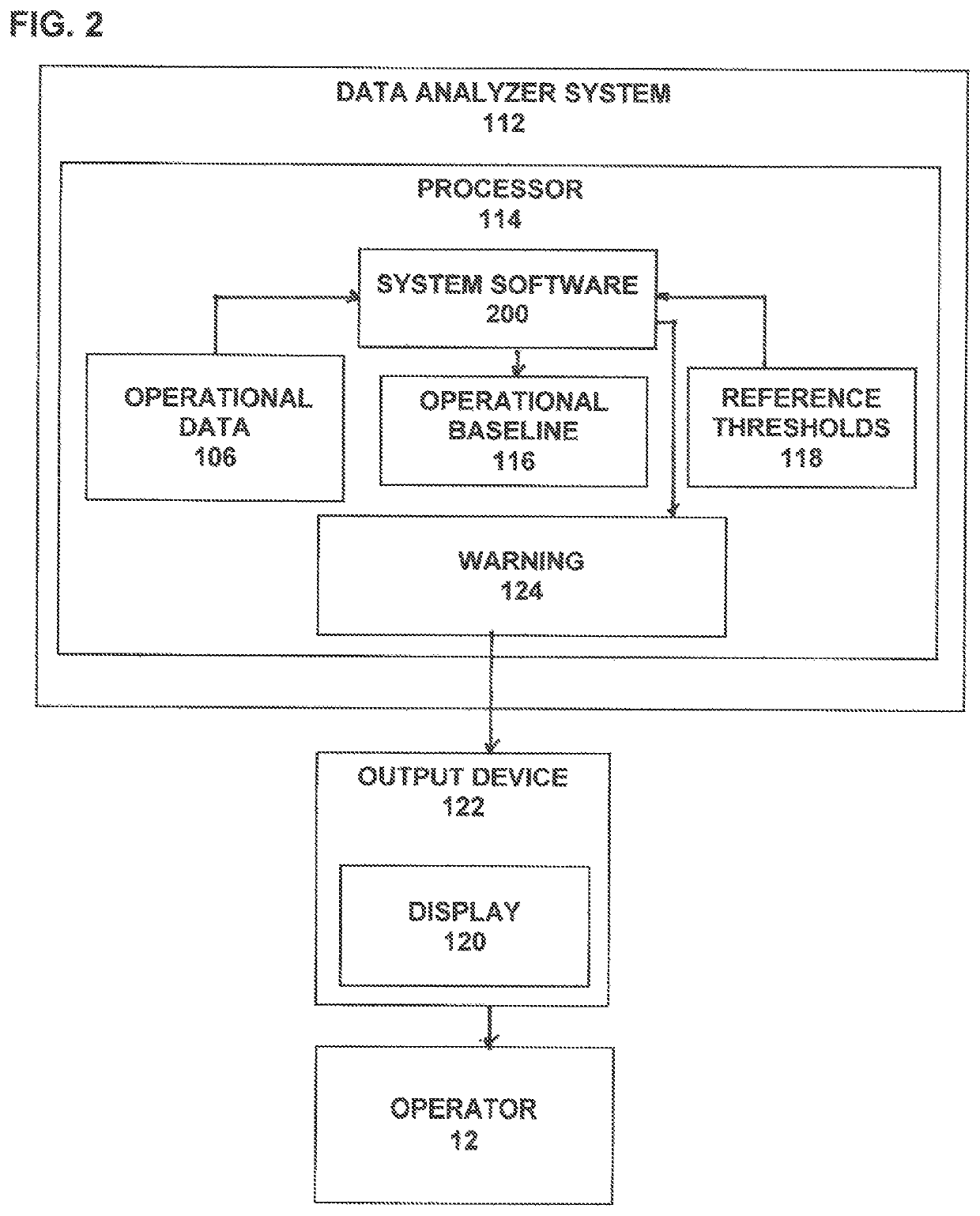

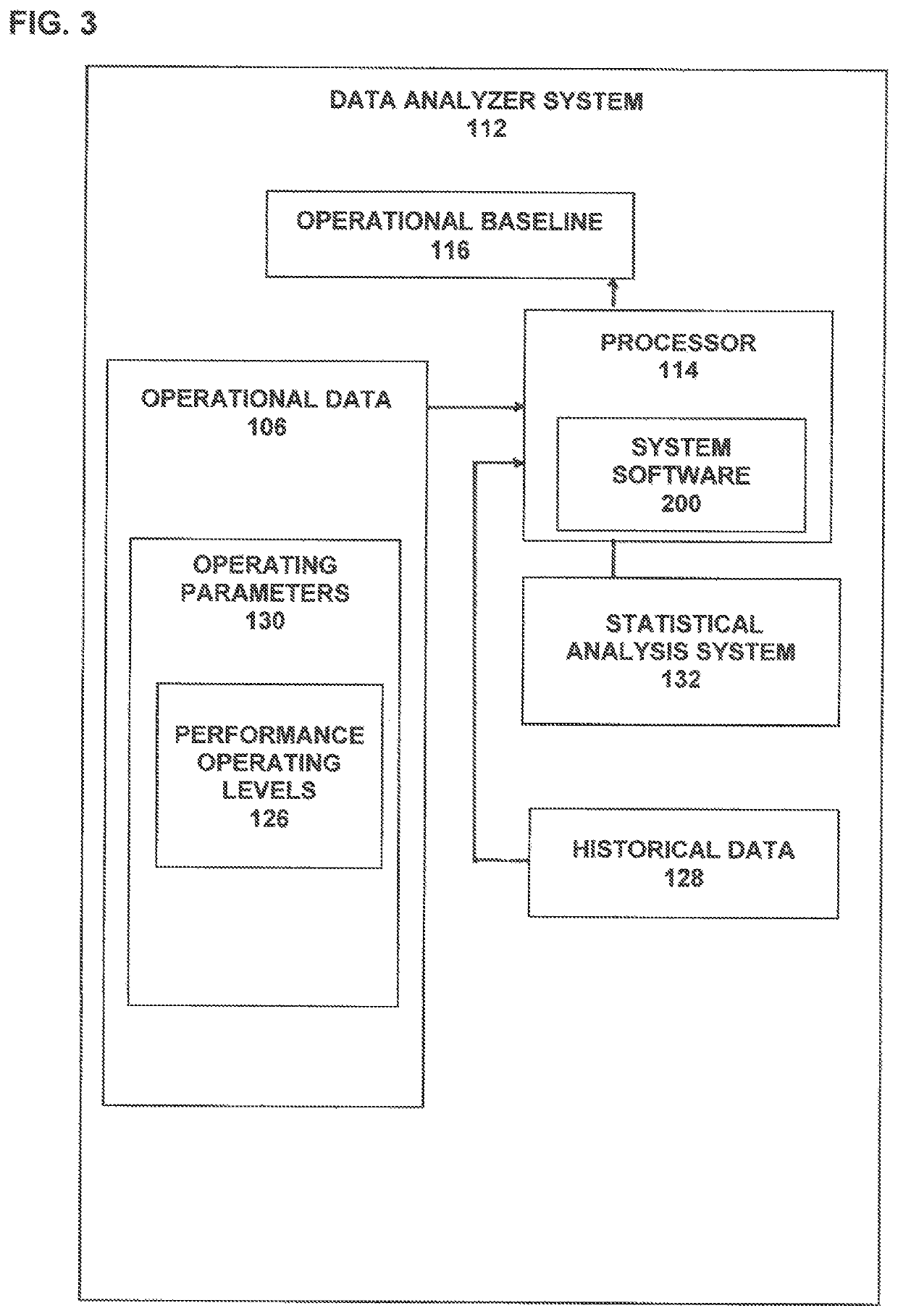

Monitoring system for use in industrial operations

A monitoring system for an industrial operation having one or more machines, the monitoring system operates to obtain operational information comprising performance operating parameters and uses the operational information to create an operational baseline and reference thresholds and monitors real-time operational data to determine if an operating parameter exceeds a reference threshold.

Owner:AI PULSE TECH LLC

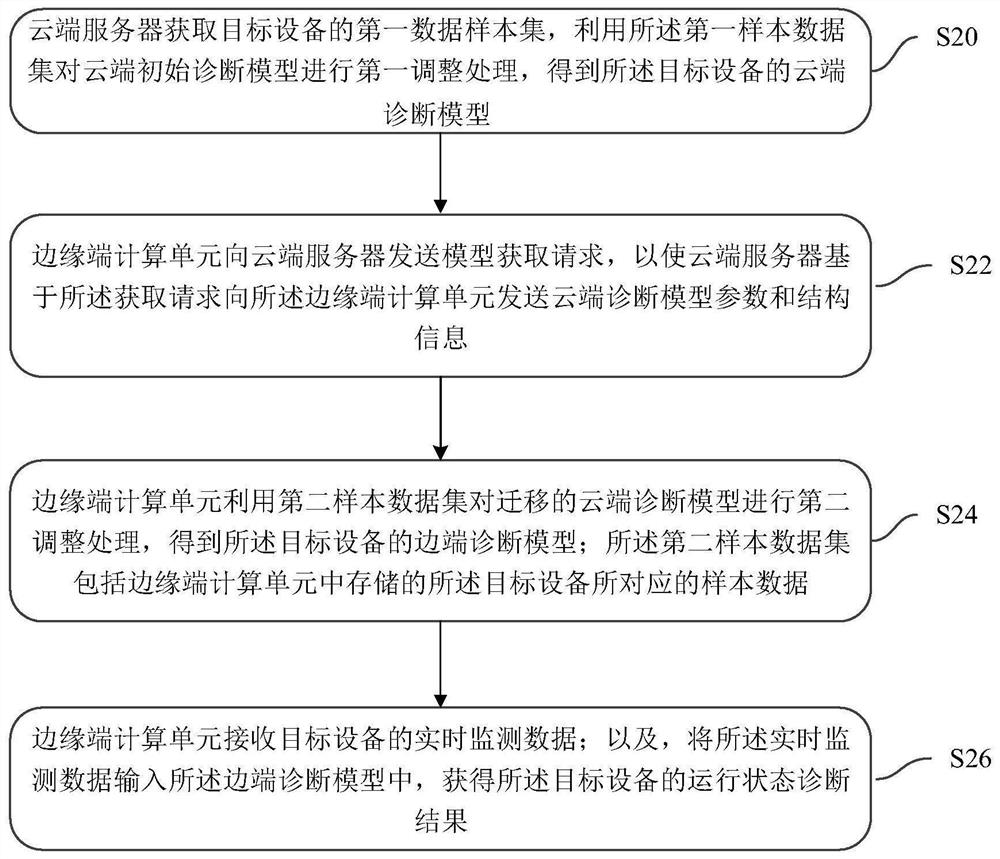

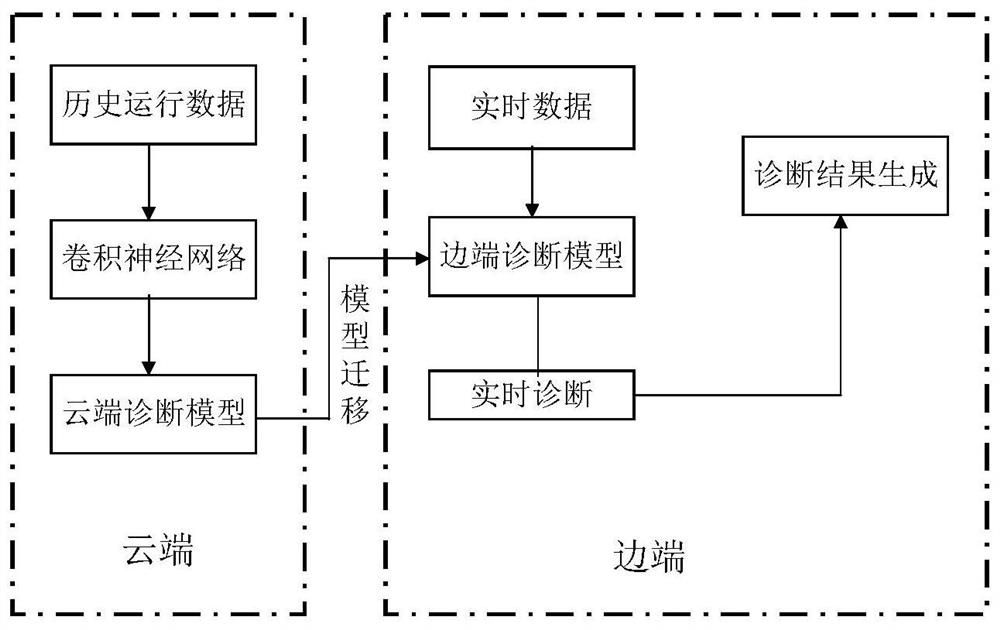

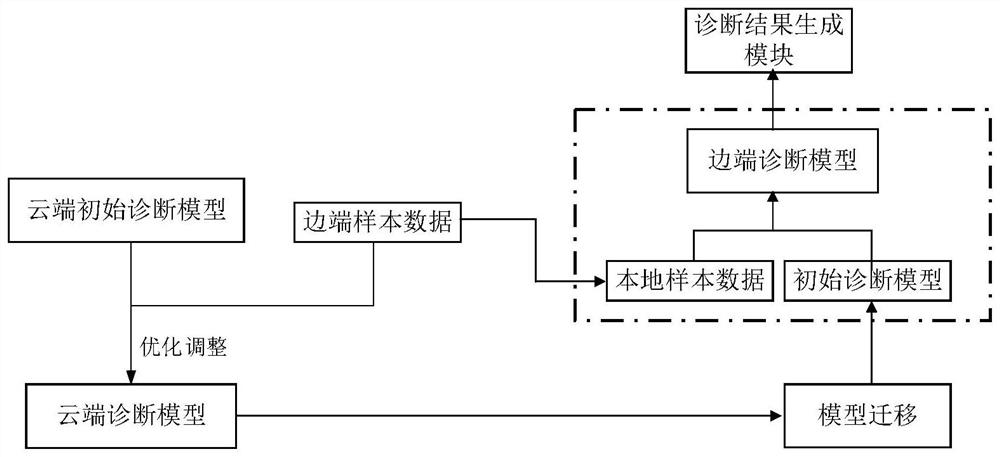

Equipment operation state edge cloud fusion diagnosis method and system

PendingCN112101767AIn line with the actual operating characteristicsRealize continuous updateResource allocationRegistering/indicating during manufacturing processReal-time dataTime data

The embodiment of the invention discloses an equipment operation state edge cloud fusion diagnosis method and system. The method comprises the steps that a cloud end carries out the adjustment of a cloud end initial diagnosis model constructed by historical data of equipment based on similar operation features through the historical data of target equipment and a fusion migration method, and a cloud diagnosis model of the target equipment is obtained. An edge end sends a cloud diagnosis model acquisition request to the cloud end, and the cloud end performs model migration based on the acquisition request; and the edge end uses the operation state data of the target equipment to adjust the cloud diagnosis model migrated to the edge end to construct an edge end diagnosis model more suitablefor the target equipment so as to perform real-time diagnosis on the target equipment and realize efficient and accurate reuse of the cloud model. Meanwhile, the diagnosis result and the real-time data can be uploaded to the cloud, a cloud sample set is updated, then the cloud diagnosis model is updated, continuous updating optimization of the edge diagnosis model is achieved, and the diagnosis accuracy and rapidity are improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

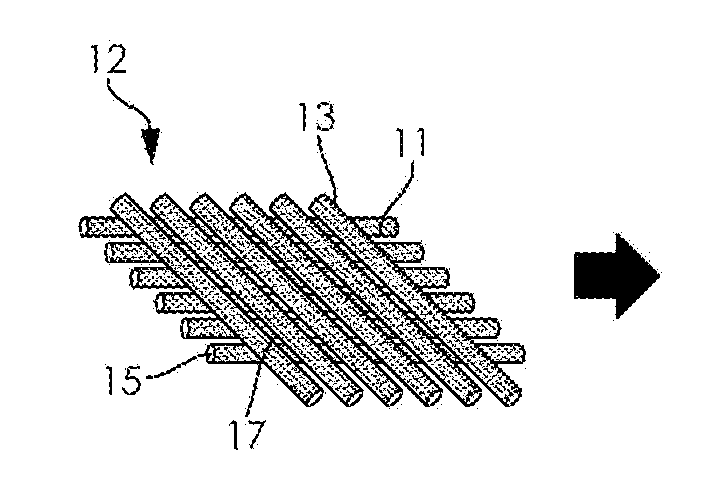

Scrim substrate material with functional detectable additives for use with nonwoven fabric and composite material

ActiveUS20170074829A1Reducing precautionary product discardMaterial analysis using wave/particle radiationSynthetic resin layered productsParticulatesPolymer science

An article is provided with a web of polymer fibers forming a scrim with openings between the polymer fiber elements. A particulate is distributed in, or on the polymer fiber in a quantity to make the scrim detectable by X-ray detection or magnetic detection. One or more layers are laminated to the scrim. A process for detecting a multi-layered laminated scrim-containing article with magnetic or X-ray detection equipment in a production setting is also provided. With process implementation article loss in a product can be detected thereby reducing precautionary product discard.

Owner:ILLINOIS TOOL WORKS INC

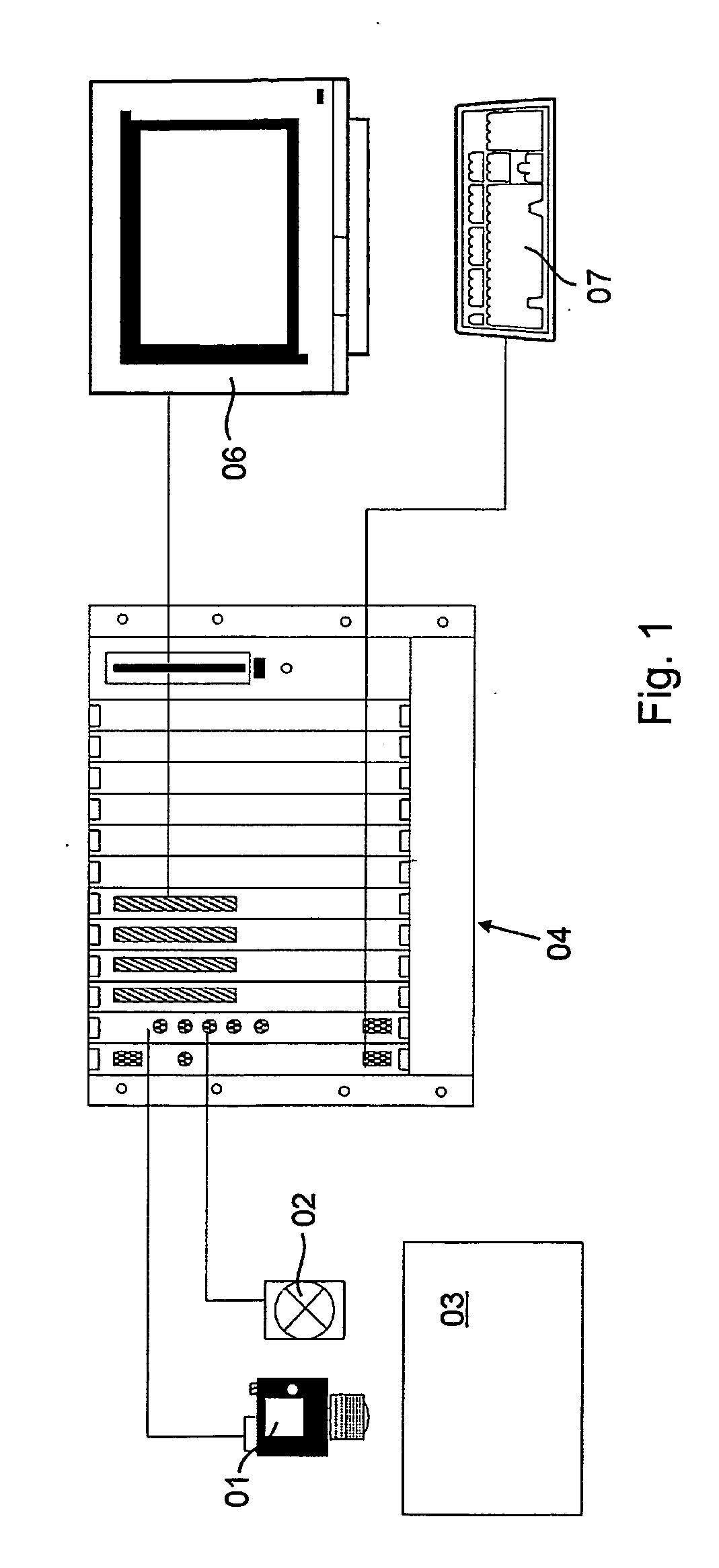

Method and apparatus for improved inspection and classification of attributes of a workpiece

InactiveUS20020040283A1Amplifier modifications to reduce noise influenceRegistering/indicating quality control systemsComputerized systemComputer science

An apparatus for detecting the probable existence, location, and type of defects in a workpiece is described. The apparatus includes a sensor subsystem, an optimizer, a control subsystem, and a computer system having a processor and computer readable memory The sensor subsystem senses a first section of the workpiece and produces signals corresponding to a physical characteristic of the workpiece. The computer system is configured to generate a workpiece model based on the signals produced by the sensor subsystem. In an alternate embodiment, a defect assembler can be provided to merge signals front a plurality of sensor subsystems. The defect assembler can also be configured to generate the workpiece data model. The optimizer is configured to generate workpiece segmentation recommendations based on the workpiece data model.

Owner:USNRKOCKUMS CANCAR

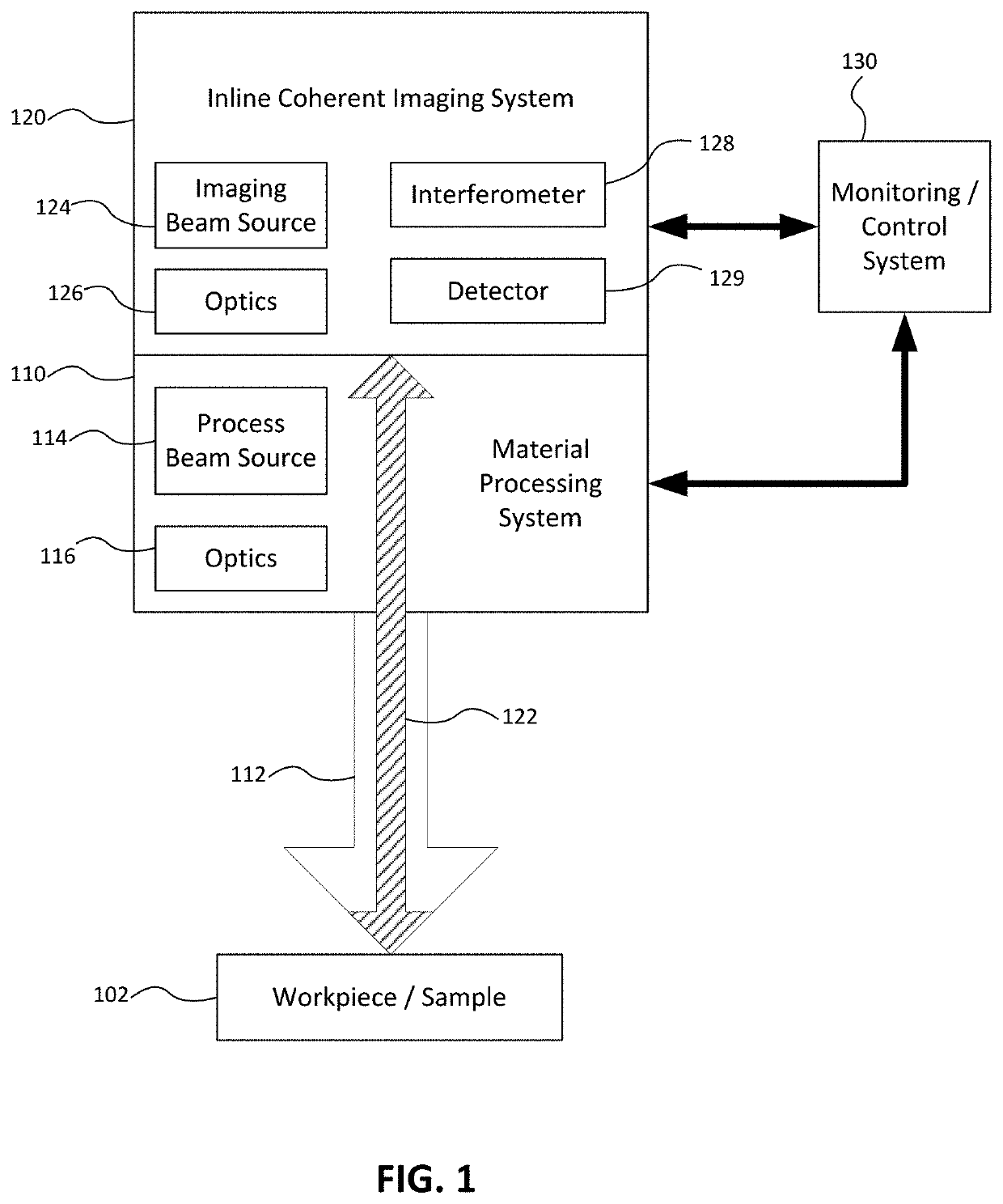

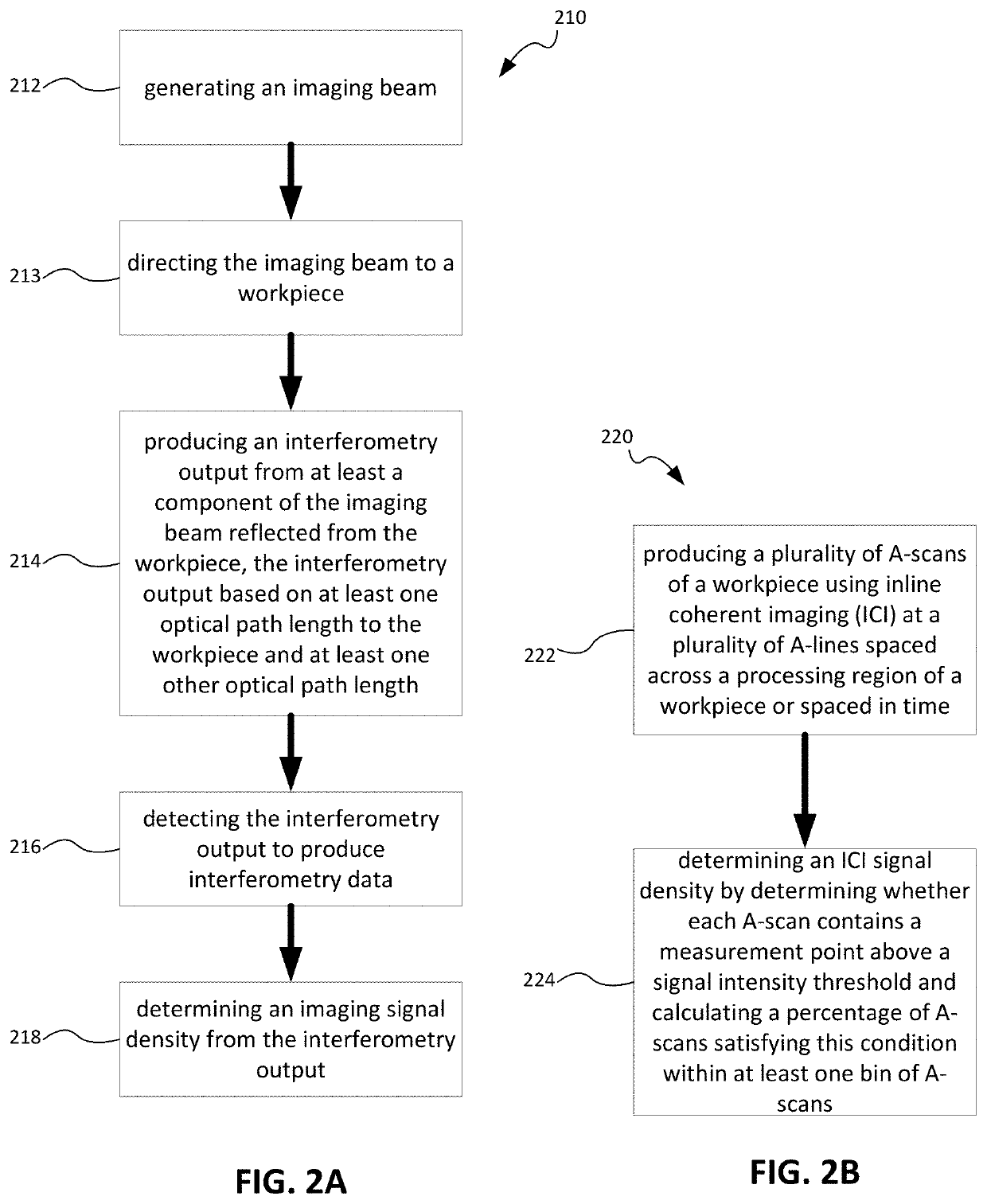

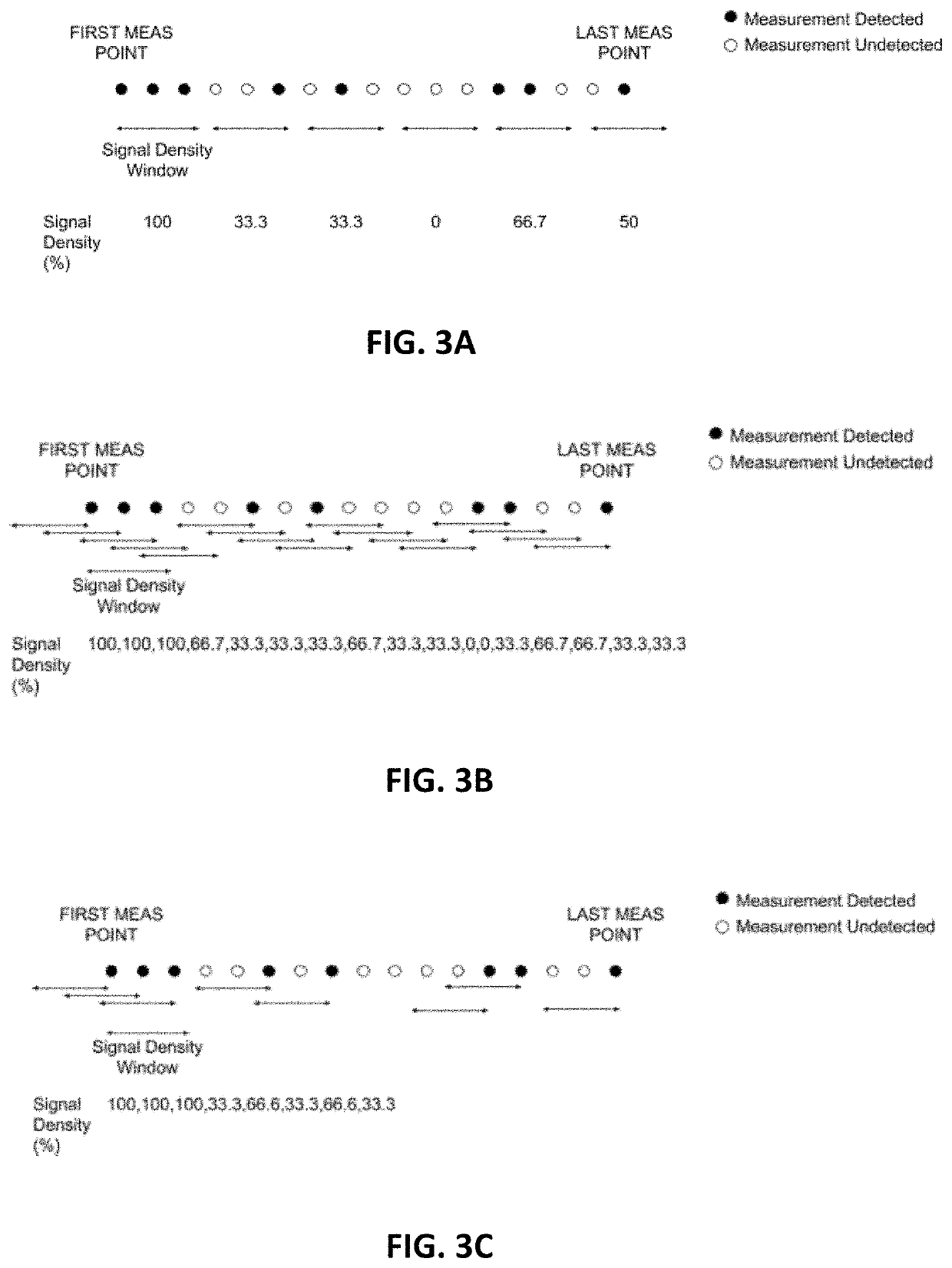

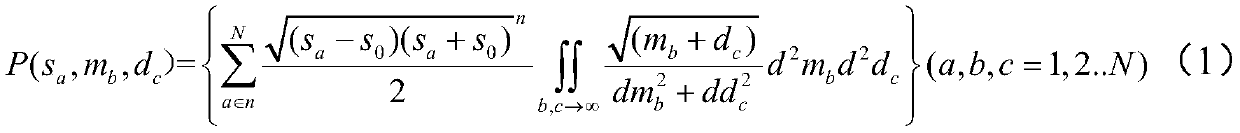

Monitoring material processing using imaging signal density determined from inline coherent imaging (ICI)

ActiveUS20200198050A1Material analysis by optical meansRegistering/indicating during manufacturing processLight beamNuclear medicine

Systems, methods and apparatuses are used for monitoring material processing using imaging signal density calculated for an imaging beam directed to a workpiece or processing region, for example, during inline coherent imaging (ICI). The imaging signal density may be used, for example, to monitor laser and e-beam welding processes such as full or partial penetration welding. In some examples, the imaging signal density is indicative of weld penetration as a result of reflections from a keyhole floor and / or from a subsurface structure beneath the keyhole. The monitoring may include, for example, automated pass / fail or quality assessment of the welding or material processing or parts produced thereby. The imaging signal density may also be used to control the welding or material processing, for example, using imaging signal density data as feedback. The imaging signal density may be used alone or together with other measurements or metrics, such as distance or depth measurements.

Owner:IPG PHOTONICS CORP

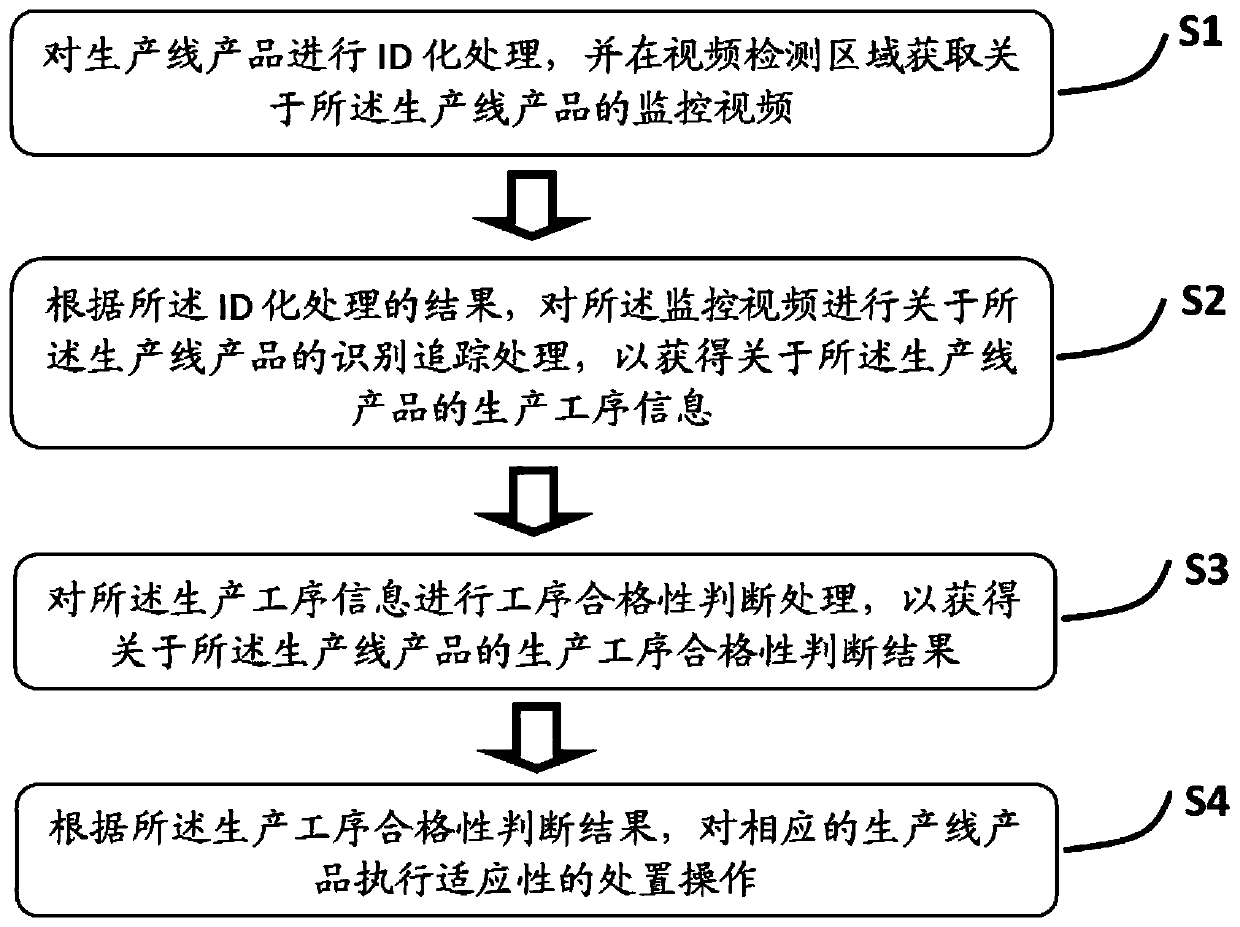

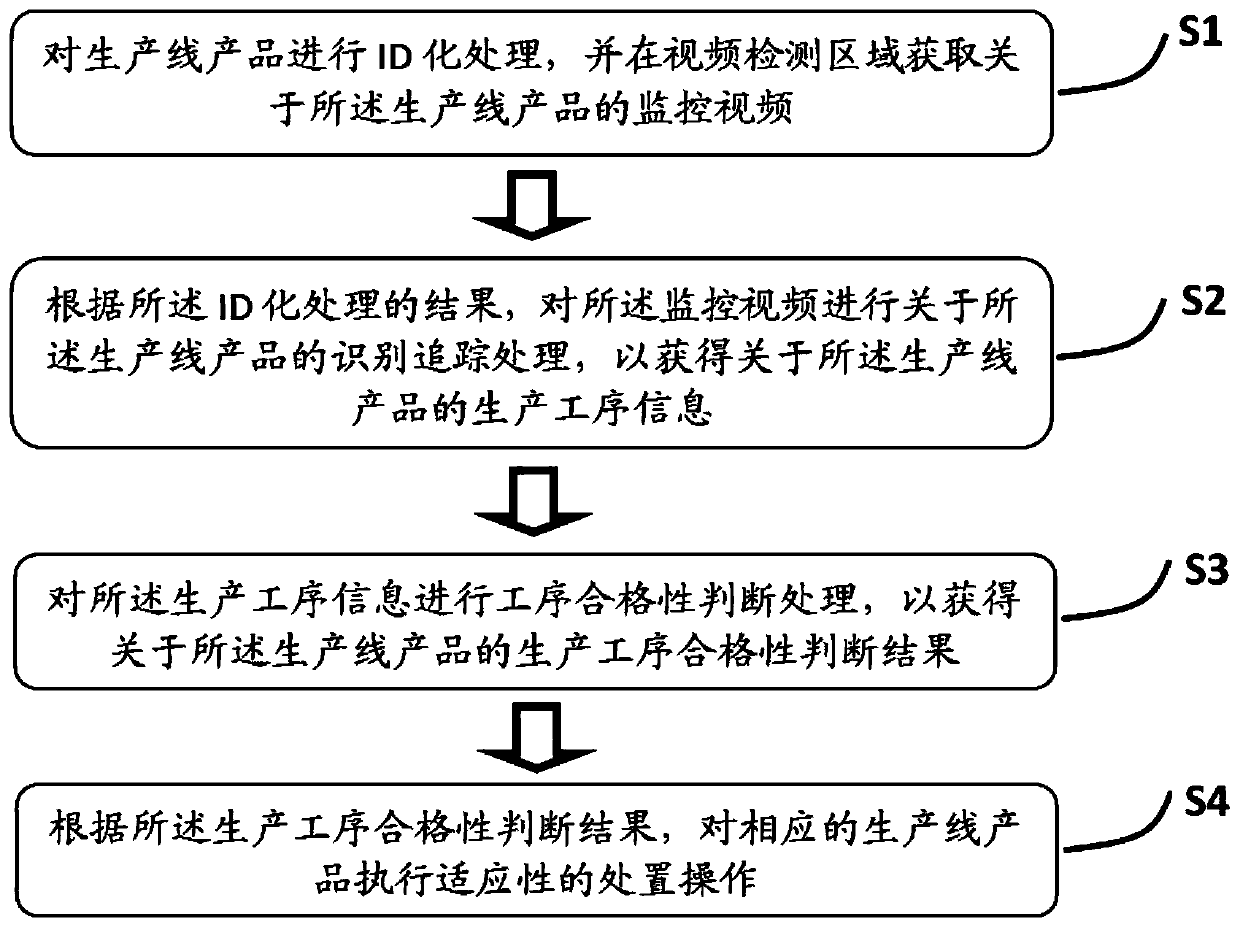

Production line product positioning method based on monitoring video

ActiveCN111127517AEasy to traceEasy to handleImage enhancementImage analysisProduction lineProcess engineering

The invention provides a production line product positioning method based on a monitoring video. According to the production line product positioning method based on the monitoring video, visual ID processing is carried out on a production line product; and the defective products are subjected to ID identification in the monitoring video, so that all the defective products can be traced and processed in a centralized manner in a certain link of production, and therefore, huge waste of manpower and material resources caused by emergency stop of the assembly line can be avoided, and the operation efficiency of the assembly line and the qualification rate of product quality can be improved.

Owner:BEIJING RONGLIAN YITONG INFORMATION TECH CO LTD

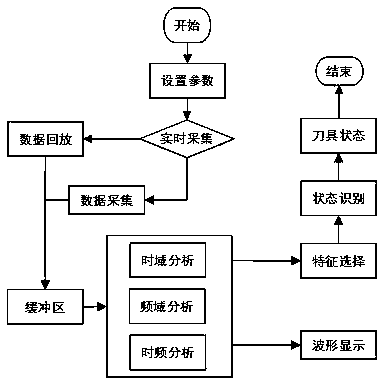

Tool wear state identification method based on vibration and acoustic emission

PendingCN109635847AEasy to installAchieving state of wear recognitionCharacter and pattern recognitionRegistering/indicating during manufacturing processFeature extractionThree stage

The invention discloses a tool wear state identification method based on vibration and acoustic emission, and belongs to the technical field of advanced manufacturing. According to the invention, advantages and disadvantages of various monitoring signals are analyzed; vibration and acoustic emission signals which are high in sensitivity and easy to install are selected as monitoring signals, and by completing signal collection and analysis, feature extraction and optimal feature selection, tool wear state recognition is finally achieved, and tool wear states of the three stages of initial wear, normal wear and severe wear are output.

Owner:KUNMING UNIV OF SCI & TECH

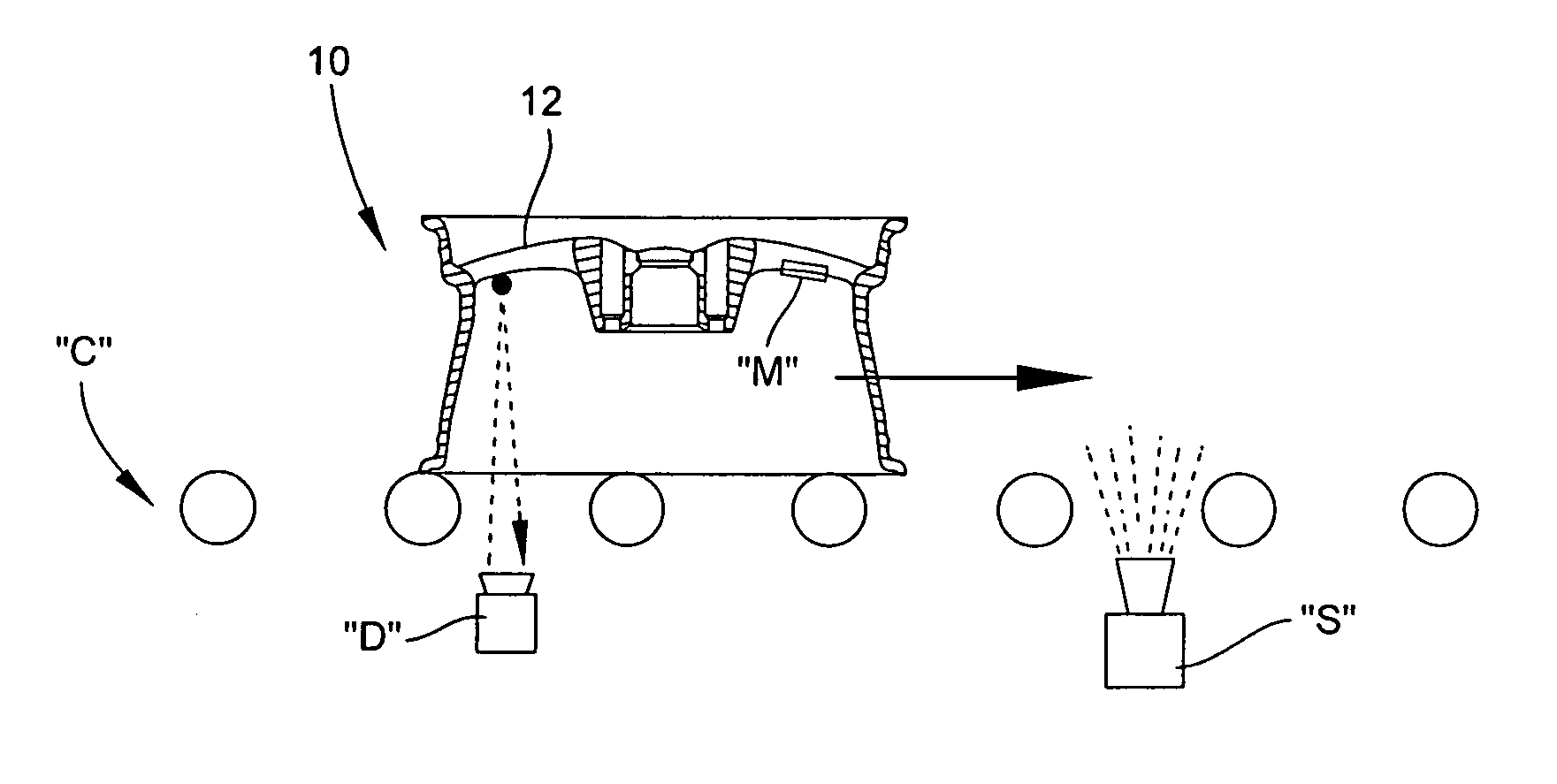

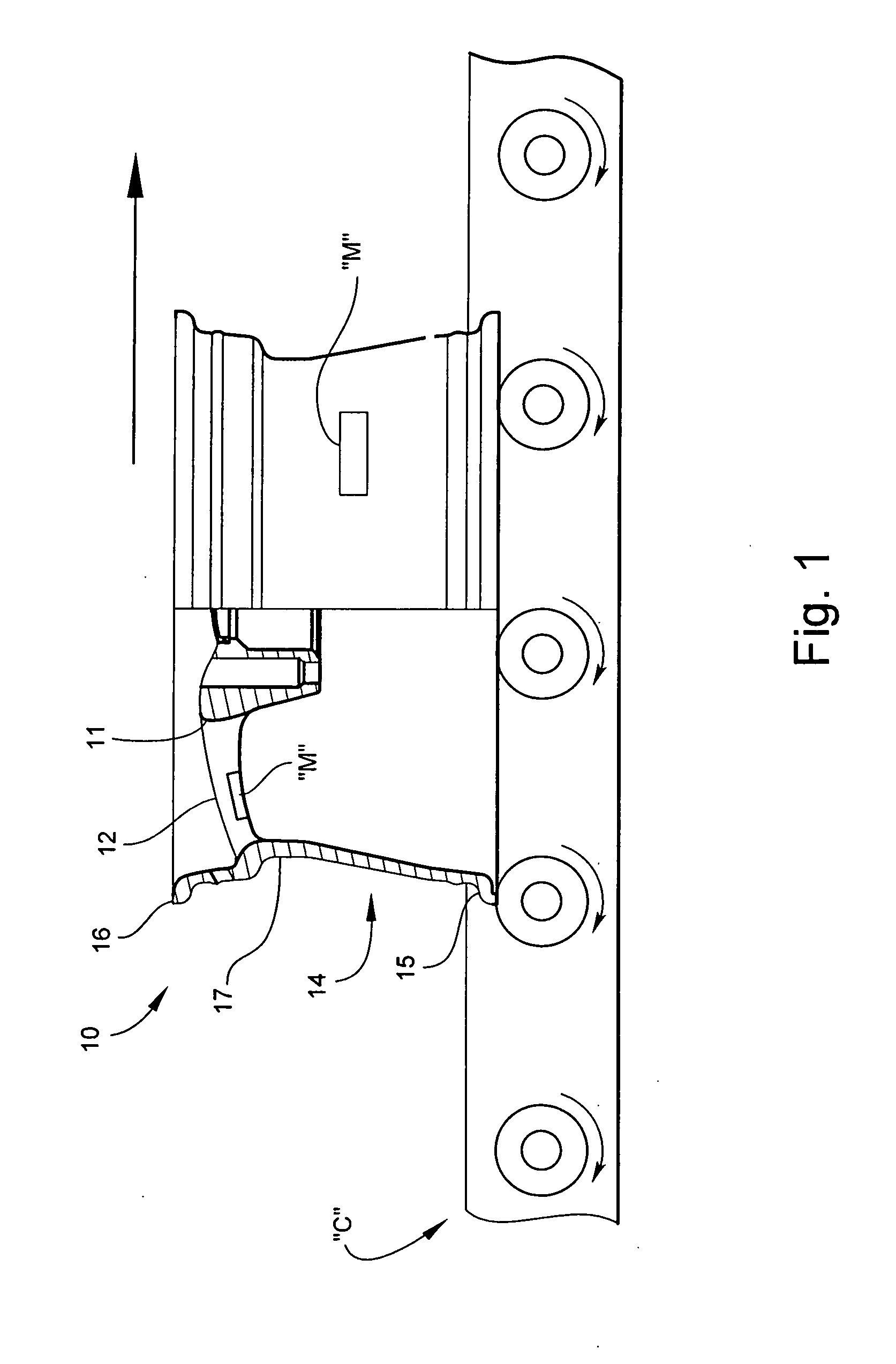

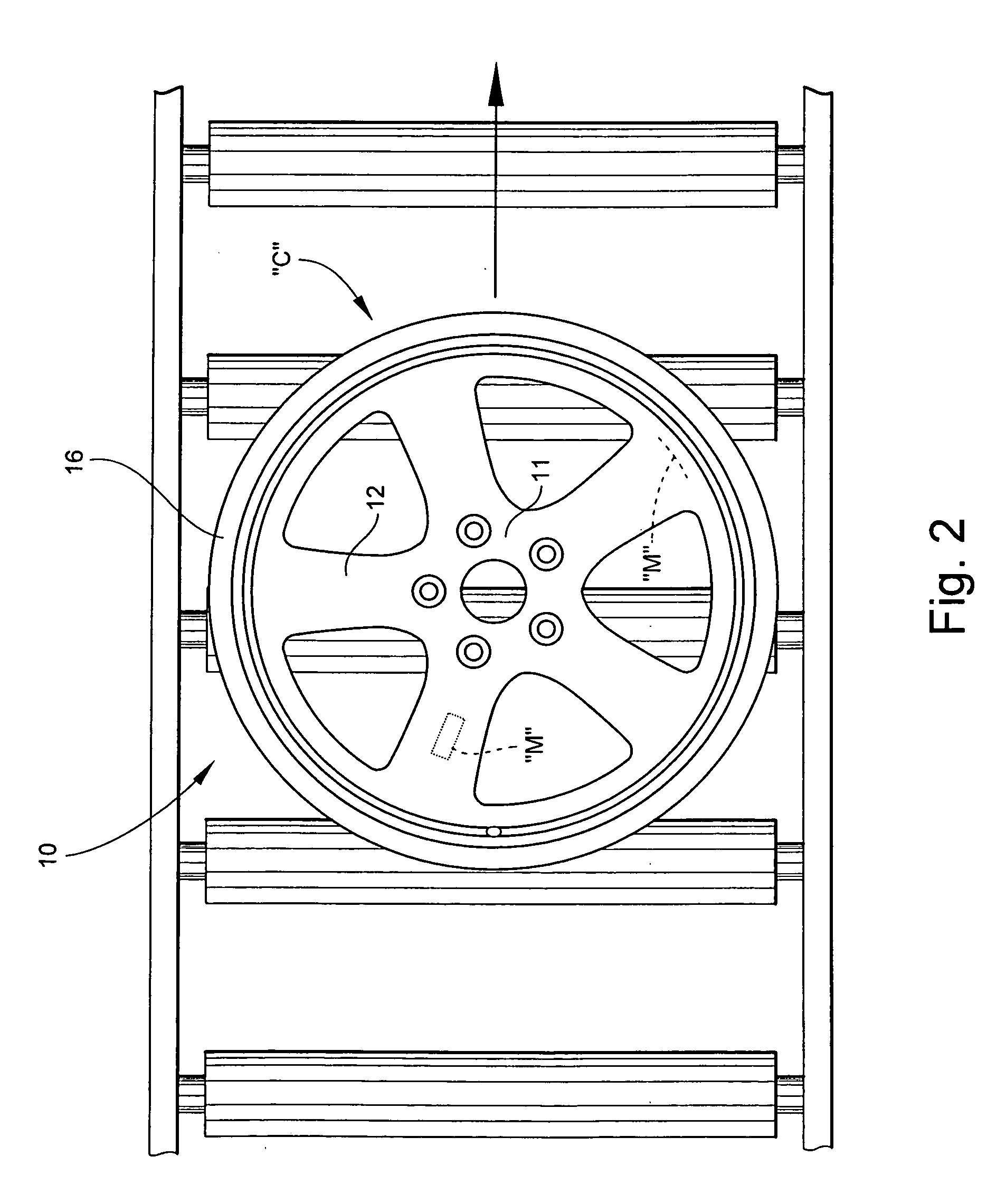

System and method for electronically identifying vehicle wheels on-the-fly during manufacture

InactiveUS20060206236A1Reliably machine-identifiedVehicle testingTicket-issuing apparatusOn the flyAutomotive engineering

The method electronically identifies a vehicle wheel on-the-fly moving downstream from one processing location to another. The method includes the steps of locating a machine-readable identification mark applied to an exposed surface of the vehicle wheel as the vehicle wheel. The identification mark is electronically read on-the-fly.

Owner:SMYTH LARRY C

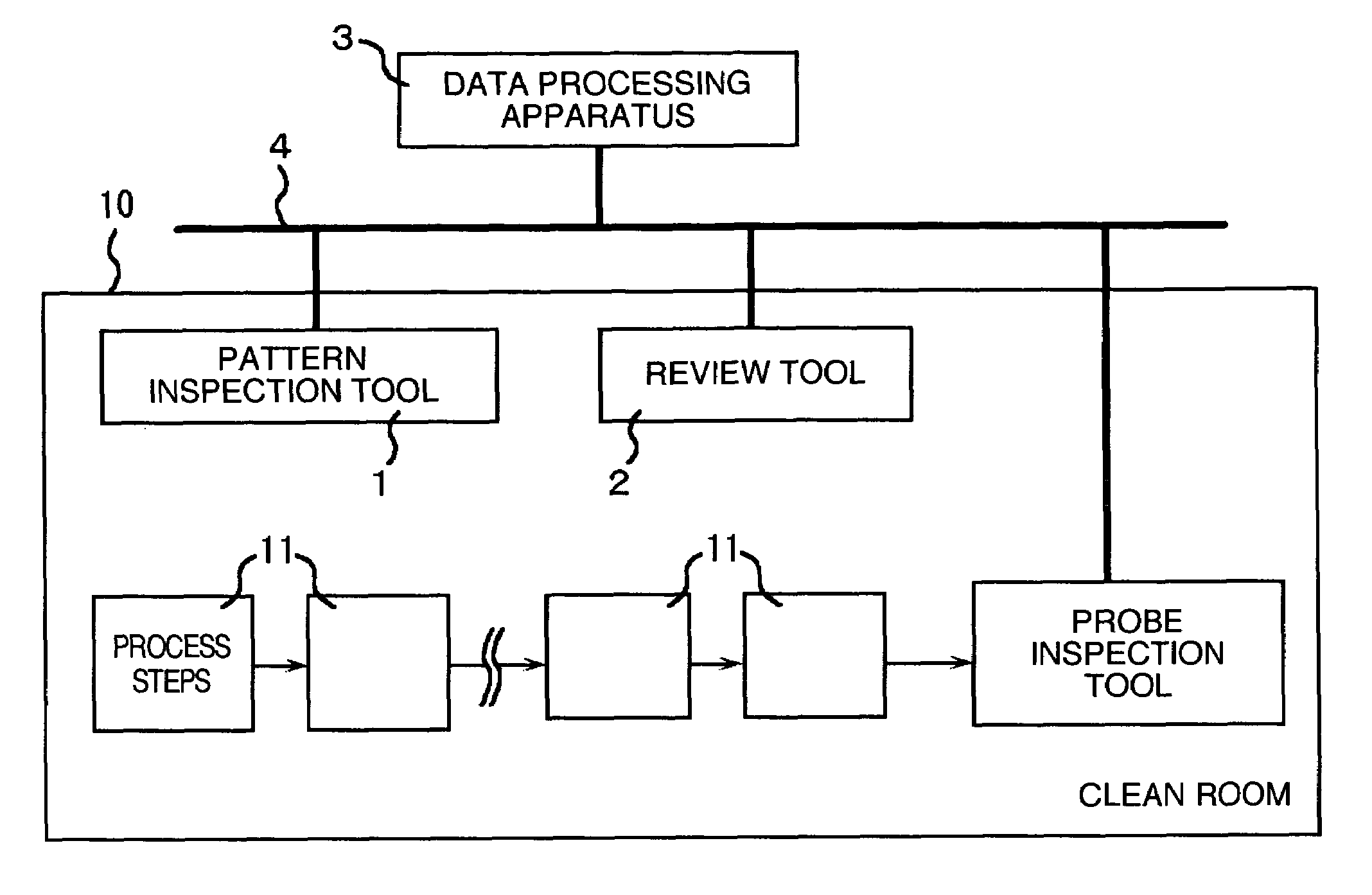

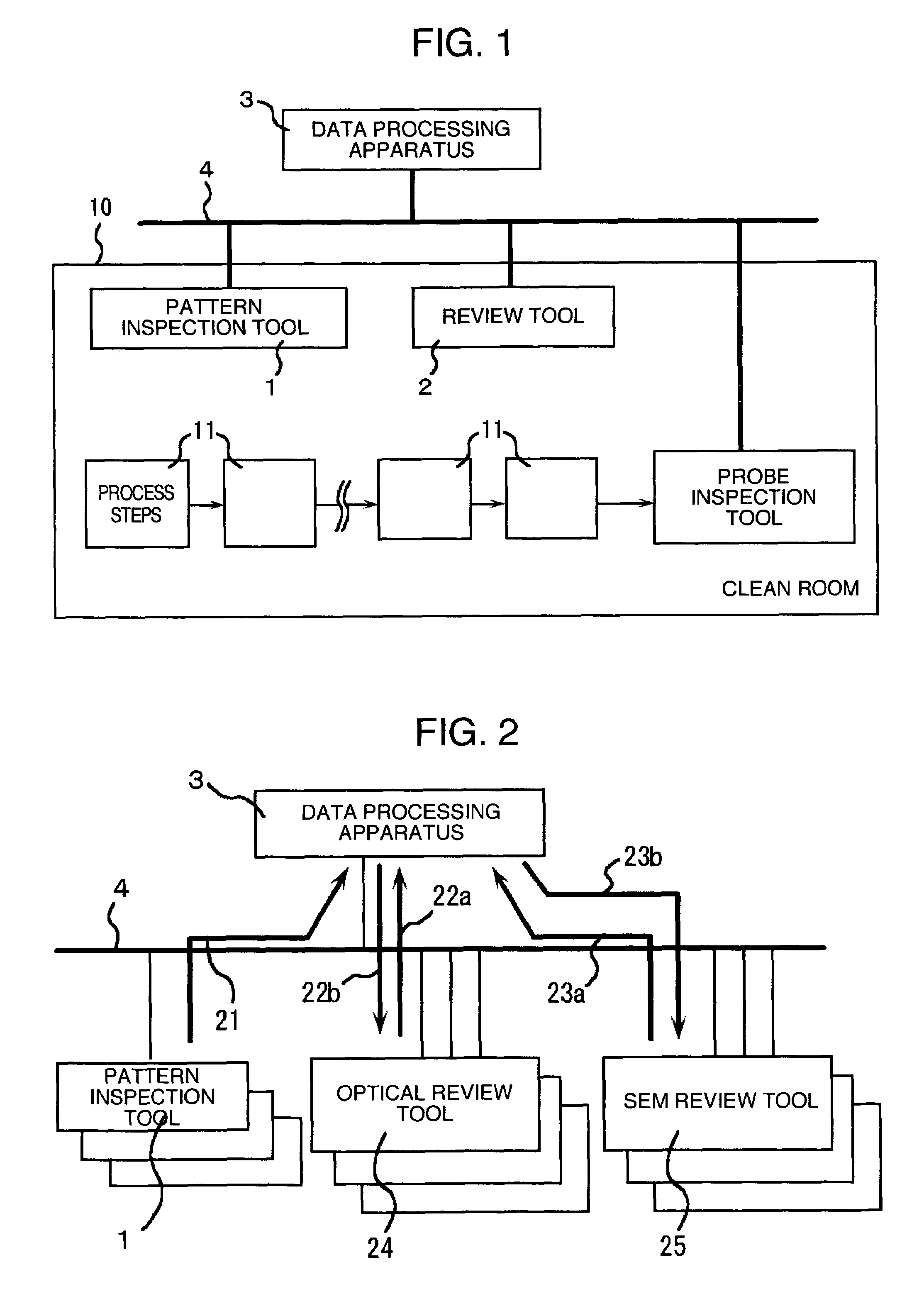

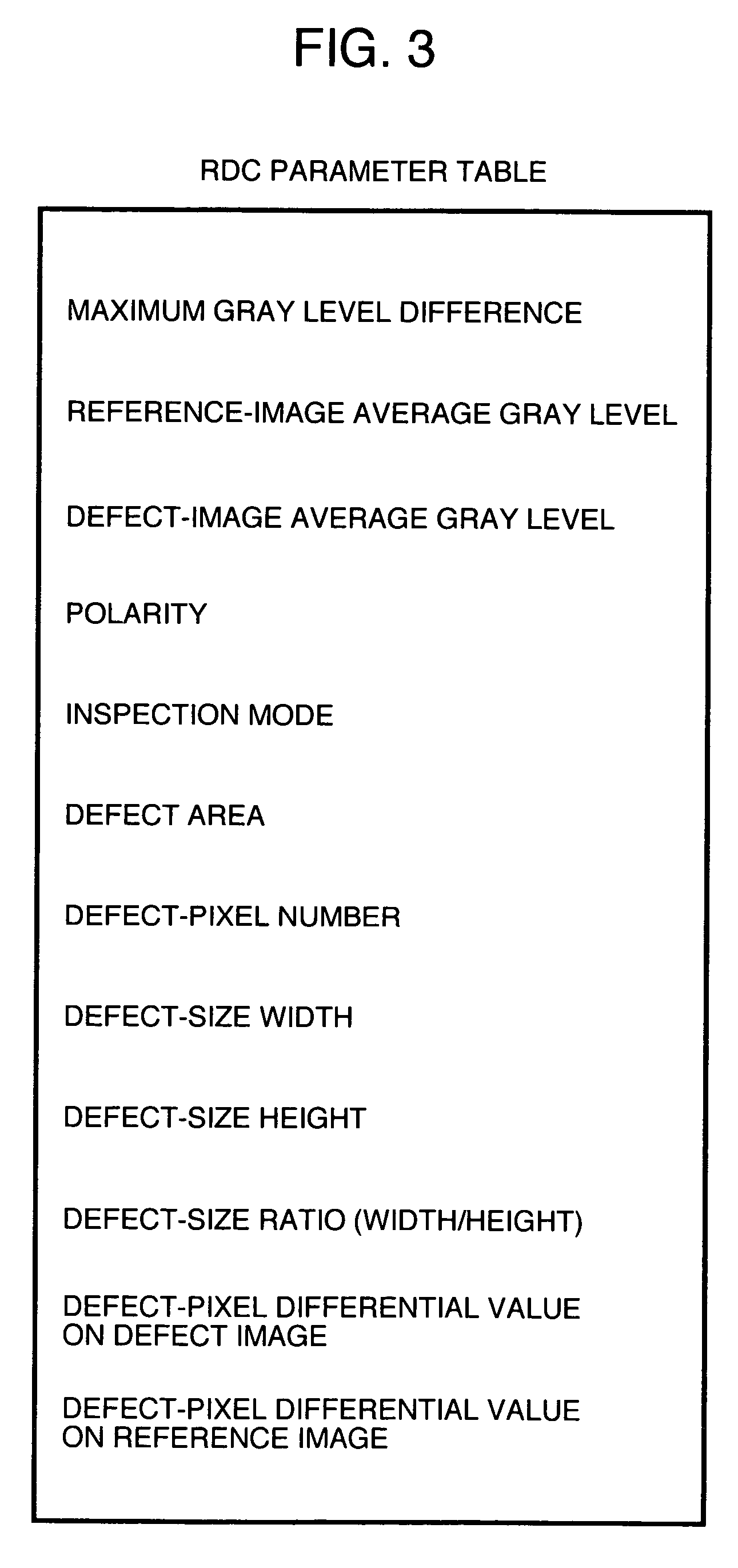

Data processing equipment, inspection assistance system, and data processing method

InactiveUS7606409B2High sensitivityAccurately determine inspection conditionCharacter and pattern recognitionColor television detailsPattern recognitionNetwork connection

A data processing apparatus, which is connected to an inspection tool and an review tool via a network, automatically receives inspection result file regarding defect information from the inspection tool and image information from the review tool. Moreover, the data processing apparatus makes comparative check between the defect, image, and attribute information outputted from the inspection tool and the defect, image, and attribute information observed in the review tool. Finally, the data processing apparatus displays, on its window, both of the above-described information in a manner of being organized and arranged side by side.

Owner:HITACHI HIGH-TECH CORP

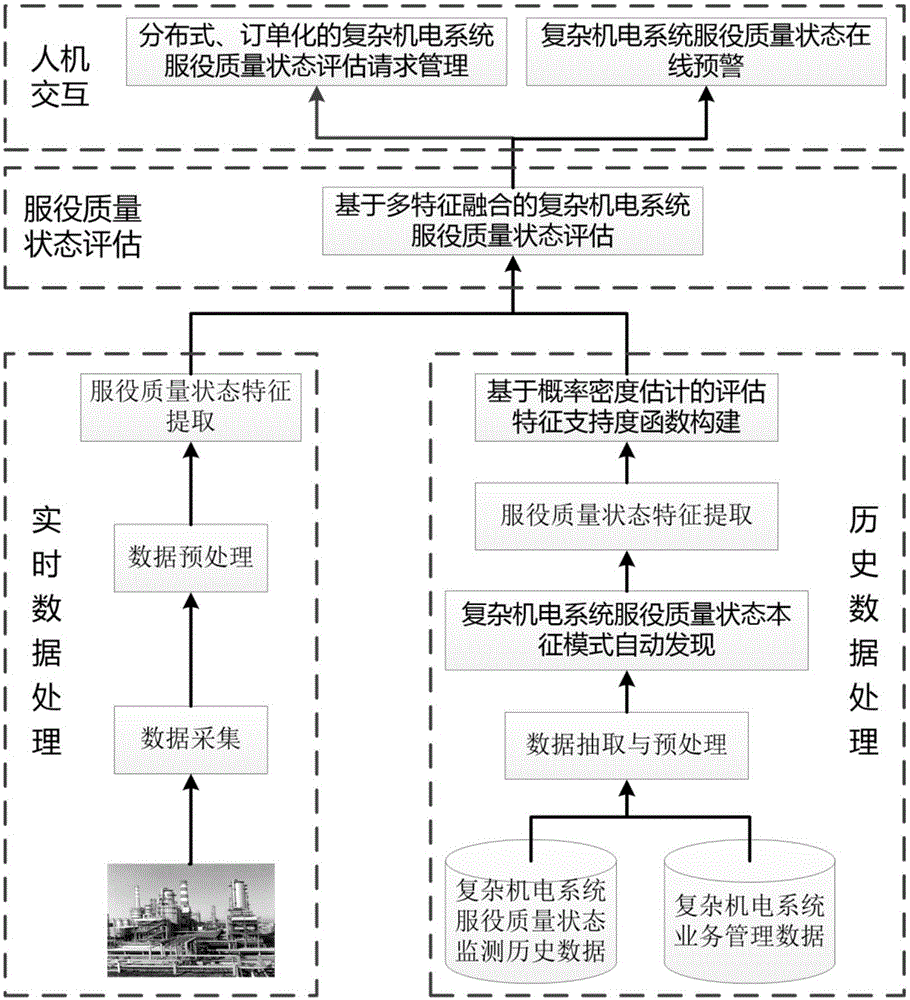

Data-driven complex electromechanical system service quality state evaluation method

ActiveCN106682835ARelaxed application conditionsAccurate assessmentRegistering/indicating during manufacturing processResourcesData-drivenComputer science

The invention discloses a data-driven complex electromechanical system service quality state evaluation method. Taking DCS state monitoring data and system service management data reflecting the system service quality state as the basis and depending on an information fusion theory, the data-driven complex electromechanical system service quality state evaluation method can perform real-time evaluation and early warning on the complex electromechanical system service quality state of an enterprise, and can perform early warning prevention on possible accidents in advance, and can assist scientific maintenance and repairing so as to improve the safety production level of the enterprise.

Owner:XI AN JIAOTONG UNIV

Abnormality detection apparatus and machine learning apparatus

InactiveCN108628253ADetect abnormalities in processing statusProgramme controlMeasurement devicesState variableMachine tool

The invention relates to an abnormality detection apparatus for machining states and a machine learning apparatus. The abnormality detection apparatus includes a machine learning apparatus for learning waveform data concerning a physical quantity detected when a machine tool is normally operating. The machine learning apparatus observes the waveform data concerning the physical quantity detected when the machine tool is normally operating, as a state variable indicating a current environmental state, and learns a feature of the waveform data concerning the physical quantity detected when the machine tool is normally operating, using the observed state variable.

Owner:FANUC LTD

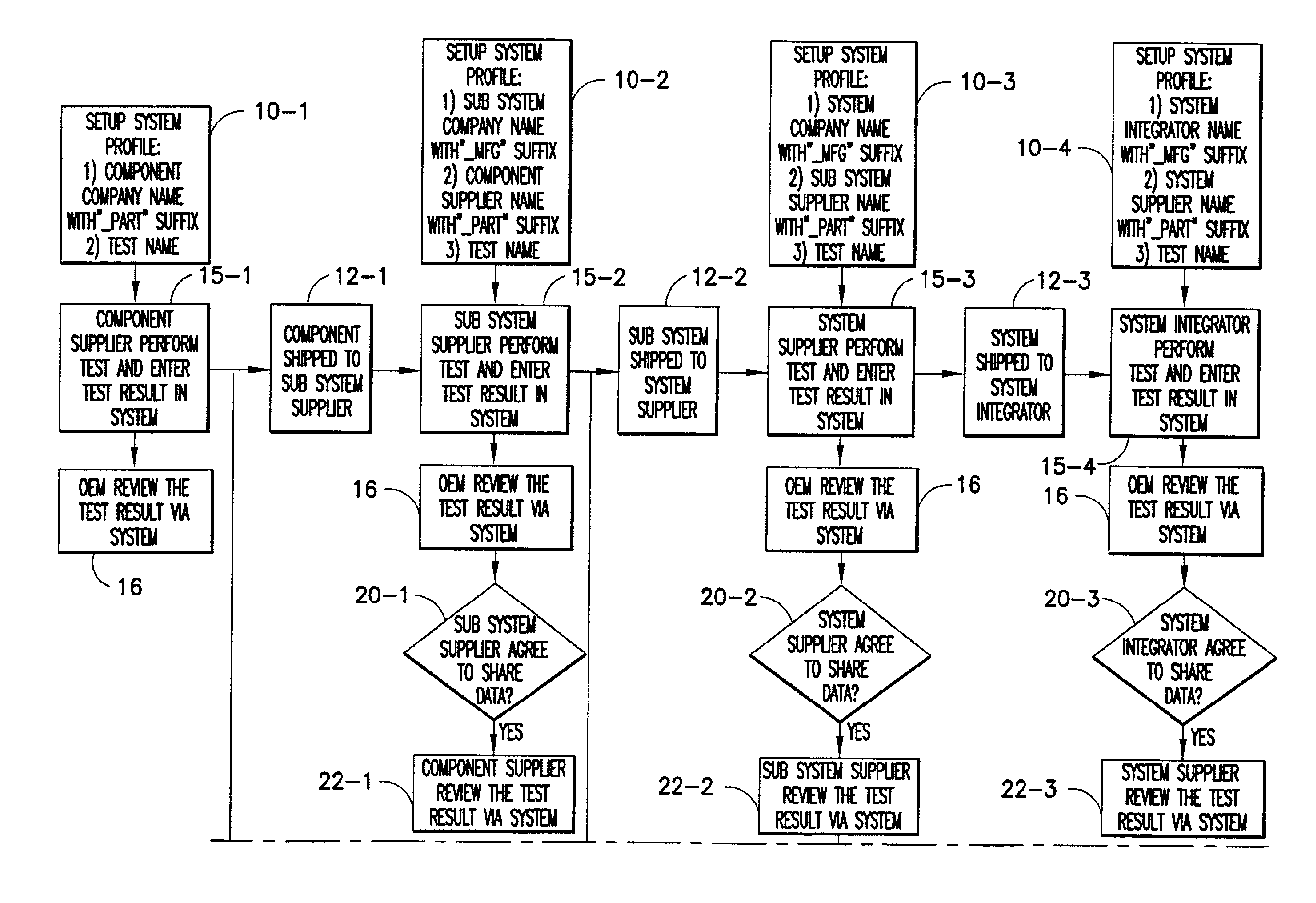

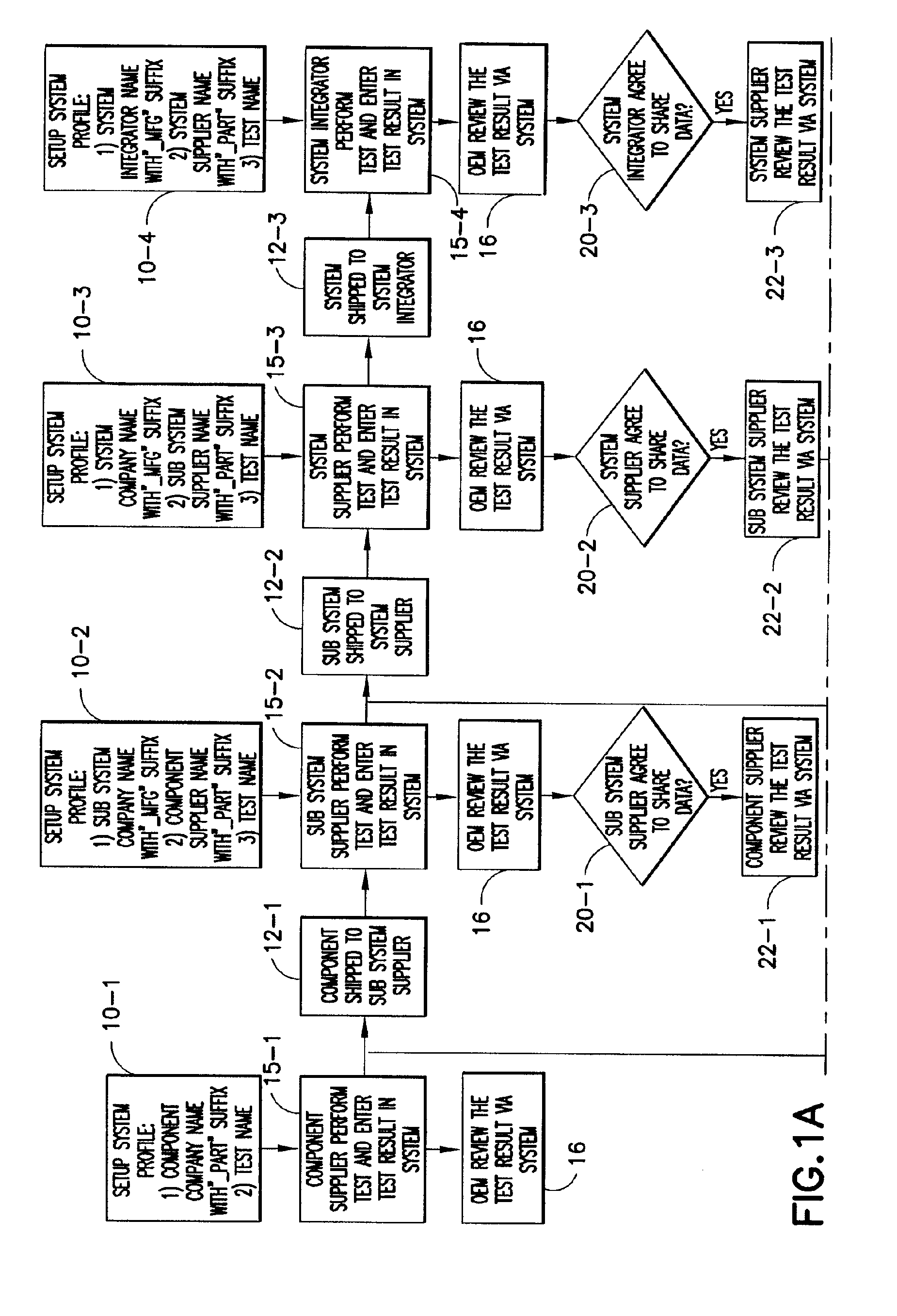

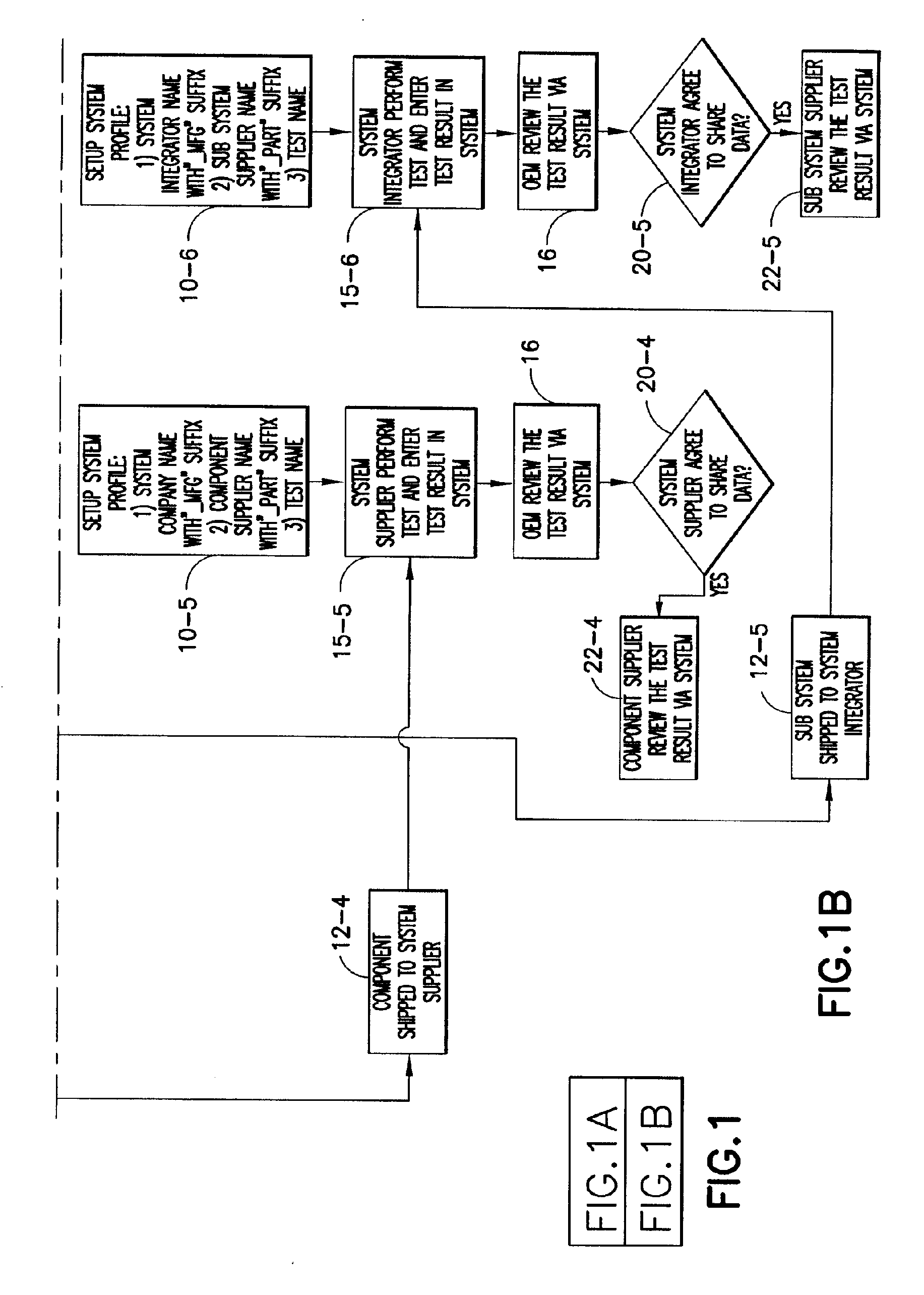

Multiple Layer Manufacturing Line Rejection Management System

InactiveUS20070061186A1Programme controlTesting/monitoring control systemsData processing systemAnalysis data

A data processing system for analyzing rejection rejections in a manufacturing process having more than one level of manufacture stores test results from an nth-level test for review by an OEM and, subject to consent of the nth level vendor, for review by a vendor on a lower level. The data for rejection analysis is linked to data in a manufacturing floor control system.

Owner:IBM CORP

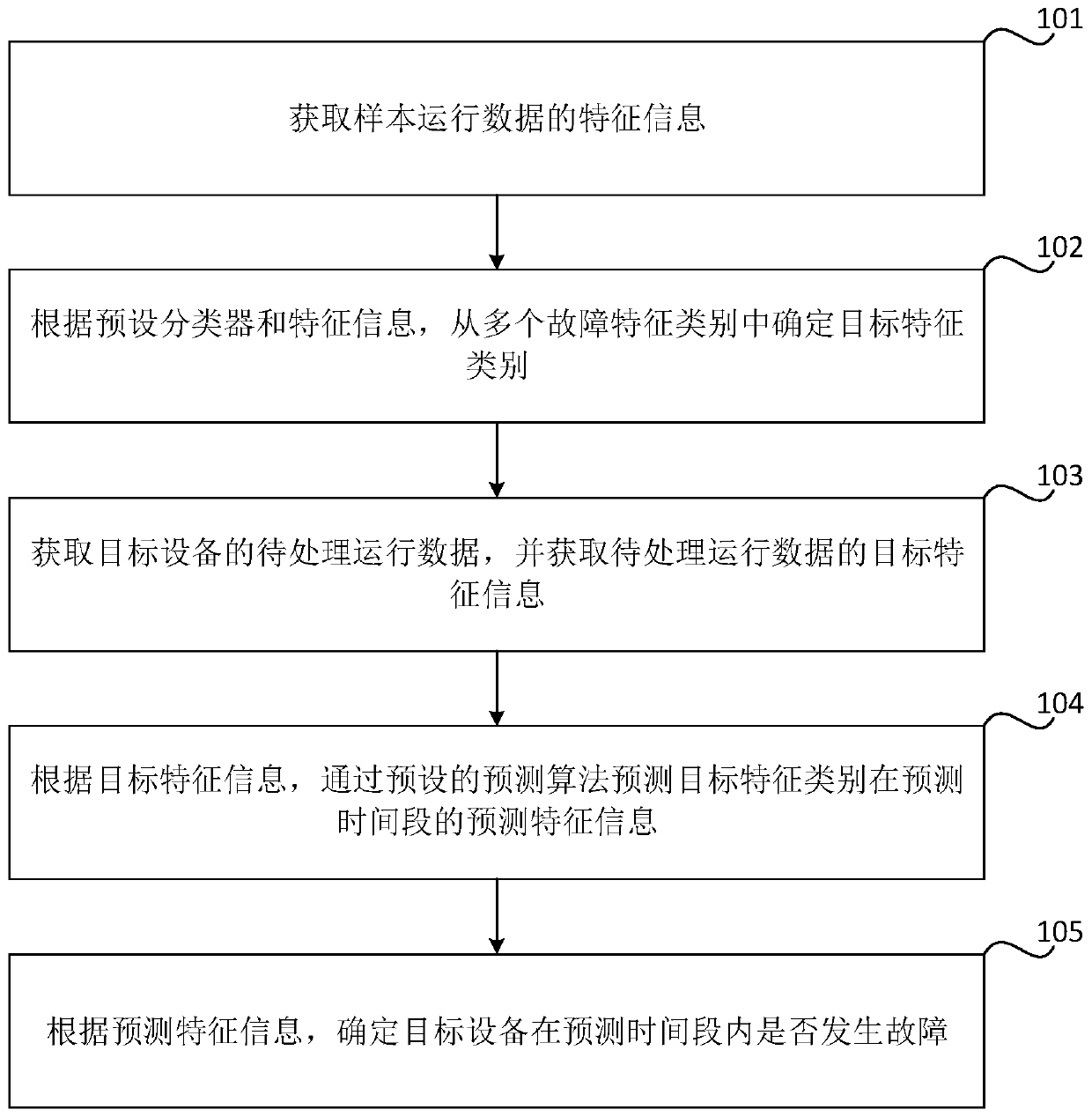

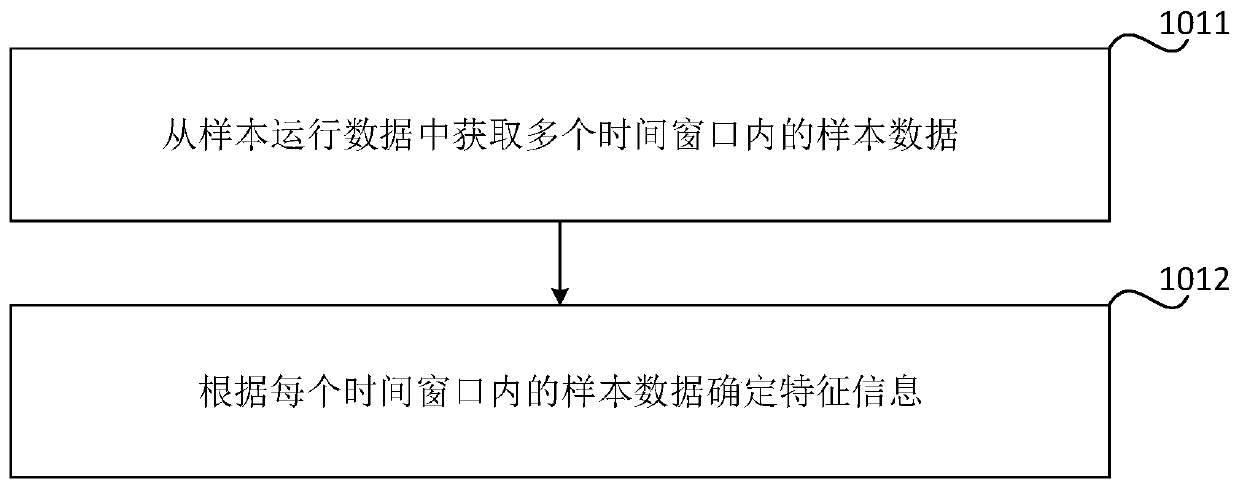

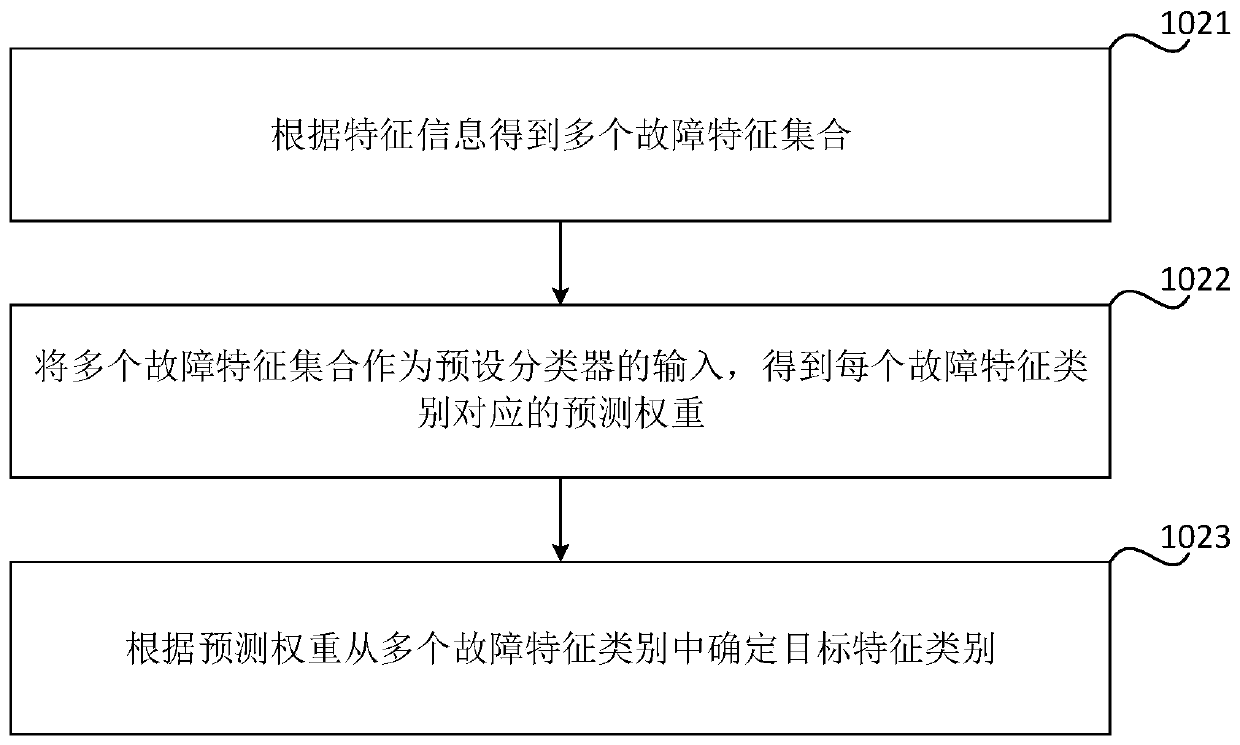

Fault prediction method and device, storage medium and electronic equipment

InactiveCN110349289AAccurate time predictionIncrease productivityCharacter and pattern recognitionRegistering/indicating during manufacturing processPrediction algorithmsFault occurrence

The invention relates to a fault prediction method and device, a storage medium and electronic equipment. Relating to the technical field of fault detection, the method comprises the following steps:obtaining feature information of sample operation data, wherein the sample operation data comprises operation data when the target equipment has a fault; according to a preset classifier and the feature information, determining a target feature category from the plurality of fault feature categories, obtaining to-be-processed operation data of the target equipment, obtaining target feature information of the to-be-processed operation data, wherein the target feature information comprises feature information corresponding to the target feature category; predicting prediction feature informationof the target feature category in a prediction time period through a preset prediction algorithm according to the target feature information, and determining whether the target equipment breaks downin the prediction time period or not according to the prediction feature information. The fault occurrence time can be accurately predicted according to the feature information contained in the operation data of the equipment, the production efficiency is improved, and the maintenance cost is reduced.

Owner:NEUSOFT CORP

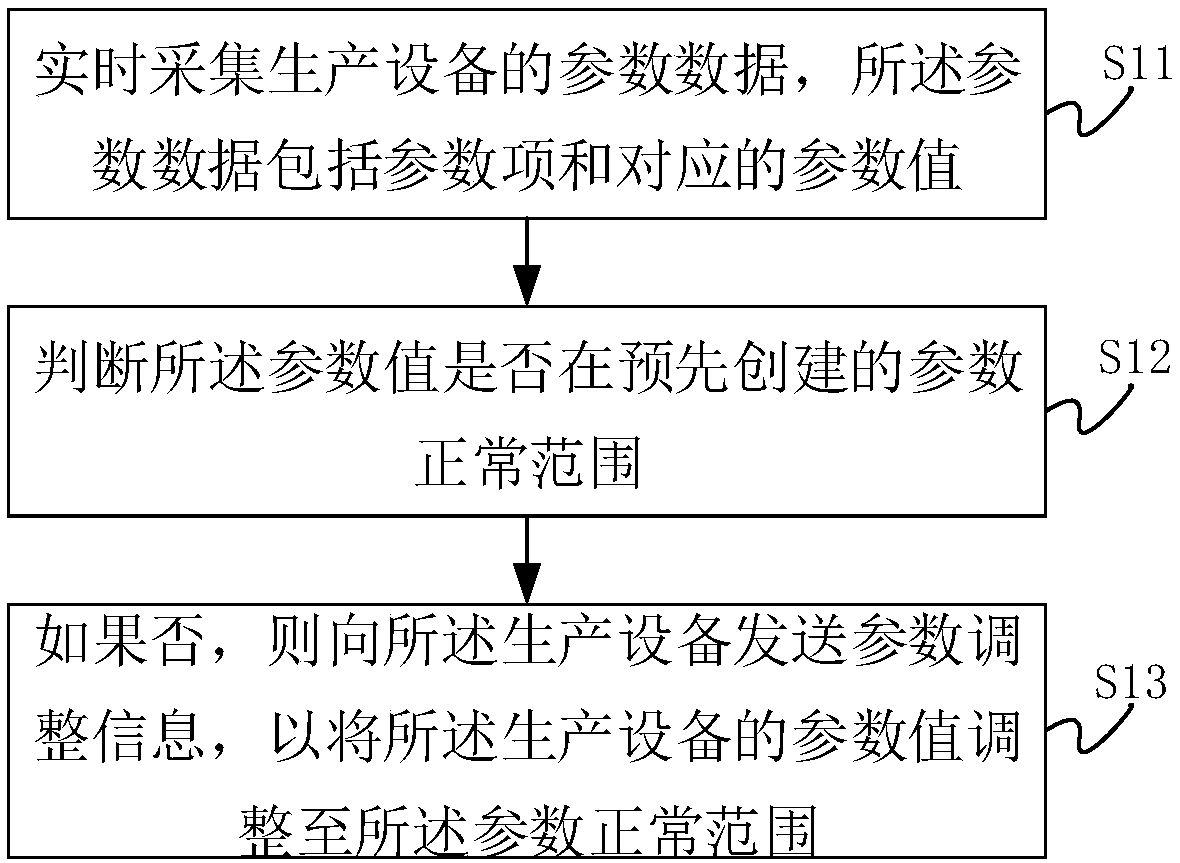

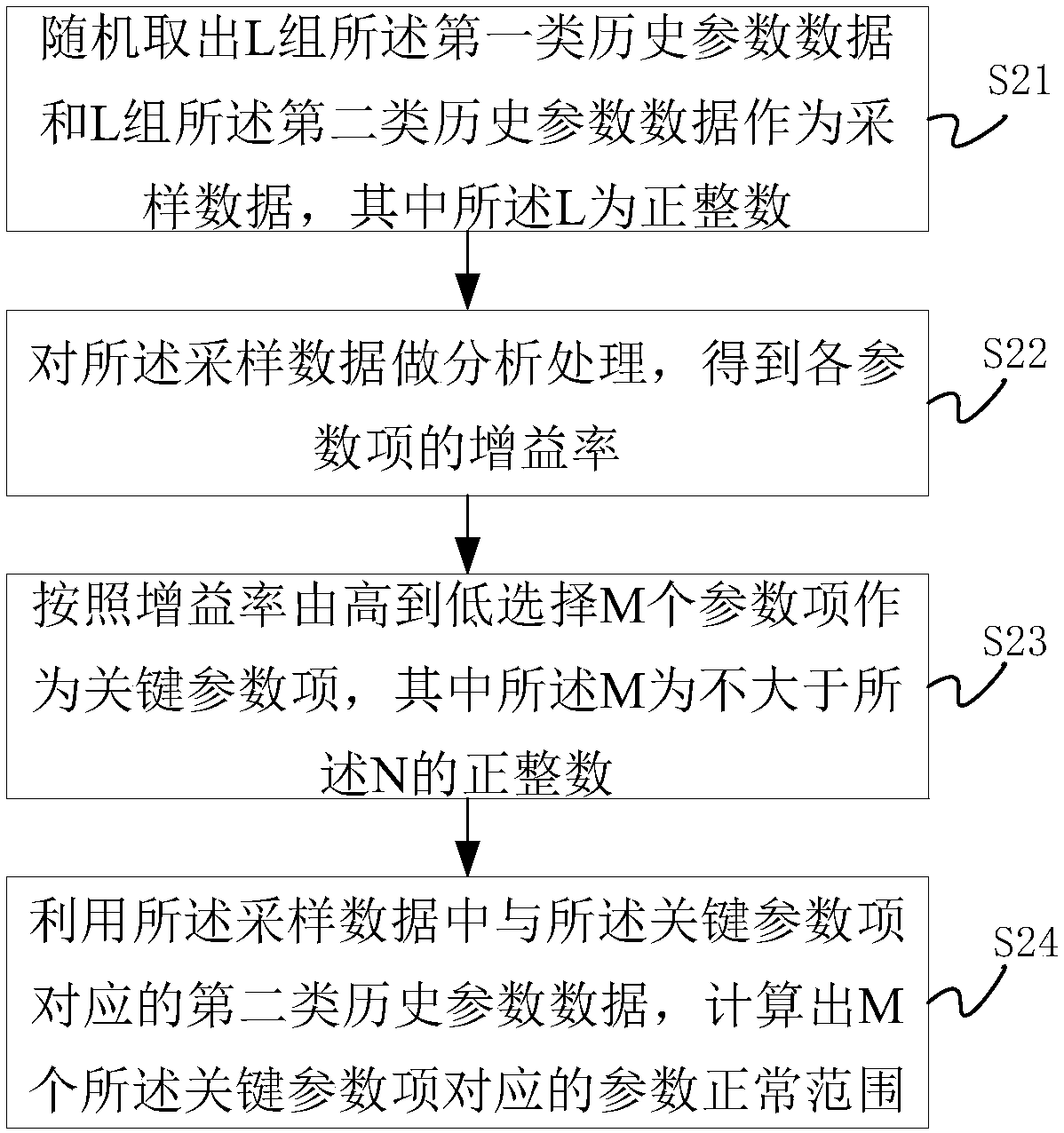

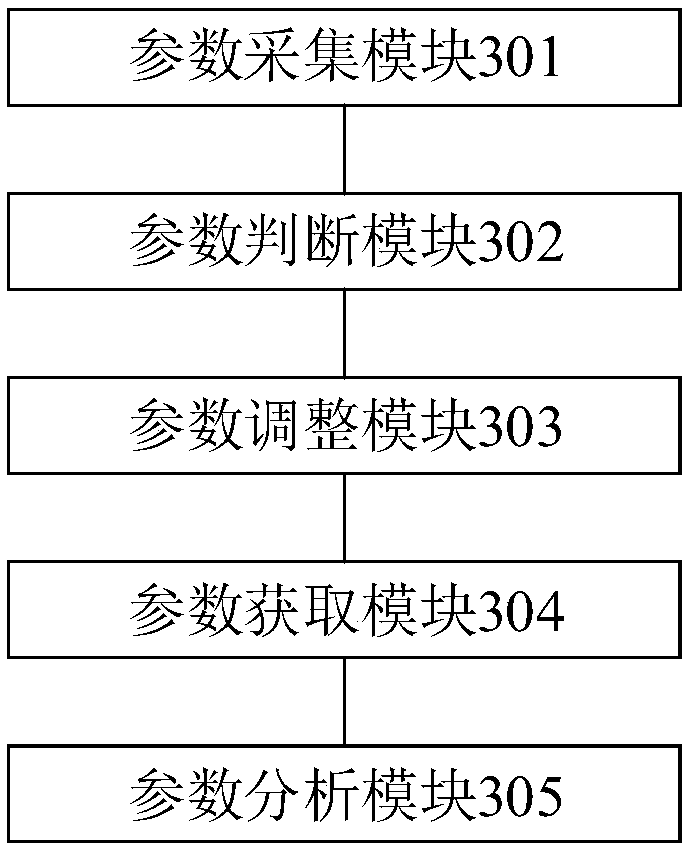

Method and device for adjusting parameters of production apparatus, computer device and readable memory

InactiveCN107657681AReduce dependenceReduce abnormal stateData processing applicationsRegistering/indicating during manufacturing processComputer scienceProduction quality

The invention provides a method and a device for adjusting the parameters of a production apparatus, a computer device and a readable memory. The method includes the following steps: acquiring parameter data of the production apparatus in real time, wherein the parameter data includes parameter items and corresponding parameter values; judging whether the parameter values are within pre-created normal parameter ranges or not; and sending parameter adjustment information to the production apparatus if the parameter values are not in the pre-created normal parameter ranges in order to adjust theparameter values of the production apparatus to the normal parameter ranges. The method for monitoring and controlling the parameters of the production apparatus in real time compares the parametersof the production apparatus with the pre-created normal parameter ranges, and the parameters of the production apparatus are adjusted if the parameters are wrong, so compared with schemes for manuallyadjusting the parameters of the production apparatus, adopted in the prior art, the method reduces the dependence on technical personnel and can timely find the abnormal state of the apparatus in order to improve the production efficiency and the production quality.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

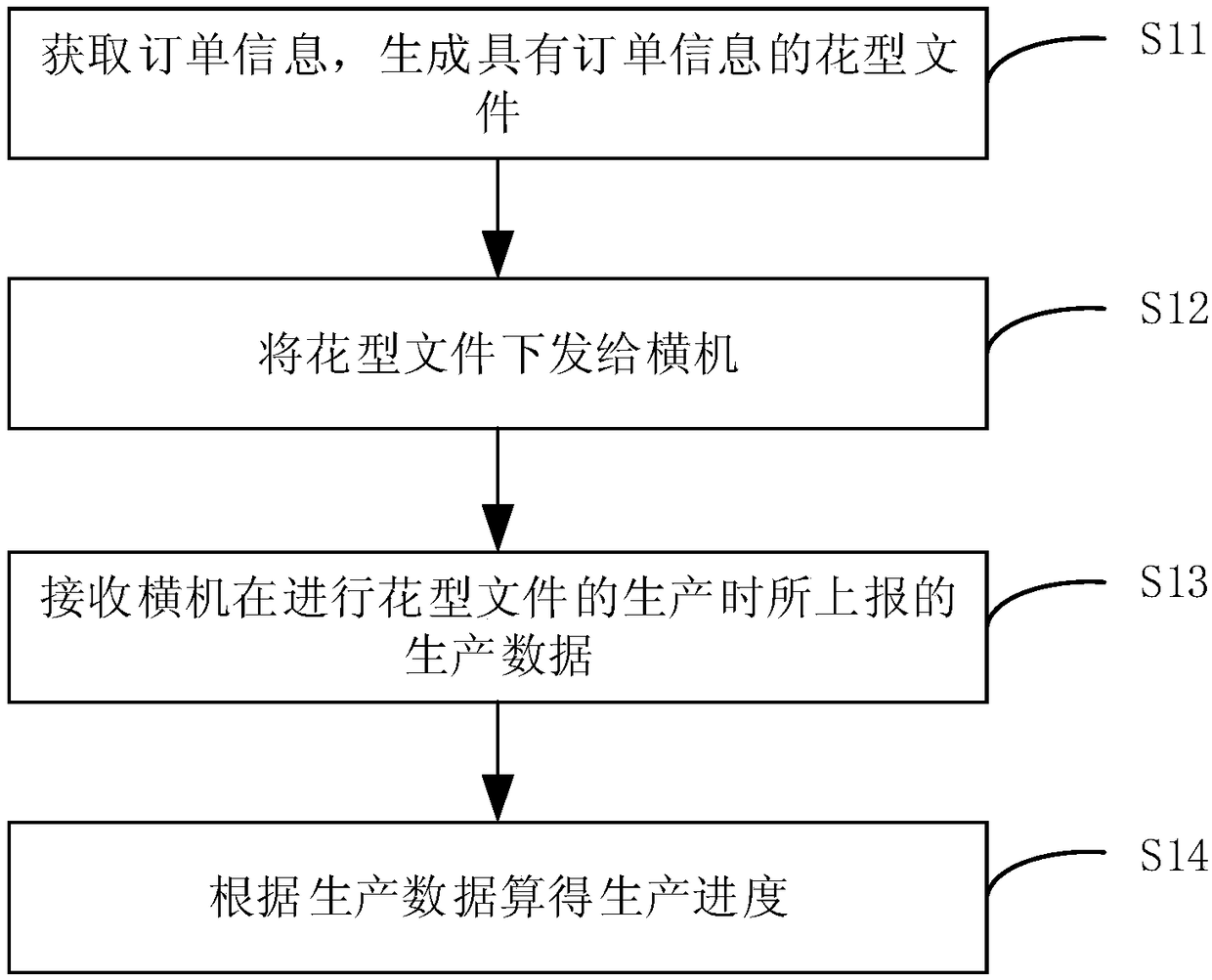

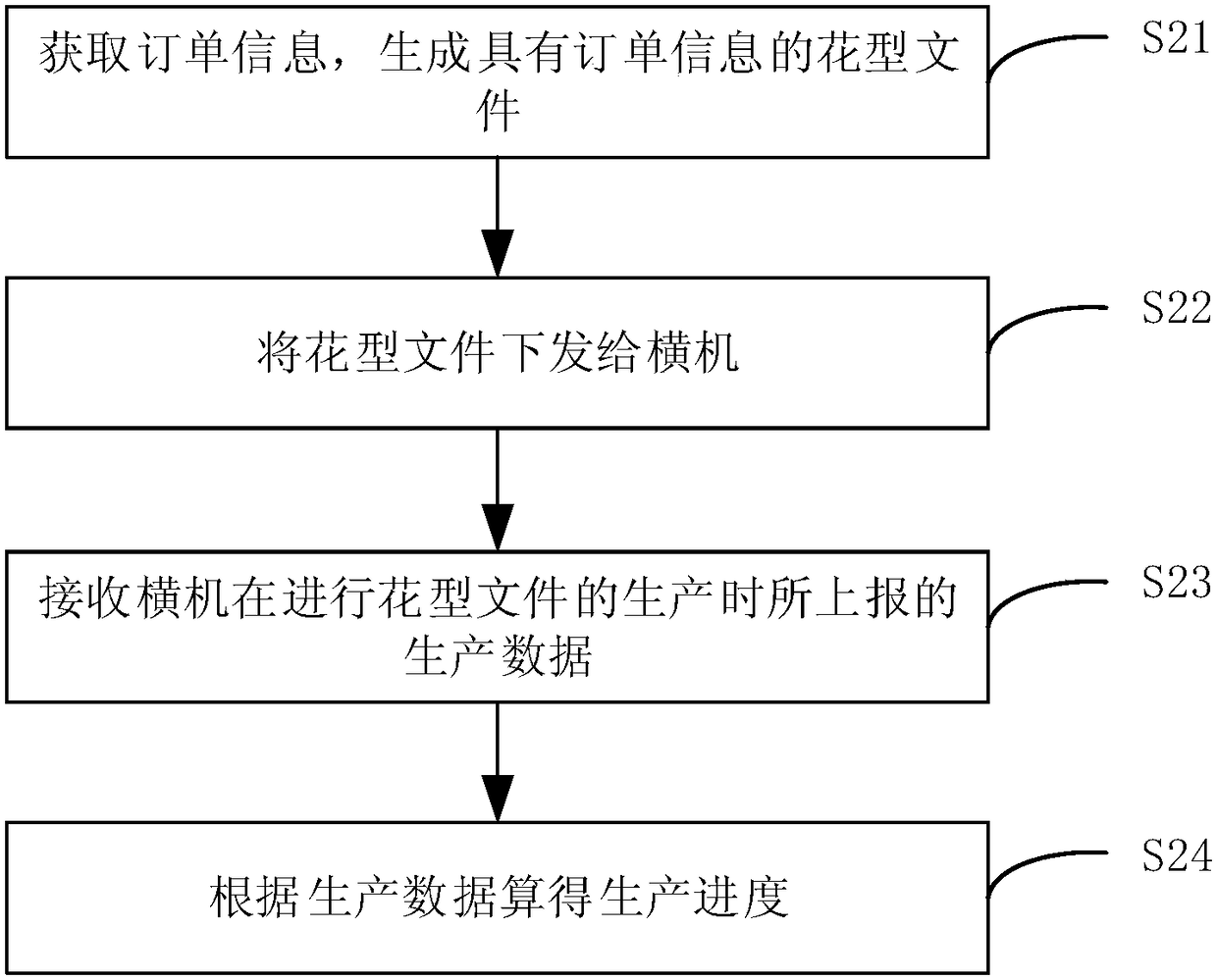

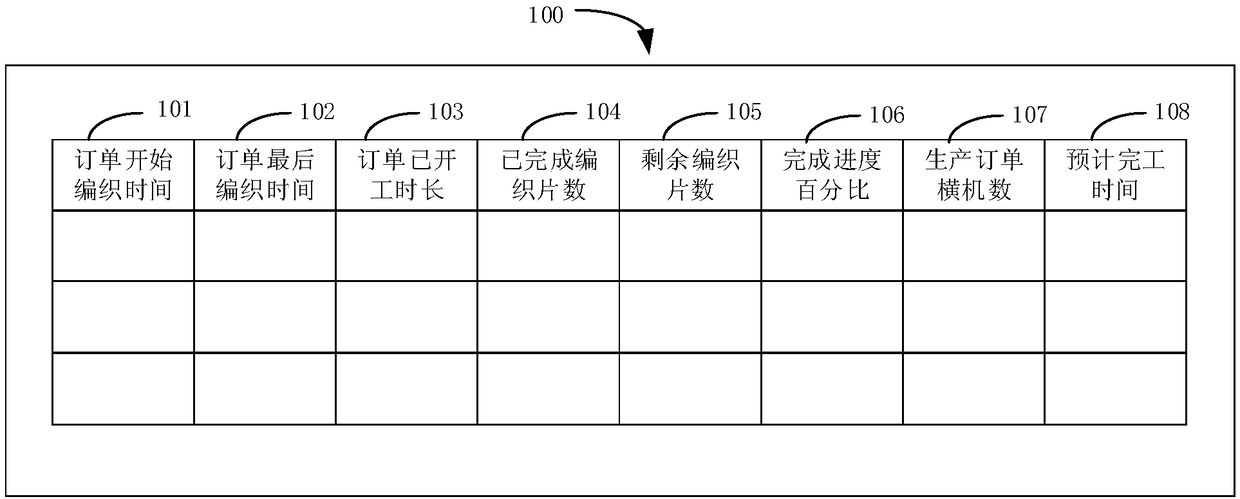

Method for monitoring production progress of flat knitting machine, terminal and computer storage medium

InactiveCN108154570AReport in timeReport accuratelyData processing applicationsRegistering/indicating during manufacturing processOrder formComputer terminal

The invention discloses a method for monitoring the production progress of a flat knitting machine, a terminal and a computer storage medium, and relates to the technical field of knitting machinery.The method for monitoring the production progress of the flat knitting machine, which is provided by the invention, comprises the following steps: acquiring order information and generating a patternfile with the order information; transmitting the pattern file to the flat knitting machine; receiving reported production data when the flat knitting machine produces according to the pattern file; and calculating the production progress according to the production data. By the method provided by the invention, the production progress can be calculated according to the production data and the production progress of the flat knitting machine can be reported timely and accurately.

Owner:FUJIAN RAYNEN TECH

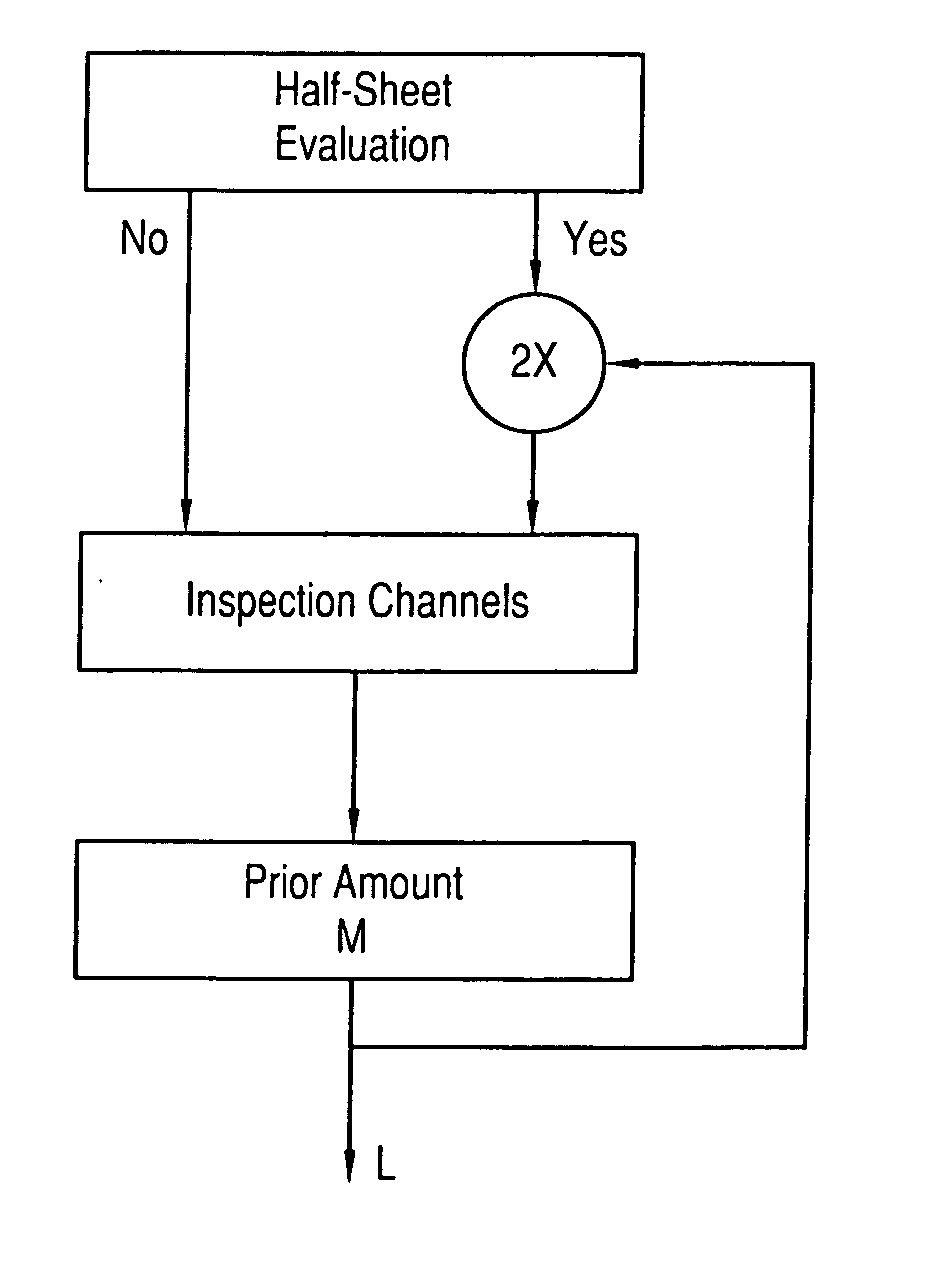

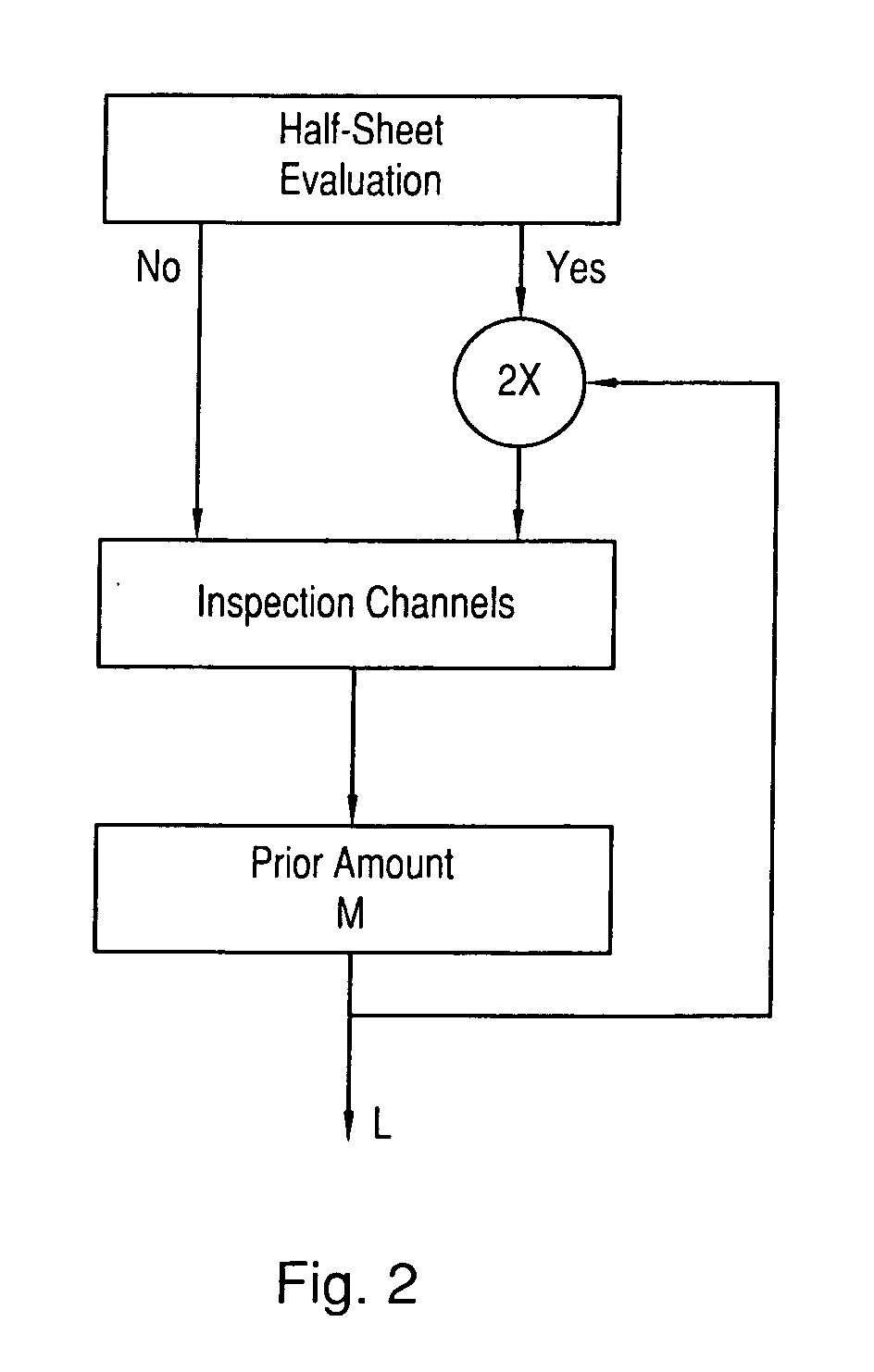

Method for Evaluating the Quality of a Printed Matter, Provided by a Printing Machine

InactiveUS20070223789A1Increase productivityImprove economyImage analysisRegistering/indicating quality control systemsEngineeringImaging data

The quality of printed matter, which is one of several copies of the same printed matter produced by a printing machine, is evaluated. An amount of copies of the printed matter is selected from the total production of this printed matter. The selected amount of these copies are evaluated with regard to at least one error type which belongs to an amount of different error types or with regard to at least one feature of the error. Within the selected amount of copies, an error of a defined error type or of a defined feature, which is detected on at least one of the copies, is evaluated in relation to at least one error of another type or feature detected on the same copy, or another copy of the selected amount. The printed matter is classified as having good or bad quality based on that evaluation. A common reading, producing image data, is obtained by an image sensor from the selected copies. All of the errors to be evaluated in relation to each other are detected from image data gathered during the same common recording.

Owner:KOENIG & BAUER AG

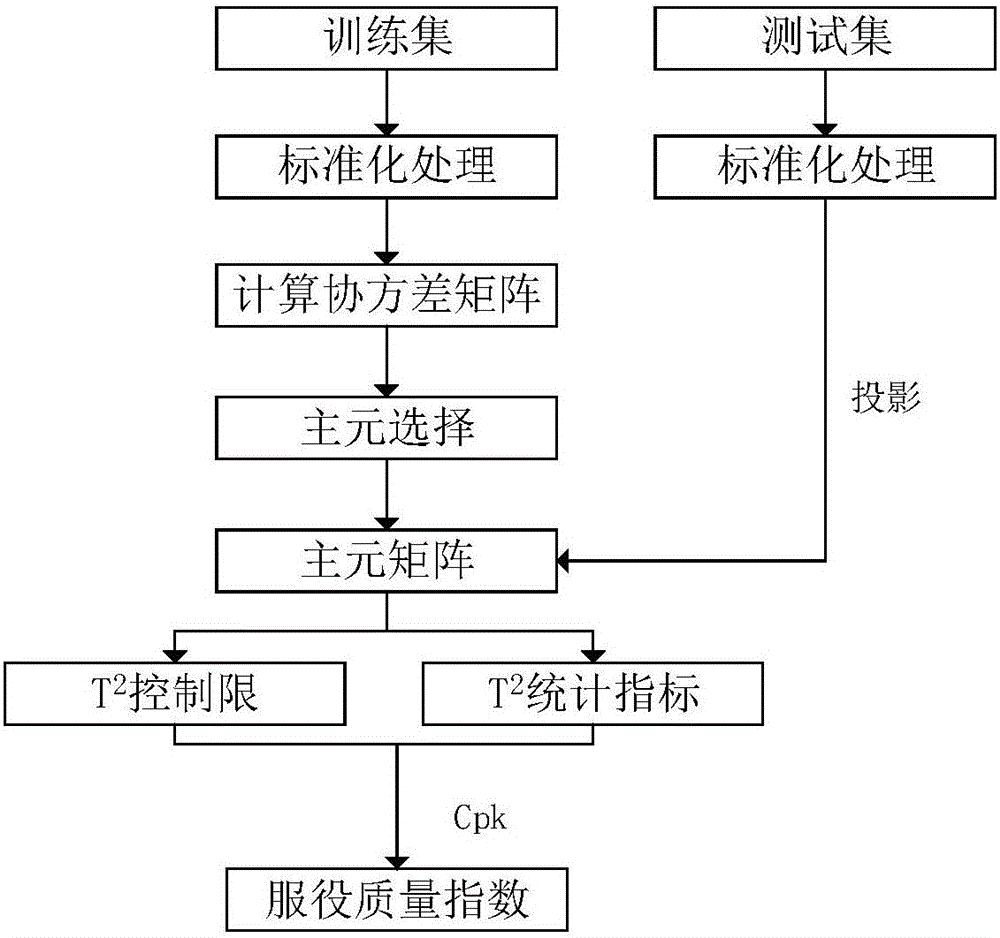

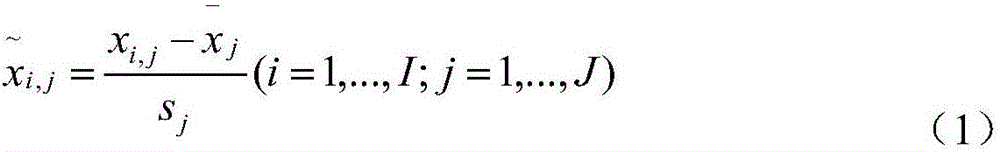

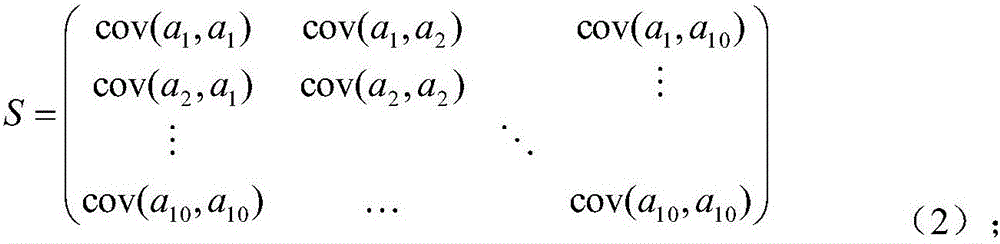

Cold continuous rolling production line service quality condition assessment method based on PCA-Cpk

ActiveCN106845826AReduce cumbersome stepsAssessing running status conciselyCharacter and pattern recognitionRegistering/indicating during manufacturing processProduction lineEngineering

The invention discloses a cold continuous rolling production line service quality condition assessment method based on PCA-Cpk. Through the three steps of data preprocessing, T2 statistical indicator and T2 control limit calculation and service quality index calculation and system service quality condition assessment, a service quality index of a cold continuous rolling production line is provided, an accurate assessment for the cold continuous rolling production line service quality conditions can be made, the early-warning and the forecasting for system failures in real time are made, accidents are prevented, and the repair and the maintenance are guided.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com