Cold continuous rolling production line service quality condition assessment method based on PCA-Cpk

A state evaluation and production line technology, applied in the direction of registering/indicating machine work, resources, registering/indicating, etc., can solve problems such as inability to reflect the operating state of the production line, difficulty in setting target values, and one-sided early warning methods, etc., to achieve guidance for maintenance, maintenance, Easy to automate and reduce the effect of cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with specific embodiments and accompanying drawings.

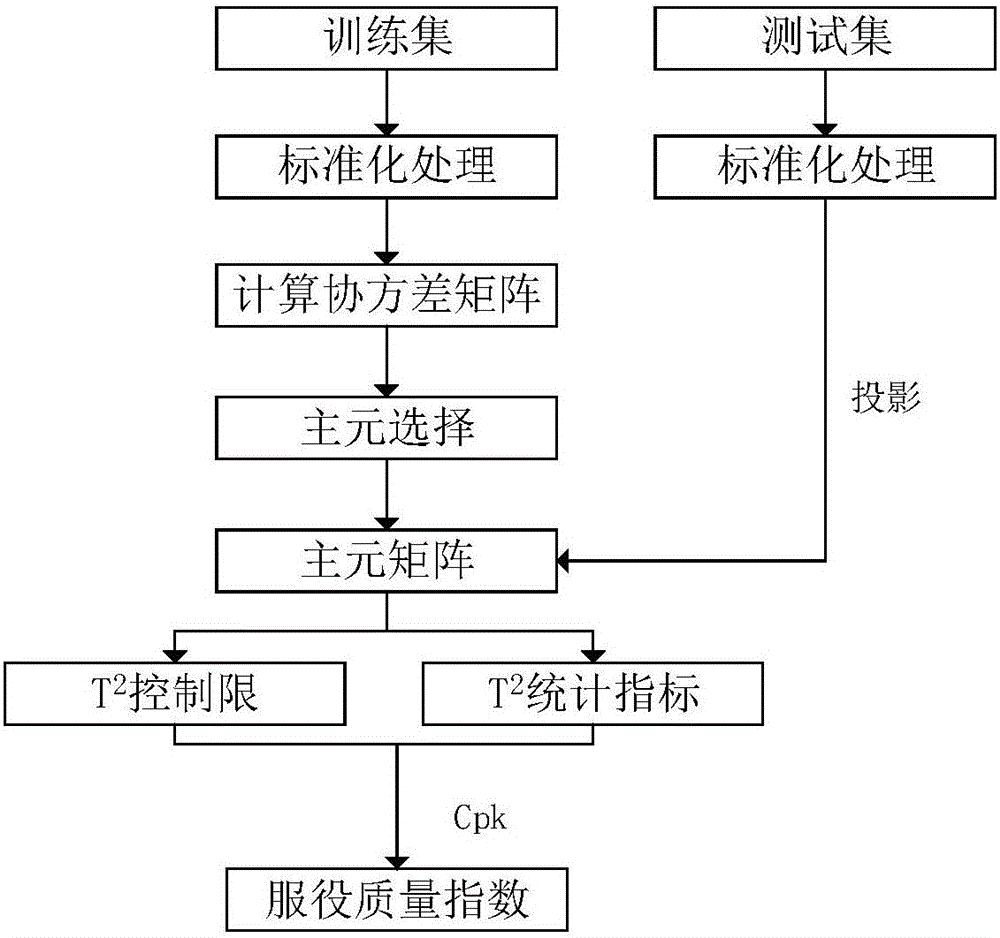

[0037] see figure 1 , the present invention comprises the following steps:

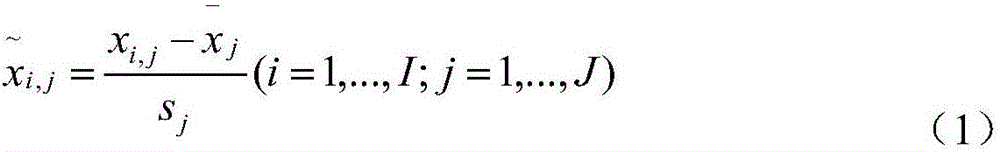

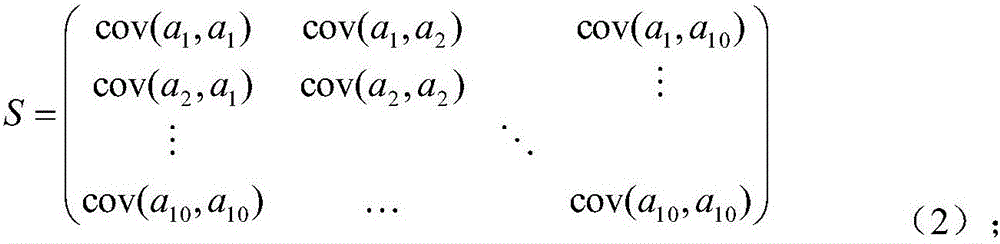

[0038] 1) Extract the service quality status evaluation data from the on-site data acquisition system of the tandem cold rolling production line, establish the original matrix, and standardize the original matrix, including the following steps:

[0039] 1.1) Select the evaluation data of service quality status during the normal operation of the cold tandem rolling production line as the training set, establish a standard model library, select the current service quality status evaluation data of the current tandem cold rolling production line as the test set, and establish the original matrix of the training set and the test set respectively. Set the original matrix; the evaluation data of the service quality state includes extracting the current, torque, speed, force, di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com