Check tool for automobile instrument panel crossbeam left bracket sub-assembly

A left bracket and sub-assembly technology, used in instruments, measuring devices, mechanical devices, etc., can solve the problems of high operator requirements, long detection time, low measurement efficiency, etc., to achieve high detection accuracy, easy to move and transport. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

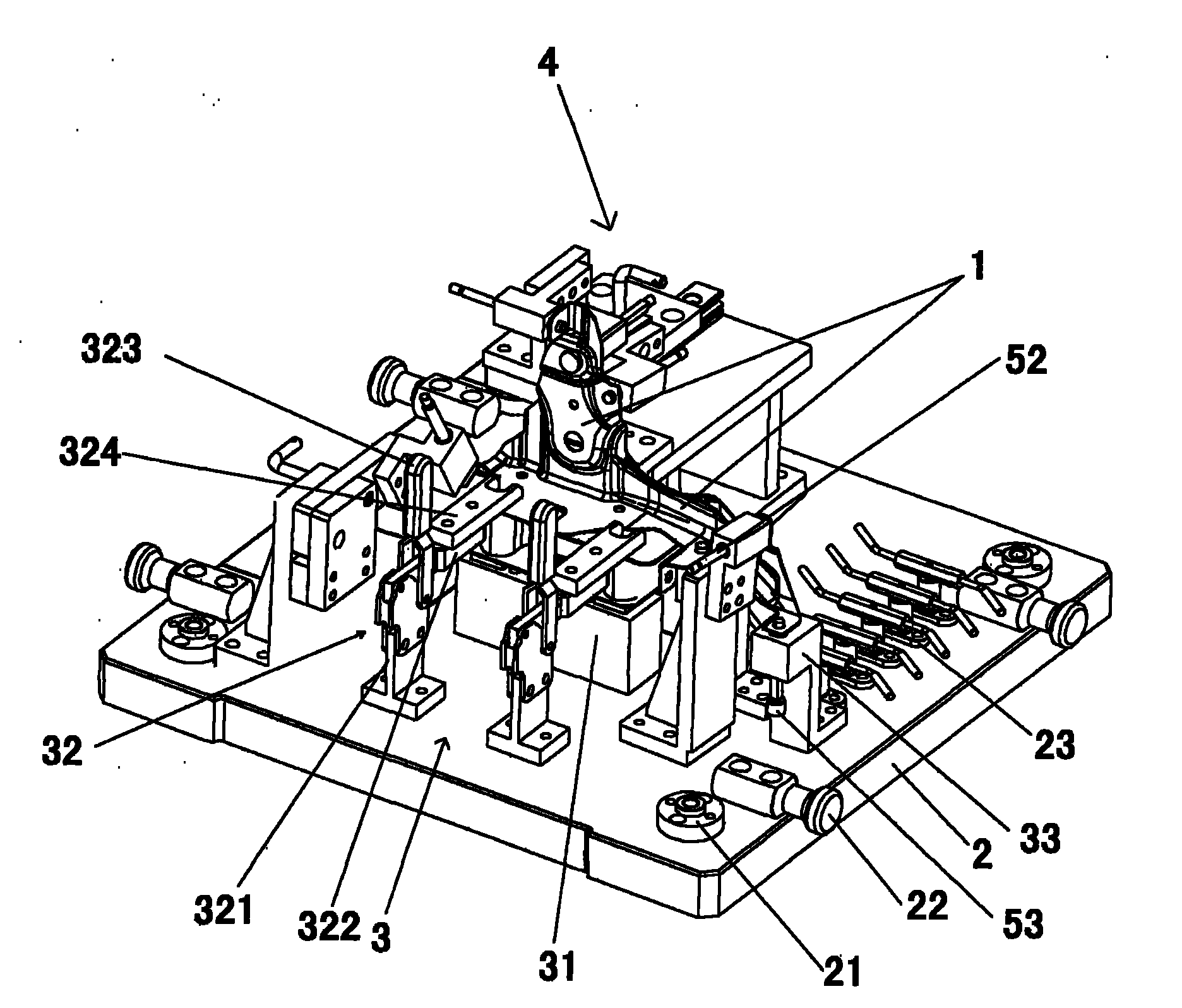

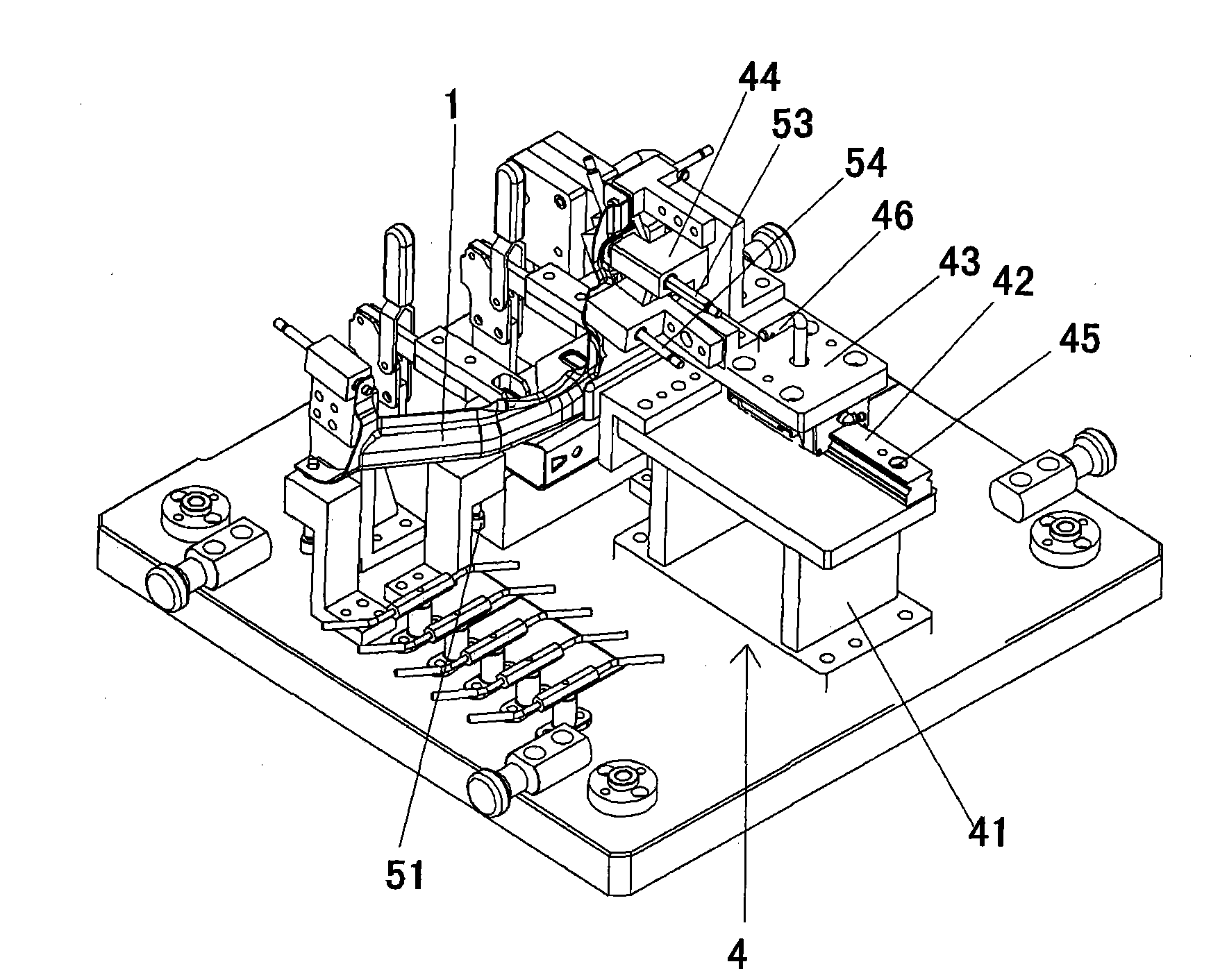

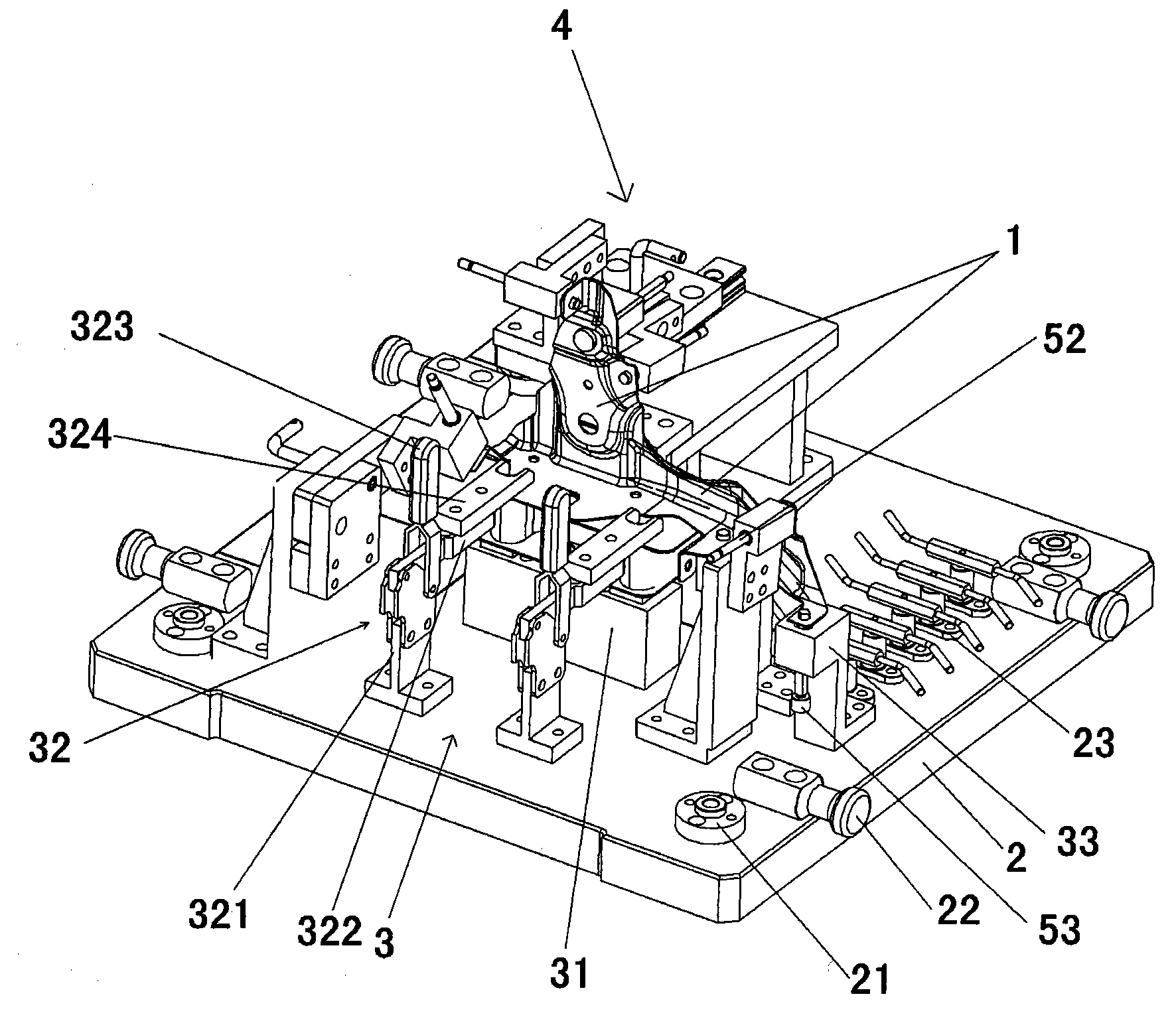

[0021] Such as figure 1 , figure 2 As shown, a test tool for the left bracket sub-assembly 1 of an automobile instrument panel crossbeam includes a base 2, a clamping mechanism 3 and a detection mechanism 4, the clamping mechanism 3 and the detection mechanism 4 are all arranged on the base 2, the instrument panel The crossbeam left bracket subassembly 1 is horizontally arranged in the middle of the clamping mechanism 3 along its length direction, and the detection mechanism 4 is arranged on the opposite side of the clamping mechanism 3 .

[0022] The base 2 can be made of metal with a cuboid structure. In order to reduce its weight, it can also adopt a hollow shell structure. The base 2 is provided with a fixing hole 21 for fixing the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com