Abnormality detection apparatus and machine learning apparatus

An anomaly detection and machine learning technology, applied in machine learning, measuring devices, neural learning methods, etc., can solve problems such as inability to detect processing content, inability to apply anomaly detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

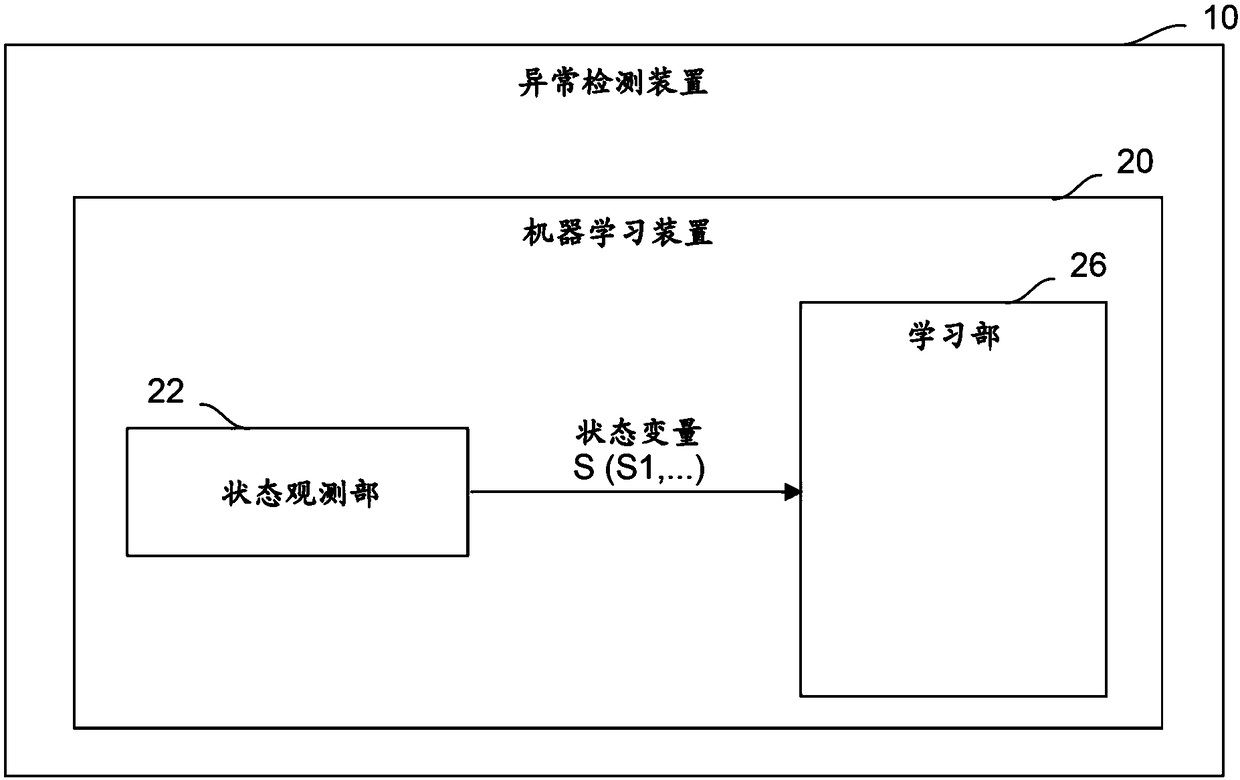

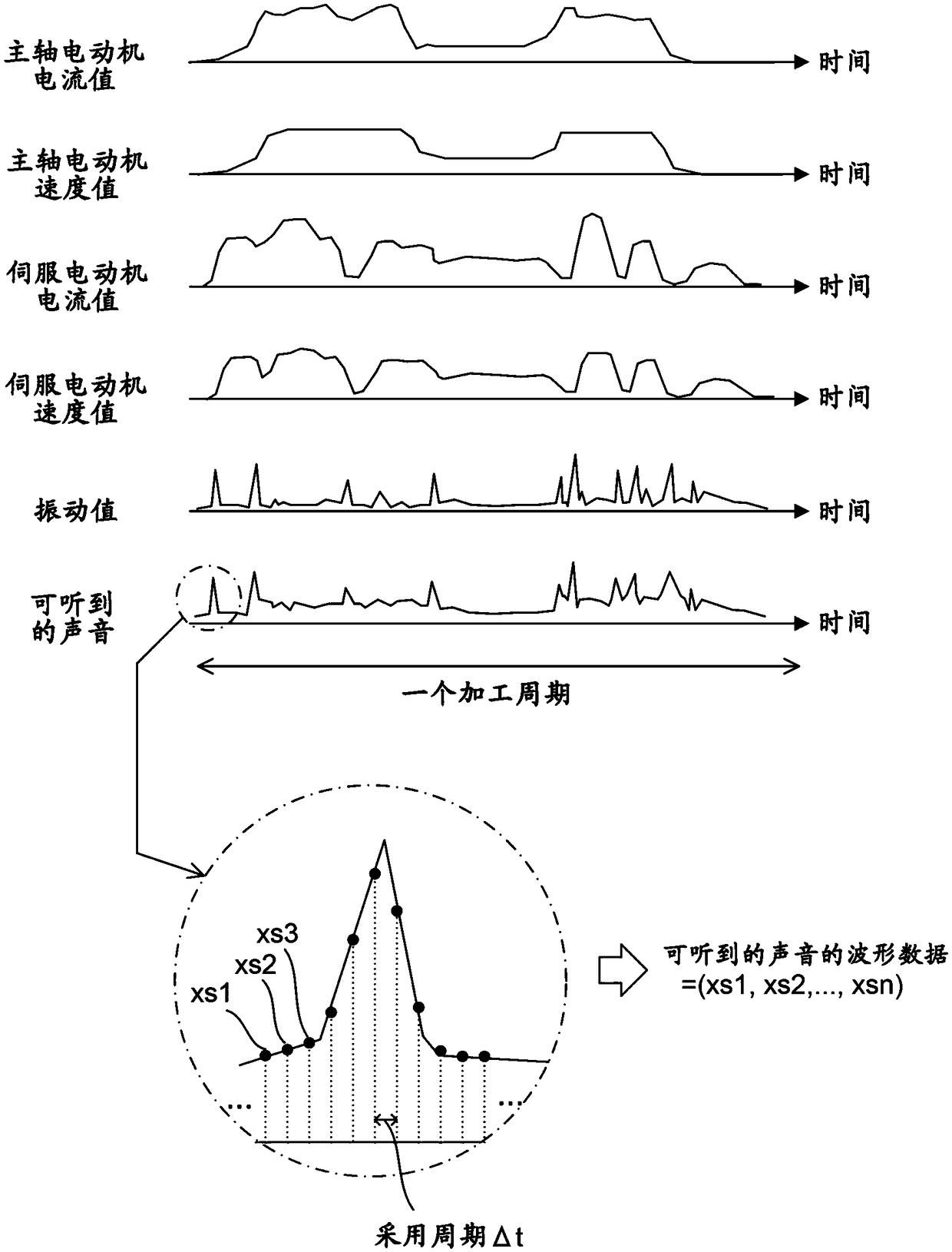

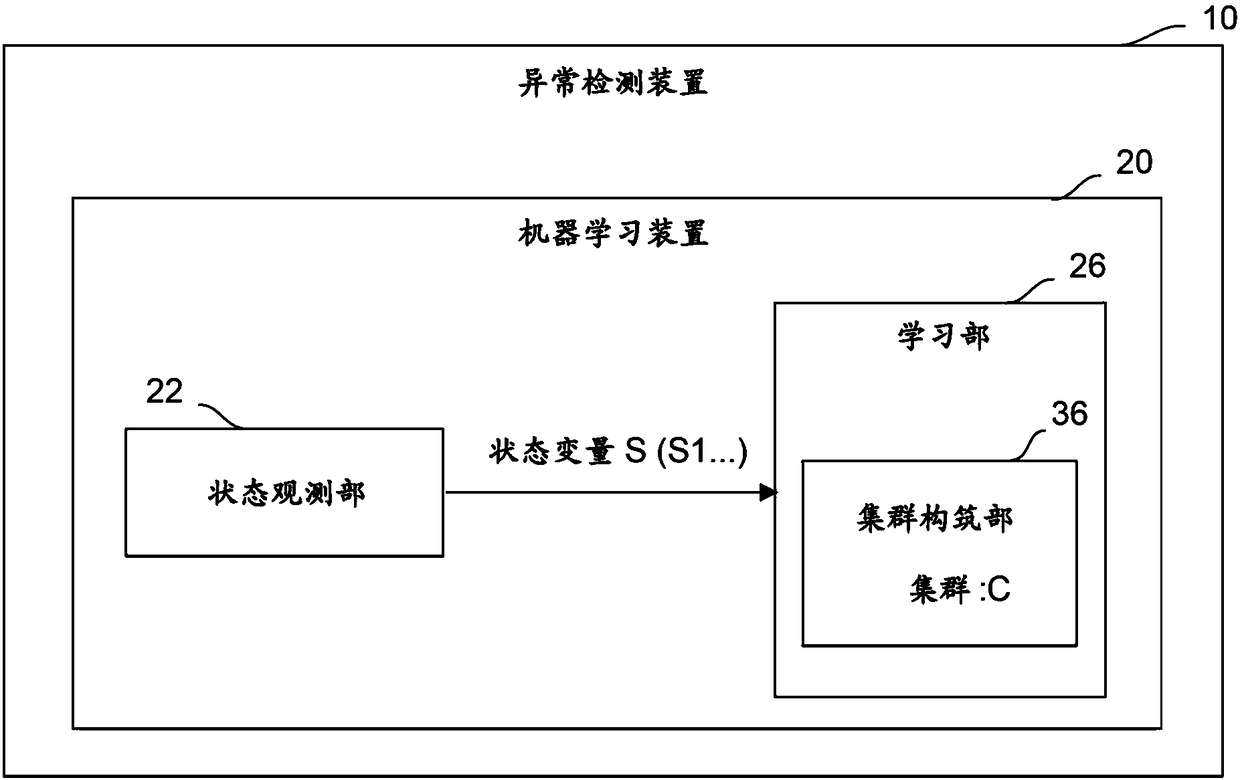

[0028] figure 1 It is a schematic functional block diagram of the abnormality detection apparatus 10 of 1st Embodiment. The abnormality detection device 10 includes a machine learning device 20 for autonomously learning, by so-called machine learning, the value of a physical quantity (current value or speed value of a spindle motor / servo motor) detected during machining performed in a normal operating machine tool. , the vibration value detected from the machine tool, the audible sound, etc.) related to the software (learning algorithm, etc.) and hardware (computer CPU, etc.) equivalent to one processing cycle or waveform data of an arbitrary interval. The content learned by the machine learning device 20 included in the abnormality detection device 10 corresponds to a model structure corresponding to one machining cycle or waveform data of an arbitrary interval related to the value of a physical quantity detected from a machine tool operating normally during machining.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com