Tool wear state identification method based on vibration and acoustic emission

A technology for tool wear and state recognition, applied in character and pattern recognition, neural learning methods, registration/indicating machine work, etc., can solve problems such as inability to apply, immature tool state monitoring technology, etc., achieve sensitivity, easy installation, The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

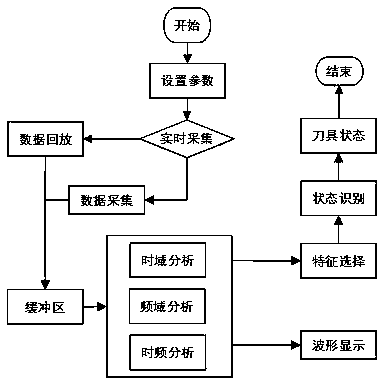

[0014] Embodiment 1: as figure 1 As shown, a tool wear state recognition method based on vibration and acoustic emission, the method steps are as follows:

[0015] The method steps are as follows:

[0016] S1. Collect vibration signals in cutting processing through vibration signal acquisition equipment, and collect acoustic emission signals in cutting processing through acoustic emission signal acquisition equipment (vibration signal acquisition equipment and acoustic emission signal acquisition equipment need to set sampling parameters: such as sampling time, sampling frequency, number of sampling points);

[0017] S2. Vibration signal and acoustic emission signal are respectively based on the amount of the three cutting elements and the wear state of the tool (according to the needs of processing, the wear state of the tool is divided into three stages: initial wear of the new knife, normal wear, and severe wear. In order to obtain these three For tools with different deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com