System and method for electronically identifying vehicle wheels on-the-fly during manufacture

a technology of electronic identification and vehicle wheels, applied in vehicle testing, structural/machine measurement, instruments, etc., can solve the problems of less than 100% reliable, high cost and high cost, and a difficult machine vision task, so as to achieve reliable machine identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

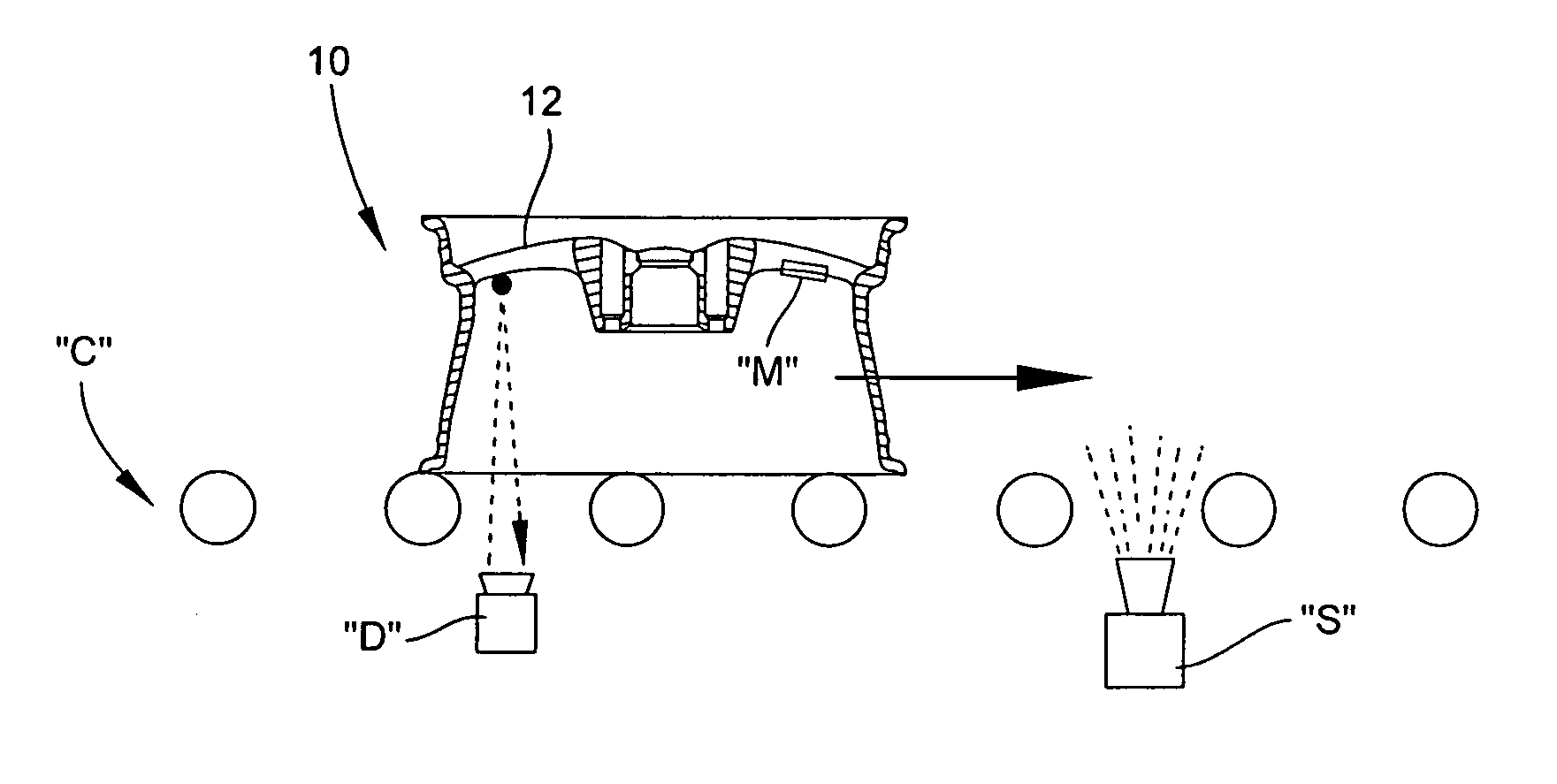

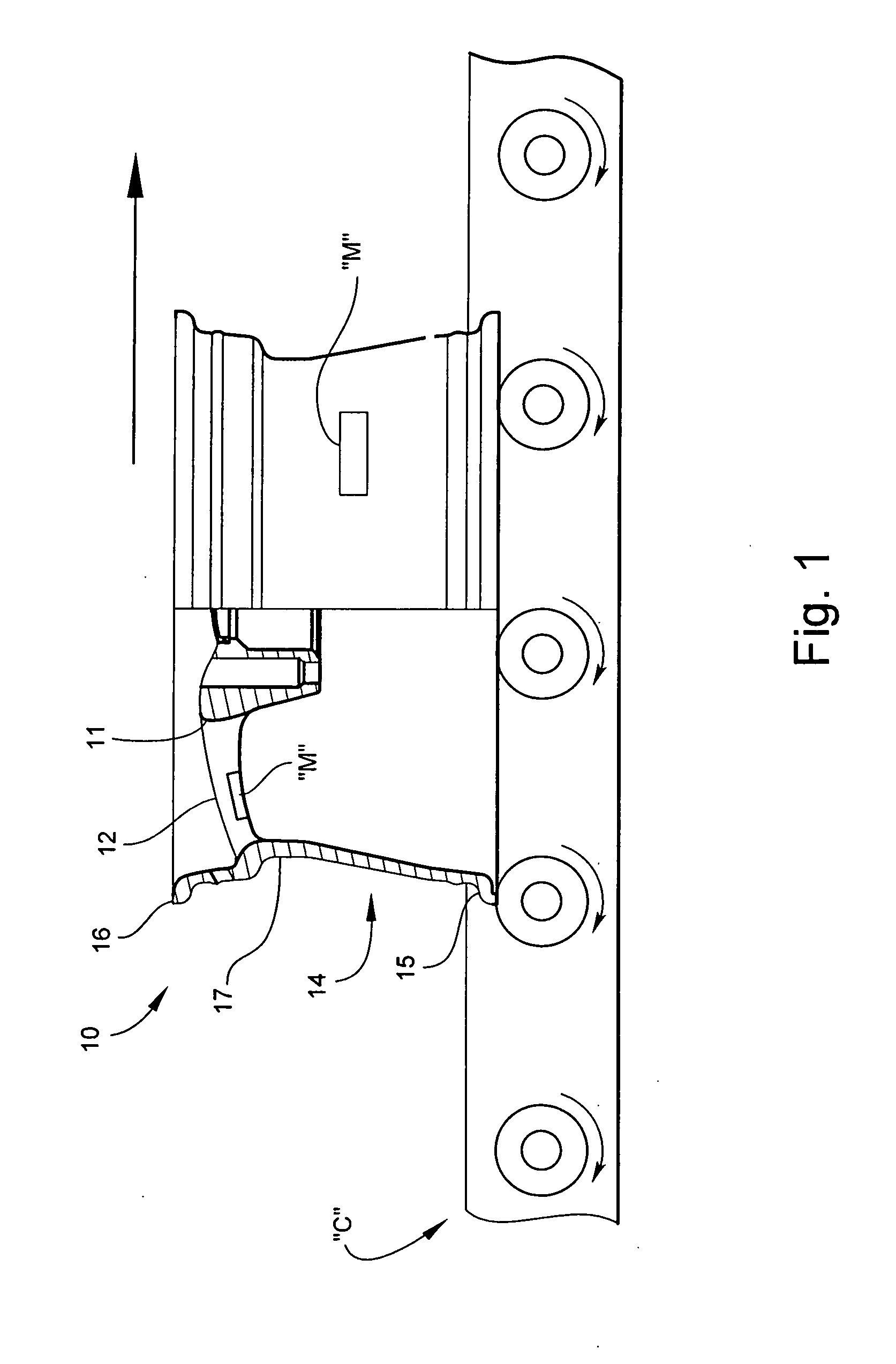

[0050] the present system is illustrated in FIGS. 6 and 7. The wheel identification mark “M” is applied to the underside of a hub spoke 12, as previously described. As the vehicle wheel 10 is moved downstream on the roller conveyor “C”, an under-mounted distance measurement device “D” determines the exact distance between the device and the underside of the hub spoke 12. Motion sensors or other suitable means (not shown) are employed to activate the device “D”. This distance measurement is then transmitted to a series of laterally-spaced scanners “S” having respective overlapping fields of view. Based on the transmitted distance, the DOF is automatically adjusted for each of the scanners “S”. As the wheel 10 passes vertically over the scanners “S”, the identification mark is electronically read by at least one of the scanners “S” and the wheel information relayed to downstream processing locations. The identification mark “M” is read by the scanner “S” on-the-fly without slowing or ...

fourth embodiment

[0051]FIG. 8 illustrates the wheel identification system. According to this embodiment, the wheel identification mark “M” is applied to an outer surface of the rim barrel 17. While moving downstream on the roller conveyor “C”, the wheel 10 enters an identification zone comprising a number of side-mounted strategically arranged scanners “S” operable for reading the entire outer circumferential surface area of the wheel 10. The identification mark “M” is located and electronically read by at least one of the scanners “S” regardless of the wheel's orientation on the roller conveyor “C”, and without slowing or stopping the wheel 10.

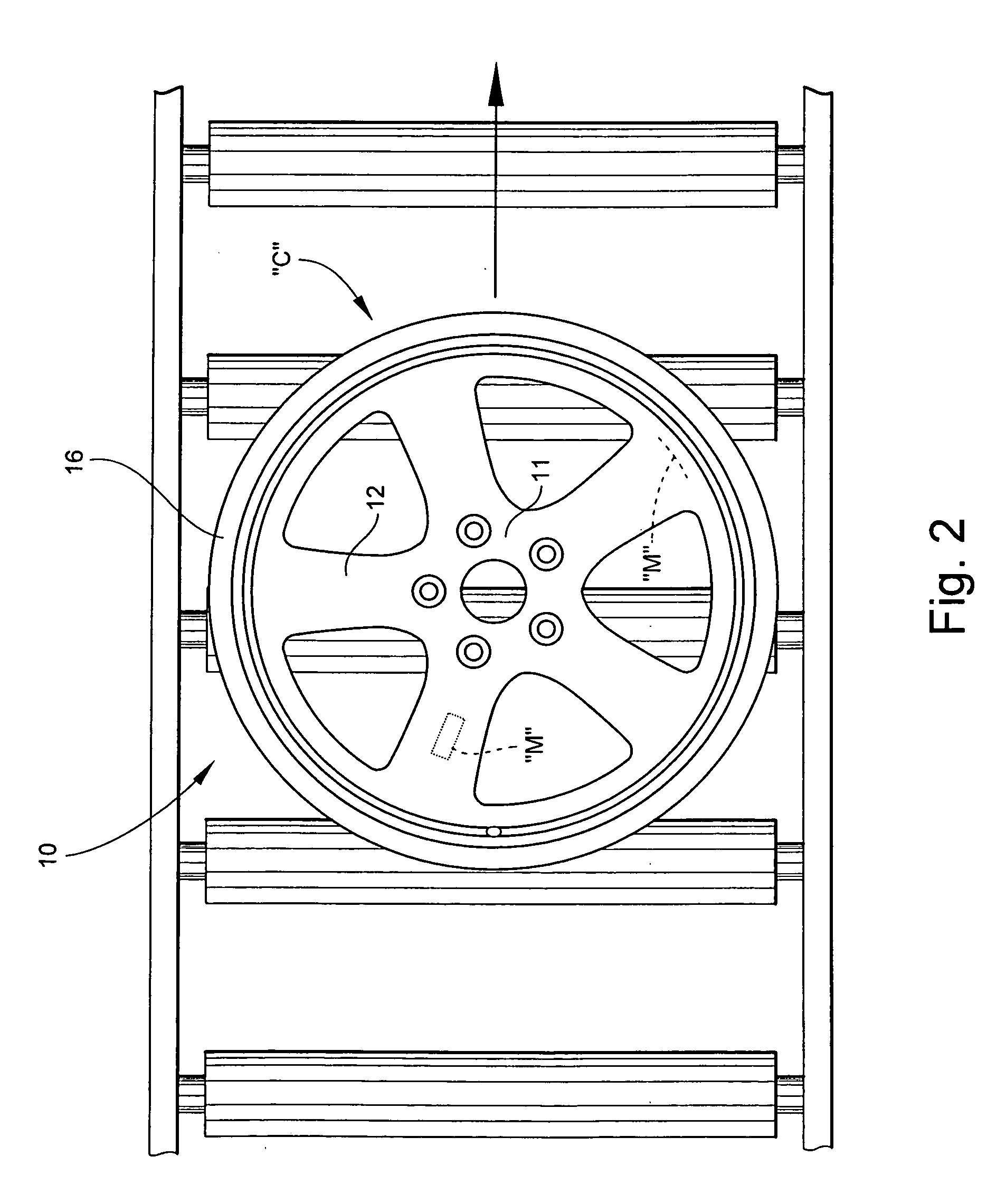

[0052]FIGS. 9, 9A and 10 illustrate application of the present method in a vehicle wheel 10 with eight identical, circumferentially-spaced identification marks “M” formed with its inboard flange 15. The identification marks “M” are equally spaced 45-degrees apart. As shown in FIG. 9, the scanner “S” is under-mounted below the roller conveyor “C”. As the wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com