Patents

Literature

66results about How to "Avoid or" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

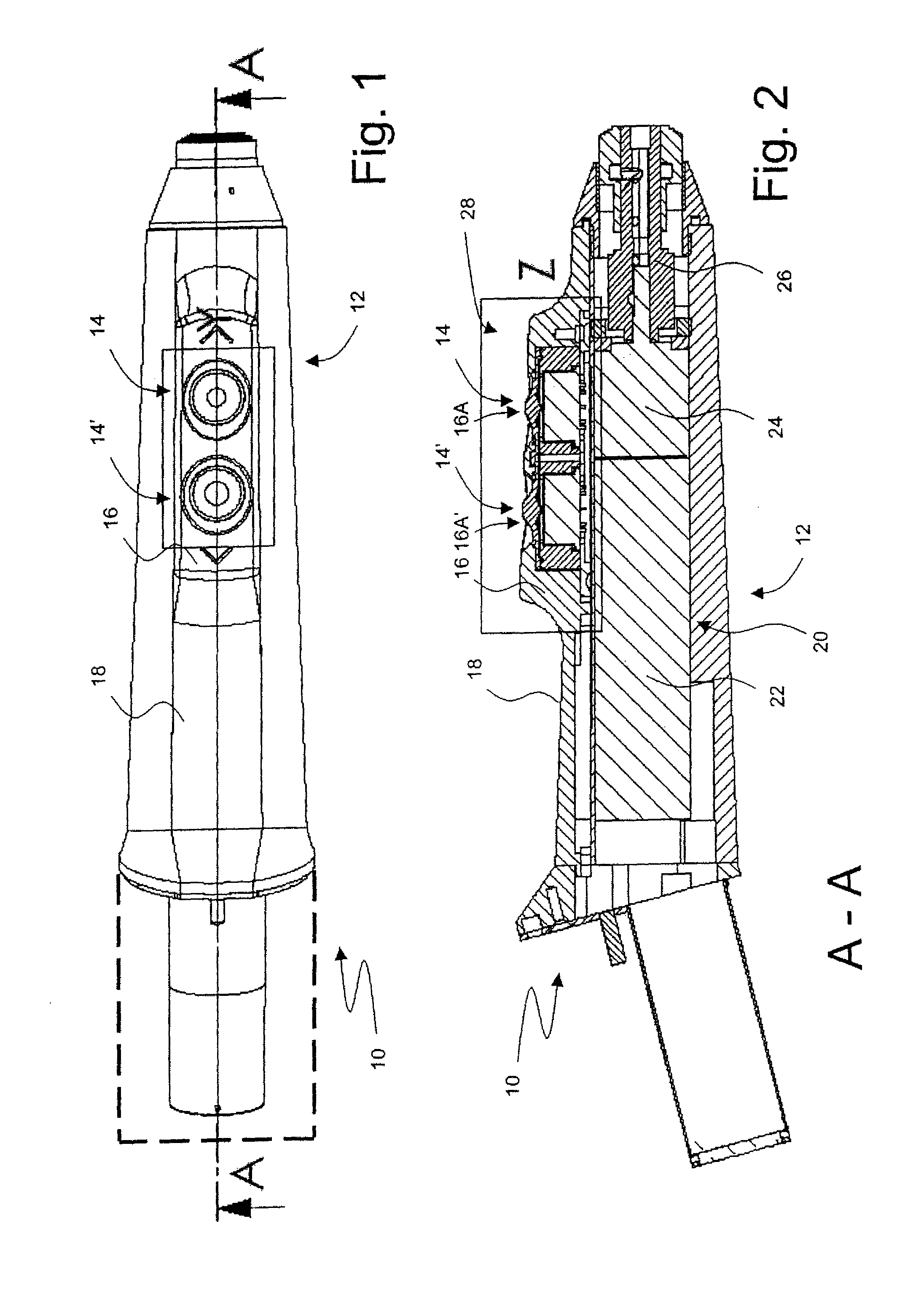

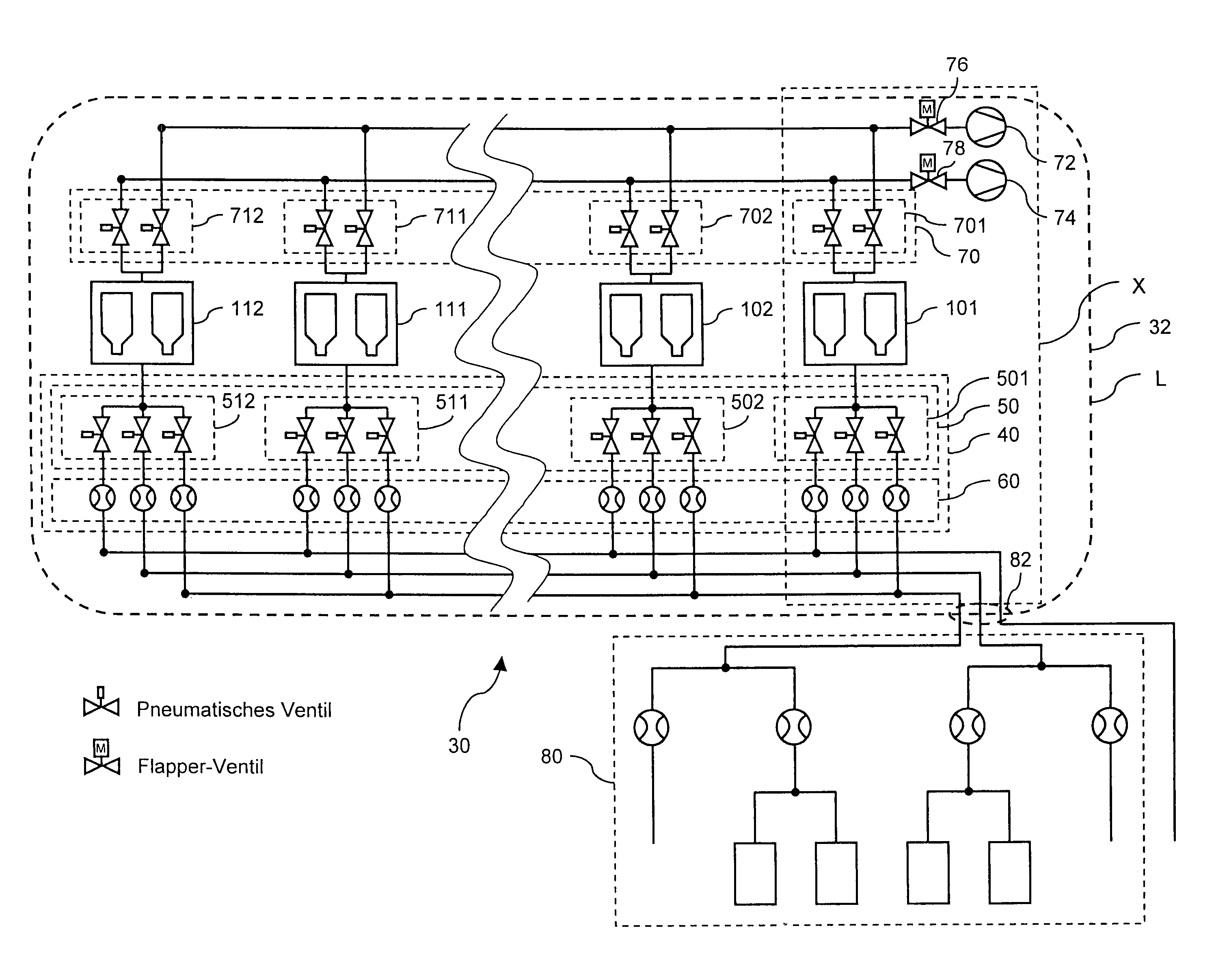

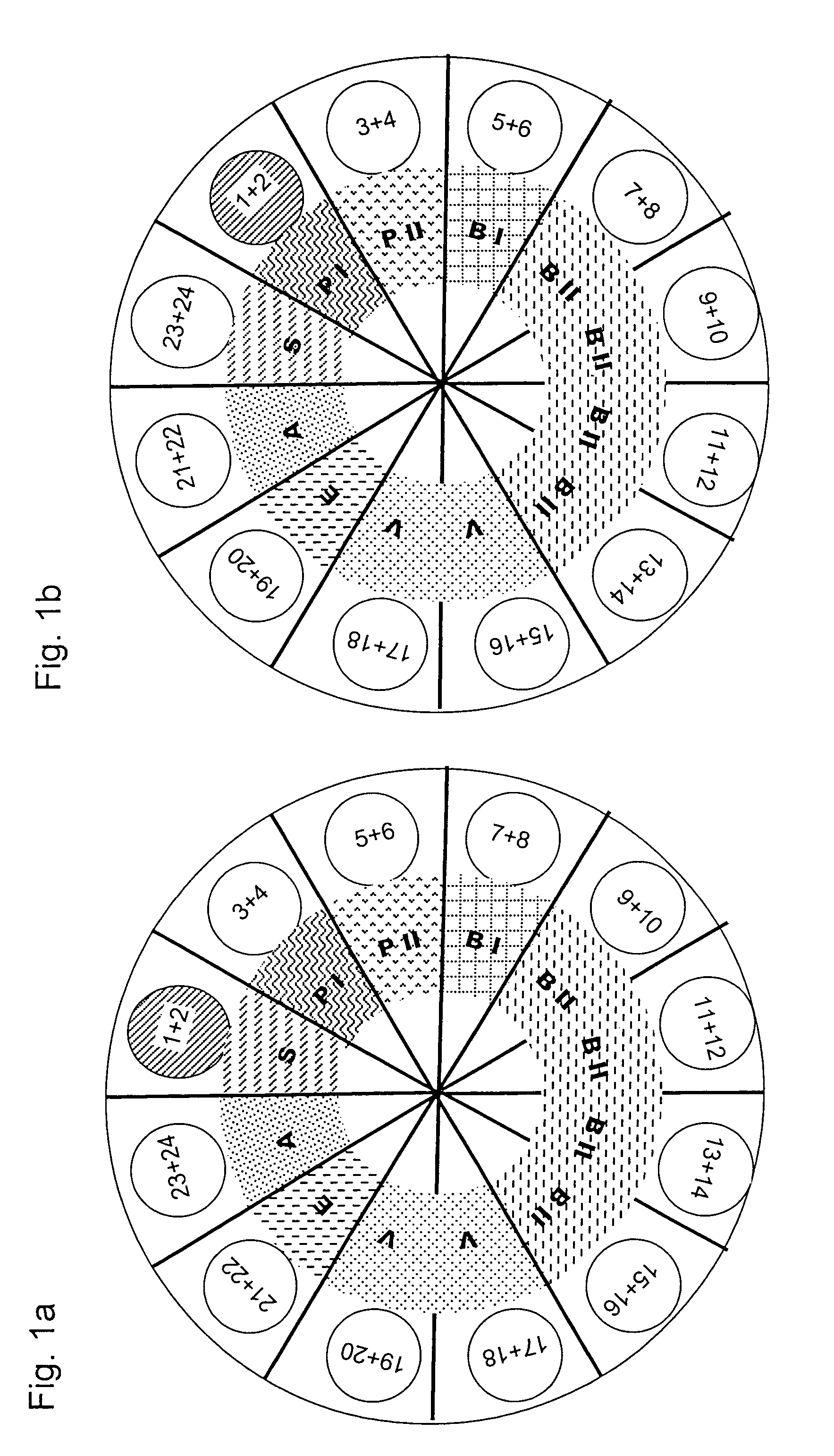

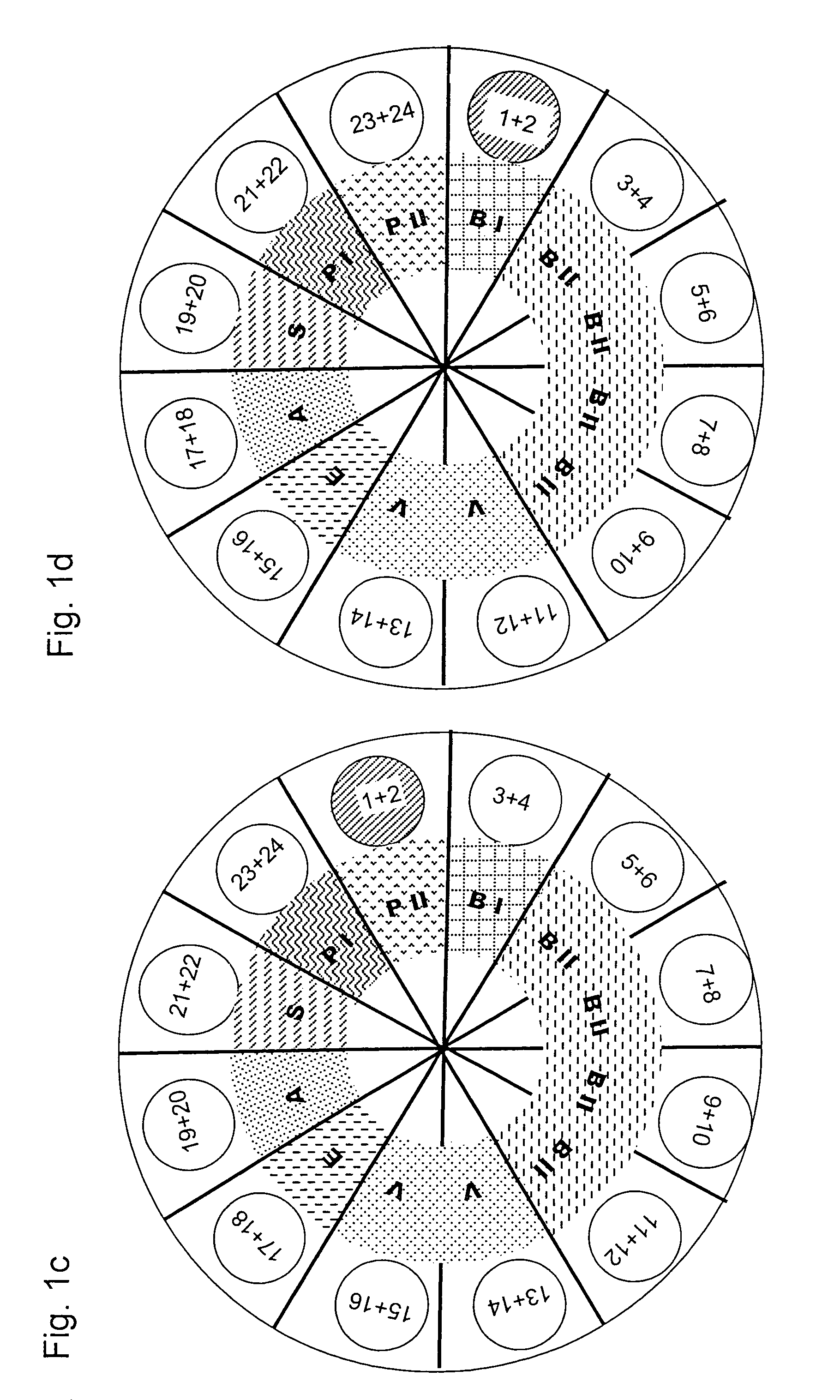

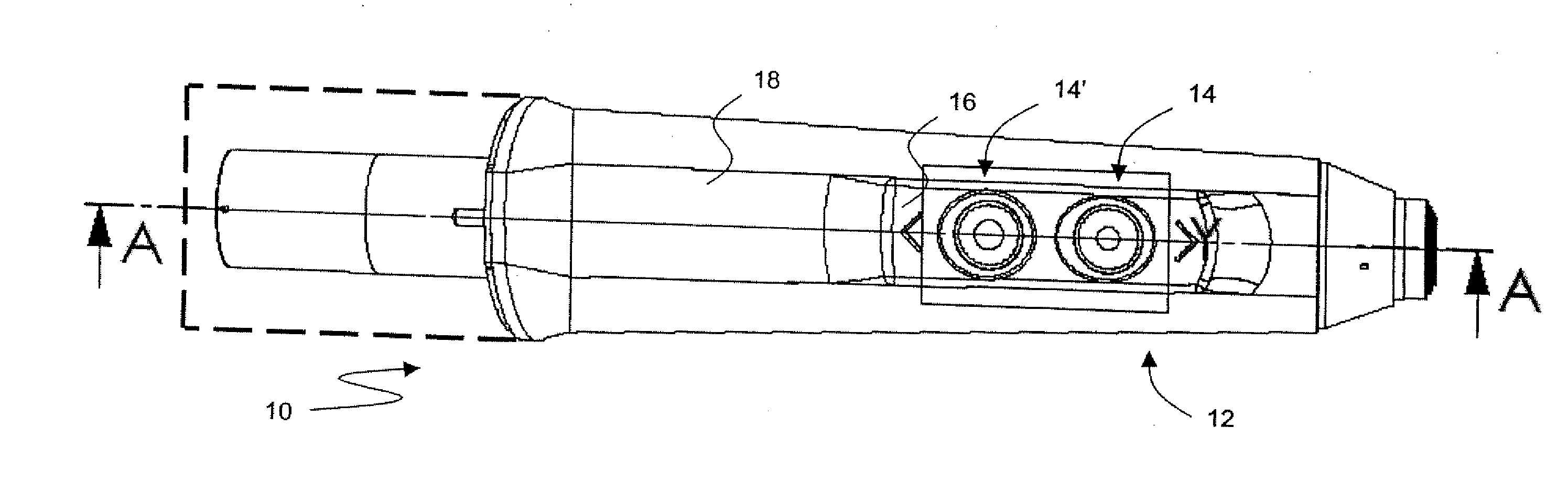

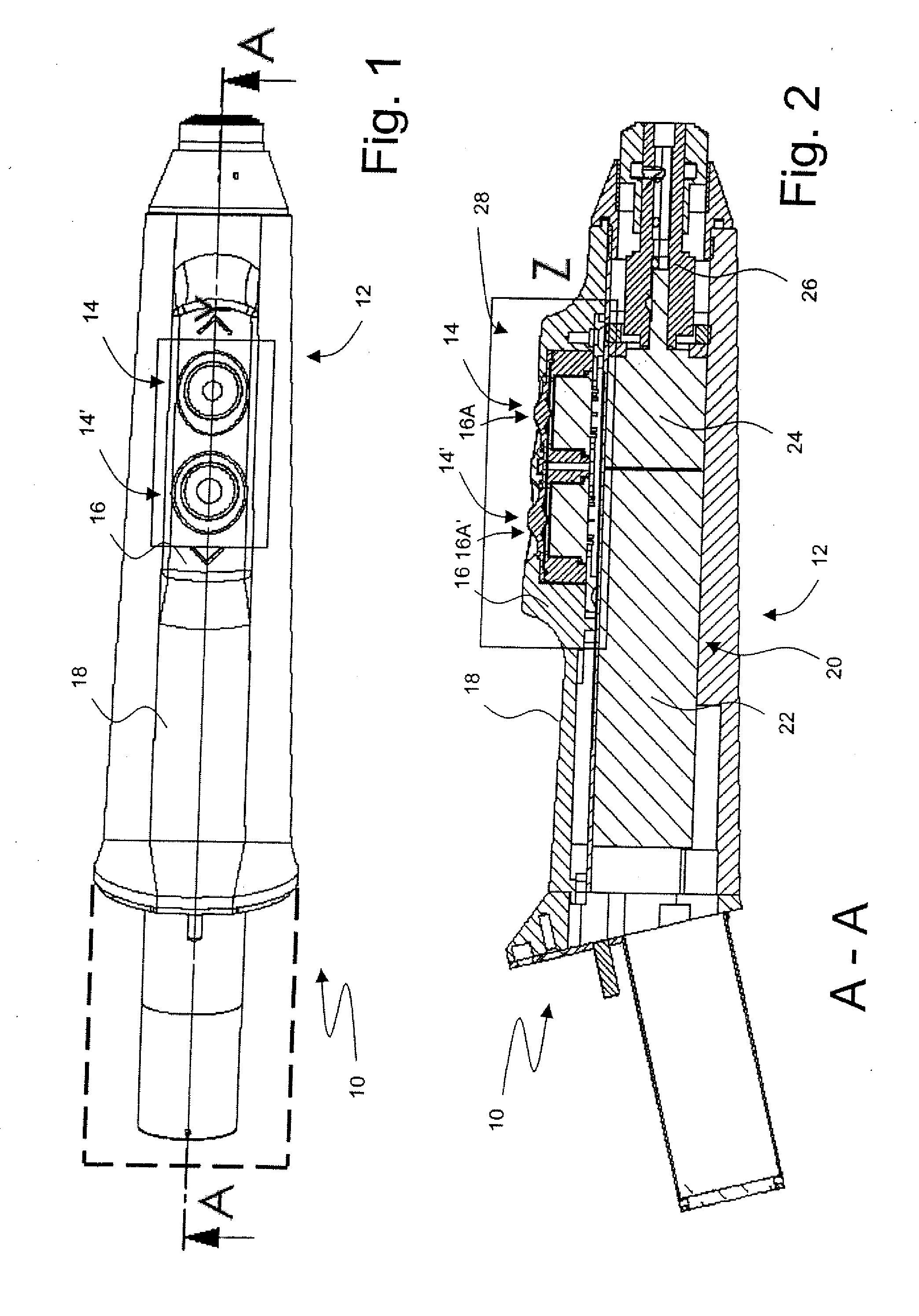

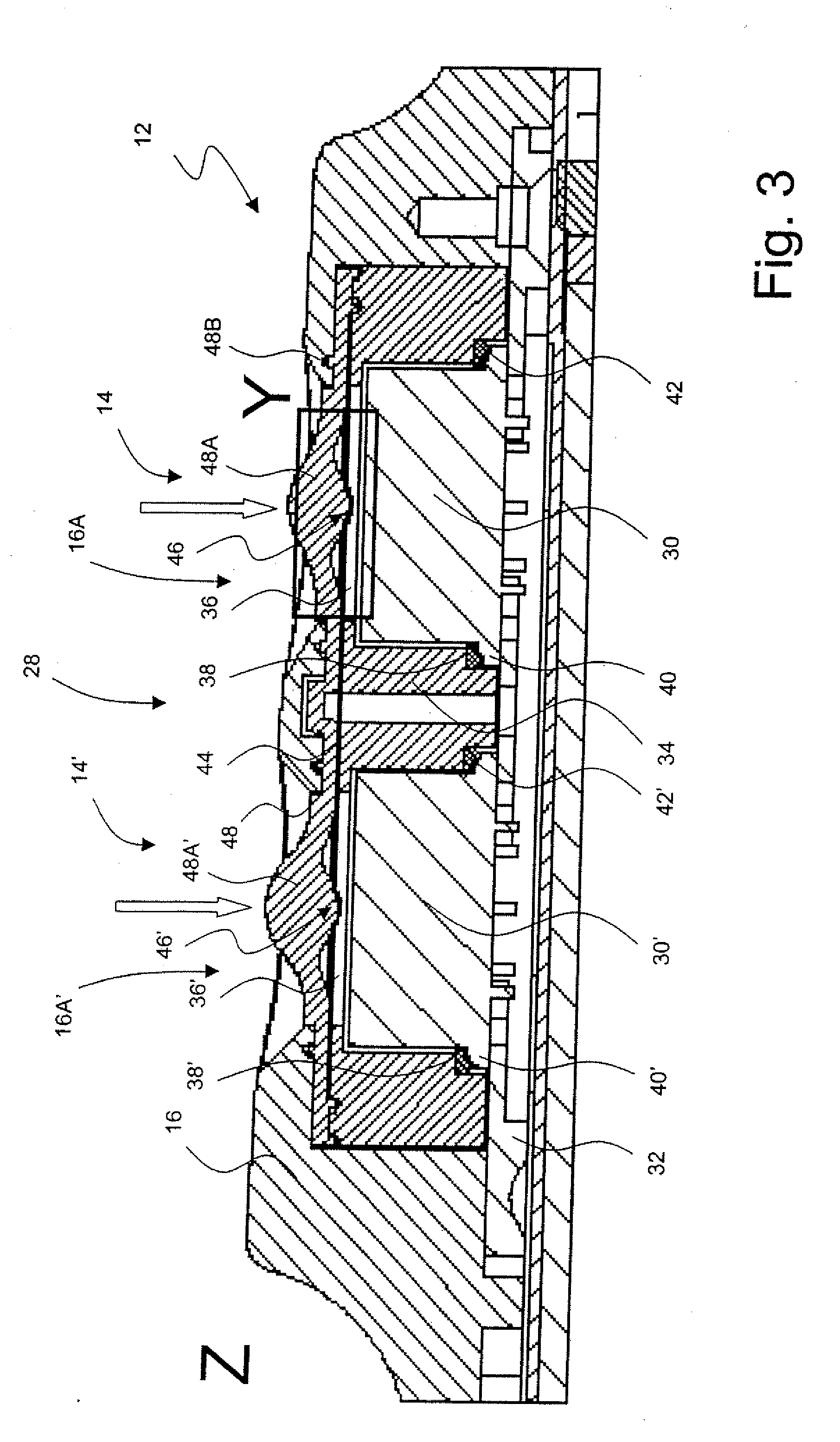

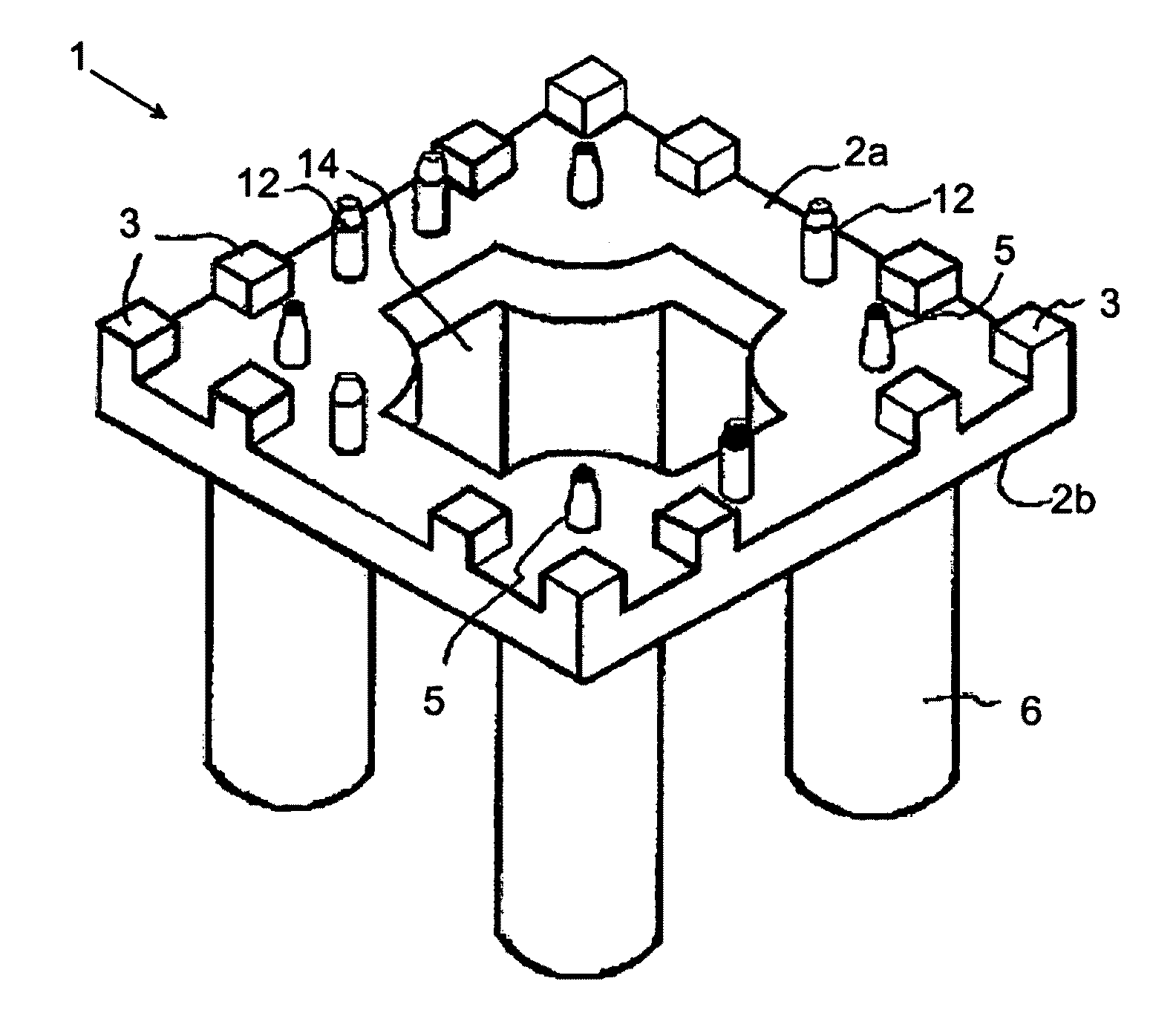

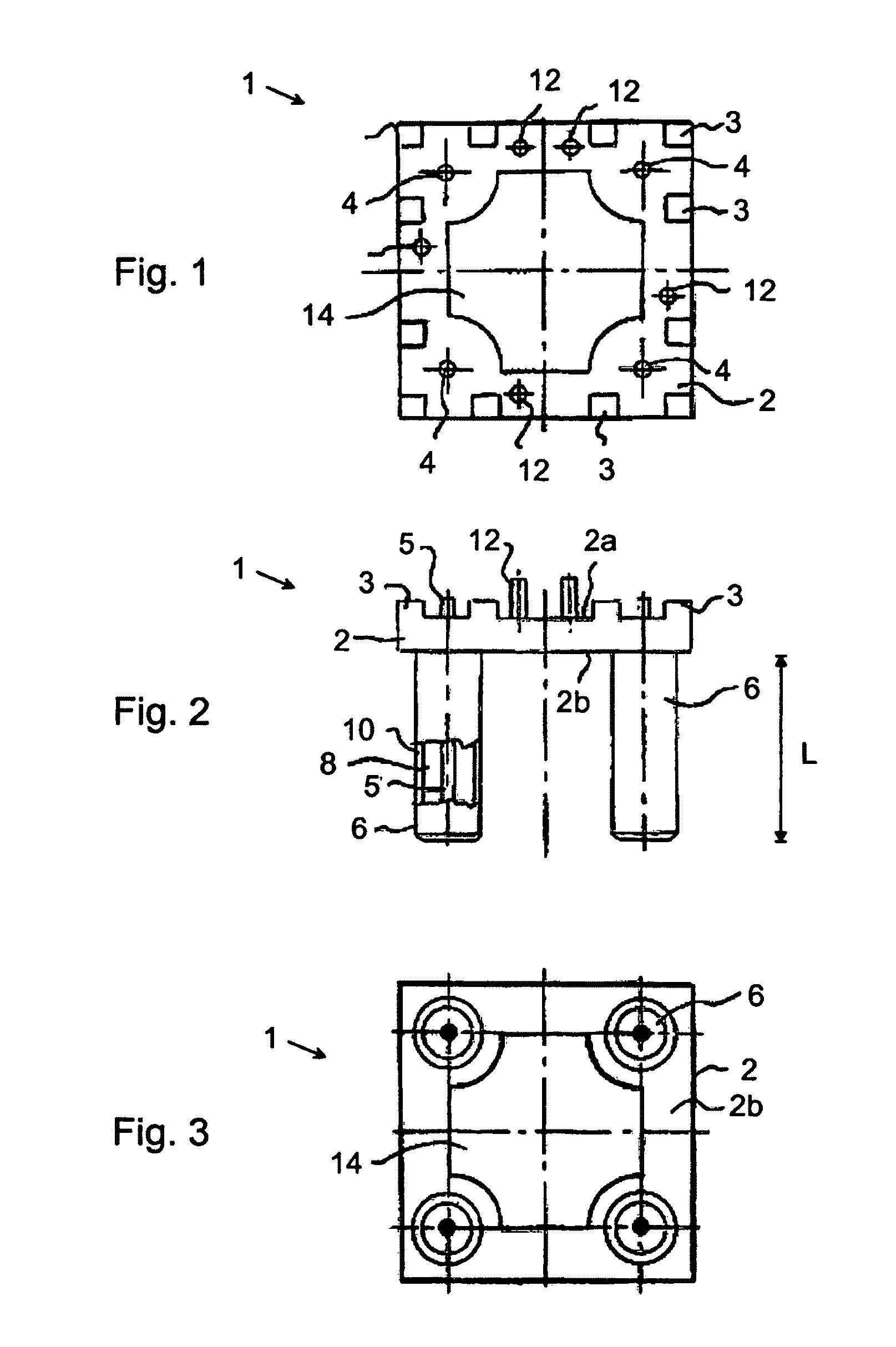

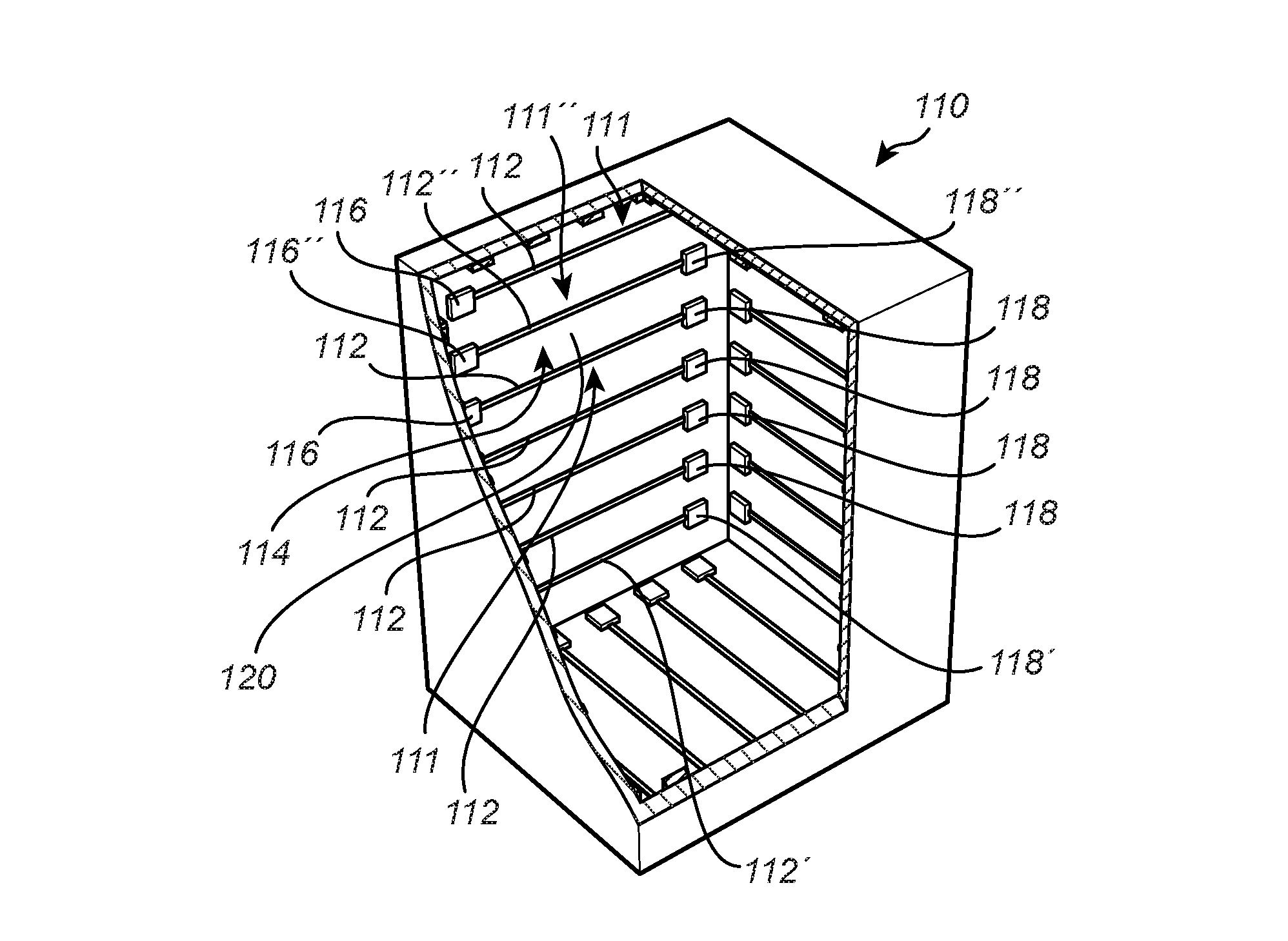

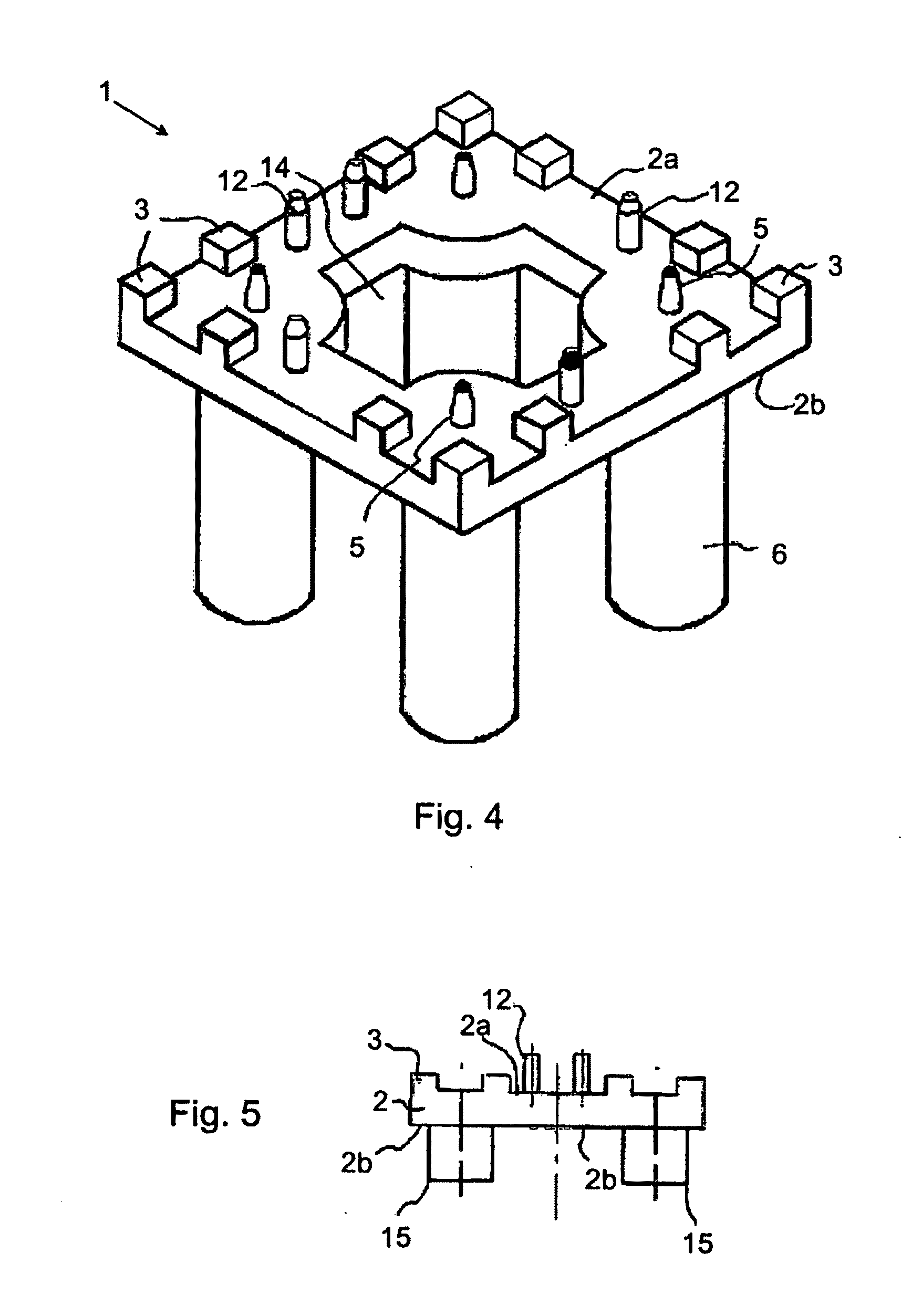

Device and method for treating workpieces

ActiveUS20060099340A1Inhibition productionAvoid and reduce extentLiquid surface applicatorsConveyorsFluid controlHigh flux

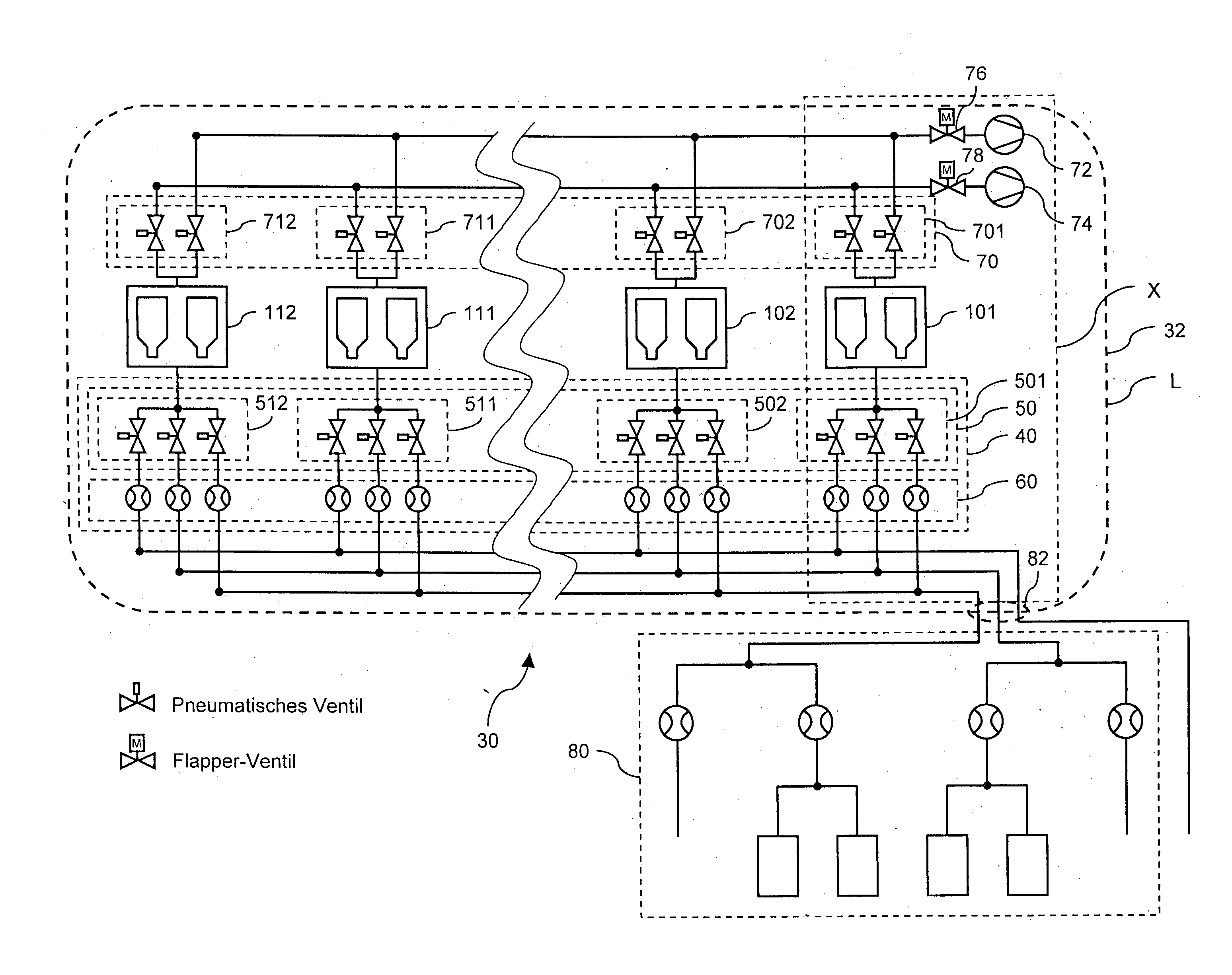

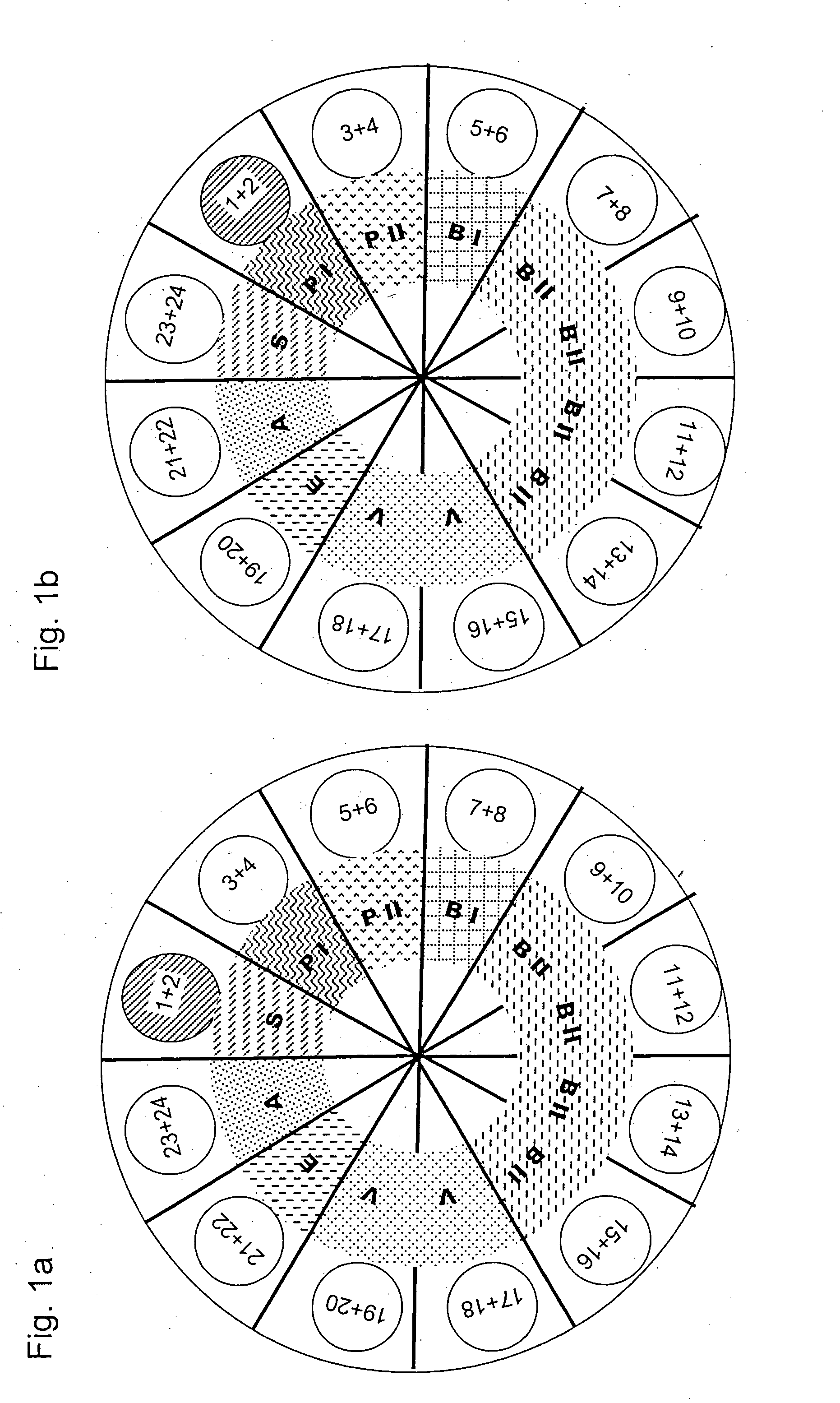

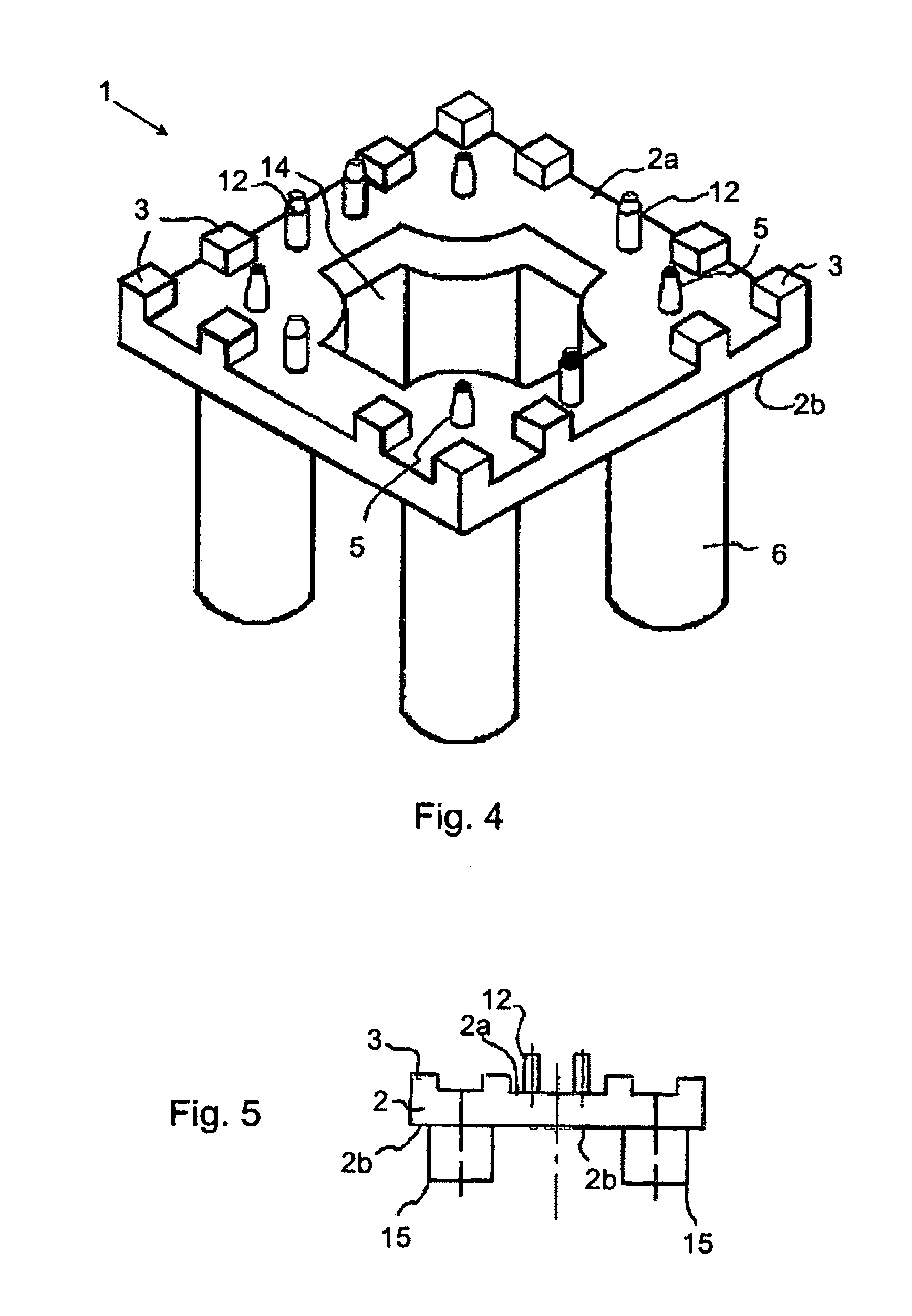

An apparatus and a method for the coating of hollow bodies, in particular for the internal coating of plastic drinks bottles by means of a PICVD is provided. The method ensures a flexible process sequence, a high throughput, an improved supply of fluid and a high-quality coating. The rotary apparatus includes a treatment device with double reactors for receiving in each case at least one workpiece, a fluid supply apparatus and at least one fluid control device, which can be used to control the supply of fluid to the treatment device. It is preferable for the vacuum pumps to be arranged on the rotor such that they rotate therewith.

Owner:SCHOTT AG

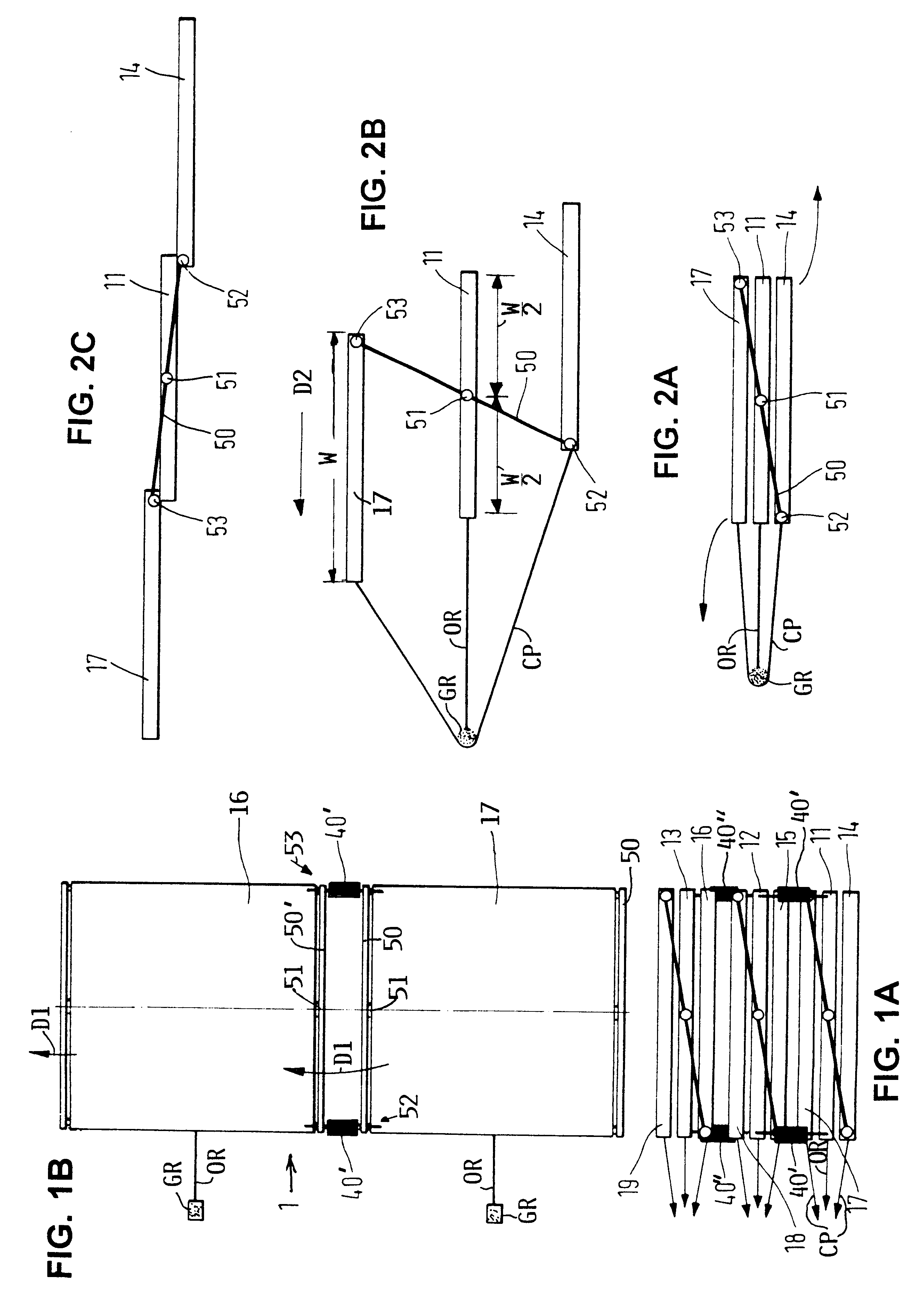

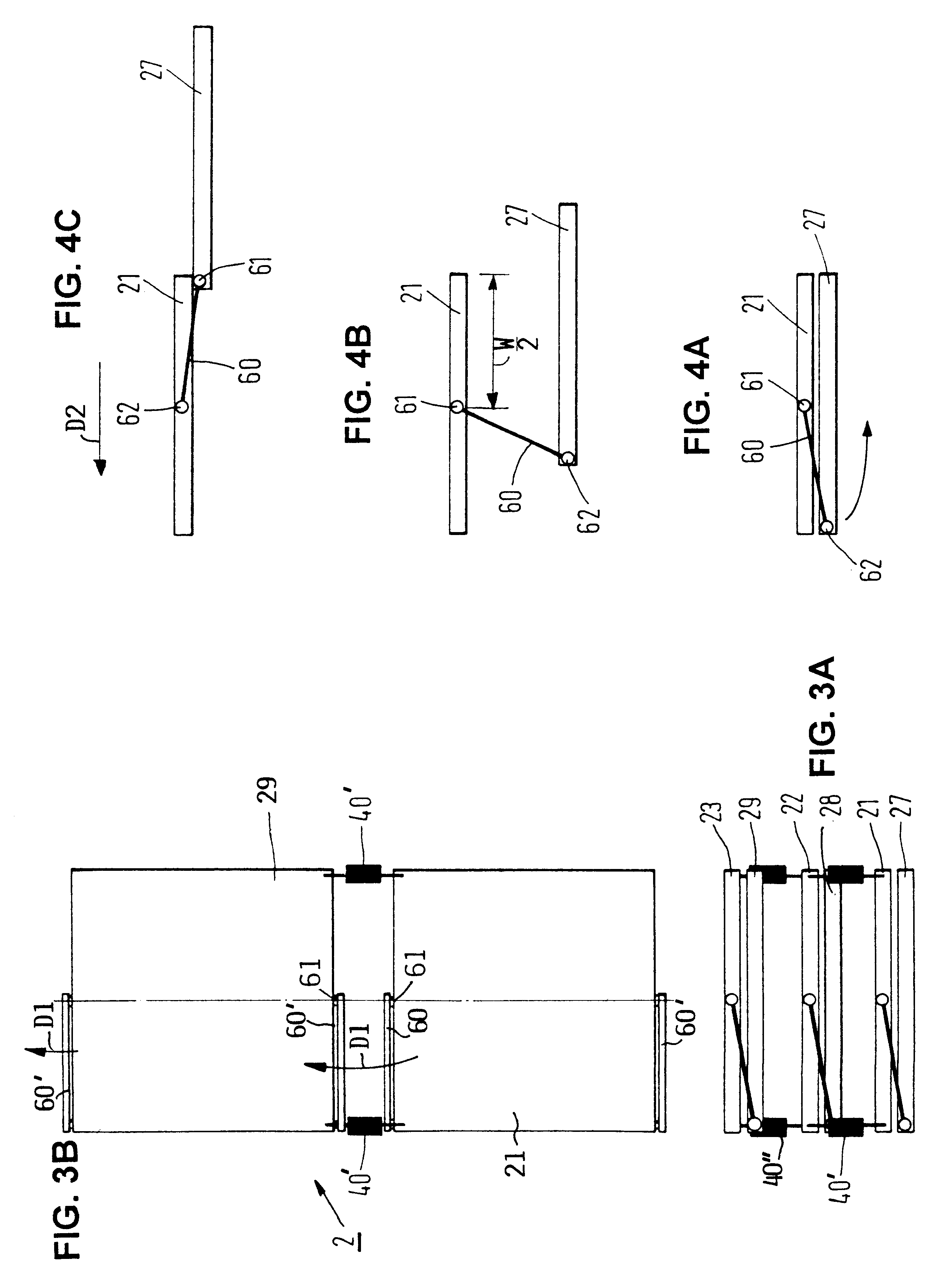

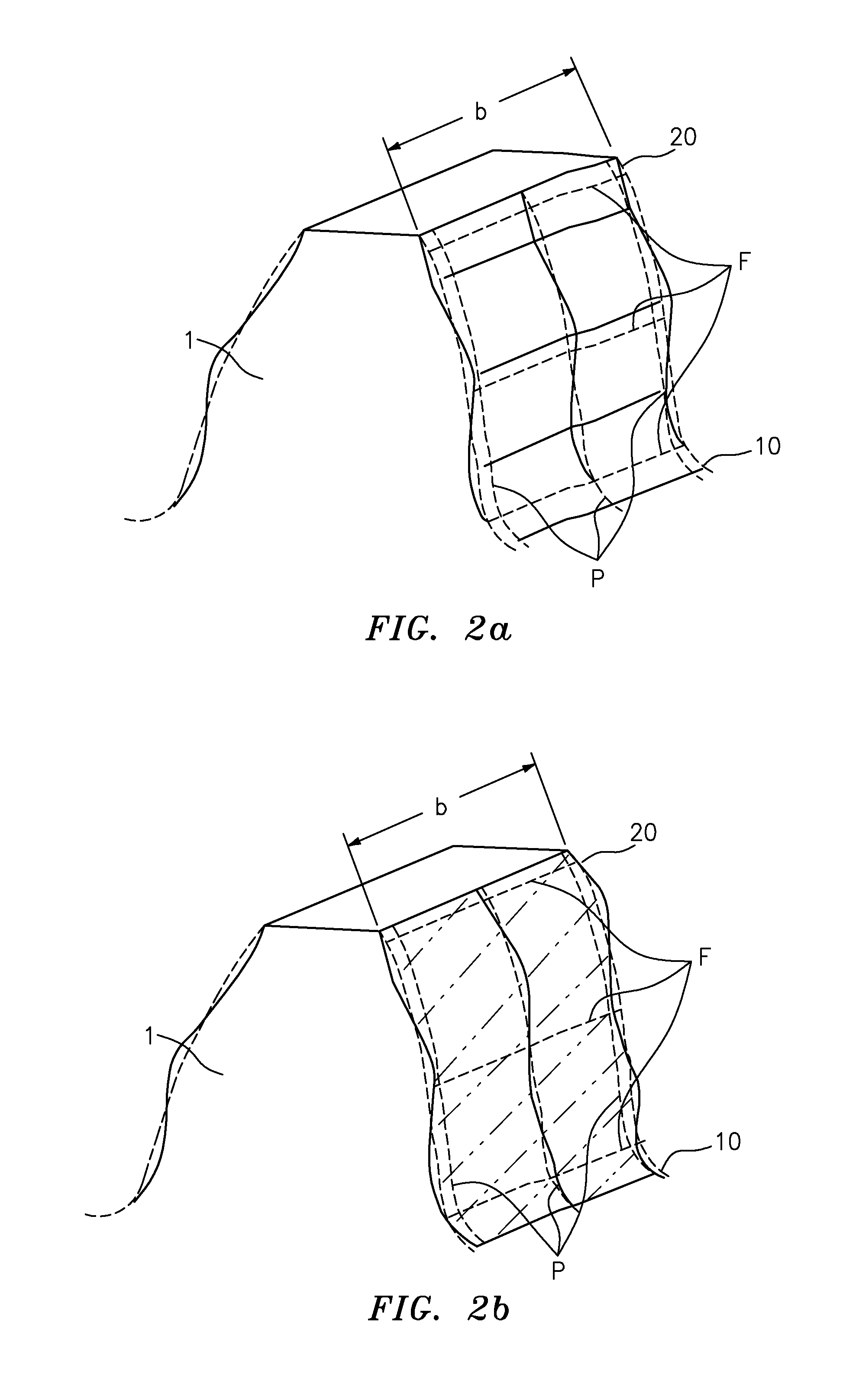

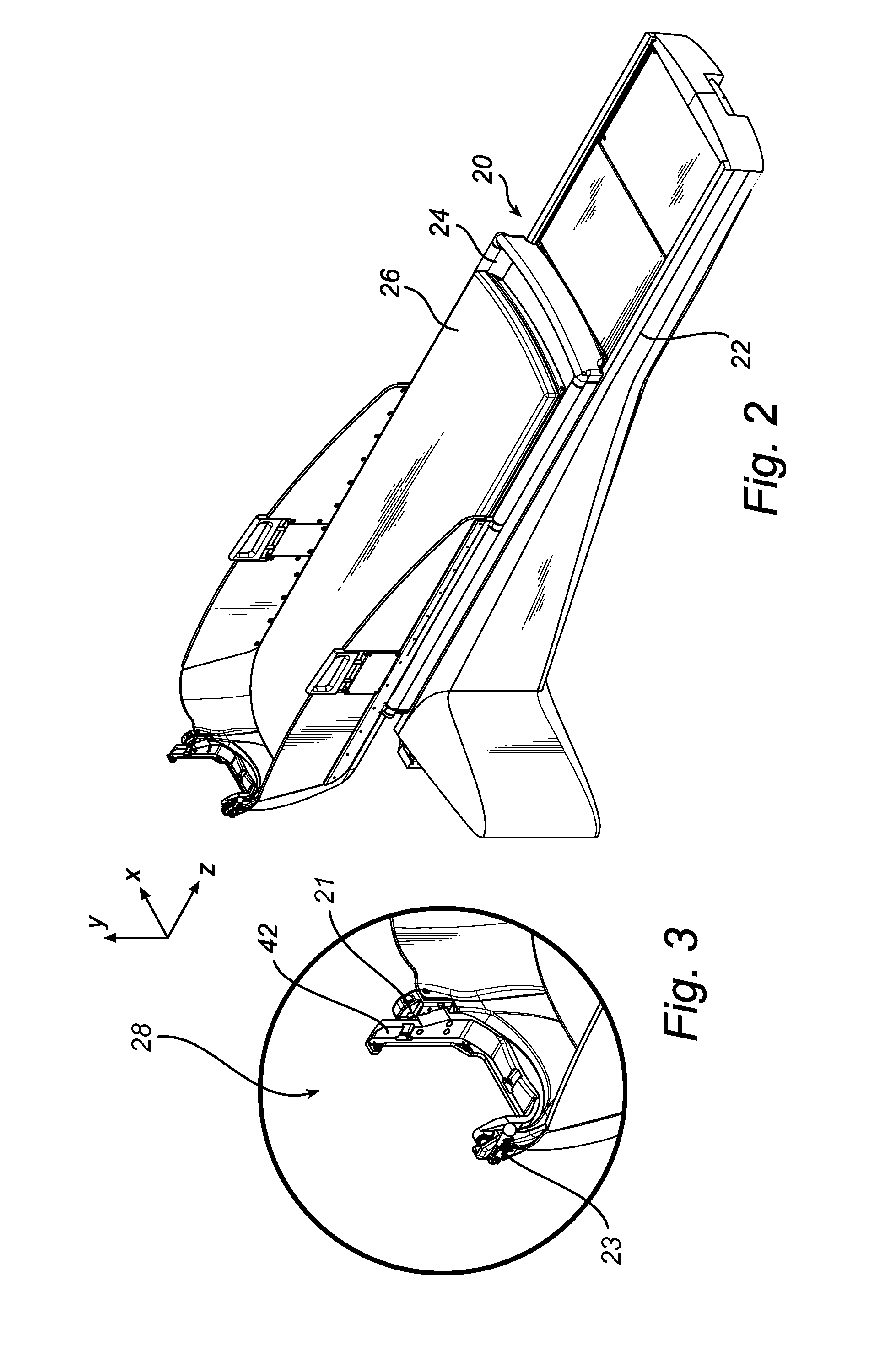

Solar generator with foldable panels especially for a spacecraft

InactiveUS6284967B1Avoid disadvantagesAvoid orCosmonautic vehiclesCosmonautic power supply systemsSolar generatorSpacecraft

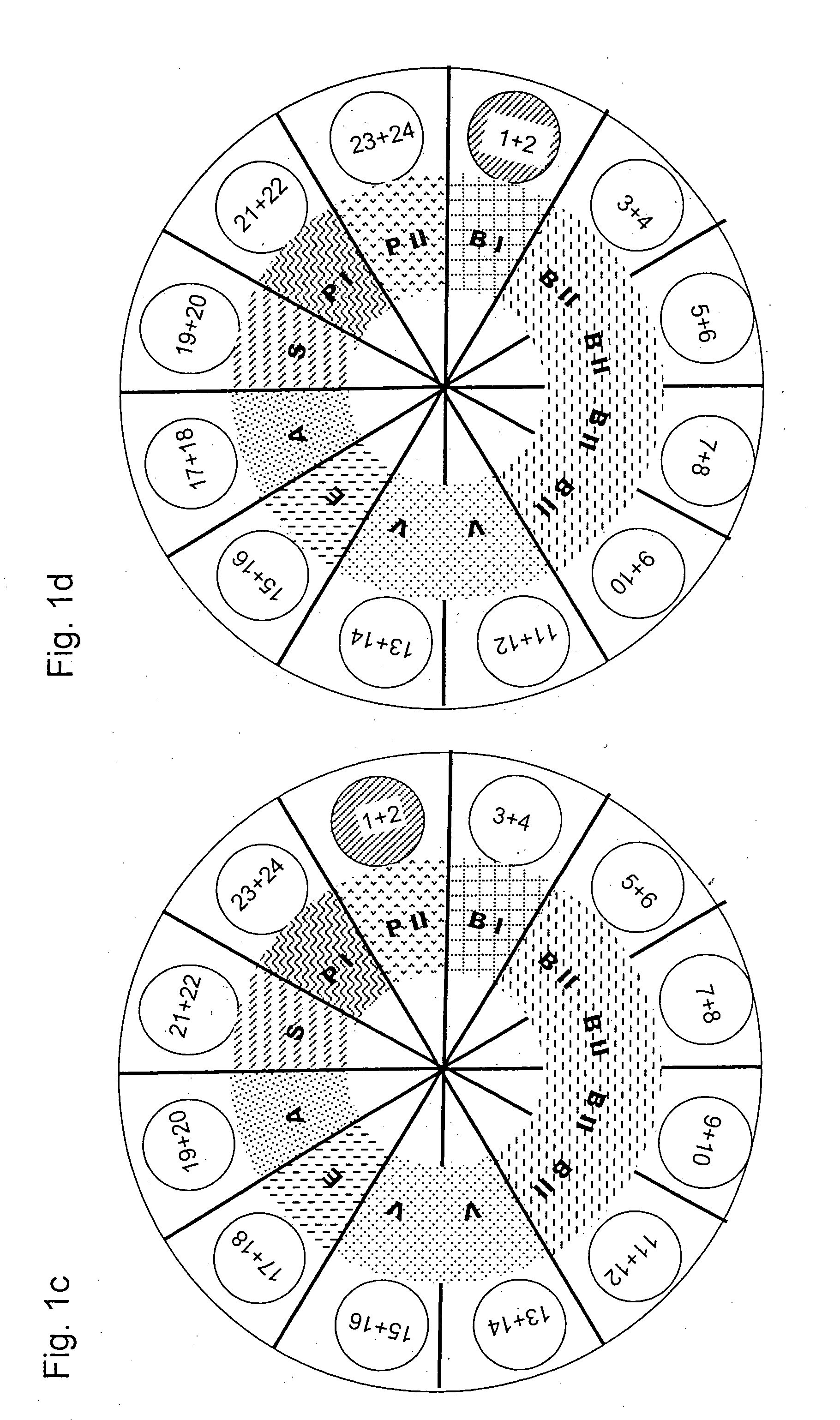

A solar generator especially for a spacecraft or space flight body has a plurality of first collector panels hinged to each other in a column extending in a first direction (D1) when the first collector panels are unfolded and a plurality of second panels coupled to the first panels so that the second panels can be unfolded in a second direction (D2) only after the first panels have been unfolded. The second panels are coupled to the first panels by journal struts or by hinges so that at least one first panel forms with at least one second panel, preferably with two or more second panels, a panel packet. The hinges (40) that articulate the first panels to each other permit unfolding the panel packets in said first direction (D1), whereupon the second panels in the individual packets can be unfolded in the second direction (D2).

Owner:DAIMLER AG

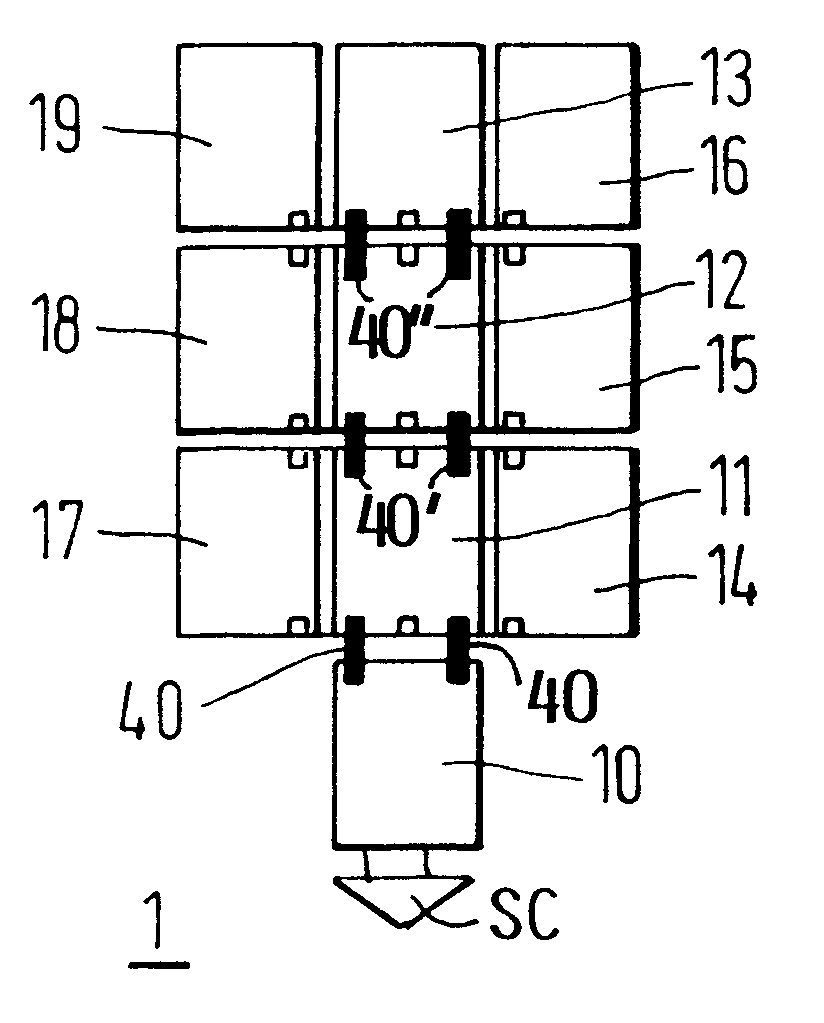

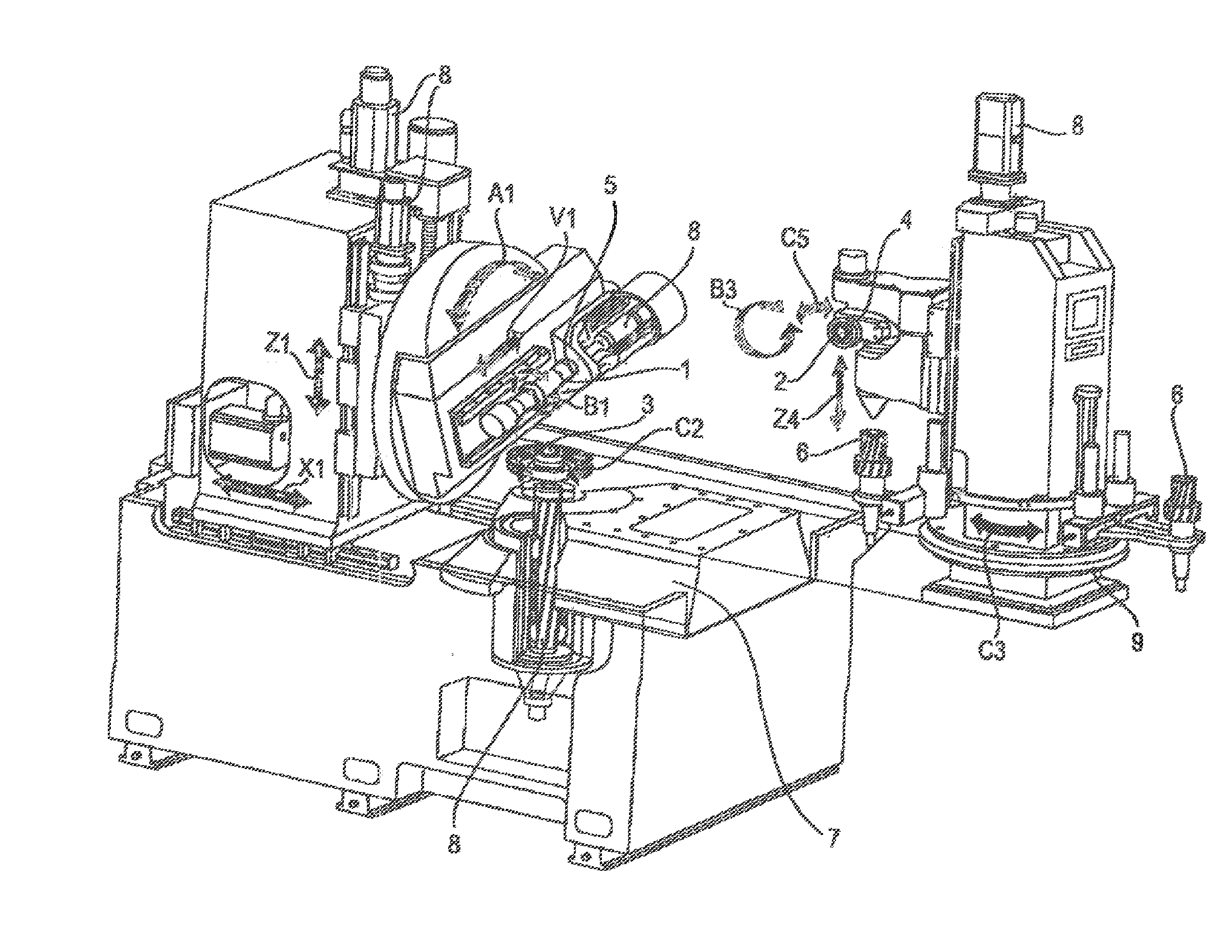

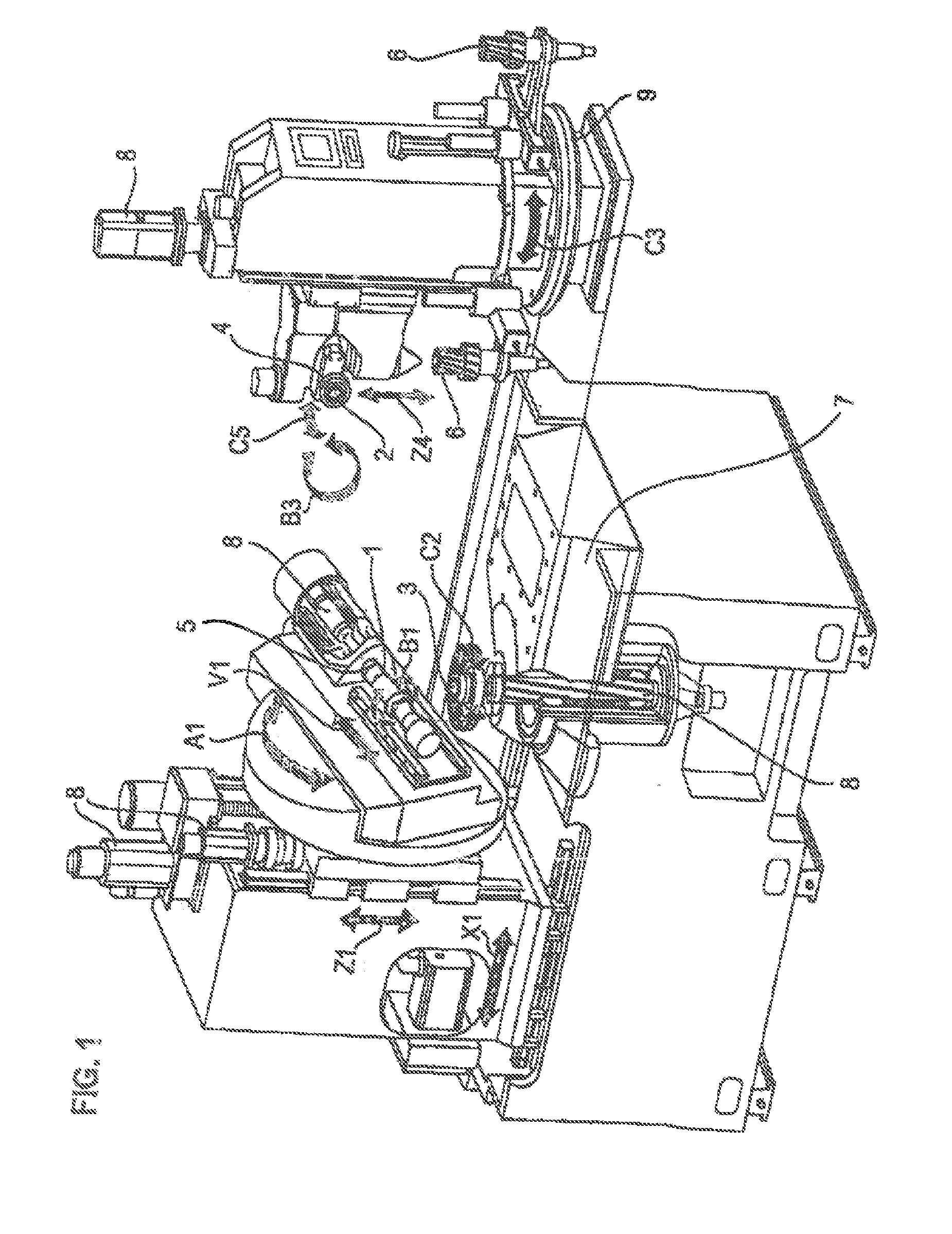

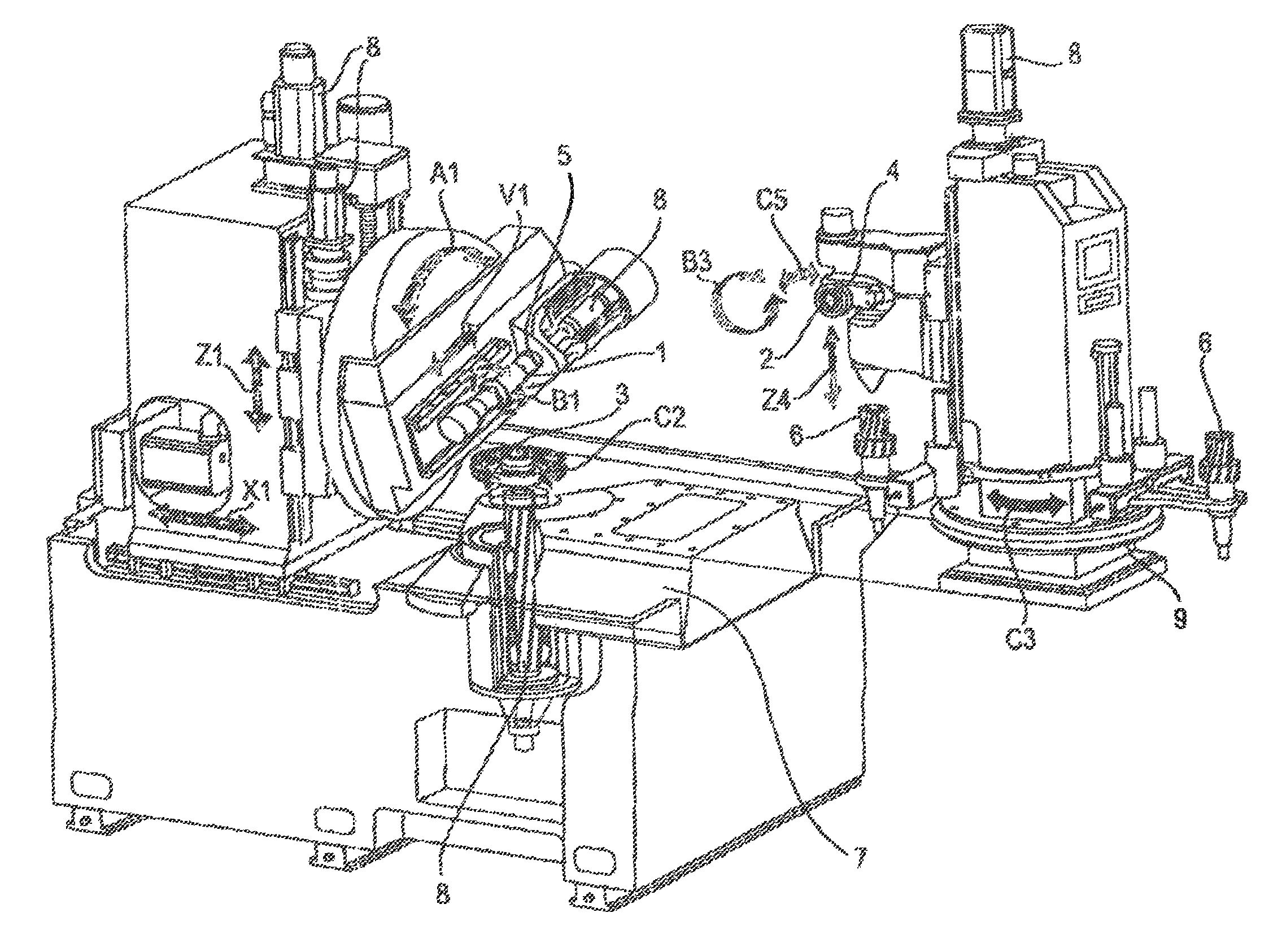

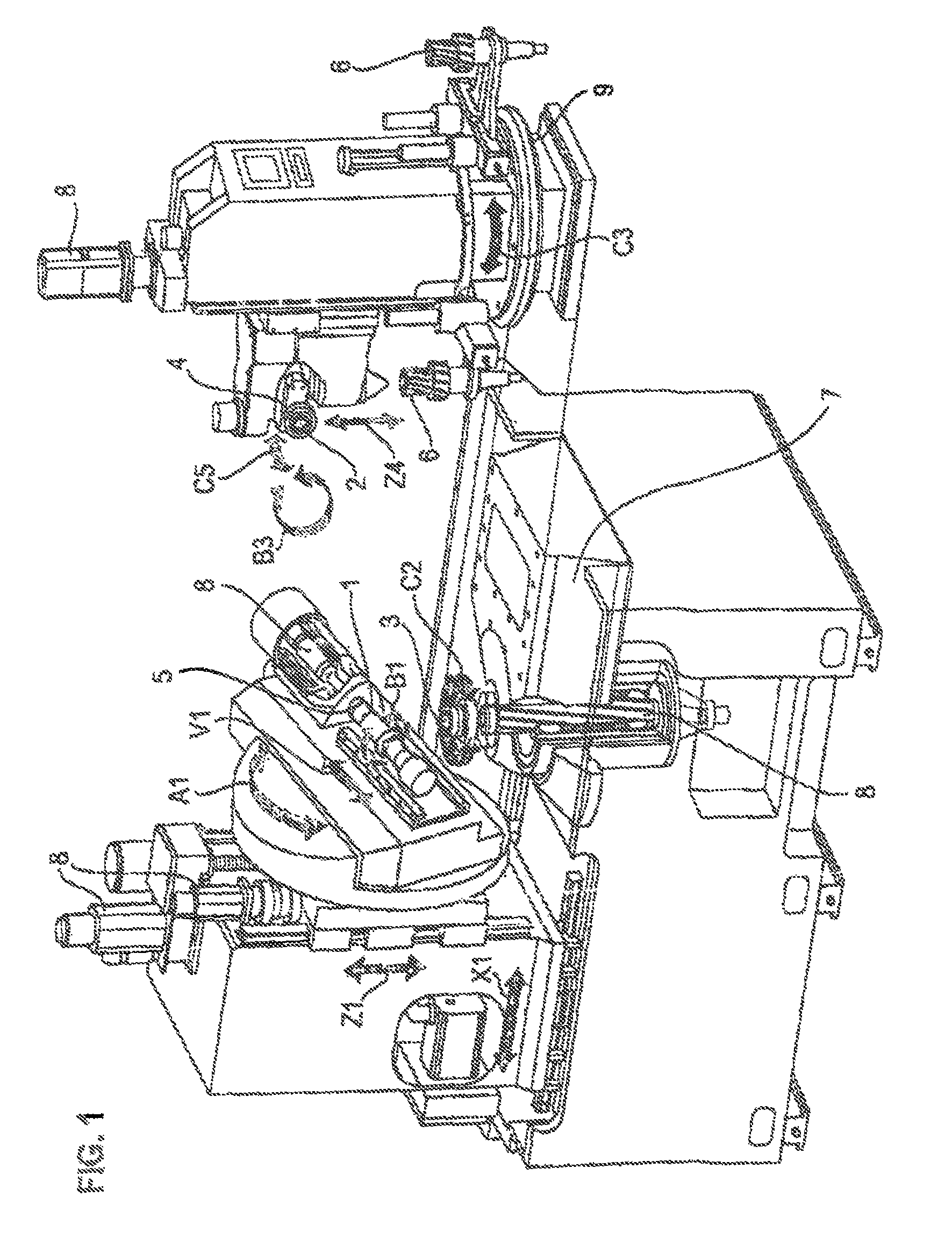

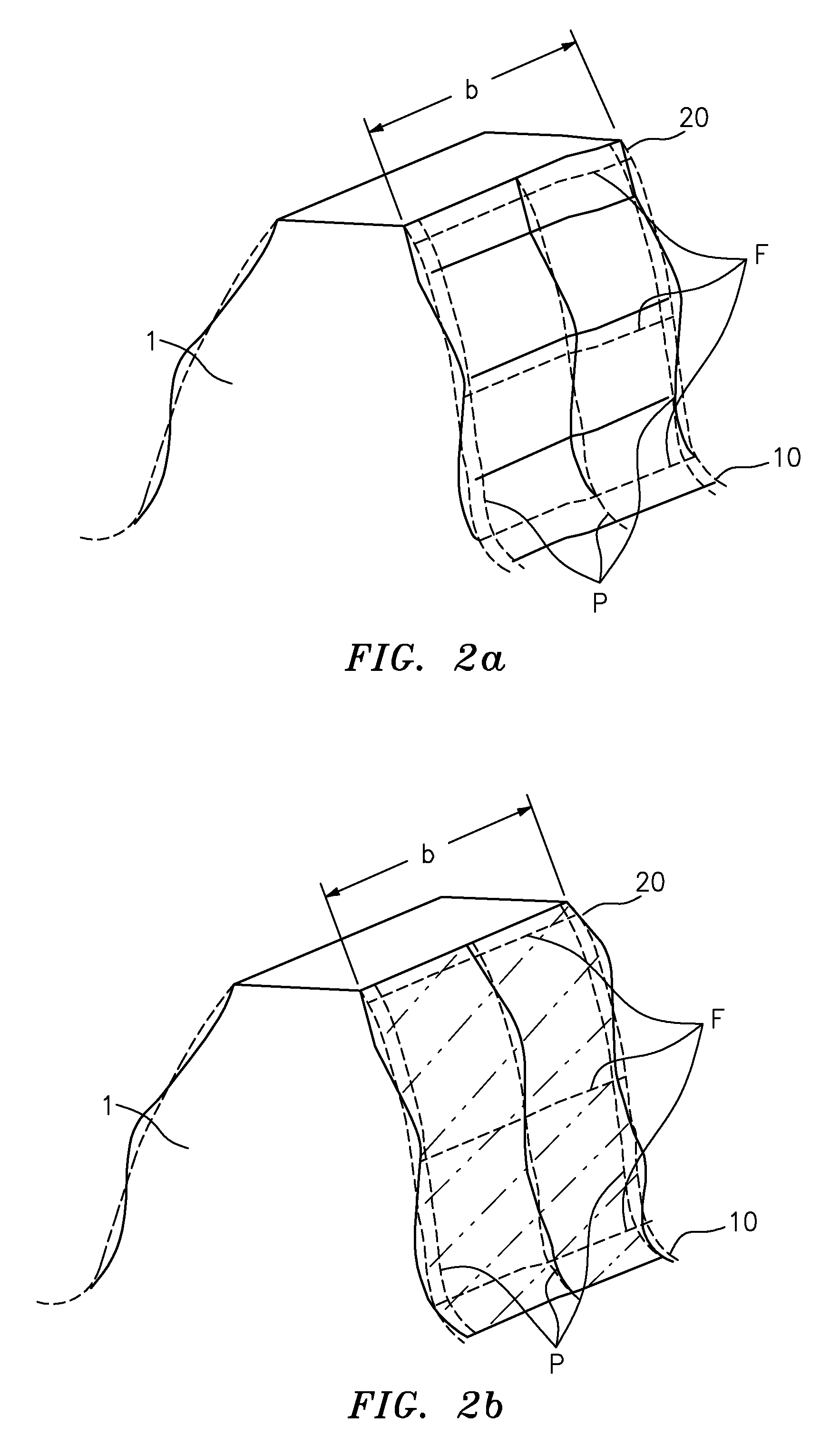

Machining Method for Hard-Fine Machining of Noise-Optimized Gears on a Gear-Cutting Machine

ActiveUS20140256223A1Improve uniformityAvoid and at least minimize vibration excitationAutomatic control devicesGrinding feed controlRotational errorEngineering

The present invention relates to a method for hard-fine machining of tooth flanks with corrections and / or modifications on a gear-cutting machine, wherein respective toothed wheel pairings which mesh with one another within a transmission or a test device are machined while taking account of the respective mating flanks, and wherein the tooth flanks of the relevant workpieces are provided with periodic waviness corrections or waviness modifications. In accordance with the invention, the rotational error extent is determined by means of rotational distance error measurement of the toothed wheel pairs in a gear measuring device and / or transmission. This measurement result serves as an input value for defining the amplitude, frequency and phase position for the periodic flank waviness corrections on the tooth flanks of the toothed wheel pairings for production in the gear-cutting machine.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

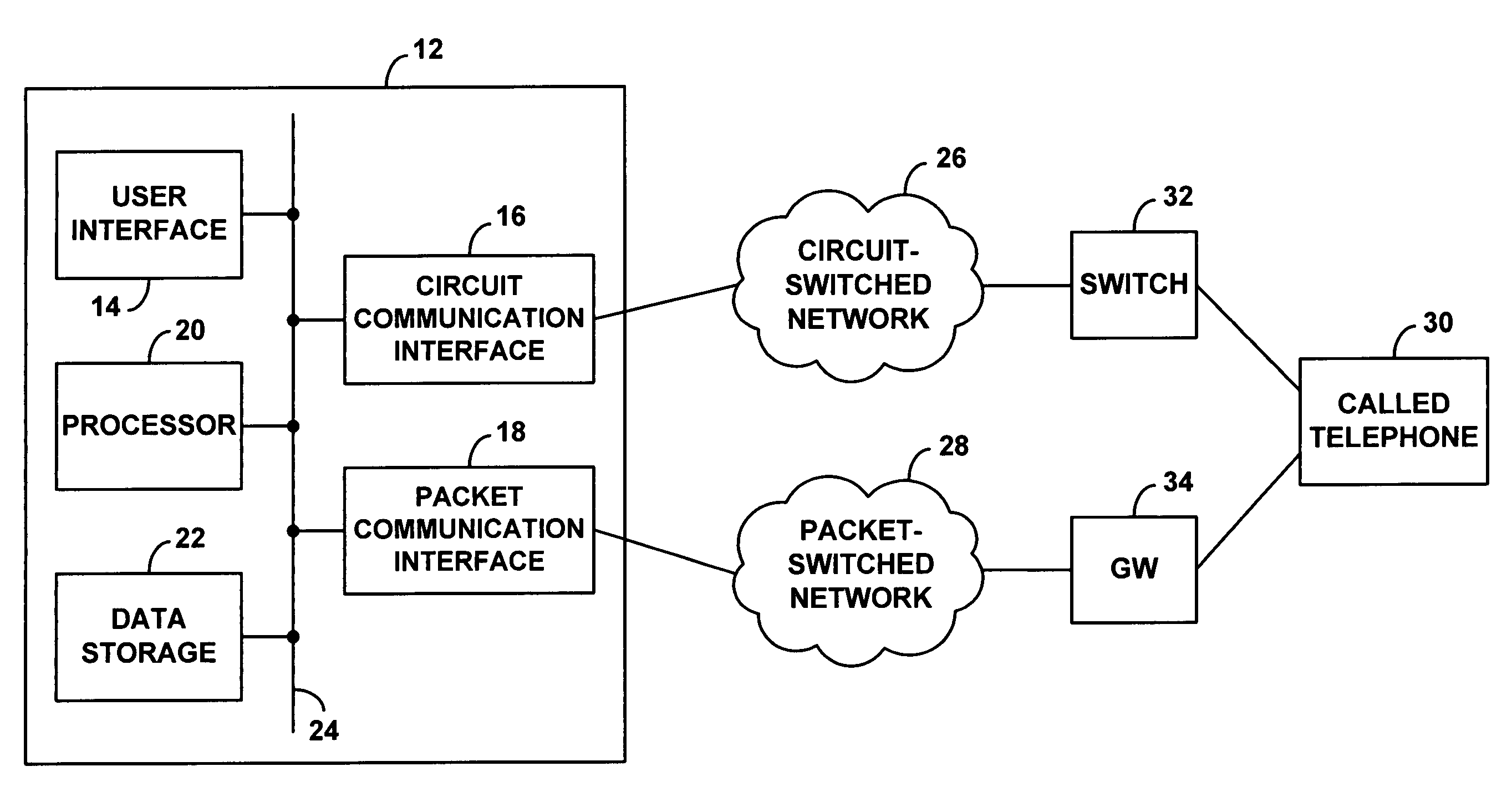

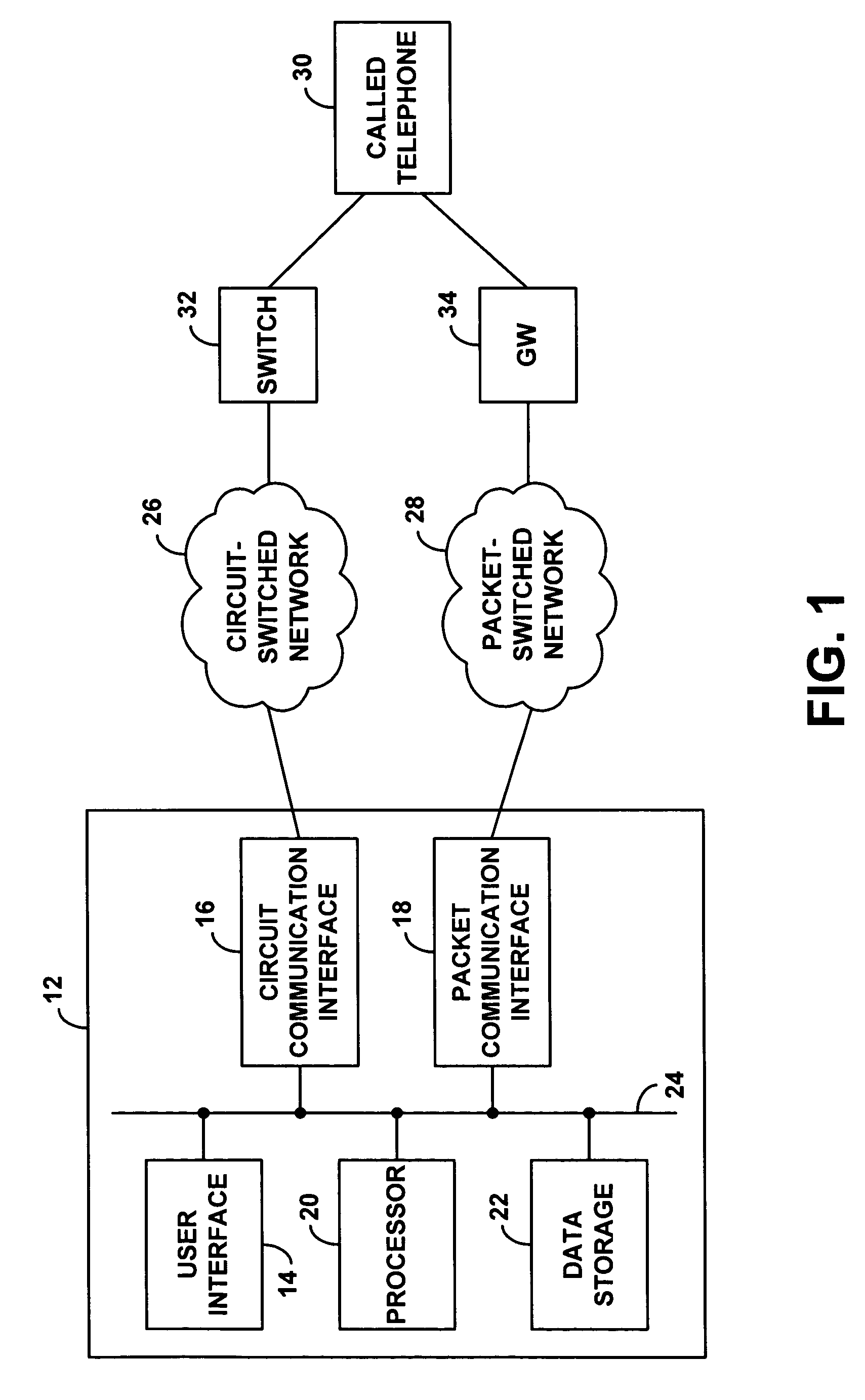

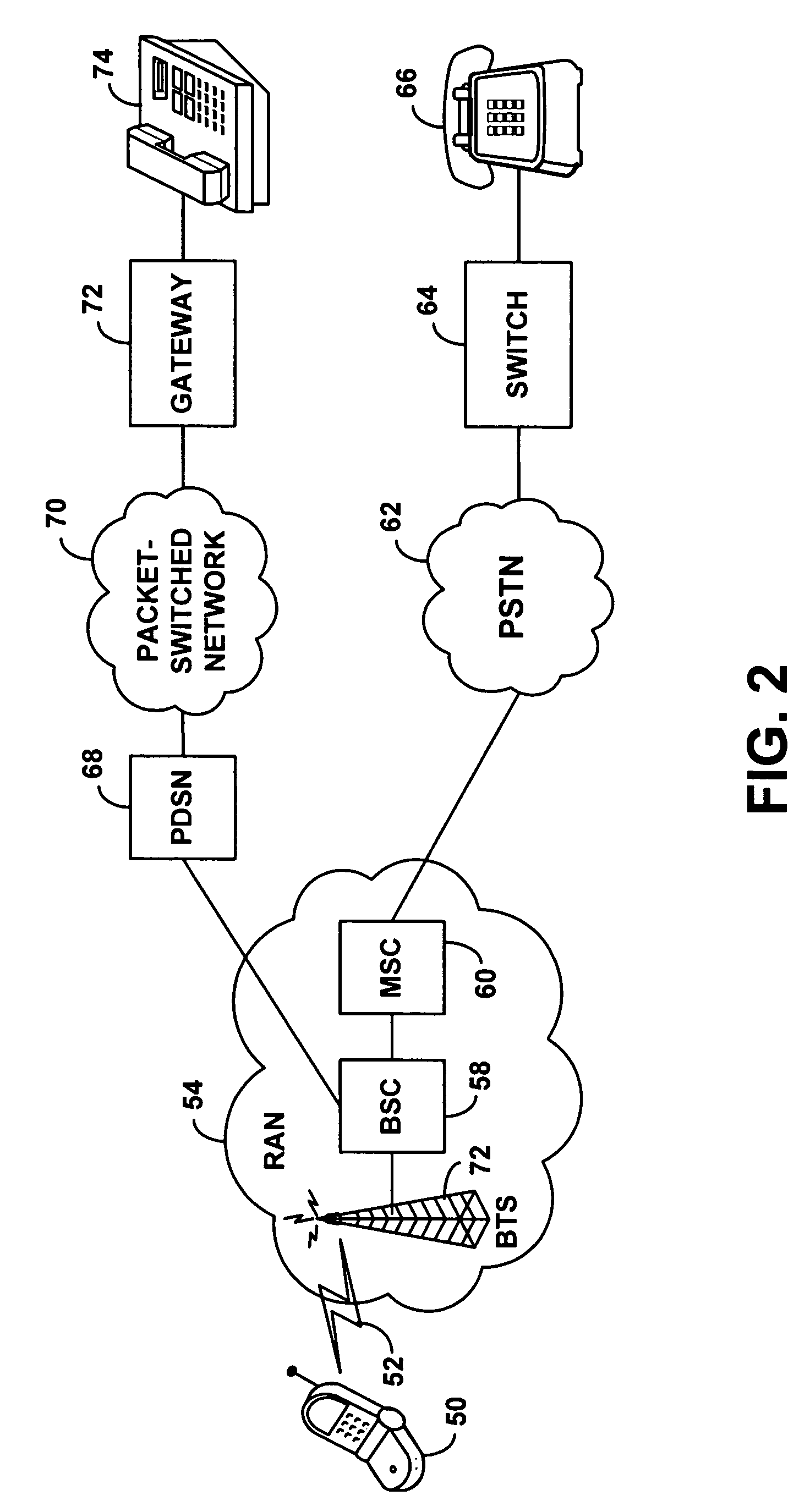

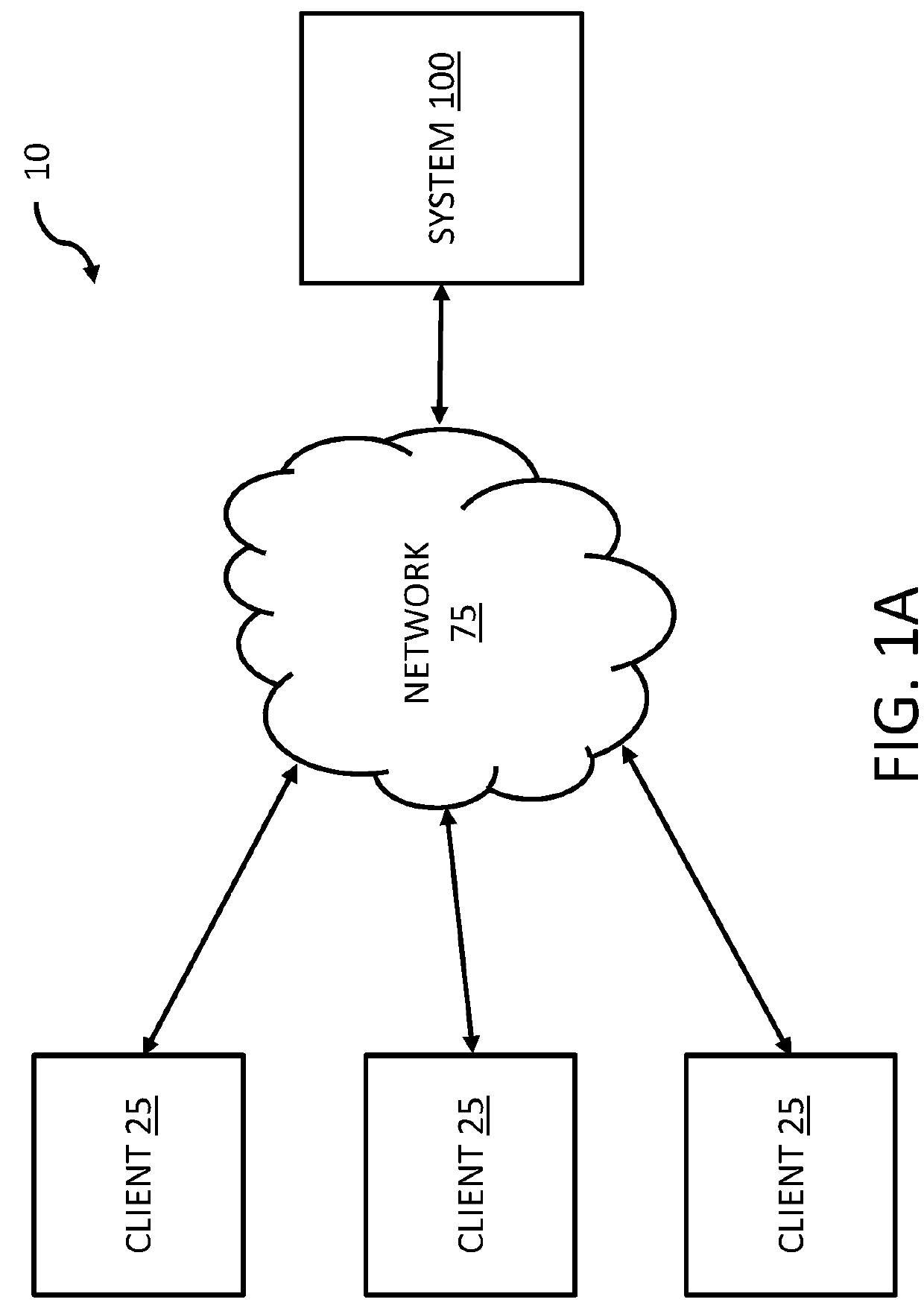

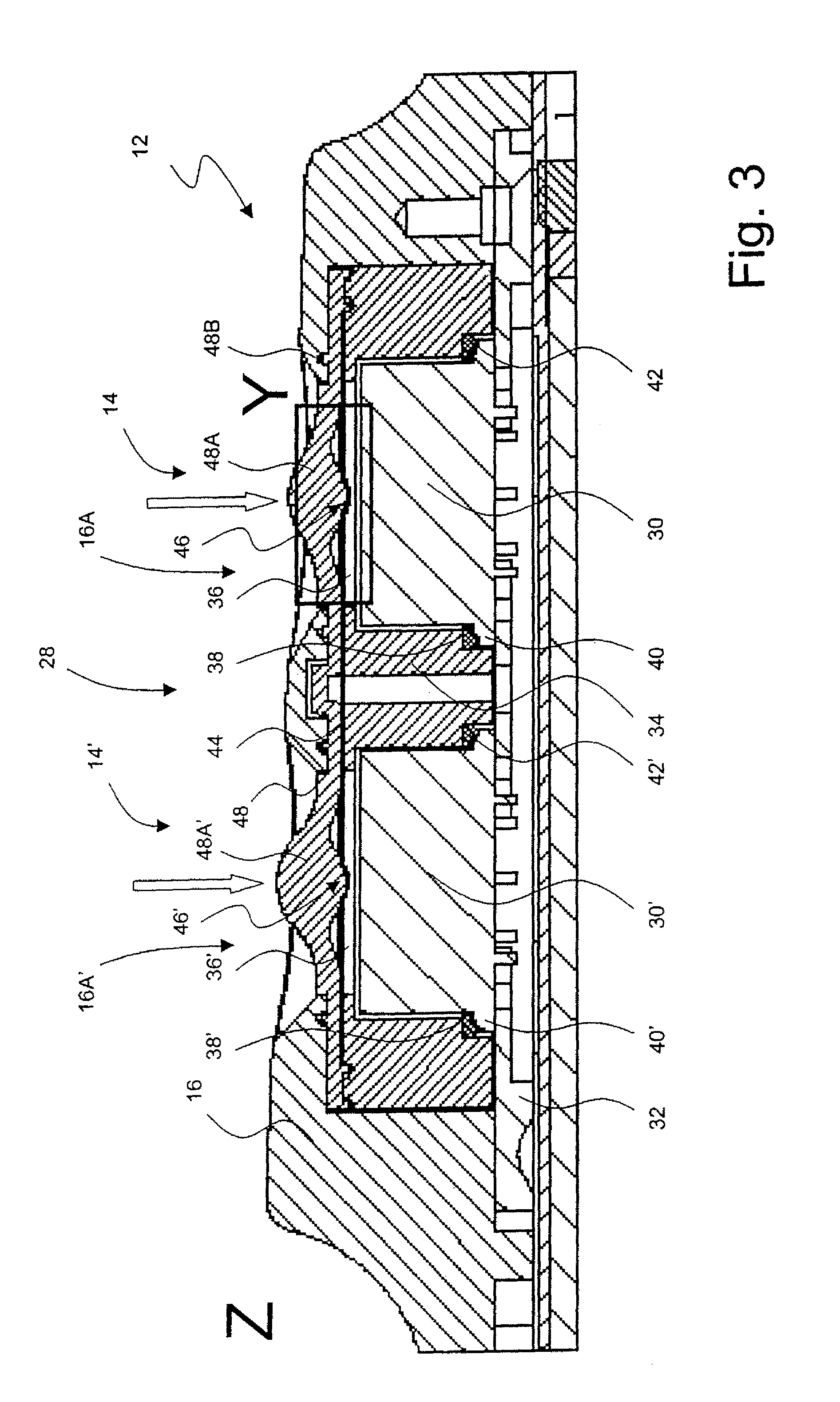

Dialed-digit based determination of whether to originate a call as a circuit-switched call or a packet-switched call

InactiveUS7570630B1Easy to place automaticallyAvoid and greatly reduce international calling chargeInterconnection arrangementsAutomatic exchangesPacket switchTelephone equipment

A method and apparatus are disclosed for causing a telephone device to selectively originate a call as a circuit-switched call or a packet-switched call, depending on the telephone number dialed by a user of the telephone device. By way of example, the telephone device can determine that the dialed telephone number is an international telephone number and can responsively originate the call as a packet-switched call, or the telephone device can determine that the dialed telephone number is not an international telephone number and can responsively originate the call as a circuit-switched call.

Owner:SPRING SPECTRUM LP

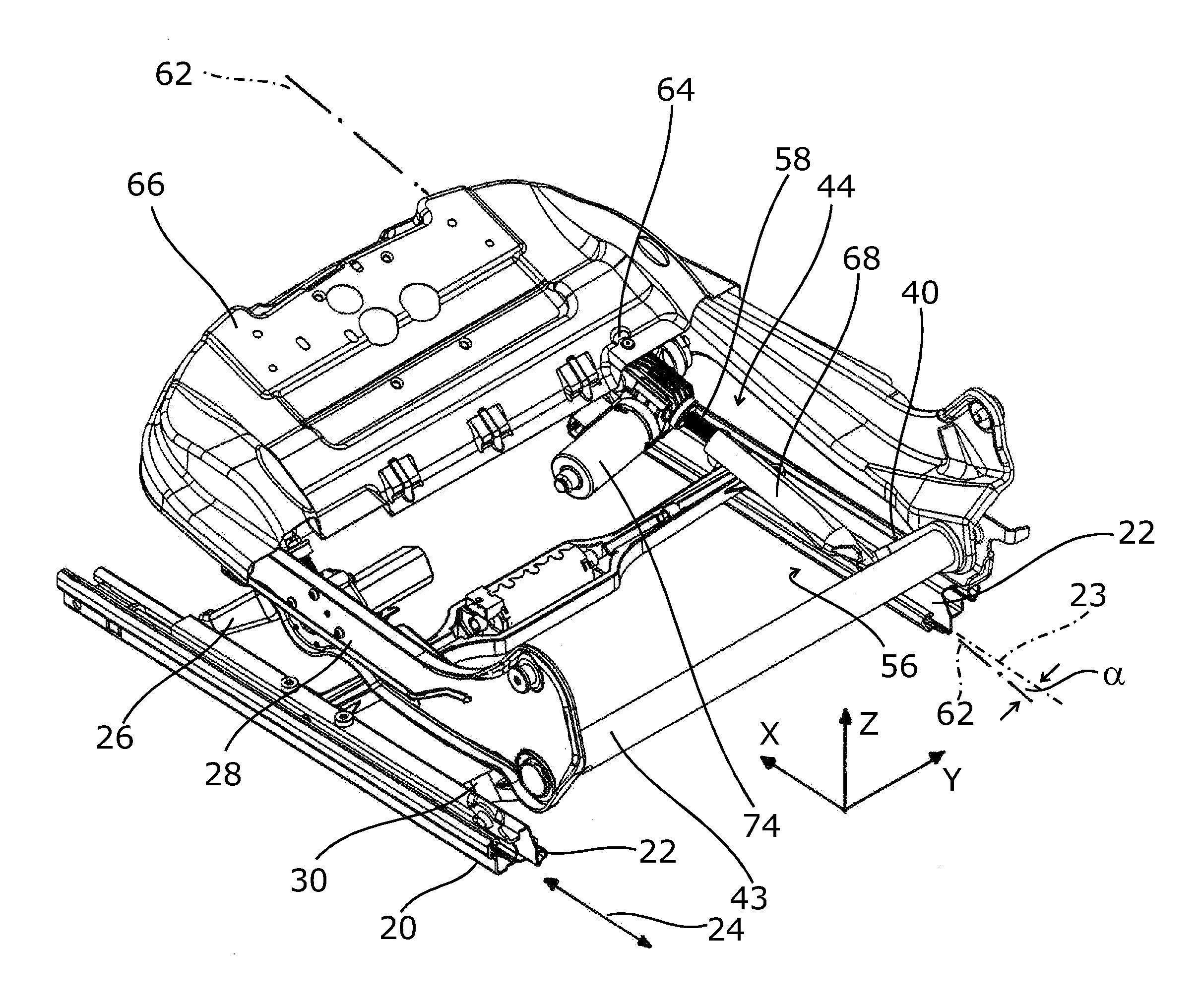

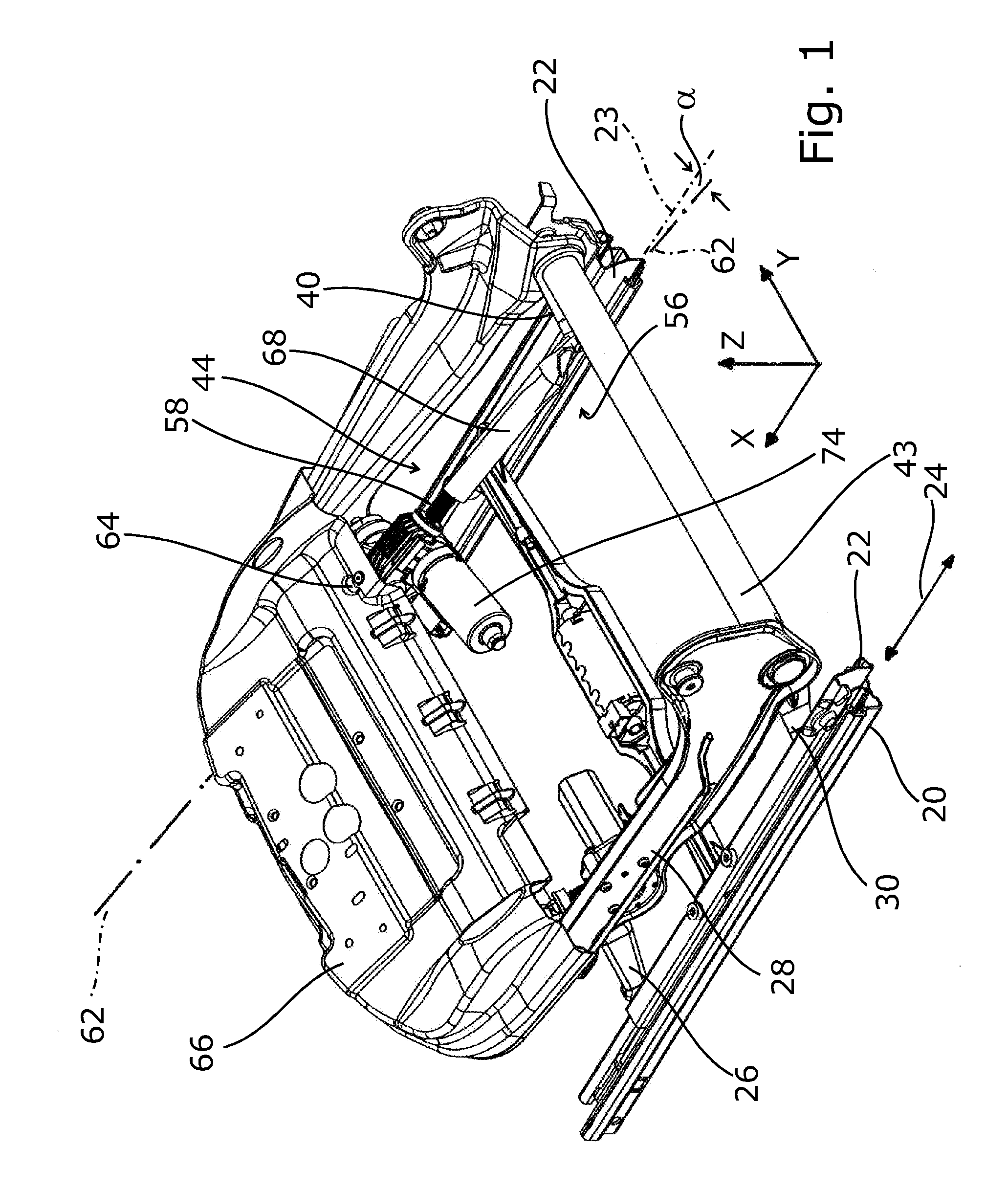

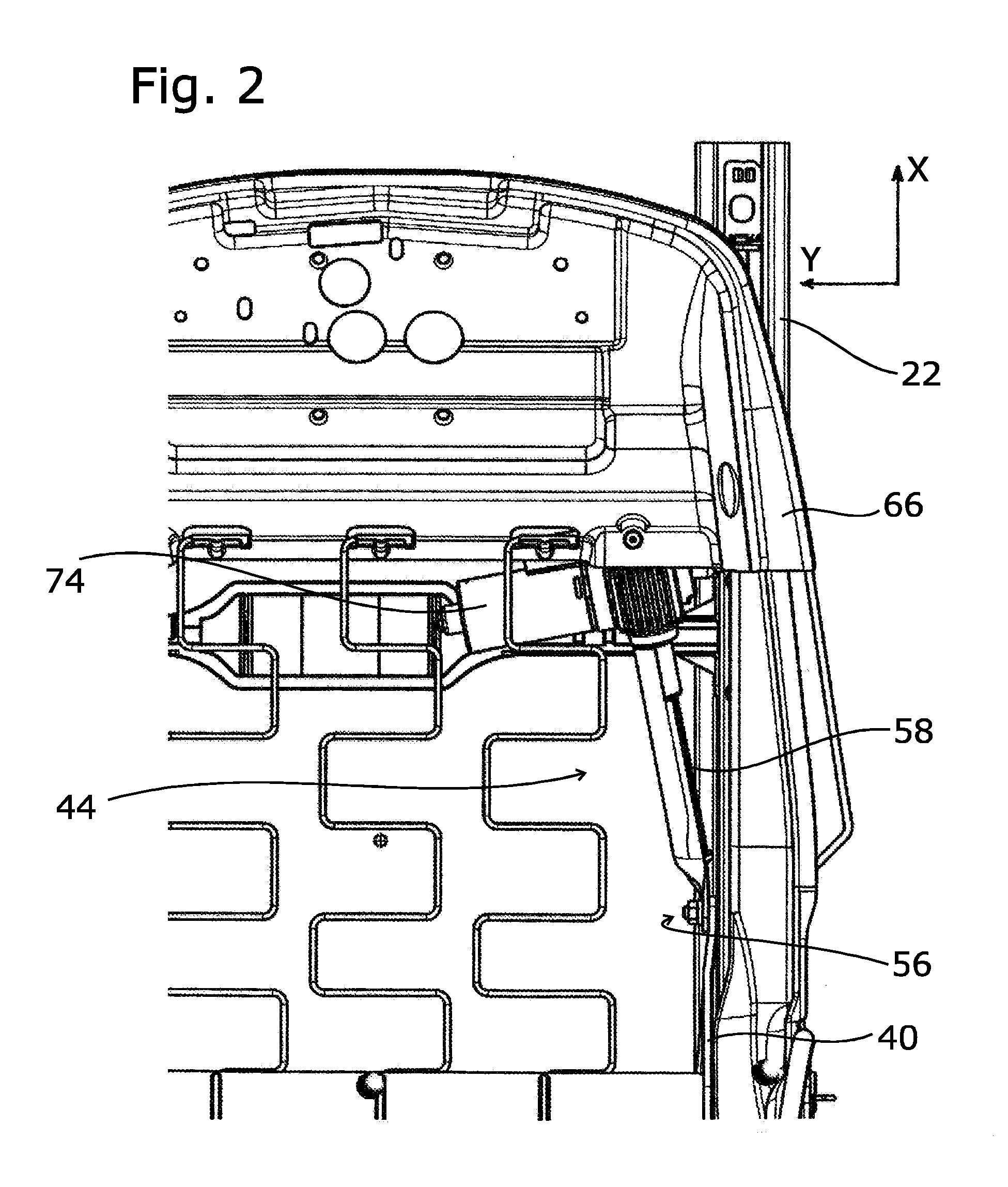

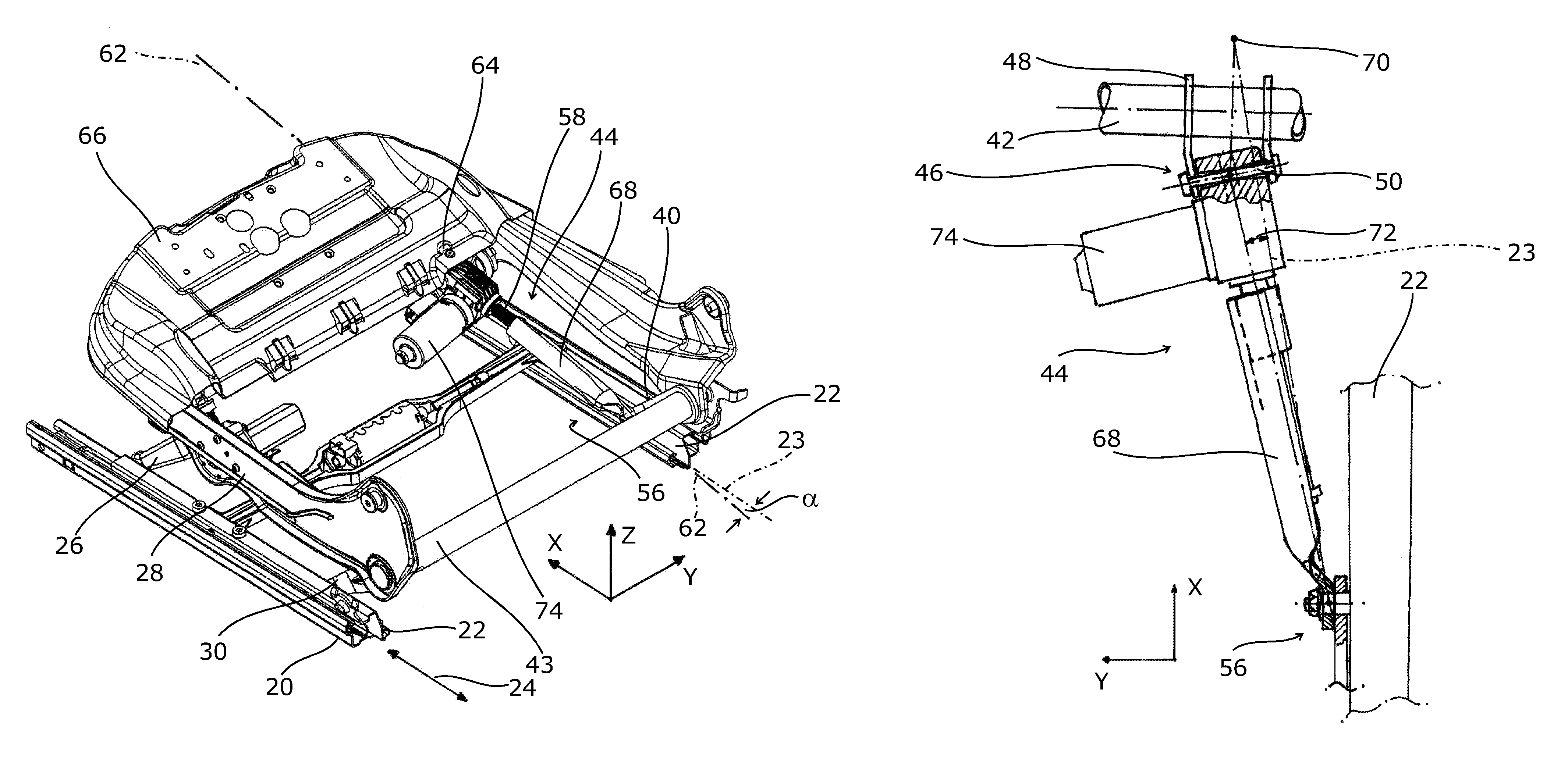

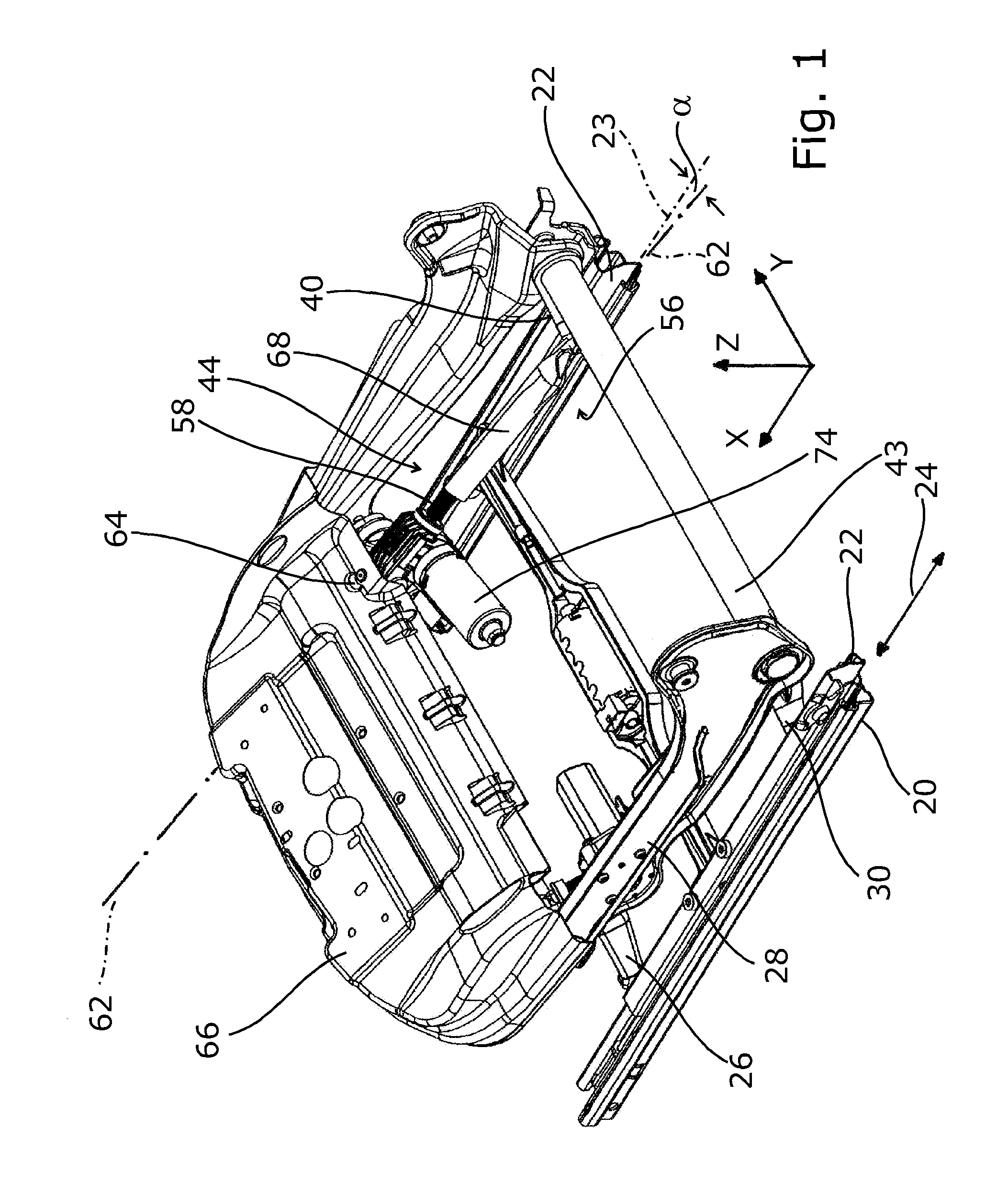

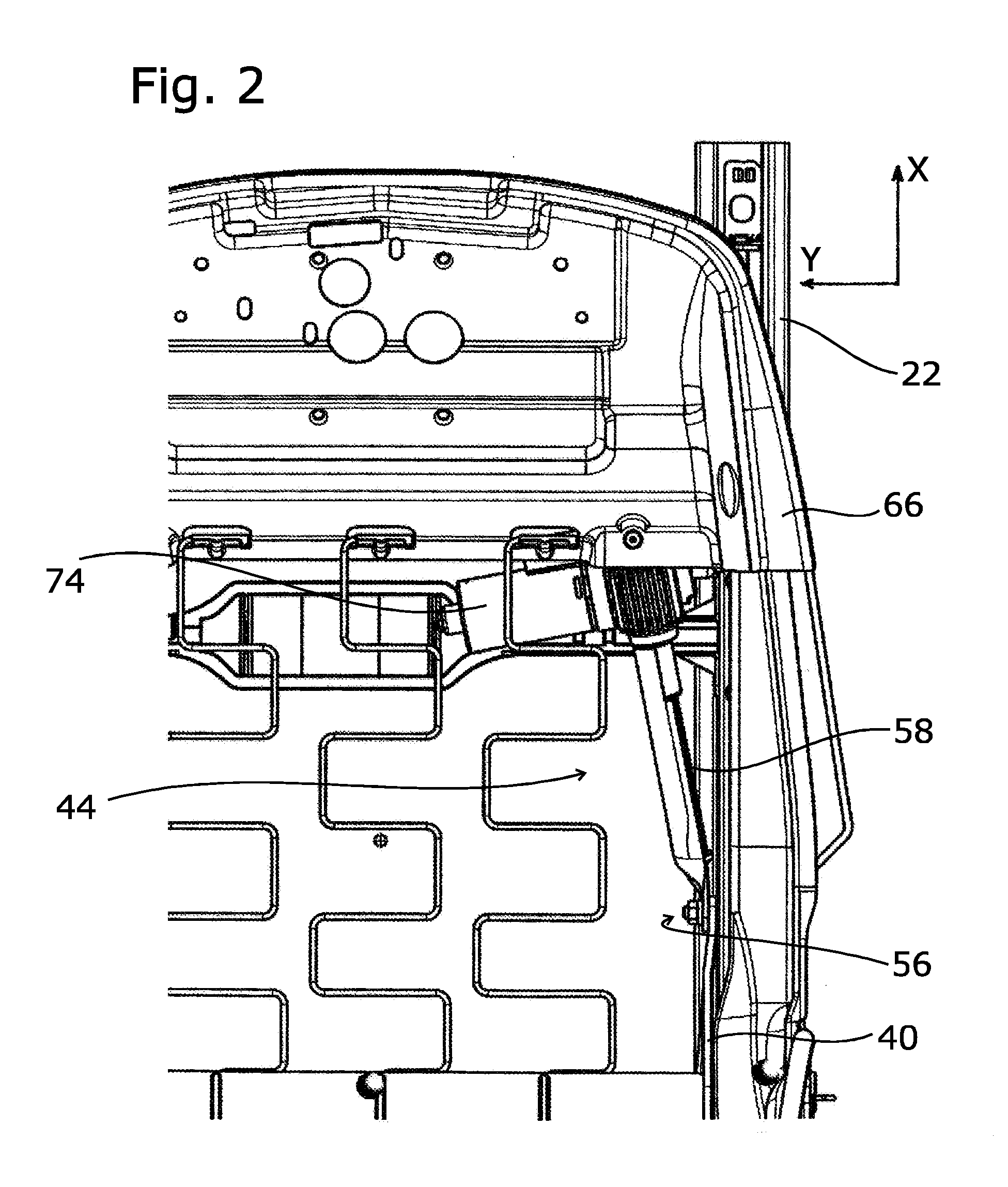

Height-Adjustable Motor Vehicle Seat with a Spindle Drive

ActiveUS20100213341A1Improve cooperationAvoid orToothed gearingsStands/trestlesMobile vehicleMotorized vehicle

Owner:KEIPER SEATING MECHANISMS CO LTD

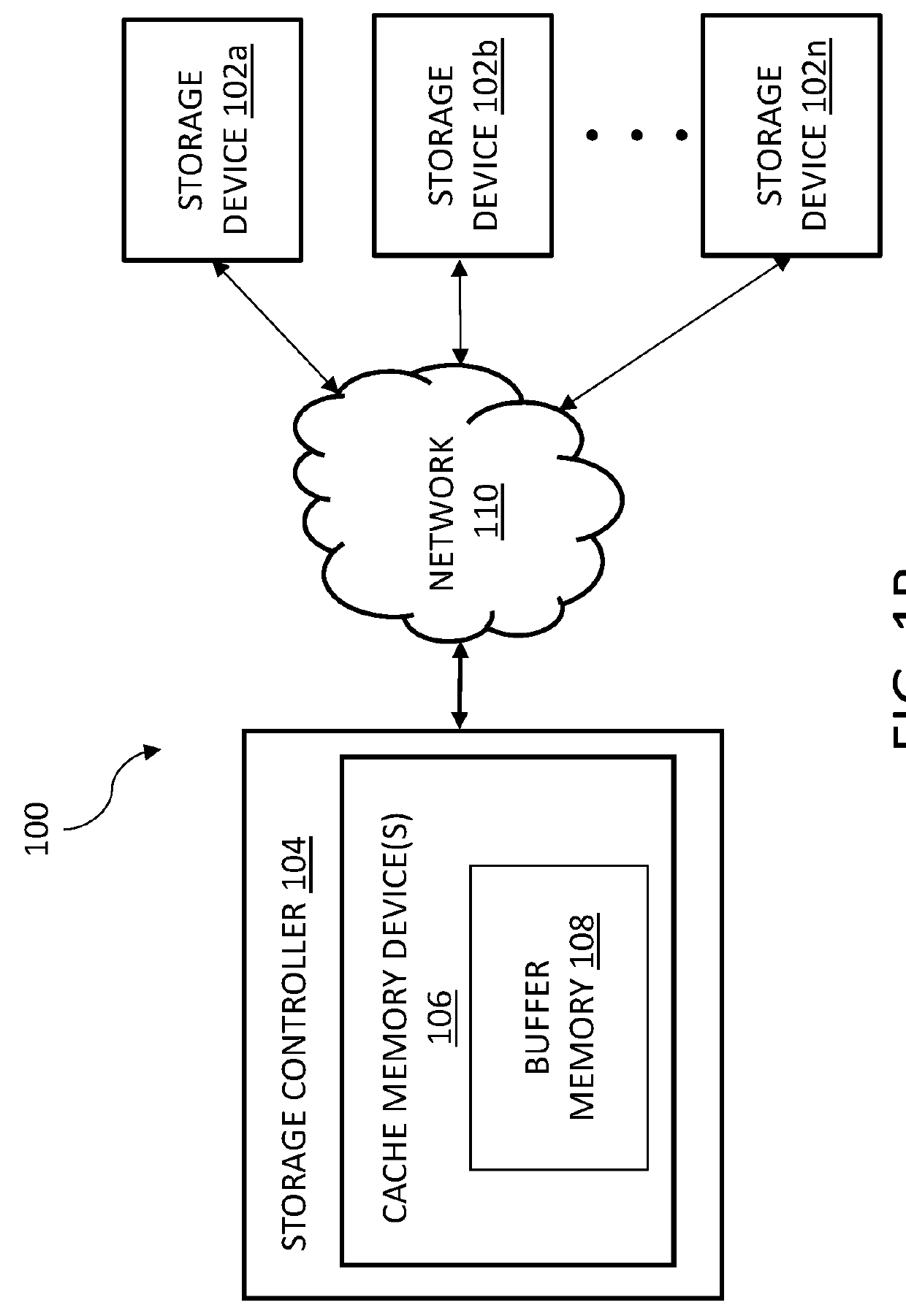

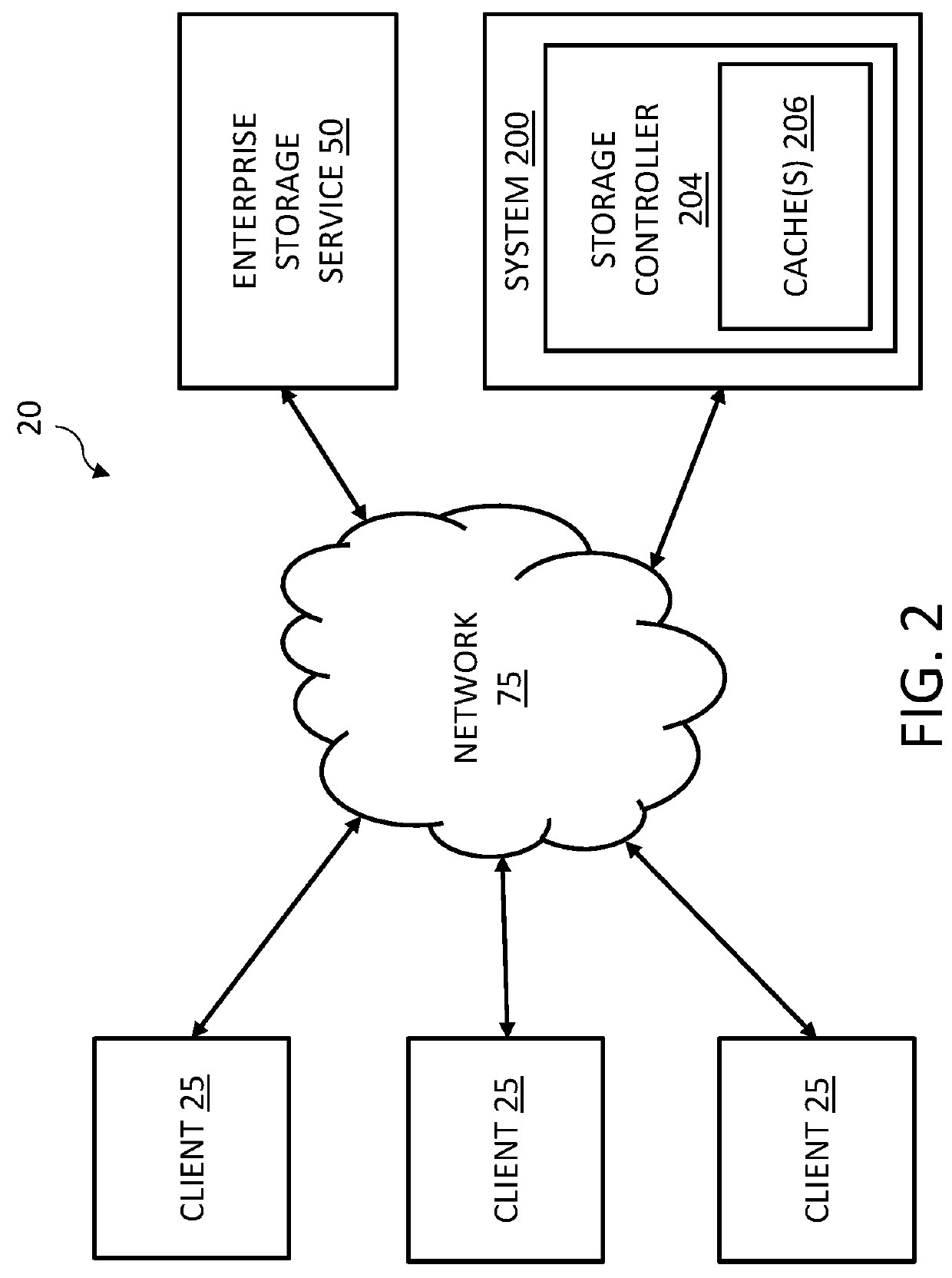

Managing I/O Operations for Data Objects in a Storage System

ActiveUS20180275898A1More reliableReduce latencyMemory architecture accessing/allocationInput/output to record carriersLTM - Long-term memoryRemovable media

Various aspects for managing input / output (I / O) operations for data objects (e.g., large data objects (LOBs)), in a storage system are provided. For instance, a method may include receiving an I / O request for executing an I / O operation on a data object, determining the size of the data object, and determining the data object to be a non-conforming data object relative to a storage threshold of a cache memory device. The method may further include dividing the non-conforming data object into multiple data chunks, each of the data chunks having a size that is less than the storage threshold, moving one or more data chunks stored in one or more memory spaces of the cache memory device to a long-term memory device to free up the one or more memory spaces, and storing one or more of the data chunks of the non-conforming data object in the freed-up memory space(s).

Owner:WESTERN DIGITAL TECH INC

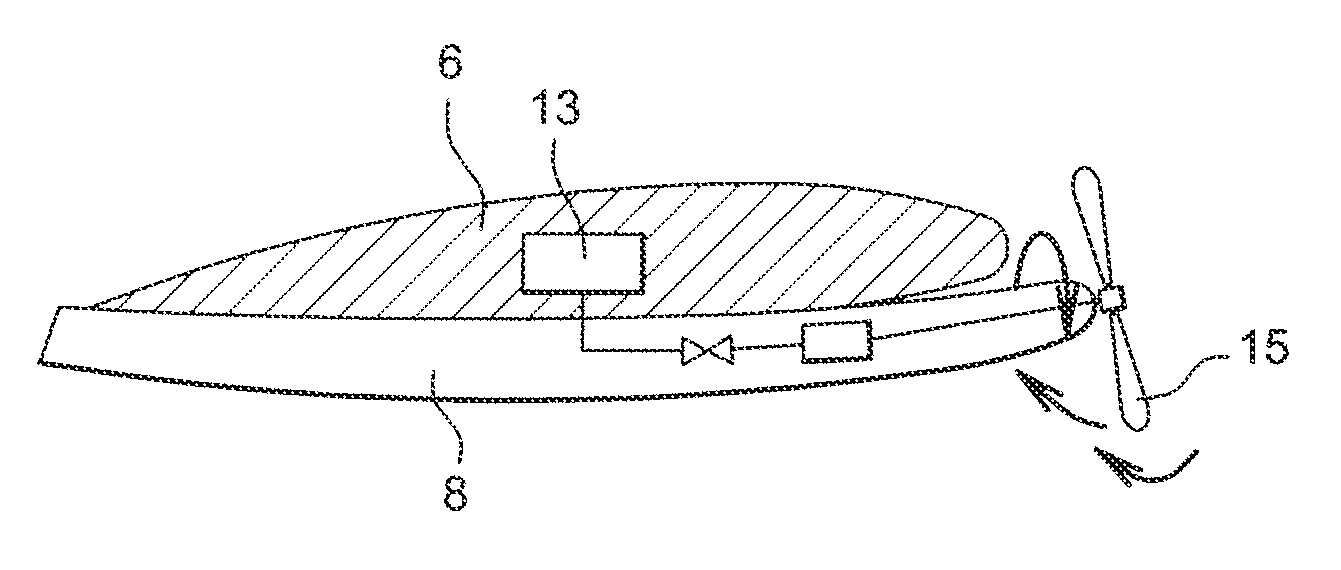

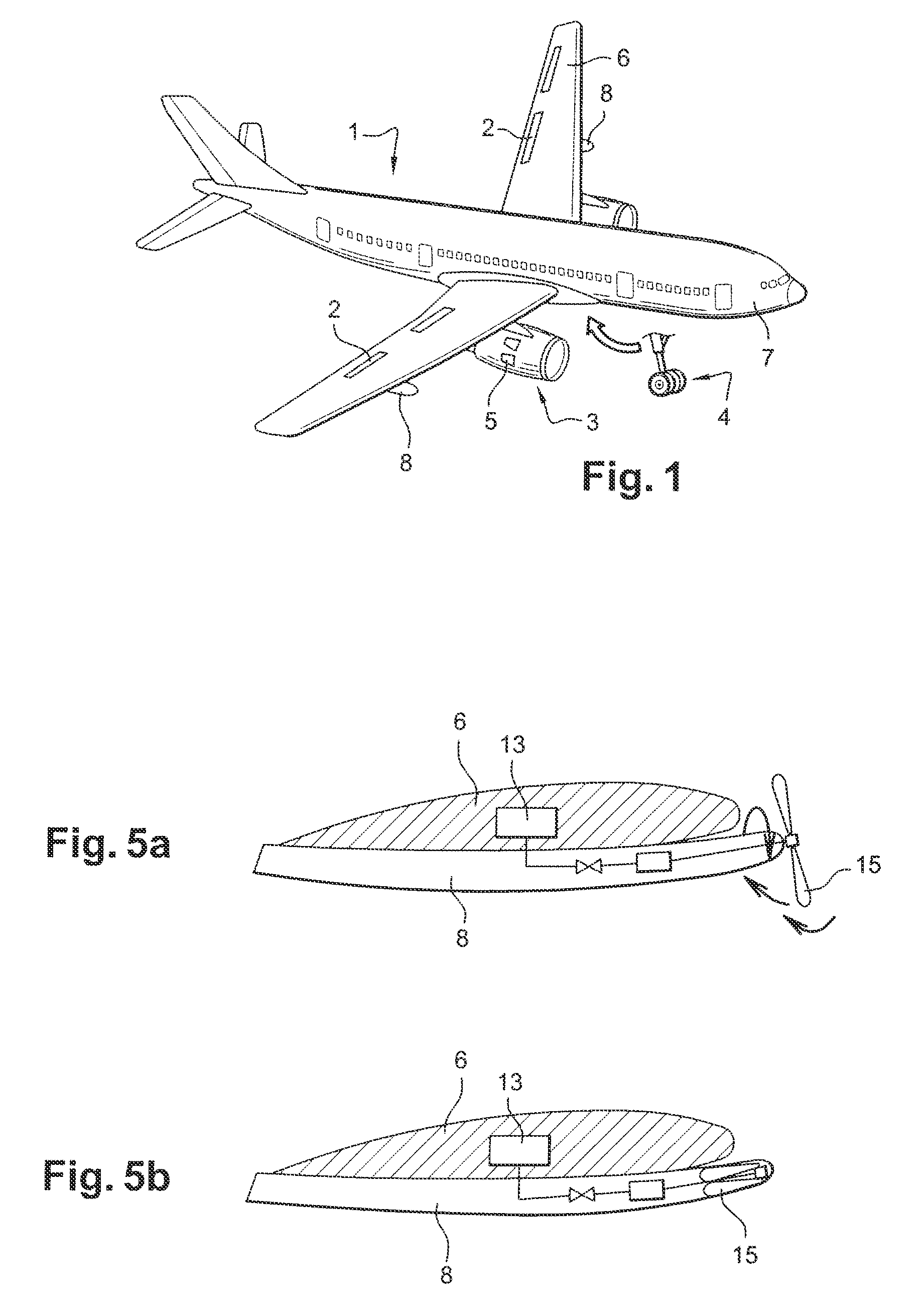

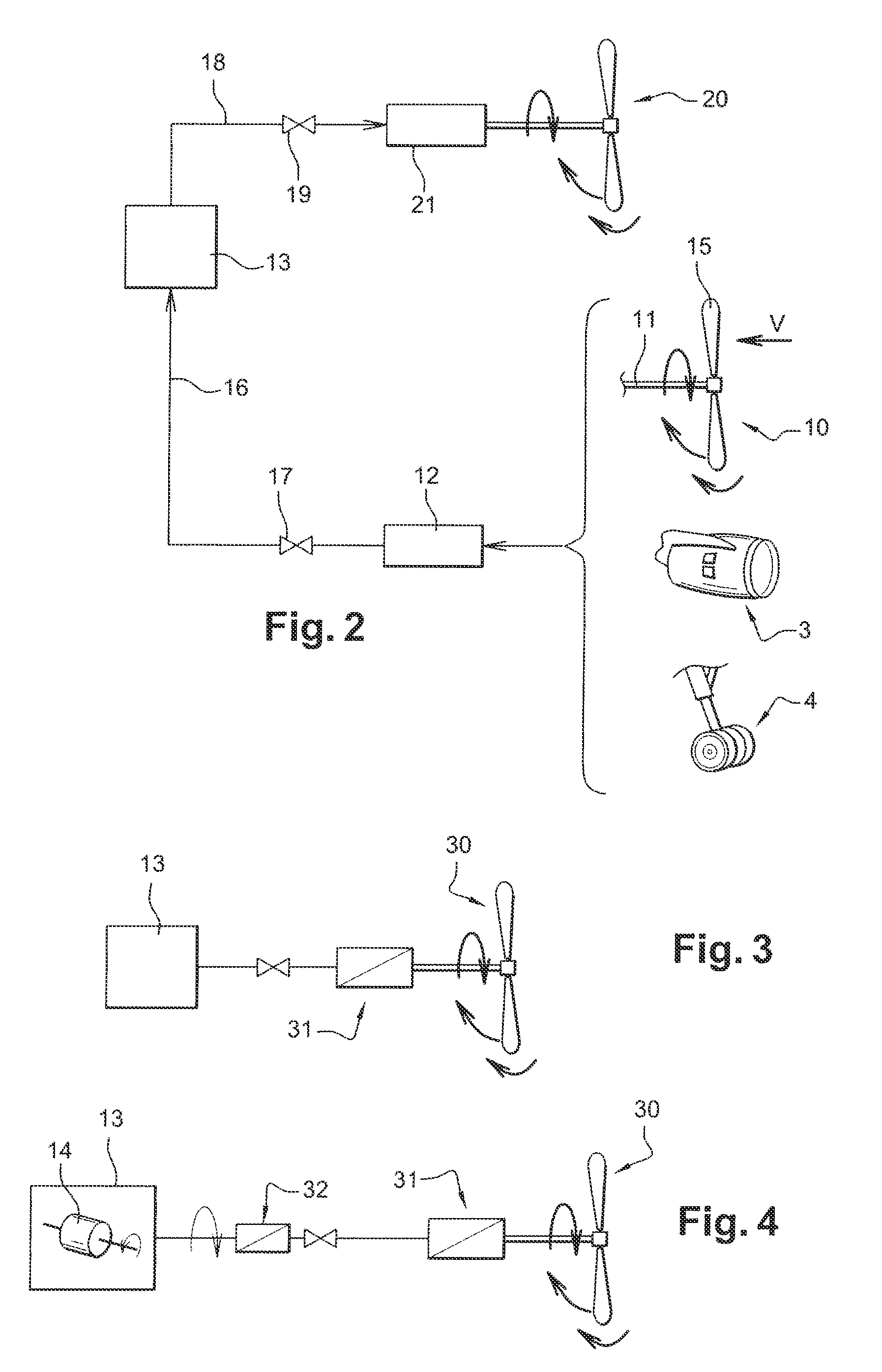

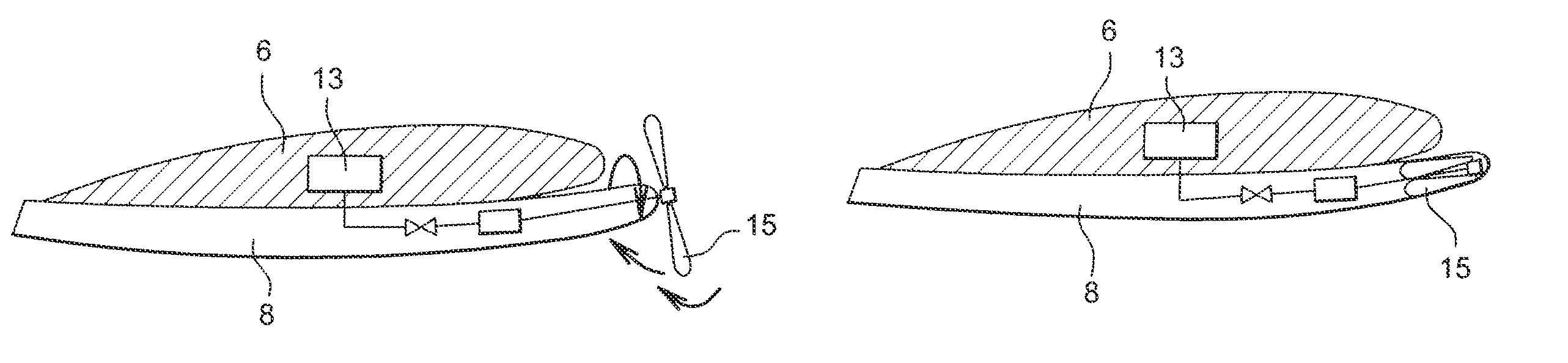

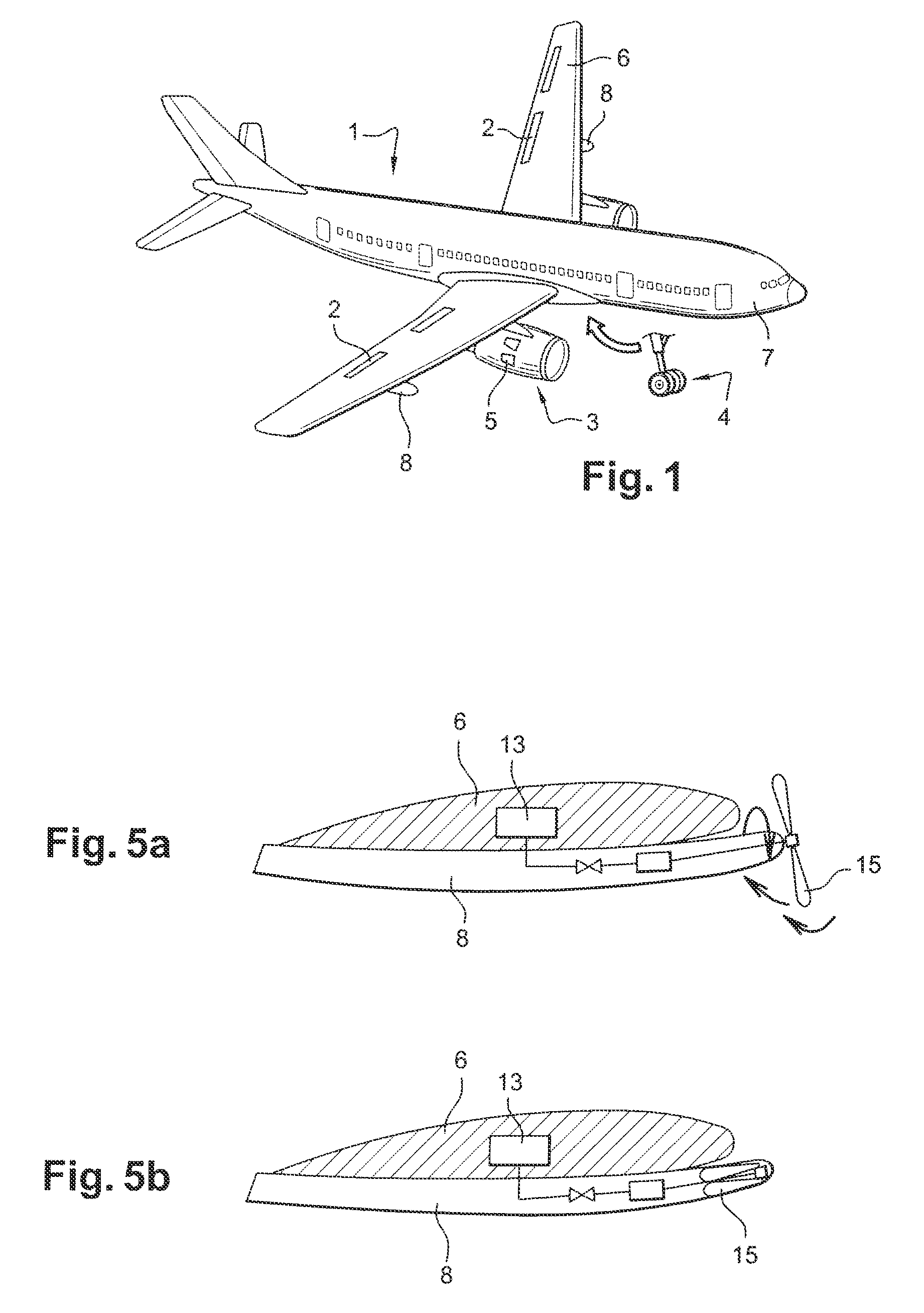

Energy storage aerodynamic braking device and method

InactiveUS20100170981A1Avoiding and limiting useAvoid orPower installationsEnergy efficient operational measuresPropellerEnergy storage

In order to generate an efficient aerodynamic braking force, whatever the speed of a vehicle such as an airplane flying in the air, the method includes a step for the production of energy by the vehicle, a step of storage of the energy produced and a step of utilisation of such energy to drive a propeller which generates a force opposing the forward motion of the vehicle. Energy is produced by using the displacement of the vehicle with respect to air using a propeller driving a generator, or using the displacement with respect to the ground, using wheels driving a generator, or using generators driven by motors of the vehicle. The energy can be stored in the pneumatic, electric or kinetic form and the generation and driving means are selected according to the technology used for the storage means.

Owner:AIRBUS OPERATIONS (SAS)

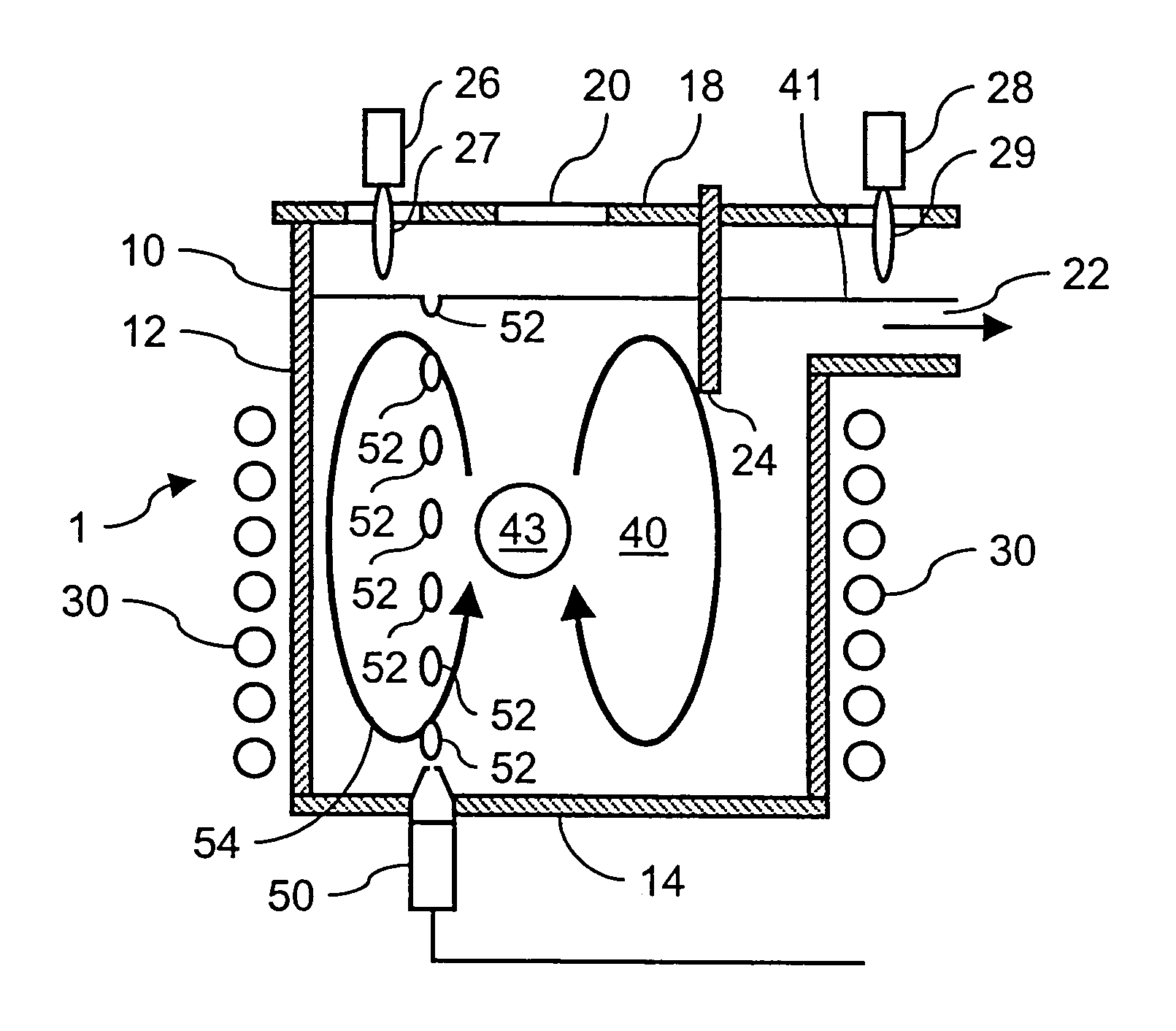

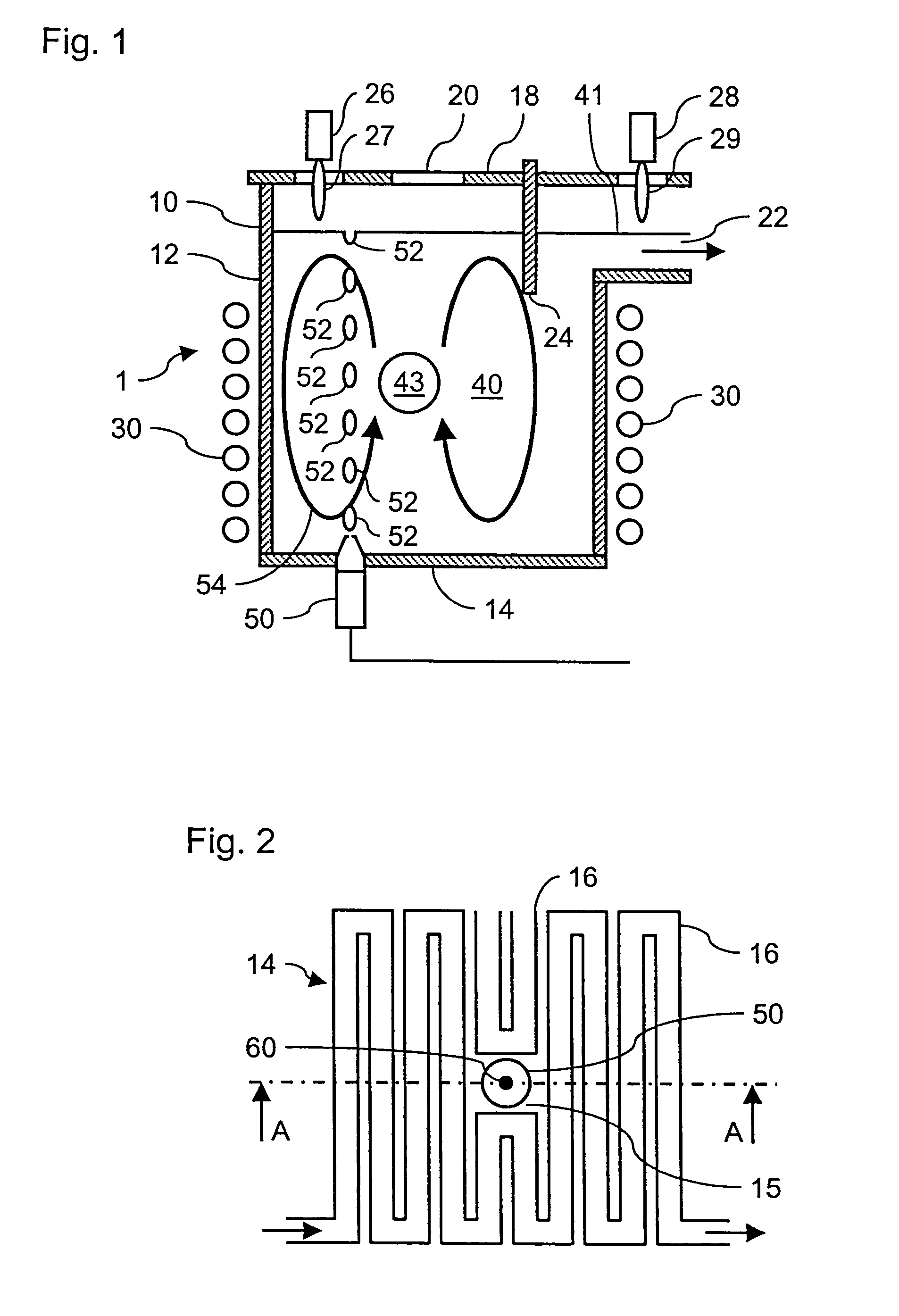

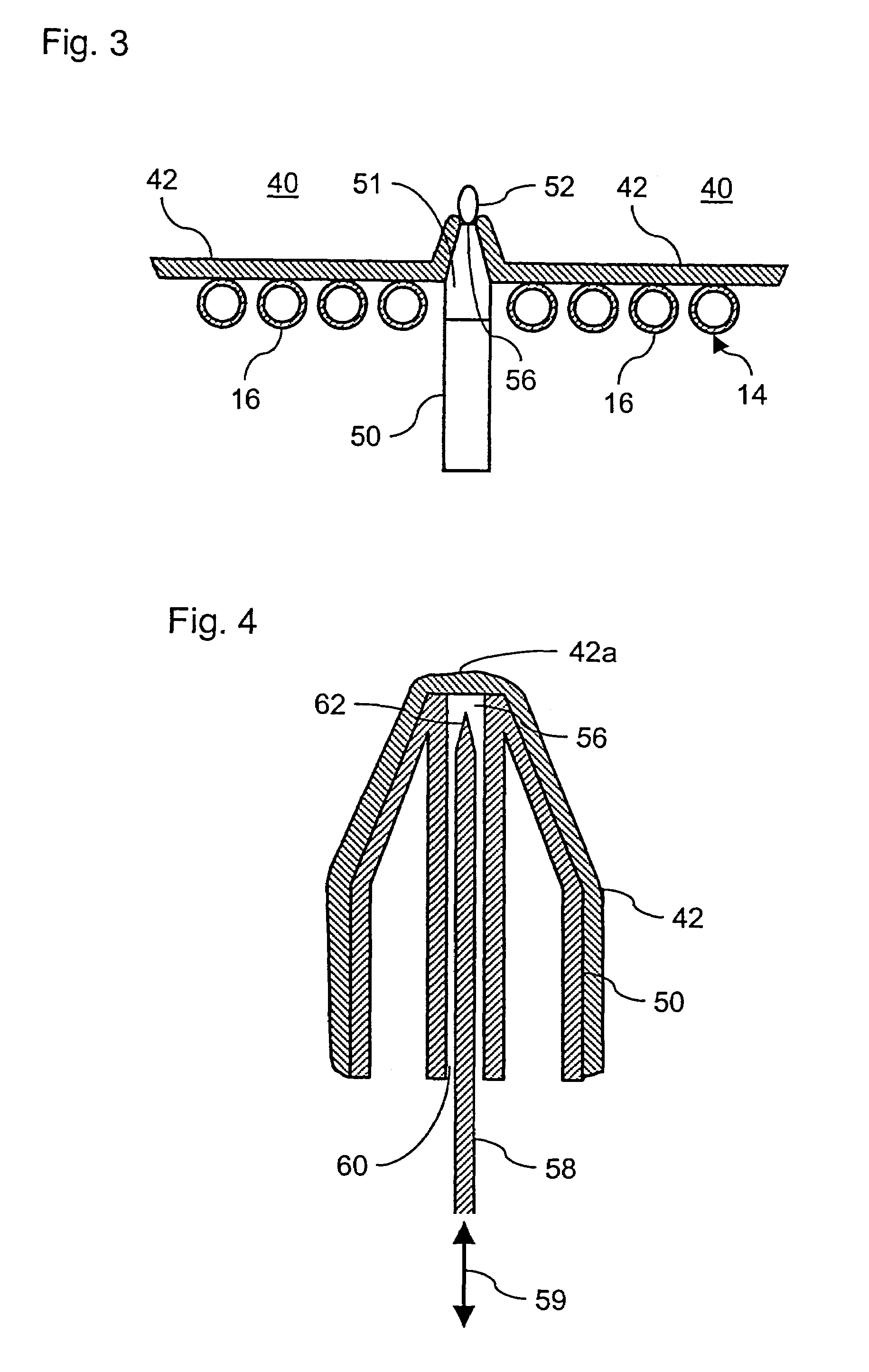

Device and method for melting a substance with the occurrence of a low level of contamination

InactiveUS7296441B2Improve homogeneityImprove smelting effectPot furnacesGlass drawing apparatusOxidation-Reduction AgentOxygen

The invention relates to an apparatus and a method for low-contamination melting of high-purity, aggressive and / or high-melting glass or glass-ceramic. According to the invention, for this purpose a melt is heated in a crucible or melting skull crucible by means of high-frequency radiation and is mixed or homogenized in the melting crucible. It is preferable for a gas nozzle, from which gas bubbles, e.g. oxygen bubbles (known as O2 bubbling), escape into the melt, to be provided at the base of the crucible. This alone makes it possible to achieve surprising multiple benefits in the melting skull crucible. Firstly, unmelted batch which drops into the melt in solid form, for example from above, is melted down more quickly as a result of more intensive mixing with the liquid fraction of the melt, secondly the temperature distribution in the melt is made more even, thirdly a uniform distribution or mixing of different glass constituents is achieved, and fourthly the redox state of the glass can be adjusted.

Owner:SCHOTT AG

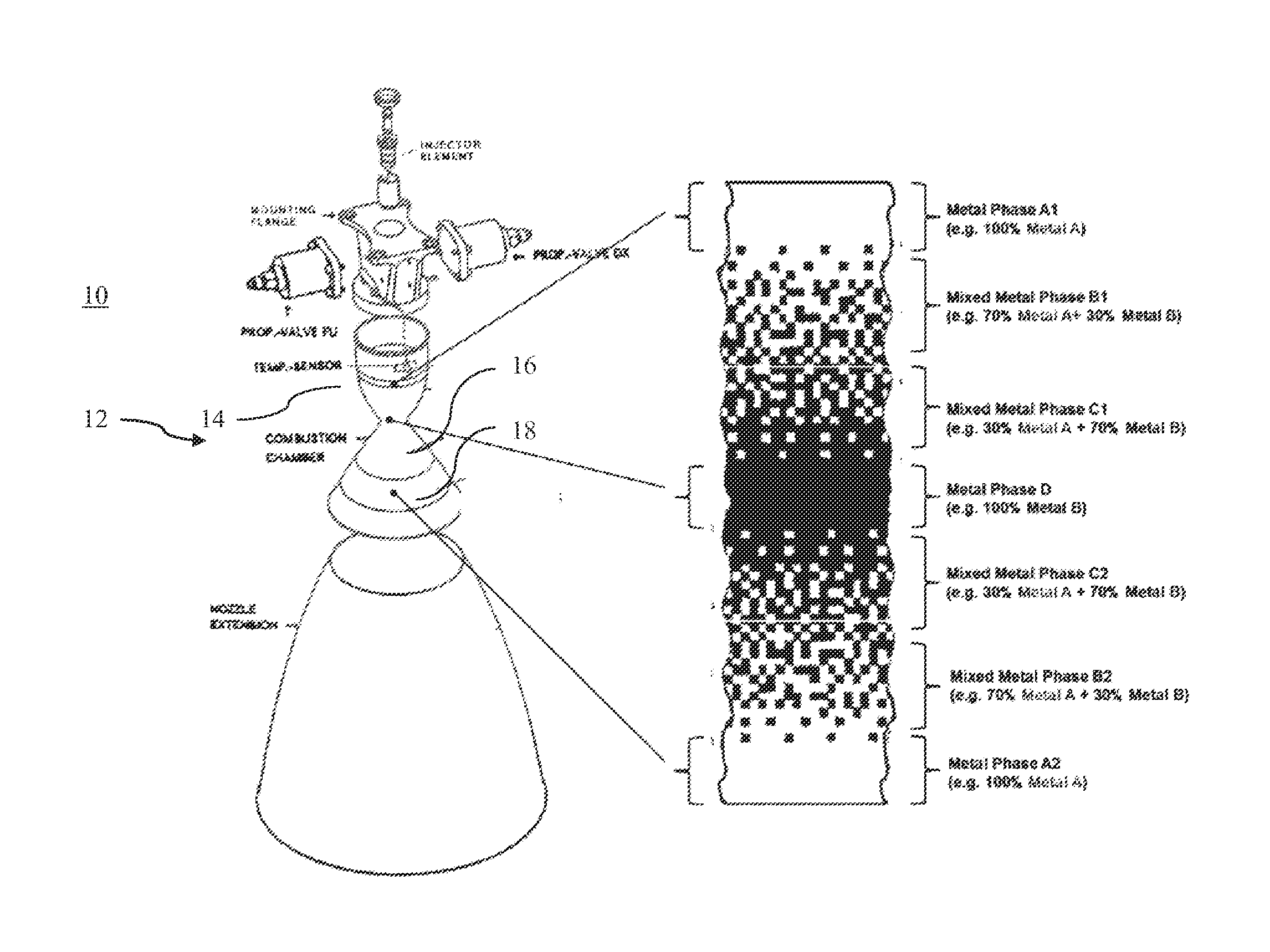

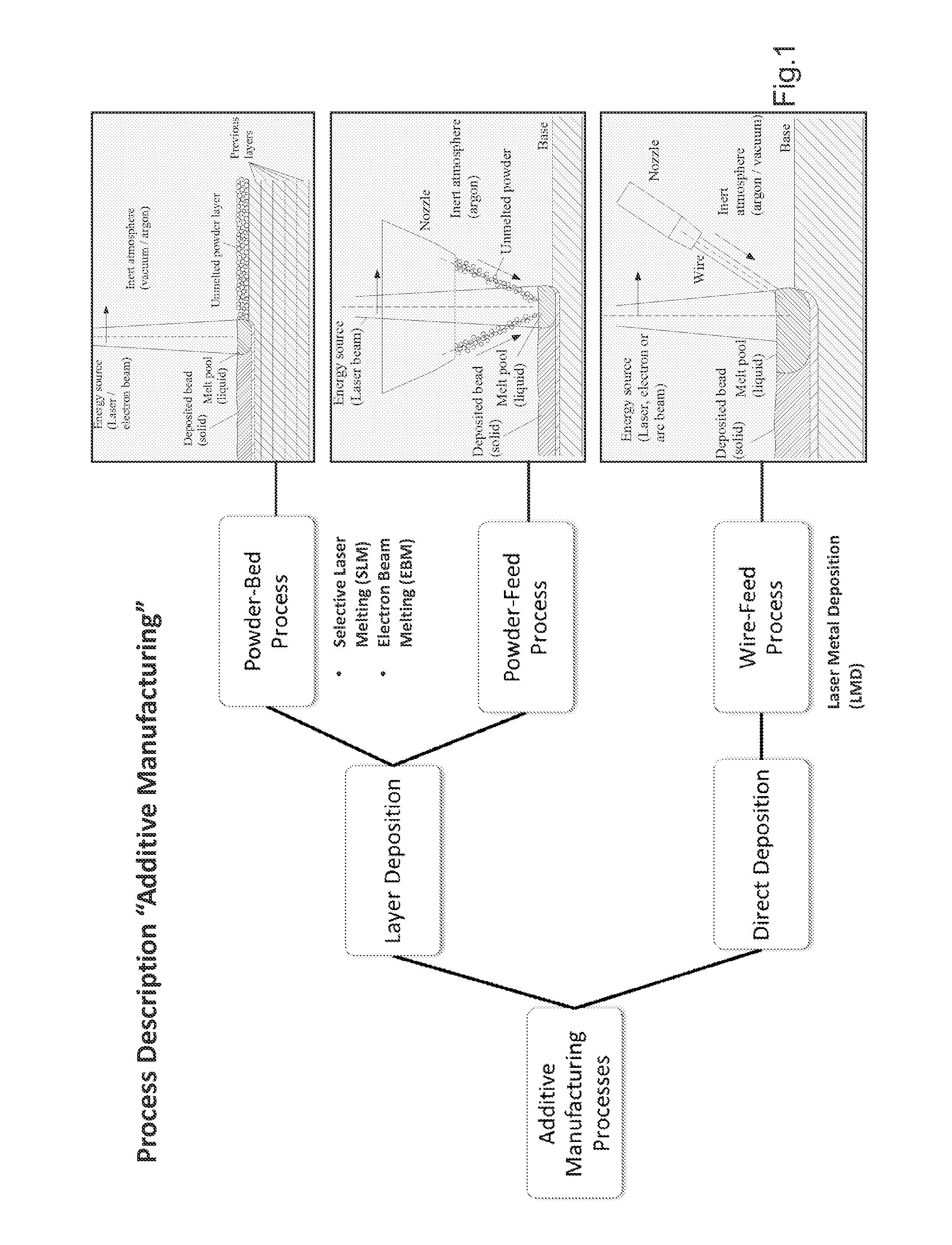

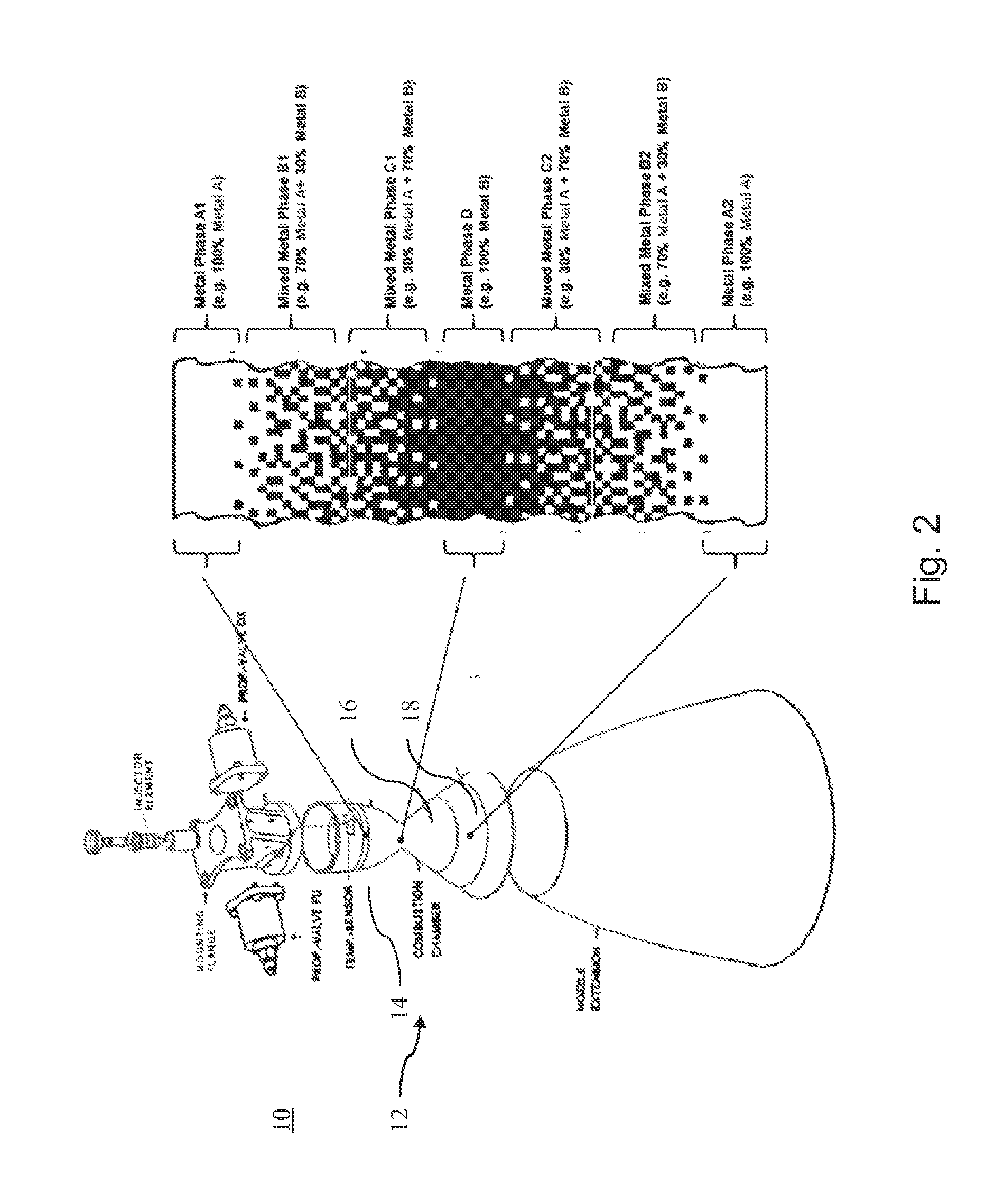

Manufacturing of Components from Parts Made from Different Materials, Particularly of Space Transportation Components Such as Combustion Chambers for Thrusters

InactiveUS20150298213A1Reduce the impactReduce impactAdditive manufacturing apparatusIncreasing energy efficiencyCombustion chamberAdditive layer manufacturing

A method for manufacturing components from parts made from different materials involves producing a transition between one part made from a first material and another part made from a second material by an additive layer manufacturing method. The additive layer manufacturing method involves starting with the first material and then gradually changing the material composition to the second material.

Owner:ARIANEGRP GMBH

Method for operating a surgical power tool

ActiveUS8523845B2Increase material thicknessAvoid orCoupling device connectionsEmergency casingsEngineeringPower tool

A surgical power tool has an actuation assembly which comprises a force sensor and a switch. The force sensor is provided to determine an actuation force produced by the user, and the switch is transferred by the actuation force from a first switching state to a second switching state. A combined evaluation of the force sensor signal and of the switching state enables, for example, a plausibility check for increasing the operational reliability of the power tool.

Owner:STRYKER EURO OPERATIONS HLDG LLC

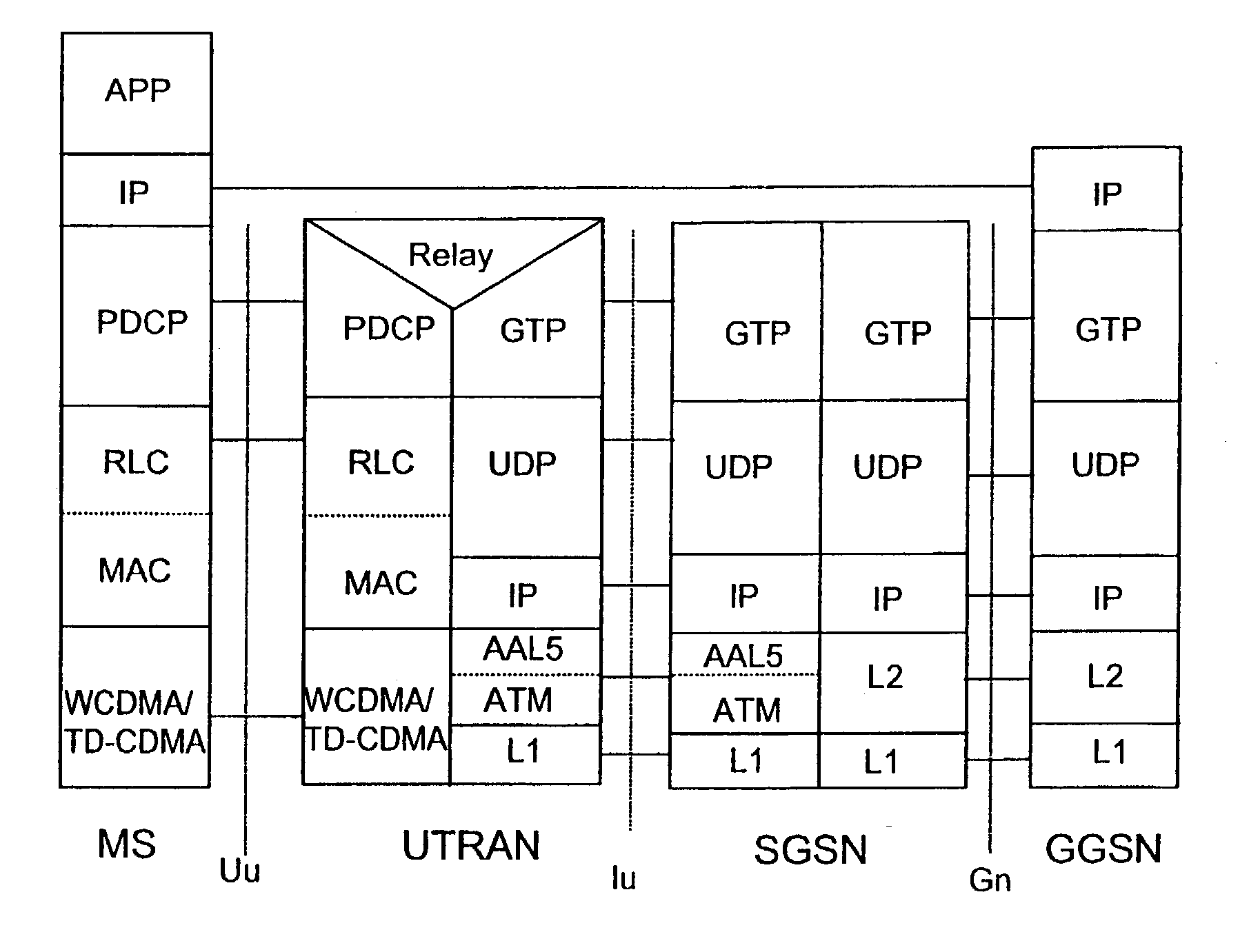

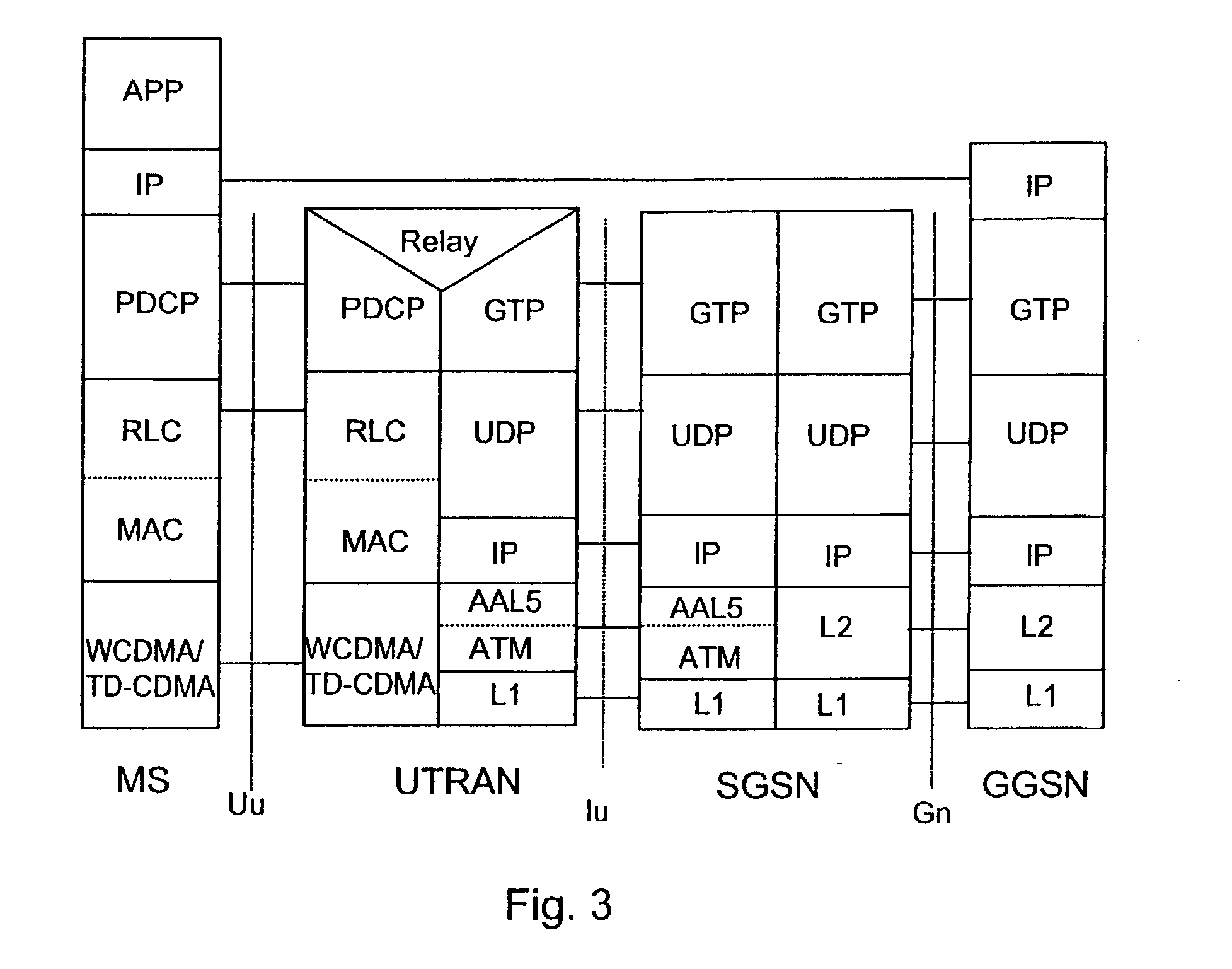

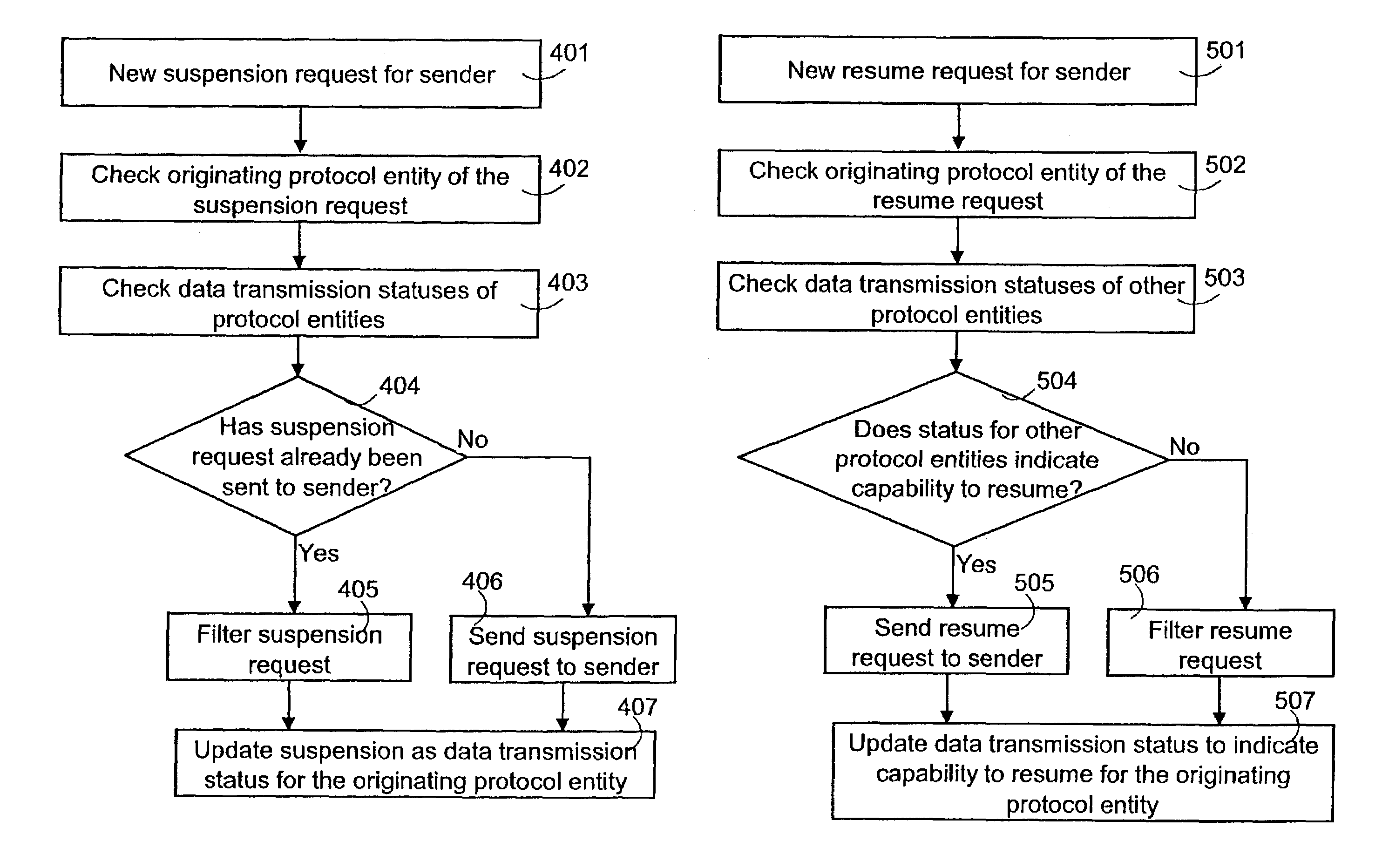

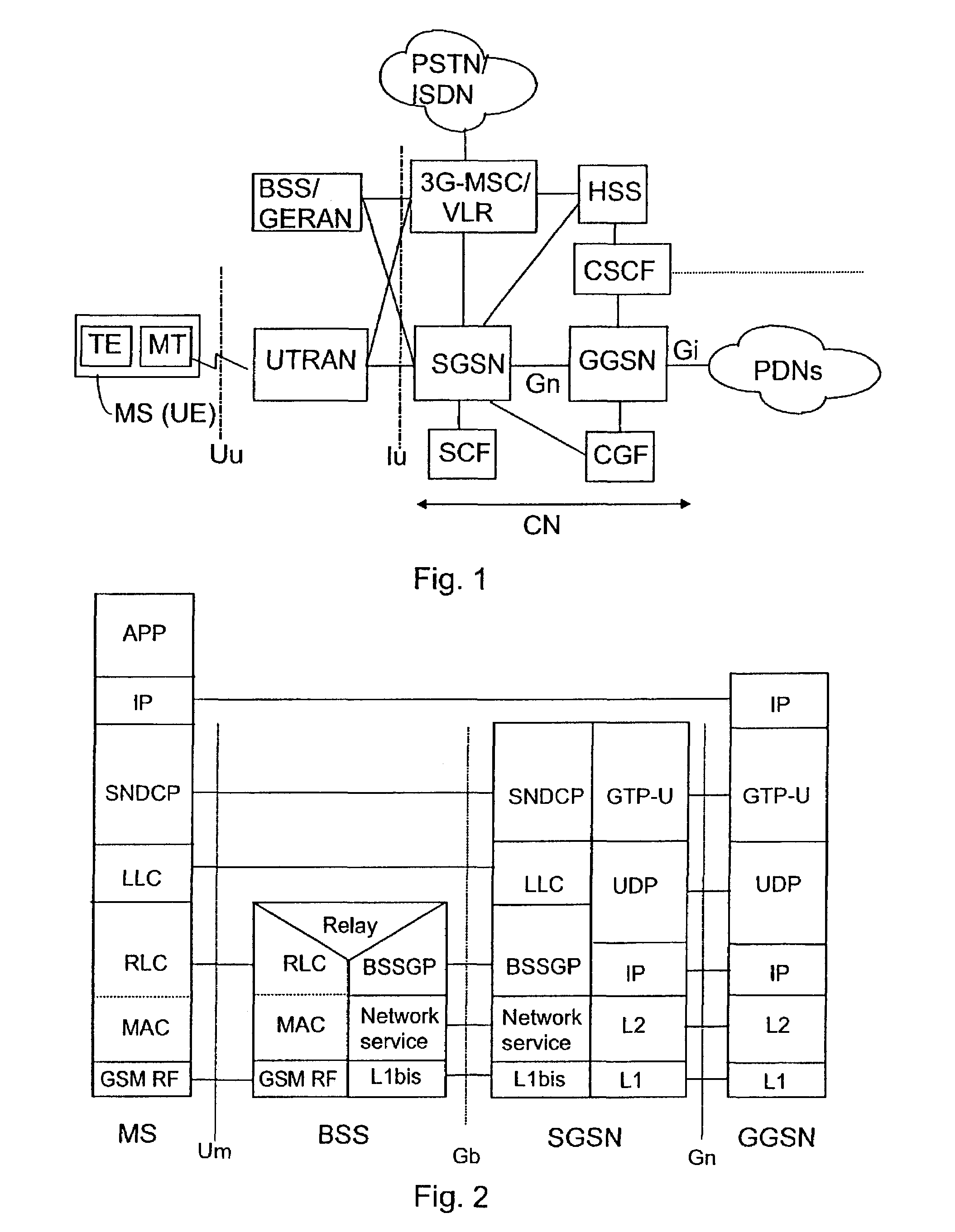

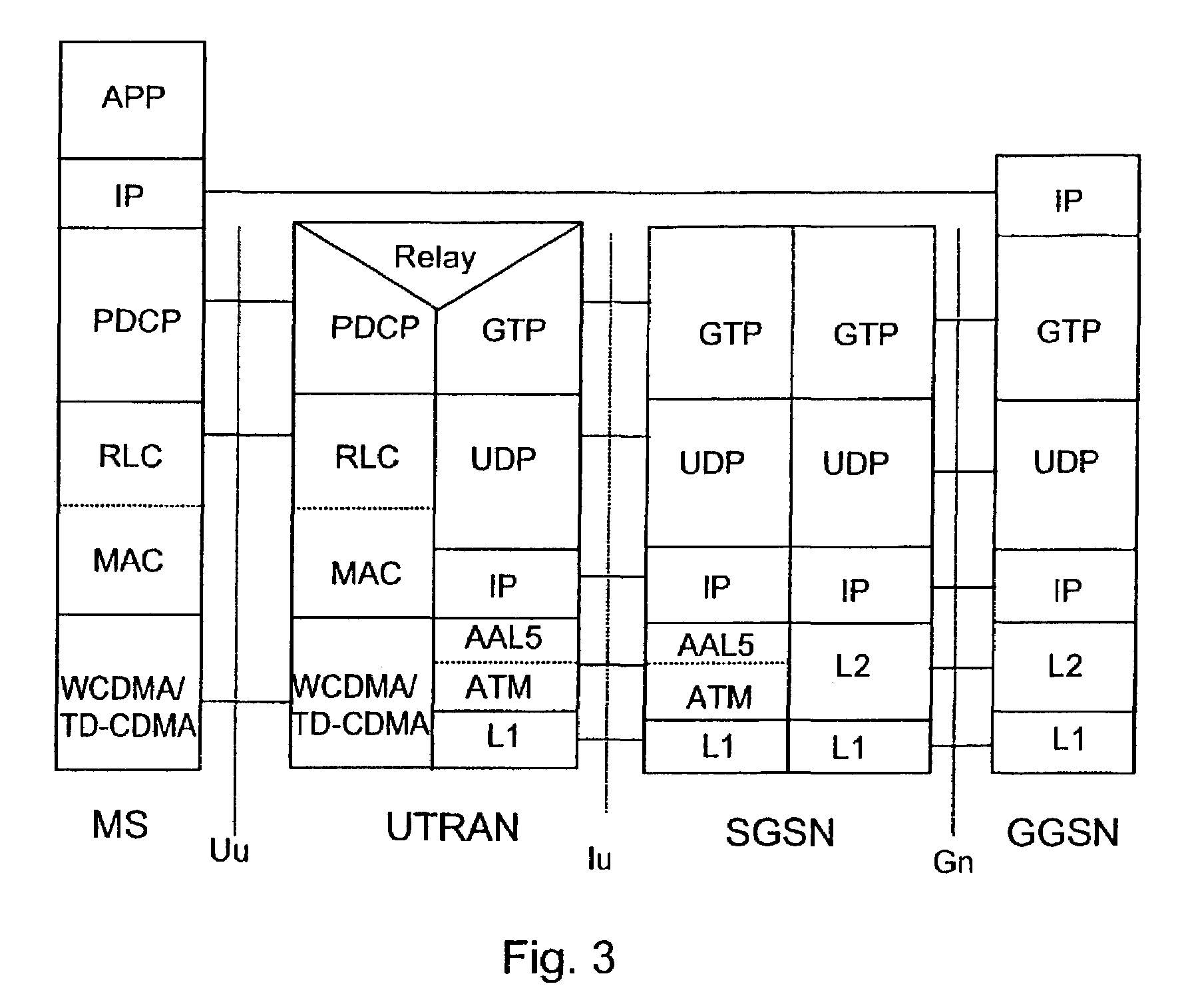

Data flow control

ActiveUS20050254425A1Avoid problemsAvoid orError preventionTransmission systemsComputer hardwareData stream

The invention relates to arranging data flow control in a data transfer system comprising a sender and at least two protocol entities serving the transmission of data from the sender. The originating protocol entity of a suspension request primitive is checked. Suspension is set as the data transmission status for the protocol entity that has originated a suspension request primitive. The originating protocol entity of a resume request primitive is checked before sending it to the sender. Also the status information is checked. Transmission of the resume request primitive to the sender is prevented if suspension is set for any other protocol entity than the originating protocol entity of the resume request primitive.

Owner:NOKIA TECHNOLOGLES OY

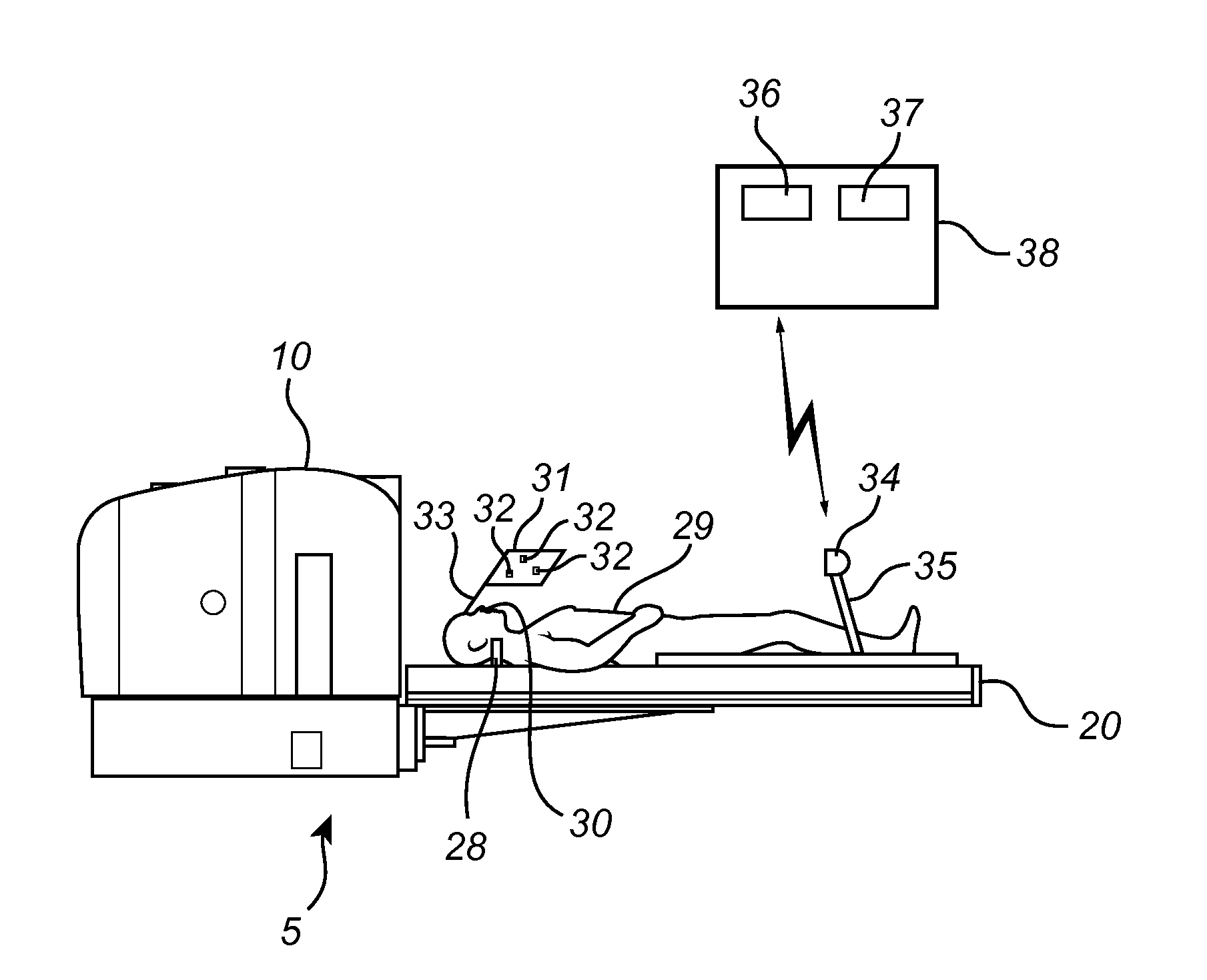

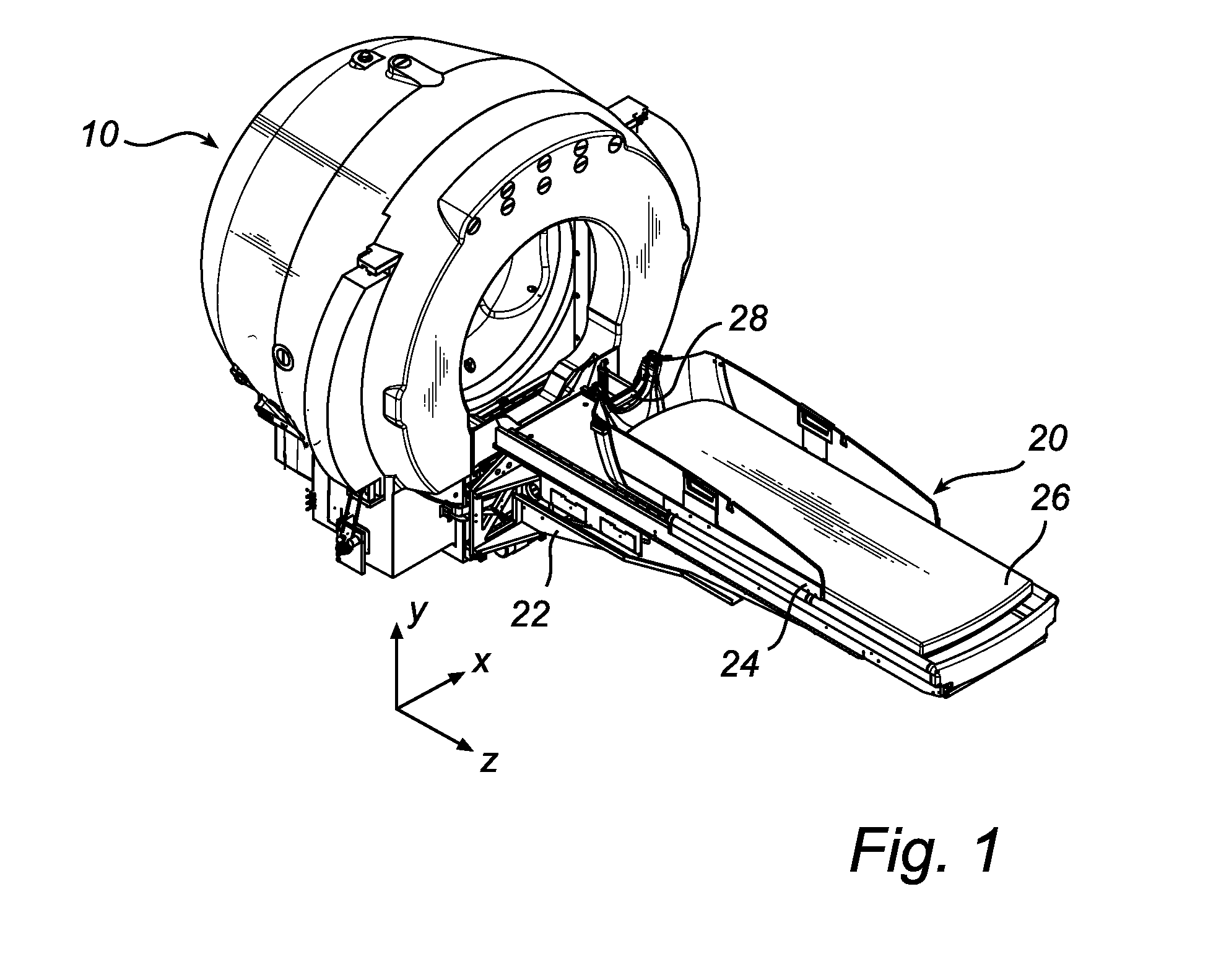

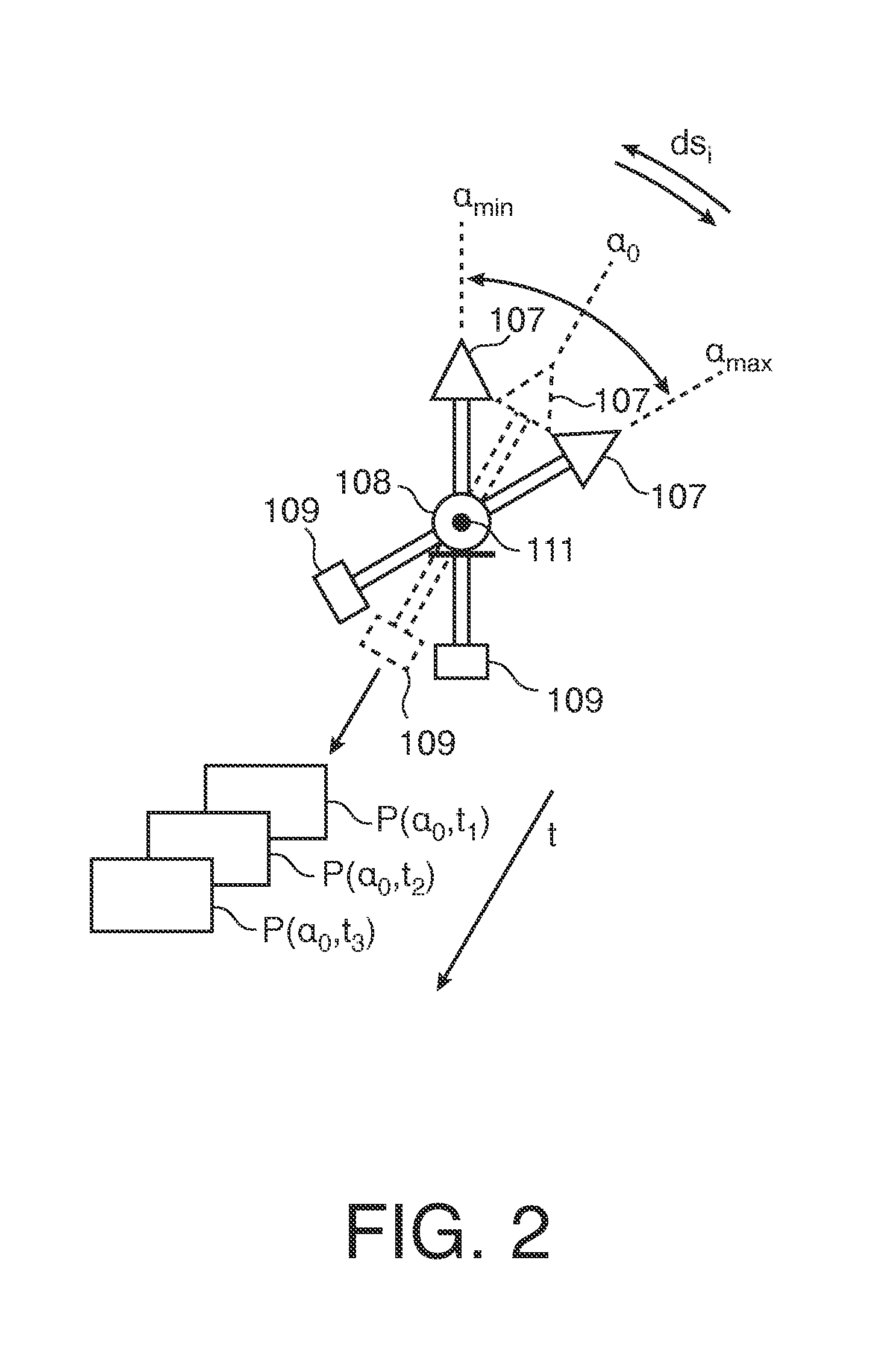

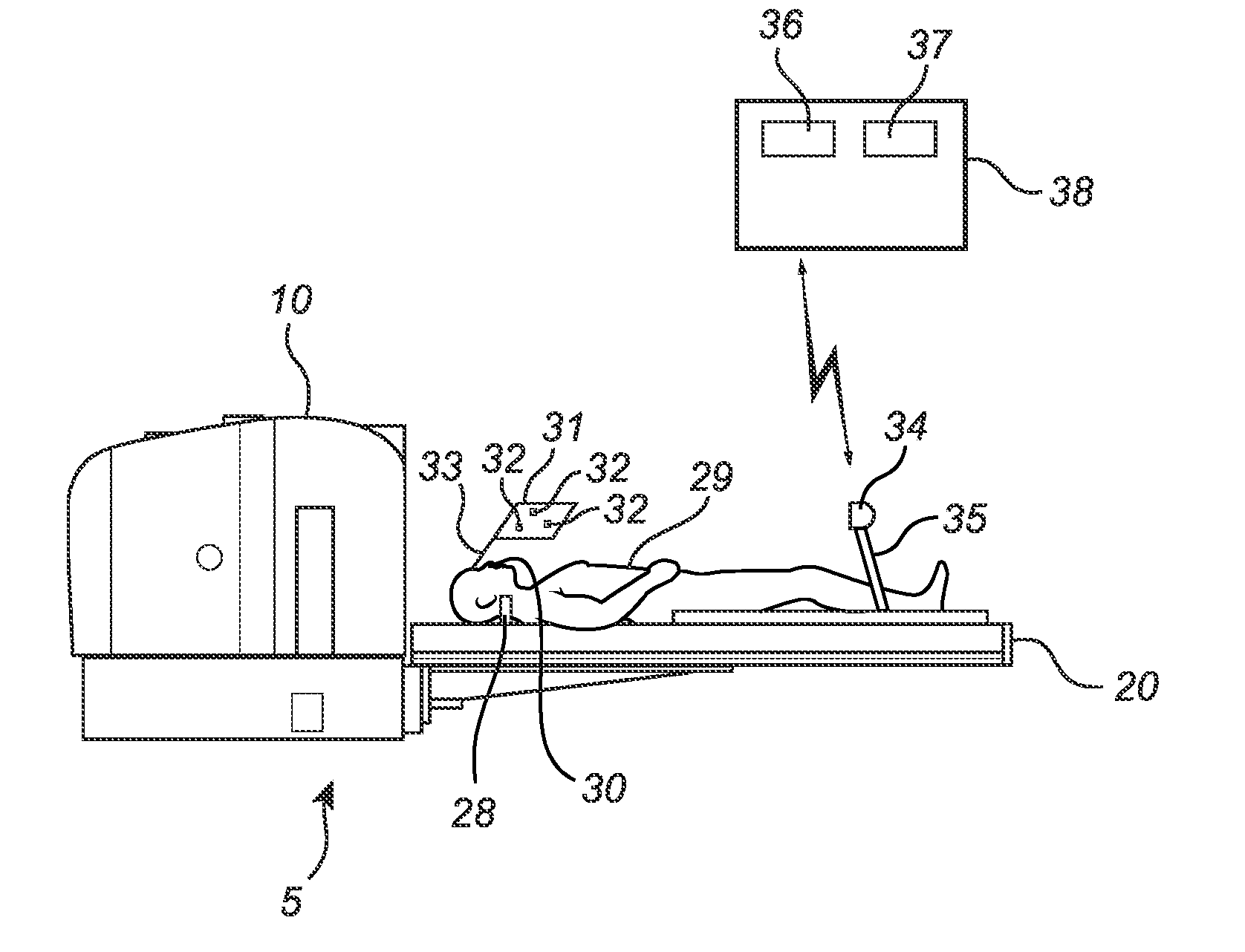

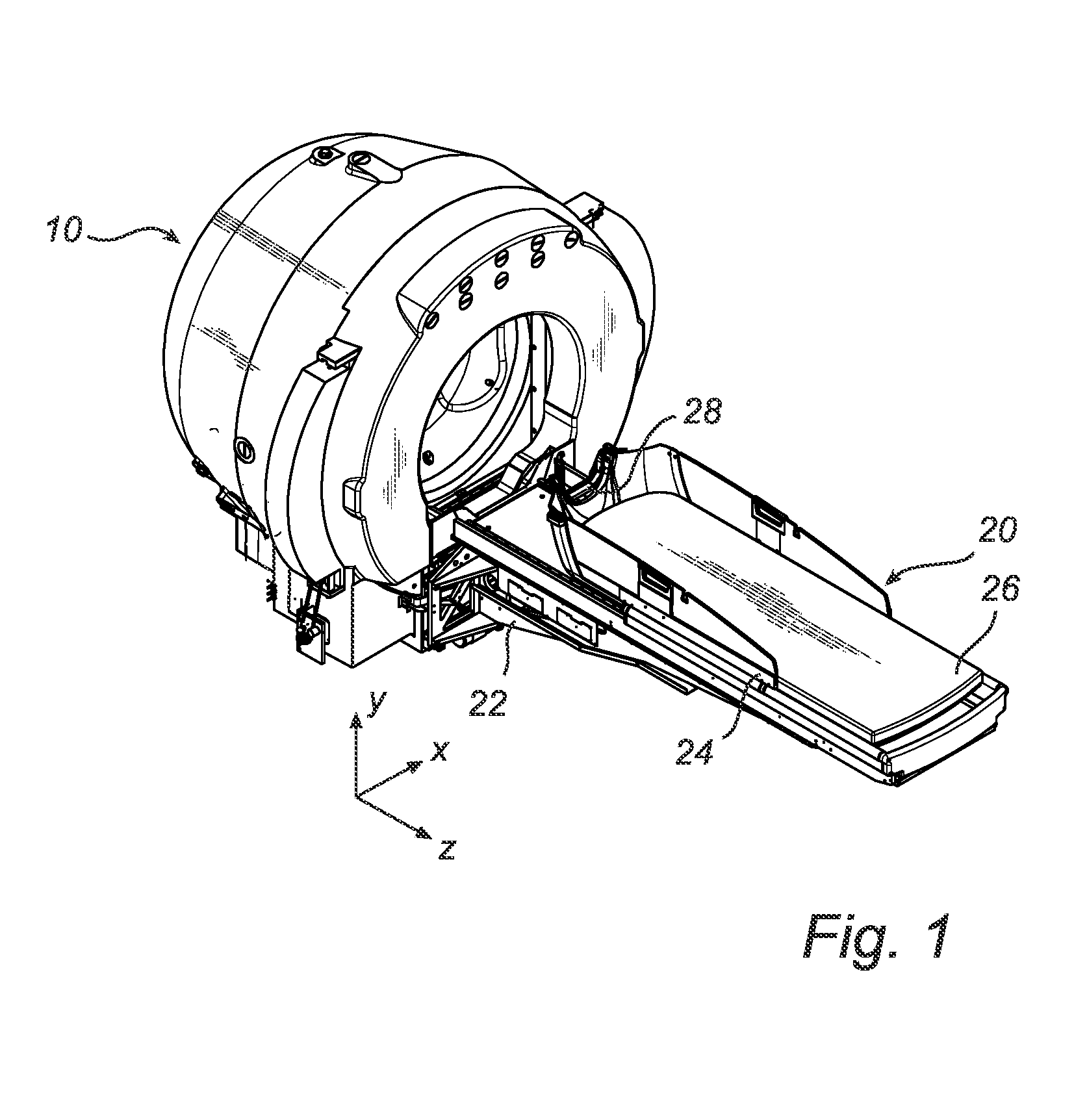

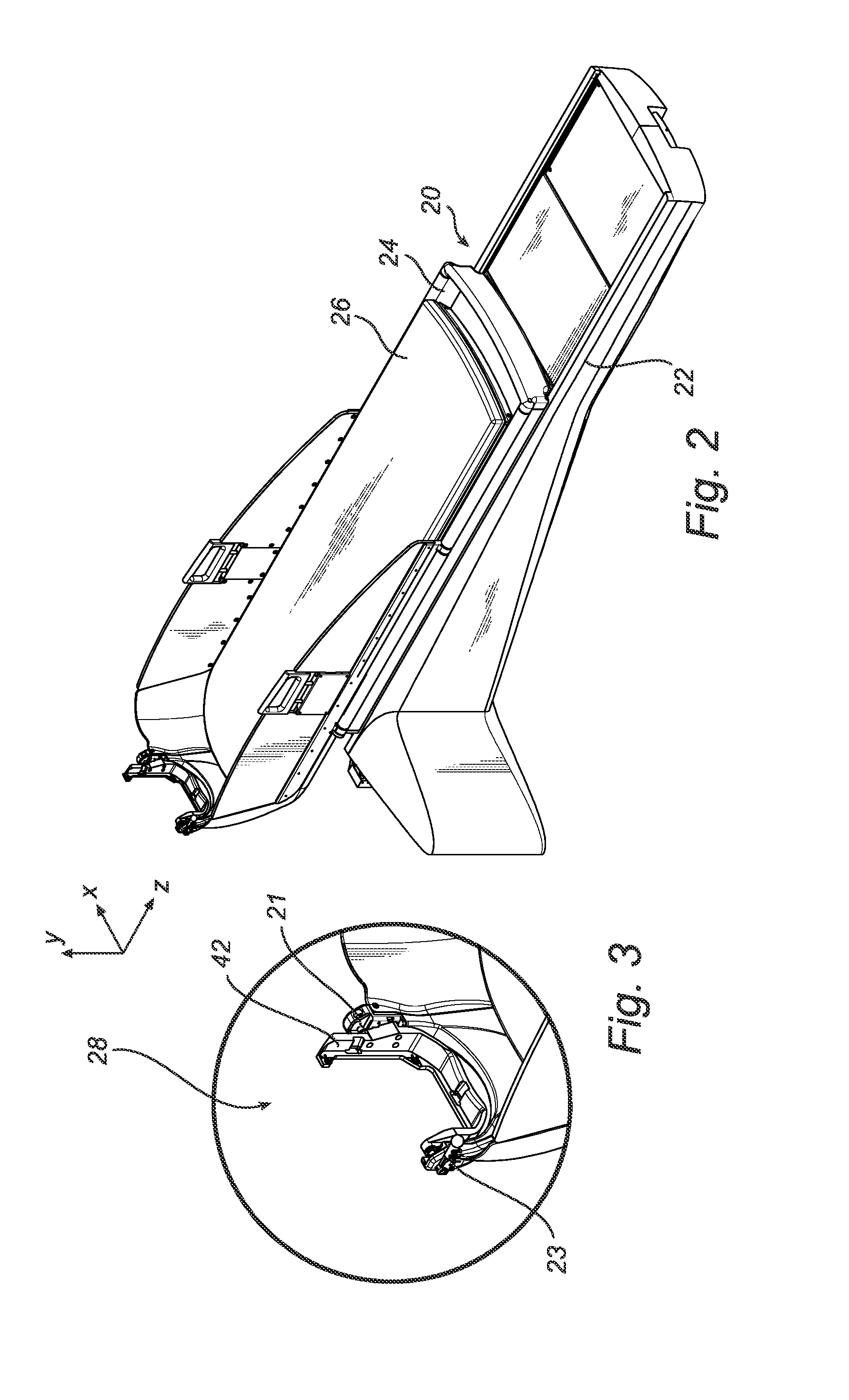

Intra-fraction motion management system and method

InactiveUS20140275698A1High degree of accuracyImprove reliabilityDiagnosticsSurgeryNoseOptical tracking

The present invention relates to the field of radiation therapy. In particular, the invention concerns systems and methods for monitoring intra-fraction motions of patients in connection with treatment cancer in radiation therapy system. A patient marker is attached on the nose of the patient and images of the patient marker and reference markers of a reference tool is captured at predetermined time intervals, wherein the reference tool comprises reference markers and is arranged in a defined position relative to a patient fixation arrangement for fixation of the patient during treatment. A position of the patient marker relative the reference tool is determined based on images captured by an optical tracking system, wherein changes in the position provide information if the patient or a part of the patient has moved.

Owner:ELEKTA AB

Machining method for hard-fine machining of noise-optimized gears on a gear-cutting machine

ActiveUS9409244B2Improve uniformityAvoid orAutomatic control devicesFeeding apparatusRotational errorGear wheel

Owner:LIEBHERR VERZAHNTECHNIK GMBH

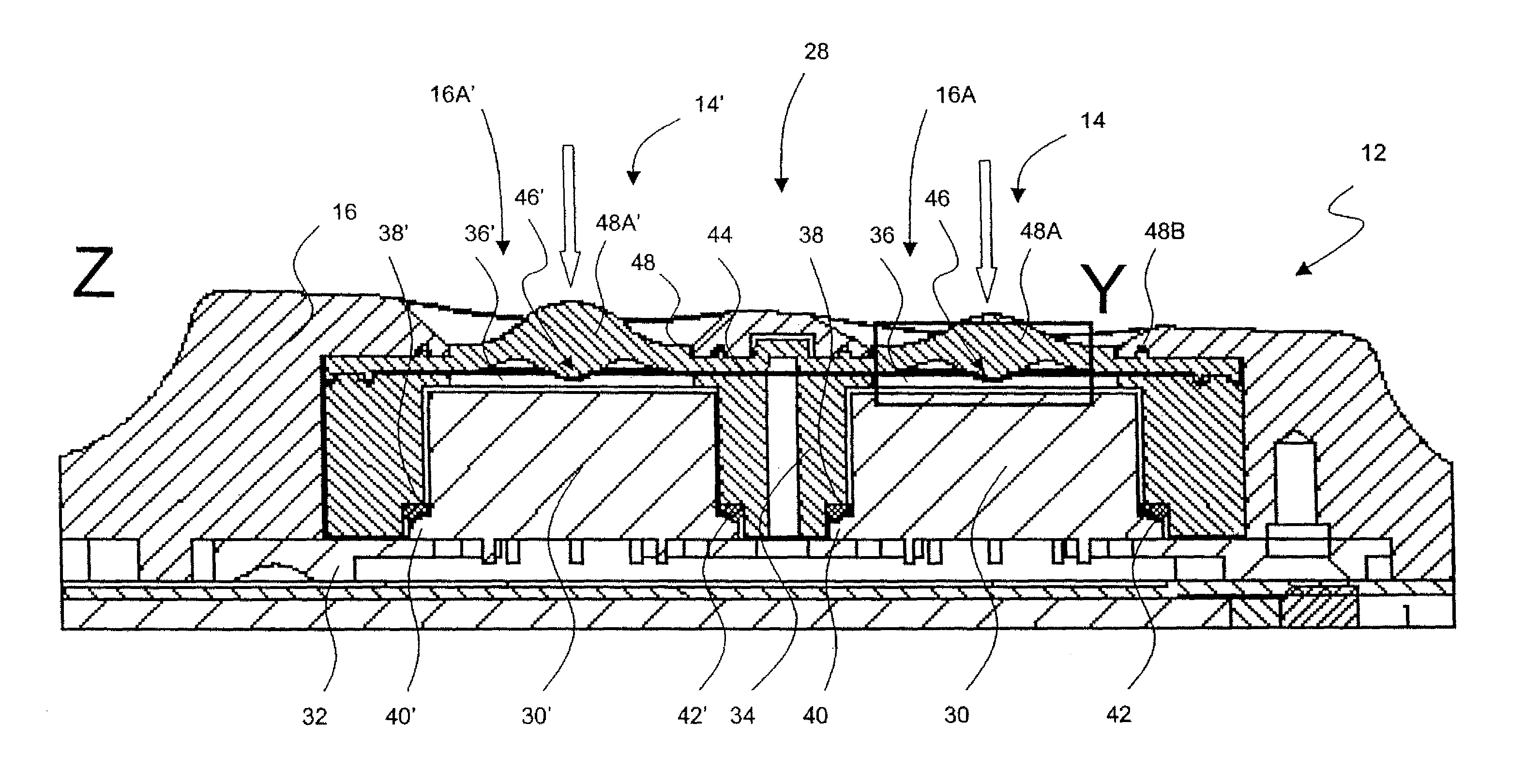

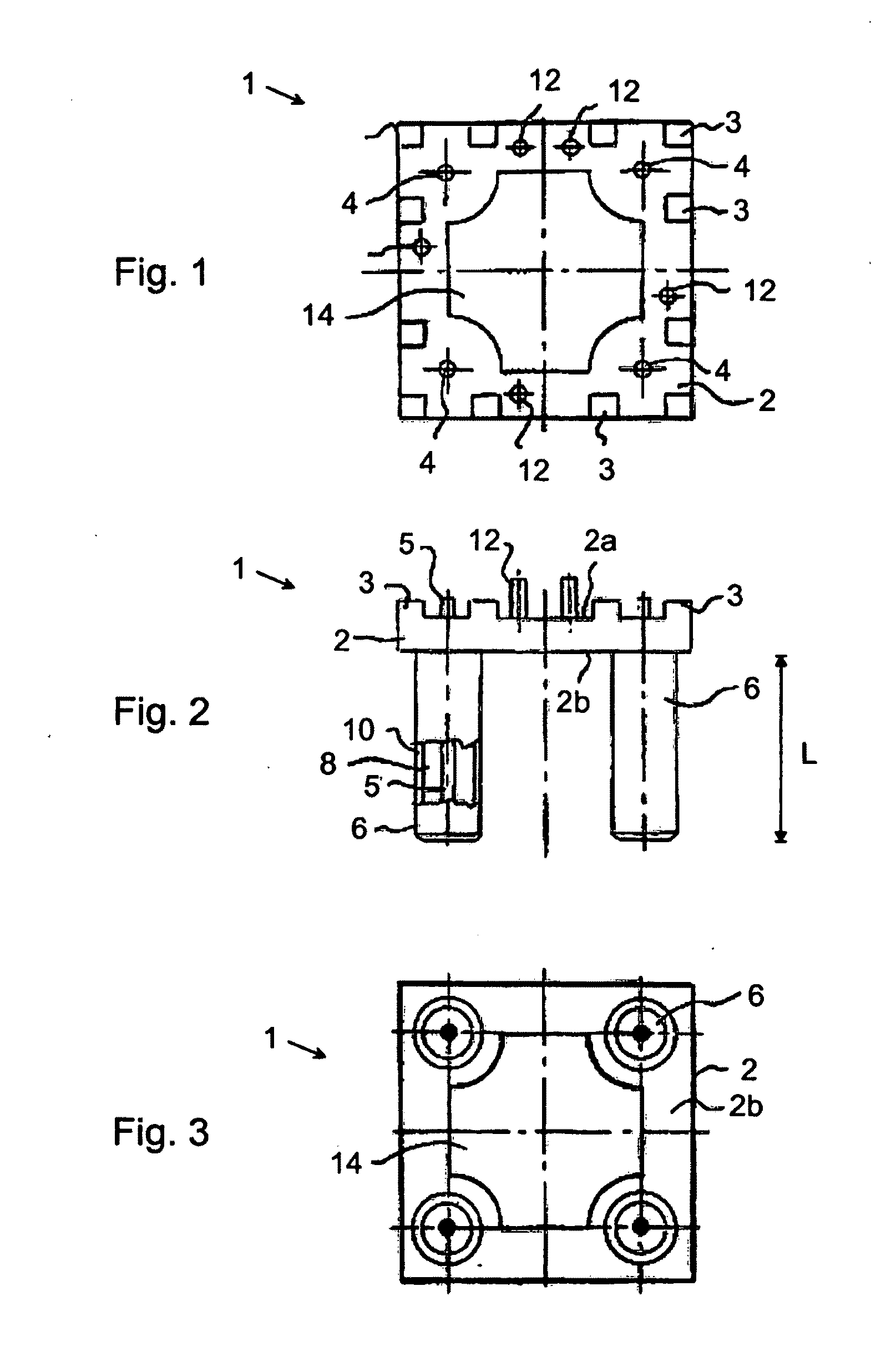

Apparatus and method for the treating of workpieces

ActiveUS7810448B2Avoid orMethod of has some drawbackLiquid surface applicatorsConveyorsFluid controlEngineering

The invention relates to an apparatus and a method for the coating of hollow bodies, in particular for the internal coating of plastic drinks bottles by means of a PICVD. It is an object of the invention to ensure a flexible process sequence, a high throughput, an improved supply of fluid and a high-quality coating. The invention in particular proposes a rotary apparatus which comprises a treatment device with double reactors for receiving in each case at least one workpiece, a fluid supply apparatus and at least one fluid control device, which can be used to control the supply of fluid to the treatment device. It is preferable for the vacuum pumps to be arranged on the rotor such that they rotate therewith.

Owner:SCHOTT AG

Method for operating a surgical power tool

ActiveUS20100204685A1Increase material thicknessDamage to componentCoupling device connectionsDiagnosticsEngineeringPower tool

A surgical power tool has an actuation assembly which comprises a force sensor and a switch. The force sensor is provided to determine an actuation force produced by the user, and the switch is transferred by the actuation force from a first switching state to a second switching state. A combined evaluation of the force sensor signal and of the switching state enables, for example, a plausibility check for increasing the operational reliability of the power tool.

Owner:STRYKER EURO OPERATIONS HLDG LLC

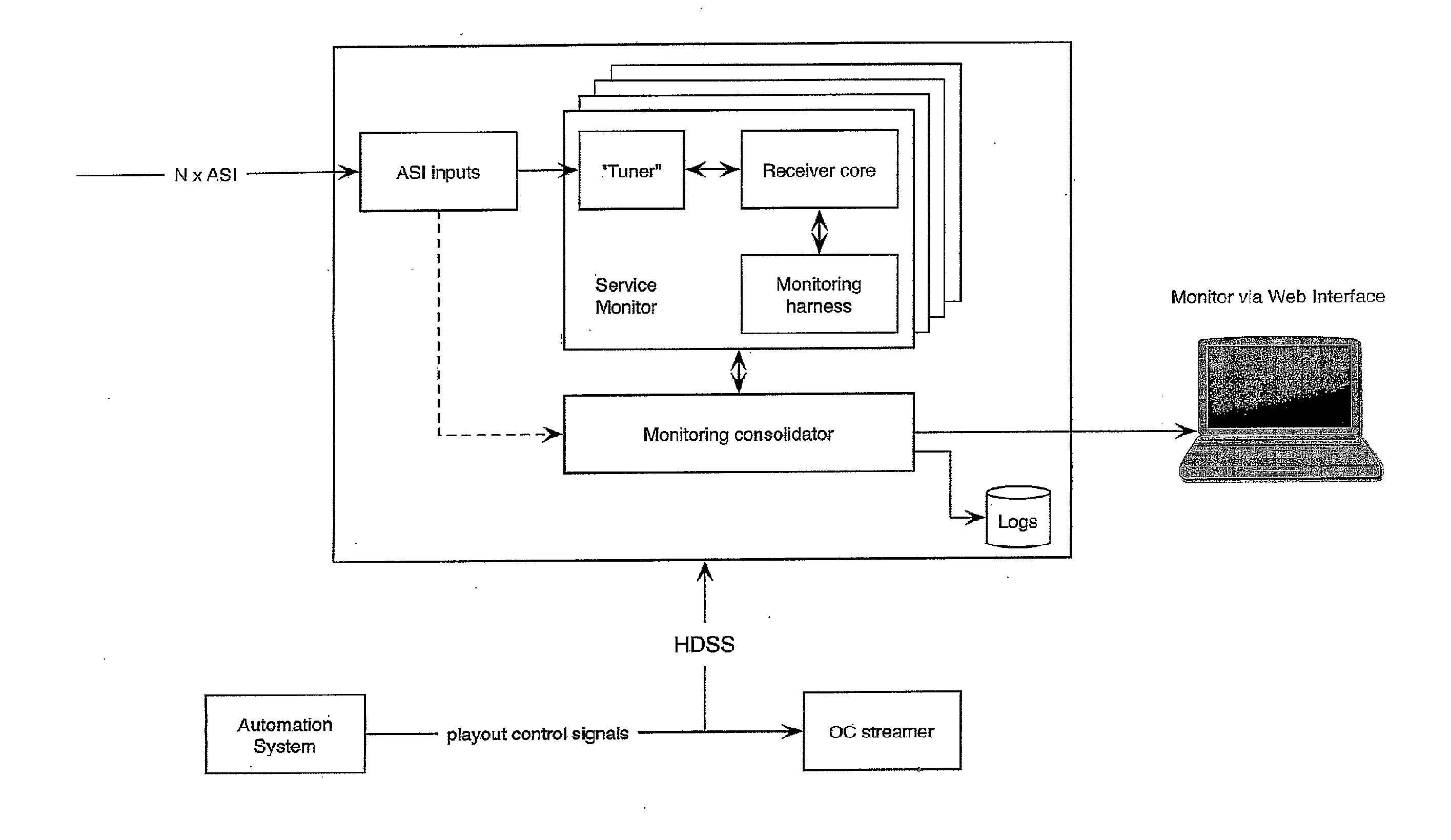

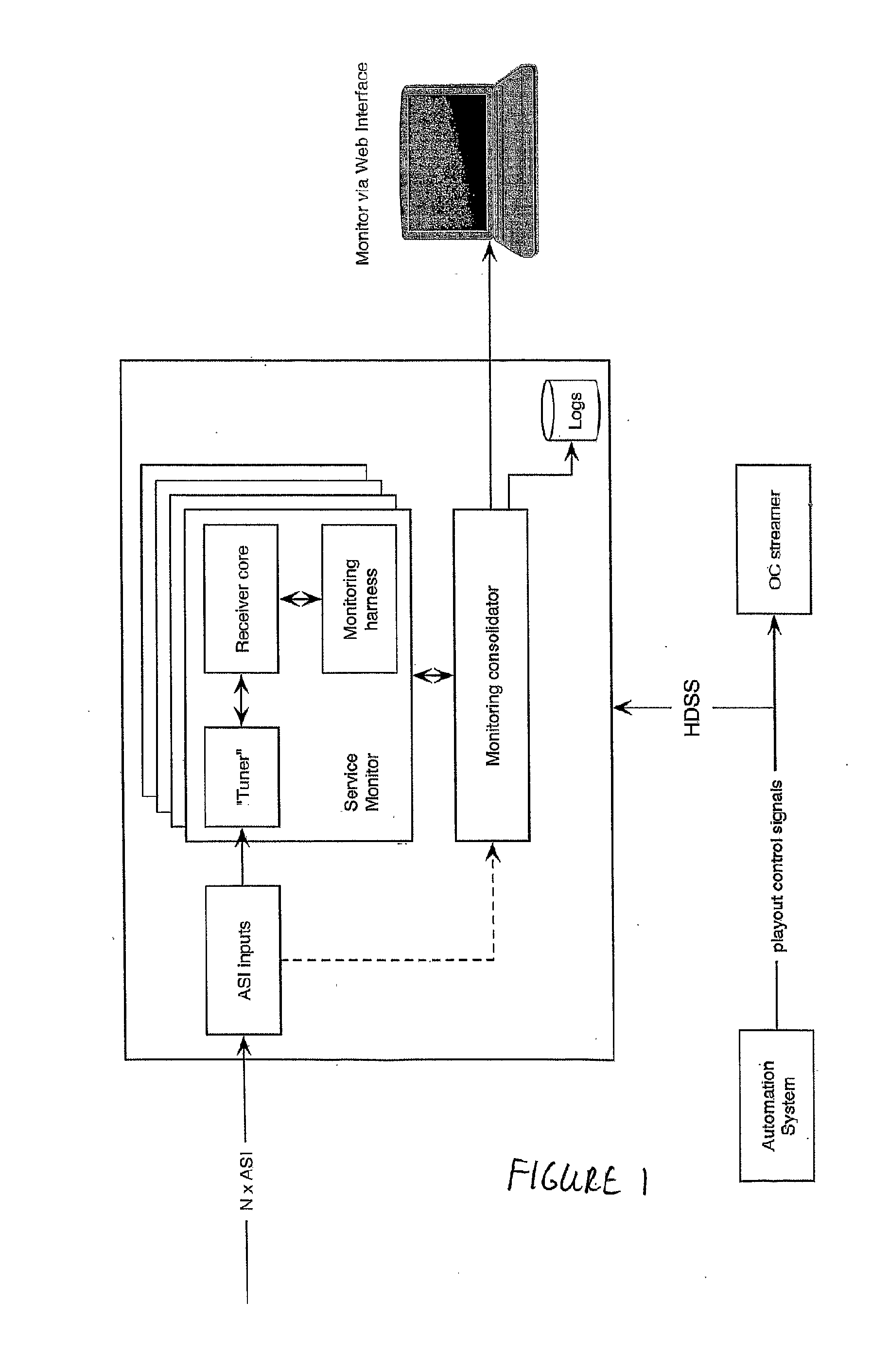

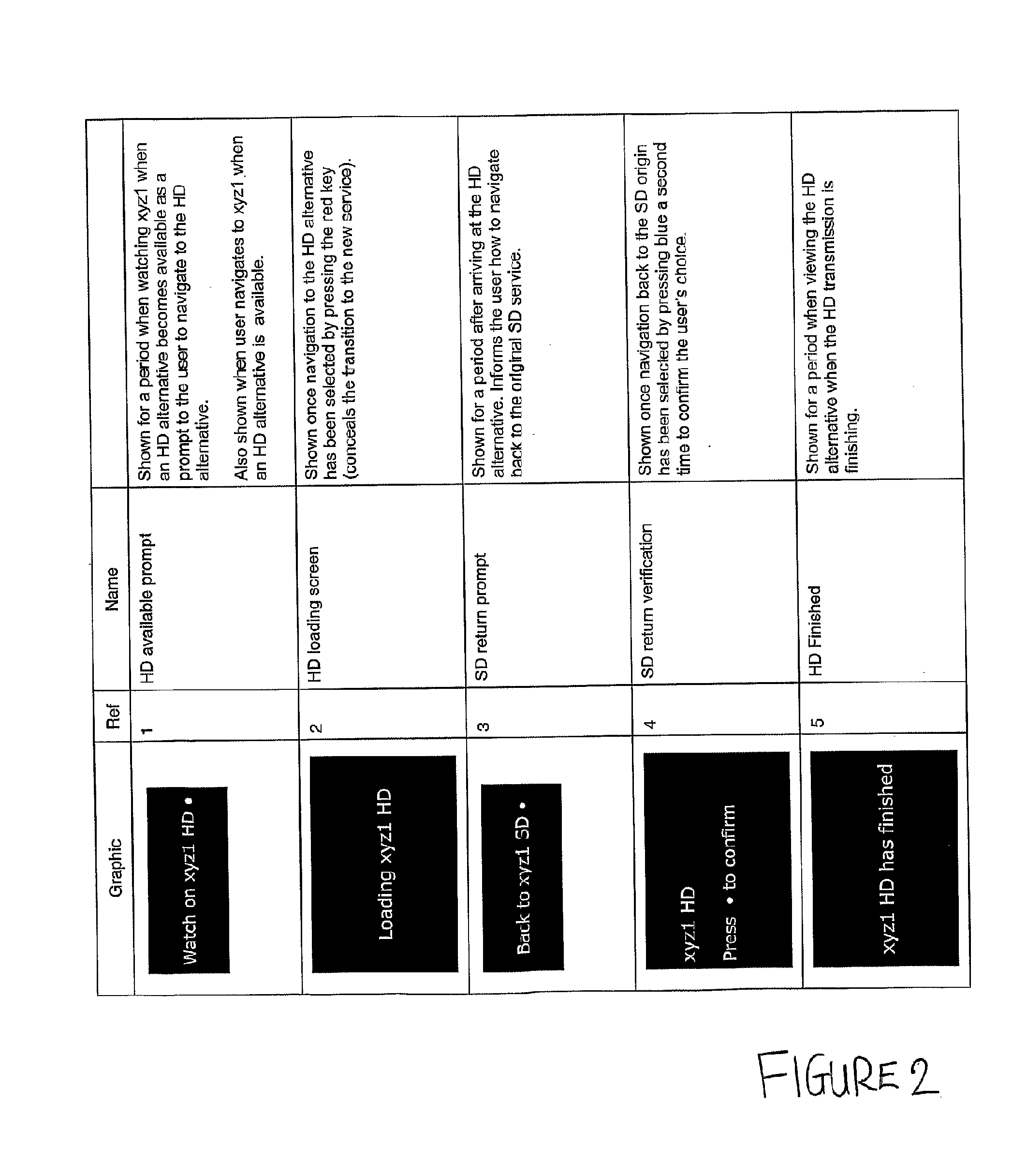

Receiver and a transmitter

InactiveUS20120113269A1Poor matchingAccelerate corrective actionTelevision system detailsColor television detailsComputer hardwareData stream

Owner:STRATEGY & TECH

Method and system for arranging data flow control in a data transfer system

ActiveUS7266081B2Avoid orReduce too early resumptionsError preventionFrequency-division multiplex detailsData streamTransfer system

Owner:NOKIA TECH OY

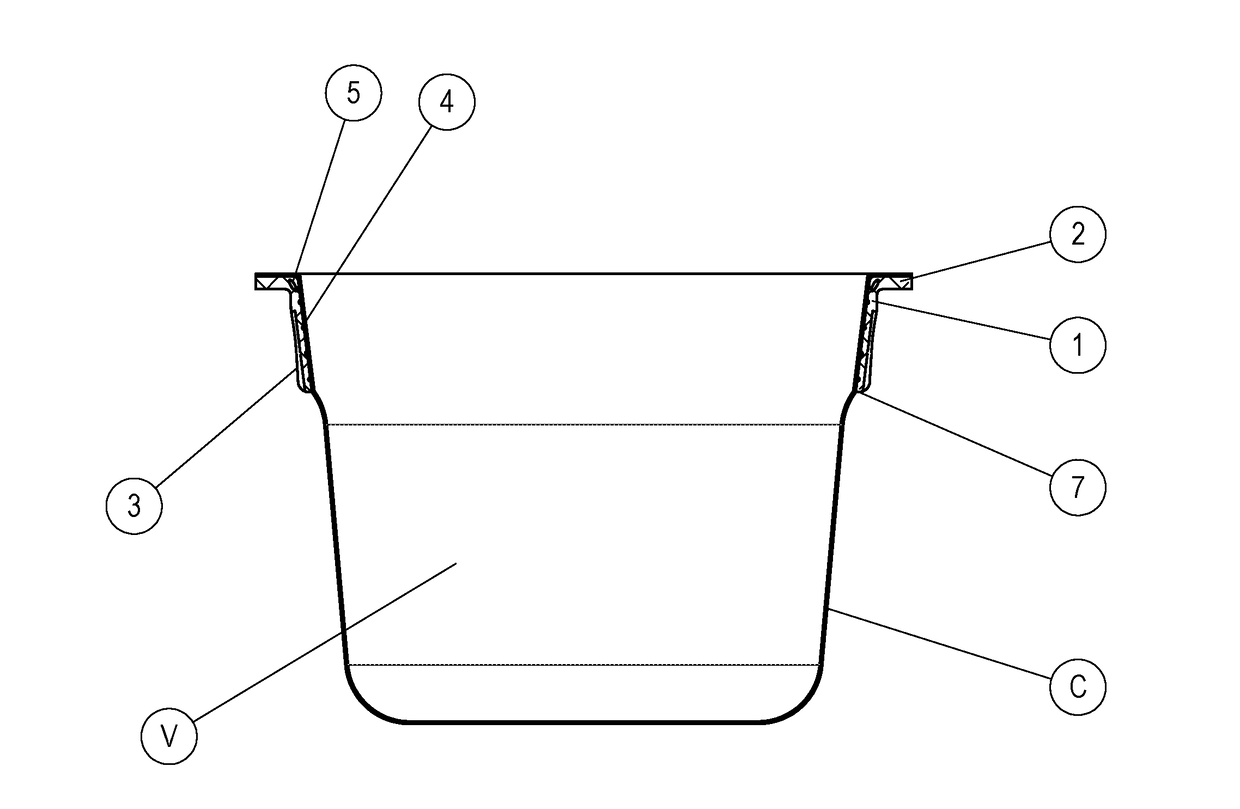

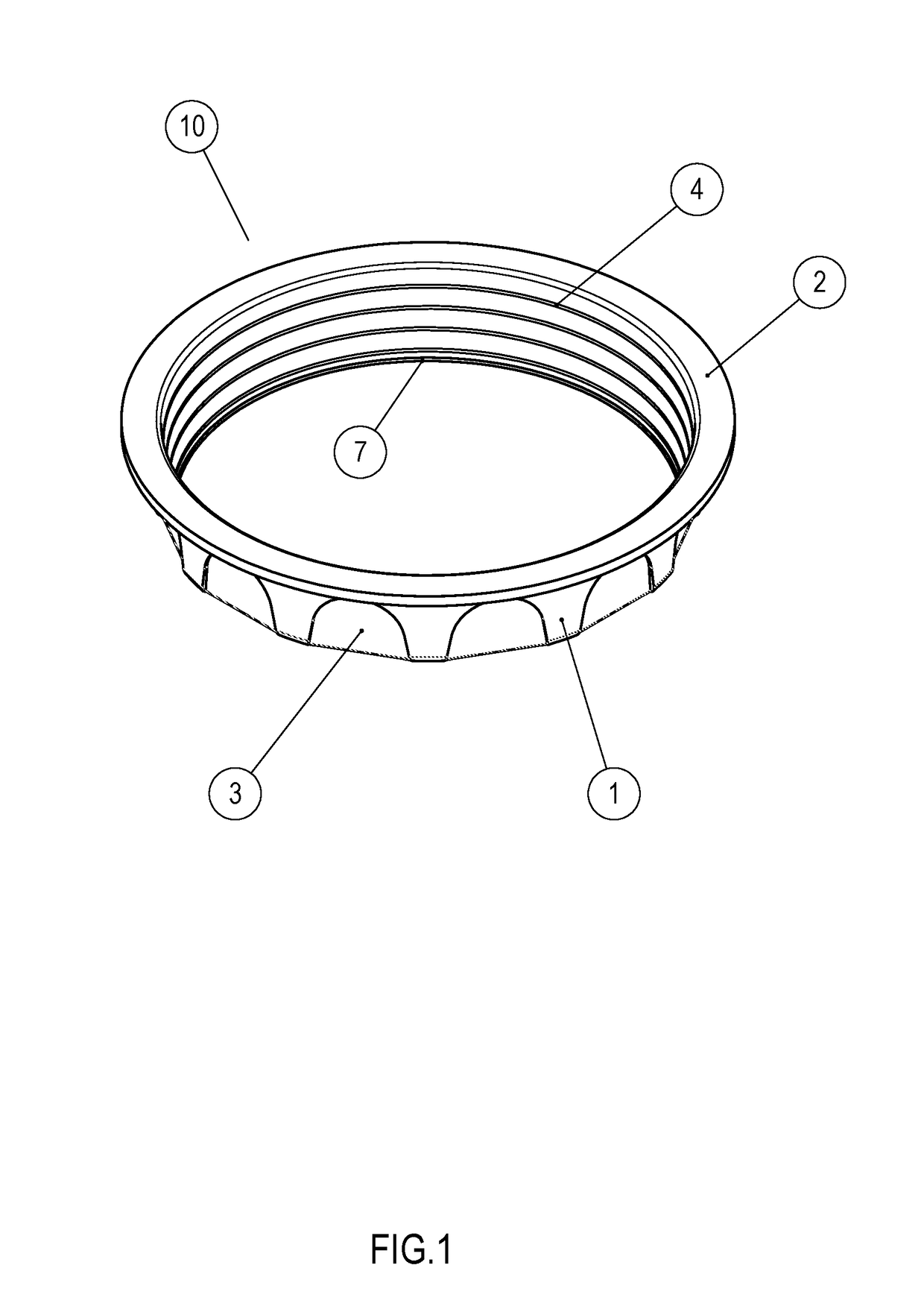

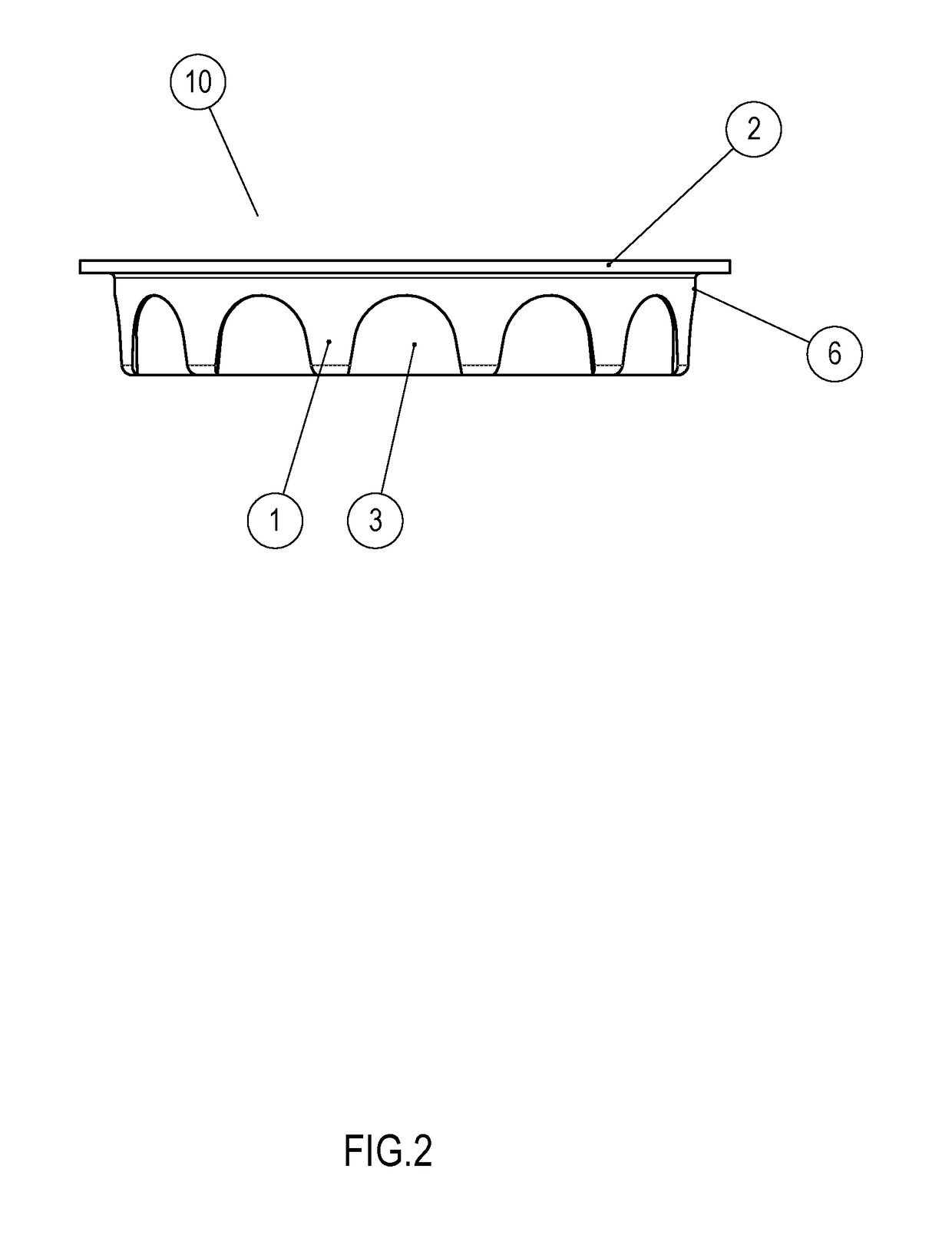

Reinforcement ring for capsules for obtaining beverages

ActiveUS20170210534A1Reduce material usageGuaranteed smooth progressFlexible coversWrappersEspresso coffeeBiomedical engineering

The present invention provides a reinforcement ring (10) for capsules for obtaining beverages, for example espresso coffee, comprising a side wall (1) and a flat surface, preferably having a uniform thickness (2), protruding from the side wall (1), wherein the side wall (1) and the protruding flat surface (2) are made in a single body and wherein the side wall (1) comprises reduced thickness areas (3), so as to reduce the total amount of material used for the production of the ring. A capsule for obtaining beverages

Owner:RAPPARINI GINO

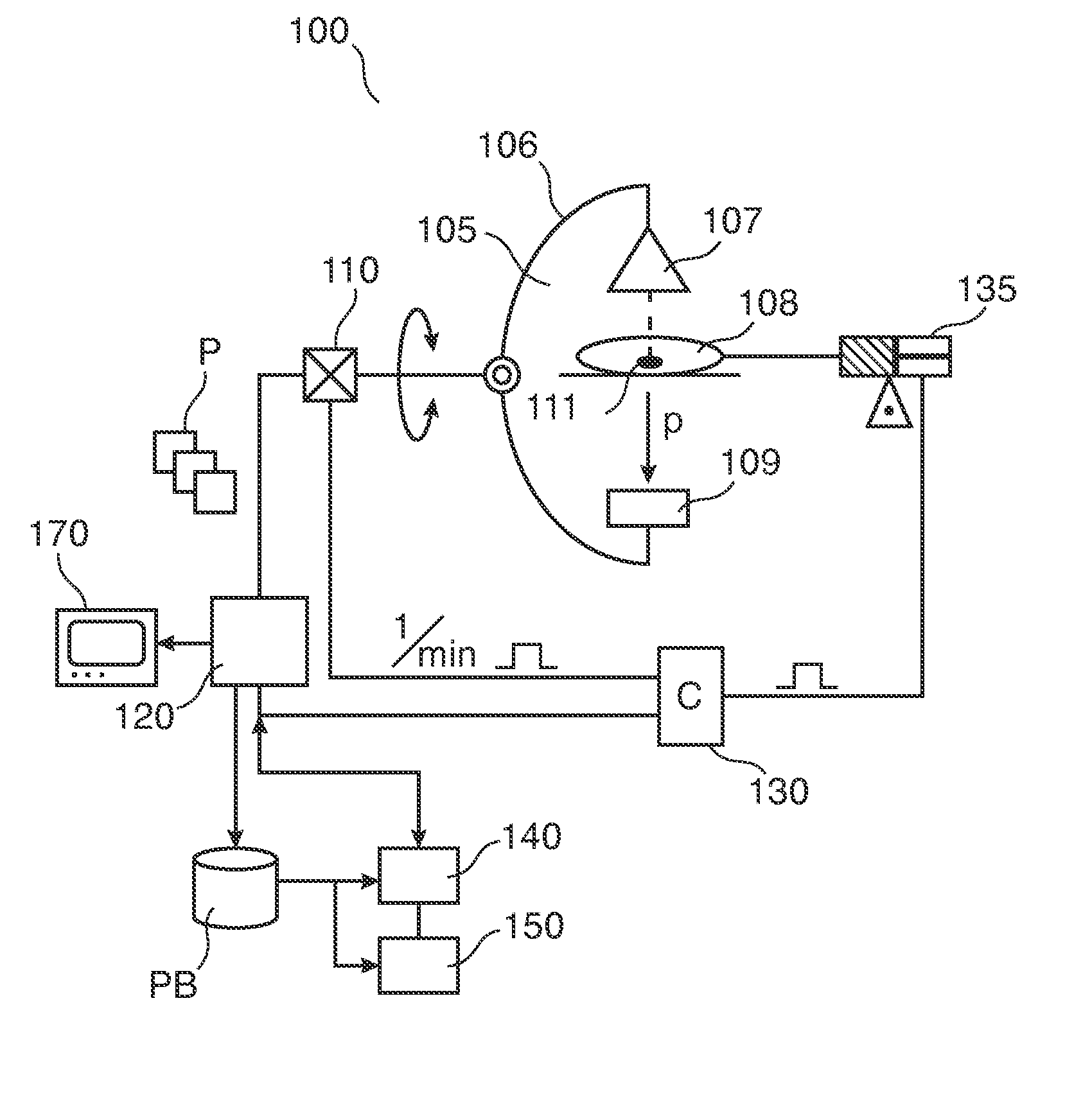

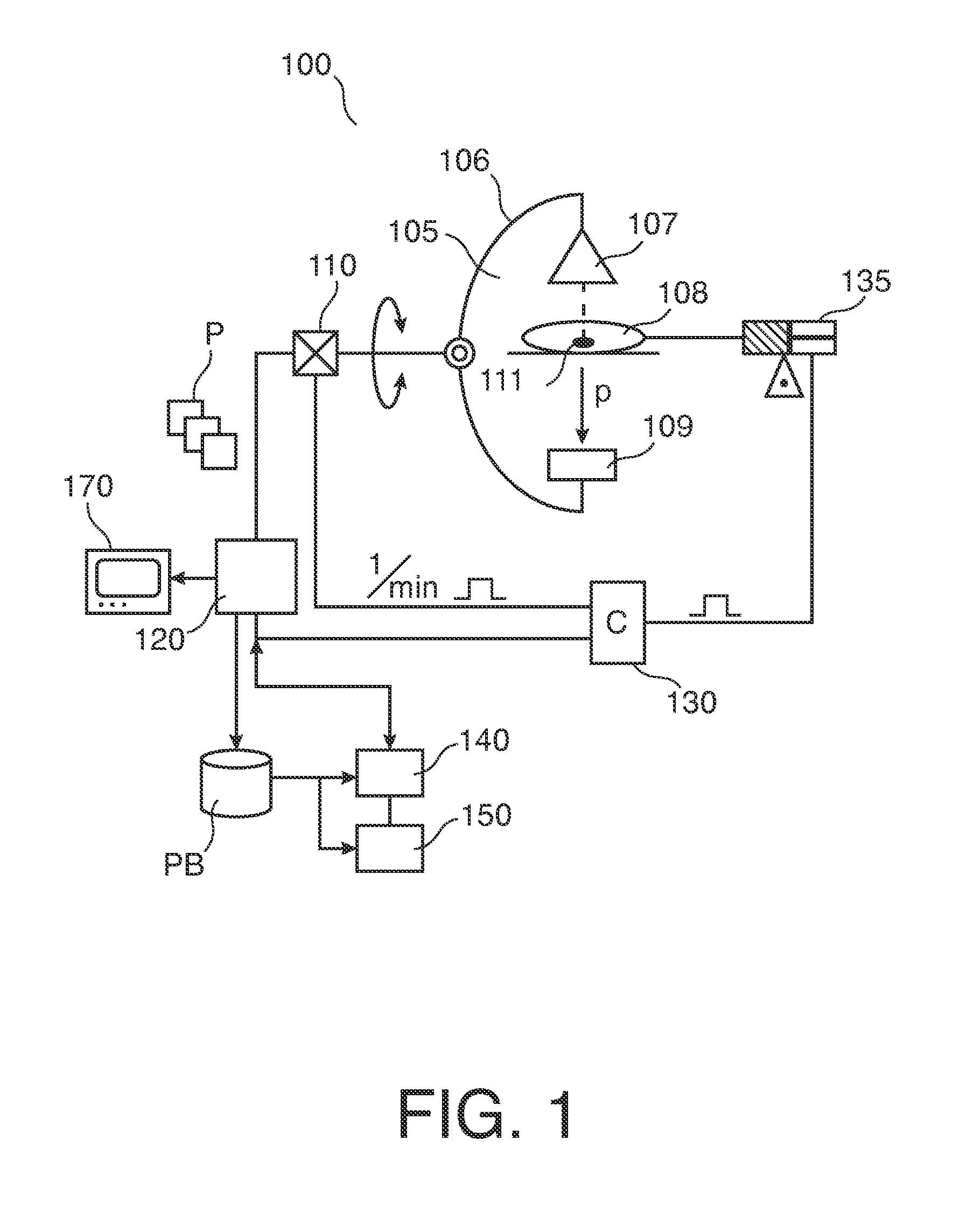

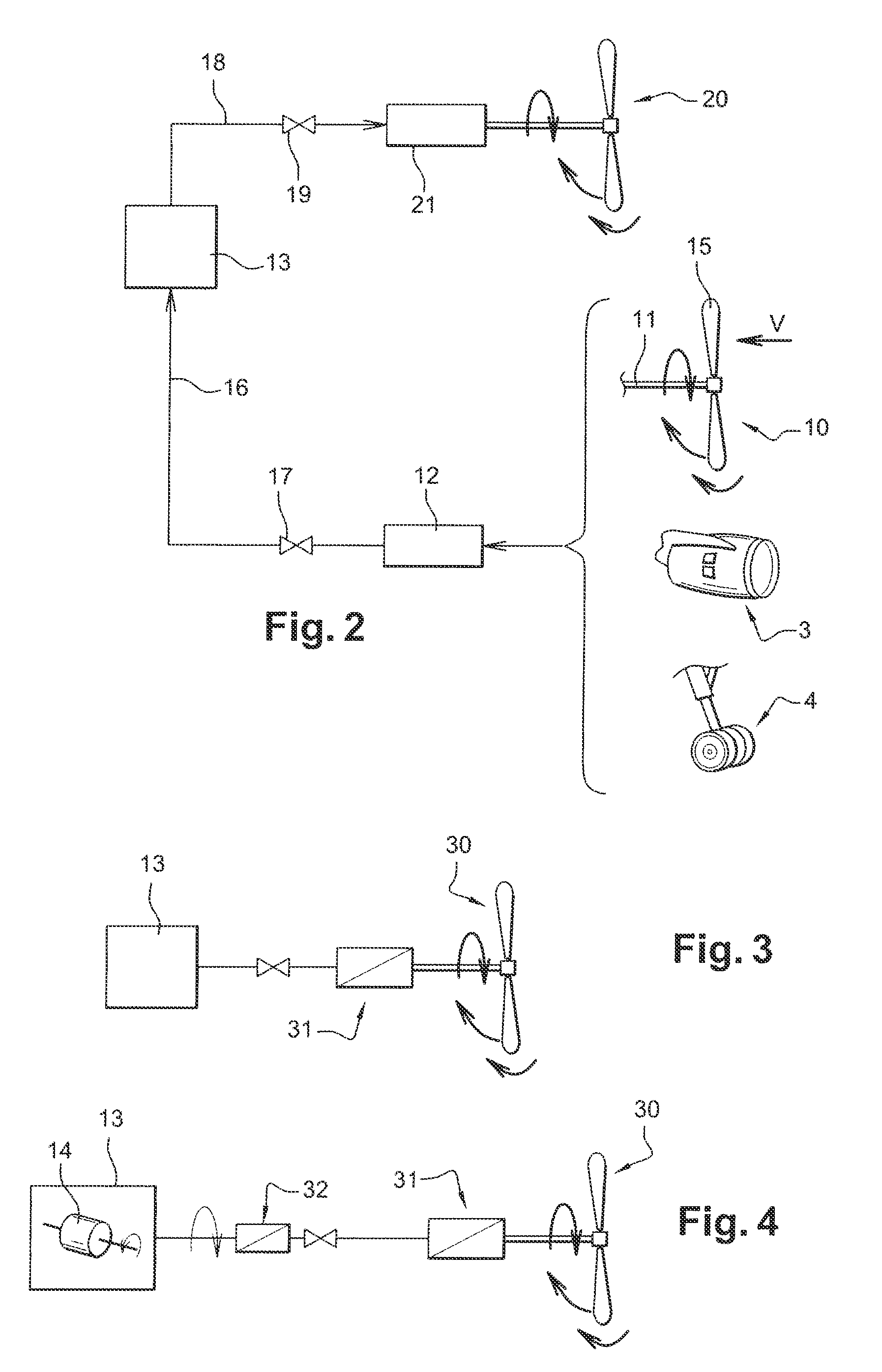

Periodic contrast injections and analysis of harmonics for interventional x-ray perfusion imaging

InactiveUS20150025370A1Reduce signalingSufficient level of accuracyHealth-index calculationTomosynthesisUltrasound attenuationHarmonic

An apparatus (130) and a method for adjusting, in perfusion imaging system, a periodic contrast agent injection rate signal (IS) for an injector (135) as function of an image sampling rate determined by the rotational speed of an X-ray source (107)-detector (109) assembly of an X-ray imager (100). Frequency, periodicity and pulse width of the contrast agent injection rate signal (IS) is adjusted to mitigate temporal signal aliasing in a sample of a time attenuation contrast (TAC) signal.

Owner:KONINKLJIJKE PHILIPS NV

Energy storage aerodynamic braking device and method

InactiveUS8708275B2Avoiding and limiting useAvoid orPower installationsEnergy efficient operational measuresPropellerDynamo

In order to generate an efficient aerodynamic braking force, whatever the speed of a vehicle such as an airplane flying in the air, the method includes a step for the production of energy by the vehicle, a step of storage of the energy produced and a step of utilization of such energy to drive a propeller which generates a force opposing the forward motion of the vehicle. Energy is produced by using the displacement of the vehicle with respect to air using a propeller driving a generator, or using the displacement with respect to the ground, using wheels driving a generator, or using generators driven by motors of the vehicle. The energy can be stored in the pneumatic, electric or kinetic form and the generation and driving means are selected according to the technology used for the storage means.

Owner:AIRBUS OPERATIONS (SAS)

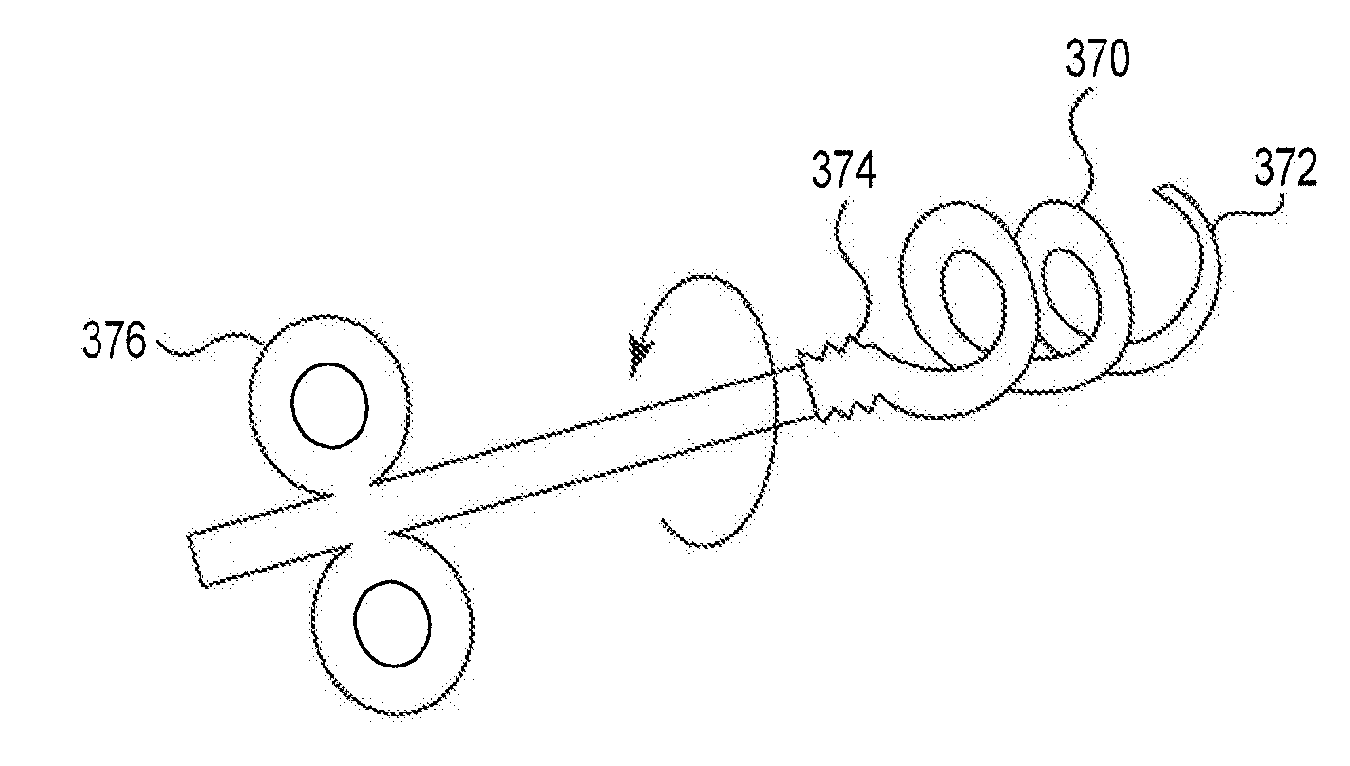

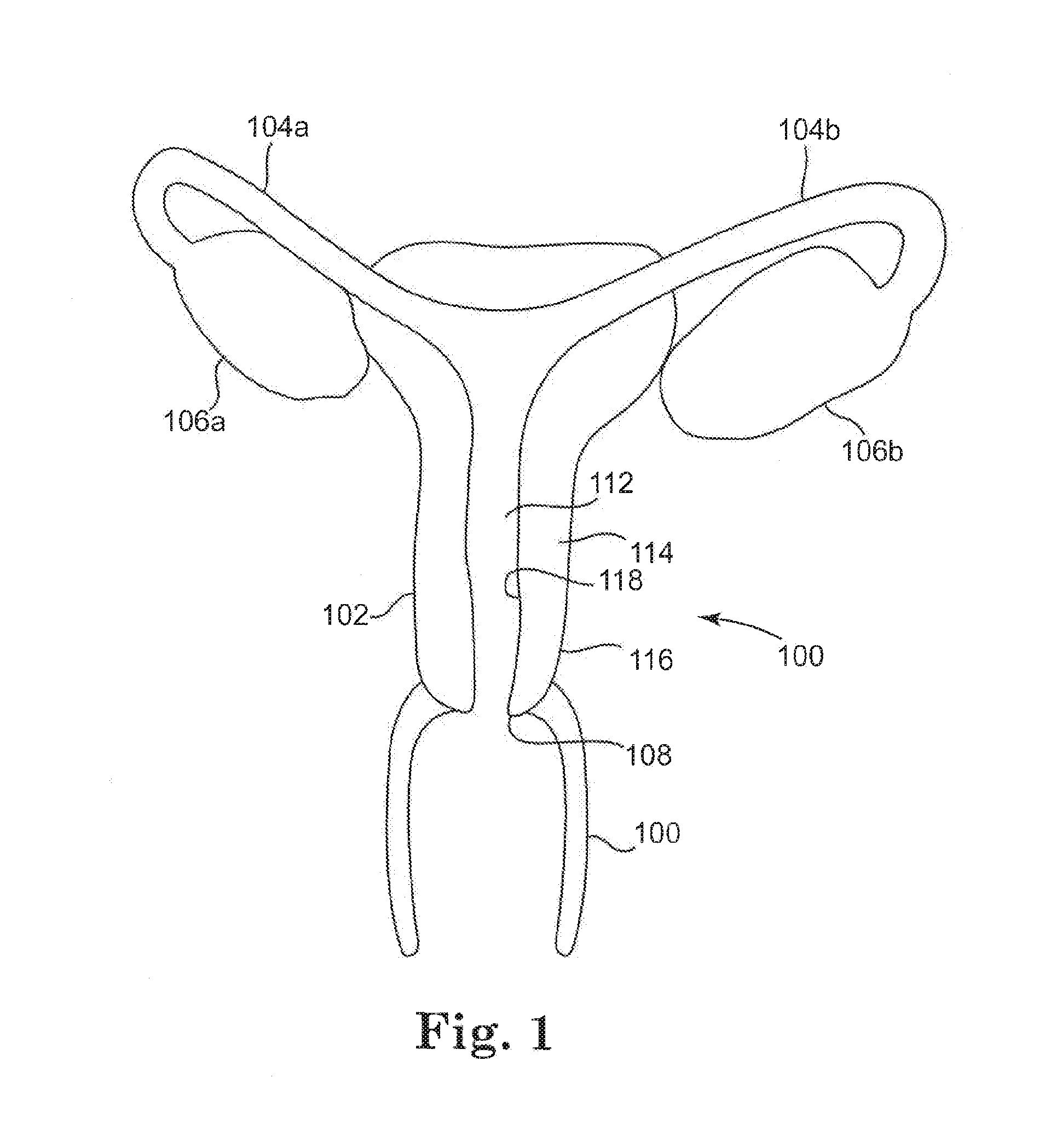

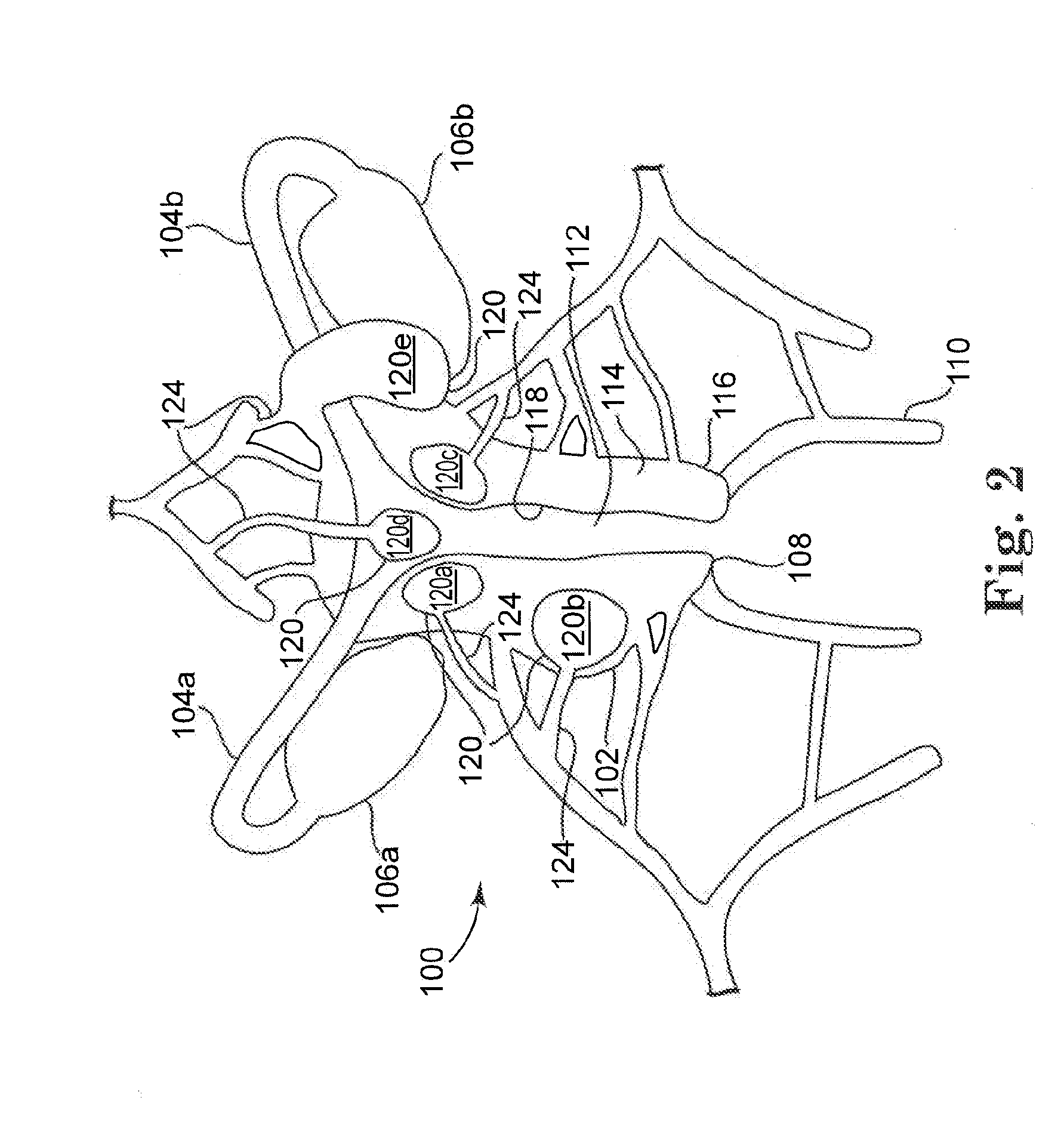

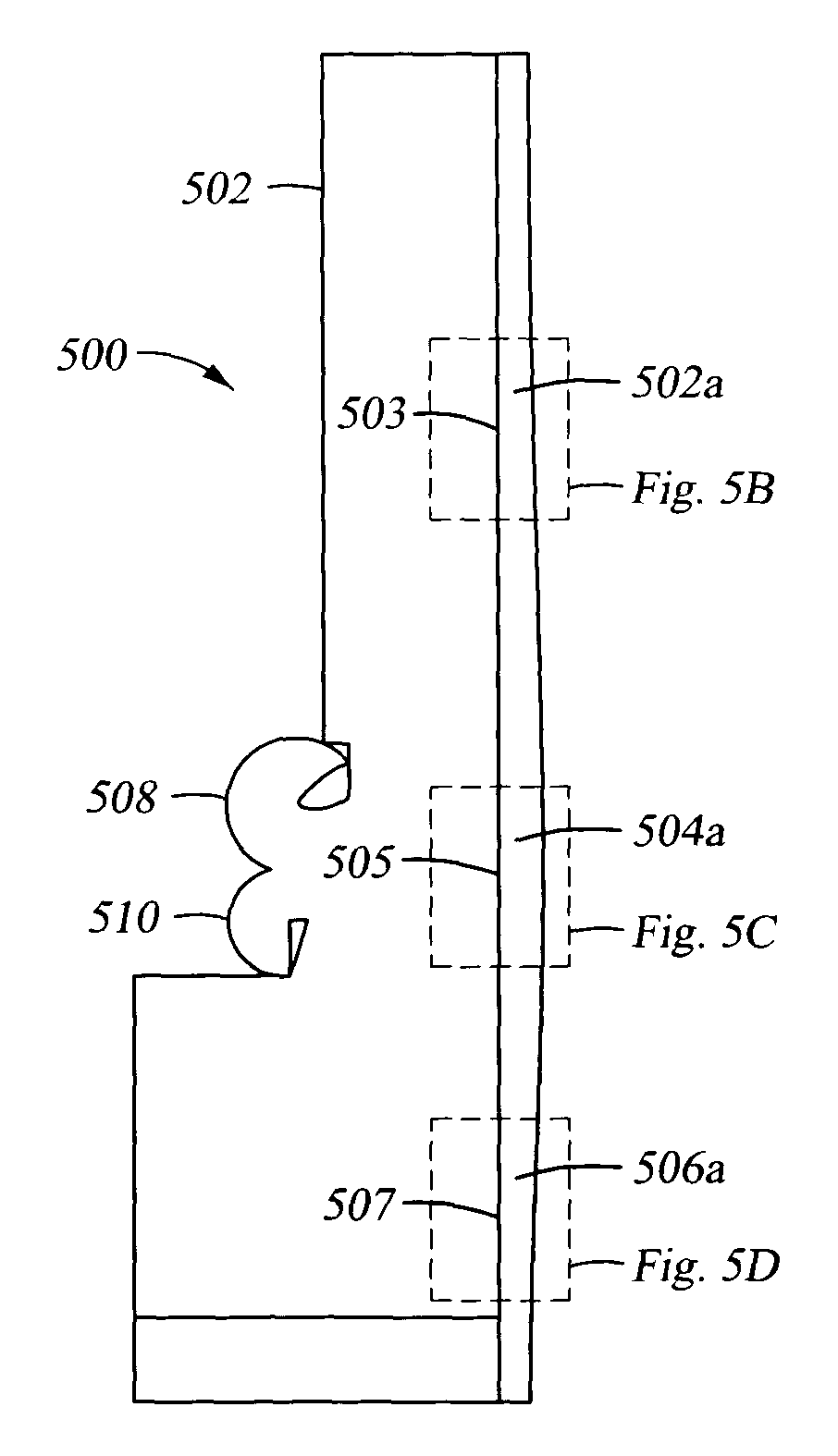

Apparatus and methods of treatment of pathologic proliferative conditions uterine tissue

ActiveUS20120150105A1Inhibition formationPrevent revivalSuppositories deliveryFemale contraceptivesUterine bleedingBlood vessel

A uterine fibroid treatment device providing for localized delivery of one or more treatment drugs for treating various uterine conditions including, for example, uterine fibroids, abnormal uterine bleeding, pelvic adhesions and endometriosis. Generally, the uterine treatment device comprises a physical positioning element that can be inserted, positioned and maintained in close proximity to the uterine tissue to be treated. The treatment drugs delivered to the treatment location can include various combinations of anti-proliferative agents and angiogenesis inhibitors to provide different treatments concurrently. In some embodiments, the physical element can also serve the dual purpose of delivering the treatment drugs while simultaneously cutting off blood flow to a mature fibroid to initiate hypoxic / ischemic conditions within the mature fibroid.

Owner:BOSTON SCI SCIMED INC

Intra-fraction motion management system and method

InactiveUS20140275707A1High degree of accuracyImprove reliabilityDiagnosticsSurgical navigation systemsMedical physicsImage capture

The present invention relates to the field of radiation therapy. In particular, the invention concerns systems and methods for monitoring intra-fraction motions of patients in connection with treatment cancer in radiation therapy system. A patient marker is attached on the nose of the patient and images of the patient marker and reference markers is captured at predetermined time intervals. The reference markers are arranged in defined positions relative to a patient fixation arrangement for fixation of the patient during treatment. A position of the patient marker relative the reference markers is determined based on images captured by an optical tracking system, wherein changes in the position provide information if the patient or a part of the patient has moved.

Owner:ELEKTA AB

RF connector mounting means

InactiveUS7909612B2Quick and secure and space-saving mountingAvoid orPrinted circuit assemblingVehicle connectorsElectrical conductorEngineering

Owner:LAIRD TECH INC

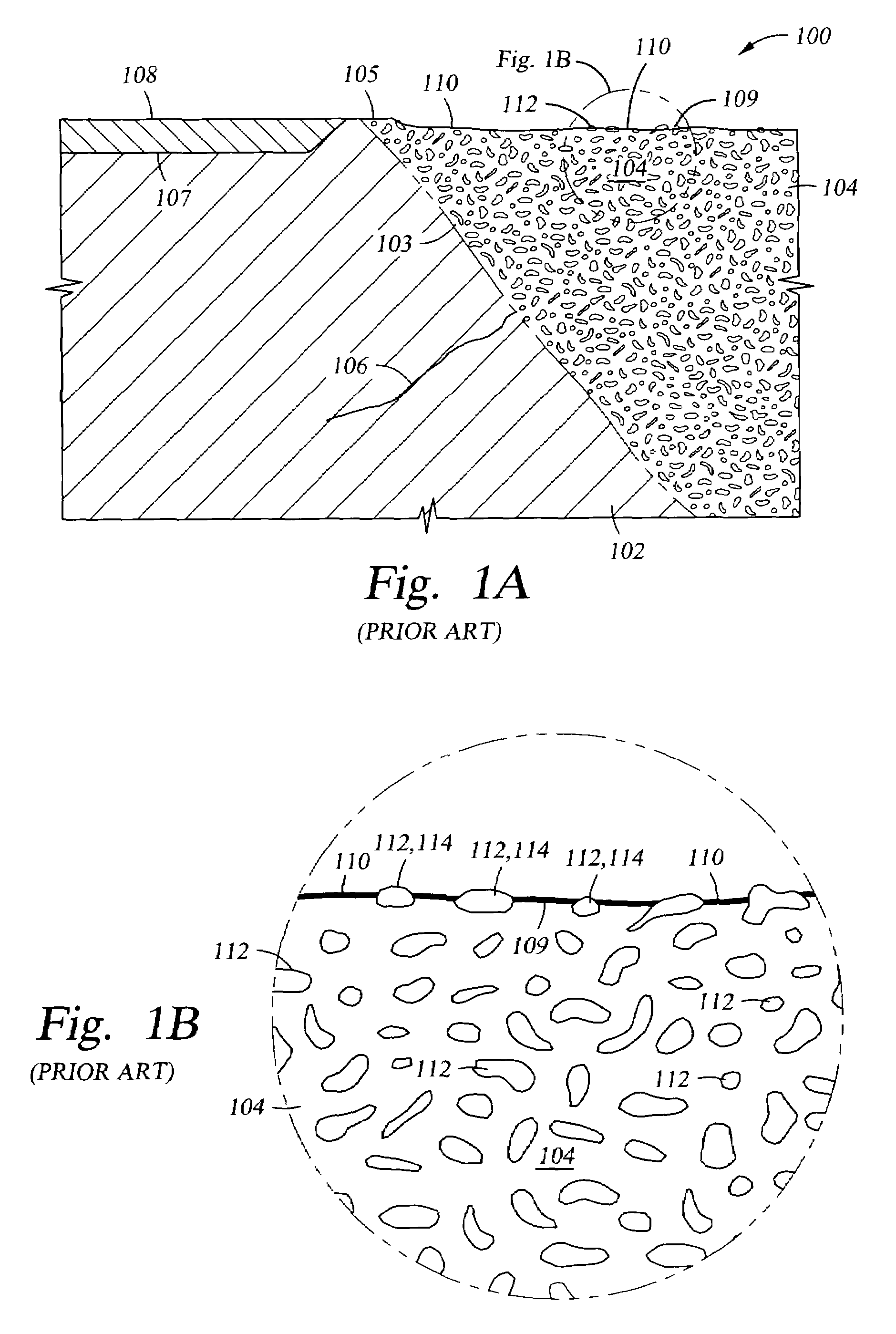

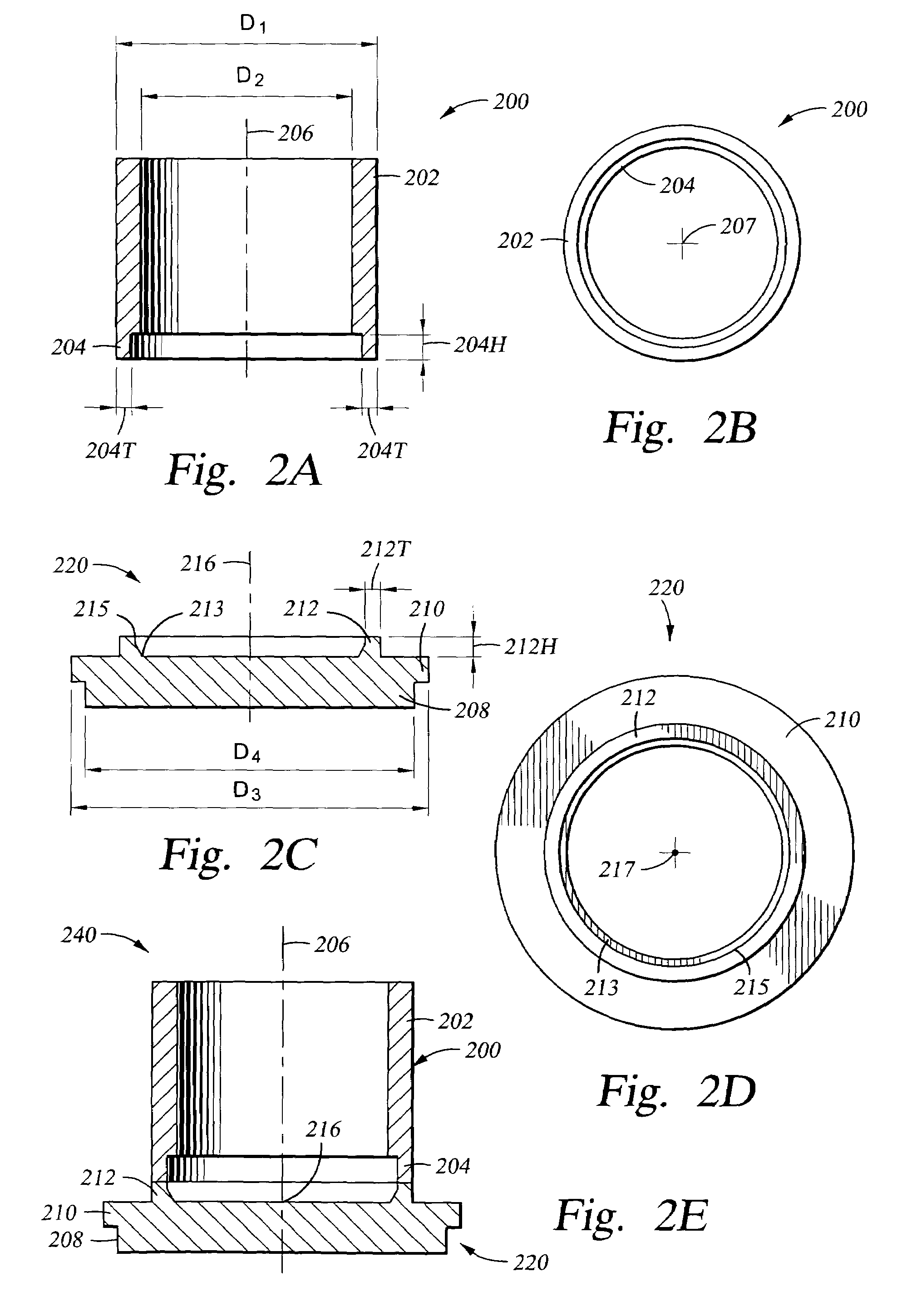

Semiconductor processing apparatus including plasma-resistant, welded aluminum structures

InactiveUS7055732B2Improve performanceDevice performance lifetime is reducedWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingAluminum coatingSemiconductor

We have discovered a method of producing a complex-shaped aluminum alloy article, where welding has been employed to form the article, where an anodized aluminum coating is produced over a surface of the article including the weld joint, and where the anodized aluminum coating is uniform, providing improved performance over that previously known in the art for welded articles exposed to a corrosive plasma environment.

Owner:APPLIED MATERIALS INC

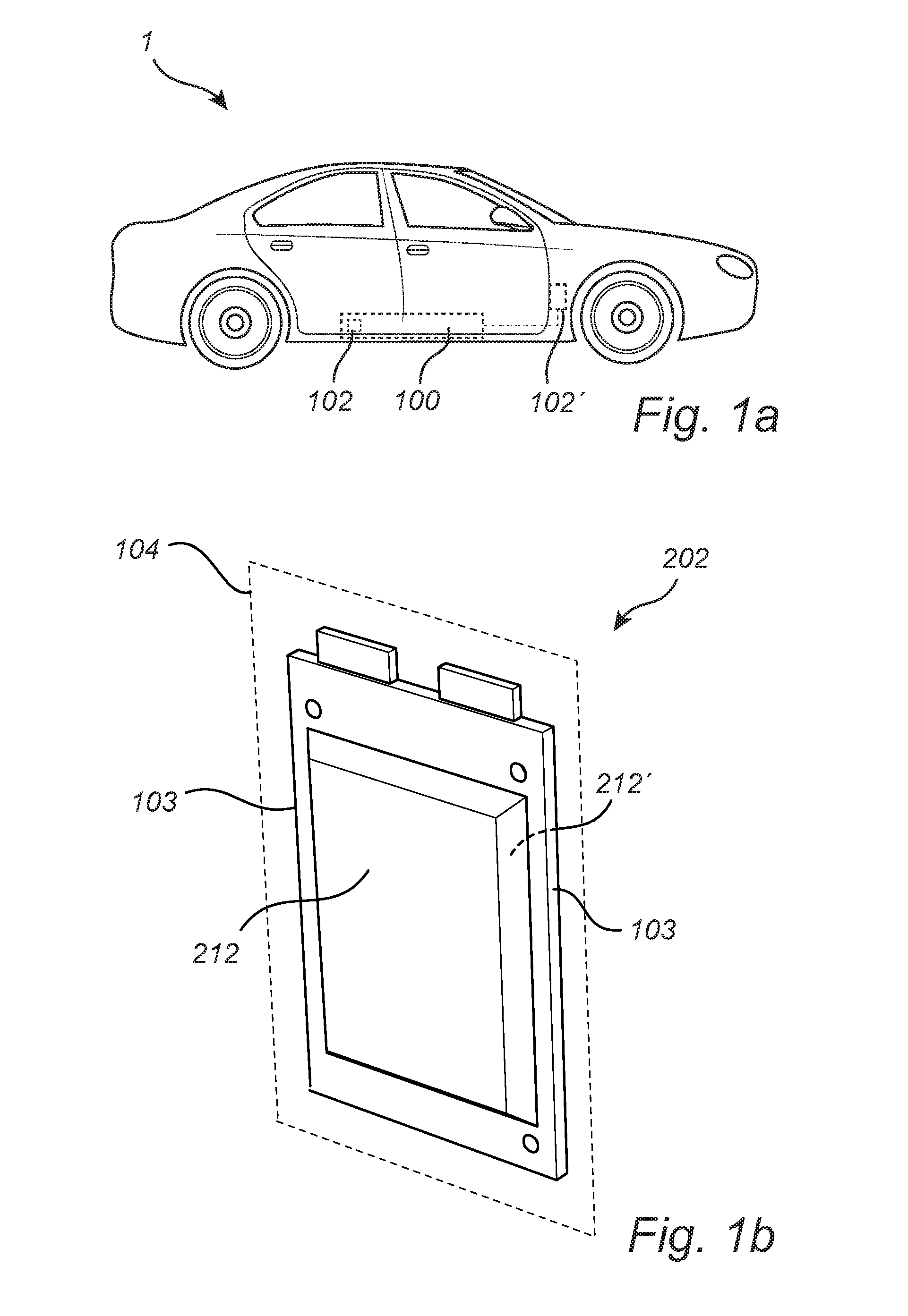

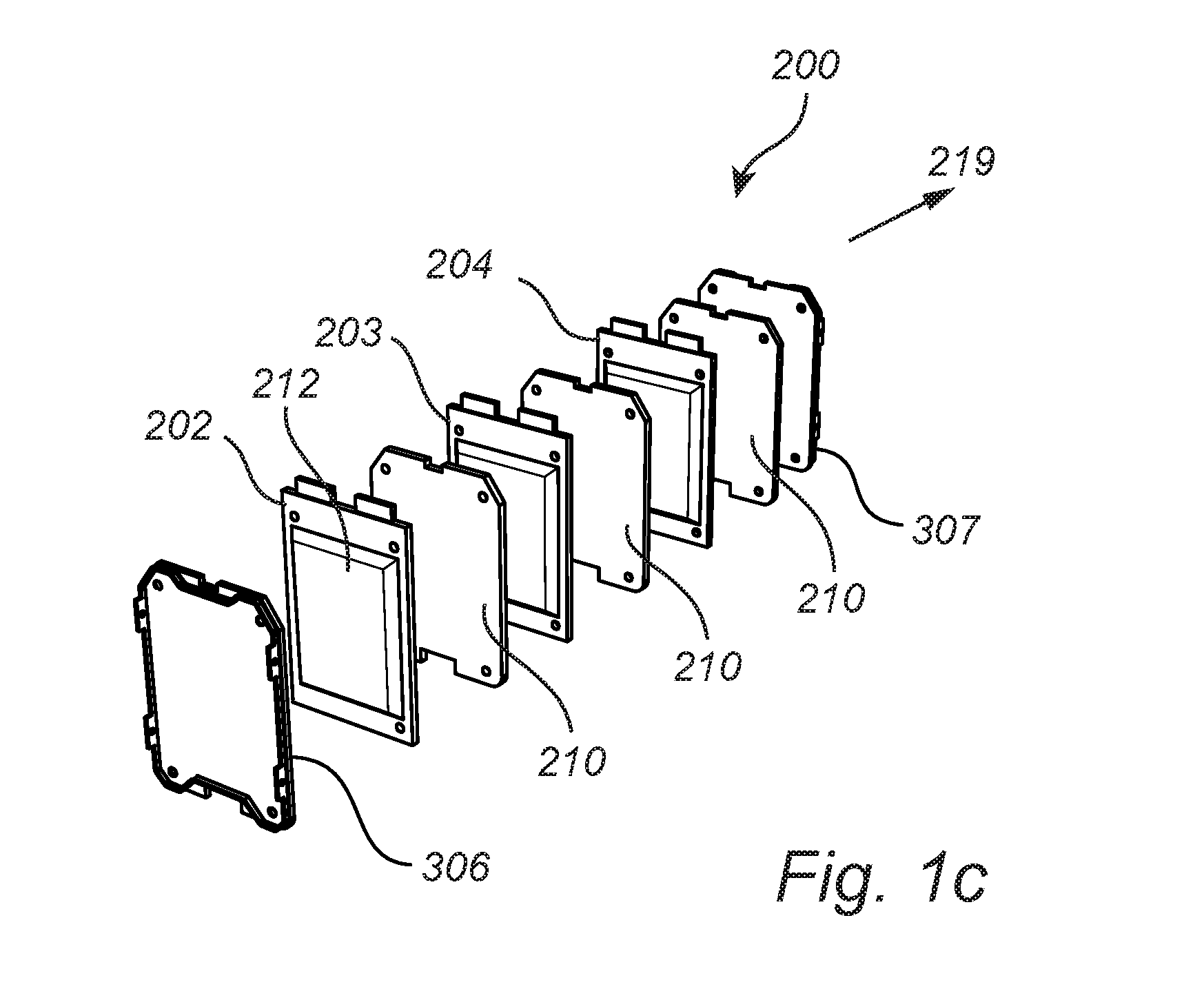

Damage detection and warning system of a battery pack

ActiveUS20160365611A1Easy damage detectionAvoid orBatteries circuit arrangementsElectric propulsion mountingEngineeringOptical fiber transmission

An energy storage module for a vehicle includes an energy storage enclosure adapted to accommodate an energy storage cell, the energy storage enclosure having an enclosure wall, an optical sensor including an optical fiber, an optical receiver and an optical emitter, the optical fiber attached to an inner side of a first enclosure wall along a distance of a portion of the inner side. The optical receiver is configured to detect an optical signal transmitted through the optical fiber, and the optical sensor is configured to detect an alteration of the optical signal being indicative of a deformation.

Owner:VOLVO CAR CORP

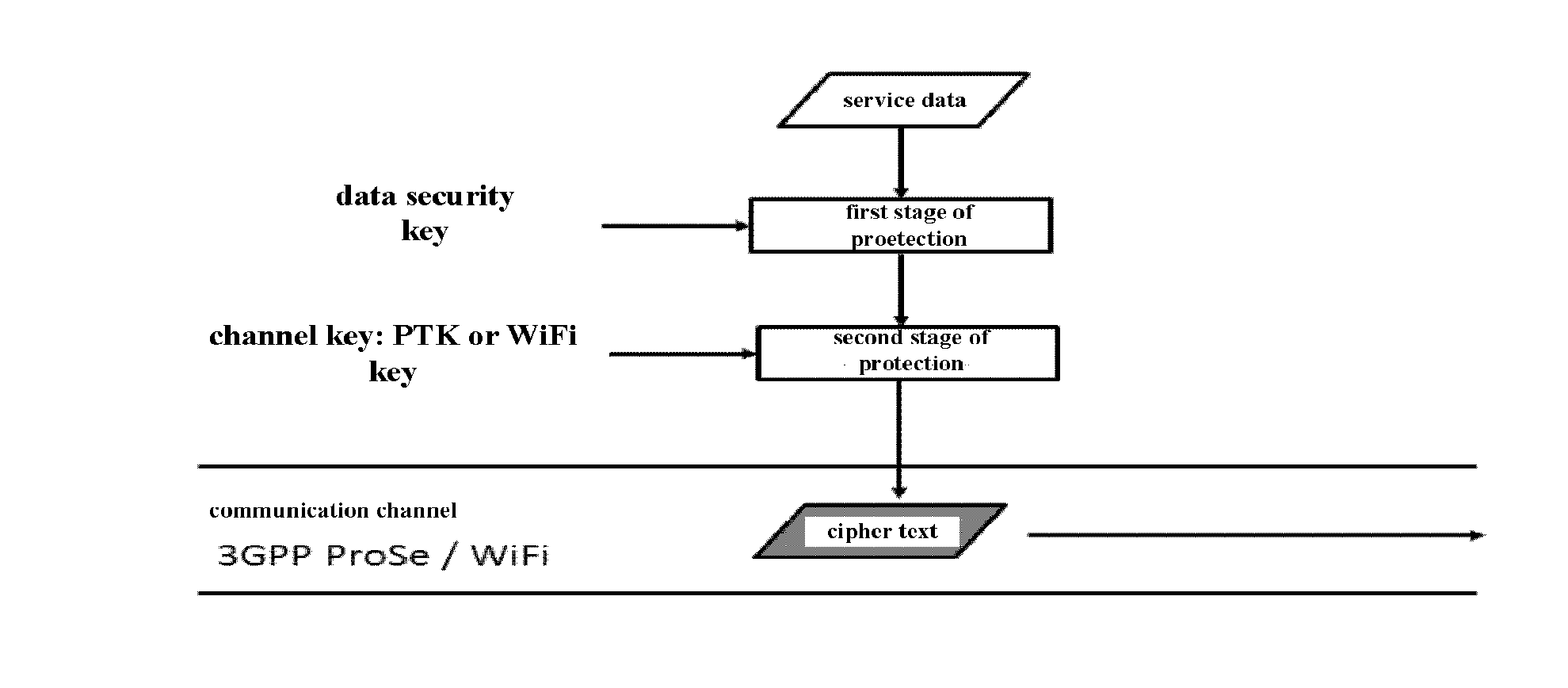

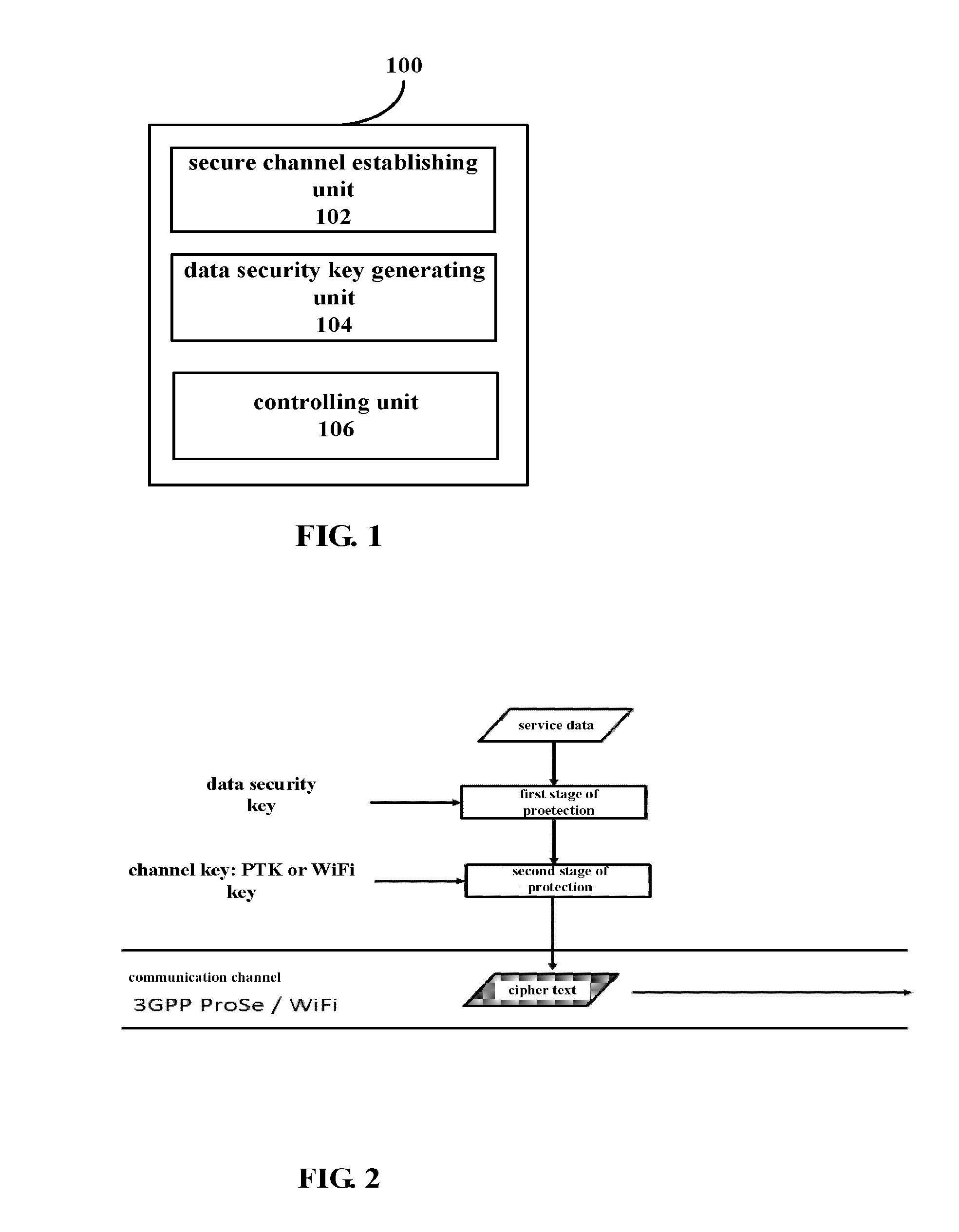

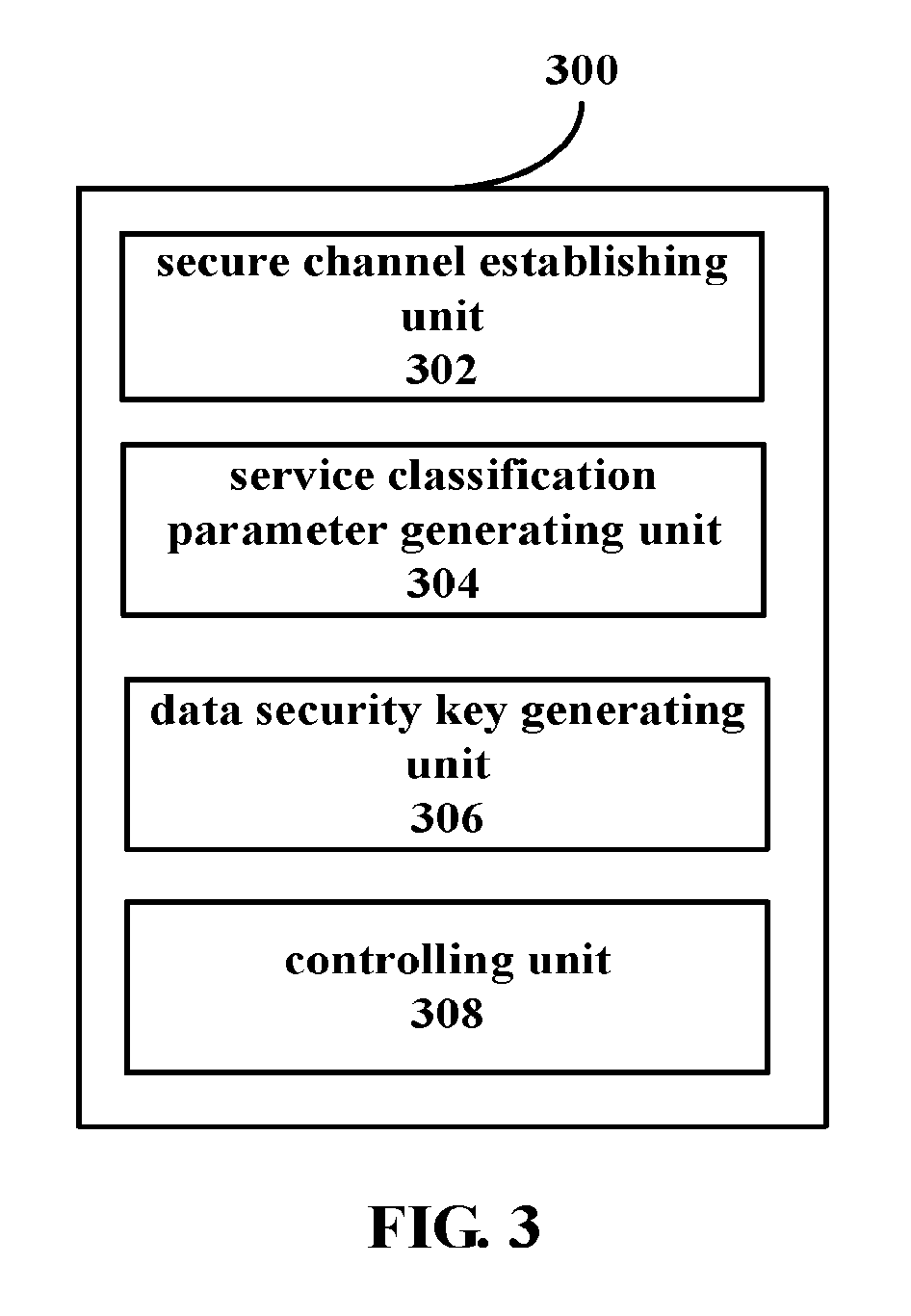

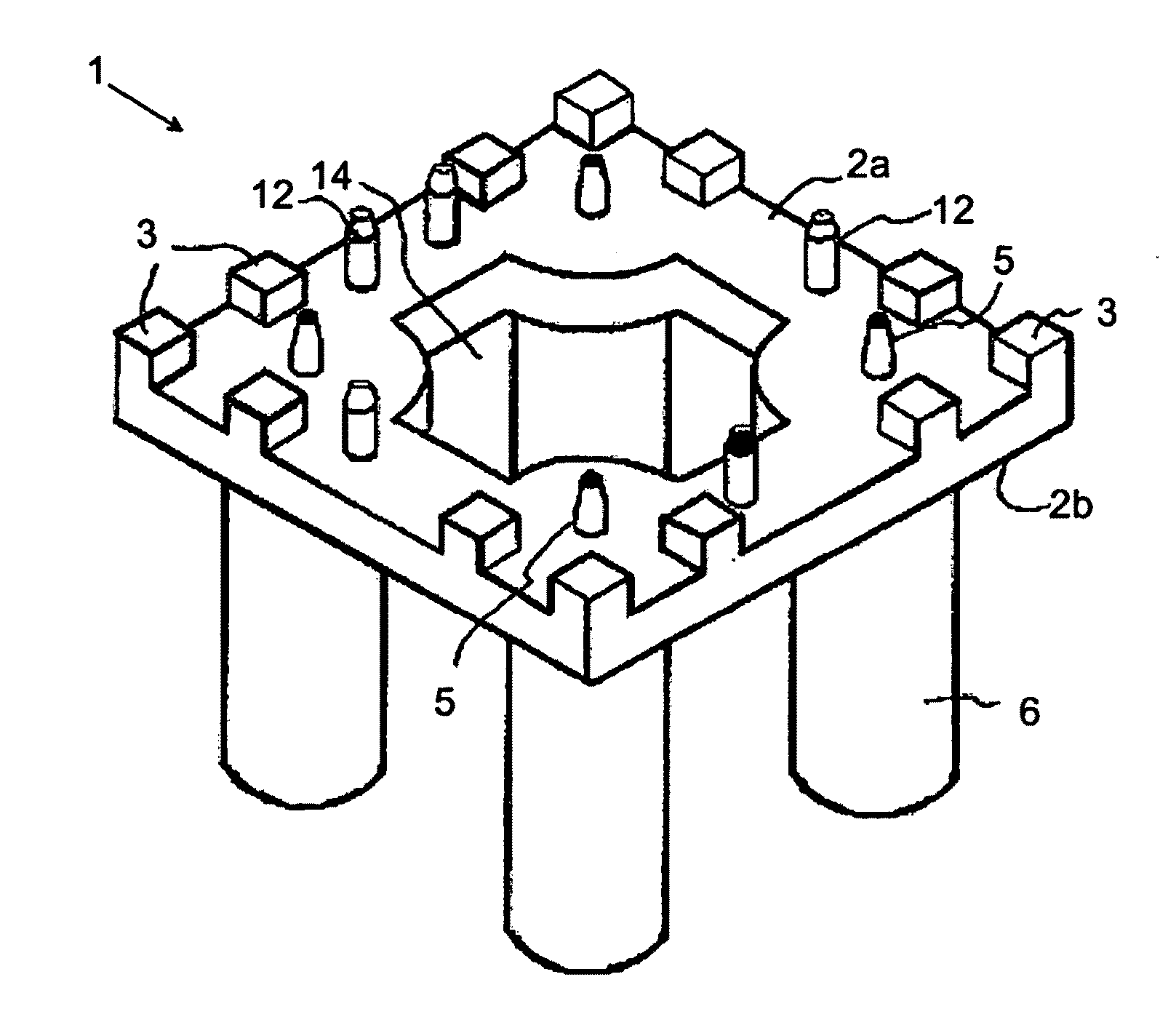

Device and method in wireless communication system and wireless communication system

ActiveUS20170041786A1Avoid orImproving security and privacyCryptography processingParticular environment based servicesCommunications systemData transmission

There is disclosed a device and method in a wireless communication system and a wireless communication system, the device including: a secure channel establishing unit configured to establish a secure communication channel between a first apparatus and a second apparatus using a location-based service; a data security key generating unit configured to generate a data security key for protecting service data based on at least a channel key extracted from the secure communication channel; and a controlling unit configured to control the service data protected using the data security key to be transmitted on the secure communication channel. According to the embodiments of the disclosure, it is possible to improve security of data transmission.

Owner:SONY CORP

RF connector mounting means

InactiveUS20100255688A1ToleranceQuick and secure and space-saving mountingPrinted circuit assemblingVehicle connectorsRF connectorElectrical conductor

Owner:LAIRD TECH INC

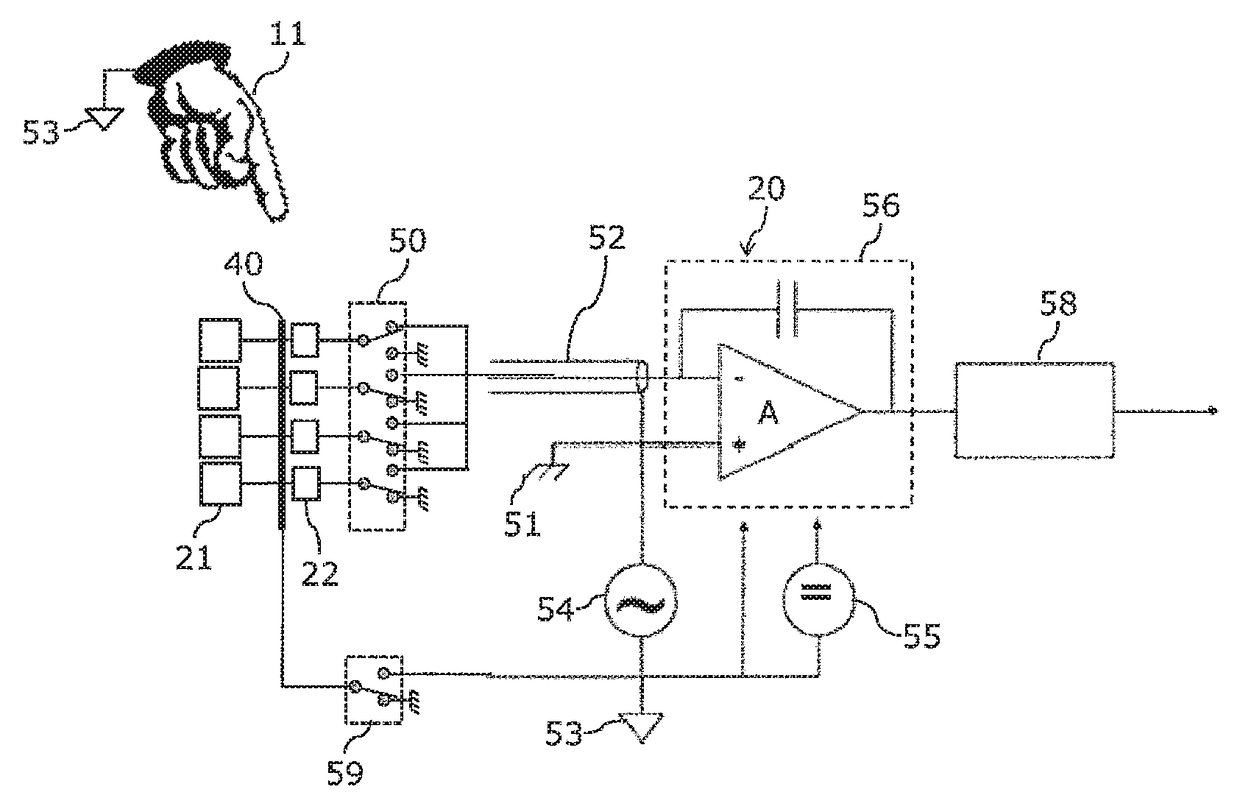

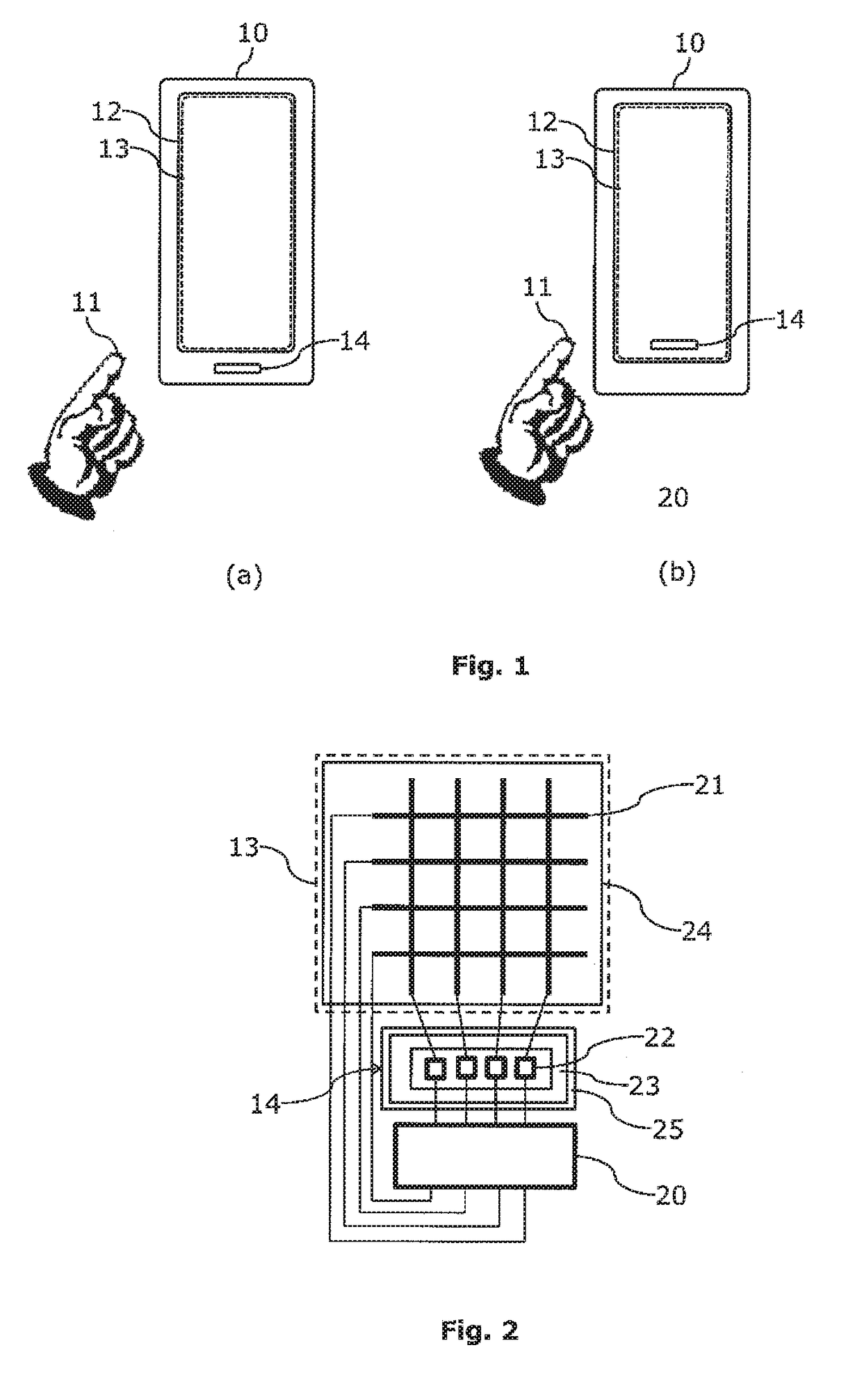

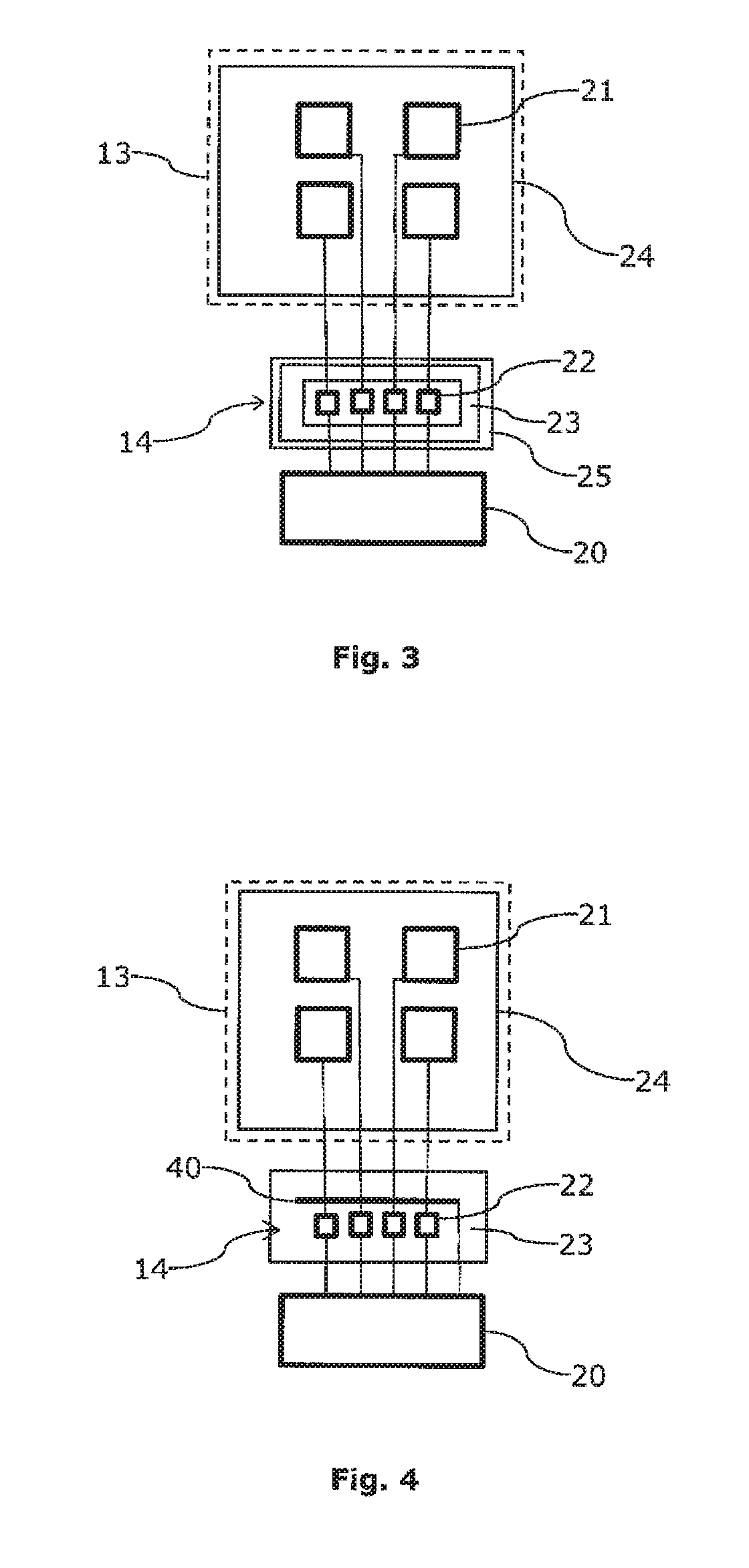

Control interface device and fingerprint sensor

ActiveUS20170285869A1Avoid problemsAvoid orPrint image acquisitionInput/output processes for data processingCapacitive couplingCapacitive measurement

The present invention relates to a device or apparatus comprising a touch surface provided with first capacitive measurement electrodes (21), a fingerprint sensor (14) provided with second capacitive measurement electrodes (22) distinct from the first electrodes (21), capacitive electronic detection means (20) arranged so as to allow the detection of control objects (11) in a neighborhood of the first electrodes (21) by measuring a capacitive coupling between said first measurement electrodes (21) and said control objects (11) wherein said capacitive electronic detection means (20) comprise inputs electrically connected simultaneously to at least one first measurement electrode (21) and at least one second measurement electrode (22).

Owner:QUICKSTEP TECH

Height-adjustable motor vehicle seat with a spindle drive

ActiveUS8328154B2Improve cooperationAvoid orVehicle seatsToothed gearingsEngineeringMotorized vehicle

Owner:KEIPER SEATING MECHANISMS CO LTD

Process for the production of paper and board

InactiveUS20140124154A1Easy thickness controlKeep the thicknessNatural cellulose pulp/paperSpecial paperFiberCellulose

The present invention relates to a process for the production of paper and board which comprises: (a) introducing one or more fillers, one or more anionic polysaccharides and one or more cationic agents into a mixing zone to form a filler composition; (b) introducing by means of a pump the filler composition into an aqueous suspension comprising cellulosic fibres; and (c) dewatering the obtained suspension. The present invention also relates to a process for the production of a filler composition which comprises: (a) introducing one or more fillers,one or more anionic polysaccharides and one or more cationic agents into a mixing zone to form a filler composition; (b) introducing by means of a pump the filler composition into a storage tank.

Owner:AKZO NOBEL CHEM INT BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com