Patents

Literature

132results about How to "Improve smelting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smelting process of low-grade scrap copper

ActiveCN104131170AFlexible feeding methodFlexible working methodsProcess efficiency improvementScrapSmelting process

The invention discloses a smelting process of low-grade scrap copper. The process comprises the following steps: 1) generation of an initial molten pool; 2) a melting process, namely continuously adding auxiliary materials into a top blowing furnace, inserting a spray gun into melt, spraying oxygen-enriched air and fuel into the melt, carrying out submerged combustion and top-blown smelting, and stopping adding the auxiliary materials when the liquid level of the melt in a to-be-blown furnace is 0.3m to 0.5m higher than a bleed hole, repeatedly carrying out smelting and slagging operations after opening the bleed hole for slagging, and stopping charging and melting when the black copper melt surface inside the top blowing furnace ascends to the position which is 100mm to 200mm below the bleed hole; (3) a blowing process, namely exhausting slag inside the top blowing furnace, inserting the spray gun into black copper, and spraying the oxygen-enriched air and fuel to carry out submerged combustion and blowing, and respectively discharging the produced raw copper and blowing slag from a copper discharge hole and the bleed hole; and 4) repeating of the smelting and blowing processes. According to the technical scheme disclosed by the invention, the operation for smelting scrap copper is flexible, and the smelting process is strong in adaptability on raw materials, high in safety, and high in recovery rate of copper and valuable metal.

Owner:TONGLING NON FERROUS METAL GROUP CORP

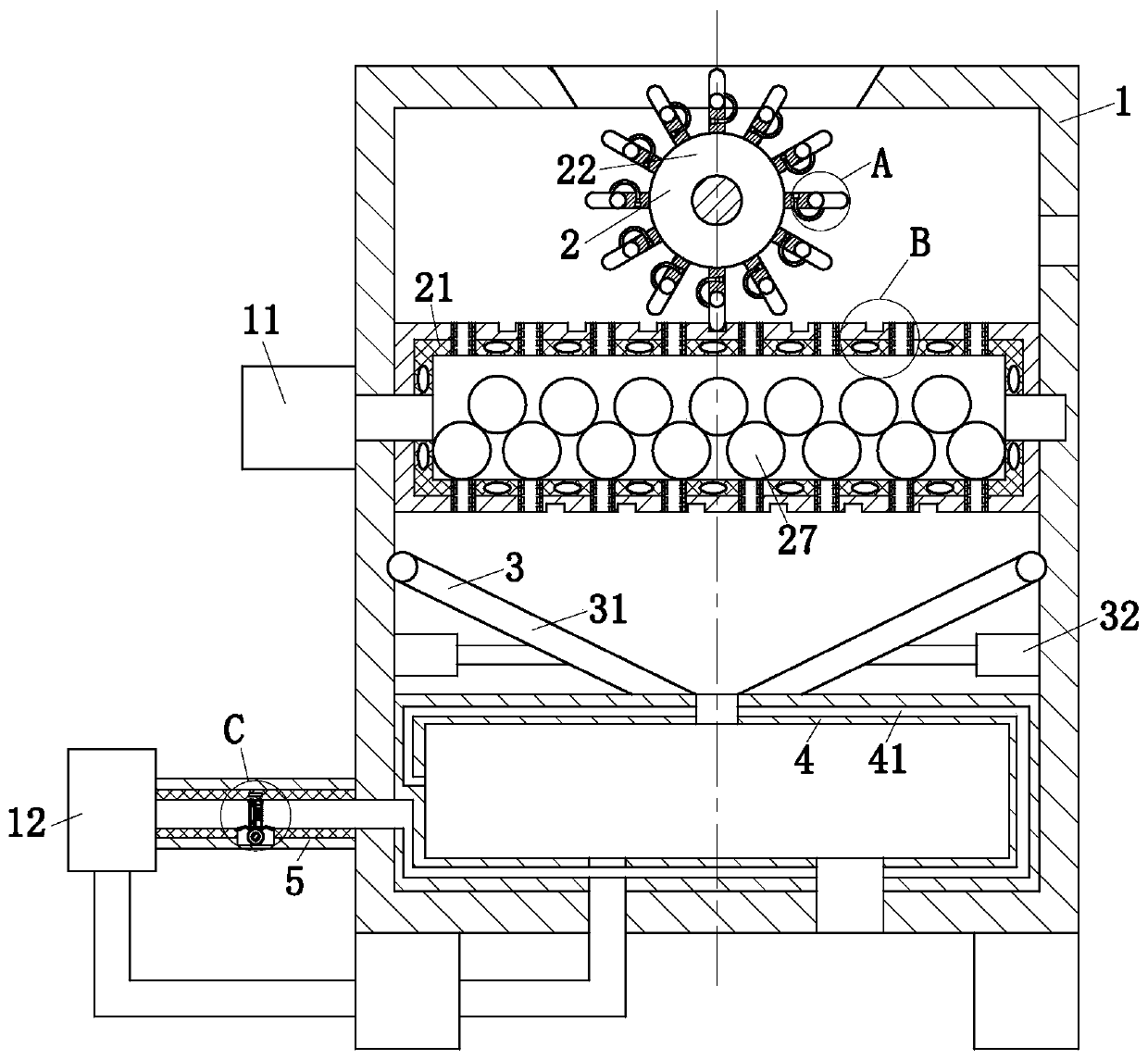

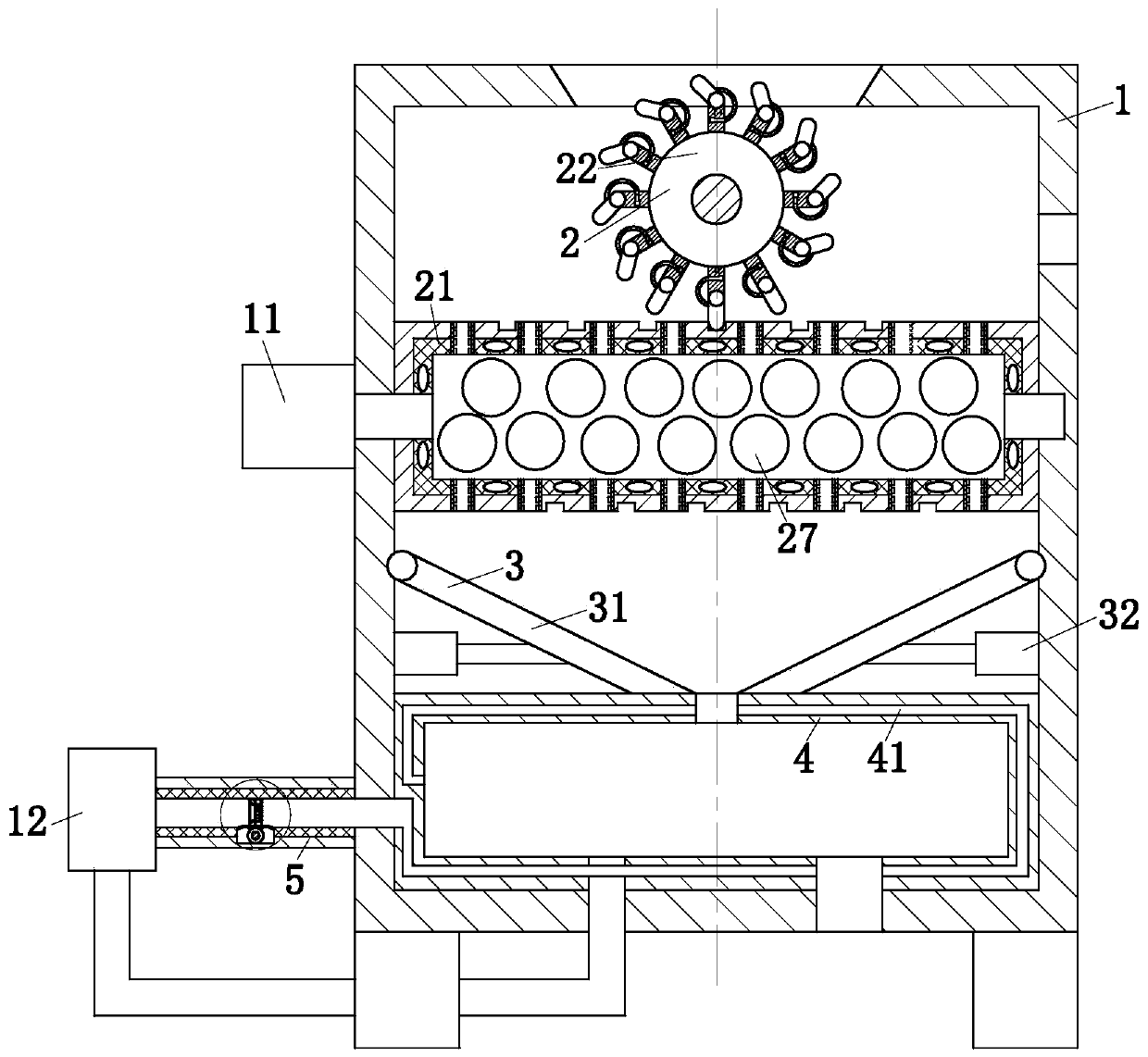

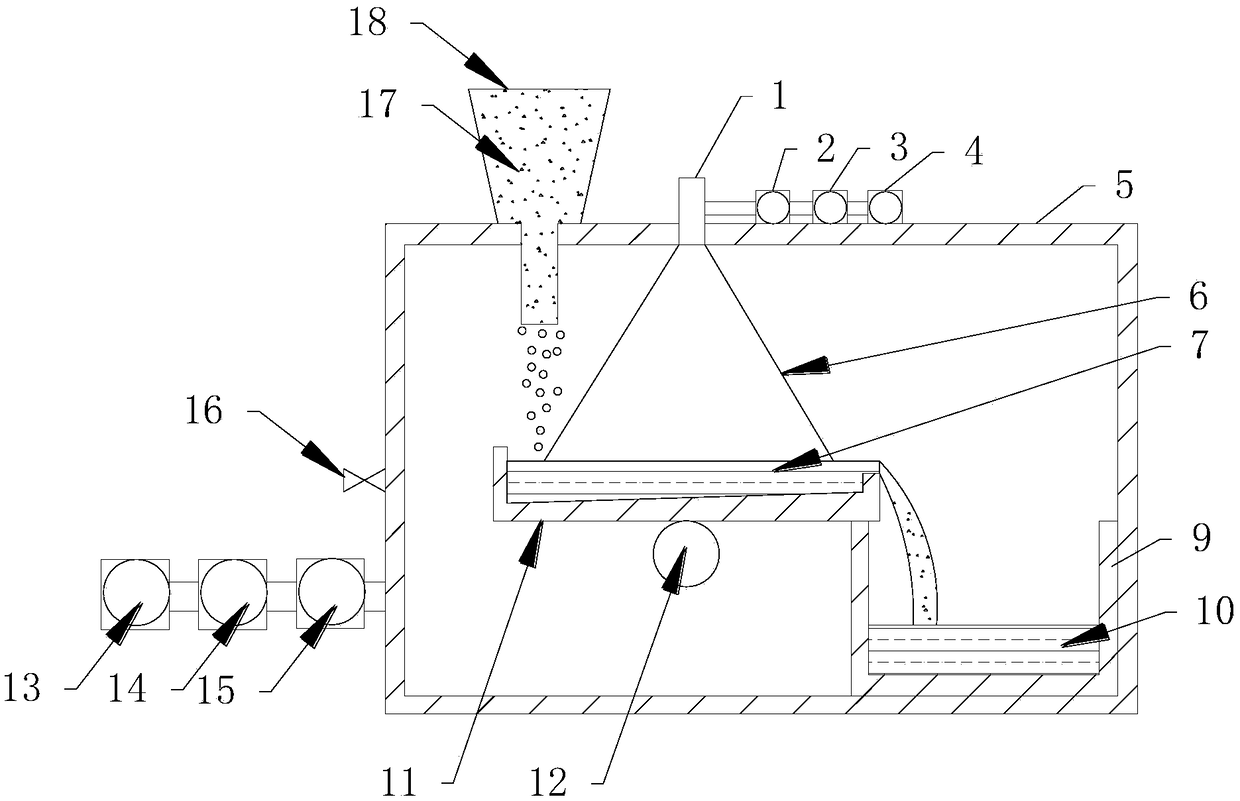

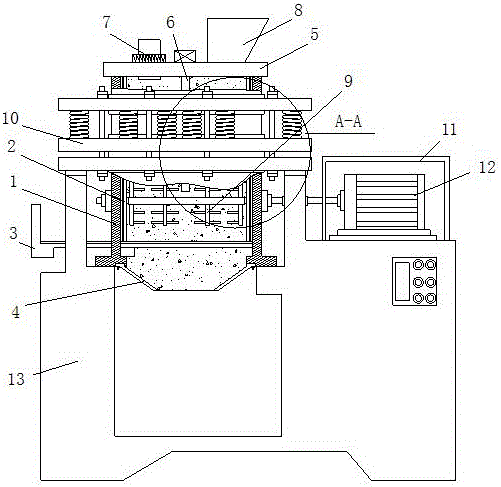

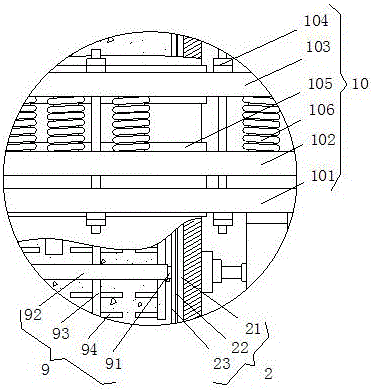

Ore breaking device for smelting

InactiveCN107138211ABroken comprehensiveGood crushing effectDirt cleaningGrain treatmentsEngineeringSmelting

The invention relates to an ore breaking device for smelting, in particular to an ore breaking device for the smelting, so as to achieves the effects that the ore breaking device for the smelting is easy and simple to operate and uniform in breaking, and thus the smelting effect during ore smelting is improved without affecting the quality after the smelting. The ore breaking device for the smelting comprises a bottom plate, a collection frame, support rods, a breaking frame, a discharge pipe, a valve, a support plate, a top plate, a first air cylinder and the like; the support rods are symmetrically arranged in the top middle of the bottom plate in a bolted connection manner; the top ends of the support rods are in bolted connection with the breaking frame; the lower part of the right side of the breaking frame is connected with the discharge pipe; and the discharge pipe communicates with the interior of the breaking frame, and is arranged obliquely. The ore breaking device achieves the effects that the ore breaking device is easy and simple to operate and uniform in breaking, and thus the smelting effect during ore smelting is improved without affecting the quality after the smelting.

Owner:雷海涛

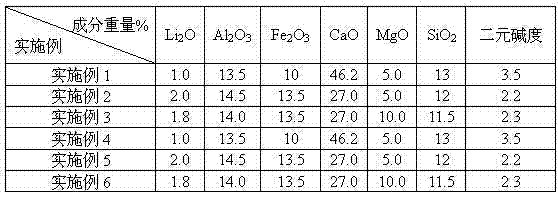

Magnesium binder used for pellet and preparation method and addition method thereof

InactiveCN102719662AIncrease the content of MgOImprove metallurgical performance indicatorsPass rateUltimate tensile strength

The invention provides a magnesium binder used for a pellet and a preparation method and an addition method thereof. The preparation method comprises: adding 30-35% of magnesite powder having a passing rate more than 80% through a 320 mesh, 40-55% of bentonite and 12-15% of active lime into a mixer; mixing a mixture above while adding 3-5% of sodium carbonate; and pulling the mixture out and airing the mixture for 7-9h to get a finished product. The addition method comprises adding the binder to a surface of a pellet mixture on a material conveying belt according to a preset weight of the binder that should be conveyed of a unit time and a unit length and based on a ratio by weight from 2.5% to 4.5%. Pellet MgO can be improved by 1-2%, mechanical strength of the pellet can be improved by 1-2%, and an initial softening temperature can be improved by 100-150 DEG C with the magnesium binder added into the pellet mixture. Blast furnace output can be improved by about 5% and coke ratio can be reduced by 10 kg by the pellet using the binder in the invention.

Owner:ANGANG STEEL CO LTD

Furnace charge for vanadium-titanium magnetite blast furnace smelting, and blast furnace smelting method

InactiveCN102206718AImprove smelting effectLow cost of industrializationBlast furnace detailsProduction rateBlast furnace smelting

The invention provides a furnace charge for vanadium-titanium magnetite blast furnace smelting and a blast furnace smelting method. The furnace charge comprises a vanadium-titanium agglomerated ore and a vanadium-titanium pellet ore. The vanadium-titanium agglomerated ore is produced from a mixture of a vanadium-titanium iron concentrate and a common iron concentrate through sintering. The vanadium-titanium pellet ore is produced from a vanadium-titanium iron concentrate or a mixture of a vanadium-titanium iron concentrate and a common iron concentrate through roasting. The common iron concentrate is a vanadium-free and titanium-free iron concentrate. In the invention, the present furnace charge only comprises a vanadium-titanium agglomerated ore and a vanadium-titanium pellet ore and a common lump ore is not utilized in smelting processes, thus a clinker production rate is increased. Through the present furnace charge, a droplet interval and a maximum pressure difference of a stock column are reduced and it is shown that a cohesive zone of blast furnace smelting processes is low and a permeability of the stock column is improved. Therefore, blast furnace smelting is intensified and blast furnace charge smelting performances are improved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

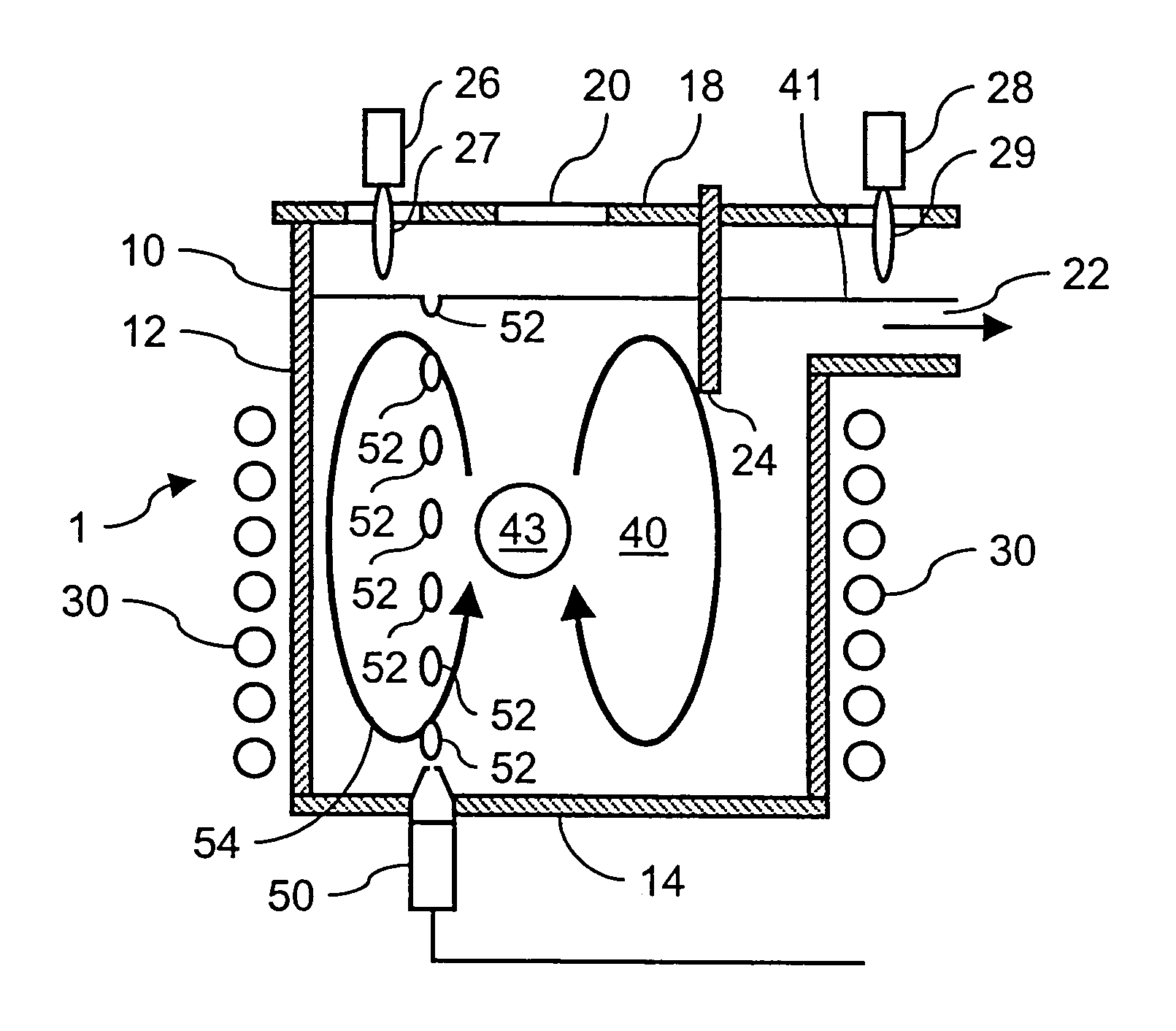

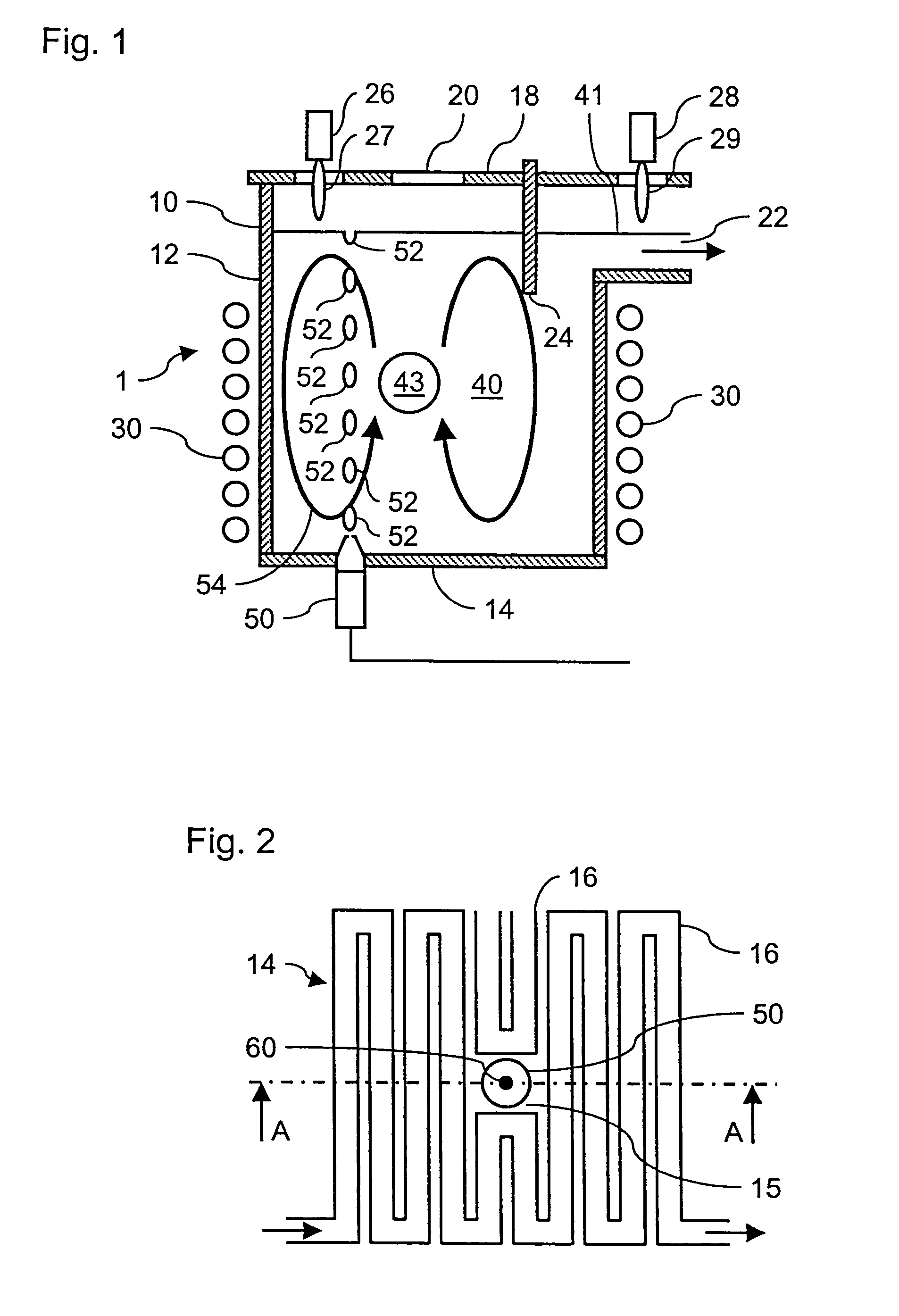

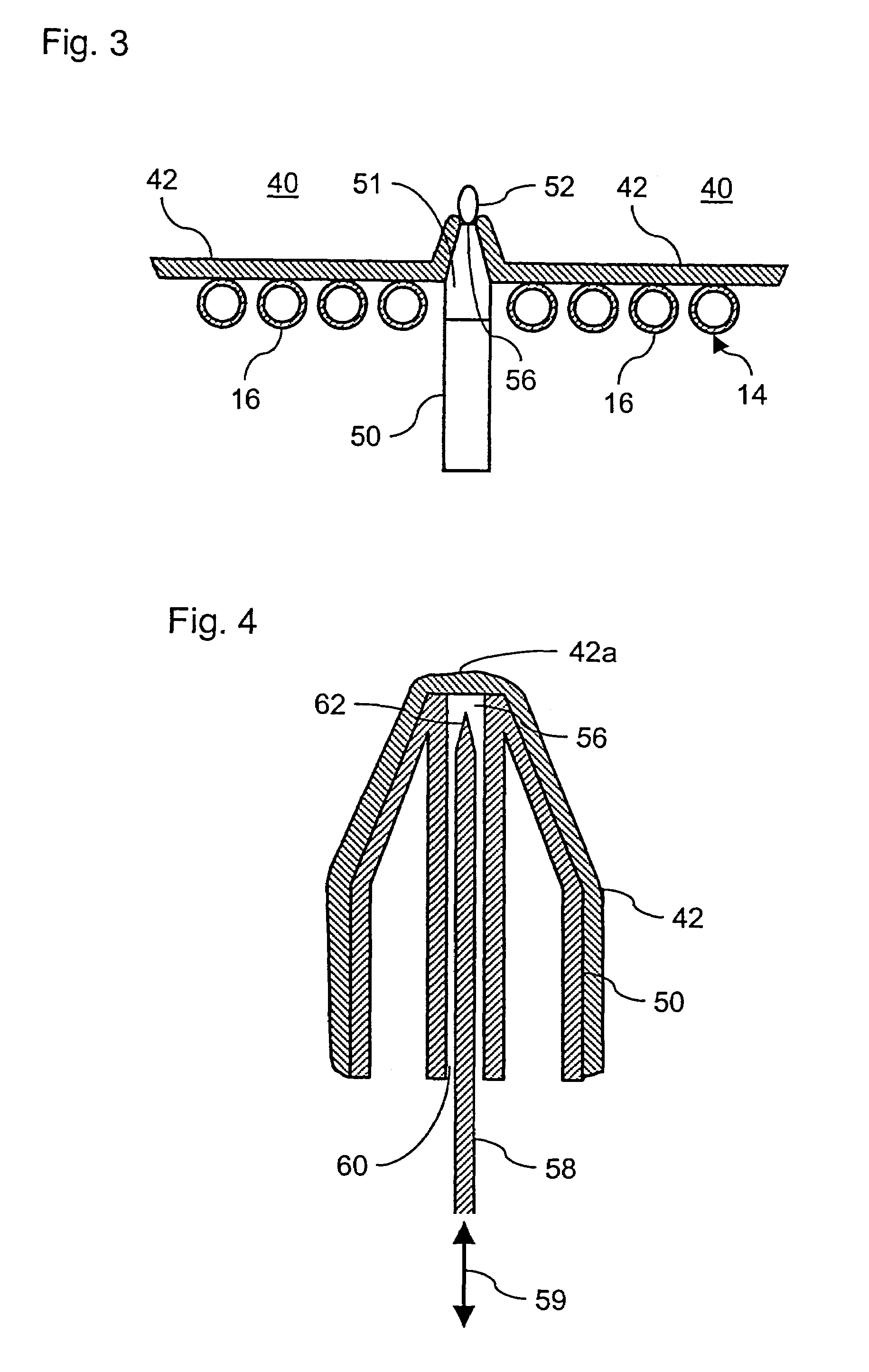

Device and method for melting a substance with the occurrence of a low level of contamination

InactiveUS7296441B2Improve homogeneityImprove smelting effectPot furnacesGlass drawing apparatusOxidation-Reduction AgentOxygen

The invention relates to an apparatus and a method for low-contamination melting of high-purity, aggressive and / or high-melting glass or glass-ceramic. According to the invention, for this purpose a melt is heated in a crucible or melting skull crucible by means of high-frequency radiation and is mixed or homogenized in the melting crucible. It is preferable for a gas nozzle, from which gas bubbles, e.g. oxygen bubbles (known as O2 bubbling), escape into the melt, to be provided at the base of the crucible. This alone makes it possible to achieve surprising multiple benefits in the melting skull crucible. Firstly, unmelted batch which drops into the melt in solid form, for example from above, is melted down more quickly as a result of more intensive mixing with the liquid fraction of the melt, secondly the temperature distribution in the melt is made more even, thirdly a uniform distribution or mixing of different glass constituents is achieved, and fourthly the redox state of the glass can be adjusted.

Owner:SCHOTT AG

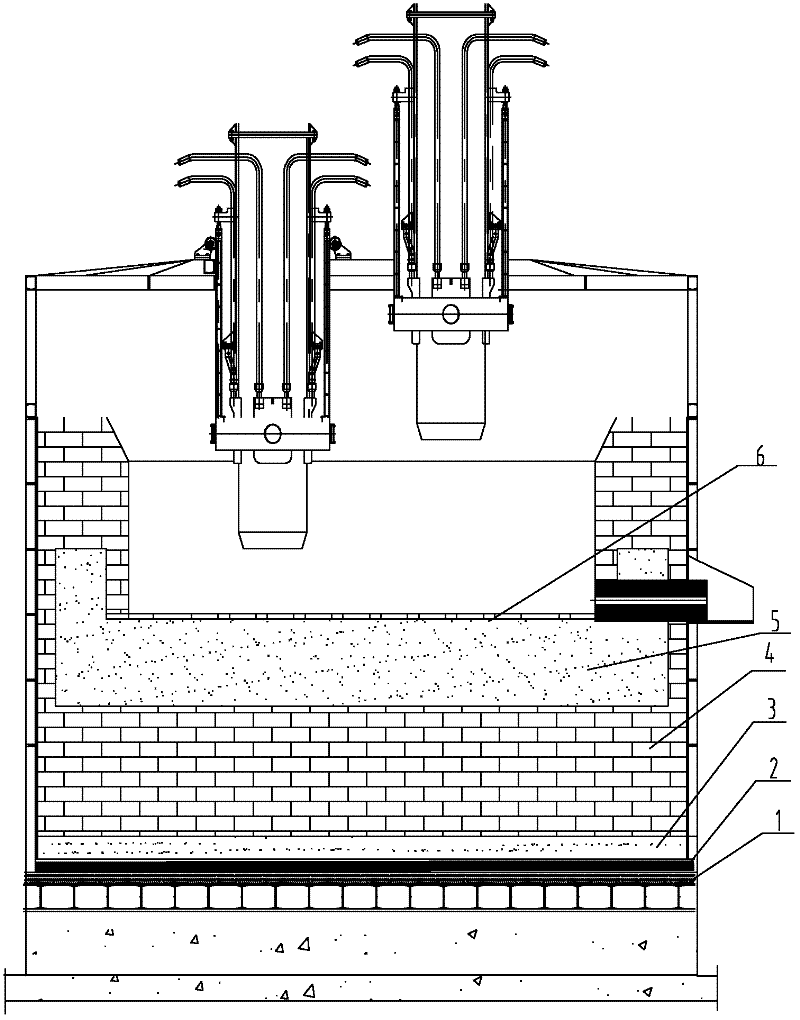

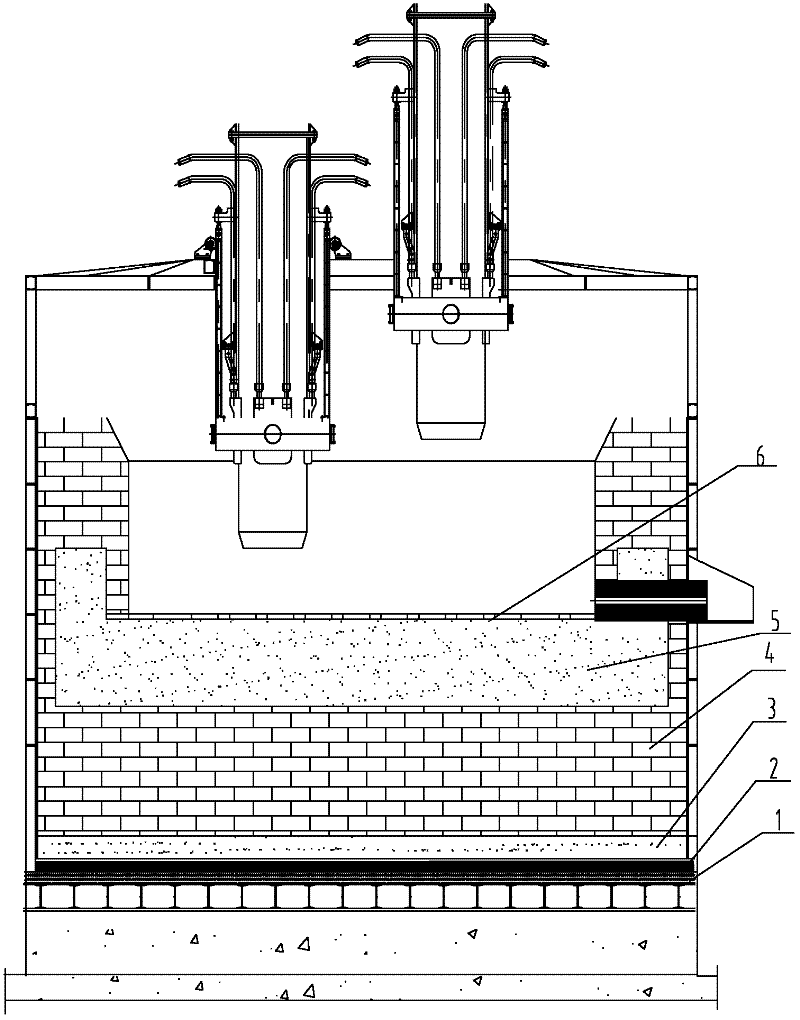

Submerged arc furnace body and constructing method thereof

The invention provides a submerged arc furnace body. The submerged arc furnace body comprises a furnace bottom and a furnace wall which is connected with the furnace bottom; the furnace bottom comprises an asbestos board layer, a refractory grain layer, a refractory brick layer, a ramming material layer and a refractory material layer, wherein the asbestos board layer is laid on a furnace bottom steel plate; the refractory grain layer is paved on the asbestos board layer; the refractory brick layer is constructed on the refractory grain layer, and comprises refractory bricks and refractory clays filled among the refractory bricks; the ramming material layer is paved on the refractory brick layer; and the refractory material layer is constructed on the ramming material layer. The invention further provides a constructing method for the submerged arc furnace body. Ramming materials are used to replace carbon bricks to construct the submerged arc surface body, the ramming materials can form a firm integrated sintering layer under the high-temperature sintering condition, so that the sintering layer has no seam and does not easily generate cracks in a smelting process while alternatively acted by cold and heat, thus molten iron can be prevented from eroding and burning through the furnace bottom, the service life of the submerged arc furnace is prolonged, the cost of metal melting is reduced, and the safety of the submerged arc furnace body is increased.

Owner:李成武

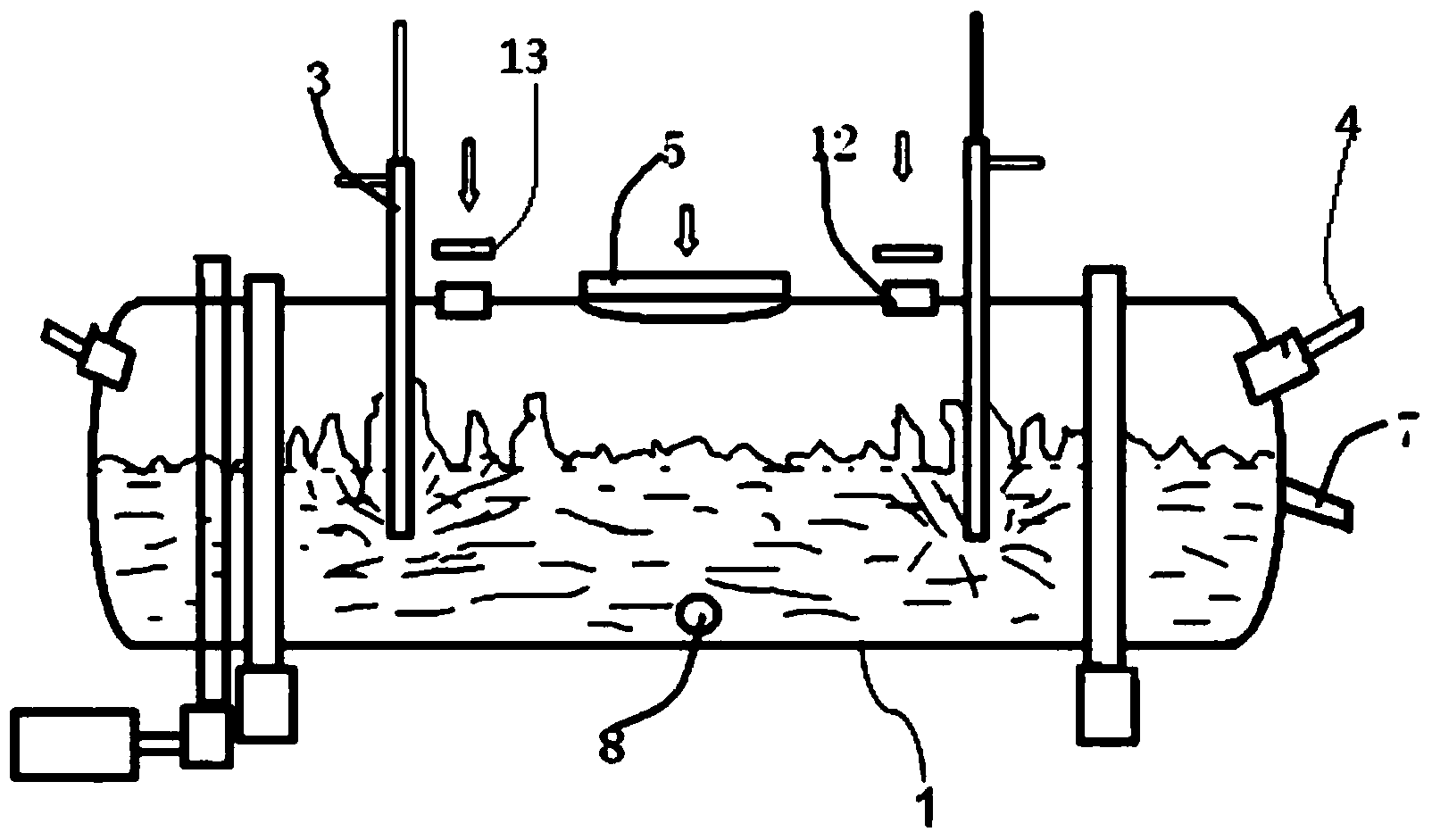

Non-ferrous metal smelting furnace

InactiveCN107764063AImprove smelting effectImprove efficiencyRemovable covers for furnacesCharge manipulationDrive shaftNon-ferrous extractive metallurgy

The invention discloses a non-ferrous metal smelting furnace, which comprises a furnace body, a feeding port, a smelting chamber and a bracket. At the lower end of the furnace body, an exhaust fan is arranged on one side of the furnace body, an exhaust pipe is connected to the upper end of the exhaust fan, and the exhaust fan is connected to the smelting chamber through the exhaust pipe, and a motor is installed on the other side of the furnace body. , one end of the motor is connected with a transmission shaft. In the present invention, an exhaust fan is arranged on one side of the furnace body to extract dust and toxic and harmful gases, thereby improving the smelting effect of non-ferrous metals. By setting a crushing shaft under the feeding port, the volume of the solid metal is more uniform after crushing. It is convenient for smelting operation. By setting a mesh screen at the lower end of the crushing shaft and connecting a vibrating spring at the lower end of the mesh screen, the mesh screen can be used to select different standards of screening, so that the non-ferrous metal smelting is more sufficient.

Owner:WUXI SANZHONG MOLD CO LTD

Metal electroslag remelting smelting atmosphere protection method

The invention discloses a metal electroslag remelting smelting atmosphere protection method. According to the method, a protector and an inert gas source, which are connected with each other, are arranged in a metal electroslag remelting smelting device, and a protector is used for spraying inert gas into the metal electroslag remelting smelting device to carry out the atmosphere protection in the smelting process. The metal electroslag remelting smelting atmosphere protection method is characterized by arranging the protector at the position near the part above a metal electroslag remelting solution when in smelting, and linking the protector to an electrode rod, so that when the electrode rod gradually falls and the liquid surface rises, the protector is linked to the liquid surface to rise, and the protector and the liquid surface stay in a fixed height range so as to guarantee the atmosphere protection effect of the liquid surface. By adopting the method, the follow-up atmosphere protection can be realized along with the rising of the liquid surface. The method has advantages of simplicity in implementation, stability and reliability in operation and good atmosphere protection effect; moreover, the smelting effect can be improved.

Owner:宝武特冶航研科技有限公司

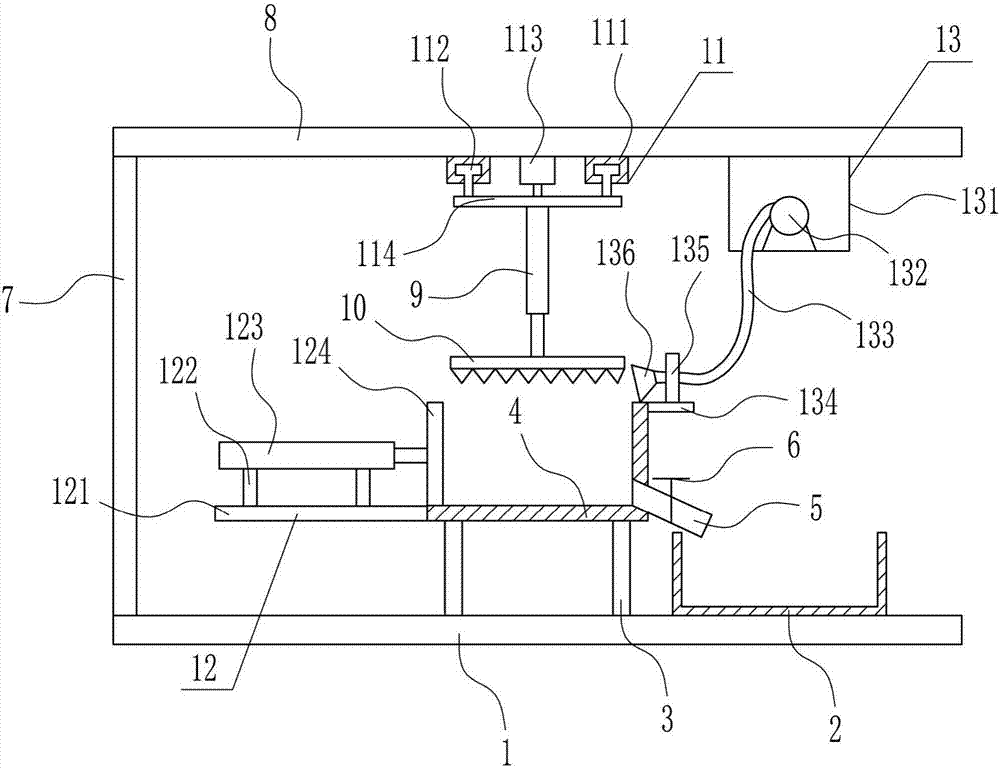

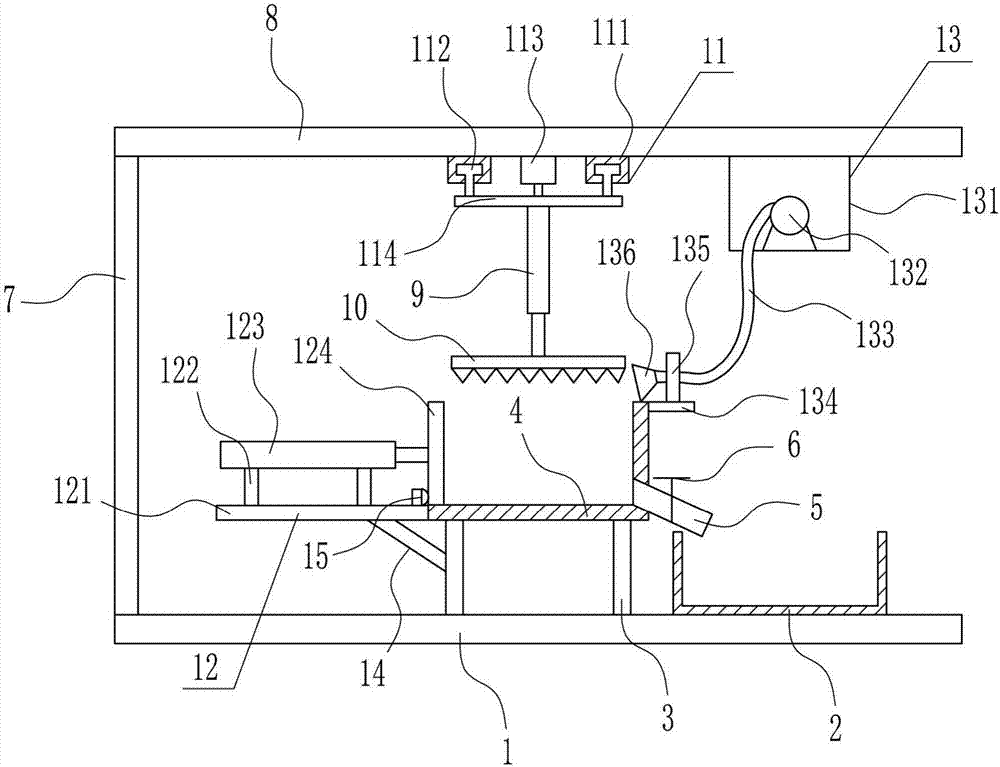

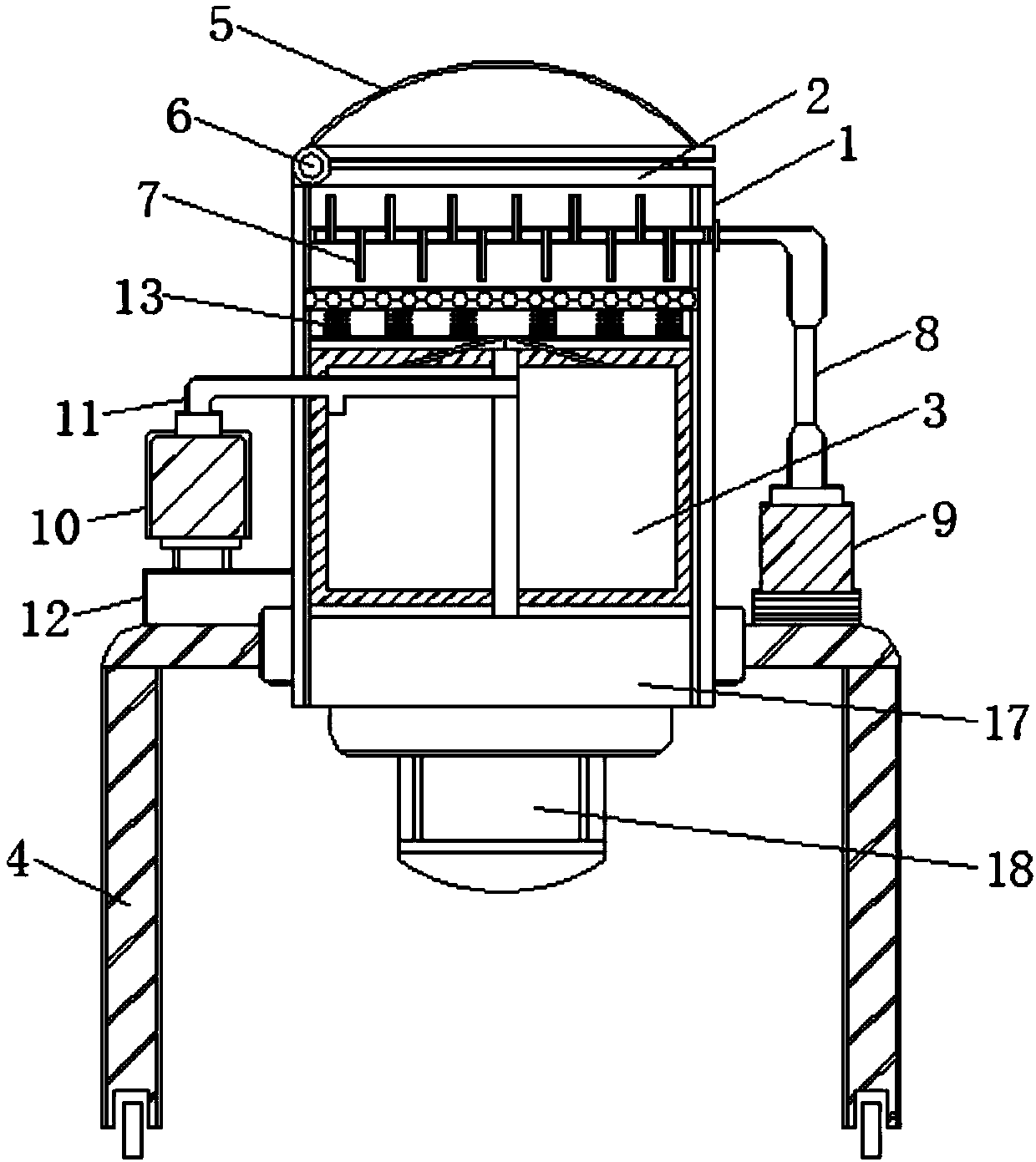

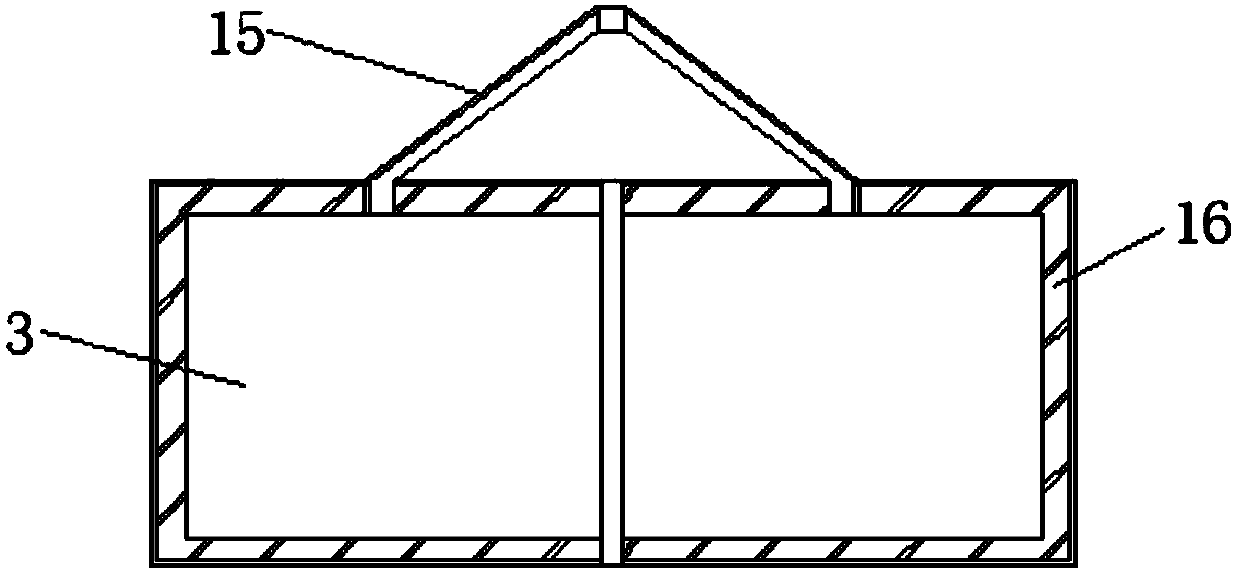

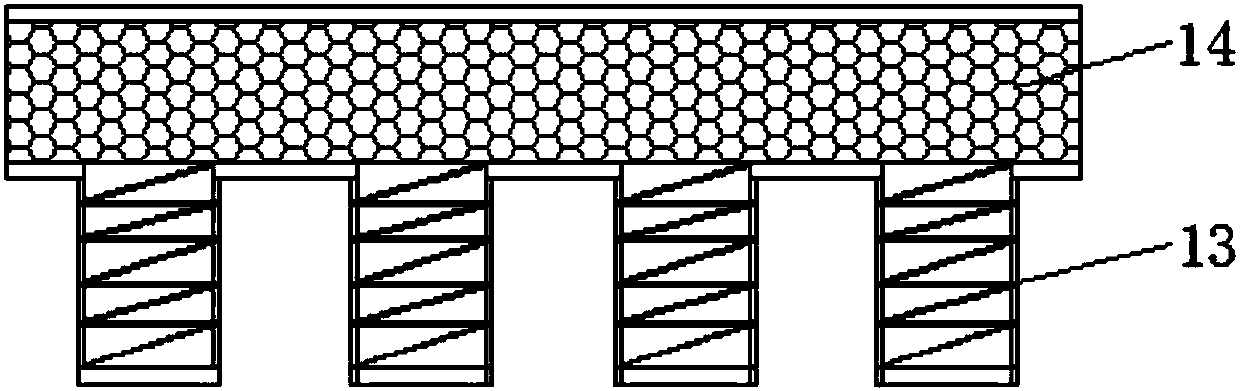

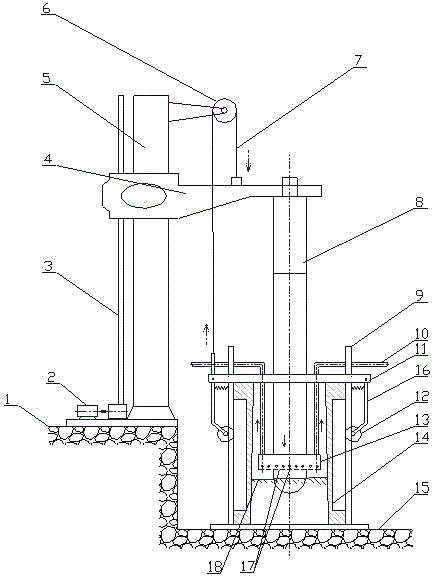

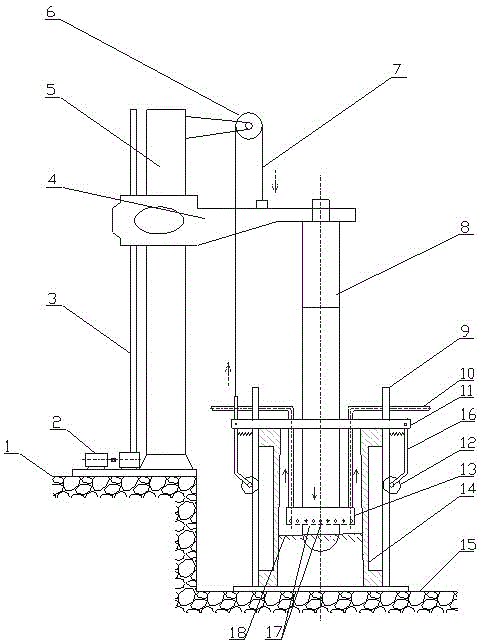

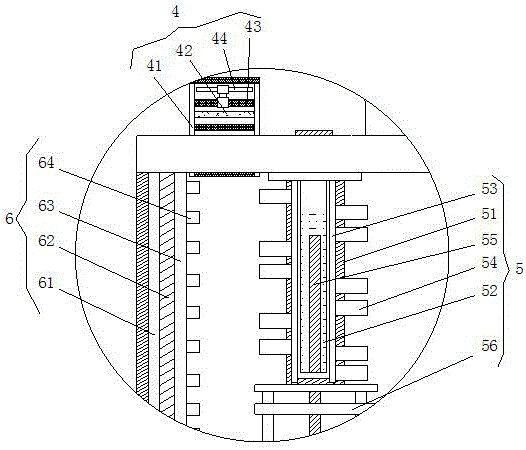

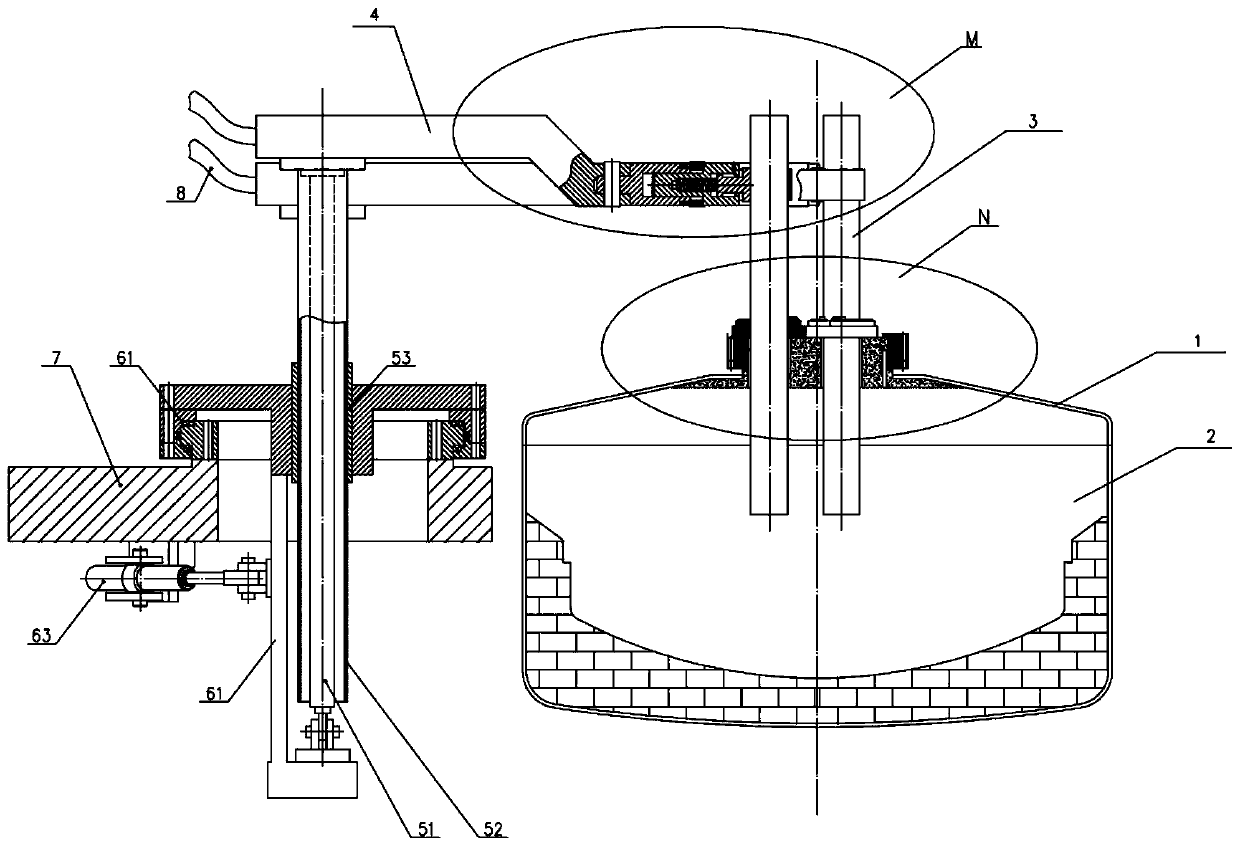

Metal electroslag remelting smelting device

The invention discloses a metal electroslag remelting smelting device. The metal electroslag remelting smelting device comprises an overall furnace body structure and a crystallizing device which is installed on a plane below a step, and also comprises a stand column which is vertically installed on a plane above an installation step at one side of the crystallizing device, wherein a transverse cantilever is arranged above the stand column, an electrode bar which extends downwards to enter the crystallizing device is installed right opposite to the crystallizing device and adjacent to the an electrode bar chuck on the transverse cantilever, and the metal electroslag remelting smelting device is characterized by also comprising an atmosphere protection device, wherein the atmosphere protection device comprises a protection part structure and a transmission part structure, the protection part structure is provided with a protector, the protector is arranged in the furnace body and sleeves an annular hollow structure outside the electrode bar in a spacing manner, air outlets are uniformly distributed in the protector along the circumferential direction, the protector is connected with an inert gas source through a gas pipe, and the transmission part structure is used for controlling the protector to rise along with the rising of the liquid surface. By adopting the metal electroslag remelting smelting device, the follow-up atmosphere protection along with the rising of the liquid surface can be realized. The metal electroslag remelting smelting device has advantages of simplicity in structure, stability and reliability in operation and good atmosphere protection effect and good smelting effect.

Owner:宝武特冶航研科技有限公司

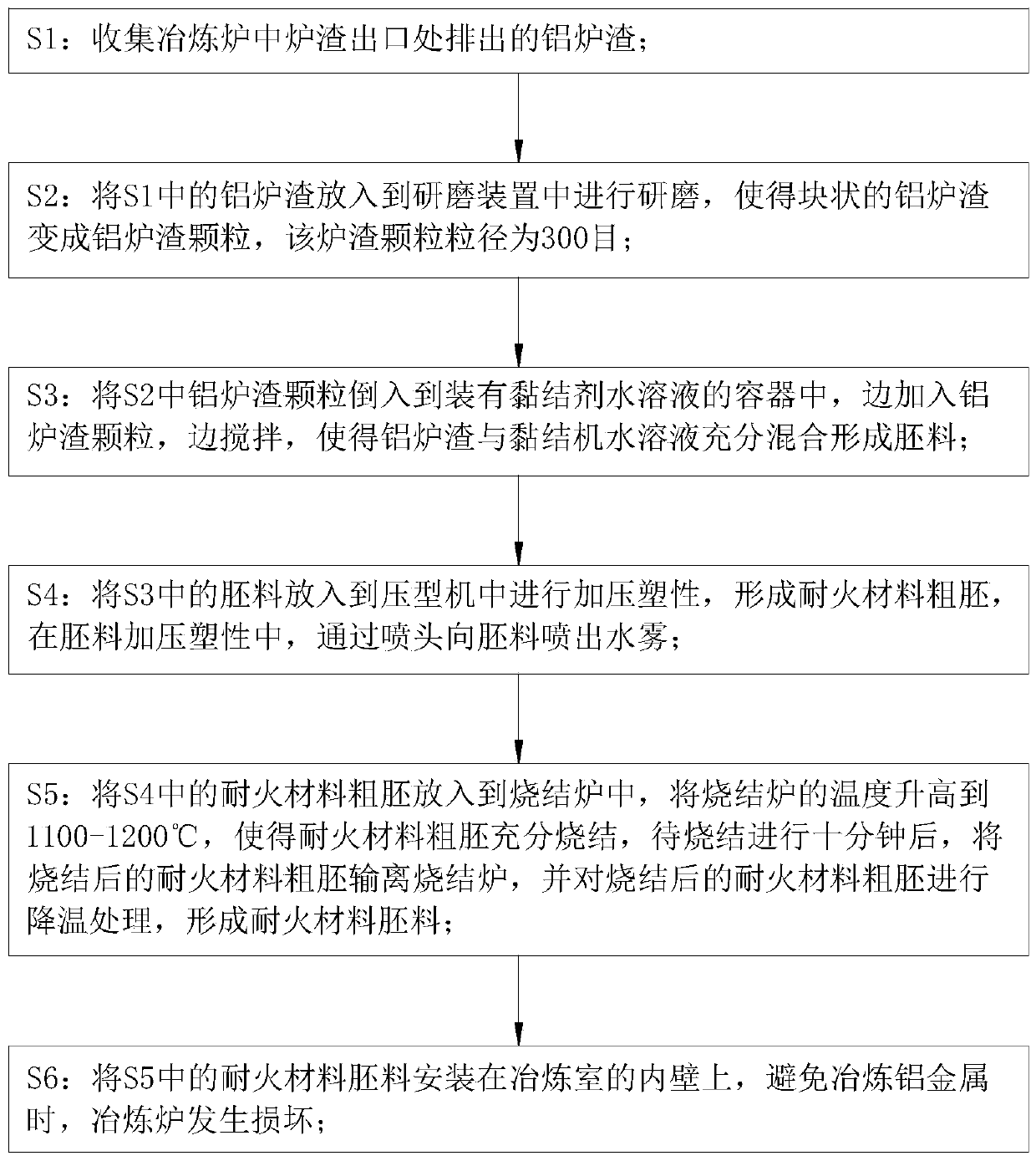

Process for reusing slag of aluminum smelting furnace

ActiveCN109719114AImprove qualityExtended service lifeSolid waste disposalIncreasing energy efficiencySlagSpray nozzle

The invention belongs to the technical field of slag reutilization and particularly relates to a process for reusing slag of an aluminum smelting furnace. The process adopts the smelting furnace. Thesmelting furnace comprises a box body and further comprises a crushing unit, material guide units, a smelting chamber, a motor, a collecting box, a first pipe, a purifying unit and a controller. By the adoption of the process, on the one hand, in the process of mixing the aluminum slag and an aqueous solution of a sintering machine, the aluminum slag and the aqueous solution of the sintering machine are fully mixed to form blanks while being added and stirred; meanwhile, spray nozzles are used to spray water mist to the blanks during the pressurization and plasticity of the blanks, so that theblanks are tightly attached, no fracture occurs between the blanks during sintering in the sintering furnace, and thus the quality of a refractory blank is improved; and on the other hand, the formedrefractory blank is installed on the inner wall of the smelting chamber to prevent the smelting furnace from being damaged when aluminum metal is smelted, so that the service life of the smelting chamber is prolonged.

Owner:绥化春达矿渣高细制造有限公司

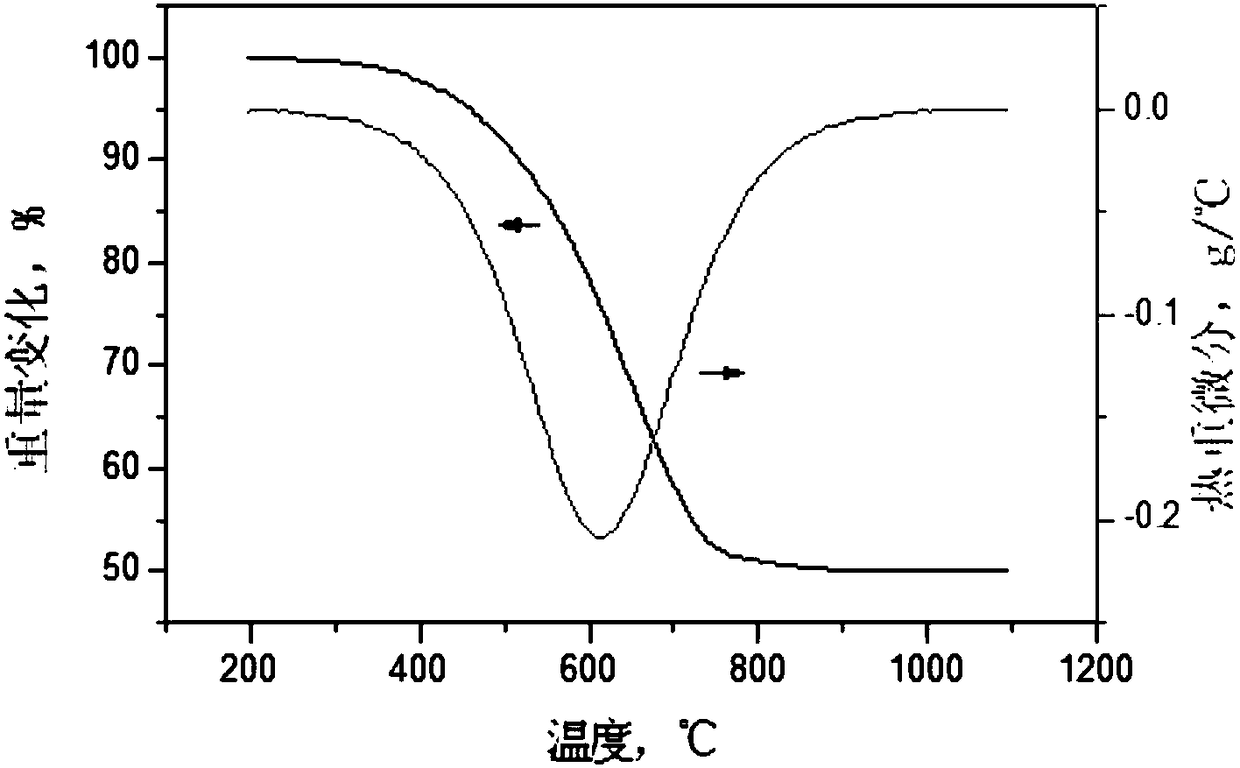

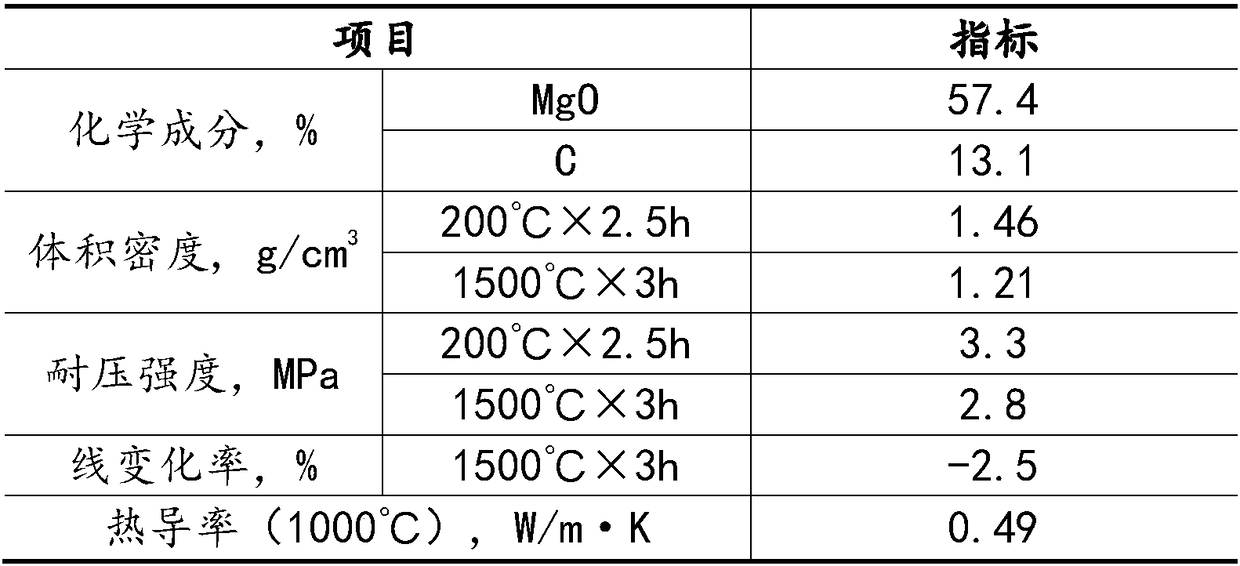

Light tundish working lining and method for preparing same

ActiveCN108530090AImprove corrosion resistanceObvious volume shrinkage (≤-4.0%) phenomenonCeramic materials productionClaywaresFiberBrick

The invention discloses a light tundish working lining and a method for preparing the same. Ingredients for the light tundish working lining comprise waste magnesia-carbon bricks, magnesite tailing, aluminum oxide, fibers, compound bonding agents and additives. The method for preparing the light tundish working lining includes dry vibration forming or wet smearing forming. The light tundish working lining and the method have the advantages that the light tundish working lining prepared by the aid of the method is low in volume density, erosion rate, cost and consumption and long in service life, energy can be saved, and the like. Besides, the problem of excessive consumption of resources of existing refractory raw materials (including waste magnesia-carbon brick reclaimed materials and thelike), the problems in the aspects of energy conservation and heat preservation and the like can be solved by the aid of the light tundish working lining and the method.

Owner:PUYANG REFRACTORIES GRP CO LTD

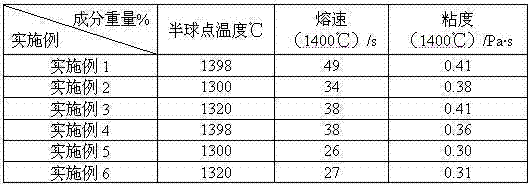

Composite adhesive for metallurgical pellet and production method thereof

The invention discloses a composite adhesive for a metallurgical pellet and a production method thereof, relates to an adhesive used in a metal smelting process and a method for producing the adhesive, and aims to provide an adhesive for favorably improving the metal smelting performance of subsequent smelting and reducing the smelting energy consumption and the emission of pollution gases. The composite adhesive for the metallurgical pellet comprises organic powder and bentonite, wherein the mass ratio of the organic powder to the bentonite is 1:1; the organic powder comprises a dispersant and an organic adhesive in percentage by mass: 95-99.5 percent of dispersant and 0.5-5 percent of organic adhesive. In order to produce the composite adhesive, the three steps of taking the materials, manufacturing the organic powder and manufacturing the composite adhesive are required.

Owner:LIAONING JINSHI TECH GROUP

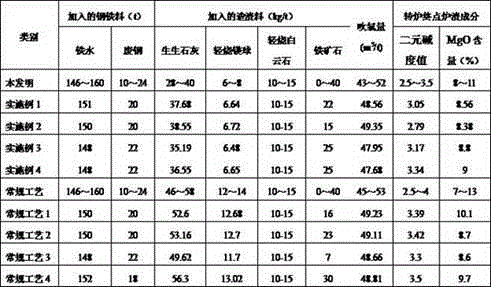

Smelting method for retaining hot dreg of converter

ActiveCN104451023AEnsure safetyReduce the amount addedManufacturing convertersSmelting processDolomite

The invention discloses a smelting method for retaining hot dreg of a converter, which mainly solves the technical problem in the prior art that retained hot dreg of the converter is easy to splash in the early converter converting period and the retaining amount of hot dreg of the converter is hard to control accurately. According to the technical scheme disclosed by the invention, the smelting method for retaining hot dreg of the converter comprises the following steps: a, pouring dreg: after tapping of the converter, pouring dreg, and returning the converter to zero degree after 30-50% of the total weight of dreg is poured; b, splashing dreg to protect the converter: adding a certain amount of caustic calcined magnesite balls and caustic calcined dolomite into dreg of the converter to splash dreg to protect the converter; c, adding raw dolomite or limestone into the converter for mixing dreg, and after mixing the dreg, adding molten iron and waste steel into the converter; and d, adding a converter dreg making material into the converter and then converting the molten iron, the waste steel and the converter dreg making material in the converter. Compared with conventional smelting process without retaining dreg, the converting process is stable and the consumption of the converter dreg making material is greatly reduced.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

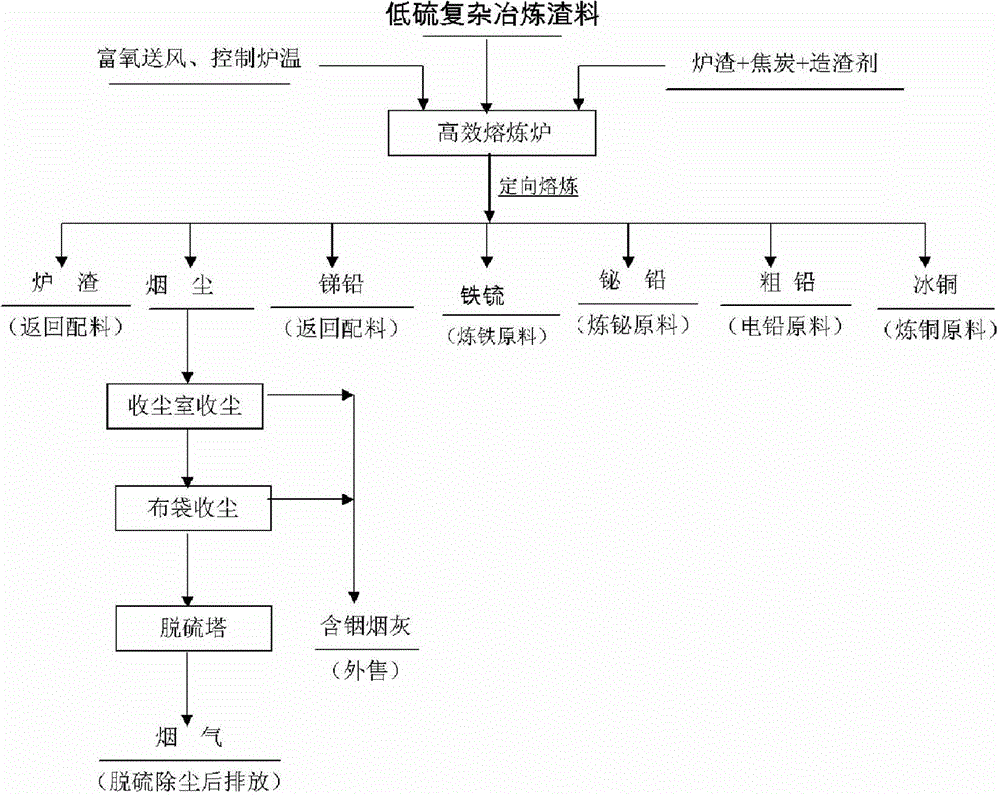

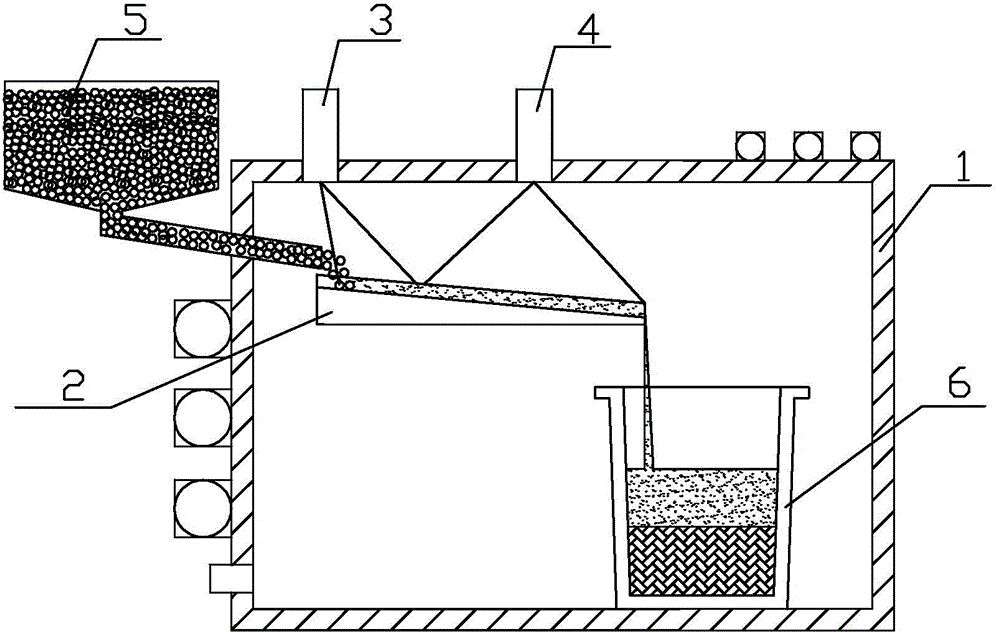

Airtight oxygen-rich negative pressure efficient smelting furnace directional smelting clean production process

ActiveCN104894380AEffective regulation of response behaviorImprove protectionProcess efficiency improvementIndiumSlag

The invention discloses an airtight oxygen-rich negative pressure efficient smelting furnace directional smelting clean production process. The process includes: adopting an efficient smelting furnace; feeding low sulfur complex smelting slag and fusion agent ingredients into the furnace through a feed inlet; using coal gas or natural gas and coking coal as the heat supply fuel of reducing smelting, injecting oxygen at the efficient smelting furnace bottom side into the furnace; and carrying out reducing smelting by the efficient smelting furnace so as to ultimately realize directional separation and enrichment of lead, copper, zinc, tin, antimony, bismuth, gold, silver, indium and other valuable metals in soot, slag, iron matte, crude metals and other products. The process provided by the invention realizes the real sense of efficient clean production, the production process is short, and project investment is saved.

Owner:长沙瑾瑶环保科技有限公司

Lead plaster desulfurization transforming method for waste lead-acid storage batteries

InactiveCN103000968AHigh recovery rateReduce pollutionWaste accumulators reclaimingProcess efficiency improvementThermodynamicsProcess engineering

The invention discloses a lead plaster desulfurization transforming method for waste lead-acid storage batteries, which belongs to the field of waste battery disposal. The method comprises the following steps: (1) the preparation of a lead plaster original sample: carrying out decomposition on waste lead-acid storage batteries, taking out a grid alloy, taking out lead plaster from a grid, removing impurities in the lead plaster, drying the lead plaster in an environment at a temperature of 80-90 DEG C, and grinding the lead plaster in a grinding machine for 10-30 min so as to obtain the lead plaster original sample with a particle size of 50-300 mu m; (2) the configuration of a desulfurization transforming agent: preparing a desulfurization transforming agent into transforming liquid, and heating the desulfurization transforming liquid to 20-90 DEG C by using a constant-temperature water bath bed; (3) full reaction: adding weighted lead plaster into the transforming liquid obtained in step (2), and stirring the obtained mixture, so that the mixture is fully reacted; and (4) after the transforming is completed, cooling and filtering the obtained product, and carrying out repeated washing and residue filtering on the obtained product for many times by using distilled water. According to the method, the desulfurization transforming process parameters of lead plaster in waste lead-acid storage batteries are determined, PbSO4 is effectively transformed into easily-decomposed PbCO3, the energy consumption is lowered, and the environmental pollution is reduced.

Owner:高金菊

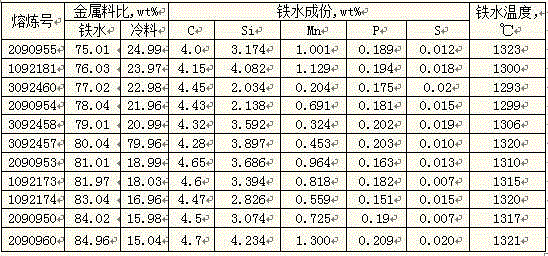

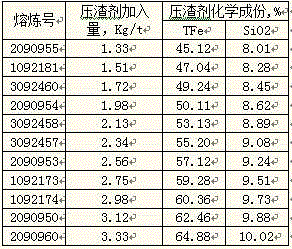

High-silicon molten iron smelting method

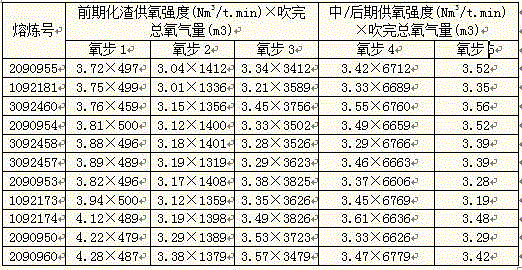

ActiveCN103060509AImprove smelting effectImprove smelting qualityManufacturing convertersAlkalinityOxygen

The invention discloses a high-silicon molten iron smelting method. The method comprises earlier-stage oxygen blast control, regulation and control of slagging material composition and alkalinity and deslagging stability, earlier-stage deslagging control, later-stage deslagging control and other regulation and control means, thereby implementing desilication smelting of high-silicon molten iron. By using high-silicon molten iron and light scrap steel as raw materials, the method disclosed by the invention controls the oxygen blast quantity in different stages to control the smelting slagging rhythm and effectively lower the silicon content of the smelted molten iron, thereby enhancing the smelting effect and smelting quality of the molten iron.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Method and device for efficient removal of impurity oxygen from polysilicon by electron beam melting

Belonging to the field of polysilicon purification, the invention in particular relates to a method and device for efficient removal of impurity oxygen from polysilicon by electron beam melting, and breaks the traditional electron beam melting mode to carry out electron beam deoxygenation smelting by means of a diversion trench rather than in a melting crucible. As a silicon liquid can spread in a diversion area, the specific surface area increases, and the electron beam melting deoxygenation effect can be better. According to the method and device provided by the invention, (1) the technological method and use of electron beam deoxygenation are put forward, the problem of difficult removal of impurity oxygen from polysilicon is solved, and the oxygen content can be reduced to less than 0.0571ppmw, thus meeting the requirement of solar cells for polysilicon ingot oxygen content; (2) the polysilicon material efficient banded deoxygenization technology can increase the silicon liquid surface area by over 30% and shorten the deoxygenation time by more than 20%; and (3) continuous production can be realized, and the production efficiency can be improved by more than 35%.

Owner:QINGDAO NEW ENERGY SOLUTIONS

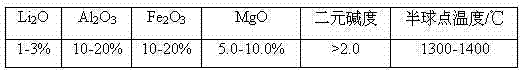

Fluoride-free slagging flux for electric-arc furnace steelmaking

The invention belongs to the technical field of iron and steel smelting and particularly relates to a fluoride-free slagging flux for the electric-arc furnace steelmaking and a preparation method thereof. The invention aims to provide the fluoride-free slagging flux for the electric-arc furnace steelmaking and the preparation method thereof and solve various problems of low slagging speed, poor slag melting effect, fluorine pollution, high cost, serious corrosion of a furnace lining, large dust capacity and the like which are generated due to the case that currently, lime, fluorite, calcium aluminate and iron oxide are used as slags. The fluoride-free slagging flux is characterized by being prepared from the following raw materials in percentage by weight: 20 to 40 percent of spodumene, 15 to 20 percent of red bauxite, 30 to 50 percent of active lime, 5 to 10 percent of iron oxide and 5 to 10 percent of magnesia.

Owner:JIANGSU UNIV

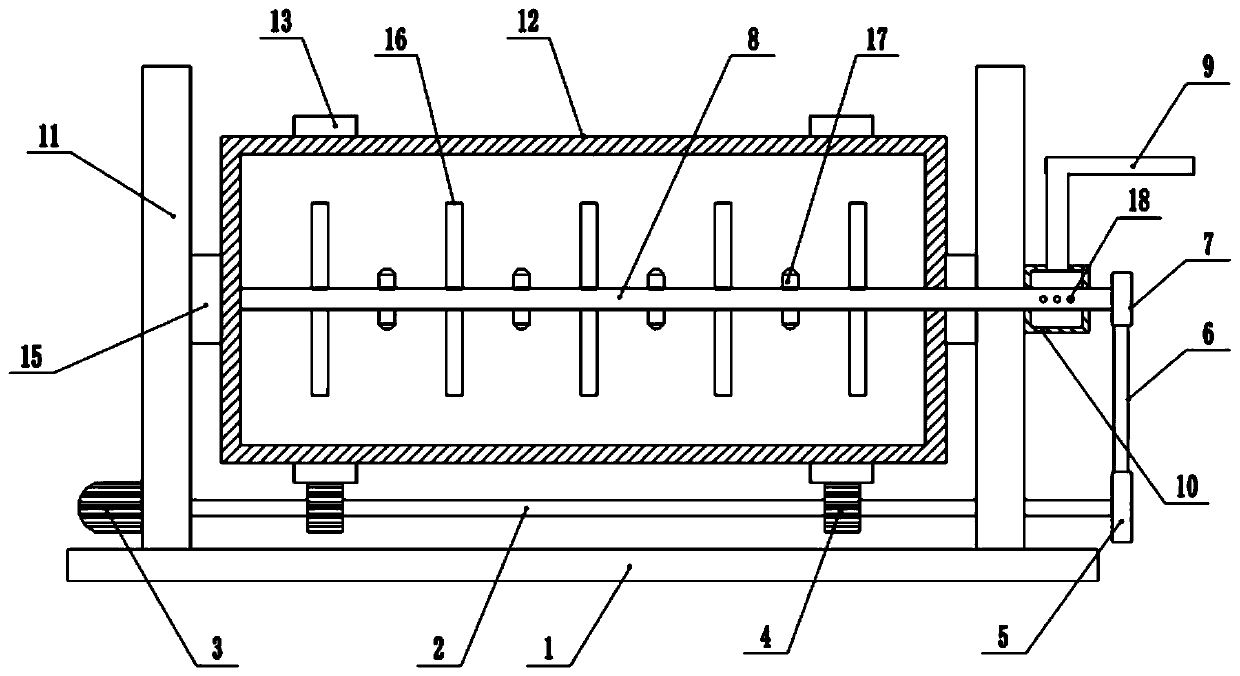

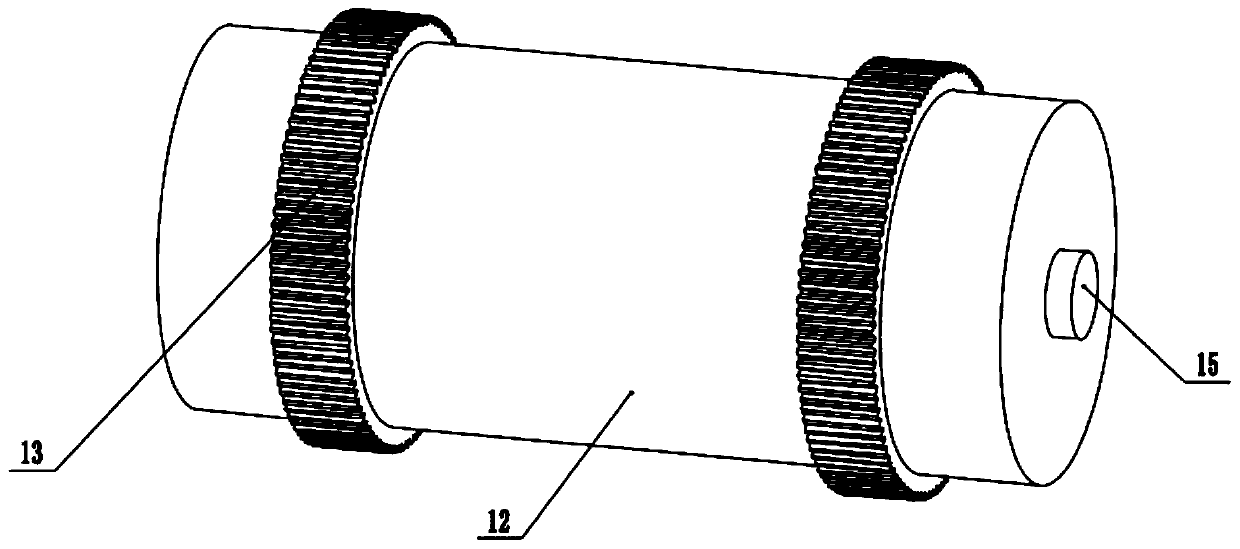

Fused quartz uniform smelting device

InactiveCN111470758AReasonable structureInnovative designGlass furnace apparatusRotational axisMining engineering

The invention relates to the technical field of quartz melting, and discloses a fused quartz uniform smelting device including a fixed bottom plate; supporting frames are installed on the two sides ofthe upper end of the fixed bottom plate. A bearing seat is arranged in the middle inside the support frame; a smelting cylinder is arranged between the bearing seats; ring gears are mounted on two sides of the outer side of the smelting cylinder; column gears are engaged with the lower ends of the ring gears; rotary shaft installed in middle of column gear, the outer side of the driving belt wheel is connected with a driven belt wheel through a belt, a smelting shaft is installed on the left side of the driven belt wheel, an air inlet box is installed in the middle of the right side of the supporting frame on the right side, a plurality of stirring blades are installed on the outer side of the smelting shaft, the interior of the smelting shaft is of a hollow structure, and the outer sideof the smelting shaft communicates with a combustion column. According to the invention, rotation of the smelting barrel is achieved, the solidification effect of internal fused quartz is avoided, meanwhile, the smelting shaft opposite to the smelting cylinder in rotation is arranged in the smelting cylinder, rotation is conducted while combustion is conducted, and the uniform smelting effect is further improved.

Owner:新沂市嘉新矿业有限公司

Automatic welding system for electrode shell of submerged arc furnace

PendingCN108436349AReduce labor intensityHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesControl systemDigital control

The invention provides an automatic welding system for an electrode shell of a submerged arc furnace. The automatic welding system comprises a clamping mechanism and a digital control system, whereinthe clamping mechanism is used for clamping and fixing the upper section of an electrode shell, a welding mechanism is used for welding the upper section and the lower section of the electrode shell,and the digital control system is used for controlling the welding mechanism; and the welding mechanism comprises an annular rail, a servo annular vehicle and an electric welding machine, wherein theservo annular vehicle is arranged on the annular rail and can move in the circumferential direction of the electrode shell, and the electric welding machine is installed on the servo annular vehicle.When the electric welding machine rotates around the electrode shell along with the walking of the servo annular vehicle, automatic welding is carried out on the upper section and the lower section ofthe electrode shell, manual welding of workers is not needed, the automation degree is high, the efficiency is high, the labor intensity of workers is reduced, the smelting condition is also improved, and the production efficiency is greatly improved. The digital control system comprises a control system, an annular power supply system and a variable-frequency speed reducing driving system, wherein the control system is used for controlling the walking of the servo annular vehicle and the welding of the electric welding machine, the annular power supply system is used for providing a power source for the servo annular vehicle and the electric welding machine, and the variable-frequency speed reducing driving system is used for controlling the walking speed of the servo annular vehicle.

Owner:LIUZHOU JINLUO MACHINERY

High-heating-rate smelting equipment with waste gas purification function

InactiveCN106225479ASimple structureEasy to useIncreasing energy efficiencyCrucible furnacesExhaust fumesSmelting process

The invention discloses high-heating-rate smelting equipment with a waste gas purification function. The high-heating-rate smelting equipment with the waste gas purification function comprises a smelting cylinder. A top cover is connected to the top of the smelting cylinder. A charging table and a waste gas purification device are sequentially arranged in an inner cavity of the top cover. A main heating device located in the smelting cylinder is connected to the middle of the bottom of the top cover. An auxiliary heating device is arranged on the inner wall of the smelting cylinder. A discharging port is formed in the bottom of the inner cavity of the smelting cylinder. According to the high-heating-rate smelting equipment with the waste gas purification function, generated waste gas can be effectively purified in the metal smelting process, and air pollution in a work area for metal smelting is prevented; ore and additives in the smelting cylinder can be comprehensively and evenly heated, the heating speed for the ore and the additives is increased, and the metal smelting effect is improved to a great extent while the smelting efficiency is greatly improved.

Owner:越研环境工程盐城有限公司

Method for remelting and smelting metal electro slag

The invention discloses a method for remelting and smelting metal electro slag. The electro slags are placed into a crystallizer, an electrode is inserted from an upper position, then the electrode is energized to enable the electrode, the electro slags and short net guide wires in the crystallizer to be switched on to form a current loop, and during the energizing, joule heat is discharged by the electrode and a slag pool, metal slag in the slag pool are molten, the molten metal is converged into a liquid state to flow through the slag pool to fall into the crystallizer to form a metal molten pool, and then the metal molten pool is solidified to form steel ingots; at the same time, during the smelting, auxiliary materials using aluminum particles as the main bodies are added, and the deoxygenation is carried out. The method is characterized in that during the smelting, the electrode is firstly inserted into the upper positions of the electro slags, the electro slags start to melt to fall into the crystallizer to form the metal molten pool, the electrode is controlled to slowly move downwards to be smelted, and the auxiliary materials are continuously and uniformly fed in a linkage control manner when the electrode move downwards. The method has the advantages of low cost, easy implement, automatic feeding of the auxiliary materials during smelting, stable and reliable feeding control process of the auxiliary materials, good smelting effect and the like.

Owner:宝武特冶航研科技有限公司

Environment-friendly smelting furnace for nickel-based alloy powder coating

InactiveCN110411208AIncrease temperatureExtended service lifeCharge manipulationIncreasing energy efficiencySmelting processAlloy

The invention belongs to the technical field of smelting furnaces, and particularly relates to an environment-friendly smelting furnace for a nickel-based alloy powder coating. The furnace aims to solve the problem that an existing smelting furnace is not energy-saving and environment-friendly. According to the technical scheme, the furnace comprises a smelting furnace body, a smelting furnace cover body, a material storage tank and a purification heat absorption tank, wherein the smelting furnace cover body is arranged on the smelting furnace body, the material storage tank is arranged on thesmelting furnace cover body, a material conveying pipe is arranged on the material storage tank, a liquid storage cavity is formed in the material storage tank, a connecting pipe communicates the liquid storage cavity and the purification heat absorption tank, a water pump is arranged on the connection pipe, a liquid discharge pipe is arranged on the material storage tank and communicates with the liquid storage cavity, the purification heat absorption tank is arranged on the smelting furnace cover body, one end of an air inlet pipe extends into the smelting furnace body, the other end of theair inlet pipe extends into the purification heat absorption tank, and a gas exhaust pipe is arranged on the purification heat absorption tank. According to the furnace, the operation is convenient,the safety performance is good, the heat preservation effect is good, the energy consumption is reduced, waste gas in the smelting process can be purified, the heat in the waste gas can be absorbed and utilized, and the energy-saving and environment-friendly effects are realized.

Owner:扬州安泰威合金硬面科技有限公司

Method and apparatus for efficiently purifying silicon material after medium smelting

ActiveCN109110766AEfficient smeltingIncrease production energy consumptionChemical industrySilicon compoundsCrucibleImpurity

The invention relates to the field of production of solar-grade polycrystalline silicon, in particular to a method and an apparatus for efficiently purifying a silicon material after the medium smelting. A structure of a smelting crucible of the apparatus is arranged in a manner that the rear end inclines towards a liquid guiding opening; a plurality of compartments are provided in the smelting crucible, an inner groove of each compartment corresponds to one smelting groove, and each smelting groove corresponds to the liquid guide opening; and when in use, the electron beam smelting energy distribution mode corresponding to the structure of the smelting crucible is gradually reduced from the rear end to the liquid guide opening. By selecting the electron beam smelting energy distribution mode and selecting a multi-mode smelting crucible structure, the silicon carbide and volatile impurity element in the silicon material after the medium smelting can be eliminated, the cost is low, andthe effect is good.

Owner:QINGDAO BLUE LIGHT NEW MATERIAL CO LTD

Smelting metal furnace convenient to cool and clean

ActiveCN106839767ASimple structureEasy to useCrucible furnacesFurnace coolingWater storage tankHot melt

The invention discloses a smelting metal furnace convenient to cool and clean. The smelting metal furnace comprises a furnace body, one side of the furnace body is connected with a first water pump through a water outlet pipe, a water outlet on one side of the first water pump is connected with a water storage tank, the upper end of one side of the water storage tank is connected with an intermediate conversion water tank through a water pipe, the top of the intermediate conversion water tank is connected with a filter tank through a filter pipe, a water conveying tank is installed at the top of the filter tank, a water inlet at the top of the water conveying tank is connected with a second water pump, one side of the water conveying tank is connected with an inner cavity of the furnace body through a water conveying pipe, a heating plate is installed at the bottom of the inner cavity of the furnace body, a hot melting cylinder is installed at the top of the heating plate, and a ladle is installed at the top of the hot melting cylinder. According to the smelting metal furnace convenient to cool and clean, on the whole through the ladle arranged in the furnace body and the hot melting cylinder adaptive with the ladle, frequency movement of molten metal and filling of the molten metal are avoided, the smelting metal furnace is a circulation type washing water cooling device, and dirt and waste metal in the metal furnace can be cleaned.

Owner:广西埃索凯循环科技有限公司

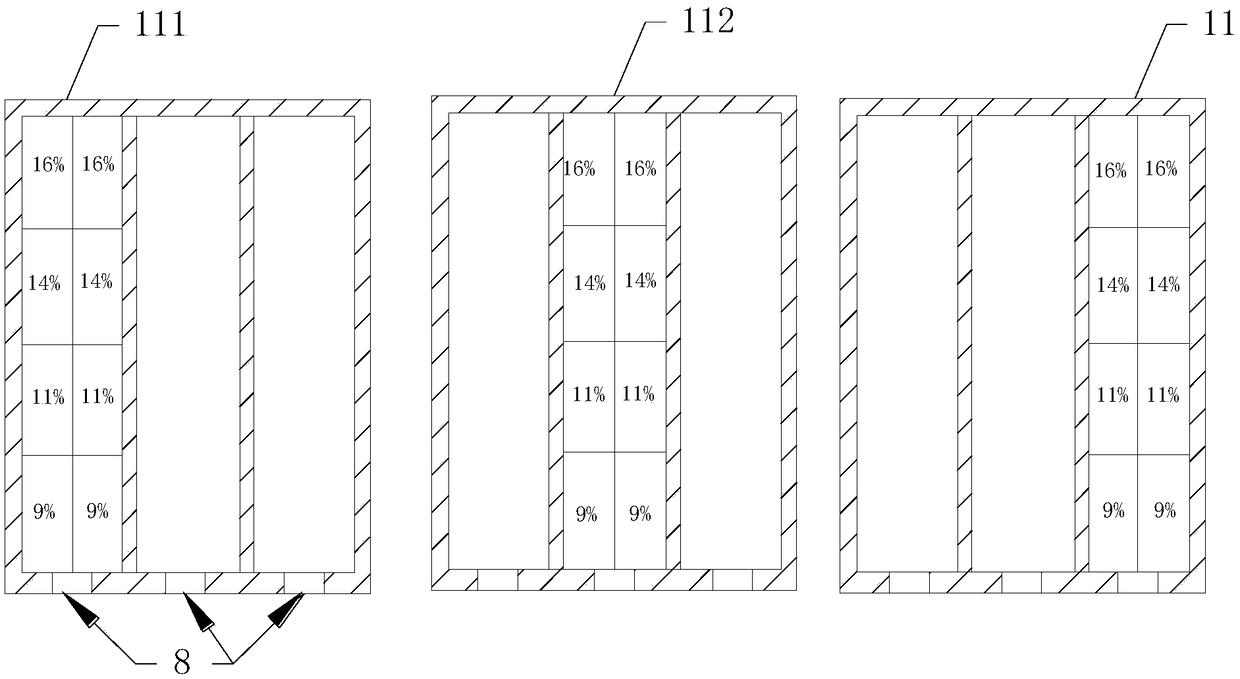

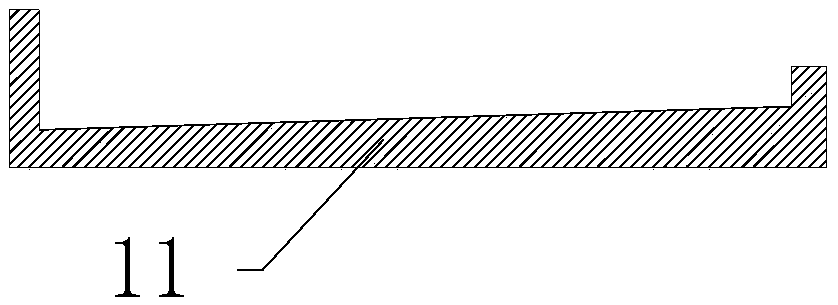

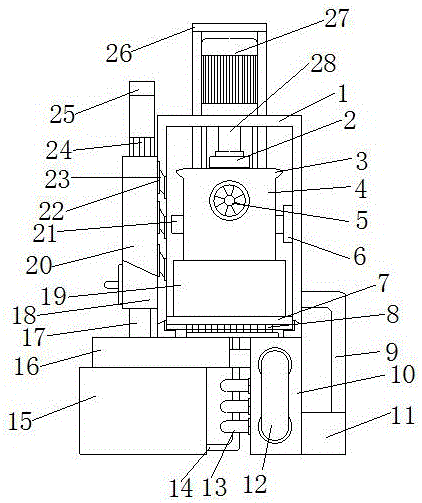

Zinc slag melting and liquating method and device

ActiveCN108677023AReduce consumptionReasonable layoutPhotography auxillary processesProcess efficiency improvementDistillationSlag

The invention discloses a zinc slag melting and liquating method and device. Zinc slag is thrown into a smelting furnace to be molten, a protective medium and aluminum are thrown into the smelting furnace, and the aluminum and the liquid zinc slag are fully mixed; the temperature is constant for a period of time, zinc liquid on the bottom layer and floating slag on the upper layer are fully separated through a slagging-off mechanism, and the zinc liquid is discharged to an ingot casting device to be cooled to form a zinc ingot; and the floating slag is fed to be dissolved and subjected to ironremoval and then is fed into an electrolytic cell to be electrolyzed or is directly fed into the electrolytic cell to be electrolyzed, the iron in the floating slag is dissolved in a dissolving tank,deposits and is dried and then is directly used for iron making, a solution inside the dissolving tank is conveyed into the electrolytic cell, zinc generated after electrolysis returns to the smelting furnace after being washed and dried, waste acid in the electrolytic cell can be conveyed into the dissolving tank to be used, and aluminum in the electrolyte is separated by distillation and crystallization or the simple aluminum is obtained in a molten salt electrolysis mode and then is added into the smelting furnace. The method provided by the invention can reduce the raw materials, energy consumption and the investment on the premise of meeting the product requirements.

Owner:武汉扬光实业有限公司资源循环科技分公司

Electric arc furnace and furnace cover thereof

PendingCN110701912AImprove smelting effectReduce energy consumptionFurnace componentsElectric arc furnaceEngineering

The invention relates to an electric arc furnace and a furnace cover thereof. The furnace cover comprises a fixed cover body and a movable cover body, wherein the movable cover body is provided with at least one electrode penetrating an installation position, and the fixed cover body is provided with an electrode rotation driving mechanism for driving the movable cover body to rotate around the axis of the movable cover body. According to the electric arc furnace and the furnace cover thereof, the furnace cover is decomposed into the fixed cover body and the movable cover body, and the movablecover body can rotate relative to the fixed cover body, so that the movable cover body can drive the electrodes to rotate together, the temperature distribution of a furnace hearth in the electric arc furnace can be effectively improved, the temperature in the furnace is more uniform, the smelting effect of the electric arc furnace is improved, and the energy consumption is saved; based on the furnace cover with the split structure, due to the fact that the movable cover body rotates, the movable cover body is easy to drive, the energy consumption is low, and the rotation stability and precision are easy to control; and in addition, rotary driving equipment can be arranged on the fixed cover body and does not need to occupy extra space, so that the device arrangement structure is compact.

Owner:WISDRI ENG & RES INC LTD

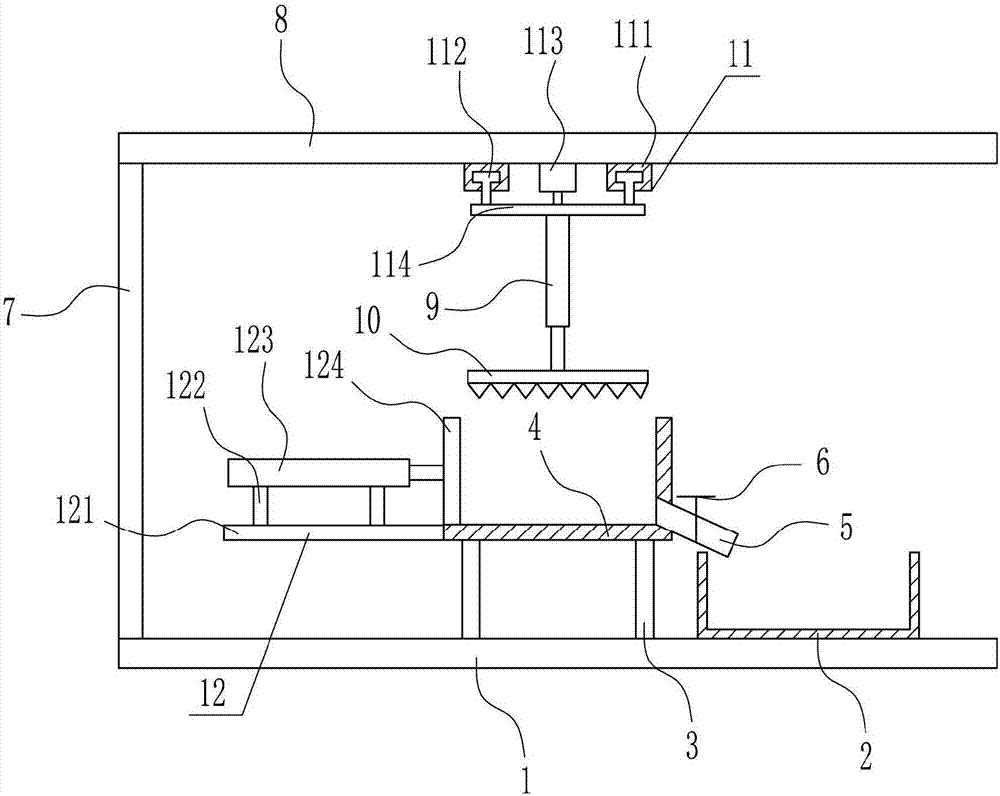

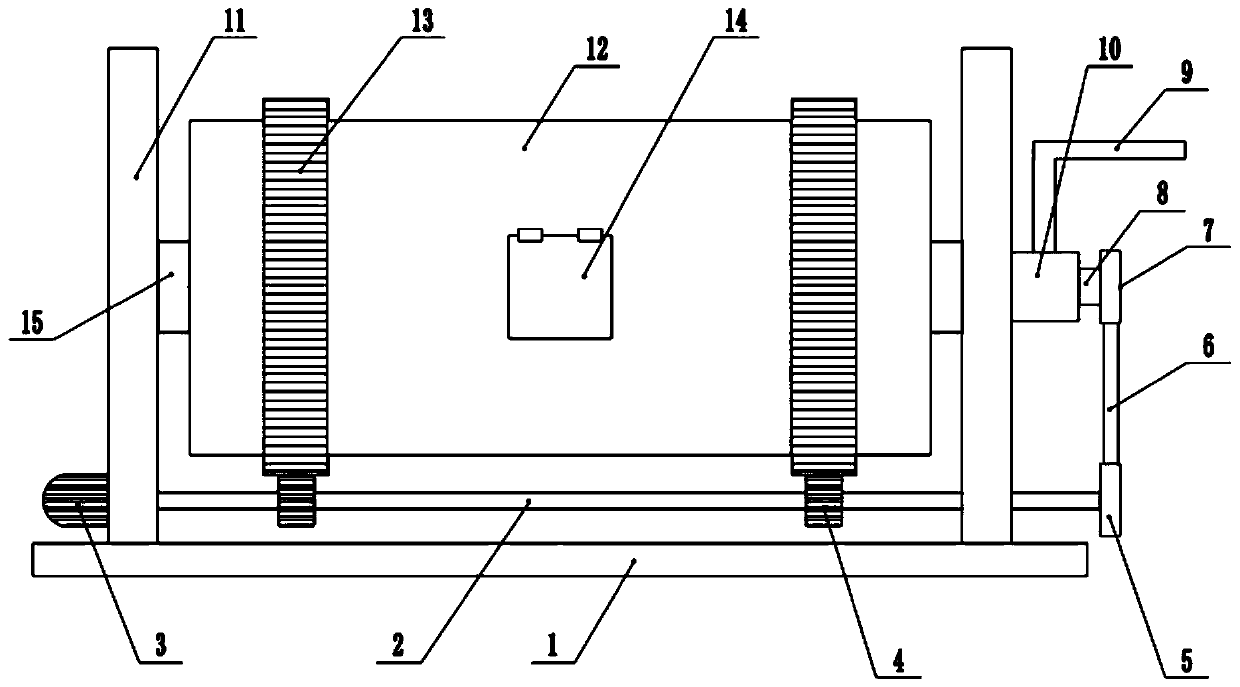

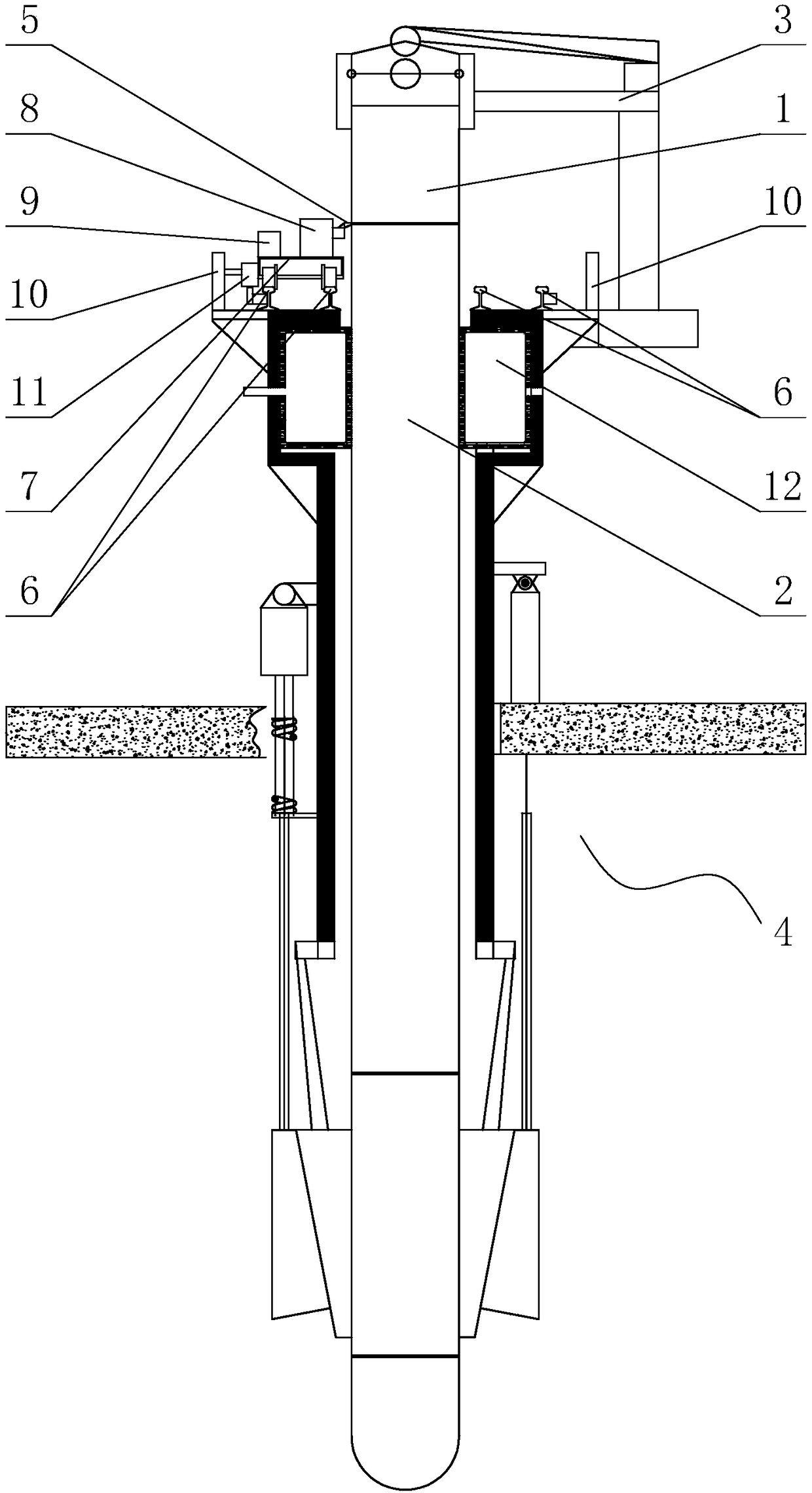

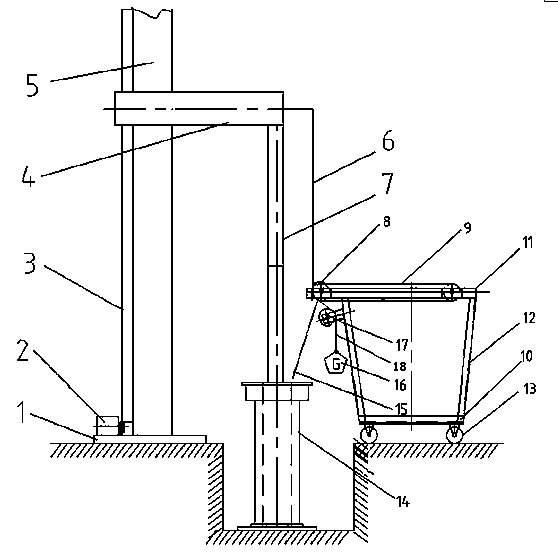

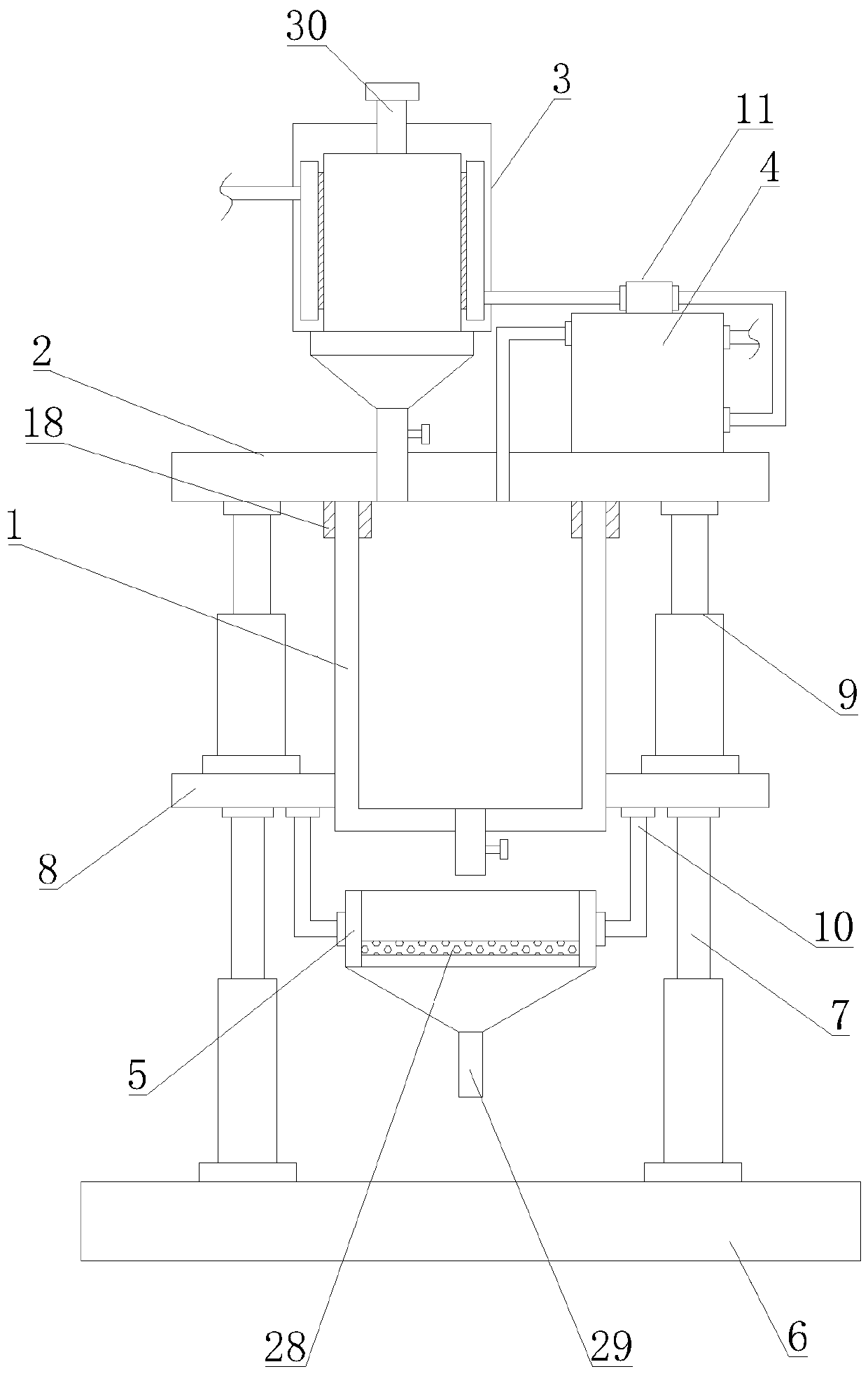

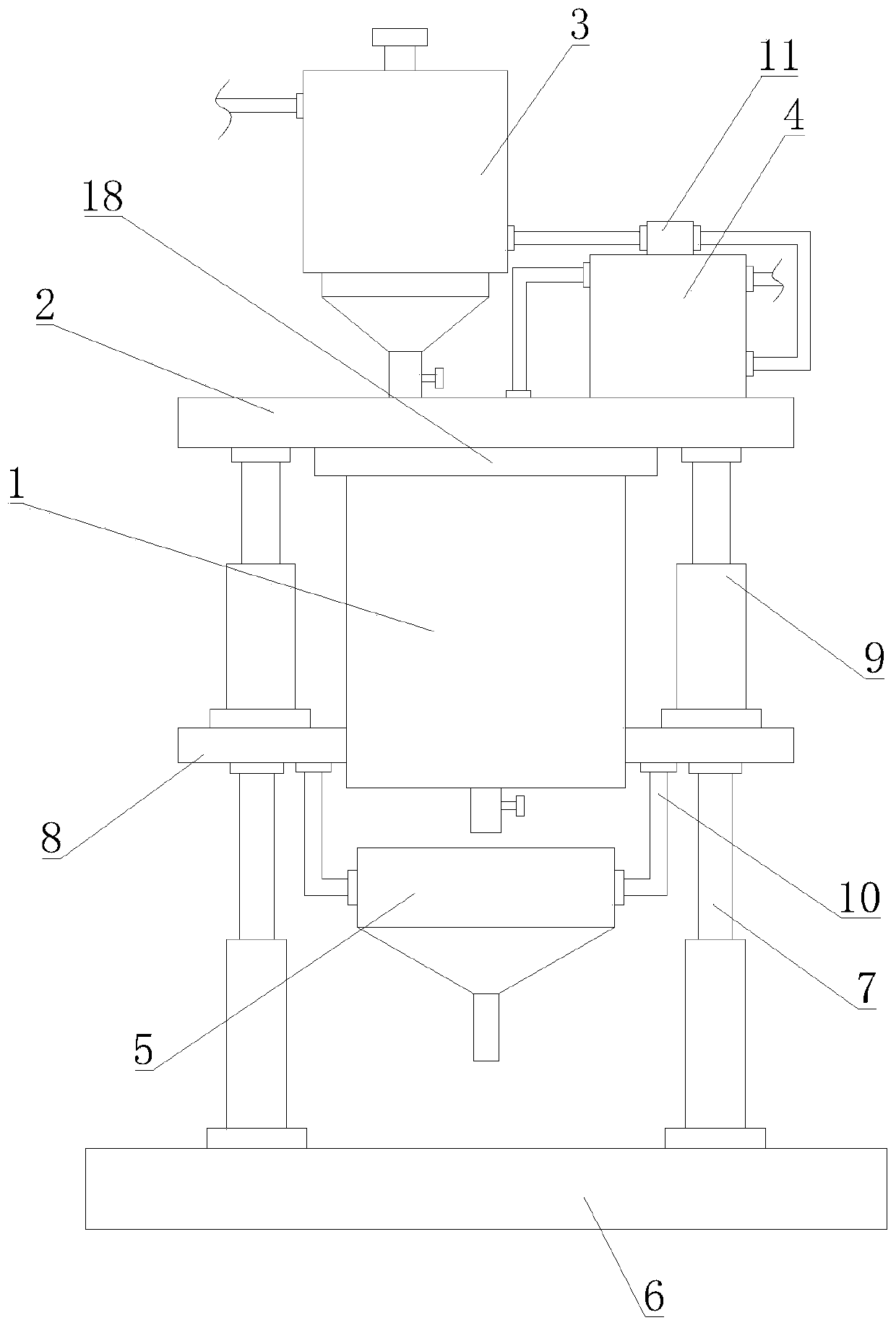

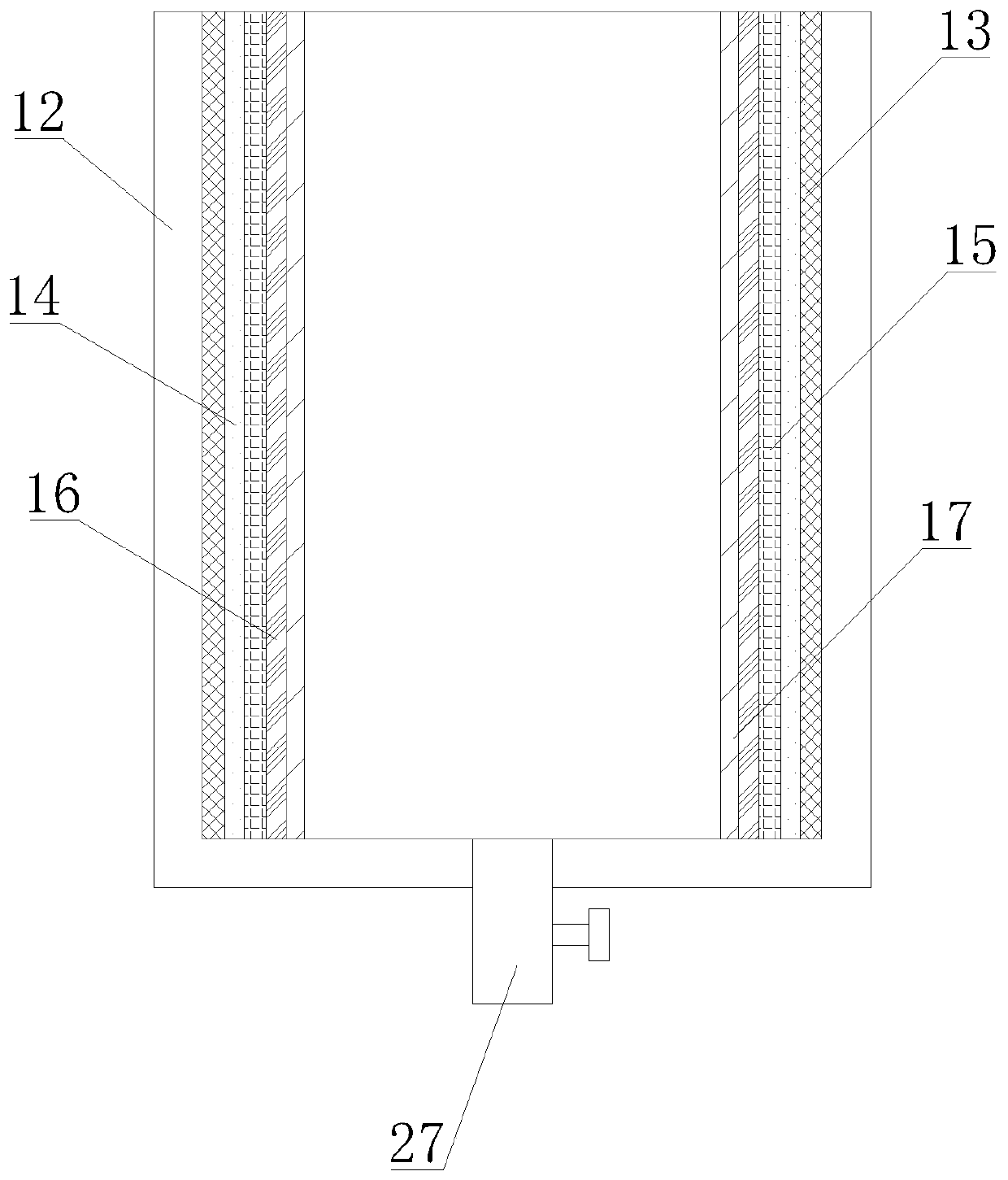

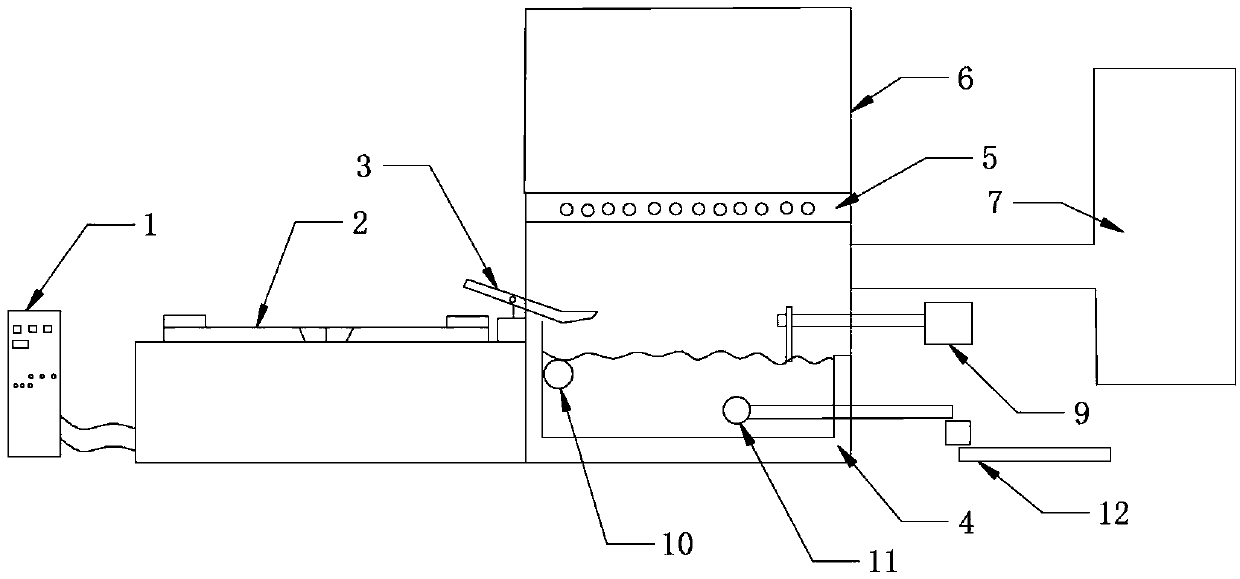

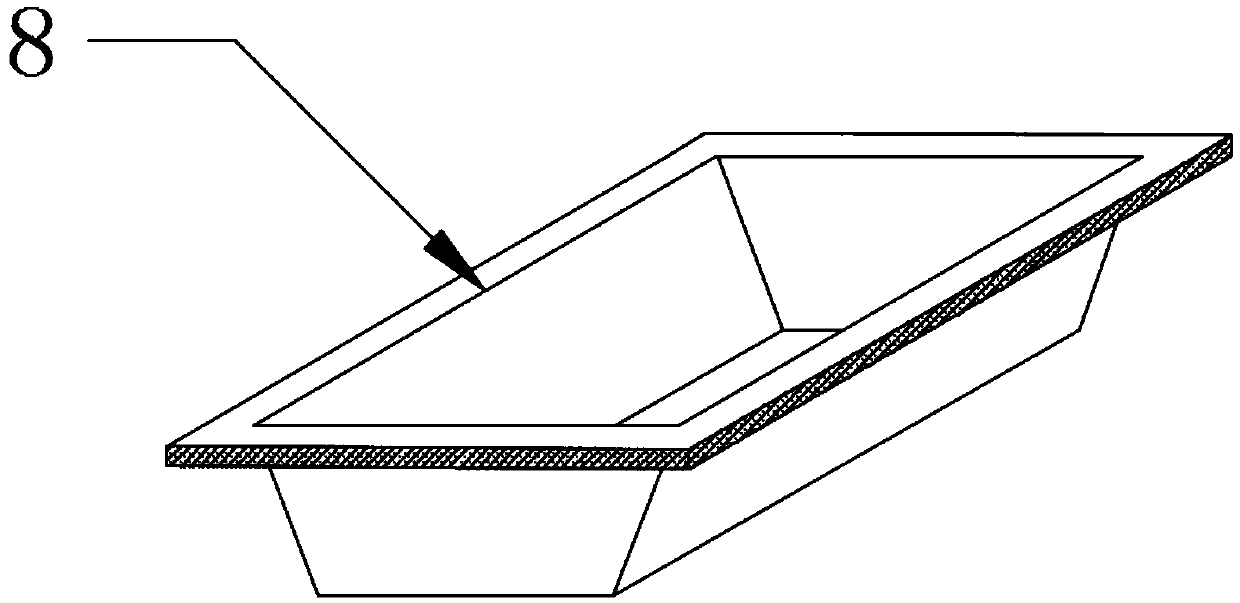

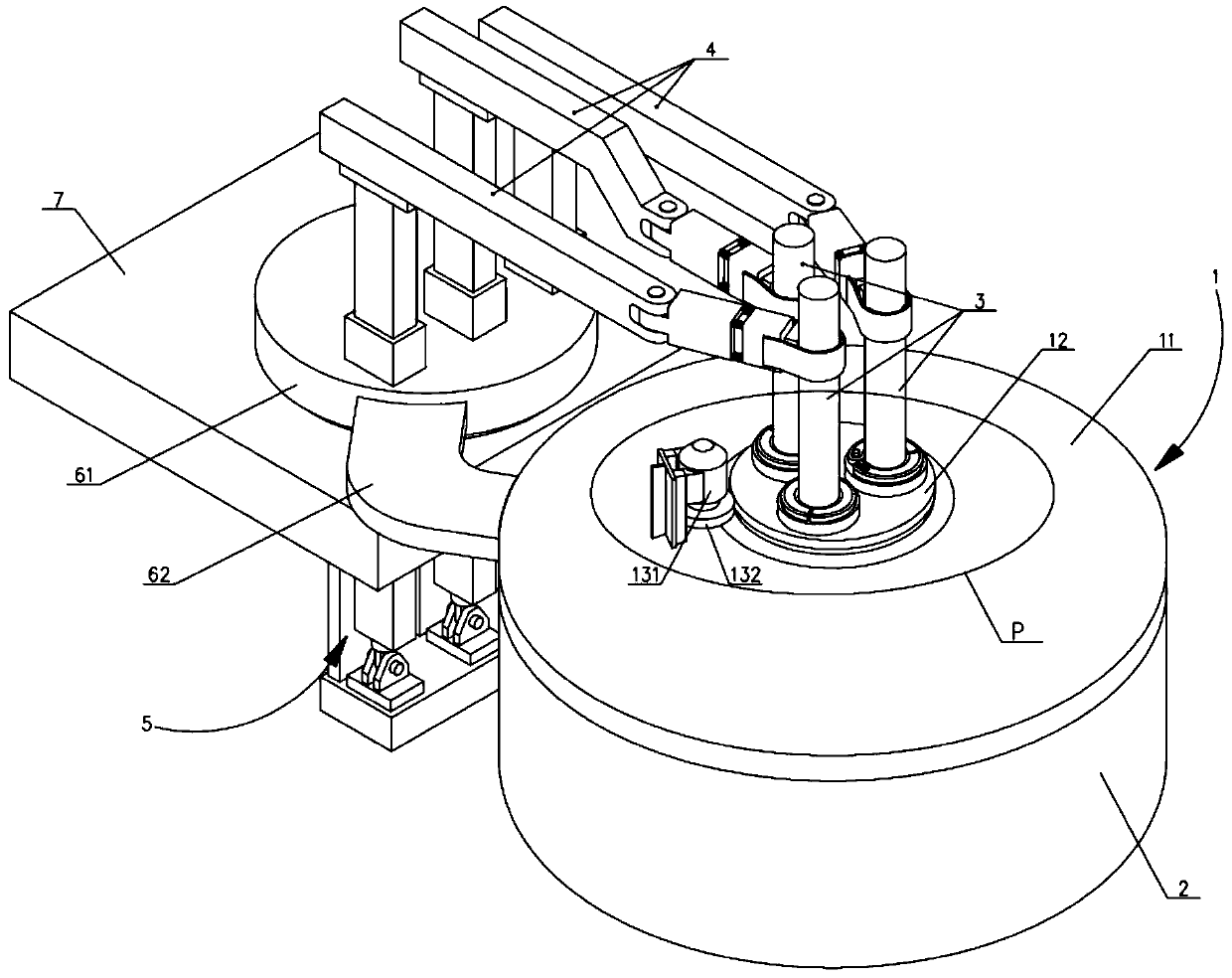

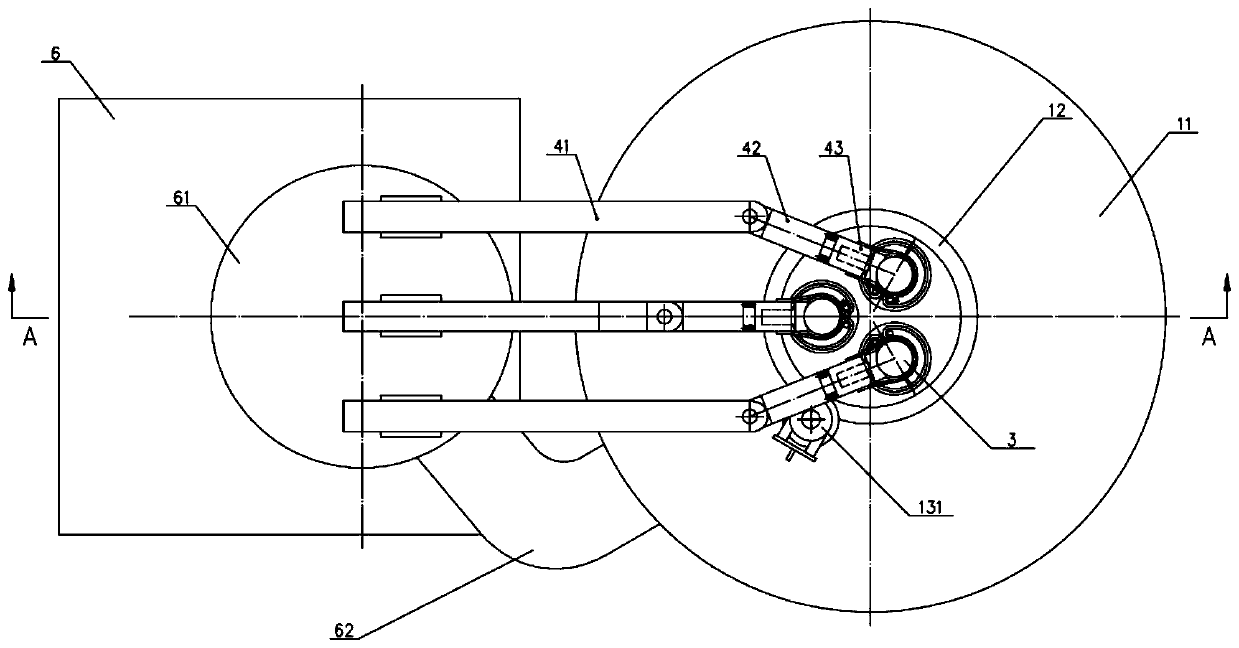

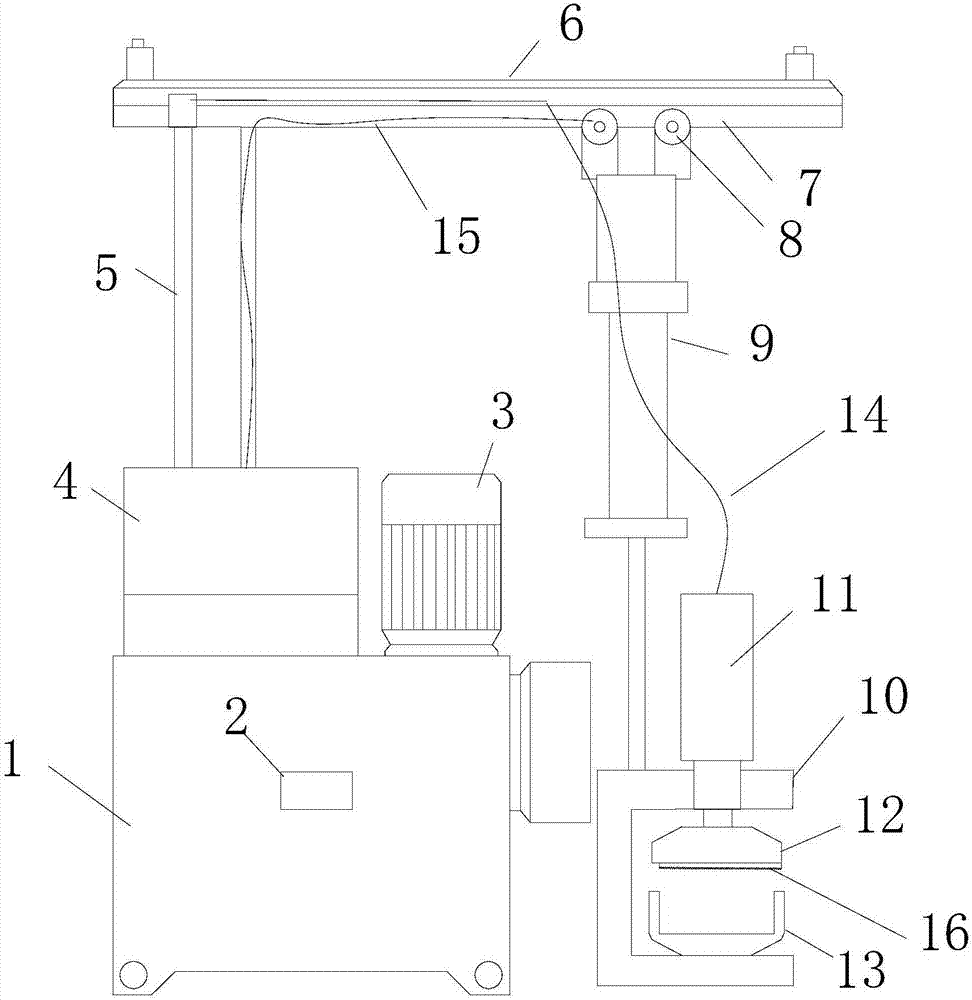

Casting smelting raw material transportation pulverizer

ActiveCN105728095BImprove smelting effectImprove work efficiencyGrain treatmentsFuel tankEngineering

The invention discloses a casting smelting raw material transporting and pulverizing machine. The casting smelting raw material transporting and pulverizing machine comprises an oil tank (1), wherein an oil pump (2) is arranged inside the oil tank (1) and is connected with a driving motor (3); an electric control box (4) is arranged on the oil tank (1); an upright column (5) is arranged on the electric control box (4); a cross beam (6) is arranged on the upright column (5); a sliding rail (7) is arranged on the cross beam (6); travelling wheels (8) are arranged on the sliding rail (7); the lower parts of the travelling wheels (8) are connected with a cantilever (9); a C-shaped transport block (10) is arranged below the cantilever (9); a hydraulic cylinder (11) is arranged on the transport block (10); a pulverizing block (12) is arranged at the push rod end of the hydraulic cylinder (11) and in the transport block; a pulverizing trough (13) is arranged below the pulverizing block (12); the oil pump (2) is connected with the hydraulic cylinder (11) by an oil circuit (14); the electric control box (4) is connected with the travelling wheels (8) by an electric circuit (15). The casting smelting raw material transporting and pulverizing machine can pulverize metal raw materials while transporting the metal raw materials, thus not only improving the work efficiency but also improving the casting smelting effects.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

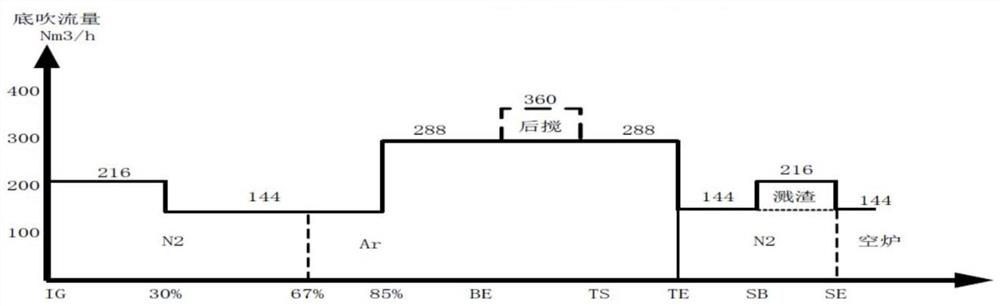

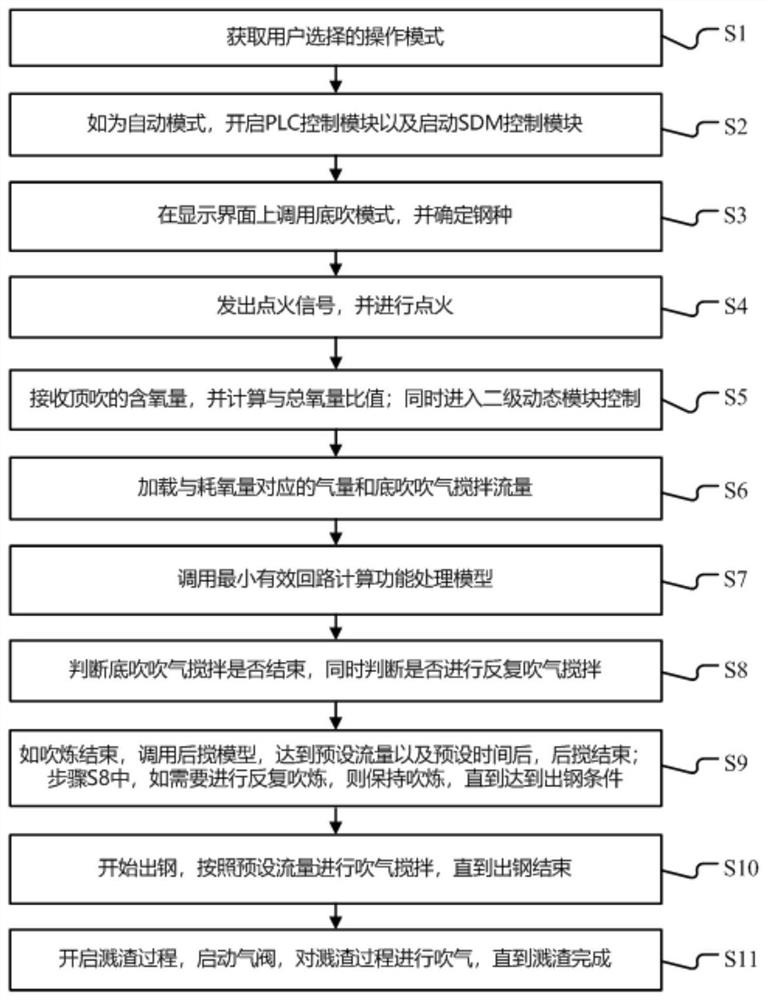

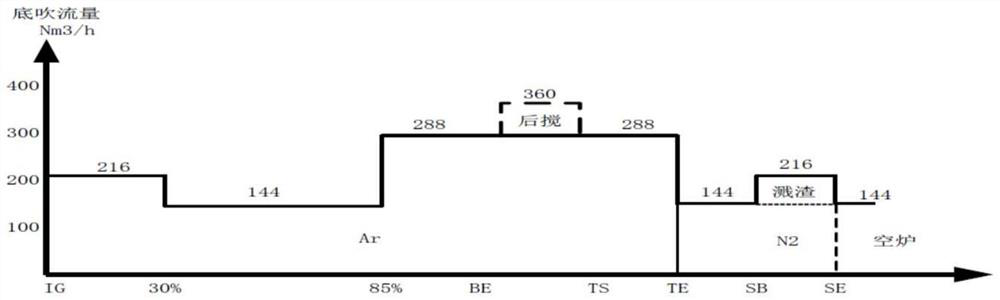

Intelligent control method for bottom blowing of converter

InactiveCN112725557AGuaranteed uptimeHigh degree of automationSteel manufacturing process aspectsIncreasing energy efficiencySteelmakingControl manner

The invention provides an intelligent control method for bottom blowing of a converter. The bottom blowing in the method comprises the following steps of: preparing for deslagging, blowing at the earlier stage, blowing at the later stage, waiting for sampling, reblowing, tapping and protecting the converter by splashing slag according to the process sequence. By analyzing a bottom blowing control system of the converter, the intelligent control of the bottom blowing of the converter is realized, and the complexity of the operation of smelting, slag splashing, empty converter, post-stirring and other links in the steelmaking production process of the converter and the disturbance caused by switching of control modes are overcome. The intelligent control method for the bottom blowing of the converter has stable operation and extremely high automation degree, and provides reliable basis and practical basis for realizing high-quality steel and full-automatic steelmaking control. The method meets the requirements of steelmaking production of different steel types and different smelting modes; and compared with the prior art, the method achieves good smelting effects of homogenizing the temperature and components of molten steel, accelerating thermal chemical reaction, removing inclusions and the like, can accurately control the flow of nitrogen and argon, and greatly reduces the steelmaking cost.

Owner:济南工程职业技术学院

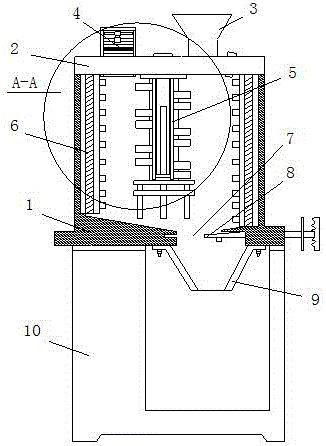

Smelting device

ActiveCN106802081AImprove stabilityImprove securityStirring devicesCharge manipulationSmelting processEngineering

The invention discloses a smelting device. The smelting device comprises a smelting box. An auxiliary heating mechanism is arranged on the inner wall of the smelting box. A sealing cover is arranged at the top of the smelting box. The bottom of an inner cavity of the sealing cover is connected with a main heating mechanism located in an inner cavity of the smelting box. A stirring flow device is arranged in the inner cavity of the smelting box. A stability augmentation device is arranged on the outer surface of the smelting box. A base platform is arranged at the bottom of the smelting box. A motor is arranged inside a sound absorption tank located at one side of the top of the base platform. By the adoption of the smelting device, warming can be achieved quickly, and the warming efficiency is improved; objects like smelted metal can be rotated and stirred in the smelting process, the smelting effect is improved, stability of the smelting device can be greatly improved, the shaking phenomenon happening in the using process of the smelting device is prevented, the phenomenon of abrasion and even collapse occurring in the using process of the smelting device is avoided, and the using safety coefficient of the smelting device is increased to a great extent.

Owner:丽水市正明机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com