Metal electroslag remelting smelting atmosphere protection method

An electroslag remelting and metal technology, which is applied in the field of metal smelting, can solve the problems of large space between the gas nozzle and molten metal, difficulty in protecting the effect, and difficulty in exhausting the air, so as to achieve stable and reliable operation, improve the smelting effect, and implement simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in combination with specific embodiments.

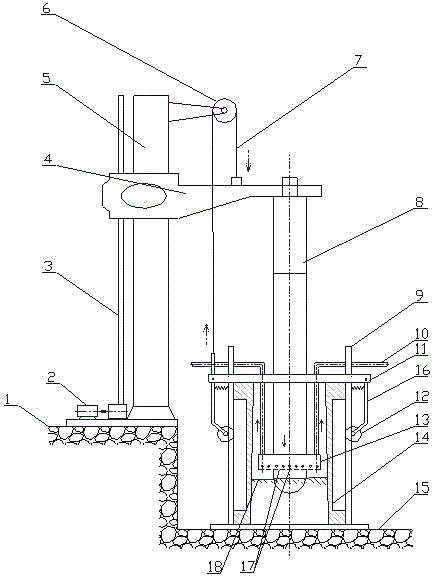

[0027] A metal electroslag remelting smelting atmosphere protection method, the method is that in the metal electroslag remelting smelting device, a protector is provided to connect with an inert gas source, and the metal electroslag remelting is smelted through the protector during the smelting process The inside of the device sprays inert gas for atmosphere protection. The key point is that the protector is placed near the top of the metal electroslag remelting liquid during smelting, and it is linked with the electrode rod so that the liquid level rises when the electrode rod gradually descends. At this time, the protector and the liquid level rise in linkage, and make the protector and the liquid level within a fixed height range, so as to ensure the atmosphere protection effect of the liquid level.

[0028] More specifically, when the present invention is imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com