Patents

Literature

67results about How to "Improve smelting quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

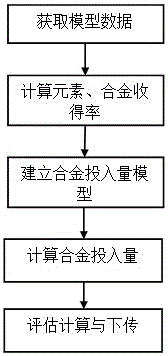

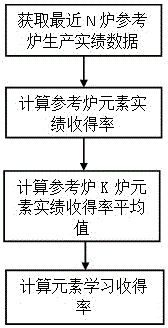

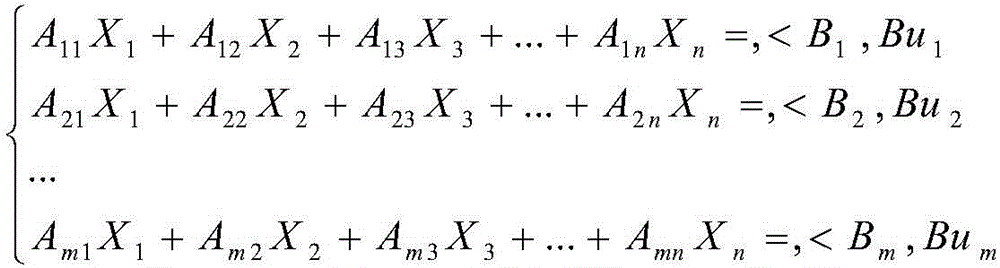

Control method for input amount of alloys in steelmaking

ActiveCN107179703AImprove smelting qualityEasy to controlSimulator controlIncreasing energy efficiencyControl systemSmelting

The invention relates to the production and control fields in the metallurgy process, and especially to a control method for the input amount of different types of alloy in steelmaking. Standard yielding rates of different elements and target tapping components are set according to a smelting technology, and molten steel is selected as reference furnaces; production actual-performance data of the reference furnaces is used to calculate learning yield rates of the alloys; and an alloy input amount model is established, and the alloy input amounts are calculated according to the learning yield rates and used to control an alloy feeding operation of a bunker control system. According to the control method, the learning yield rates of the elements are obtained by selecting the reference furnaces and converted into an integrated alloy yielding rate, the alloy cost is optimized, a linear programming manner is used to determine the alloy input amount in a steelmaking area, components of the molten steel are controlled accurately, the alloy cost is reduced, and the smelting quality of the molten steel is improved by avoiding alloy with harmful elements.

Owner:BAOSHAN IRON & STEEL CO LTD

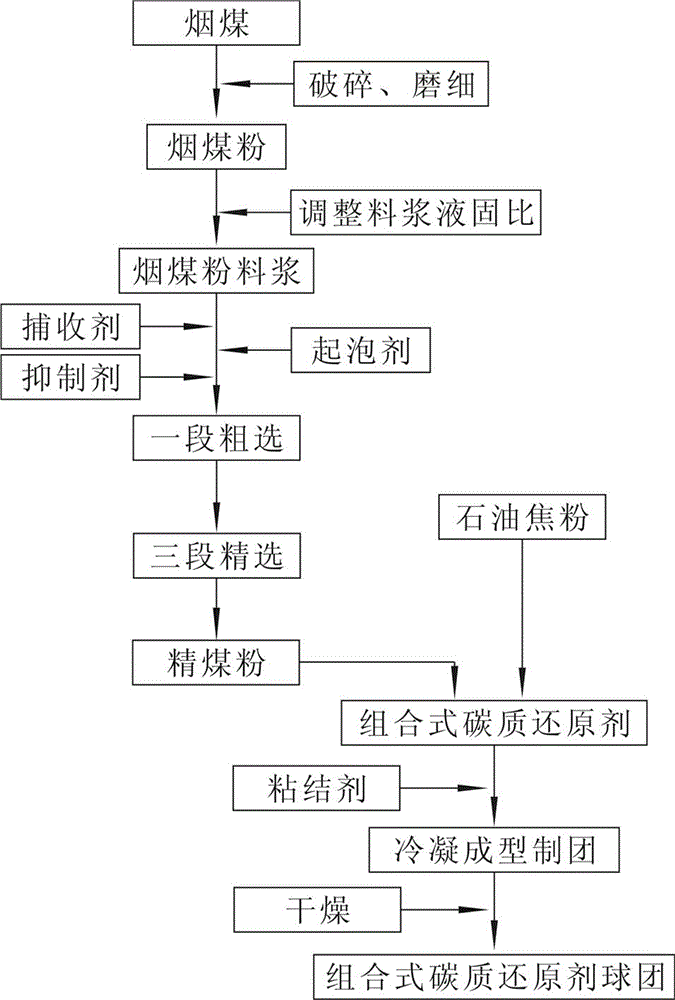

Combined carbonaceous reducing agent for smelting metal silicon and preparation method thereof

ActiveCN102976330AMeet physical and chemical performance requirementsPoor improvementSilicon compoundsPetroleumPetroleum coke

The invention discloses a combined carbonaceous reducing agent for smelting metal silicon and a preparation method thereof. The combined carbonaceous reducing agent comprises refined pulverized coal and petroleum coke powder, wherein the refined pulverized coal accounts for 70-80% of the total weight; the refined pulverized coal is prepared from the raw material soft coal by oil agglomeration selective flocculation de-ashing treatment; the refined pulverized coal contains 75-80% of fixed carbon, 3.5-4.5% of ash content and 16-21% of volatile content by weight; and 2-3% of binder is added into the mixture of the refined pulverized coal and the petroleum coke powder, and then a combined carbonaceous reducing agent pellet is prepared by cold press molding briquetting and drying treatment. According to the invention, the ash content and impurities in the soft coal are removed by a flotation method, the petroleum coke powder serves as supplement of the fixed carbon, and the two are combined to obtain a combined carbonaceous reducing agent with high content of fixed carbon, low ash content and low content of impurities. Through the invention, the problem that the reducing effect is unsatisfactory by using the soft coal only is solved, the smelting efficiency and the product quality are improved, and the added value of the soft coal is increased.

Owner:KUNMING METALLURGY INST

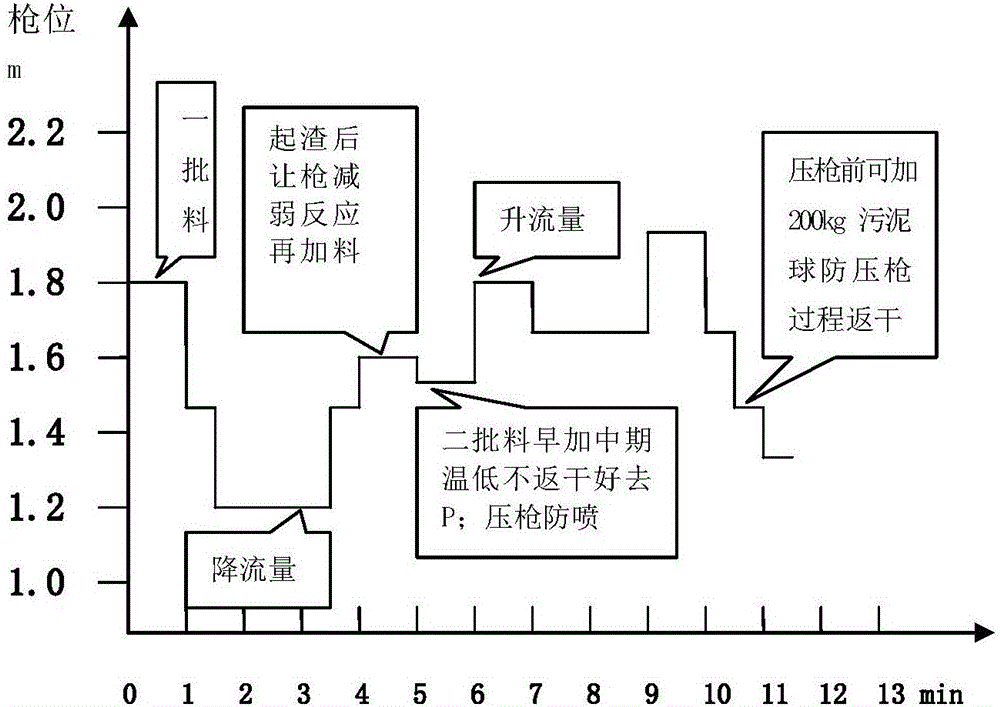

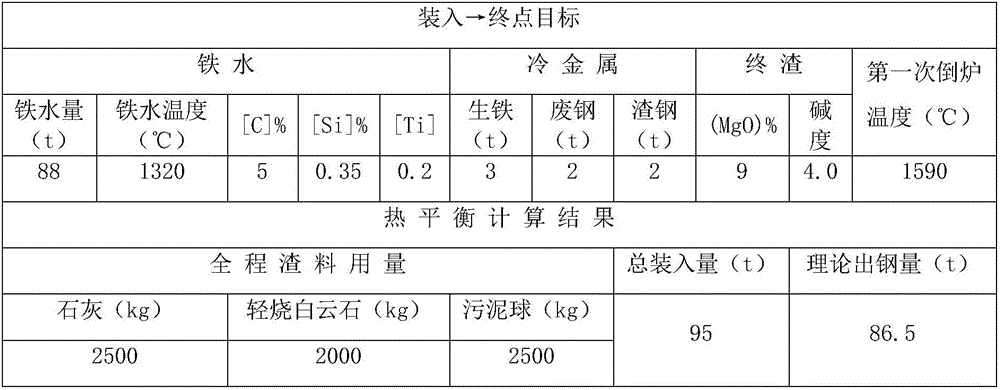

High-silicon molten iron smelting method

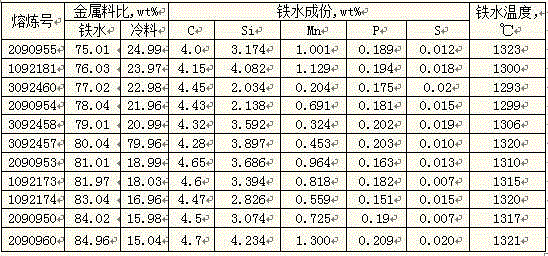

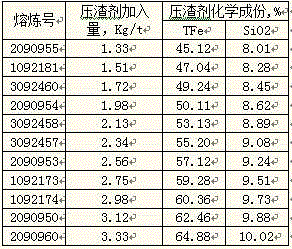

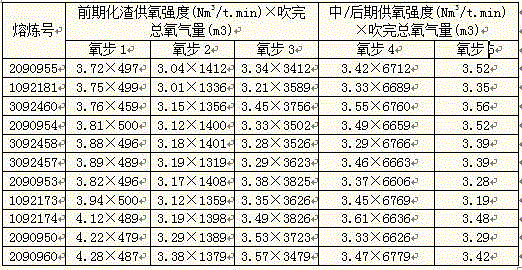

ActiveCN103060509AImprove smelting effectImprove smelting qualityManufacturing convertersAlkalinityOxygen

The invention discloses a high-silicon molten iron smelting method. The method comprises earlier-stage oxygen blast control, regulation and control of slagging material composition and alkalinity and deslagging stability, earlier-stage deslagging control, later-stage deslagging control and other regulation and control means, thereby implementing desilication smelting of high-silicon molten iron. By using high-silicon molten iron and light scrap steel as raw materials, the method disclosed by the invention controls the oxygen blast quantity in different stages to control the smelting slagging rhythm and effectively lower the silicon content of the smelted molten iron, thereby enhancing the smelting effect and smelting quality of the molten iron.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

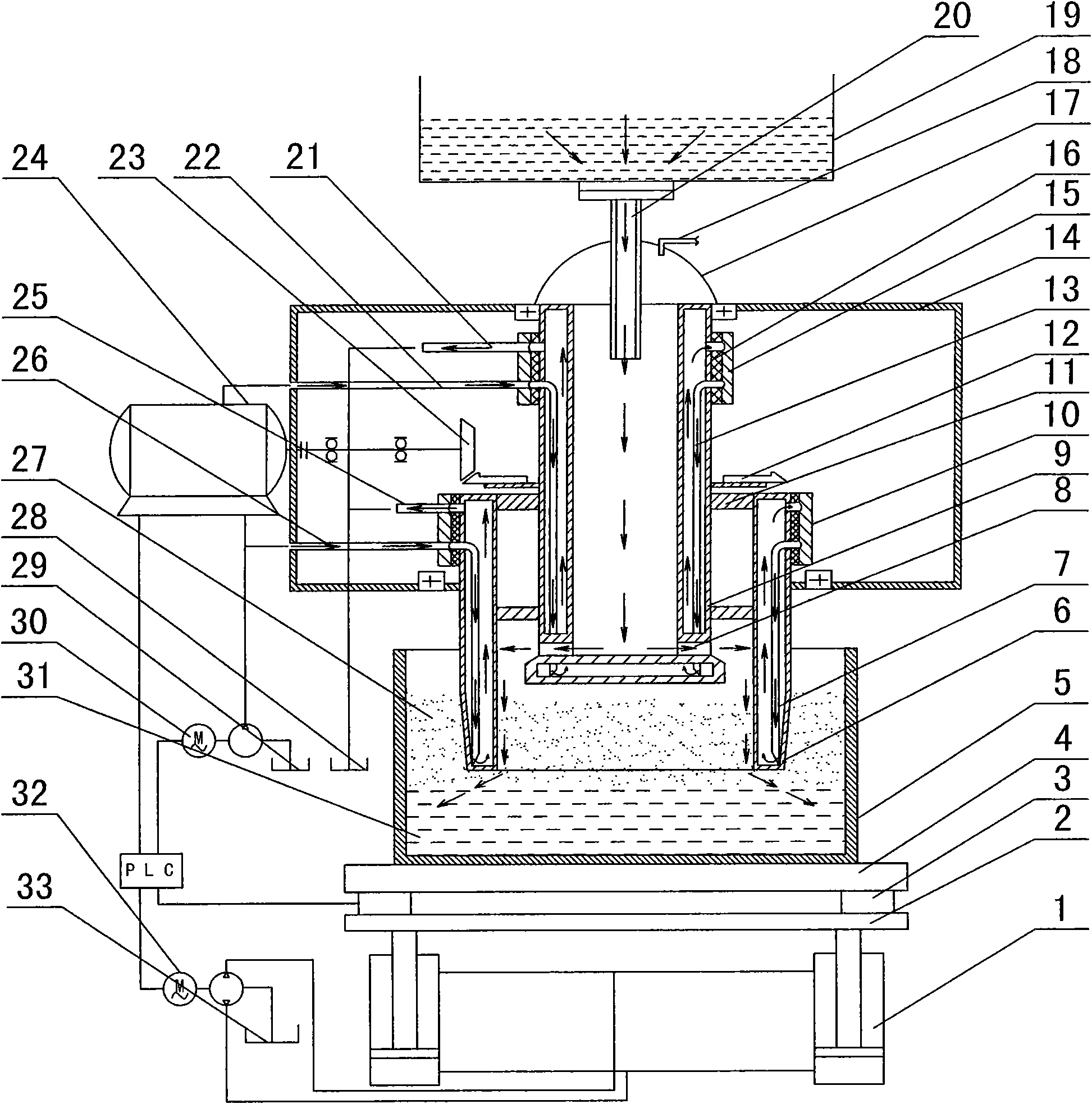

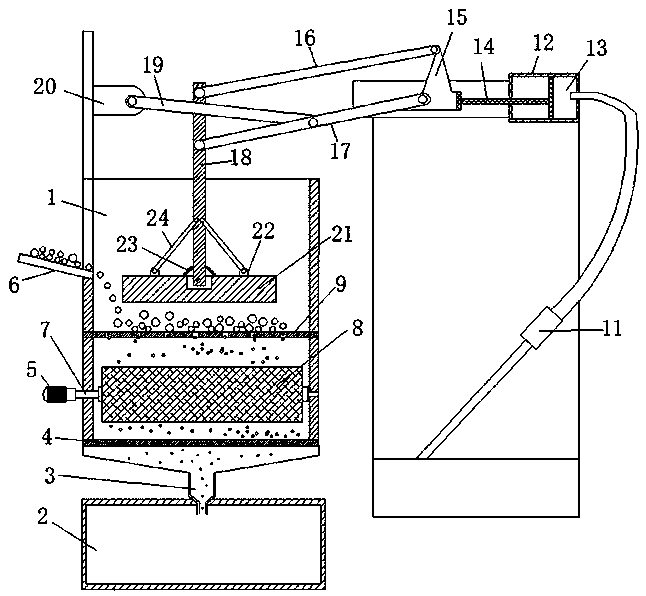

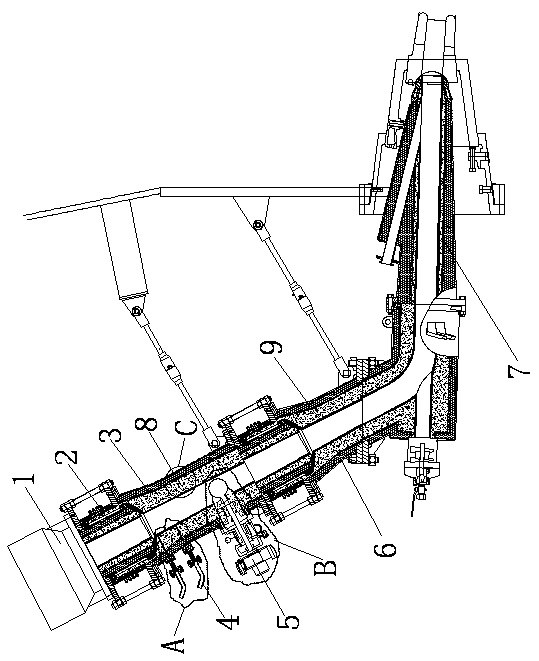

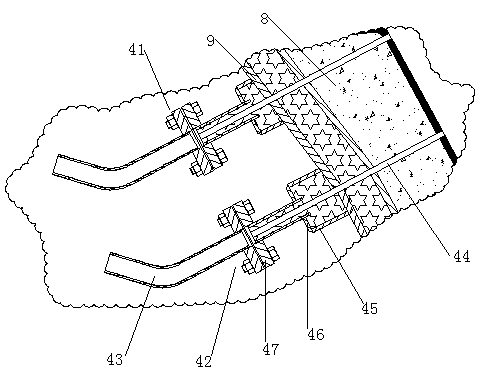

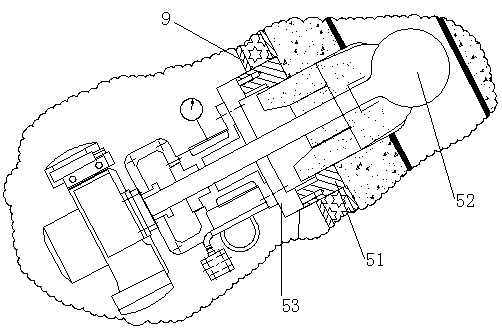

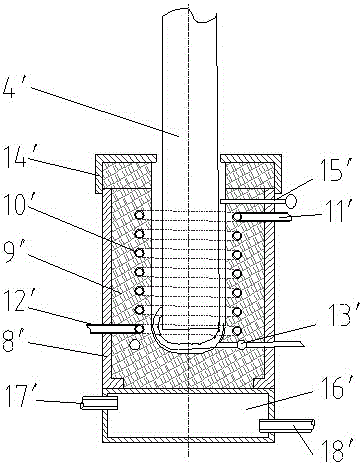

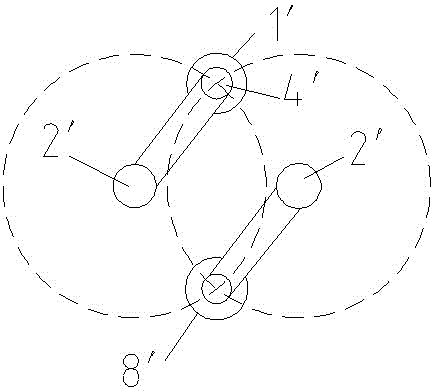

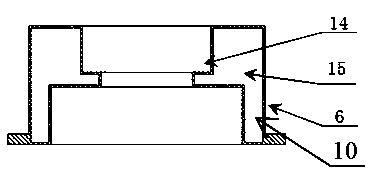

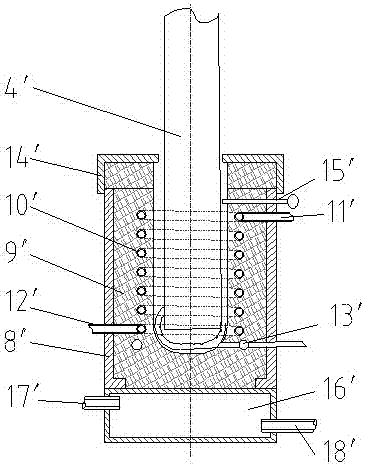

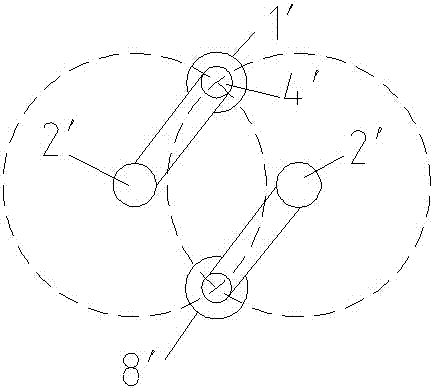

Equipment and method for removing nonmetallic slag inclusion in steel and iron smelting process

InactiveCN102091777ACan't solveSolve the adsorption problemCasting cleaning apparatusSmelting processCentrifugation

The invention discloses equipment for removing nonmetallic slag inclusion in a steel and iron smelting process. The equipment comprises a primary centrifugal barrel communicated with a tundish, and also comprises a box body, a secondary centrifugal barrel, a ladle and a hydraulic lifting device. A method for removing the nonmetallic slag inclusion by using the equipment comprises that: the nonmetallic slag inclusion is adsorbed through cleaning slag by two times of centrifuging and cleaned, and the passing cleaning slag is accumulated at the bottom of the ladle, so that high-cleanliness molten steel is obtained. Compared with the traditional technology, the equipment and the method overcome the defect that the slag inclusion of big granules cannot be timely adsorbed by the cleaning slag in a process of removing the nonmetallic slag inclusion in the electromagnetic driving centrifugal rotating tundish technology, improve the adsorption effect, and ensure high cleanliness of the centrifuged molten steel; and the nonmetallic slag inclusion is timely adsorbed by the cleaning slag in a two-stage centrifuging mode after the molten steel is subjected to two-time centrifugation, the working process is continuous, the centrifuging effect is good, the smelting efficiency and the quality of the high-cleanliness steel are greatly improved, and the production quantity of the high-cleanliness steel is improved.

Owner:冯顺新

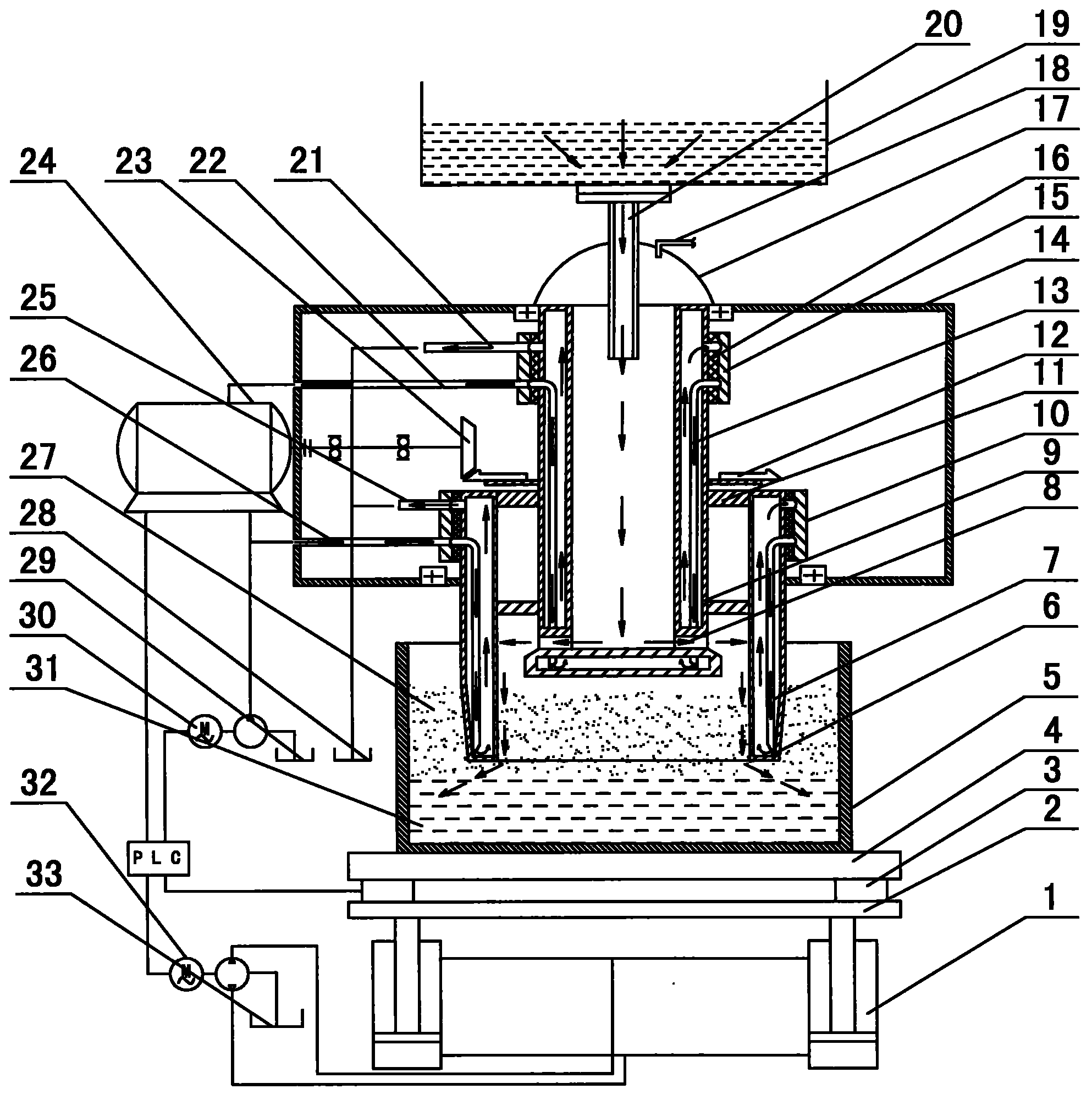

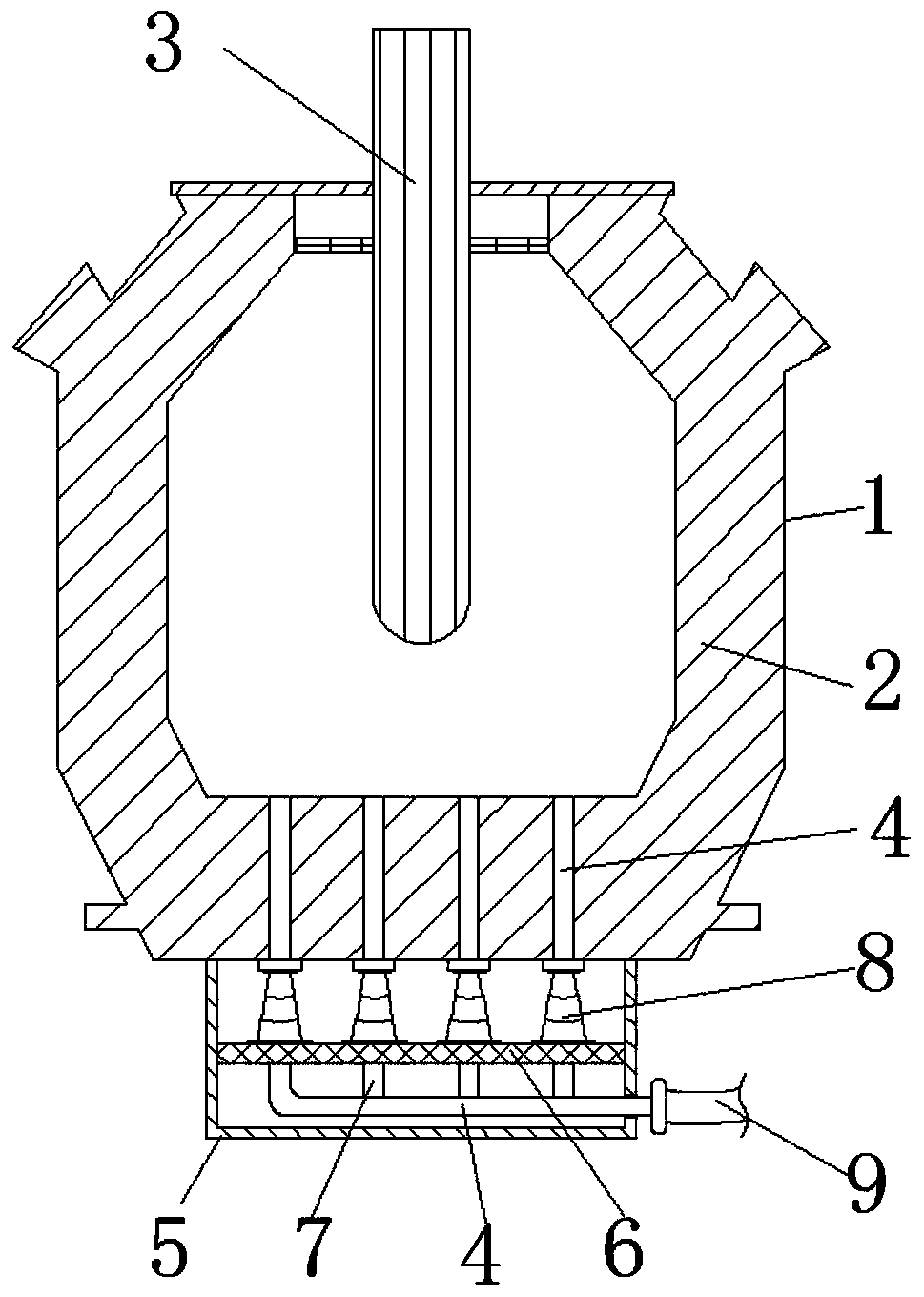

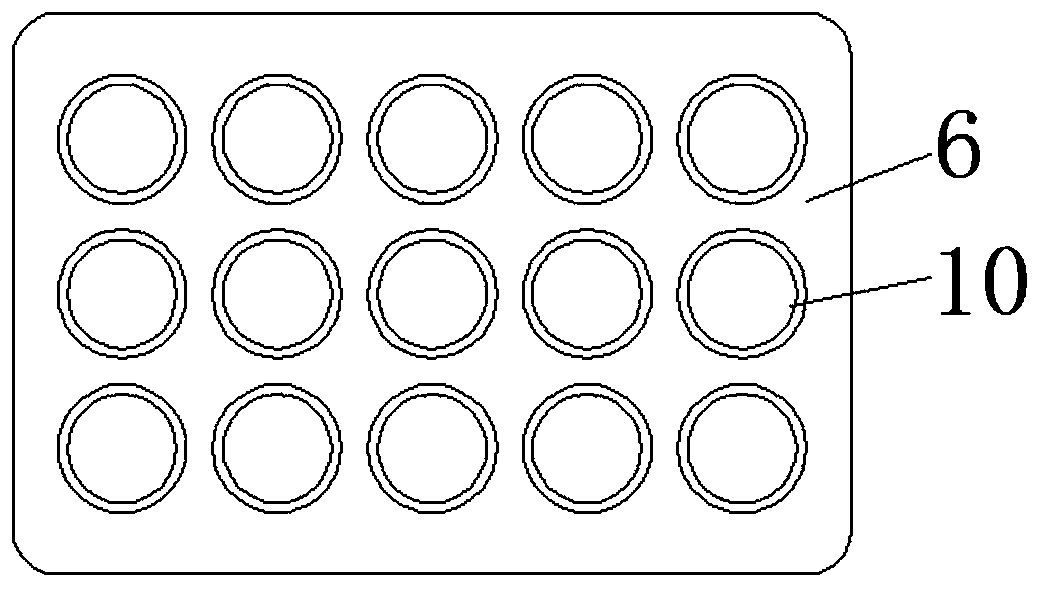

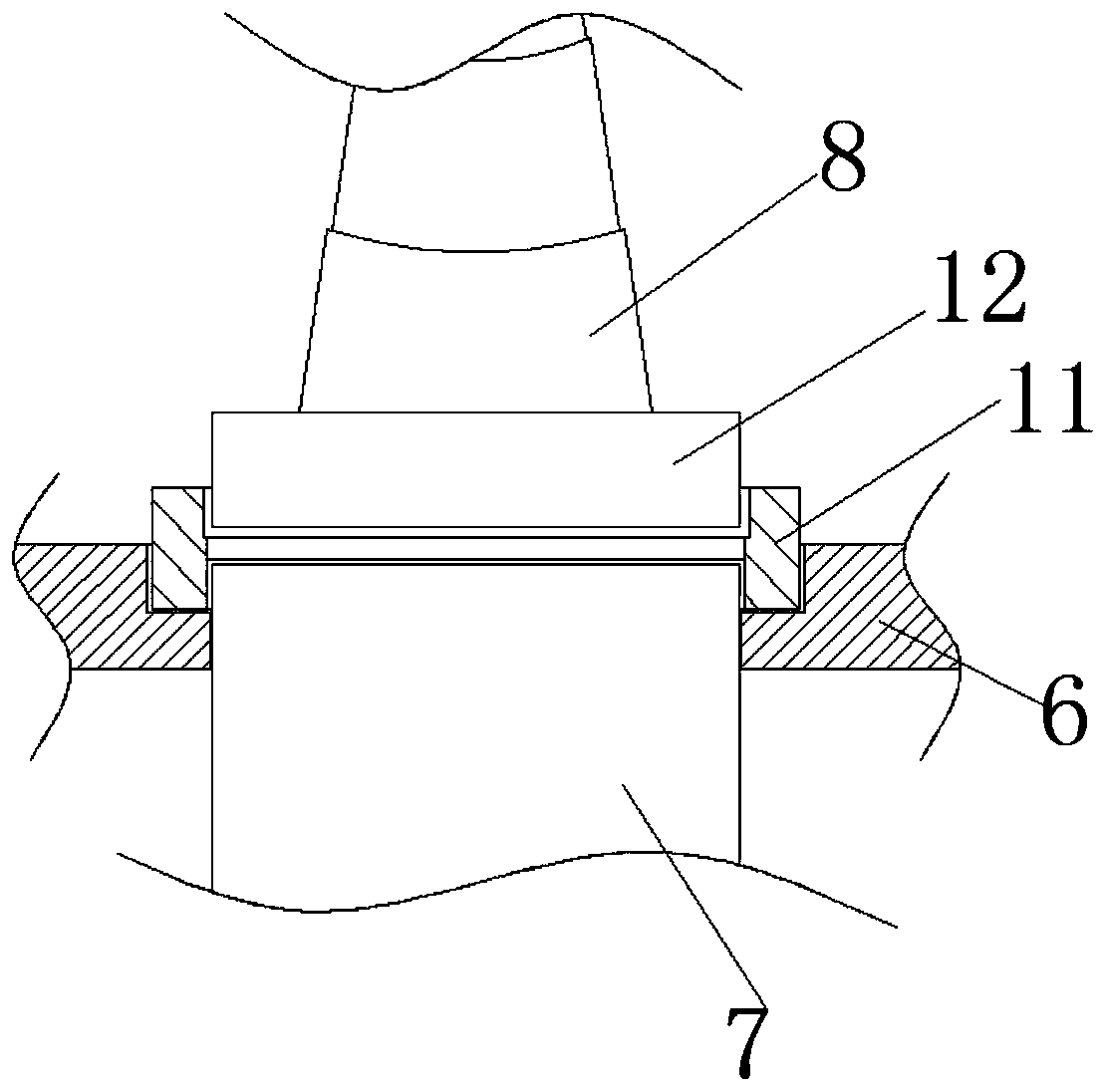

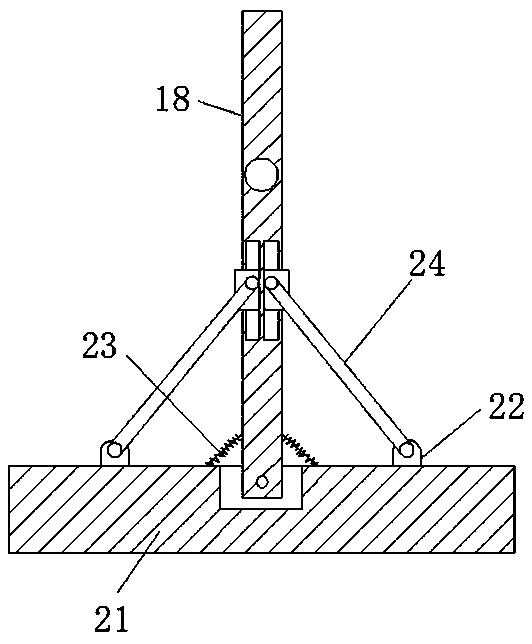

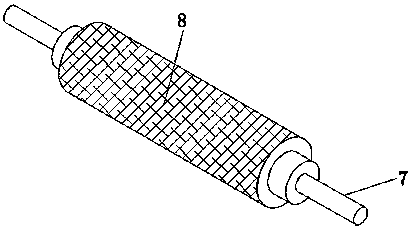

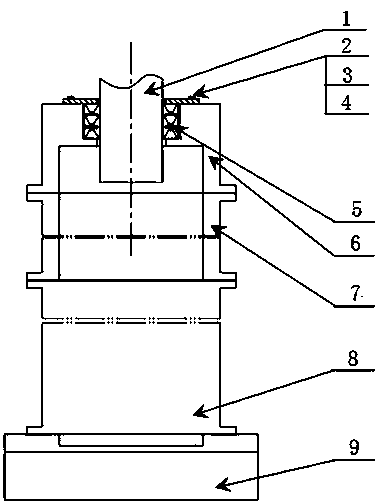

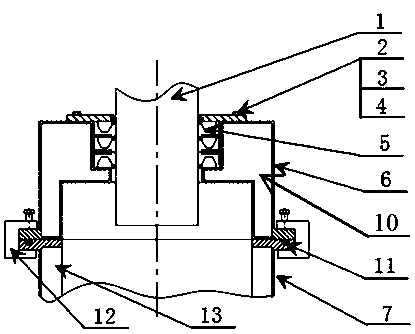

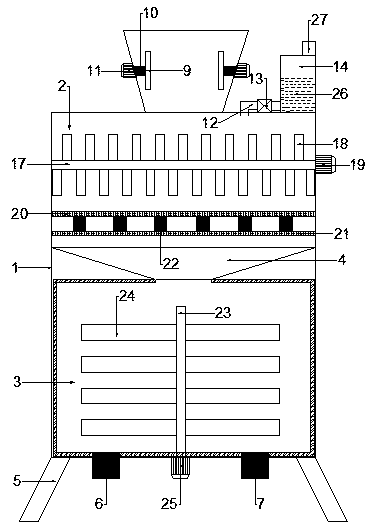

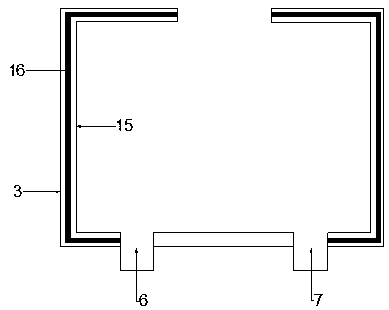

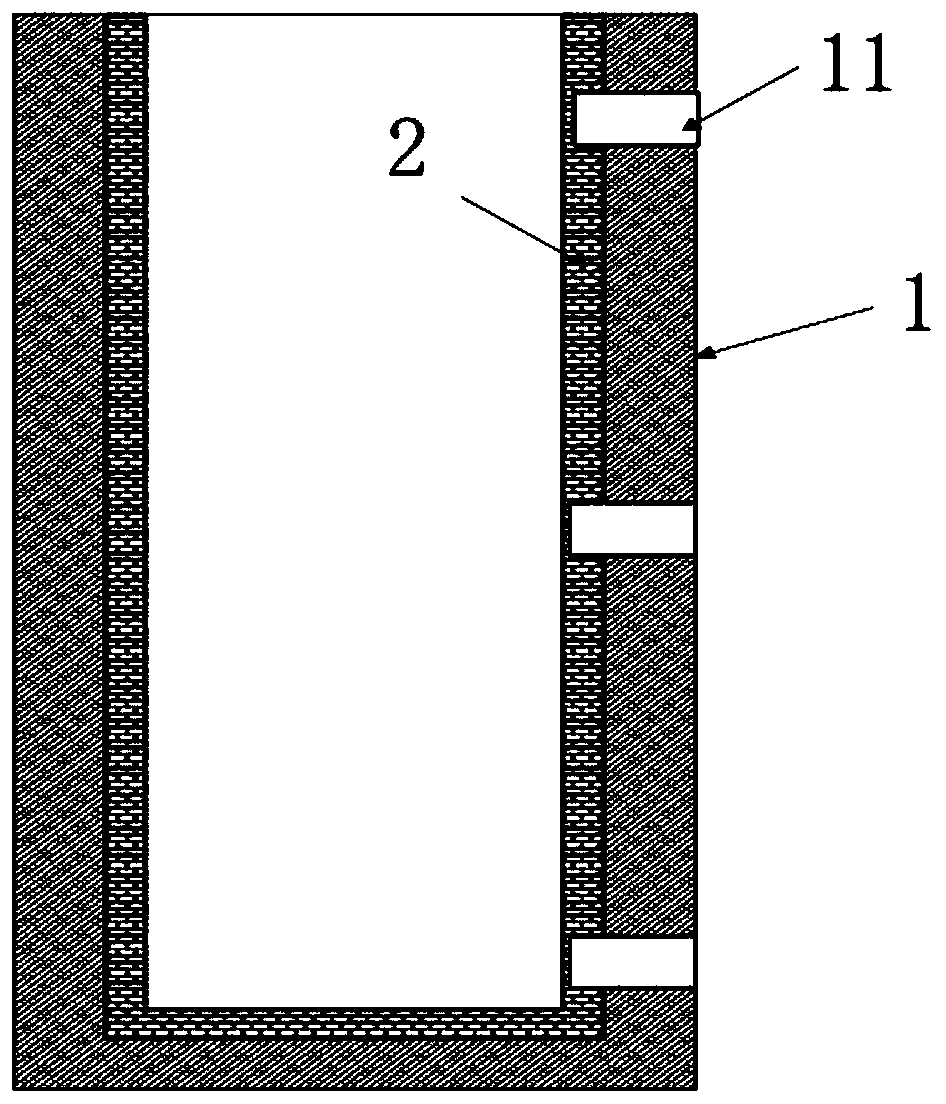

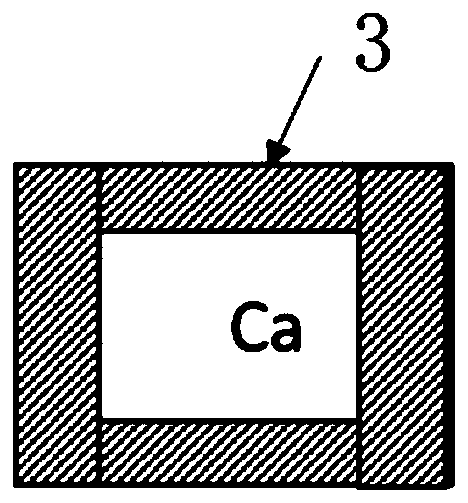

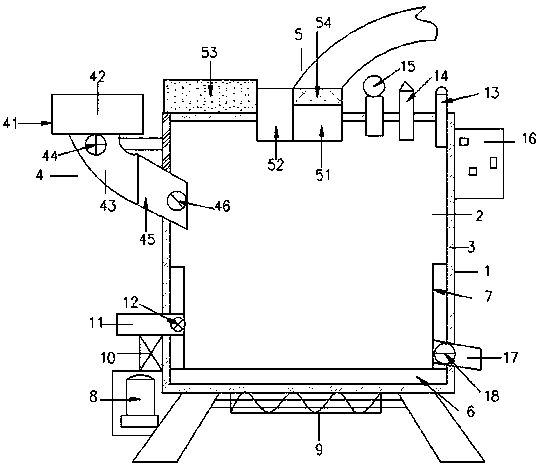

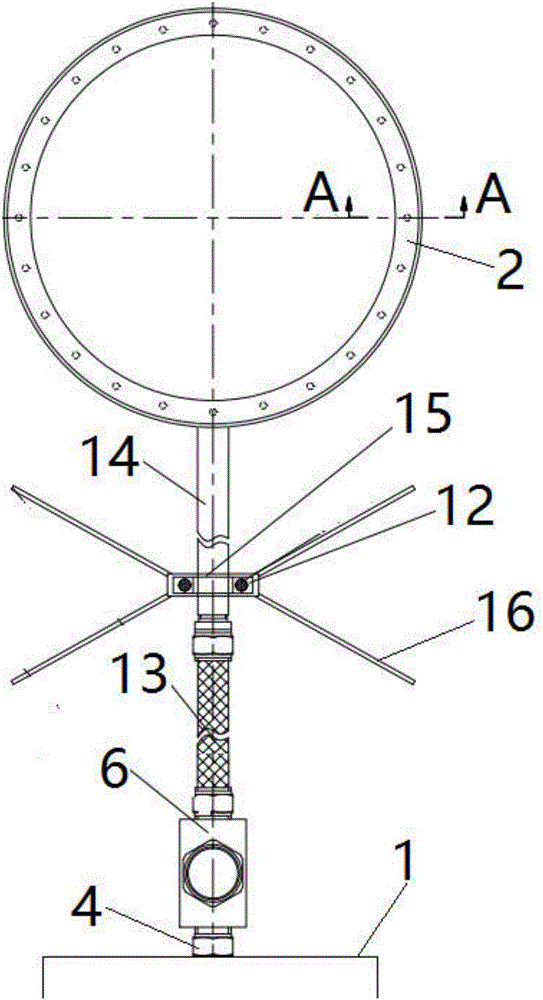

Airtight negative pressure electric arc smelting furnace

ActiveCN104713349AImprove airtightnessReduce lossesLighting and heating apparatusComing outHeat losses

The invention relates to an airtight negative pressure electric arc smelting furnace which comprises electrode frames (3), electrodes (5), a smoke gas cover (4), a furnace body (8) and a base station (2). The airtight negative pressure electric arc smelting furnace is characterized in that a lifting table (9) which is used for containing the furnace body (8) is arranged below the base station (2); the smoke gas cover (4) is formed by enclosing a surrounding cover wall (11) and a cover cap (12) at the upper end of the smoke gas cover (4), the cover wall (11) is provided with grooves (13) concave towards the inner side of the cover wall (11), the number of the grooves (13) is the same as that of the electrodes (5), each groove (13) is formed by enclosing two opposite groove walls and an inner side groove wall and a lower end plate (20), and electrode sockets (6) which make the electrodes come in and come out are formed in the lower end plates (20), the lower ends of uprights (21) of the electrode frames (3) are connected with the base station (2) through transverse shafts (24), and one side of each upright (21) is provided with a pulling mechanism. The airtight negative pressure electric arc smelting furnace has the advantages that the airtight performance of a furnace mouth and the smoke gas cover can be significantly enhanced, the heat loss can be reduced, the environmental pollution is avoided, and the working condition is improved. The electrodes can adjust the angle of inclination through being driven by the uprights, and the electrodes are sensitive in action and sturdy and durable. The temperature in the furnace is even, the heat efficiency is high, the negative pressure smelting atmosphere is formed, and the smelting quality is greatly improved.

Owner:通辽中硼新材料科技有限公司

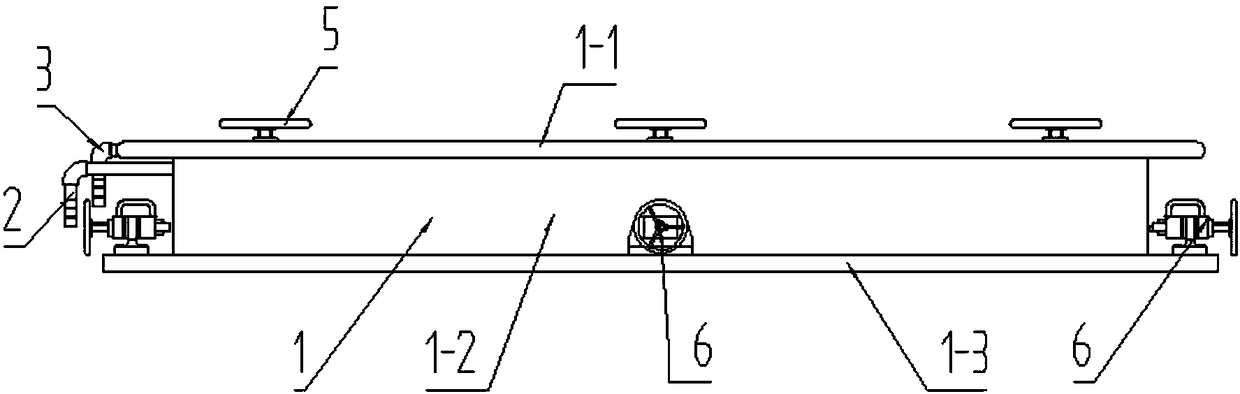

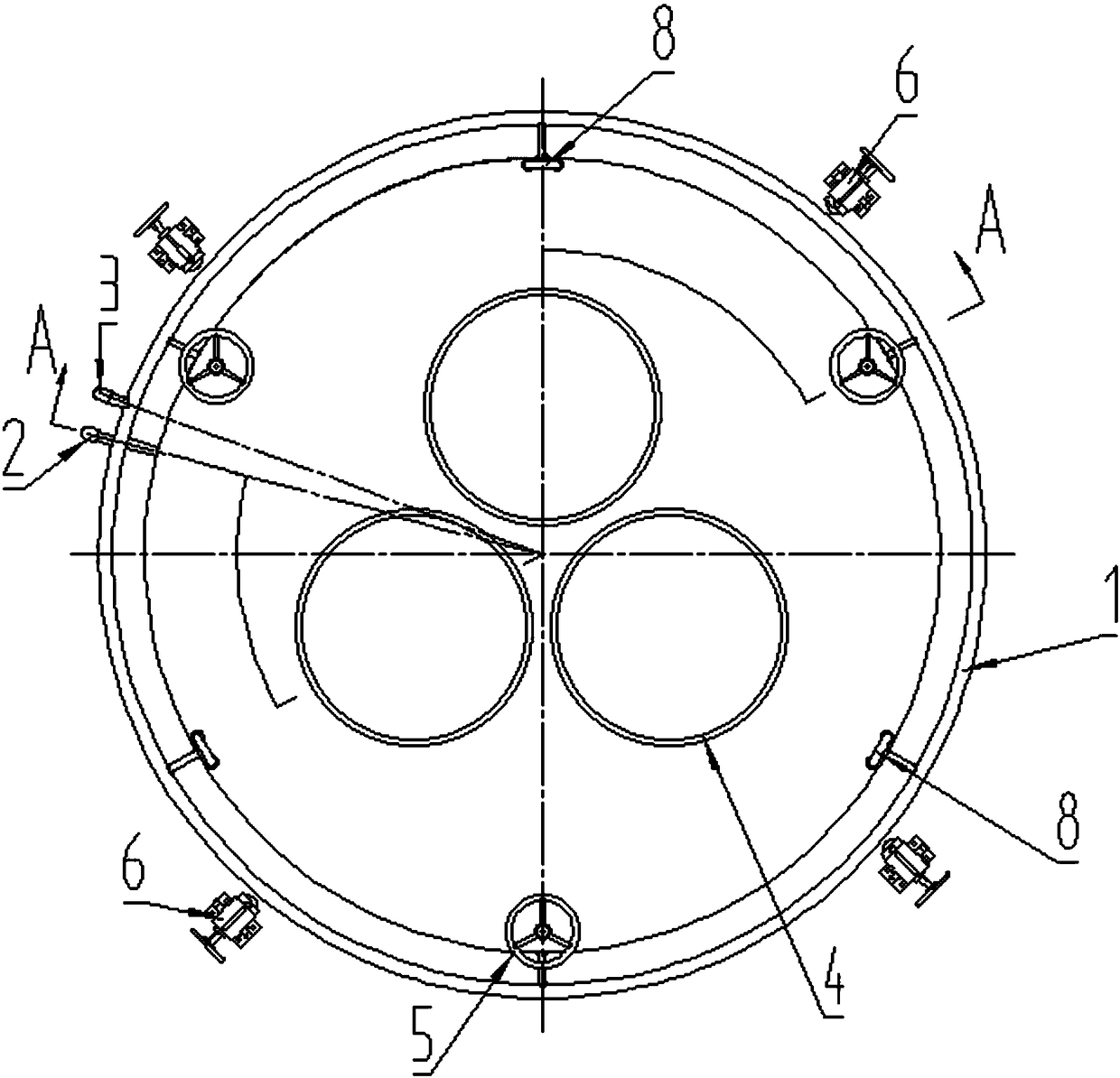

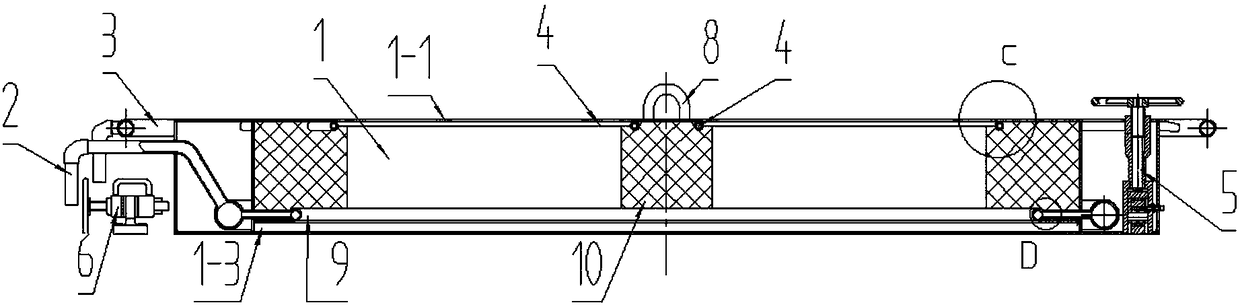

Converter bottom blowing gas supply device and using method thereof

The invention relates to the technical field of converter gas supply, in particular to a converter bottom blowing gas supply device which comprises a furnace body. An oxygen pipe used for conveying oxygen is arranged at the top of the furnace body, an inert gas pipe used for conveying inert gas is arranged at the bottom of the furnace body, a gas supply box is arranged at the bottom of the furnacebody, an installation plate is arranged in the gas supply box, through grooves distributed in an array mode are formed in the plate surface of the installation plate, the bottom end of each through groove is provided with a conveying pipeline in an inserted mode, the top end of each through groove is provided with a pressurization pipeline in an inserted mode, and the top ends of the conveying pipelines are in butt connection with the bottom ends of the pressurization pipes. The problem that a gas supply device cannot guarantee that sufficient inert gas is conveyed to a converter for steelmaking and influence steelmaking quality is solved, and sufficient inert gas can be introduced into the converter through pressurization, so that molten steel in a molten pool is stirred more uniformly,and molten steel smelting quality is obviously improved.

Owner:JIANGSU BINXIN STEEL GRP

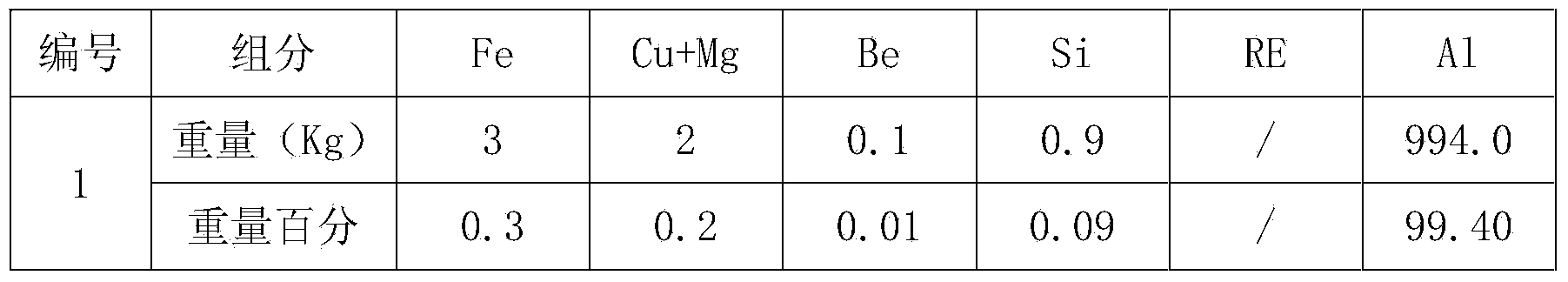

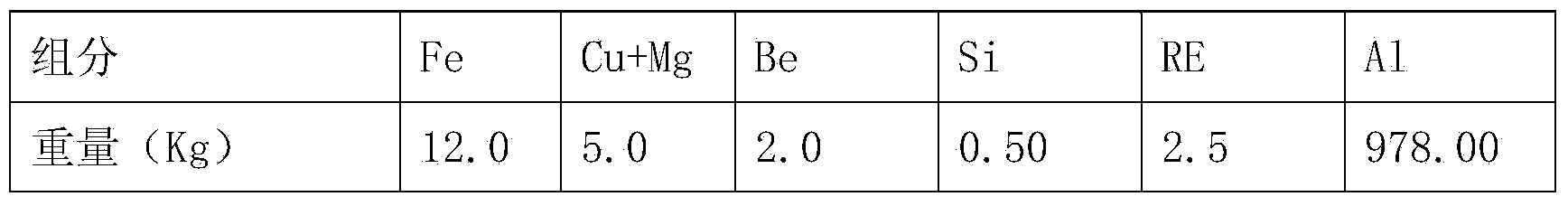

Al-Fe-Cu-Mg-Be alumium alloy for automobile wire and wiring harness therefore

PendingCN103725930AHigh mechanical strengthImprove tensile propertiesNon-insulated conductorsMetal/alloy conductorsSurface finishUltimate tensile strength

The invention discloses an Al-Fe-Cu-Mg-Be alumium alloy for an automobile wire and a preparation method thereof, and an automobile wiring harness prepared by the preparation method. The Al-Fe-Cu-Mg-Be alumium alloy for the automobile wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu+Mg, 0.001-0.2wt% of Be, and the balance of Al and inevitable impurities. According to the invention, Fe element is added so that the mechanical strength and the tensile property of the alloy can be improved; Fe is also capable of obviously improving the high-temperature creep resistance and the fatigue resistance of the alloy; the addition of Cu+Mg is capable of improving the strength and the high-temperature creep property and the fatigue resistance of the alloy; Be is capable of improving the smelting quality of the alloy and the compactness of the surface oxide film, so that good-quality castings good in surface smoothness, high in strength and improved in ductility can be obtained; Be is also capable of improving the fluidity of the alloy so that the fluidity of the melt is improved, and can further improve the tensile strength and the limit of yielding of the alloy.

Owner:ANHUI JOY SENSE CABLE

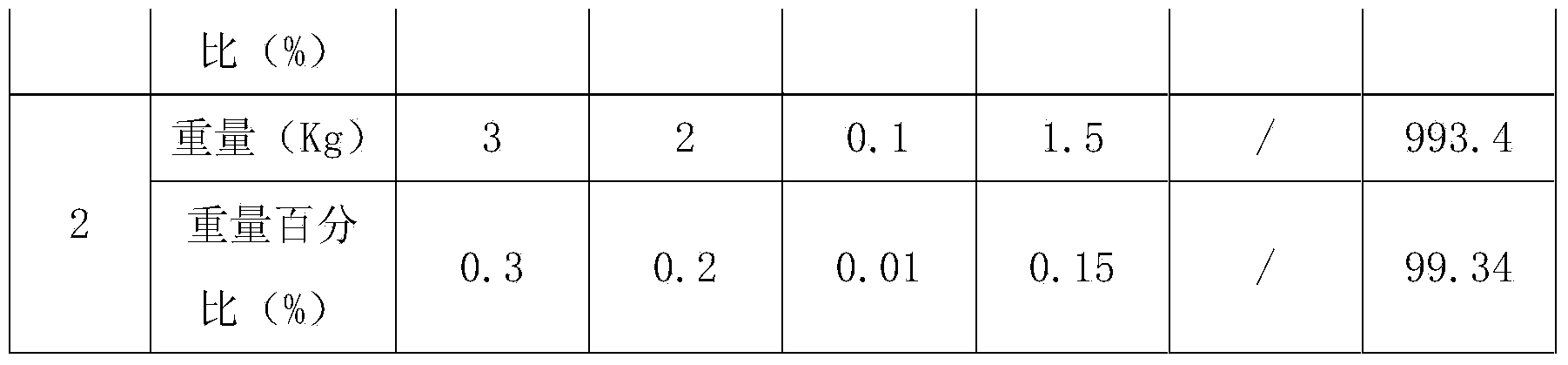

Converter smelting process for 82B steel

InactiveCN106498113AIncrease C4 contentReduce C contentManufacturing convertersSmelting processMolten steel

The invention discloses a converter smelting process for 82B steel and belongs to the technical field of steel smelting. The converter smelting process comprises the steps of mixing of converter molten iron, converter bottom argon blowing, process charging and end point charging. According to the technical scheme, single-slag operation is adopted for smelting the 82B high-carbon steel, so that at the converter smelting end point, the C content of molten steel is high, the P content of the molten steel is controlled, and the problems that with rising converter temperature, phosphorus in initial stage slag returns to the molten steel again, and consequently previous efforts are wasted are solved. Meanwhile, the initial stage slag contains a large amount of metal iron, is not poured during single-slag operation and is used until the end, waste of the metal iron is reduced greatly, consumption of slag making materials is also reduced, thus the smelting cost is reduced, and the smelting quality is improved.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

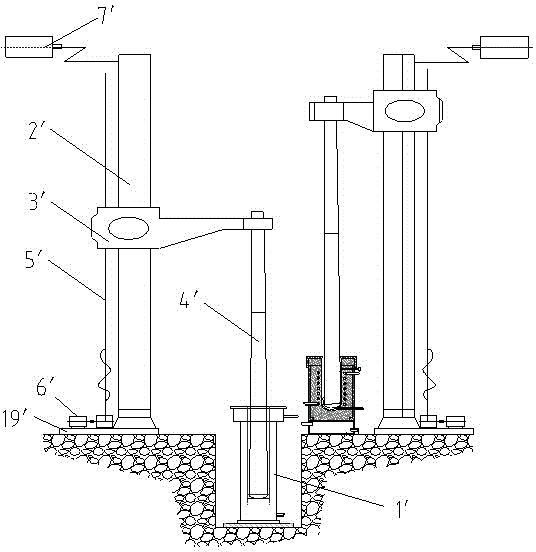

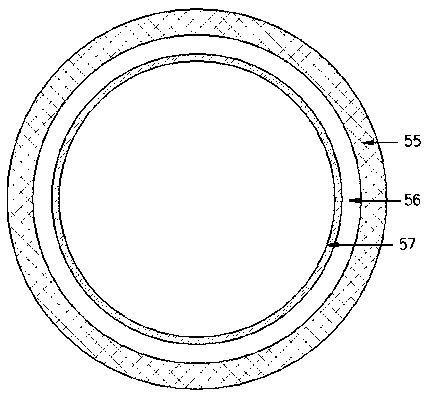

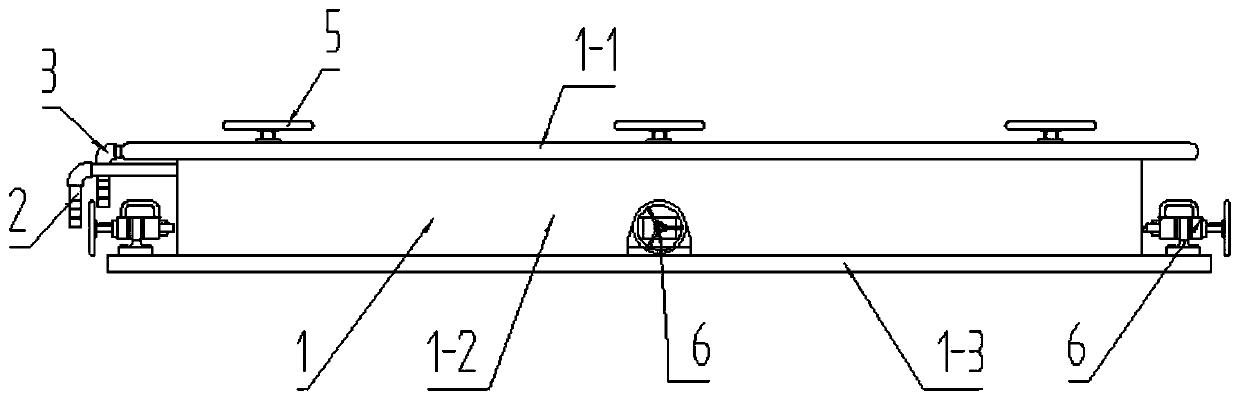

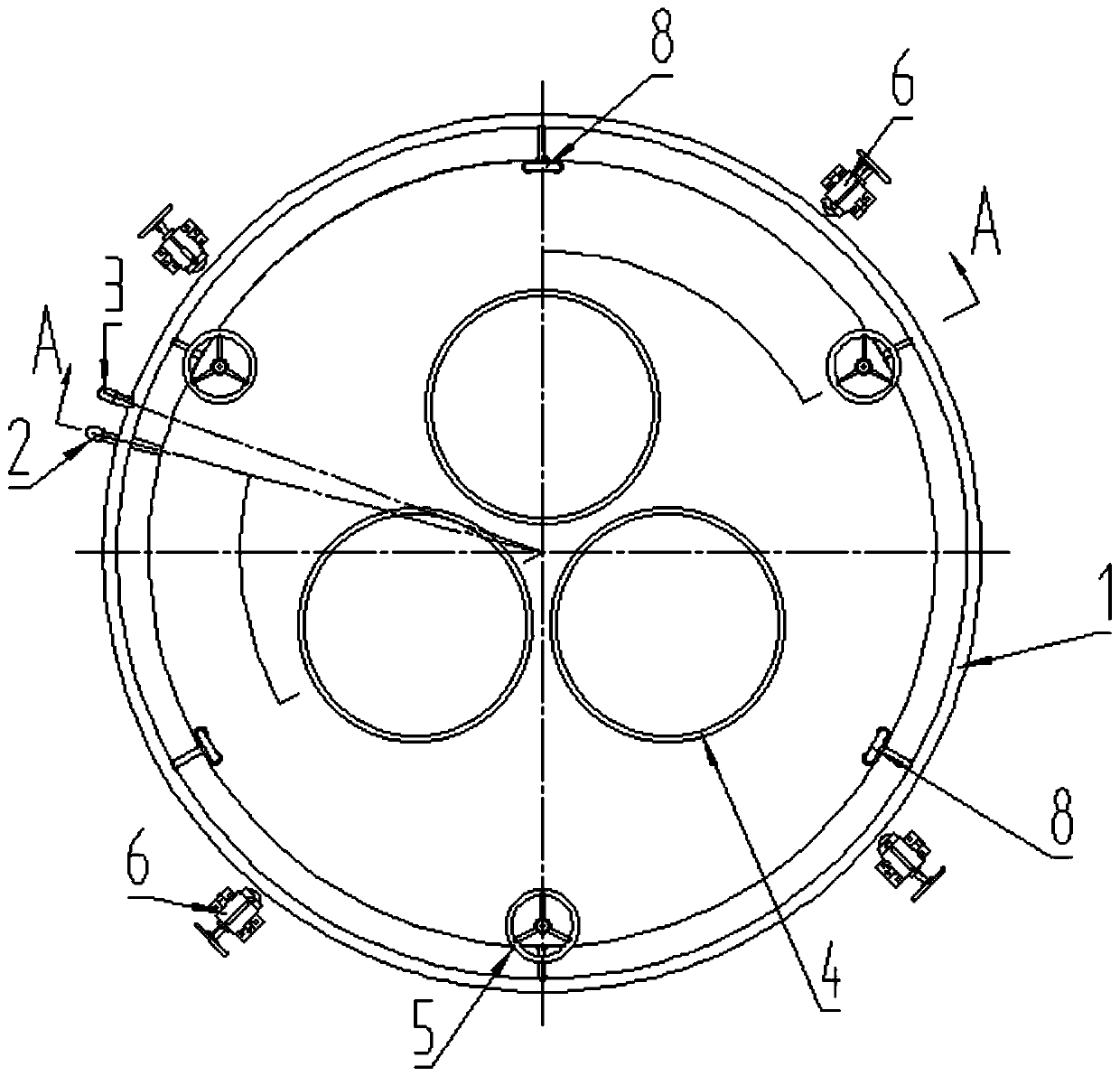

Atmosphere protective cover for electric slag furnace and electric slag furnace smelting system

The invention relates to an atmosphere protective cover for an electric slag furnace. The atmosphere protective cover comprises a shell, wherein the shell is provided with at least one electrode installation through hole; a cover plate of the shell is provided with at least one electrode blowing ring, the inner side of the electrode blowing ring is provided with a plurality of upwardly-oblique upper blowing holes which are uniformly distributed, a shell bottom plate is provided with a lower blowing ring, and the lower blowing ring is provided with a plurality of downwardly-oblique lower blowing holes; by adopting double layers of air routes, the upper blowing holes spray air to an electrode to form a conical air curtain, thereby playing a good sealing effect. The invention also relates toan electric slag furnace smelting system adopting the atmosphere protective cover. The electric slag furnace smelting system comprises a first rotating arm, a second rotating arm, a crystallizing device, a first electrode roasting apparatus and a second electrode roasting apparatus, and the atmosphere protective cover is arranged on the crystallizing device; the first rotating arm and the second rotating arm are separately used for clamping the electrode, and the first rotating arm and the second rotating arm work alternatively; and the smelting efficiency is high, and the quality of a steel ingot is good.

Owner:烟台台海玛努尔核电设备有限公司

Smelting furnace for repeated lapping of polymetallic ore

The invention relates to the technical field of metal smelting, and discloses a smelting furnace for repeated lapping of polymetallic ore. The smelting furnace includes a crushing box and a smelting furnace body. The smelting furnace body is provided with a collecting funnel, and a driving mechanism is provided with a hydraulic pump. A motor and a feeding trough are movably installed on the wall surface of the crushing box, and a hydraulic cylinder is arranged above the driving mechanism. A cylinder barrel and a piston rod are arranged in the hydraulic cylinder, and one end of the piston rod is connected to a support. The other ends of a first connecting rod and a second connecting rod are connected to a crushing rod, and a crushing plate is movably arranged below the crushing rod. Supporting lugs and buffer springs are arranged on the crushing plate. According to the smelting furnace for repeated lapping of the polymetallic ore, the feeding trough is arranged to be inclined to the outer wall of the smelting furnace body, so that the metal ore conveniently enters the crushing box easily; and the crushing plate is provided with the buffer springs for buffering the rigid rebound received by the crushing plate when crushing the metal ore.

Owner:HUNAN CHEM VOCATIONAL TECH COLLEGE

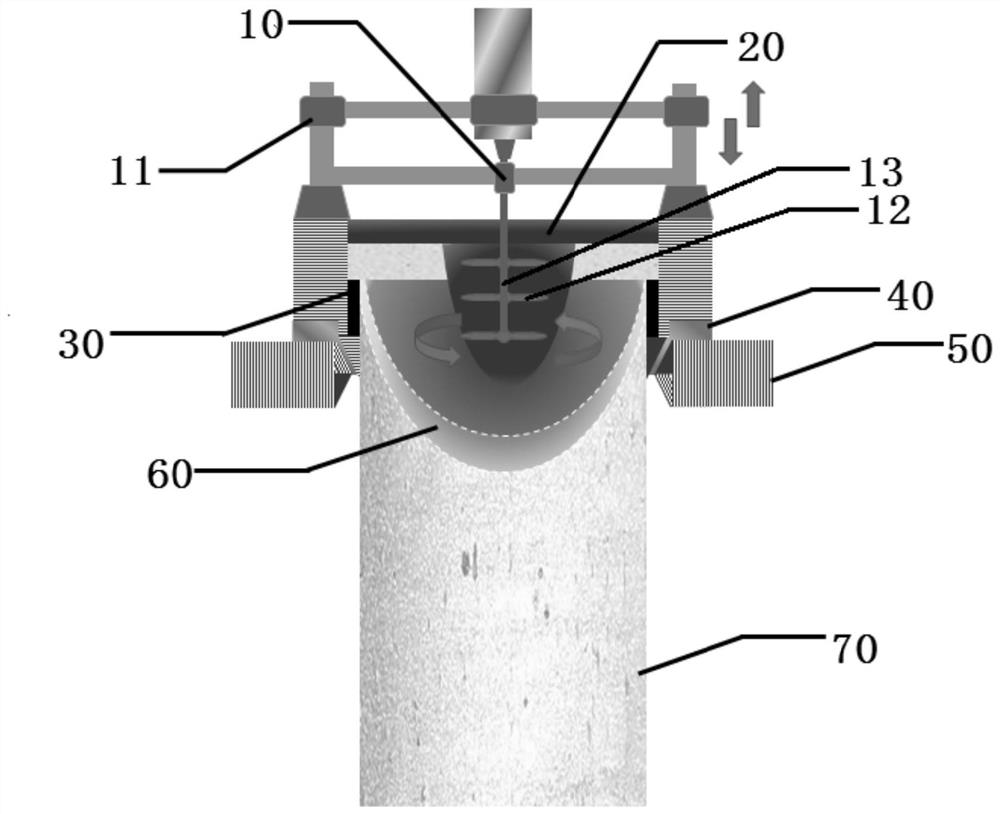

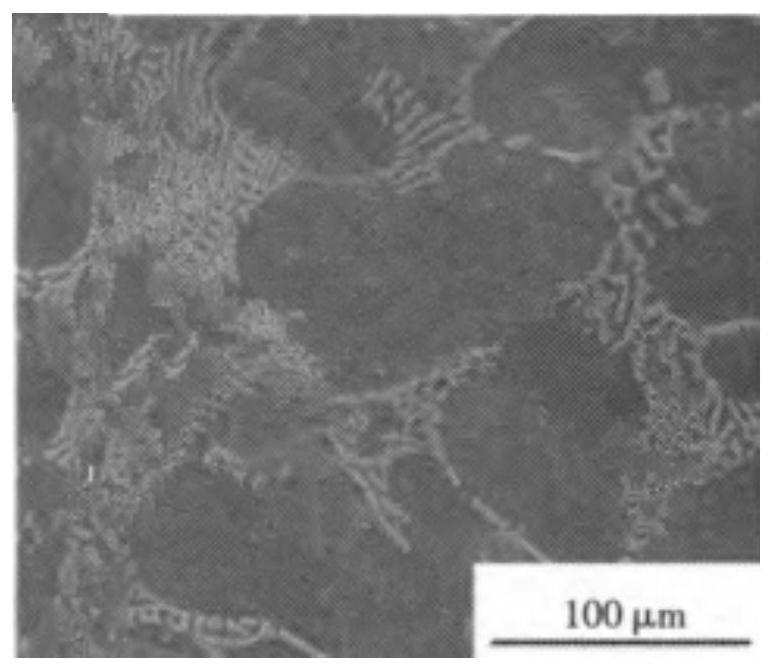

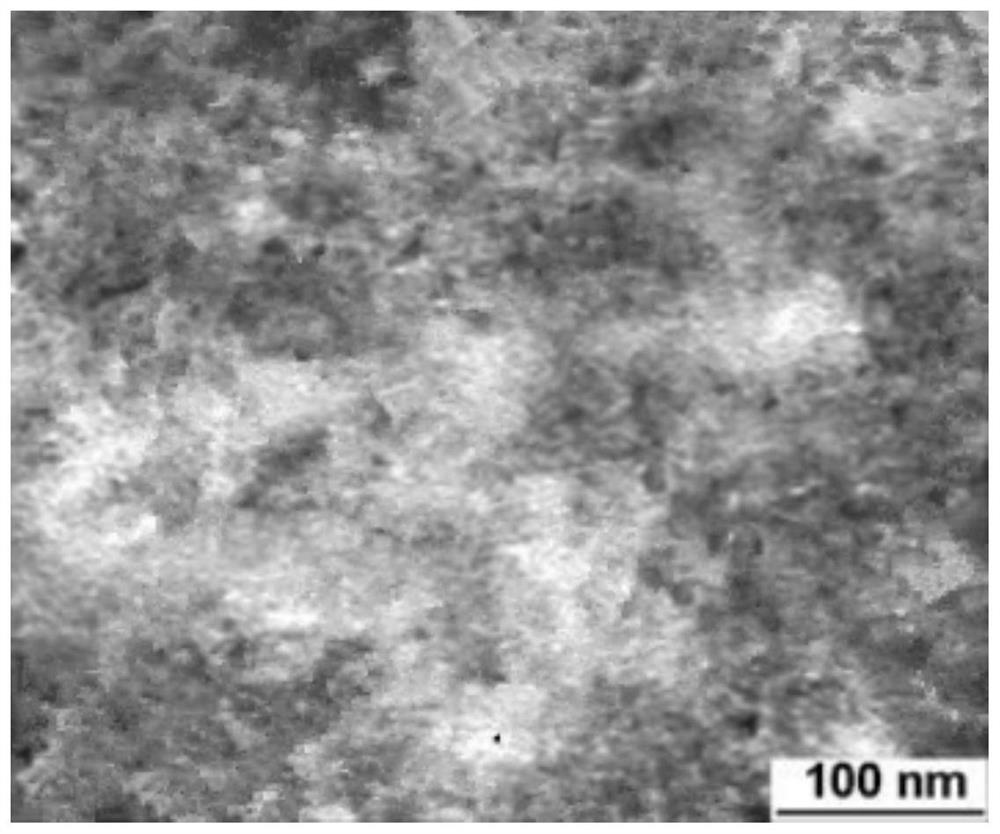

Casting method of aluminum alloy cast rod

The invention provides a casting method of an aluminum alloy cast rod. Chemical composition elements of the aluminum alloy cast rod and the structure of a crystallizer are optimized so that when the aluminum alloy cast rod is cast, a temperature adjusting device, the stirring speed and the stirring time can be more accurately controlled through a controller, formability of aluminum alloy melt is guaranteed, meanwhile, uniformity of the internal temperature of the aluminum alloy melt can be guaranteed, the situation that an aluminum alloy dendritic crystal arm is broken into dendritic crystal fragments is effectively reduced, nucleation positions are added, more non-uniform nucleation occurs, the grain refining effect is remarkably generated, then the tendency that cracks are generated on the cast rod is reduced, the casting smelting quality is improved, and the yield is increased. The problems that when a large-size and large-diameter aluminum alloy cast rod is cast, the temperature of aluminum alloy melt is not uniform due to the high casting temperature, consequently, the cooling speeds and the cooling degrees of all parts of the cast rod are different, the cracking tendency exists, and cracks are generated in the cast rod are effectively solved.

Owner:佛山市三水凤铝铝业有限公司 +1

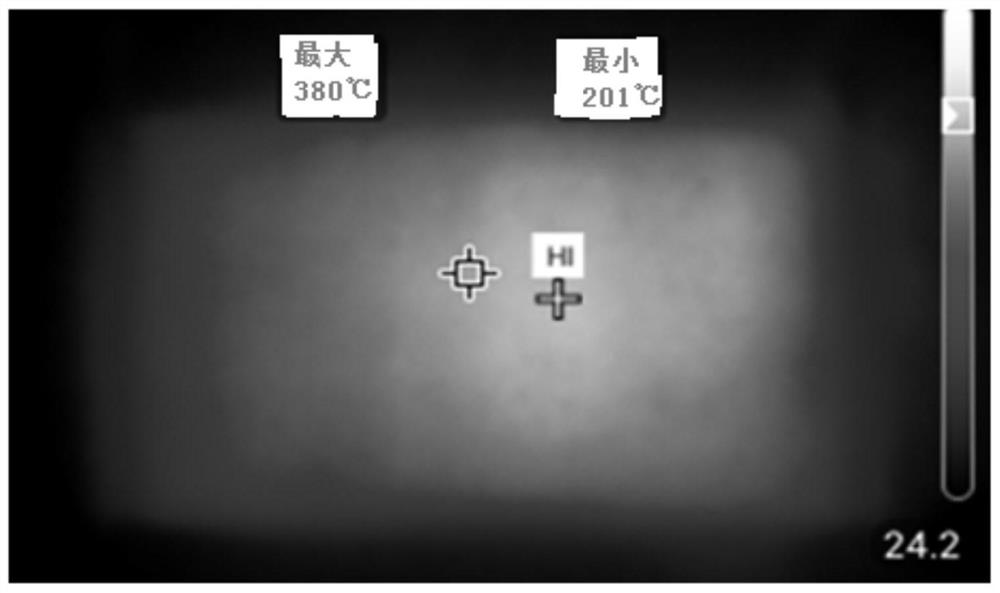

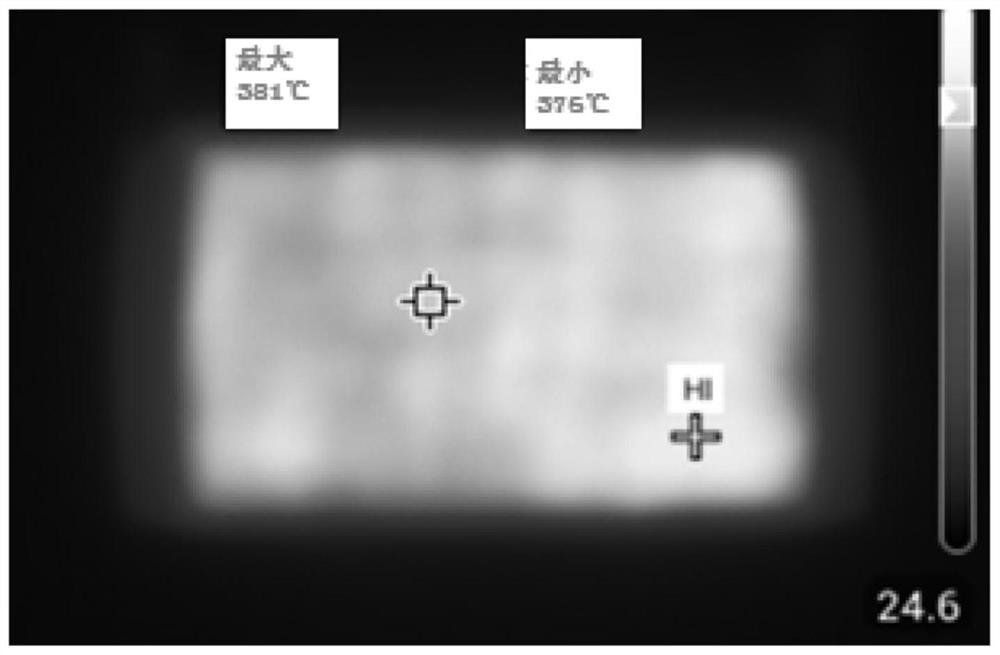

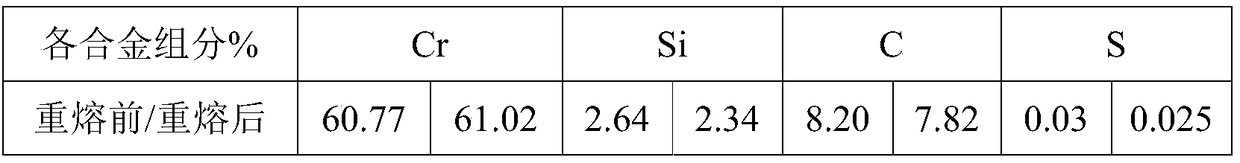

High-carbon ferro-chrome smelting method

InactiveCN108977621AEfficient recyclingRealize the conversion of magnetism-electricity-heatElectric furnaceSmelting processMolten steel

The invention relates to a high-carbon ferro-chrome smelting method and belongs to the technical field of smelting of high-carbon ferro-chrome. The high-carbon ferro-chrome smelting method comprises the following steps of: 1, firstly, energizing a current with an alternative frequency into a spiral water cooling coil outside an induction furnace so as to generate a magnetic field in a space surrounded by the coil and around, then adding natural block high-carbon ferro-chrome, adding powder and / or granular high-carbon ferro-chrome after melting down, then adding a mixture formed by the powder and / or granular high-carbon ferro-chrome and a slag forming constituent after melting down, and melting down; 2, operating molten steel which is molten down by adopting a dominant pool method, then continuously adding the mixture formed by the high-carbon ferro-chrome and the slag forming constituent into the residual molten steel, and melting down; 3, repeating the step 2. According to the smelting method disclosed by the invention, when the high-carbon ferro-chrome is smelted, not only can a problem that a great amount of dust generated in the smelting process cannot be recycled be effectively solved, but also yield of chrome in the ferro-chrome can be greatly improved, harmful elements of phosphorus, sulphur and the like are reduced, and smelting quality in the ferro-chrome is improved.

Owner:JINAN JIGANG IRON ALLOY FACTORY

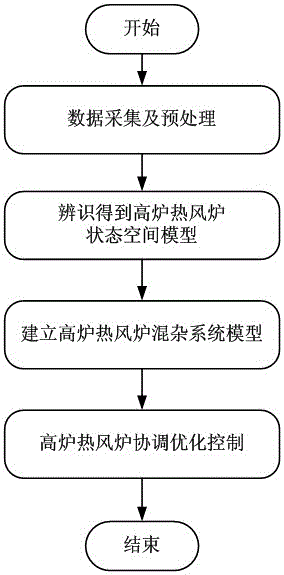

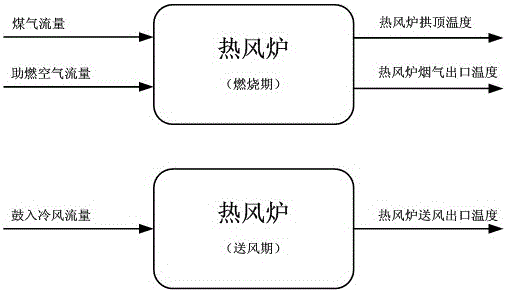

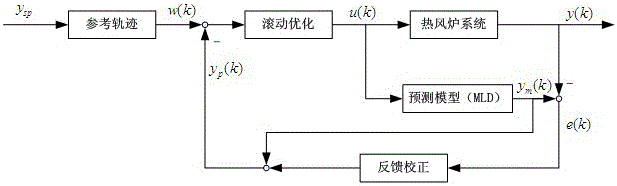

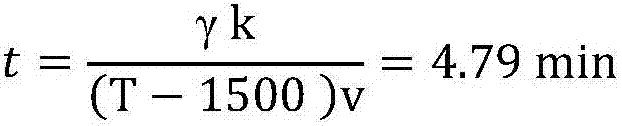

Method of Modeling and Coordinated Optimal Control of Hybrid System of Blast Furnace Hot Blast Stove

InactiveCN103293955BReasonably control the quality of air supplyControl the quality of air supplyAdaptive controlWork cycleIndustrial engineering

The invention discloses a method for hybrid system modeling and coordinated optimization control of a blast-furnace hot blast stove. The method includes the steps of using subspace identification for respectively obtaining a combustion period model and an air supply period model of the blast-furnace hot blast stove so that process conditions can be effectively reflected, integrating the combustion model and the air supply model, establishing a hybrid system model based on a mixed logical dynamical method and finally realizing the coordinated optimization control of the blast-furnace hot blast stove by the use of a predictive control for the hybrid system. The method has the significant advantages of more closely reflecting the working cycle of the hot blast stove, more reasonably controlling the air supply quality of the hot blast stove and having strong adaptability. Furthermore, the method has the good effects on guaranteeing stable production and safe operation of the blast furnace, improving the smelting quality of the blast furnace, saving gas resource consumption, and the like. And thus, the method has better economic and social benefits.

Owner:ZHEJIANG UNIV

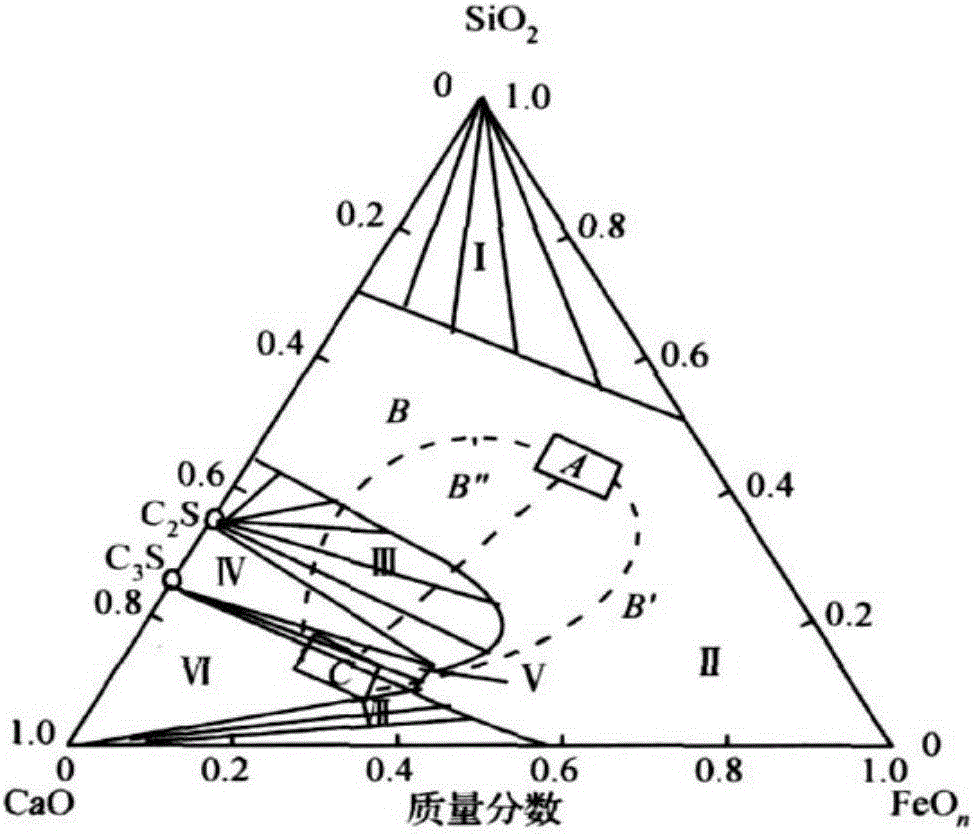

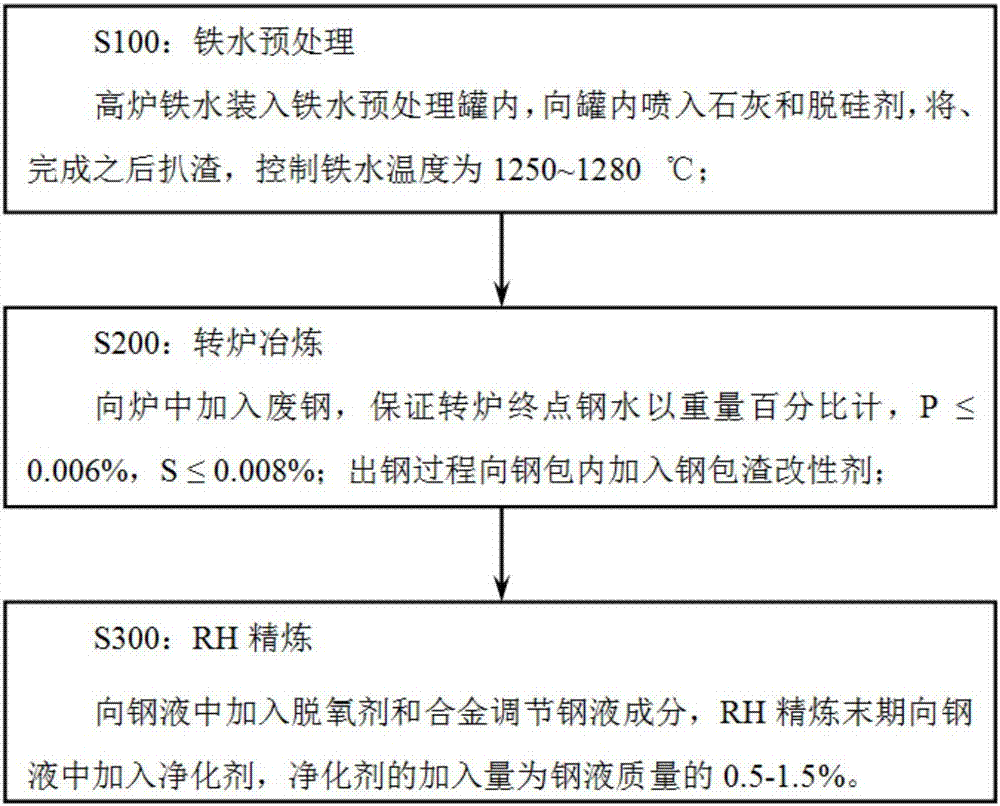

Smelting method and production process of clean steel

ActiveCN107236844AImprove smelting qualityImprove purification effectManufacturing convertersProcess efficiency improvementSteelmakingPre treatment

The invention discloses a smelting method and a production process of clean steel and belongs to the technical field of steelmaking. Molten iron is subjected to desilicication and desulphurization treatment through molten iron pretreatment and then is smelted in a converter; in the tapping process, a steel ladle slag modifier is added into a steel ladle; the steel ladle slag modifier comprises light-burning dolomite; the content of P and S in the treated molten iron is controlled to meet the relation of P<=0.006% and S<=0.008%; and at the terminal stage of RH refining, a purifying agent with the adding quantity accounting for, by mass, 0.05-1.5% of the molten steel is added into the molten steel. The molten iron is subjected to desilicication and desulphurization treatment through molten iron pretreatment and then is smelted in the converter, in the tapping process, the steel ladle slag modifier is added into the steel ladle, and at the terminal stage of RH refining, the purifying agent is added into the molten steel, so that the purifying effect of the molten steel is improved, and the smelting quality of the clean steel is further improved.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

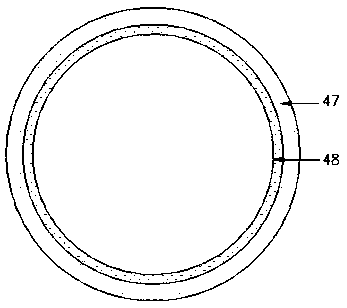

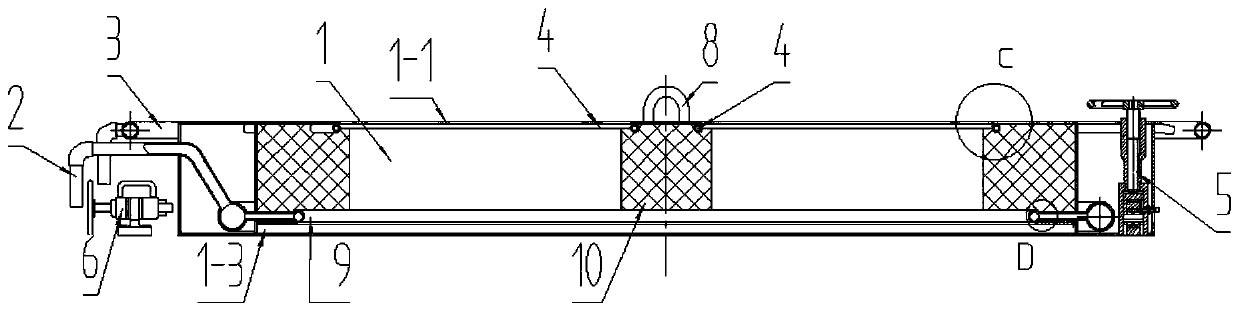

Energy-saving environment-friendly air supply branch pipe

InactiveCN105506208AConserve non-renewable energyReduce heat lossBlast furnace detailsHeating stovesAir volumeThermal insulation

The invention relates to a blast furnace air supply pipeline, in particular to an energy-saving environment-friendly air supply branch pipe. The energy-saving environment-friendly air supply branch pipe comprises a gooseneck, a compensator, a middle segment, a lower segment, and a straight blow pipe, wherein a piezometric pipe used for measuring temperature, pressure and volume of hot wind in the air supply branch pipe and a flow control valve used for adjusting the pressure of the wind in the air supply branch pipe are mounted in the middle segment; a multiple heat-insulating thermal insulation structure is arranged on the inner side of the metal steel shell of the air supply branch pipe. Due to flow rate and wind pressure adjustment, hot wind parameters of all air supply branch pipes can be consistent, so that smelting efficiency and molten iron quality of a blast furnace can be improved greatly, and energy consumption can be reduced; due to the multiple heat-insulating thermal insulation structure, temperature on the outer surface of each air supply branch pipe can be lowered effectively, temperature of hot wind sent into the blast furnace is raised, the operation environment is improved, and non-renewable energy is saved.

Owner:TANGSHAN JINSHAN TENGYU SCI & TECH

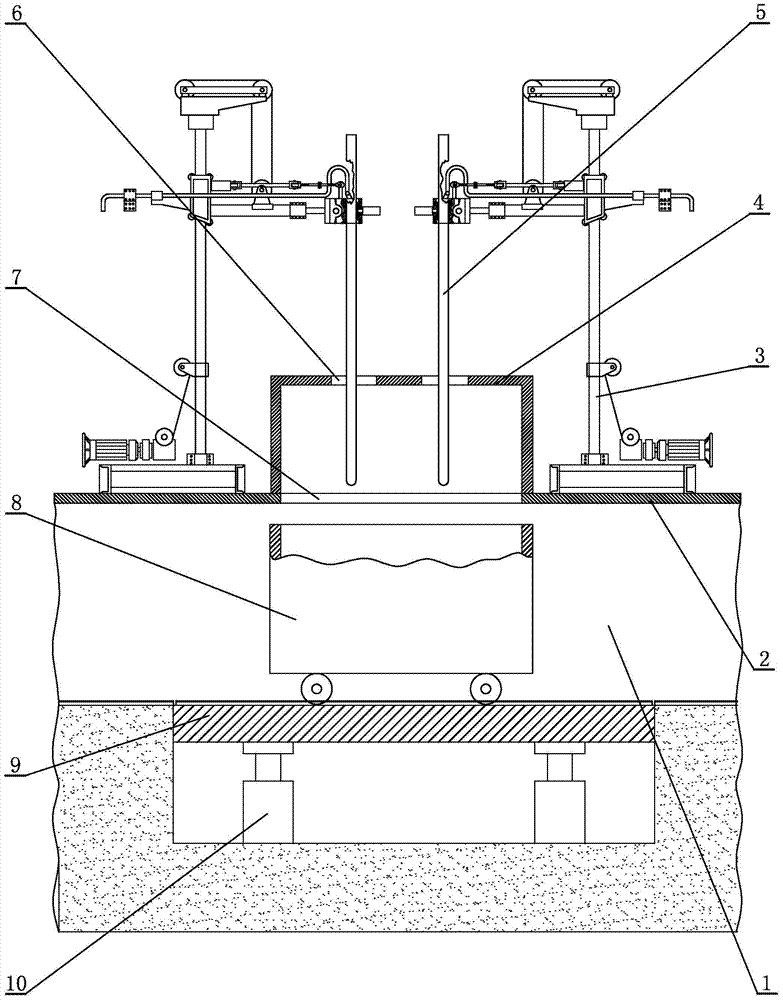

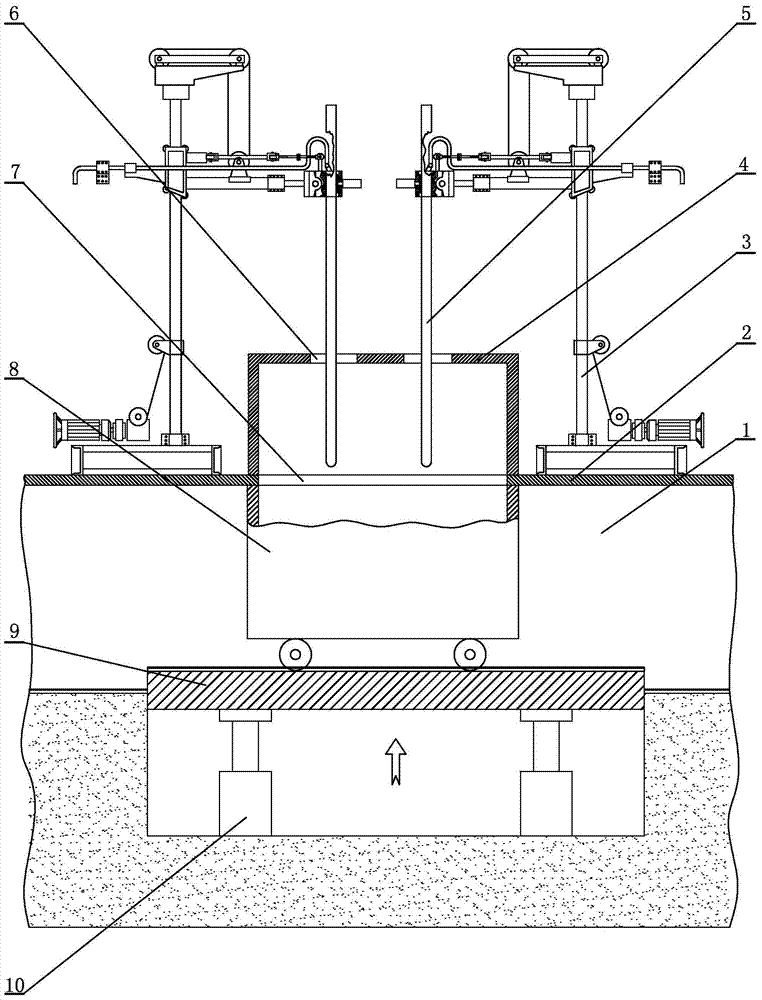

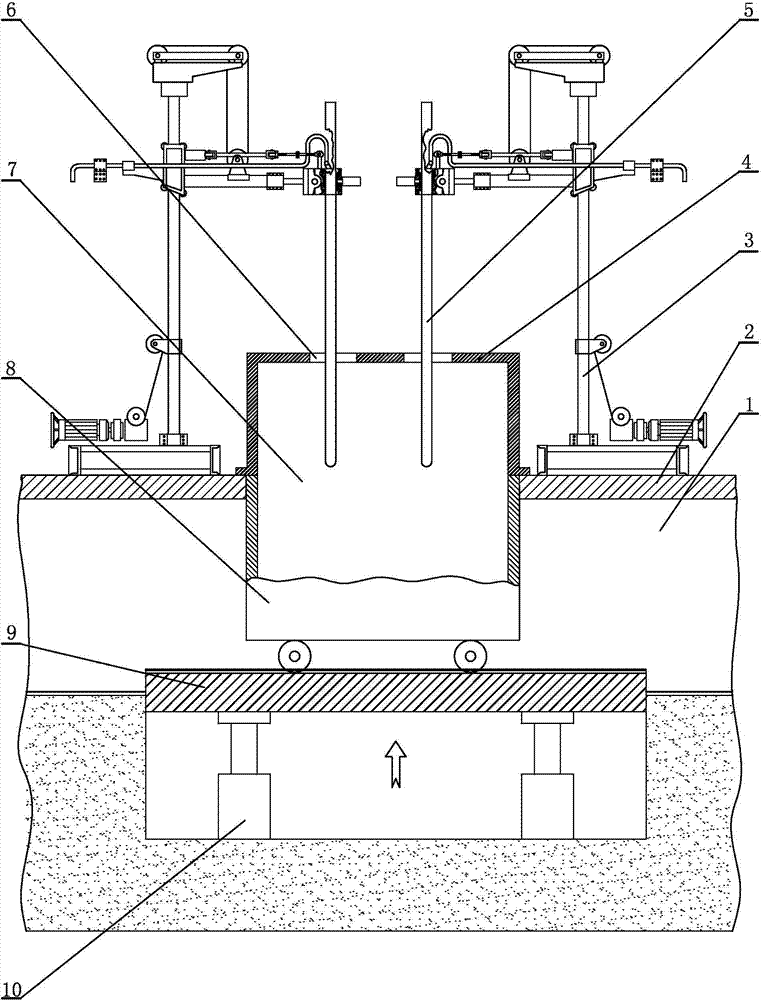

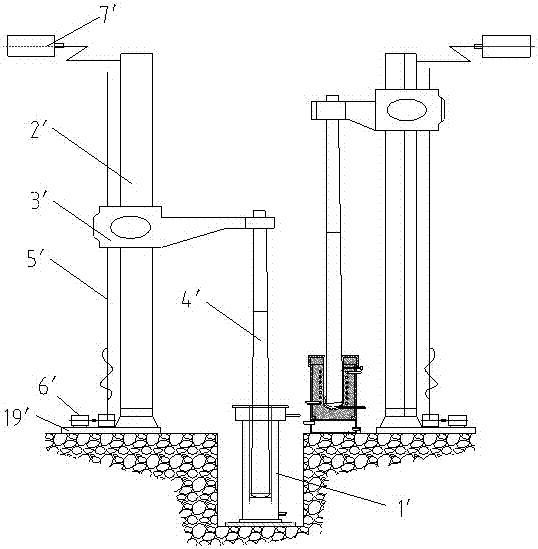

Electroslag smelting method

The invention discloses an electroslag smelting method. The electroslag smelting method is characterized in that two electrode devices are arranged beside a crystallizer and used for smelting in the crystallizer by turns, an electrode is installed on one electrode device and preheated when the other electrode device is used for smelting, an electrode of the electrode device used for smelting is moved away after smelting is completed, the preheated electrode is moved into the crystallizer for smelting after slag is fed again and the crystallizer is arranged well, and the process is repeated so as to achieve high-efficiency electroslag smelting. The electroslag smelting method has the advantages of high smelting efficiency and safety, excellent smelting effect, high efficiency, energy conservation, higher electroslag steel ingot smelting quality, great convenience in maintenance and replacement of the bottom water tank, lower maintenance cost and higher cooling efficiency.

Owner:宝武特冶航研科技有限公司

Vacuum electroslag furnace

The invention relates to a vacuum electroslag furnace, and belongs to the technical field of smelting equipment in the metallurgical industry. According to the technical scheme, the furnace comprisesa conductive material rod (1), a sealing cover (6), a smoke hood (7), a crystallizer (8) and a bottom water tank (9), wherein the upper end and the lower end of the smoke hood (7) are connected with the sealing cover (6) and the crystallizer (8) respectively through flanges and U-shaped clamps, the conductive material rod (1) is arranged above the sealing cover (6), and the bottom water tank (9) is arranged below the crystallizer (8); and the furnace is characterized in that seals are arranged between the conductive material rod (1) and the sealing cover (6), between the sealing cover (6) andthe smoke cover (7), between the smoke cover (7) and the crystallizer (8) and between the crystallizer (8) and the bottom water tank (9). The furnace has the beneficial effects that a common electroslag furnace can reach the vacuum sealing condition, and vacuum electroslag smelting can be carried out after vacuum pumping is carried out through a vacuum system; and when vacuum smelting is not needed, the corresponding seals are removed, and then the recovery is achieved.

Owner:HEBEI IRON AND STEEL

Smelting furnace used for steel material

InactiveCN110205438AUnified size and sizeEasy for smelting operationExhaust gas handlingProcess efficiency improvementSmelting processExtrusion

The invention discloses a smelting furnace used for a steel material. The smelting furnace comprises a furnace body. The furnace body is composed of a breaking chamber and a smelting chamber. The breaking chamber is connected with the smelting chamber through a discharging hopper and communicates with the smelting chamber. Supporting frames are arranged at the bottom of the furnace body, and a first discharging opening and a second discharging opening are formed in the two ends of the bottom of the furnace body correspondingly. A feeding hopper is arranged at the top end of the furnace body. Extruding blocks are arranged on the two sides of the inner wall of the feeding hopper, and the extrusion blocks are connected with the inner wall of the feeding hopper through compression springs. Theother end of each compression spring is provided with an extrusion motor, and the extrusion motors are arranged on the outer wall of the feeding hopper. A dust suction pipe is arranged on one side ofthe top end of the breaking chamber, one end of the dust suction pipe penetrates in the breaking chamber, the other end of the dust suction pipe is connected with a gas suction pump, and the other end of the gas suction pump is connected with a dust collection box. By means of the smelting furnace used for the steel material, the steel material needing to be smelted can be extruded and smashed, smoke generated in the smelting process can be effectively collected and filtered, and cleanliness of the working environment is ensured.

Owner:MAANSHAN ZHONGTIAN MACHINERY INSTALLED

Metal material smelting method

ActiveCN111187928AImprove purityGuaranteed purityCharge treatment typeCrucible furnacesCrucibleMetallic materials

The invention discloses a metal material smelting method, and relates to the technical field of metal smelting. According to the technical scheme mainly adopted by the invention, the metal material smelting method comprises the following steps that a detachable crucible inner layer is manufactured, specifically, the inner wall of a crucible body is provided with a plurality of crucible inner layermodules, the multiple crucible inner layer modules form the detachable crucible inner layer, and a double-layer crucible is obtained, wherein the crucible inner layer modules are made of a material having a purifying effect on molten metal; and metal material smelting is conducted, specifically, a metal material is put into the double-layer crucible to be smelted. The metal material smelting method is mainly used for ensuring the smelting purity degree of the metal material, and the smelting cost can be reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

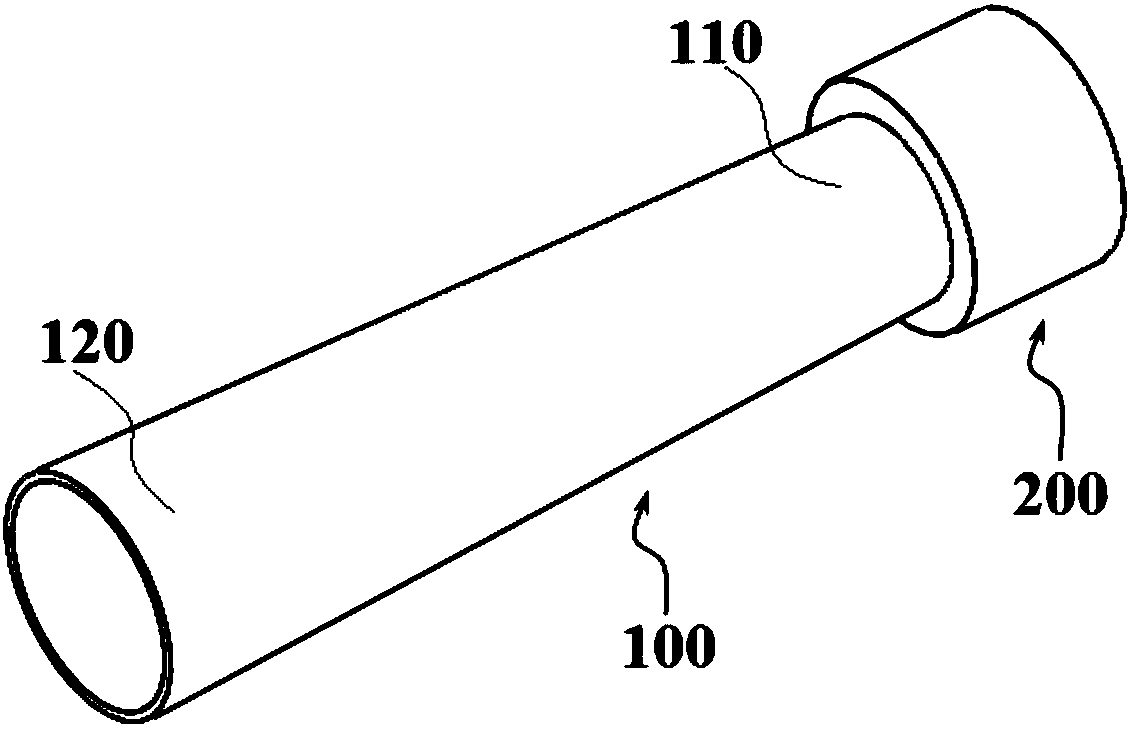

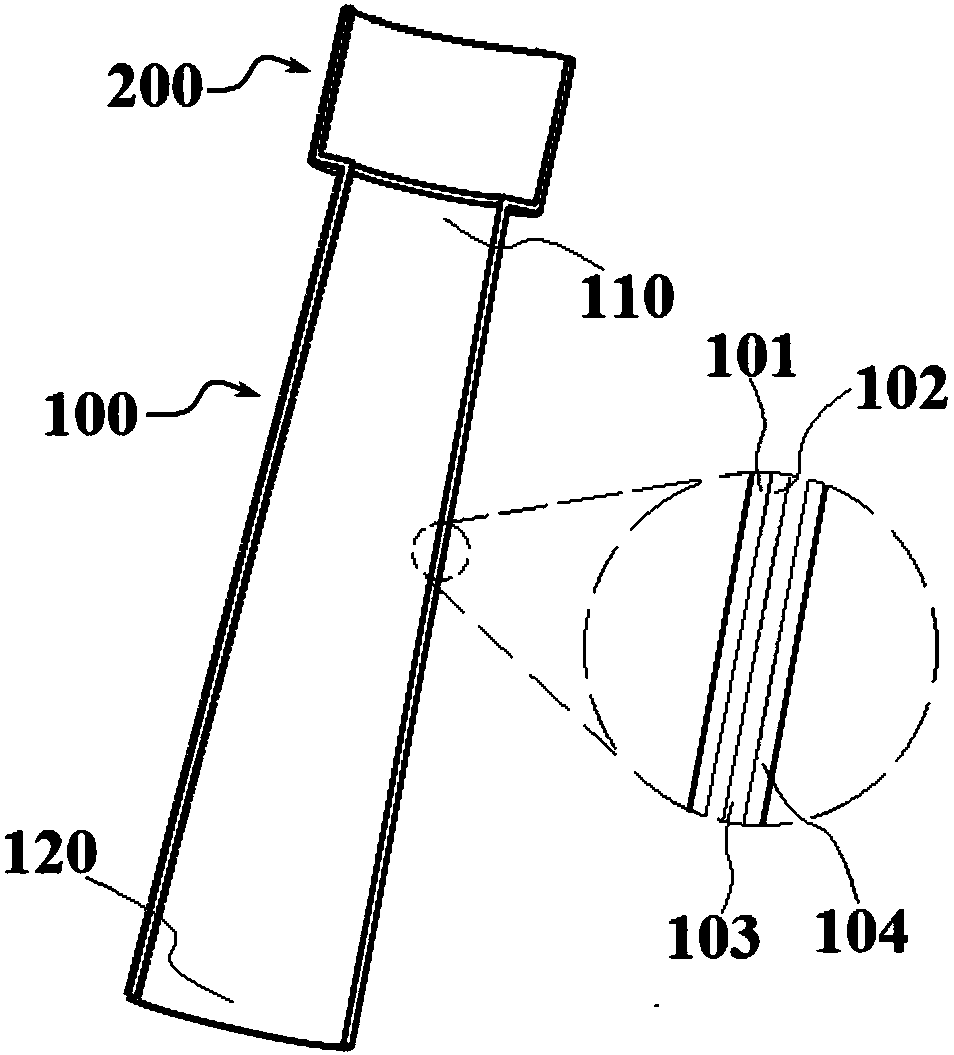

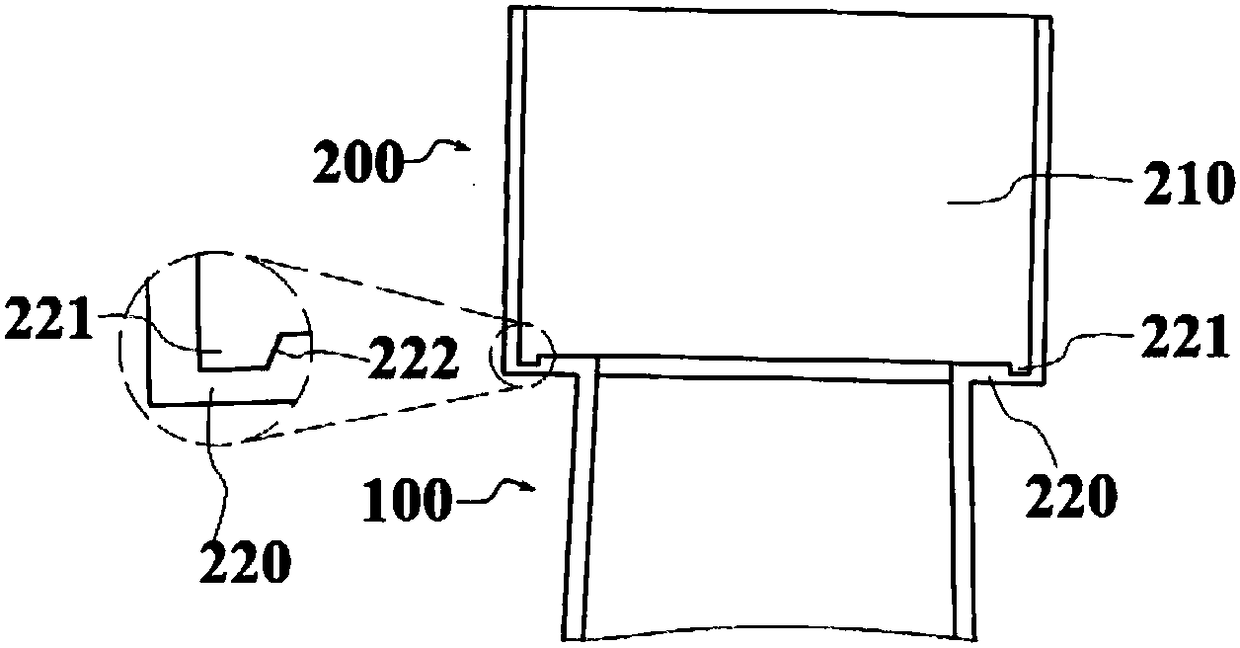

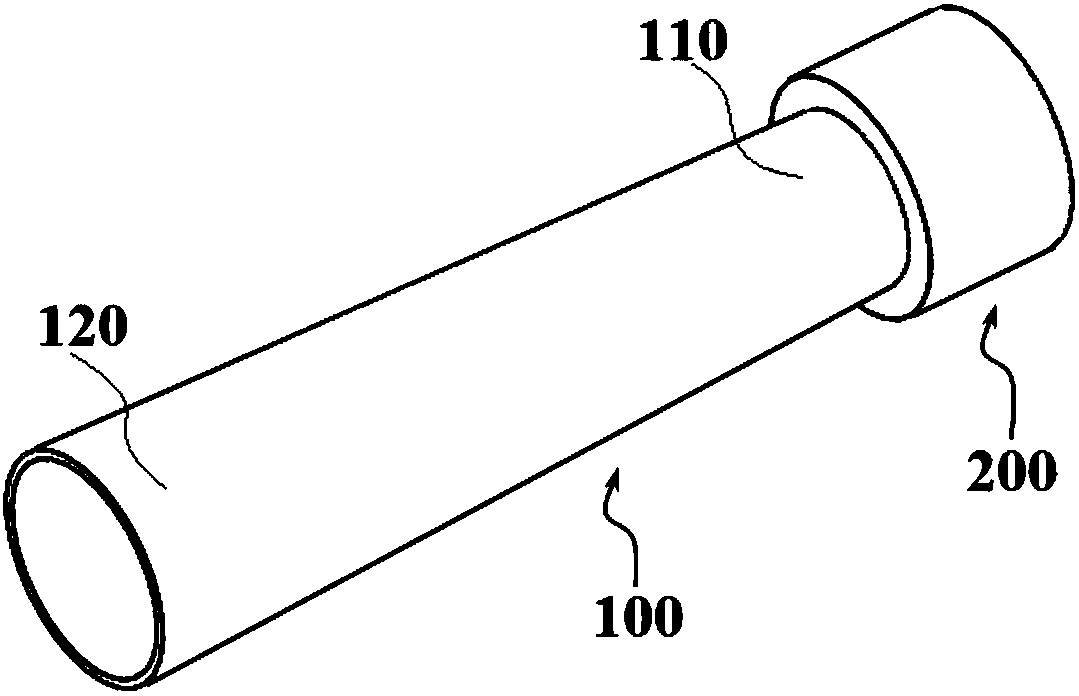

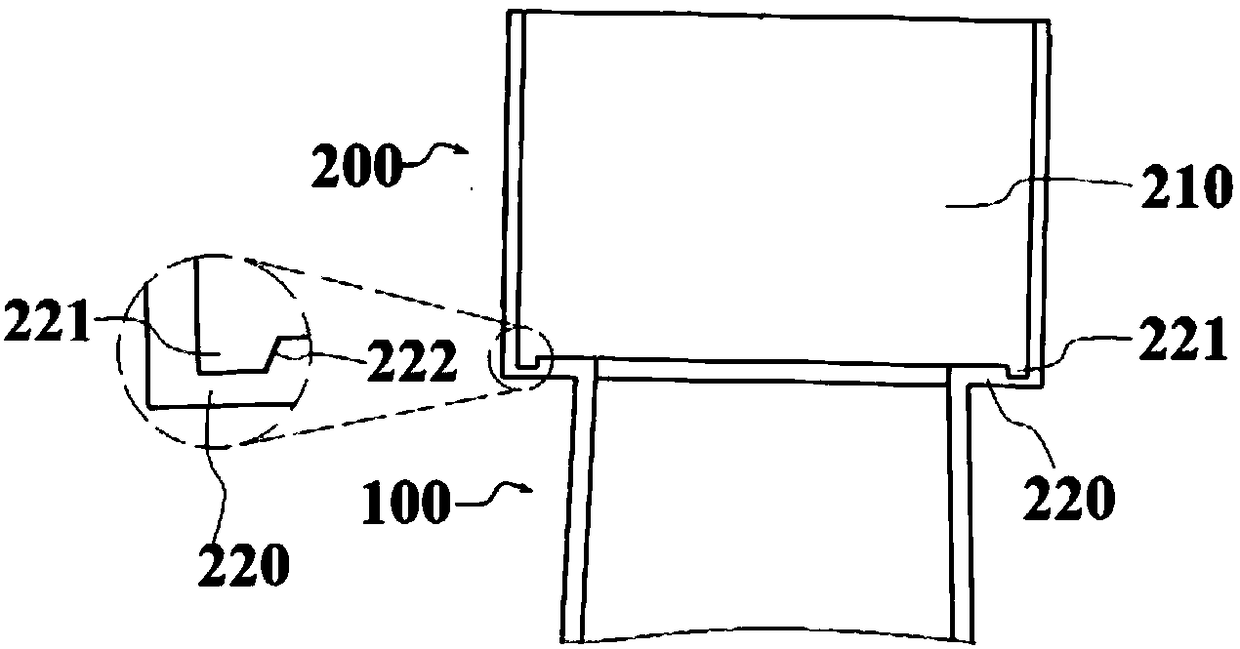

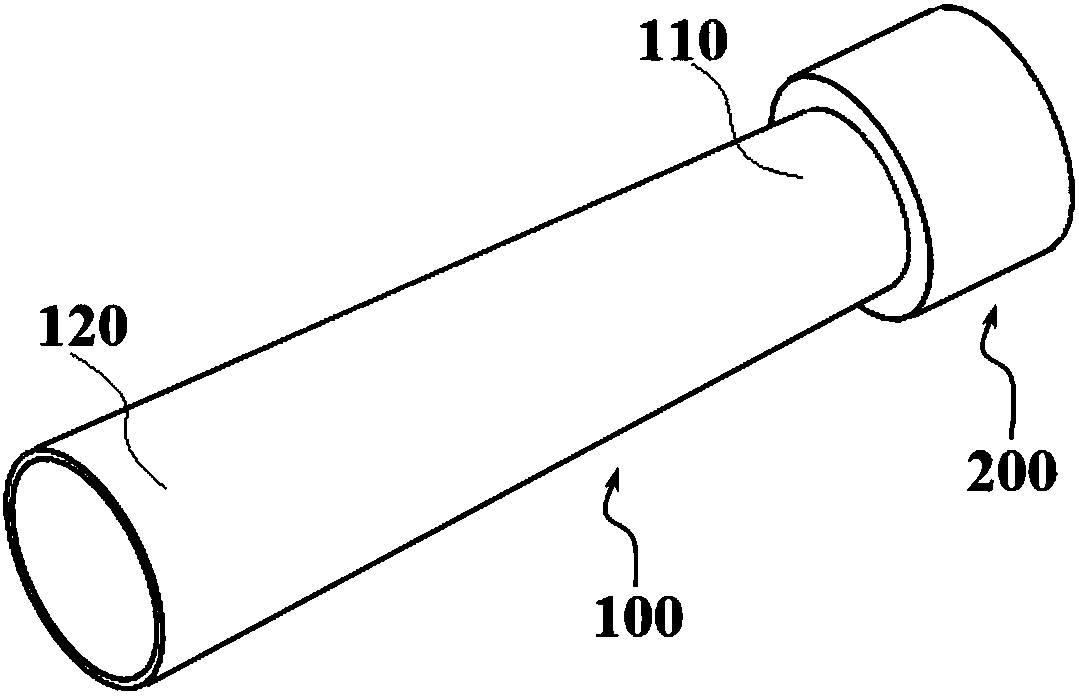

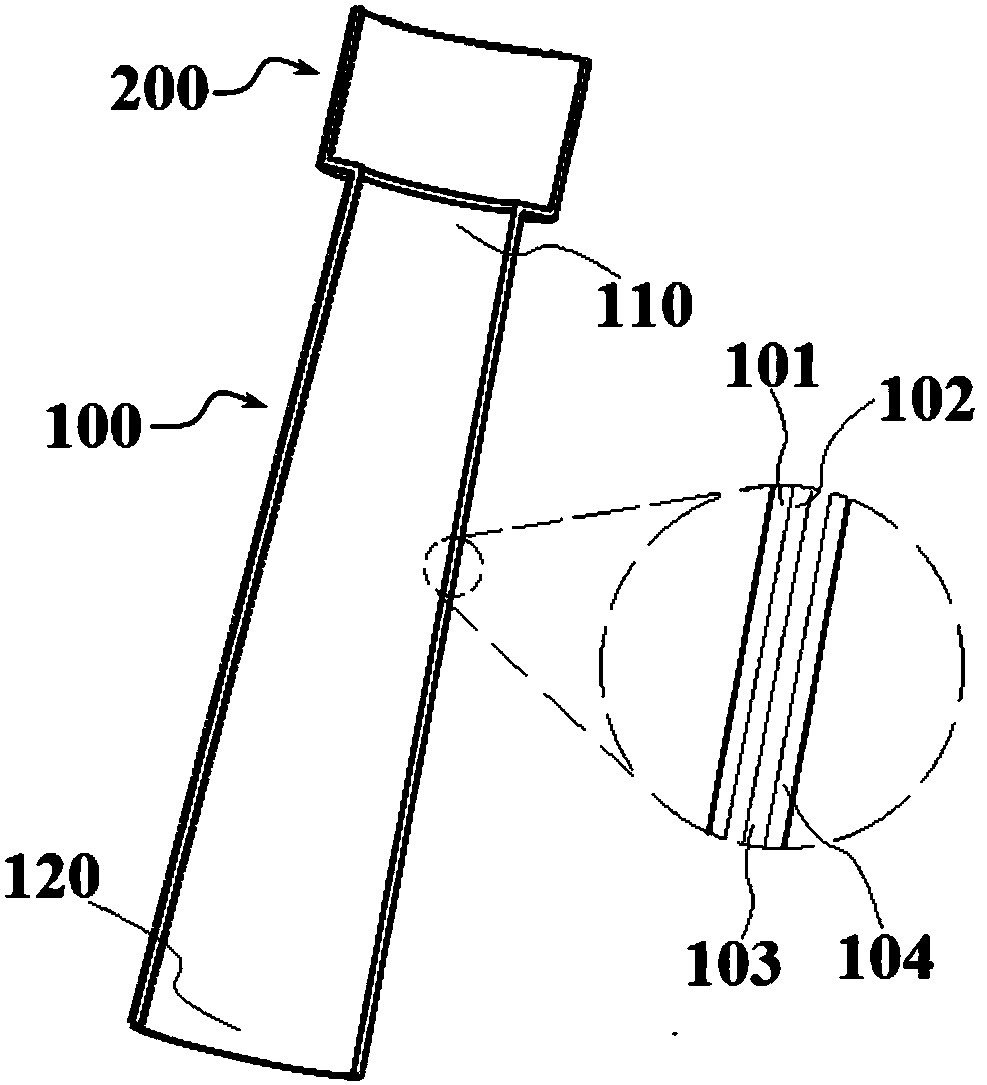

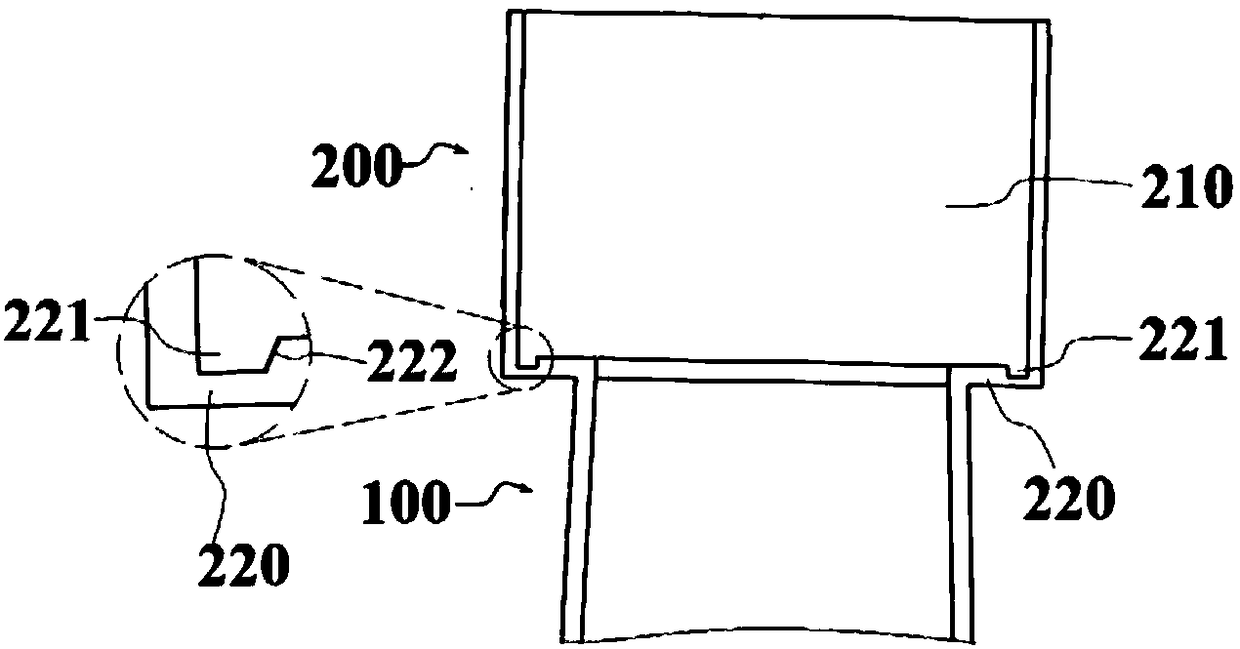

Protective tube for molten steel tapping process

PendingCN108115120AReduce the amount of adsorptionGood insulation effectMolten metal conveying equipmentsThermal insulationMetallurgy

The invention discloses a protective tube for the molten steel tapping process and belongs to the technical field of steel metallurgy steelmaking. The protective tube comprises a protective sleeve anda connecting component, wherein the internal diameter of the protective sleeve is greater than the diameter of a steel tapping opening, so that a gap is reserved between steel flow and the inner wallof the protective sleeve when the steel flow flows through the protective sleeve; the connecting component is used for being connected with the steel tapping opening; the sleeve inlet end of the protective sleeve is connected with the connecting component and forms a penetrating protective tube; and the steel flow flows to the protective sleeve from the steel tapping opening via the connecting component. The protective tube establishes a closed steel flow passage to effectively isolate contact between molten steel and the air and protect the steel tapping process of molten steel, so that theadsorbing capacity of molten steel to harmful gas including nitrogen and hydrogen is greatly reduced, an excellent thermal insulation effect to molten steel is realized, heat loss of molten steel is effectively reduced, and temperature reduction of molten steel during the steel tapping process is reduced to further improve the quality of molten steel.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

High-temperature-resistant smelting furnace

The invention relates to a high-temperature-resistant smelting furnace. The high-temperature-resistant smelting furnace comprises a shell, wherein a heat-resistant layer is arranged between the shell and an inner cavity, a feeding device is arranged on the inner cavity, the feeding device extends to the position above the shell and is fixed through a fixing part, the top of the shell is provided with a ventilation device, the ventilation device extends into the inner cavity, a heat-resistant plate is arranged at the bottom of the inner cavity, the heat-resistant plate is connected to a combustion cavity, and the combustion cavity is connected to a variable-frequency motor; and the variable-frequency motor is fixed to the shell, a plurality of layers of surrounding coils are arranged at the bottom of the shell, current passes through the coils to be connected to the variable-frequency motor, the variable-frequency motor is connected to a vacuum pump, and the vacuum pump extends into the inner cavity through a vacuum pipe. The high-temperature-resistant smelting furnace has the advantages of being simple in structure and easy to operate, the working efficiency and the working precision of the overall structure are effectively improved through use of a controller, errors are reduced, the overall structure is stable and firm, the service time is long, and the comprehensive economic benefit is improved.

Owner:MAANSHAN ZHONGTIAN MACHINERY INSTALLED

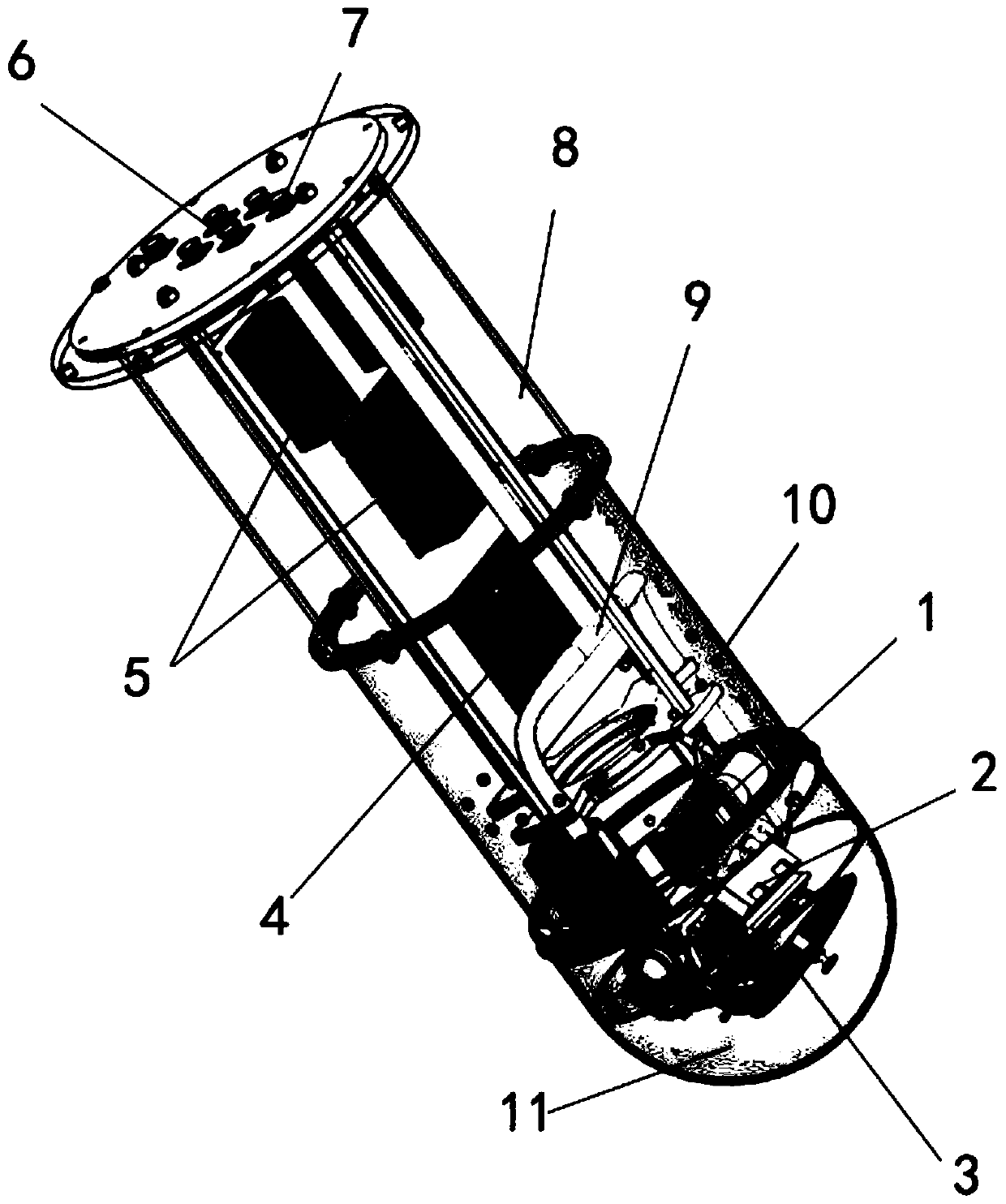

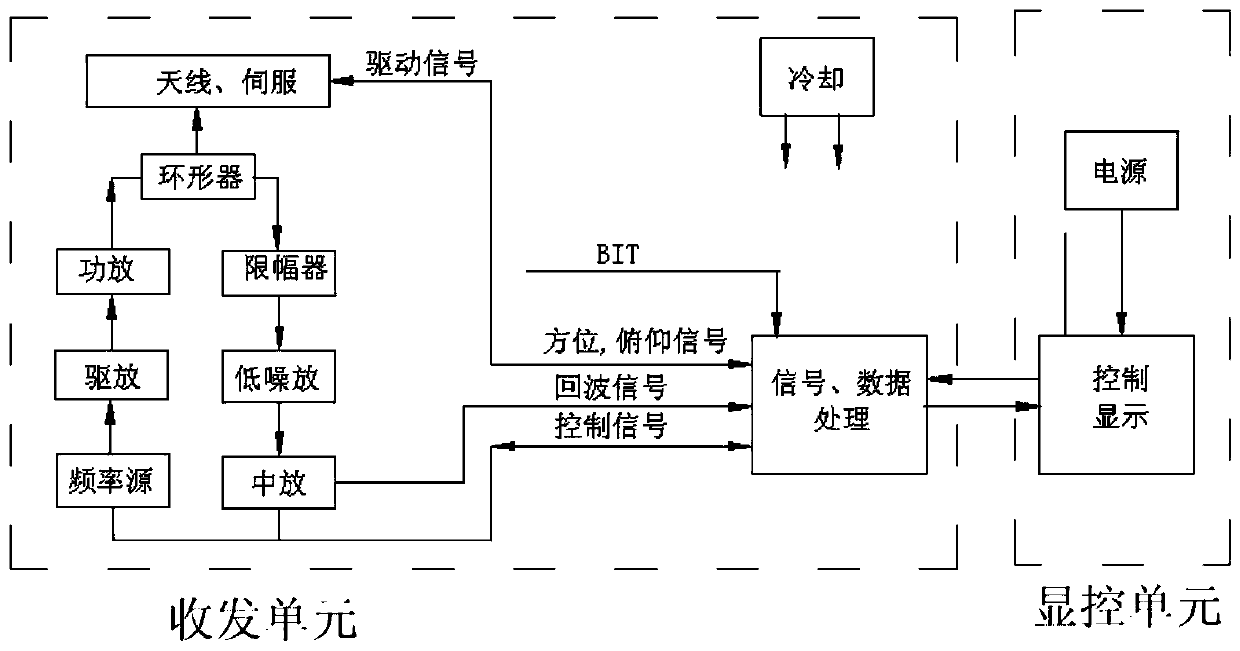

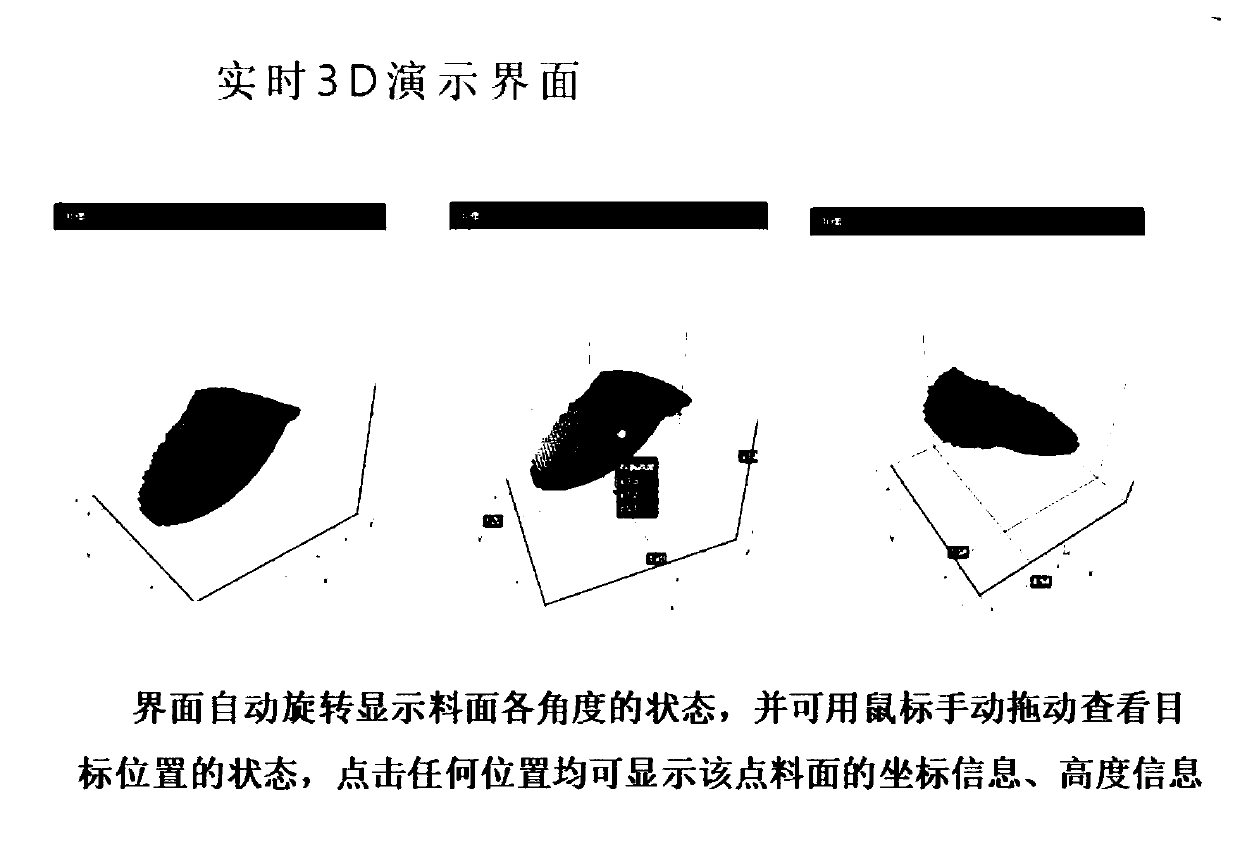

Blast furnace burden surface imaging device and system and measuring method thereof

InactiveCN111273287AReduce the number of openingsMore intuitive than thermal imagingMachines/enginesLevel indicatorsLow noiseEngineering

The invention discloses a blast furnace burden surface imaging device and system and a measuring method thereof. The device comprises a radar antenna, a frequency synthesizer system, a transceiving system and a signal processor, the transceiving system is in signal connection with the radar antenna; the transceiving system mixes and amplifies frequency modulation signals generated by the frequencysynthesizer system and then transmits the signals to the radar antenna; low-noise noise amplification, filtering and frequency mixing processing are carried out on echo signals received by the radarantenna; the frequency synthesizer system is in signal connection with the transceiving system and provides frequency modulation signals and frequency mixing signals for the transceiving system; the signal processor is in signal connection with the transceiving system and the frequency synthesizer system; and the signal processor performs coherent processing on the echo signals processed by the transceiving system to obtain echo distance and azimuth information of targets, processes the echo distance and azimuth information to obtain height information of the targets, and fits an image of thematerial surface in the blast furnace according to the height information of the plurality of targets.

Owner:NANJING HUALEI ELECTRONICS ENG INST

Molten steel transfer device capable of protecting tapping and electric furnace steelmaking system capable of protecting tapping

ActiveCN108127110AQuality improvementFlow restrictionMelt-holding vesselsProcess efficiency improvementSteelmakingHydrogen

The present invention discloses a molten steel transfer device capable of protecting tapping and an electric furnace steelmaking system capable of protecting tapping, and relates to the steelmaking technical field of steel metallurgy. The electric furnace steelmaking system comprises an electric furnace body and the molten steel transfer device. The molten steel transfer device comprises a buggy ladle and a tapping protection tube. The buggy ladle comprises a protection tube control unit and a ladle pot. The tapping protection tube is installed to the protection tube control unit. The protection tube control unit is used for controlling the tapping protection tube to move in the vertical direction or the horizontal direction. The tapping protection tube comprises a protection bushing and aconnection bushing. A bushing inlet of the protection bushing is connected with the connection bushing so as to form the through tapping protection tube. A gap is provided between molten steel and aninner wall of the protection bushing when the molten steel flows through the protection bushing. A relative closed type molten steel channel is established by the tapping protection tube, gas flow onthe molten steel surface is effectively restricted, the quantity of harmful gas such as nitrogen and hydrogen adsorbed by the molten steel is reduced, and steel quality is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

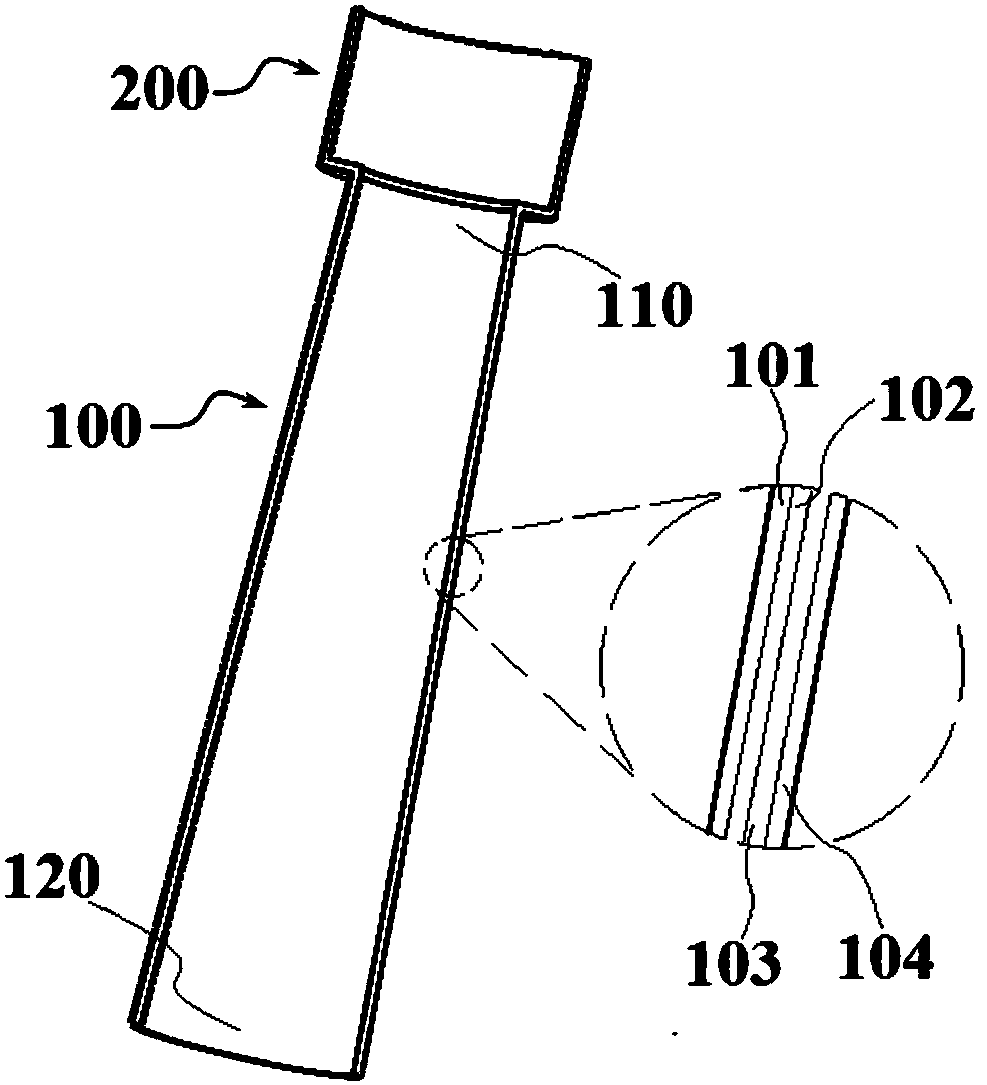

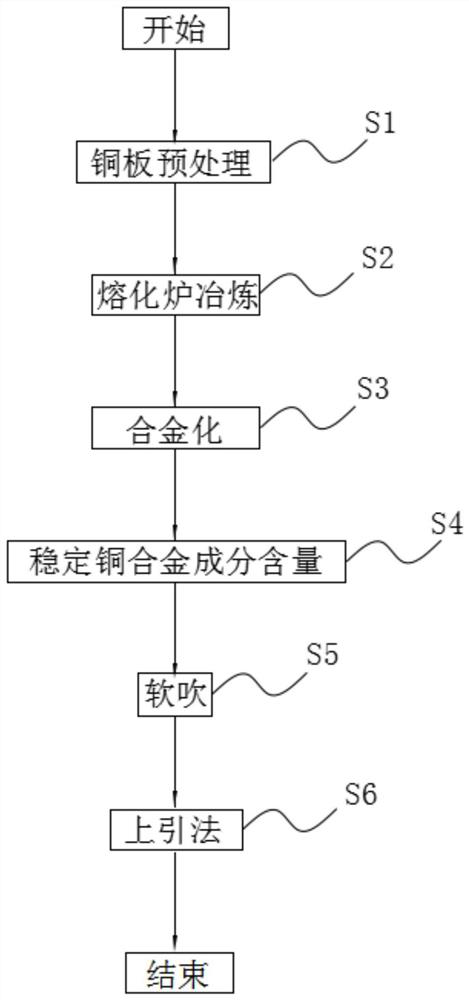

Molten copper smelting up-drawing process for controlling copper alloy inclusions

PendingCN113770321APromote circulationAvoid affecting the quality of the finished productArgon gasCopper alloy

The invention discloses a molten copper smelting up-drawing process for controlling copper alloy inclusions. The process comprises the following steps that (1), a copper plate is cleaned; (2), the copper plate is smelted into molten copper, and a covering agent is added when the molten copper is smelted; (3), alloy elements are added into the molten copper for alloying, and ultrasonic treatment is carried out; (4), the content of a molten copper alloy in a melting furnace is detected, if the content is lower than the standard, an alloy is added for supplementation, if the content is higher than the standard, a copper plate is added, and when the content of the alloy meets the standard, the purpose of stabilizing the content of the copper alloy component is achieved by controlling the adding rate of the copper plate and the alloy; (5), soft argon blowing is conducted at the bottom of the melting furnace; and (6), an up-drawing method is adopted, specifically, the up-drawing method is adopted for producing a copper rod, and the molten copper in the melting furnace is electrified in the up-drawing process. According to the molten copper smelting up-drawing process, ultrasonic treatment is adopted, argon is softly blown from the bottom after the molten copper is alloyed, so that the inclusions in the molten copper float upwards, the stability of the cleanliness of the molten copper can be effectively guaranteed, meanwhile, the molten copper refining effect is improved by electrifying the melting furnace, and the inclusions are controlled from the source.

Owner:CENTURAY TECH CO LTD

A kind of electroslag smelting method

The invention discloses an electroslag smelting method, which is characterized in that two sets of electrode devices are arranged beside a crystallizer, and then the two sets of electrode devices are smelted by using the crystallizer in turn, during the smelting process of one electrode device, the other electrode device The device performs the work of installing electrodes and preheating the electrodes. When the electrode device used for smelting is smelted and the electrodes are removed, re-feeding and the crystallizer are arranged, the preheated electrodes are moved into the crystallizer for smelting, and so on. Realize high-efficiency electroslag smelting. The invention has the advantages of high smelting efficiency, good safety, excellent smelting effect, safety, high efficiency and energy saving, and improves the smelting quality of electroslag steel ingots; at the same time, the bottom water tank is very convenient for maintenance and replacement, reduces maintenance costs, and improves cooling efficiency.

Owner:宝武特冶航研科技有限公司

An atmosphere protective cover for electroslag furnace and electroslag furnace smelting system

Owner:烟台台海玛努尔核电设备有限公司

Titanium and titanium alloy pressing lump material drying method

ActiveCN102853636BImprove drying efficiencyReduce moisture contentDrying solid materialsDrying machines with local agitationIngotTitanium

The invention discloses a titanium and titanium alloy pressing lump material drying method. Heat of a quartz tube is adopted for drying titanium and titanium alloy pressing lump materials. According to the method, the efficiency for drying the sponge titanium pressing lump materials is improved by utilizing the far infrared characteristics of a quartz tube, meanwhile, the temperature can be controlled accurately, and the condition that the sponge titanium pressing lump materials can not be oxidized is ensured, and the component quality of titanium ingot products is improved.

Owner:攀枝花云钛实业有限公司

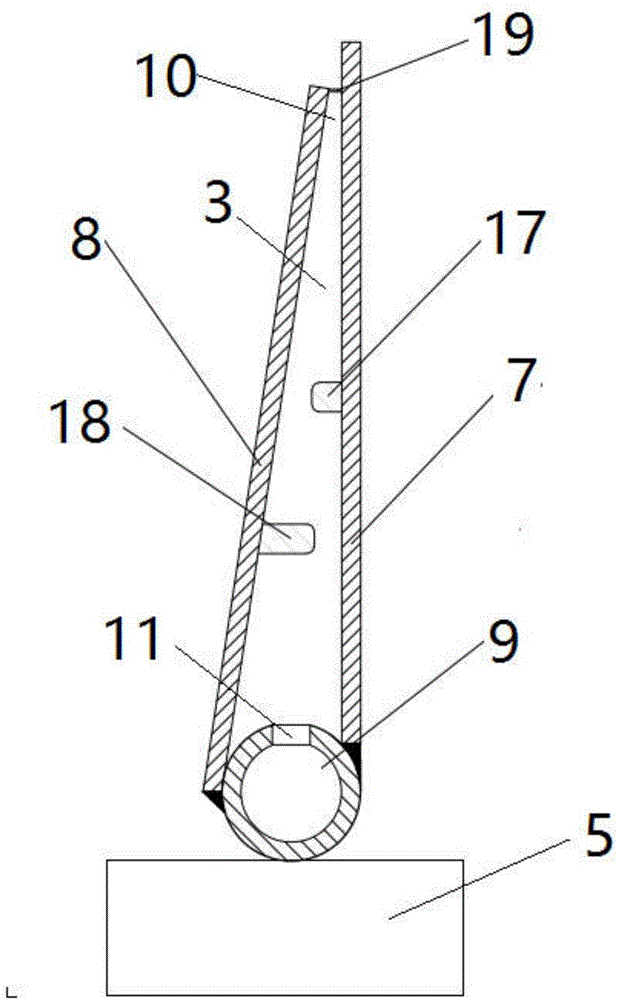

Argon blowing protection device for die-casting die

The invention provides an argon blowing protection device which is used for a die-casting die and applied to the technical field of auxiliary components for die-casting dies. A circular cavity (3) is formed inside a plugging ring (2) of the argon blowing protection device for the die-casting die; an argon source (1) communicates with the circular cavity (3) by the aid of a connecting pipeline (4); the position above a casting gate (5) is sleeved with the plugging ring (2); a throttling valve (6) for adjustment is arranged on the connecting pipeline (4); and a gas outlet gap (10) for outputting argon is formed in the circular cavity (3). The device is simple in structure and low in manufacturing cost and can provide argon for the casting gate in the molten steel pouring process, continuous high-pressure argon exists at the casting gate part, outside air cannot get close to the casting gate, molten steel is prevented from making contact with the air, steel ingots cannot be scrapped due to the effect of impurities in the air, and the steel smelting quality is improved.

Owner:MAANSHAN IRON AND STEEL COMPANY

Molten steel alloying apparatus for protecting molten steel during tapping process and electric furnace steelmaking system having apparatus

PendingCN108127090AQuality improvementReduce heat lossMelt-holding vesselsProcess efficiency improvementSteelmakingHydrogen

The present invention discloses a molten steel alloying apparatus for protecting molten steel during a tapping process and an electric furnace steelmaking system having the apparatus, and relates to the steelmaking technical field of steel metallurgy. The molten steel alloying apparatus comprises a buggy ladle, a tapping protection tube and an alloy feeder. The buggy ladle comprises a protection tube control unit, a feeder control unit and a ladle pot. The tapping protection tube is installed on the protection tube control unit. The protection tube control unit is used for controlling the position of the tapping protection tube. The tapping protection tube is used for protecting the molten steel during the tapping process. The alloy feeder is installed on the feeder control unit. The feeder control unit is used for controlling the position of the alloy feeder. A relative closed type molten steel channel is established by the tapping protection tube, gas flow on the molten steel surfaceis restricted, alloy materials are added to the ladle for alloying, the quantity of harmful gas such as nitrogen and hydrogen adsorbed by the molten steel during the tapping and alloying processes isreduced, uniform distribution of the alloy elements in the molten steel is promoted by flowing of the molten steel, and quality of alloy steel is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com