High-carbon ferro-chrome smelting method

A technology of high-carbon ferrochromium and smelting methods, which is applied in the direction of electric furnaces, furnaces, furnace types, etc., can solve the problems that dust cannot be recycled, achieve the effects of reducing energy consumption, improving smelting quality, and avoiding remelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

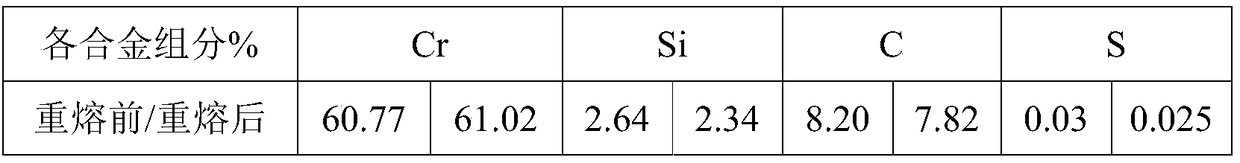

Embodiment 1

[0038](1) Firstly, pass a current of alternating frequency 1000HZ into the spiral water-cooled coil outside the intermediate frequency induction furnace, so that a magnetic field will be generated in the space surrounded by the coil and around it, and then add natural block high carbon with 1 / 2 of the furnace cavity volume For ferrochrome, add powdered high-carbon ferrochrome after the melting reaches 2 / 3, and then add powdery and / or granular high-carbon ferrochrome and slagging agent with a mass ratio of 7:3 after melting Mixed material, melt clear; the particle size of the mixed material is 3-7mm, and the ratio of the particle size of the powdery and / or granular high-carbon ferrochrome to the penetration depth of the current is controlled between 5-6; the slagging agent made of SiO 2 , CaO, Gr 2 o 3 、Al 2 O composition, the mass ratio is 2:3:1:1.

[0039] (2) the liquid steel that melts clear in the step (1) is adopted to stay the steel method operation: promptly tapping...

Embodiment 2

[0044] (1) Firstly, pass a current of alternating frequency 1200HZ into the spiral water-cooled coil on the outside of the intermediate frequency induction furnace to generate a magnetic field in the space surrounded by the coil and around it, and then add natural block high carbon with 1 / 6 of the furnace cavity volume For ferrochrome, add powdered high-carbon ferrochrome after the melting reaches 2 / 3, and then add a 10:1 mixture of powdery and / or granular high-carbon ferrochromium and slagging agent after melting, Melt clear; the particle size of the mixture is 3-7mm, the particle size of the powdery and / or granular high-carbon ferrochrome and the penetration depth ratio of the current are controlled between 5-6; the slagging agent is made of SiO 2 , CaO, Gr 2 o 3 、Al 2 O composition, the mass ratio is 1:2:0.5:0.5.

[0045] (2) the liquid steel that melts clear in the step (1) is adopted to stay the steel method operation: promptly tapping amount is 65% of furnace chamber ...

Embodiment 3

[0047] (1) Firstly, pass a current of alternating frequency 1100HZ into the spiral water-cooled coil outside the intermediate frequency induction furnace to generate a magnetic field in the space surrounded by the coil and around it, and then add natural block high carbon with 1 / 6 of the furnace cavity volume For ferrochrome, add powdered high-carbon ferrochrome after the melting reaches 2 / 3, and then add a 9:2 mixture of powdery and / or granular high-carbon ferrochrome and slagging agent after melting, Melt clear; the particle size of the mixture is 3-7mm, the particle size of the powdery and / or granular high-carbon ferrochrome and the penetration depth ratio of the current are controlled between 5-6; the slagging agent is made of SiO 2 , CaO, Gr 2 o 3 、Al 2 O composition, the mass ratio is 3:5:2:2.

[0048] (2) the liquid steel that melts clear in the step (1) is adopted to stay the steel method operation: promptly tapping amount is 80% of furnace chamber volume, and reten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com