Molten steel alloying apparatus for protecting molten steel during tapping process and electric furnace steelmaking system having apparatus

A technology of molten steel alloying and tapping process, applied in the field of iron and steel metallurgy and steelmaking, can solve problems such as the reduction of molten steel quality, and achieve the effects of reducing steelmaking energy consumption, reducing heat loss, and improving molten steel quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

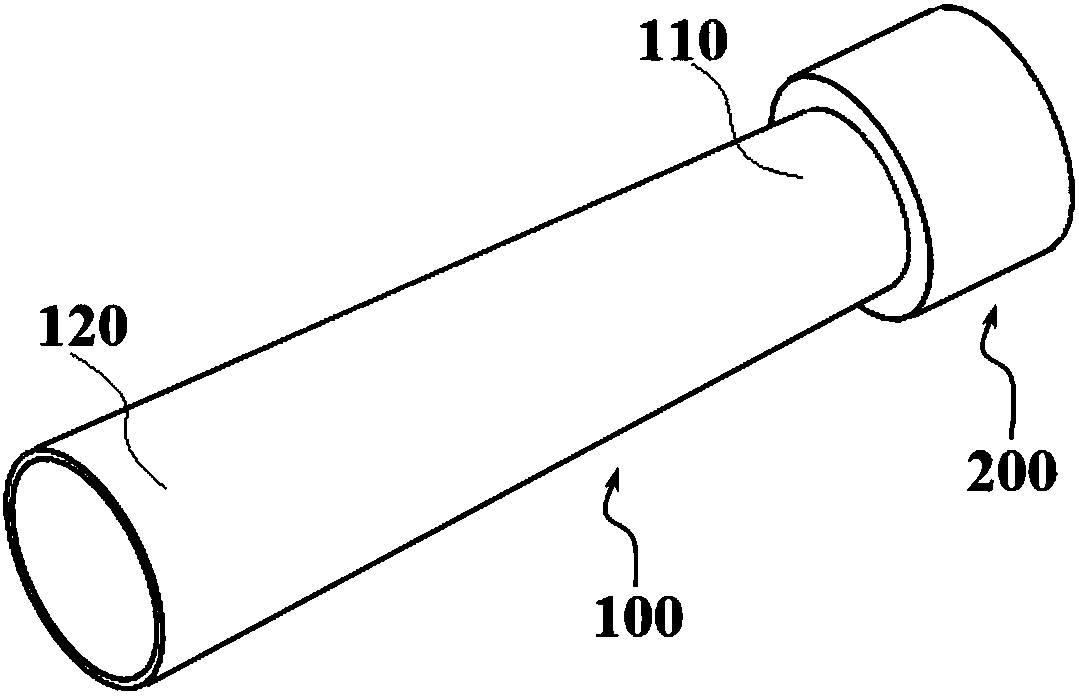

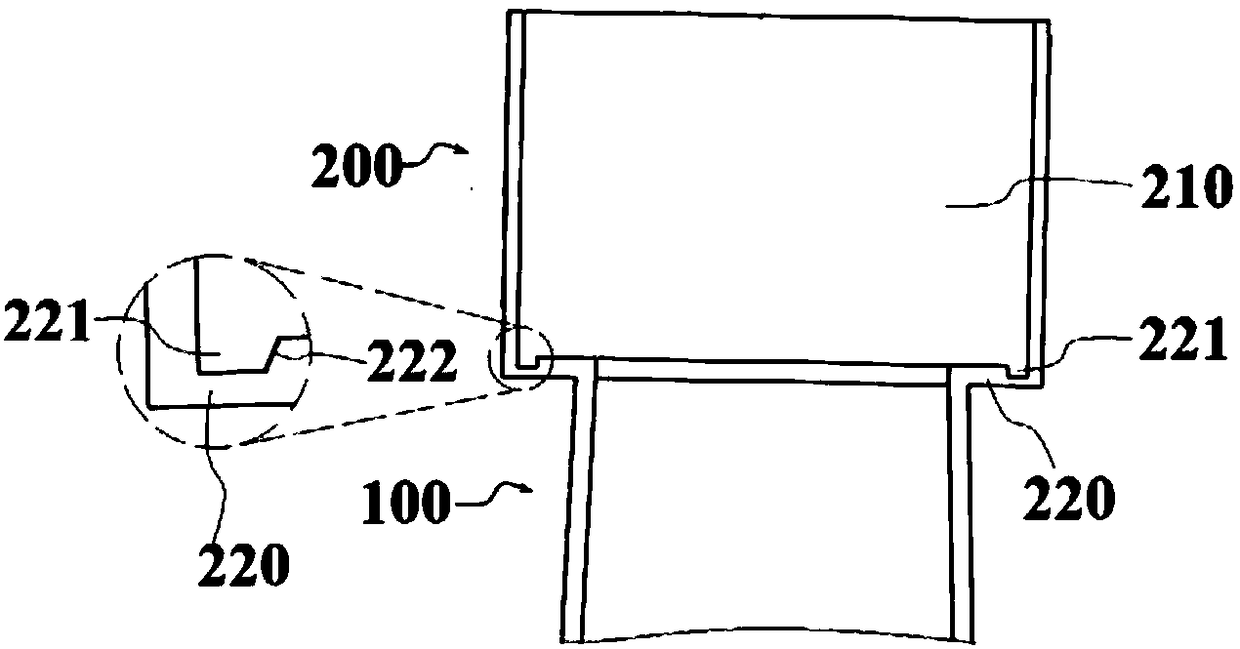

[0051] combine figure 1 and Figure 5 , a molten steel alloying device in the protection tapping process of the present invention includes a ladle car 300, a steel tapping protection pipe and an alloy feeder 500, and the ladle car 300 includes a transport car bottom plate 310, a protection pipe control unit 321 and Ladle tank 330 (such as Figure 5 Shown); Wheels are installed on the transport vehicle floor 310 to facilitate the movement of the ladle vehicle 300; the ladle tank 330 is fixedly arranged on the transport vehicle bottom plate 310, and the ladle tank 330 opening is upward;

[0052] The structure of the protection tube control unit 321 and the feeder control unit 322 of this embodiment are the same, and it includes a vertical telescopic mechanism 301, a horizontal telescopic mechanism 302 and a rotation mechanism 303, and the vertical telescopic mechanism 301 is fixedly installed on the ladle car 300 On the bottom plate 310 of the transport vehicle, the horizontal...

Embodiment 2

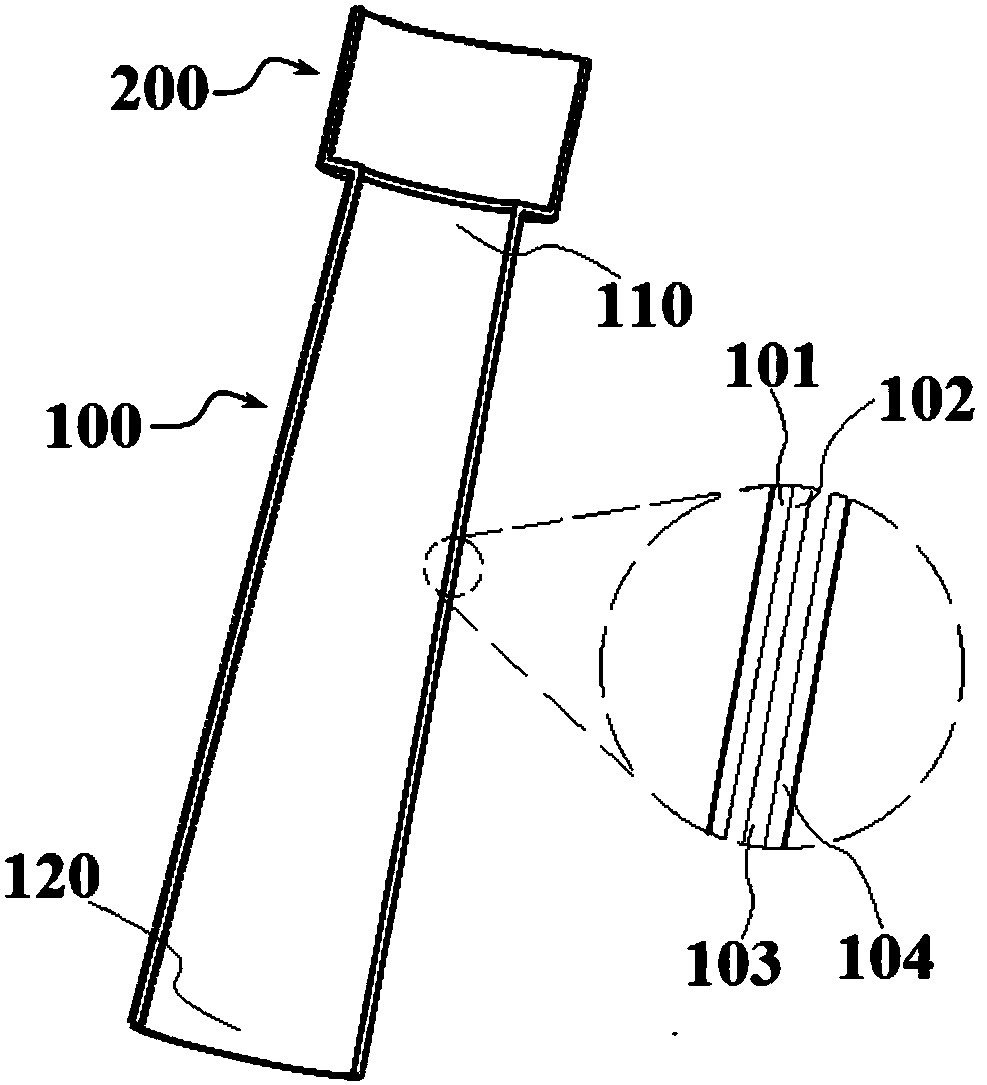

[0060] The basic content of this embodiment is the same as that of Embodiment 1, except that: the pipe wall of the protective sleeve 100 is provided with an outer shell 104, a heat insulating layer 102 and a refractory material layer 101 (such as figure 2 shown); the shell 104 is made of steel structure with high mechanical strength, and the heat insulating layer 102 is made of heat insulating material, wherein the heat insulating material is glass fiber, asbestos, rock wool or silicic acid Salt, or a combination of the above; the heat insulation material of the heat insulation layer 102 can effectively limit the heat of molten steel in the protective sleeve 100 from dissipating heat to the outside of the protective sleeve 100, reducing the temperature loss in the tapping process, and then reducing the temperature of the tapping. Temperature, saving steelmaking energy consumption. The refractory material layer 101 is arranged on the inner wall of the protective sleeve 100, an...

Embodiment 3

[0062] The basic content of this embodiment is the same as that of Embodiment 2, except that a gap layer 103 (such as figure 2 As shown), that is, a gap is arranged between the shell 104 and the heat insulating layer 102, and constitutes a gap layer 103. The gap layer 103 can be a vacuum condition, or the gap layer 103 filled with any gas. The gap layer 103 of this embodiment Layer 103 is filled with air. The gap layer 103 between the shell 104 and the heat insulation layer 102 changes the heat transfer conditions of the protective sleeve 100, thereby limiting the heat transfer from the molten steel in the protective sleeve 100 to the outside, and reducing the heat loss during the tapping process of the molten steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com