Patents

Literature

212results about How to "Avoid direct flushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

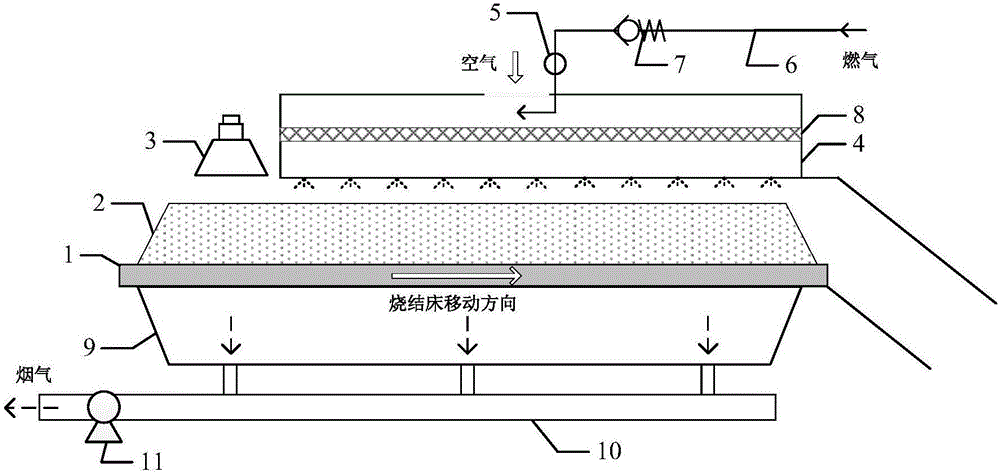

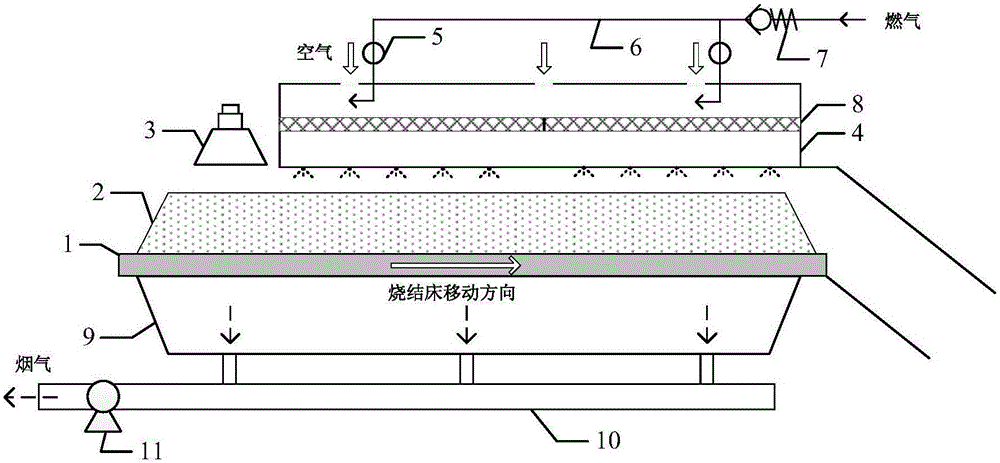

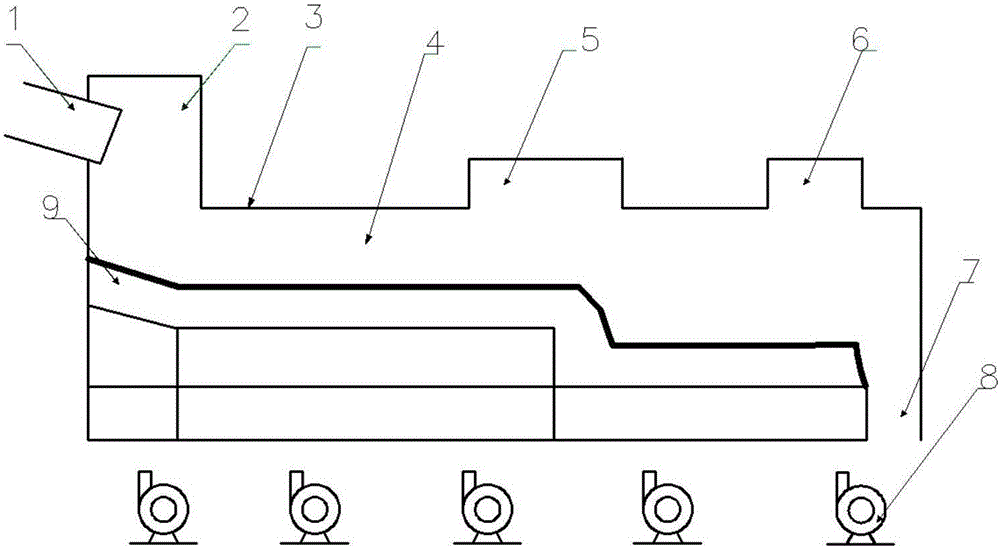

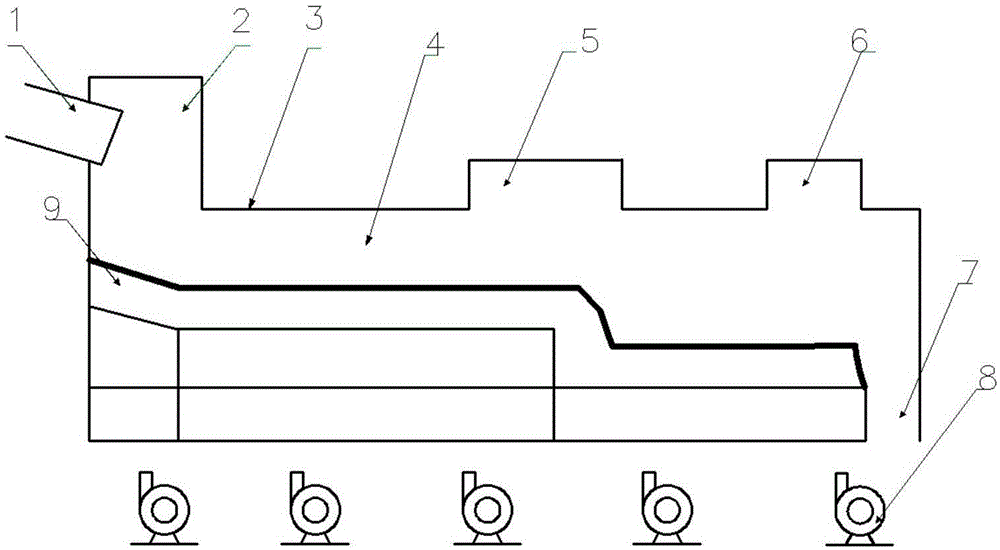

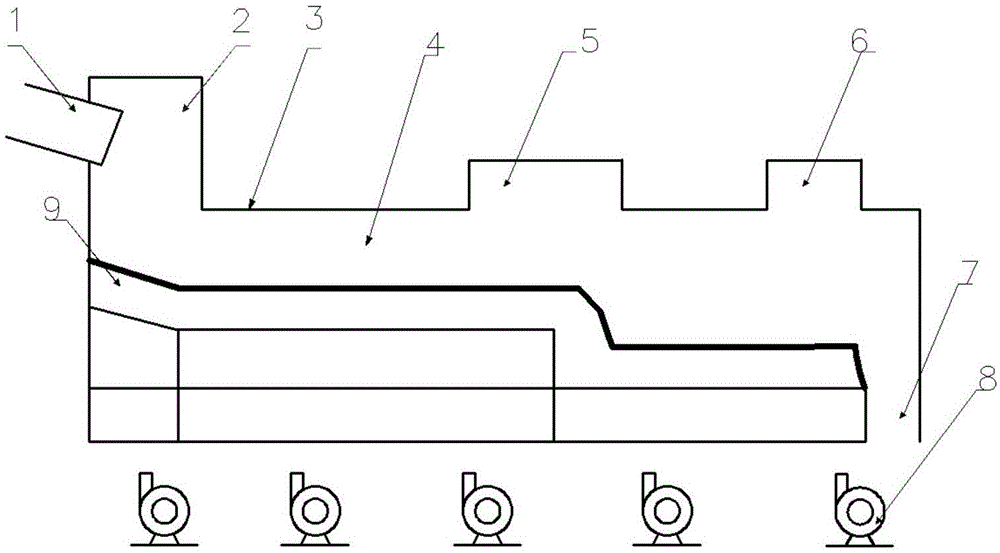

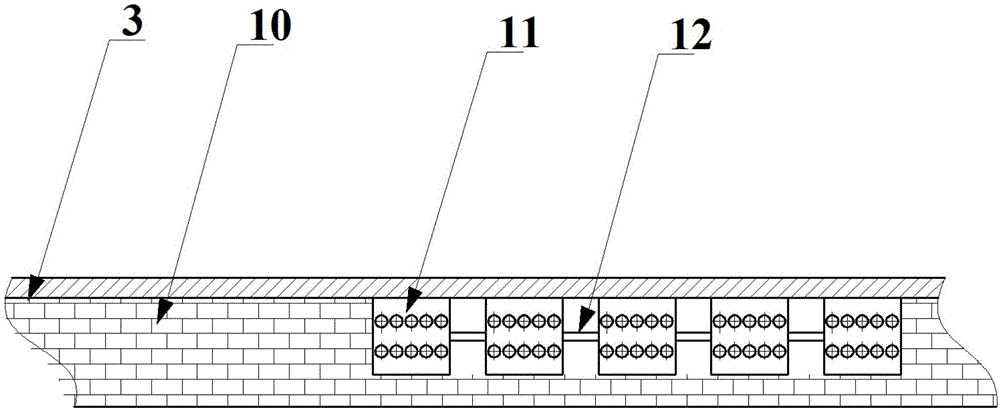

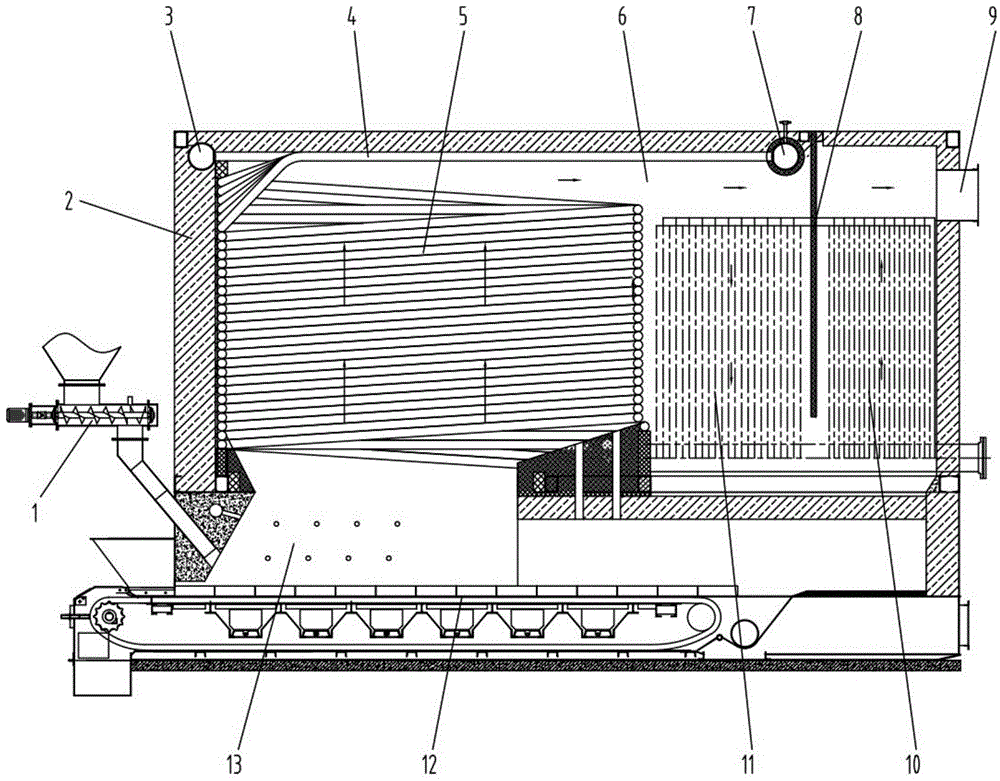

Sintering machine

ActiveCN106440810AIncreasing the thicknessReduce cooling rateFurnace typesControl devices for furnacesSolid fuelControllability

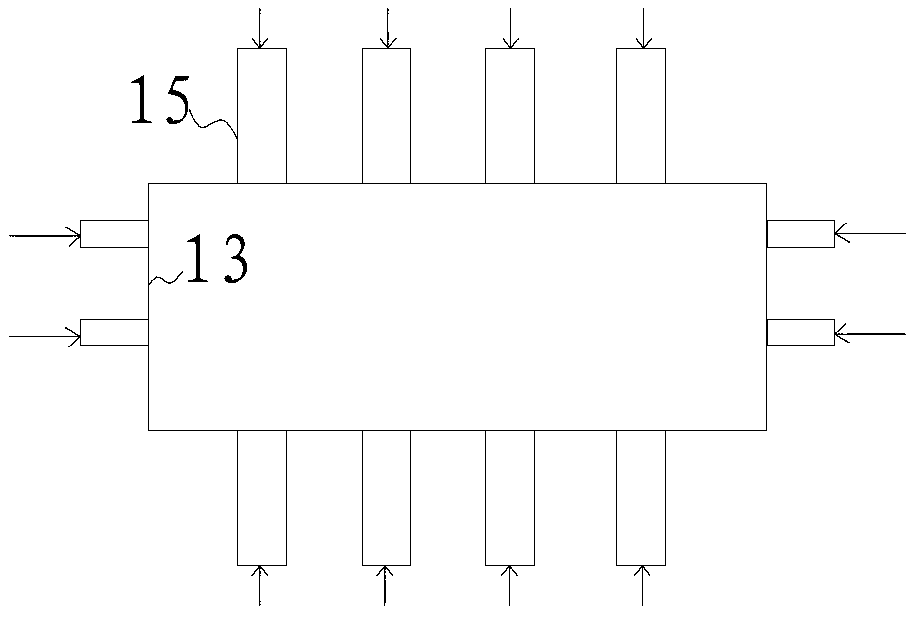

A sintering machine comprises a sintering pallet, an igniter, a wind cover and an air bellow. The sintering pallet allows a sintering raw material bed layer including solid fuel to move on the sintering pallet; the igniter is located on the front portion above the sintering pallet; the air cover is located on the rear portion above the sintering pallet; the air bellow is located below the sintering pallet, used for converging smoke obtained after combustion and connected with a smoke pipeline allowing the smoke to be exhausted. The sintering machine is characterized by further comprising at least one air inlet located in the top of the wind cover, at least one fuel gas inlet located in the top of the wind cover and connected with respective fuel gas supply pipelines, and a fuel gas blowing controller arranged on at least one fuel gas supply pipeline and used for controlling the fuel gas blowing amount entering the fuel gas inlets. According to the sintering machine, the energy efficiency of the sintering process can be remarkably improved, and the universality and operation controllability of a system are improved. Based on a variable-fuel-gas-flow blowing system of the sintering machine, the problem of outstanding sintering anisotropism can be effectively relieved.

Owner:XI AN JIAOTONG UNIV

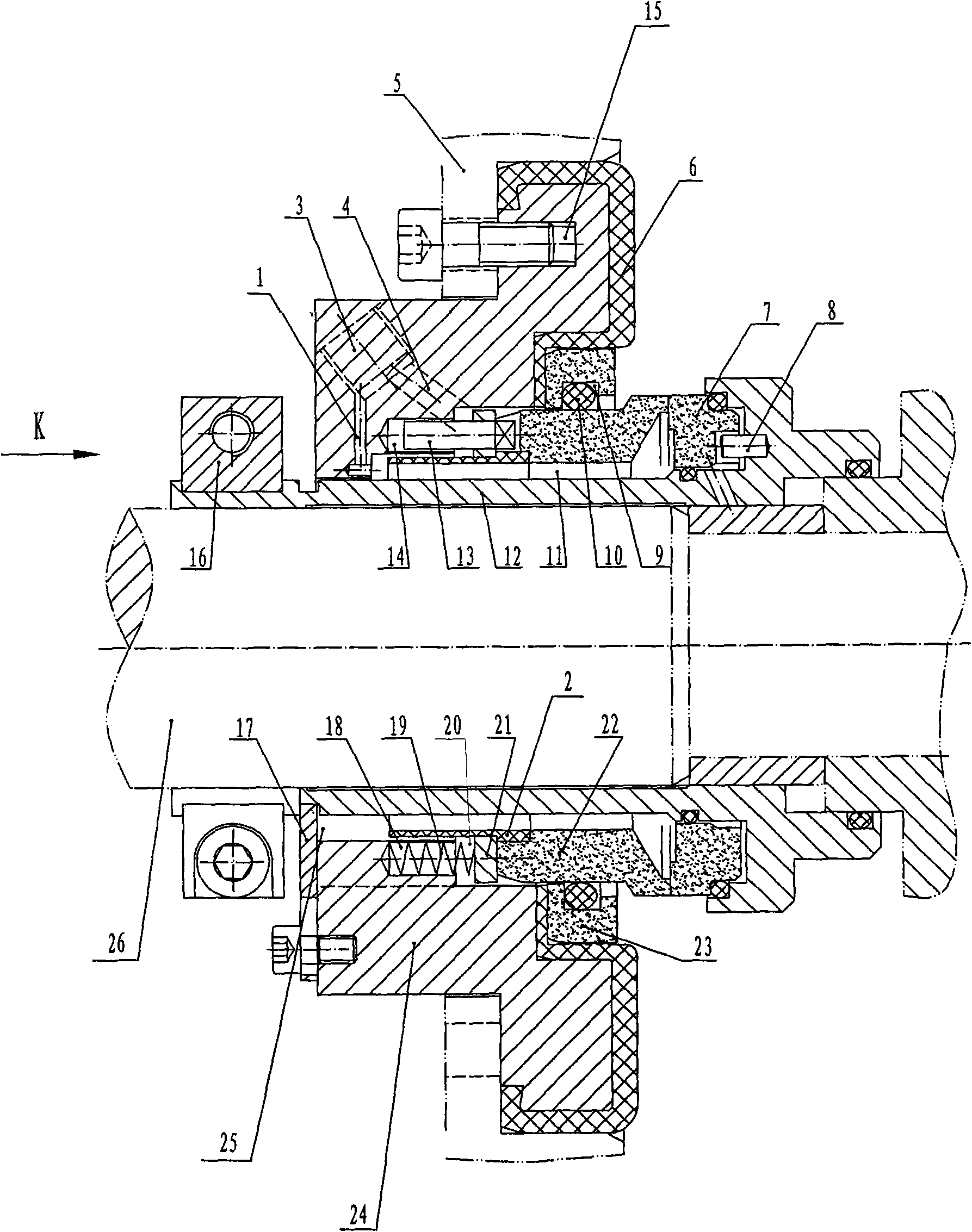

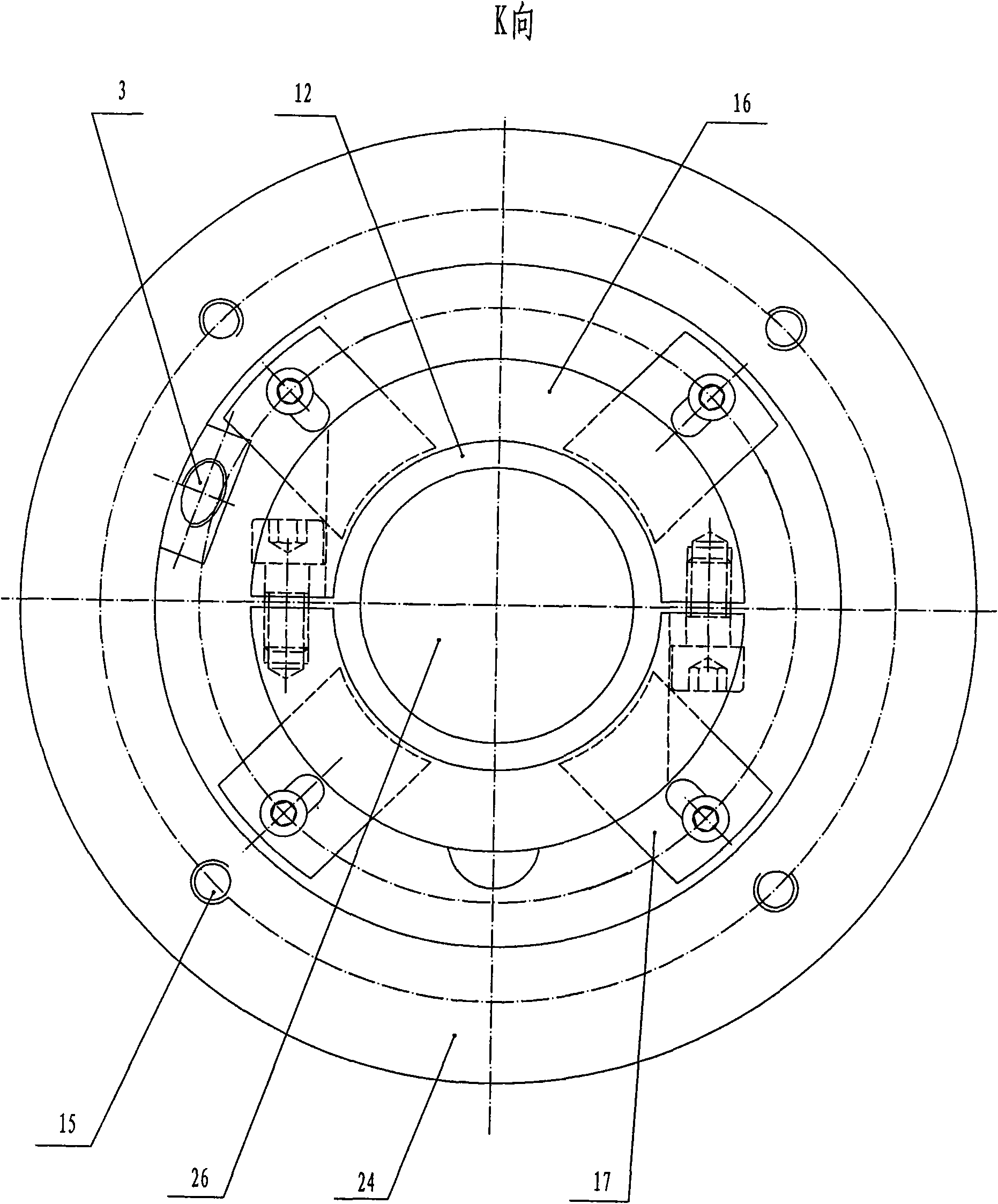

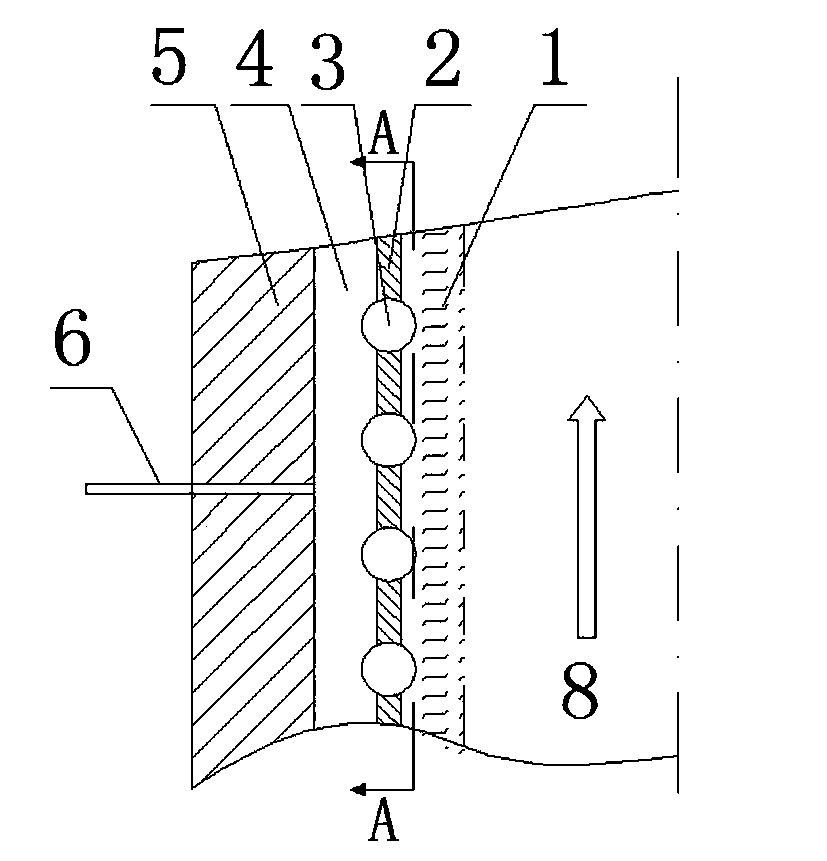

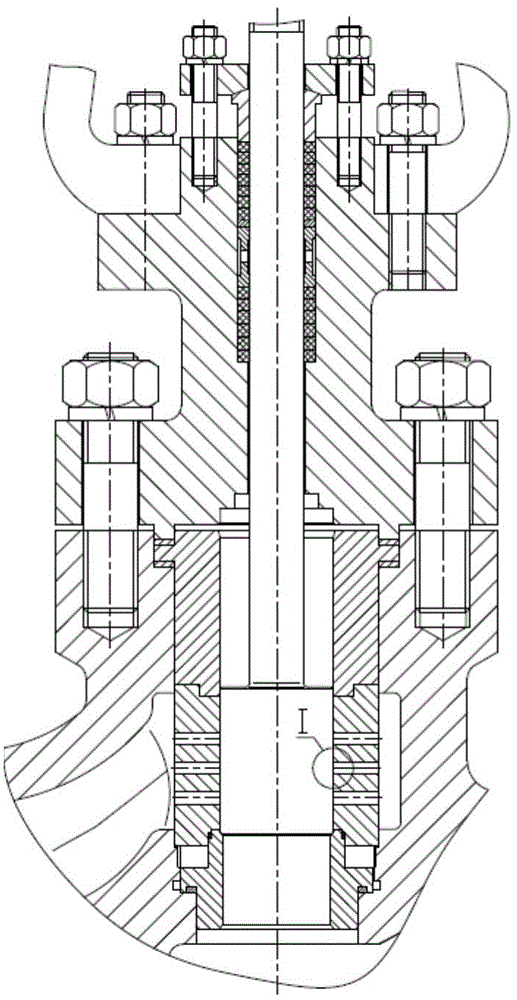

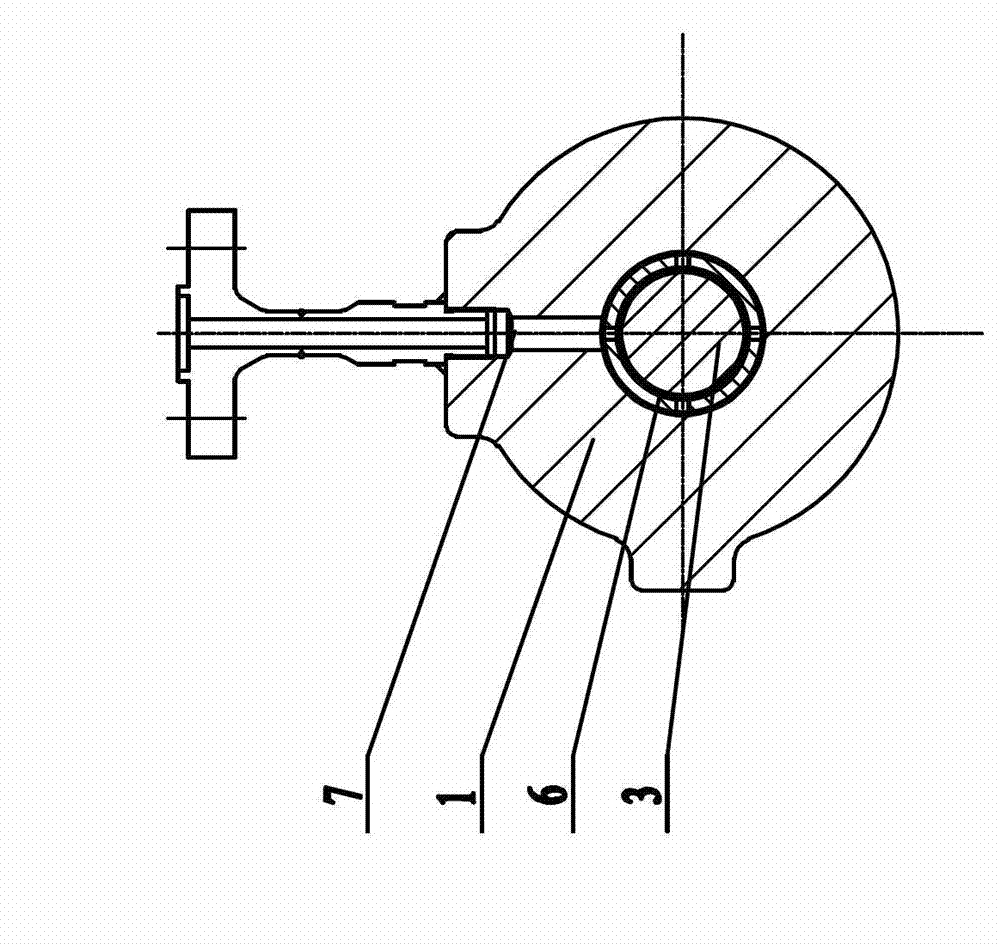

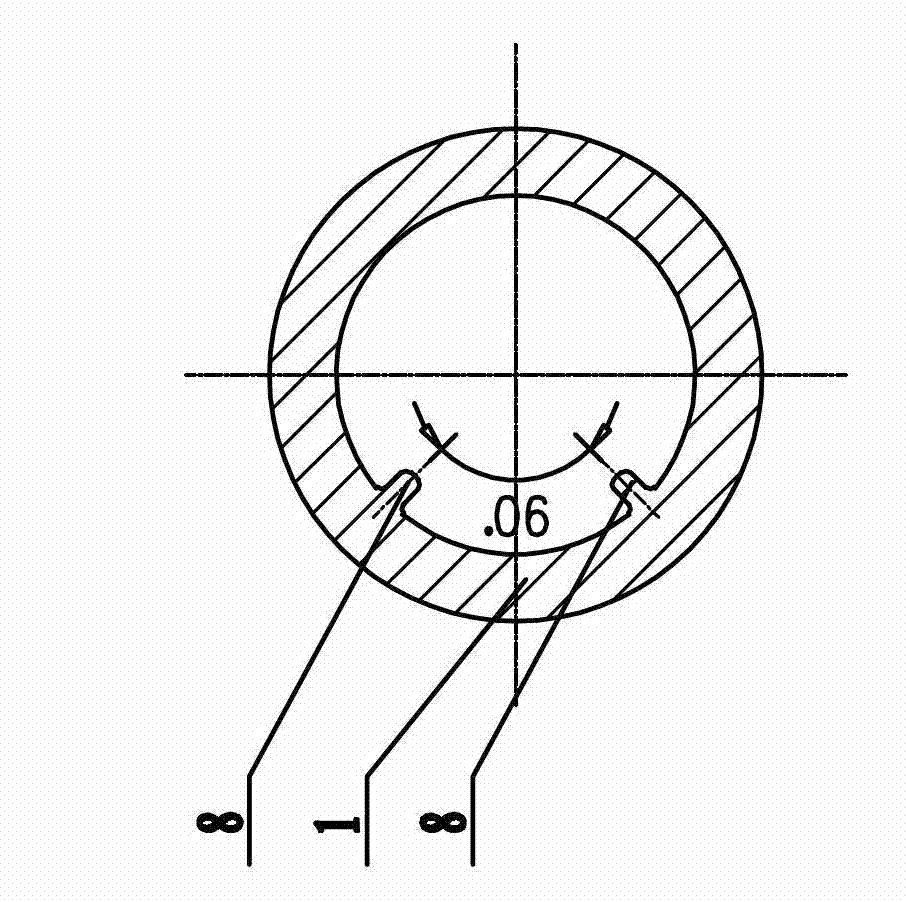

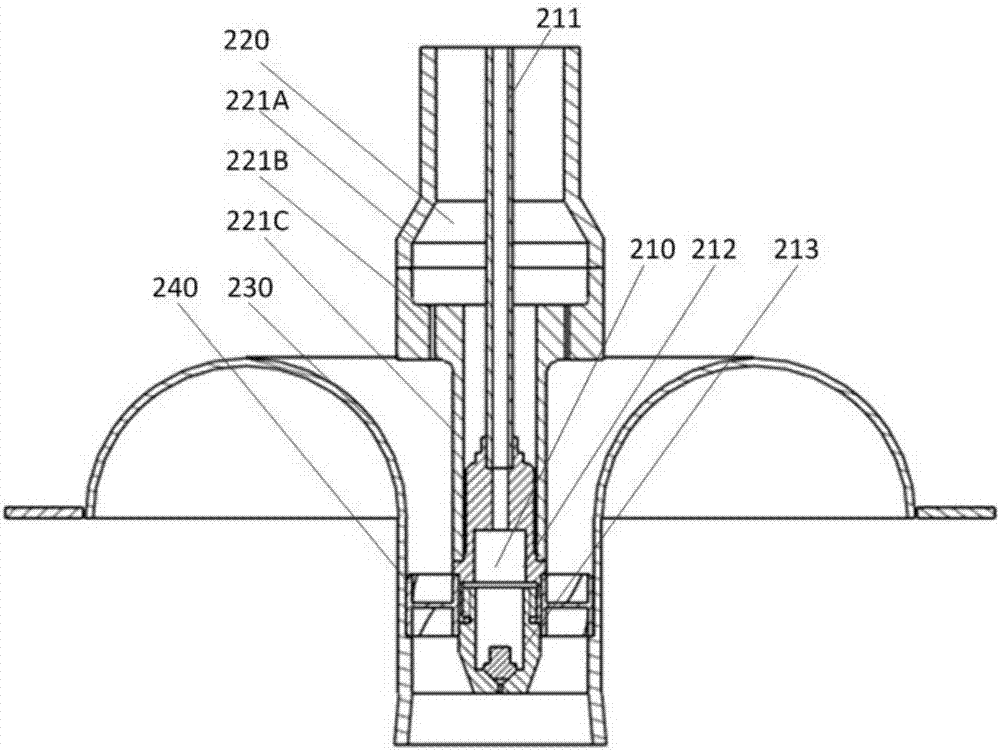

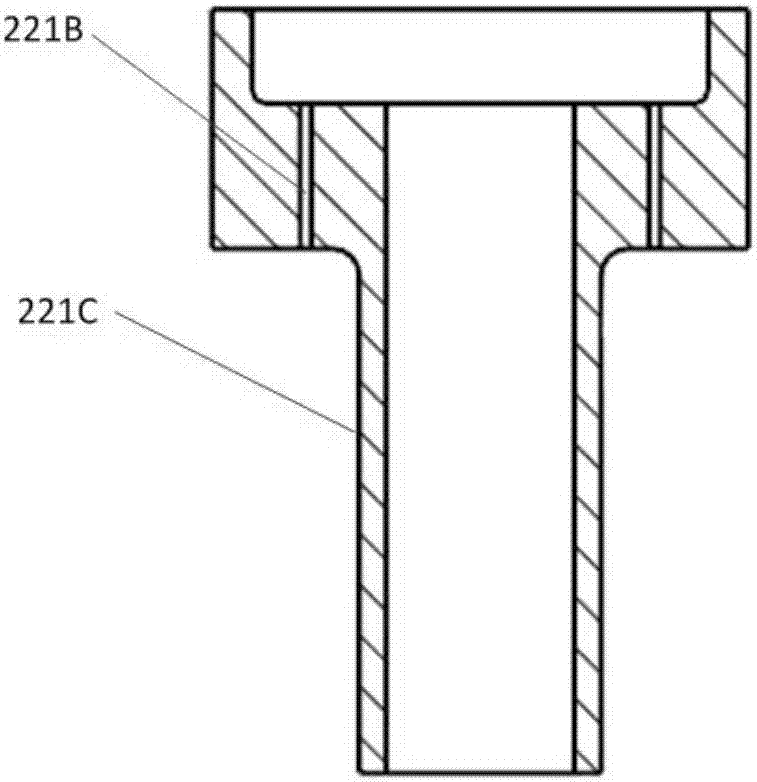

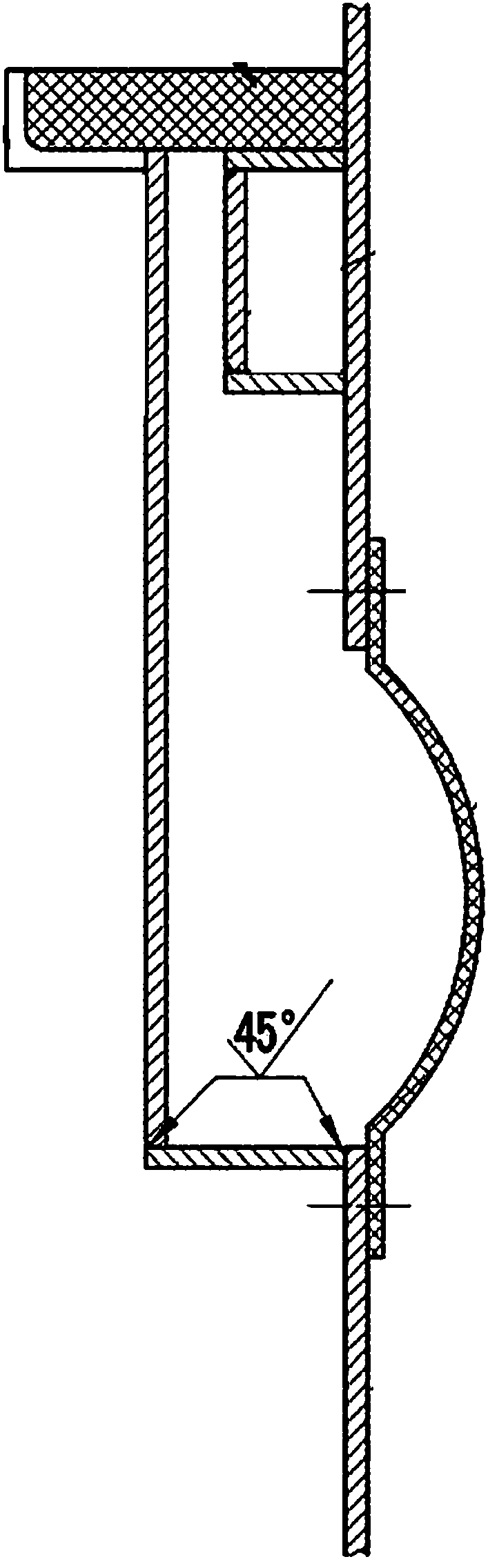

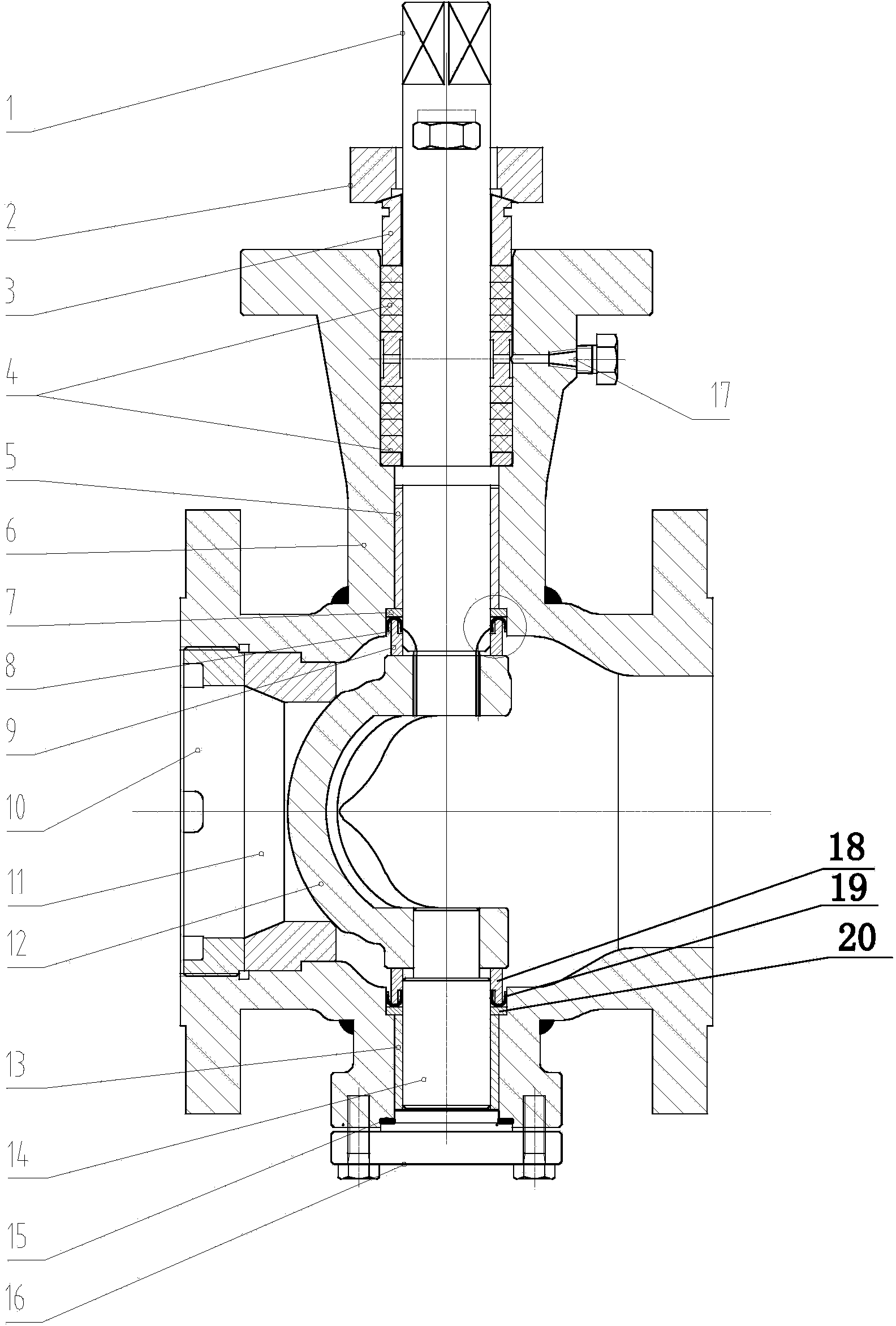

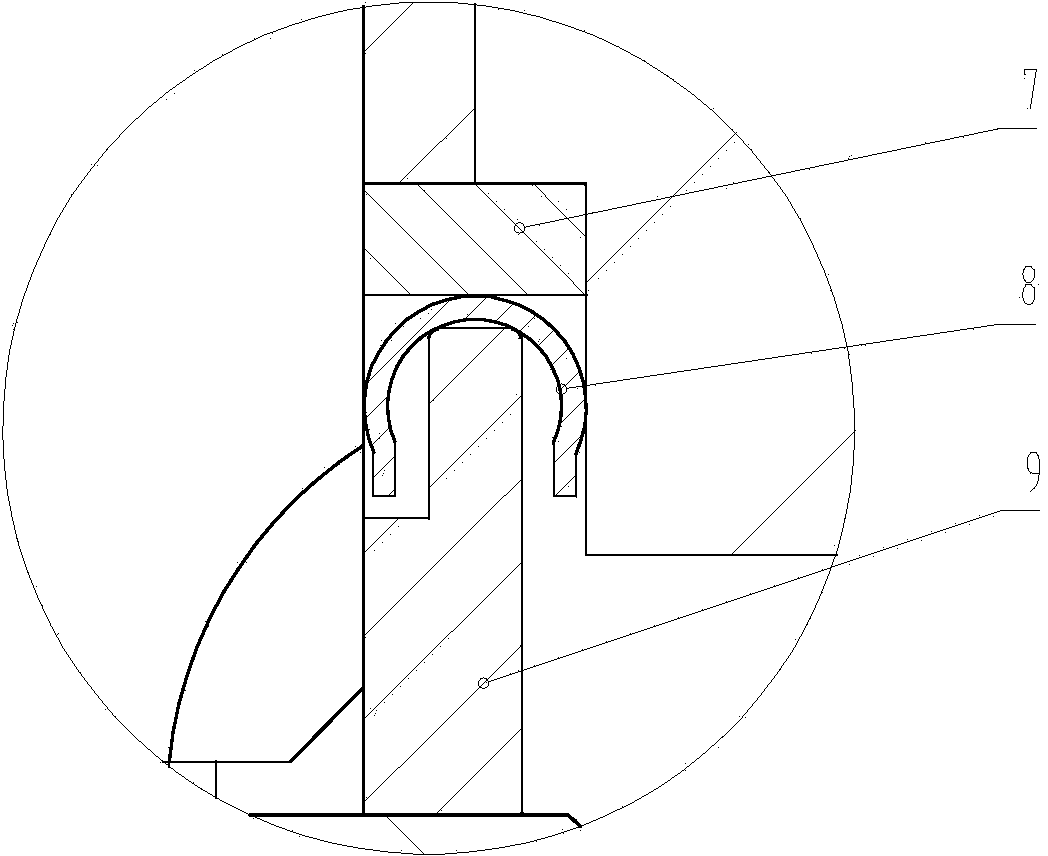

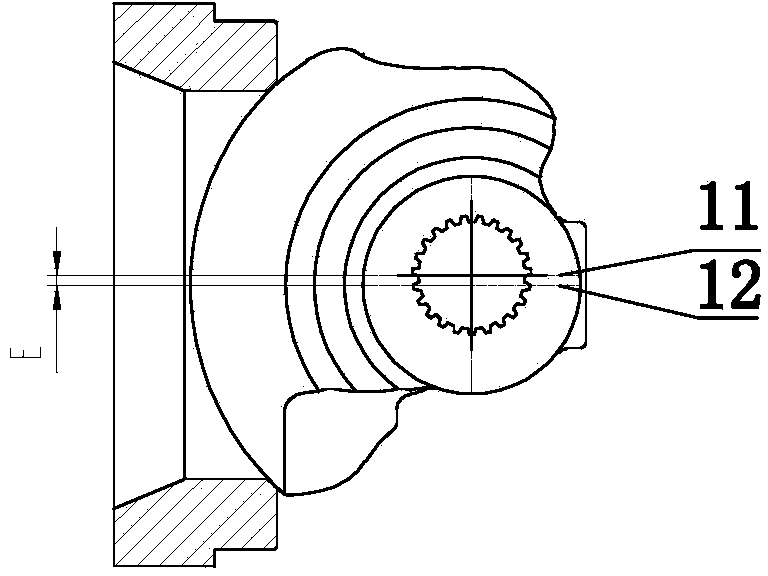

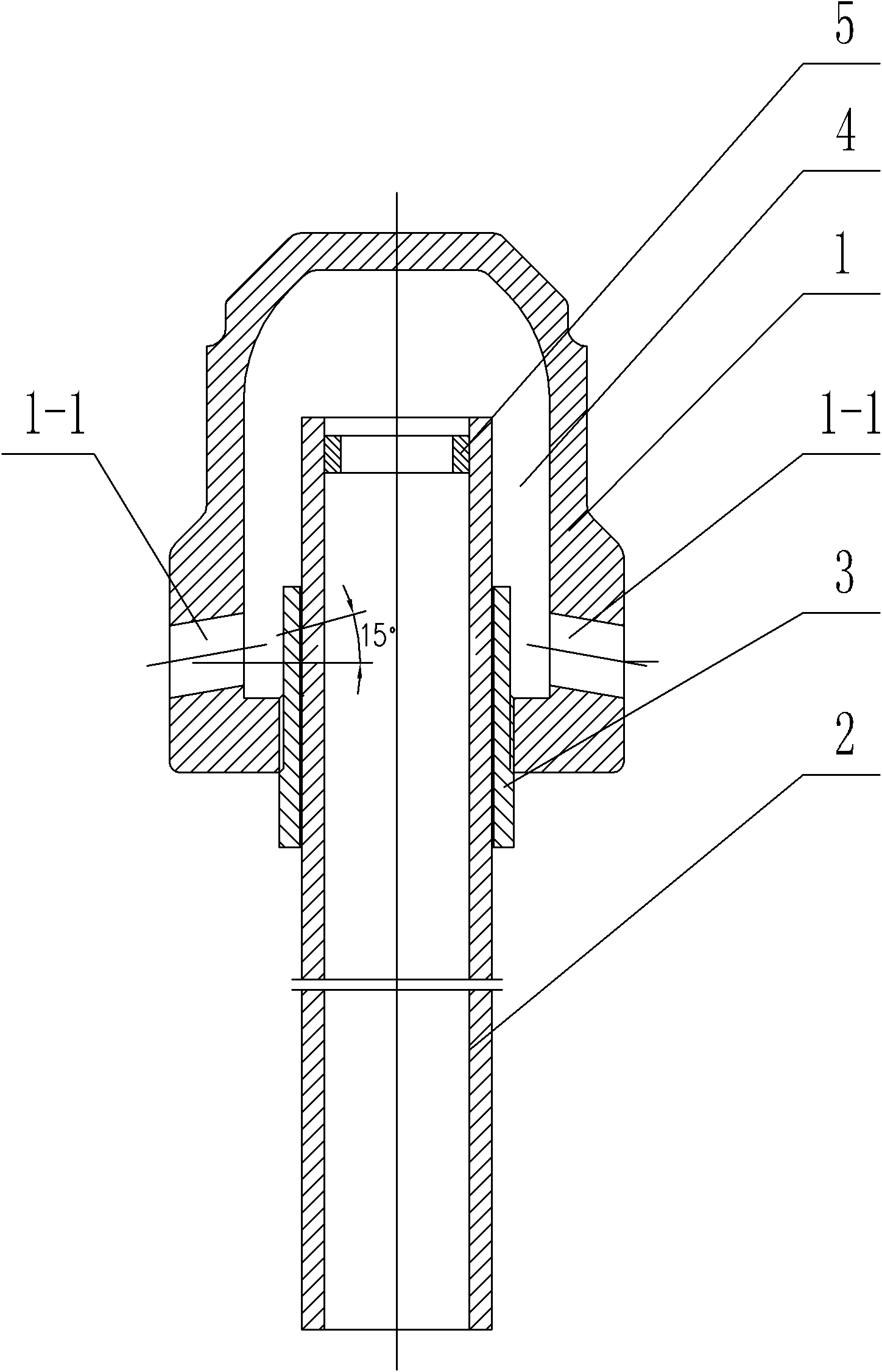

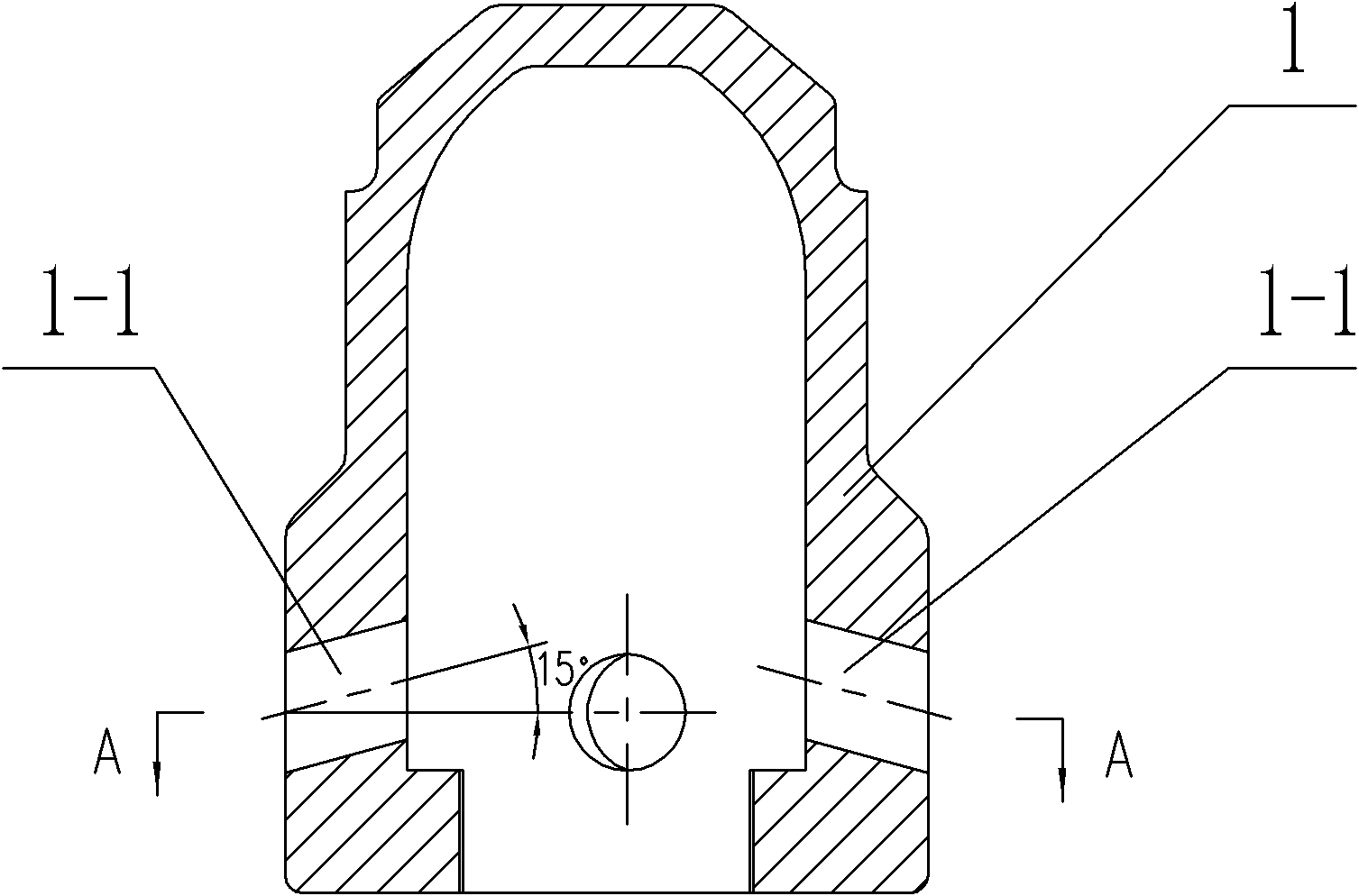

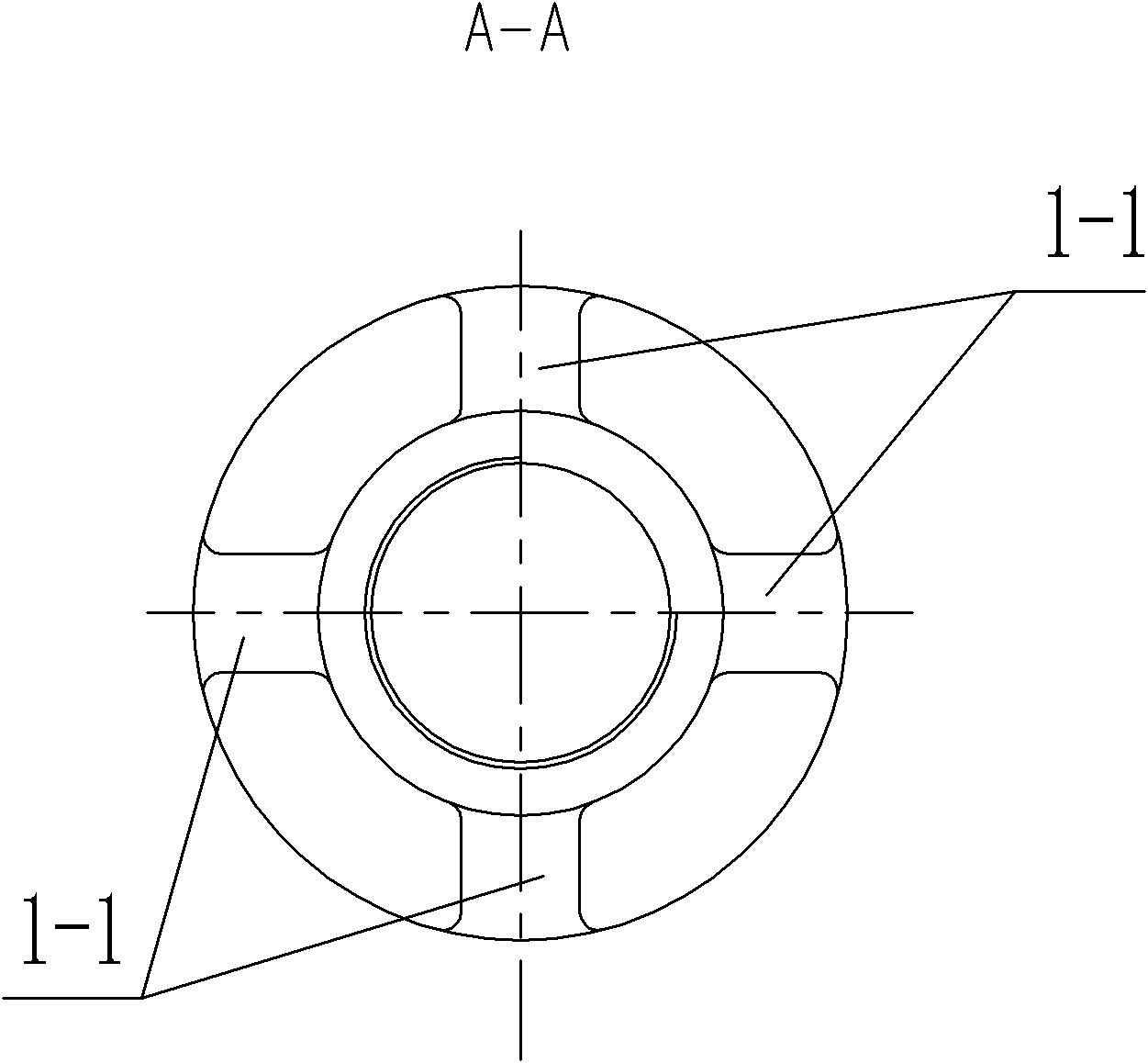

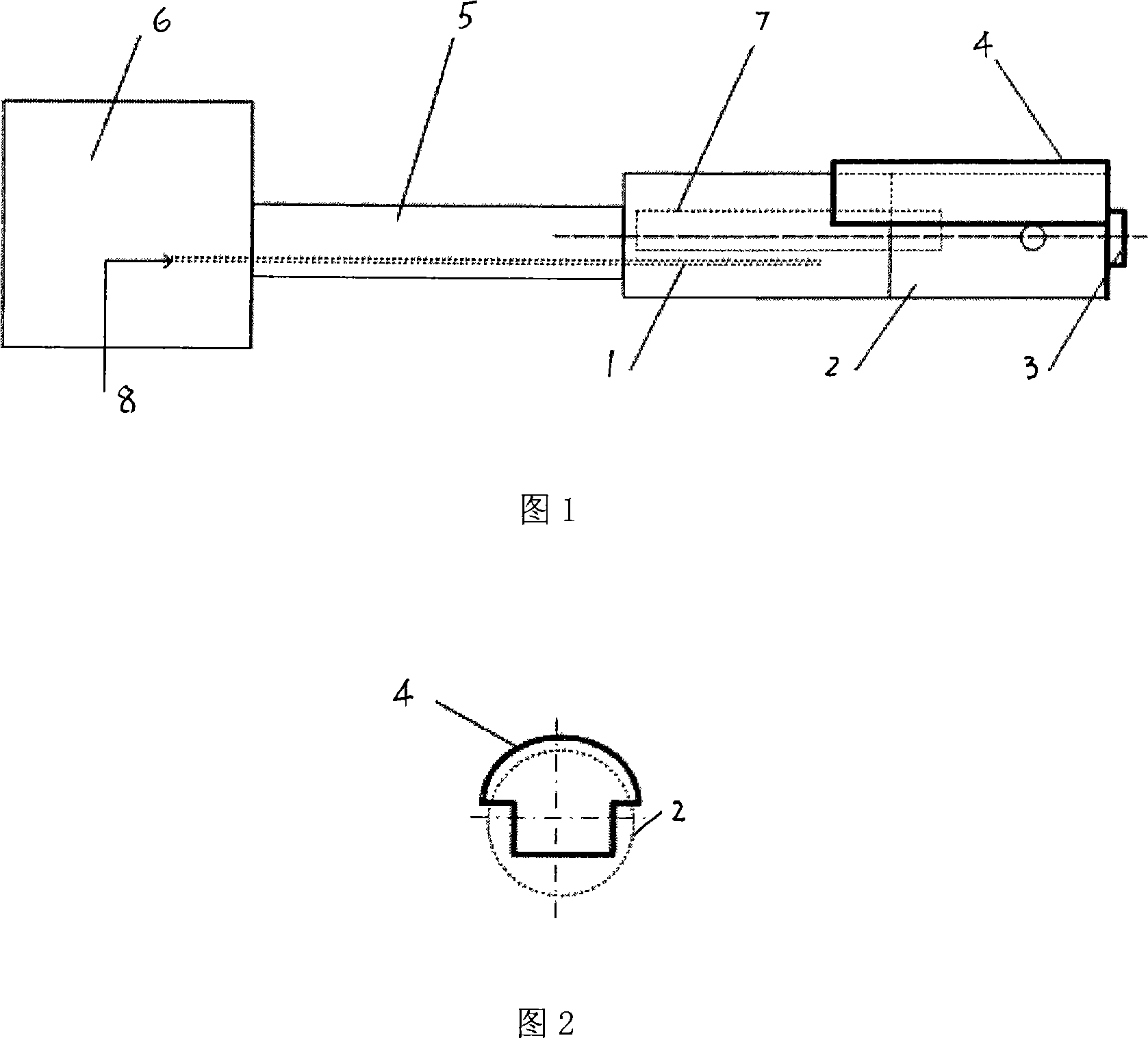

Anti-vortex wearable mechanical seal

InactiveCN101586666AAvoid direct flushingThere will be no outward leakageEngine sealsPump componentsInlet channelEngineering

The invention discloses an anti-vortex wearable mechanical seal comprising a rotating ring assembly, a sealing base (24) and a stationary ring assembly composed of a stationary ring (22), a stationary ring base (23), a spring (19), a plug-proof (13), a stationary seal ring (10) and a drive ring (21); the stationary ring base (23) is sleeved on rear of the stationary ring (22); the stationary seal ring (10) is arranged between the stationary ring base (23) and the stationary ring (22); the spring (19), the drive ring (21) and the plug-proof (13) are located between the stationary ring (22) and the sealing base (24); the sealing base (24) is provided with a washing water inlet (3), an inlet channel I (4) and a screw hole (15); right end surface of the sealing base (24) is coated by a rubber protection cover (6); the stationary ring base (23) is sleeved on a step of the rubber protection cover (6). The invention can ensure that the sealing ring in the whole process is not brushed to loss, which effectively ensures sealing performance of mechanical seal.

Owner:蒋敏

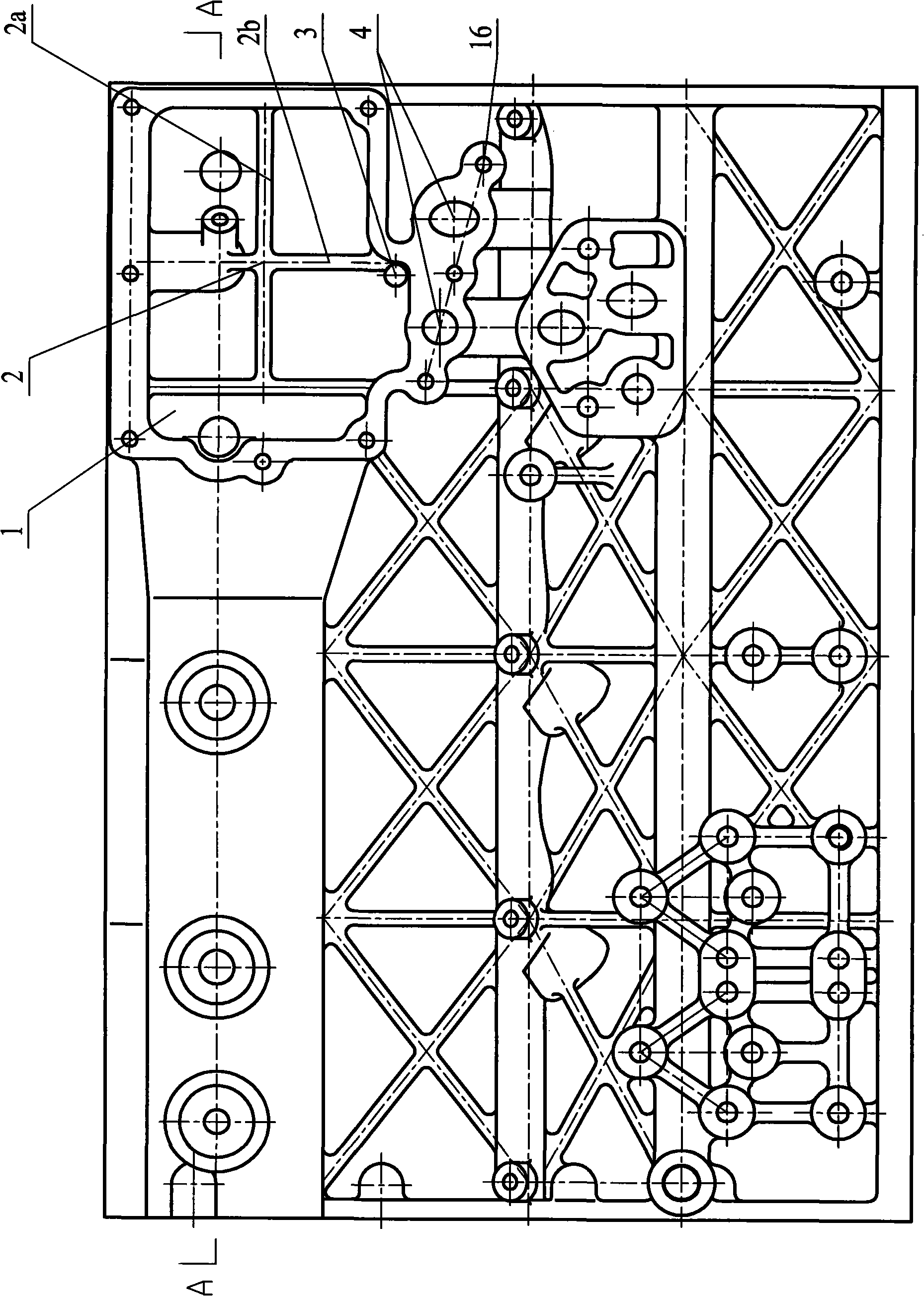

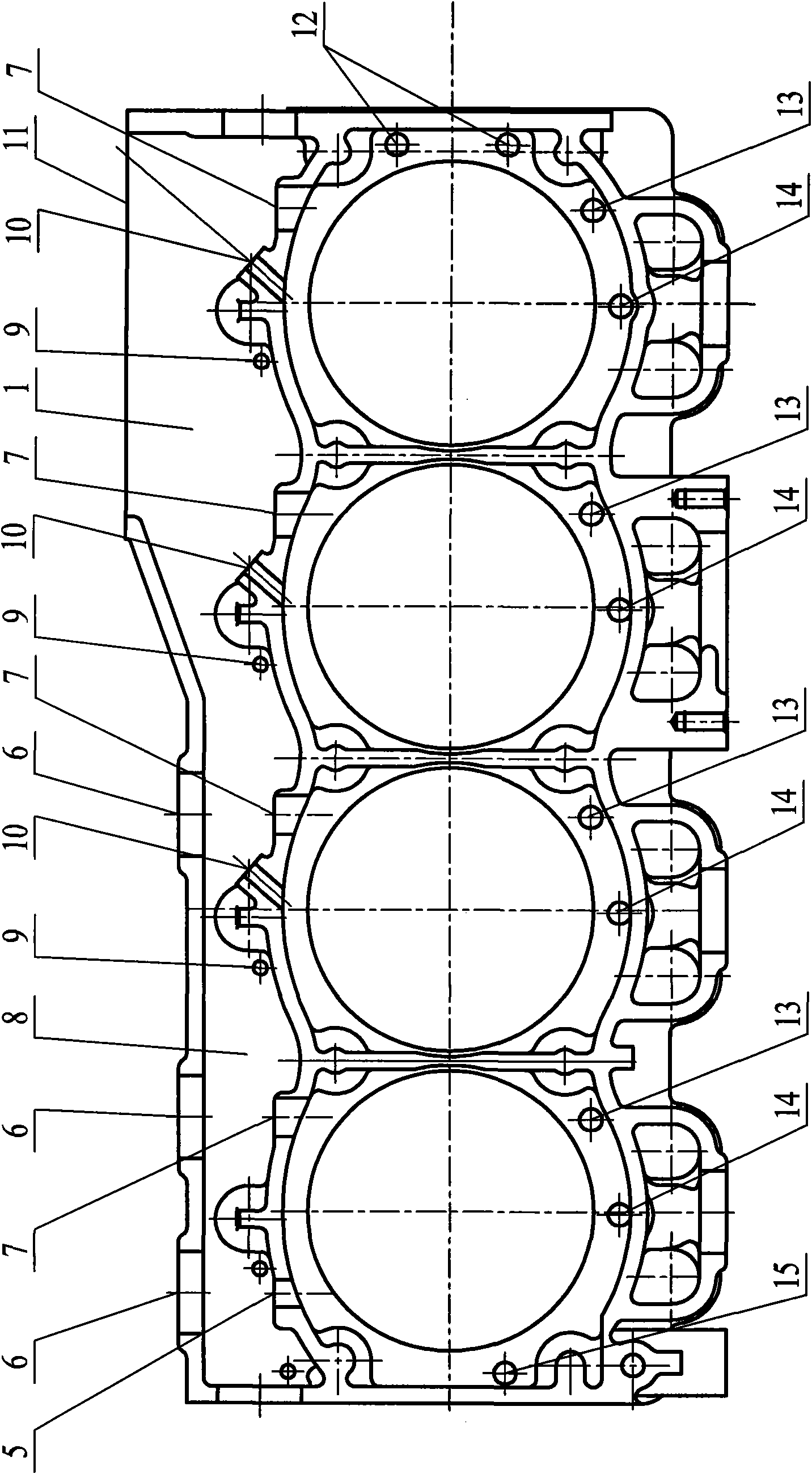

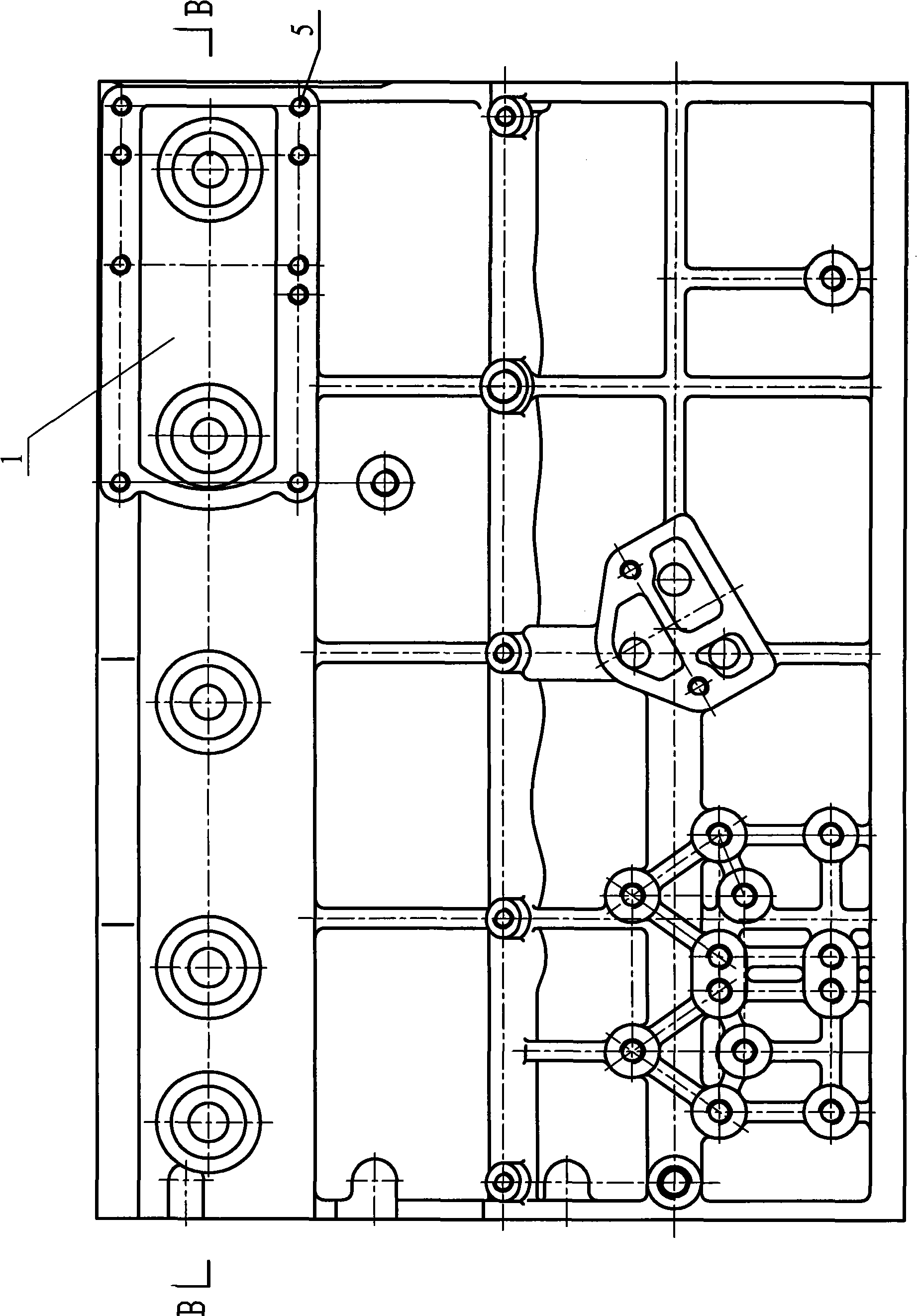

Water jacket structure of diesel cylinder block

InactiveCN101787936AAvoid cylinder liner deformationAvoid direct flushingCylinder headsCylindersCylinder blockEngineering

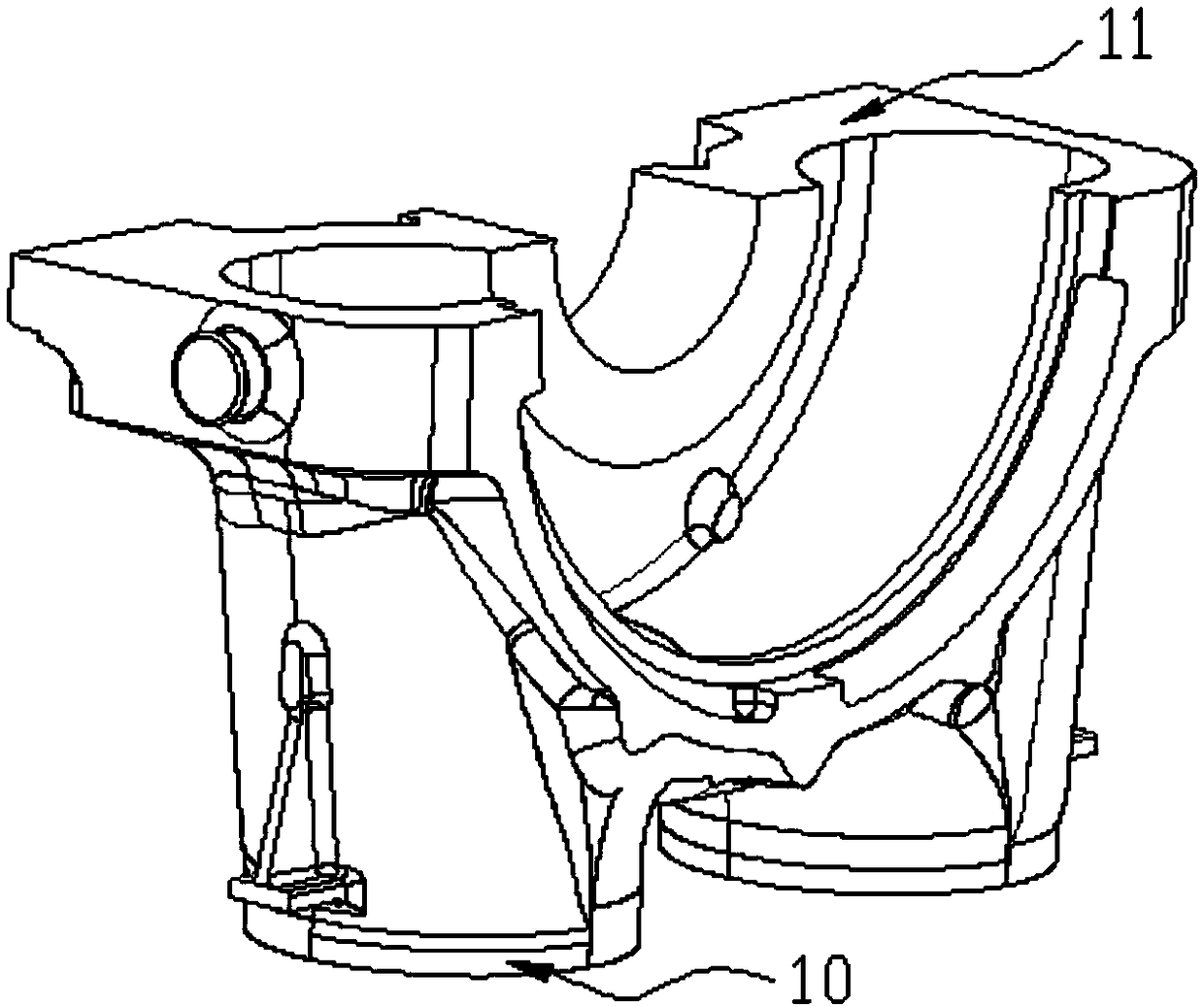

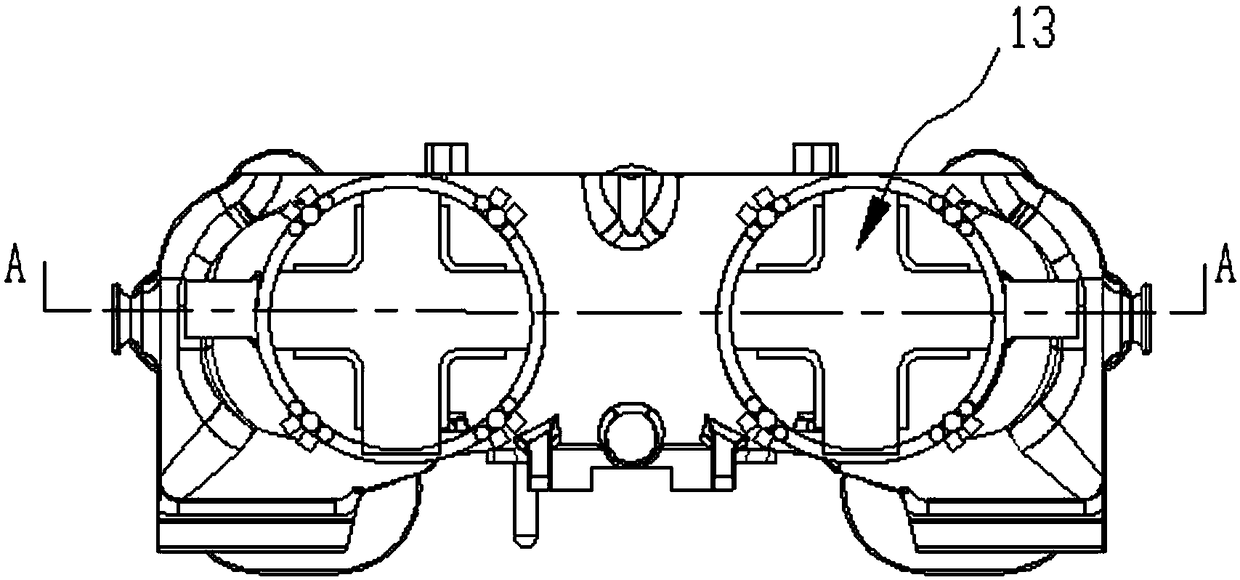

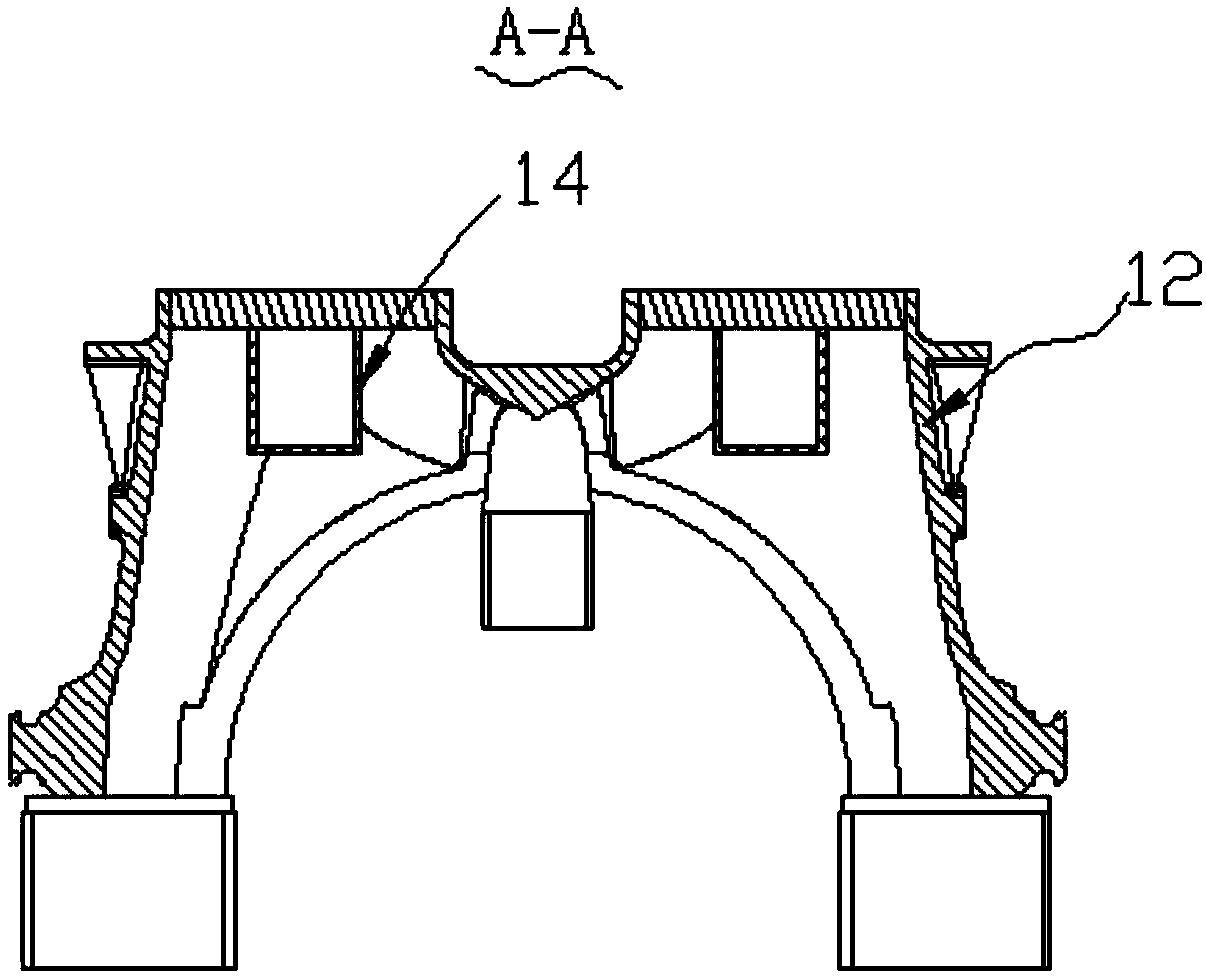

The invention relates to a water jacket structure of a diesel cylinder block. The upper portion of an intake side of the cylinder block is provided with a water distributing channel, the front end of which is connected with a water pump and the rear end of which is provided with an engine oil cooler cavity; a cylinder block water jacket is formed at the middle / upper portion of the cylinder block and comprises at least two transversely parallel single water jacket bodies, each of which is provided with an water intake hole and a water drainage hole, the water distributing channel is communicated with the interior of each of the single water jacket bodies through the water intake holes; the water intake hole on the first single water jacket body at the front end of the cylinder block water jacket comprises a front straight water intake hole and a rear straight water intake hole, the water intake holes on other single water jacket bodies each comprise a rear straight water intake hole, wherein all the single water jacket bodies are each provided with an oblique water intake hole except the first single water jacket body, the front straight water intake hole, the rear straight water intake hole and the oblique water intake hole are all tangential to the periphery of the single water jacket bodies. The water jacket structure, skillful and reasonable in structure, can effectively cool the cylinder block and the engine oil, increase the rigidity of the intake side of the cylinder block and lower noise.

Owner:JIANGSU SIDA POWER MECHANICAL GROUP

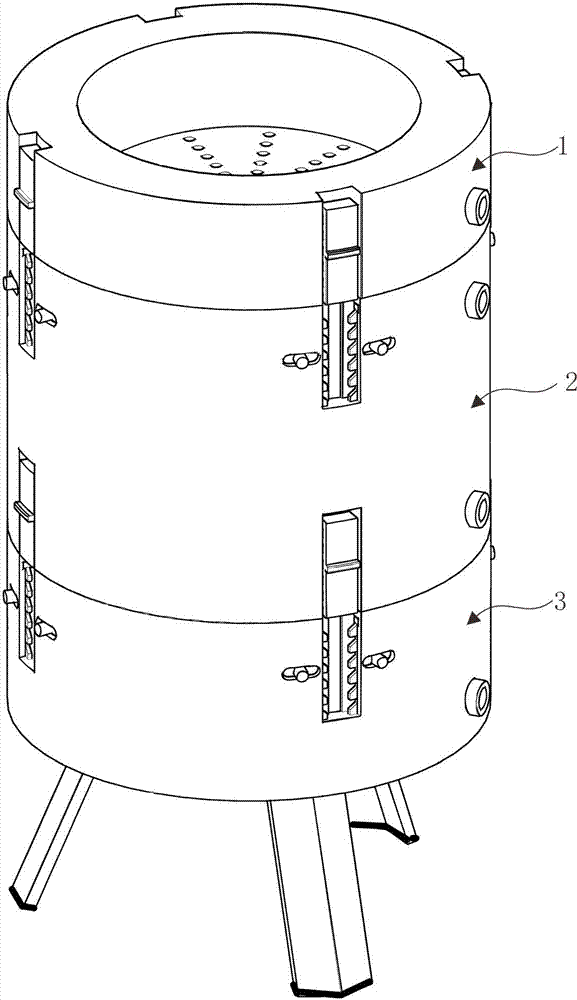

Boiler water-cooled wall protecting device capable of preventing coking and high temperature corrosion

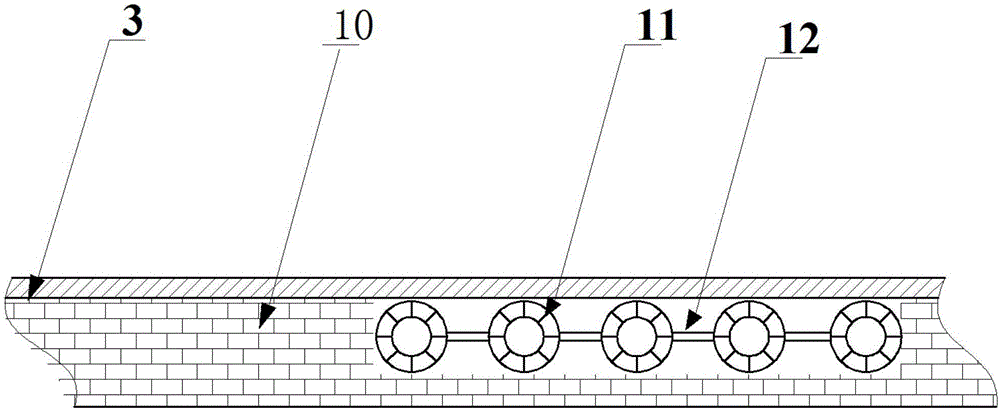

ActiveCN103912893AReduce nitrogen oxide emissionsIncrease disturbanceFluidized bed combustionCasings/liningsEngineeringSmall hole

The invention belongs to the field of low nitrogen discharge of boilers, and particularly relates to a boiler water-cooled wall protecting device capable of preventing coking and high temperature corrosion. The boiler water-cooled wall protecting device comprises water-cooled tubes, flat bars, a heat preserving boiler wall and an air line, small holes are formed in the flat bars which are welded together with the water-cooled tubes in a spacing manner to form a membrane water-cooled wall, an annular space is formed between the membrane water-cooled wall and the heat preserving wall, the upper and lower ends of the annular space are sealed to form a cavity, and the air line is mounted on the heat preserving boiler wall and communicated with the cavity. A boiler combustion air distribution mode is improved, coking and high temperature corrosion of the water-cooled wall are prevented, and high efficient combustion of coal dust and low nitrogen discharge are realized at the same time.

Owner:TAIYUAN UNIV OF TECH

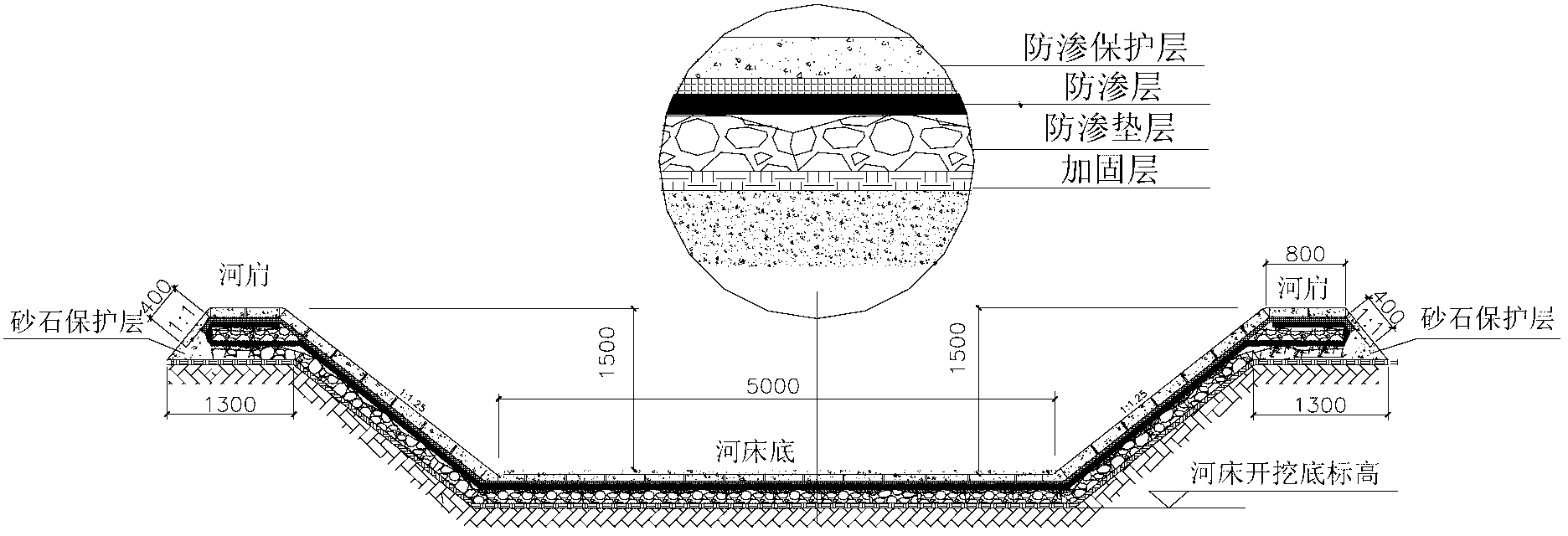

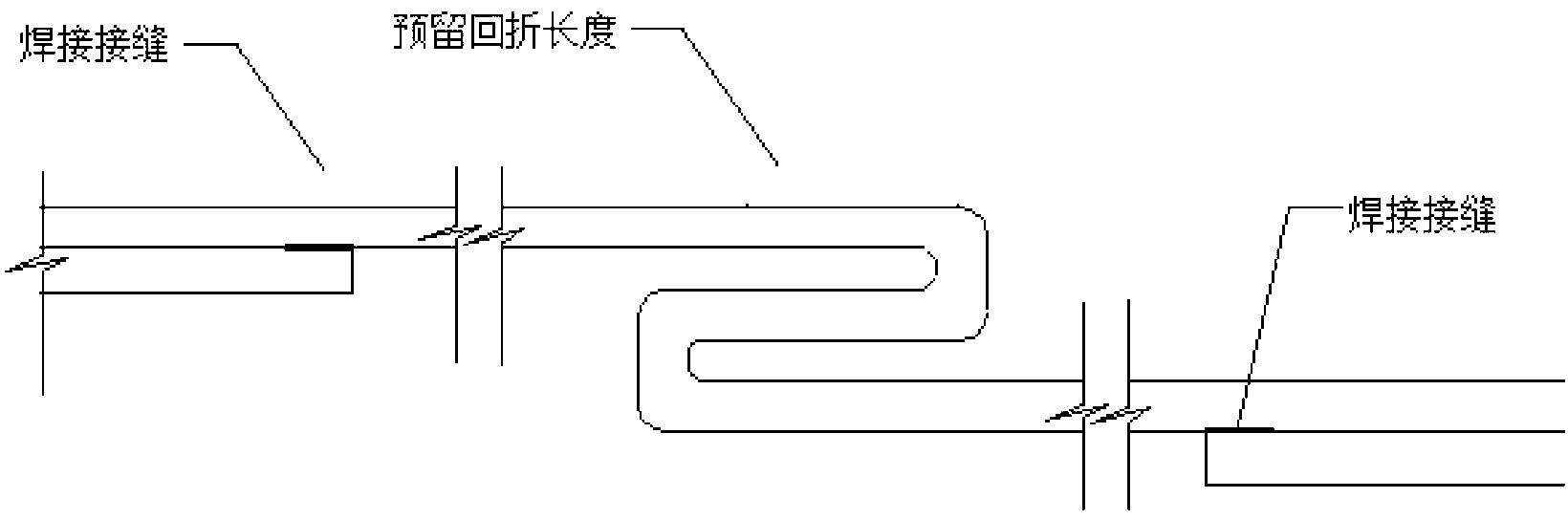

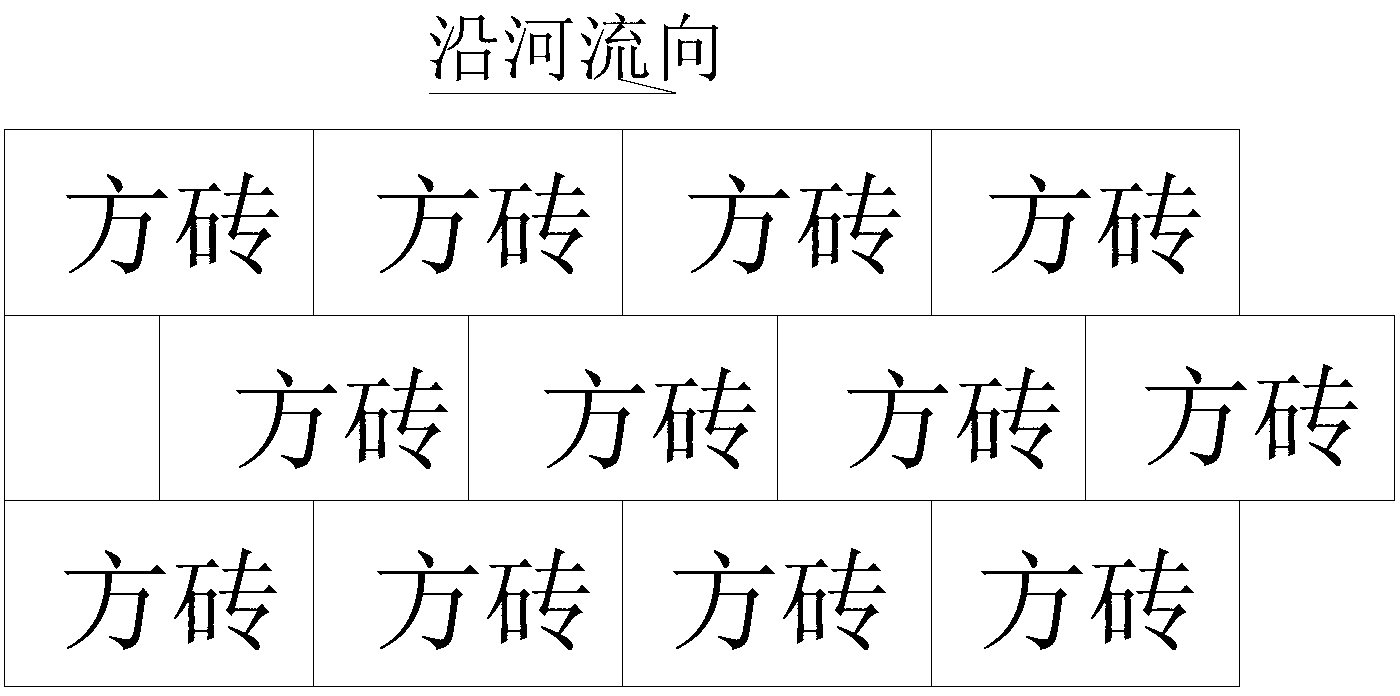

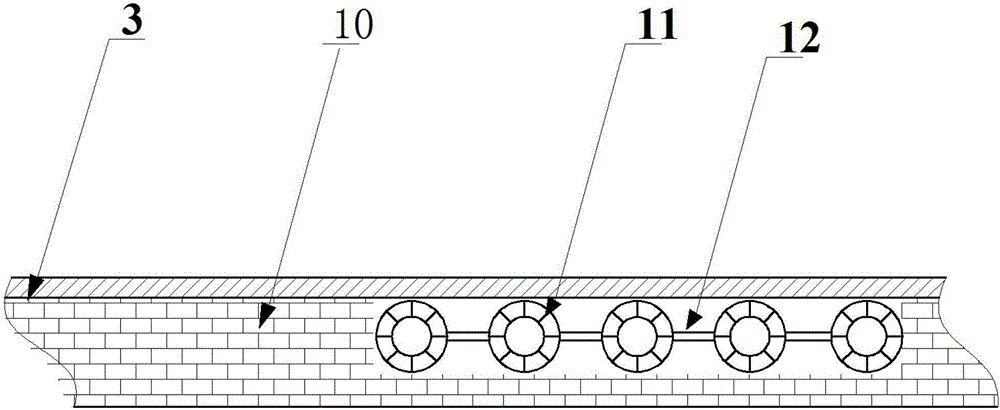

Method and structure for disturbed riverbed seepage-proof governing

The invention belongs to the field of mines, and relates to a riverbed seepage-proof governing structure. According to the riverbed seepage-proof governing structure, a quaternary seepage-proof structure is arranged on a disturbed riverbed, and the quaternary seepage-proof structure is divided into four layers from bottom to top, namely a riverbed reinforcing layer, a seepage-proof cushion layer, a seepage-proof layer and a seepage-proof protective layer are sequentially laid. According to the design, engineering geology, environment characteristics and technical features of a composite geo-membrane are fully considered, and therefore the effect of the disturbed riverbed seepage-proof governing is enabled to good, and governing cost is lower.

Owner:UNIV OF SCI & TECH BEIJING +1

Foamed plastic mold

Owner:龙海市永隆泡沫包装有限公司

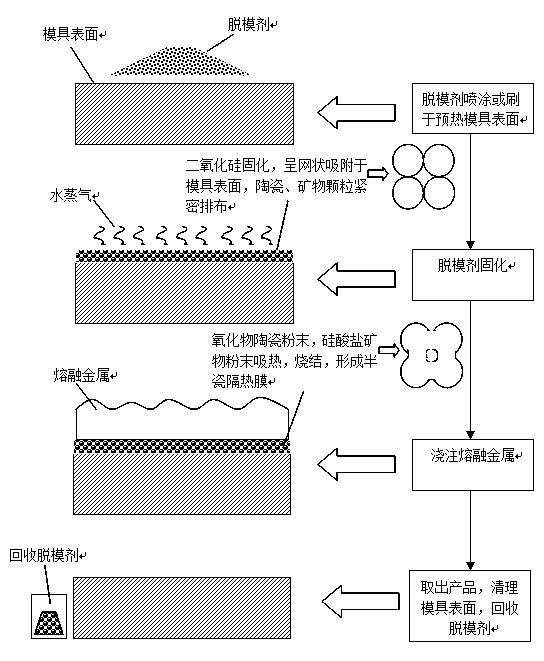

Mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding

ActiveCN103537613AIncrease contact interfaceReduce porosityFoundry mouldsFoundry coresThermal fatiguePhysical chemistry

The invention provides a mold-releasing type complexing agent with effects of resisting a high temperature of more than 1450 DEG C, insulating heat and demolding and a preparation method thereof. The mold-releasing type complexing agent comprises the following raw materials in percentage by weight: 20-60% of nano colloidal silicon dioxide solution; 5-30% of composite oxide ultramicro (0.1-1.0 microns) powder including Na, Mg, Ca, Fe, Li, Al, Si, B, Zr and other elements; 0.2-2% of water-based dispersing agent;0.02-0.5% of water-based thickening agent and the balance of water; and the sum of the weight of the components is 100%. According to the mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding, the nano colloidal silicon dioxide solution is cooperated with the ultramicro (0.1-1.0 microns) multielement composite oxide powder, so that the excellent performances of high temperature resistance, heat insulation, demolding, environment protection and the like are achieved, the thermal fatigue resistance of the mold surface is effectively improved, and the service life of the mold is prolonged. The mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding is particularly applicable to using at the part of a mold directly contacting molten steel in fired mold casting and other high temperature forming technologies of metal.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Waste heat recovery system for circular cement production grate cooler

InactiveCN105066723AReduce energy consumptionImprove utilizationEnergy industryIncreasing energy efficiencyWaste heat recovery unitThermal insulation

The invention provides a waste heat recovery system for a circular cement production grate cooler. The grate cooler comprises a housing and a clinker channel, wherein a thermal insulation material is arranged between the housing and the clinker channel; waste heat recovery equipment is arranged in the thermal insulation material, and comprises a barrel; a heat exchange tube is arranged in the barrel; the barrel and the heat exchange tube are in a concentric circle structure. According to the grate cooler provided by the invention, sensible heat released by a clinker in a cooling machine in a fast cooling process can be fully absorbed; energy consumption of the clinker is reduced; the waste heat utilization quantity can also be effectively improved.

Owner:SHANDONG UNIV

Heat-absorbing material-coated grate cooler waste heat recycling device and system

InactiveCN105066722AReduce energy consumptionImprove utilizationEnergy industryIncreasing energy efficiencyEnergy consumptionWaste heat

The invention provides a heat-absorbing material-coated grate cooler waste heat recycling device and system. The device comprises barrels, wherein heat exchange tubes are arranged in the barrels; each barrel and the corresponding heat exchange tube are in a concentric circle structure; and a heat-absorbing material is coated on the outer surface of each barrel. According to the device and the system, the heat-absorbing material is arranged, so that the waste heat absorption can be further enhanced, the clinker energy consumption is reduced, and the utilization amount of waste heat also can be increased effectively.

Owner:SHANDONG UNIV

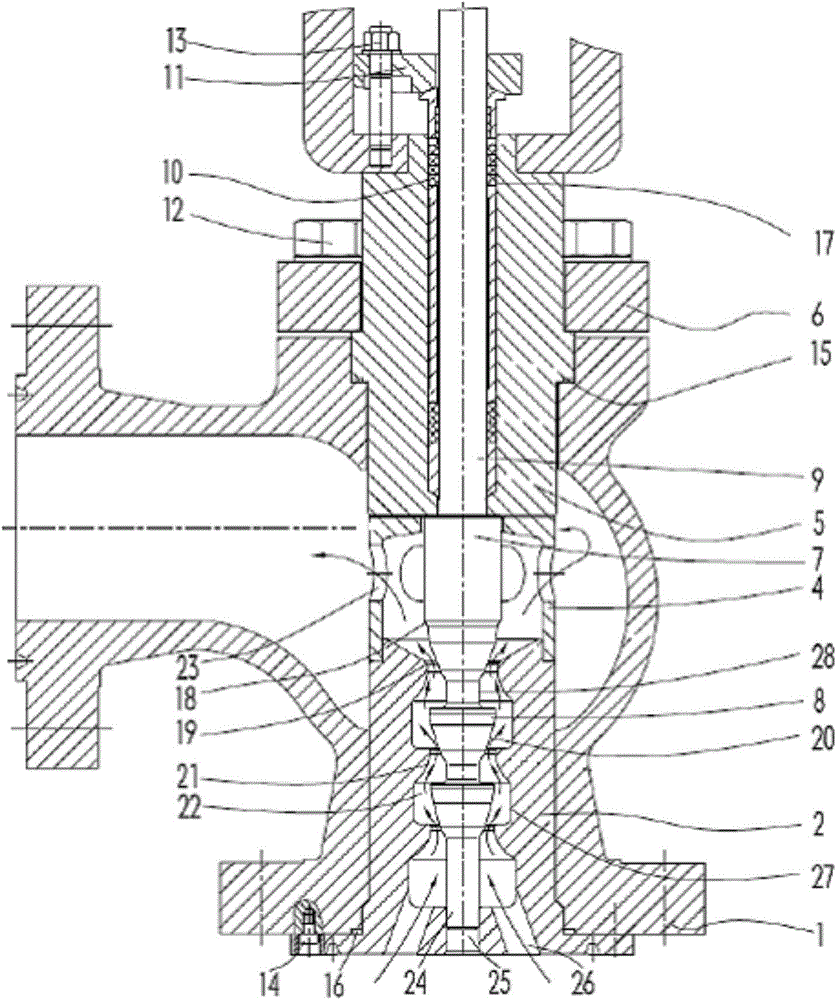

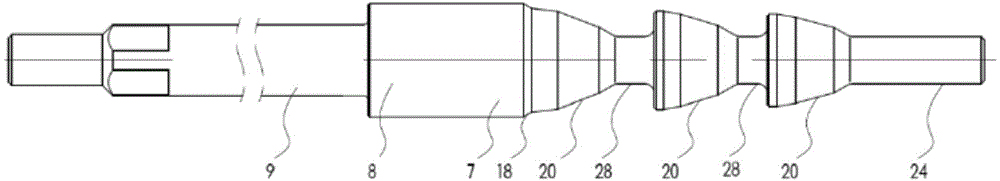

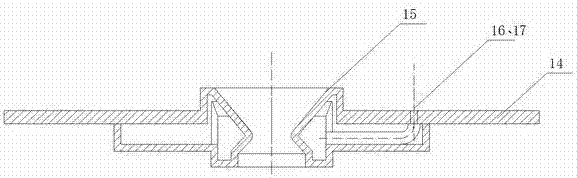

Throttling serial type multistage pressure reduction and adjustment valve

InactiveCN104455469APrecise pressure/flow controlEliminate cavitationValve members for absorbing fluid energyLift valveSolid particlePressure difference

The invention provides a throttling serial type multistage pressure reduction and adjustment valve. A valve rod and a valve element assembly are arranged inside a valve body; a valve seat assembly is provided with multistage pressure reduction units, and each stage of pressure reduction unit of the valve seat assembly is composed of a cylindrical fluid expansion unit and a throttling unit, wherein the throttling unit is shaped like a circular truncated cone, and the area of the throttling unit decreases gradually; correspondingly, the pressure reduction units are arranged on corresponding positions of the valve element assembly, wherein the stage number of the pressure reduction units in the valve element assembly is equal to that of the pressure reduction units in the valve seat assembly; each stage of the pressure reduction unit of the valve element assembly is composed of a bowl-shaped molded surface for controlling flow and a cylindrical shrinkage unit; the upper portion of the valve element assembly is provided with valve elements, and the lower portion of the valve element assembly is provided with guide rods; valve bottom drainage holes are formed in the positions, located on the outer sides of valve seat guide holes, of the bottom of the valve seat assembly; a flow diversion sleeve is arranged on the top of the valve seat assembly, and a flow diversion hole is formed in one side of the flow diversion sleeve. According to the throttling serial type multistage pressure reduction and adjustment valve, the service life of the valve can be prolonged, vibration and noise of pipelines behind the valve can be eliminated, and it is guaranteed that the adjustment accuracy of the valve is high and operation is stable under the working condition that the pressure difference is large and solid particles exist in media in the Texaco process of coal chemical industries.

Owner:BEIJING AEROSPACE PROPULSION INST +3

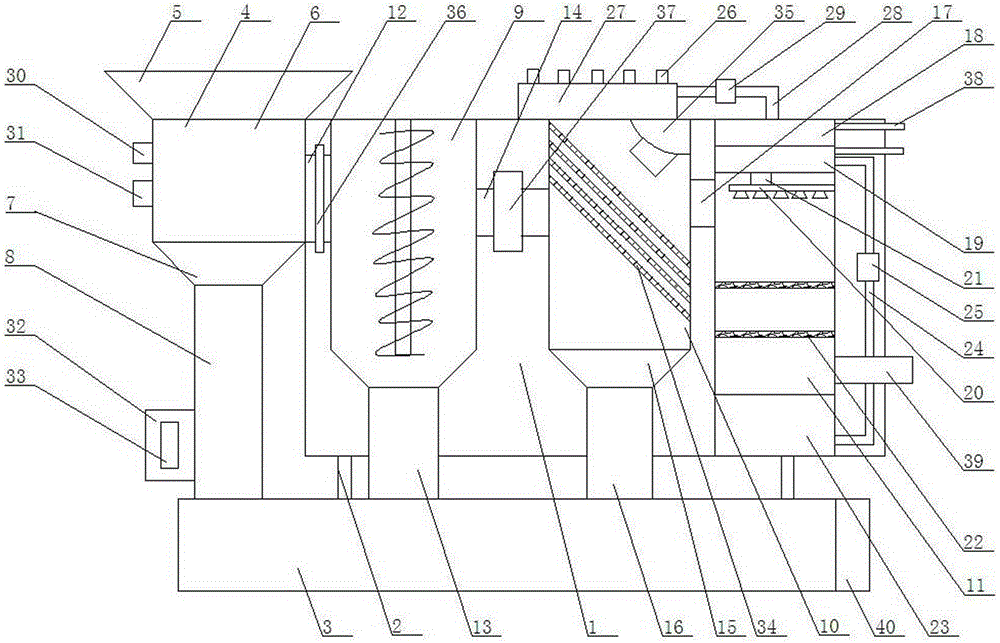

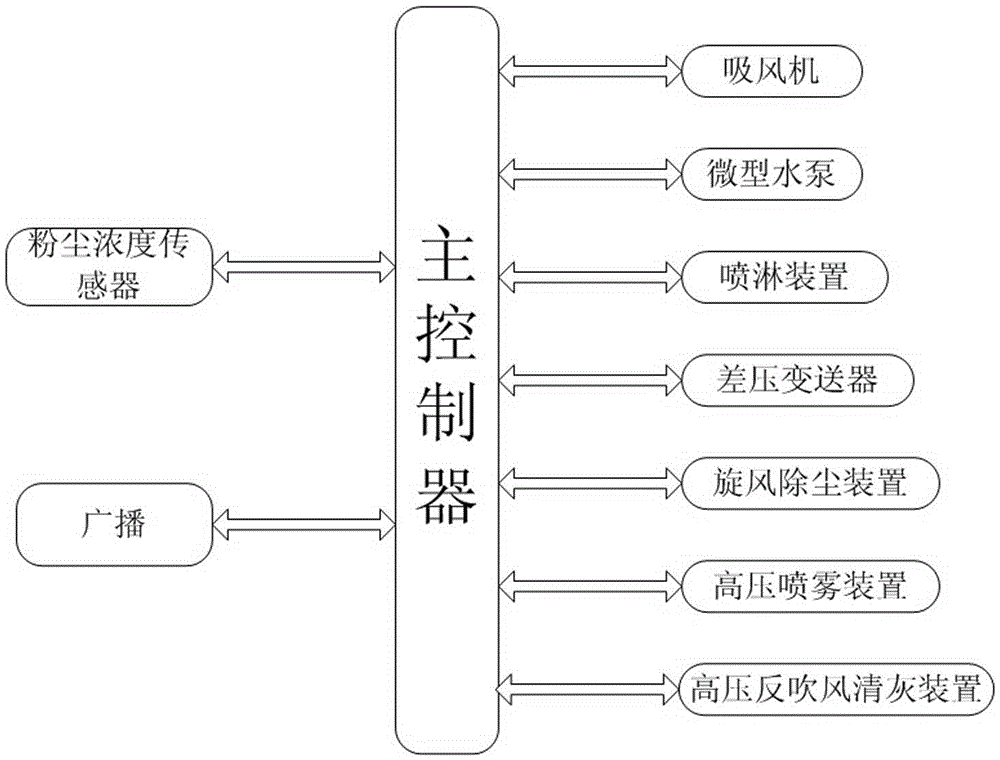

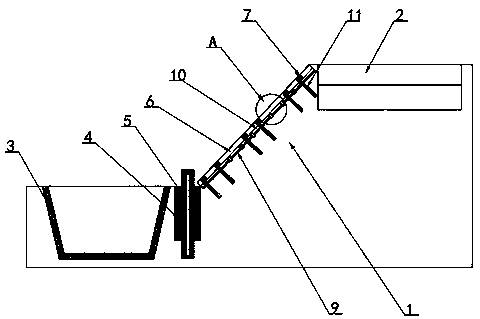

Mine dedusting apparatus

InactiveCN105268270AExtended service lifeEasy to useCombination devicesDirt cleaningThermodynamicsEngineering

A mine dedusting apparatus comprises an outer box body, supports, an ash discharge chamber and a dust collecting device, the left end of the outer box body is provided with the dust collecting device, the dust collecting device is arranged at the left side of the top of the ash discharge chamber, the top end of the ash discharge chamber supports the outer box body through a left row of supports and a right row of supports, and a cyclone dedusting chamber, a filtering chamber and a spray chamber are arranged in the outer box body from left to right. The mine dedusting apparatus adopts a dust collecting chamber, cyclone dedusting chamber, filtering chamber and spray chamber combination structure, so large granule dusts can be effectively and discharged to the ash discharge chamber through the dedusting chamber, are dedusted through the cyclone dedusting chamber in a cyclone manner to avoid direct flushing of high-speed dust-containing airflow to a filter cloth bag in the filtering chamber, are filtered by the filter cloth bag in the filtering chamber, enter the spray chamber, and are sprayed to thoroughly dedust. The apparatus has the advantages of high dedusting efficiency, good dedusting effect, and safe and reliable use.

Owner:哈尔滨市阿城区昌利矿山除尘设备厂

Special material regulating angle valve for high-pressure hydrogenation reaction

InactiveCN102927299AAffect the circulation capacityEliminate dead zoneLift valveValve housingsHydrogenation reactionGranular media

The invention relates to a special material regulating angle valve for a high-pressure hydrogenation reaction. A valve seat is fixed on a valve body, a valve rod is spliced in the valve body in a sealing and sliding manner, a valve core is in integrated connection with the bottom end part of the valve rod, an auxiliary guide seat is mounted between the valve body and the valve seat, an anti-erosion sleeve is mounted on the auxiliary guide seat, one end of the anti-erosion sleeve is embedded into the auxiliary guide seat, the other end of the anti-erosion sleeve is embedded into the valve body, and the valve rod is spliced in the anti-erosion sleeve in a sliding manner. With the adoption of the special material regulating angle valve, the accumulation of a medium on an inner wall is prevented, the erosion of the high speed medium to internal pieces of the valve is reduced, the valve rod is not blocked by the granular medium, the service life of the valve rod is prolonged, and the stability and reliability of the auxiliary guide seat are ensured.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

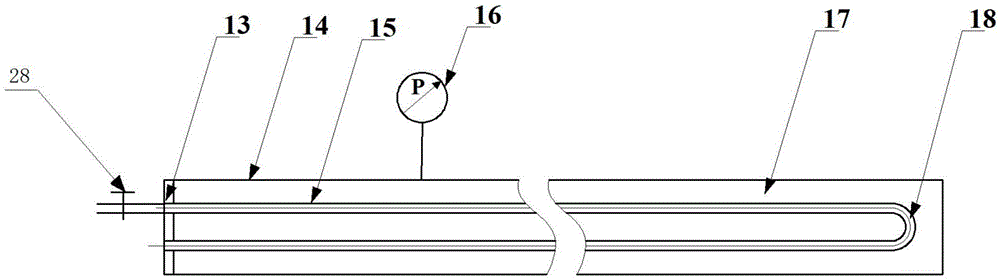

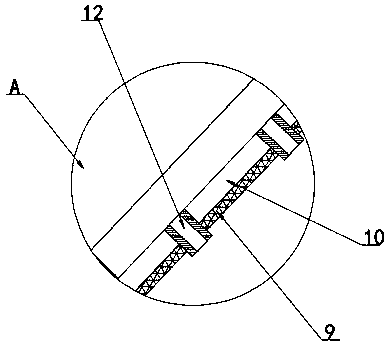

Double-acting double-pipe single-bit coring drilling tool and application method thereof

ActiveCN106837230AIncrease water flow areaImprove coaxialityDrilling rodsDrilling casingsRock coreOutcrop

The invention discloses a double-acting double-pipe single-bit coring drilling tool and an application method thereof, and belongs to the field of geological exploration boring machines. The double-acting double-pipe single-bit coring drilling tool comprises an inner-outer core barrel connector, an outer pipe, an inner pipe and a drill bit body arranged at one end of the inner pipe. The outer pipe and the inner pipe are fixed to the inner-outer core barrel connector. An annular gap is reserved between the outer pipe and the inner pipe. A water dividing hole is formed in the inner-outer core barrel connector. Four to eight flange ribs are uniformly distributed on the outer side face of the drill bit body and each provided with a step. The steps of the flange ribs are sleeved with the end of the outer pipe. A row of hard alloy drill bits is embedded in the bottom face of the drill bit body, and a row of hard alloy drill bits are embedded in the bottom faces of the flange ribs. The coaxiality and the integral rigidity of the drilling tool are improved by means of the flange rib type drill bits, and vibration of the drilling tool during drilling is reduced; in addition, the rock core sampling quality and efficiency of quaternary loose strata, bed rock weathering zones and coal seam outcrops are remarkably improved; and meanwhile, the drilling efficiency is improved.

Owner:JIANGSU JIANYUAN CONSTR CO LTD

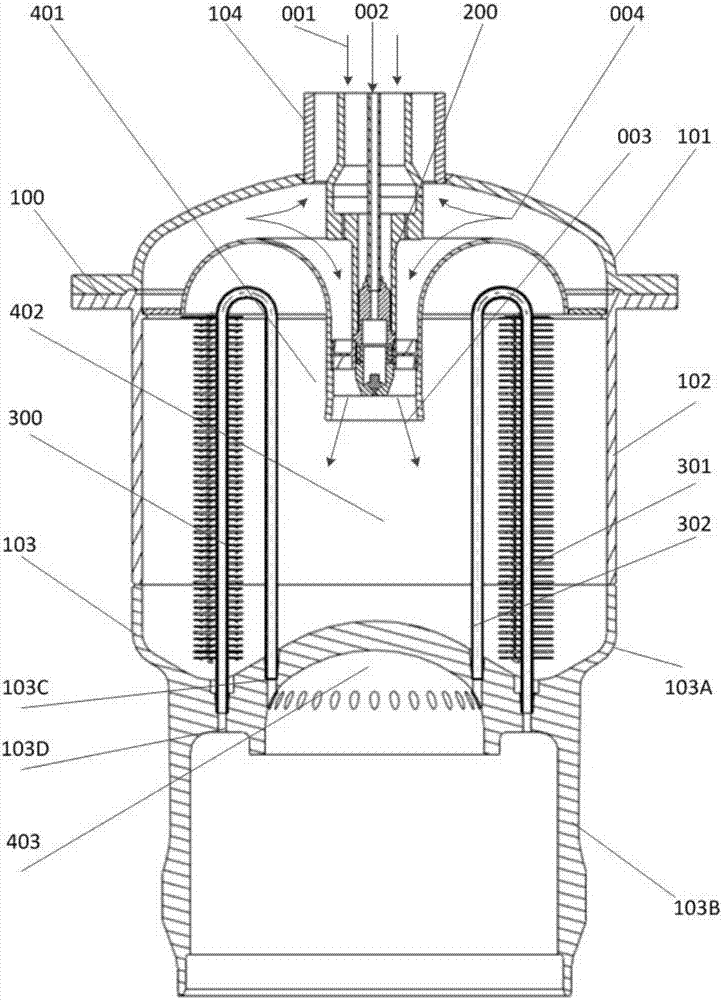

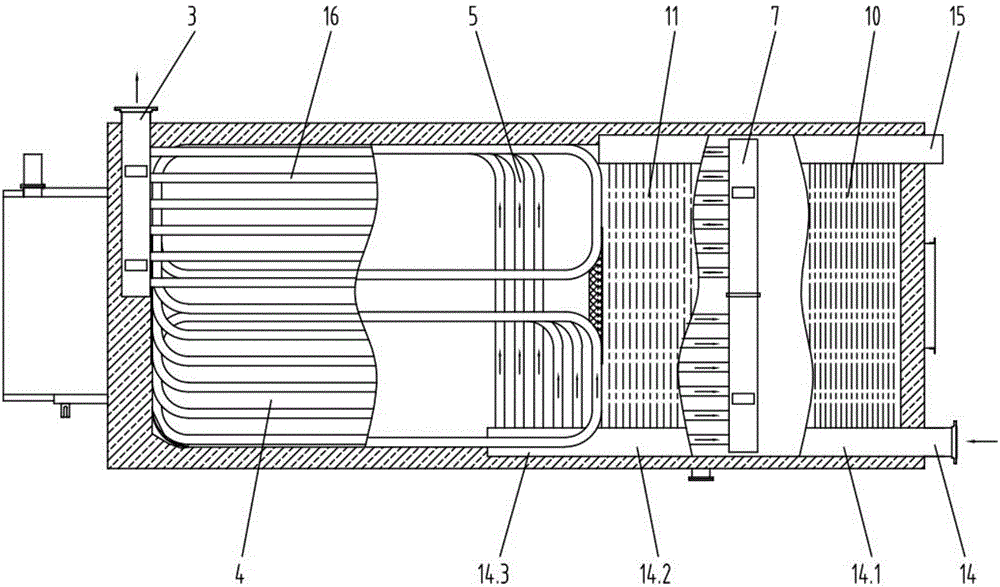

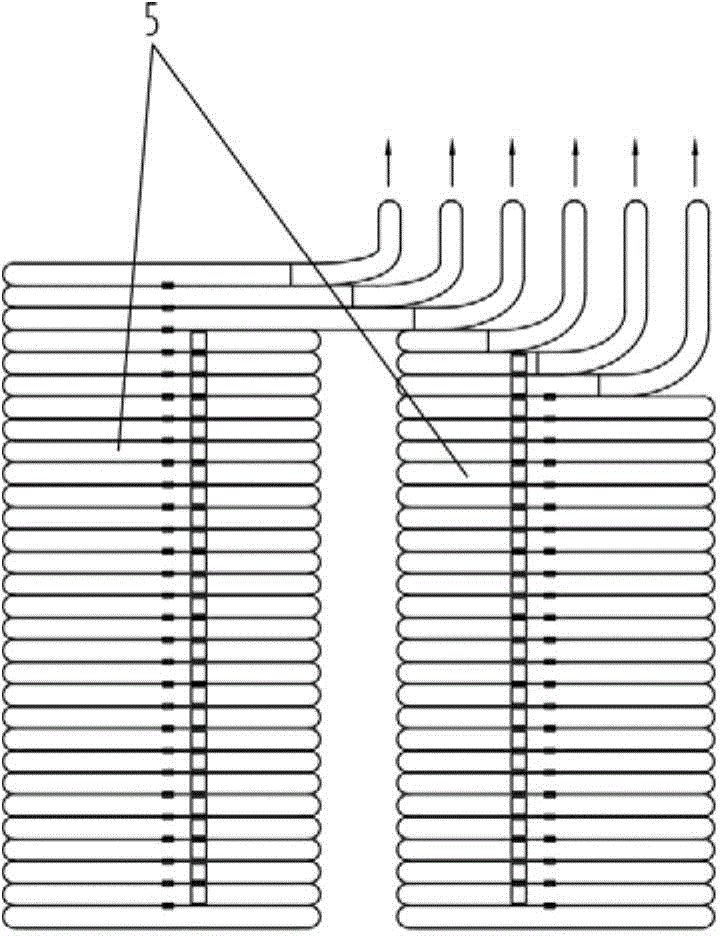

Flameless combustion chamber for Stirling engine and implementation method of flameless combustion chamber

PendingCN107883406AImprove uniformityImprove efficiencyContinuous combustion chamberIndirect carbon-dioxide mitigationStirling engineCombustion chamber

The invention discloses a flameless combustion chamber for a Stirling engine and an implementation method of the flameless combustion chamber. The flameless combustion chamber comprises a combustion chamber housing, a combustor and a heat exchanger; the housing consists of an upper housing part and a lower housing part; an exhaust pipe is arranged at the top of the housing; a heat exchanger barrelis arranged at the bottom of the housing; the lower housing part is connected with the top of the heat exchanger barrel into a whole; the top of the heat exchanger barrel, the lower housing part andthe upper housing part form a combustion chamber space; a hot cavity of the Stirling engine is formed in the lower end of the heat exchanger barrel; the top of the heat exchanger barrel separates thecombustion chamber from the hot cavity; the combustor and the heat exchanger are arranged in the housing from the top to the bottom sequentially; the heat exchanger comprises a circle of heat exchangepipes arranged in a reverse-U-shaped manner; and one ends of the heat exchange pipes communicate with the hot cavity of the Stirling engine, and the other ends of the heat exchange pipes communicatewith a reheater, thus a circuiting working medium system is formed. The implementation method comprises the step that the combustion chamber is used for combustion. The flameless combustion chamber and the implementation method have the characteristics that the combustion chamber is uniform in temperature, the combustion efficiency is high and the safety and reliability are achieved. The flamelesscombustion chamber is particularly suitable for the Stirling engine for use.

Owner:SHANGHAI MICROPOWERS

Waste heat recovery system for cement production grate cooler employing square equipment

InactiveCN105066724AReduce energy consumptionImprove utilizationEnergy industryIncreasing energy efficiencyWaste heat recovery unitThermal insulation

The invention provides a waste heat recovery system for a cement production grate cooler employing square equipment. The grate cooler comprises a housing and a clinker channel, wherein a thermal insulation material is arranged between the housing and the clinker channel; waste heat recovery equipment is arranged in the thermal insulation material, and comprises at least one barrel; a heat exchange tube is arranged in the at least one barrel; the barrel is a rectangle; a plane is arranged at the lower part of the barrel. According to the grate cooler provided by the invention, sensible heat released by a clinker in a cooling machine in a fast cooling process can be fully absorbed; energy consumption of the clinker is reduced; the waste heat utilization rate can also be effectively increased.

Owner:SHANDONG UNIV

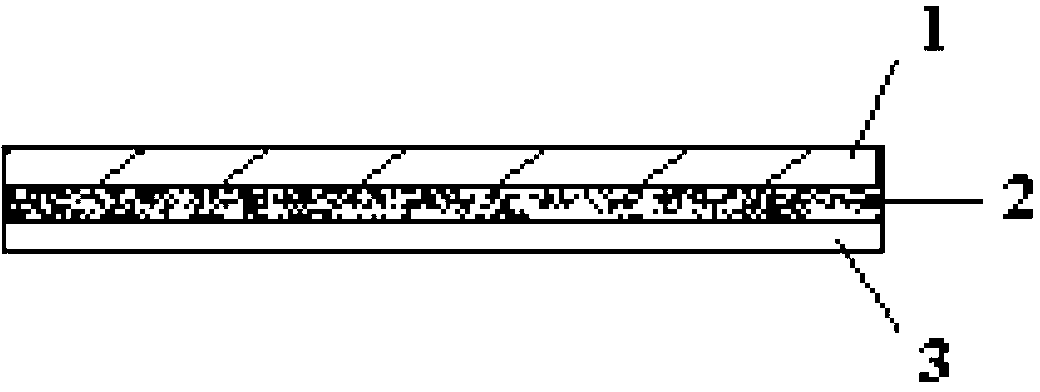

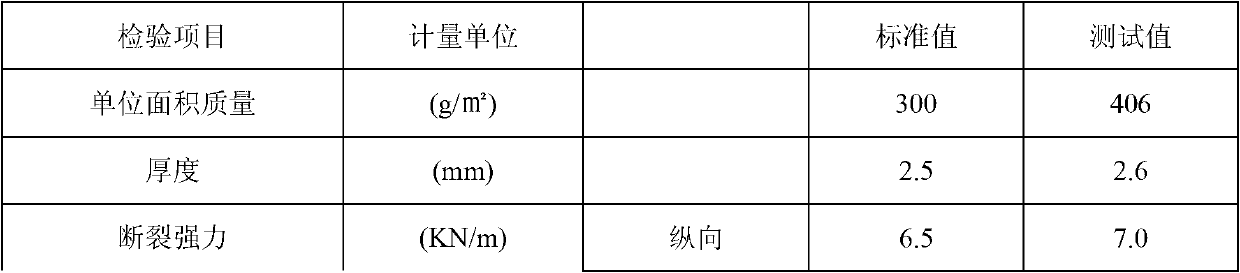

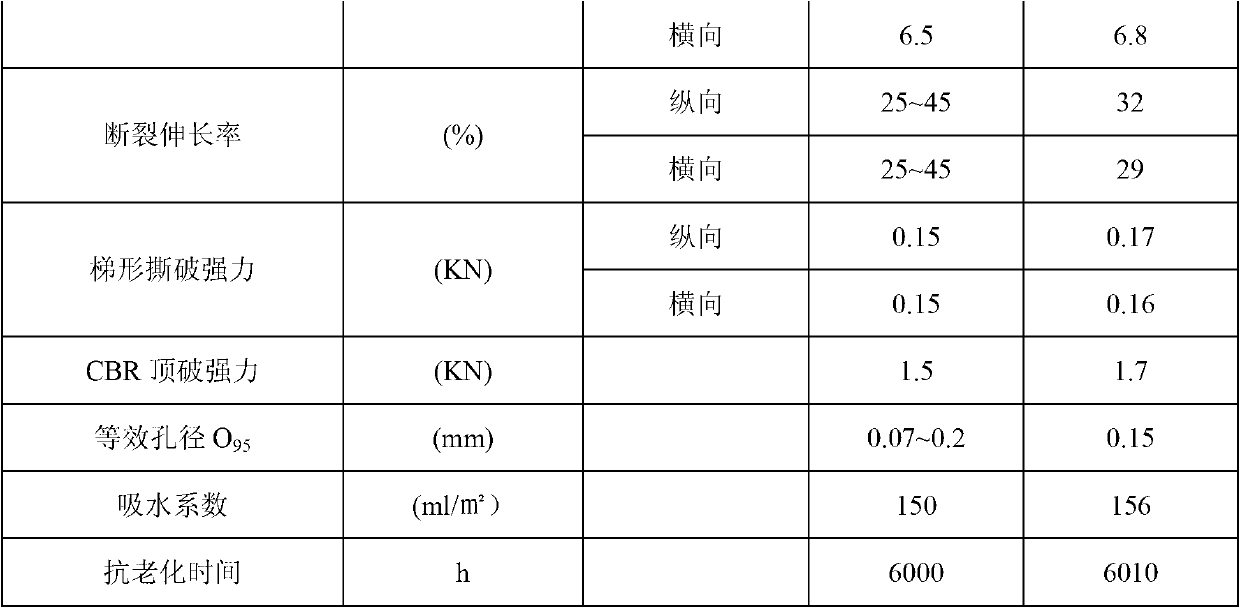

Weeding moisturizing material, weeding moisturizing cloth and preparation method

ActiveCN102986490AGrowth inhibitionFast growthSynthetic resin layered productsNon-woven fabricsFiberPolyethylene terephthalate

The invention discloses a weeding moisturizing material, a weeding moisturizing cloth and a preparation method. A weed killer is loaded on a non-woven fabric with polyethylene terephthalate (PET) as a raw material and composited with a super absorbent resin to form the weeding moisturizing material; according to the weeding moisturizing cloth, a bottom layer is a non-woven geotextile fabric, an upper layer is the non-woven fabric which is loaded with the weed killer and uses the PET as the raw material, a middle layer is the super absorbent resin, and the three layers are punctured and composited to form the weeding moisturizing cloth; and the preparation method of the weeding moisturizing cloth includes that the PET is spun into as-spun fibers, the obtained as-spun fibers are drafted and subjected to air flow spinning jet to form a fiber mesh, the obtainer fiber mesh is subjected to punching strengthening, an aqueous solution of weed killer is sprayed on the surface of the fiber mesh, the fiber mesh is dried to obtain the non-woven fabric which is loaded with the weed killer and uses the PET as the raw material, and the obtained three materials of the non-woven fabric, the super absorbent resin and the non-woven geotextile fabric are punctured and composited to form the weeding moisturizing cloth. The weeding moisturizing material and the weeding moisturizing cloth have the advantages that the weeding and moisturizing effects are good, the seedling raising costs are lowered, the weeding moisturizing material and the weeding moisturizing cloth are environment-friendly, and water and soil can be conserved. The preparation method of the weeding moisturizing cloth is simple, low in costs and capable of achieving massive industrialized production.

Owner:长沙建益新材料有限公司

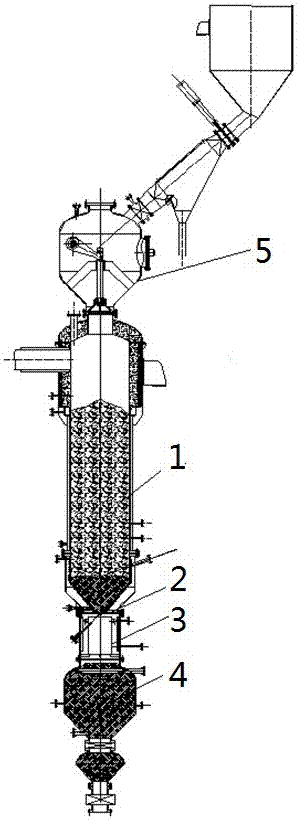

Novel fixed bed slag gasification reaction furnace and gas production method thereof

PendingCN107446628AImprove decomposition rateRaise the pyrolysis gasification reaction temperatureChemical industryGasification processes detailsCombustion chamberDecomposition

The invention belongs to the field of coal chemical industry and coke gasification, and relates to chemical engineering, chemical technology and chemical equipment technology, and particularly relates to a reaction furnace with fixed bed slag gasification, liquid slag removal and fractional gasification and a technology thereof. The reaction furnace comprises a gasifier furnace, a slag hole, a combustion chamber, a quench chamber and an automatic coke or coal adding machine. The invention provides the novel reaction furnace with the fixed bed slag gasification, liquid slag removal and fractional gasification which utilizes crushed coal (anthracite, bituminous coal and coke) as raw materials, and can operate under normal pressure to 0.09MPa pressure. The reaction furnace can improve the gasification temperature, carbon conversion rate and steam decomposition rate and cold coal efficiency, has a high content of effective gases, relatively simple operation and maintenance, and compact and reliable equipment, is less in investment, small in waste water quantity and safe and environmentally friendly, can convert into relatively clean water gas, and completely realizes localization.

Owner:江西昌昱实业有限公司

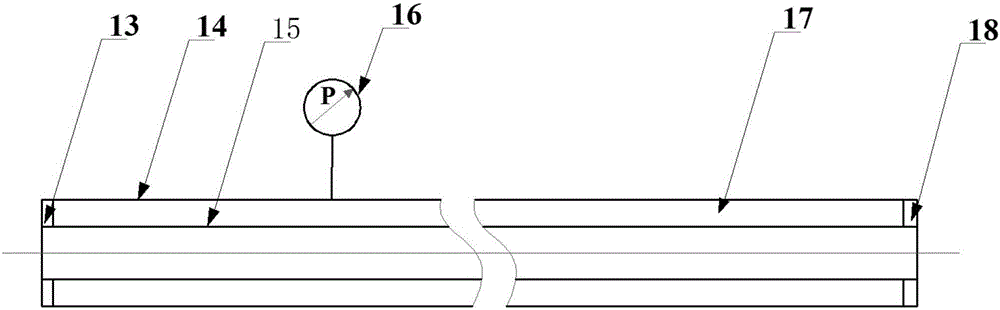

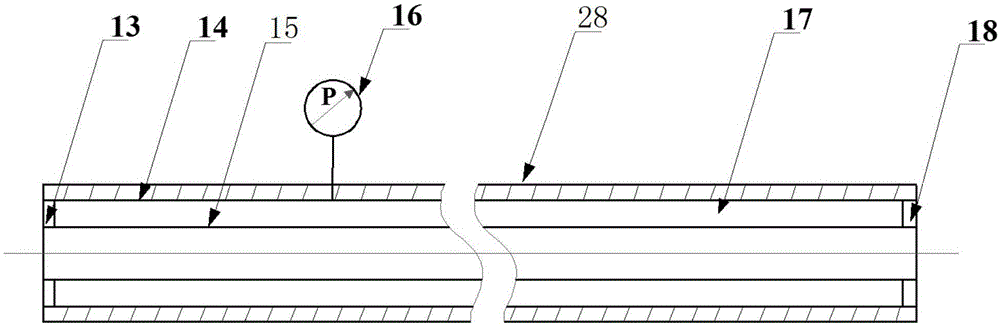

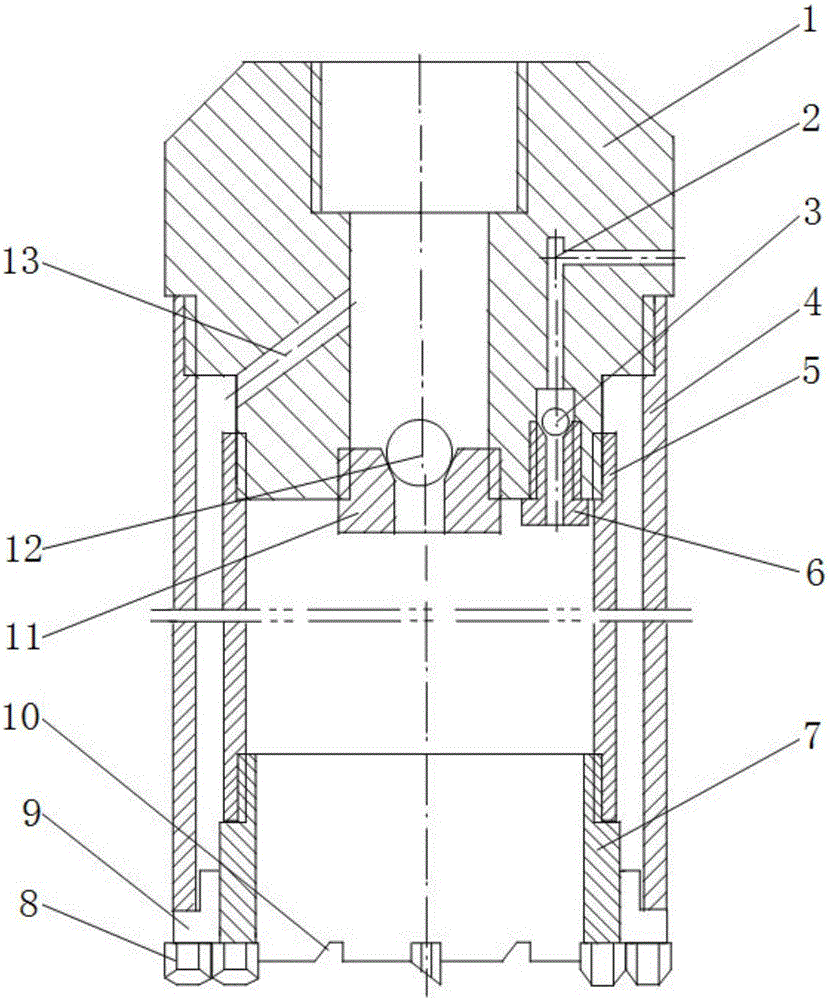

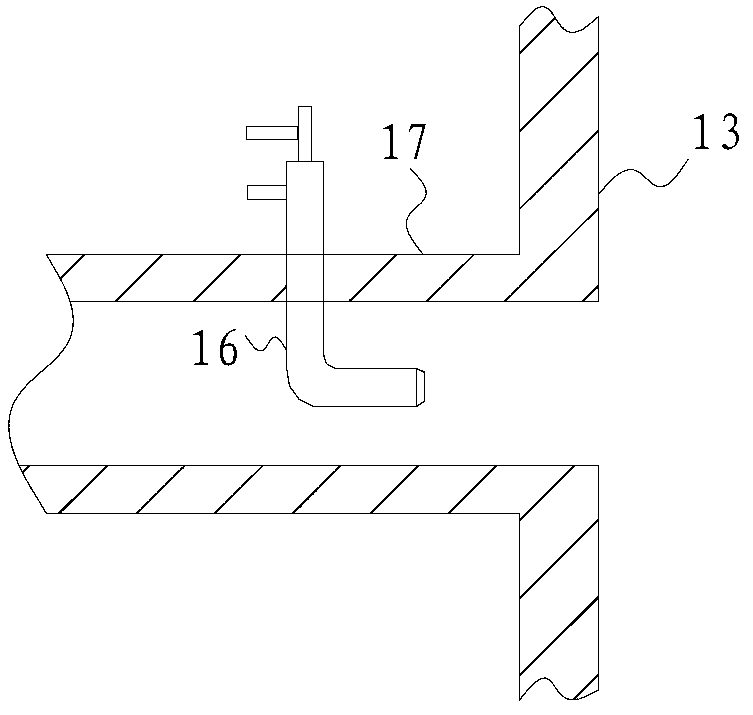

Undisturbed soil penetration test device and method for measuring permeability coefficient

ActiveCN107014739AAvoid damageIntegrity guaranteedPermeability/surface area analysisSoil scienceStructural engineering

The invention discloses an undisturbed soil penetration test device and a method for measuring a permeability coefficient. The undisturbed soil penetration test device comprises a top cover and a base, wherein at least one specimen tube is arranged between the top cover and the base; the specimen tube is partitioned into an upper chamber and a lower chamber by a seepage plate arranged on the base; water via holes communicated with the outside are formed in the side wall of the upper part of the top cover with a seepage hole and the side wall of the lower chamber of the base; at least two accommodating grooves are formed in the top cover and the upper ends and the lower ends of the base and the specimen tube; installation cavities communicated with the accommodating grooves are formed in two sides of the accommodating grooves in the upper ends of the base and the specimen tube; and insertion parts sliding along the accommodating grooves are arranged in the accommodating grooves in the lower ends of the top cover and the specimen tube; and carrying parts which are paired with the insertion parts and clamp the insertion parts are arranged in the installation cavities of the base and the specimen tube.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

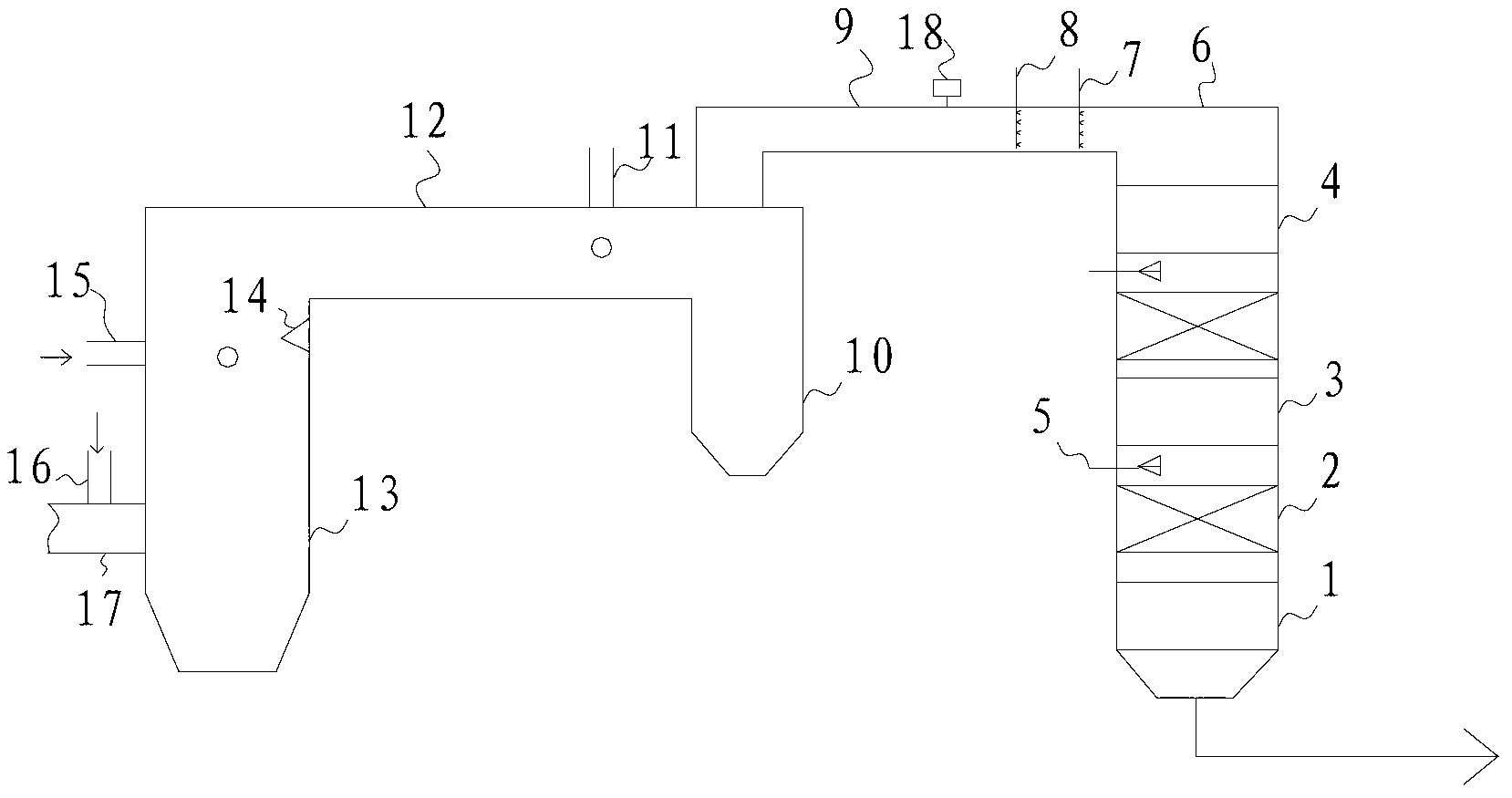

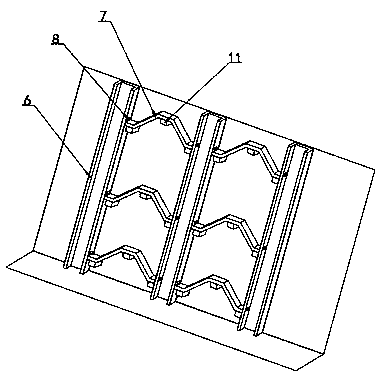

Device for removing NOX from smoke by combining ammonia agent spraying and built-in catalytic reaction

ActiveCN103252163AAvoid direct flushingExtended service lifeDispersed particle separationCirculating fluidized bed boilerCombustion chamber

The invention discloses a device for removing NOX from smoke by combining ammonia agent spraying and built-in catalytic reaction. The device comprises a combustion chamber, a cyclone barrel, a boiler steering chamber, a high-temperature economizer, a low-temperature economizer and an air preheater which are sequentially connected with one another, wherein the middle part of the combustion chamber is communicated with a tertiary air pipe; and a furnace arch is arranged on the upper part in the combustion chamber. The device also comprises a first layer spraying gun arranged in the tertiary air pipe, a second layer spraying gun which is arranged on the wall of the combustion chamber and is positioned at the furnace arch, a third layer spraying gun arranged at an inlet of the cyclone barrel, and catalyst beds which are built in spaces between the high-temperature economizer and the low-temperature economizer and between the low-temperature economizer and the air preheater and is used for carrying silicon controlled rectifier (SCR) denitration catalysts. According to the device, by improving the arrangement way of a reducing agent spraying gun, the smoke denitration efficiency is improved and the denitration cost is reduced; the device is particularly suitable for denitration improvement of circulation fluidized bed boilers with a limited space and preliminary NOX discharging concentration being higher than 400 mg / Nm<3>.

Owner:江苏富春江环保热电有限公司

Casting method capable of preventing defects of air cylinder casting pipe orifice

ActiveCN109128046APrevent inflowSolve the problem that the gate cannot be set when the wall thickness is thinFoundry mouldsFoundry coresSlagCasting defect

The invention belongs to the field of casting and mainly relates to a casting method capable of preventing defects of an air cylinder casting pipe orifice. When the pipe orifice part is casted in theprior art, one loop of cold iron is adopted, and the casting defects such as shrinkage porosity and slag inclusion exist among the cold iron through RT ray detection; in consideration of the above problem, the invention provides a casting method capable of preventing casting defects for an air cylinder casting pipe orifice part. The casting method comprises: a casting process scheme of placing theair cylinder casting with the upward combined surface and the downward pipe orifice is selected, a crossed riser neck is arranged at the radial part of the air cylinder casting pipe orifice, a blindriser is arranged at the middle position of the crossed riser neck, and partitioned cold iron is arranged on the end face part of a crossed riser neck feeding superposed area of the air cylinder casting pipe orifice, so that the casting defects such as shrinkage porosity, slag inclusion and crack on the air cylinder casting pipe orifice part are effectively avoided, the quality of the air cylindercasting is improved, and the standard requirement for the RT ray detection first level of the air cylinder casting pipe orifice part is met.

Owner:KOCEL STEEL

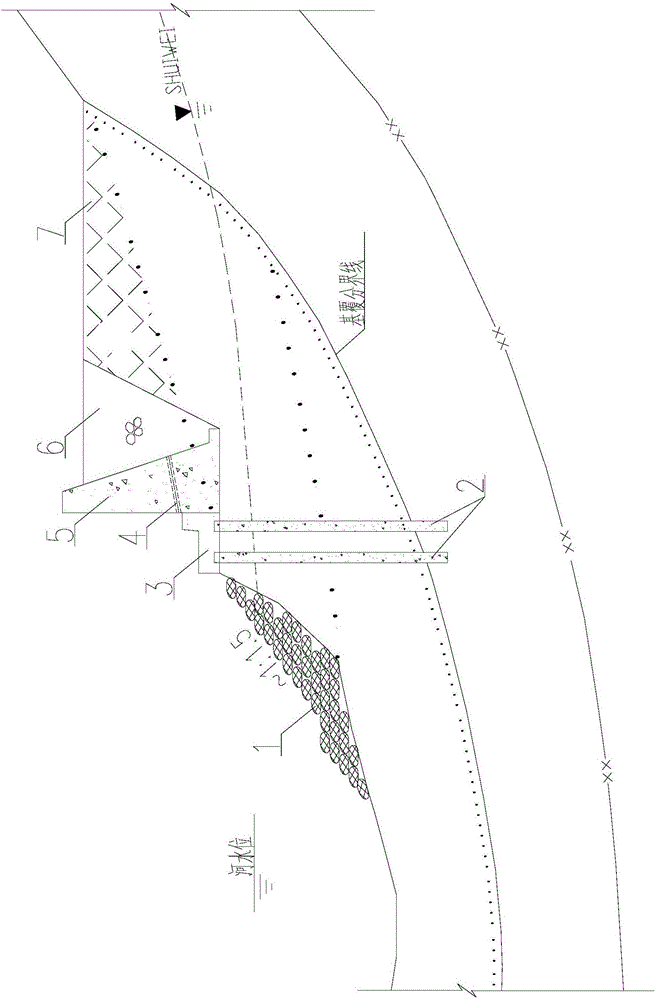

Comprehensive side-slope treatment structure for preventing river channel erosion and construction method thereof

ActiveCN106400744AEasy constructionImprove integrityCoastlines protectionWater flowStructural engineering

The invention relates to a comprehensive side-slope treatment structure for preventing river channel erosion and a construction method thereof. The comprehensive side-slope treatment structure aims at preventing the phenomenon that a river channel covering layer at the downstream position of a flood releasing structure is thick and is frequently scoured by water flow, and therefore side slopes at both shores and a river channel are comprehensively treated, and stability and safety of the side slopes and buildings near the side slopes are ensured. According to the technical scheme, the comprehensive side-slope treatment structure for preventing river channel erosion is characterized in that concrete guard walls are arranged on the river channel side slopes at the downstream position of a flood releasing structure, two to three rows of cement cast-in-place piles stretching into the bed rock surface are arranged on the side, close to a river channel, of each concrete guard wall, and the space between each concrete guard wall and the corresponding river bank is backfilled with rock ballast; concrete foundations connected with the corresponding concrete guard walls are arranged at the tops of the cement cast-in-place piles, and a structural joint is arranged between each concrete foundation and the corresponding concrete guard wall; and alloy net stone bags which are connected in series and extend to the bottom of a riverbed are arranged on the side, close to the river channel, of each concrete foundation.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

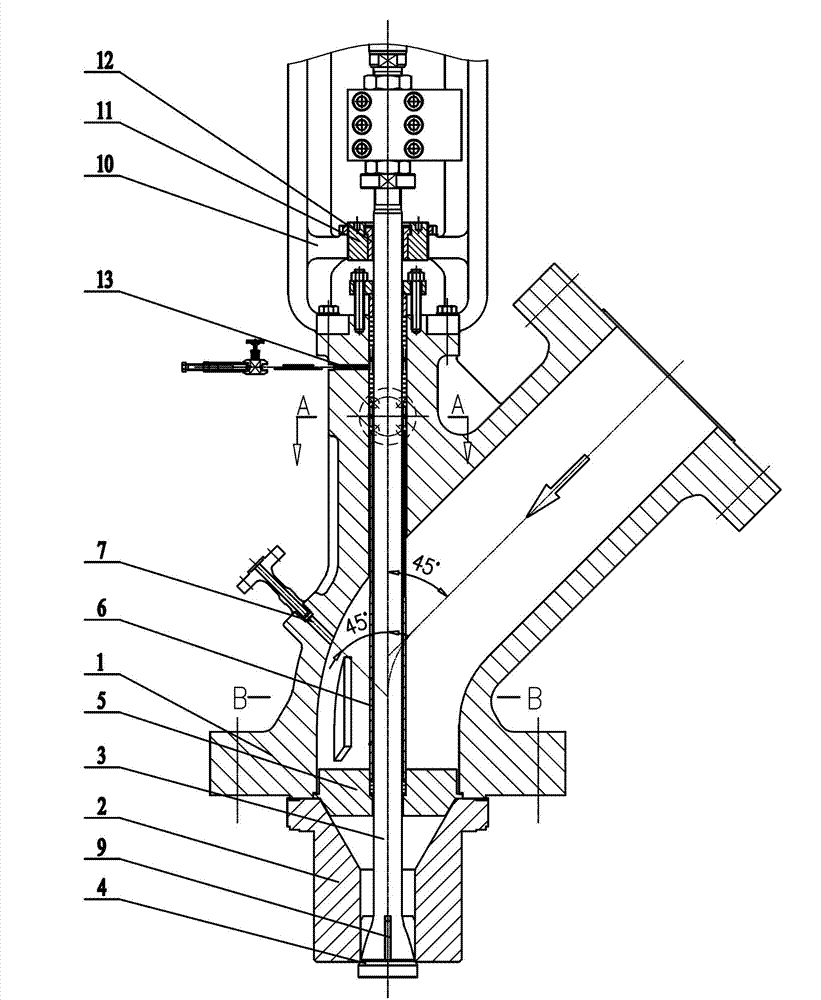

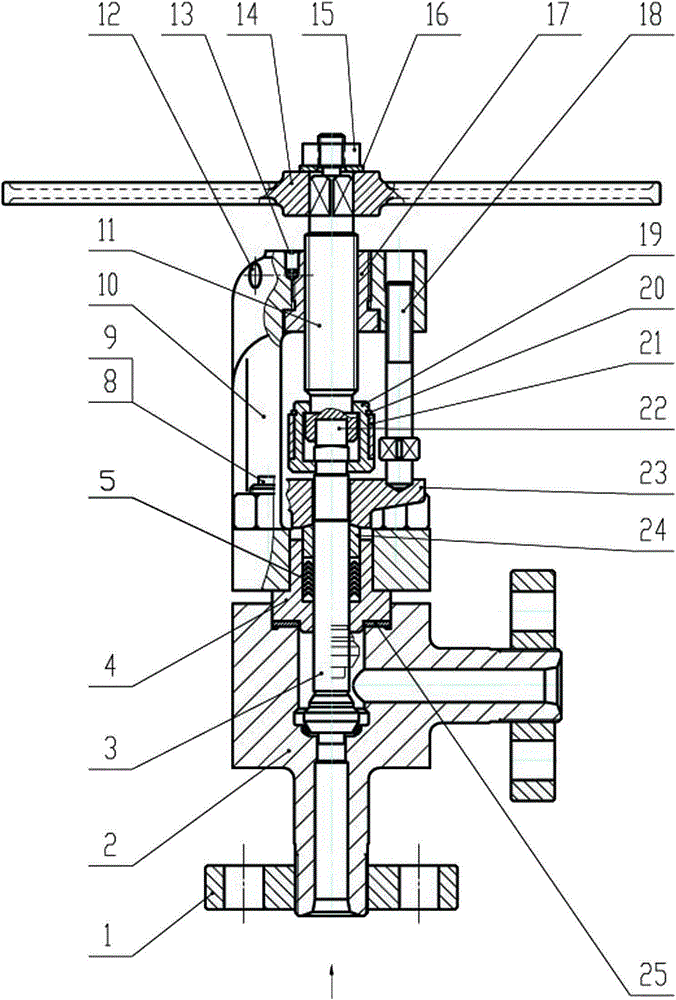

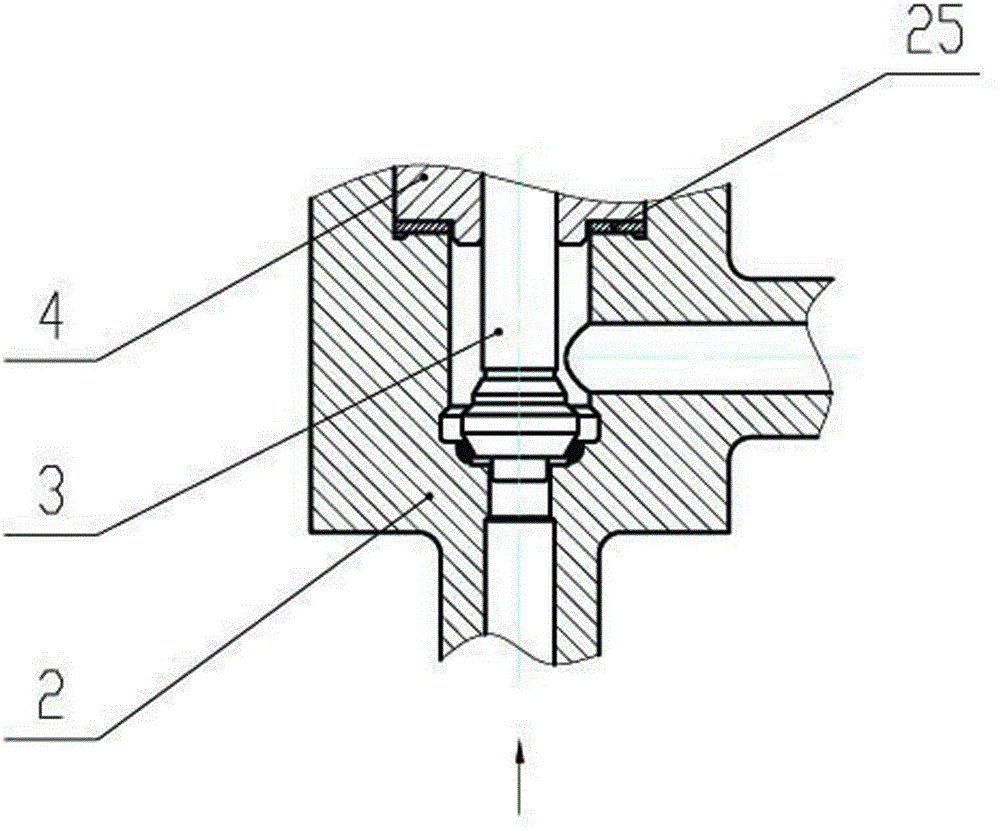

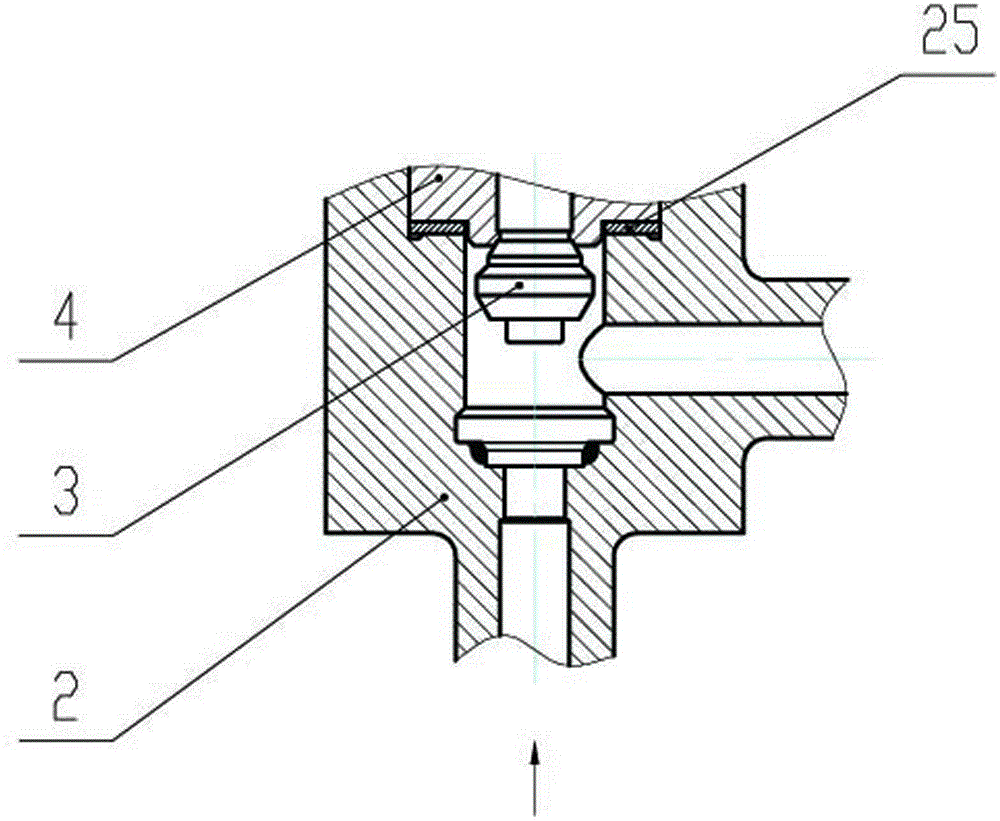

Angle type drain valve

InactiveCN102748484AAvoid direct flushingReduce washoutSpindle sealingsOperating means/releasing devices for valvesEngineeringMechanical engineering

The invention relates to an angle type drain valve. The angle type drain valve comprises a handle component, a support component and a valve component, wherein a packing box component is arranged between the support component and the valve component; the packing box component is internally provided with a valve rod; the top end of the valve rod is connected with the handle component by the support component; the bottom end of the valve rod is provided with a valve rod sealing surface matched with a valve component fluid inlet sealing surface; the valve rod and the valve rod sealing surface are controlled by the support component and the handle component; the valve rod sealing surface and the valve component fluid inlet sealing surface are tightly compressed so that the valve is closed; and the valve rod sealing surface and the valve component fluid inlet sealing surface are separated so that the valve is opened. With the adoption of the angle type drain valve, the direct scouring of a high-speed fluid and residues is avoided; and at the same time, an eddy zone with a pressure more than that of the fluid centre is generated when the high-speed fluid flows near a socket close to the valve sealing surface, and the eddy zone is more in favour of preventing the high-speed fluid from closing to the valve sealing surface, so that the scouring of the high-speed fluid and the residues on the valve sealing surface is further avoided.

Owner:YUEYANG ZHUSHENG VALVE PIPELINE

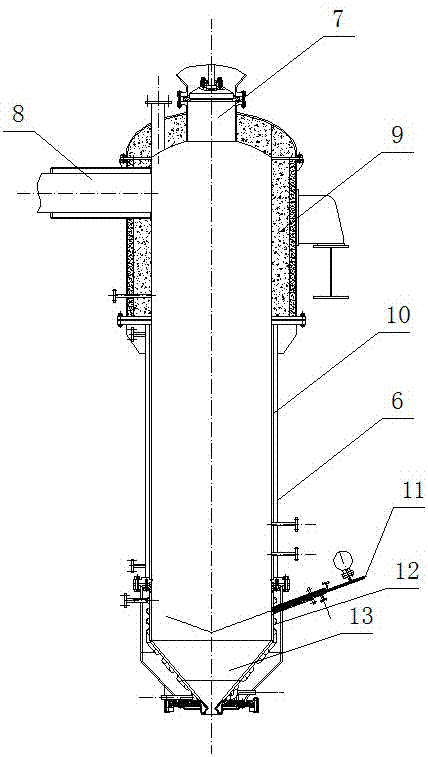

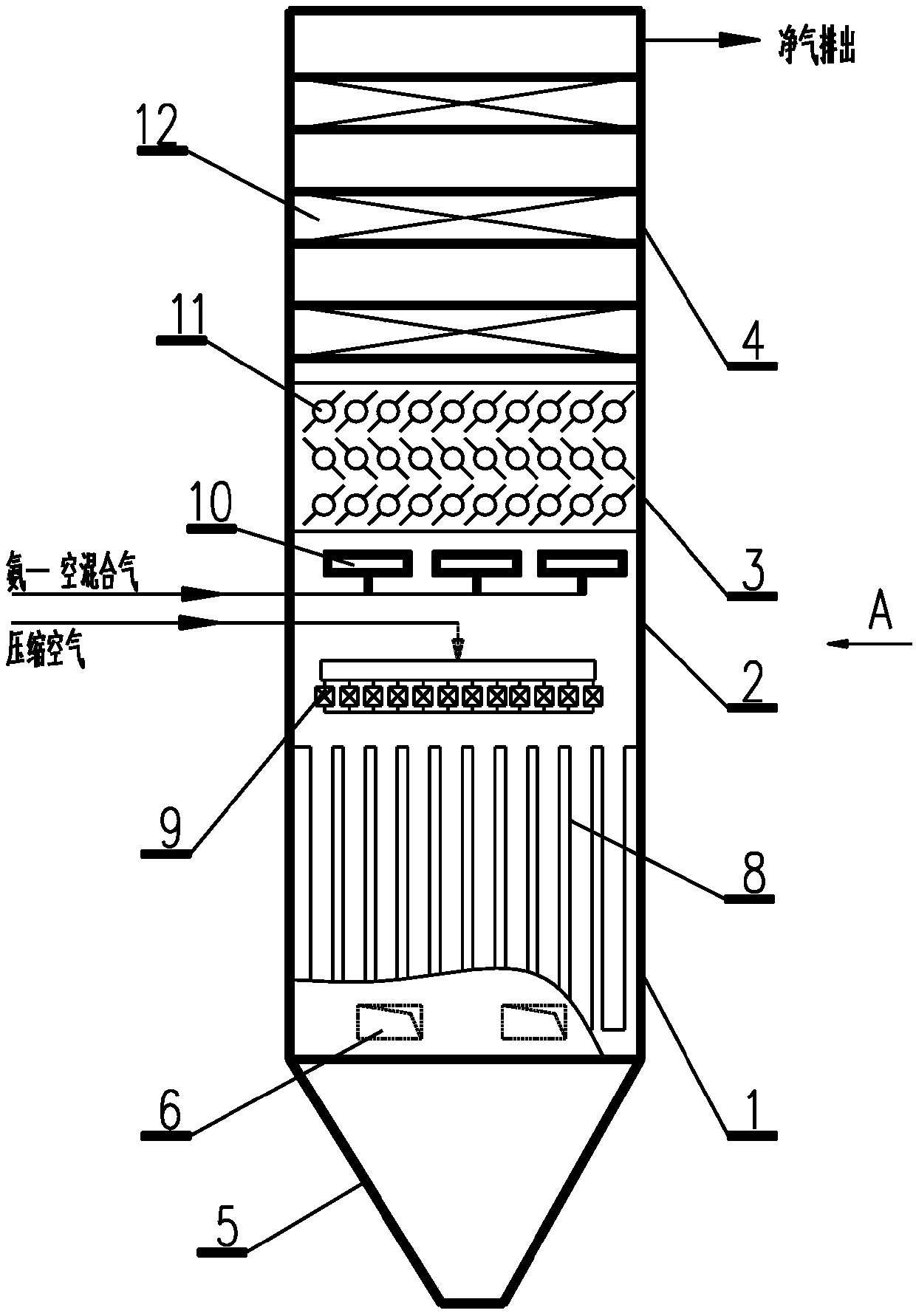

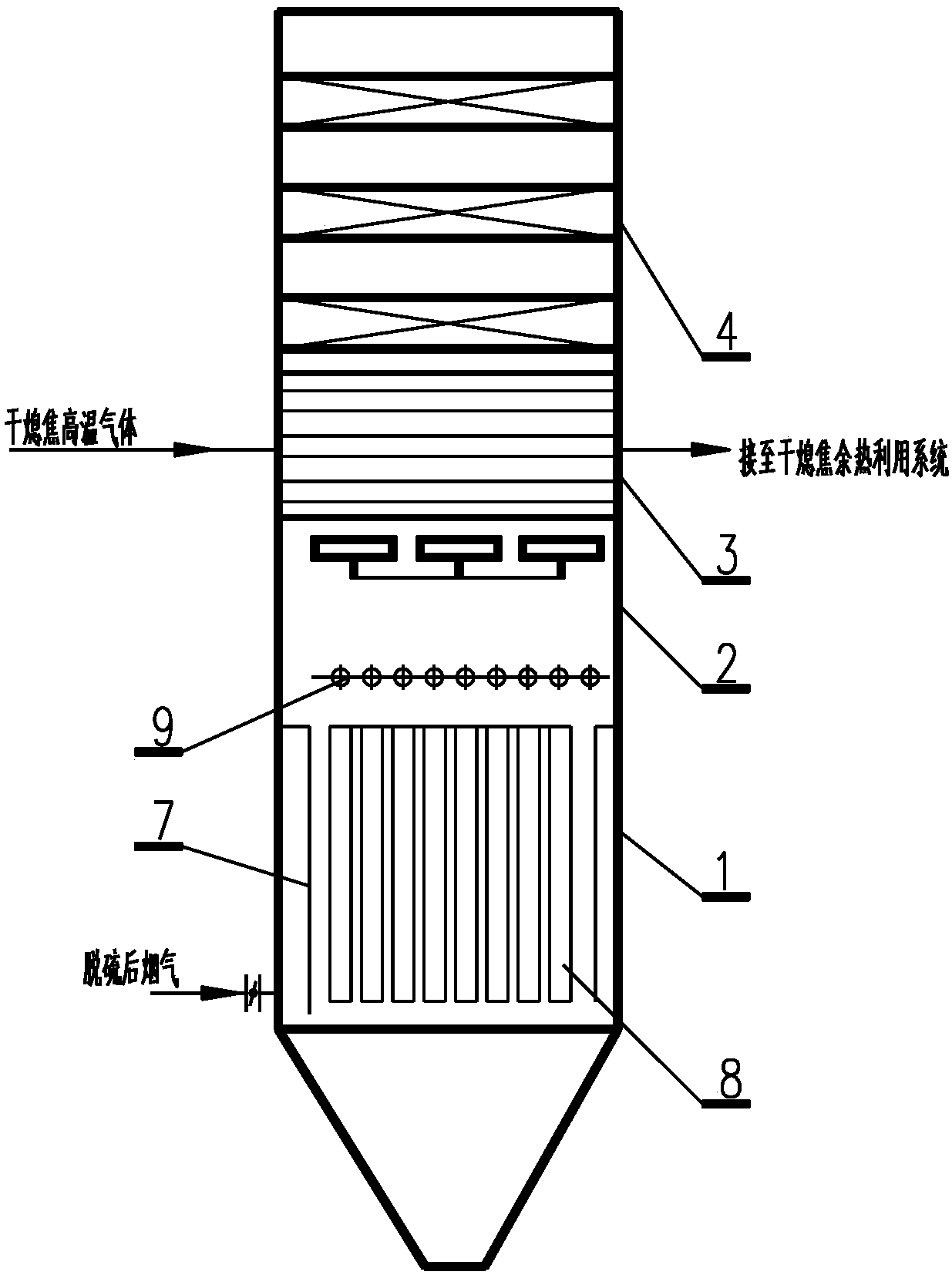

A dust removing-denitration integrated device and method for medium- and low-temperature flue gas

PendingCN107890776AHigh removal rateAdapt to fluctuationsGas treatmentDispersed particle filtrationFlue gasAmmonia

The invention relates to a dust removing-denitration integrated device and method for medium- and low-temperature flue gas. The device includes a dust removing purification unit, an ammonia-air mixingand injecting unit, a heat exchange unit and a denitration unit which are arranged in a column body in order from bottom to top. The lower part of the column body of the dust removing purification unit is provided with a plurality of air inlets along the circumferential direction. Each air inlet is connected to one end of a flue gas feeding pipe through an air feeding branch pipe. The other end of the flue gas feeding pipe is connected to a desulfurated flue gas outlet of an outer desulfuration unit. Air inflow evenly-distributing guide plates and filter bags are disposed in the column body of the dust removing purification unit. A plurality of rows of the filter bags are evenly and vertically distributed in the column body. The air inflow evenly-distributing guide plates are disposed between the air inlets and the filter bags. Pulse-jetting apparatuses are arranged above the filter bags, and are connected to an outer compressed air conveying pipe. The device and the method integratedust removing, heat exchange and denitration, and are high in dust and NOx removing efficiencies. The device is simple in structure, reliable to operate, low in investment and operation cost, and longin service lifetime.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

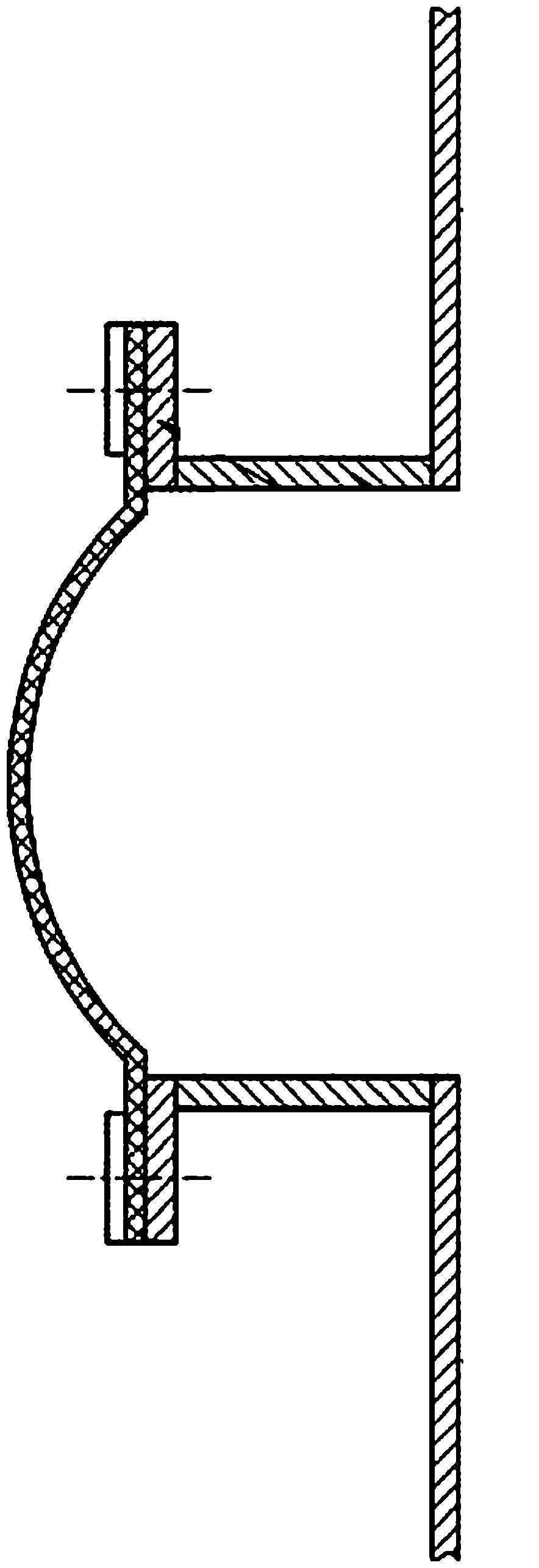

Chimney expansion joint

InactiveCN103075602AAvoid direct flushingAvoid scourPipeline expansion-compensationCorrosion preventionEngineeringExpansion joint

The invention discloses a chimney expansion joint. The technical scheme is that the chimney expansion joint comprises a steel inner cylinder, a flange rack part and a seal ring, wherein the seal ring is fixedly connected with the steel inner cylinder through the flange rack part; the flange rack part comprises an upper taper angle flange, a lower taper angle flange, an upper pressing flange, a lower pressing flange and a bolt component; inner rings of the upper taper angle flange and the lower taper angle flange are welded with the steel inner cylinder; mounting surfaces at the two ends of the seal ring are fixedly pressed between the upper taper angle flange and the lower taper angle flange through the upper pressing flange and the lower pressing flange; the mounting surfaces at the two ends of the seal ring are positioned between corresponding upper and lower taper angle flanges and upper and lower pressing flanges respectively; the upper and lower taper angle flanges and the upper and lower pressing flanges tilt upwards at an angle of 9-16 degrees; and anti-corrosion parts are arranged on corresponding welding parts of the upper and lower taper angle flanges and the inner side of the steel inner cylinder. By using the scheme, the manufacturing cost can be reduced, the construction period can be shortened, the maintenance is convenient, and the service life is prolonged.

Owner:山东龙泰电站技术有限公司

Water conservancy project waterproof construction method

ActiveCN110747813AAvoid direct flushingShort stayCoastlines protectionArchitectural engineeringWater flow

The invention discloses a water conservancy project waterproof construction method, and particularly relates to the technical field of water conservancy projects. The method involves a slope body, wherein a road is arranged at the top of the slope body, a diversion canal is arranged at the bottom of the slope body, a supporting blocking body is fixedly arranged between the bottom end of the slopebody and the diversion canal in a poured mode, a fixing anchor pile is fixedly arranged inside the supporting blocking body, drainage grooves are fixedly formed in the surface of the slope body, the top ends of the drainage grooves are fixedly connected with the road, the bottom ends of the drainage grooves are fixedly connected with the supporting blocking body, the number of the drainage groovesis multiple, and drainage baffles are fixedly arranged between the top portions, the middle portions and the bottoms of every two adjacent drainage grooves. According to the method, soil of the slopebody is supported through the arrangement of the supporting blocking body, the stability of the slope body is improved, water flows downwards on the surface of a waterproof layer, is guided into thedrainage grooves through the drainage baffles and is directly guided into the diversion canal, so that scouring to the slope body is avoided, and the protection effect on the slope surface is improved.

Owner:郴州市水电建设公司

Wear-resisting small eccentric V-ball regulating valve special for salt chemical engineering

ActiveCN103591330AAvoid corrosionPrevent crystallizationPlug valvesValve housingsDrive shaftStructural engineering

The invention relates to a wear-resisting small eccentric V-ball regulating valve special for salt chemical engineering. The wear-resisting small eccentric V-ball regulating valve comprises a valve body, a packing box is machined on the valve body, a packing seal assembly, a packing gland and a packing pressing plate are sequentially arranged in the packing box and connected with the valve body in a fastening mode; a small eccentric valve ball is concentric with a transmission shaft and a driven shaft, the small eccentric valve ball is connected with the transmission shaft and the driven shaft and arranged in the valve body, an upper bush and the transmission shaft are arranged in the valve body from the top, a lower bush and the driven shaft are arranged in the valve body from the bottom, and a valve seat and a pressing ring are arranged in the valve body from the side face; a first distance adjustment pad and a second distance adjustment pad are arranged on the upper end face and the lower end face of the small eccentric valve ball; a first C-shaped seal ring is arranged in a clamping groove between the valve body and the first distance adjustment pad; a first supporting ring is arranged between the upper bush and the lower bush, and a second supporting ring is arranged between the first C-shaped seal ring and a second C-shaped seal ring. According to the wear-resisting small eccentric V-ball regulating valve, blocking of a flow channel of the valve body can be effectively prevented, corrosion of a cavity by crystals can be effectively prevented; the adjustment accuracy of the valve can be improved; scouring and corrosion of media on the valve body and components in the valve can be reduced; particle media can be prevented from entering valve shaft gaps, the adjustment accuracy of the valve can be greatly improved, and the service life of the valve can be greatly prolonged.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

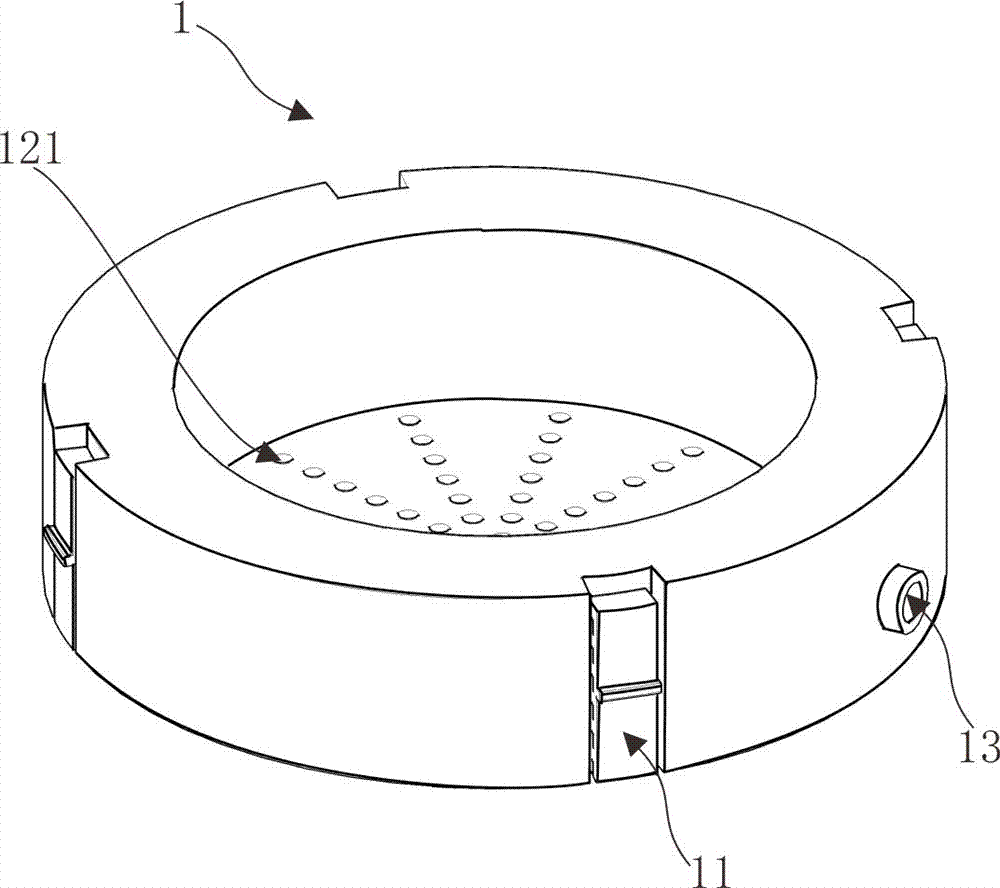

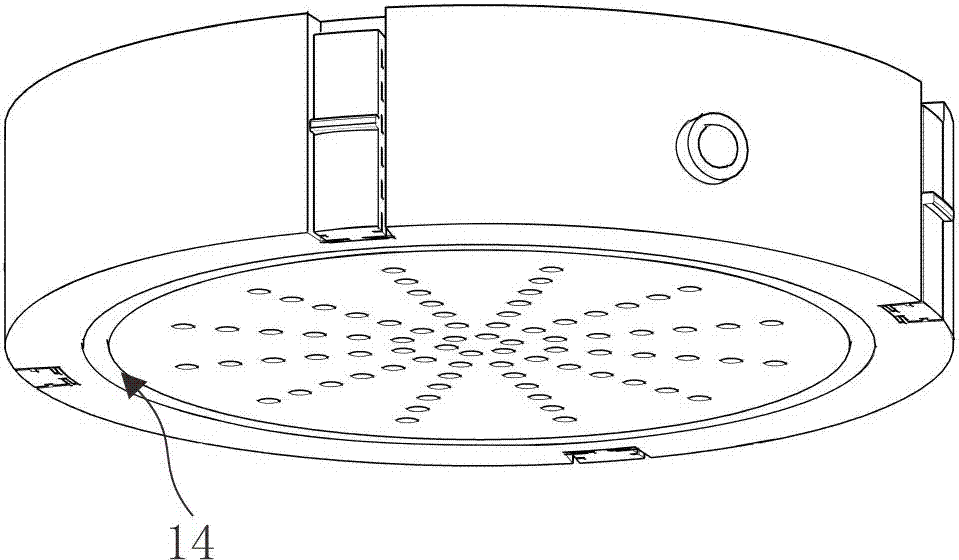

Circulating fluidized bed boiler air hood

InactiveCN101975396AReduce wearReduce cloggingFluidized bed combustionApparatus for fluidised bed combustionEngineeringDust particles

The invention provides a circulating fluidized bed boiler air hood, relating to a boiler air hood. The invention solves the problems that the air outlet of the existing boiler air hood is easy to be blocked by larger dust particle and air hood is easy to be abrased. The anti-abrasion sleeve is sheathed on the upper part of an air inlet pipe, the lower end of the air hood outer cover is sheathed on the anti-abrasion sleeve, and the lower end of the air hood outer cover is hermitically connected with the anti-abrasion sleeve, air flue is formed between the air hood outer cover and the air inlet pipe as well as between the air hood outer cover and the outer wall of anti-abrasion sleeve, the lower side wall of the air hood outer cover is uniformly distributed with a plurality of inclined holes communicated with the air flue along the peripheral direction, and the peak of intersecting line formed by each inclined hole and the inner surface of the air hood outer cover is higher than the peak of intersection line formed by each inclined hole and the outer surface of the air hood outer cover. The boiler air hood of the invention is processed with inclined air outlets, the probability that larger dust particle is blocked in air outlet is greatly reduced, meanwhile the phenomenon that air current washes adjacent air hood is avoided, and abrasion of air hood is reduced.

Owner:HARBIN HAGUO BOILER ENG TECH

Biomass double square coil pipe heat conduction oil furnace

InactiveCN104697170AReduce heating temperatureSolve high temperature resistanceStorage heatersHeat transfer efficiencyEngineering

The invention discloses a biomass double square coil pipe heat conduction oil furnace. Two groups of square coil pipes are parallelly arranged in a smoke chamber in a furnace body, and three side rings of each group of square coil pipes are attached to side walls of the furnace body. The three side rings of each group of square coil pipes are attached to the side walls of the furnace body and one side ring of each group of square coil pipes is disposed at a flame center so that the two groups of square coil pipes are attached to over 90% area of four side walls of the furnace body, the maximum space utilization rate of the smoke chamber is achieved, heating area is increased, double sides of the side rings of the flame center are heated, the heat transfer efficiency is increased, meanwhile, the square coil pipes are tightly attached to the side walls so that heating temperature of the side walls is lowered, and the problem in terms of high temperature resistance of the side walls is solved.

Owner:GUANGZHOU DEVOTION THERMAL TECH +2

High temperature flue gas moisture instrument anti-abrasive anti-plugging method and device

ActiveCN101126732AAvoid direct flushingSolve wear and tearMaterial capacitanceFlue gasWear resistant

The utility model relates to a wear and block preventing method of a moisture meter for high temperature flue gases, which comprises a wear resistant arc baffle sampling apparatus 1), an anti-wear sampling sleeve 2), and an anti-clogging backblowing pipe; wherein, the sampling apparatus can be adjusted at any angles, and comprises an auto-exciting anti-wear sampling sleeve, an anti-wear arc baffle which can be adjusted at any angles; the two devices can be combined into an anti-wear and anti-clogging sampling apparatus of gas flue moisture meter, according to the flow direction of the gas flues and the sampling points for measurement; the sampling device adopts the composite wear resistant coating of SS316 stainless steel as protective layer, and a steam stop sleeve is arranged in the sampling sleeve to prevent the corrosion due to dew condensation on the surface; an air tube is arranged in the auto-clogging backblowing pipe for conducting air backblowing automatically or manually.

Owner:NANJING ASSEN ENVIRONMENT TECH

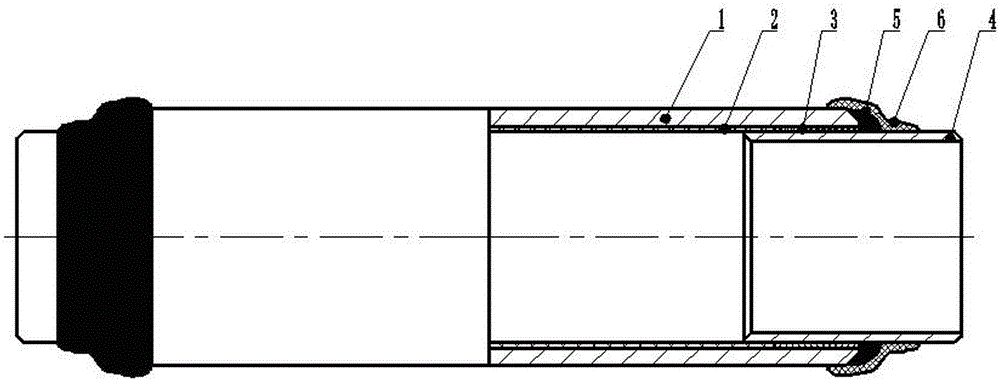

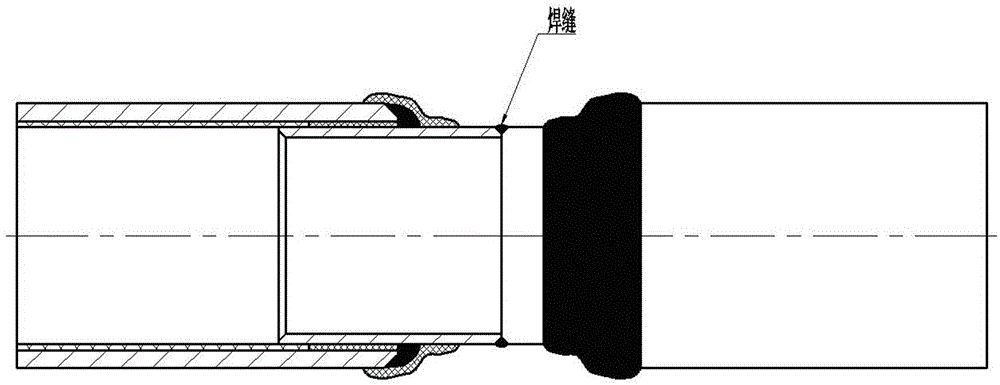

Method for manufacturing lining plastic pipe by using welded connection

ActiveCN105697896ASolve the problem of electrochemical corrosionSolve the defects of utility modelsCoatingsRigid pipesStructural ProblemEngineering

The present invention discloses a method for manufacturing lining plastic pipe by using welded connection. The method comprises the following steps: (1) stripping one section of the plastic anticorrosive coating of the lining plastic pipe port that has been subjected to lining plastic recombination, wherein the lining plastic pipe port being stripped the plastic anticorrosive coating is the connection end of the external steel pipe; (2) lining the inner wall of the connection end that is not lined with the plastic anticorrosive coating with a hot melt adhesive, wherein the hot melt adhesive is adhered to the inner wall of the connection end to form a hot melt adhesive layer; (3) inserting a stainless steel pipe into the external steel pipe from the connection end of the external steel pipe, wherein the outer wall of the stainless steel pipe is adhered with the hot melt adhesive layer; and (4) welding the outer wall of the stainless steel pipe and the port of the external steel pipe. The lining plastic pipe manufactured by this method can efficiently solve the problem of electrochemical corrosion after welding the dissimilar steel, solve the structural problem that the steel-plastic pipe cannot directly adopt welded connection, and expands the application of the stainless steel in steel-plastic pipe manufacture.

Owner:SICHUAN XIN YUAN TONG STEEL PLASTIC PIPE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com