Circulating fluidized bed boiler air hood

A circulating fluidized bed and wind cap technology, applied in the field of boiler wind caps, can solve the problems of wind cap wear and air outlet dust particles clogging in the air outlet, and achieve the effects of avoiding wear, reducing wear and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

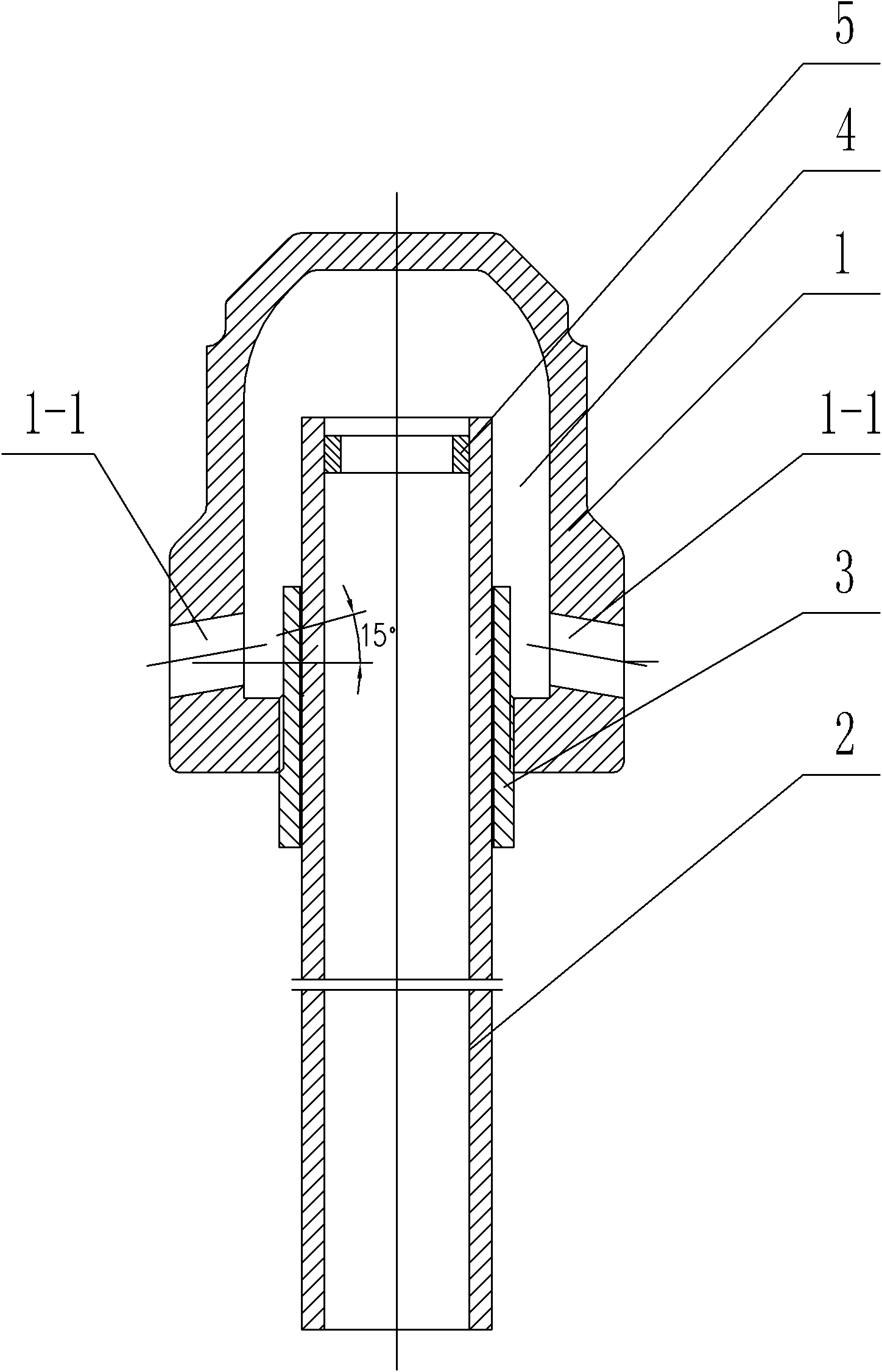

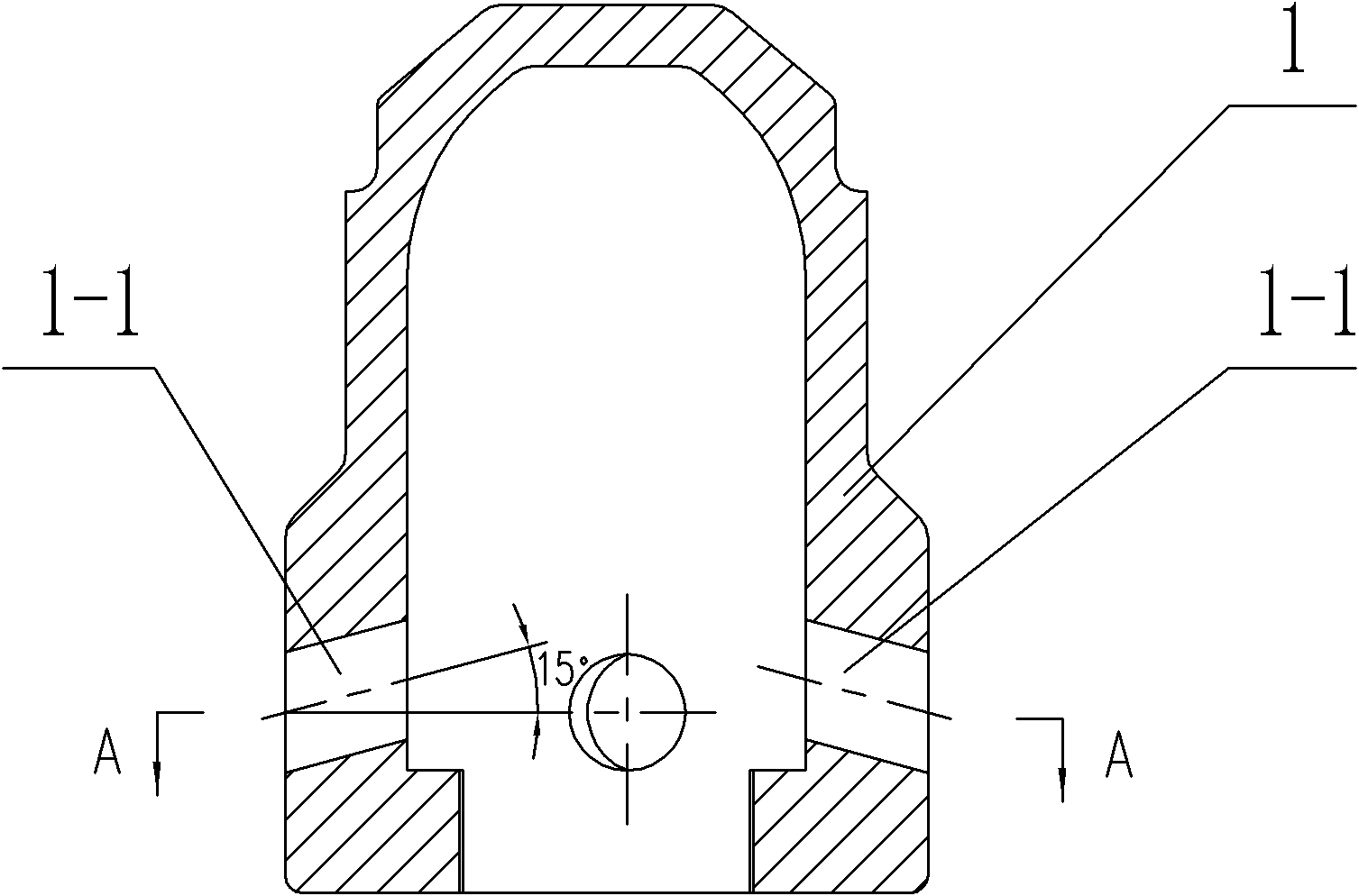

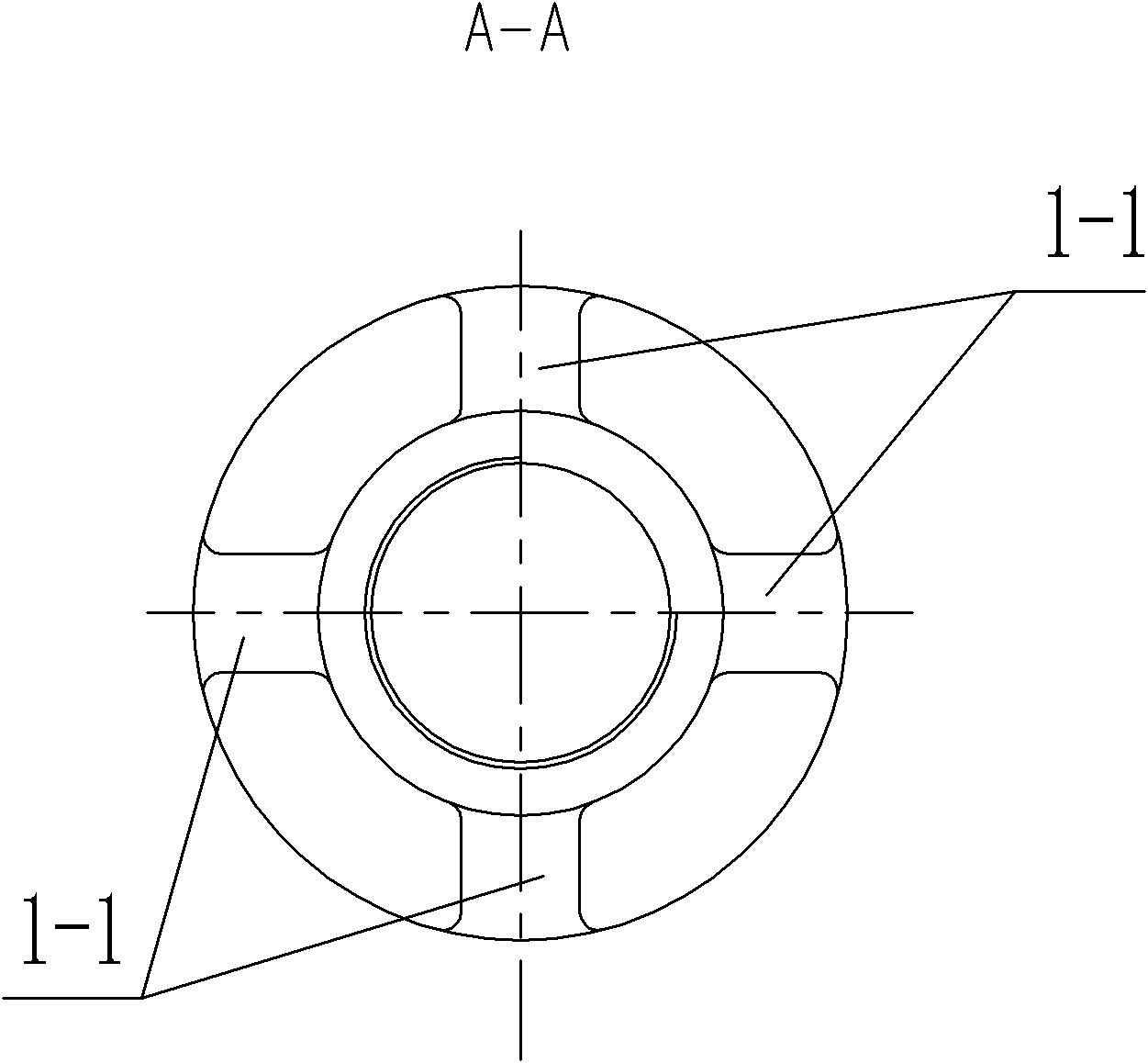

[0007] Specific implementation mode one: as Figure 1~3 As shown, the air cap of the circulating fluidized bed boiler in this embodiment includes an air cap cover 1 and an air inlet pipe 2, and the boiler air cap also includes an anti-wear sleeve 3, and the anti-wear sleeve 3 is set on the upper part of the air inlet pipe 2 , the lower end of the hood cover 1 is set on the wear-resistant sleeve 3, and the lower end of the hood cover 1 is airtightly connected with the wear-resistant sleeve 3, and the outer wall of the hood cover 1 and the air inlet pipe 2 and the wear-resistant sleeve 3 There is an air channel 4 between them, and the lower side wall of the hood cover 1 is uniformly processed with a plurality of oblique holes 1-1 communicating with the air channel 4 along the circumferential direction, and each slanted hole 1-1 is connected with the hood cover 1. The highest point of the intersecting line formed by the inner surface is higher than the highest point of the inters...

specific Embodiment approach 2

[0008] Specific implementation mode two: as Figure 1~2 As shown, the included angle α between the axis of the inclined hole 1 - 1 in this embodiment and the horizontal direction is 15°. Such a design can reduce the probability of larger dust particles clogging the holes, and at the same time prevent the airflow from scouring the adjacent air caps, reducing the wear of the air caps. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: as image 3 As shown, the number of inclined holes 1-1 in this embodiment is three to four. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com