Weeding moisturizing material, weeding moisturizing cloth and preparation method

A wet material and wet cloth technology, applied in chemical instruments and methods, non-woven fabrics, plant protection covers, etc., can solve problems such as weeding alone or moisturizing effect, and meet long-term outdoor use, improve survival rate and growth speed, and ensure Effect of Humid Conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] To prepare the weeding wet cloth:

[0052] 1. Textile fiber web:

[0053] The PET chips are sent to the fluidized bed for pre-crystallization through the conveying device. The temperature is controlled at 145~160°C. The pre-crystallized PET chips are sent to the drying tower for further drying. The drying temperature is controlled at 165~175°C so that the final moisture content is less than 30ppm, reaching Spinning requirements: the dried slices are fed into the extruder to be melted and mixed with the added black anti-aging masterbatch, and sent to the spinning box under a pressure of 6 kg, and the spinning temperature is controlled at 275~285°C. Through the spinning metering pump and spinning components, the as-spun silk with a diameter of 0.3-0.5mm is produced, and the as-spun silk is drawn 4000-5000 times to make the silk reach a fineness of 4-12dtx, and then it is evenly formed into a net by air-jet spinning;

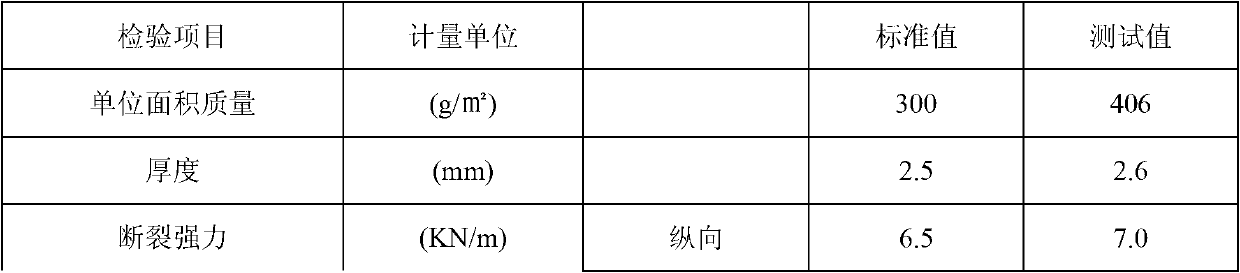

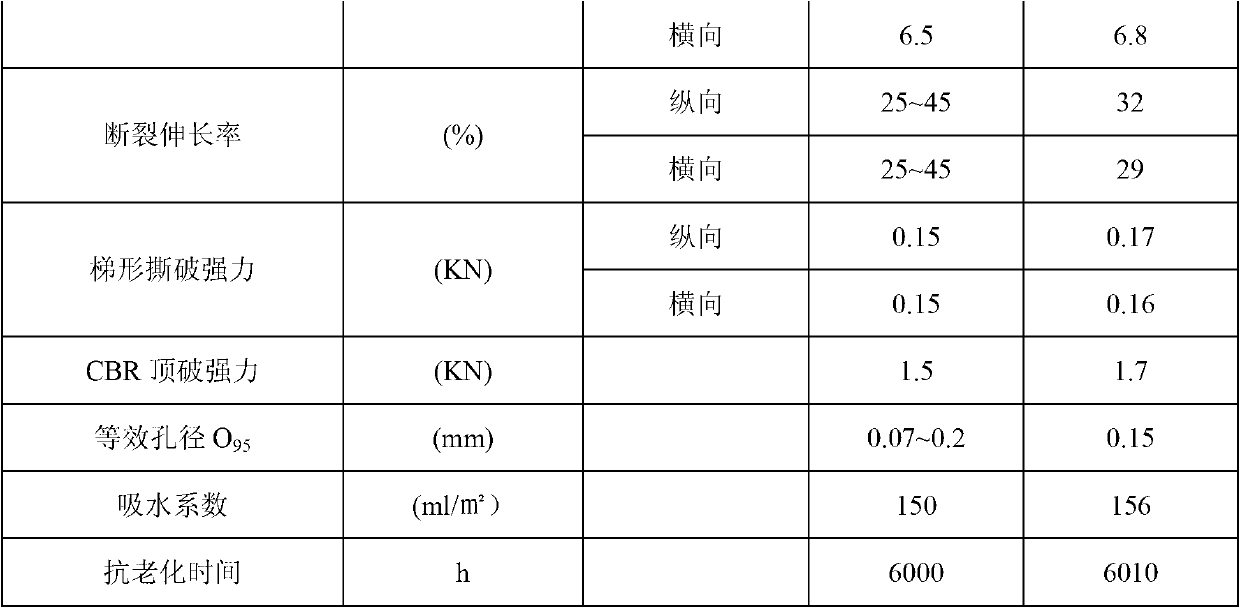

[0054] 2. Preparation of non-woven fabrics loaded wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com