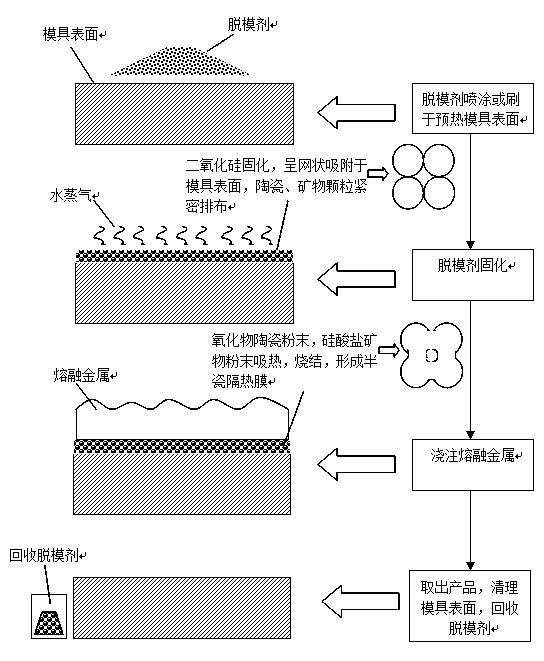

Mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding

A compounding agent and mold release technology, applied in the direction of casting mold, core, casting mold composition, etc., can solve the problems of no substantial improvement, mold thermal fatigue, thermal cracking, etc., to delay thermal fatigue and reduce mold temperature difference. , the effect of low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Take 625g of nano-colloidal silica solution, 289g of water and stir at room temperature for 5 minutes, then add 80g of composite oxide ultrafine (average particle size 1.0μm) powder containing silicate minerals, alumina, and zirconia, stir at room temperature and slowly evenly Add 5 g of polyvinyl alcohol (200) and 1 g of hydroxyethyl cellulose, and stir at room temperature until a uniform and stable dispersion system is formed.

Embodiment 2

[0023] Example 2: Take 650g of nano-colloidal silica solution, 247g of water and stir at room temperature for 5 minutes, then add 100g of composite oxide ultrafine (average particle size 0.5μm) powder containing silicate minerals, magnesium oxide, and calcium oxide, stir at room temperature and slowly evenly Add 2 g of sodium polyacrylate and 1 g of sodium hydroxymethyl cellulose, and stir at room temperature until a uniform and stable dispersion system is formed.

Embodiment 3

[0024] Example 3: Take 700g of nano-colloidal silica solution, 177g of water and stir at room temperature for 5 minutes, then add 120g of composite oxide ultrafine (average particle size 0.8μm) powder containing silicate minerals, magnesium oxide, calcium oxide, and zirconia, and stir at room temperature And slowly and uniformly add 2.5 g of hydrolyzed polymaleic anhydride and 0.5 g of polyacrylamide, and stir at room temperature until a uniform and stable dispersion system is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com