Patents

Literature

144results about How to "Promote interdiffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

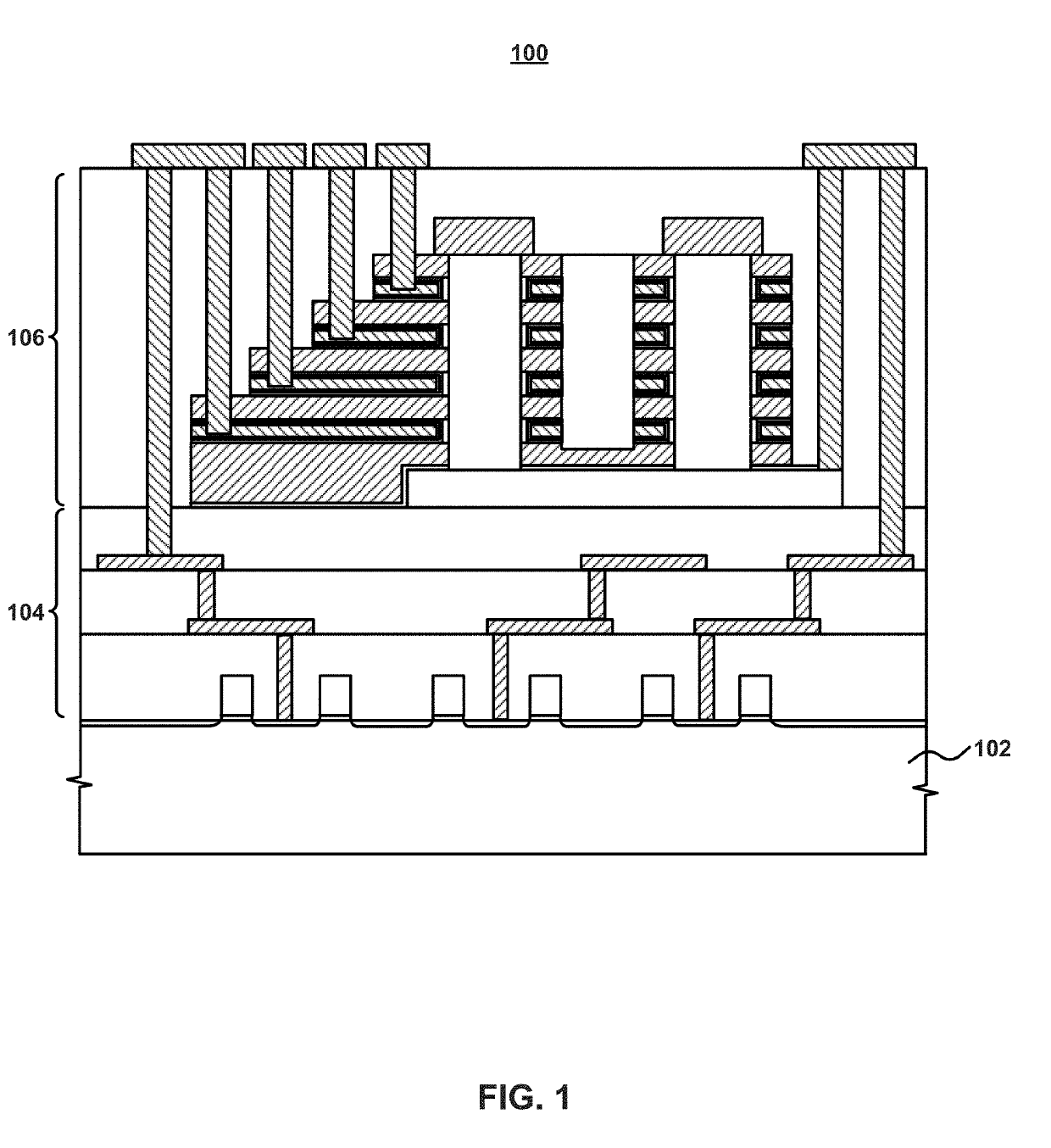

Three-dimensional memory devices having a plurality of NAND strings

ActiveUS10283452B2High bonding strengthPromote interdiffusionSemiconductor/solid-state device detailsSolid-state devicesBond interfaceCrystalline silicon

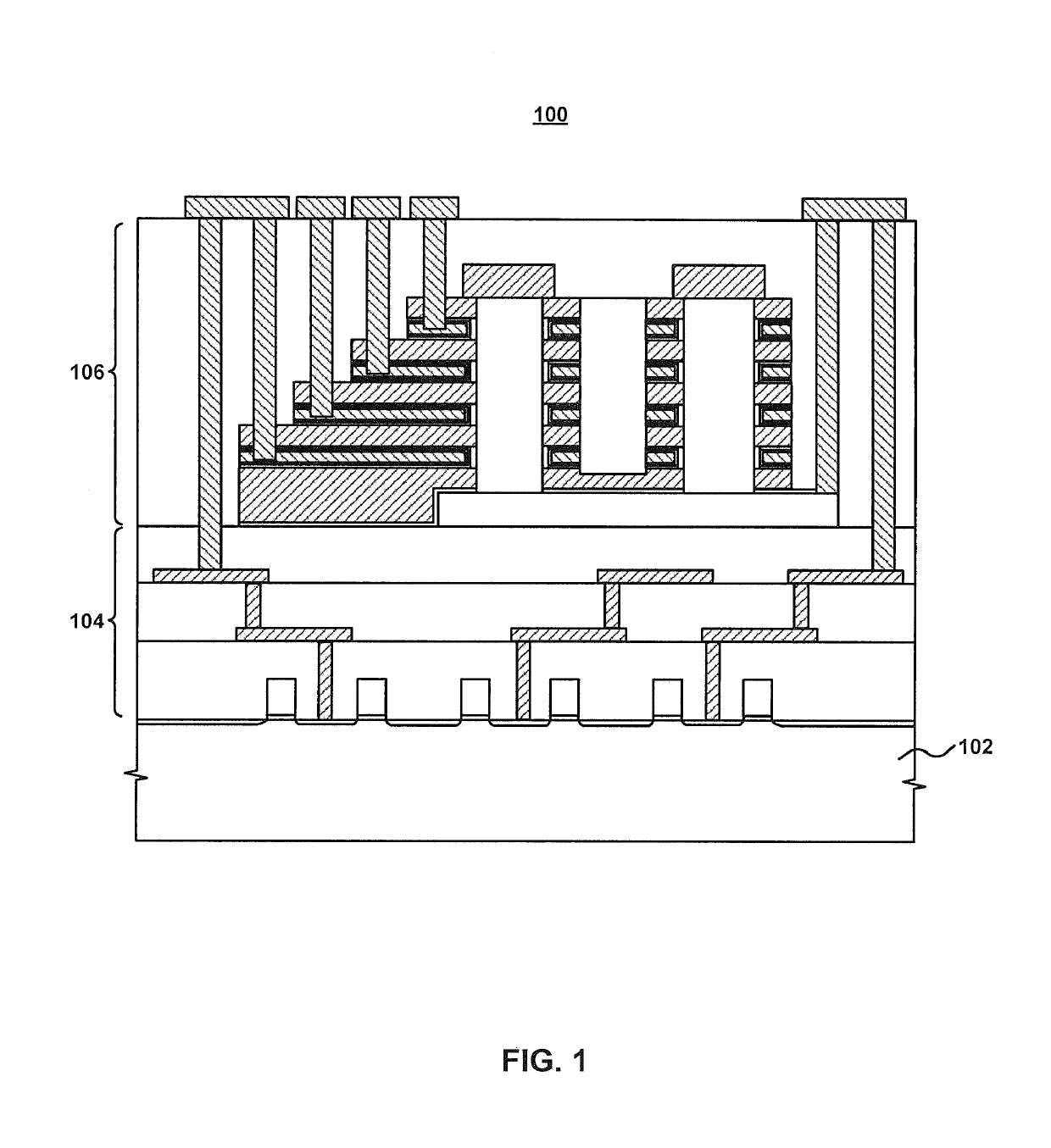

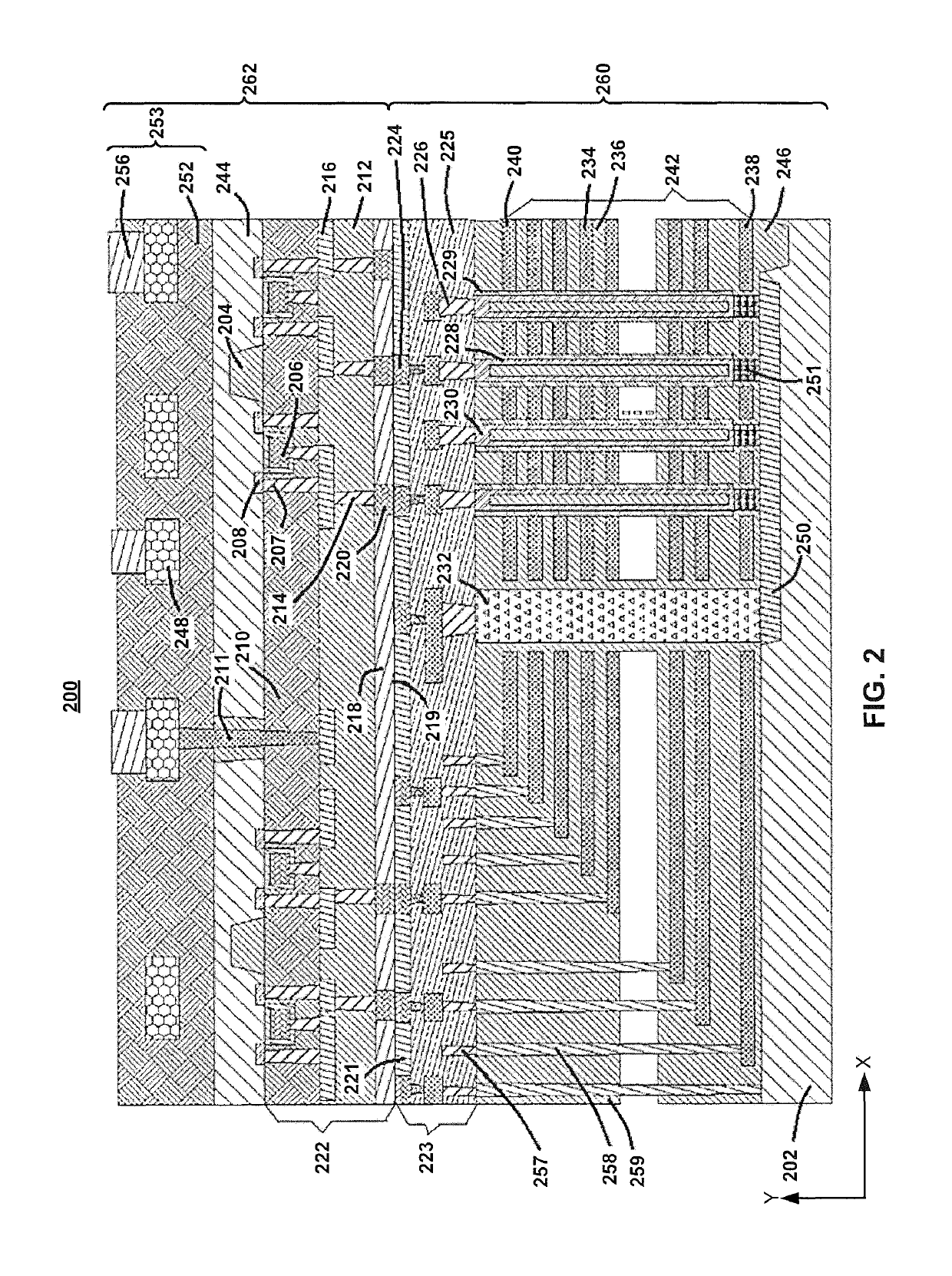

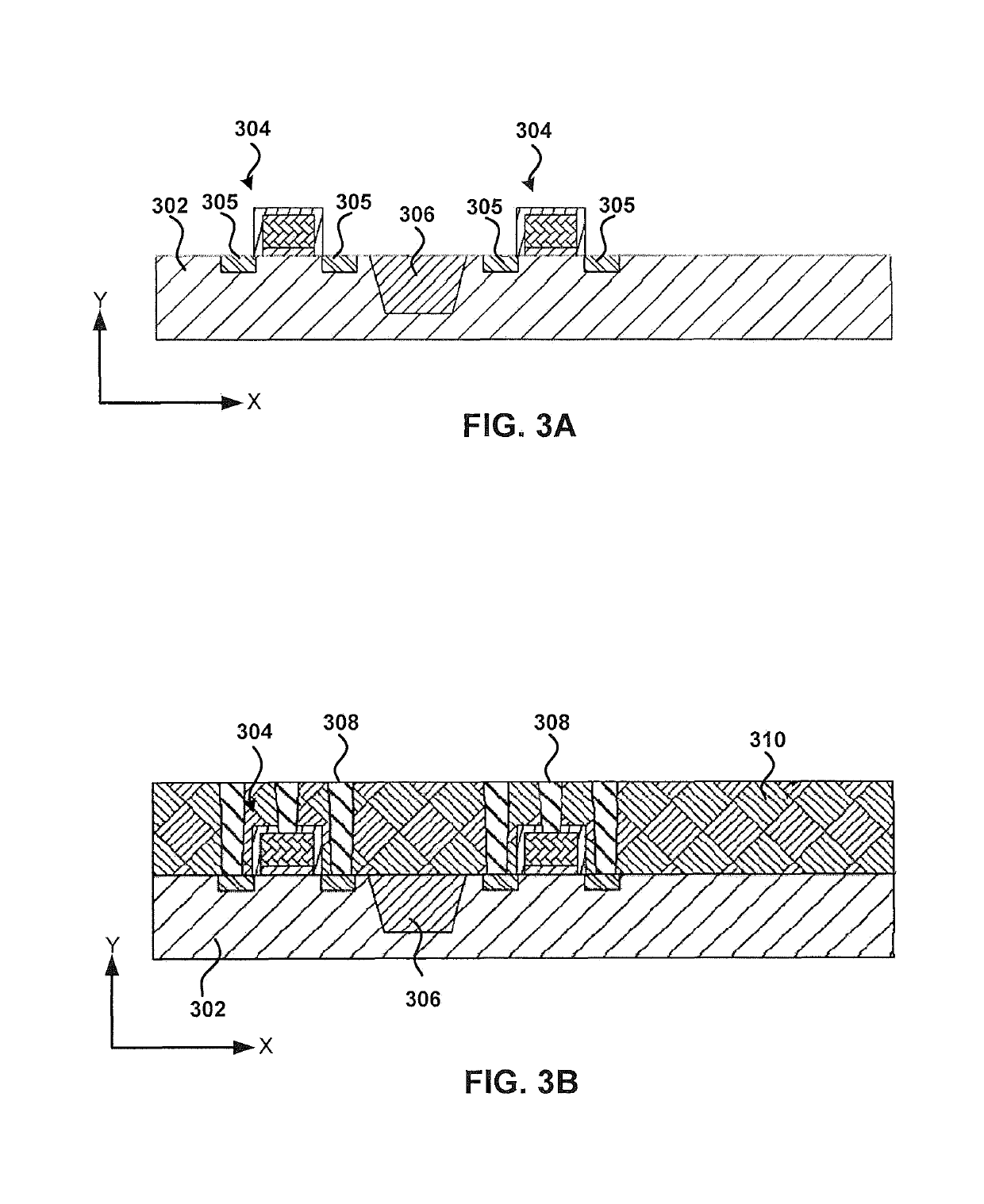

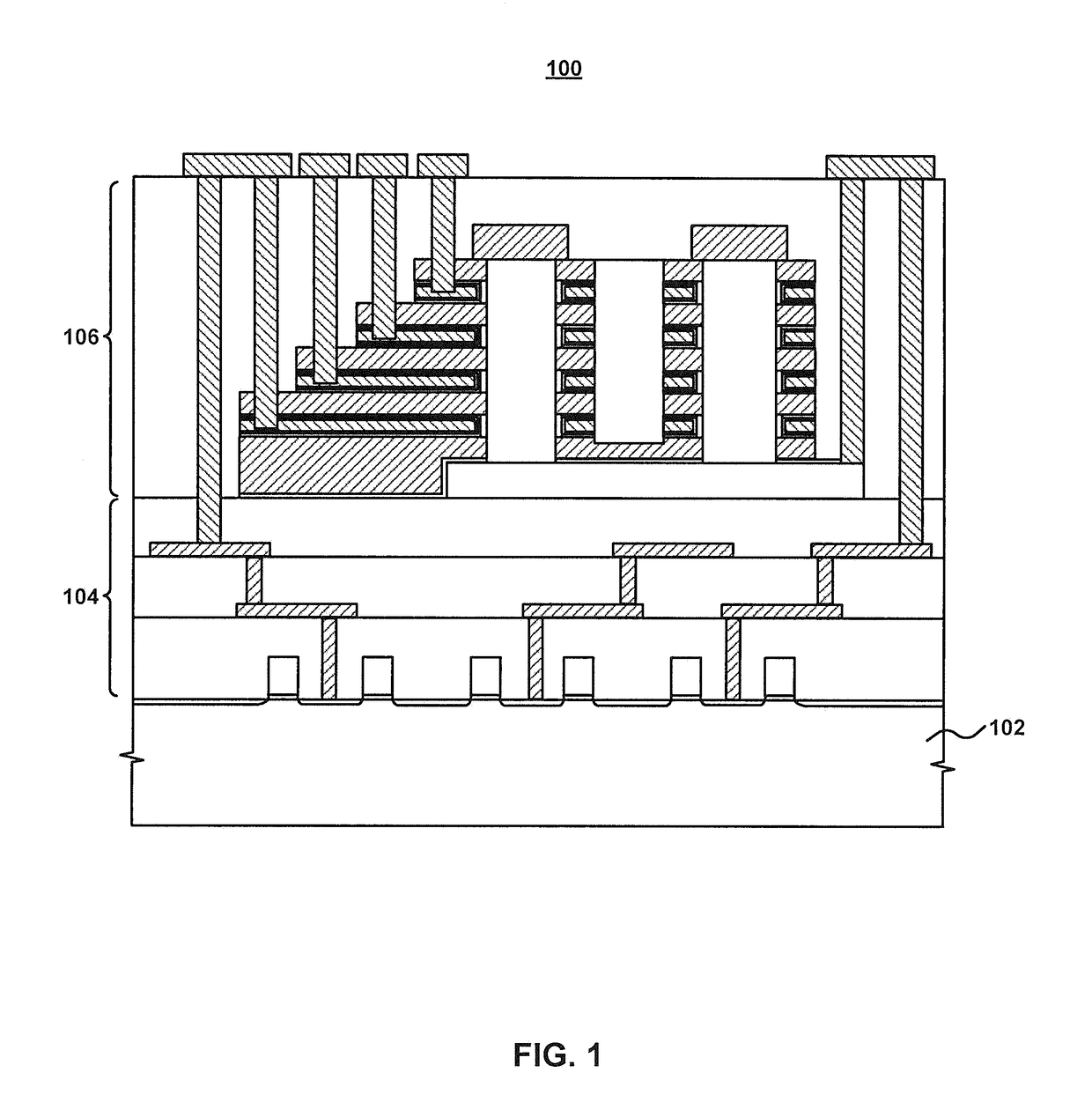

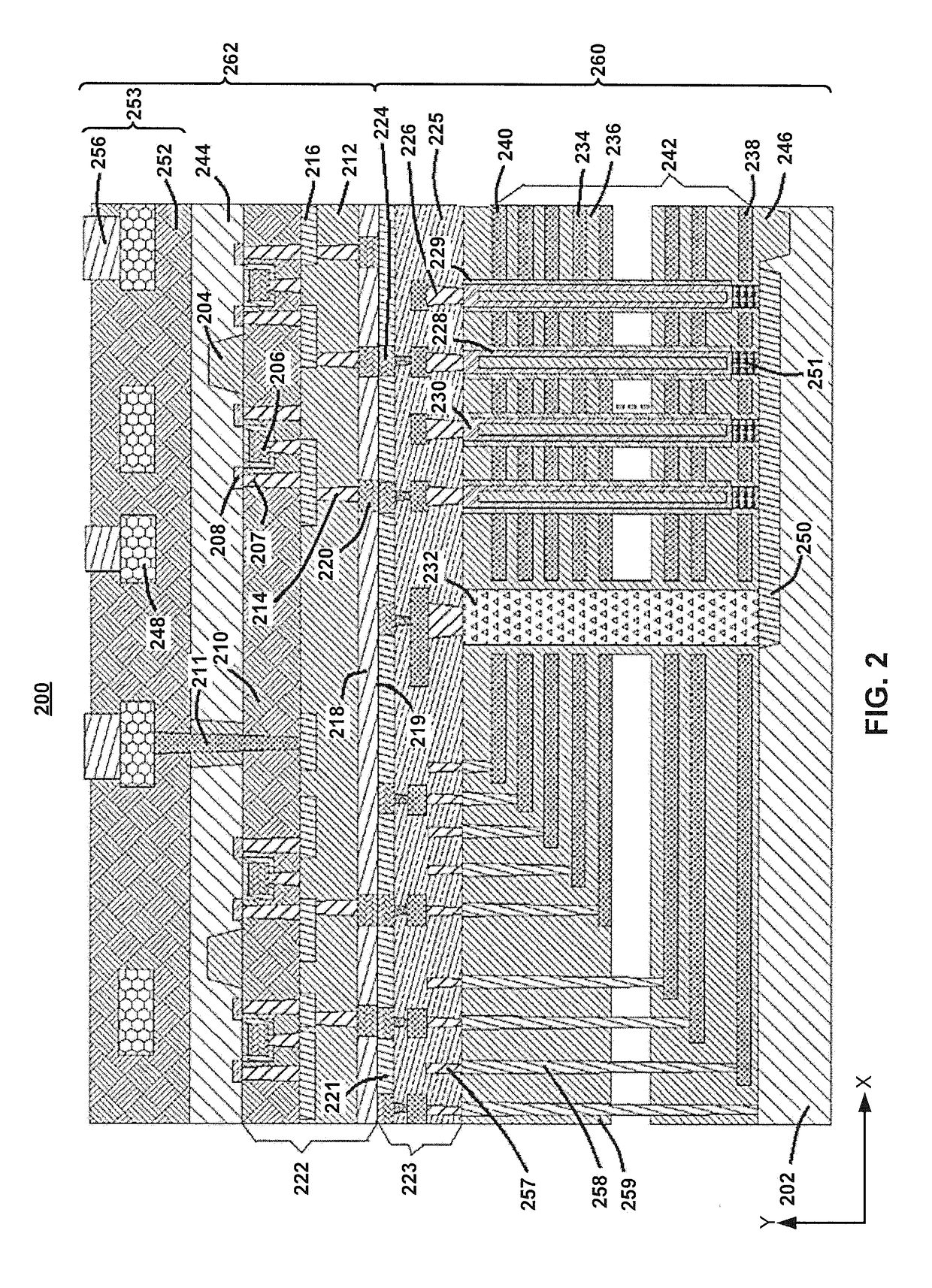

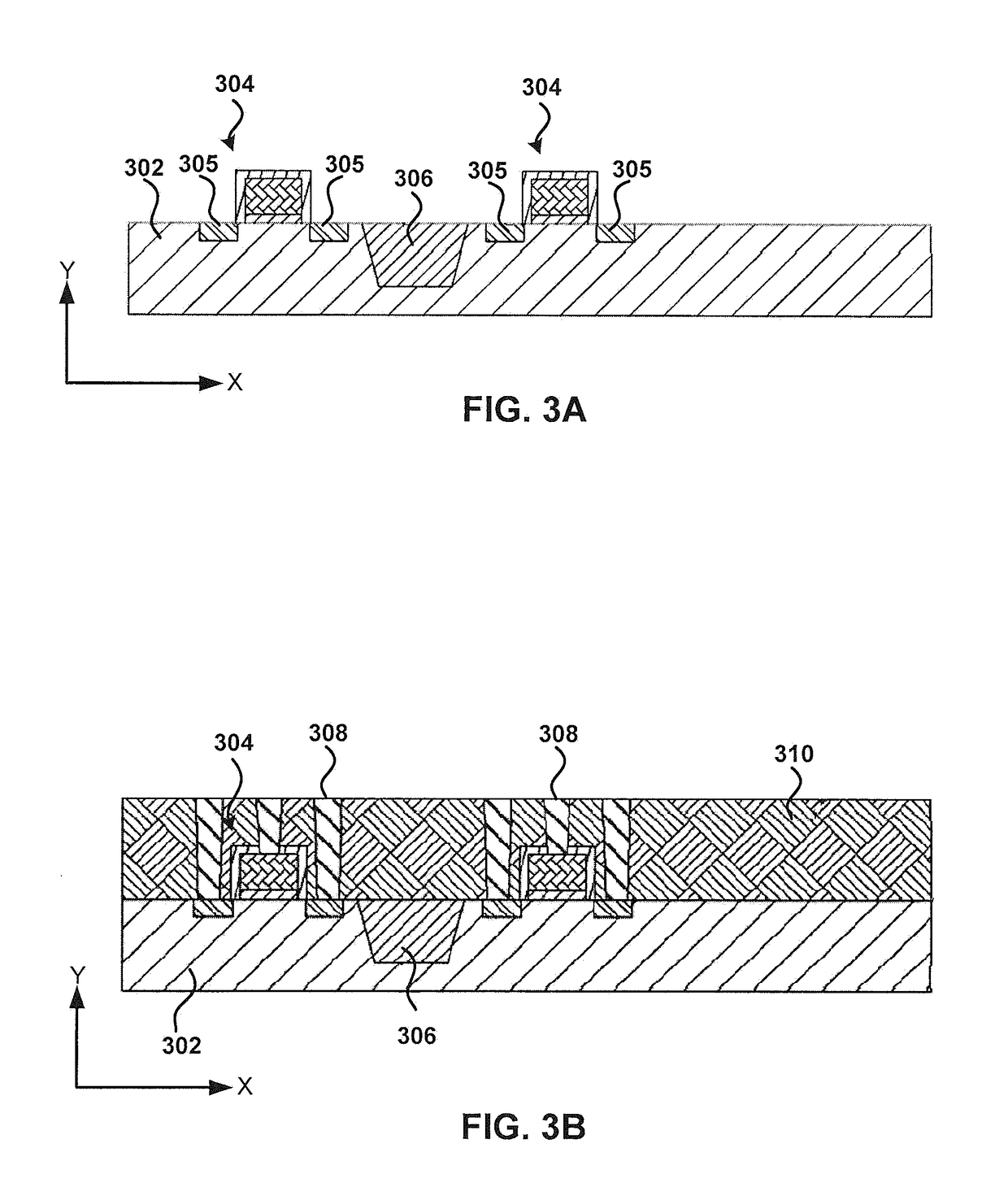

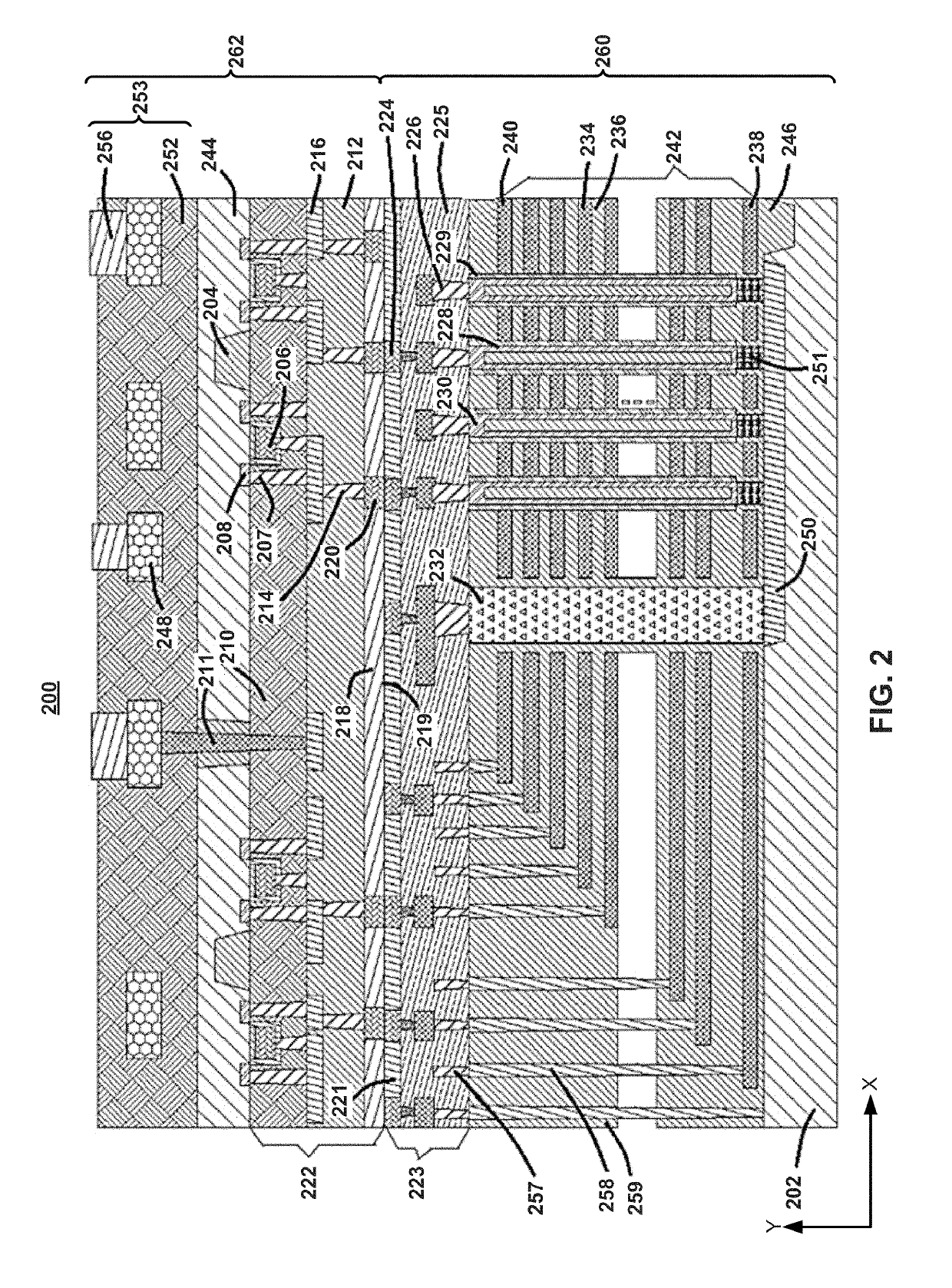

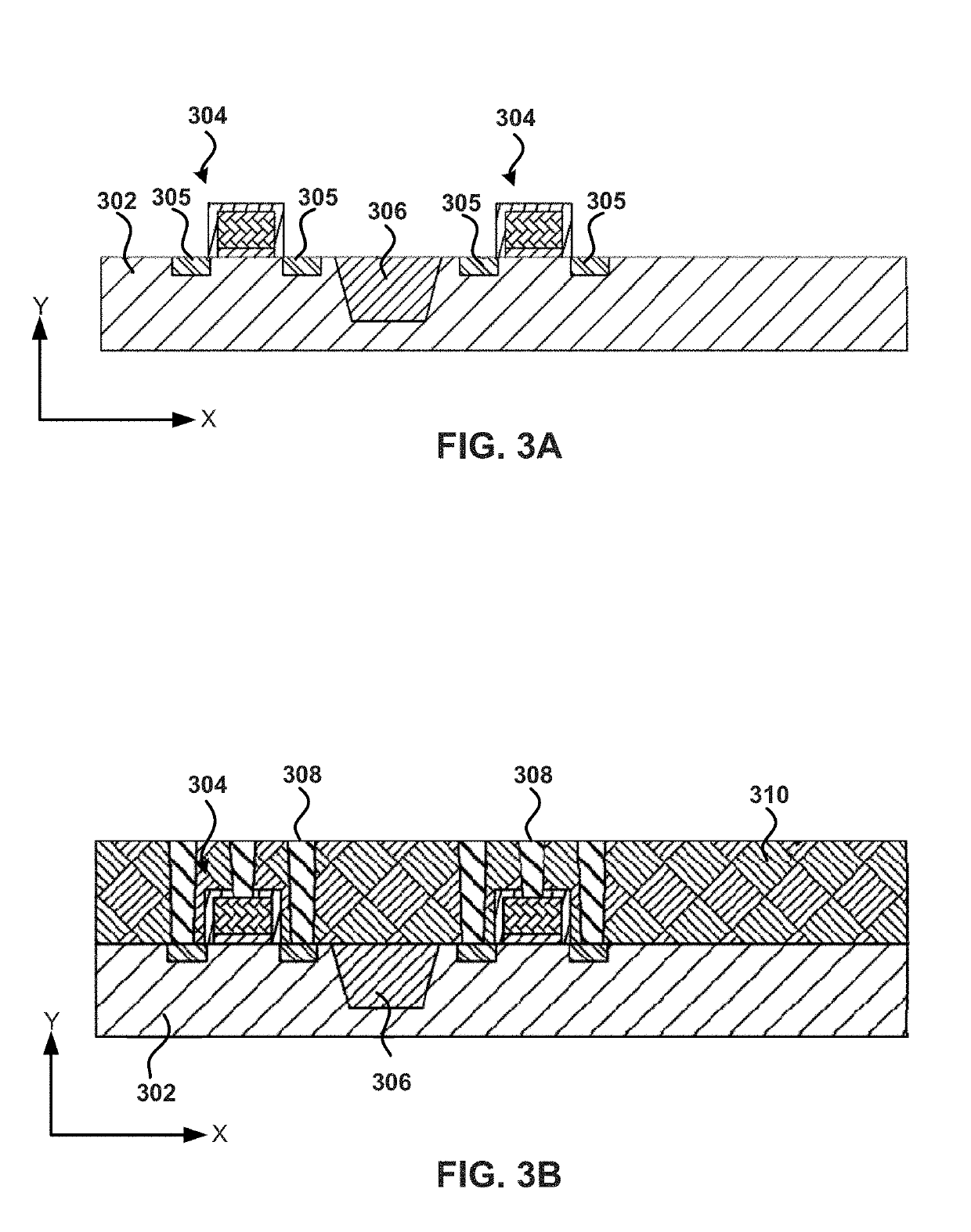

Embodiments of three-dimensional (3D) memory devices and methods for forming the 3D memory devices are disclosed. In an example, a NAND memory device includes a substrate, a plurality of NAND strings on the substrate, one or more peripheral devices above the NAND strings, a single crystalline silicon layer above the peripheral devices, and one or more interconnect layers between the peripheral devices and the NAND strings. In some embodiments, the NAND memory device includes a bonding interface at which an array interconnect layer contacts a peripheral interconnect layer.

Owner:YANGTZE MEMORY TECH CO LTD

Three-Dimensional Memory Devices and Methods for Forming the Same

ActiveUS20190088589A1High bonding strengthPromote interdiffusionSemiconductor/solid-state device detailsSolid-state devicesBond interfaceCrystalline silicon

Embodiments of three-dimensional (3D) memory devices and methods for forming the 3D memory devices are disclosed. In an example, a NAND memory device includes a substrate, a plurality of NAND strings on the substrate, one or more peripheral devices above the NAND strings, a single crystalline silicon layer above the peripheral devices, and one or more interconnect layers between the peripheral devices and the NAND strings. In some embodiments, the NAND memory device includes a bonding interface at which an array interconnect layer contacts a peripheral interconnect layer.

Owner:YANGTZE MEMORY TECH CO LTD

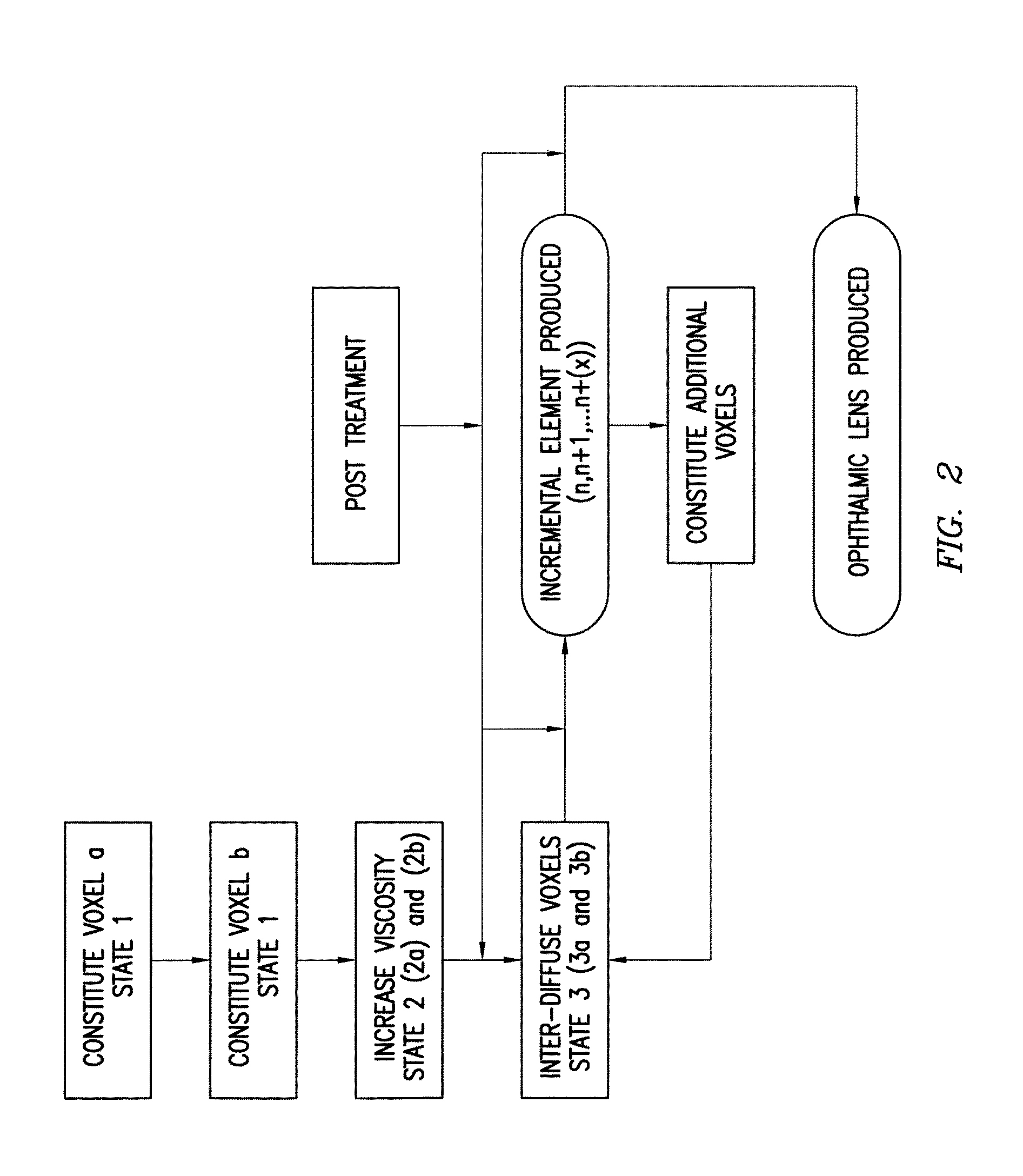

Additive manufacturing for transparent ophthalmic lens

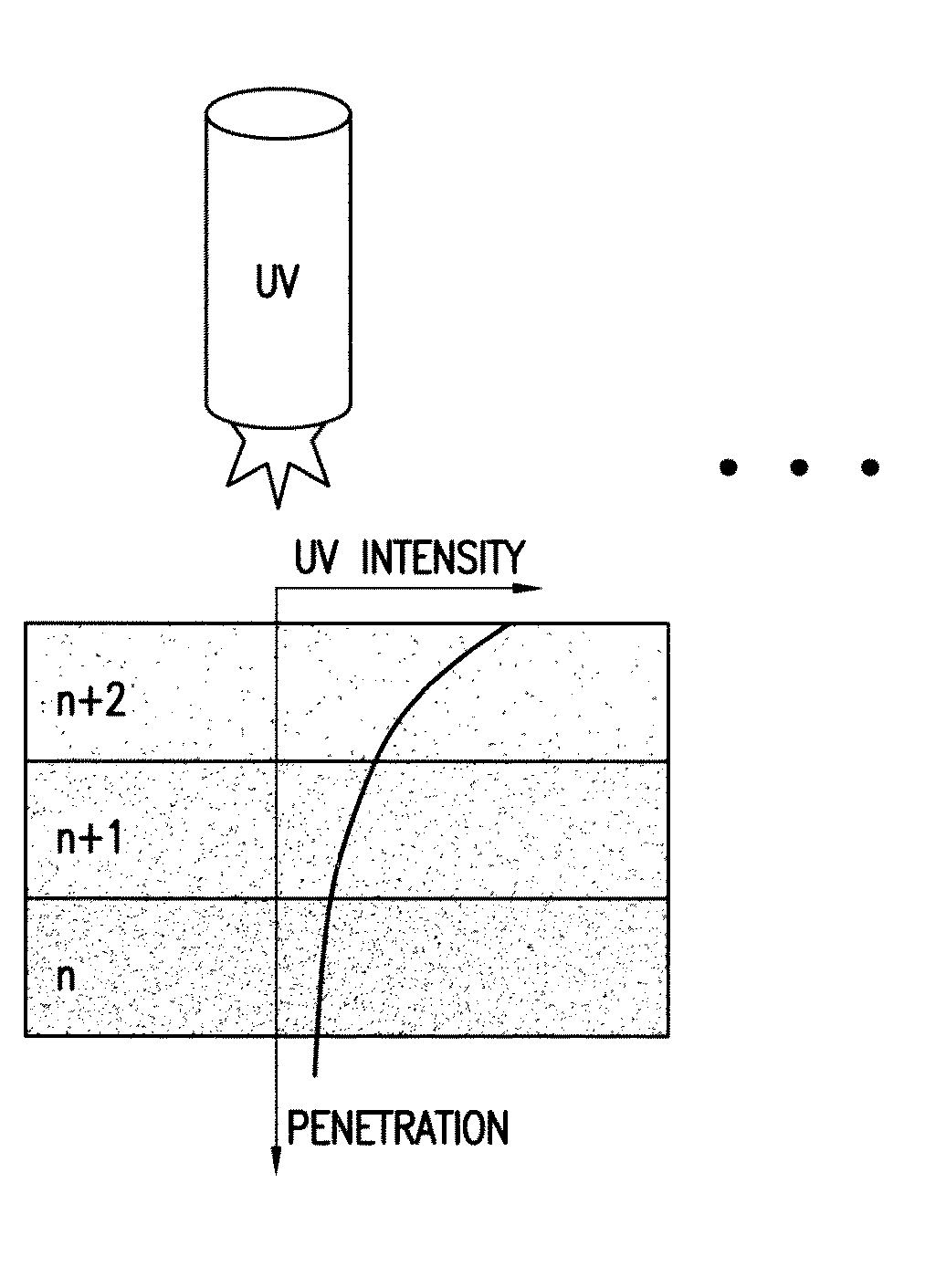

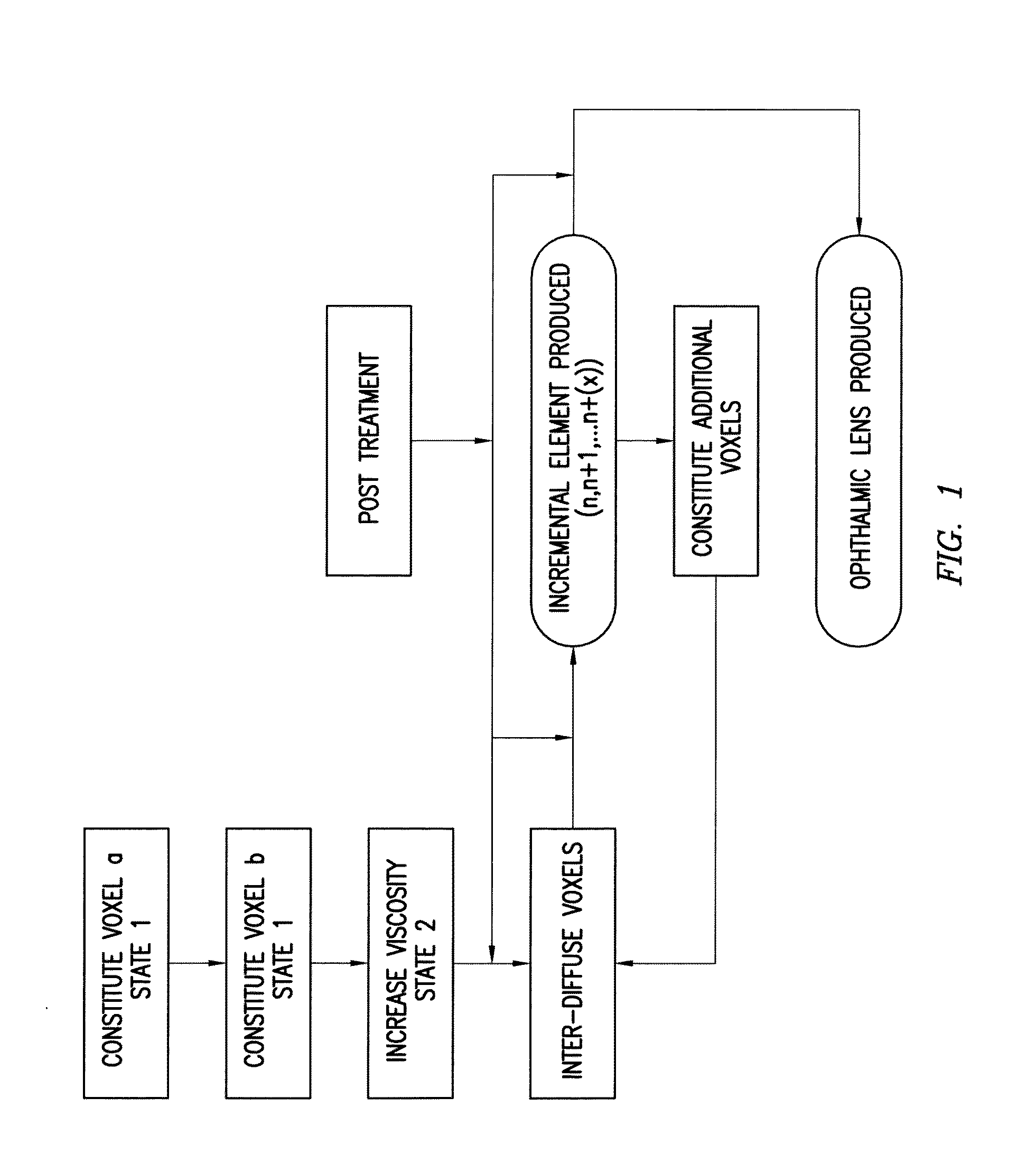

ActiveUS20160167323A1High levelModification of viscosityAdditive manufacturing apparatusOptical articlesChemical treatmentVoxel

A method using additive manufacturing technologies and processes to manufacture a three-dimensional ophthalmic lens with a high management level of the homogeneity during the construction of the ophthalmic lens, through a control of two technical characteristics of voxel: the ability to modify their viscosity, and the ability to inter-diffuse together to provide a final homogeneous element. These two technical characteristics are managed by the choice of component(s) used to manufacture each voxel and by the kind of physical and / or chemical treatment apply to each of them.

Owner:ESSILOR INT CIE GEN DOPTIQUE

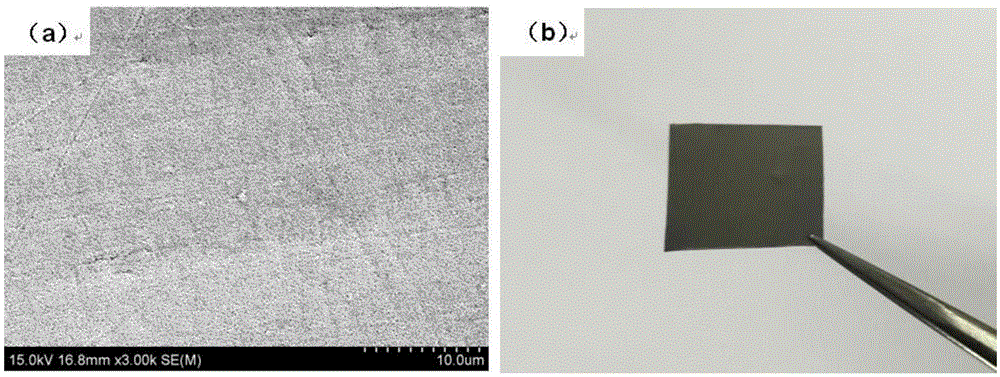

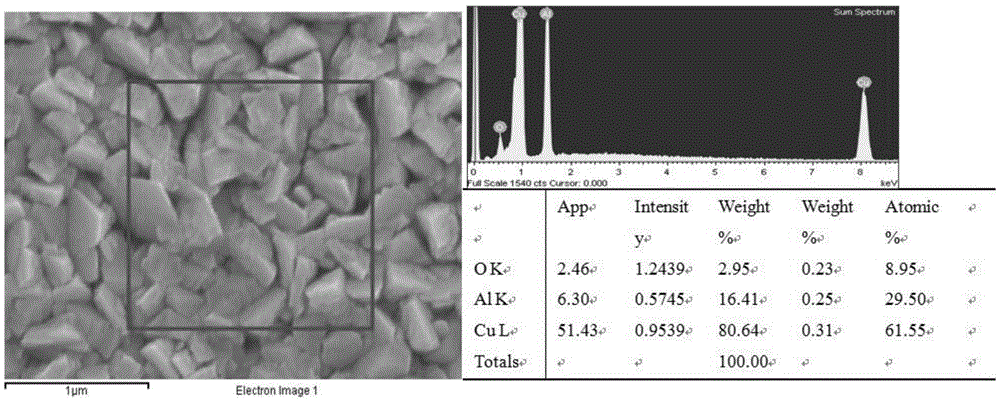

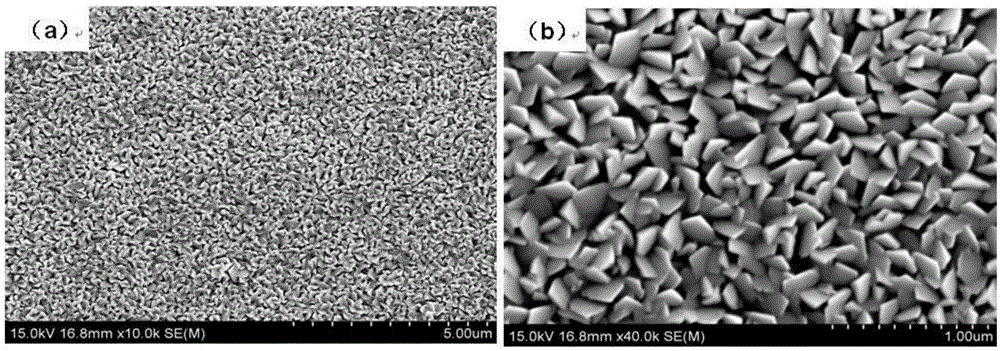

Method for preparing nano porous copper thin film material by magnetron sputtering

ActiveCN105543796AStructural continuityMeet the areaVacuum evaporation coatingSputtering coatingAlloyCopper foil

The invention relates to a method for preparing a nano porous copper thin film material by magnetron sputtering. The method takes a commercial copper foil as a base body material and takes high-purity copper target and aluminum target as sputtering materials; magnetron sputtering equipment is a preparation tool; a nano porous copper thin film is obtained by sputtering a copper-aluminum thin film through a glow discharge principle, and dealloying and corroding to remove an active component aluminum after annealing and alloying. The method provided by the invention is a two-step reaction method, the problems in the prior art that steps for carrying out smelting, ball milling and melt spinning on alloy auxiliary materials are complicated and consumed time is long are solved, and steps of a preparation process are simplified; a nano porous structure of nano porous copper is obtained and the size of the thin film is controllable; the obtained structure is better than a nano porous copper powder sample obtained by a traditional method; furthermore, an application range of the nano porous copper is enlarged and the nano porous copper has a commercial prospect.

Owner:SHANDONG UNIV

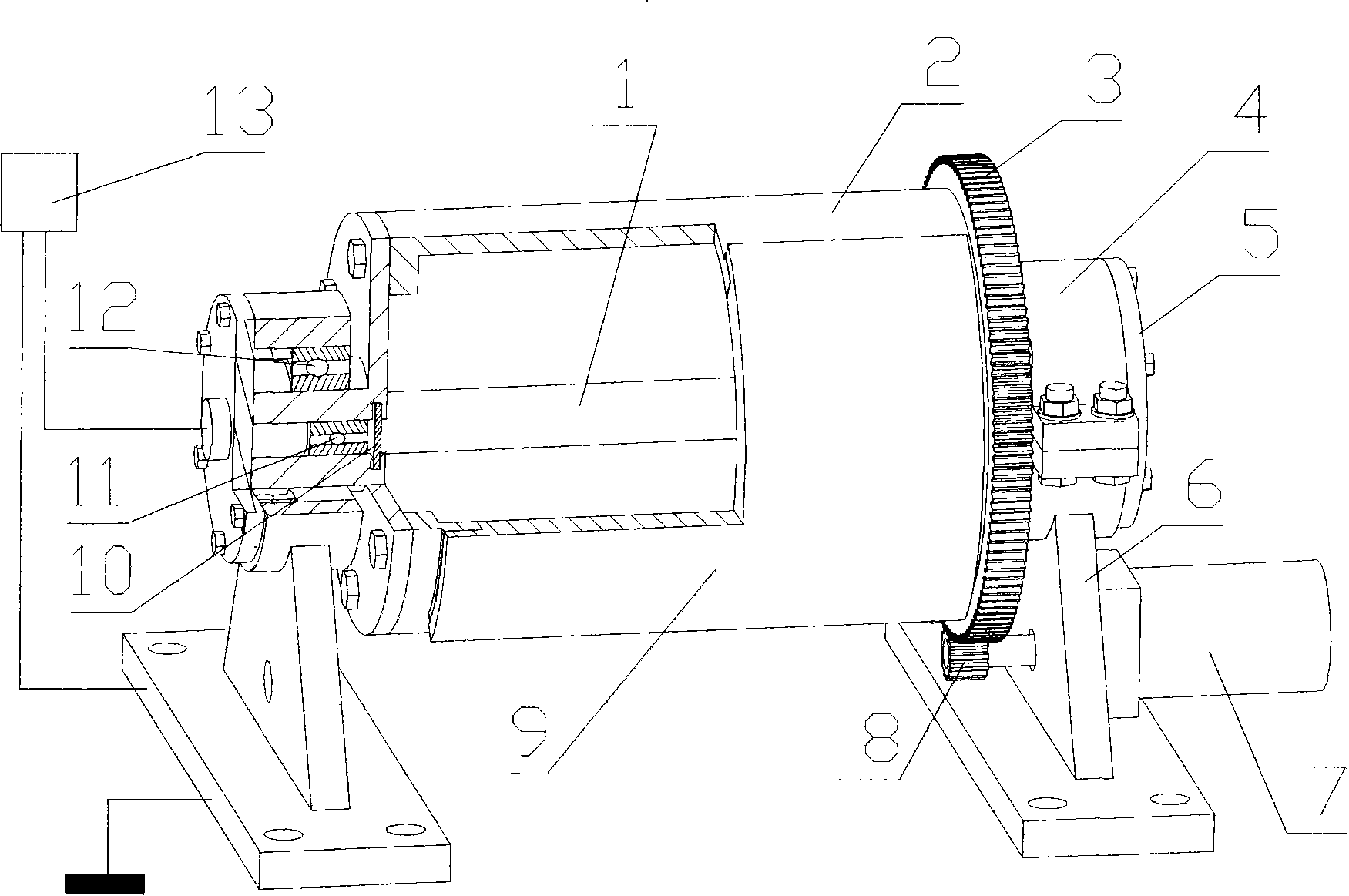

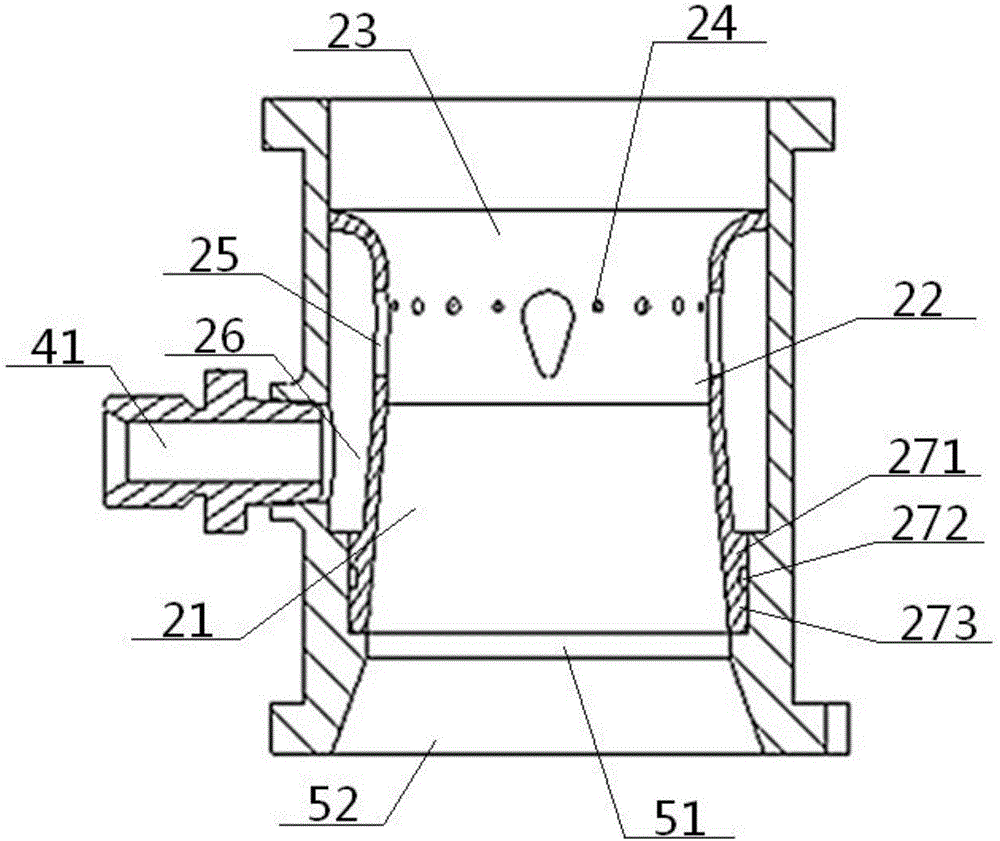

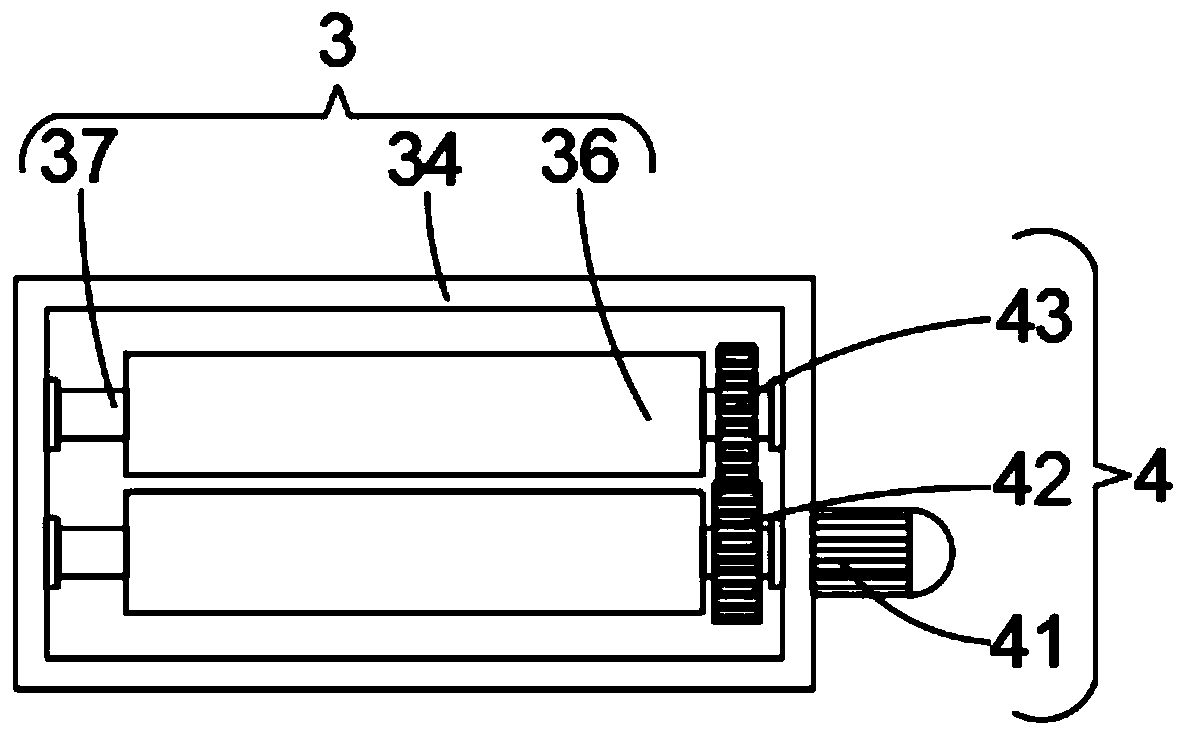

Plasma auxiliary high-energy roller ball mill device

ActiveCN101239334ASolve the difficult problem of mutual interferenceImplementation importGrain treatmentsHigh energyCoaxial line

The present invention provides a high-powered ball grinding technology, specifically a plasma assisting high powered roller ball grinder. The device is changed on the base of traditional roller ball grinder, specifically an electrode axis having a coaxial-line with the roller mounted and fixed by bearing base lid in the roller ball grinder. The aim of the introducing plasma to the roller ball grinder by the device is achieved, the ball grinding speed is accelerated, the diameter distribution is narrow, the grinding efficiency is effectively enhanced at the same time. The device overcomes the deficiency of high vibration and noise of plasma assisting high powered roller ball grinder. The device of the invention has a simple structure, reasonanle and easy to prepaation, the method is easy to achieve, and the device also effectively pushes the application and popularization of the plasma assisting high powered roller ball grinder in the large-scale production in batch of the micronano.

Owner:SOUTH CHINA UNIV OF TECH

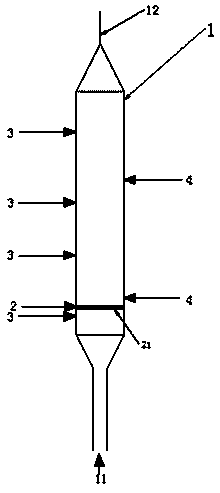

Homogeneous three-phase reactor for jet aeration

ActiveCN103861532AWell mixedMix well and evenlyChemical/physical processesTreatment with moving solid particlesInlet channelHydrogen

The invention relates to a homogeneous three-phase reactor for jet aeration. A three-phase homogenizing plate for jet aeration is arranged at the bottom of a reactor shell or inside a slurry inlet channel; a micro-pore penetrating through the three-phase homogenizing plate for jet aeration is formed in the three-phase homogenizing plate for jet aeration, so that a three-phase mixture of an oil product, hydrogen and a catalyst flows through the micro-pore, and air bubbles of the gas and liquid drops of the liquid become fine and even. Thus, diffusion and full contact of gas, liquid and solid three-phase substances are facilitated by fine and homogenized air bubbles and liquid drops. The homogeneous three-phase reactor for jet aeration disclosed by the invention can achieve full and even mixing of the oil product, the hydrogen and the catalyst, thus a full touch opportunity is created for reaction of the oil product and the hydrogen on the surface of the catalyst, so that reaction is complete and the reaction efficiency is high.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

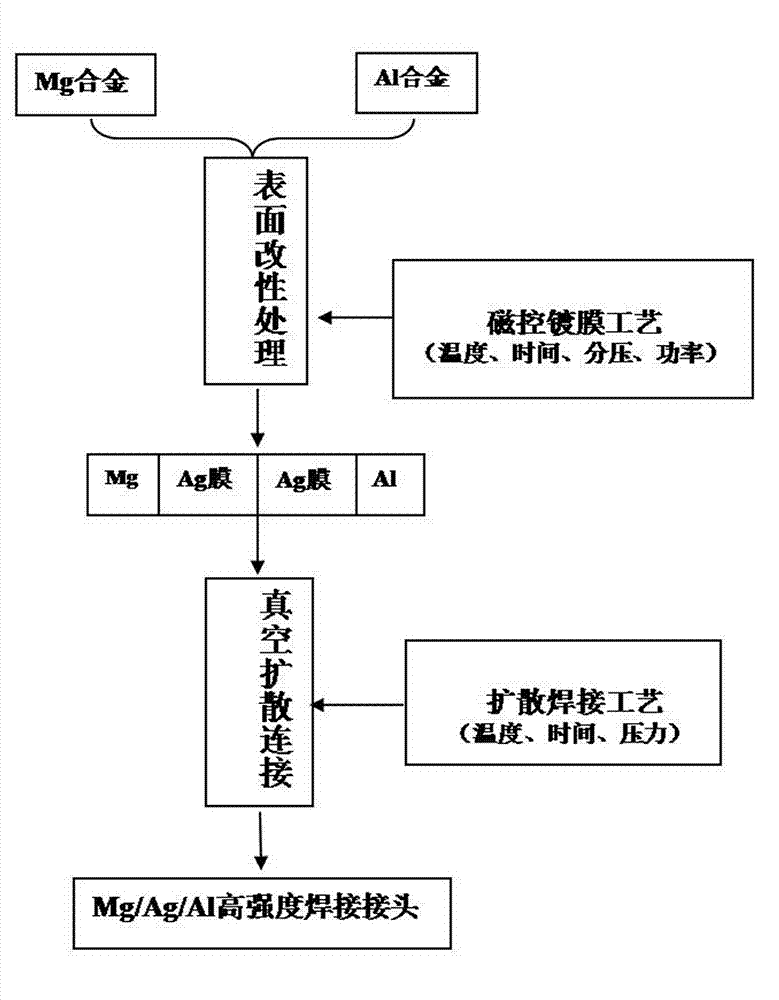

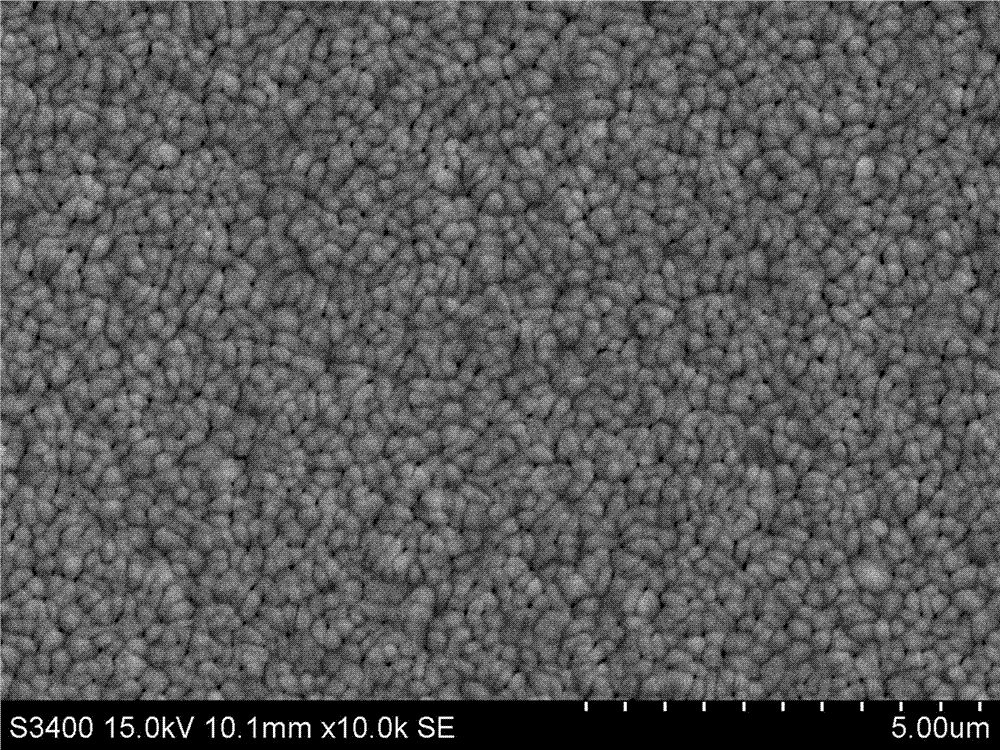

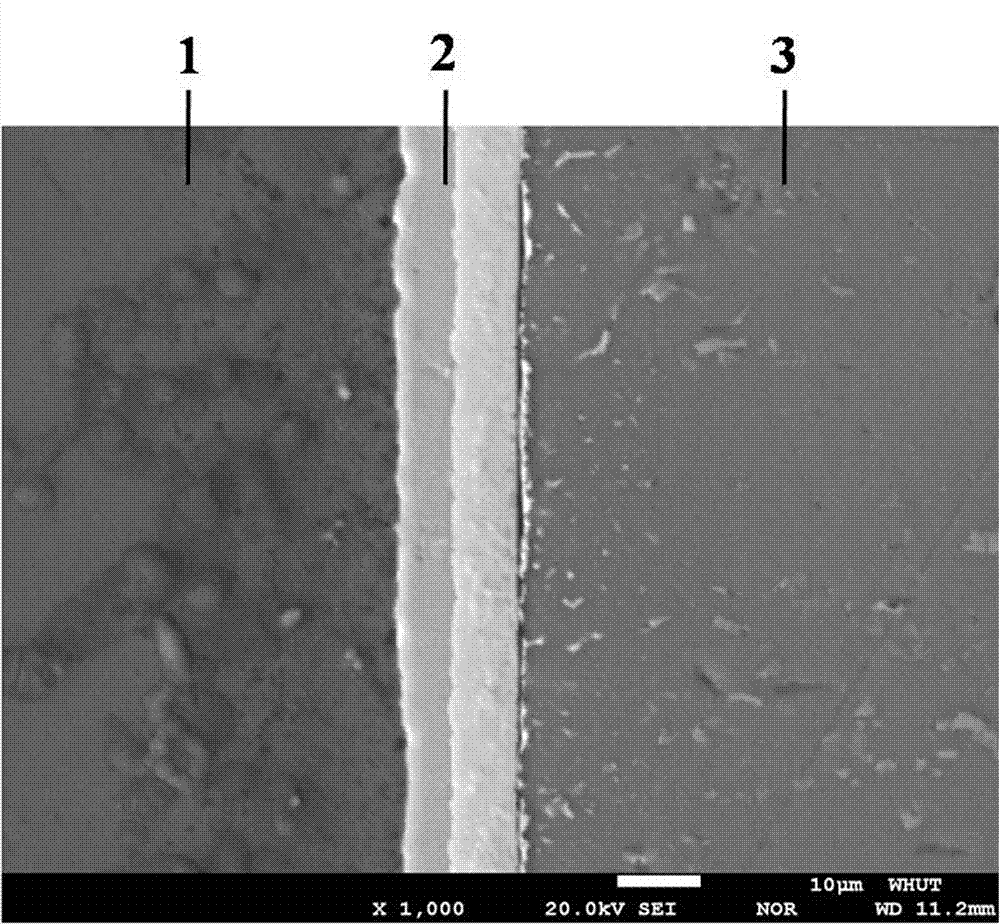

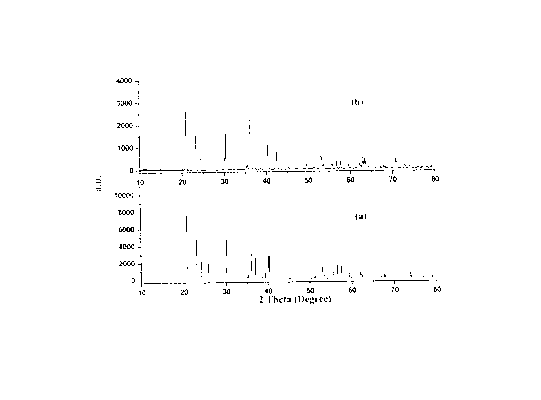

Method for surface modification and high strength connection of magnesium alloy and aluminum alloy

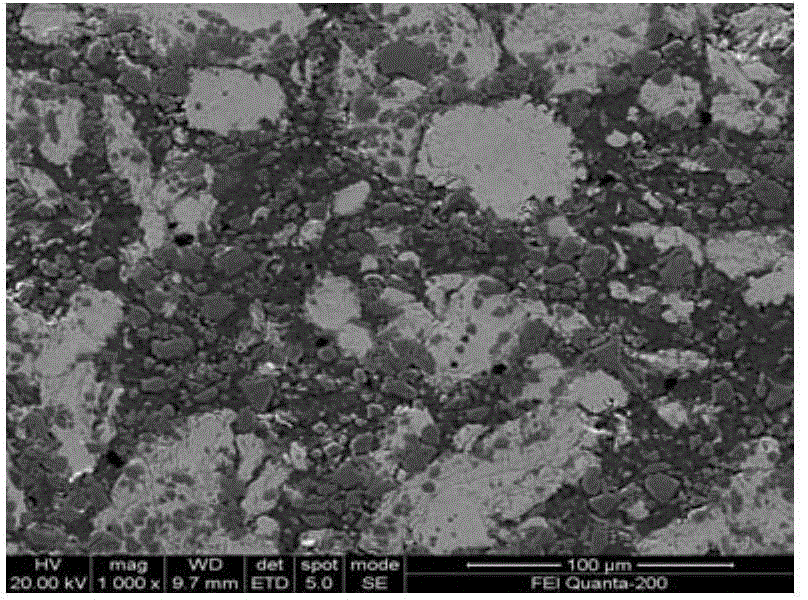

InactiveCN102732849ASolve the problem of low activityPromote interdiffusionVacuum evaporation coatingSputtering coatingSurface oxidationPhase composition

The invention provides a method for surface modification and high strength connection of magnesium alloy and aluminum alloy. The method is as follows: carrying out surface modification on magnesium alloy and aluminum alloy by using the technology of magnetron sputtering and depositing a silver thin layer with micron thickness as a barrier layer and an active layer; and realizing high strength connection of the magnesium alloy and the aluminum alloy at a low temperature by using the technique of vacuum diffusion welding. The invention has the following advantages: coating modification enables surface oxidation resistance of the easily-oxidizable aluminum alloy and magnesium alloy to be improved; diffusion connection of the magnesium alloy and the aluminum alloy at a low temperature is realized for the first time by using the highly active silver thin layer; the silver thin layer changes the phase composition and microstructure of a magnesium / aluminum connection interface and prevents formation of a high-hardness brittle magnesium-aluminum intermetallic compound on the interface, and high strength Mg-Ag and Ag-Al intermetallic transition layers are formed and have a shear strength of 20 to 30 MPa, increased by nearly 4 times compared with a shear strength obtained through direct welding of magnesium aluminum. The method provided in the invention has the advantages of a simple process and high control precision; an obtained connecting piece has small deformation and residual stress.

Owner:WUHAN UNIV OF TECH

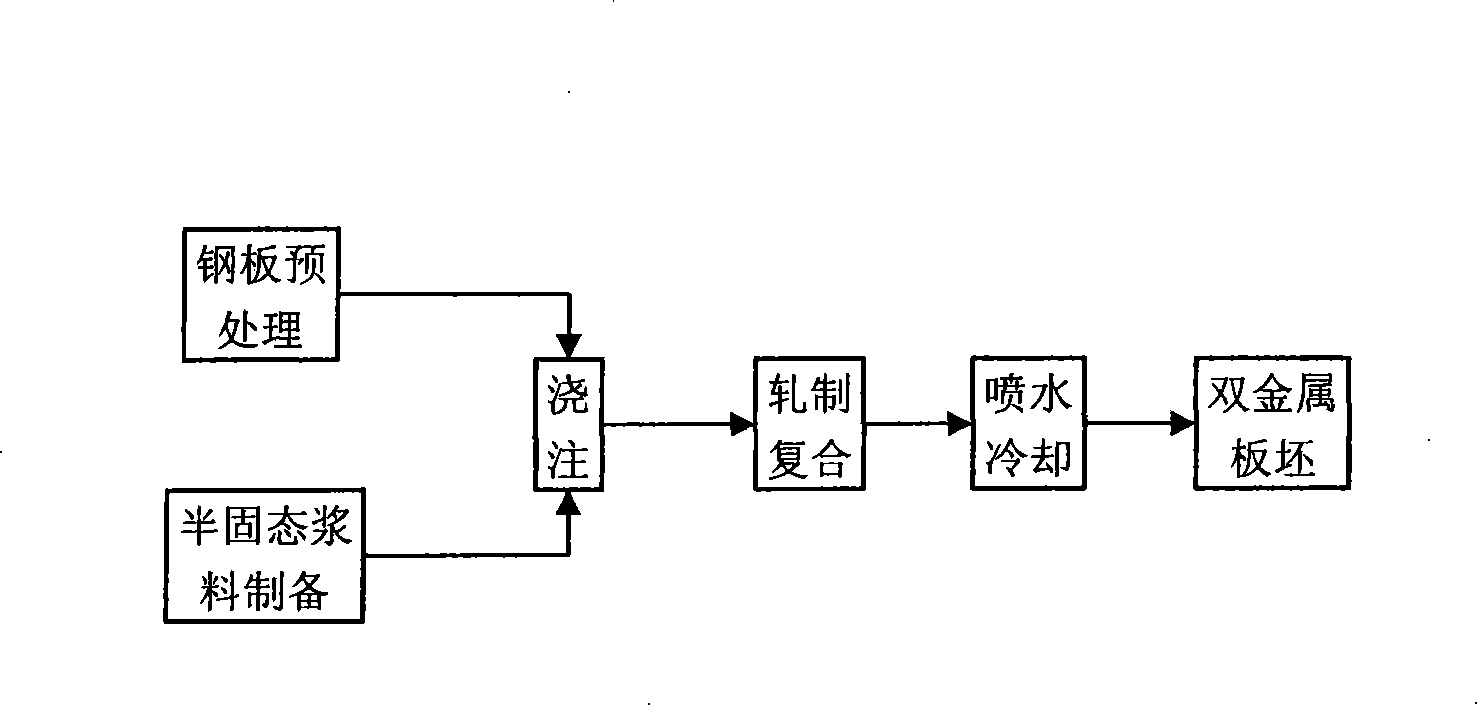

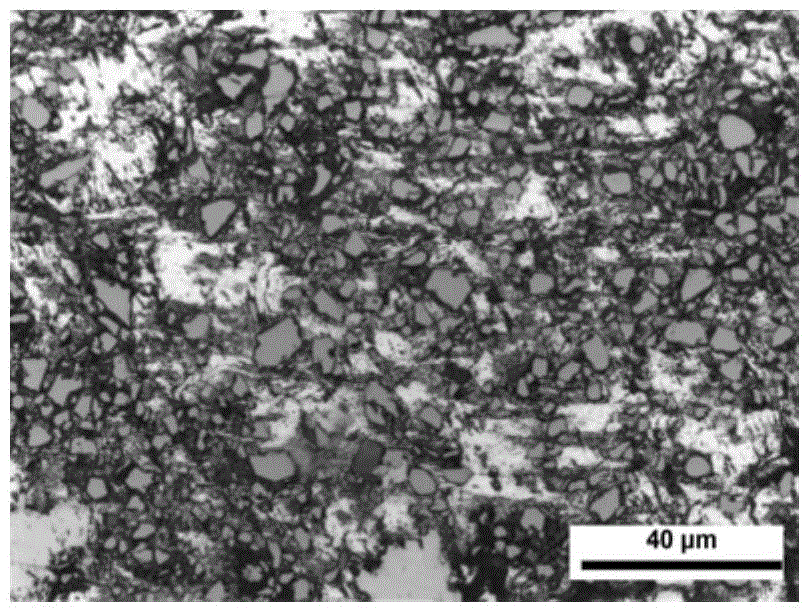

Composite technique for rolling semi-solid state copper-lead bearing alloy/steel bi-metal

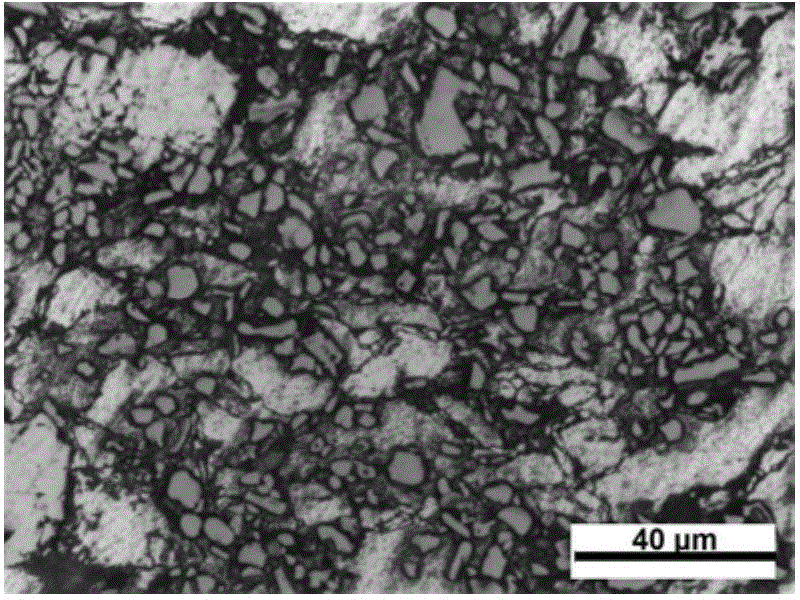

InactiveCN101244430ASolve the problem of lead segregationPromote interdiffusionTemperature control deviceWork treatment devicesRare earthComposite plate

The invention relates to a roll-bonding process for semisolid copper-lead bearing alloys / steel bimetals. The weight content percentage of the lead in the copper-lead bearing alloy is 10.0 to 30.0%. In order to refine the crystalline grain of the lead and improve the mechanical property of the alloy, sulfur, tin, nickel, manganese, rare earth and other the third alloy elements can be added in the copper-lead alloy. The process comprises four steps: pretreatment of steel plates, preparation of semisolid sizing agent, roll bounding and water cooling. The detailed process comprises the following steps: performing mechanical agitation to the melted copper-lead bearing alloys at 930 to 1050 DEG C to obtain the semisolid sizing agent; pouring the semisolid sizing agent on the pretreated steel plates; synchronously feeding the semisolid copper-lead bearing alloys and solid steel plates in to a mill for rolling; spraying water for cooling to obtain the bimetallic composite plate. The invention effectively overcomes the defect of lead segregation in the production of the copper-lead bearing alloys in the prior art, therefore, metallographic structure with fine lead particle and even distribution is obtained. According to mechanical test results, the interfacial shear strength of the copper-lead bearing alloys / steel bimetallic slabs prepared using the process is more than 60Mpa, increased by about 10Mpa.

Owner:UNIV OF SCI & TECH BEIJING

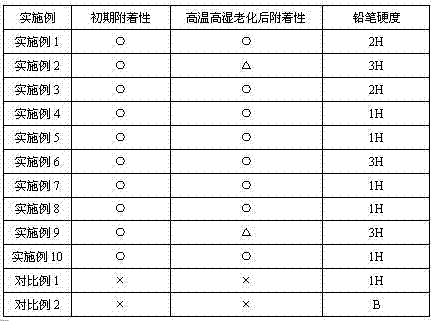

A hard coating composition and hardened film containing the hard coating composition

ActiveCN102268201AReduce internal stressImprove adhesionSynthetic resin layered productsCoatingsIndium tin oxidePet substrate

Provided are a hard coating composition and a hardened membrane containing the same. The hard coating composition comprises, by weight, 30 to 80 parts of hydroxyl-containing acrylate monomers, 1 to 10 parts of an photoinitiator, 20 to 70 parts of a solvent and 0.1 part to 5 parts of a reactive organosilicon surface wetting auxiliary agent, wherein, the hydroxyl-containing acrylate monomers are a mixture of hydroxyl-containing multi-functional acrylate monomers and hydroxyl-containing low functional acrylate monomers mixed according to a weight ratio of 2:8 to 8:2. The composition provided in the invention has excellent adhesion to a PET substrate surface which is never treated and a PET substrate surface which has corona or a failure coating bottom; hardness of the hardened layer of the obtained hardened membrane is greater than 1H, and therefore, the hardened membrane can be used as a hardened membrane of an indium tin oxide (ITO) touch screen, an in-mold label (IML), or the like.

Owner:CHINA LUCKY FILM CORP

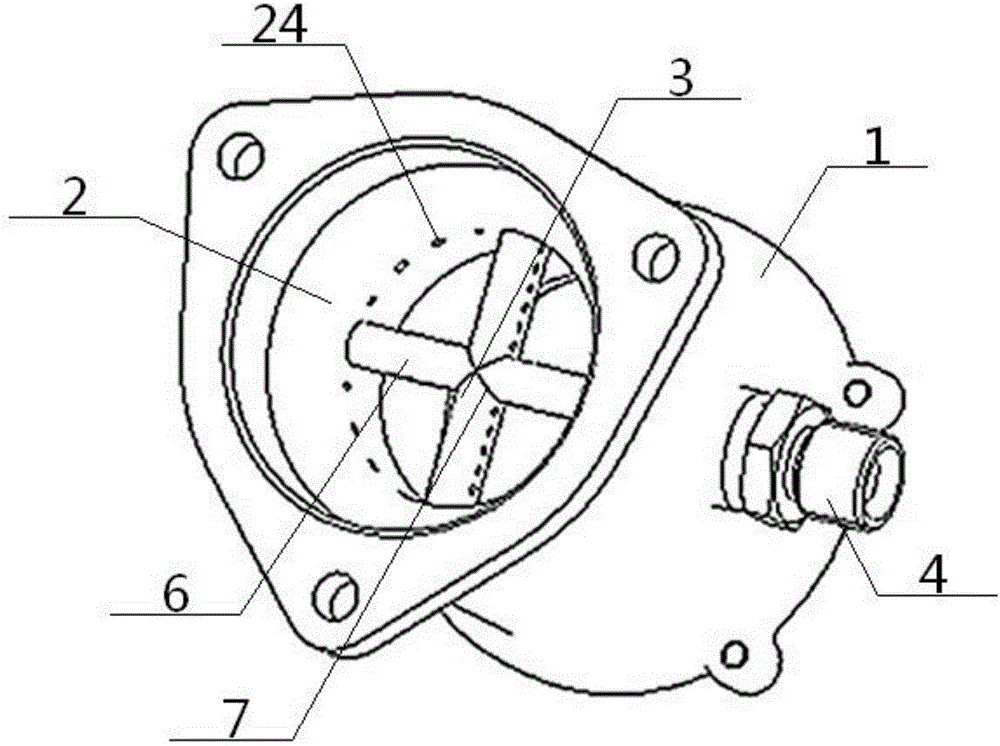

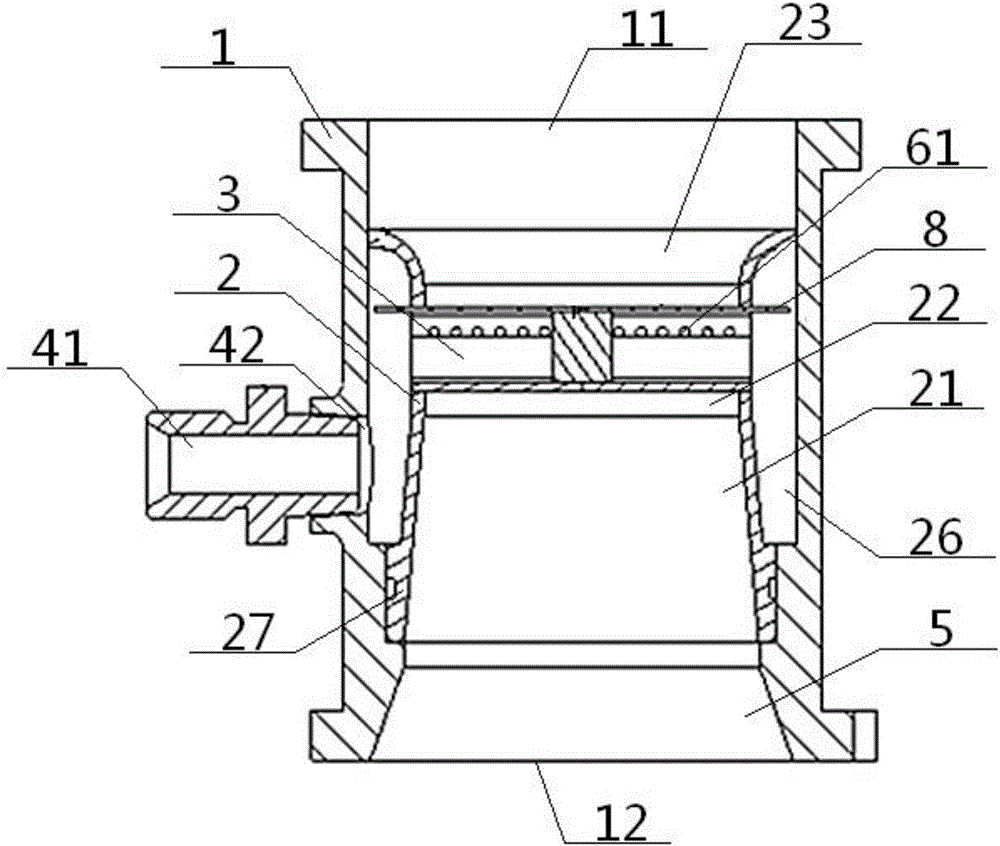

Natural gas mixer

ActiveCN106438115AEvenly distributedEasy to moveInternal combustion piston enginesFuel supply apparatusEngineeringGas chamber

The invention relates to a natural gas mixer which comprises an outer shell, an inner chamber and a gas chamber, wherein the inner chamber is coaxially arranged in the outer shell; the gas chamber is arranged in the inner chamber; the inner chamber has a hollow waist-shaped structure; the inner chamber comprises an air inlet part, a mixing part, a mixed gas outlet part which are successively communicated with each other from bottom to top; a natural gas pressure-stabilizing chamber is encircled by the air inlet part, the mixing part, the mixed gas outlet part and the inner wall of the outer shell; the gas chamber comprises a connecting plate and a gas chamber gas-inlet pipe corresponding to the plate; the outer end of the gas chamber gas-inlet pipe penetrates through a connecting hole of the gas chamber and then extends into the natural gas pressure-stabilizing chamber; a cross section of the gas chamber gas-inlet pipe has a water drop shaped structure with wide top and narrow bottom; an anti-tailing structure is arranged an upper arc part of the outer end. The natural gas mixer has the advantages of larger space of the pressure-stabilizing chamber, smooth mixed gas flow, high mixing uniformity, better mixing effect and higher stability.

Owner:DONGFENG COMML VEHICLE CO LTD

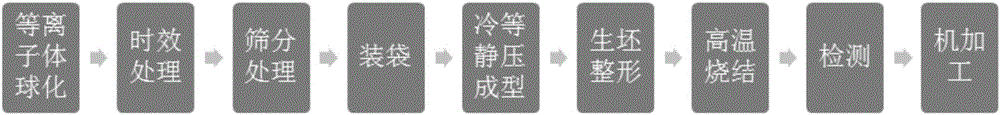

Manufacturing method of high-density pure-rhenium test tube

ActiveCN106270530AImprove liquidityEliminate performance impactTransportation and packagingMetal-working apparatusRheniumHigh density

The invention discloses a manufacturing method of a high-density pure-rhenium test tube. The manufacturing method comprises the following steps: 1) preparing raw materials, that is, carrying out radio-frequency plasma spheroidization on high-purity rhenium powder; preparing high-purity spherical rhenium powder or high-purity sphere-like rhenium powder of which the spheroidization rate is not less than 80% and the average particle size is 5 to 35 mum; 2) carrying out aging treatment on the rhenium powder, that is, carrying out the aging treatment on the rhenium powder subjected to the spheroidization in a protective atmosphere II; 3) forming, that is, putting the rhenium powder which is subjected to the aging treatment into an elastic die sleeve; using cold isostatic pressing techniques to carry out pressing to form and manufacture a test tube green compact; 4) sintering, that is, placing the formed test tube green compact in a high-temperature sintering furnace, and sintering in a protective atmosphere IV; 5) machining to manufacture a test tube finished product. Finally, the high-density pure-rhenium test tube of which the density is greater than 20.2g / cm<3> (the theoretical density is 96%) and the ratio of the length to the outer diameter is greater than 15 is manufactured.

Owner:中铼新材料有限公司

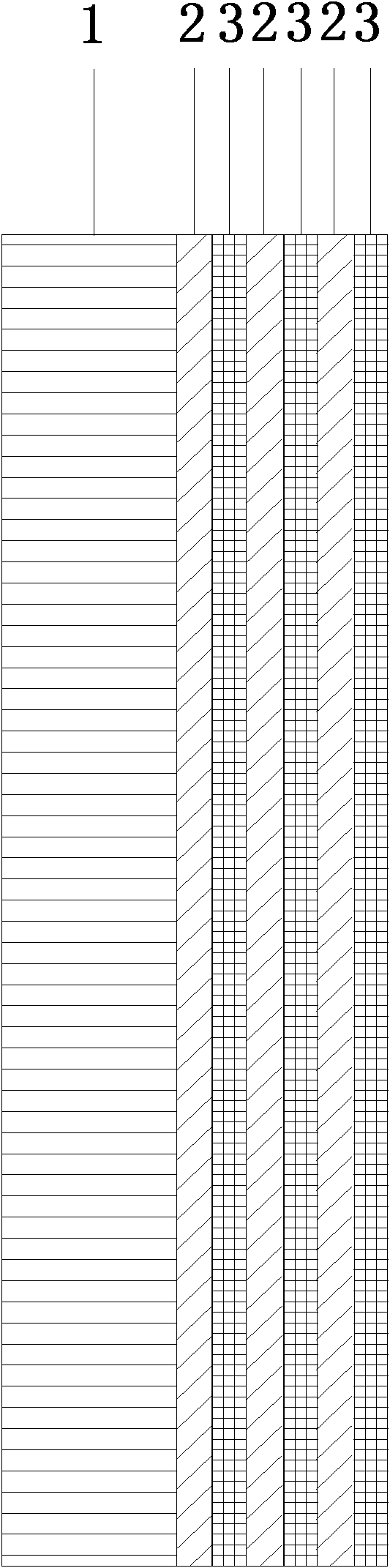

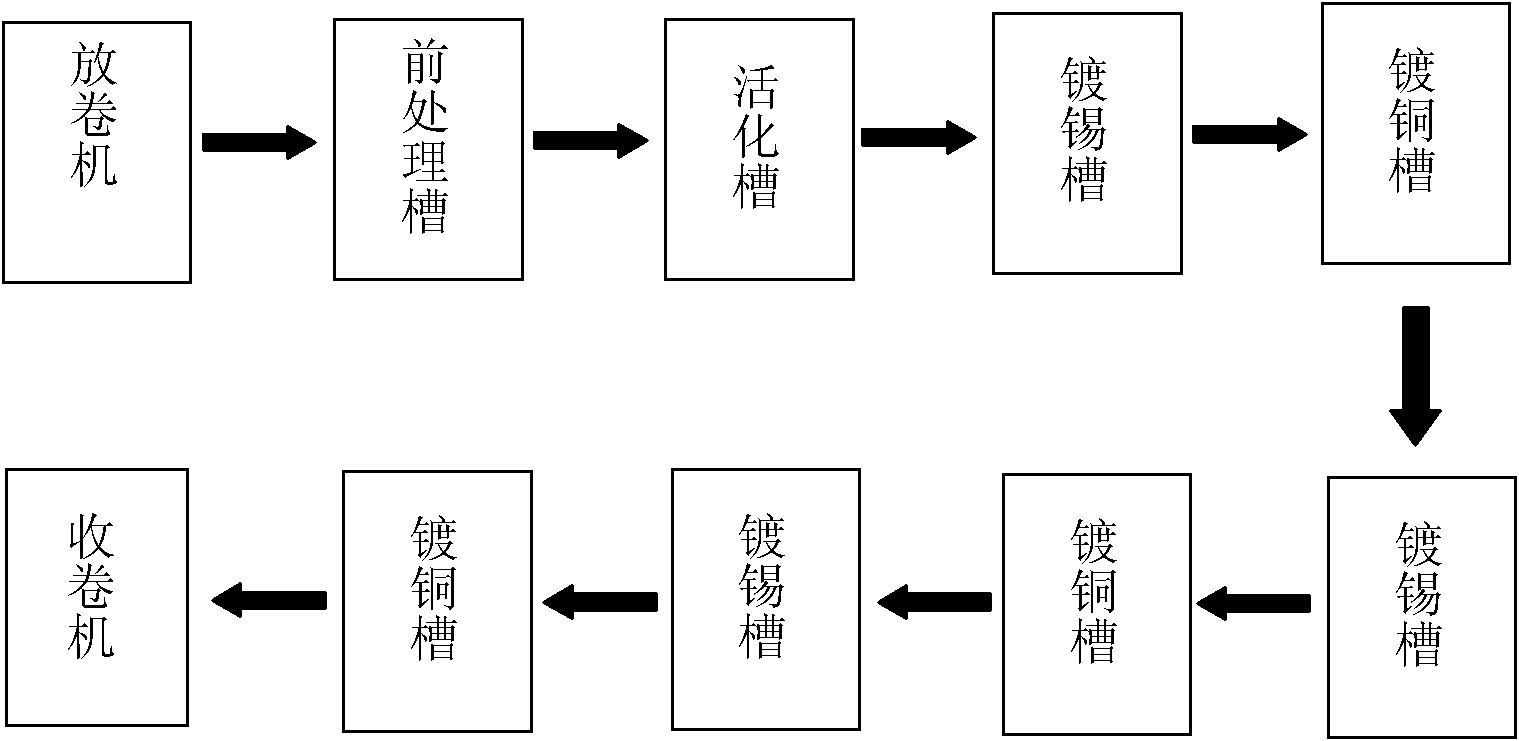

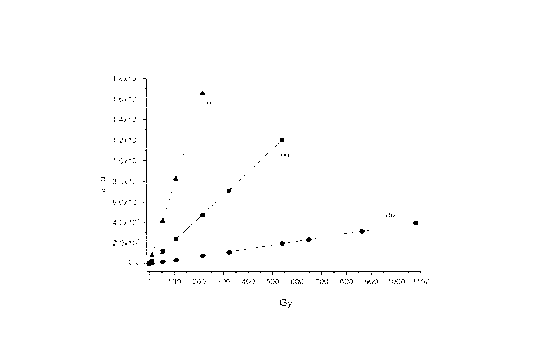

Tin-copper alloy cathode material used for lithium ion battery and preparation method thereof

InactiveCN101969124APromote interdiffusionGood for continuous platingCell electrodesPre treatmentLithium electrode

The invention discloses a tin-copper alloy cathode material used for a lithium ion battery and a preparation method thereof. Tin coatings and copper coatings are sequentially and alternately electrotinned on one side of the surface of a copper strip substrate subjected to pretreatment to form a multilayer laminated structure of the tin coatings and the copper coatings, a coating which is adhered to the copper strip substrate is a tin coating, and an outmost coating is the copper coating; in the multilayer laminated structure, the thickness of each coating is 0.1 to 1.0 mu m, and the thicknessof homogeneous coatings is the same; and a thickness ratio of each tin coating and each copper coating is 1:1.7-1:2.1, so that a lithium ion battery cathode material which contains the impure phase content lower than that of a 5 percent Cu6Sn5 layer on the one side of the surface of the copper strip substrate is prepared. The first discharge specific capacity of the lithium ion battery cathode material prepared by the invention can reach 600 mAh / g, and the attenuation of the specific capacity after 50 times of circulation is only 5 to 8 percent. The preparation method of the invention is simple and is suitable for large-scale industrial production.

Owner:XIANGTAN UNIV

Preparation method of Sn-base composite solder sheet based on porous Ni/Cu alloy

ActiveCN109848611AControl thicknessChange sintering timeWelding/cutting media/materialsSoldering mediaComposite solderUltimate tensile strength

The invention relates to a preparation method of a Sn-base composite solder sheet based on a porous Ni / Cu alloy. The preparation method comprises the steps that first of all, a layer of Cu is preparedon the surface of porous Ni metal, and then high-temperature sintering is carried out, so that mutual diffusion between Ni and Cu is facilitated, and bonding of Ni and Cu is further tight; and then the porous Ni / Cu alloy is immersed into the molten Sn-base solder, and finally is rolled into a foil. In the porous Ni / Cu alloy subjected to high-temperature sintering treatment, the bonding strength of Ni and Cu is higher and the oxidation resistance is better through the mutual diffusion between Ni and Cu, and the relatively high strength, good plasticity, high corrosion resistance and high ductility are shown. Along with change of sintering parameters and electroplating parameters, concentration distribution gradients of Ni and Cu in the porous Ni / Cu alloy are different, reaction between theporous Ni / Cu alloy and the Sn-base solder is rapider in the brazing process, and the soldering reliability is high.

Owner:无锡继平新材料科技有限公司

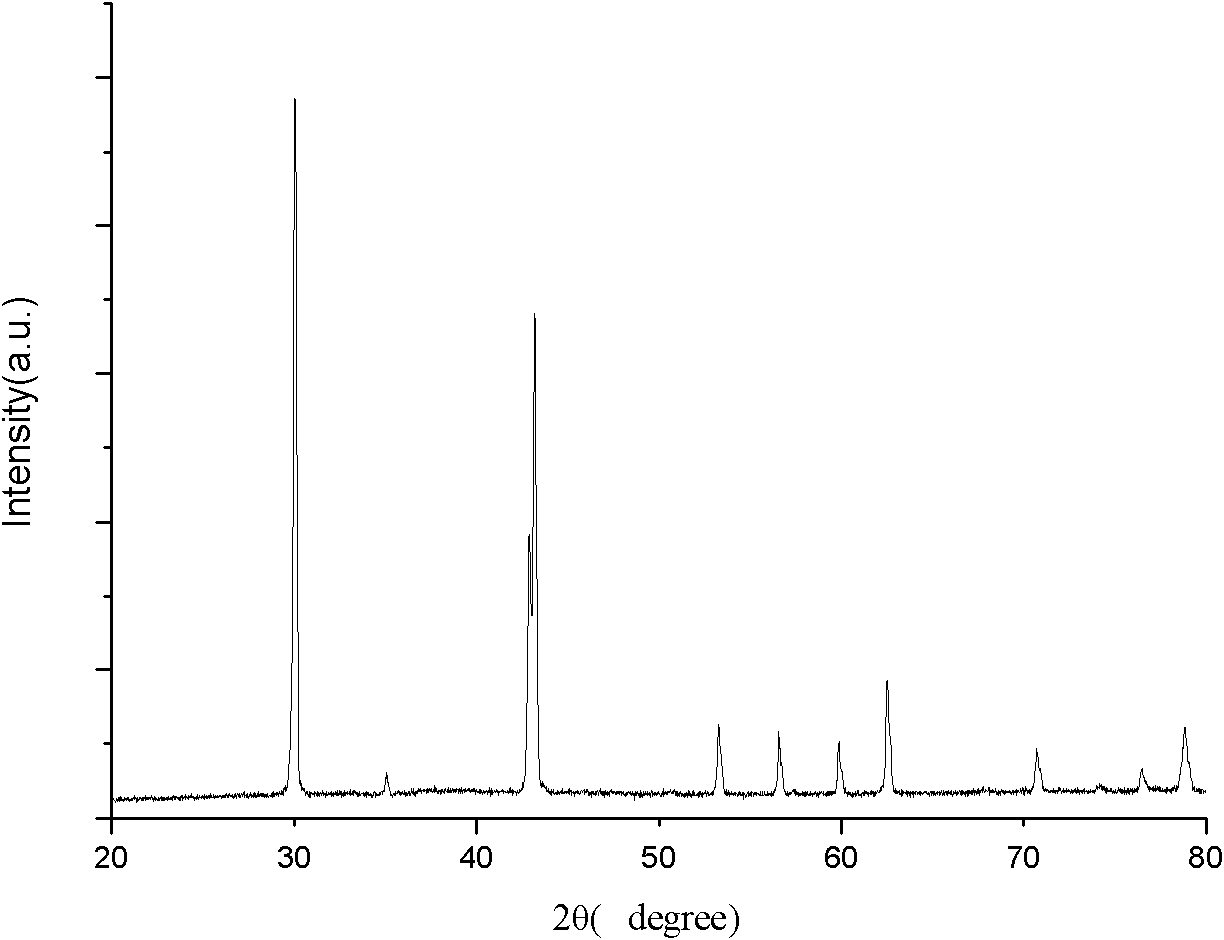

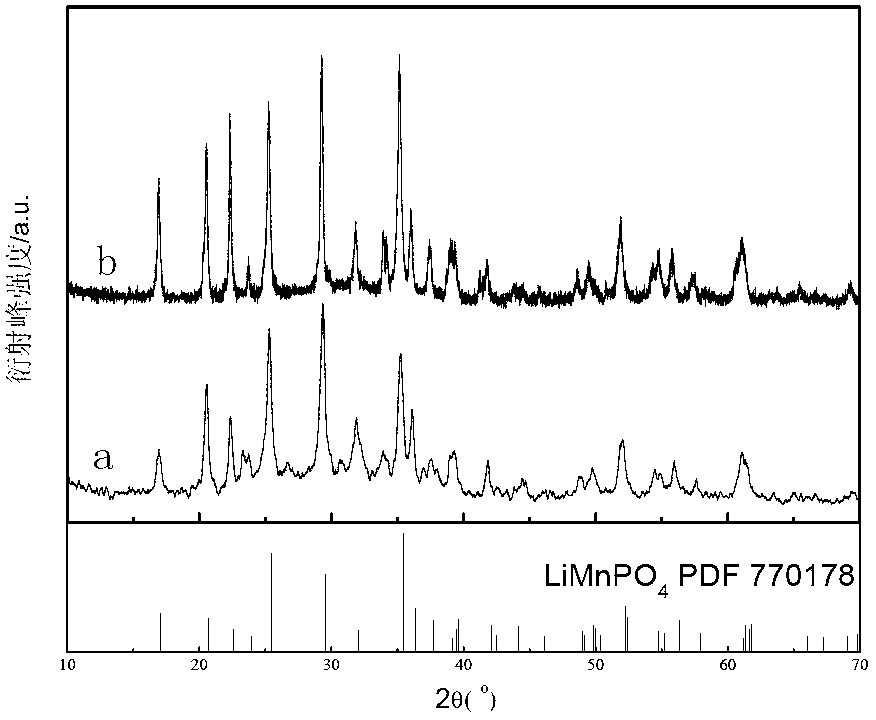

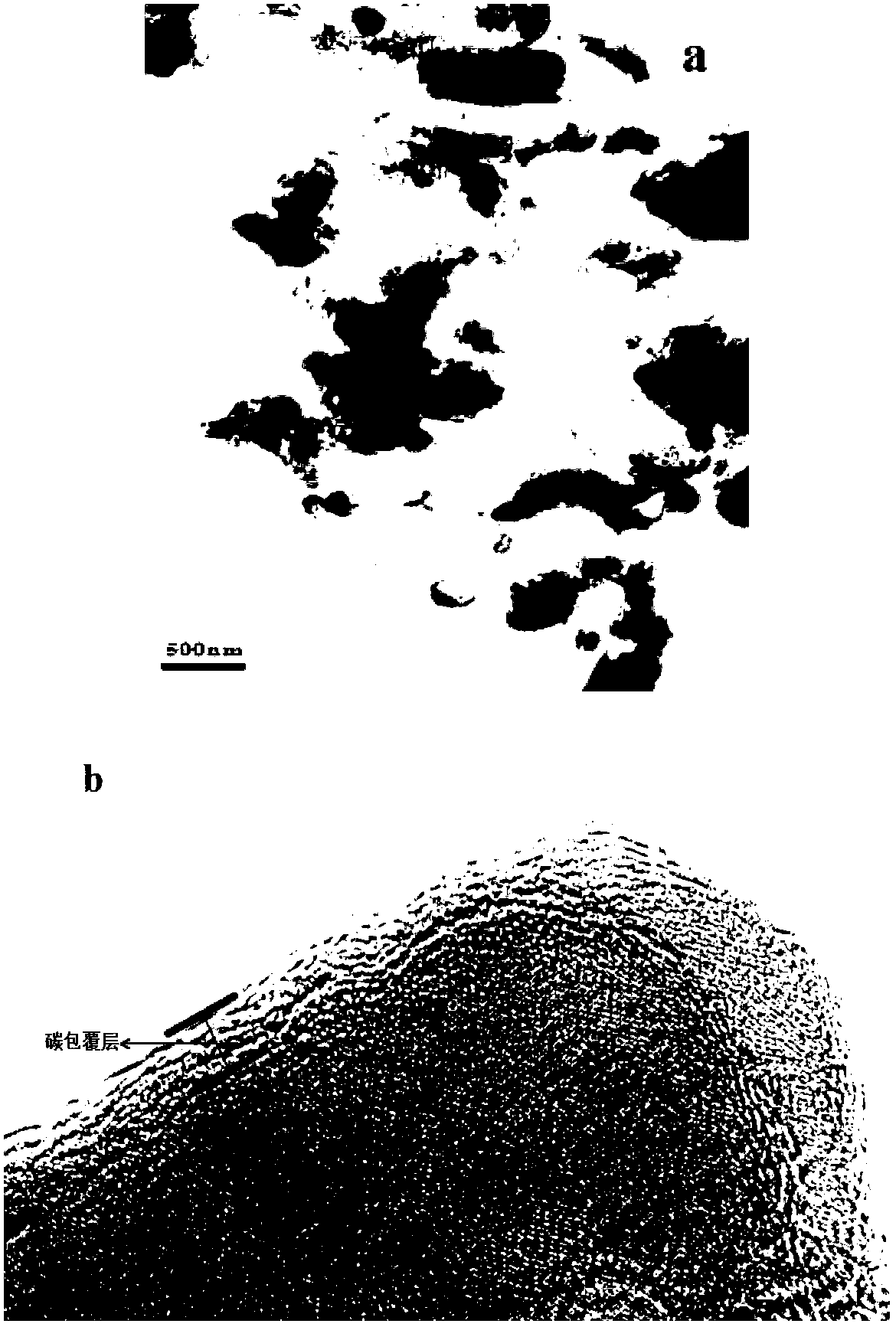

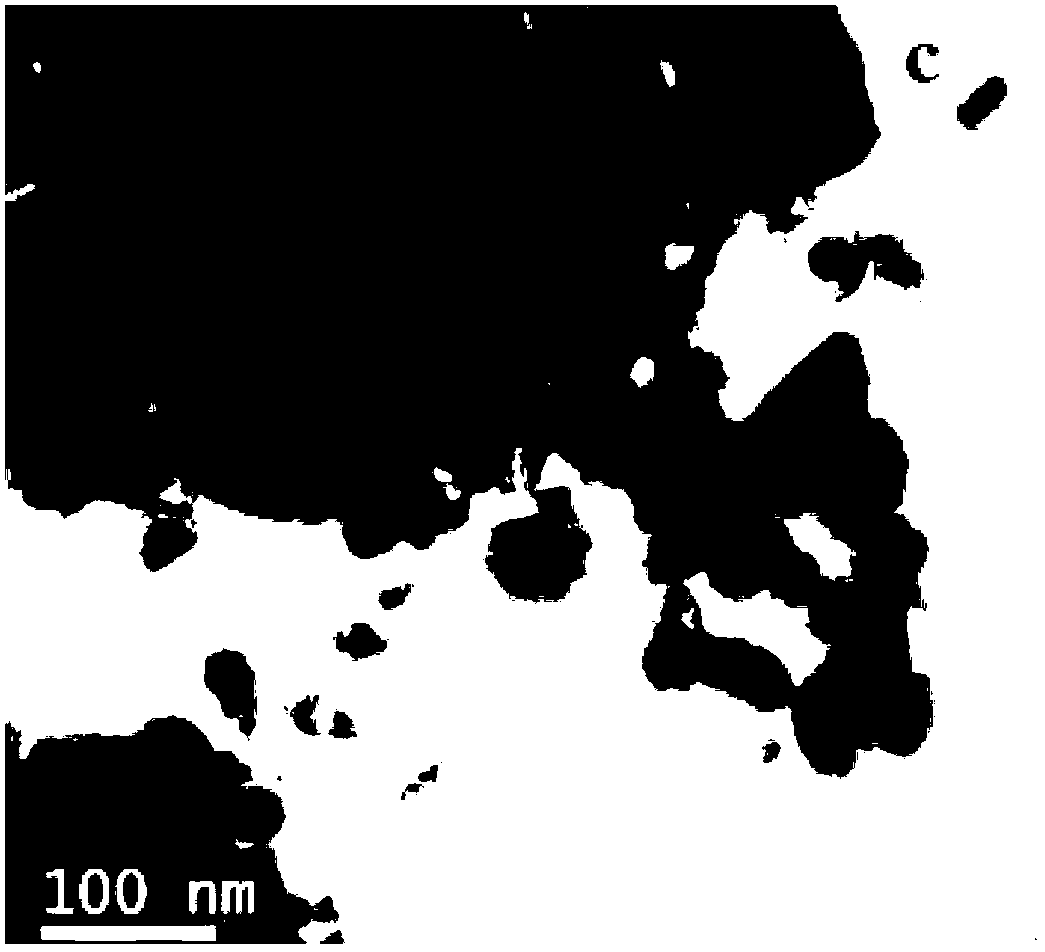

Synthesizing method of nano-grade lithium ion battery composite positive electrode material LiMnPO4/C

InactiveCN102931400AIncrease contact interfacePromote interdiffusionCell electrodesCarbon layerHigh energy

The invention relates to a synthesizing method of a nano-grade lithium ion battery composite positive electrode material LiMnPO4 / C. According to the invention, a lithium source, a phosphorous source, a manganese source and an organic carbon source are well mixed in a solvent medium; the mixture is processed for 2-7h in a high-energy ball mill, and a uniformly dispersed precursor slurry is obtained with the activation effect of mechanical forces; the precursor slurry is subjected to ultrasonic dispersion in a high-boiling-point polyol solvent, and is subjected to a reflux reaction; an obtained product is filtered and washed; and the product is subjected to a heat treatment for 1-10h under inert atmosphere protection and under a temperature of 600-800 DEG C, such that the nano-grade lithium manganese phosphate / carbon (LiMnPO4 / C) positive electrode material is obtained. According to the material provided by the invention, primary particles are well distributed nano-particles, and a conductive carbon layer is formed in-situ on the surfaces of the LiMnPO4 / C particles. The method provided by the invention is simple and highly efficient. With the method, no pollutant such as ammonia gas or wastewater is produced during the entire process. Therefore, a development requirement of green chemistry is satisfied.

Owner:CENT SOUTH UNIV

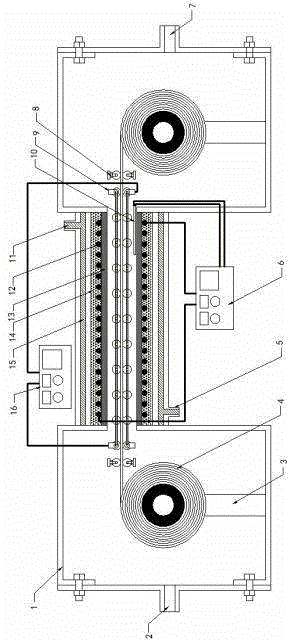

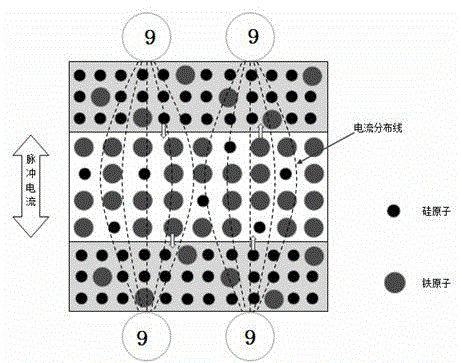

Method and device for continuously preparing high-silicon silicon steel thin strip through current composite diffusion method

ActiveCN105002460APromote interdiffusionShorten the timeSolid state diffusion coatingDc currentAlloy

The invention discloses a method and device for continuously preparing high-silicon silicon steel thin strip through a current composite diffusion method and is applied to the technical field of the silicon steel manufacturing process. According to the method, a silicon steel base strip which is manufactured in advance and is to be processed is placed in a vacuum thermal treatment furnace, and direct current or pulse current with a certain current intensity is applied to the base strip through an external power source; then, the thin strip is located under a proper temperature condition to be subjected to thermal treatment diffusion for proper time. An influence mechanism of current on diffusion can be explained in the mode that under the action of electron wind, thermal balance vacancy concentration in thin strip alloy crystal rises, movement and aggregation of defects such as dislocation and grain boundaries in the crystal are promoted through migration of a large number of electrons, a fast channel is provided for atom migration, and the Fe atom and Si atom diffusion process is accelerated. Compared with a manufacturing method of common high-silicon steel, the diffusion homogenization time of the thin strip can be saved, energy consumption in the technological process is reduced, and therefore cost for manufacturing the high-silicon steel is reduced.

Owner:SHANGHAI UNIV

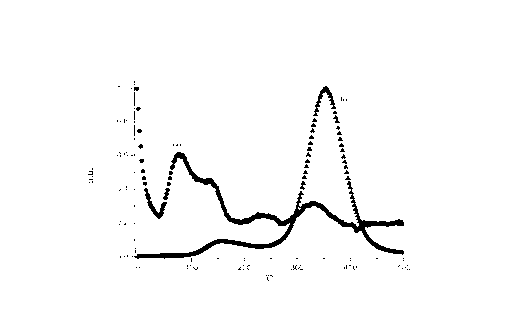

Europium and samarium-doped lithium magnesium phosphate photostimulated luminescent material and preparation method thereof

InactiveCN103194230AImproving photostimulated luminescent propertiesImprove thermoluminescence performanceLuminescent compositionsThermoluminescenceSpace group

The invention relates to a europium and samarium-doped lithium magnesium phosphate photostimulated luminescent material and a preparation method thereof. The chemical formula of the material is LiMgPO4: Eu, Sm, B, and the specific preparation method comprises the following steps of: mixing and grinding raw materials, namely lithium hydroxide, magnesium nitrate, ammonium dihydrogen phosphate, boric oxide, europium oxide and samarium oxide, loading into a porcelain crucible made of an aluminum oxide material, placing into a high-temperature sintering furnace for performing sectional constant-temperature sintering, and further cooling the aluminum oxide crucible to room temperature to obtain the europium and samarium-doped lithium magnesium phosphate LiMgPO4: Eu, Sm, B photostimulated luminescent material. The material is of an olivine type structure, the space group is Pnma, the lattice constants are as follows: a=10.147., b=5.909. and c=4.692., and the doping of europium and samarium does not change the basic structure of the LiMgPO4 material; and the thermoluminescence performance of the material is greatly upgraded, the sensitivity and the stability in storage of radiation dose information are effectively improved, the addition of the samarium oxide upgrades the luminescence performance of rare earth europium ions, and the material has low environmental pollution and low cost and can be applied to environments, medicines and offline and real-time online measurement of human body radiation doses.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Three-dimensional memory devices having a plurality of NAND strings

ActiveUS20190244893A1High bonding strengthPromote interdiffusionSemiconductor/solid-state device detailsSolid-state devicesComputer hardwareComputer architecture

Owner:YANGTZE MEMORY TECH CO LTD

Electroluminescent device of organic thin film

InactiveCN1728905APromote interdiffusionImprove luminous brightnessElectrical apparatusElectroluminescent light sourcesTransport layerOrganic electroluminescence

The Electroluminescent device is composed of following layers and parts prepared on clear electrode: cavity transport layer, organic luminous layer, inorganic electron transport layer, electronic potentiometric compensator layer and back electrode. Inorganic electron transport layer is prepared from n type ZnS or n type ZnO with thickness 1nm-10nm. Inorganic electron transport layer is also prepared from other n type wide forbidden band inorganic materials: n type CoO, n type GaN, n type BaO, n type MgO or n type AIN. The invention raises luminescence brightness, efficiency and service life since mutual diffusion between luminous layer and electrode in electroluminescent device and inadequate balance between cavities and electrons are improved in the disclosed structure.

Owner:BEIJING JIAOTONG UNIV

Adhesive bonding technique between layers of rubber hose

An interlayer adhering technology for multi-layer rubber pipe features that after a reinforcing layer is spread on the internal rubber layer and before the external rubber layer is added, a particular surface treating agent is sprayed. The organic solvent chosen from benzene, toluene, ethyl acetate, solvent gasoline and their mixture, in which the rubber can be dissolved and swollen, is used as the primary component of said surface treating agent.

Owner:上海新上橡汽车胶管有限公司

Hot pressing sintering particle reinforcing zinc-based composite material and preparation method thereof

The invention relates to a hot pressing sintering particle reinforcing zinc-based composite material and a preparation method thereof, and belongs to the technical field of composite material preparation. The method includes the steps of preparing Zn powder, Al power, Cu power and TiB2 power as raw materials according to the mass ratio of 50-90 to 15-40 to 1-3 to 1-20, conducting high energy ball-milling and prepressing, and then obtaining the hot pressing sintering particle reinforcing zinc-based composite material through a segmented sintering method. The prepared components are reasonable in design, the preparation process is simple, and the zinc-based composite material which is high in interface combination strength and low in porosity and defect rate is obtained through the coordinative effects of all the components and all parameters.

Owner:CENT SOUTH UNIV

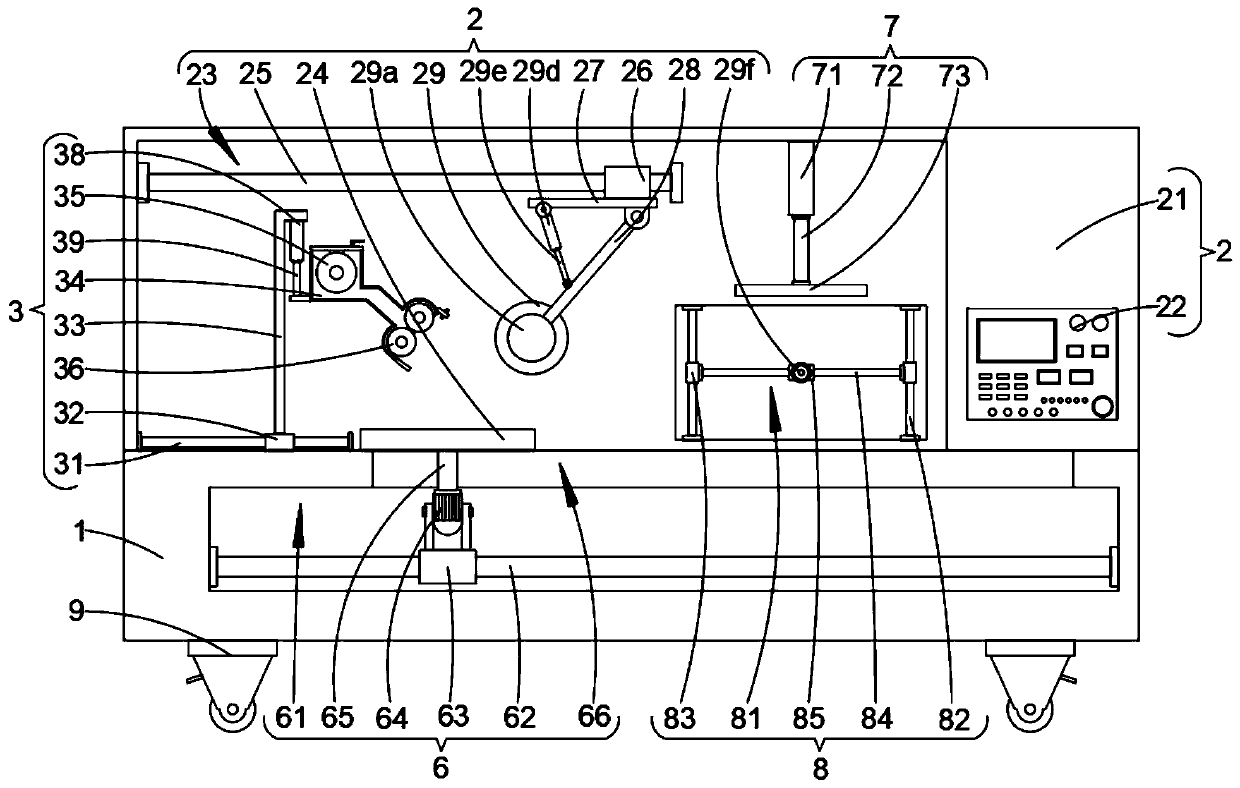

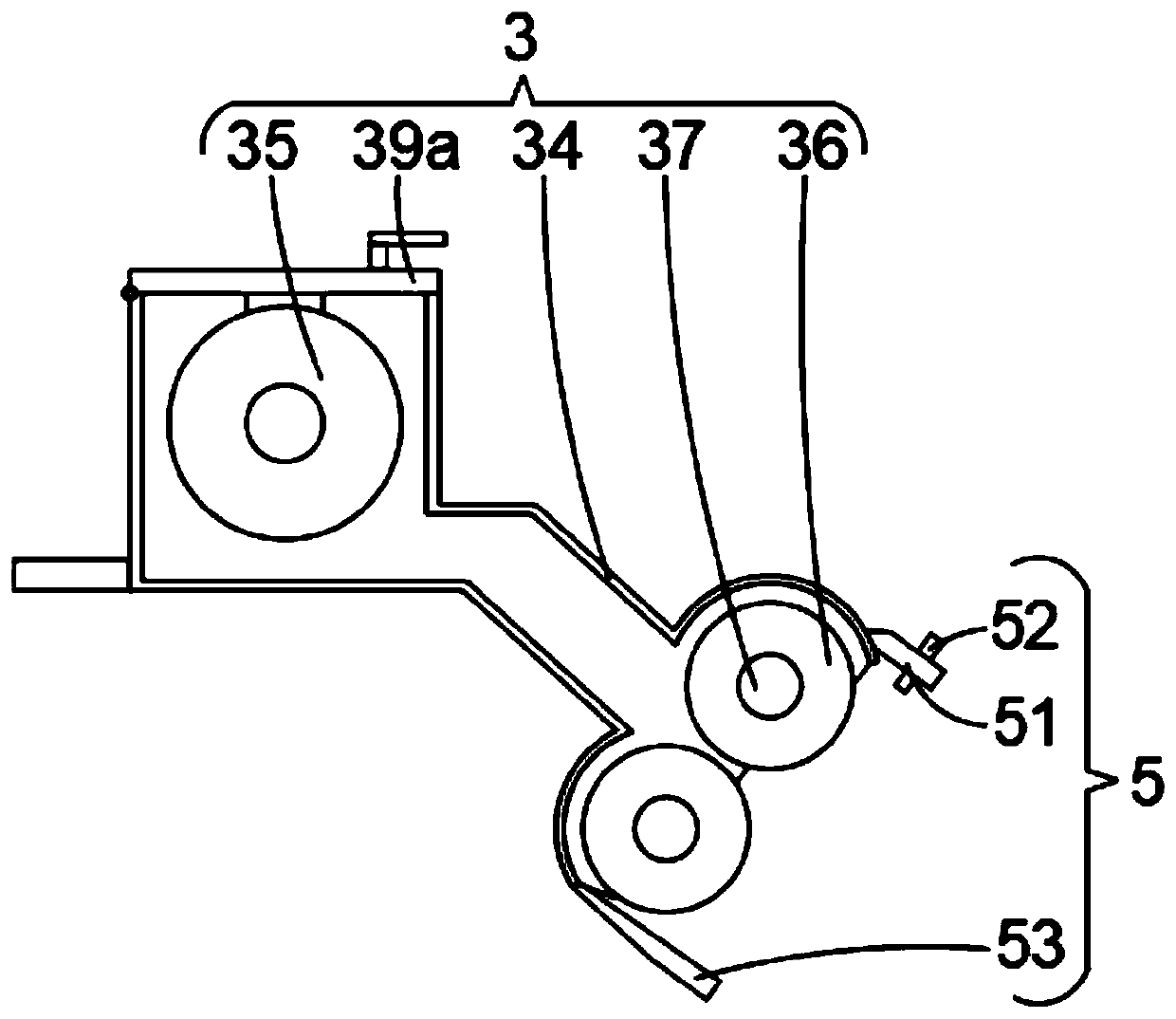

Ultrasonic solidification-friction stir composite added material manufacturing device and application method

ActiveCN110587166APromote interdiffusionImprove mechanical propertiesAdditive manufacturing apparatusWelding apparatusNumerical controlMetal foil

The invention provides an ultrasonic solidification-friction stir composite added material manufacturing device and an application method. The ultrasonic solidification-friction stir composite added material manufacturing device comprises a shell, a machining mechanism, a metal foil conveying mechanism, a driving mechanism, a cutting mechanism, a movable steering mechanism, an extrusion mechanism,an adjusting mechanism and locking universal wheels; the machining mechanism is fixedly connected into the shell; and the machining mechanism comprises a numerical control machining center, a controlpanel, a machining cavity, a substrate, a first electric slide rod, a first electric slide sleeve, a mounting plate, a connecting plate, a machining head, a transducer, an amplitude change rod, an insulation sleeve, a first cylinder, a first piston rod and a friction stir head. The ultrasonic solidification-friction stir composite added material manufacturing device can prepare high-performance metal samples; the mechanical performances of the samples are higher than forgings by 20-50%; and the device is low in size limiting, can machine large-size complex-structured parts, can from more thantwo metal materials according to working conditions and typical performance requirements of parts, and realizes preparation of heterogeneous / gradient function materials.

Owner:ZHEJIANG OCEAN UNIV

Process for preparing lithium nickelate and process for preparing enamel using it as adherence promotor

InactiveCN1587070AImprove adhesion strengthImprove yieldLithium compoundsNickel compoundsLithiumNickel

The present invention prepares superfine lithium nickelate crystal with Li2CO3 and Ni(NO3)2.6H2O in the ratio of 1 to 10-40 and through mixing and treatment in controlled temperature and time. The enamel preparing process with lithium nickelate as the adherence promoter includes introducing lithium nickelate into enamel material during milling, smelting at controlled temperature, ball milling, grinding and baking. Using lithium nickelate as the adherence promoter can overcome the demerit of scalelike enamel crack and raise the performance of enamel product greatly.

Owner:DONGHUA UNIV

Electrochemically assisted powder metallurgy method for preparing porous titanium or titanium alloy

The invention discloses an electrochemically assisted powder metallurgy method for preparing porous titanium or titanium alloy, and belongs to the field of porous biomedical titanium or titanium alloy. The method comprises the steps that titanium powder or titanium alloy powder are completely mixed and pressed into a titanium or titanium alloy porous metal precursor; then a fine molybdenum wire isconnected to a molybdenum rod, thus, a cathode is prepared, and a graphite rod is connected with a molybdenum rod, so that an anode is prepared; after molten salt raw materials are heated to a melting temperature, molten salt is formed, the cathode and the anode are inserted into the molten salt, a two-electrode system is formed, constant voltage of 2.0-3.0 V is applied into the two electrodes, electrochemically assisted sintering is conducted for 10-15 h, after electrolysis is completed, the cathode is taken out, cooled, washed with deionized water, subjected to vacuum drying and polished, and the porous titanium or titanium alloy is obtained. Through the method, the operation temperature can be lowered, the product performance is improved, and the method is environmentally friendly andeasy to operate.

Owner:NORTHEASTERN UNIV

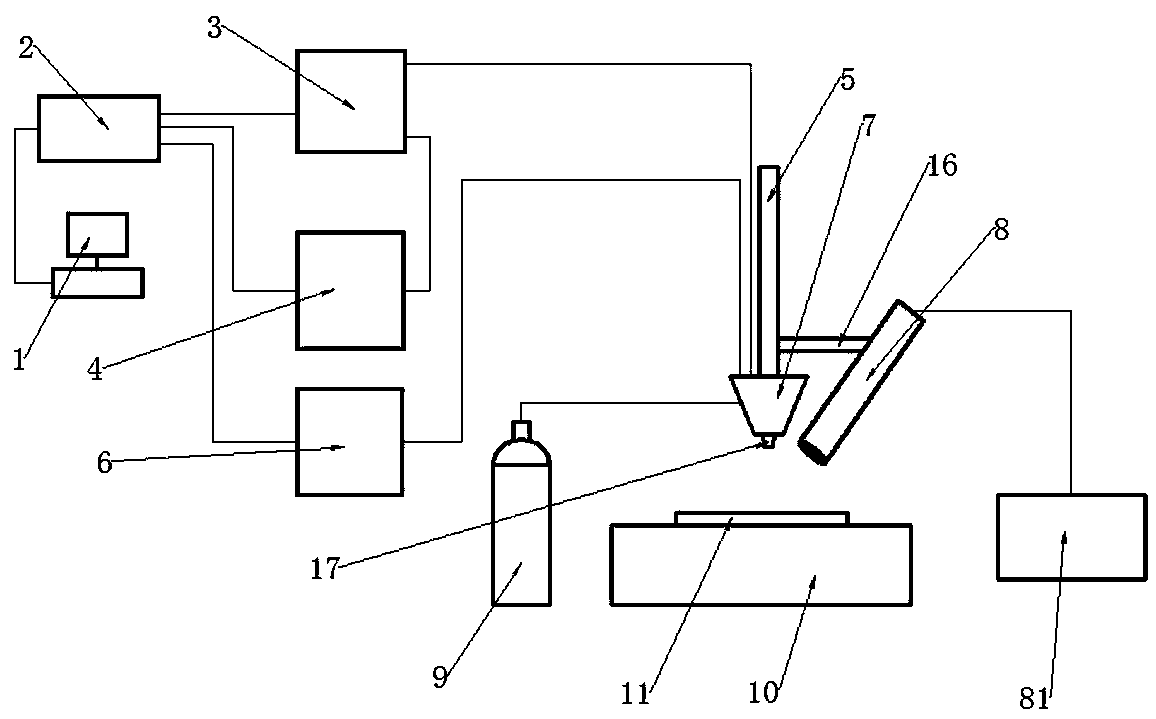

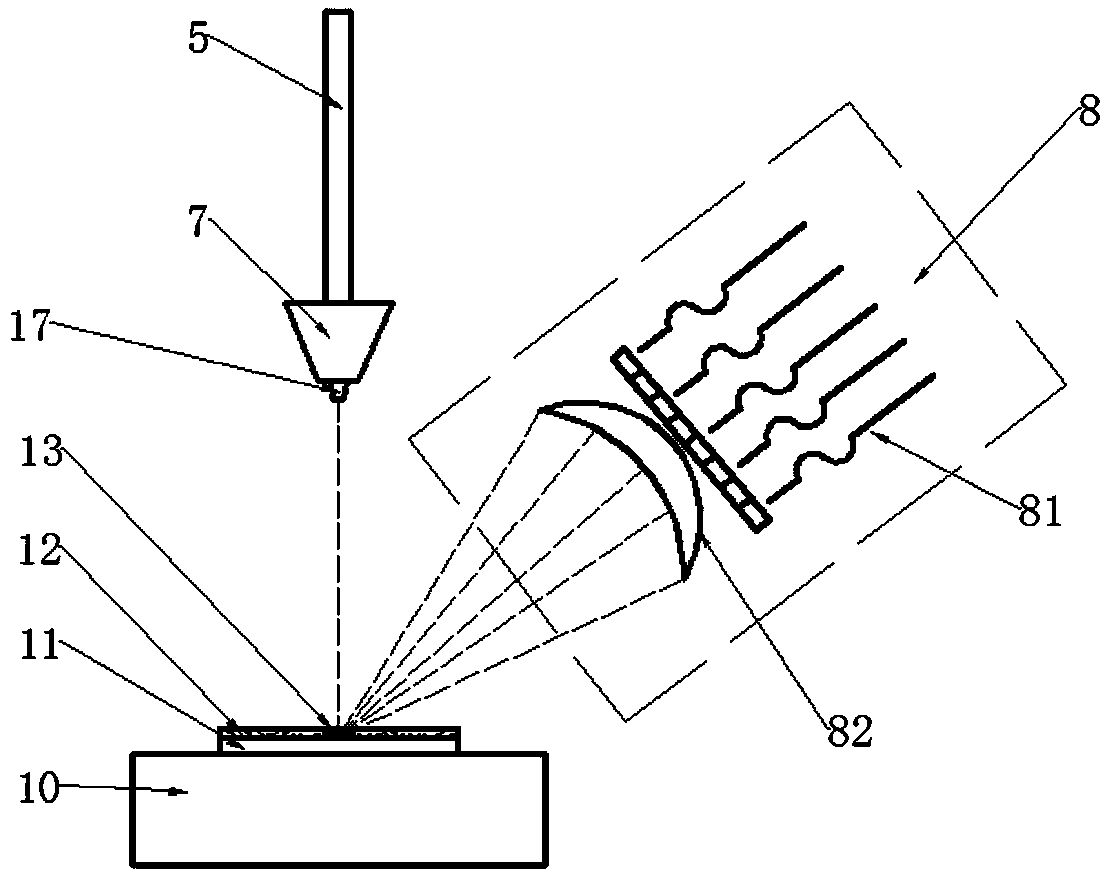

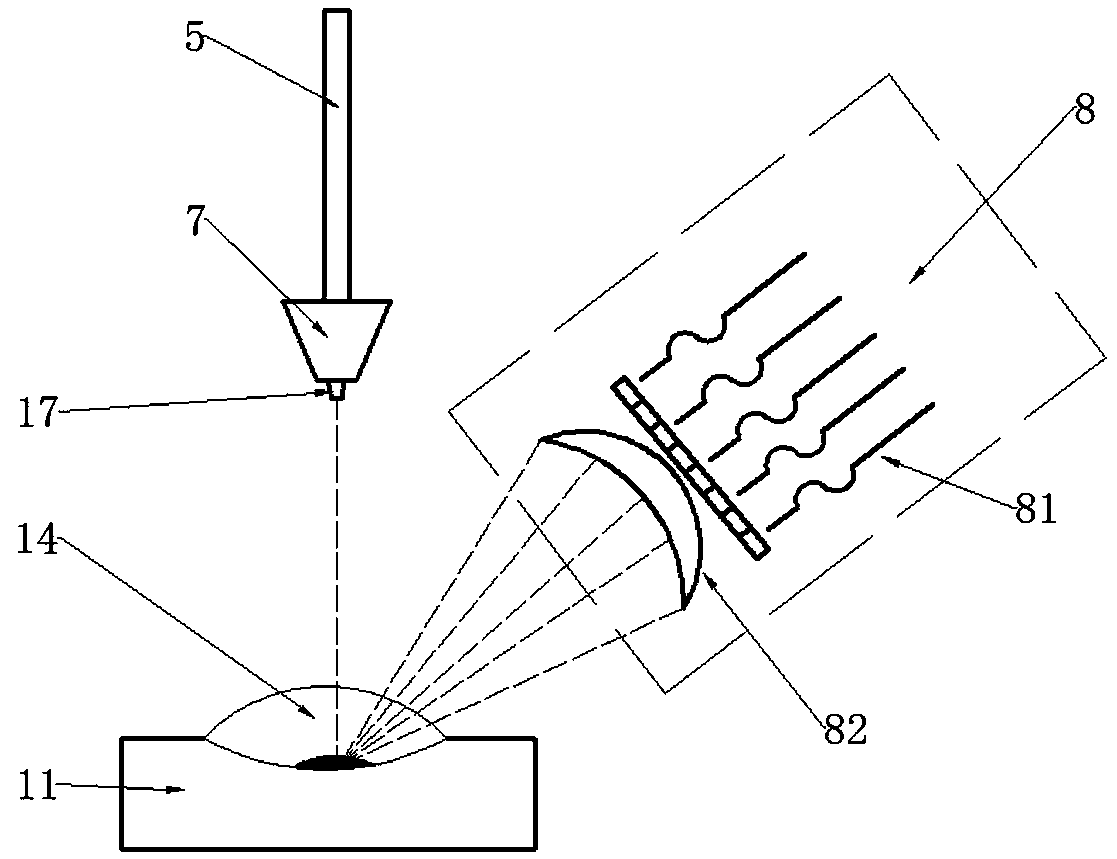

Method for carrying out nano ceramic coating laser cladding on surface of metal under assistance of ultrasonic fixed-point focusing

PendingCN110158082APromote interdiffusionGood metallurgical bondMetallic material coating processesCavitationCeramic coating

The invention relates to a method for carrying out nano ceramic coating laser cladding on the surface of metal under assistance of ultrasonic fixed-point focusing. In a laser cladding process, fixed-point ultrasonic focusing is introduced to act on a bonding surface of a metal matrix and a nano ceramic powder layer, mutual diffusion of elements between the metal matrix and the nano ceramic powderlayer is promoted, so that good metallurgical bonding is formed between the metal matrix and the nano ceramic powder layer; meanwhile, the heat effect, the cavitation effect and the sound flow effectgenerated by ultrasonic focal points can promote formation of crystal nucleus and the fluidity of liquid meta, structure components are more uniform, the structure is more compact, and the strength,the wear resistance and other performances of a cladding layer are improved. The utrasonic fixed-point focusing is adopted, so that the defects that a traditional ultrasonic wave can only act on all molten pools and matrix, so that a cladding layer is thinned and diffuse to the periphery are overcome, the size of the bonding surface of the cladding layer and the matrix as well as the thickness ofthe cladding layer can be accurately controlled, in addition, the flexibility degree is high, and the method is suitable for various complex laser cladding processing environments.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

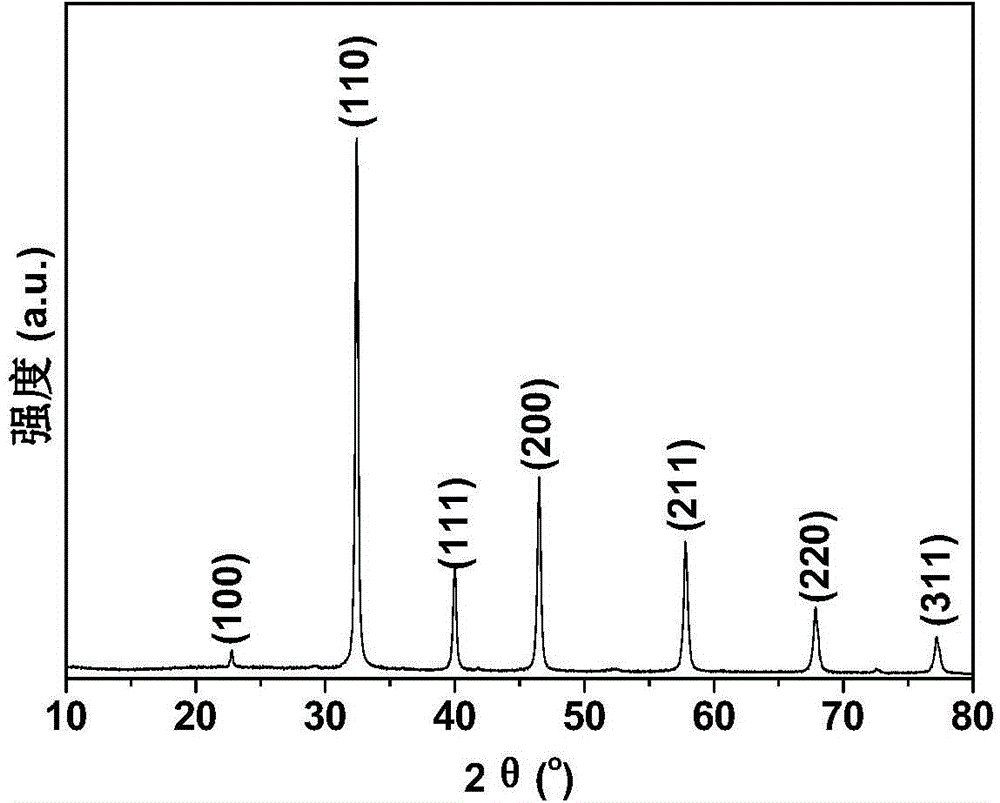

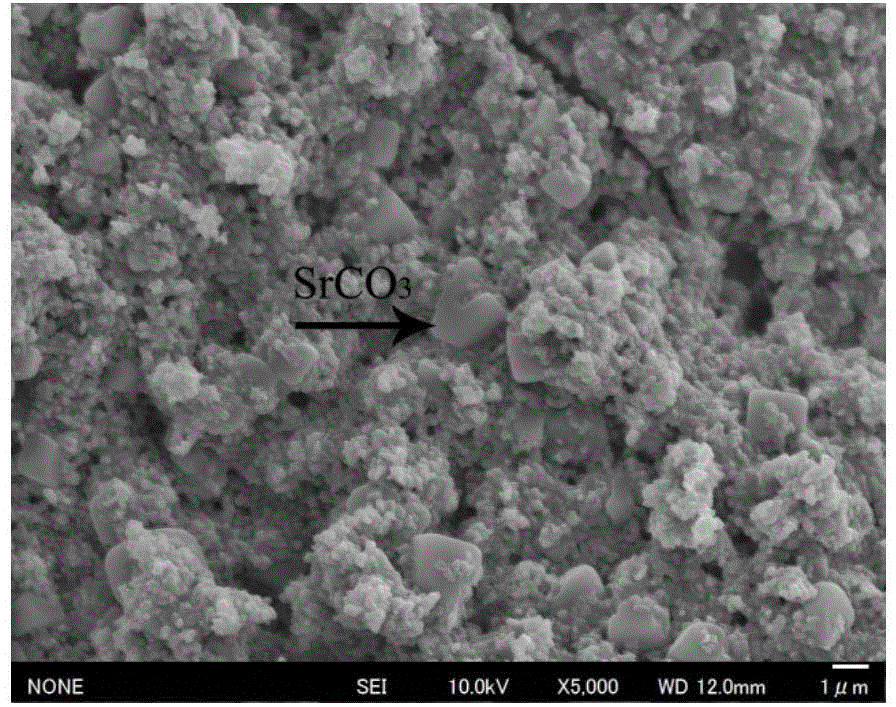

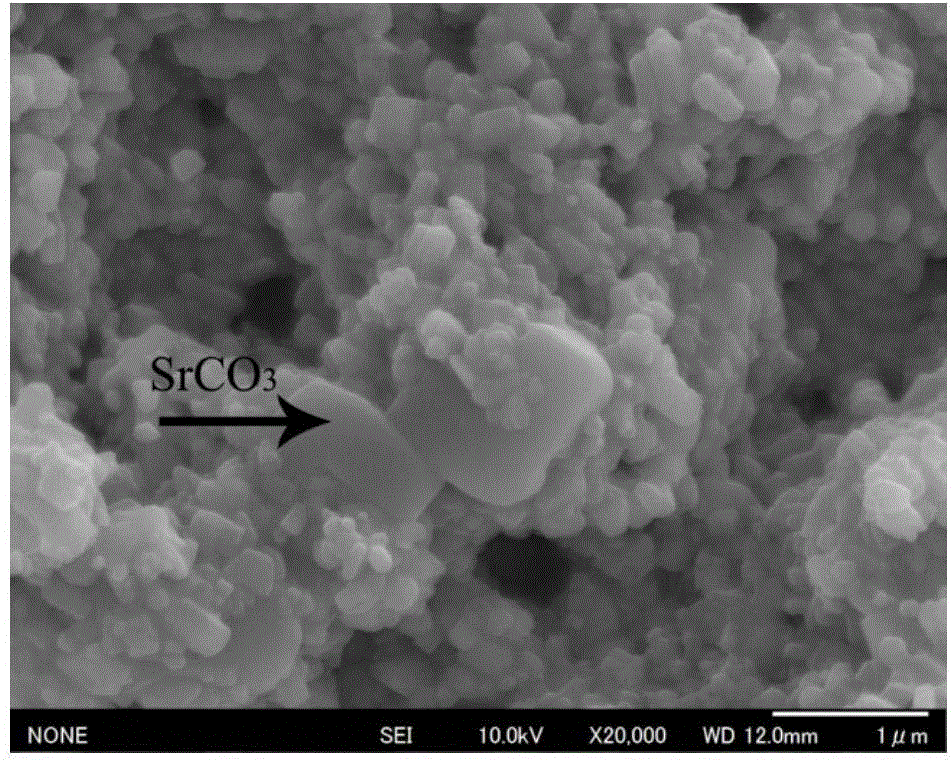

Method for preparing strontium titanate nanopowder by low temperature solid phase reaction

InactiveCN104003437ASmall particlesEasy to controlMaterial nanotechnologyTitanium compoundsStrontium titanateWater vapor

A method for preparing strontium titanate nanopowder by a low temperature solid phase reaction comprises the following steps: performing ball milling of strontium carbonate, titanium dioxide and sodium chloride according to a mol ratio of 1:1:0-16 with ethanol as a dispersant to obtain a paste, drying the paste at 80 DEG C for 6 hours, grinding and sieving the paste to prepare powder with a particle size of not more than 150 microns, putting the powder into a porcelain boat, putting the porcelain boat in a tubular furnace, heating to 500-900 DEG C in the presence of water vapor to react for 2 hours, washing the product with water and ethanol, and performing centrifugal separation and drying to obtain the strontium titanate nanopowder. The method of the invention adopts solid phase reaction technology, and carries out a solid reaction of SrCO3 and TiO2 with the assistance of NaCl(l)-H2O(g) to enable all the SrCO3 and TiO2 to be converted into nanometer SrTiO3 powder; when compared with reaction technology in the prior art, the method of the invention has the characteristics of simple and easily controlled process, low reaction temperature, cheap raw materials, small product particles, environment friendliness and no pollution, and the like.

Owner:JIANGSU UNIV OF SCI & TECH

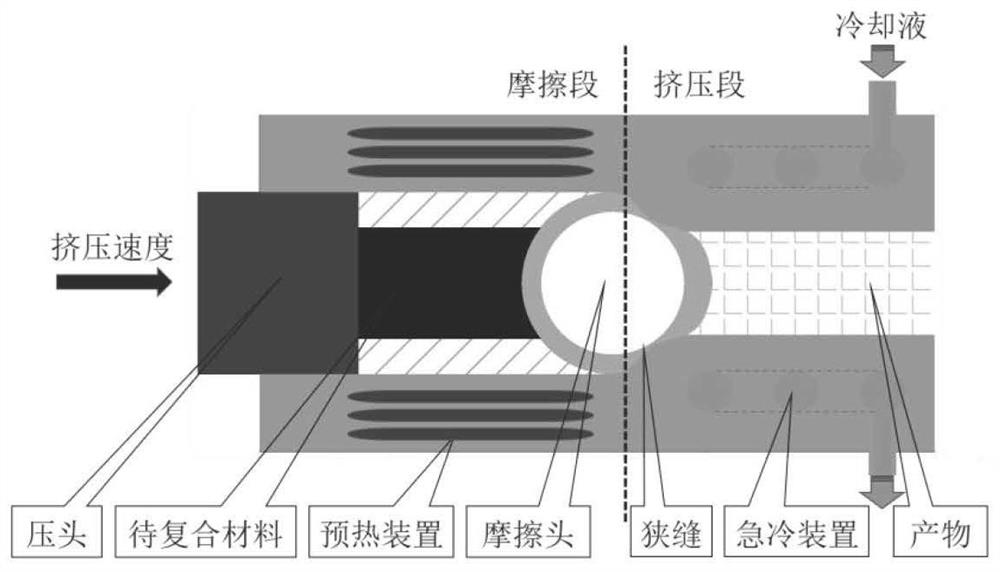

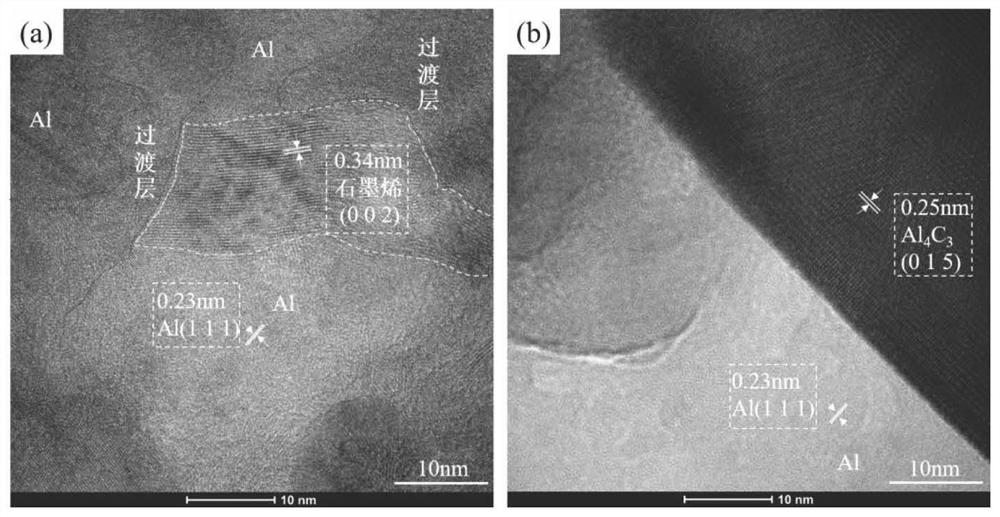

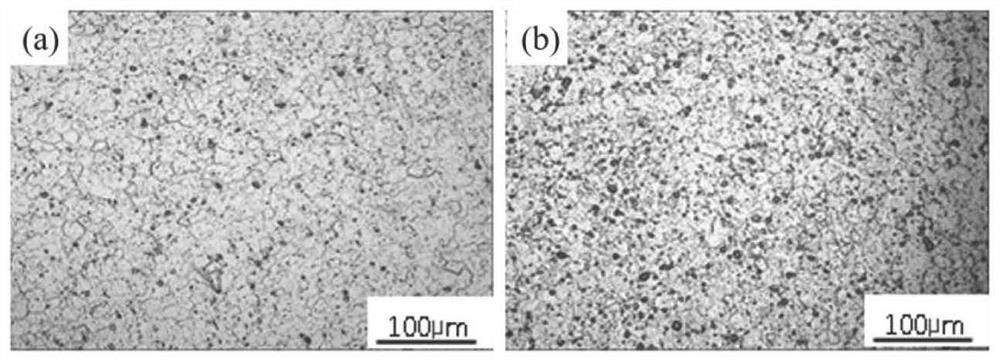

Carbon material-aluminum-based composite material with good interface bonding and preparation method

The invention discloses a preparation method of a carbon material-aluminum-based composite material with good interface bonding, and belongs to the technical field of composite material preparation. The preparation method comprises the following steps that after a carbon material and an aluminum-based material are mixed to form a to-be-compounded material, preheating is conducted, then friction extrusion is conducted, rapid cooling is conducted in the extrusion process, and the carbon material-aluminum-based composite material is obtained, wherein the preheating temperature ranges from 100 DEG C to 150 DEG C. According to the preparation method provided by the invention, the mixing temperature is increased when the to-be-compounded material passes through a friction head rotating at a high speed through preheating at the front section of friction extrusion, so that mutual diffusion of carbon and metal atoms is promoted; and a carbon material-aluminum-based interface subjected to atomic diffusion does not have enough time for a further interface reaction due to quenching at the rear section of friction extrusion, a diffusion type interface with good interface bonding is formed, and the method has important significance on improving the performance of the composite material.

Owner:NANCHANG HANGKONG UNIVERSITY

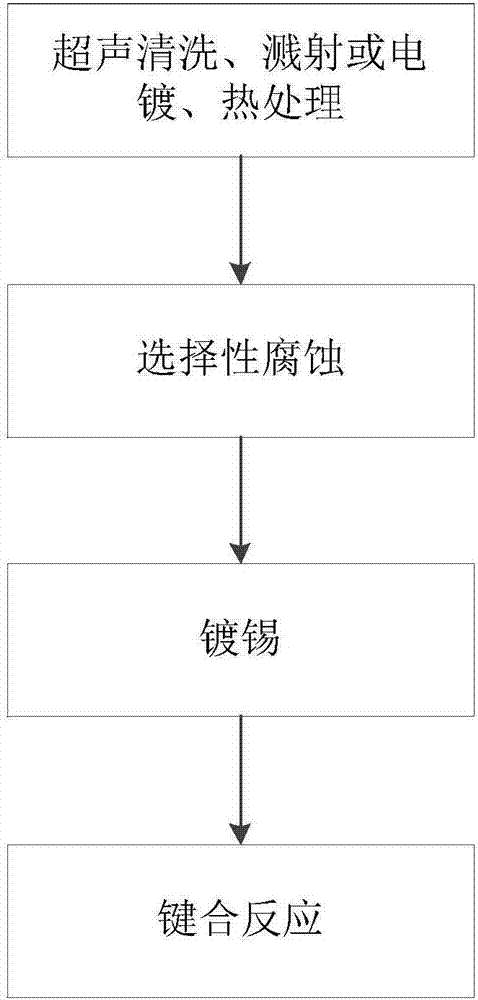

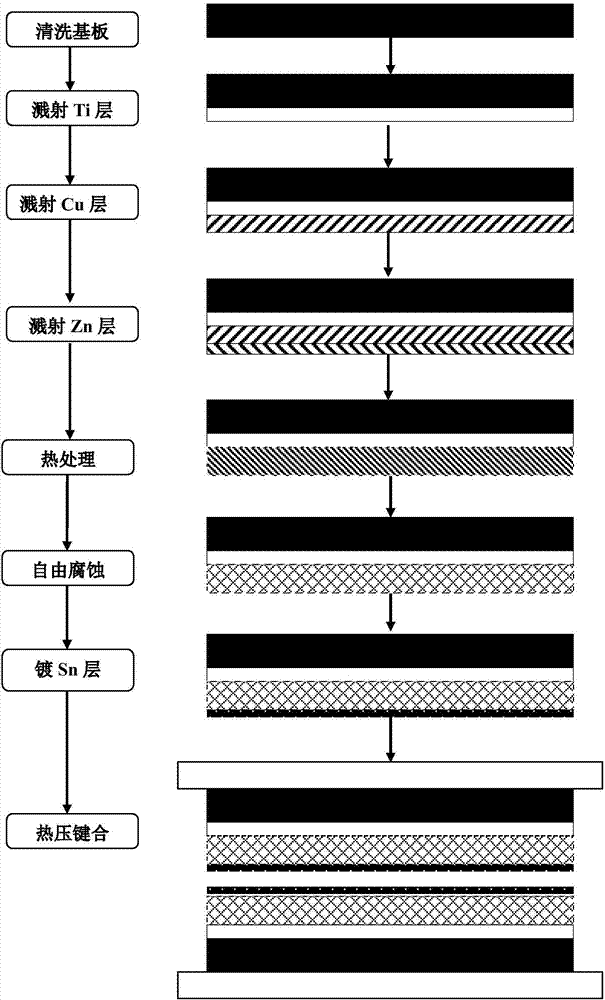

Low-temperature bonding method for tin-coated nano porous copper

InactiveCN107195559AReduce the characteristics of easy oxidationPromote interdiffusionMaterial nanotechnologySolid-state devicesBonding processElectron

The invention belongs to the field of electronic manufacturing, and discloses a low-temperature bonding method for tin-coated nano porous copper. The low-temperature bonding method comprises the steps of: firstly, preparing a copper alloy thin film on an initial substrate by means of ultrasonic cleaning, sputtering or electroplating, and thermal treatment; secondly, preparing a nano porous copper structure by adopting a selective corrosion process; thirdly, depositing tin on the surface of the nano porous copper structure to form a tin-coated nano porous copper structure; and utilizing the tin-coated nano porous copper structure as a bonding layer to realize bonding at low temperature and low pressure. The low-temperature bonding method is simple in process, can realize low-temperature and low-pressure bonding, serves at high temperature, reduces thermal stress generated by adopting the bonding process, and has wide application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

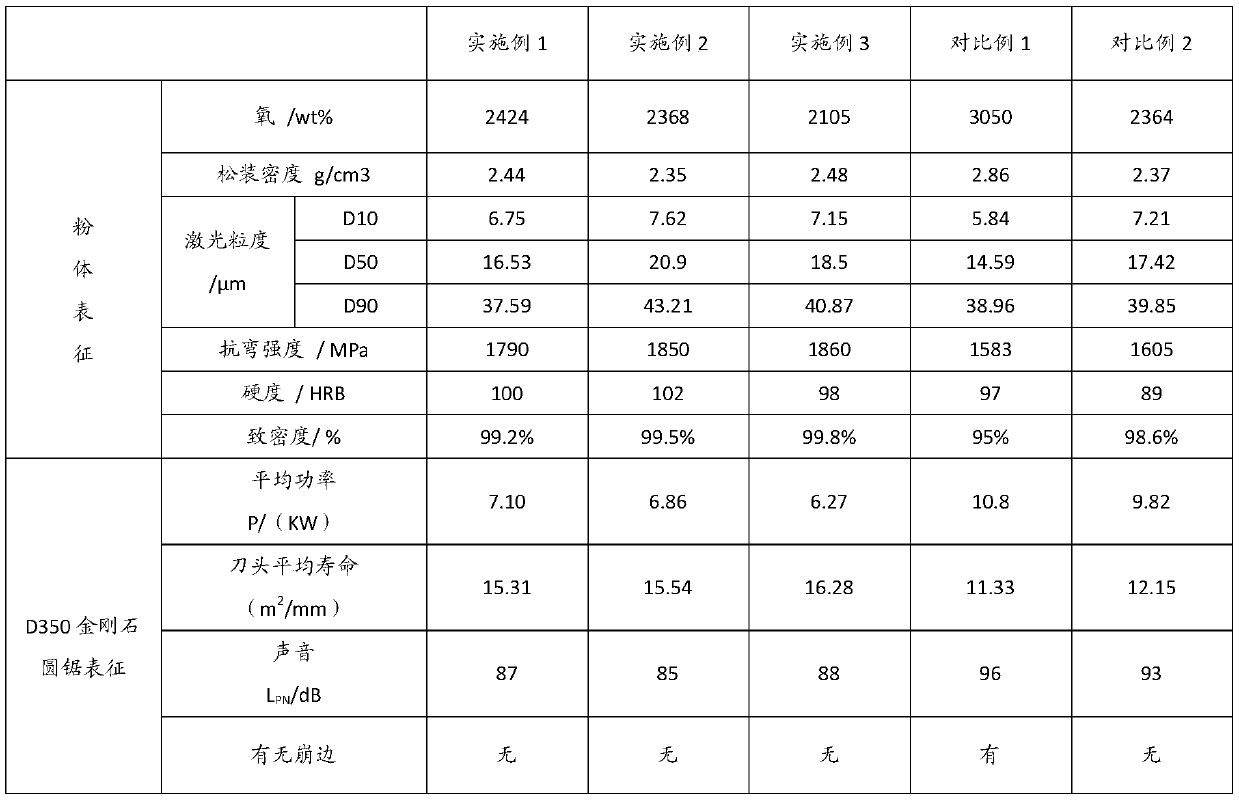

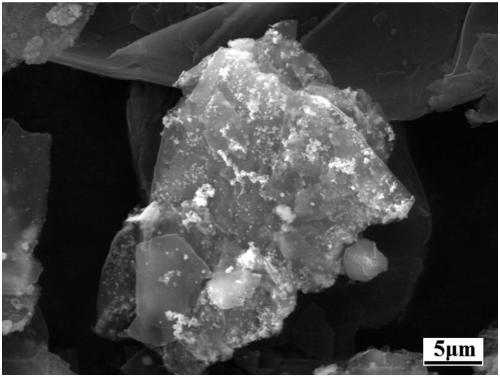

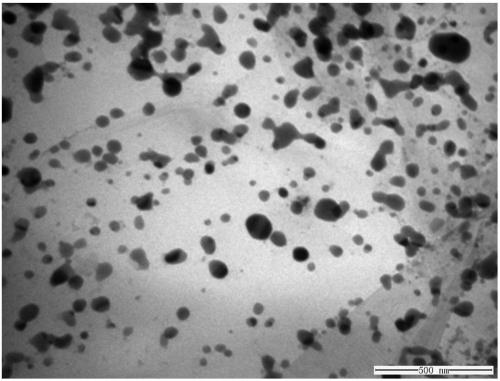

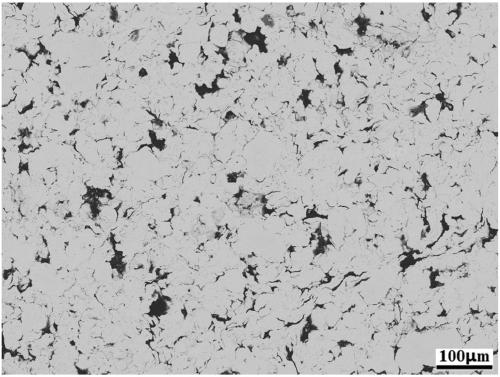

FeNiCuSn prealloy powder and preparation method and application thereof

The invention discloses FeNiCuSn prealloy powder and a preparation method and application thereof. The FeNiCuSn prealloy powder comprises the following components in percentage by weight: 30.0-40.0 %of Cu, 2.0-5.0 % of Ni, 2.0-6.0 % of Sn, 0.1-2.0 % of Si, 0.5-3.0 % of Ti, 0-2.0 % of Cr, 0.5-1.5 % of Mo, and the balance Fe; the powder components are correspondingly mixed with two precursors meeting the following conditions: a CuSn15 prealloy powder precursor and an ultra-fine FeNiCuSn prealloy powder precursor, and the CuSn15 prealloy powder precursor accounts for 2-10% of the total weight. The FeNiCuSn prealloy powder prepared by the method is low in oxygen content, good in pressing formability, high in sintering activity, and uniform and fine in alloy component and structure; the relative density, hardness, bending strength and other mechanical properties of a diamond product matrix prepared from the powder are greatly improved, the matrix has better mechanical embedding effect andmetallurgical bonding force to diamond particles, and a diamond tool prepared from the powder is more excellent in cutting effect and longer in service life.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

Preparation method for copper element modified copper base graphite wear-resistance hydraulic plunger pump cylinder blocks

InactiveCN109676130AGuaranteed service lifeNo generationTransportation and packagingMetal-working apparatusChemical platingHydraulic pump

The invention discloses a preparation method for copper element modified copper base graphite wear-resistance hydraulic plunger pump cylinder blocks. Graphite powder is cleaned, sensitized, activated,reduced and dried; then, a chemical plating method is adopted to put the graphite powder in plating liquid to plate copper metal layers on the surfaces; and then, the graphite powder and metal powderare poured in a mold for cold pressing, sintering, repressing and reburning, and are cooled for demolding to obtain the copper base graphite wear-resistance hydraulic plunger pump cylinder blocks. Inthe prepared hydraulic plunger pump cylinder blocks, graphite is dispersed in copper basal bodies; and when the hydraulic pump cylinder blocks are relatively rubbed with oil distribution discs, the friction reducing effect can be achieved through self-lubricating effect of graphite, so that the wear resistance of the hydraulic plunger pump cylinder blocks is improved.

Owner:XI AN JIAOTONG UNIV +1

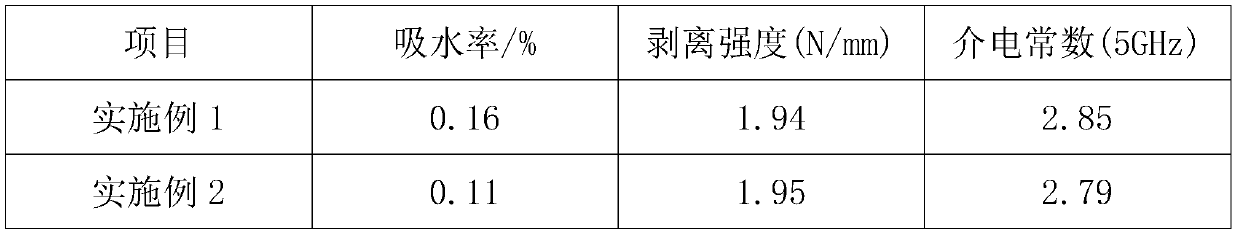

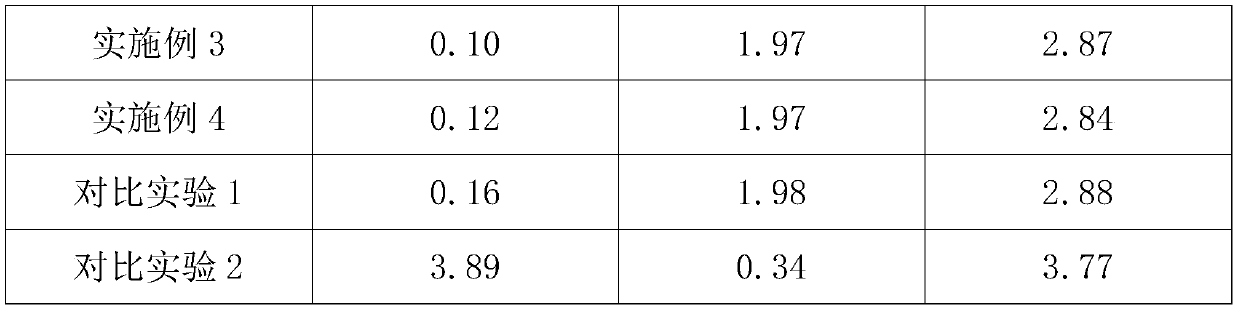

Preparation method of fluorine-containing resin mixture film and copper-clad plate

ActiveCN109880133AStable dielectric constantOvercoming thermal stabilitySynthetic resin layered productsLaminationPolymer scienceResource utilization

The invention discloses a preparation method of a fluorine-containing resin mixture film and a copper-clad plate. The preparation method comprises the following steps: preparing a uniform dispersion solution of a fluorine-containing resin mixture; and uniformly dispersing the fluorine-containing resin mixture solution on PTFE (polytetrafluoroethylene), and performing baking and drying to obtain the fluorine-containing resin mixture film of PTFE; then preparing the copper-clad plate by using the fluorine-containing resin mixture film of the PTFE; the method of invention aims to utilize PTFE with poorer performance, a unique film preparation technology is adopted, the problems of poor thermal stability, poor mechanical properties, poor cohesiveness, poor strength and the like of the copper-clad plate caused by the problems of PTFE are solved, the finally obtained copper-clad plate has low hygroscopicity, stable dielectric constant and low transmission loss, the peel strength and the adhesiveness of the product are both at a high level, meanwhile, resource utilization is achieved, and waste is avoided.

Owner:久耀电子科技(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com