FeNiCuSn prealloy powder and preparation method and application thereof

A pre-alloyed powder, powder technology, applied in the field of preparation, FeNiCuSn pre-alloyed powder, can solve the problems of low bulk density of fine powder, uneven distribution of green compact density, deterioration of mechanical properties, etc., to solve the problem of ultra-fine powder cold pressing Poor properties, promotion of interdiffusion process, and excellent diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

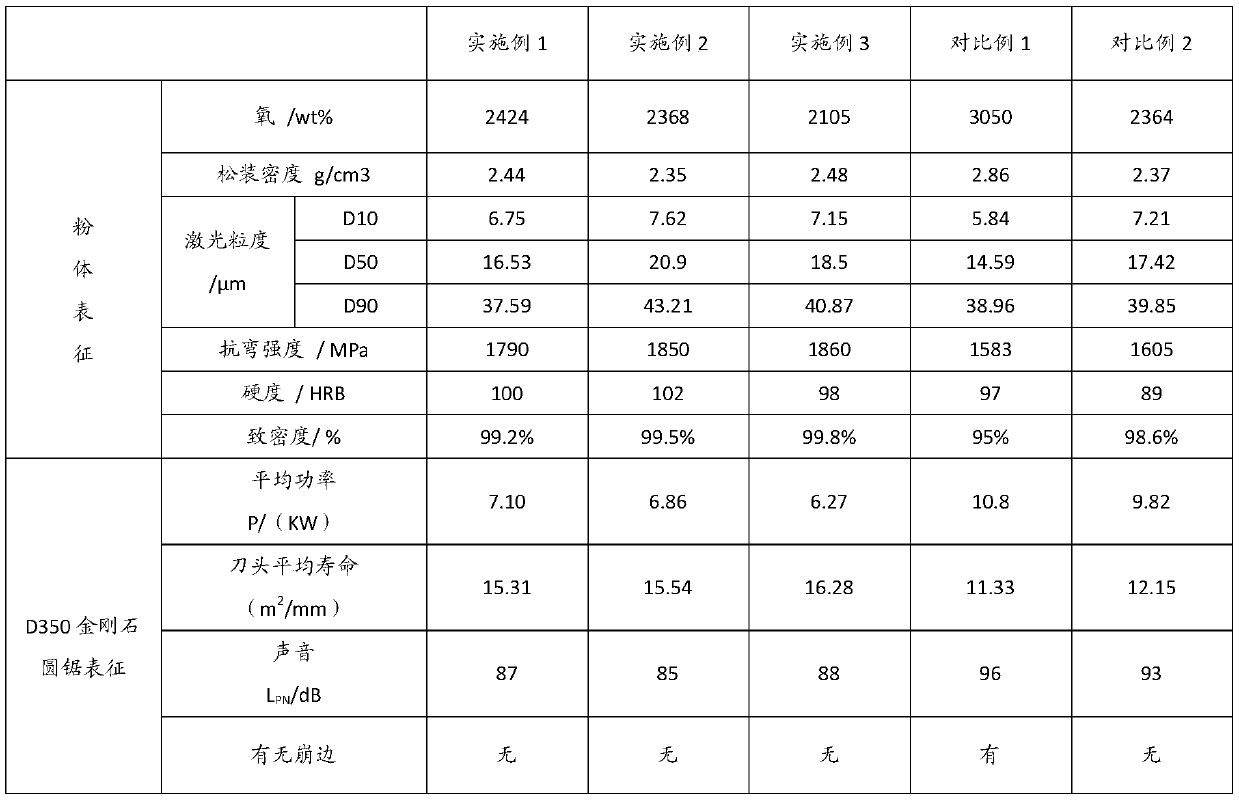

Examples

Embodiment 1

[0034]The FeNiCuSn pre-alloyed powder, powder composition by weight percentage is: 30.00% Cu, 3.0% Ni, 4.0% Sn, 0.3% Si, 1.0% Ti, 0.5% Cr, 0.8% Mo, balance Fe; wherein CuSn15 pre-alloyed The ratio of powder precursor and ultrafine FeNiCuSn pre-alloyed powder precursor is 5:95. Corresponding ultrafine FeNiCuSn pre-alloyed powder precursor composition weight percent is:

[0035] 3.16wt%Ni-27.1wt%Cu-3.4%Sn-0.31wt%Si-1.05wt%Ti-0.53wt%Cr-0.84wt%Mo, balance Fe.

Embodiment 2

[0037] The FeNiCuSn pre-alloyed powder, powder composition by weight percentage is: 35.00% Cu, 4.0% Ni, 3.0% Sn, 0.2% Si, 1.0% Ti, 0.5% Cr, 1.2% Mo, balance Fe; wherein CuSn15 pre-alloyed The ratio of powder precursor and ultrafine FeNiCuSn pre-alloyed powder precursor is 7:93. Corresponding ultrafine FeNiCuSn pre-alloyed powder precursor composition weight percent is:

[0038] 4.3wt%Ni-31.24wt%Cu-2.1%Sn-0.22wt%Si-1.07wt%Ti-0.54wt%Cr-1.3wt%Mo, balance Fe.

[0039] The present invention also provides a method for preparing FeNiCuSn pre-alloyed powder, which adopts ultra-high pressure water-gas combined atomization to prepare two precursors: CuSn15 pre-alloyed powder precursor and ultrafine FeNiCuSn pre-alloyed powder precursor; after that, the The prepared two precursors are fully mixed evenly according to a certain ratio, and the weight percentage is: 2-10% of the CuSn15 pre-alloyed powder precursor, and 90-98% of the ultra-fine FeNiCuSn pre-alloyed powder precursor; then car...

Embodiment 1

[0062] A preparation method applicable to FeNiCuSn pre-alloyed powder for diamond tools, comprising:

[0063] 1) Medium frequency induction smelting: FeNiCuSn pre-alloyed powder alloy composition weight percent is Fe-3.0wt% Ni-30.0wt% Cu-4.0wt% Sn-0.3wt% Si-1.0wt% Ti-0.5wt% Cr-0.8wt% Mo. Among them, the weight percentage of the prepared FeNiCuSn pre-alloyed powder precursor is: Fe-3.16wt%Ni-27.1wt%Cu-3.4%Sn-0.31wt%Si-1.05wt%Ti-0.53wt%Cr-0.84wt%Mo , CuSn15 pre-alloyed powder precursor composition is Cu-15wt%Sn.

[0064] Select pure iron, pure nickel, ferro-titanium, ferromolybdenum, pure copper, pure tin, high-purity silicon and ferrochrome according to the composition of the two precursor alloys, and smelt the raw materials in an intermediate frequency furnace, controlling the smelting power to 100-300KW , the smelting time is 40.0-70.0 minutes, when the temperature of the molten steel reaches ≥1620°C, the power is reduced to 60-80KW, the alloying process of the molten steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com