Closestool automatic cleaning mechanism

A cleaning mechanism and toilet technology, applied in the field of cleaners, can solve the problems of weakening the decontamination effect, etc., and achieve the effect of good diffusion effect and better cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

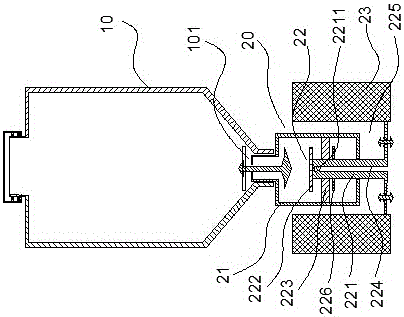

[0020] A toilet automatic cleaning mechanism, as attached figure 1 As shown, it includes a tank body 10 for containing cleaning agent used in conjunction with the toilet, and the tank body 10 is suspended or fixed on the inner wall of the toilet tank. The bottom of the tank body 10 is provided with a diversion port 101, and the diversion port 101 is connected with a control structure 20 for controlling the addition of detergent to the toilet through a one-way valve, including a cylinder body 21 for temporarily storing a small amount of detergent and controlling the The cleaning agent in the cylinder body 21 enters the control body 22 in the toilet. The control body 22 includes a piston tube 221 extending from the bottom of the cylinder body 21 into the inside of the cylinder body 21, a limit plate 222 arranged on the top of the piston tube 221 and a sleeve The piston ring 223 on the outer circumference of the piston tube 221 and the lower baffle plate 226 arranged below the pi...

Embodiment 2

[0022] An automatic toilet cleaning mechanism includes a tank body 10 used in conjunction with the toilet for containing cleaning agents. The bottom of the tank body 10 is provided with a diversion port 101, and the diversion port 101 is connected with a control structure 20 for controlling the addition of detergent to the toilet through a one-way valve, including a cylinder body 21 for temporarily storing a small amount of detergent and controlling the The cleaning agent in the cylinder body 21 enters the control body 22 in the toilet. The control body 22 includes a piston tube 221 extending from the bottom of the cylinder body 21 into the inside of the cylinder body 21, a limit plate 222 arranged on the top of the piston tube 221 and a sleeve The piston ring 223 on the outer circumference of the piston tube 221 and the lower baffle plate 226 arranged below the piston ring 223, the piston tube 221 is provided with a guide channel 224 leading to the bottom of the piston tube 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com