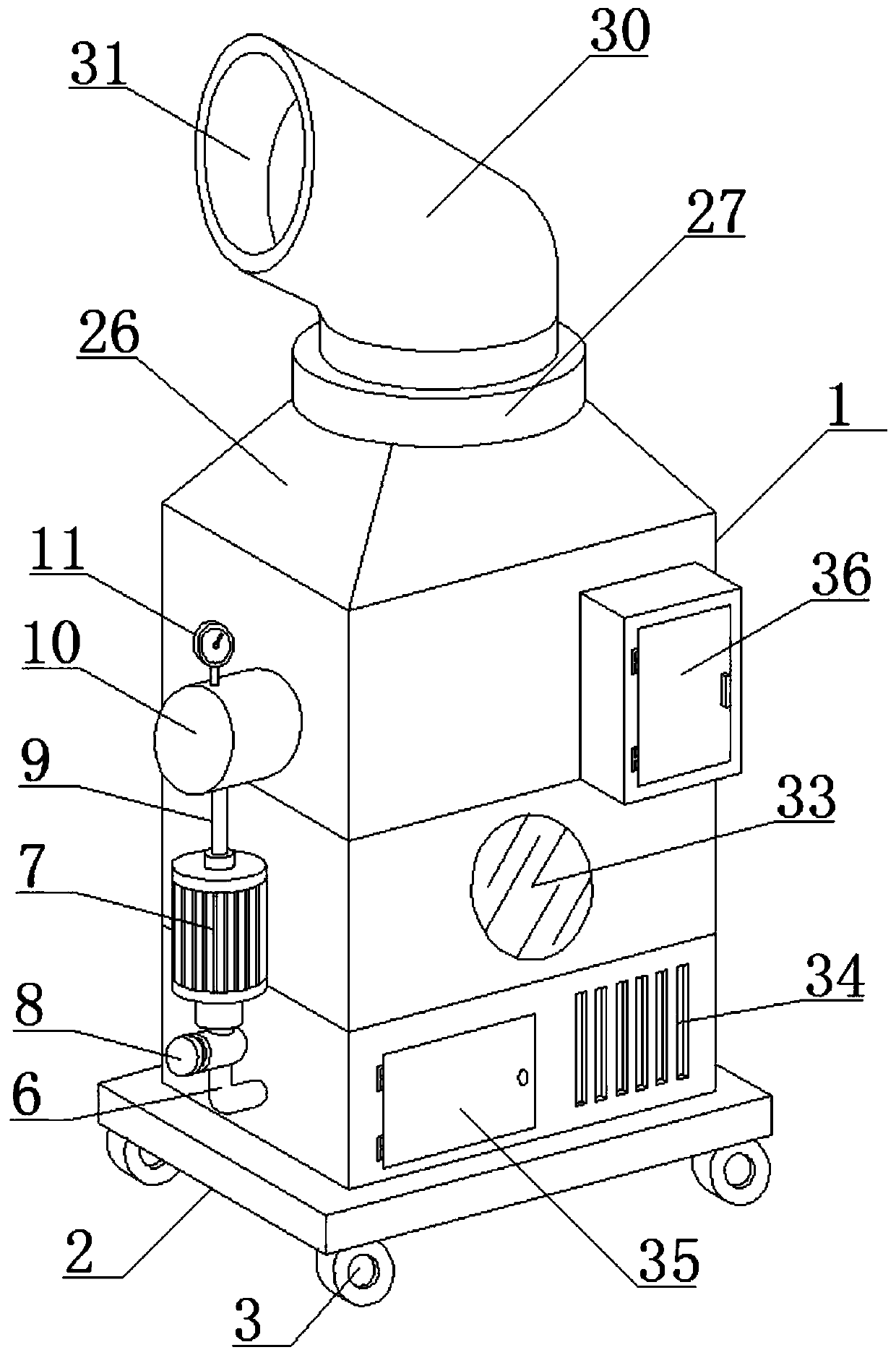

Efficient-sterilization diffusion device with micro-bubbling function

A diffusion device and micro-bubble technology, applied in the direction of sterilization/microdynamic water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of slow rise of bubbles, insufficient sterilization, melting High efficiency and other issues, to achieve the effect of preventing water waste, saving water sources, and good diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

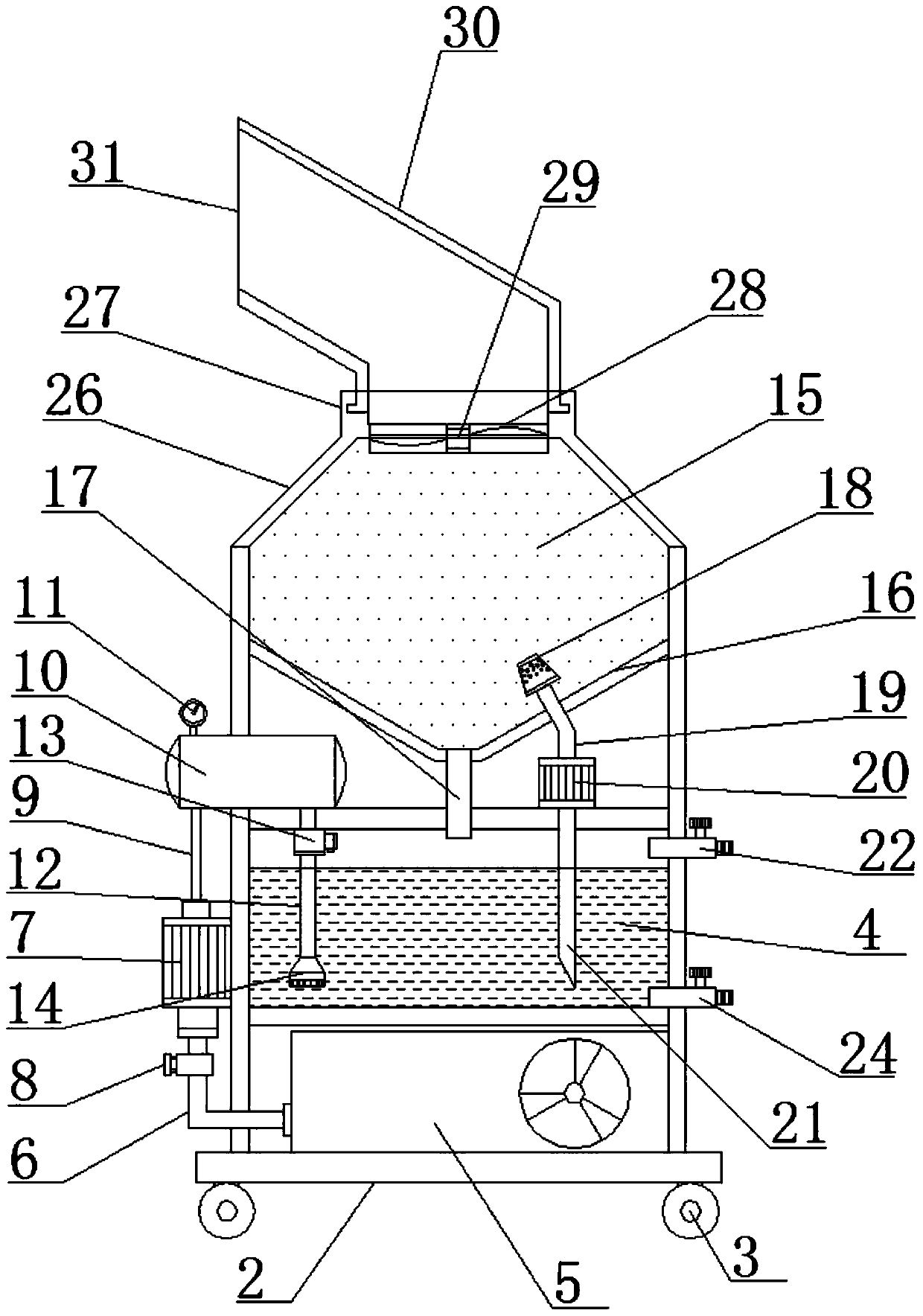

[0027] As a preferred embodiment of the present invention, an electronic barometer 11 is installed on the top of the booster tank 10.

[0028] As a preferred embodiment of the present invention, a return pipe 17 is installed at the bottom of the funnel wall 16, and the return pipe 17 communicates with the mist chamber 15 and the sump 4.

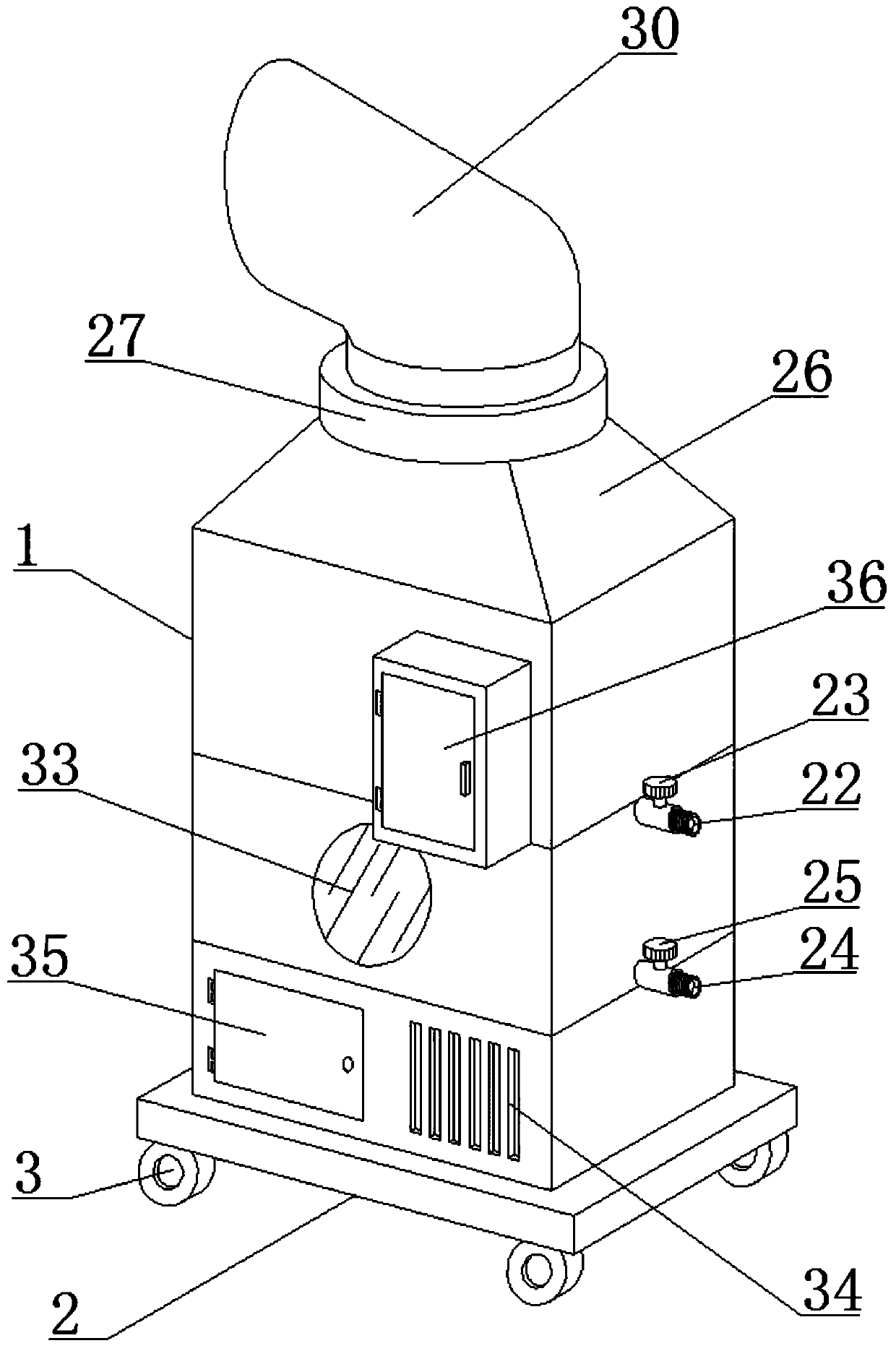

[0029] As a preferred embodiment of the present invention, a water inlet knob 23 is installed on the water inlet valve 22, and a water outlet knob 25 is installed on the water outlet valve 24.

[0030] As a preferred embodiment of the present invention, a rotating buckle 32 is installed at a position where the bottom of the rotating spray head 30 is connected to the spray head base 27.

[0031] As a preferred embodiment of the present invention, a transparent window 33 is installed on the front side wall of the device main body 1 at the position of the water tank 4 part.

[0032] As a preferred embodiment of the present invention, the bottom of the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com