Method and device for continuously preparing high-silicon silicon steel thin strip through current composite diffusion method

A technology of high silicon steel and diffusion method, applied in solid diffusion coating, coating, metal material coating process and other directions, can solve the problems of uneven diffusion of silicon element, restricting the performance of high silicon steel, low speed, etc. Ease of mass production, reduced time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

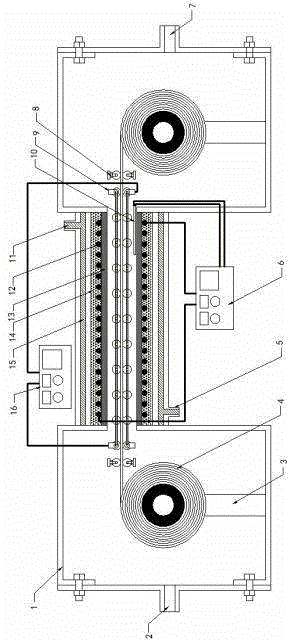

[0027] In this example, see figure 1 and figure 2 , a high-silicon steel thin strip continuous preparation device, including a thin strip winding device and a vacuum heat treatment furnace, the vacuum furnace device is composed of a furnace sleeve 13, a heating element 12, a temperature control device 6, a thermocouple 10, a refractory material 14, a cooling The water inlet valve 5, the cooling water outlet valve 11 and the water cooling casing 15 are composed. The furnace body casing 13 is a corundum casing arranged horizontally, the refractory material 14 is made of refractory fiber, and the heating element 12 is arranged on the outside of the furnace body casing 13 , the refractory material 14 is located between the heating element 12 and the water cooling sleeve 15 to form the body of the vacuum heat treatment furnace, the cooling water inlet valve 5, the cooling water outlet valve 11 and the water cooling sleeve 15 form the body of the vacuum heat treatment furnace Cool...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, especially in that:

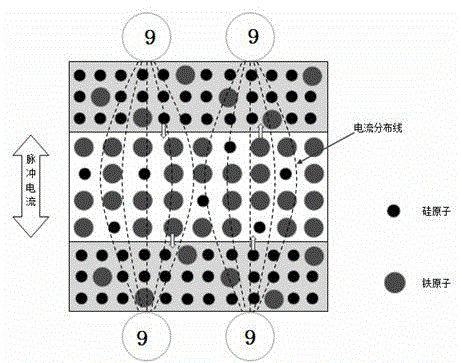

[0034] In this example, iron powder and silicon powder were weighed according to the required silicon content, mixed evenly, and a low-silicon steel composite strip was prepared by powder rolling, and direct current or alternating current was applied to the low-silicon steel composite strip, and placed After the diffusion is complete under high temperature conditions, a high-silicon steel strip with uniform content can be obtained.

[0035] In this embodiment, the Fe-Si powder thin ribbon blank is bundled on two coiling devices, put into the vacuum / atmosphere protection vacuum box, and the ribbon is driven by the two coiling devices through the vacuum / atmosphere protection chamber. At the same time, direct current or alternating current is applied to both ends of the strip, and heat treatment and diffusion are carried out under high temperature conditions to promote the uniform diffusion of Fe-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com