Preparation method for copper element modified copper base graphite wear-resistance hydraulic plunger pump cylinder blocks

A hydraulic plunger pump and graphite technology, applied in liquid chemical plating, metal processing equipment, coating, etc., can solve the problems of poor wettability between copper and graphite, low interface bonding strength, and poor mechanical properties such as bending strength , to achieve the effect of ensuring service life, improving wear resistance and improving interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

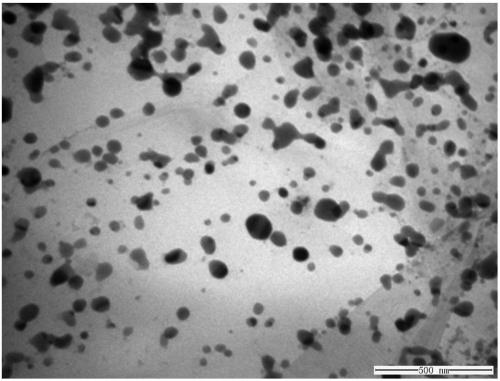

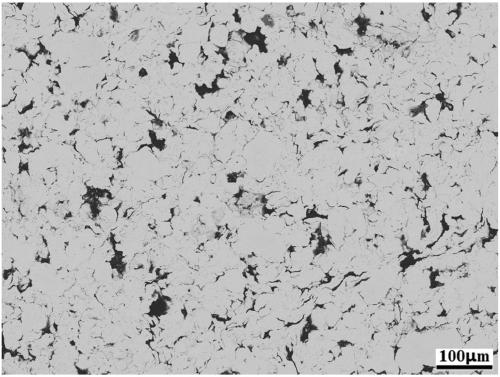

[0040] The invention discloses a method for preparing a copper element modified copper-based graphite wear-resistant hydraulic plunger pump cylinder, comprising the following steps:

[0041] S1. Use a NaOH solution with a concentration of 18 to 24wt.% to clean the graphite powder, and then rinse the graphite powder with distilled water to neutralize it after fully washing;

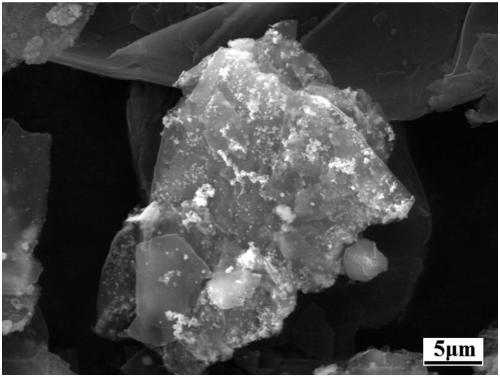

[0042] The graphite powder is flake graphite powder with a particle size of 40-50 μm, a particle size of 325 mesh, and a purity of 98.5-99.0%.

[0043] S2. Add the cleaned graphite into the sensitizing solution, and mechanically stir it with a magnetic stirrer for 10-25 minutes. After the graphite is fully sensitized, wash the powder with distilled water until neutral;

[0044] The sensitization solution is SnCl with a concentration of 5-10g / L 2 And concentration of 10 ~ 15ml / L of HCl, SnCl 2 The volume ratio of HCl and HCl is 1:1~1:1.5.

[0045] S3. Add graphite to the activation solution, and mechanic...

Embodiment 1

[0067] Marine hydraulic piston pump cylinder

[0068] S1, utilize the NaOH solution that concentration is 18wt.% to clean graphite powder, after fully washing, graphite powder is rinsed neutral with distilled water;

[0069] The graphite powder is flake graphite powder with a particle size of 40 μm, a particle size of 325 mesh, and a purity of 98.5%.

[0070] S2. Add the cleaned graphite into the sensitizing solution, and mechanically stir it with a magnetic stirrer for 10 minutes. After the graphite is fully sensitized, wash the powder with distilled water until neutral;

[0071] The sensitization solution is SnCl with a concentration of 5g / L 2 and HCl with a concentration of 10ml / L, SnCl 2 The volume ratio of HCl and HCl is 1:1.

[0072] S3. Add graphite to the activation solution, and mechanically stir with a magnetic stirrer for 10 minutes, then wash the graphite powder with distilled water until neutral, and put it into a vacuum drying oven for vacuum drying at 65°C. ...

Embodiment 2

[0081] Heavy-duty machinery hydraulic plunger pump cylinder

[0082] S1, utilize the NaOH solution that concentration is 24wt.% to clean graphite powder, after fully washing, graphite powder is rinsed neutral with distilled water;

[0083] The graphite powder is flake graphite powder with a particle size of 50 μm, a particle size of 325 mesh, and a purity of 99.0%.

[0084] S2. Add the cleaned graphite into the sensitizing solution, and mechanically stir it with a magnetic stirrer for 25 minutes. After the graphite is fully sensitized, wash the powder with distilled water to neutrality;

[0085] The sensitization solution is SnCl with a concentration of 10g / L 2 and HCl with a concentration of 15ml / L, SnCl 2 The volume ratio of HCl and HCl is 1:1.5.

[0086]S3. Add graphite to the activation solution, and mechanically stir with a magnetic stirrer for 25 minutes, then wash the graphite powder after the reaction with distilled water until neutral, and put it into a vacuum dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com