Preparation method of fluorine-containing resin mixture film and copper-clad plate

A technology for preparing fluorine-containing resins and films, which is applied in the field of communication materials, can solve the problems of poor mechanical properties, unstable dielectric constant, and low fracture strength of copper clad laminates, and achieve improved dispersion, stable dielectric constant, and interaction force enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

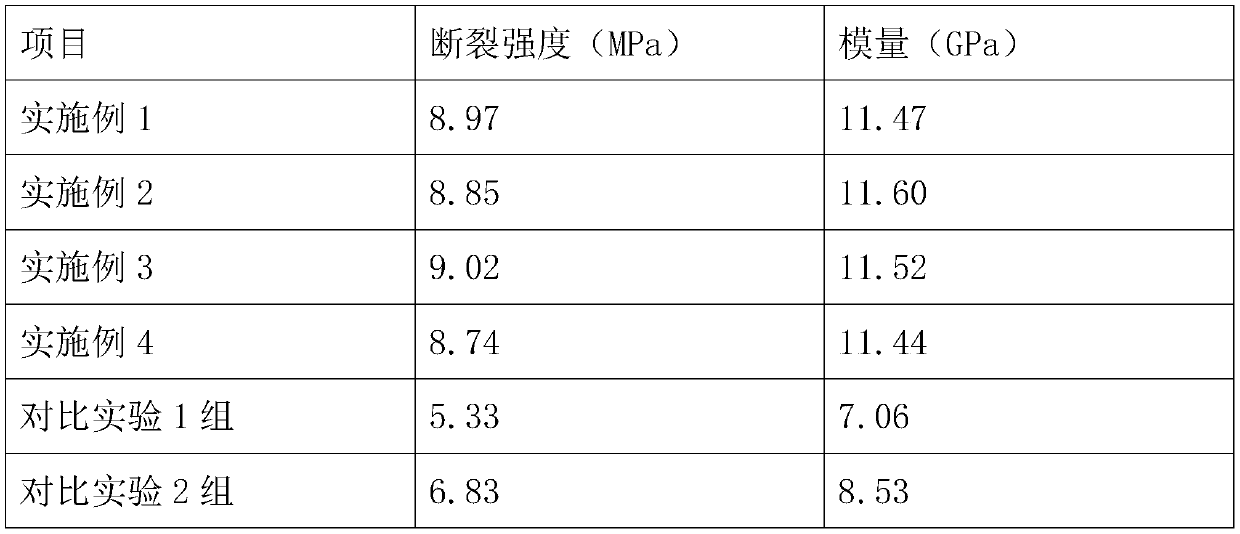

Embodiment 1

[0032] The number of prepregs used is 5, the models of the prepregs used are prepreg 2116 and prepreg 7628, and the number of copper foils is 2. The combination sequence from top to bottom is copper foil, PTFE fluorine-containing resin mixture film, Prepreg 2116, PTFE fluorine-containing resin mixture film, prepreg 7628, prepreg 2116, prepreg 7628, PTFE fluorine-containing resin mixture film, prepreg 2116, PTFE fluorine-containing resin mixture film, copper foil. The pressing temperature is 150°C and the pressure is 150kg / cm 2 , The pressing time is 52h.

[0033] The fluorine-containing resin mixture includes the following raw materials in parts by weight: 30 parts of fluorine-containing resin emulsion, 70 parts of inorganic filler, 15 parts of coupling agent, and 15 parts of improver.

[0034] Preparation of modification reagent: mix pyromellitic dianhydride and nano-silica, stir mechanically for a certain period of time, weigh a certain amount of 4,4′-diaminodiphenyl ether,...

Embodiment 2

[0038] The number of prepregs used is 5 sheets, the models of prepregs used are prepreg 2116 and prepreg 7628, the number of copper foil sheets is 2 sheets, and the order of combination is copper foil and PTFE fluorine-containing resin mixture film from top to bottom. , Prepreg 2116, Prepreg 7628, Prepreg 2116, Prepreg 7628, Prepreg 2116, PTFE fluorine-containing resin mixture film, copper foil. The pressing temperature is 150°C, the pressure is 150kg / cm2, and the pressing time is 52h.

[0039] The fluorine-containing resin mixture includes the following raw materials in parts by weight: 60 parts of fluorine-containing resin emulsion, 80 parts of inorganic filler, 10 parts of coupling agent, and 5 parts of improver.

[0040] Preparation of modification reagent: mix pyromellitic dianhydride and nano-silica, stir mechanically for a certain period of time, weigh a certain amount of 4,4′-diaminodiphenyl ether, divide it into 3 equal parts, and store it in a helium-protected enviro...

Embodiment 3

[0044] The number of sheets of prepreg used is 5 sheets, the number of sheets of copper foil is 2 sheets, the type of prepreg used is prepreg 106, prepreg 7628, the number of sheets of copper foil is 2 sheets, and the order of combination is copper from top to bottom. Foil, PTFE fluororesin mixture film, prepreg 106, PTFE fluorine resin mixture film, prepreg 7628, prepreg 106, prepreg 7628, PTFE fluorine resin mixture film, prepreg 2116, PTFE fluorine resin mixture film, copper foil. The pressing temperature is 430°C, the pressure is 100kg / cm2, and the pressing time is 24h.

[0045] The fluorine-containing resin mixture includes the following raw materials in parts by weight: 40 parts of fluorine-containing resin emulsion, 90 parts of inorganic filler, 12 parts of coupling agent, and 10 parts of improver.

[0046] Preparation of modification reagent: mix pyromellitic dianhydride and nano-silica, stir mechanically for a certain period of time, weigh a certain amount of 4,4′-di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com