Preparation method of modified dicyclopentadiene type cyanate ester resin with low hygroscopicity

A technology of dicyclopentadiene-type cyanate ester and low hygroscopicity is applied in the field of preparation of modified dicyclopentadiene-type cyanate ester resin, and can solve the problems of high hygroscopicity, poor toughness, accelerated system aging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

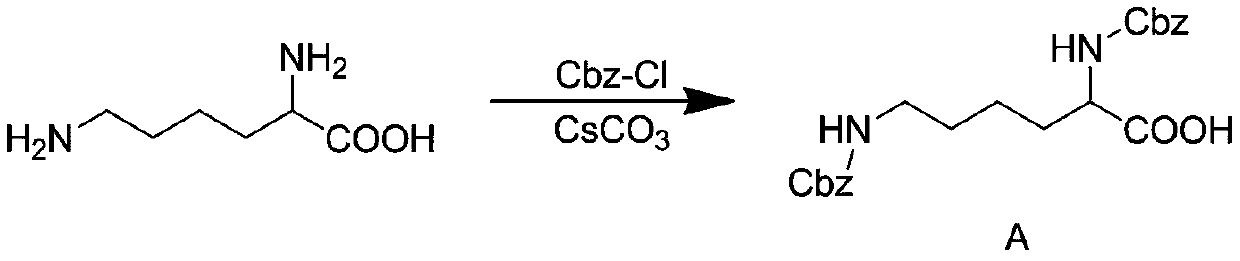

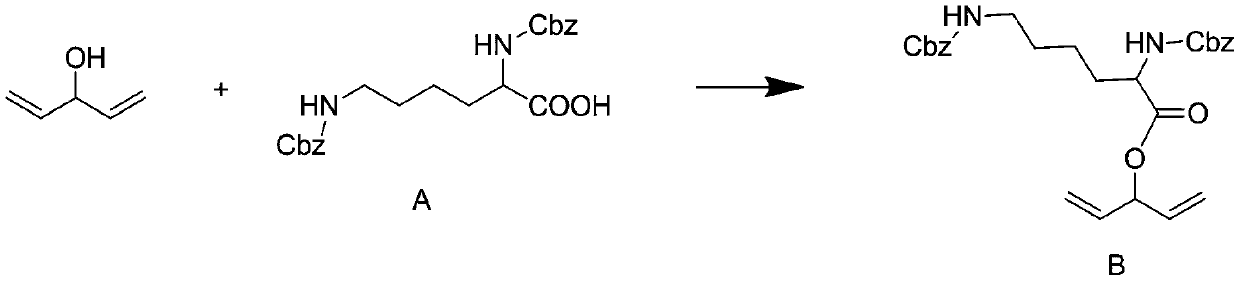

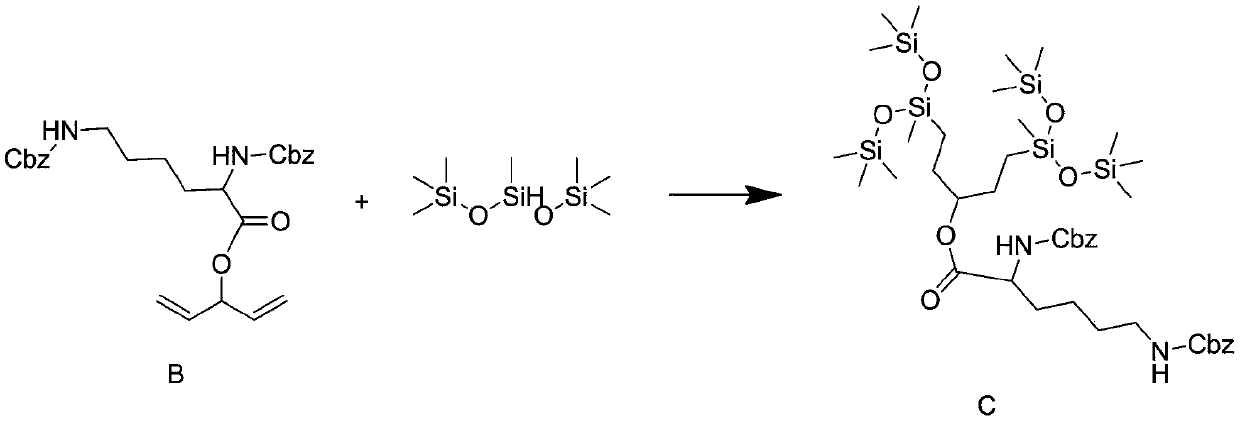

Method used

Image

Examples

Embodiment 1

[0049] The preparation method of the modified dicyclopentadiene type cyanate resin with low hygroscopicity is:

[0050] Weigh 10g of dicyclopentadiene-type cyanate and add it to a three-necked flask equipped with an electric stirring device, add 1g of modifier D, heat up to 85°C, keep stirring and mix for 20min, then add 0.1g of catalyst dilauric acid dilaurate Butyl tin, heat up to 140°C, keep stirring at constant temperature for curing reaction for 30 minutes, and then obtain modified dicyclopentadiene cyanate resin; dicyclopentadiene cyanate viscosity is 30-150mpa·S / 25°C;

[0051] The infrared characterization of modified dicyclopentadiene type cyanate resin is as follows: IR(KBr): 1742(-NH-C(=O)-NH-), 1732(-COO-), 1562 / 1367(triazine ring), 1177(-O-Si-C-)cm -1 ;2271cm -1 At-OCN disappeared, 1742cm -1 -NH-C(=O)-NH- is a strong absorption peak, and the amino group on the modifying agent has undergone block polymerization with dicyclopentadiene cyanate.

Embodiment 2

[0053] The preparation method of the modified dicyclopentadiene type cyanate resin with low hygroscopicity is:

[0054] Weigh 10g of dicyclopentadiene-type cyanate into a three-necked flask equipped with an electric stirring device, add 1.5g of modifier D, heat up to 90°C, keep stirring and mix for 20min, then add 0.3g of catalyst dilauric acid For dibutyltin, heat up to 150°C, keep stirring at constant temperature to carry out curing reaction for 45 minutes, and then obtain a modified dicyclopentadiene cyanate resin; the viscosity of dicyclopentadiene cyanate is 30-150mpa·S / 25°C;

[0055] The infrared characterization of modified dicyclopentadiene type cyanate resin is as follows: IR(KBr): 1742(-NH-C(=O)-NH-), 1732(-COO-), 1562 / 1367(triazine ring), 1177(-O-Si-C-)cm -1 ;2271cm -1 At-OCN disappeared, 1742cm -1 -NH-C(=O)-NH- is a strong absorption peak, and the amino group on the modifying agent has undergone block polymerization with dicyclopentadiene cyanate.

Embodiment 3

[0057] The preparation method of the modified dicyclopentadiene type cyanate resin with low hygroscopicity is:

[0058] Weigh 10g of dicyclopentadiene-type cyanate into a three-necked flask equipped with an electric stirring device, add 1.2g of modifier D, heat up to 90°C, keep stirring and mix for 20min, then add 0.2g of catalyst dilauric acid Dibutyltin, heat up to 145°C, keep stirring at constant temperature for curing reaction for 35 minutes, and then obtain modified dicyclopentadiene cyanate resin; the viscosity of dicyclopentadiene cyanate is 30-150mpa·S / 25°C

[0059] The infrared characterization of modified dicyclopentadiene type cyanate resin is as follows: IR(KBr): 1742(-NH-C(=O)-NH-), 1732(-COO-), 1562 / 1367(triazine ring), 1177(-O-Si-C-)cm -1 ;2271cm -1 At-OCN disappeared, 1742cm -1 -NH-C(=O)-NH- is a strong absorption peak, and the amino group on the modifying agent has undergone block polymerization with dicyclopentadiene cyanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com