Patents

Literature

121results about How to "With low temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper super-hydrophobic surface with decay resistance and preparation method thereof

InactiveCN103085380AAcid resistantAlkali resistantLiquid/solution decomposition chemical coatingSpecial surfacesTemperature resistanceStructural stability

The invention discloses a super-hydrophobic surface of a metal copper micron array and a preparation method thereof. The method comprises the steps of firstly, building a coarse structure of micro-size copper on a metal substrate by chemical deposition; then carrying out hydrophobic treatment on the surface of a self-assembled low-surface energy matter to cover a layer of hydrophobic film on the coarse structure, so as to obtain the super-hydrophobic metal copper surface. The metal copper surface prepared by the method disclosed by the invention has an excellent super-hydrophobic property; the contact angle with water drops can achieve 156 degrees; the rolling angle is smaller than 1 degree; meanwhile, the copper hydrophobic surface has a good surface structure stability, has excellent performances such as acid resistance, alkali resistance, organic solvent resistance, low temperature resistance, and high temperature resistance, and can meet the requirements of the industrial field on the metal copper super-hydrophobic surface. The technique has the advantages that any template is not needed; complicated equipment is not needed; and the super-hydrophobic surface has no special requirements on the shape of a substrate and is suitable for industrial mass production.

Owner:SHANGHAI JIAO TONG UNIV

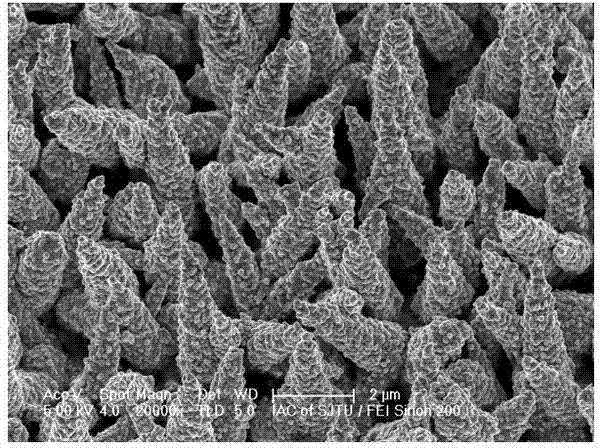

Copper-silver micro-nano multi-stage structure super-hydrophobic surface and production method thereof

InactiveCN103588164AAcid resistantAlkali resistantSemi-permeable membranesFixed microstructural devicesMicro nanoSilver ion

The invention discloses a copper-silver micro-nano multi-stage structure super-hydrophobic surface formed on a metal base surface. The copper-silver micro-nano multi-stage structure super-hydrophobic surface comprises a copper-sliver micro-nano multi-stage structure and a hydrophobic film. The hydrophobic film is self-fitted on the surface of the copper-sliver micro-nano multi-stage structure. The copper-sliver micro-nano multi-stage structure comprises a plurality of copper-sliver micro-nano cones which longitudinally grow perpendicular to a metal base and which are tightly arranged. The hydrophobic film is self-composed of low surface energy material. Compared with common self-assemblies, the copper-silver micro-nano multi-stage structure super-hydrophobic surface has the advantages that sulfydryl of hydrophobe long-chain mercaptan and outermost silver ions of the copper-sliver micro-nano multi-stage structure form a coordinate bond having a large stable constant, and accordingly, the copper-silver micro-nano multi-stage structure super-hydrophobic surface is well stable, resistant to acid, alkali, organic solutions, high temperature and low temperature.

Owner:SHANGHAI JIAO TONG UNIV

Epoxy modified polyurethane cryogenic adhesive

InactiveCN101298548AWater resistantWith low temperature resistancePolyureas/polyurethane adhesivesEpoxy resin adhesivesSolid componentEpoxy

The invention discloses an epoxy modified polyurethane ultra-low temperature resistant adhesive. The components and the mass percentage of the adhesive are: 30-50 percent of polyurethane modified prepolymer, 5-15 percent of epoxy resin, 10-20 percent of solvent, 1-15 percent of chain extender, and 30-50 percent of filler. First, uniformly blend all the liquid components, and then add solid components to uniformly blend, and pack after grinding on a grinding mill. The epoxy modified polyurethane ultra-low temperature resistant adhesive of the invention has the nature of ultra-low temperature resistance, the mechanical property of which can remain stabilized even being used for a long term at 200 DEG C below zero, and has the advantages of high bond strength and shear strength as well as good cohesiveness and corrosion resistance.

Owner:广东海拓创新精密设备科技有限公司

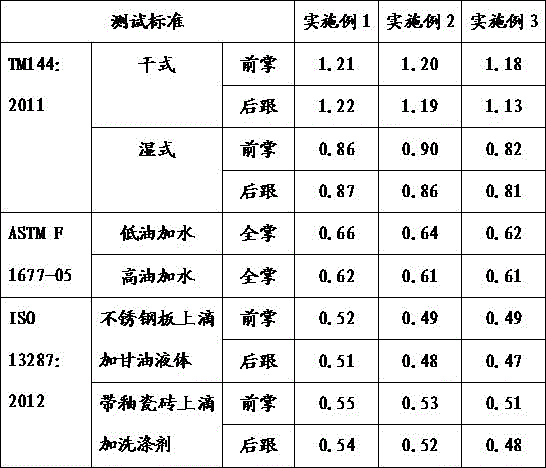

Antiskid rubber outsole and manufacturing method of same

ActiveCN106589491AImprove grip performanceEasy to processSolesDomestic footwearPolymer scienceVulcanization

The invention relates to shoe soles and provides an antiskid rubber outsole which is specially used on surfaces containing surfactants and oil stains and a manufacturing process of the outsole. The antiskid rubber outsole is prepared from nitrile butadiene rubber, integrated rubber, solution polymerized styrene-butadiene rubber, modified liquid polybutadiene rubber, fumed silica, a plasticizer, an anti-aging agent, petroleum resin, a white smoke activator, a silane coupling agent, polyethylene wax, zinc oxide, sulfur, and a vulcanization accelerator. The antiskid rubber outsole has excellent antiskid effect not only on a regular dry or wet surface or a surface containing surfactants, for example, detergents, and an oil stain surface. People can walk safely and stably on the outsoles. The manufacturing process has simple processes and is easy to carry out, and is suitable for large-scale production.

Owner:MAOTAI FUJIAN SOLES CO LTD +1

Liquid silicon resin foam material and preparation method thereof

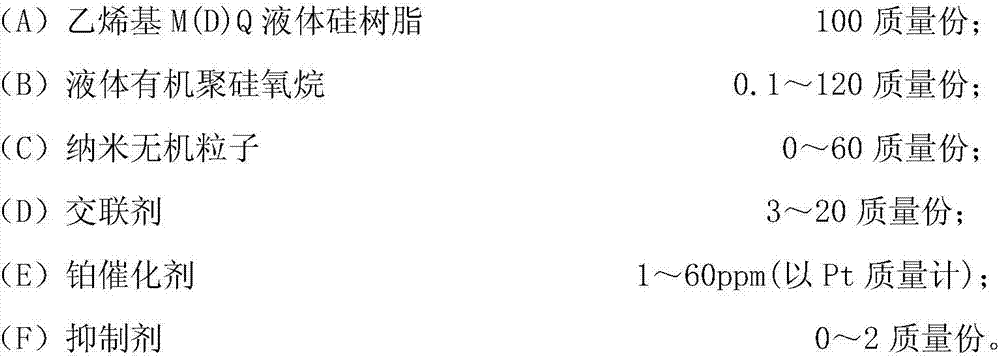

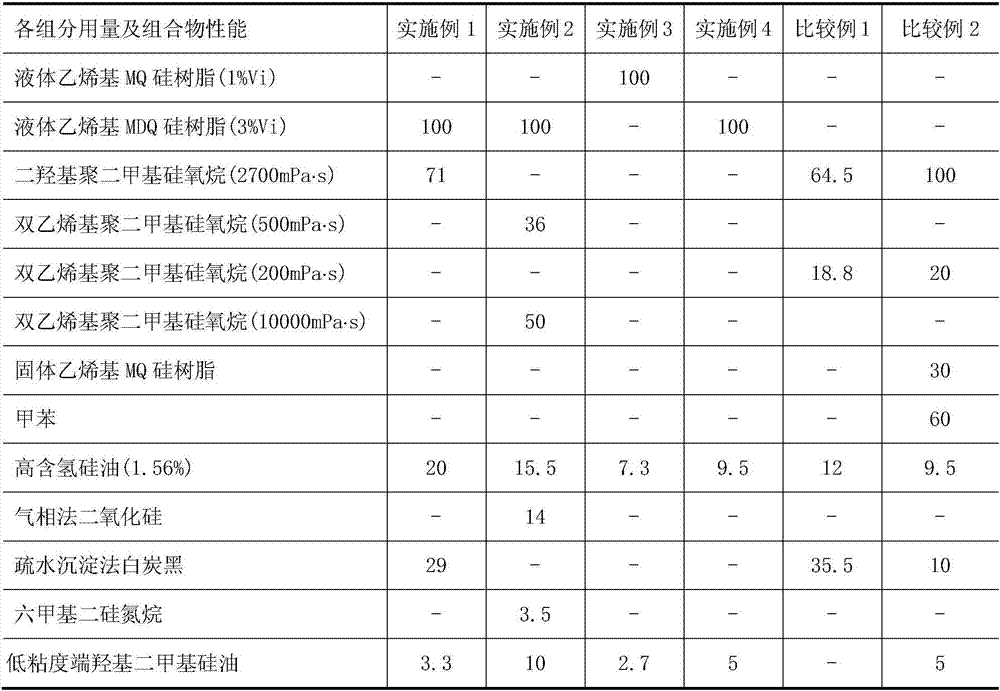

The invention discloses a liquid silicon resin foam material. The liquid silicon resin foam material comprises the following components: (A) 100 parts by mass of vinyl M(D)Q liquid silicon resin; (B)0.1 to 120 parts by mass of liquid organopolysiloxane; (C) 0 to 60 parts by mass of micro-nano inorganic particles; (D) 1 to 30 parts by mass of a crosslinking agent; (E) 1 to 60 ppm of a platinum catalyst (based on the weight of Pt); and (F) 0 to 2 parts of an inhibitor. The invention also discloses a preparation method of the liquid silicon resin foam material. According to the liquid silicon resin foam material obtained by the method, no matter a compression molding forming method or an injection and casting molding method is used, the liquid silicon resin foam material with high mechanicalstrength and good appearance can be obtained.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

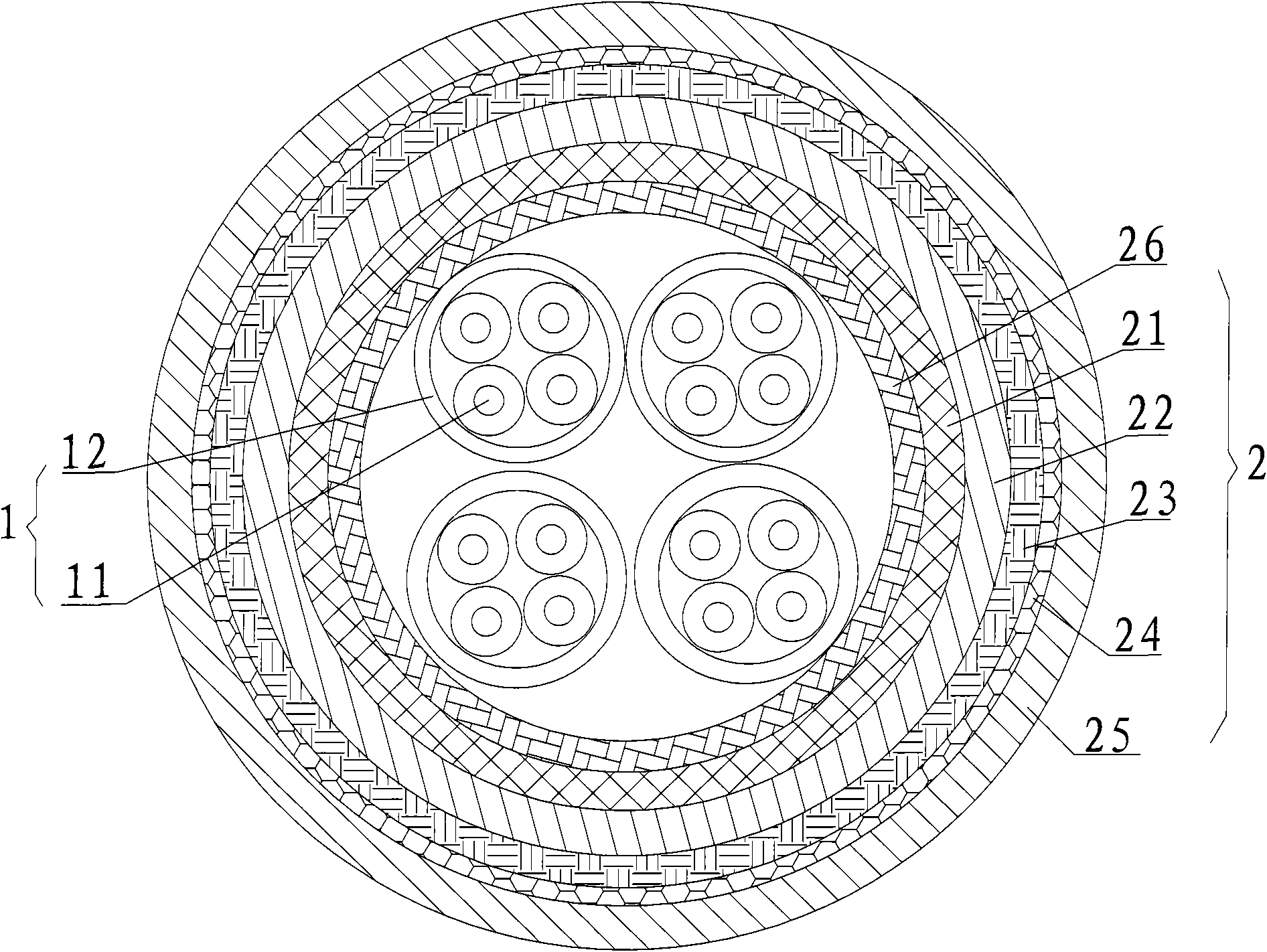

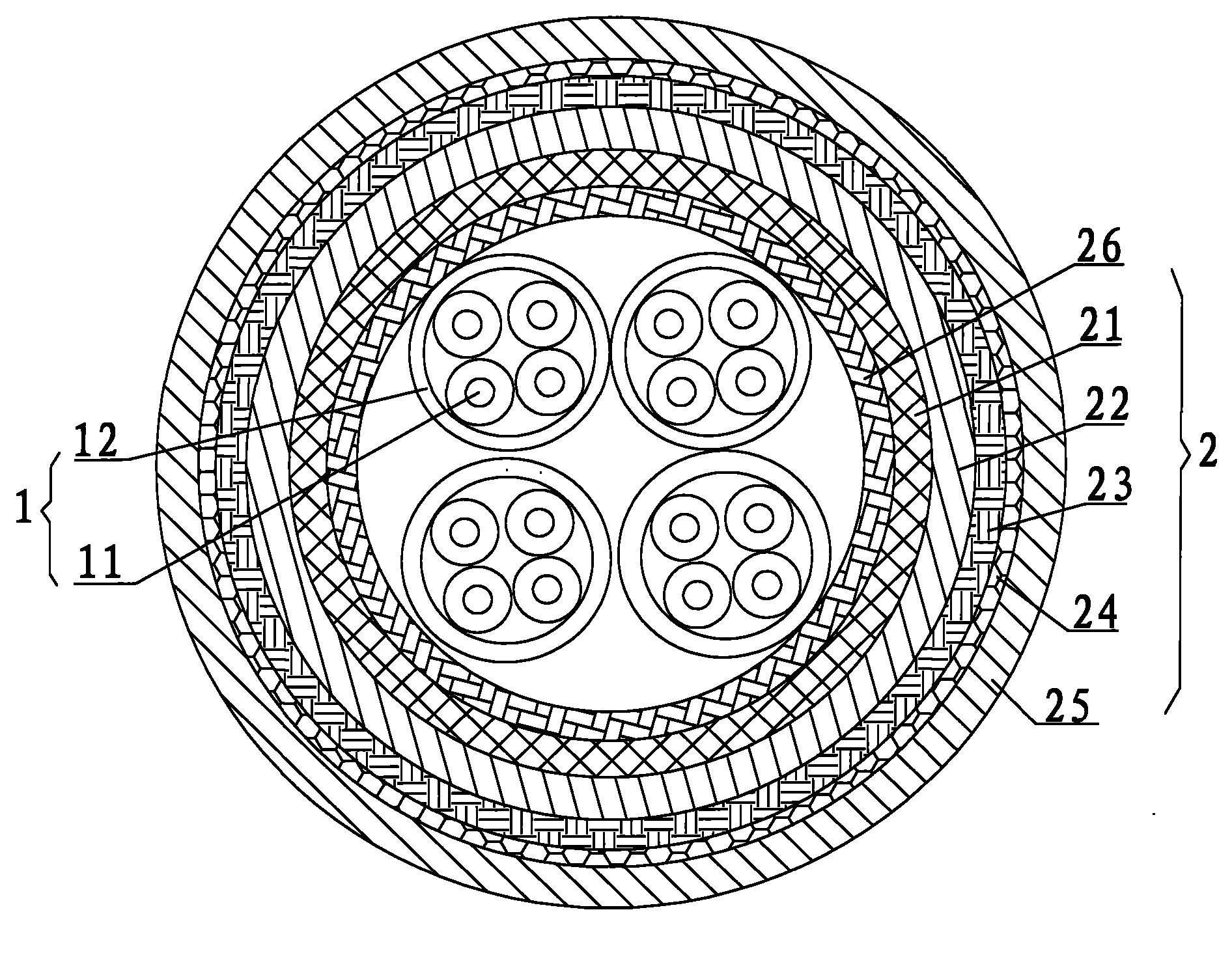

Manufacturing method of cable for high power transmission equipment and cable

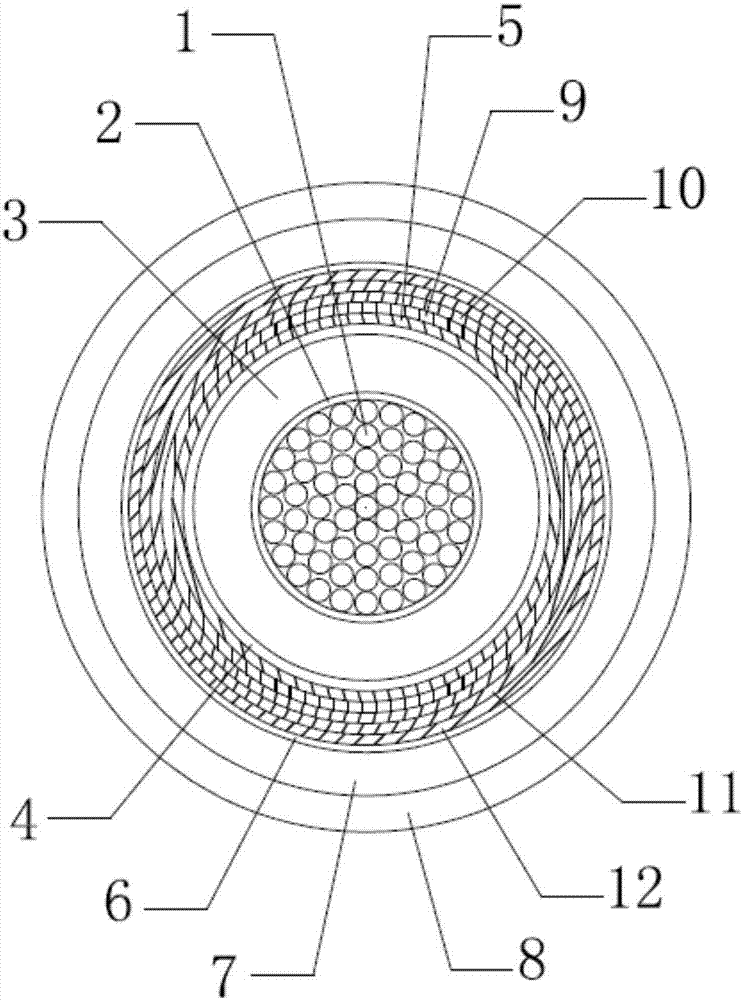

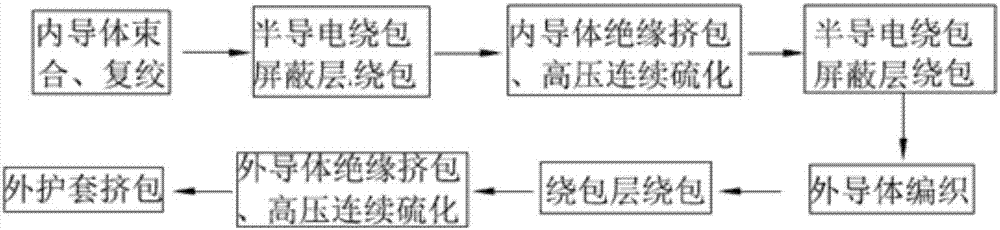

InactiveCN107154285ANo damageReduce weightConcentric cablesPower cables with screens/conductive layersReliable transmissionElectrical conductor

A cable for high power transmission equipment, its structure from inside to outside is: inner conductor, first semiconductive wrapping shielding layer, inner conductor insulation, second semiconducting wrapping shielding layer, outer conductor, wrapping layer, Outer conductor insulation and outer sheath. The insulating layer of the inner conductor is made of silicon rubber; the outer conductor is braided with one or more layers of tinned copper wire; the insulating layer of the outer conductor is made of silicon rubber; the outer sheath layer is made of polyurethane. The manufacturing method of the cable comprises: 1) manufacturing the inner conductor; 2) manufacturing the first semiconductive wrapping shielding layer; 3) manufacturing the inner conductor insulating layer; 4) manufacturing the second semiconductive wrapping shielding layer; 5) manufacturing 6) manufacturing the wrapping layer; 7) manufacturing the insulating layer of the outer conductor; 8) manufacturing the outer sheath layer. In each step, a specific process method is adopted, so that the electrical and mechanical properties of the cable prepared by this method can meet or exceed the detection requirements, so that the cable for high-power transmission equipment can transmit high power safely and reliably, and has the advantages of light weight. , miniaturization, low temperature resistance, good flexibility, small bending radius and other excellent performances, suitable for high electric energy technical equipment.

Owner:JIANGSUSNGSHANG CABLE GROUP

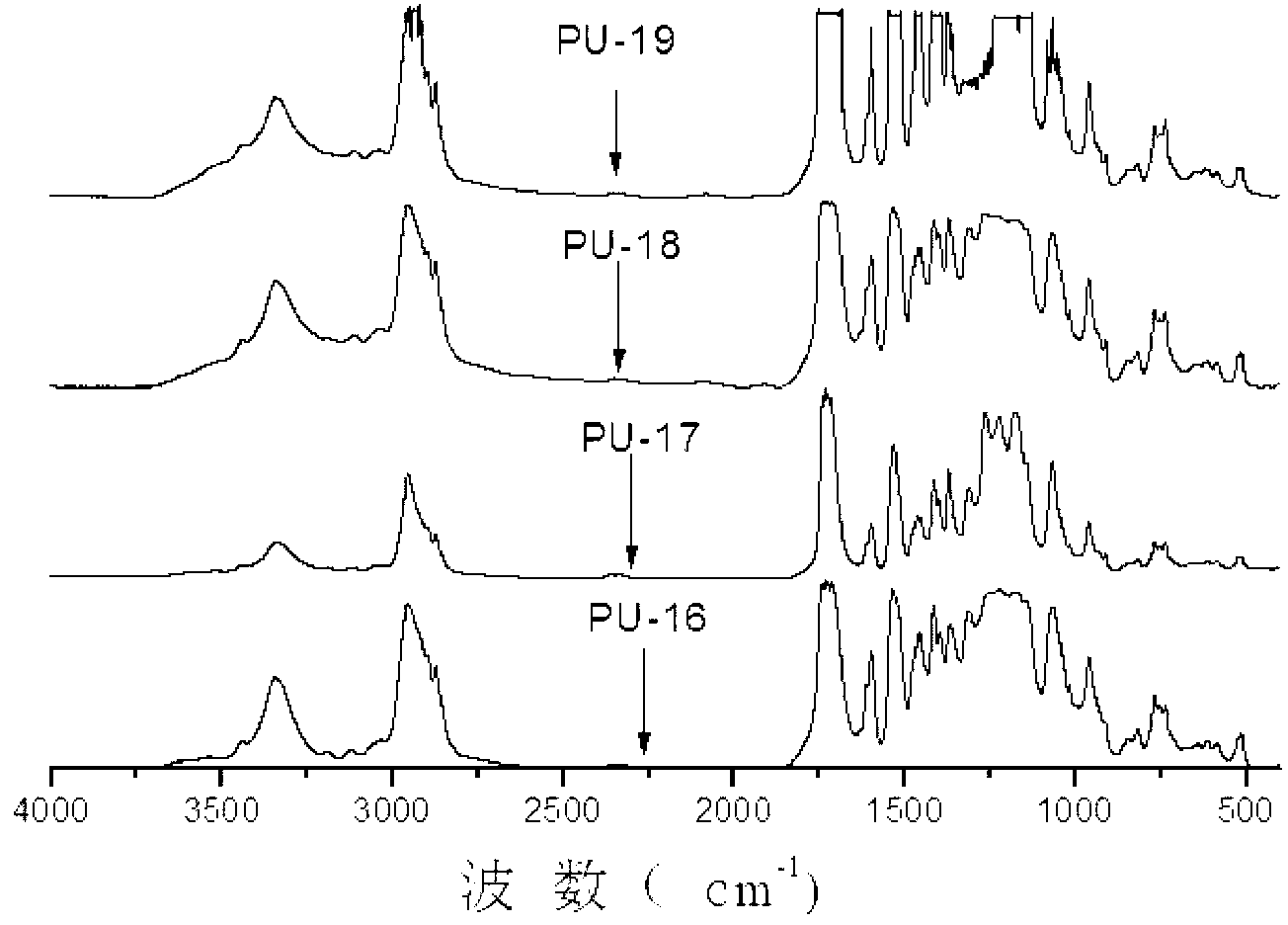

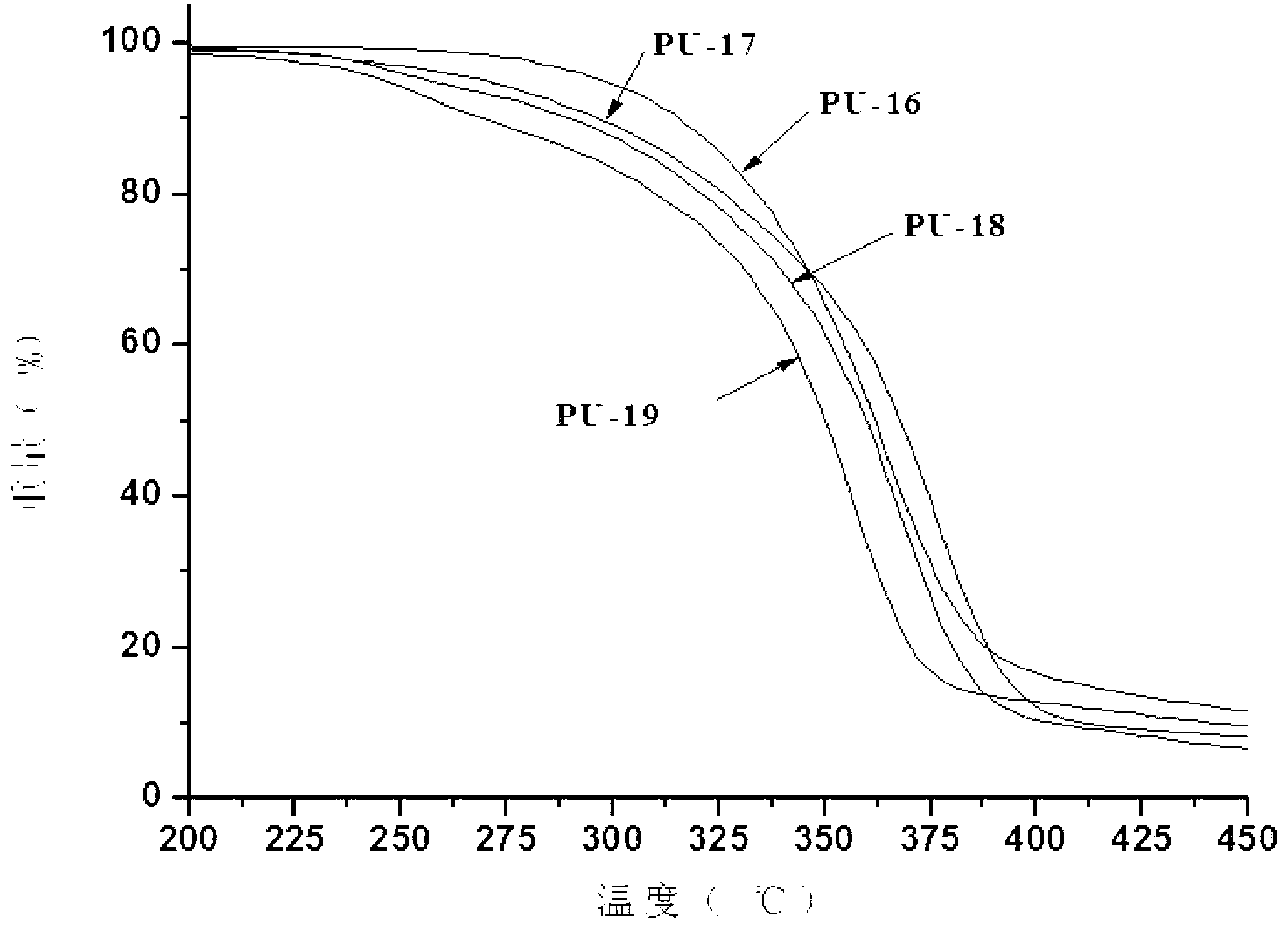

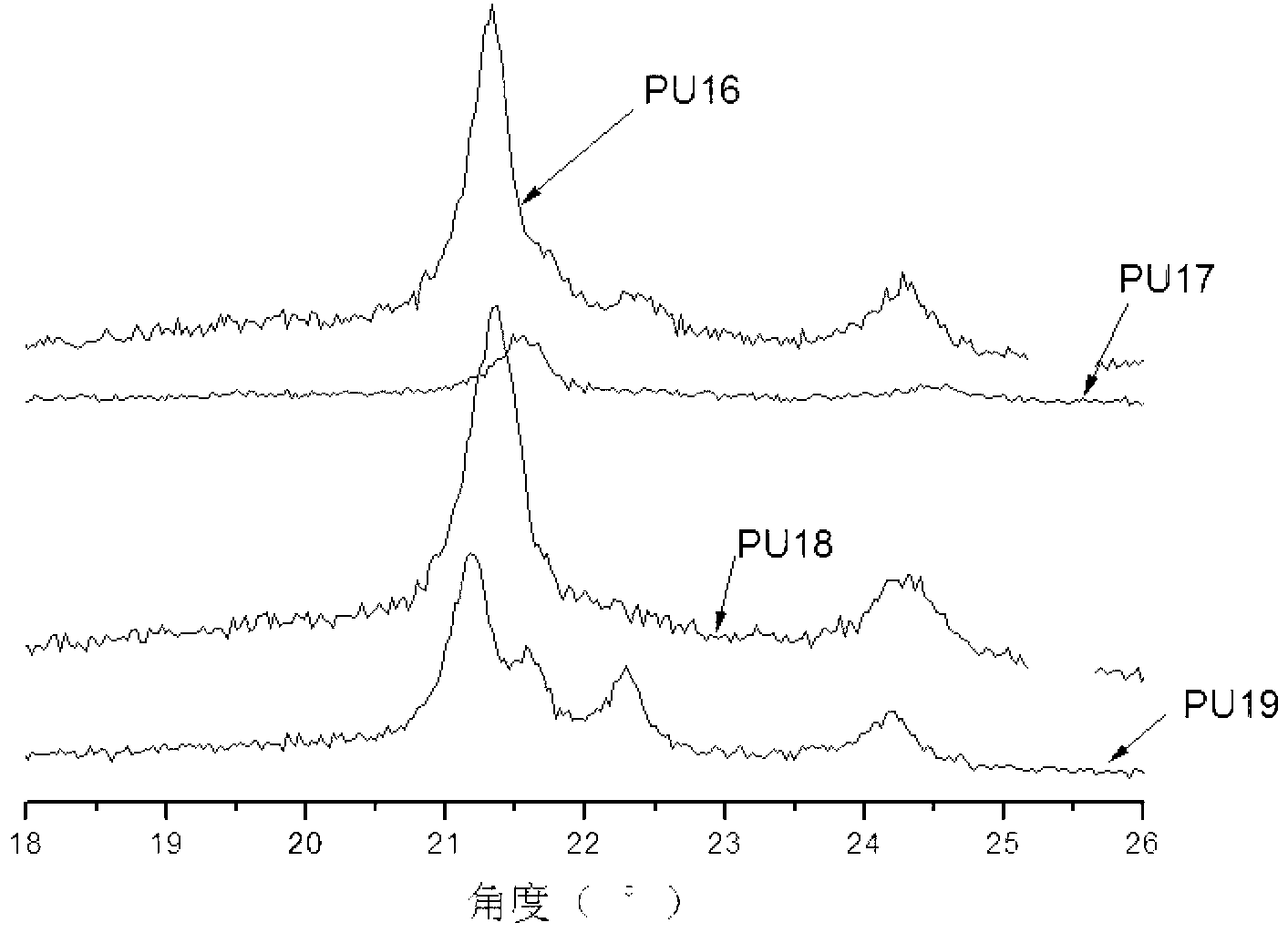

Preparation method of imidazole-containing cationic antistatic polyurethane

The invention discloses a preparation method of imidazole-containing cationic antistatic polyurethane. The preparation method provided by the invention is characterized by comprising the following steps: carrying out a reaction between imidazole and an acrylic acid ester compound at the mole ratio of 1:1-5 to obtain an esterified imidazole derivative; carrying out a reaction between the imidazole ester derivative and 2-bromoethanol at the mole ratio of 1:1-5 to obtain a hydroxyl-terminated imidazole ionic liquid, performing ester interchange between the hydroxyl-terminated imidazole ionic liquid and polyester or polyether glycol so as to obtain dihydroxy-terminiated imidazole cationic polyester or polyether glycol; and finally carrying out a reaction between 1-10 mol of dihydric alcohol with the molecular weight being 90-2000, 1-10 mol of dihydroxy-terminiated imidazole cationic antistatic long-chain dihydric alcohol and 1-20 mol of diisocyanate in a solvent in the presence of a catalyst so as to obtain the cationic antistatic polyurethane with the main chain containing imidazole. The imidazole-containing cationic polyurethane is prepared in the invention. The polyurethane has excellent antistatic performance. Electric property of the polyurethane will not be damaged by alkalinity or acidity, and electroconductibility of the polyurethane is not dependent on environment humidity. Thus, the polyurethane has a wider application field.

Owner:SICHUAN UNIV

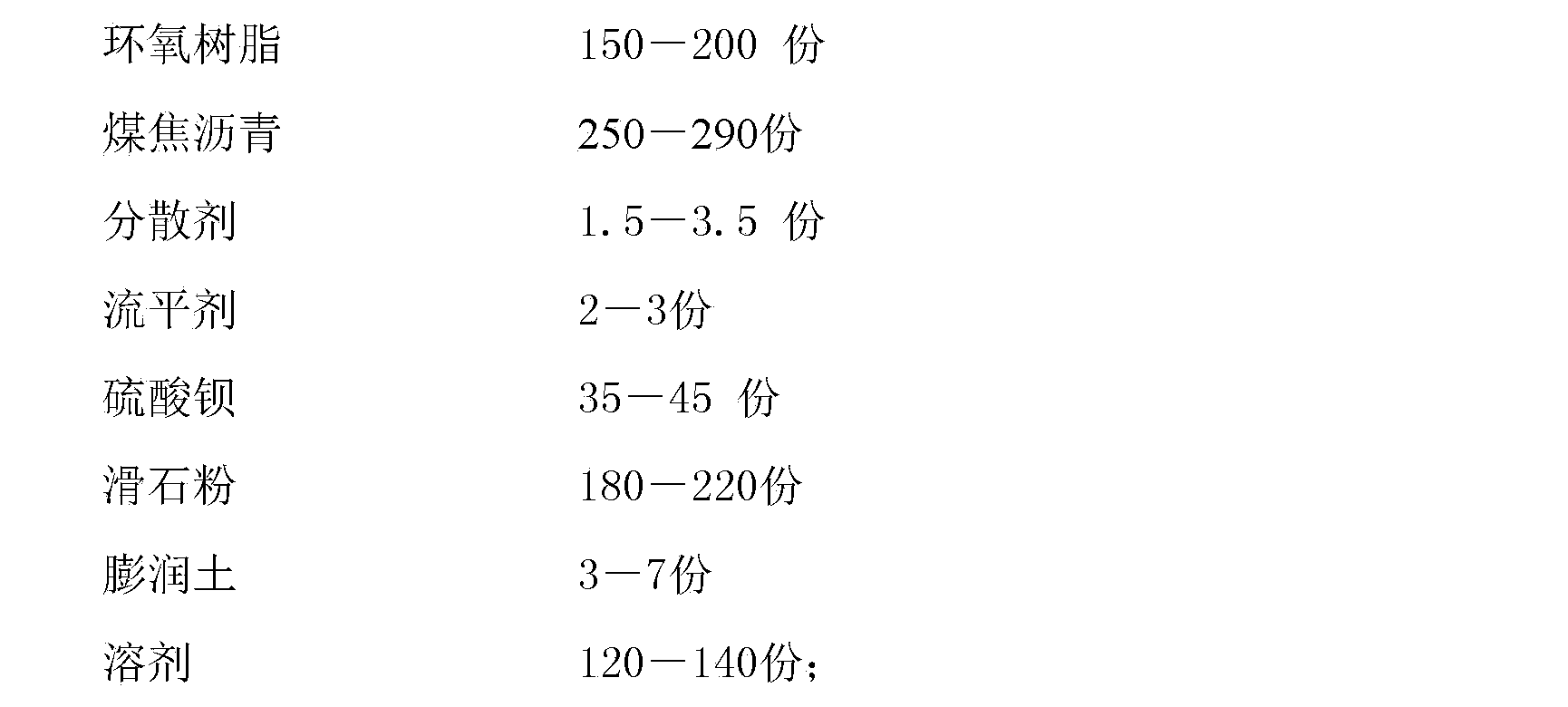

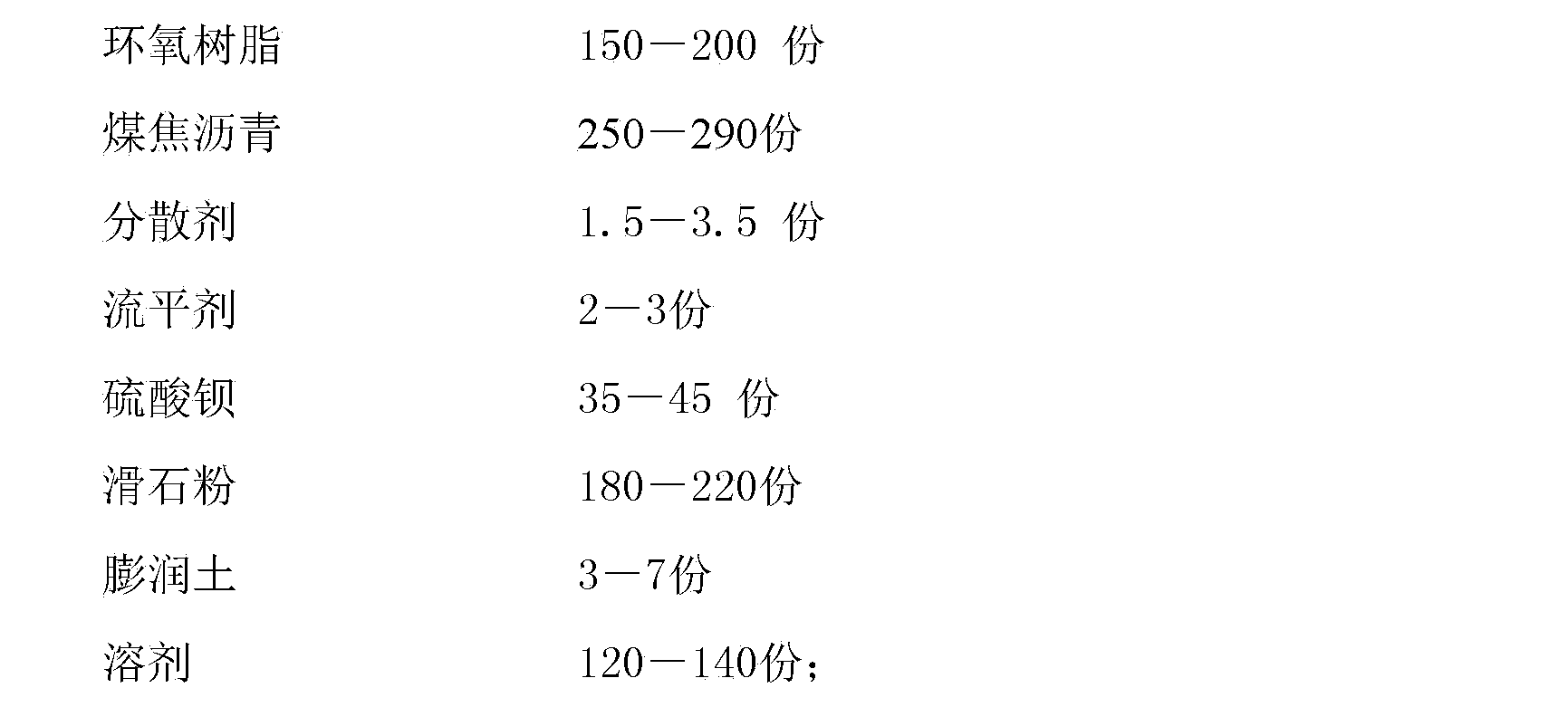

Low temperature resistant winter epoxy coal tar pitch coating

InactiveCN103360948AGood film formingImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyBituminous materials

The invention provides a low temperature resistant winter epoxy coal tar pitch coating comprising a component A and a component B according to a weight ratio of 5-7:1. The component A is prepared from an epoxy resin, coal tar pitch, a dispersing agent, flatting agents, barium sulfate, a talcum powder, bentonite, and solvents in parts by weight; the component B comprises polyamide and xylene according to a weight ratio of 1:1. With combination of the epoxy resin and the coal tar pitch, not only excellent film-forming and corrosion resistance properties of the epoxy resin are exerted, but also the problems of high temperature flow and low temperature cold brittleness of a pitch material are better solved, the coating layer is resistant to low temperature and can be used in winter, and the service life of the coating is prolonged.

Owner:TIANCHANG YINHU PAINT

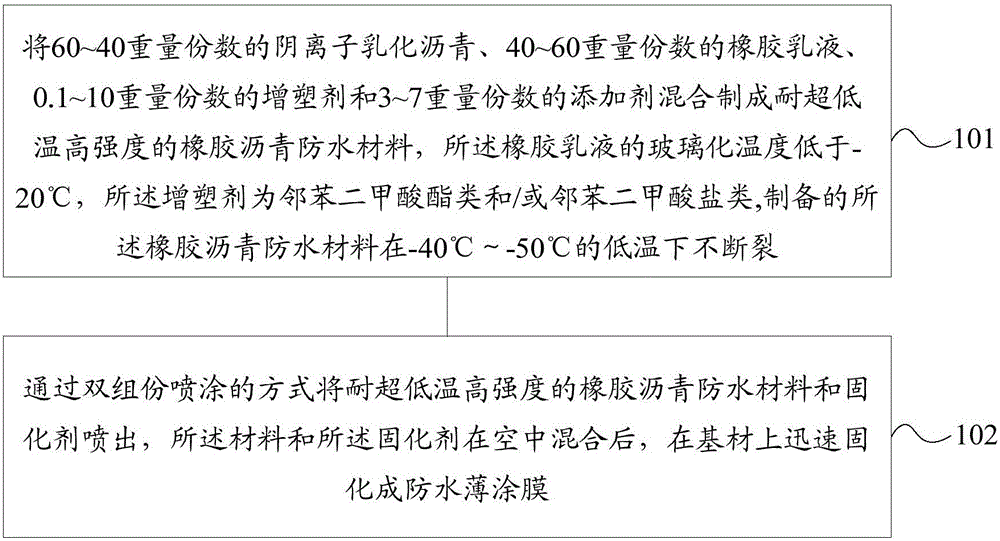

Ultralow-temperature-resistant high-strength rubber asphalt waterproof material, and preparation and construction methods thereof

InactiveCN105860555AFast constructionLow construction environment requirementsBuilding insulationsPolymer sciencePlasticizer

The invention provides an ultra-low temperature resistant and high-strength rubber asphalt waterproof material and a preparation and construction method thereof. The ultra-low temperature resistant and high-strength rubber asphalt waterproof material is composed of anionic emulsified asphalt, rubber emulsion, plasticizer and additives, the weight parts of the anionic emulsified asphalt is 60-40, and the weight parts of the rubber emulsion is 40 ~60, the parts by weight of the plasticizer are 0.1~10, the parts by weight of the additives are 3~7; the glass transition temperature of the rubber emulsion is lower than -20°C; the plasticizer is o Phthalate esters and / or phthalates; the material does not break at a low temperature of -40°C to -50°C after being cured into a film.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

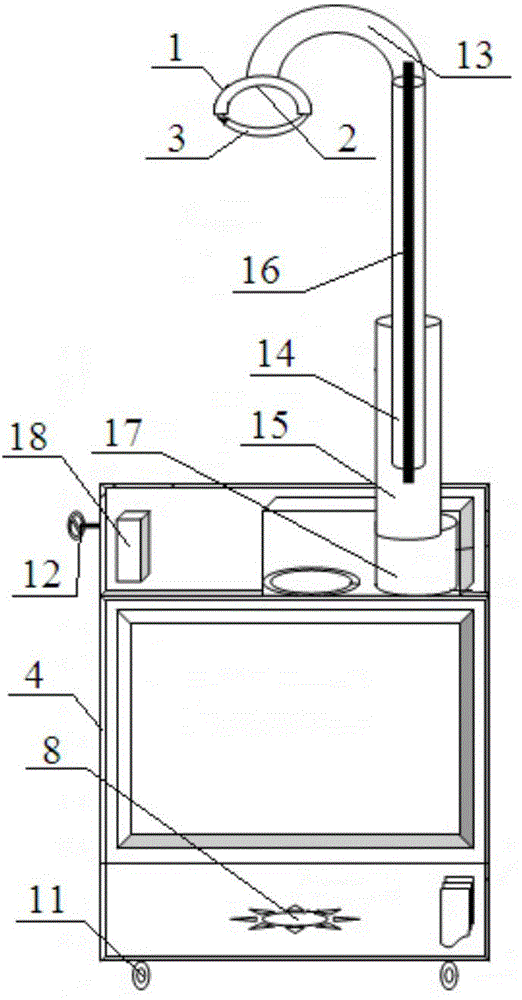

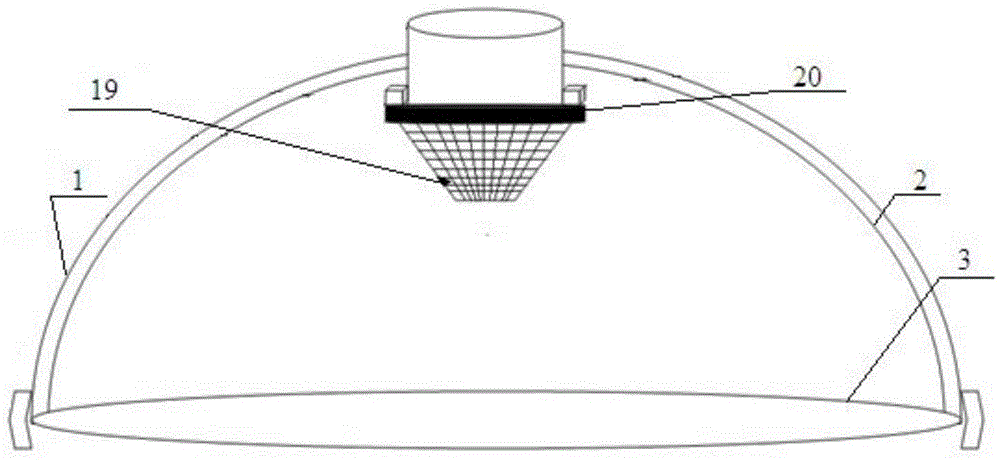

Biophysical warm-tonification medicinal moxibustion instrument adopting traditional Chinese medicine

InactiveCN104666072AEffective preservationSolve the problem of unclear acupoint recognitionDevices for heating/cooling reflex pointsDispersed particle filtrationInsulation layerMedicine

A biophysical warm-tonification medicinal moxibustion instrument adopting traditional Chinese medicine comprises a lead-in device, a medicine reaction chamber, a telescopic device and a smoke purification device. The lead-in device comprises a semispherical cover with the open side down, a reflection board is arranged on the inner side of the cover, an ash isolation net is arranged at the bottom end of the cover and fixedly clamped to the cover, a cavity formed between the ash isolation net and the reflection board serves as a medicine reaction chamber, and a bag filled with traditional Chinese medicine is put in the medicine reaction chamber. The top end of the medicine reaction chamber is provided with a smoke outlet which is communicated with a smoke inlet of the telescopic device, a smoke outlet of the telescopic device is communicated with a smoke inlet of the smoke purification device, and the bottom of the smoke purification device is provided with an air outlet. The instrument is characterized in that a heat insulation layer is arranged between the cover and the reflection board. The biophysical warm-tonification medicinal moxibustion instrument adopting the traditional Chinese medicine has the advantages that the instrument is flexible in use and convenient to operate, heat generated by burning of the bag filled with the traditional Chinese medicine is less prone to dispersion and can act on acupoints for a long time, and curative effects are multiplied due to concentrated lasting fire power.

Owner:刘瑜

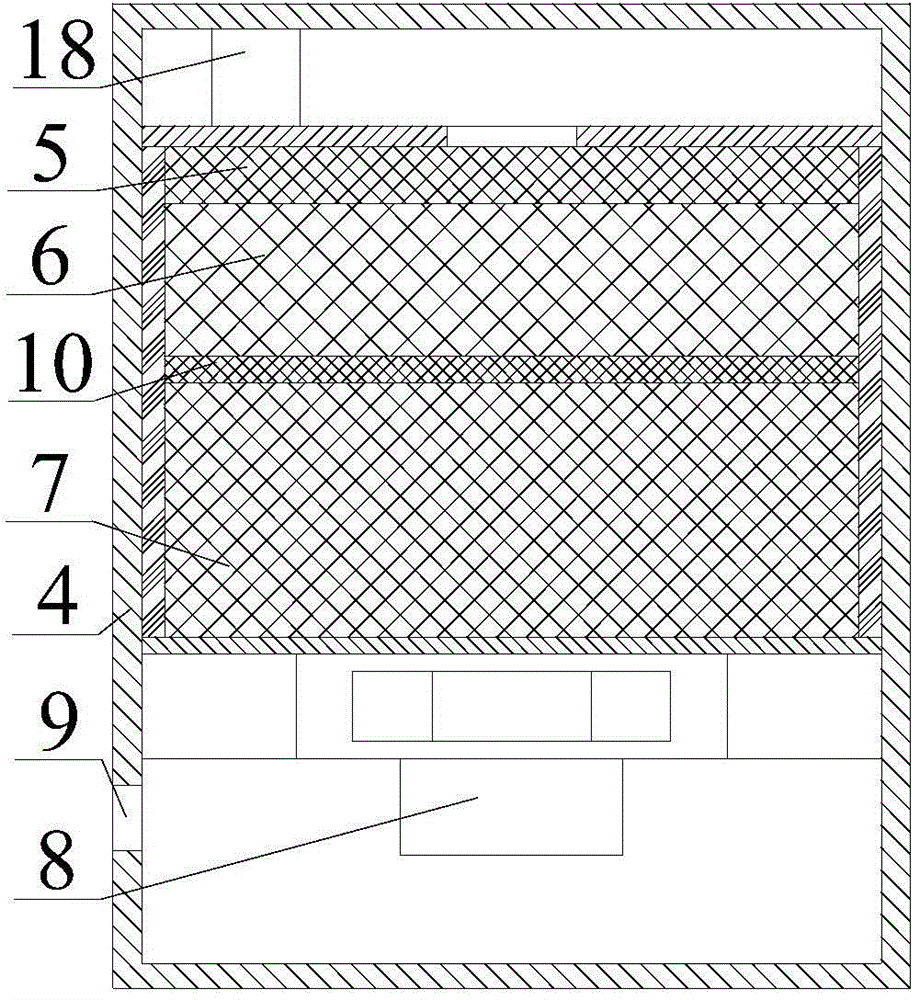

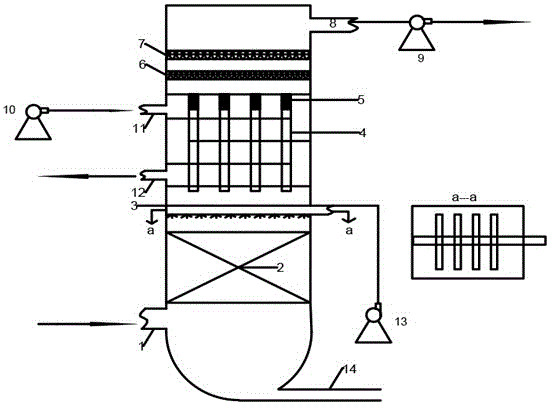

Integrated dust-fog removing device and dust-fog removing method for wet desulphurization system

The invention relates to the field of flue gas treatment, in particular to an integrated dust-fog removing device and a dust-fog removing method for a wet desulphurization system. According to the device, the principle of glass tube condensation, the principle of screen filtration and the characteristic of different porosities of polytetrafluoroethylene (PTFE) monofilament fibers are utilized to realize the simultaneous efficient purification of original micron-grade solid smoke dust fine particles with different particle sizes and micron-grade fogdrop particles with different particle sizes in flue gas of the wet desulfurization system. After the device is adopted, the micron-grade solid dust and the micron-grade fogdrops in the flue gas can be efficiently removed in an integrated way; furthermore, the device is compact in structure, is easily installed in the wet desulphurization system of the flue gas, and is simple and convenient to operate, thus having wide market prospect and higher promotional value. The device and the method which are provided by the invention are suitable for large-load and high-power wet flue gas desulphurization treatment systems of coal in a power plant, the coal chemical industry, and the like.

Owner:LIAONING TECHNICAL UNIVERSITY

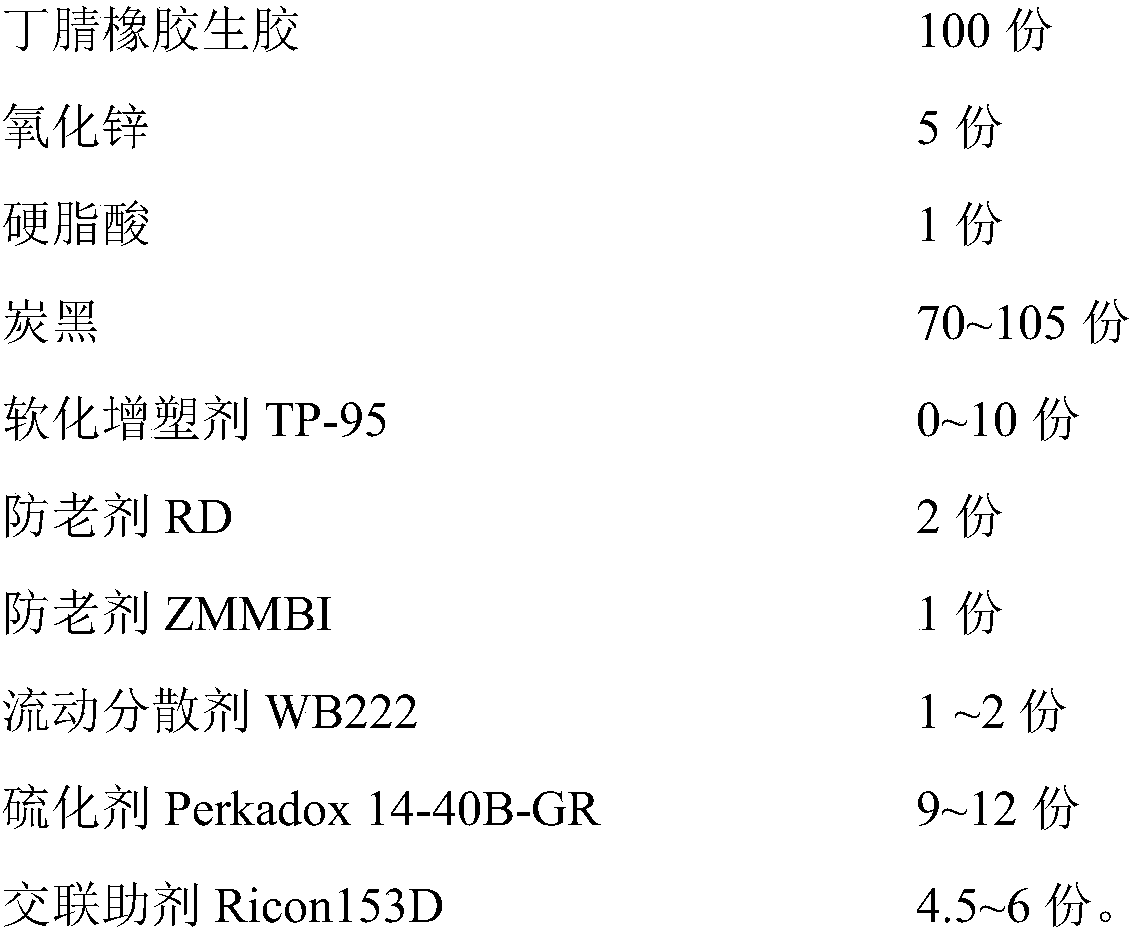

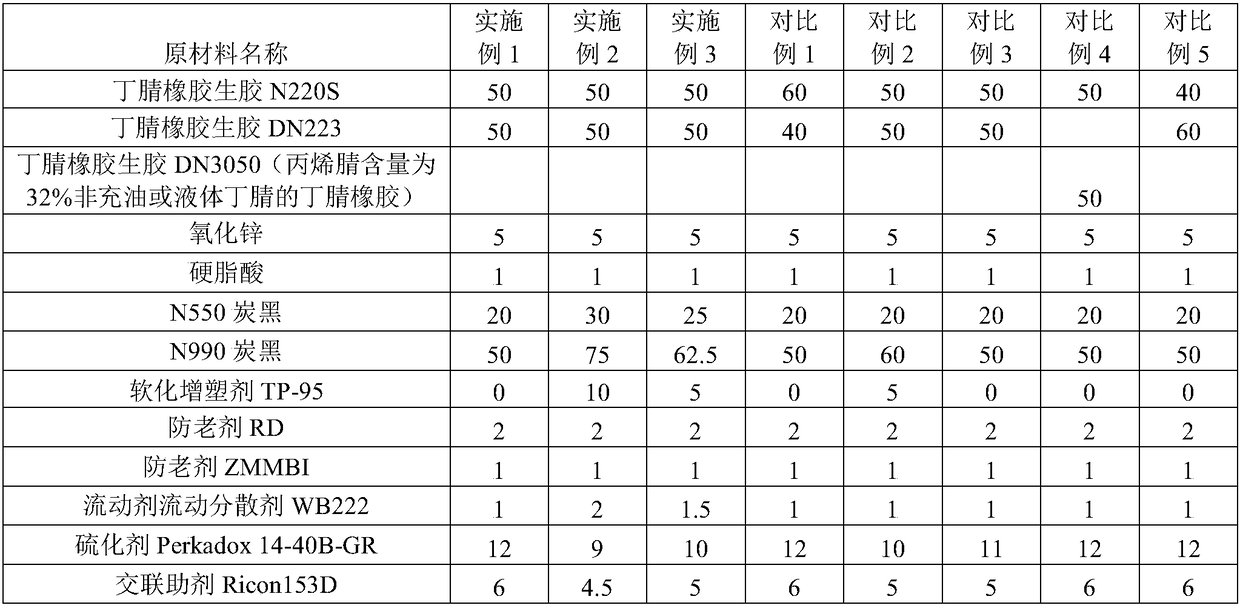

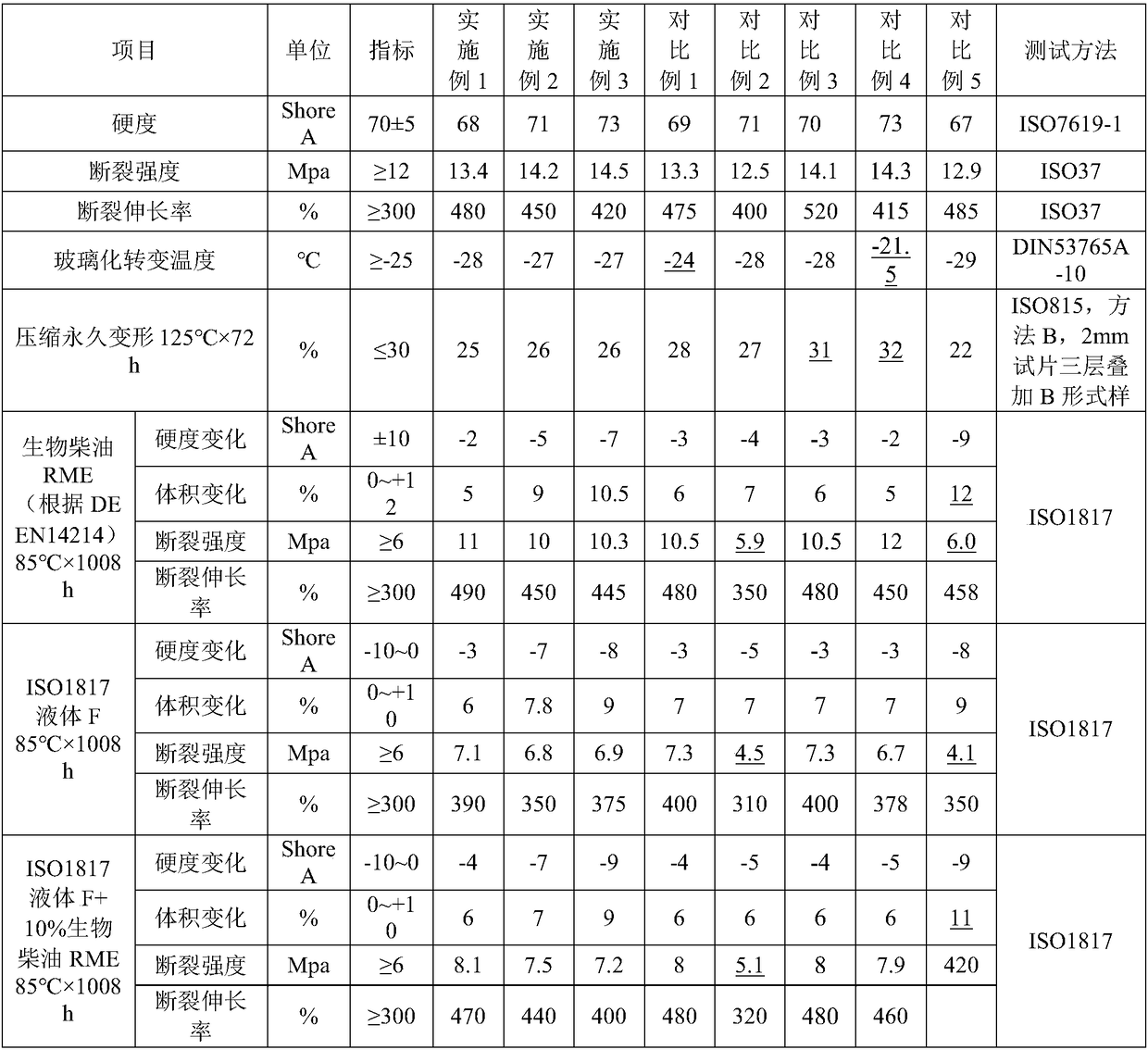

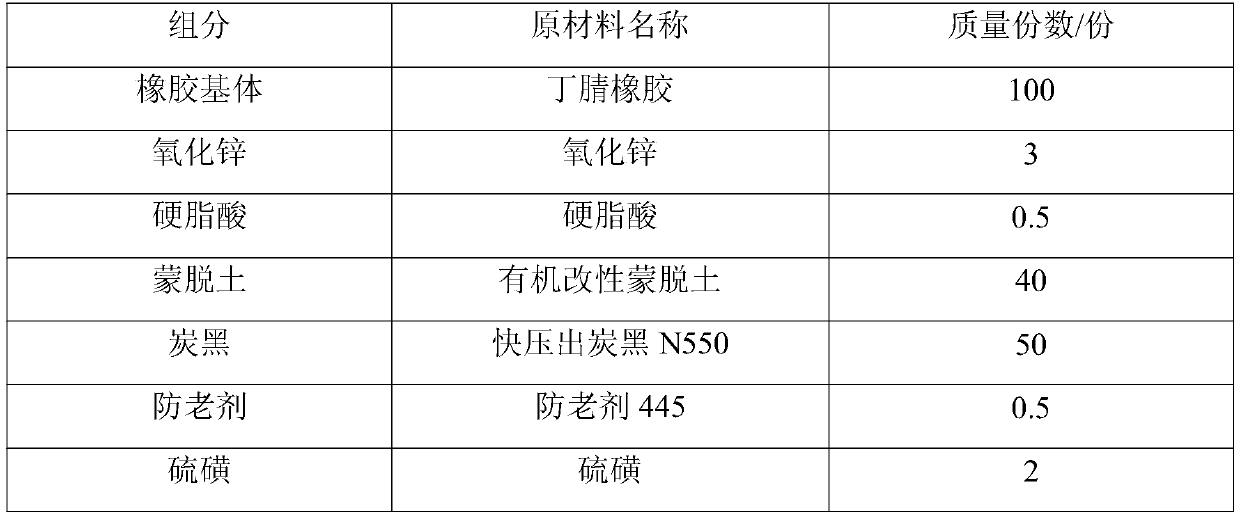

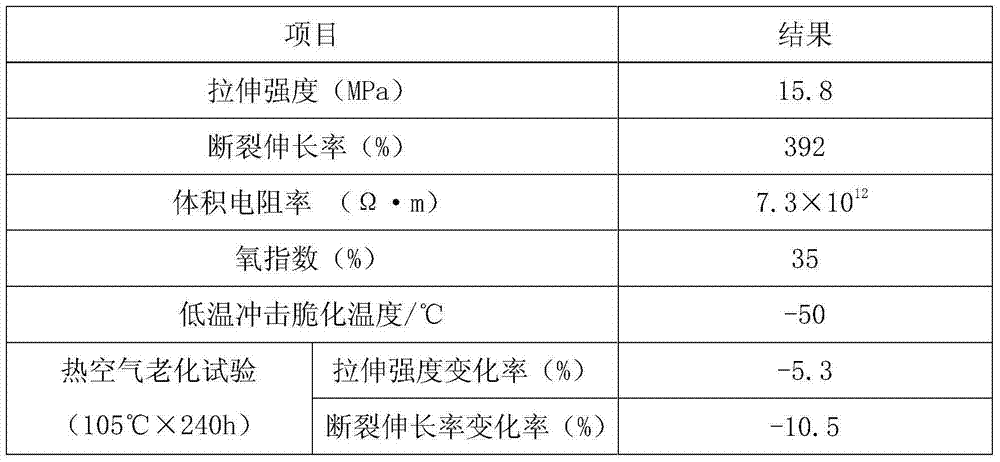

Diesel oil-resisting low pressure change nitrile rubber material and preparation method thereof

ActiveCN108424557AGood oil resistanceResistance to erosion and swellingRubber materialPolymer science

The invention discloses a diesel oil-resisting low pressure change nitrile rubber material and a preparation method thereof and belongs to the technical field of rubber. The rubber material is prepared from the following components: 100 parts of raw nitrile rubber, 5 parts of zinc oxide, 1 part of stearic acid, 70 to 105 parts of carbon black, 0 to 10 parts of a softened plasticizer TP-95, 2 partsof an antiager RD, 1 part of an antiager ZMMBI, 1 to 2 parts of a flow dispersant WB222, 9 to 12 parts of a vulcanizing agent Perkadox 14-40B-GR and 4.5 to 6 parts of a crosslinking agent Ricon153D.According to the preparation method disclosed by the invention, by reasonably matching the components of the raw nitrile rubber, nitrile rubber with high-content acrylonitrile is combined with the rawnitrile rubber filled with liquid nitrile and containing middle-content acrylonitrile; and the prepared nitrile rubber material has the characteristics of excellent diesel oil resistance, low compaction set and low temperature resistance.

Owner:南京金三力高分子科技有限公司

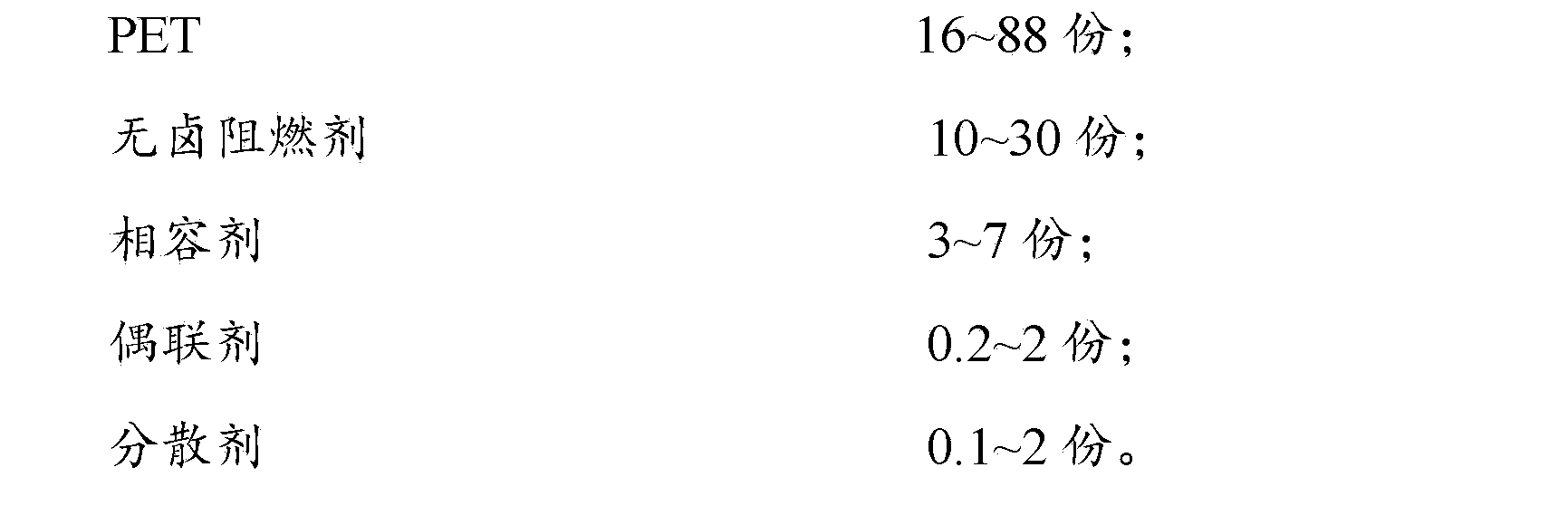

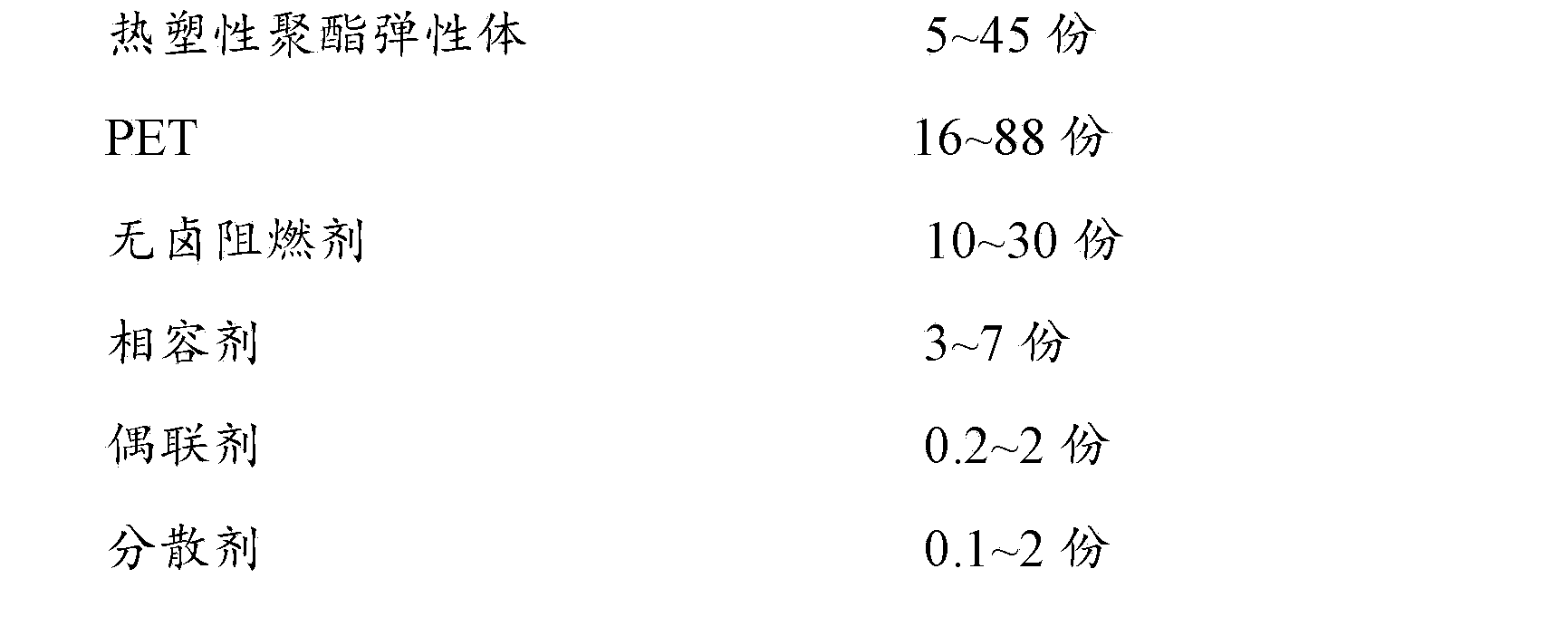

PET composite material and preparation method thereof

InactiveCN103435978AImprove low temperature resistanceAchieving Low Temperature ResistancePolyesterElastomer

The invention discloses a PET composite material and a preparation method thereof. The composite material is composed of, by weight, 5-45 parts of a thermoplastic polyester elastomer, 16-88 parts of PET, 10-30 parts of a halogen-free flame retardant, 3-7 parts of a compatilizer, 0.2-2 parts of a coupling agent and 0.1-2 parts of a dispersing agent. Low temperature resistance of the PET composite material is obviously enhanced by adding the thermoplastic polyester elastomer in PET; flame retardation of the composite material is significantly improved by adding the halogen-free flame retardant; and the compatibility among the thermoplastic polyester elastomer, PET and the halogen-free flame retardant are modified by the compatilizer and the coupling agent, so that influence of the halogen-free flame retardant to the low temperature resistance of the composite material is effectively eliminated; and the PET composite material has the low temperature resistance and the flame retardation at the same time. The PET composite material provided by the invention is simple in preparation process, low in cost, high in production efficiency and very suitable for industrial production.

Owner:ANHUI KEJU NEW MATERIALS

Fiber toughened polyethylene wrapping film, and preparation method thereof

The invention discloses a fiber toughened polyethylene wrapping film. The fiber toughened polyethylene wrapping film is composed of, by weight, 1 to 2 parts of sodium diacetate, 100 to 110 parts of linear low density polyethylene, 1 to 2 parts of p-aminobenzene sulfonic acid, 7 to 10 parts of aluminium isopropoxide, 2 to 3 parts of cyanoethyl cellulose, 3 to 5 parts of isopropyl palmitate, 4 to 6 parts of cellulose phosphate, 0.7 to 2 parts of polybenzimidazole, 4 to 6 parts of oxidized polyethlene wax, 0.1 to 0.2 part of methyl stannum mercaptide, 3 to 4 parts of diacetone alcohol, 0.2 to 0.6 part of dialkyl hydroquinone, 1 to 2 parts of alkanolamide, 2 to 3 parts of antimonous oxide, 0.4 to 1 part of isothiazolinone, 1 to 2 parts of calcium propionate, and 10 to 13 parts of diatomite. According to a preparation method, a plurality of kinds of fiber are added, so that the strength and toughness of the fiber toughened polyethylene wrapping film are increased greatly, broken is not easily caused, the fiber toughened polyethylene wrapping film possesses both low temperature resistance and high temperature resistance, application effect is excellent, no pollution is caused, and cost is application is reduced.

Owner:宁波大名包装材料科技有限公司

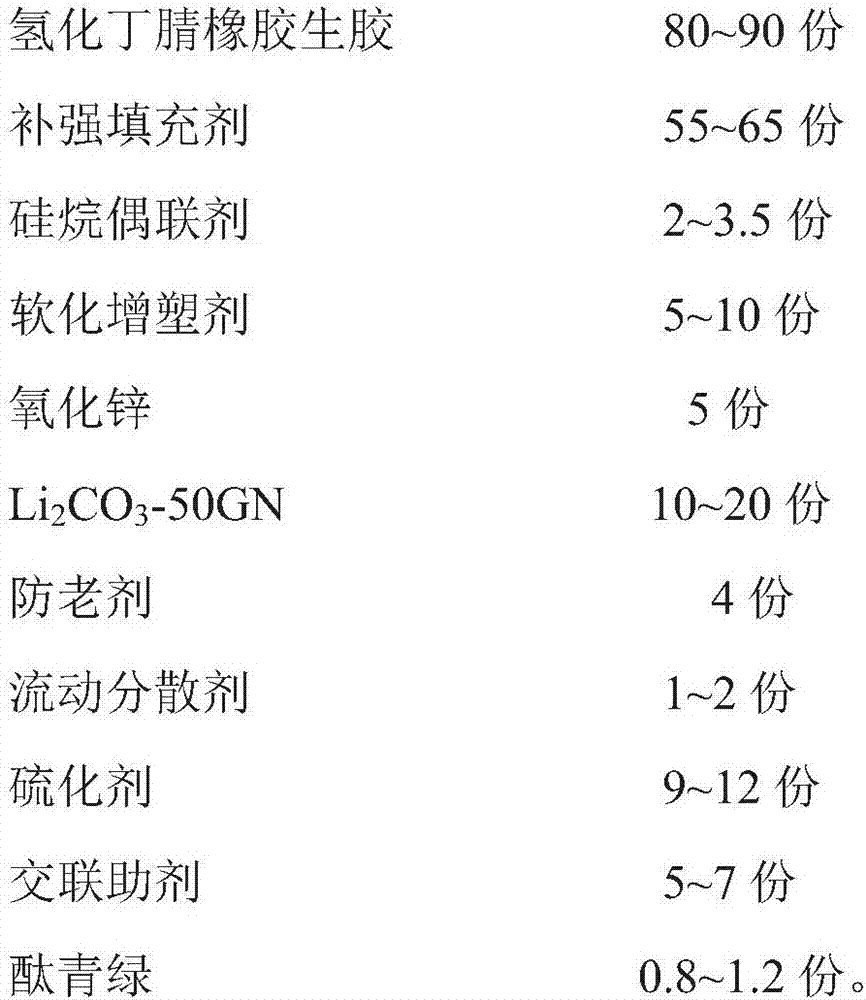

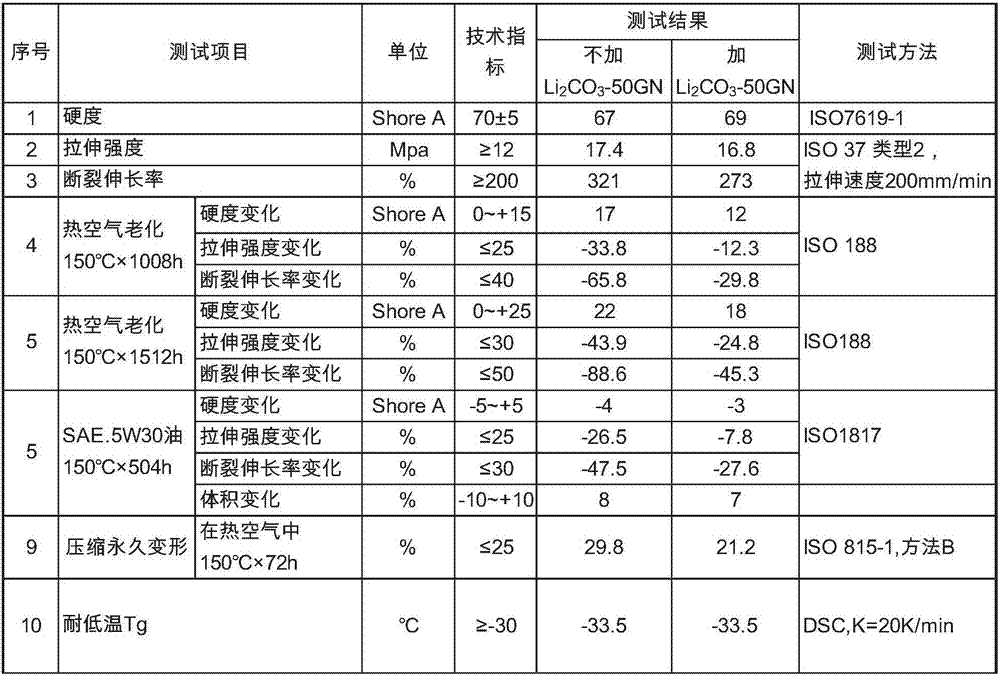

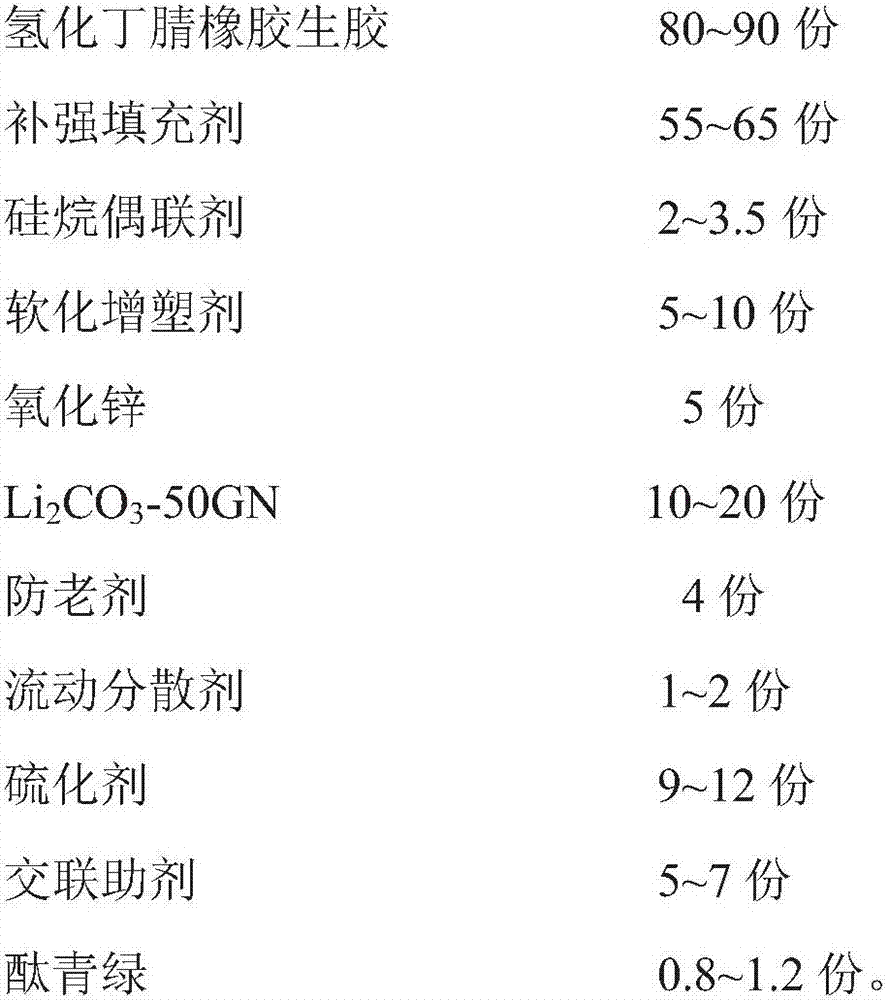

High temperature resistant color hydrogenated butadiene-acrylonitrile rubber material and preparing method thereof

The invention discloses a high temperature resistant color hydrogenated butadiene-acrylonitrile rubber material and a preparing method thereof, and belongs to the technical field of rubber. The high temperature resistant color hydrogenated butadiene-acrylonitrile rubber material is prepared from, by weight, 80-90 parts of hydrogenated butadiene-acrylonitrile rubber crude rubber, 55-65 parts of reinforcing filler, 2-3.5 parts of silane coupling agent, 5-10 parts of softening plasticizer, 5 parts of zinc oxide, 10-20 parts of Li2CO3-50 GN, 4 parts of anti-aging agent, 1-2 parts of flowing dispersing agent, 9-12 parts of vulcanizing agent, 5-7 parts of crosslinking agent and 0.8-1.2 parts of phthalocyanine green. The high temperature resistant color hydrogenated butadiene-acrylonitrile rubber material has the advantages of being excellent in temperature resistant performance and oil resistant performance, resistant to low temperature, and low in compression deformation at the same time.

Owner:南京金三力高分子科技有限公司

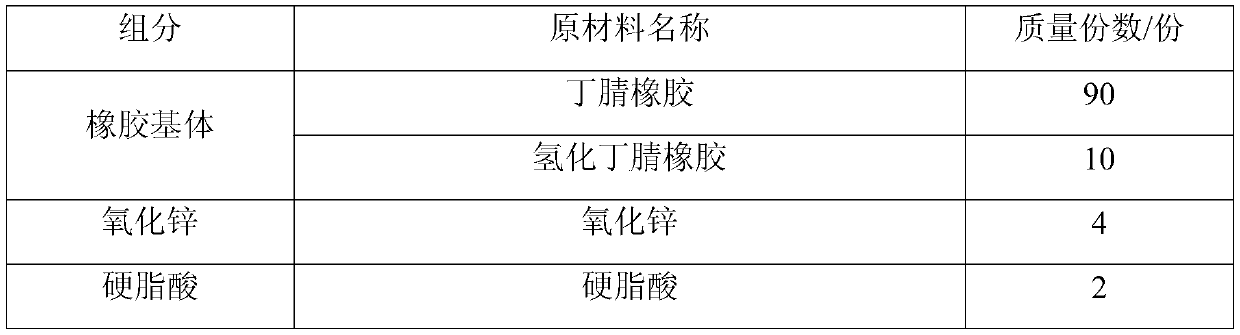

Low-temperature-resistant salt-spray-resistant rubber sealing material and preparation method thereof

InactiveCN111004420AExtended service lifePrevents and slows the oxidation processVulcanizationPlasticizer

The invention discloses a low-temperature-resistant salt-spray-resistant rubber sealing material and a preparation method thereof. The invention belongs to the technical field of rubber sealing materials. The sealing material comprises the following components in parts by mass: 100 parts of a rubber matrix, 3-5 parts of zinc oxide, 0.5-3 parts of stearic acid, 10-40 parts of montmorillonite, 5-50parts of carbon black, 0.5-3 parts of an anti-aging agent, 5-20 parts of a plasticizer, 1.5-3 parts of an accelerant, and 0-10 parts of a vulcanizing agent and an auxiliary of the vulcanizing agent. The raw materials are subjected to an open mill plastication process, an internal mixer mixing process, an open mill mixing process and a vulcanization process to prepare the rubber sealing material, and the rubber sealing material has low-temperature resistance and salt spray resistance and can meet the requirements of deck mechanical sealing and low-temperature pipeline system oil-resistant sealing on polar ships.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Low temperature resistant rubber

Owner:QINGDAO GUOQIANG ENVIRONMENTAL PROTECTION TECH

Multiple-effect anti-hair loss shampoo and preparation method thereof

InactiveCN109646357AEnhanced hair growth effectGentle stimulationCosmetic preparationsHair cosmeticsAdditive ingredientHair loss scalp

The invention belongs to the technical field of daily supplies, and particularly relates to multiple-effect anti-hair loss shampoo and a preparation method thereof. The multiple-effect anti-hair lossshampoo is prepared from a multiple-effect anti-hair loss extracting solution, a foaming agent, a thickening agent, a conditioner, an acidity regulator, an antipruritic agent, a viscosity regulator, amoisturizing agent, a preservative, essence and water. The multiple-effect anti-hair loss shampoo adopts a natural medicinal plant formula, various active traditional Chinese medicine essence ingredients are fused, special effects of Chinese herbal medicines are fully given play to, the shampoo can be quickly absorbed by hair follicles, the shampoo does not irritate hair and does not damage the hair, the shampoo can be quickly absorbed deep in the hair follicles, blood circulation of the scalp is promoted, the life vigor of the hair follicles is kept, and the shampoo has the advantages of caring the hair and continuously improving hair loss and is suitable for various kinds of hair-loss people.

Owner:林世施

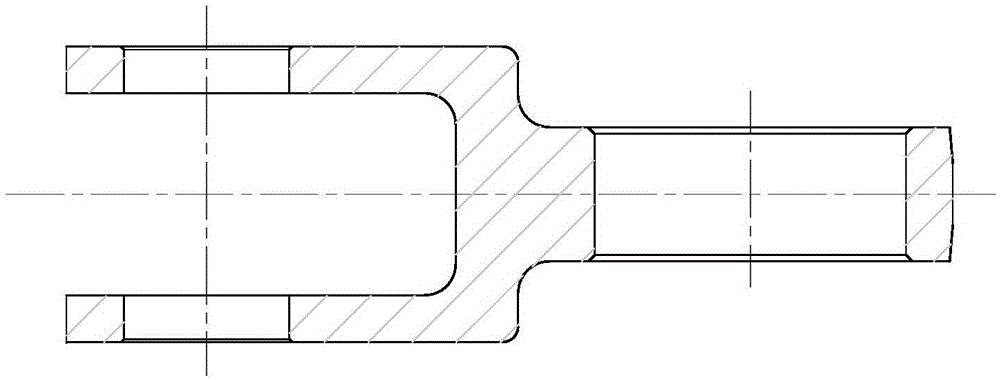

Wedge top type ultralow-temperature ball valve

ActiveCN105619027AReduce frictionReduce the impactPlug valvesOther manufacturing equipments/toolsBall valveImpact test

The invention discloses a wedge top type ultralow-temperature ball valve and a preparation method. Chemical element components of stainless steel are determined in percentage by weight as follows: 0.02-0.5% of carbon, 0.10-0.15% of silicon, 0.7-1.1% of manganese, 0.5% of nickel, 15-19% of chromium, 4% of molybdenum, 0.5% of copper, 0.05% of boron, 0.05% of phosphorus, 0.3% of nitrogen, and the balance of Fe. The wedge top type ultralow-temperature ball valve has unexpected ultralow-temperature performance. A welding line between a butt-welded end of a valve body and a short pipe has an impact value of below -285 DEG C. A welding process qualification report can refer to the ASMEB31.3 standard requirements; the V-shaped impact test below -285 DEG C is performed; and the transverse expansion value of standard sample test is lower than 0.25 mm.

Owner:JIANG SU YAN DIAN FA MEN CO LTD

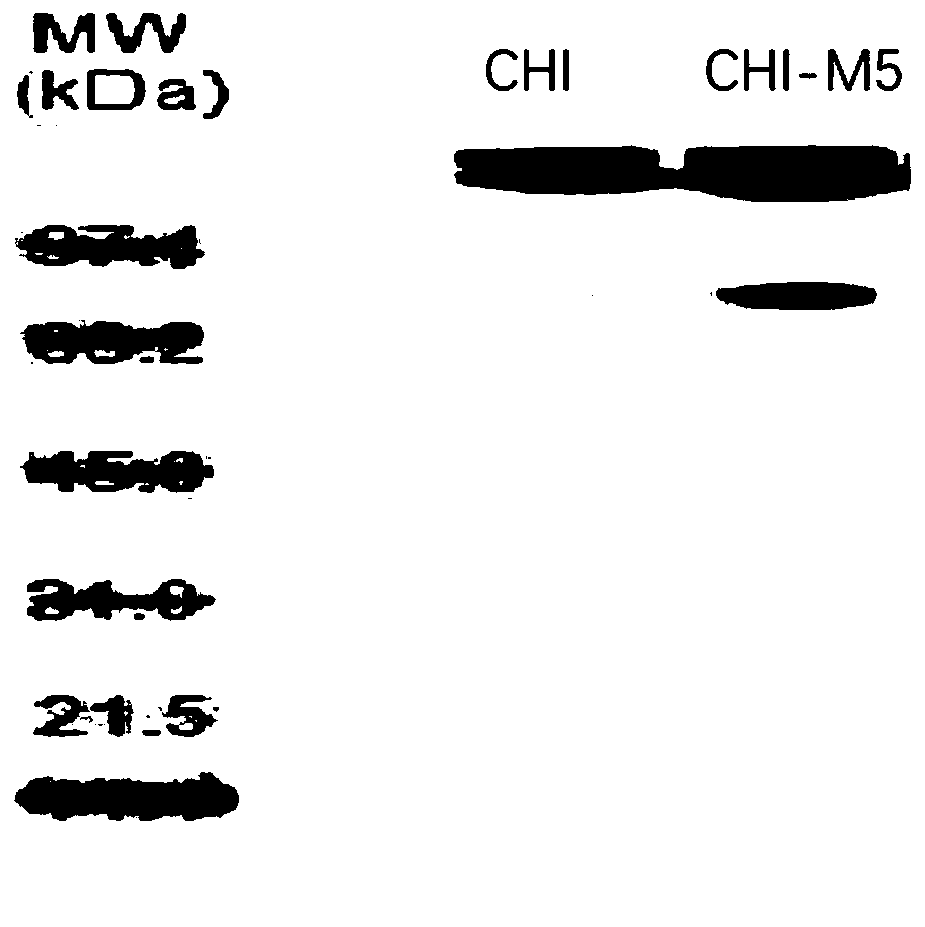

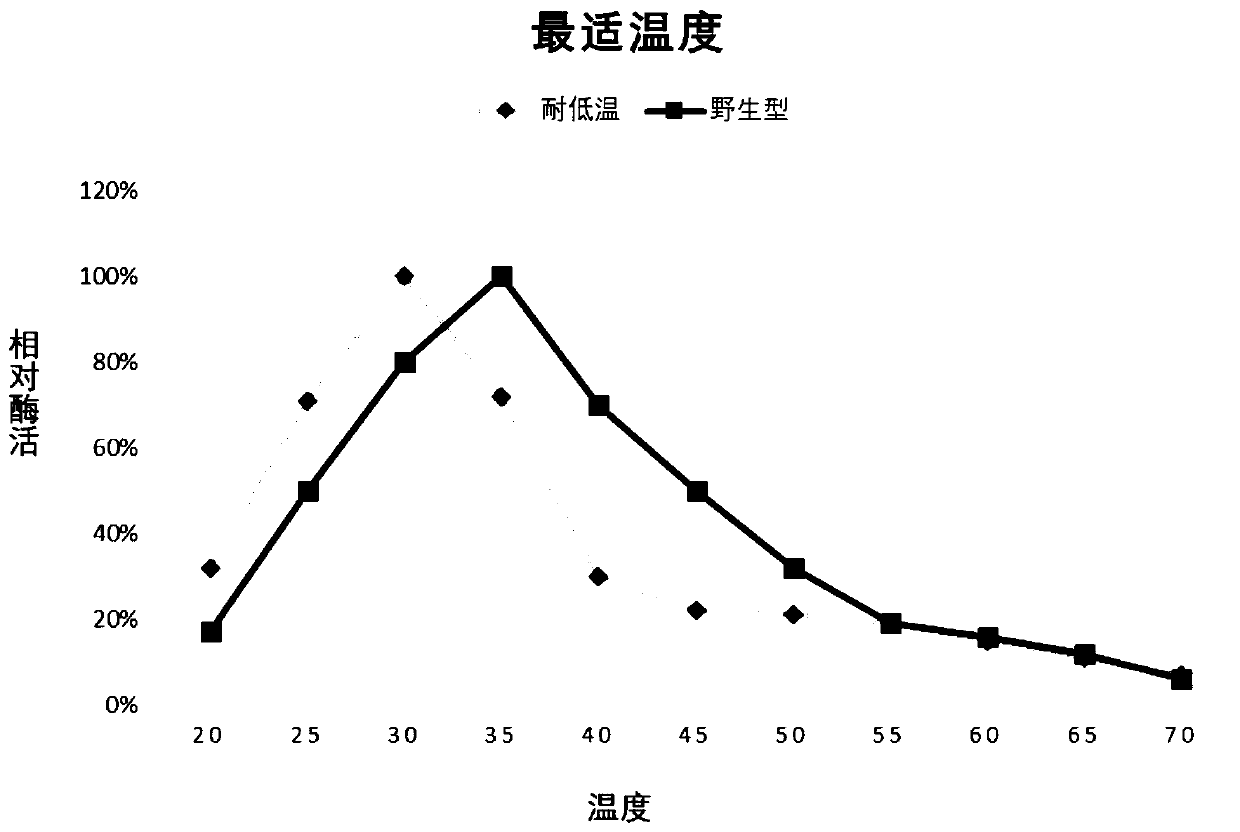

Chitinase low temperature resistant mutant and application thereof

ActiveCN109943553AAbsolute Enzyme Activity EnhancementWith low temperature resistanceBacteriaMicroorganism based processesChitin formationAmino acid

The invention obtains a mutant having 5 amino acid locus mutation in comparison with a wild type by screening a low temperature resistant chitinase from a marine microorganism disclosed in the prior art through PCR introduction mutation. Through appropriate temperature detection, the most suitable temperature of the mutant is reduced by 5 DEG C compared with the wild type, which is more conduciveto the application of the chitinase to the hydrolysis of chitin.

Owner:DALIAN UNIVERSITY

Anti-cracking railway digital signal cable

InactiveCN102110496AExtended service lifeAvoid damageInsulated cablesCommunication cablesDiphenyl etherUltraviolet

The invention relates to an anti-cracking railway digital signal cable which comprises a plurality of cable units and a jacket wrapped at the periphery of the cable units, wherein the jacket sequentially comprises an alloy aluminum protective layer which is longitudinally wrapped and welded at the periphery of the cable units, a high-density polyethylene inner protective layer extruded outside the alloy aluminum protective layer, a steel belt wrapped at the periphery of the high-density polyethylene inner protective layer, a diphenyl ether weftless belt wrapped at the periphery of the steel belt and a high-density polyethylene outer protective layer extruded outside the weftless belt. By using the high-density polyethylene materials as the inner protective layer and the outer protective layer of the cable, the railway digital signal cable has the characteristics of environmental stress crack resistance, low temperature resistance, wear resistance and ultraviolet irradiation resistance, and can be used in all regions. Simultaneously, the diphenyl ether weftless belt is used outside the steel belt, thereby preventing the steel belt from damaging the outer protective layer, and further prolonging the service life of the cable.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

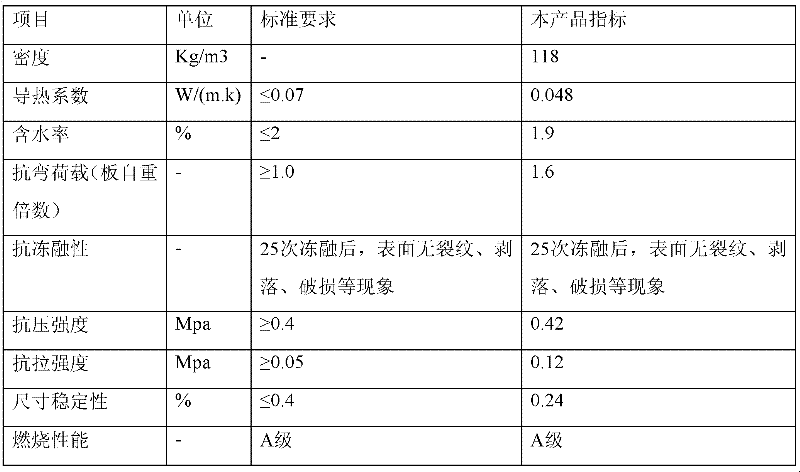

Fiber expansion bead thermal insulation board and production method thereof

InactiveCN102557568AComply with fire regulationsMeet building fire rating requirementsHeat proofingFiberCombustion

The invention relates to a hard inorganic non-ignitable adiabatic fiber expansion bead thermal insulation board. The combustion performance level of the fiber expansion bead thermal insulation board is level A. The fiber expansion bead thermal insulation board is low in water absorption, high in compression strength and tensile strength, long-term and stable in thermal conductivity, good in dimensional stability and freezing resistance, resistant to high temperature and low temperature, anti-aging, long in service life and capable of being applied to thermal insulation of various building outer walls, floors and roofs.

Owner:毛文艺

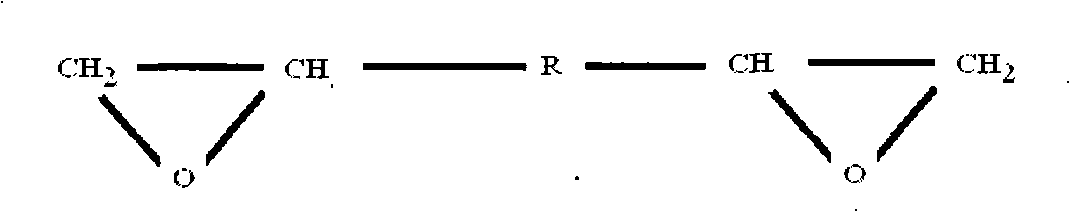

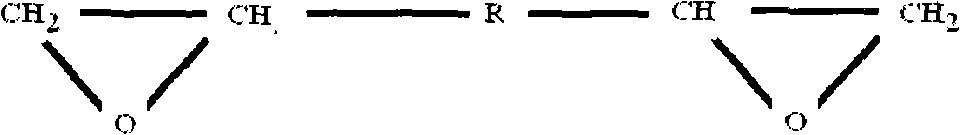

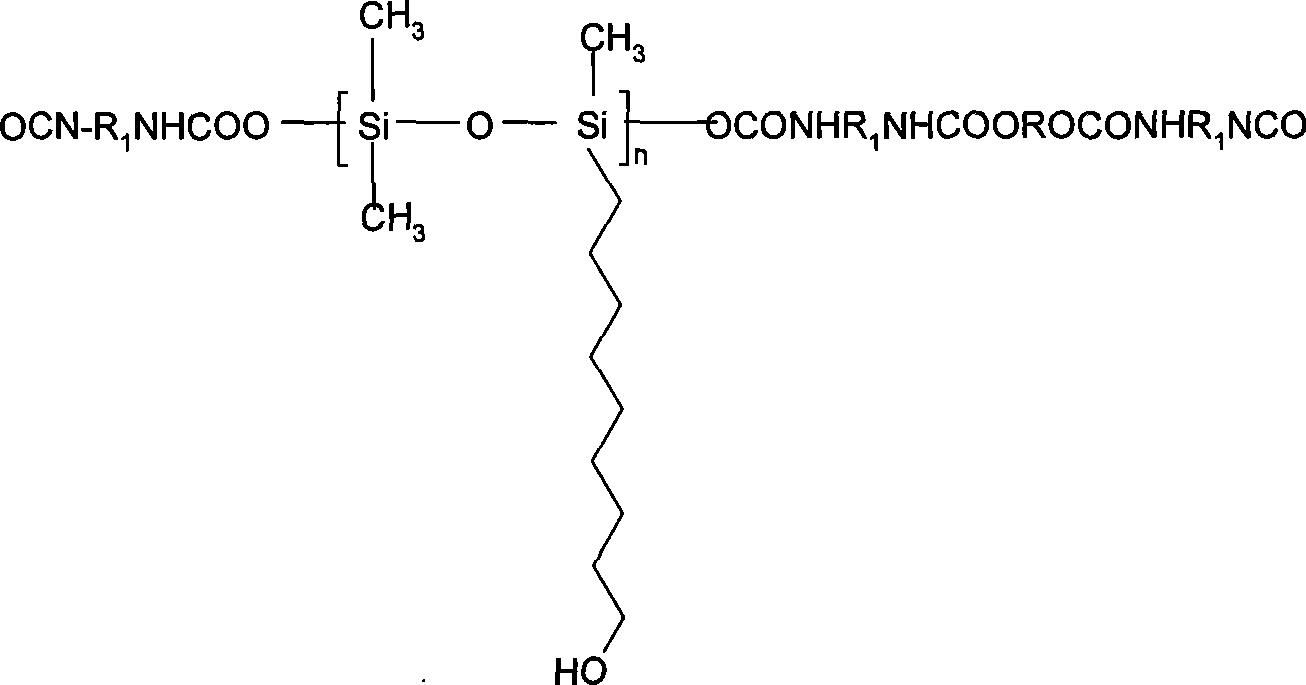

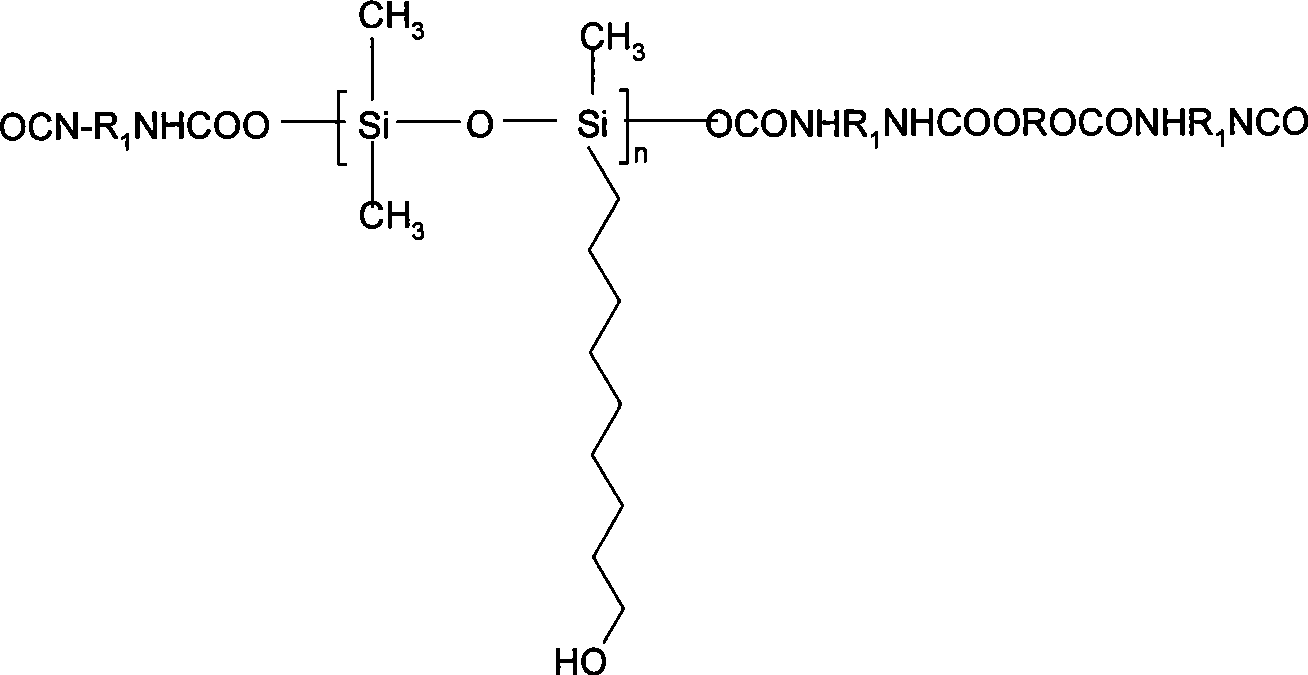

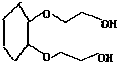

Binder used between urethane foam and glass fiber reinforced plastic of LNG ships

InactiveCN101531879AWater resistantWith low temperature resistancePolyureas/polyurethane adhesivesEpoxyGlass fiber

The invention discloses a binder used between urethane foam and glass fiber reinforced plastic of LNG ships, which comprises the following compositions by mass percentage: 30 to 50 percent of organosilicone polyurethane modified prepolymer, 5 to 15 percent of epoxide resin, 10 to 20 percent of solvent, 1 to 15 percent of chain extender, 1 to 10 percent of vermiculite, 10 to 18 percent of SiO2, 10 to 20 percent of CaCO3 and 2 to 10 percent of CaCl2. The liquid compositions are uniformly mixed firstly, and then added with the solid compositions for uniform stirring, and the mixture is ground on a grinding machine and then packaged. The binder used between the urethane foam and the glass fiber reinforced plastic of the LNG ships has large binding power between the urethane foam and the glass fiber reinforced plastic, and properties of ultralow temperature resistance and water resistance, and can be used at 200 DEG C below zero for a long time and keep the mechanical property to achieve the aim of fully protecting heat insulating materials.

Owner:JIANGSU UNIV OF SCI & TECH +1

Double-component polyurethane repairing adhesives and preparation method thereof

InactiveCN109593504ASolve problems that require closed traffic for long periods of timeEasy to operateNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveSolvent

The invention relates to double-component polyurethane repairing adhesives and a preparation method thereof. The weight ratio of a component A to a component B is 1 to 1, and the double-component polyurethane repairing adhesives are prepared from the following substances in parts by weight: the component A is prepared from 30 parts to 40 parts of oil polyols, 3 parts to 5 parts of chain extender,15 parts to 20 parts of butoxy-bisphenol A, 0.7 part to 0.8 part of pigment, 0.1 part to 0.2 part of catalyst, 23 parts to 24 parts of flame retardant, and 18.2 parts to 20 parts of calcium sulfate whiskers; and the component B is prepared from 100 parts of polyurethane prepolymer. The two components A and B of the double-component polyurethane repairing adhesives are prepared according to the weight ratio of 1 to 1, an operation is simple, solvents are not needed to be added additionally in a using process, environmental protection and no toxicity are achieved, and moreover, even under a low-temperature condition in winter, low viscosity required by crack pouring also can be met, and the double-component polyurethane repairing adhesives have the advantages of higher water resistance performance, low temperature resistance performance, high adhesion performance, flexibility and higher mechanical performance.

Owner:YANTAI DARBOND TECH

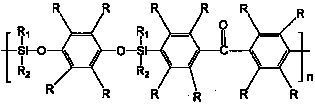

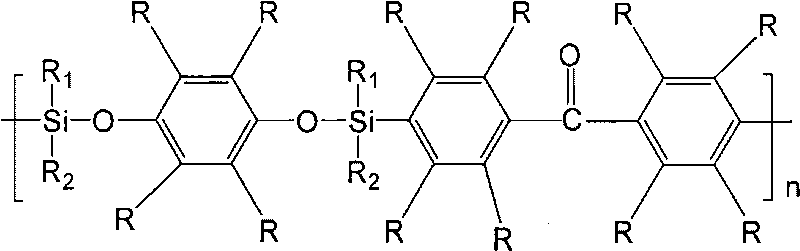

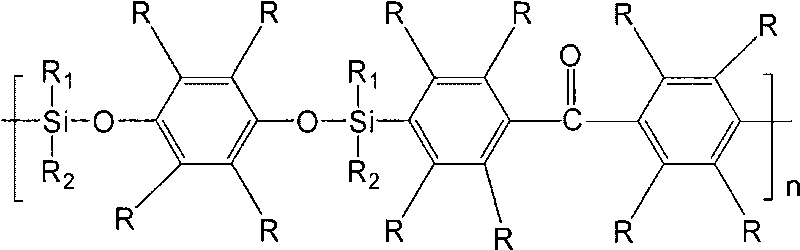

Organic silicon function material and preparation method thereof

The invention relates to an organic silicon function material which is characterized by comprising an organic silicon polyether ketone functional polymer material represented by the following general formula (1), wherein R in the general formula (1) represents H, halogen, Cl-C20 alkyls and C1-C20 naphthenic bases or C1-C20 aryls; R1 or R2 represents the Cl-C20 alkyls, the C1-C20 naphthenic bases, the C1-C20 aryls, C1-C20 alkoxys and C1-C20 cycloalkyloxys, or C1-C20 aryloxys; and the relative number-average molecular weight of the organic silicon polyether ketone functional polymer material ranges from 5000 to 100000. The invention also discloses a preparation method. The organic silicon polyether ketone functional polymer material has high temperature and low temperature resistance and combines the excellent performances of organic silicon polymer materials and polyether-ether-ketone.

Owner:BEIJING UNIV OF CHEM TECH

Low temperature resistant high elasticity chlorinated polyethylene power line jacket material as well as preparation method thereof

InactiveCN103540043AWith low temperature resistanceIncrease elasticityPlastic/resin/waxes insulatorsInsulated cablesTriallyl isocyanurateAntimony trioxide

The invention discloses a low temperature resistant high elasticity chlorinated polyethylene power line jacket material as well as a preparation method thereof. The low temperature resistant high elasticity chlorinated polyethylene power line jacket material is prepared from the following substances in parts by weight: 70-90 parts of chlorinated polyethylene, 20-30 parts of an ethylene-vinyl acetate copolymer, 10-15 parts of a thermoplastic polyurethane elastomer, 0.4-0.8 part of bis(tert-butyldioxyisopropyl)benzene, 1.5-2.5 parts of triallyl isocyanurate, 4-8 parts of molybdenum disulfide, 10-15 parts of antimonous oxide, 8-12 parts of silicon micropowder, 5-10 parts of polytetrafluoroethylene micropowder, 10-15 parts of dioctyl nylon acid, 3-5 parts of sorbitol, 5-10 parts of dioctyl sebacate, 20-25 parts of precipitated white carbon black, 2-3 parts of a flexibilizer TMTD (Tetramethyl Thiuram Disulfide), 1-2 parts of an anti-aging agent ODA [bis(4-octylphenyl)amine], 1-2 parts of an anti-aging agent TPPD [N-(p-toluene-sulphonylamido-N'-phenylenediamine)] and 3-5 parts of composite filler, wherein the accelerant has low temperature resistance and high elasticity, so that the jacket material still maintains good elasticity under a condition of a low temperature of -50 DEG C. The jacket provided by the invention is tough, has excellent physical and mechanical performances, electric insulating performance, anti-aging resistance, wear resistance and impact resistance, and is durable, safe and reliable and wide in application prospect.

Owner:天长市富达电子科技股份有限公司

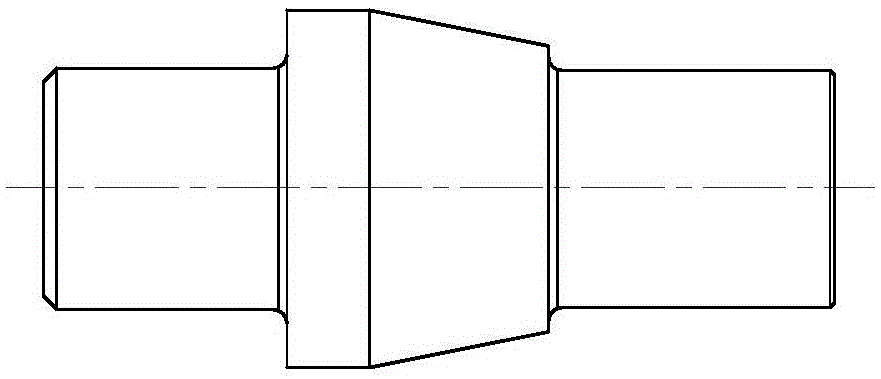

Titanium alloy and application of titanium alloy to machining of train connecting piece

The invention discloses a titanium alloy. The titanium alloy comprises the following components by weight percentage: 3.8-4.8% of Al, 2.0-3.2% of V, 0.7-1.7% of Fe, 0.2-0.3% of O and the balance of Ti. Machining steps are as follows: step (1), heating a titanium alloy ingot in a temperature range of 100-150 DEG C above a phase transformation point, controlling the final forging temperature in a range of 900 DEG C + / -20 DEG C, performing cogging forging, and controlling rolling reduction at every time within 10-25 mm; step (2), heating in a temperature range of the phase transformation point + / - 20 DEG C, performing upsetting and drawing forging, and controlling the final forging temperature in a range of 850 DEG C + / -20 DEG C and the rolling reduction not to excess 30%of the length; step (3), heating at 30-50 DEG C below the phase transformation point, performing finished-product forging, controlling deformation to be about 60%, and performing heat treatment after the finished-product forging; step (4), performing vacuum annealing as the heat treatment, controlling the annealing temperature to be in a range of about 150 DEG C within the phase transformation point, controlling the temperature changeless to be 60-90 min, and performing air cooling. The titanium alloy is applied to manufacturing of a drive pin, a connecting rod, a motor suspending lever and a fastening of a train or a motor car; weight losing and corrosion resisting effects are achieved.

Owner:沈阳泰恒通用技术有限公司

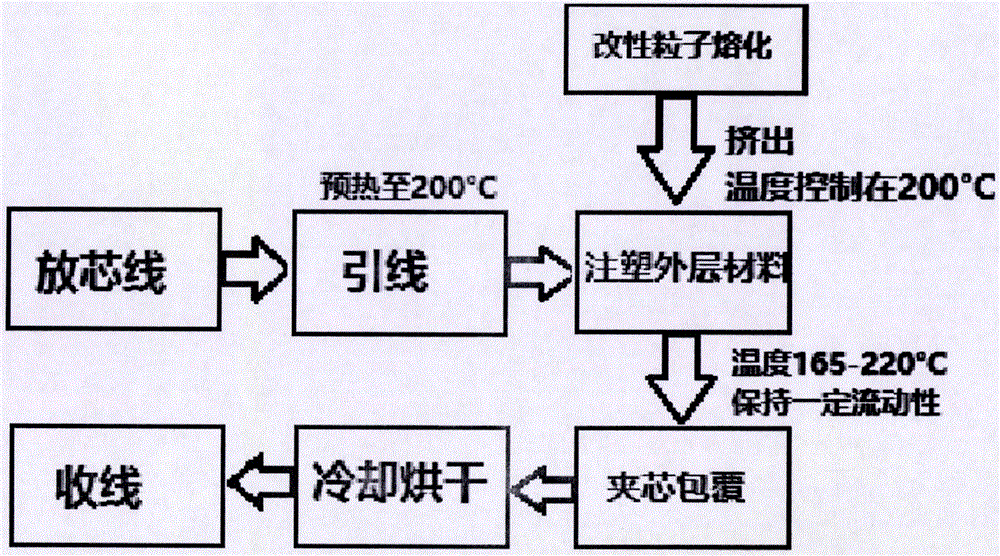

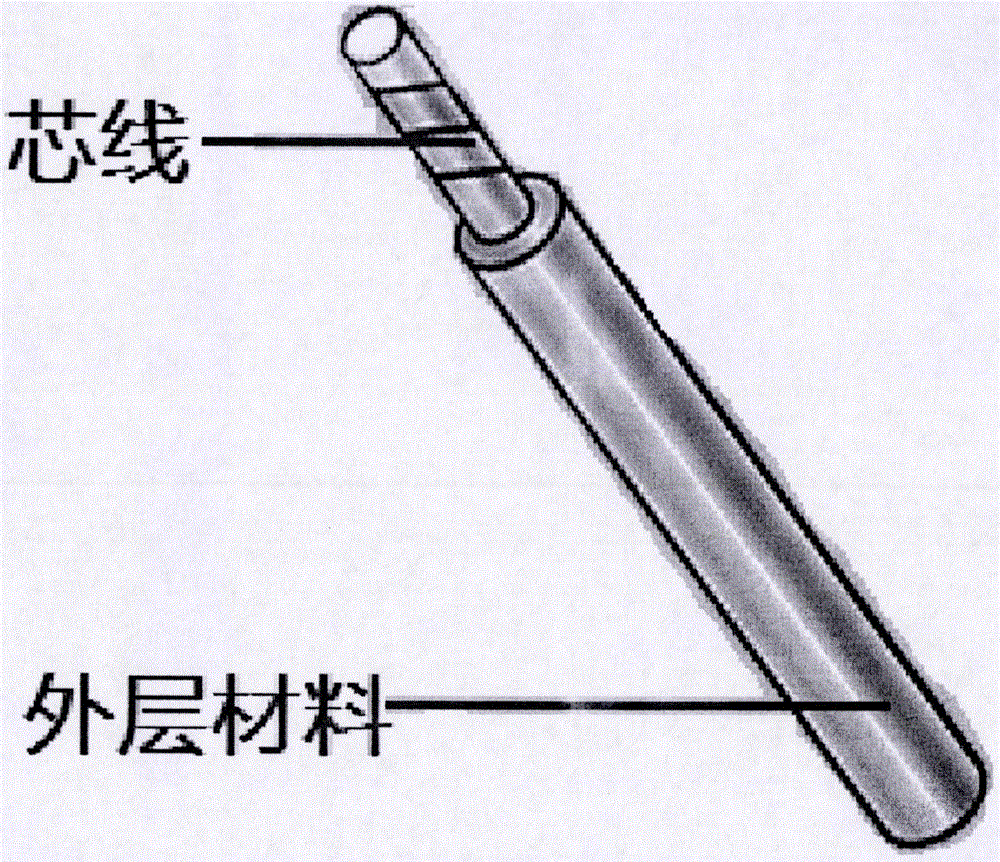

Production process of sandwiched developing line

InactiveCN106827379ASuper high tensile strengthGood developing effectSurgeryDomestic articlesMedical treatmentWire rod

The invention discloses a production process of a sandwiched developing line and relates to the field of medical equipment and functional wire rods. According to the production process of the sandwiched developing line disclosed by the invention, a special injection molding sandwiched process is adopted, so that the outer layer structure has a developing function, and the core wire has relatively high tensile strength. The developing line prepared by the injection molding sandwiched process is high-temperature-resistant, low-temperature-resistant, ultrahigh in tensile strength and good in developing effect. By means of properties of different materials, sandwiched wire rods combined in different properties can be obtained.

Owner:南京普诺特科技有限公司

Antifouling paint and preparation method thereof

InactiveCN109251621AIncrease release rateReduce usageAntifouling/underwater paintsPaints with biocidesAntioxidantAcrylic resin

The invention discloses antifouling paint which is prepared from the following raw materials: modified acrylic resin, a capsaicin derivative, a copper ion slow release agent, rosin, a filler, an antioxidant and a solvent. The capsaicin derivative can repel and kill microorganisms, so that the microorganisms are difficult to get close, and microbial pollution is reduced; a copper ion complex in thepaint serves as a second defensive line, copper ions can be continuously and uniformly released, the retention time of the copper ions on the surface is prolonged, and the durability of the antifouling and antibacterial properties of the paint is enhanced; and finally the modified acrylic resin is low in surface energy so as to enable the killed microorganisms and other pollutants to be difficultto attach, and the surface of an object is kept smooth and pollution-free. The three components of the capsaicin derivative, the copper ion slow release agent and the modified acrylic resin cooperatewith each other to play a role to achieve efficient and anti-fouling effects of the paint. The paint disclosed by the invention is remarkable in antifouling effect and low in addition amount of anti-fouling effective components, and is environment-friendly antifouling paint.

Owner:山东陆邦涂料有限公司

Plastic special for refrigerator inner plate and preparation method of plastic

InactiveCN104927189AStrong low temperature resistanceNo problems such as corrosionEngineeringEPDM rubber

The invention discloses a plastic special for a refrigerator inner plate, and relates to the technical field of plastic products. The plastic is prepared from the following raw materials in parts by weight: 80-90 parts of polypropylene, 50-60 parts of EPDM rubber, 20-30 parts of high density polyethylene, 8-10 parts of a nucleating agent, 4-6 parts of an anti-oxidant, 20-30 parts of calcium stearate, 25-35 parts of epoxidized soybean oil, 30-40 parts of a filling material and 100-120 parts of deionized water. The plastic has the benefits that the process flow is concise, the raw material ratio is reasonable, and the plastic is produced by adopting chemical substances which are all nontoxic and harmless. The prepared plastic special for the refrigerator inner plate is good in use effect, has the functions of low temperature resistance and corrosion resistance, and is obvious in use effect, pollution-free, high in market value and convenient to popularize and apply.

Owner:ANHUI JINZHENG PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com