Low-temperature-resistant salt-spray-resistant rubber sealing material and preparation method thereof

A technology of rubber sealing and salt spray resistance, which is applied in the field of rubber sealing materials, can solve problems that do not involve meeting the salt spray resistance performance, and achieve the effects of improving weather resistance, low temperature resistance and crosslinking state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

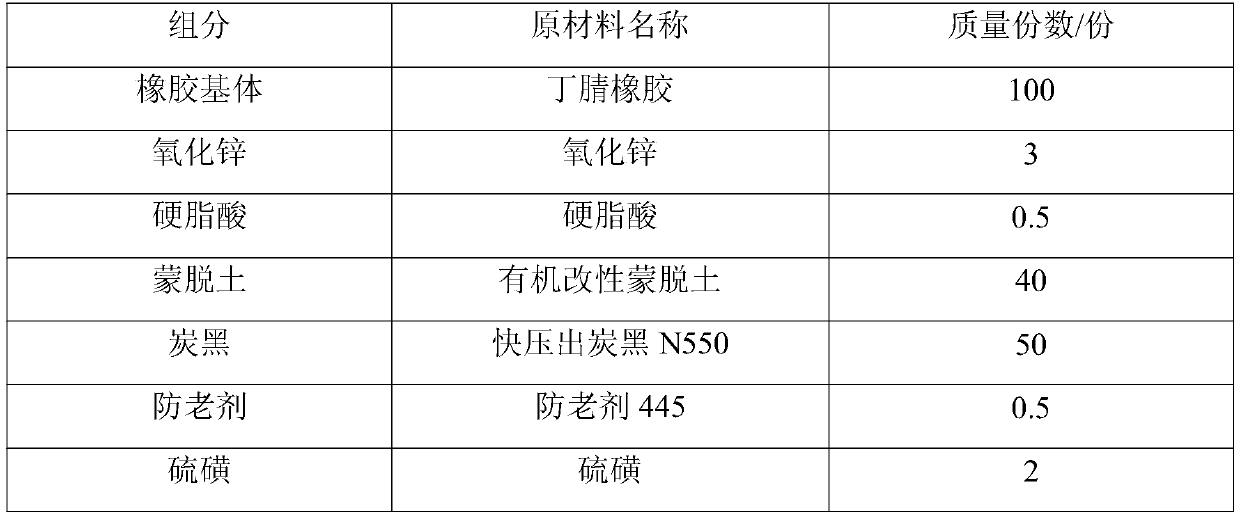

[0039] A low temperature and salt spray resistant rubber sealing material, the components of which are shown in Table 1.

[0040]The rubber sealing material of table 1 embodiment 1 is calculated by mass parts

[0041]

[0042]

[0043] The preparation method of the rubber sealing material comprises an open mill plasticating process, an internal mixer mixing process, an open mill mixing process and a vulcanization process, specifically comprising the following steps:

[0044] Step 1, open mill masticating: Weigh each component according to the above ratio, fully masticate the rubber matrix (hydrogenated nitrile rubber) on the double-roller open mill, turn on the cooling water, beat the roller distance to the minimum, thin Pass 6 to 8 times, increase the roller distance, and make 6 to 8 triangle bags.

[0045] Step 2, internal mixer mixing: (1) Put the hydrogenated nitrile rubber, zinc oxide, stearic acid, and anti-aging agent after mastication into the internal mixer for...

Embodiment 2

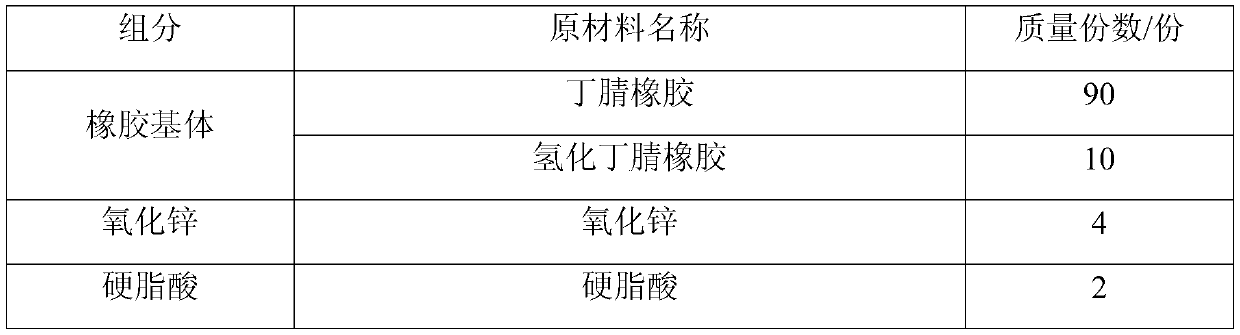

[0051] A low temperature and salt spray resistant rubber sealing material, the components of which are shown in Table 2.

[0052] The rubber sealing material of table 2 embodiment 2 is calculated by mass parts

[0053]

[0054]

[0055] The preparation method of this rubber sealing material comprises the steps:

[0056] Step 1, open mill mastication: take each component according to the above ratio, fully carry out mastication on the rubber matrix (nitrile rubber, hydrogenated nitrile butadiene rubber) on the double-roller open mill, turn on the cooling water, and beat the roller distance To the minimum, thin pass 6 to 8 times, increase the roller distance, and then make 6 to 8 triangle bags.

[0057] Step 2, internal mixer mixing: (1) Put the plasticized rubber base, zinc oxide, stearic acid, anti-aging agent (anti-aging agent 445, anti-aging agent 4010NA) into the internal mixer to carry out a internal mixing, control The rotor speed is 20-40 rpm, banburying for 2 mi...

Embodiment 3

[0063] A low temperature and salt spray resistant rubber sealing material, the components of which are shown in Table 3.

[0064] The rubber sealing material of table 3 embodiment 3 is calculated by mass parts

[0065]

[0066] The preparation method of this rubber sealing material comprises the steps:

[0067] Step 1, open mill masticating: Weigh each component according to the above ratio, fully masticate the rubber matrix (hydrogenated nitrile rubber) on the double-roller open mill, turn on the cooling water, beat the roller distance to the minimum, thin Pass 6 to 8 times, increase the roller distance, and make 6 to 8 triangle bags.

[0068] Step 2, internal mixer mixing: (1) Put the masticated hydrogenated nitrile rubber, zinc oxide, stearic acid, anti-aging agent (anti-aging agent 4010NA, anti-aging agent ODA) into the internal mixer for one internal mixing , control the rotor speed to 20-40 rpm, banbury for 2 minutes, and control the temperature below 80°C;

[0069...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com