Fiber expansion bead thermal insulation board and production method thereof

A production method and technology for thermal insulation boards, which are applied in the field of fiber expanded bead thermal insulation boards and their production fields, can solve the problems of difficult fireproof insulation board technology, difficult promotion and application, product dependence on imports, etc., and achieve excellent antifreeze performance, obvious thermal insulation effect, The effect of economical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A fiber expanded bead insulation board is made of the following materials in volume percentage:

[0028] Expanded beads: 80%;

[0029] Silicone: 13%;

[0030] Silicone water repellent: 5%;

[0031] Polyamide curing agent 650#: 1%;

[0032] Wood fiber: 1%.

[0033] The production method is as follows: firstly put the expanded beads into the container, then add additives and auxiliary materials in sequence and proportion, and stir evenly. Send it into the automation equipment and press it into insulation boards of various thicknesses as required. Standard plate length × width: 600 × 300 and 600 × 400 and so on.

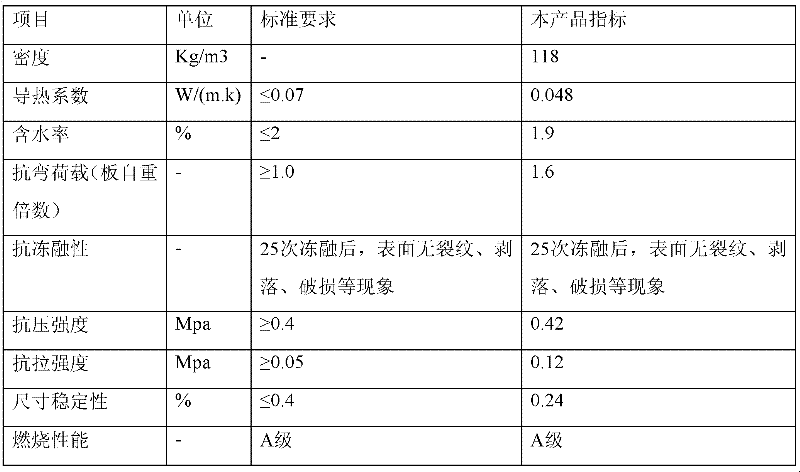

[0034] The performance test results are:

[0035]

Embodiment 2

[0037] A fiber expanded bead insulation board is made of the following materials in volume percentage:

[0038] Expanded beads: 90%;

[0039] Silicone: 5%;

[0040] Silicone water repellent: 4%;

[0041] Polyamide curing agent 650#: 0.6%;

[0042] Wood fiber: 0.4%.

[0043] The production method is as follows: firstly put the expanded beads into the container, then add additives and auxiliary materials in sequence and proportion, and stir evenly. Send it into the automation equipment and press it into insulation boards of various thicknesses as required. Standard version length × width: 600 × 300 and 600 × 400, etc.

[0044] The performance test results are:

[0045] Thermal conductivity 0.048-0.056w / mk

[0046] Tensile strength 0.12mpa

[0047] Compressive strength 0.5mpa

[0048] Combustion class Class A

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com