A reflective thermal insulation coating

A technology of reflective heat-insulating coating and topcoat layer, applied in the field of coatings, can solve the problems of unfavorable environmental protection, high cost, and poor heat-insulating performance of heat-insulating coatings, and achieve the effects of low construction costs, improved adhesion, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A reflective heat-insulating paint, comprising a putty layer, a primer layer and a topcoat layer successively, the thickness of the putty layer is 2cm, the thickness of the primer layer is 30um, and the thickness of the topcoat layer is 100um;

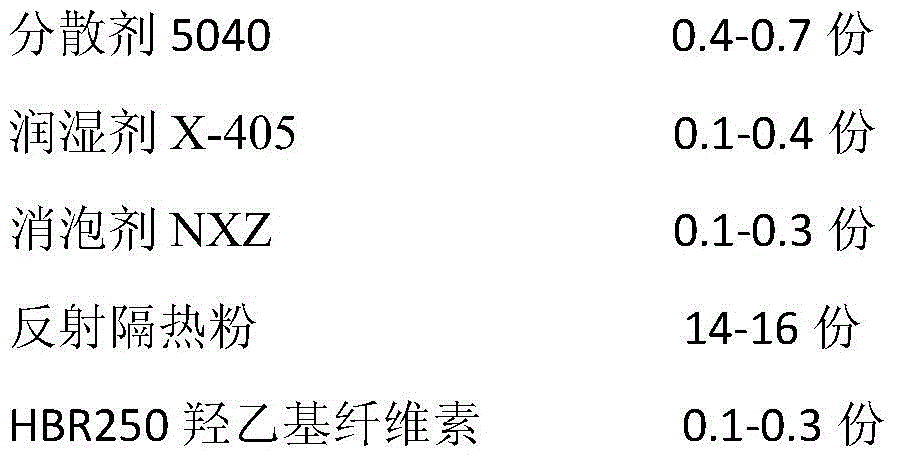

[0037] The topcoat layer comprises the following materials in parts by weight:

[0038]

[0039]

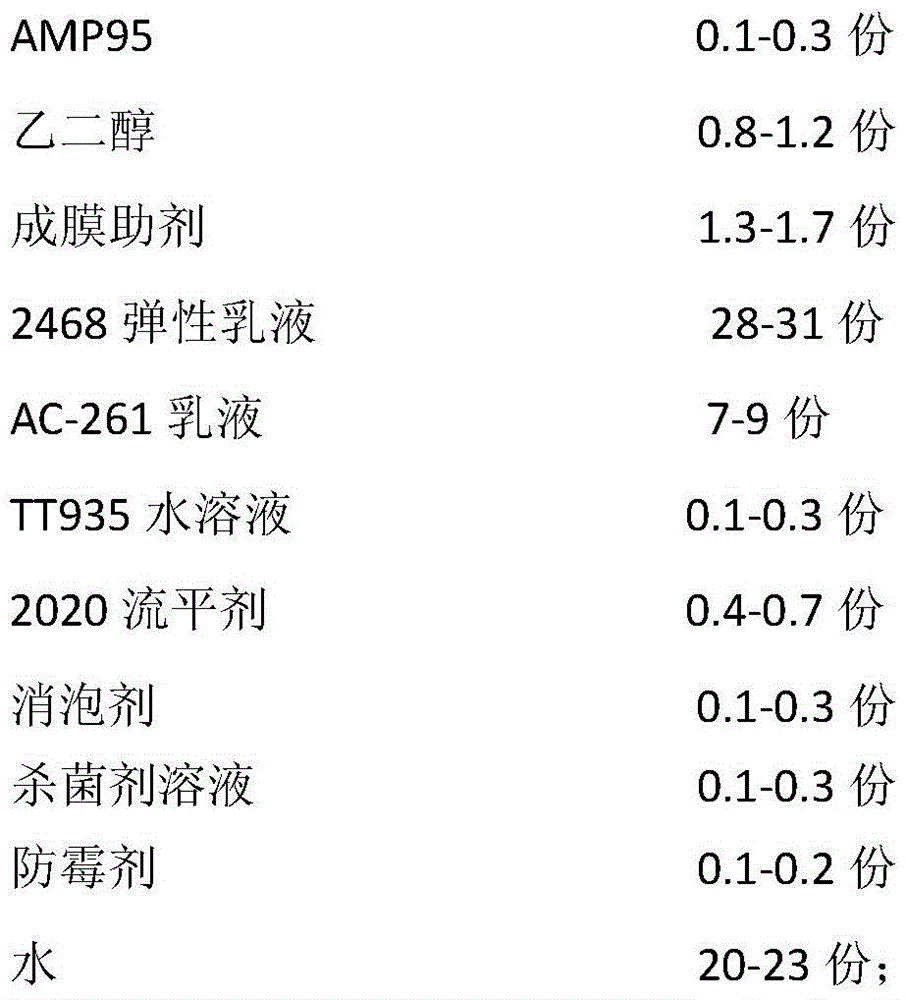

[0040] The primer layer includes the following materials in parts by weight:

[0041]

Embodiment 2

[0043] A reflective heat-insulating paint, comprising a putty layer, a primer layer and a topcoat layer successively, the thickness of the putty layer is 1.3cm, the thickness of the primer layer is 25um, and the thickness of the topcoat layer is 110um;

[0044] The topcoat layer comprises the following materials in parts by weight:

[0045]

[0046]

[0047] The primer layer includes the following materials in parts by weight:

[0048]

Embodiment 3

[0050] A reflective heat-insulating paint, comprising a putty layer, a primer layer and a topcoat layer successively, the thickness of the putty layer is 1.3cm, the thickness of the primer layer is 25um, and the thickness of the topcoat layer is 110um;

[0051] The topcoat layer comprises the following materials in parts by weight:

[0052]

[0053]

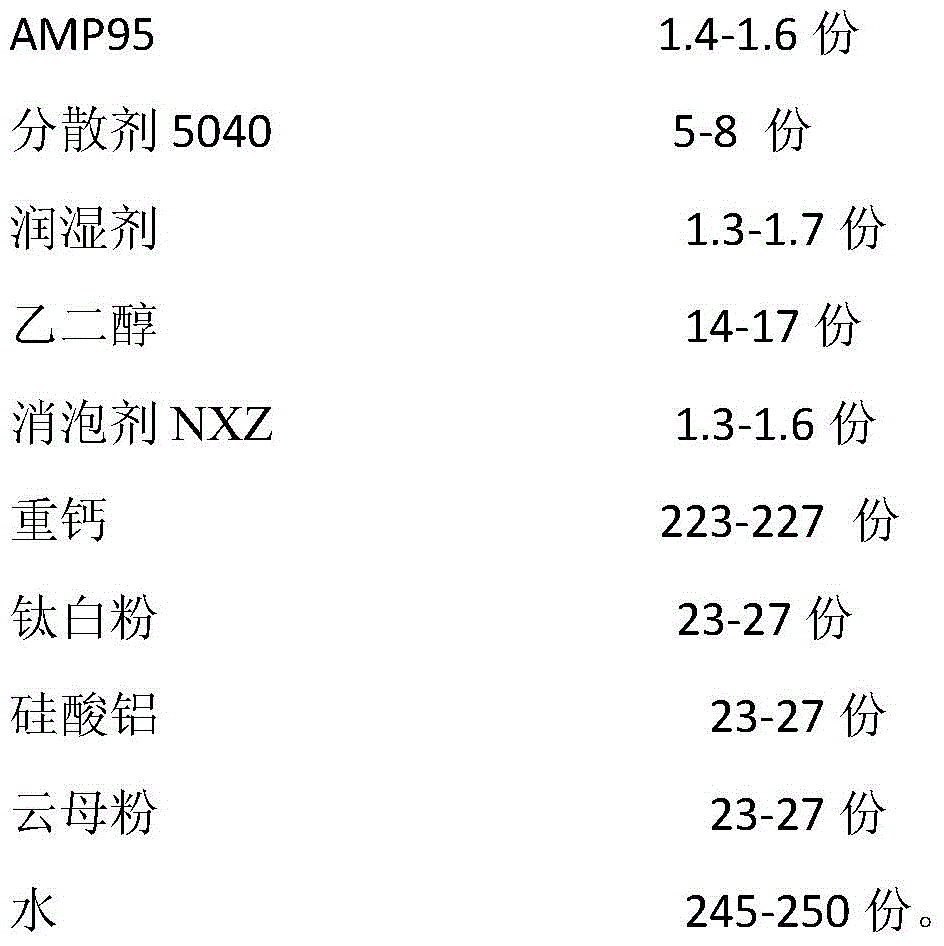

[0054] The primer layer includes the following materials in parts by weight:

[0055]

[0056] The reflective heat-insulating coating of the present invention can be applied by brushing, rolling, spraying and other construction methods. Before use, it needs to be fully stirred evenly, and the grease, dust and other attached dirt on the surface of the object to be coated must be cleaned to ensure that the wall surface is dry and It is flat, firm and ready for construction. To obtain the best effect, first apply a special primer for architectural reflective heat insulation coatings to seal the surface, then apply a layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com