A vitrified microbead fire retardant board and a fire retardant heat preservation structure

A technology of vitrified microbeads and fire-resistant boards, which is applied in the field of building materials and building structures, can solve the problem that the thickness of the fire-proof layer of the outer wall cannot meet the fire-fighting requirements, the bonding between the insulation layer and the fire-proof layer is not firm, and the vitrification is microscopic. Problems such as high density of bead mortar layer, to achieve high non-combustibility, save raw materials, and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

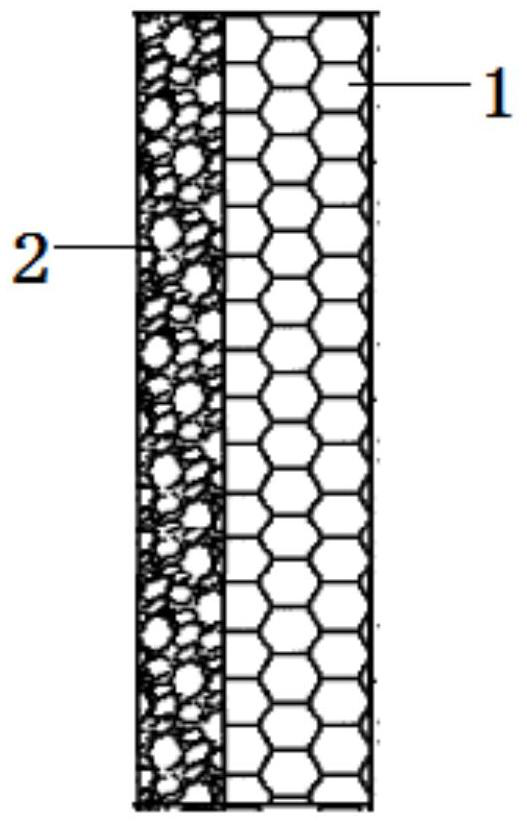

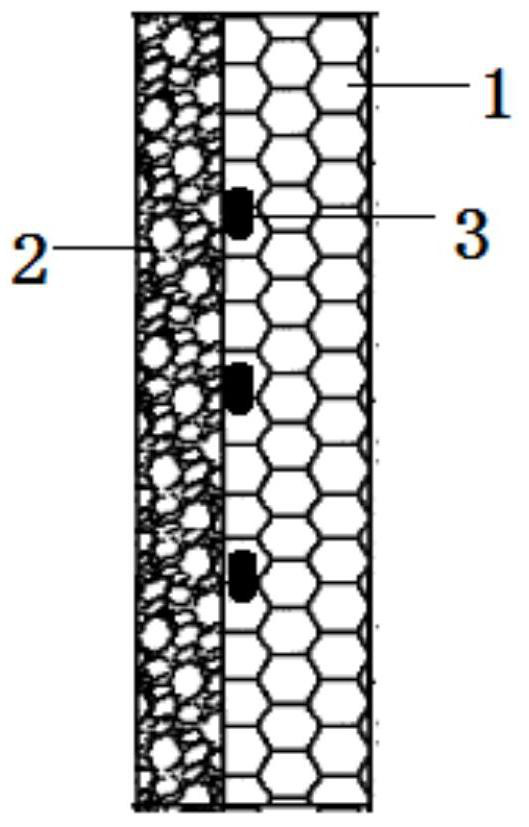

[0023] The present invention also provides a preparation method for the above-mentioned vitrified microbead fire retardant board, which includes the following steps: uniformly mixing the vitrified microbeads with the binder; compacting and smoothing the vitrified microspheres in a flat mold, and the compression ratio is 1:2-1: 3. The time is 10-60 minutes; heating and forming, the heating temperature is 350°C-650°C, and the heating time is 10-60 minutes.

[0024] The vitrified microbead fire retardant board has the following excellent properties: (1) light density, at 300kg / m 3 Below; (2) Low thermal conductivity, below 0.08W / (m·K), preferably below 0.06W / (m·K); (3) It can be well compounded with any other thermal insulation board with a thermal conductivity of 5 cm or more ; (4) easy handling and construction; and (5) high strength.

[0025] In the preparation process of the vitrified microbead fire retardant board proposed by the present invention, there is no need for dryi...

Embodiment 1

[0035] Preparation of vitrified microbead fire retardant board:

[0036] 1) Prepare raw materials: vitrified microbeads (bulk density3 Vitrified microbeads account for 5vol%, and the bulk density is 80-120kg / m 3 Vitrified microbeads account for 35vol%, bulk density>120kg / m 3The vitrified microspheres account for 60vol%) 95 parts; binder (sodium silicate, sodium silicate and calcium silicate, or the mixture of sodium silicate and calcium silicate and calcium oxide) 5 parts; binder in aqueous solution The form is added, wherein the content of solid component is 5 parts;

[0037] 2) The raw materials are mixed evenly;

[0038] 3) The raw material is placed in a flat mold and compacted and smoothed, the compression ratio is 1:2.5, and the time is 30 minutes;

[0039] 4) Place the mold with the raw materials in a heating device to heat and set the shape, the heating temperature is 550° C., and the heating time is 20 minutes.

[0040] It has been determined that the density of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com