Multiple membrane filaments automatic curtain forming device and method

A wire arrangement device and membrane wire technology, applied in the field of water treatment, can solve the problems of no protective measures for membrane modules, uneven arrangement of membrane wires, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

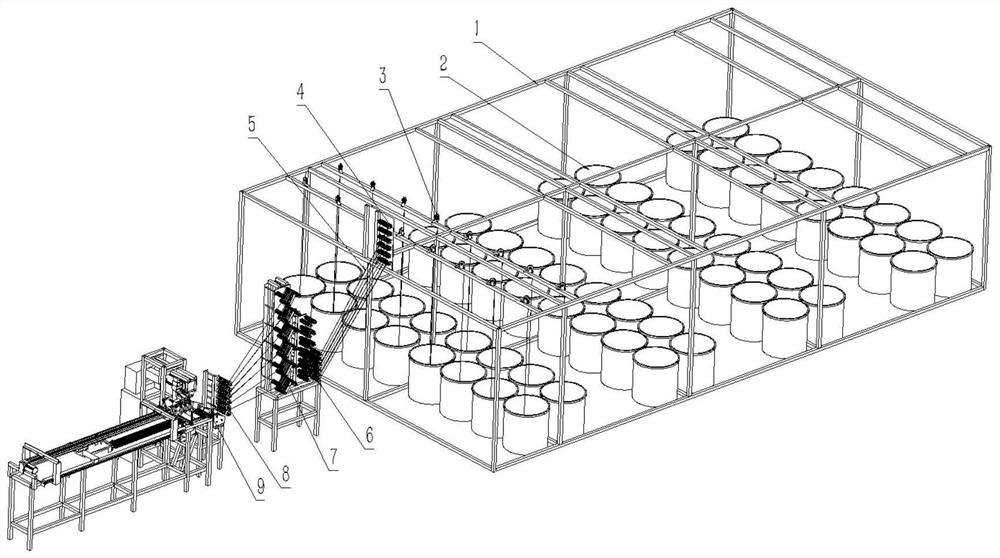

[0032] 1. The multi-filament automatic curtain forming device is composed as follows:

[0033] A new type of multi-filament automatic curtain forming device mainly includes four parts: film limit part, tension adjustment part, thread arrangement part and glue part.

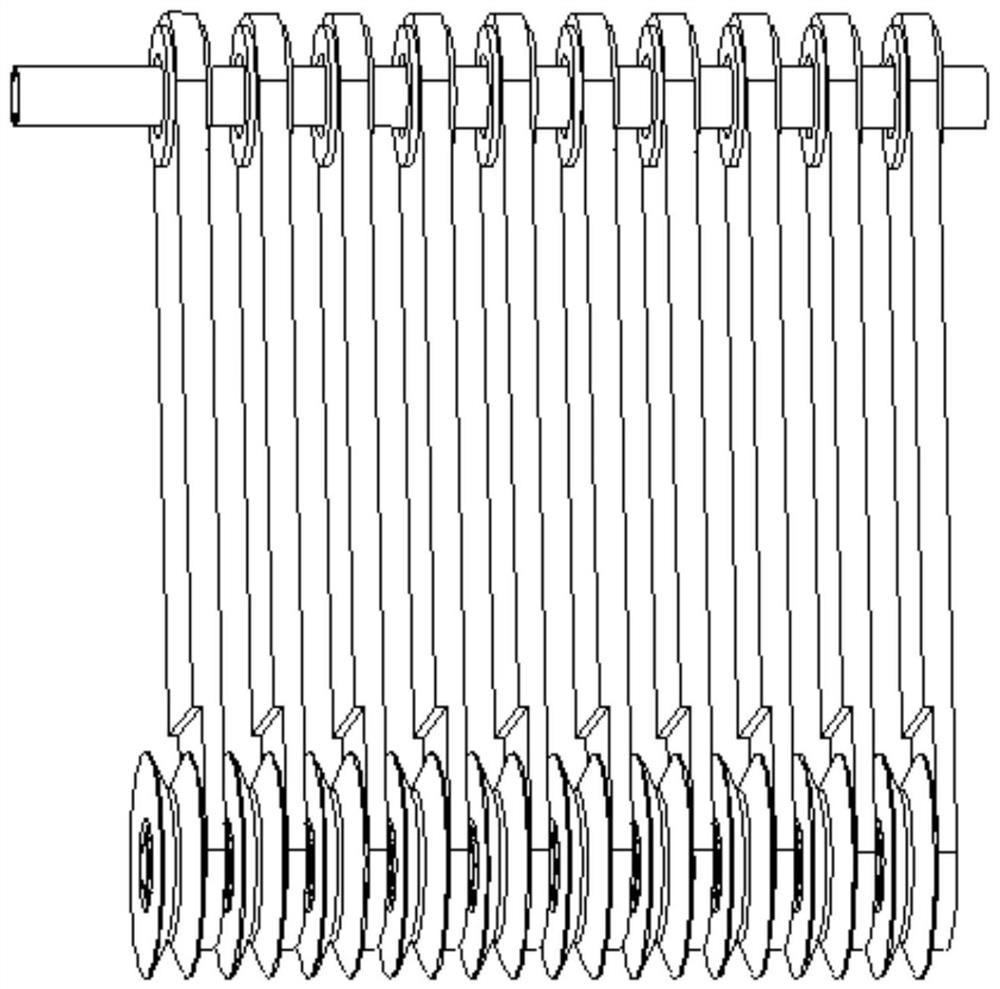

[0034] Membrane wire limit part: including membrane wire rack 1, barreled wet wire 2, porcelain eye 3 and guide wheel 4, etc., by limiting the position of a single membrane wire 5, the wires do not affect each other.

[0035] Tension adjustment part: including the tension wheel 6 and the swing rod 7, etc., to adjust the tension of the membrane filament.

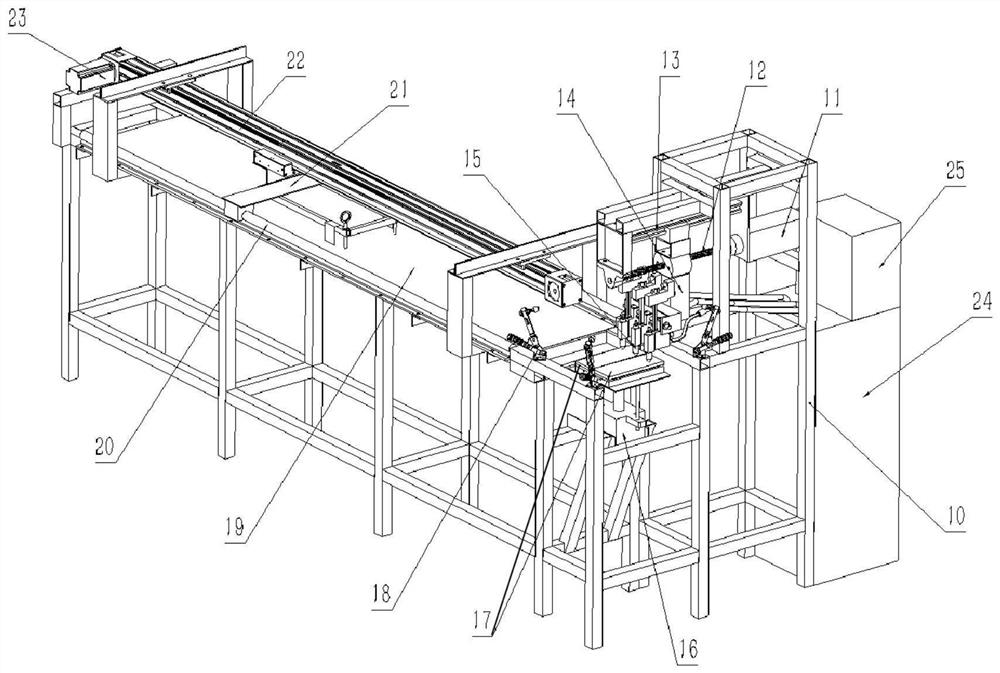

[0036] Wire arranging part: including wire receiving wheel 8, wire arranging wheel 9, wire arranging plate 17, elbow clamp 18, workbench 19, guide rail Ⅱ20, film pulling frame 21, timing belt 22, motor Ⅱ23 and electric control box 25, etc., to realize Multiple membrane wires are automatically arranged.

[0037] Gluing part: including glue frame 10, motor Ⅰ11, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com