High temperature resistant color hydrogenated butadiene-acrylonitrile rubber material and preparing method thereof

A technology of hydrogenated nitrile rubber and high temperature resistance, applied in the rubber field, can solve the problems of poor performance retention, poor thermal stability of heat resistance, etc., and achieve the effect of improving heat resistance, heat resistance and van der Waals force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

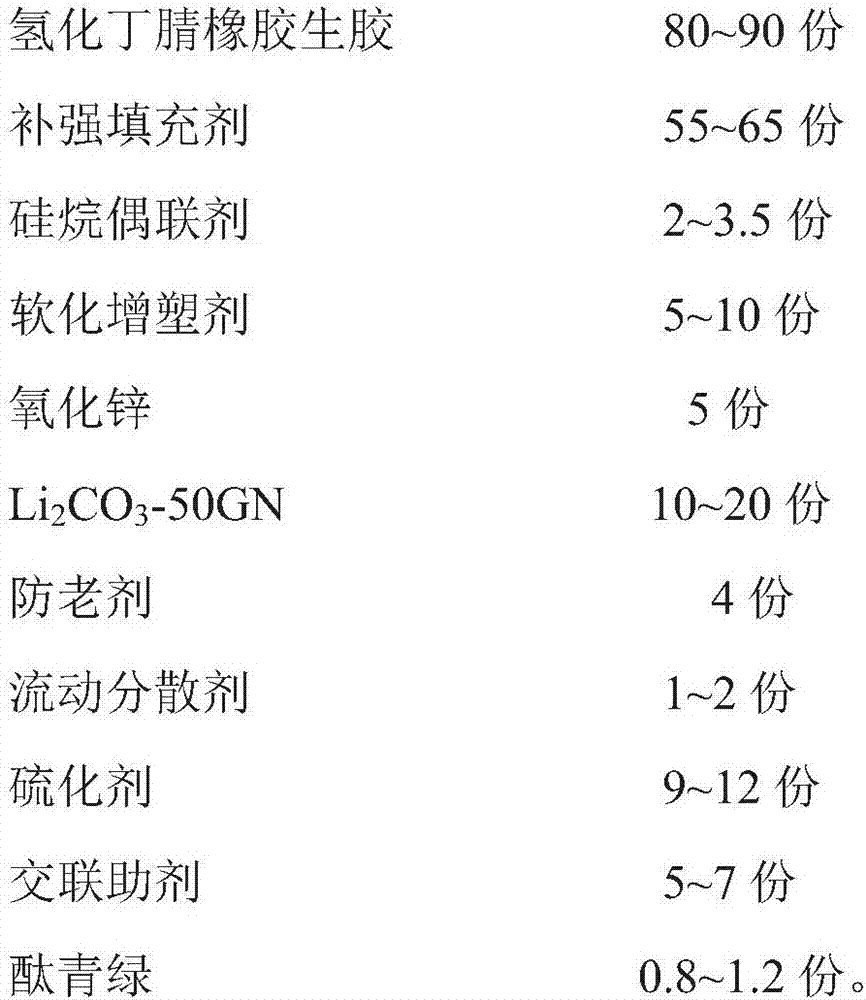

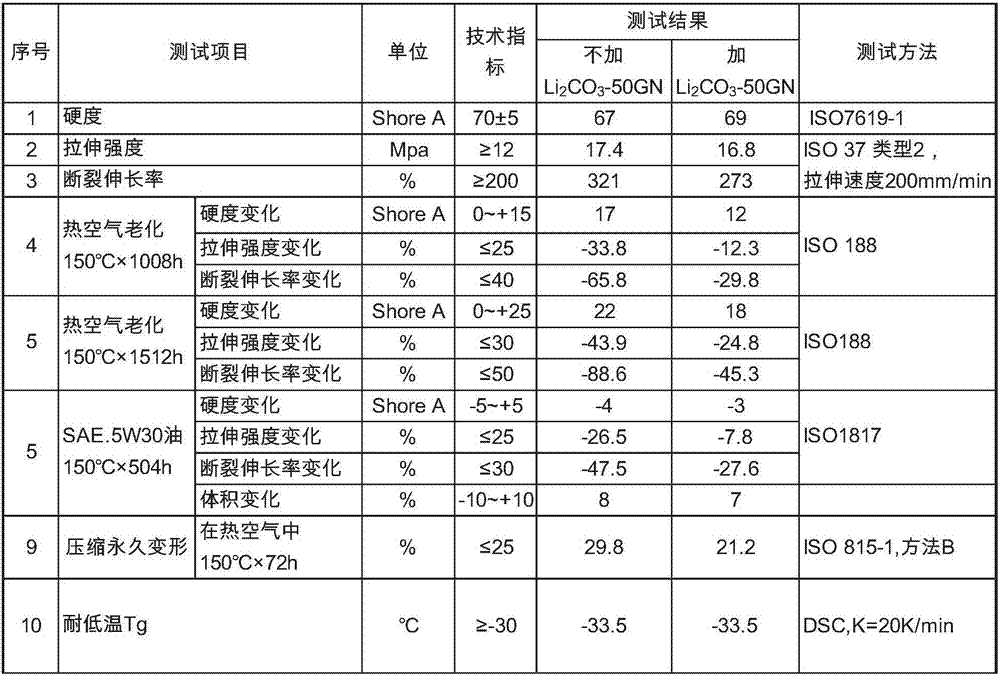

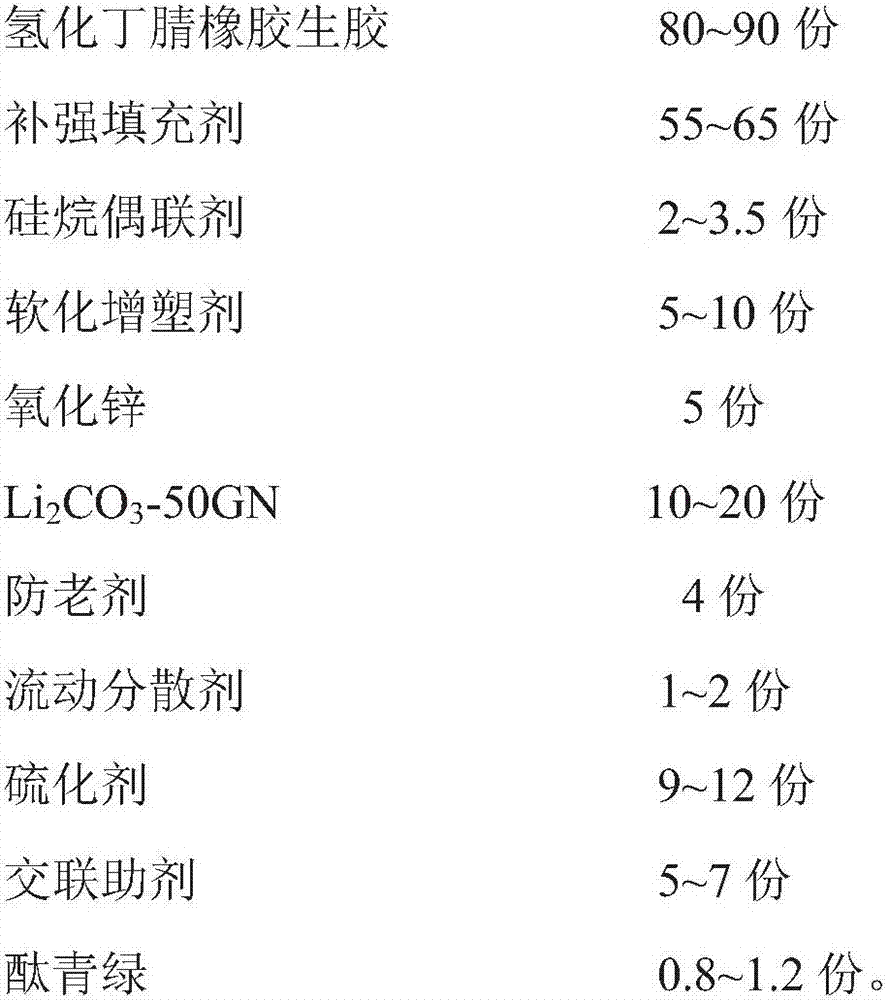

[0035] The high temperature resistant color hydrogenated nitrile rubber material of this embodiment includes the following components by weight: 80 parts of hydrogenated nitrile rubber raw rubber, 55 parts of light-colored reinforcing filler VM56, and 2 parts of silane coupling agent A172. Softening plasticizer TOTM 5 parts, zinc oxide 5 parts, Li 2 CO 3 -50GN 15 parts, antioxidant 4452 parts, antioxidant ZMMBI 2 parts, flow dispersant WB222 1.5 parts, vulcanizing agent Perkadox 14-40B-GR 12 parts, crosslinking aid Ricon153D 5 parts, phthalocyanine green 0.8 parts.

[0036] The preparation process of a high temperature resistant colored hydrogenated nitrile rubber material of this embodiment is:

[0037] (1) Preparation of masterbatch rubber A: Prepare materials according to the formula of high temperature resistant color hydrogenated nitrile rubber material, combine the hydrogenated nitrile rubber raw rubber, Li 2 CO 3 -50GN, anti-aging agent 445 and anti-aging agent ZMMBI are put ...

Embodiment 2

[0048] A high temperature resistant colored hydrogenated nitrile rubber material of this embodiment includes the following components by weight: 90 parts of hydrogenated nitrile rubber raw rubber, 65 parts of light-colored reinforcing filler VM56, and 3.5 parts of silane coupling agent A172. TOTM 10 parts, zinc oxide 5 parts, Li 2 CO 3 -50GN 20 parts, antioxidant 445 2 parts, antioxidant ZMMBI 2 parts, flow dispersant WB222 2 parts, vulcanizing agent Perkadox 14-40B-GR 9 parts, crosslinking aid Ricon153D 7 parts, phthalocyanine green 1 part.

[0049] The preparation process of a high temperature resistant colored hydrogenated nitrile rubber material of this embodiment is:

[0050] (1) Preparation of masterbatch rubber A: prepare materials according to the formula of high temperature resistant color hydrogenated nitrile rubber material, and combine raw rubber, Li 2 CO 3 -50GN, anti-aging agent 445 and anti-aging agent ZMMBI are put into the internal mixer at the same time, when the t...

Embodiment 3

[0056] The high temperature resistant color hydrogenated nitrile rubber material of this embodiment includes the following components by weight: 85 parts of hydrogenated nitrile rubber raw rubber, 60 parts of light-colored reinforcing filler VM56, and 3 parts of silane coupling agent A172. Softening plasticizer TOTM 8 parts, zinc oxide 5 parts, Li 2 CO 3 -50GN 10 parts, antioxidant 445 2 parts, antioxidant ZMMBI 2 parts, flow dispersant WB222 1 part, vulcanizing agent Perkadox 14-40B-GR 10 parts, Ricon153D 6 parts, Phthalocyanine green 1.2 parts.

[0057] The preparation process of a high temperature resistant colored hydrogenated nitrile rubber material of this embodiment is:

[0058] (1) Preparation of masterbatch rubber A: Prepare materials according to the formula of high temperature resistant color hydrogenated nitrile rubber material, combine the hydrogenated nitrile rubber raw rubber, Li 2 CO 3 -50GN, anti-aging agent 445 and anti-aging agent ZMMBI are put into the internal m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hardness change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com