Patents

Literature

108results about How to "Enhanced van der Waals force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

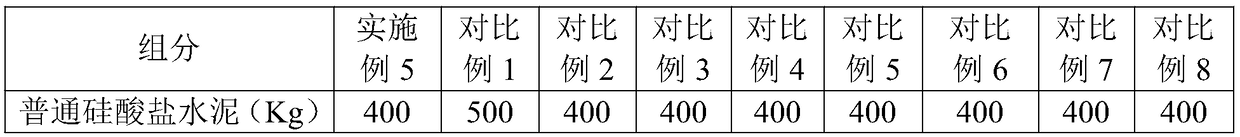

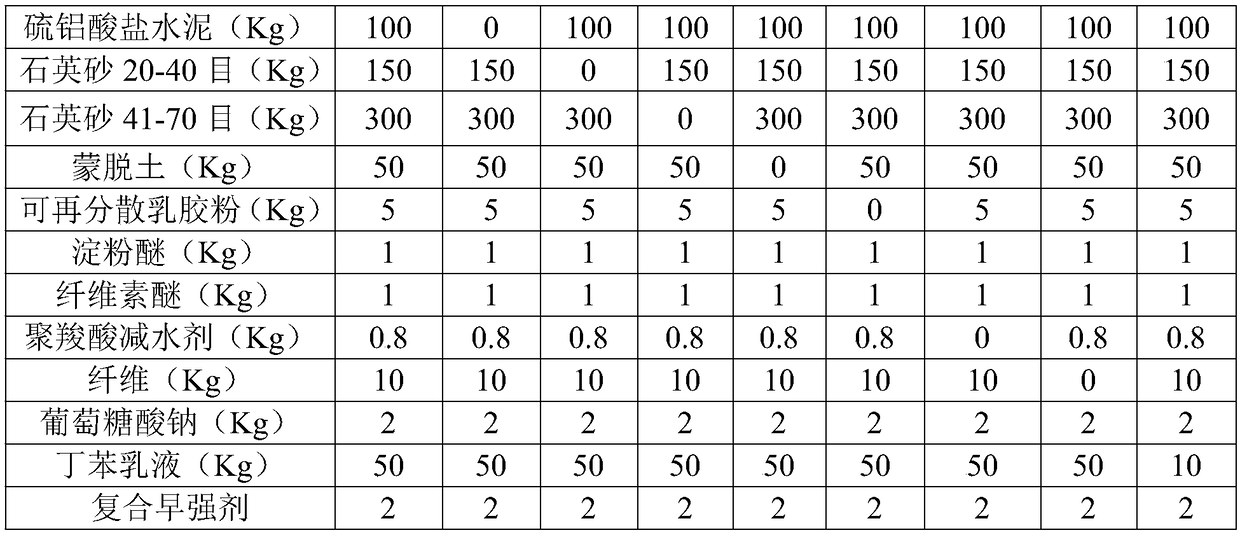

Special repair mortar for structure and preparation method thereof

The invention discloses special repair mortar for a structure. The mortar is prepared from the following components in parts by weight: 350-500 parts of common silicate cement, 50-150 parts of sulphate aluminum cement, 100-200 parts of 20-40-mesh quartz sand, 300-350 parts of 41-70-mesh quartz sand, 20-50 parts of montmorillonite, 30-50 parts of a styrene-butadiene rubber latex, 1-10 parts of redispersible latex powder, 1-5 parts of starch ether, 1-5 parts of cellulose ether, 0.5-2 parts of a polycarboxylate superplasticizer, 1-3 parts of a retarder, 1-10 parts of fibers and 1-5 parts of a compound early strength agent. According to the special repair mortar for the structure, by selecting and proportioning the components in proportion, comprehensively excellent utilizing performance of the components, the components draw on strengths of each other and act jointly, so that the shrinking percentage of the mortar is low. Mechanical properties of relatively high bonding strength, tensileand crush resistances and the like are obtained, and the cost performance is high.

Owner:GUANGDONG FUTE NEW MATERIALS TECH CO LTD

Preparation method for silane-modified moisture-curable polyurethane hot melt adhesive

ActiveCN104449535AEnhanced van der Waals forceImprove wetting effectNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterWhitening Agents

The invention discloses a preparation method for a silane-modified moisture-curable polyurethane hot melt adhesive. The method comprises the following steps: (1) heating and mixing polyester polyol, polyether polyol, tackifying resin, an antioxidant and a fluorescent whitening agent at a certain temperature, performing reduced pressure degassing for 2 hours, and cooling to 90 DEG C; (2) adding isocyanate and a catalyst into a reaction system under the nitrogen protection, and reacting at 85-95 DEG C for 45 minutes; (3) adding a chain extender and a silane coupler under the nitrogen protection, and reacting at 85-95 DEG C for 1 hour to obtain a prepolymer; (4) transferring a reaction mixture into an aluminum foil bag under the nitrogen protection, sealing, and curing at 85 DEG C for 6 hours to obtain the silane-modified moisture-curable polyurethane hot melt adhesive with excellent performance.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

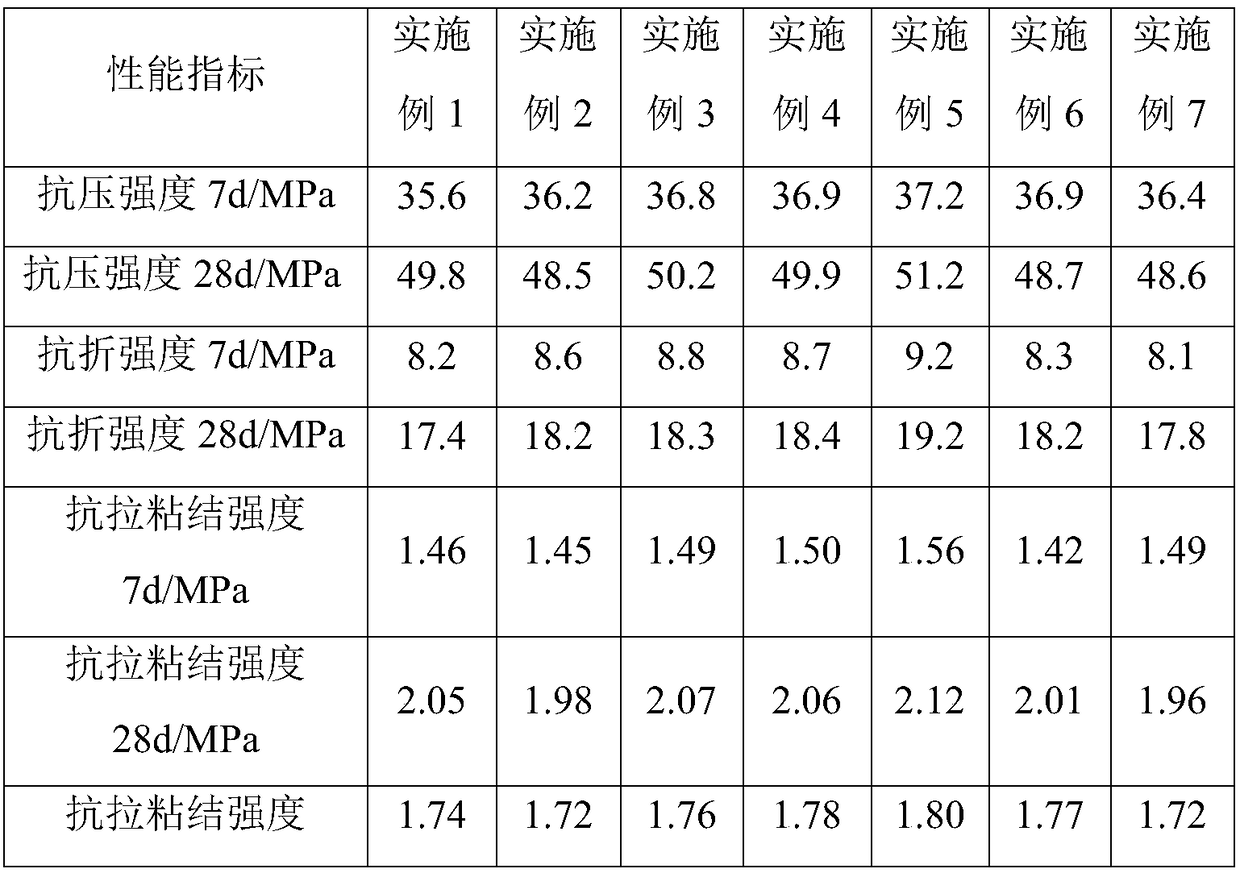

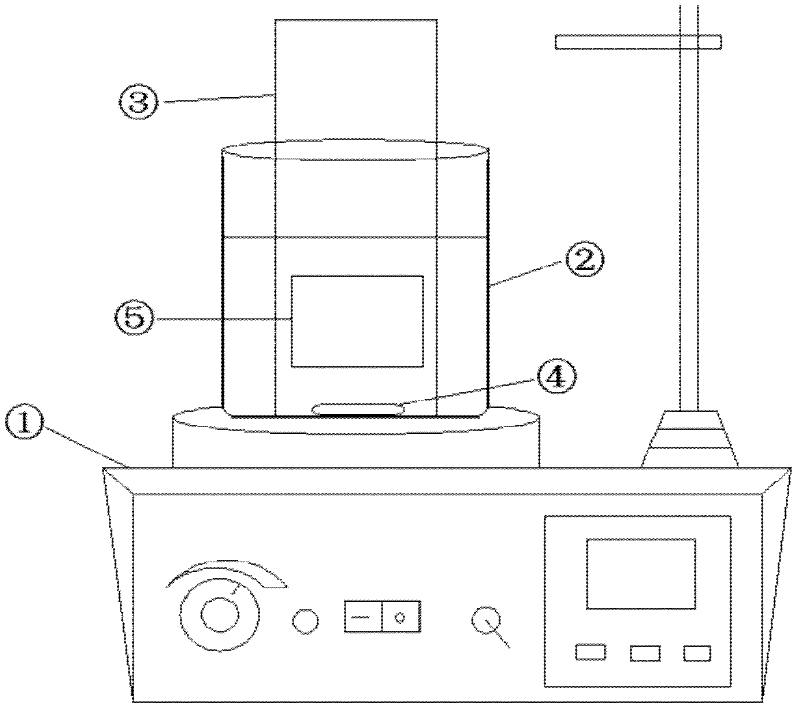

Method for preparing chitosan-like efficient flocculant

ActiveCN102977227ASignificant adsorption and bridging effectGood decolorizationWater/sewage treatment by flocculation/precipitationWater bathsAluminium sulfate

The invention discloses a method for preparing chitosan-like efficient flocculant, which comprises the following steps of: (1) pre-treatment of chitosan and derivatives of chitosan: dissolving chitosan and derivatives of chitosan in an acetic acid solution with pH value being 5, uniformly stirring, adding alkali until the pH value is 9 and chitosan separates out, and carrying out suction filtration for later use; (2) preparation of efficient flocculant: adding 1-2 parts of the pre-treated chitosan and derivatives of chitosan, 3-5 parts of cross-linking agents, 1 part of carbamide and 1.5-3 parts of aluminum sulfate in a four-port flask, stirring, pre-reacting for 0.5-1h in a water bath at 60-80 DEG C, then adding 3-8 parts of a dicyandiamide and carbamide mixed modifier, continuing to react for 2-4h, to obtain carbamide-chitosan-dicyandiamide like composite flocculant; and (3) purification of the product: after the reaction, separating out the product by using acetone; carrying out suction filtration; washing the product with ethanol; carrying out suction filtration, and drying in an oven at 90 DEG C for further use.

Owner:ZHEJIANG SILK TECH

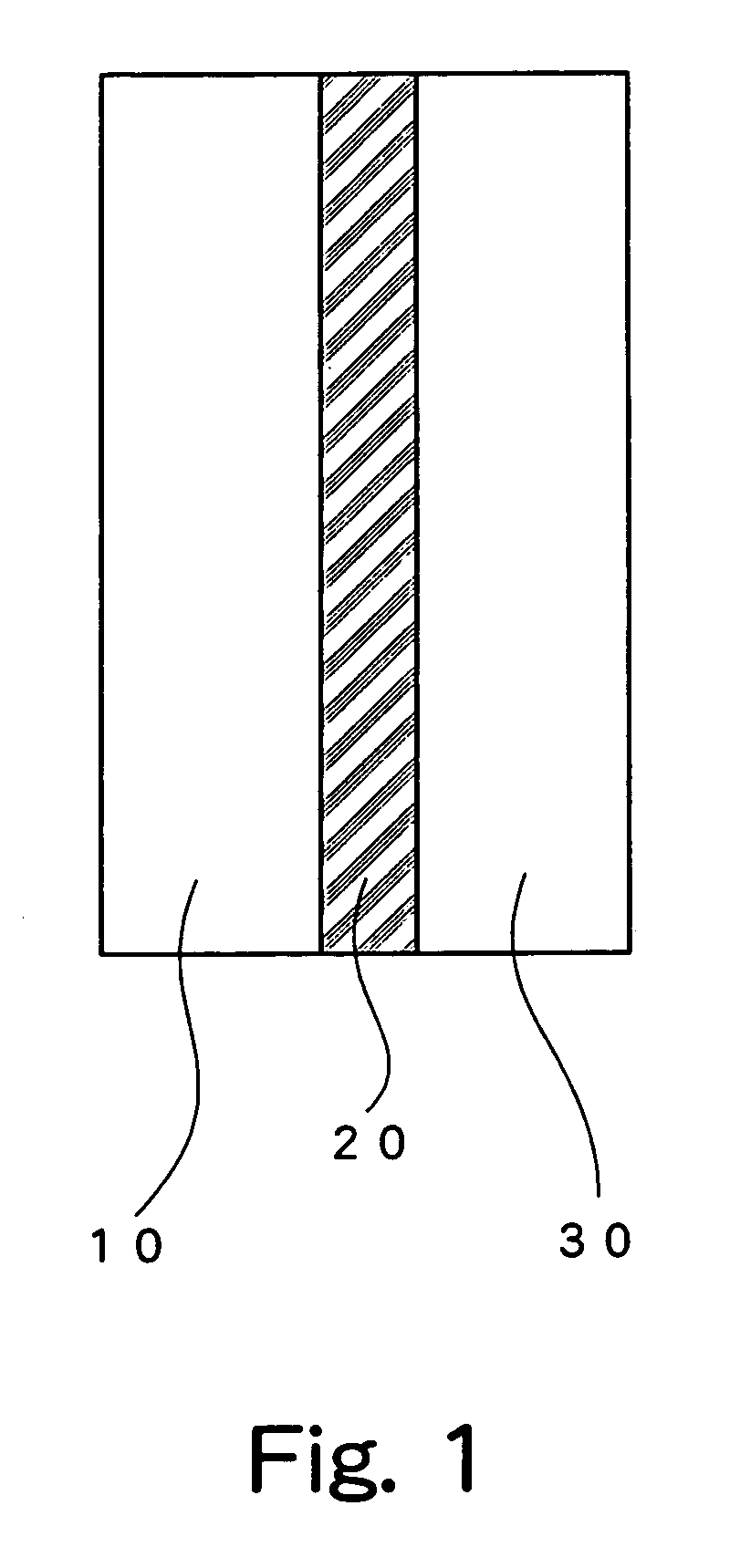

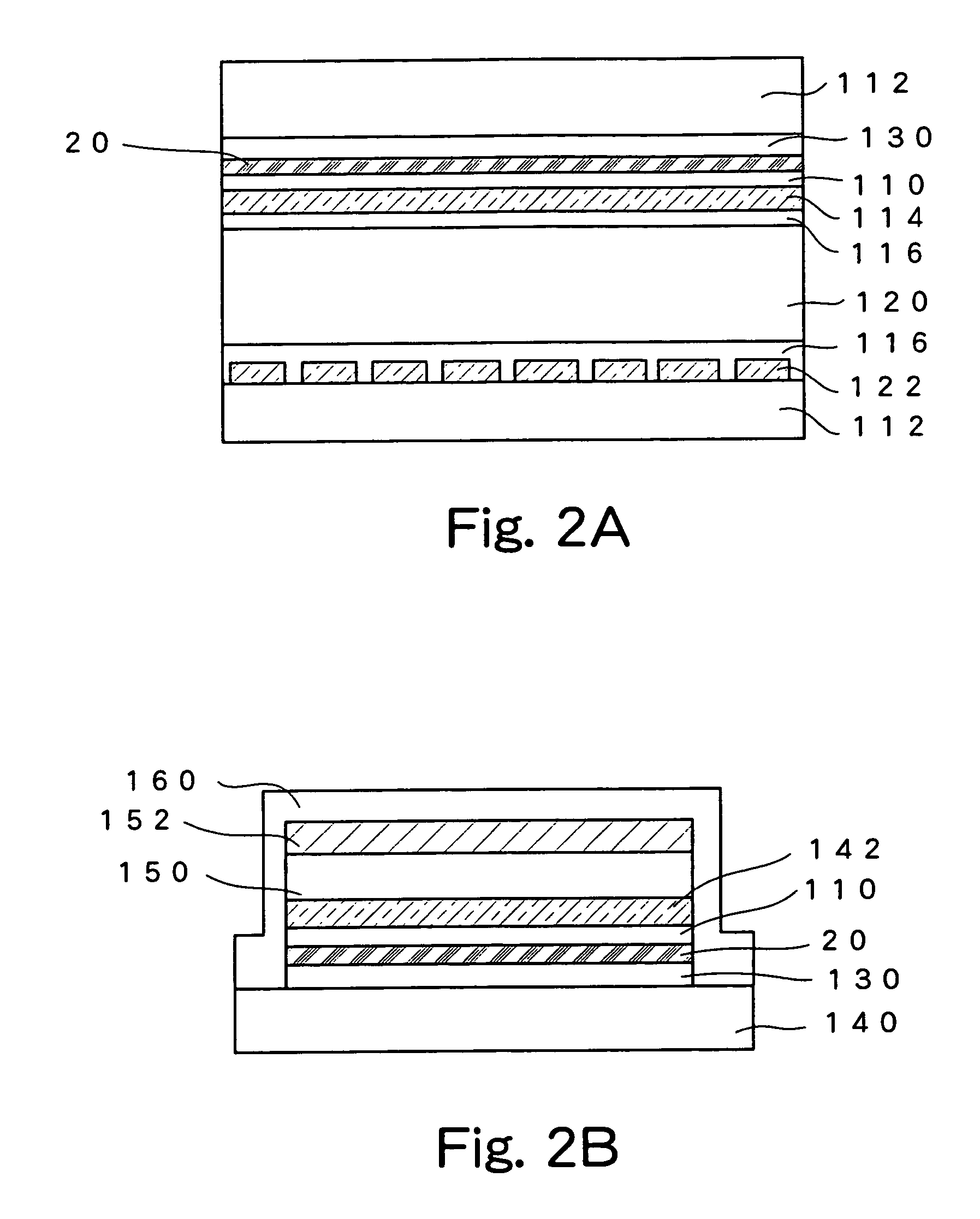

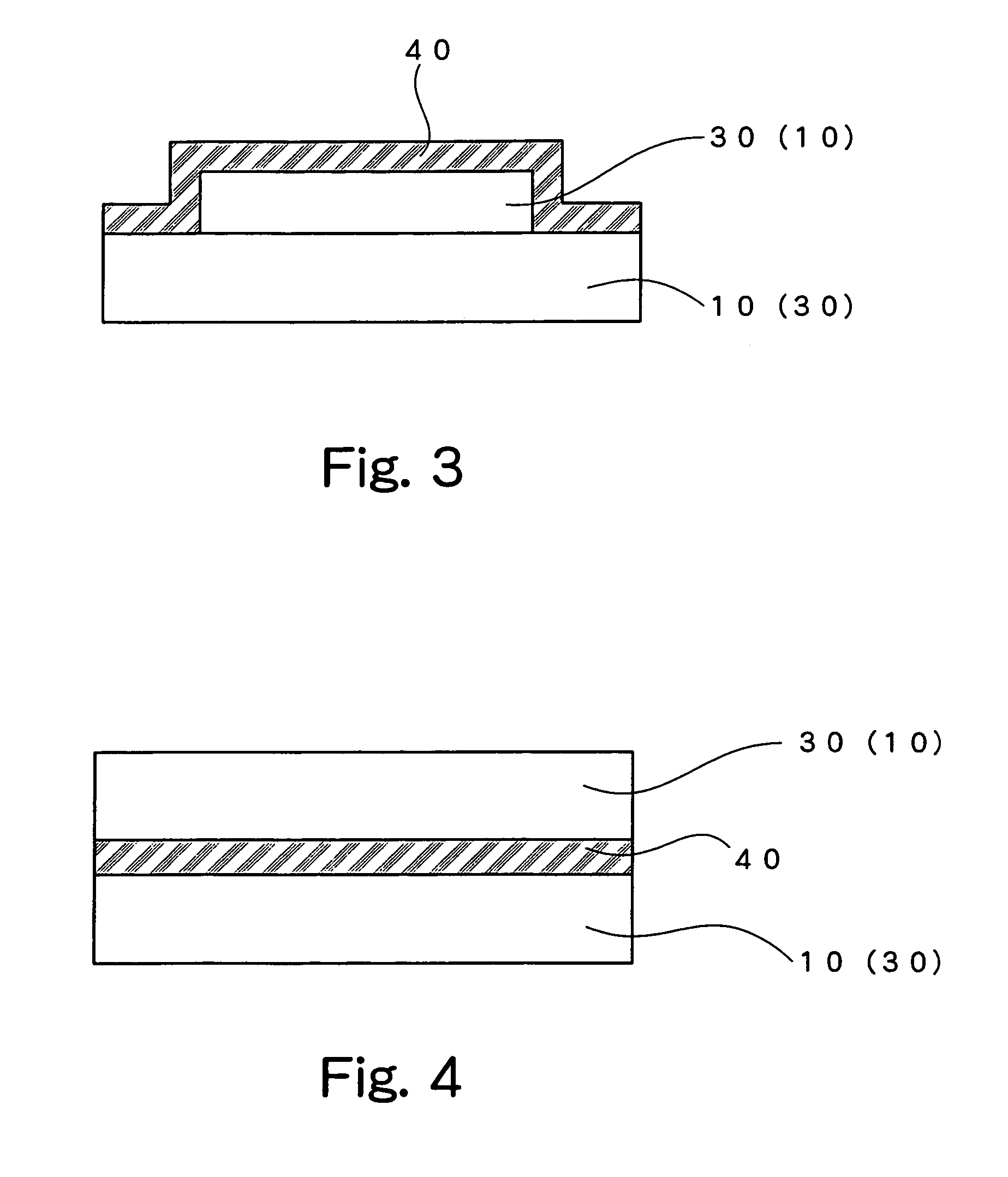

Laminating product including adhesion layer and laminate product including protective film

InactiveUS7279239B2Improve wettabilityImprove adhesionLiquid crystal compositionsLayered productsTectorial membraneGas phase

In a laminate product formed by an organic member and / or an inorganic member, high strength adhesion between the organic member and the inorganic member is achieved by providing an adhesion layer which includes amorphous carbon nitride (a-CNx:H) particularly between the organic member and the inorganic member. Further, in order to protect a laminate product formed by an organic member and / or an inorganic member, for example, an organic electronic element including an organic compound layer, such as an organic electroluminescence element, a protective film including at least amorphous carbon nitride and a protective layer having a laminate structure formed by sandwiching a vapor deposition inorganic film between plasma polymerized films are used. Thus, a protective film which is optimum to an organic electronic element, having high bending stress resistance, high shielding effect against moisture and oxygen existing in the air, and excellent resistance to high temperature and high humidity can be provided.

Owner:TOYOTA CENT RES & DEV LAB INC

Polyurethane hard-foam composition and polyurethane hard-foam plastic prepared from same

The invention discloses a polyurethane hard-foam composition and a polyurethane hard-foam plastic prepared from the same. The polyurethane hard-foam composition comprises polyisocyanate, polyether glycol, polyester polyol I, additive flame retardant and foaming agent, wherein the polyester polyol I is flame-retardant polyester polyol. The flame-retardant polyester polyol is added in the polyurethane hard-foam composition, so that the consumption of the additive flame retardant can be reduced; and the plastification action of the additive flame retardant on the polyurethane hard-foam plastic can be reduced, the Van der Waals force among macromolecular chains of polyurethane can be increased, and the relative slippage among the macromolecular chains can be reduced, thereby reducing the sizes of foaming pores formed by the composition. Meanwhile, the Van der Waals force among the macromolecular chains is increased, so that the rigidity of the pore walls of the foaming pores in the polyurethane hard-foam plastic can be increased, thereby ensuring that the foaming pores are more regular in structure and the deformation degree of the foaming pores is weakened. The foaming pores are small in size and stable in structure, and can enhance the compression strength and creep property of the polyurethane hard-foam plastic.

Owner:北京碧海云智新材料技术有限公司

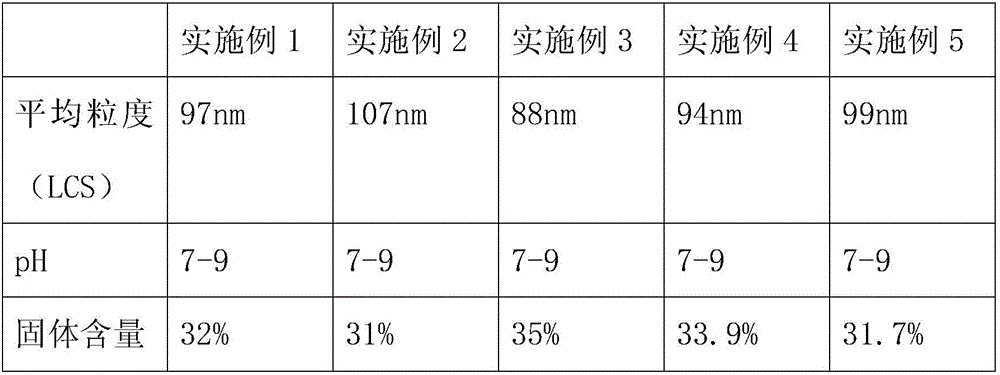

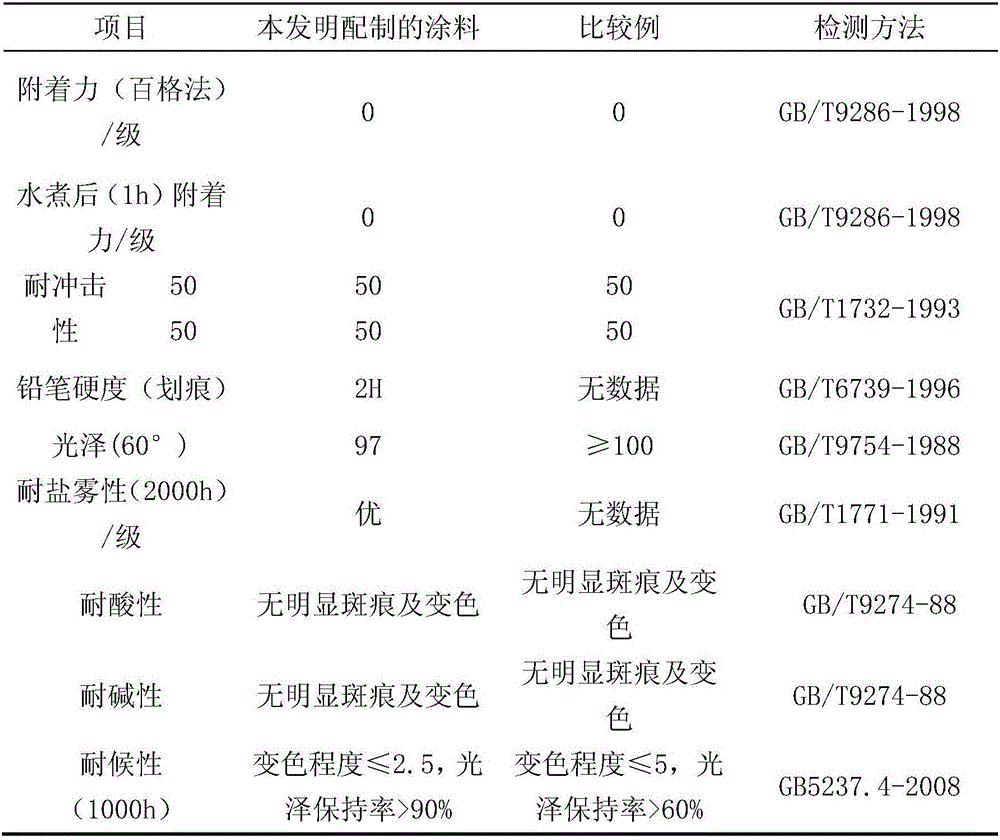

Waterborne polyurethane dispersion and application thereof

InactiveCN106243316AImprove adhesionIncrease Coulomb forcePolyurea/polyurethane coatingsPolyurethane dispersionPolymer science

The invention discloses a waterborne polyurethane dispersion and application thereof. The waterborne polyurethane dispersion is prepared from the following components through reacting: (A) one or more types of polyisocyanate; (B) one or more types of polymeric glycols; (C) one or more types of compounds containing one or more hydroxyl groups or amino groups; (D) one or more ionic, potential-ionic or non-ionic hydrophilic compounds with isocyanate activity; (E) one or more types of salt forming reagents; (F) one or more types of catalysts; the use ratios of the components are as follows: 10 weight percent to 35 weight percent of the component (A), 50 weight percent to 90 weight percent of the component (B), 0.5 weight percent to 12 weight percent of the component (C), 1.5 weight percent to 15 weight percent of the component (D), 1.5 weight percent to 8.5 weight percent of the component (E), 0.001 weight percent to 0.5 weight percent of the component (F); the total sum of all the components is equal to 100 weight percent. The waterborne polyurethane dispersion provided by the invention contains a proper amount of polar groups and has an extremely excellent attaching force on an aluminum material; the attaching force reaches grade 0.

Owner:肇庆浩城树脂科技有限公司

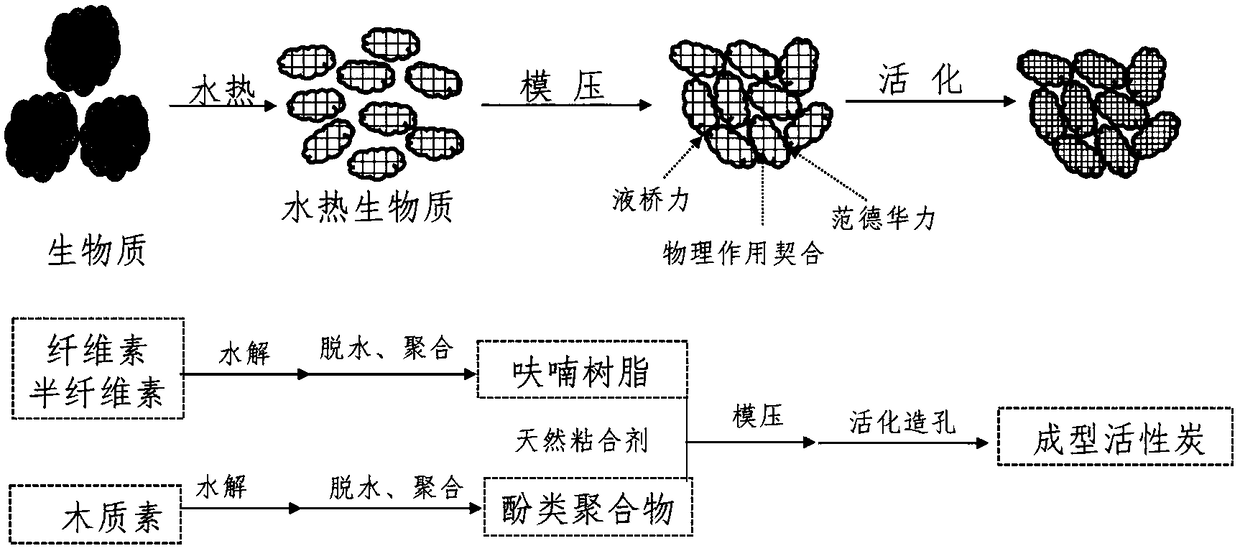

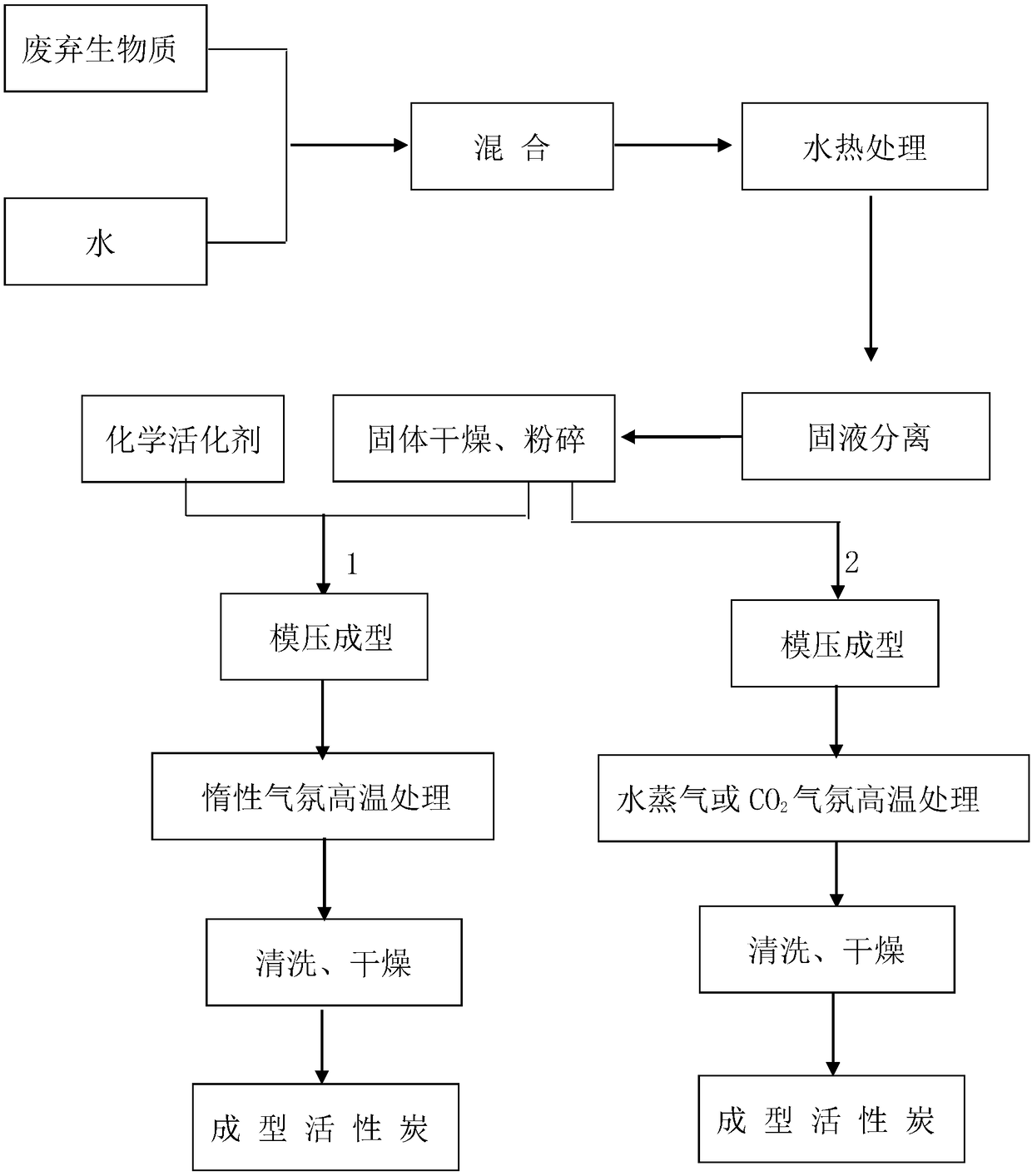

Process for preparing binder-free formed activated carbon from waste biomass

Due to the characteristics of large specific surface area and controllable shape, formed activated carbon is applied in multiple fields such as food, medicines, chemical industry and environment protection. Existing formed activated carbon is mostly prepared from powdered activated carbon formed through a binder, but the powdered activated carbon is expensive, and the binder can cause the reduction of an adsorption effect of the formed activated carbon and the secondary pollution, so that the development of the cheap, green and environmental-friendly binder-free formed activated carbon has animportant practical significance. Waste biomasses are modified under the specific condition, and the binder-free formed activated carbon is prepared from the modified waste biomasses through a chemical or physical activation method. Compared with traditional formed activated carbon, the formed activated carbon prepared through the process adopts the waste biomasses as the raw materials without theneed for using the binder so as to have the advantages of simple preparation process, low cost, renewability, greenness, environment protection and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

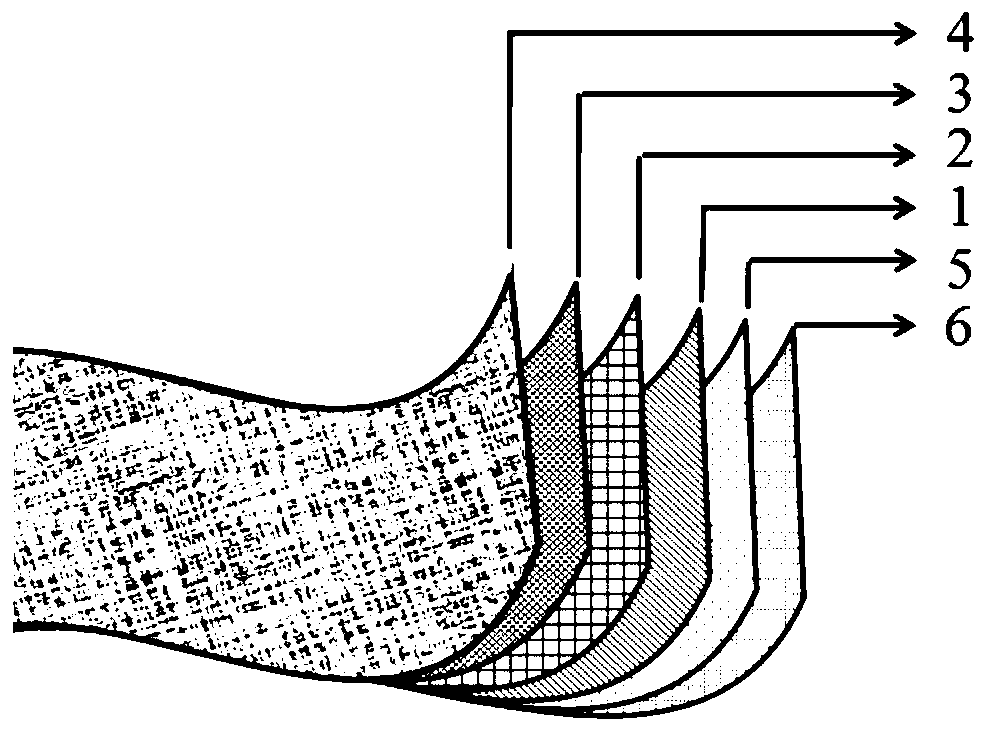

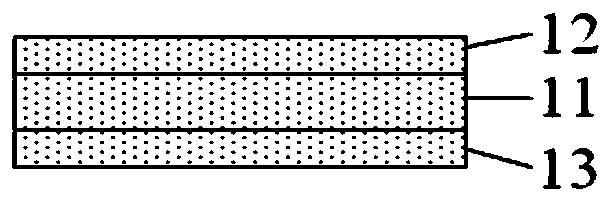

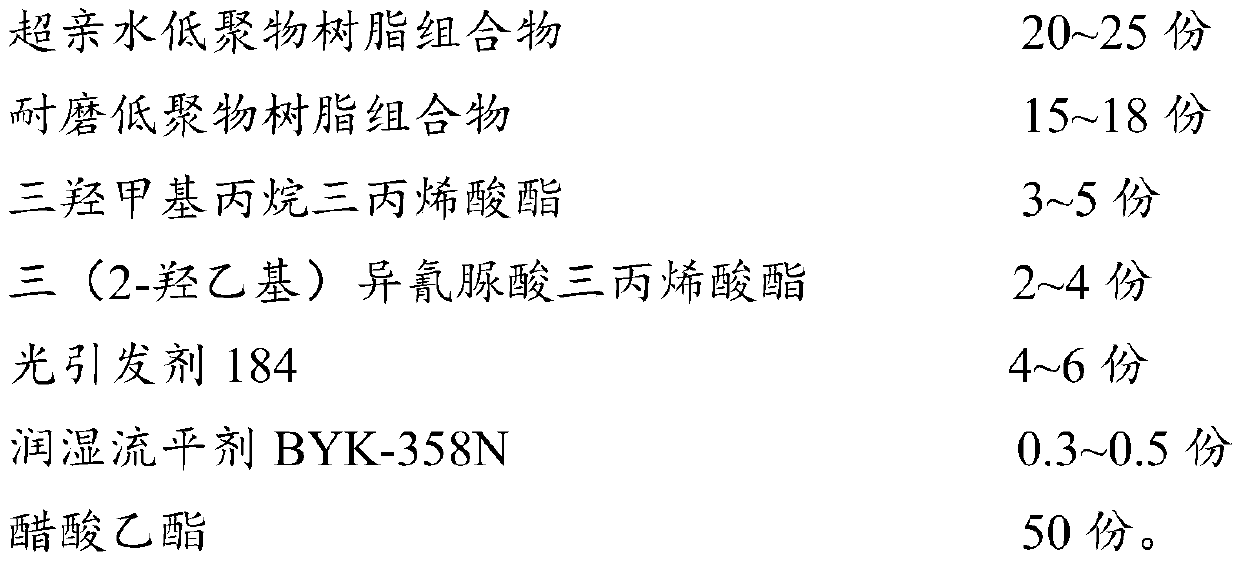

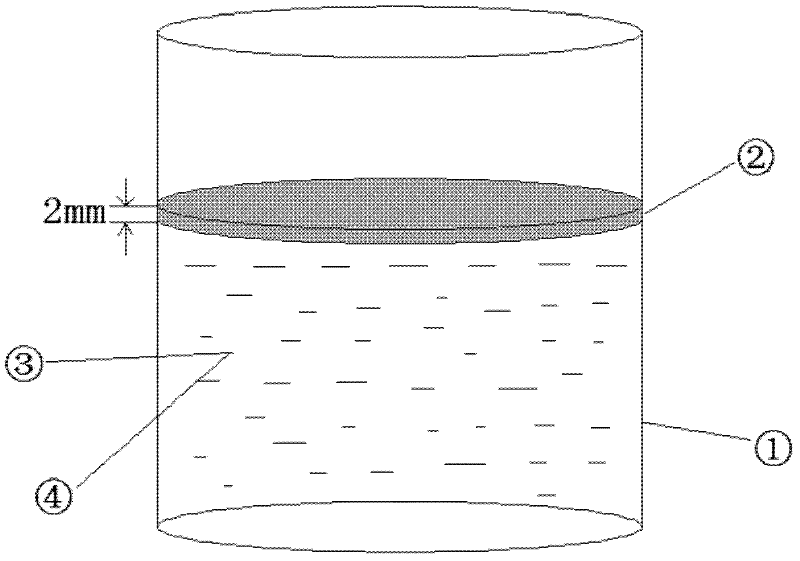

High-wear-resistance glass explosion-proof film adhesive with anti-fog effect, and preparation method thereof

ActiveCN111040653AReduce surface tensionHigh hardnessPolyurea/polyurethane coatingsPolyether coatingsPolymer scienceMeth-

The invention provides a high-wear-resistance glass explosion-proof film with an anti-fog effect. The high-wear-resistance glass explosion-proof film comprises a PET protective film (4), an anti-fog and wear-resistant resin coating (3), a polyacrylate pre-coating (2), a high-hardness transparent modified PET film (1), a mounting adhesive layer (5) and a PET release film (6). The anti-fog and wear-resistant resin coating comprises, by mass, 20 to 25 parts of a super-hydrophilic oligomer resin composition, 15 to 18 parts of a wear-resistant oligomer resin composition, 3 to 5 parts of trimethylolpropane triacrylate, 2 to 4 parts of tri(2-hydroxyethyl)isocyanurate triacrylate, 4 to 6 parts of a photoinitiator 184, 0.3 to 0.5 part of a wetting leveling agent BYK-358N and 50 parts of ethyl acetate. The high-hardness transparent modified PET film is a composite film prepared from three layers of different mass components through melt co-extrusion and two-way stretching. The product provided by the invention has good antifogging effect and excellent wear resistance, and can be used for explosion-proof films on various glass surfaces.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

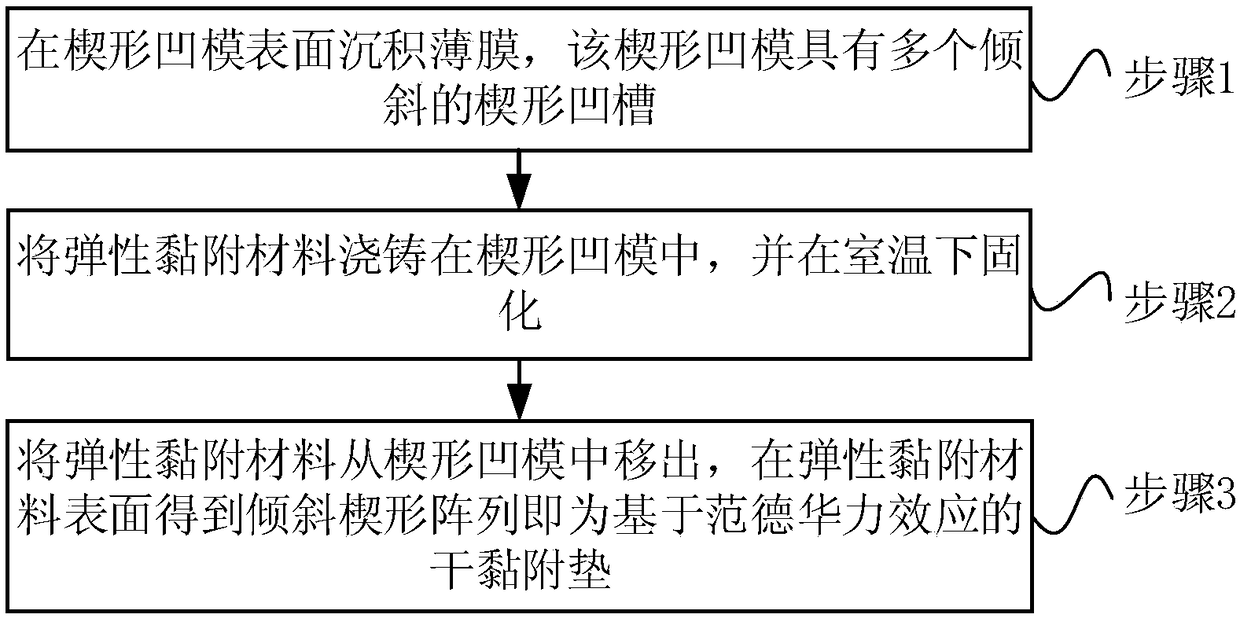

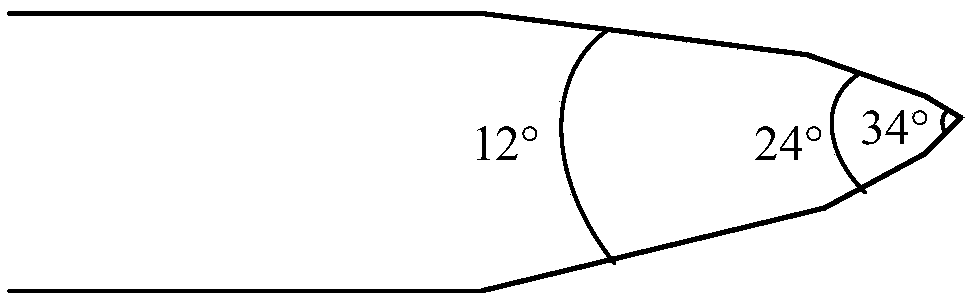

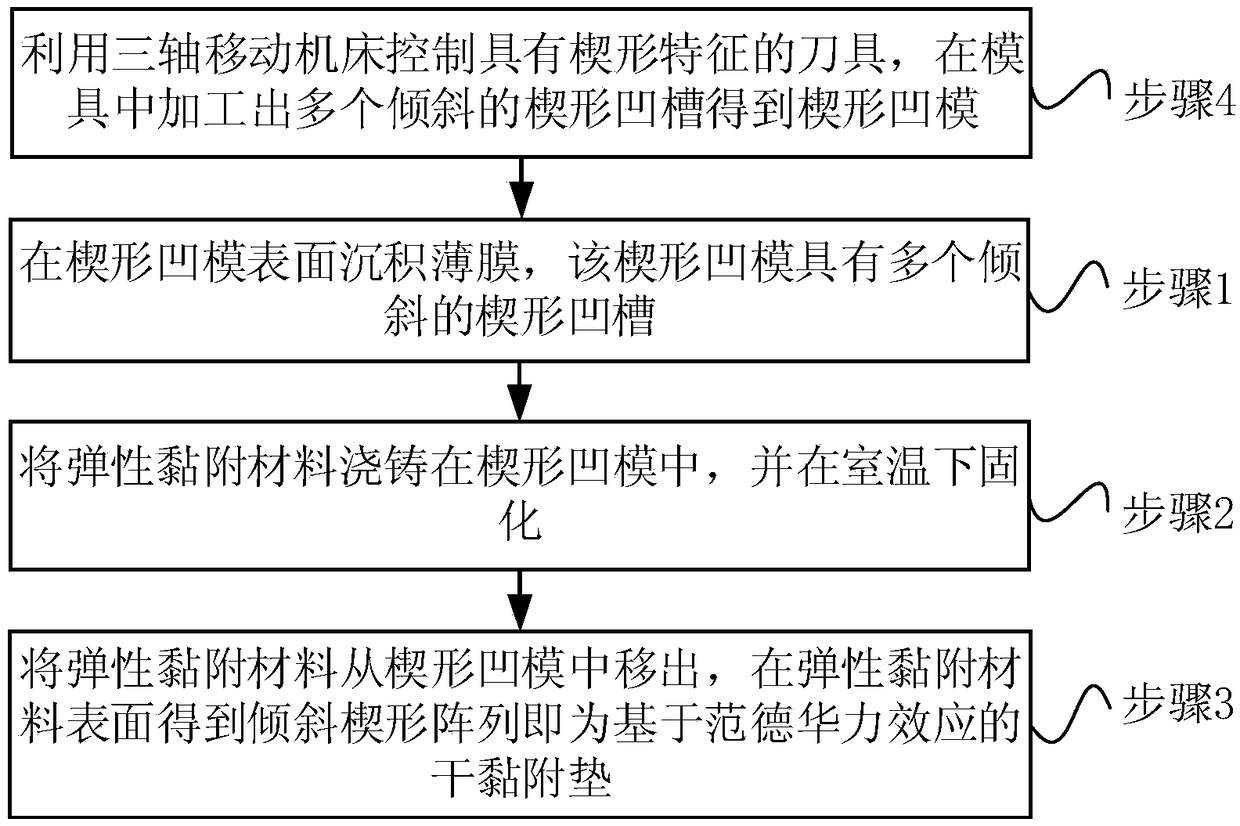

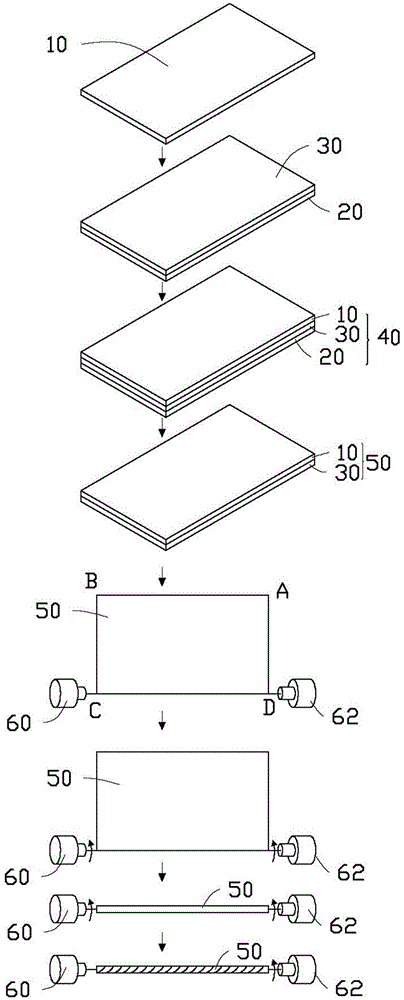

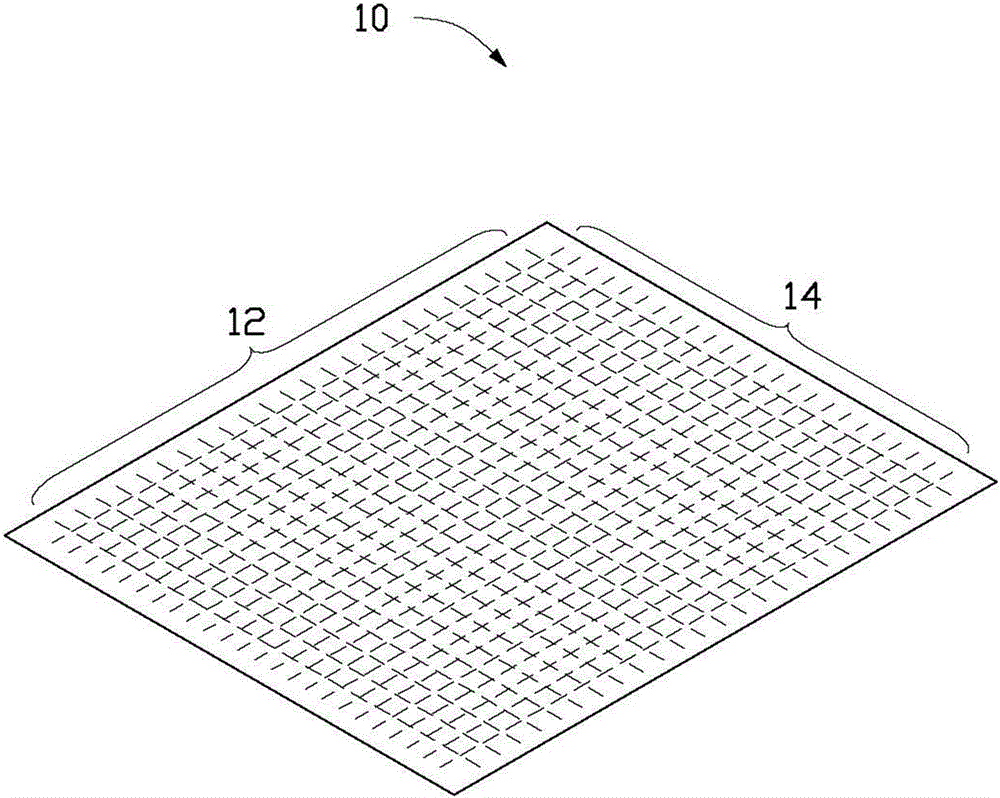

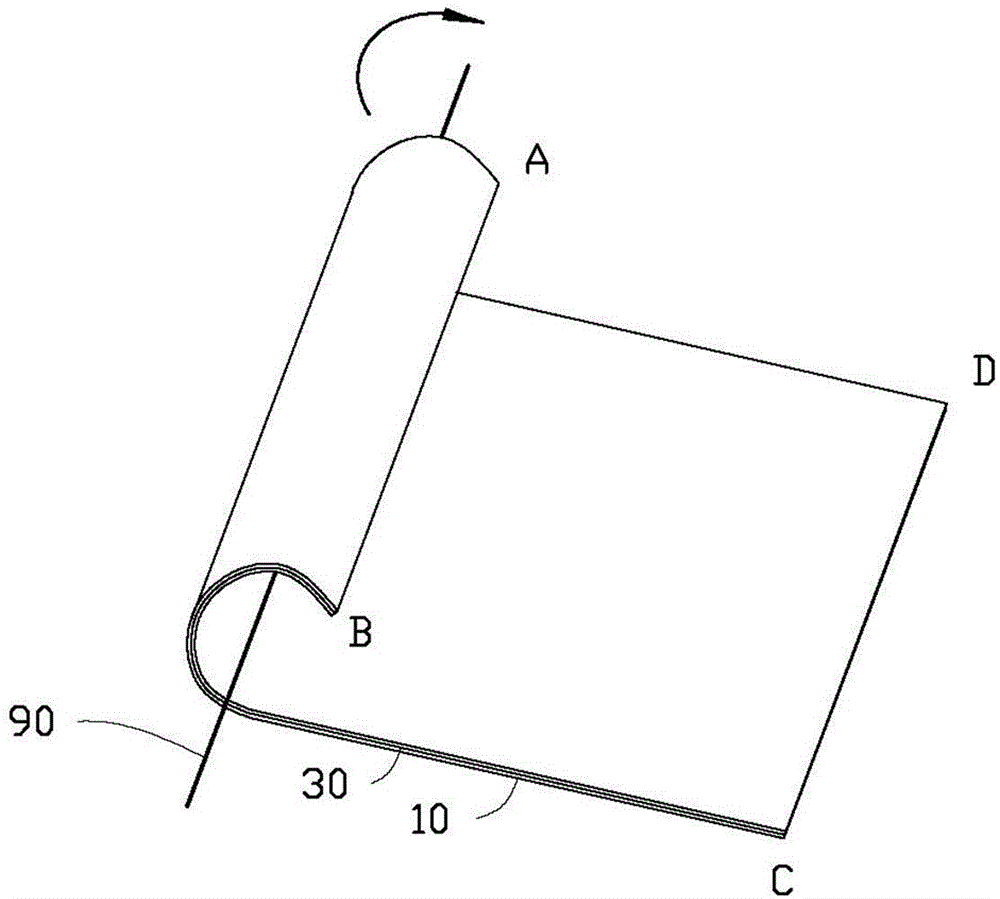

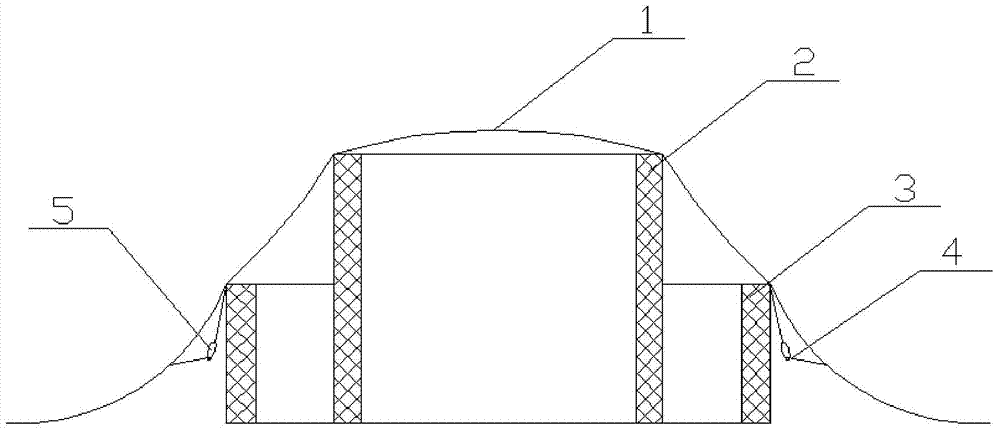

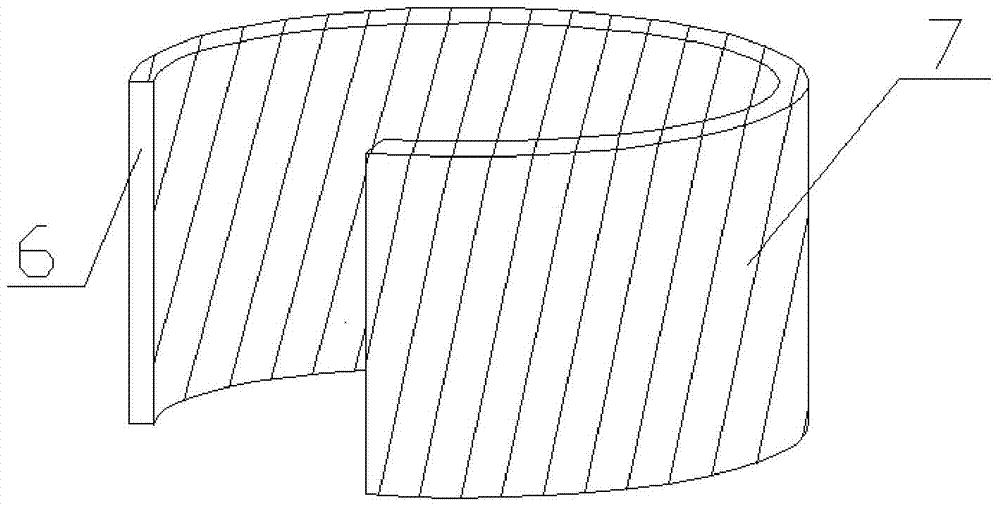

Dry adhesion pad based on Van der Waals force effect and manufacturing method thereof

The invention relates to a dry adhesion pad based on the Van der Waals force effect and a manufacturing method thereof. The method comprises the following steps of depositing a thin film on the surface of a wedge-shaped concave die, wherein the wedge-shaped concave die is provided with a plurality of inclined wedge-shaped grooves; casting an elastic adhesive material into the wedge-shaped concavedie, and carrying out curing at room temperature; and moving the elastic adhesive material out of the wedge-shaped concave die so as to obtain an inclined wedge-shaped array on the surface of the elastic adhesive material, namely the dry adhesion pad based on Van der Waals force effect. According to the dry adhesion pad based on the Van der Waals force effect and the manufacturing method thereof,the adhesion pad with low pre-load, high adhesion and easy desorption characteristics can be prepared by depositing the thin film on the surface of the wedge-shaped concave die with the multiple inclined wedge-shaped grooves, casting the elastic adhesive material into the wedge-shaped concave die, then carrying out curing at room temperature and moving the elastic adhesive material out of the wedge-shaped concave die.

Owner:BEIHANG UNIV

Preparation method of force-electricity-light conversion enhanced luminous composite thin film

ActiveCN107141666AOvercome the disadvantage of high hardnessHigh luminous intensityFilament/thread formingNon-woven fabricsMicro nanoFiber

The invention relates to a preparation method of a force-electricity-light conversion enhanced luminous composite thin film, and belongs to the technical field of material physics. The preparation method comprises the following steps: firstly preparing luminous materials with different topographic elastic stresses, performing surface modification on the luminous materials, dispersing the luminous materials in a piezoelectric organic matrix, and finally preparing the composite thin film. According to the preparation method, by control over the anisotropy of the growth morphology, a micro-nano stress luminous material with enhanced flexible-electric and photoelectric effect is obtained; by taking an organic piezoelectric material as a matrix, the flexibility is improved; by surface modification for inorganic particles to wrap a layer of macromolecules or polymers, a core-shell structure is formed, so that the compatibility between an inorganic matter and the organic matrix is improved, and the luminous intensity is enhanced; furthermore, a highly oriented composite fiber thin film is prepared through an electrostatic spinning, so that the stress intensity of the composite material is enhanced, and the luminous intensity is enhanced.

Owner:NANJING UNIV OF TECH

Smoke suppression low-odor modified asphalt coiled material coating material, preparation method thereof and modified asphalt coiled material

ActiveCN109705734AReduce generationEmission reductionOther rubber coatingsBituminous coatingsMetal-organic frameworkBULK ACTIVE INGREDIENT

The invention discloses a smoke suppression low-odor modified asphalt coiled material coating material, a preparation method thereof and a modified asphalt coiled material. The coating material comprises matrix asphalt, a softening agent, a free radical scavenger, a metal organic framework compound, an inorganic adsorption material, a reaction type odor inhibitor, a high polymer modifier, tackifying resin, rubber powder and a filler. According to the invention, the free radical scavenger is added, so that a small molecule volatile gas generated by free radical reaction is reduced; the metal organic framework compound can be used for efficiently selectively adsorbing polycyclic aromatic hydrocarbon sulfur-containing thiophene substances and reducing the emission of the polycyclic aromatic hydrocarbon sulfur-containing thiophene substances; the inorganic adsorption material is used for reinforcing the interaction between volatile organic matters and the asphalt matrix, so that the overall emission is reduced; the reaction type odor inhibitor reacts with mercaptan in the asphalt, and the emission of the mercaptan as one of peculiar smell sources and hydrogen sulfide is reduced. The test result shows that smoke-inhibiting and odor-removing active ingredients are added, the flue gas volatilization amount of the modified asphalt coating material is reduced by more than 80% at 180 DEGC, and pollutant emission and peculiar smell source emission are remarkably reduced.

Owner:苏州东方雨虹建筑材料有限公司

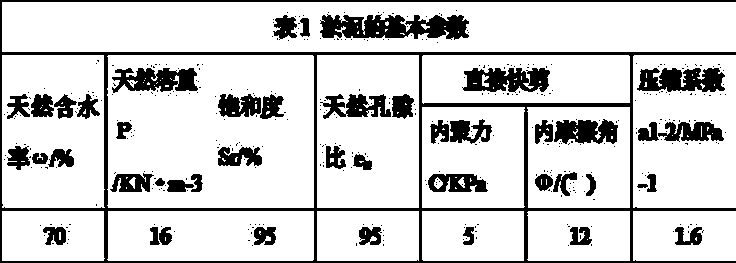

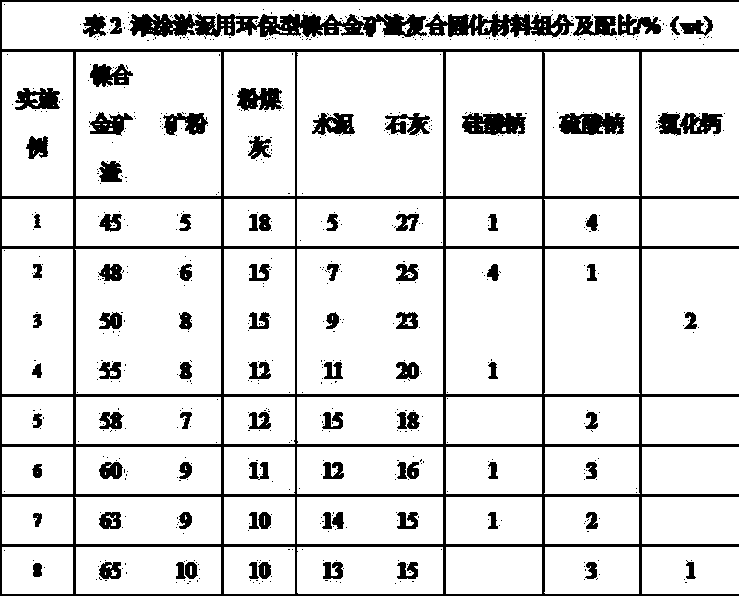

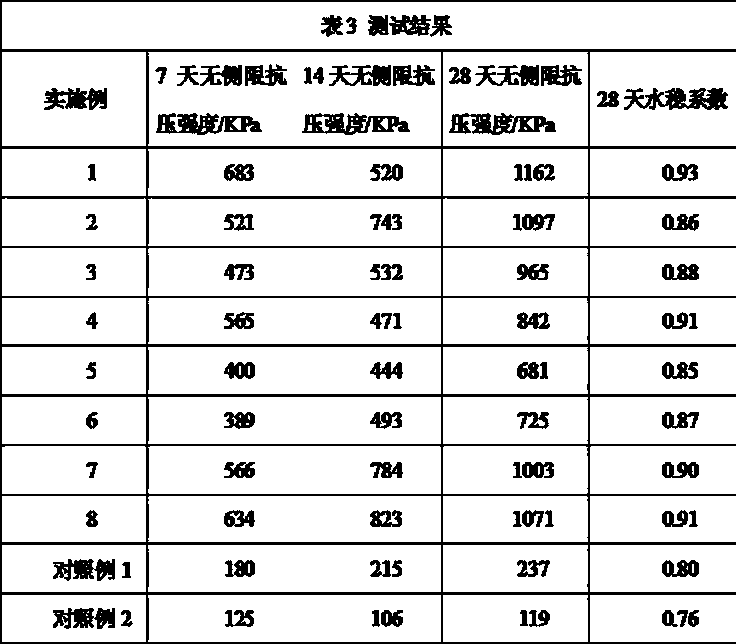

Environment-friendly nickel alloy slag composite curing material for flat sludge

InactiveCN103880379AEnhanced van der Waals forceSludge treatment by de-watering/drying/thickeningSolid waste managementSlagCoal

The invention discloses an environment-friendly nickel alloy slag composite curing material for flat sludge. The environment-friendly nickel alloy slag composite curing material is composed of the following component in percentage by weight: 45.0-65.0% of nickel alloy slag, 5-10% of mineral powder, 10-18% of coal ash, 5-15% of cement, 15-27% of lime and 1-5% of salt excitant. The environment-friendly nickel alloy slag composite curing material for the flat sludge is simple in raw material, wide in raw material source, and scientific and rational; the raw materials of the environment-friendly nickel alloy slag composite curing material most are the nickel alloy slag which is difficult to consume and utilize industrially at present and industrial solid wastes such as slag and coal ash, so that the environment-friendly nickel alloy slag composite curing material for the flat sludge accords with the state environmental protection policy, and is capable of saving energy and reducing consumption, and besides, the solidified soil is excellent in mechanical properties and water stability.

Owner:JIANGSU NATURE WAY TECH

Polyvinyl chloride floorboard substrate and preparation method thereof

The invention discloses a polyvinyl chloride floorboard substrate and a preparation method thereof, belonging to the technical field of polyvinyl chloride boards. The polyvinyl chloride floorboard substrate solves the problems of high cost and poor quality in the existing product. The polyvinyl chloride floorboard substrate is prepared from 80-100 parts of polyvinyl chloride SG8 resin, 100-120 parts of heavy calcium carbonate, 50 parts of floorboard substrate moldboard reclaimed material, 7-8 parts of foaming regulator 903, 2-3 parts of foaming regulator 902, 2.8-4.9 parts of composite stabilizer, 0.6-1.2 parts of internal lubricant ZB-60, 0.35-0.7 part of polyethylene (PE) wax, 0.2-0.5 part of AP, 0.5-0.8 part of plasticizer OA3, 0.3-0.4 part of heat-release AC (azodicarbonamide) foaming agent, 1.4-1.6 parts of heat-absorption Zhongkai c-2 foaming agent, 2-5 parts of ferrite yellow powder and 2-4 parts of CPE (chlorinated polyethylene). The preparation method comprises the following steps: mixing, plastifying and foaming, and extruding to obtain the finished product. The product can be widely used in office buildings, shopping malls, schools, gymnasia, hospitals and other locations.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

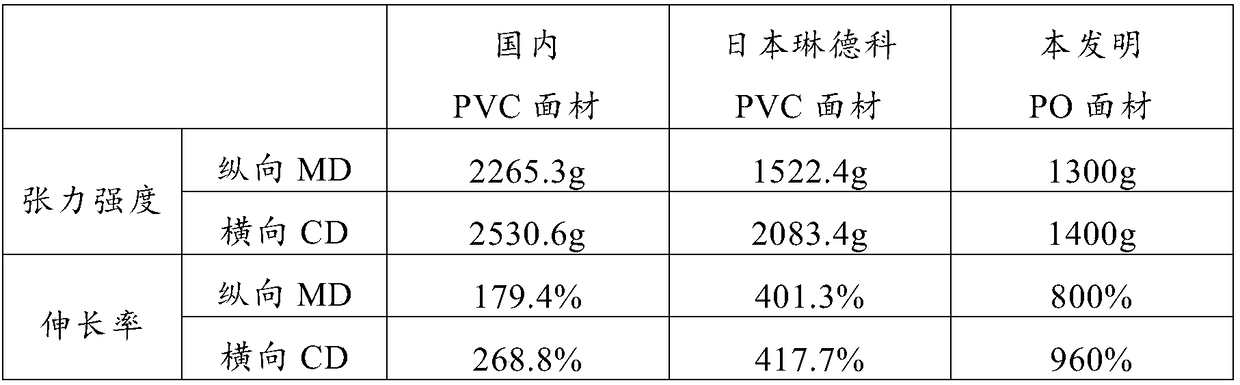

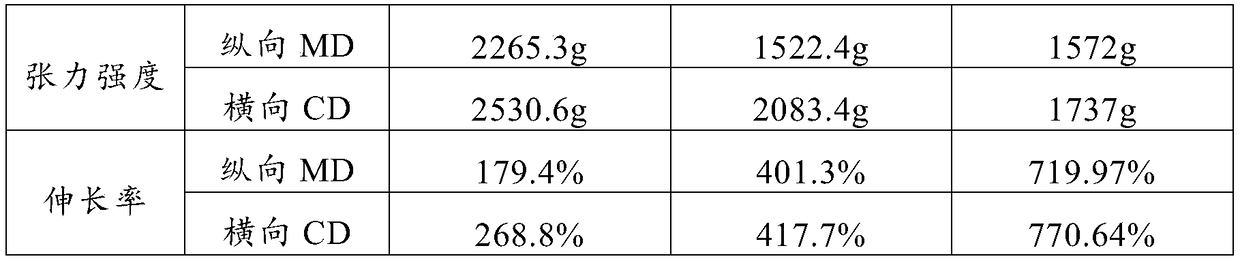

UV adhesive tape of PO panel and preparation method thereof

InactiveCN109233659AAvoid failure to reduce adhesionAvoid rangeNon-macromolecular adhesive additivesEster polymer adhesivesEpoxyTectorial membrane

The invention discloses a UV adhesive tape of a PO panel and a preparation method thereof. The adhesive tape comprises a panel, a UV adhesive layer and a PET release protecting film which are successively laminated from top to bottom. The panel is a PO film which is prepared from the following components in parts by mass: 10-40 parts of polypropylene (C3), 30-70 parts of an ethylene-propylene copolymer (C5), 10-40 parts of (C9) and 0-10 parts of (C19). The UV adhesive layer is prepared from the following components in parts by mass: 50-100 parts of acrylic resin, 0-5 parts of epoxy resin, 1-50parts of carbon-carbon double-bond polybasic unsaturated resin and 0.5-10 parts of a photoinitiator mixed solution. By taking the PO film which is more environment-friendly as the panel of the UV adhesive tape and improving the defect that the adhesive layer is too soft or hard, the adhesive force and the cohesion between the adhesive layer and the PO film are enhanced greatly as a result of a polycondensation reaction of an epoxy resin crosslinking agent and acrylic resin, so that a adhesive residue on the back of a wafer is prevented from being separated from an iron ring. The viscosity reducing effect of the adhesive tape can be also improved greatly, so that the picking rate is 100%.

Owner:陈裕旺 +1

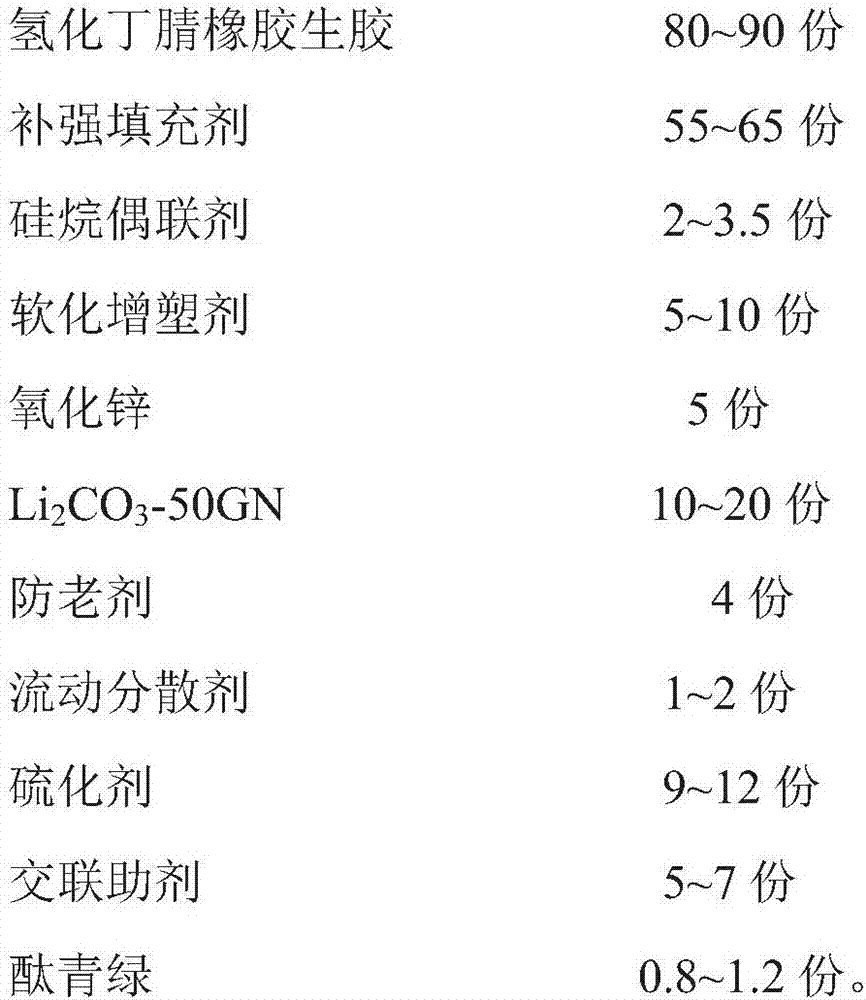

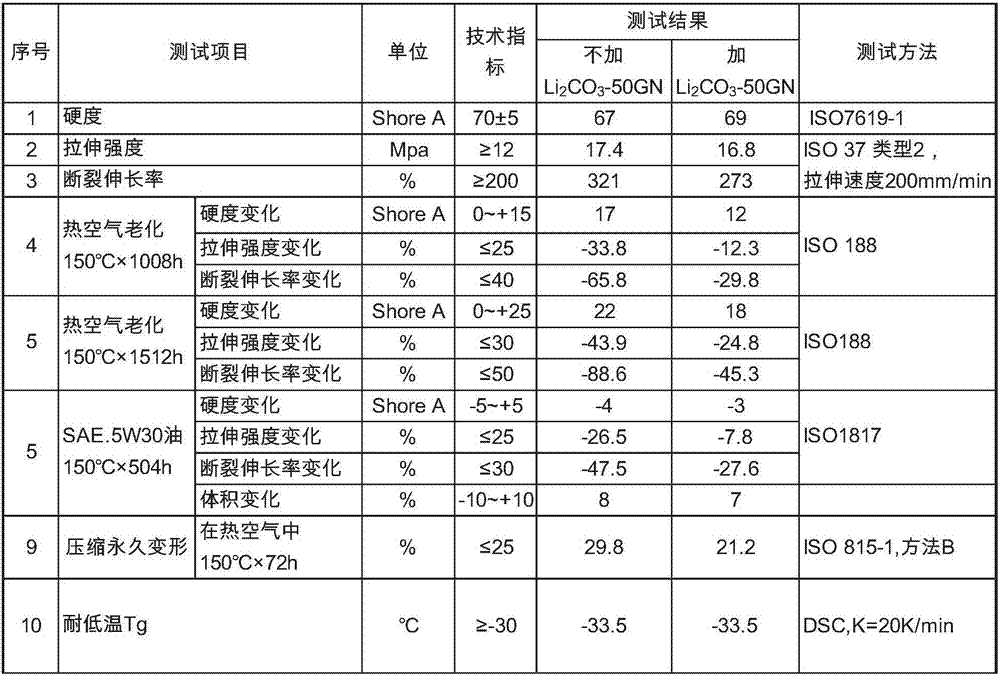

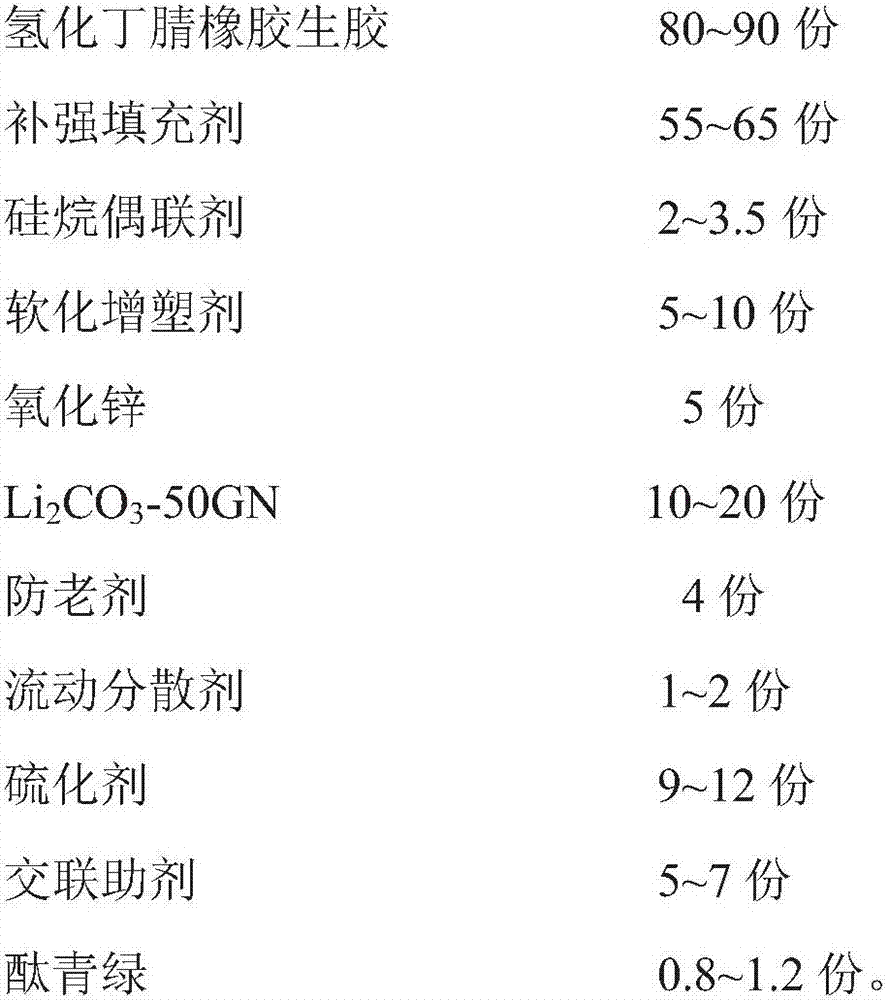

High temperature resistant color hydrogenated butadiene-acrylonitrile rubber material and preparing method thereof

The invention discloses a high temperature resistant color hydrogenated butadiene-acrylonitrile rubber material and a preparing method thereof, and belongs to the technical field of rubber. The high temperature resistant color hydrogenated butadiene-acrylonitrile rubber material is prepared from, by weight, 80-90 parts of hydrogenated butadiene-acrylonitrile rubber crude rubber, 55-65 parts of reinforcing filler, 2-3.5 parts of silane coupling agent, 5-10 parts of softening plasticizer, 5 parts of zinc oxide, 10-20 parts of Li2CO3-50 GN, 4 parts of anti-aging agent, 1-2 parts of flowing dispersing agent, 9-12 parts of vulcanizing agent, 5-7 parts of crosslinking agent and 0.8-1.2 parts of phthalocyanine green. The high temperature resistant color hydrogenated butadiene-acrylonitrile rubber material has the advantages of being excellent in temperature resistant performance and oil resistant performance, resistant to low temperature, and low in compression deformation at the same time.

Owner:南京金三力高分子科技有限公司

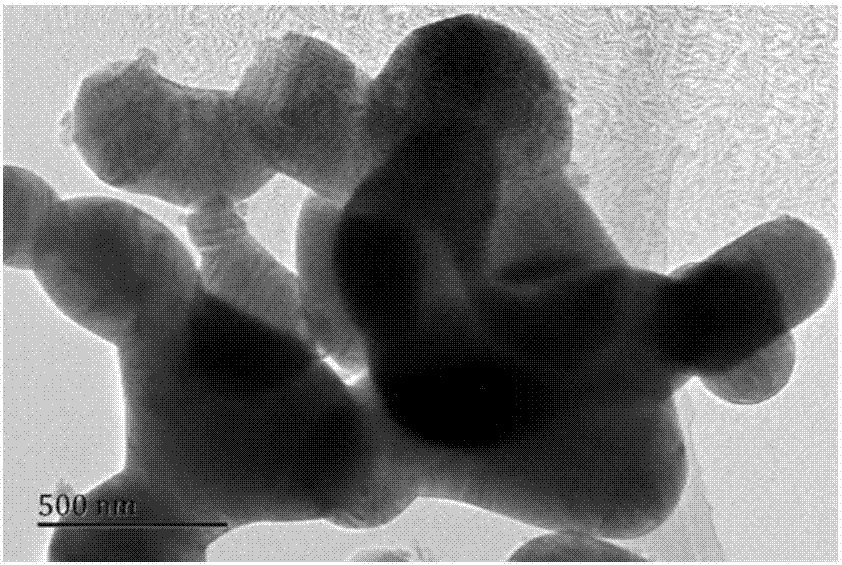

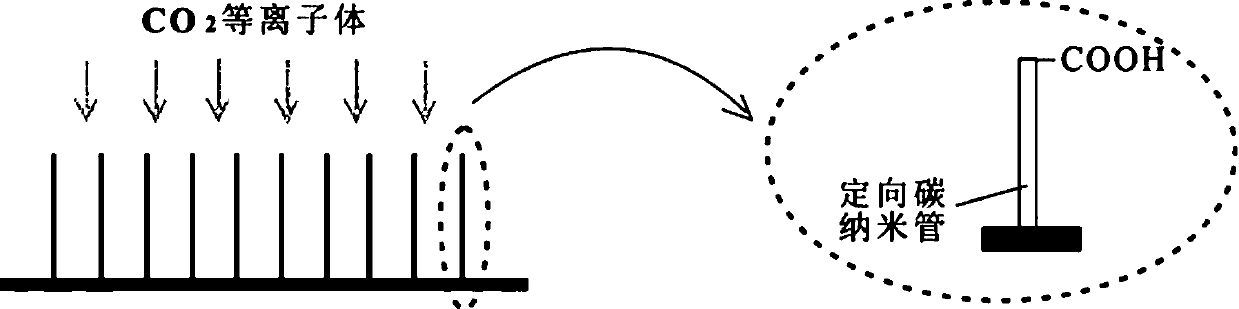

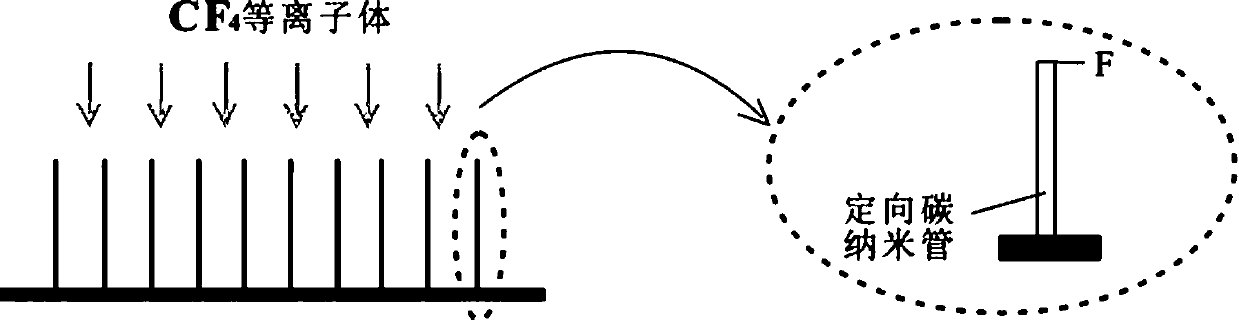

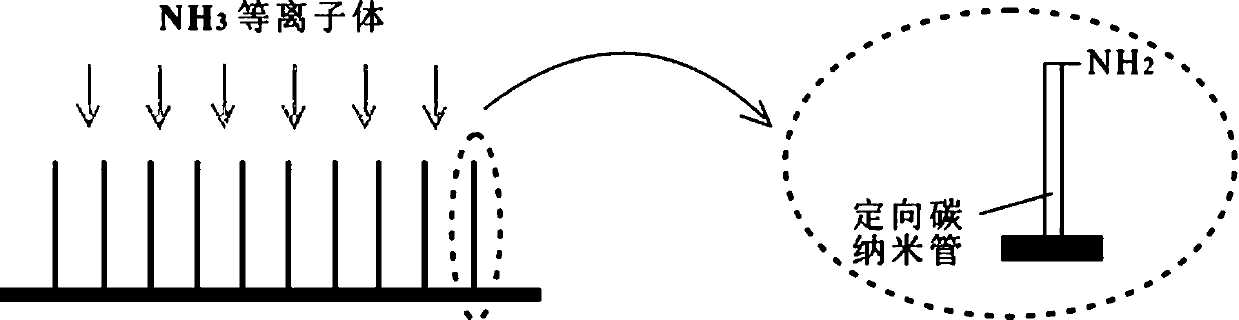

Method for preparing gecko-simulative tail end-charged aligned carbon nanotube dry adhesion array

ActiveCN107796789AEnhanced van der Waals forceImprove adhesionMaterial analysis by optical meansCarbon nanotubeGrafting

The invention discloses a method for preparing a gecko-simulative tail end-charged aligned carbon nanotube dry adhesion array and belongs to the technical field of dry adhesion. Through plasma surfacemodification of an aligned carbon nanotube array obtained by chemical vapor deposition growth and grafting of the tail end of the aligned carbon nanotube array with polar groups such as carboxyl, fluoro, and amino groups, the gecko-simulative tail end-charged aligned carbon nanotube dry adhesion array is obtained. The gecko-simulative tail end-charged aligned carbon nanotube dry adhesion array has high adhesion and can be used in the fields of gecko-simulative robot foot adhesion and solid-to-solid dry adhesion contact.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

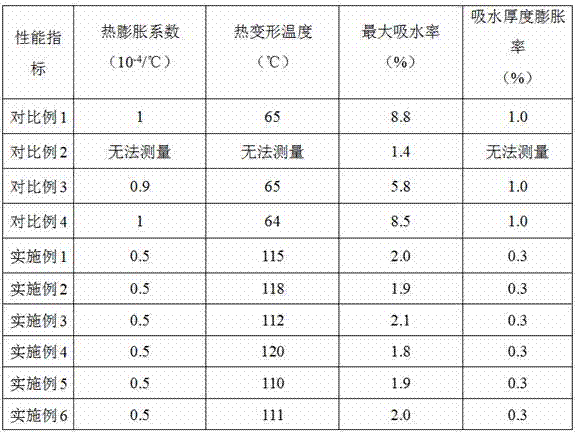

Manufacturing method of wood-plastic composite material with improved weather resistance

The invention discloses a preparation method of a novel wood-plastic composite material capable of greatly improving the weather resistance. The preparation method comprises the following steps: uniformly mixing the thermoplastic plastics, wood fibers, high-temperature lubricating agent and high-temperature coupling agent according to a ratio to obtain a mixed material; and carbonizing granulating, carbonizing extruding, conventionally cooling, stretching and cutting to obtain the wood-plastic material, wherein the carbonizing granulating temperature and the carbonizing extruding temperature are 250 to 290 DEG C. The surface and sections of the wood-plastic composite material are black, have metal luster and have metal sound when being knocked; the heat expansion and cold shrinkage deformation is small, and the thermal deformation temperature is greatly increased; the moisture absorption performance is significantly reduced, the corrosion and decomposition are unlikely to occur, and the weather resistance is good; and the ultraviolet resistance is improved.

Owner:YUNNAN ZHONGQIAN INTEGRATED HOUSING CO LTD

Preparation method of macroporous pseudo-boehmite

InactiveCN107226477AIncrease static electricityImprove hydrogen bondingAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSodium aluminateCarboxylic acid

The invention discloses a preparation method of macroporous pseudo-boehmite. The preparation method comprises adding a surfactant into an acidic aluminum salt solution and then carrying out gelation with a sodium metaaluminate solution. The surfactant comprises one or more of long chain alkyl quaternary ammonium salt CnH2n+1(CH3)3N<+>X<->, polycarboxylic acid and a polycarboxylate. In the presence of the surfactant, through a tubular reactor, the acidic aluminum salt solution and the sodium metaaluminate solution undergo a reaction in a parallel flow way to produce macroporous pseudo-boehmite. The preparation method has simple processes, reduces a cost and improves product quality stability.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Anti-rust liquor and processing method therefor

The invention relates to antirust fluid. The invention also relates to a processing method of the antirust fluid. The antirust fluid made by the method is provided with obvious antirust function and has light even no pollution to the environment. The antirust fluid is generated mainly from the action of alkcnyl succinic acid and monoethanolamine. The mole ratio of alkcnyl succinic acid to monoethanolamine is 0.5-1 to 1. The main components of the antirust fluid are alkcnyl succinic acid dodecenylbutadioic, water and monoethanolamine.

Owner:马国伟 +1

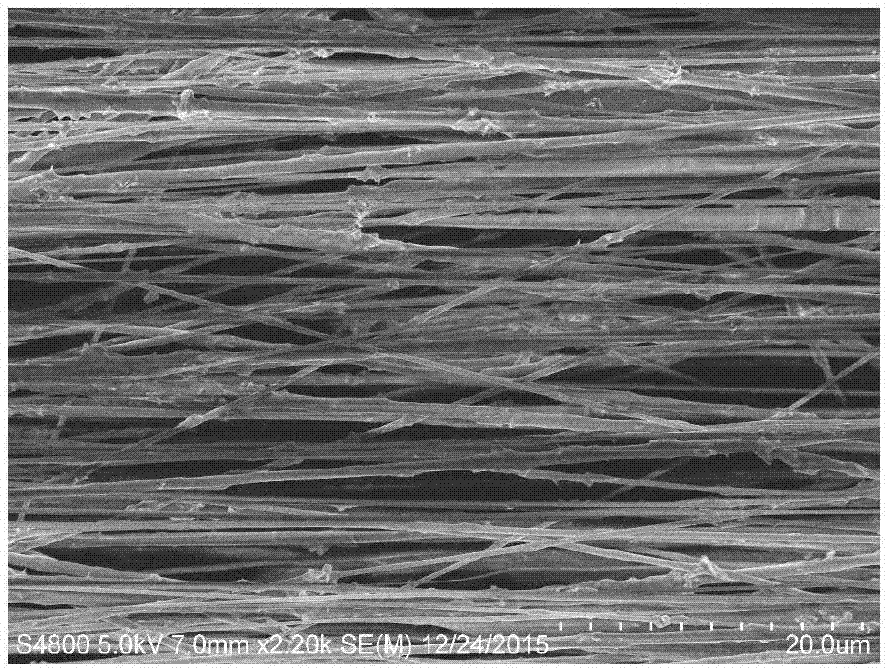

Preparation method for light bomb-proof aramid fiber composite non-woven fabric chip

ActiveCN103911769AHigh flame retardant efficiencyImprove water resistance and easy precipitationNon-woven fabricsAramidFlame resistance

The invention discloses a preparation method for a light bomb-proof aramid fiber composite non-woven fabric chip. The preparation method for the bomb-proof aramid fiber composite non-woven fabric chip includes: spreading aramid fibers, uniformly and straightly arraying in parallel, coating, drying to obtain aramid fiber composite non-woven fabric, and regulating parameters of production equipment to produce the aramid fiber composite non-woven fabrics with different surface density; preparing multilayer composite aramid fiber composite non-woven fabric through increasing the compositing times of the aramid fiber composite non-woven fabric; combining the aramid fiber composite non-woven fabrics with different surface density and different composite layer number to obtain the bomb-proof chip. The light bomb-proof aramid fiber composite non-woven fabric chip has good buffer ability and fire resistance, is resistant to bomb and vibration, is light and convenient to carry, enables the personnel load to be reduced, and enables the fighting efficiency of the fighter to be improved.

Owner:JIANGSU LINRY NEW MSTAR TECH

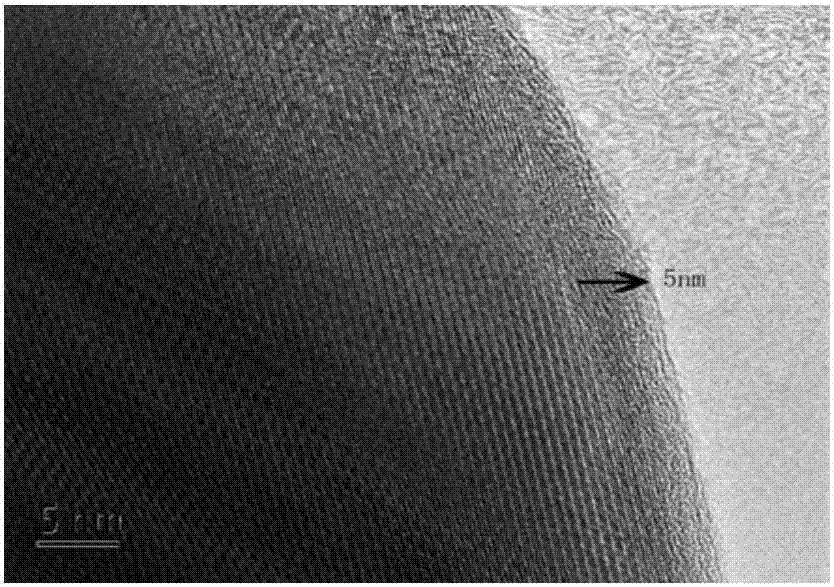

Preparation method of carbon nanotube composite line

ActiveCN105174204AImprove mechanical propertiesEnhanced van der Waals forceNanostructure manufactureDecorative surface effectsComposite filmCarbon nanotube

A preparation method of a carbon nanotube composite line comprises the following steps: providing at least one carbon nanotube film; providing a substrate, and growing a graphene film on the substrate; compounding the carbon nanotube film with the surface of the graphene film far from the substrate; removing the substrate to form a carbon nanotube-graphene composite film; and rolling up the carbon nanotube-graphene composite film, and twisting to form the carbon nanotube composite wire.

Owner:TSINGHUA UNIV +1

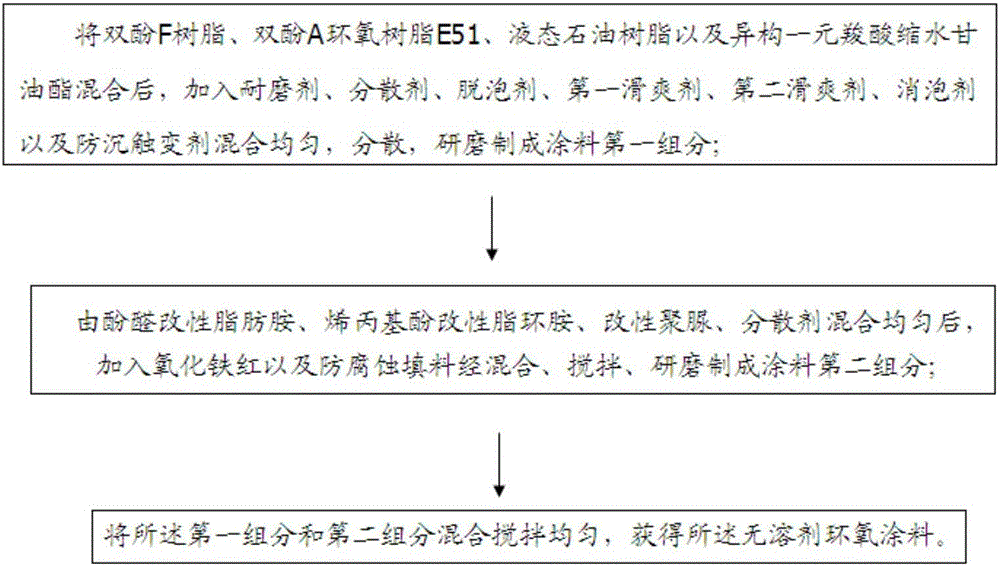

Solvent-free epoxy coating material and preparation method thereof

ActiveCN106554705ALow viscosityImprove compactnessFireproof paintsAnti-corrosive paintsSolvent freeAliphatic amine

The invention provides a solvent-free epoxy coating material and a preparation method thereof. The solvent-free epoxy coating material comprises a first component and a second component, wherein the first component comprises the following components in parts by weight: 1 part of bisphenol F resin, 0.8-1.0 part of bisphenol A epoxy resin E51, 0.1-0.2 part of liquid petroleum resin, 0.15-0.3 part of isomerous monocarboxylic acid glycidyl ester, 0.2-0.7 part of an anti-wear agent, 0.1-0.3 part of a dispersant, 0.02-0.1 part of an air-release agent, 0.01-0.1 part of a first slip agent, 0.05-0.1 part of a second slip agent, 0.05-0.1 part of a defoaming agent and 0.01-0.02 part of an anti-settling thixotropic agent; and the second component comprises the following components in parts by weight: 1 part of phenolic aldehyde modified aliphatic amine, 0. 8-1.2 parts of allylphenol modified alicyclic amine, 0.015-0.03 part of modified polyurea, 0.01-0.03 part of a dispersant, 0.1-0.3 part of iron oxide red and 0.15-0.35 part of anti-corrosion packing. A coating formed by the solvent-free epoxy coating material has an excellent thin-coating property, the one-step film-forming thickness of the solvent-free epoxy coating material can be equal to or less than 100 mu m, and the coating has high apparent quality.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

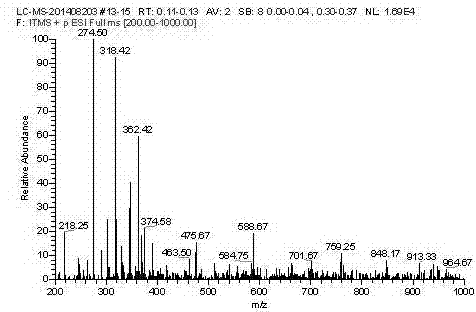

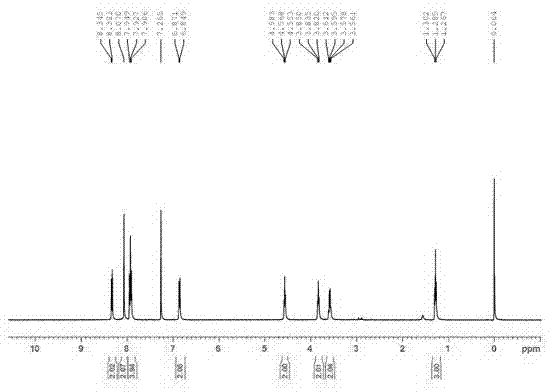

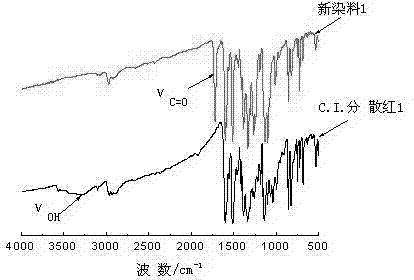

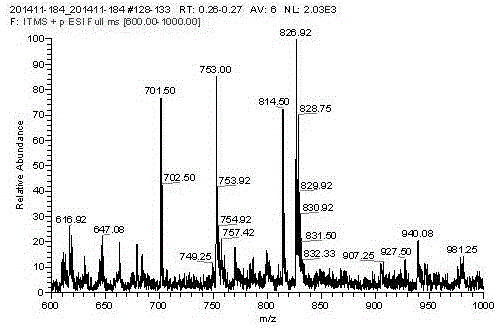

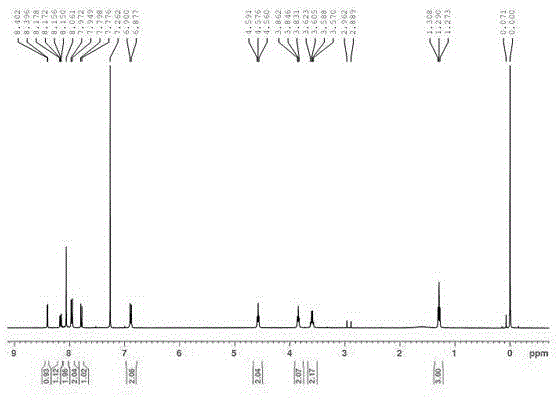

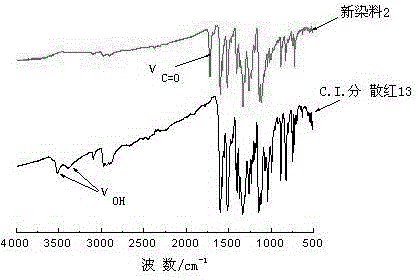

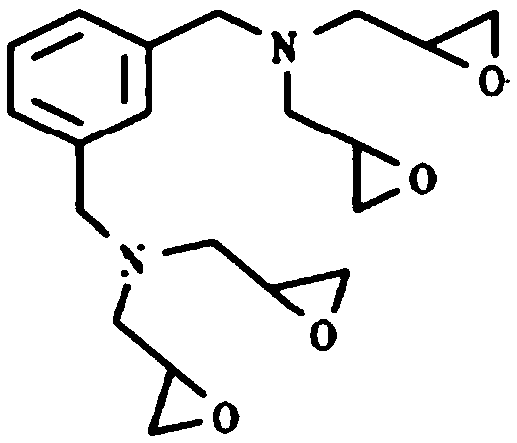

A disperse dye compound, and a preparing method and uses thereof

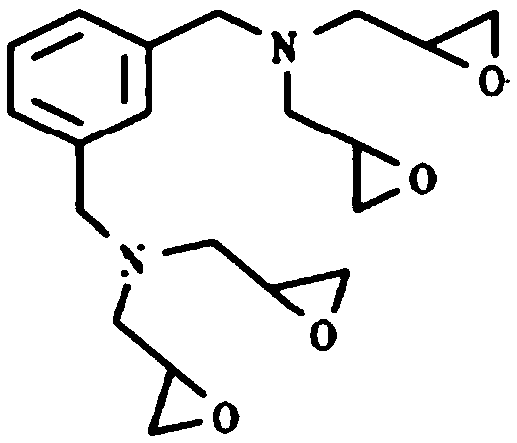

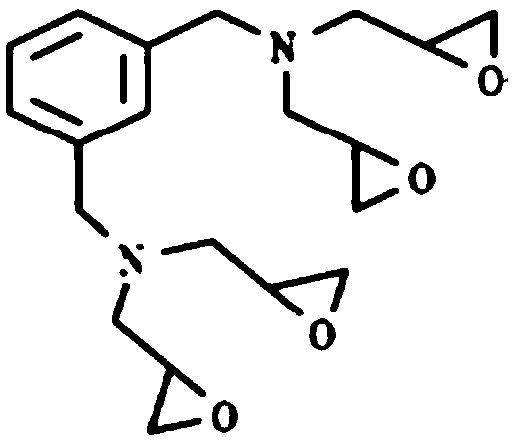

InactiveCN104761923AIncrease contact surfaceEnhanced van der Waals forcePreparation by acylationDyeing processPolylactic acidChloride

A disperse dye compound, and a preparing method and uses thereof are disclosed. The structure formula of the disperse dye compound is shown as a formula 1. The formula 1 is shown in the specification. A C.I. disperse red 1 dye is selected and subjected to a coupling reaction with a dicarbonyl chloride compound to prepare the disperse dye compound. When the disperse dye compound is used for dyeing of polyurethane fibre or polylactic acid fiber, washing fastness and sublimation fastness are obviously improved.

Owner:SHAOXING UNIVERSITY

Disperse dye compound as well as preparation method and application thereof

ActiveCN104672103AIncrease in sizeHigh molecular weightOrganic chemistryPreparation by acylationDisperse dyeChloride

The invention discloses a disperse dye compound as well as a preparation method and an application thereof. The disperse dye compound has a structural formula shown in the formula I in the specification. C.I. disperse red 13 dye is selected to have a coupling reaction with a benzenedicarbonyl chloride compound, the disperse dye compound is prepared, and washing fastness and sublimation fastness of the disperse dye compound are remarkably improved when the disperse dye compound is applied to spandex or polylactic acid fiber dyeing.

Owner:SHAOXING UNIVERSITY

High-performance explosion-proof blanket

ActiveCN103940310AImprove defenseImprove securityNon-macromolecular adhesive additivesBlastingFiberStructural engineering

The invention relates to a high-performance explosion-proof blanket which comprises an inner border, an outer border and a cover blanket body. The cover blanket body covers over the inner border and the outer border, the inner border and the outer border are both of a cylinder structure without a bottom face, the height of the outer border is half of the height of the inner border, the top end of the outside of the outer border is provided with a hanging rope, the lower surface of the cover blanket body is correspondingly provided with a hook, the inner border and the outer border are respectively composed of an inner container and an outer cover, each inner container is composed of a lining and high-performance fiber non-woven cloth, the linings are annular, the high-performance fiber non-woven cloth is wound on the surface of the corresponding lining, the center of the cover blanket body is provided with a through explosion venting hole, and the outside of the cover blanket body is provided with the outer cover. The internal structure of the inner border and the internal structure of the outer border of the explosion-proof blanket are respectively formed by winding the high-performance fiber non-woven cloth onto the corresponding lining, the capacity of absorbing impact waves is stronger, and safety of the explosion-proof blanket can be better improved.

Owner:JIANGSU LINRY NEW MSTAR TECH

Polyolefin surface material UV adhesive tape and preparation method thereof

InactiveCN109207080AVan der Waals force enhancementImprove adhesionNon-macromolecular adhesive additivesEster polymer adhesivesTectorial membraneEpoxy

The invention discloses a polyolefin surface material UV adhesive tape and a preparation method thereof. The adhesive tape comprises a surface material, a UV adhesive layer and a PET release protective film which are stacked one above another, the surface material is a PO film, and comprises, by mass, 10-40 parts of polypropylene (C3); 30-70 parts of an ethylene-propylene copolymer (C5(70)); and 10-40 parts of an ethylene-propylene copolymer (C5(80)); the UV adhesive layer comprises, by mass, 50 to 100 parts of acrylic resin; 0 to 5 parts of an epoxy resin crosslinking agent; 1 to 50 parts ofcarbon-carbon double bond polyunsaturated resin and 0.5 to 10 parts of a light initiator mixture. The more environmentally friendly PO film is used the surface material of the UV adhesive tape, and atthe same time improves the disadvantage that the rubber layer is too soft or too hard, by condensation polymerization of the epoxy resin crosslinking agent and the acrylic resin, the adhesion and thecohesive force between the adhesive layer and the PO film are greatly enhanced to avoid the case that the adhesive residue on the back side of a wafer is separated from an iron ring to be detached, and the viscosity reduction effect of the tape can be greatly improved, so that the picking rate is 100%.

Owner:陈裕旺 +1

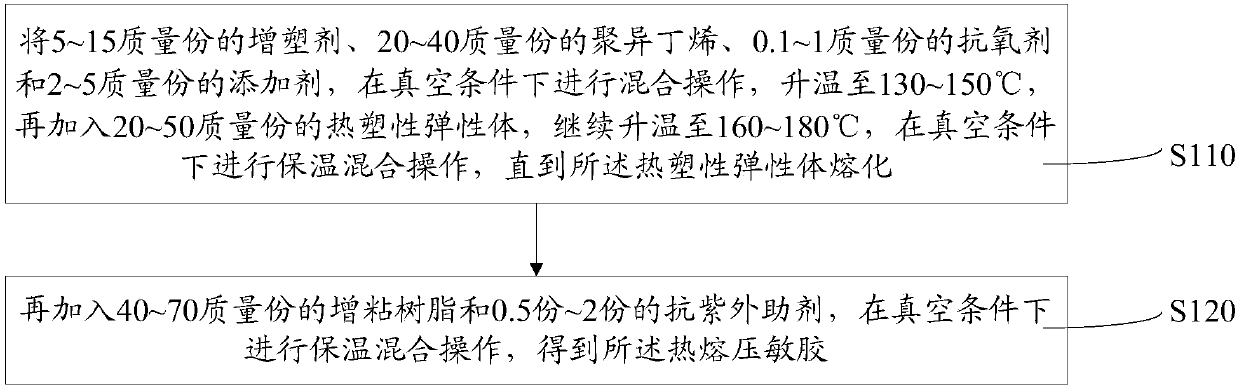

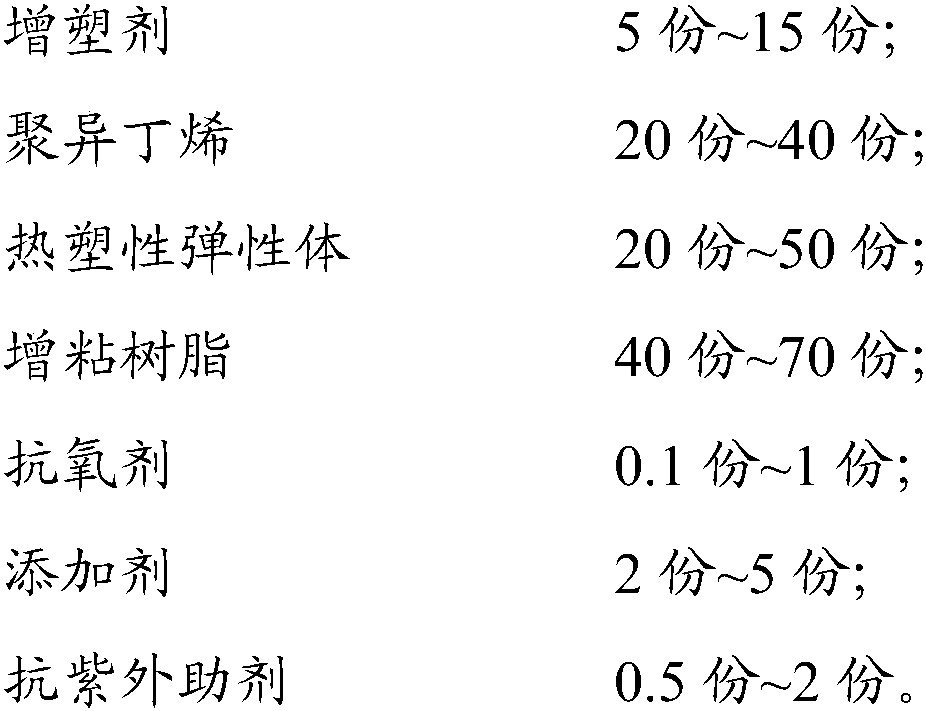

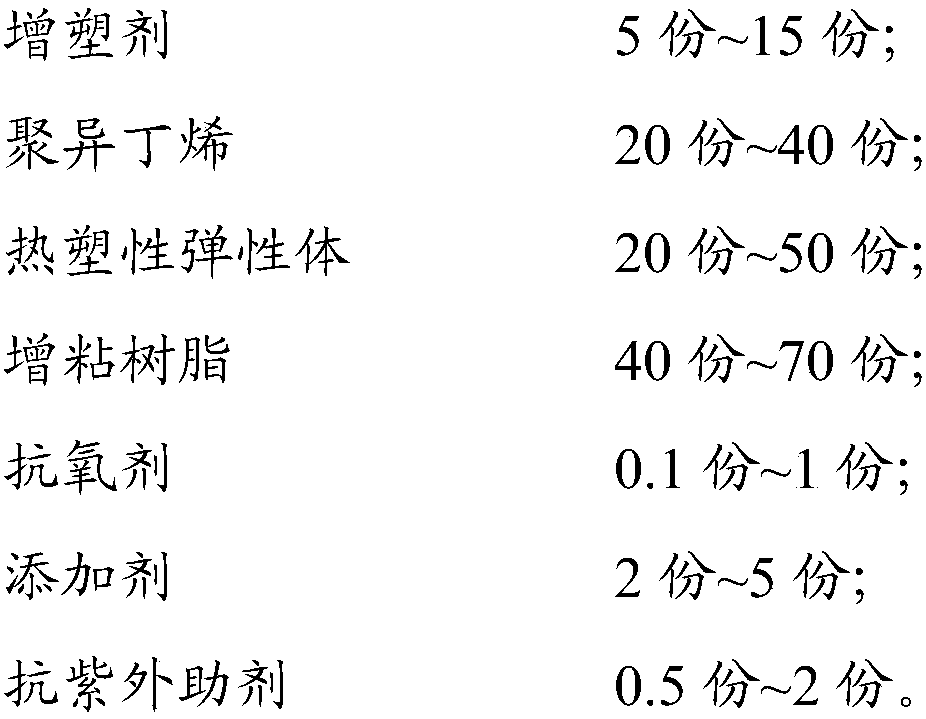

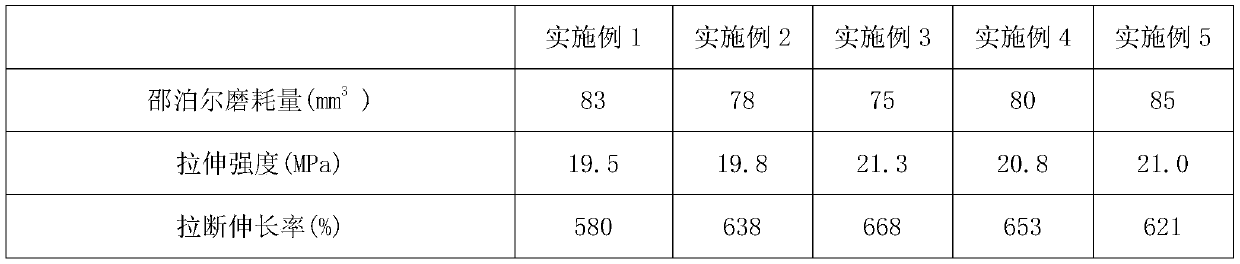

Hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN107722925ACohesion does not decreaseImprove cohesionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantUltraviolet lights

The invention relates to a hot-melt pressure-sensitive adhesive and a preparation method thereof. The hot-melt pressure-sensitive adhesive comprises, by mass, 5-15 parts of a plasticizer, 20-40 partsof polyisobutylene, 20-50 parts of a thermoplastic elastomer, 40-70 parts of tackifying resin, 0.1-1 part of an antioxidant, 2-5 parts of an additive and 0.5-2 parts of an anti-UV assistant. The additive can increase the Van der Waals force among hot-melt adhesive molecules to effectively prevent pop-open of overlap edges, caused by the sliding of an adhesive layer; and the polarity of the polyisobutylene is similar to that a waterproof coiled material, so the wettability to the waterproof coiled material of the hot-melt pressure-sensitive adhesive is enhanced, thereby the skin-like contact between the hot-melt adhesive and the waterproof coiled material is generated, the intermolecular effect between the hot-melt adhesive and the waterproof coiled material is increased, the infiltration of water molecules is blocked, water escaping from the overlap edges of the coiled material is prevented, and the peeling strength of the overlap edges is increased. The anti-UV assistant can absorb ultraviolet lights in sunshine, and releases the ultraviolet lights in a heat form in order to achieve a good anti-UV aging effect.

Owner:HUIZHOU NENGHUI CHEM CO LTD

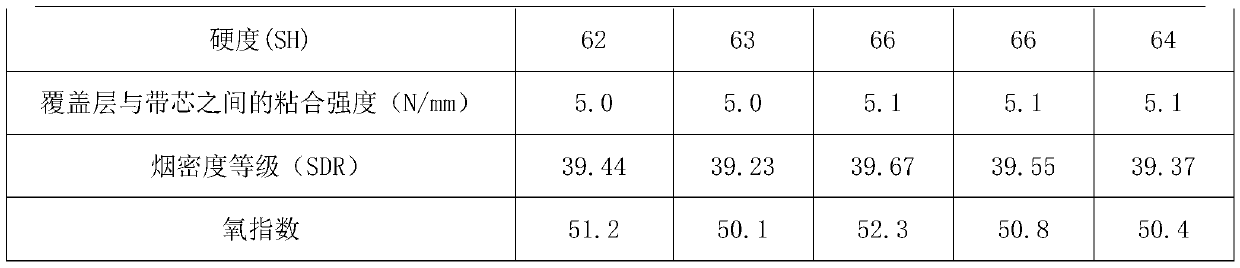

Ultrawear-resistant PVG flame-retardant conveying belt cover rubber

The invention discloses ultrawear-resistant PVG flame-retardant conveying belt cover rubber and belongs to the field of conveying belts. The ultrawear-resistant PVG flame-retardant conveying belt cover rubber is composed of the following components in parts by weight: 95-105 parts of SG-3 resin, 15-25 parts of dioctyl phthalate, 20-30 parts of tris(2-chloroethyl) phosphate, 2-4 parts of tribasic lead sulfate, 4-6 parts of dibasic lead phosphite, 13-18 parts of triaryl phosphate, 5-9 parts of tetrapropylene titanate, 3-7 parts of antimony trioxide, 13-17 parts of chlorinated paraffin-52, 3-4 parts of zinc borate hydrate, 1-3 parts of silane coupling agent and 1-3 parts of dicumyl peroxide. The ultrawear-resistant PVG flame-retardant conveying belt cover rubber provided by the invention hasthe characteristics such as high strength, large transportation volume and transportation balance, and meanwhile, the ultrawear-resistant PVG flame-retardant conveying belt cover rubber has the performances such as good flame retardance, anti-static property, shock resistance, wear resistance and corrosion resistance, high strength and excellent safety performance and the characteristics such as lower cost and lower price as comparison with other flame-retardant conveying belts.

Owner:BAODING HUAYUE RUBBER BELTS

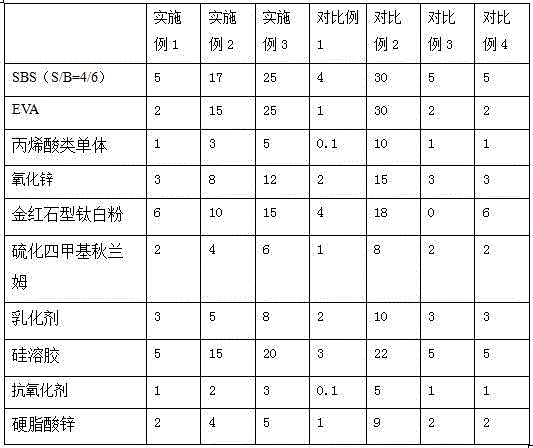

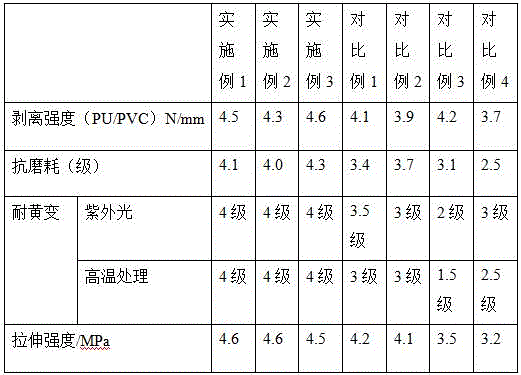

Adhesive for outdoor sports shoes

InactiveCN105647403AGuaranteed viscosityImprove adhesionNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesiveAntioxidant

The invention discloses an adhesive for outdoor sports shoes, prepared from the following components: SBS, EVA, acrylic monomers, zinc oxide, rutile type titanium dioxide, tetramethyl thiuram disulfide, an emulsifier, silica sol, 2,6-di-tert-butyl-4-methylphenol, an antioxidant and zinc stearate. The invention provides the adhesive special for the outdoor sports shoes, having the advantages of being safe, non-toxic, environmentally friendly, yellowing-resistant, aging-resistant, and high in cohesiveness, having waterproofness and air permeability, being proper in viscosity, good in fluidity, good in bonding stability, and better in water resistance and resistance to acid and base, and improving the quality of the shoes and prolonging the service life of the shoes.

Owner:SUZHOU YUEHU SPONGE COMPOUND FACTORY

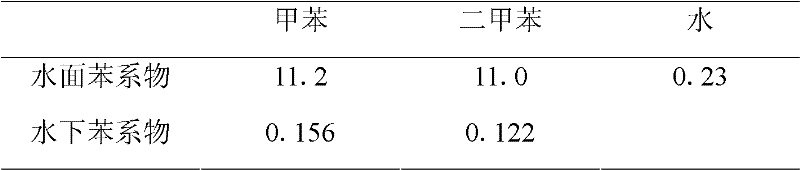

PS (poly styrene)/PP (propene polymer) fiber material adsorbing underwater benzene serial substances at high rate and preparation method

ActiveCN102505172ASmall adsorption ratioReduce the amount of adsorptionOther chemical processesSpinning head liquid feederChemistryHigh rate

The invention discloses a PS(poly styrene) / PP (propene polymer) fiber material adsorbing underwater benzene serial substances at a high rate. The material has stronger adsorption selectivity to underwater benzene serial substances (toluene, dimethylbenzene and the like), namely, the adsorption rate to the underwater benzene serial substances is remarkably improved, and the adsorption ability to the benzene serial substances on the water surface is also improved while the water adsorption is reduced to a certain extent. The PS / PP fiber adsorption material adsorbing underwater benzene serial substances at a high rate disclosed by the invention is prepared from the following raw materials in part by weight: 100 parts of PP, 1-15 parts of PS and 0.01-1 part of auxiliaries.

Owner:克拉玛依智源博创环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com