UV adhesive tape of PO panel and preparation method thereof

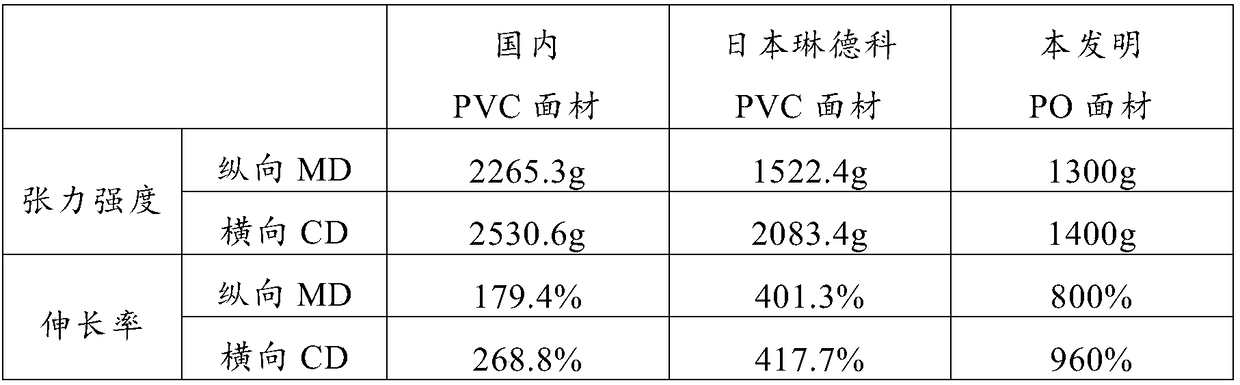

A surface material and tape technology, applied in the direction of adhesive, adhesive type, film/sheet adhesive, etc., can solve the problems of insufficient adhesion of PO film, uneven expansion of PO film, etc., to improve the problem of degumming, Improve the effect of too soft or too hard adhesive layer, enhanced adhesion and cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

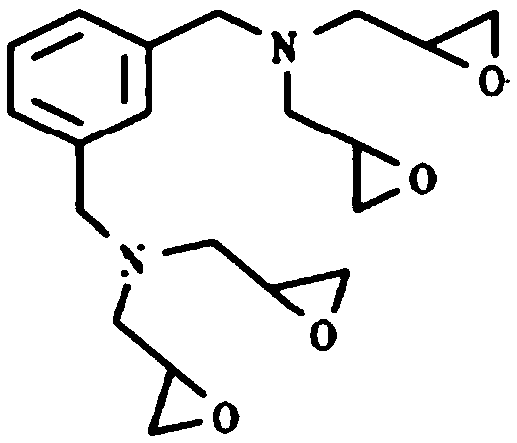

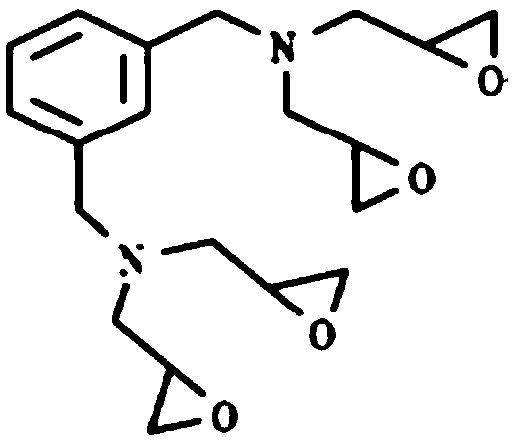

Image

Examples

Embodiment 1~4

[0039] Prepare PO face material UV tape as follows

[0040] Step S1

[0041] According to the formula described in Table 1, polypropylene (C 3 ), ethylene-propylene copolymer C 5 (ethylene content is 50wt%), C 9 (ethylene content is 10wt%), C 19 (ethylene content is 5wt%) and other polypropylene raw materials purchased from Mitsubishi Corporation of Japan were mixed, and the PO film was prepared by casting method.

[0042] The formula of the PO membrane of table 1 embodiment 1-4

[0043] raw material

Example 1

Example 2

Example 3

Example 4

C 3

30 copies

20 copies

25 copies

30 copies

C 5

40 copies

35 copies

35 copies

50 copies

C 9

30 copies

35 copies

35 copies

10 copies

C 19

0 copies

10 copies

5 copies

10 copies

[0044]PO film of the present invention adopts C during production 3 、C 5 、C 9 、C 19 When mixing other polypropylene raw materials, the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com