Friction pendulum supporting bases and bridge damping and shock insulation system

A friction pendulum bearing and sliding friction coefficient technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of low bearing life, low operational safety and reliability, bearing collision and impact, etc., to improve safety and reliability durability and service life, avoid the effect of large thickness of the bearing plate, and avoid collision and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

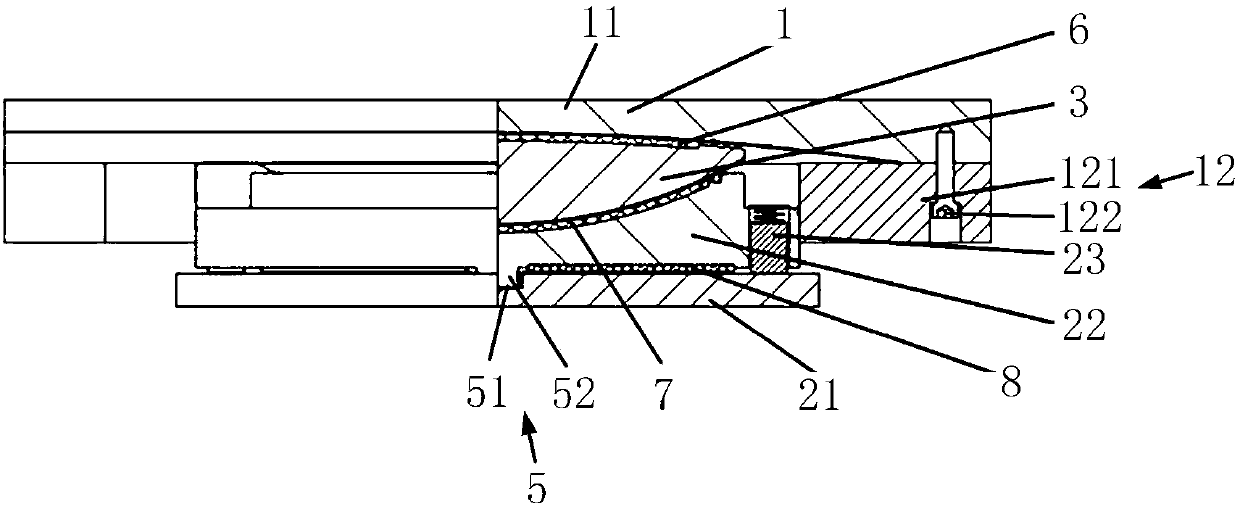

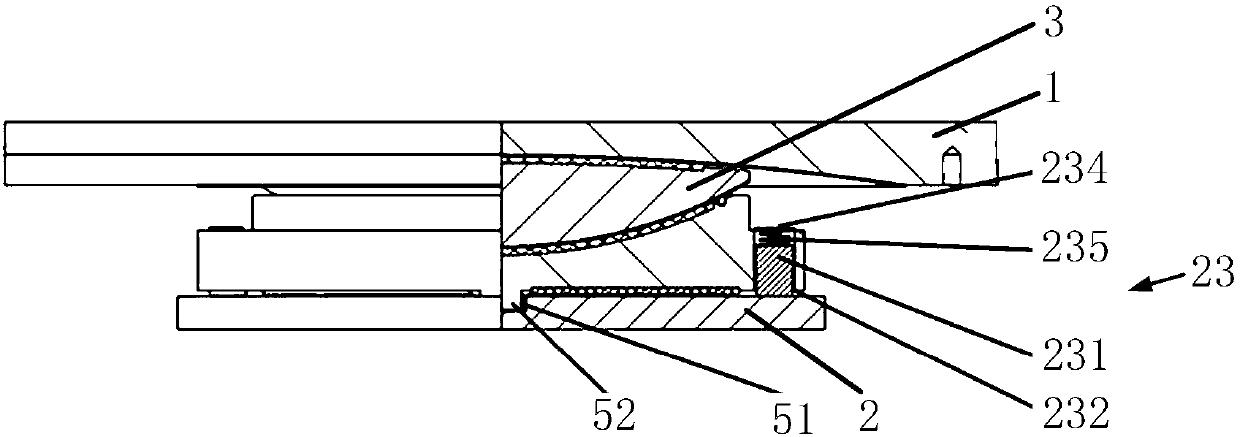

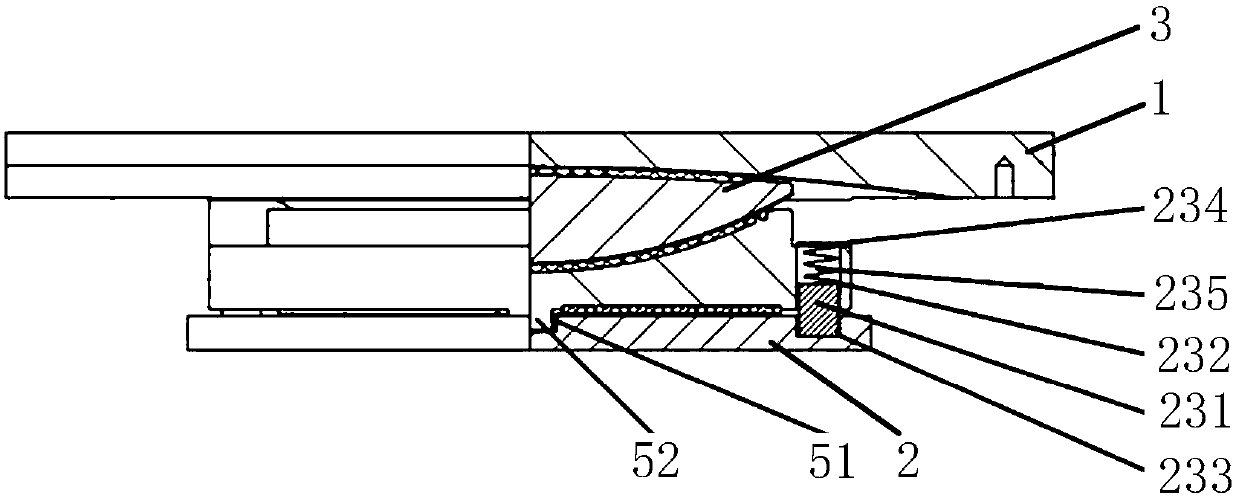

[0034] Such as Figure 1 to Figure 5 As shown, the friction pendulum support of this embodiment includes an upper seat plate assembly 1 , a lower seat plate assembly 2 and a spherical crown liner 3 . Among them, the upper seat plate assembly 1 is fixed on the bottom plate of the bridge beam, the lower seat plate assembly 2 is fixed on the bridge pier, and the spherical crown lining plate 3 is slidably installed between the upper seat plate assembly 1 and the lower seat plate assembly 2, so as to meet the multi-directional and large-scale requirements of the bridge. Corner and displacement requirements.

[0035] In this embodiment, the lower seat plate assembly 2 includes a bottom plate 21 , a lower support plate 22 and a locking assembly 23 . Among them, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com