Process method for well completion at equal borehole diameter

A process method and a drilling and completion technology, which are applied to drilling equipment and methods, wellbore/well components, drilling equipment, etc., can solve the problems of small wellbore in the target layer and the inability to drill to the target layer, and reduce the cost of drilling and drilling. Completion cost, improvement of safety reliability and drilling speed, effect of dealing with drilling risks and accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Taking an equal-diameter drilling and completion process as an example, the present invention will be further described in detail.

[0032] In the construction process of the present invention, the construction steps are as follows:

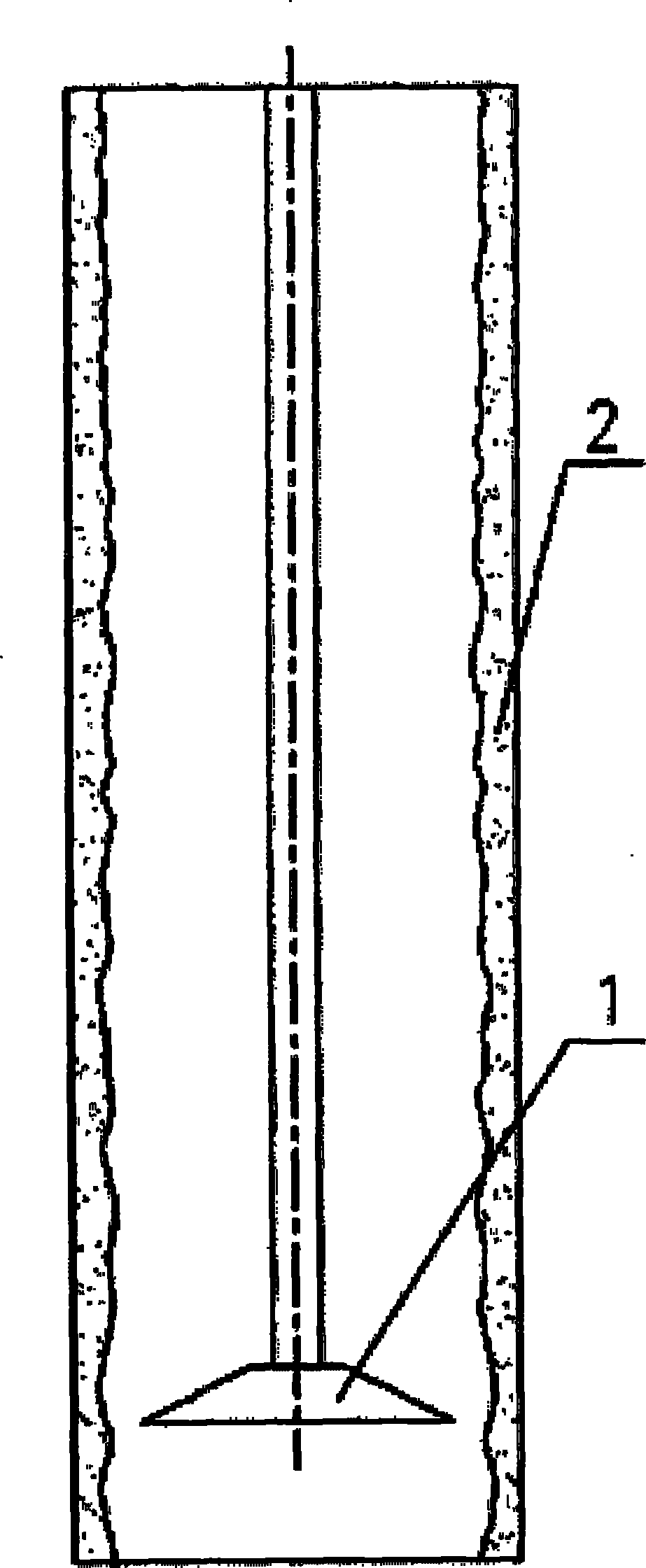

[0033] 1. Refer to Figure 1.1 . According to the design requirements, the open hole section 2 was drilled. Use an outer diameter of The drill bit 1 drills the open hole section 2, and the drill string combination used is The upper part of the drill bit 1 is connected to the drill collar, the upper part of the drill collar is connected to the centralizer, and the upper part of the centralizer is connected to a 5 "drilling pipe, and the 5" drilling pipe reaches the wellhead.

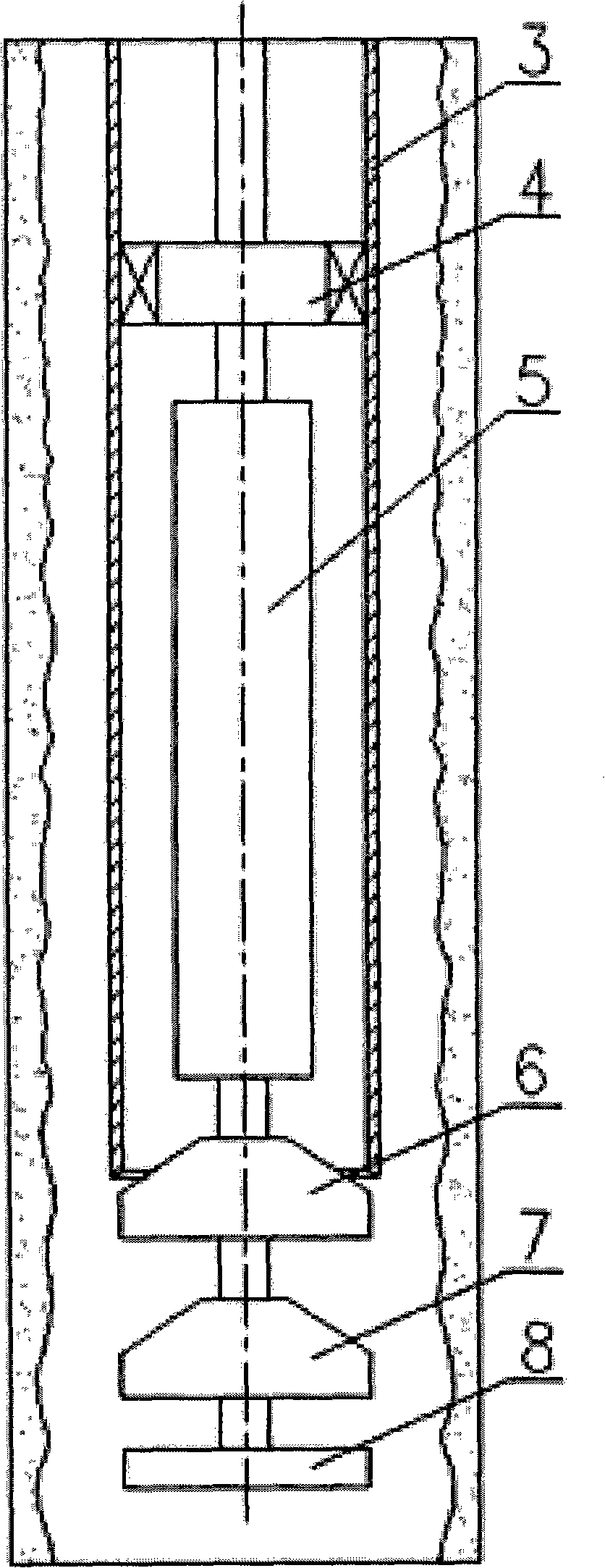

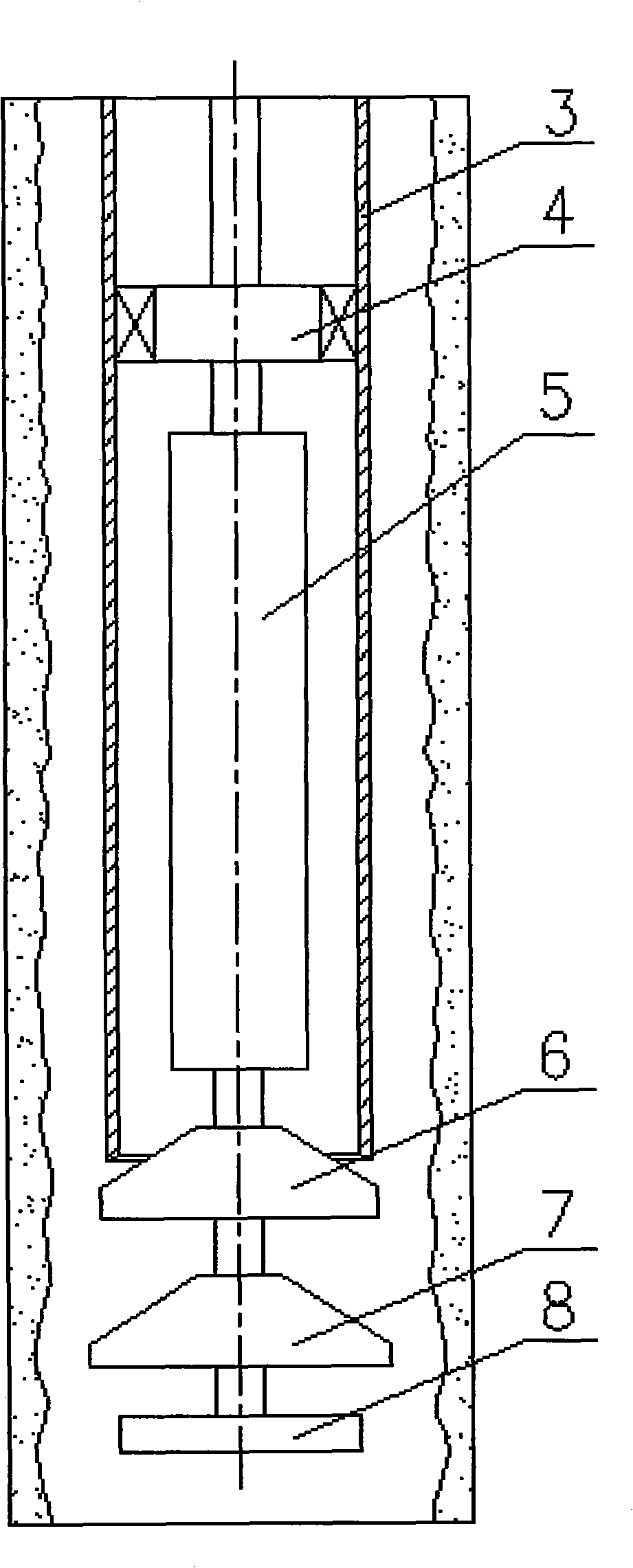

[0034] 2. Refer to Figure 1.2 . The first-stage expansion casing 3 and the expansion tool combination are lowered in the drilled open hole section 2 . The expansion sleeve 3 is processed and manufactured from a solid expansion tube material. Bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com