High-performance explosion-proof blanket

A high-performance, high-performance fiber technology, applied in the direction of blasting, non-polymer adhesive additives, adhesive types, etc., can solve the problem of aramid fiber non-weft fabric single stacking combination, bulletproof and cushioning, and impossibility Solve problems such as shock wave blocking, achieve the effect of improving defense performance, improving defense capabilities, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

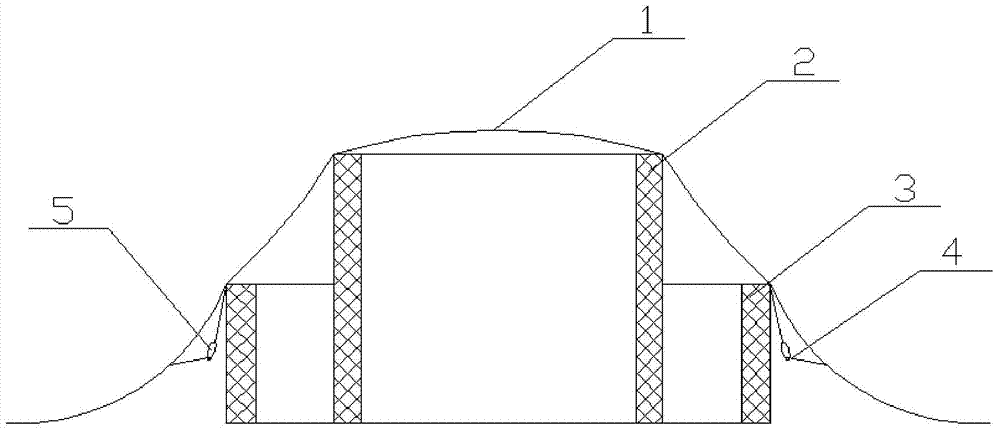

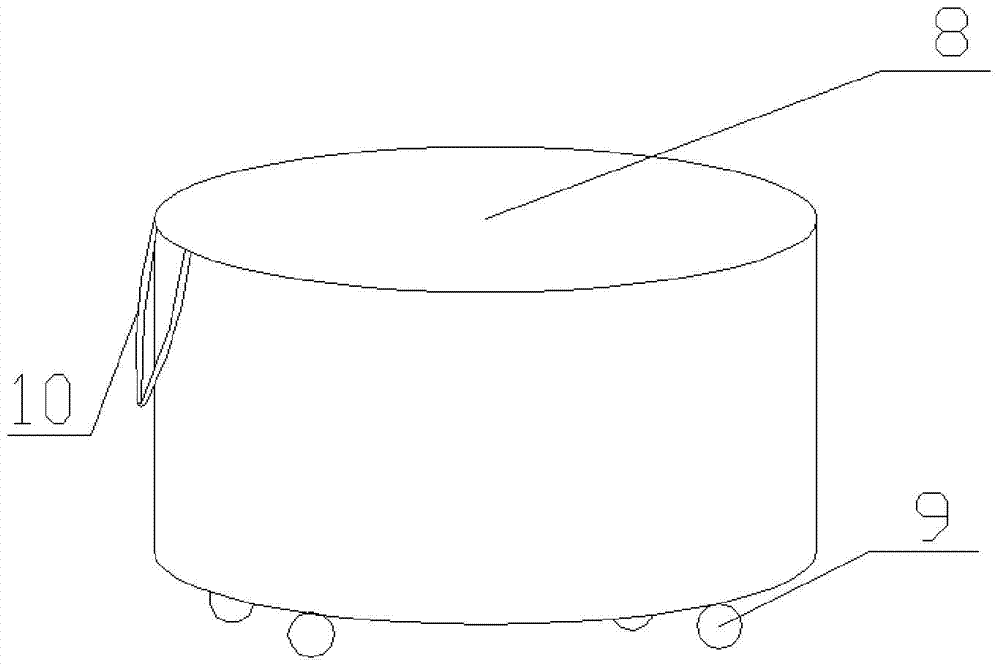

[0031] This embodiment provides a high-performance explosion-proof blanket with a structure such as Figure 1-3 Shown, comprise inner fence 2, outer fence 3, cover blanket 1, also be provided with roller bag 8, inner fence 2, outer fence 3 put into roller bag 8 when idle, place blanket 1 on the roller bag 8 top after folding.

[0032] Both the inner fence 2 and the outer fence 3 are cylindrical structures without a bottom surface, the height of the outer fence 3 is half of the height of the inner fence 2, the outer top of the outer fence 3 is provided with a hanging rope 5, and the lower surface of the blanket 1 is correspondingly provided with a hook 4. When in use, cover the blanket 1 over the inner fence 2 and the outer fence 3, and hook the hanging rope 5 with the hook 4; the unfolded size of the blanket 1 is 1600mm×1600mm.

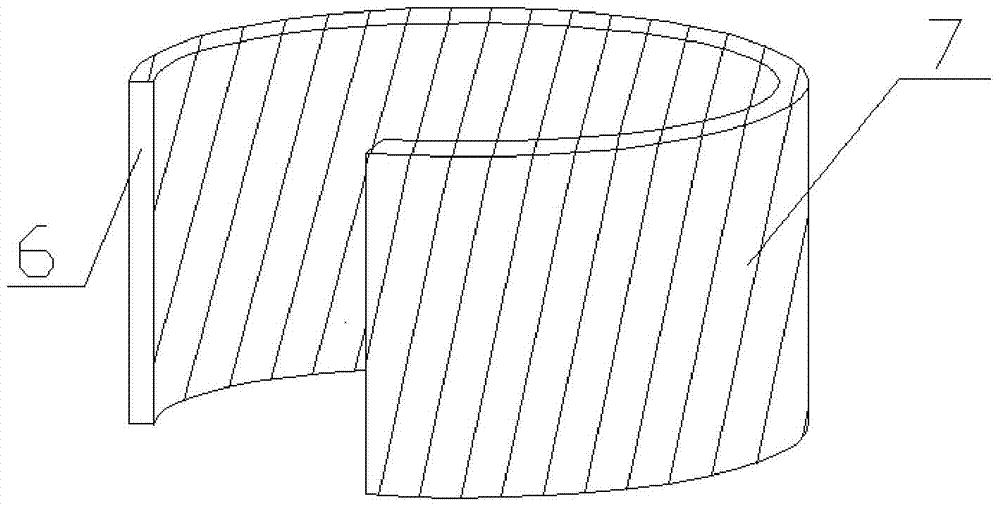

[0033] Both the inner fence 2 and the outer fence 3 include a coat and a liner wrapped by the coat. The liner is composed of an inner liner 6 and a h...

Embodiment 2

[0044] The structure of the high-performance explosion-proof blanket in this example is the same as in Example 1, the difference lies in the preparation of the modified adhesive. The modified adhesive in this example is prepared according to the following steps:

[0045] a. Add the curing agent into the adhesive aqueous solution, and fully stir and mix, then add the defoamer, filler and flame retardant for stirring and mixing to obtain the adhesive mixed liquid, the amount of the curing agent added is 1.6% of the weight of the adhesive aqueous solution, the adhesive in the adhesive aqueous solution The weight ratio of water to water is 2:5, the amount of defoamer added is 0.2% of the weight of the adhesive aqueous solution, and the amount of filler added is 0.6% of the weight of the adhesive aqueous solution; the adhesive aqueous solution used is acrylic adhesive and ethylene-vinyl acetate Copolymer emulsion is a mixture of 50:1 by volume;

[0046] b. Disperse silica in the ...

Embodiment 3

[0053] The structure of the high-performance explosion-proof blanket in this example is the same as in Example 1, the difference lies in the preparation of the modified adhesive. The modified adhesive in this example is prepared according to the following steps:

[0054] a. Add the curing agent into the adhesive aqueous solution, and fully stir and mix, then add the defoamer, filler and flame retardant for stirring and mixing to obtain the adhesive mixed liquid, the amount of the curing agent added is 1.7% of the weight of the adhesive aqueous solution, the adhesive in the adhesive aqueous solution The weight ratio with water is 2:5, the amount of defoamer added is 0.2% of the weight of the adhesive aqueous solution, and the amount of filler added is 0.7% of the weight of the adhesive aqueous solution; the adhesive aqueous solution used is acrylic adhesive and ethylene-vinyl acetate Copolymer emulsion is a mixture of 50:1 by volume;

[0055] b. Disperse silica in the adhesiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com