Solvent-free epoxy coating material and preparation method thereof

An epoxy coating, solvent-free technology, applied in the field of coatings, can solve the problems of pits, pinholes, orange peels on the surface of the coating, the thickness of the coating film easily exceeding 120um, and poor storage stability of the operational coating. Provides smoothness and gloss, provides high temperature resistance, and improves flow time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

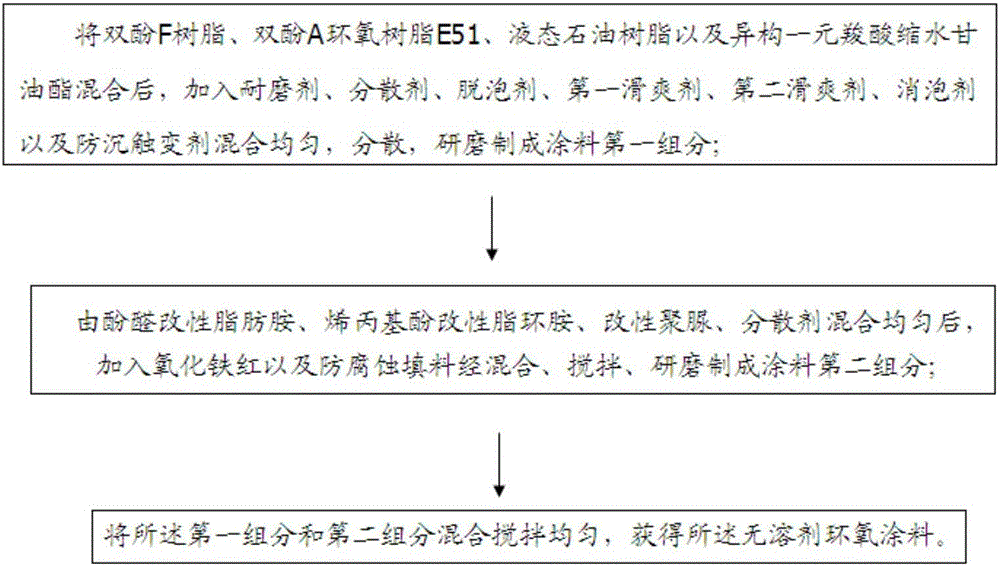

[0091] The preparation method of the solvent-free epoxy coating of the embodiment of the present invention, described method comprises the following steps:

[0092] After mixing bisphenol F resin, bisphenol A epoxy resin E51, liquid petroleum resin and isomeric glycidyl carboxylate, add anti-wear agent, dispersant, defoamer, first slip agent, second slip agent Cooling agent, defoamer and anti-sedimentation thixotropic agent are mixed evenly, dispersed, and ground to make the first component of the coating;

[0093] The second component of the coating is prepared by mixing phenolic modified fatty amine, allylphenol modified cycloaliphatic amine, modified polyurea and dispersant evenly, adding iron oxide red and anti-corrosion filler, mixing, stirring and grinding;

[0094] The first component and the second component are mixed and stirred uniformly to obtain the solvent-free epoxy coating.

[0095] In the solvent-free epoxy coating, the mass ratio of the first component to the...

Embodiment 1

[0099] The preparation method of the embodiment of the present invention 1 solvent-free epoxy paint comprises the following steps:

[0100] In a stainless steel bucket, 1 part by weight of bisphenol F resin, 0.9 part by weight of bisphenol A epoxy resin E51, 0.18 part by weight of liquid petroleum resin, and 0.2 parts by weight of isomeric glycidyl carboxylate are mixed together, and then add 0.12 Parts by weight of quartz powder, 0.3 parts by weight of alumina powder, 0.15 parts by weight of fluorine-modified polyacrylate, 0.06 parts by weight of fluorine-modified silicone, 0.04 parts by weight of silicone-modified polyorganosiloxane, 0.07 parts by weight of fluorocarbon modified Non-toxic polymer, 0.08 parts by weight of silicone modified polymer carboxylic acid, 0.016 parts of polyamide wax, etc. are mixed evenly and dispersed at a high speed. Components: 1 weight part of phenolic modified aliphatic amine, 1.2 weight part of allylphenol modified alicyclic amine, 0.015 weigh...

Embodiment 2

[0103] The preparation method of the embodiment of the present invention 2 solvent-free epoxy coatings comprises the following steps:

[0104] In a stainless steel bucket, 1 part by weight of bisphenol F resin, 0.95 parts by weight of bisphenol A epoxy resin E51, 0.16 parts by weight of liquid petroleum resin, and 0.18 parts by weight of isomeric glycidyl carboxylate are mixed together, and then add 0.15 Parts by weight of quartz powder, 0.25 parts by weight of alumina powder, 0.16 parts by weight of fluorine-modified polyacrylate, 0.08 parts by weight of fluorine-modified silicone, 0.08 parts by weight of silicone-modified polyorganosiloxane, 0.06 parts by weight of fluorocarbon modified Non-toxic polymer, 0.09 parts by weight of silicone modified polymer carboxylic acid, 0.018 parts of polyamide wax, etc. are mixed evenly, dispersed at high speed, and the temperature reaches 50-60 ° C. Keep this temperature range and continue to disperse for more than 50 minutes. Grind to mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com