Environment-friendly nickel alloy slag composite curing material for flat sludge

A solidification material, nickel alloy technology, applied in solid waste management, dehydration/drying/thickened sludge treatment, sustainable waste treatment, etc., can solve the problems of increasing construction costs, increasing transportation costs and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

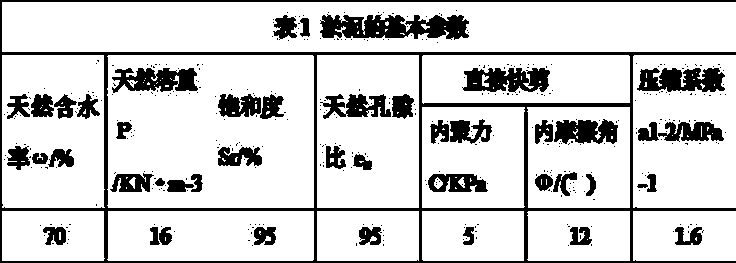

[0017] The nickel alloy slag in the following examples is water-quenched slag, the fineness modulus is 2.8, and the composite zone II gradation; cement: Conch Group P·O42.5 cement; slag: S95 grade, fly ash is third-grade ash; activator: All are industrial grade. When preparing composite cured materials, the activator can be uniformly mixed with other components as a solid phase component, or it can be formulated into a solution and added separately in proportion as a liquid phase component during use. The test soil was taken from a depth of 1.5 meters underground in Xuwei New District, Lianyungang, and it was tidal mud. The basic parameters of the mud are shown in Table 1.

[0018]

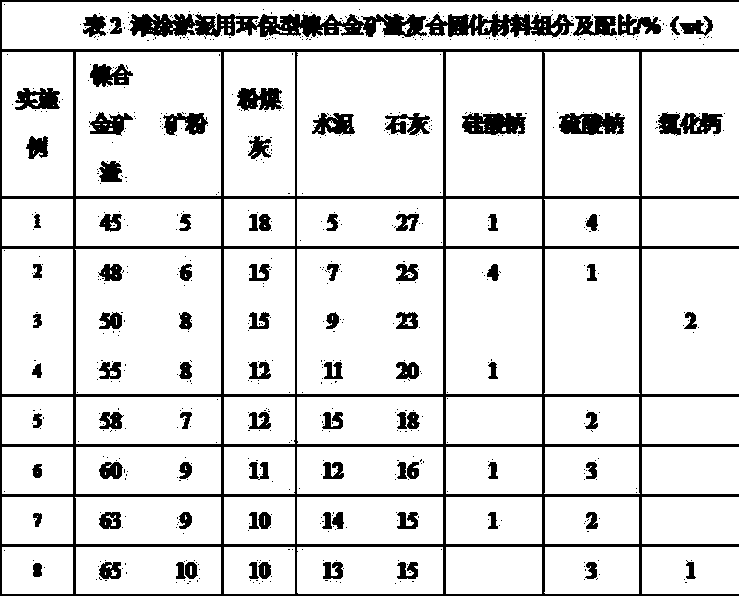

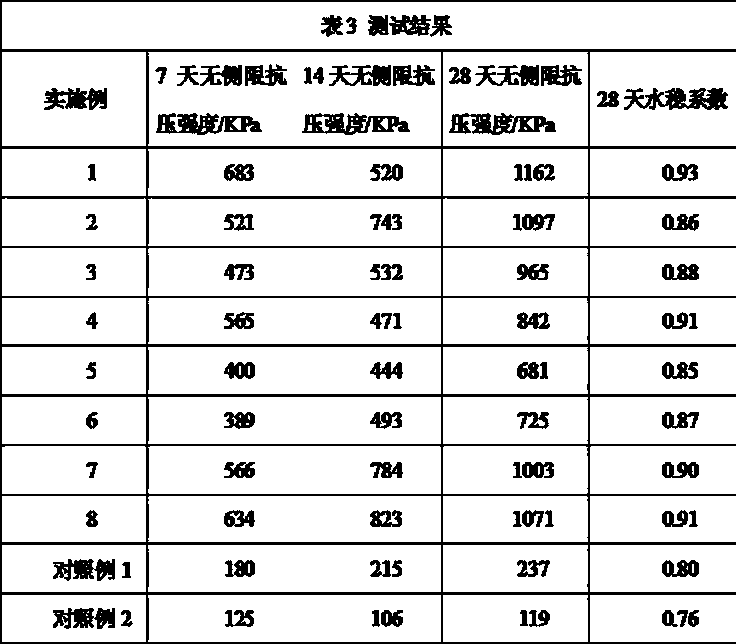

[0019] Table 2 is the composition of the percentage by weight of the environment-friendly nickel alloy slag composite solidification material for tidal flat silt of each embodiment of the present invention. First, the nickel alloy slag is dried so that its water content is controlled below 5%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com