Patents

Literature

326results about How to "Guaranteed viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bi-component polyurethane coating and preparation method thereof

ActiveCN102757722AGuaranteed viscosityGuaranteed mechanical propertiesPolyurea/polyurethane coatingsPlasticizerShock resistance

The invention relates to a bi-component polyurethane coating which is prepared from a component A and a component B in a weight ratio of 1:(1-3), wherein the component A comprises the following materials in parts by weight: 40-80 parts of polylol, 20-50 parts of polyisocyanates, 1-10 parts of plasticizer and 0-5 parts of storage stabilizing agent; and the component B comprises the following materials in parts by weight: 10-40 parts of polylol, 10-40 parts of liquid filler, 5-10 parts of crosslinking agent, 30-60 parts of solid filler, 3-15 parts of plasticizer, 0.1-8 parts of thixotropic agent, 0-5 parts of pigment and 0.2-5 parts of additive. The bi-component polyurethane coating is suitable for water prevention, permeability resistance, corrosion resistance and protection of a horizontal plane, can be thickly coated and constructed (>3mm / turn) on complex parts such as a vertical surface and an incline, does not generate sagging and bubble phenomena in a construction process, is full in color, and has the advantages of excellent mechanical property, shock resistance, water resistance and corrosion resistance.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Hydrophobically-associating polyacrylamide fracturing fluid thickener, preparation method and applications thereof

ActiveCN105542068AGuaranteed viscosityGuaranteed stabilityDrilling compositionPolymer scienceFracturing fluid

The present invention relates to a hydrophobically-associating polyacrylamide fracturing fluid thickener, a preparation method and applications thereof. In the prior art, the polyacrylamide polymer fracturing fluid thickener has disadvantages of insufficient temperature resistance, incomplete gel breaking and instability at high temperature and high shearing. A purpose of the present invention is mainly to solve the problems in the prior art. The hydrophobically-associating polyacrylamide fracturing fluid thickener is prepared by carrying out a reaction on a reaction system comprising components of 15-50 parts by weight of acrylamide, 1-50 parts by weight of a cationic monomer or anionic monomer, 1-20 parts by weight of a nonionic monomer, 0.01-0.5 part by weight of a hydrophobic monomer, 0.001-0.005 part by weight of a molecular weight regulator, 0.0001-0.0005 part by weight of a composite initiator, and 30-80 parts by weight of water. With the technical scheme, the problems in the prior art are well solved. According to the present invention, the hydrophobically-associating polyacrylamide fracturing fluid thickener can be separately applied in the oil and gas field fracturing process, or can be compounded with other auxiliary agents so as to be adopted as the fracturing fluid thickener applied in the oil and gas field fracturing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low VOC universal paint colorant compositions

ActiveCN101175827AMade preciselyNo need to stirCoatingsPigment treatment with macromolecular organic compoundsWater basedSolvent

A universal colorant composition for both solvent- and water-based paints and coatings. The universal colorant composition is a composition which includes a colorant component, such as pigment, dye, colorant, tinting agent and / or metal effect agent; a surfactant package including at least one alkyd-compatible surfactant; and at least one latex-compatible surfactant; and when the surfactant package is added to a base paint it provides a mixture having a drop in viscosity of less than about (50%).

Owner:SWIMC LLC

Solder mask screen printing method

InactiveCN102026494AImprove the effect of solder maskEasy to operateNon-metallic protective coating applicationScreen printingSolder mask

The invention relates to a solder mask screen printing method. The method comprises the following steps: manufacturing a point blocking screen; performing pre-treatment on a copper plate; screen-printing the first surface and the second surface of the point blocking screen; standing and pre-roasting in turn; standing again; and performing successive alignment, exposure, standing, development and post-roasting processes in turn, wherein the screen printing of the first surface and the second surface of the point blocking screen are performed by two screen printing machines, meanwhile, a copperplate hole plugging process is performed during the printing. In the screen printing process, the additive amount of solder mask ink is controlled within 15-25 ml / kg; an ink scraper is adjusted into a shoveling knife, the angle of the ink scraper is set as 15-25 degrees, the angle of an ink return knife is set as 35-45 degrees, the pressure of the ink scraper and the ink return knife is set as 6-8 kg / cm<2>, and the scraper speed is 3-5 m / minutes. The method is used for manufacturing a circuit board and can improve the solder mark effect relatively well, simplify the operation steps remarkably, save the time and lower the cost.

Owner:深圳喜珍科技有限公司

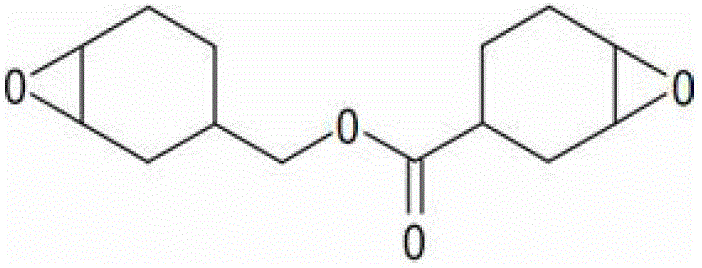

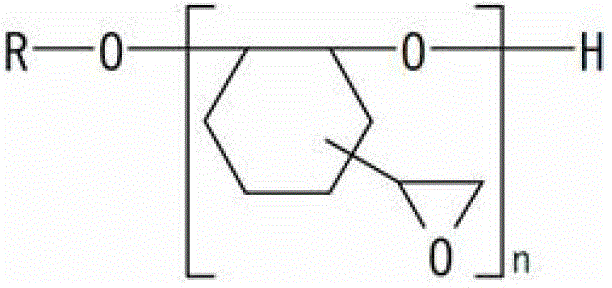

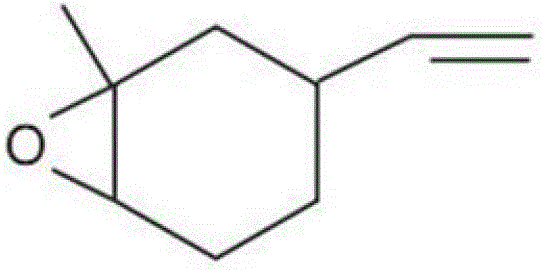

LED-packaging epoxy resin composition

InactiveCN102746487AGuaranteed crack resistanceGuaranteed craftsmanshipNon-macromolecular adhesive additivesEpoxy resin adhesivesPhosphonium saltPhosphate

The invention discloses a method for improving the performance of a large-power high-light-transmittance LED packaging epoxy resin composition. The composition is composed of a component A and a component B. The composition has excellent UV resistance and yellowing resistance. The composition is advantaged in good manufacturability, good light transmittance, and low light failure. The composition can be used in white-light and blue-light LED packaging. Compared with organosilicon, the composition is advantaged in low price. Innovatively, the component A of the composition is composed of liquid cycloaliphatic epoxy resin, solid cycloaliphatic epoxy resin, and hydrogenated bisphenol A epoxy resin. An anti-forming agent, a color complementary agent, and a dispensing agent are adopted in auxiliary. The system does not contain benzene ring, and yellowing is not easy to occur. The component B is prepared through the steps that: methyl hexahydrophthalic anhydride and hexahydrophthalic anhydride are subjected to a polymerization reaction with promoting agents or cationic initiators such as quaternary phosphonium salt, quaternary ammonium salts, DBU salt, and imidazole; with added phosphate antioxidant, a thermal yellowing capacity is improved. With the applications of an ultraviolet absorber and a light stabilizer, a UV yellowing resisting effect is further improved.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS +1

High-temperature resistant water spray coating polyurea flexible composition, preparation, construction method and uses thereof

InactiveCN101368062AGuaranteed storage stabilityGuaranteed viscosityPretreated surfacesAnti-corrosive paintsPrepolymerIsocyanate

The invention provides a high temperature resistant water spray polyurea elastic combination, a preparation and construction method and an applications thereof. The high temperature resistant water spray polyurea elastic combination solves the problem that the high temperature resistance and the water resistance of the prior art are poor, and the scope of application is limited. In the technical proposal, the high temperature resistant water spray polyurea elastic combination comprises a component A and a component R; the component A is a semi-prepolymer which is synthesized by using 35 to 65 portions of polyisocyanates and 35 to 65 portions of polyhydric alcohol; the component R comprises 20 to 50 portions of amine chain extenders and 45 to 80 portions of amine-terminated polyethers. The component A and the component R are used according to the isocyanate index of 1.1. By adopting the high temperature resistant water spray polyurea elastic combination, not only the high temperature resistance and the water resistance of the polyurea elastomer are improved; but also the miscibility and the mechanical property of the material are improved as a whole.

Owner:MARINE CHEM RES INST

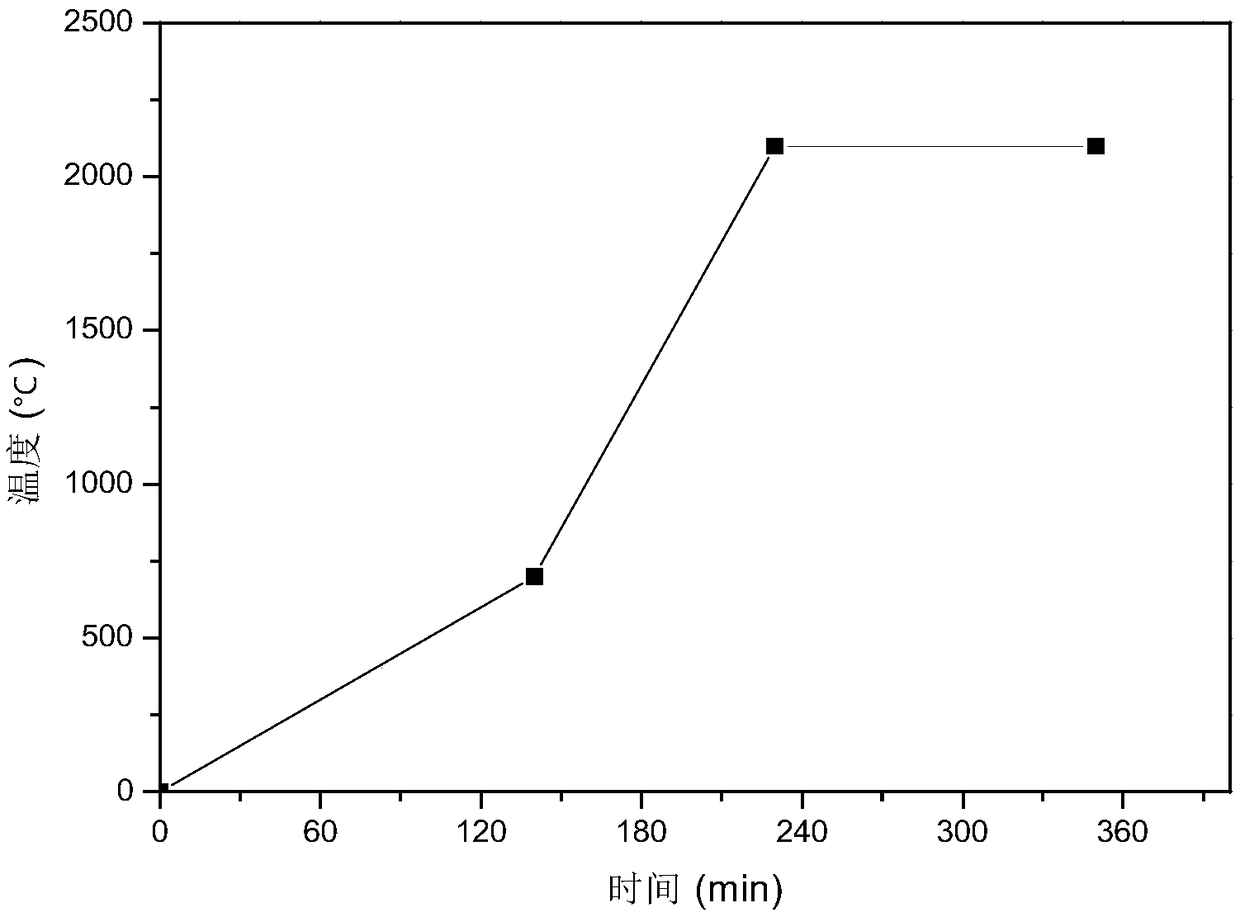

Method for adjusting furnace charge structure before damping-down period of blast furnace for smelting high-titanium schreyerite

ActiveCN104694682AGuaranteed viscosityFast air supplyBlast furnace detailsAir volumeBlast furnace smelting

The invention belongs to the technical field of schreyerite blast furnace smelting, and particularly relates to a method for adjusting a furnace charge structure before a long damping-down period (the damping-down period is longer than five hours and shorter than five days) of a blast furnace for smelting high-titanium schreyerite. The method for adjusting the furnace charge structure before the damping-down period of the blast furnace for smelting the high-titanium schreyerite includes the step that in the smelting period before the damping-down period of the blast furnace, the furnace charge structure is adjusted to enable slag newly generated in the damping-down period of the blast furnace to meet the conditions that the content of TiO2 ranges from 1% to 20%, the binary alkalinity (CaO / SiO2) of the slag ranges from 1.00 to 1.03, the content of CaF2 ranges from 0.50% to 2.0%, and the content of MnO2 ranges from 1.0% to 4%. By means of the method, after damping-down overhauling is completed, the air volume can be rapidly (a period with the length 1 time to 1.5 times that of the damping-down period is needed) recovered to the air volume required by normal production.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Low-temperature-resistant non-sensitive single-mode fiber

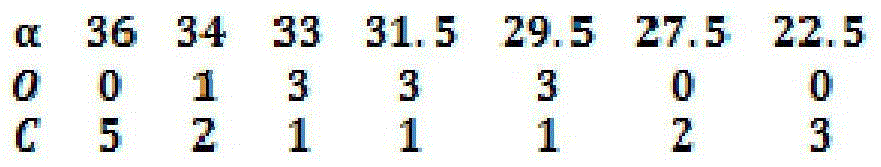

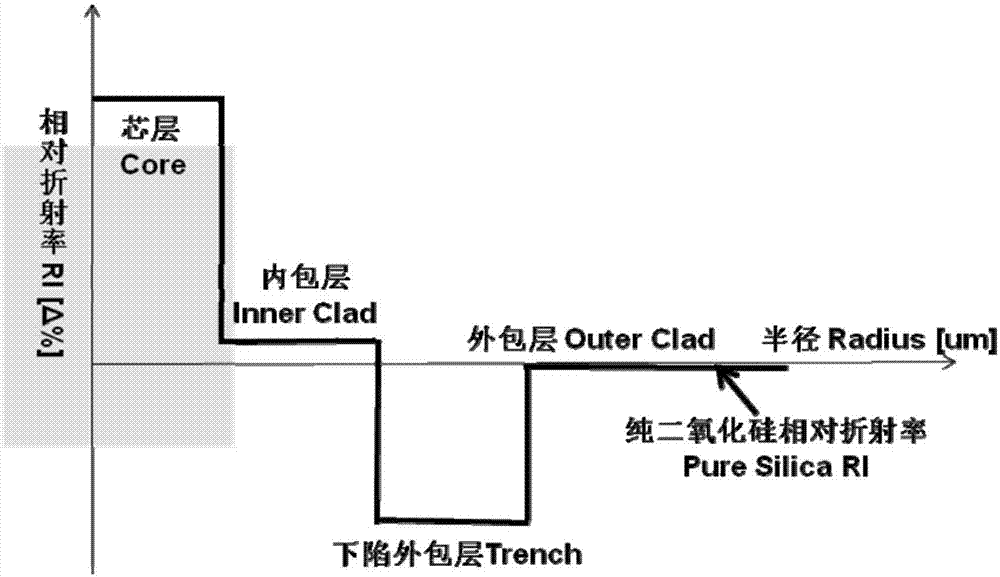

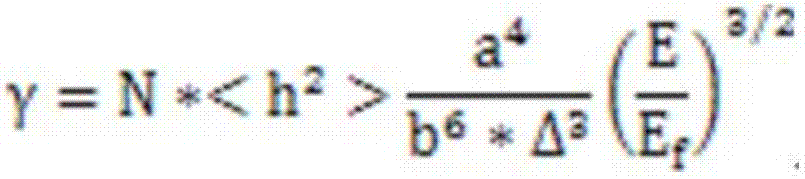

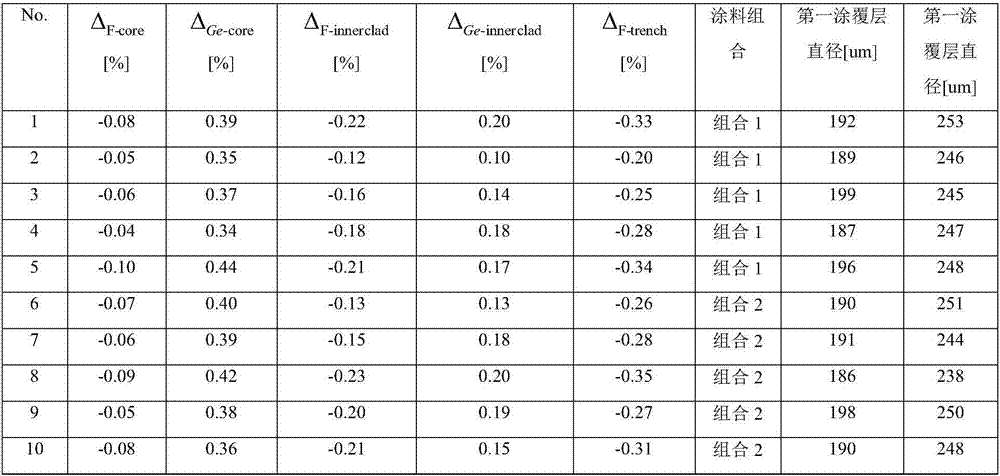

ActiveCN107272111AReduced microscopic bending sensitivityImprove fade stabilityOptical fibre with multilayer core/claddingUltrasound attenuationRelative refractive index

The invention relates to a low-temperature-resistant non-sensitive single-mode fiber comprising a glass part and two high-molecular polymer protective coating layers coating the glass part. The glass part consists of a core layer, an inner cladding, a recessed outer cladding, and an outer cladding; the core layer and the inner cladding are germanium-and-fluorine-doped quartz glass parts; an F-doped relative refraction index contribution value deltaF-core of the core layer is -0.04 to -0.10% and a Ge-doped relative refraction index contribution value deltaGe-core of the core layer is 0.35 to 0.48%; an F-doped relative refraction index contribution value deltaF-inner clad of the inner cladding is -0.10 to -0.24% and a Ge-doped relative refraction index contribution value deltaGe-inner clad of the inner cladding is 0.05 to 0.20%, and the |deltaF-inner clad| is larger than or equal to deltaGe-inner clad; an F-doped relative refraction index contribution value deltaF-trench of the recessed outer cladding is -0.20 to -0.35%; and the F-doped relative refraction index contribution values of the core layer, the inner cladding, and the recessed outer cladding form the following a relationship: |deltaF-Trench| is larger than or equal to the sum of the |deltaF-core| and the |deltaF-inner clad|, wherein the product of the |deltaF-core| and 1.5 is less than or equal to the |deltaF-inner clad|. Because the composition of materials of the fiber glass part and the composition of the cured coating materials, the micro bending-resistant performance of the fiber is enhanced and the attenuation performance and stability of the fiber at a low temperature are improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Solar positive silver paste with high aspect ratio and preparation method thereof

ActiveCN106887270AModerate viscosityPromote recoveryNon-conductive material with dispersed conductive materialCable/conductor manufactureSolventAspect ratio

The invention provides a solar positive silver paste with high aspect ratio. The solar positive silver paste comprises, by weight, 82 to 90 percent of conductive phase silver powder, 1 to 3 percent of inorganic phase glass powder and 7 to 15 percent of organic phase carrier. The organic phase carrier comprises, by weight, 15 to 30 percent of plasticizer, 7 to 15 percent of ethyl cellulose, 1 to 15 percent of thixotropic agent, 0 to 12 percent of surfactant, and the balance of solvent. According to the invention, the prepared silver paste has excellent screen printing property, and the aspect ratio of a printed line is high.

Owner:无锡晶睿光电新材料有限公司 +1

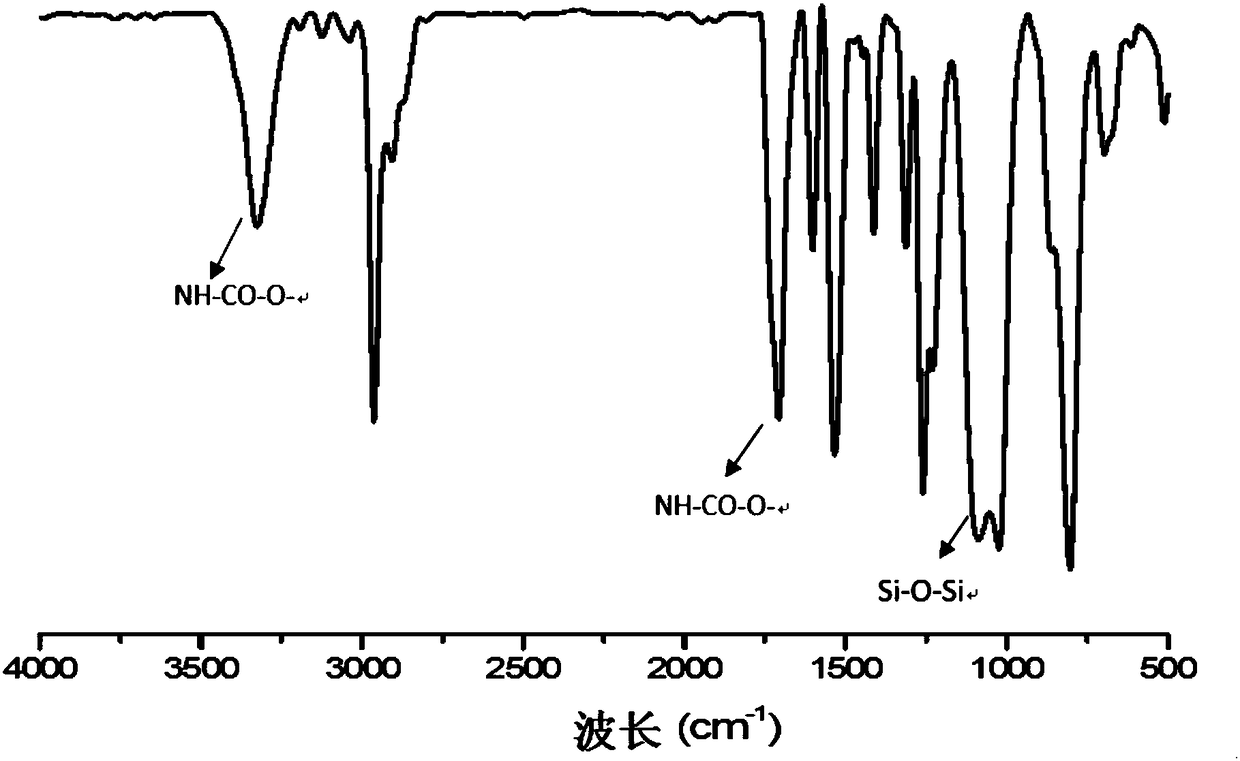

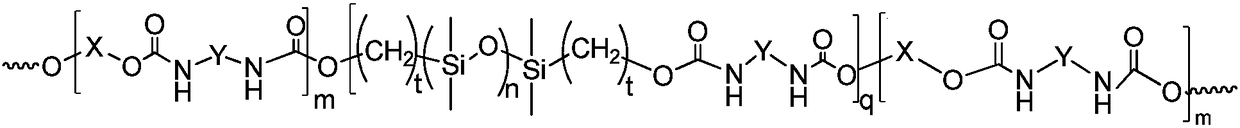

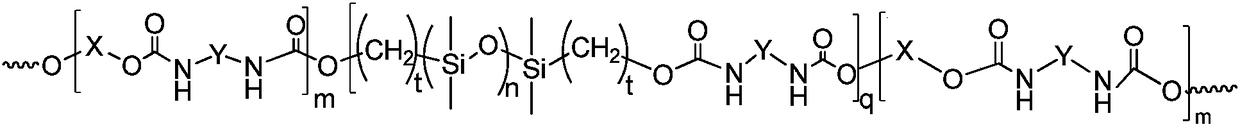

Organosilicone modification polyurethane elastomer and preparation method thereof

The invention relates to an organosilicone modification polyurethane elastomer and a preparation method thereof. The method comprises the steps that firstly, silicones at the carbon function hydroxylsealed end are adopted as a flexible chain and subjected to bulk polymerization with polyisocyanates under the solvent-free state, and therefore the mechanical property of the elastomer is improved; then, a certain amount of organic solvent is added to the chain extension stage for attenuation, a catalyst is used, the compatibility and viscosity of the system are effectively balanced, macroscopicincompatibility is avoided so as to ensure smooth conduction of the reaction, and a high molecular weight polymer with the large viscosity is generated. The method can obtain the elastomer with the good transparency and glossiness, meanwhile, due to the fact that the catalyst is added into the chain extension stage, the chain extension speed under the solvent is increased, the reaction time can begreatly shortened, the reaction efficiency is improved, and side reactions are avoided.

Owner:SHANDONG UNIV

Method for preparing flavored fermented milk by stirring type heat treatment

InactiveCN103828915AGuaranteed viscosityGuarantee that the product has viscosityMilk preparationFlavorWhey protein

The invention discloses a method for preparing flavored fermented milk by stirring type heat treatment. The flavored fermented milk is prepared from the following ingredients in parts by weight: 50-100 parts of white granulated sugar, 10-15 parts of whey protein powder, 20-25 parts of a stabilizer, 0.03-0.1 part of strains, 0.1-1 part of essence, and 1000 parts of milk without antibiotics. The flavored fermented milk stored at normal temperature is normal in texture without whey being separated out and is normal in flavor within the shelf life; within the shelf life, the acidity and the pH value of the flavored fermented milk do not change fundamentally, and an appropriate sour-sweet ratio as well as normal texture and mouthfeel of the flavored fermented milk are maintained, so that yogurt can be stored, sold and drunk at normal temperature; besides, the method can be performed under existing technical conditions without extra equipment investment, and consequently, the method has a significant business value and a big market efficiency space.

Owner:KUNMING XUELAN MILK

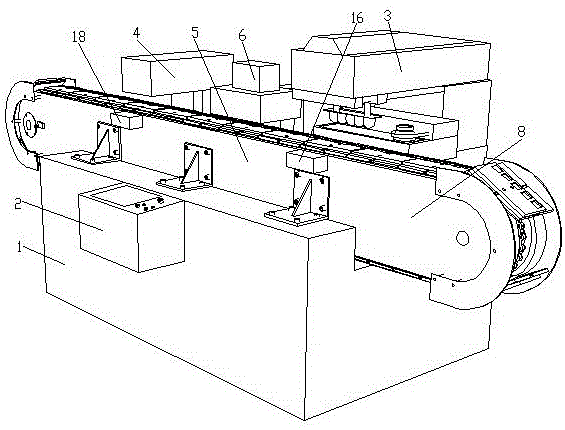

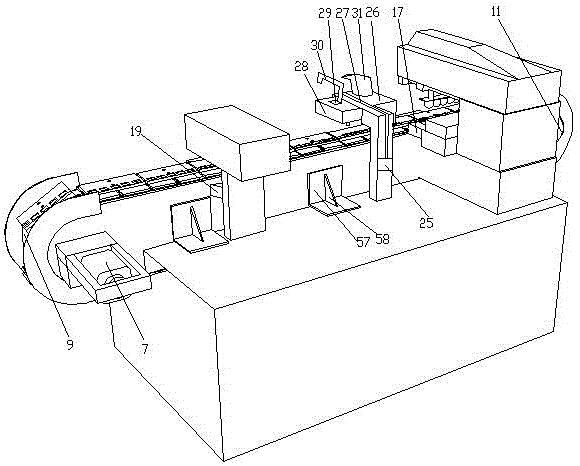

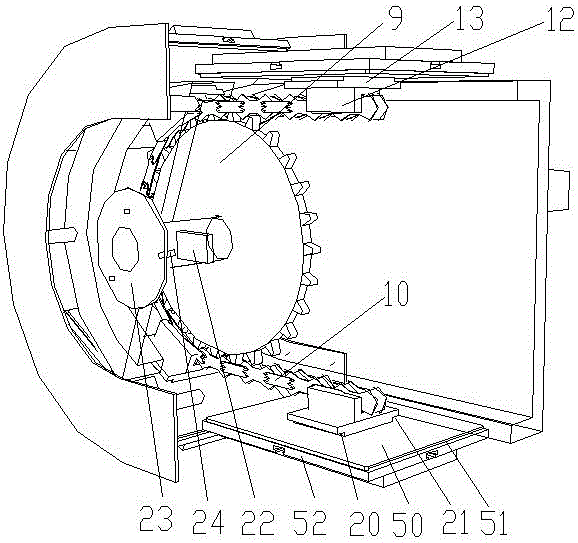

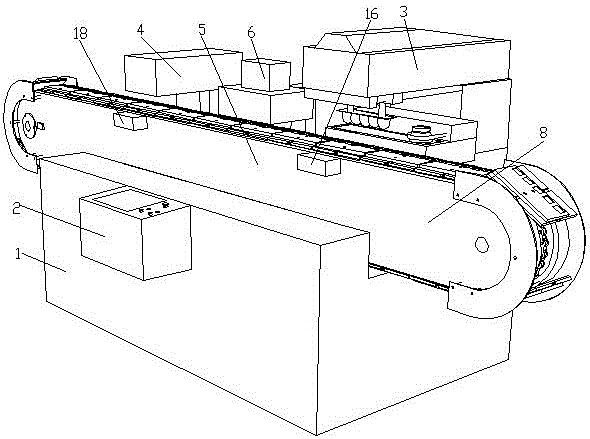

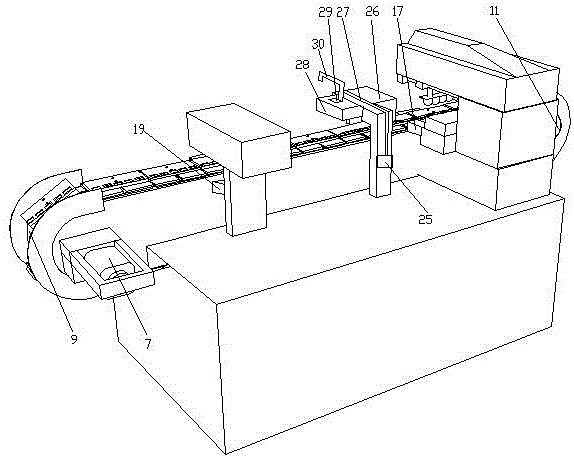

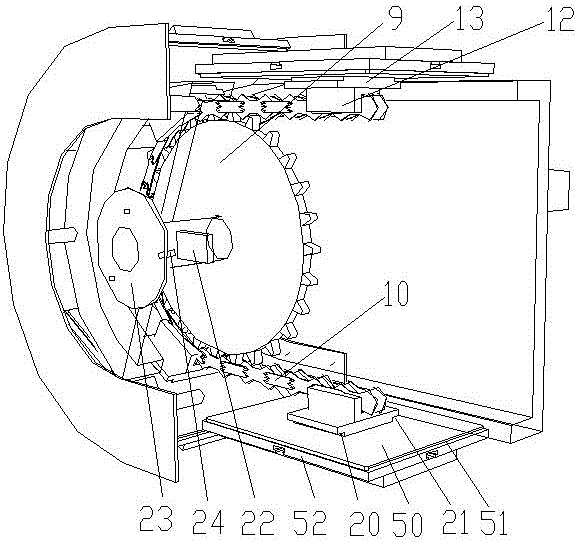

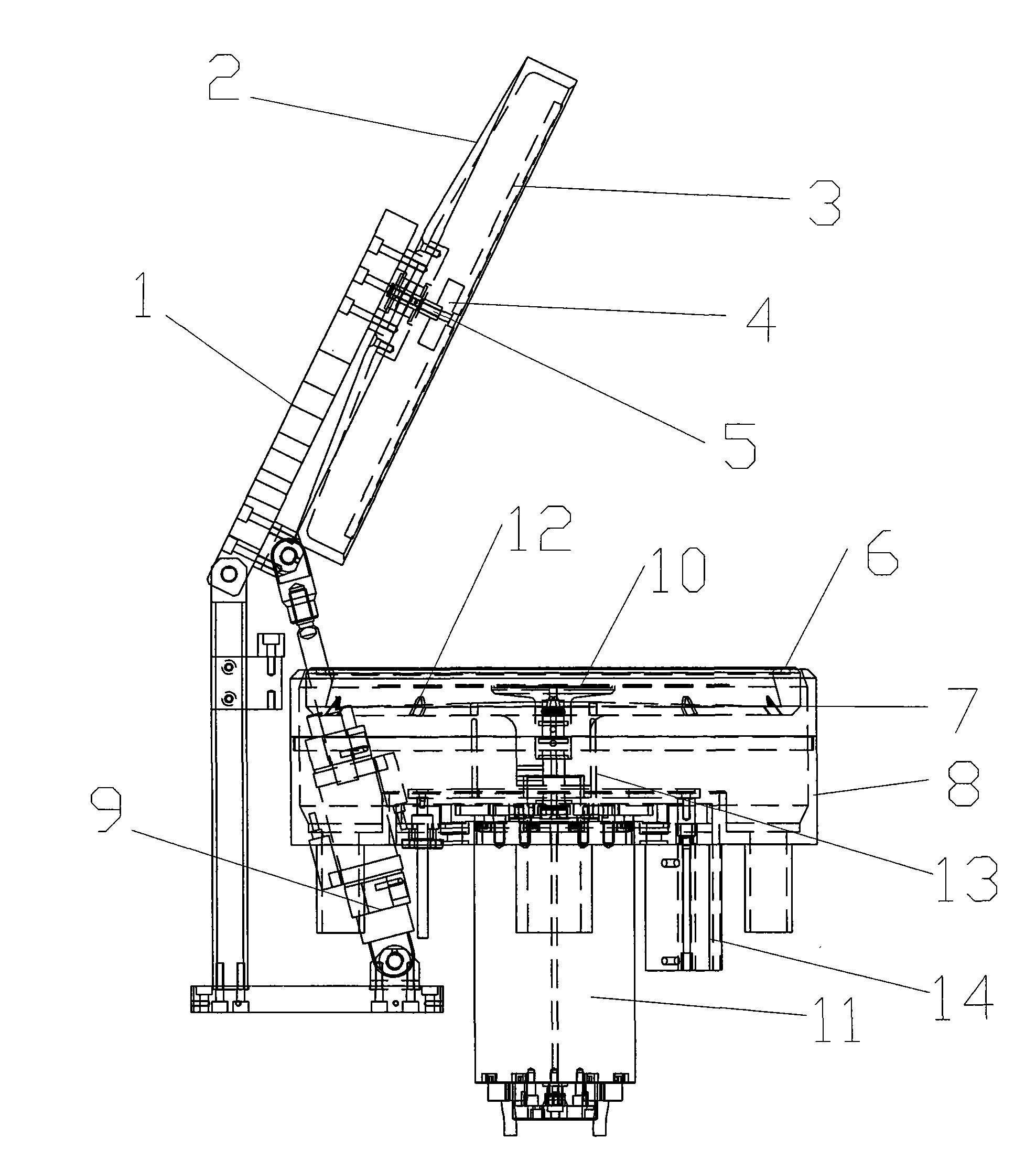

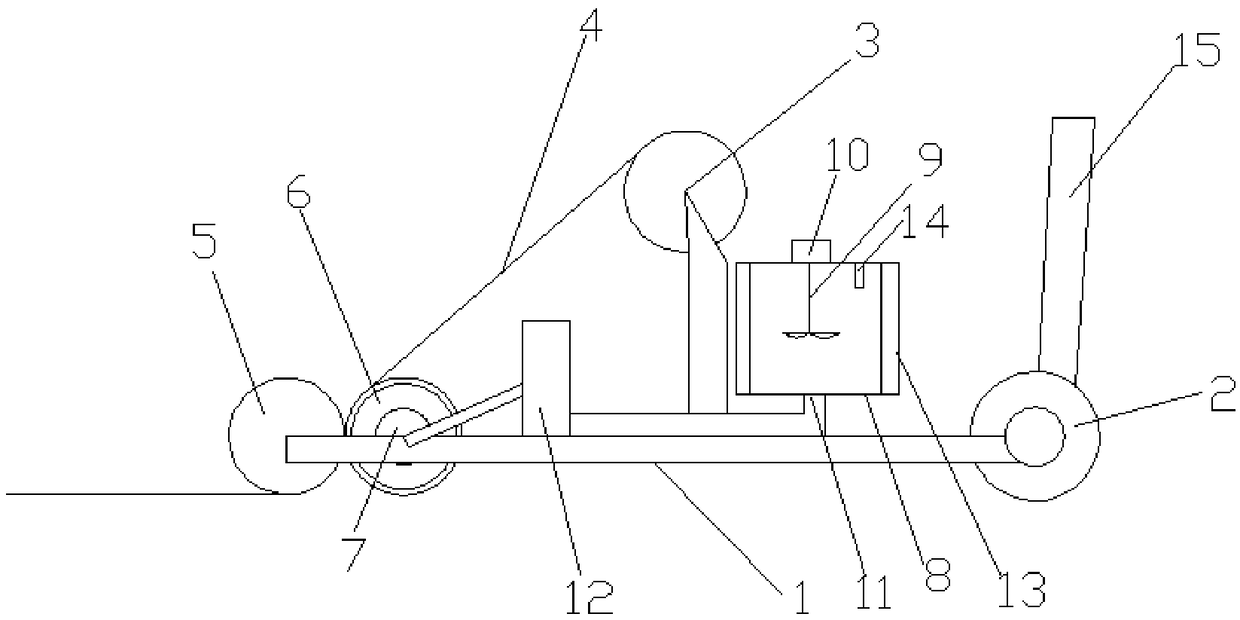

Continuous type pad printing and coding device

ActiveCN106364152APad printing stabilityPad printing precisionRotary pressesPrinting press partsPad printingEngineering

The invention discloses a continuous type pad printing and coding device. The continuous type pad printing and coding device comprises a workbench, a PLC controller and a pad printing machine. The continuous type pad printing and coding device further comprises a laser coding machine, a conveying component and a drying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. The chain is fixedly provided with multiple fixing seats. Locating blocks are connected to the fixing seats. Brackets are connected to the locating blocks, and the brackets are provided with mold grooves. The side wall of the transmission case is provided with a pad printing locating piece and a coding locating piece. Each locating block is provided with a left groove and a right groove. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disk. Three sensing columns are distributed on the wheel disk. The infrared sensor, the pad printing machine and the laser coding machine are electrically connected with the PLC controller. The continuous type pad printing and coding device conducts continuous pad printing and coding operations on printed objects on a large scale and greatly improves the production efficiency; and pad printing and coding are clearer, the precision is high, the manufactured products are free from fading after being used for a long time and high in recognition capacity.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

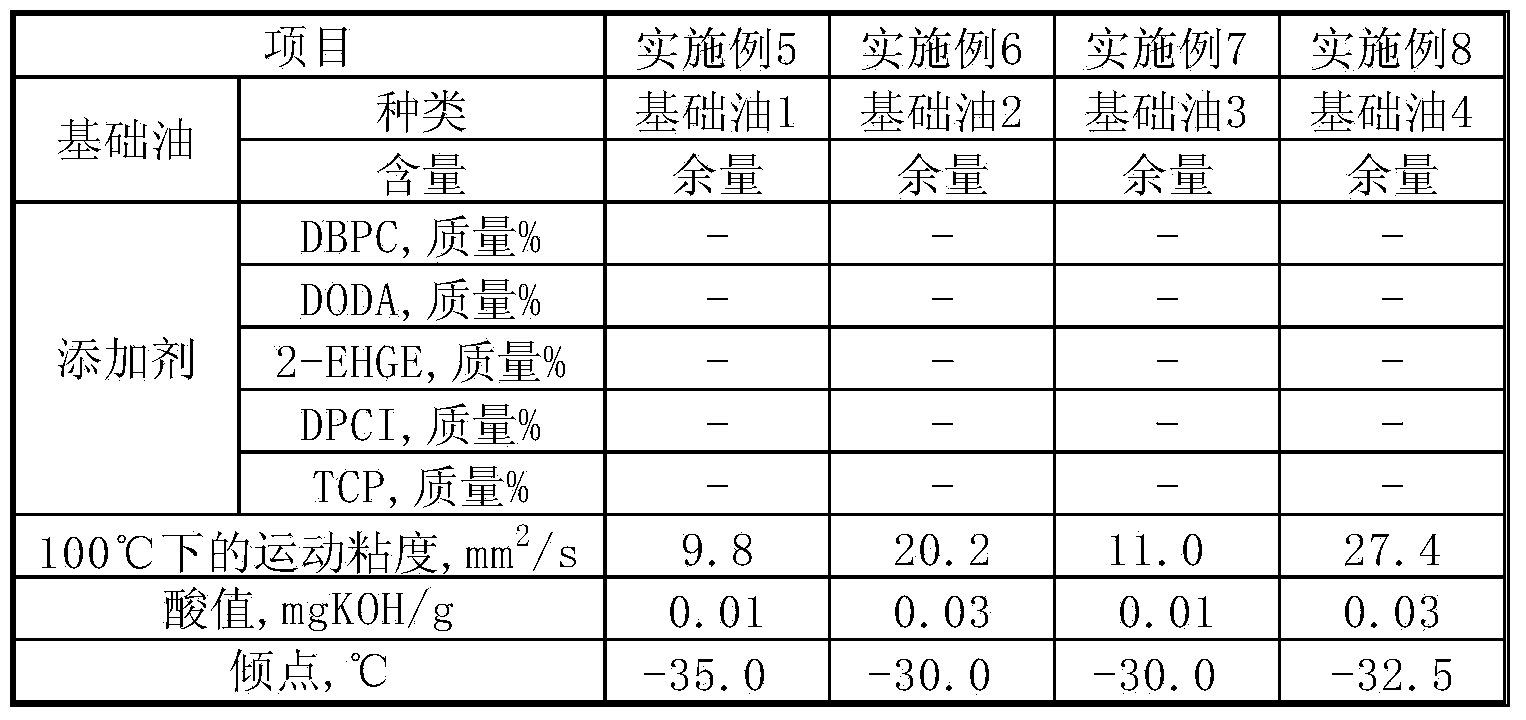

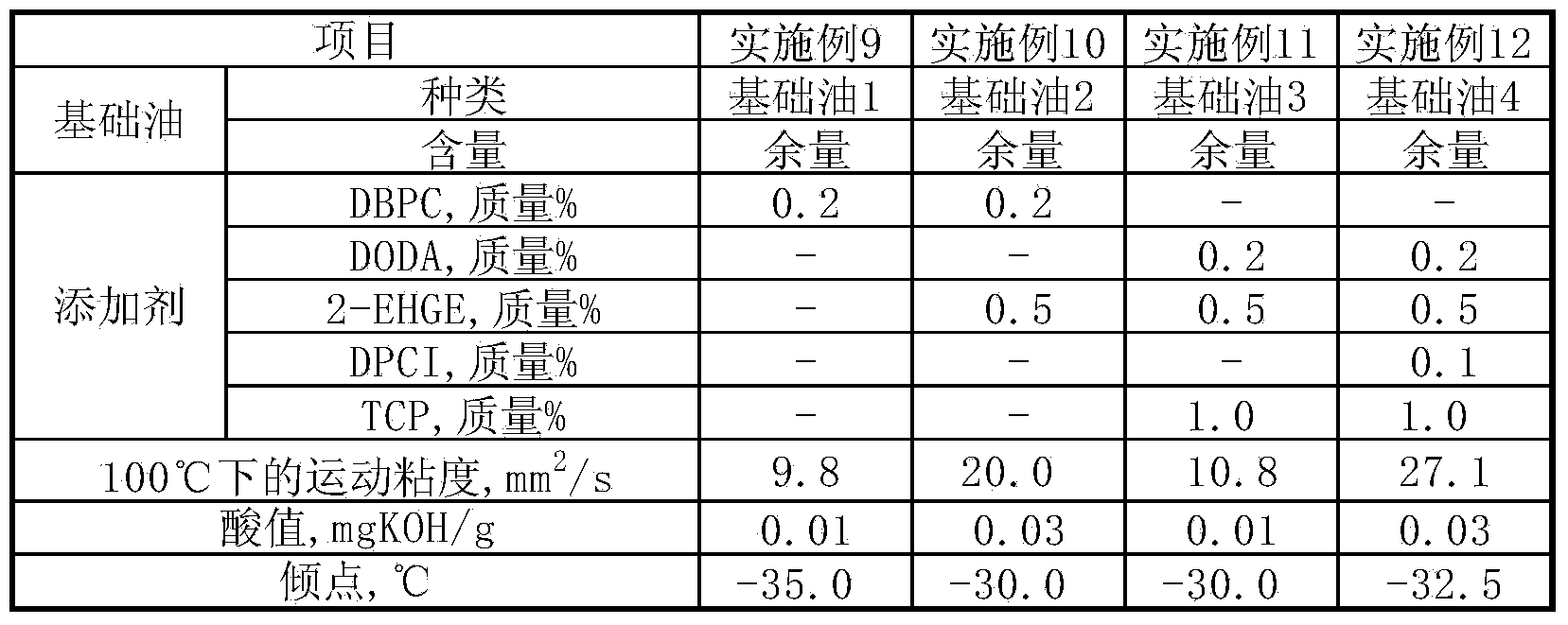

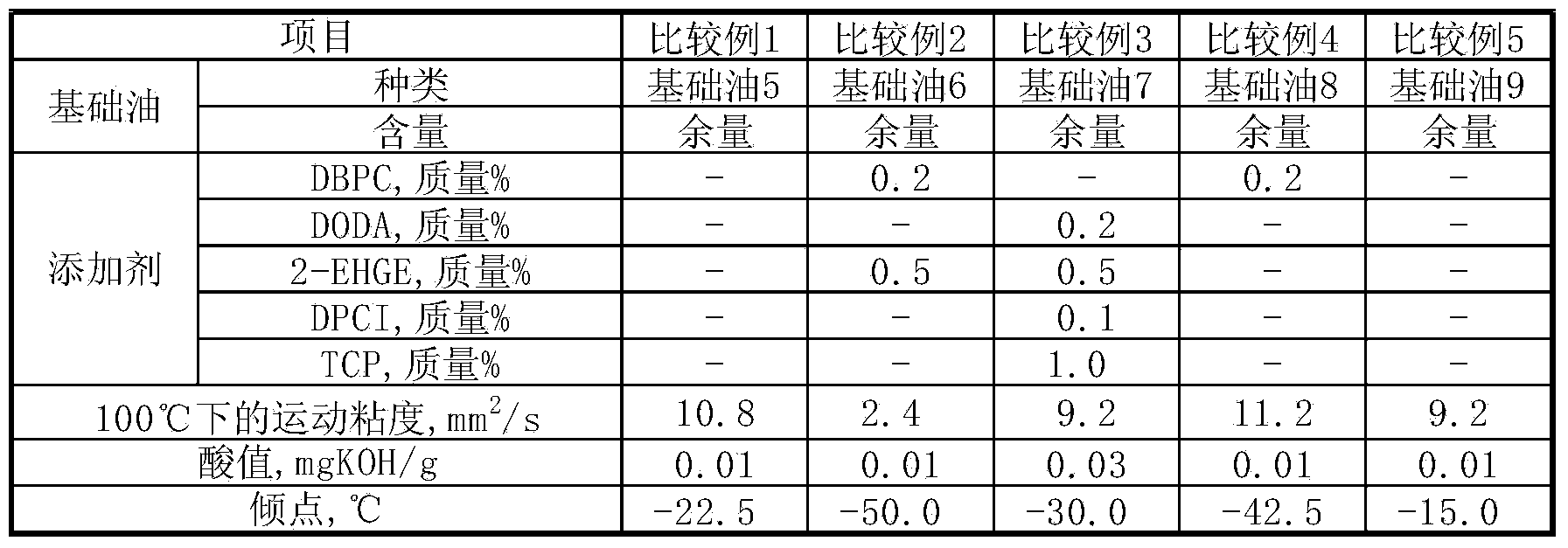

Working fluid composition for refrigerator, refrigeration oil, and method for producing same

ActiveCN104145006AReduce fillingDoes not damage viscosityHeat-exchange elementsAdditivesWorking fluidFatty acid

This working fluid composition for a refrigerator comprises: a refrigeration oil having a kinematic viscosity at 100°C of 2-50 mm2 / s and including, as a base oil, a complex ester having an acid value of 0.5 mgKOH / g or less and obtained by further esterifying, with at least one type of compound selected from C1-20 monovalent alcohols and C2-20 fatty acids, an ester intermediate obtained by reacting a neopentylpolyol and a dibasic acid; and a C2-4 hydrocarbon refrigerant.

Owner:JX NIPPON OIL & ENERGY CORP

Continuous transfer-printing coding method

ActiveCN106379042AClear outlineSqueegee steps increaseRotary pressesPrinting press partsContinuous operationLaser

The invention discloses a continuous transfer-printing coding method. The continuous transfer-printing coding method comprises the following steps: step (a) inking an etching plate by using a sealed oil cup of a transfer-printing coding device; step (b) forwards pushing a rubber head of a transfer printing machine to the upper portion of the etching plate, subsequently driving the rubber head to move down to have contact with the etching plate, and downwards pressing the rubber head to make the rubber head be stained with ink with patterns; step (c) backwards pushing the rubber head to a transfer printing work position, and then driving the rubber head to be pressed downwards so that the rubber head is capable of printing the ink with patterns on a to-be-printed object inside a mold groove; step (d) moving the transfer-printed object to a drying work position for drying by using a conveying component; step (e) moving the transfer-printed and dried object to a coding work position and coding the transfer-printed and dried object by using a laser coding machine. The continuous transfer-printing coding method disclosed by the invention is capable of realizing continuous operation on large-batch to-be-printed objects and improving the production efficiency; the patterns are clearer after the printed objects are dried at the drying work position; a coded product is high in exquisite degree and is fadeless after being used for a long time.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

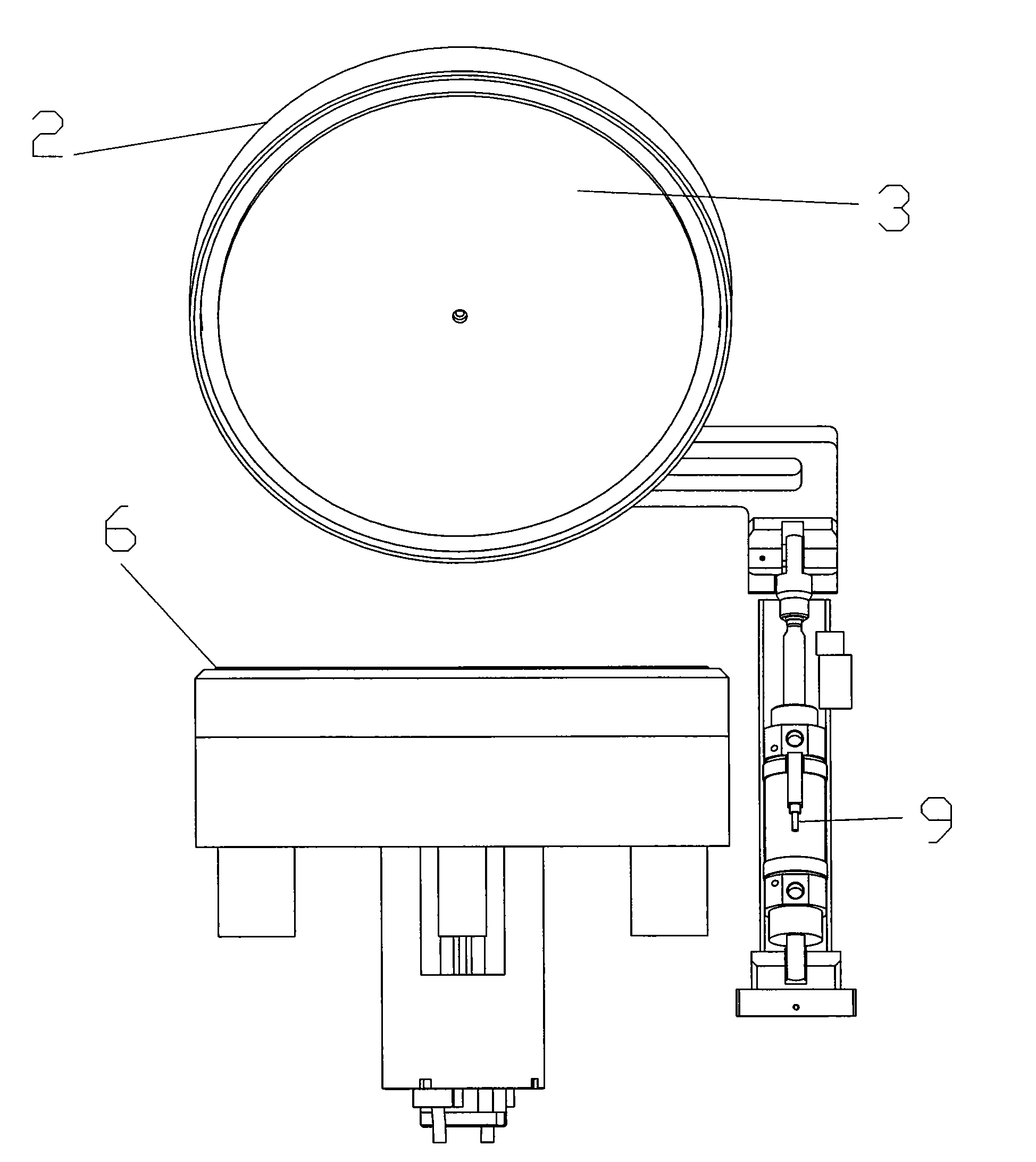

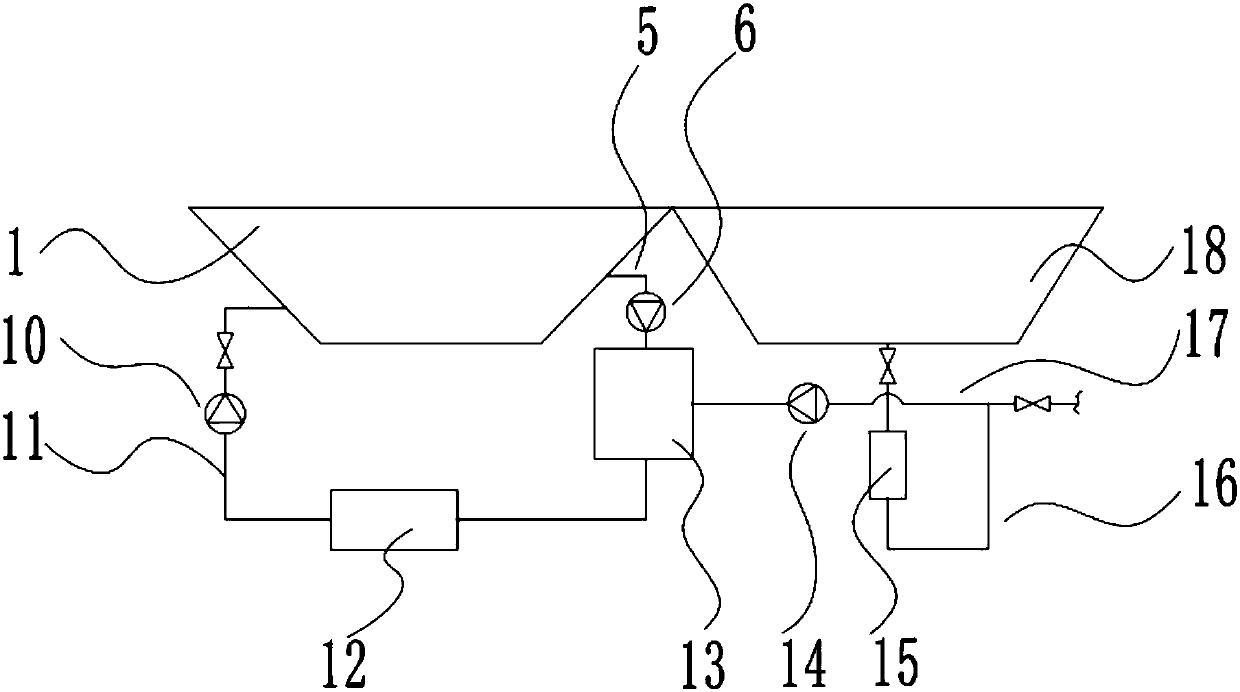

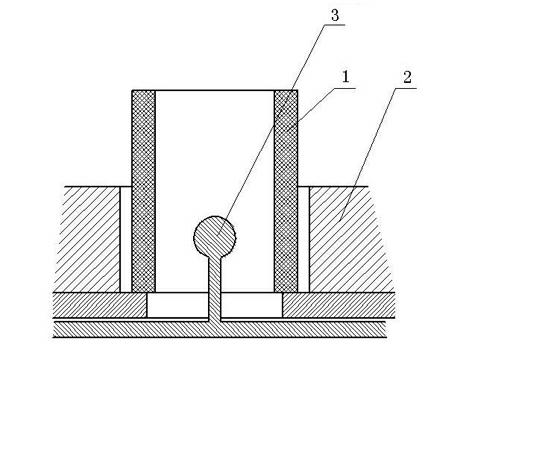

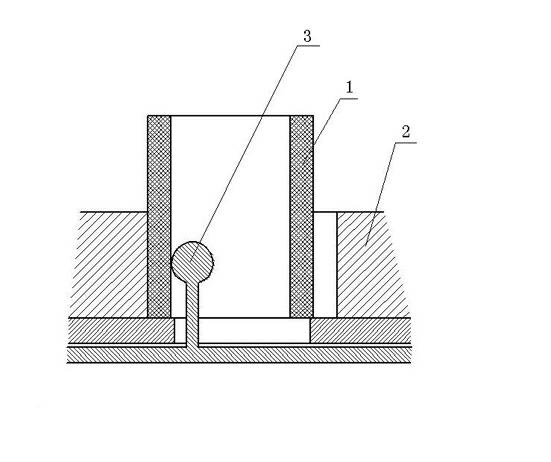

Glue spreading device

InactiveCN101491797AReduce volatilityGuaranteed viscosityLiquid surface applicatorsCoatingsColloidEngineering

The invention relates to a glue coating device for semiconductor backend encapsulation, namely a device for coating high-consistency photoresist on the surface of a wafer. A rotating cavity is formed in a gas-discharging and liquid-gathering outer gathering cup of the glue coating device; an upper opening of the gas-discharging and liquid-gathering outer gathering cup is provided with a sealing ring; the gas-discharging and liquid-gathering outer gathering cup is provided with a colloid discharge outlet; a upper cover of the glue coating device has a matched structure corresponding to the gas-discharging and liquid-gathering outer gathering cup through rotation; a wafer loading bracket driven to lift by a wafer bracket driving cylinder is provided with a wafer sucker; the wafer sucker is arranged in the rotating cavity of the gas-discharging and liquid-gathering outer gathering cup; and a rotating machine driving the wafer loading bracket to rotate is provided with a vacuum line communicated with the wafer sucker inside. The glue coating device can solve the problem of easy falling off of the coated high-consistency photoresist and the like, and is not only suitable for the common photoresist for backend encapsulation but also suitable for higher-consistency photoresist.

Owner:SHENYANG KINGSEMI CO LTD

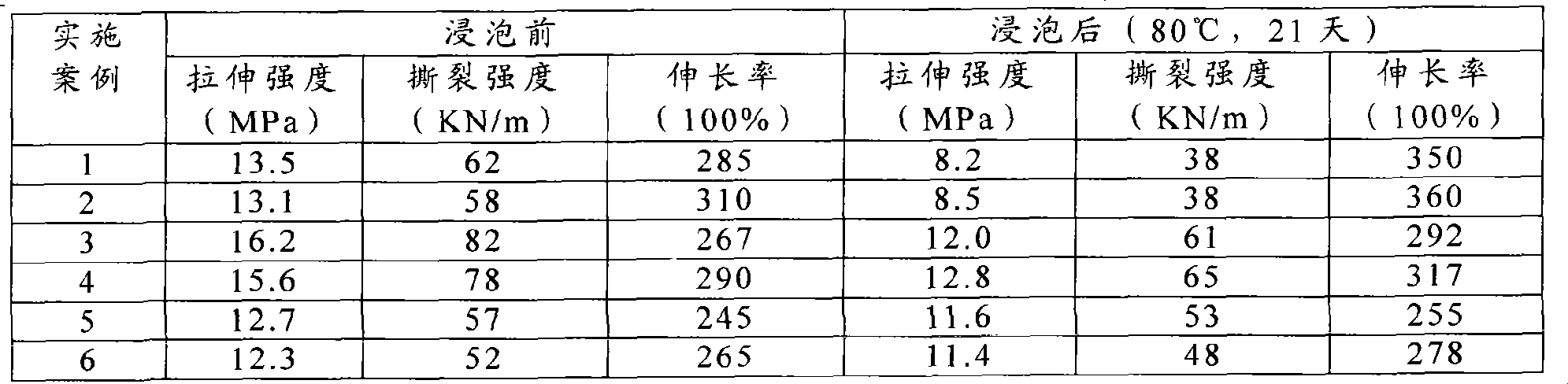

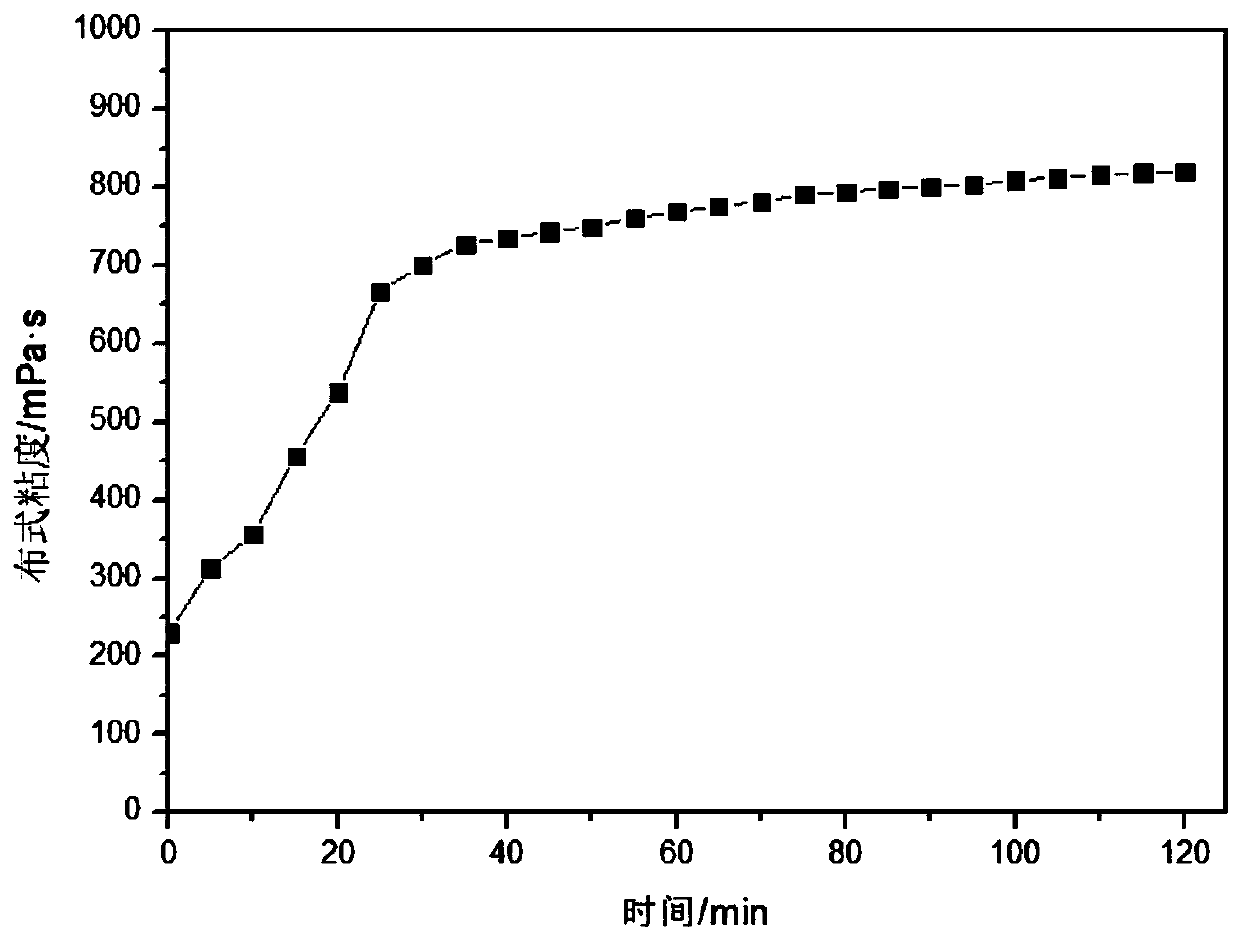

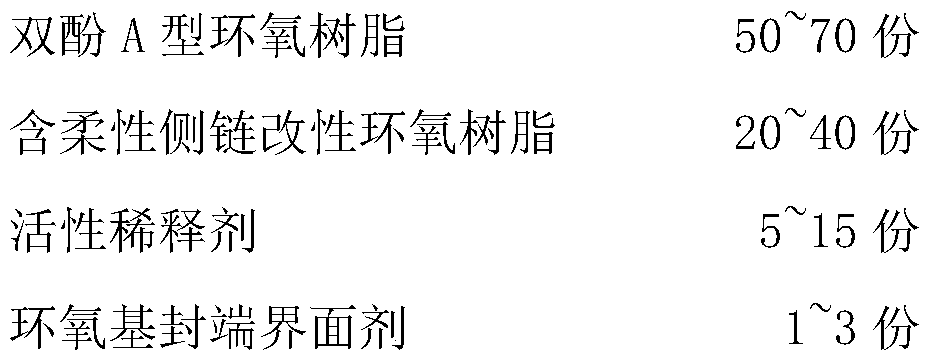

Ultrahigh-toughness epoxy resin material for hot-mixed epoxy asphalt and preparation method thereof

ActiveCN110713695AReduce crosslink densityGuaranteed viscosityBuilding insulationsPolymer scienceSide chain

The invention discloses an ultrahigh-toughness epoxy resin material for hot-mixed epoxy asphalt and a preparation method of the ultrahigh-toughness epoxy resin material. The key points of the technical scheme are as follows: the ultrahigh-toughness epoxy resin material for the hot-mixed epoxy asphalt consists of a main agent A and a curing agent B, wherein the main agent A comprises bisphenol A epoxy resin, modified epoxy resin containing a flexible side chain, a reactive diluent and an epoxy terminated interface agent; the curing agent B comprises following components in parts by weight: long-chain fatty primary amine and an accelerant. The crosslinking density of an epoxy cured product is controlled by synthesizing monofunctional long-chain fatty primary amine, and finally, the operabletime of the hot-mixed epoxy asphalt material is longer than 2 hours; the compatibility problem between an asphalt phase and an epoxy phase is solved on the basis of a 'reaction induced phase splitting' technical principle; by introducing the modified epoxy resin containing the flexible side chain, the fatigue resistance of the hot-mixed epoxy asphalt material is greatly improved.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD +1

Preparation method of tackifier for drilling fluid

InactiveCN102336867AGood ability to increase viscosity and adjust flow patternStrong salt resistanceDrilling compositionChemical recyclingChemistryPolyacrylamide

The invention discloses a preparation method of a tackifier for a drilling fluid. The method comprises the following steps of: adding 71 kg of acrylamide and 700 kg of water into a polymerizing kettle, preparing a 20 percent acrylamide aqueous solution, adding 0.1 kg of initiator after a certain period of time, and reacting at constant temperature for a certain period of time to obtain gel polyacrylamide; taking the gel polyacrylamide out, pelletizing, and preparing into 2 percent polyacrylamide aqueous solution; adjusting the pH of a system to 11 with a sodium hydroxide solution, adding 85 kg of formaldehyde and 100 kg of sodium bisulfite aqueous solution, and reacting with stirring for a certain period of time to obtain sulfomethylated polyacrylamide gel; precipitating and separating reactants with 95 percent ethanol, and recycling and distilling an ethanol aqueous solution for circular use; and taking a precipitated polymer, removing ethanol, drying in vacuum and crushing to obtain a product. The tackifier has large tackifying and flow pattern adjusting capabilities, and can be used for keeping the viscosity of the drilling fluid under severe conditions such as high temperature, high salinity, high calcium-magnesium ions and the like.

Owner:陆明富

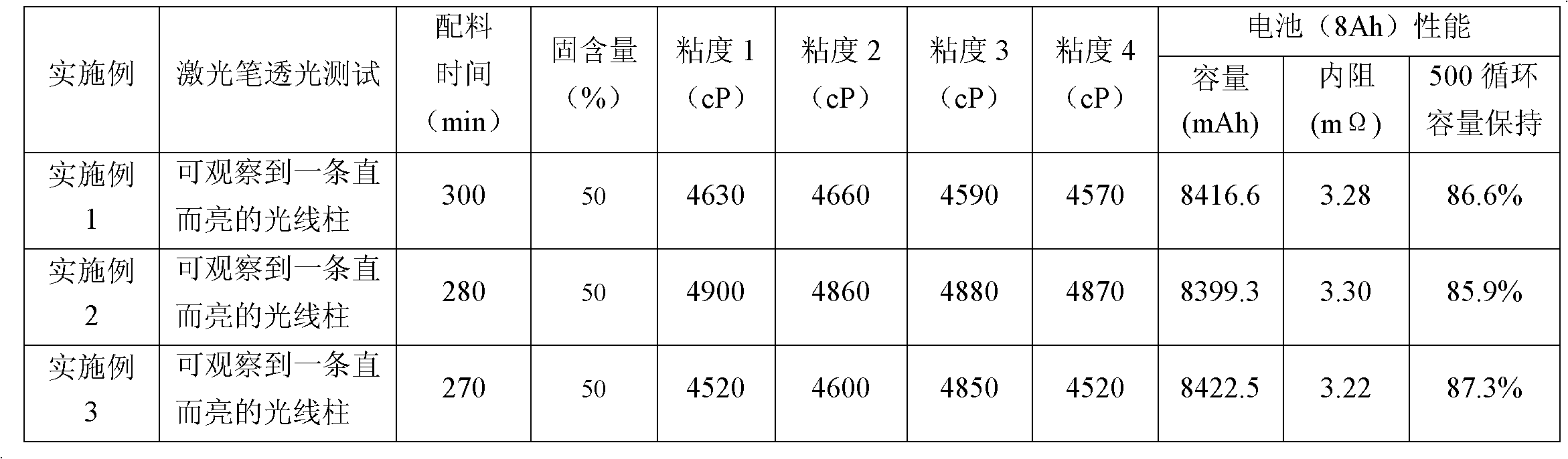

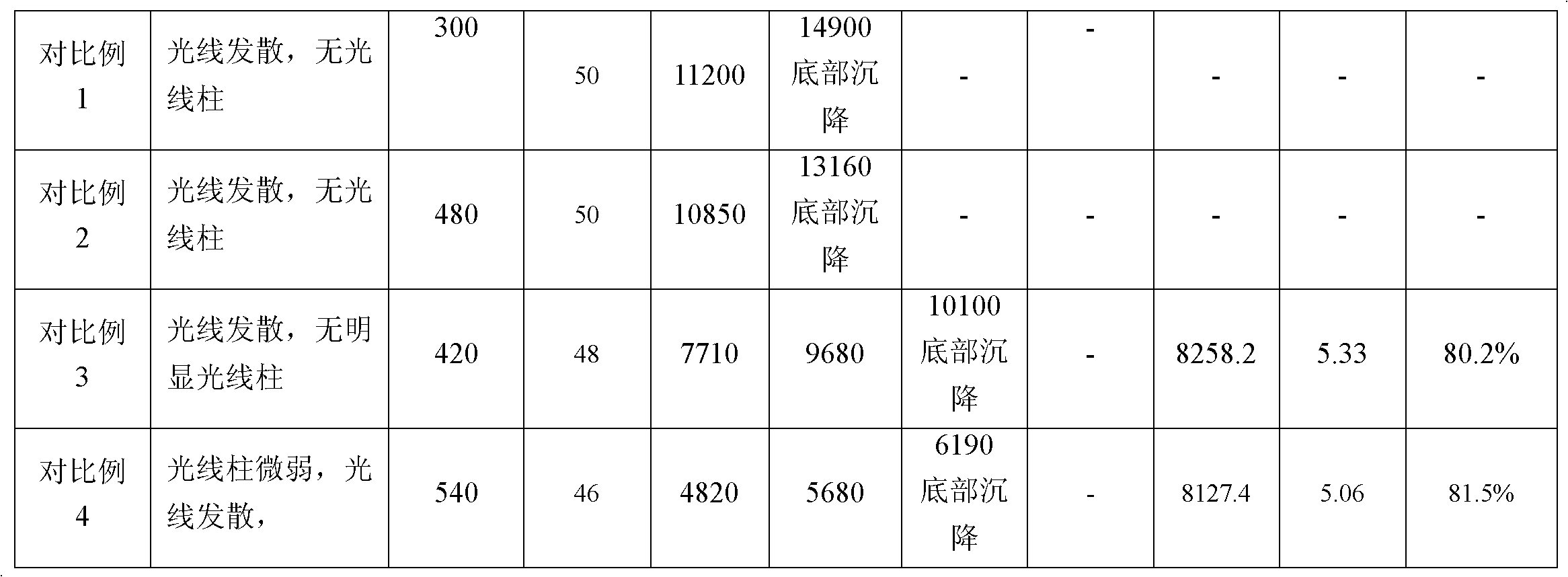

Burdening technology for slurry used by nanometer ferrous phosphate lithium ion battery

The invention relates to a burdening technology for slurry used by a nanometer ferrous phosphate lithium ion battery. Nanometer ferrous phosphate lithium ion, conductive agent, binder and N-methyl pyrrolidone are prepared into primary slurry; the primary slurry is stirred and dispersed for 60-90 minutes in a reciprocating mode between a stirring pot and a dispersion machine to obtain the slurry used by the nanometer ferrous phosphate lithium ion battery; and the linear velocity of the dispersion machine is 35-45m / s. The slurry prepared with the burdening technology disclosed by the invention can be evenly dispersed. The viscosity of the slurry slightly changes with the extending of placing time, and performance is stable. The lithium ion battery prepared by the slurry has the advantages of excellent electrochemistry performance, high retention rate of capacity-grading volumes and low resistance.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

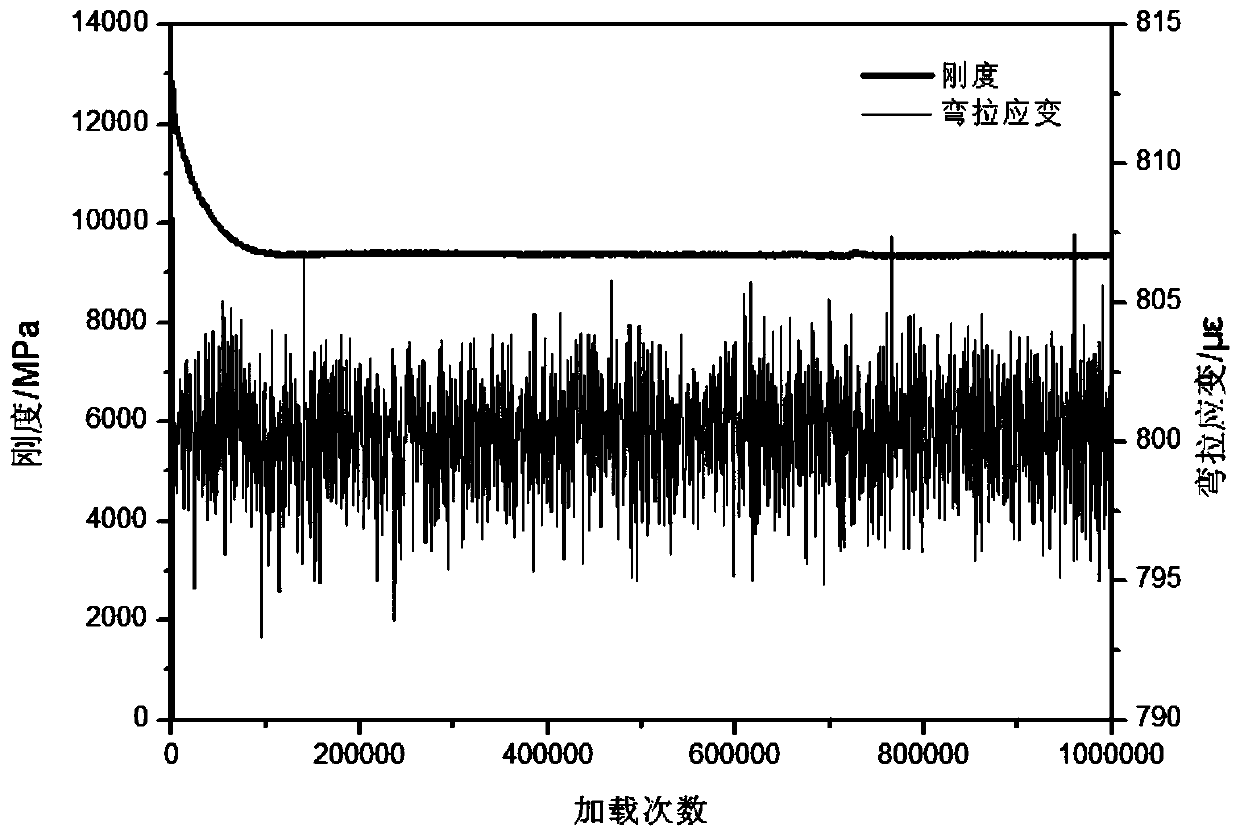

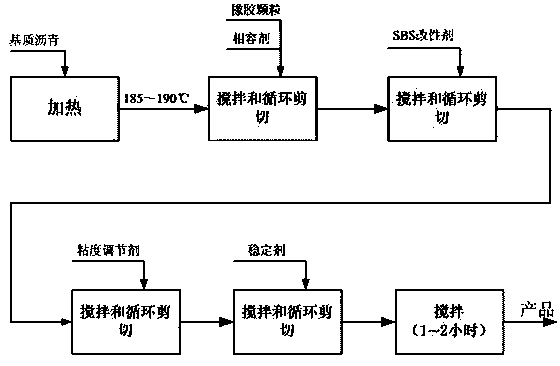

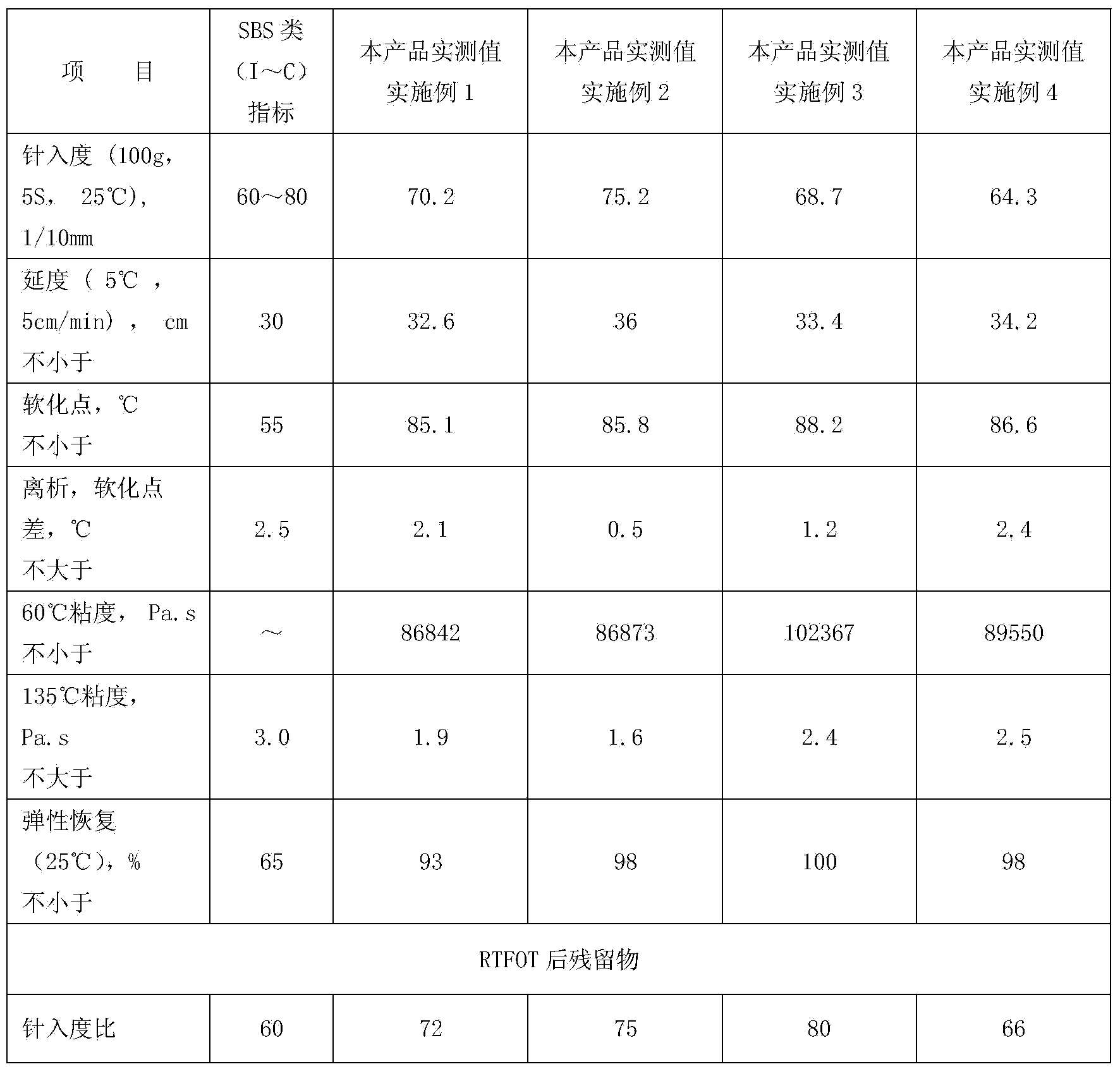

High-viscosity high-elasticity pitch and preparation method thereof

ActiveCN103849153AEasy constructionImprove workabilityBuilding insulationsViscosityMaterials science

The invention discloses high-viscosity high-elastic pitch and a preparation method thereof. The high-viscosity high-elasticity pitch prepared according to the invention has high viscosity and high elasticity as well as excellent workability, and meets the requirements of deformation resistance, fatigue resistance and long service life of large-span bridges, and with the high-viscosity high-elasticity pitch, the problem of poor workability of the existing high-viscosity high-elasticity pitch is solved; the viscosity of the pitch at 60 DEG C is larger than 80000 Pa.s, the viscosity at 135 DEG C is smaller than 3 Pa.s, the softening point reaches up to 85 DEG C above, and the cost is 20% lower than that of the common similar high-viscosity high-elasticity pitch in China at present.

Owner:CNPC JIANGSU FUEL ASPHALT

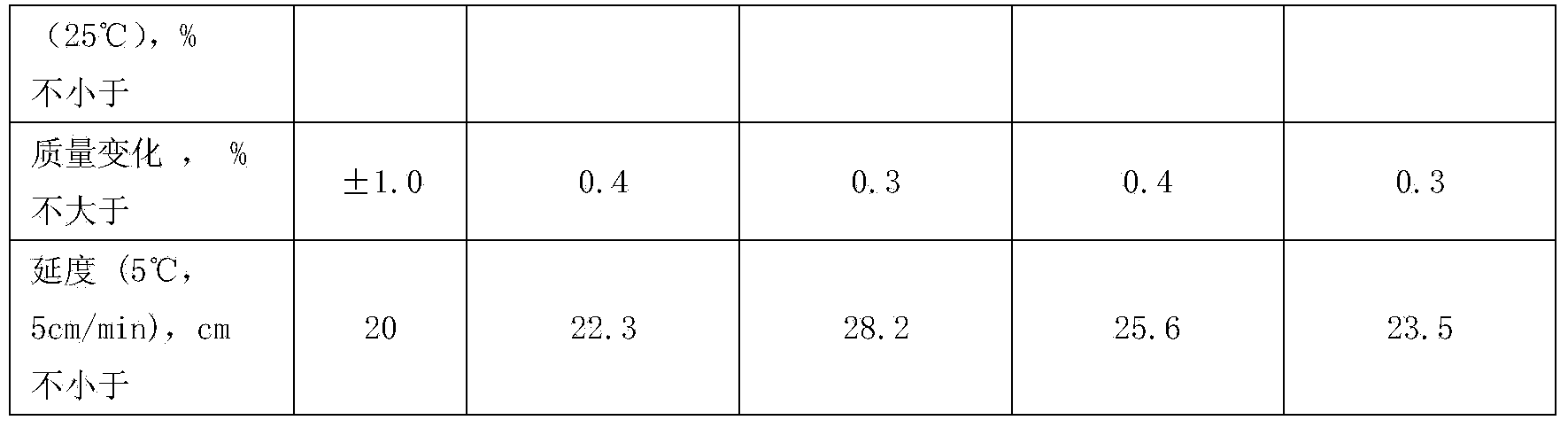

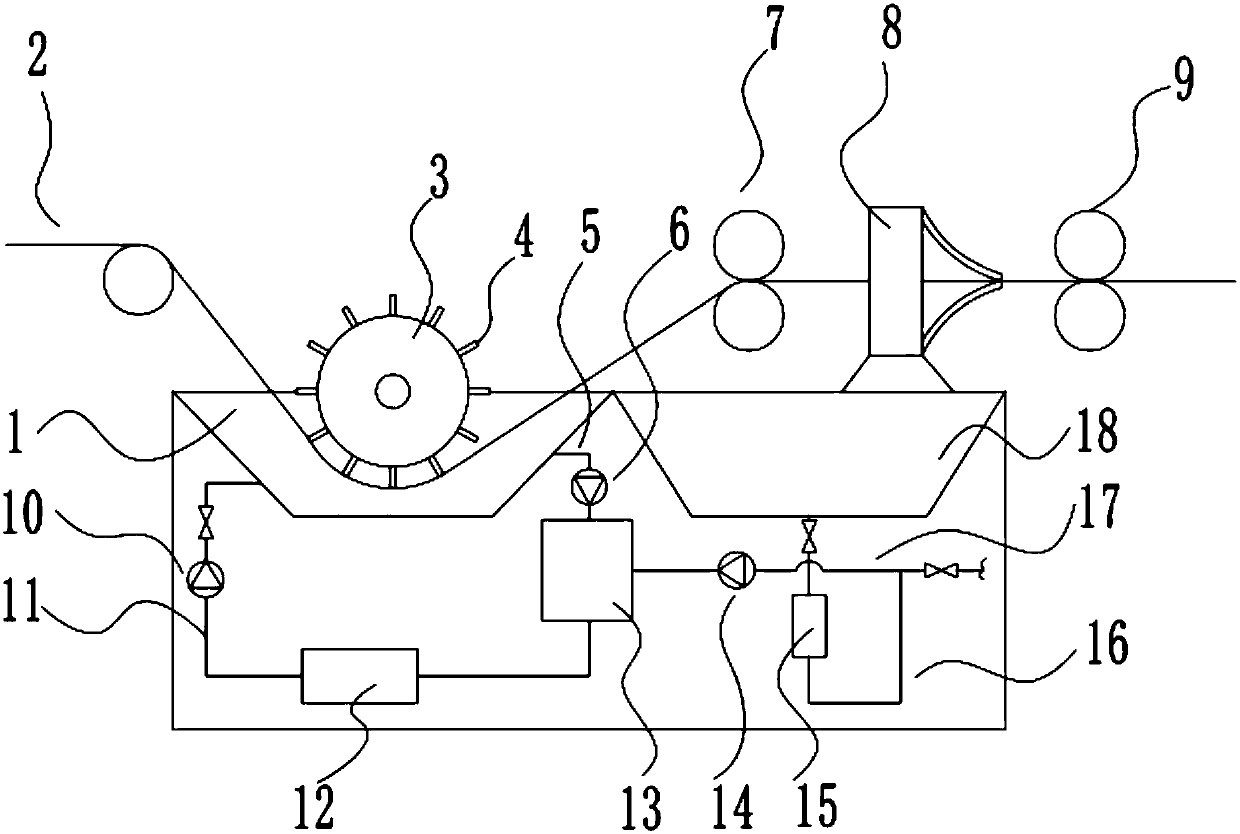

Efficient bituminous waterproof coiled material oiling device

InactiveCN107597496AEasy accessGuaranteed temperatureLiquid surface applicatorsCoatingsFuel tankFeeding pumps

The invention discloses an efficient bituminous waterproof coiled material oiling device which comprises an oiling pool, a coiled material base cloth, an oiling roller and an oil scraper device. The oiling roller is installed in the oiling pool, the surface of the oiling roller is evenly provided with multiple oiling plates, the two sides of the oiling pool are connected with an oil return tank through an oil return pipe and an oil feeding pipe correspondingly, the oil feeding pipe is further provided with a heating device for heating oil liquid, the oil return pipe and the oil feeding pipe are further provided with an oil return pump and an oil feeding pump correspondingly, one side of the oiling pool is provided with the oil scraper device, and the two sides of the oil scraper device areprovided with first pair pressing rollers and second pair pressing rollers for guiding the movement of the coiled material base cloth. The efficient bituminous waterproof coiled material oiling device has the beneficial effects that a gap can be formed between the coiled material base cloth and the oiling roller through the design of the oiling plates, both the two faces of the coiled material base cloth can make good contact with oil liquid, and the oiling effect is improved. Oil liquid scraped away can be recycled, reuse of resources is achieved, and the production cost is saved.

Owner:SHENZHEN SHENGTENG ENTERPRISE MANAGEMENT CO LTD

Electrochemistry method for treating oilfield produced water into confecting polymer water

InactiveCN101391846AGood for maintaining viscosityGuaranteed viscosityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationIon contentPolymer solution

The invention discloses an electrochemical method for processing oil field output water to be distributed polywater. The method utilizes the strong basicity of a cathode area (including cathode surface) to lead the dissociative Ca<2+>, Mg<2+> ions to generate CaCO3, Ca(OH)2 and Mg(OH)2 deposits, and finally the distributed polywater with calcium ion content not more than 30mg / L and magnesium ion content not more than 50mg / L, can be obtained by flocculation, sedimentation and filter treatments, thus achieving the object of removing the bivalent positive ions such as Ca<2+>, Mg<2+>, Fe<2+> and the like as well as the tervalence positive ions such as Fe<3+> in the oil field output water, moreover, without increasing the concentration of the monovalent positive ions such as K<+>, Na<+> and the like in the oil field output water so as to maintain the viscosity of polymer solution to the greatest extent. The method has no pollution, saves resources and cost, does not generate drug fastness, has simple, safe and convenient operation, is easy to regulation and control as well as automation realization, thus having wide suitability on the water amount and facilitating popularization and utilization.

Owner:SOUTH CHINA UNIV OF TECH

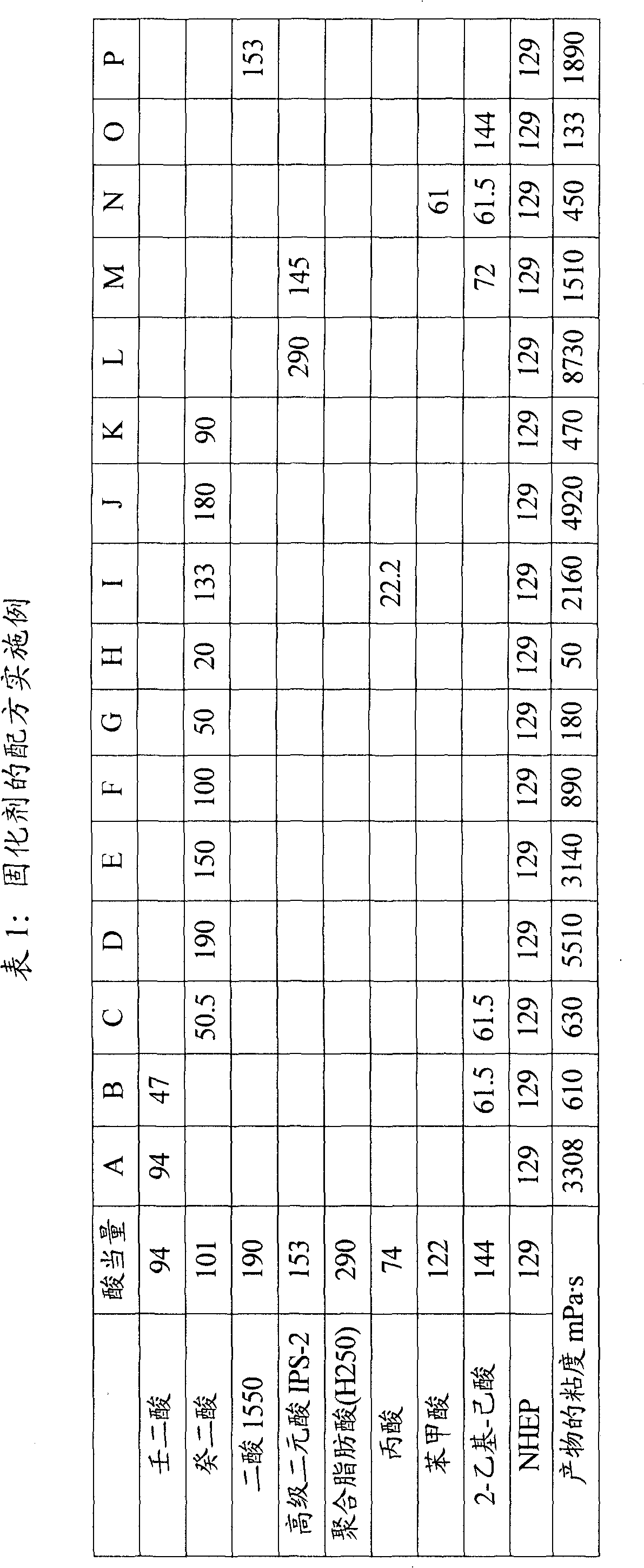

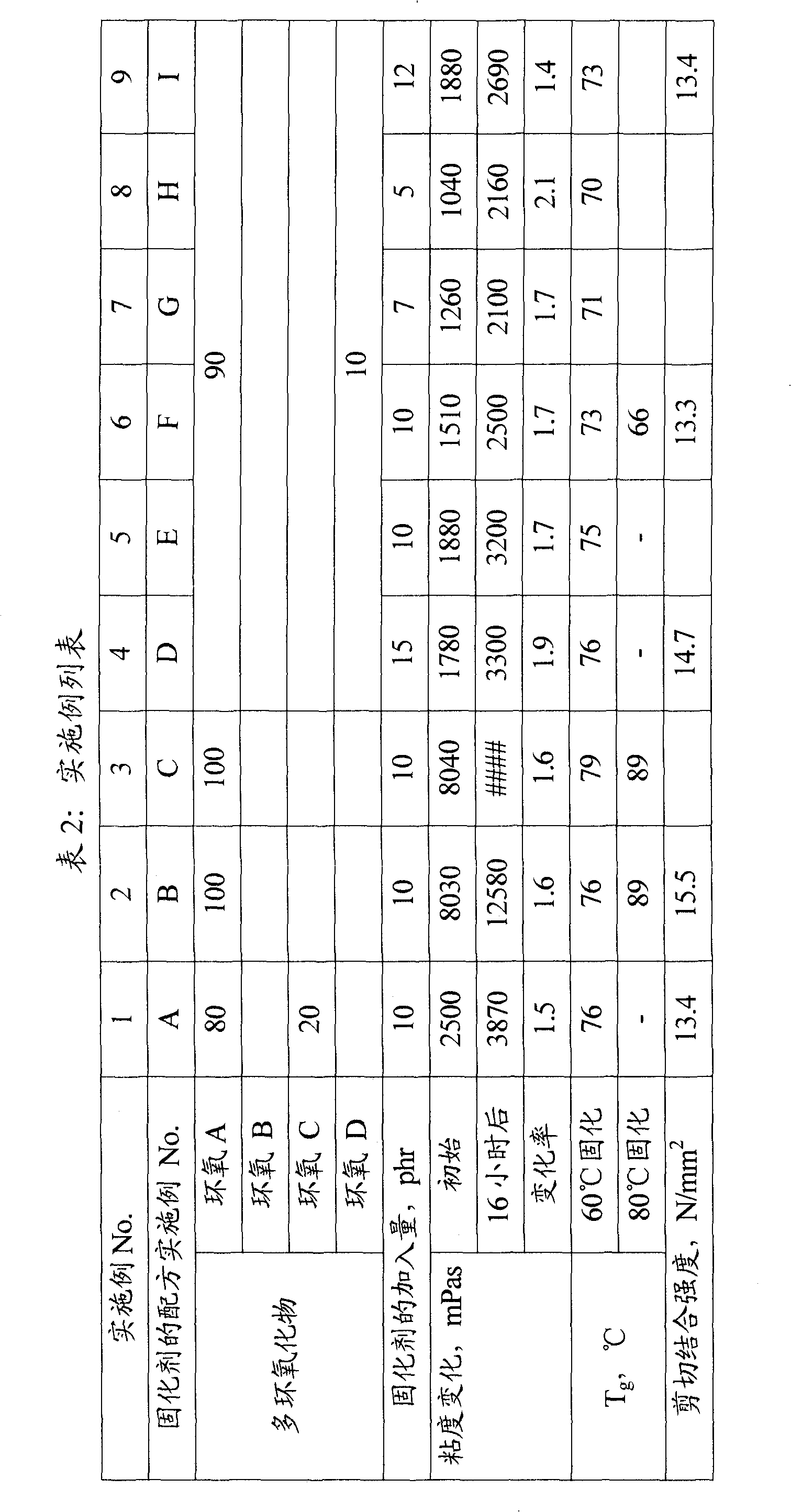

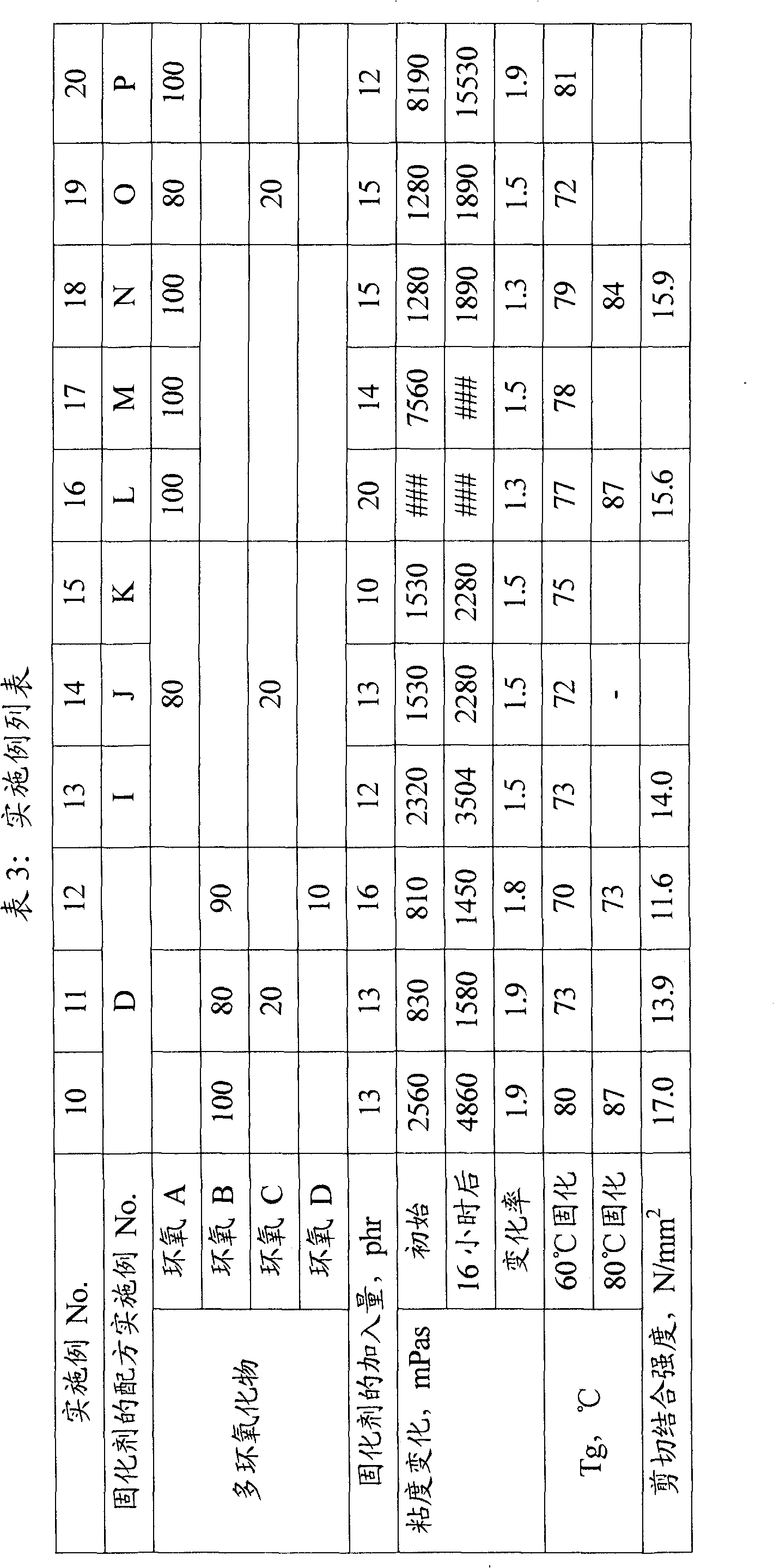

Epoxide-based composition

An epoxide-based composition comprising a combination of an epoxide and a curing agent, wherein the epoxide is selected from a phenyl glycidyl ether-based polyepoxide and the curing agent is a salt compound composed of a N-alkanol piperidine and a carboxylic acid.

Owner:AIR PROD & CHEM INC

Pre-molten slag for smelting electroslag remelting continuous directional solidification high-temperature alloy ingot and application thereof

InactiveCN111172403AIncreased high temperature plasticity and strengthGuaranteed viscosity and fluidityDirectional solidificationMolten slag

The invention discloses a pre-molten slag for smelting an electroslag remelting continuous directional solidification high-temperature alloy ingot and application thereof. The pre-molten slag comprises, by weight, 50%-60% of CaF2, 15%-25% of Al2O3, 15%-25% of CaO, 1%-5% of MgO, 0.5%-5% of TiO2, 0.5%-5% of ZrO2 and the balance impurities. The pre-molten slag is applied to high-temperature alloy ingot smelting by adopting an electroslag remelting continuous directional solidification technology. An application method comprises the following steps that the pre-molten slag is baked; the pre-moltenslag is fully molten through a slag melting furnace; and the molten pre-molten slag is transferred into a crystallizer of an electroslag remelting continuous directional solidification device, consumable electrodes are inserted into the crystallizer for smelting, and the high-temperature alloy ingot is obtained. According to the pre-molten slag for smelting the electroslag remelting continuous directional solidification high-temperature alloy ingot and application thereof, the pre-molten slag can effectively control active element burning losses, ensure the chemical component uniformity and especially inhibit the burning losses of titanium and zirconium and can ensure electroslag remelting continuous conducting, the pre-molten slag is applied to smelting of the high-temperature alloy ingot, the ingot obtained by adopting the method is uniform in axial component, and the surface quality of the ingot is improved.

Owner:BEIJING CISRI GAONA TECH +1

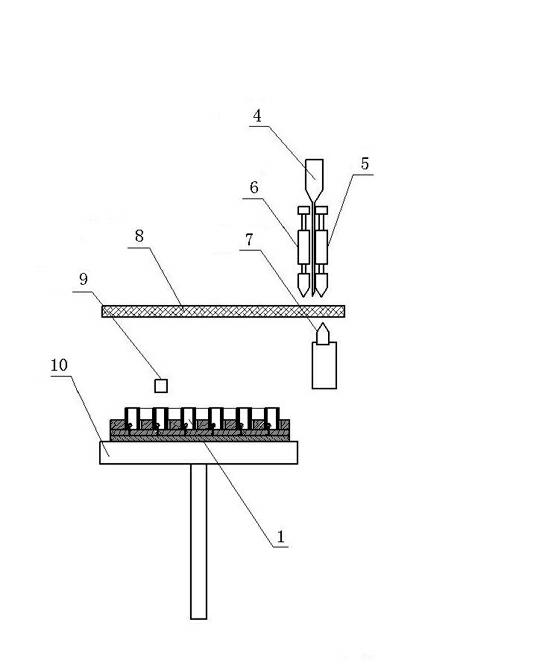

Automatic plane screen paste printing technology for metalizing ceramic discharge tube

ActiveCN102490454AUniform thicknessImprove consistencyScreen printersOther printing apparatusMetallurgySieve

The invention discloses an automatic plane screen paste printing technology for metalizing a ceramic discharge tube. Apart from a paste preparation step, the technology also comprises the following steps of: 1) fixing a ceramic piece; 2) mounting a stainless steel sieve, wherein the screen mesh of the stainless steel sieve is 100, and tension is about 300+ / -20 N / cm<2>; 3) adjusting a doctor blade, an objective table and a leakage blade; 4) uniformly distributing the paste; and 5) printing the paste. Through the invention, the metallized paste layer has uniform thickness, good consistency and smooth surface; the technology adopts automatic operation and has high paste coating efficiency; and the process is easy to control, and the quality is easy to guarantee.

Owner:XIAOGAN HANDA ELECTRONICS COMPONENT

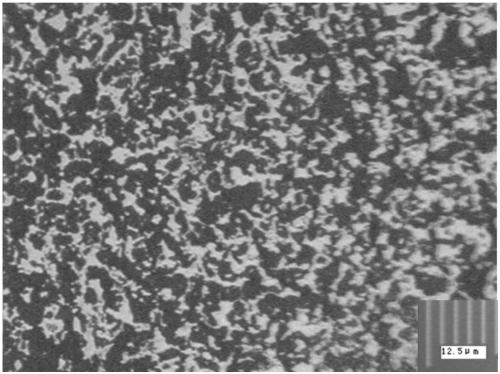

Method for preparing high-strength boron carbide porous ceramics

The invention discloses a method for preparing high-strength boron carbide porous ceramics. The method comprises the following steps: (1) proportioning raw materials: 80-95wt% of boron carbide powder,0-3.0wt% of suspending agent, 3-15wt% of binder, 5-12wt% of sintering assistant and 0-12wt% of lubricant; (2) adding distilled water into the raw materials, and carrying out mixing in a ball mill orstirring mill, so as to obtain boron carbide slurry, wherein boron carbide granules 1# and boron carbide granules 2# in the boron carbide slurry are uniformly distributed and suspended; (3) subjectingthe boron carbide slurry to spraying granulation, and carrying out drying, so as to obtain boron carbide powder with fluidity; (4) molding the boron carbide powder, so as to obtain boron carbide biscuits; and (5) placing the boron carbide biscuits into a vacuum or atmosphere no-pressure sintering furnace. According to the method, the weak points that the quantity of sealed pores is large, a ceramic matrix is complicated in ingredient, the strength is low, and the like can be overcome, and boron carbide can have more extensive application.

Owner:NINGBO VULCAN TECH CO LTD

Production method for preparing low-substituted cellulose acetate

InactiveCN106317229AReduce product substitutionGuaranteed viscosityDrug coatingBiocompatibility Testing

The invention discloses a production method for preparing low-substituted cellulose acetate, comprising the main steps of (1) pretreating raw materials; (2) esterifying; (3) hydrolyzing; (4), neutralizing; (5) precipitating filtrate; (6) washing and drying. By modifying existing cellulose acetate production technology and optimizing based on heterogeneous process, the method for preparing high-viscosity low-substituted cellulose acetate is implemented; the low-substituted cellulose acetate prepared by the method has well lyophilic, is soluble in dilute acid solution, acetone and water mixture, is good in degradability and biocompatibility, and may serve as a good drug coating material, a drug auxiliary material and a drug taste covering material to the field of medicine.

Owner:SICHUAN NITROCELLULOSE CORP

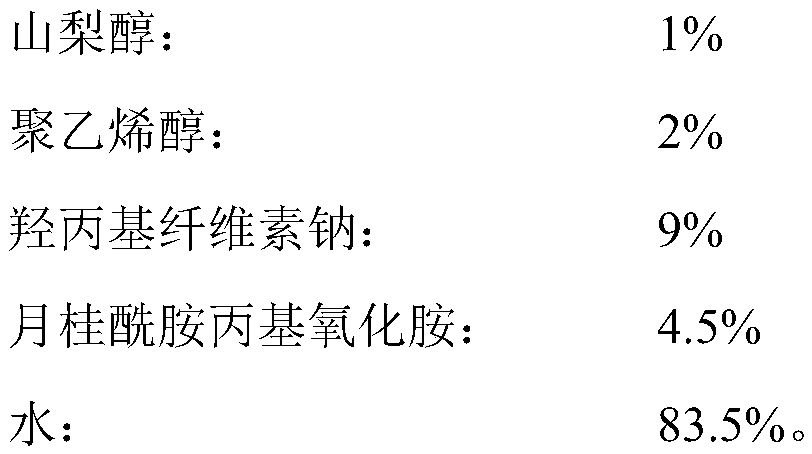

Bonding type dust suppressant for road dust and preparation method of bonding type dust suppressant

ActiveCN111100600AExcellent wetting typePromote degradationOther chemical processesPolyvinyl alcoholAdhesive

The invention aims to solve the problem of poor wettability of a bonding type dust suppressant, provides a bonding type dust suppressant for road dust and a preparation method of the bonding type dustsuppressant, and belongs to the technical field of dust suppressants. The bonding type dust suppressant is prepared from the following raw material components in percentage by mass: 0.1-1% of a humectant, 2-5% of polyvinyl alcohol, 0.5-9% of adhesive, 0.5-4.5% of a surfactant and the balance of water. The dust suppressant is environment-friendly in component, good in wettability and small in loss, and the dust suppression effect reaches 90% or above.

Owner:ANSTEEL GRP MINING CO LTD

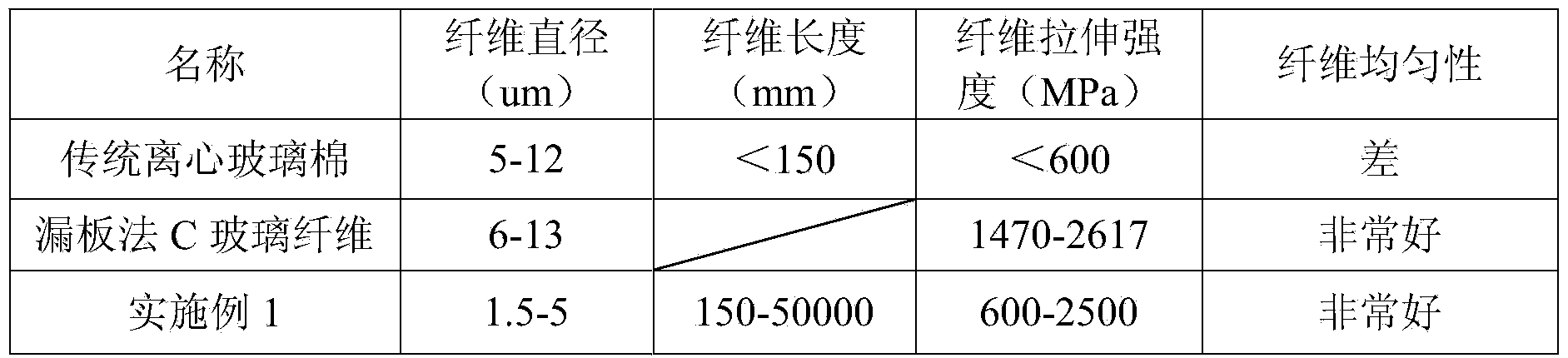

Continuous ultrafine glass fibre and centrifugation manufacturing method thereof

The invention discloses continuous ultrafine glass fibre. The glass fibre comprises following components by weight: 60-67 parts of SiO2, 2-6 parts of Al2O3, 3-7 parts of CaO, 1.5-4.5 parts of MgO, 0.1-2 parts of K2O, 14-18 parts of Na2O and 3-8 parts of B2O3. The diameter of the glass fibre is 1-5 [mu]m and the length of the glass fiber is 150-50000 mm. A method of manufacturing the continuous ultrafine glass fibre includes: selecting a certain amount of borax, quartz sand, potassium feldspar powder, albite powder, dolomite, sodium carbonate and calcite, mixing and smelting to obtain a glass liquid; feeding the glass liquid into a centrifugation disk having a revolving speed of 3800-4500 r / min and centrifuging to form glass trickle; and finally jetting and blowing to stretch the glass trickle by utilization of high-temperature fuel gas to form a finished product of the glass fibre. The diameter of the glass fibre is 1-5 [mu]m and the length of the glass fiber is 150-50000 mm. The glass fiber is high in strength.

Owner:宣汉正原微玻纤有限公司

Anti-edge-warping coil material laying device

InactiveCN108756091AImprove laying efficiencyGuarantee the construction qualityRoof covering using flexible materialsRoof toolsVehicle frameAdhesive

The invention discloses an anti-edge-warping coil material laying device which comprises a vehicle frame, a coiled material suspending frame, a compacting roller and gluing rollers, wherein a drivingwheel is arranged at one end of the bottom of the vehicle frame; the coiled material suspending frame is horizontally arranged on the vehicle frame and used for storing a coiled material to be laid; the compacting roller is horizontally arranged at the other end of the vehicle frame; the gluing rollers are arranged behind the compacting roller side by side, and a coiled material inlet gap is reserved between the compacting roller and the corresponding gluing roller; and gluing holes are evenly distributed in the surface of each gluing roller, and adhesives are arranged inside the gluing rollers. A coiled material is pulled out from the suspending frame and enters the coiled material inlet gap between the gluing roller and the compacting roller after passing the upper portions of the gluingrollers, and the gluing rollers are used for smearing the adhesives on the lower surface of the coiled material and a construction surface; and the coiled material is compacted on the construction surface through the compacting roller, the driving wheel drives the whole vehicle frame to move in the laying direction of the coiled material, the laying efficiency is improved, and the construction quality is guaranteed.

Owner:芜湖市星龙防水保温材料有限公司

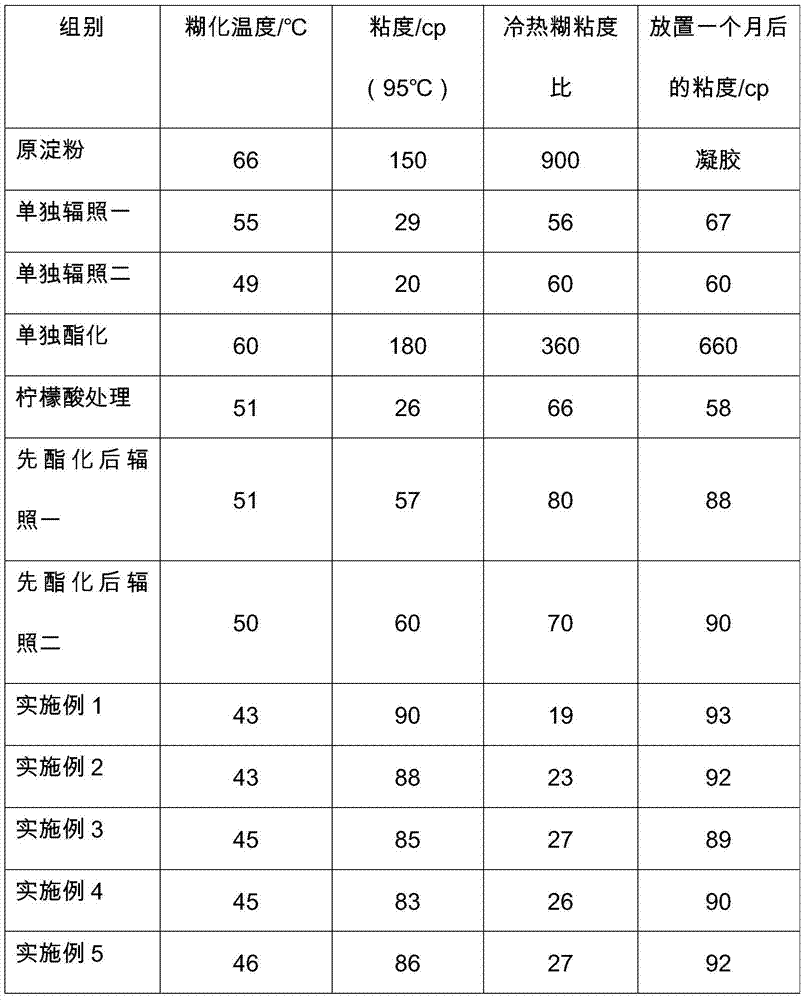

Preparation method of irradiation and chemistry co-modified starch

The invention relates to a preparation method of an irradiation and chemistry co-modified starch. The preparation method comprises the following steps: irradiating starch by 60 Co gamma rays, and then subjecting the irradiation modified starch to a chemical esterification treatment so as to obtain the irradiation and chemistry co-modified starch. The obtained starch has the characteristics of low gelatinization temperature and strong bonding force, the stability of paste liquid (6%) is good, the viscosity of paste liquid barely changes, the starch is suitable for being used as an adhesive for spraying between layers during the production process of paper and paperboard, the starch has a good bonding force at a low drying temperature, and the drying cost is reduced. At the same time, due to the low primary gelatinization temperature, the peeling strength between the starch and paper or paper machine is reduced, and the phenomenon that the starch is adhered on the cylinder is reduced.

Owner:广西农垦明阳生化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com