High-temperature resistant water spray coating polyurea flexible composition, preparation, construction method and uses thereof

A composition and high-temperature-resistant technology, applied in polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve the problems of limited application range, poor high-temperature water resistance, etc., to enhance mechanical properties and improve high-temperature water resistance , Improve the effect of mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Several typical examples are given below, but the present invention is not limited to the following examples.

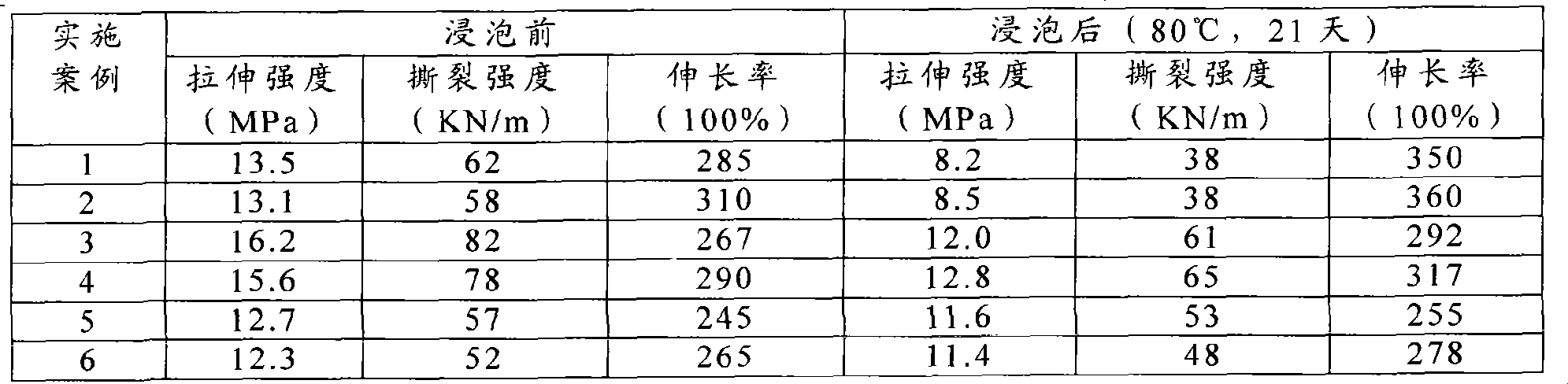

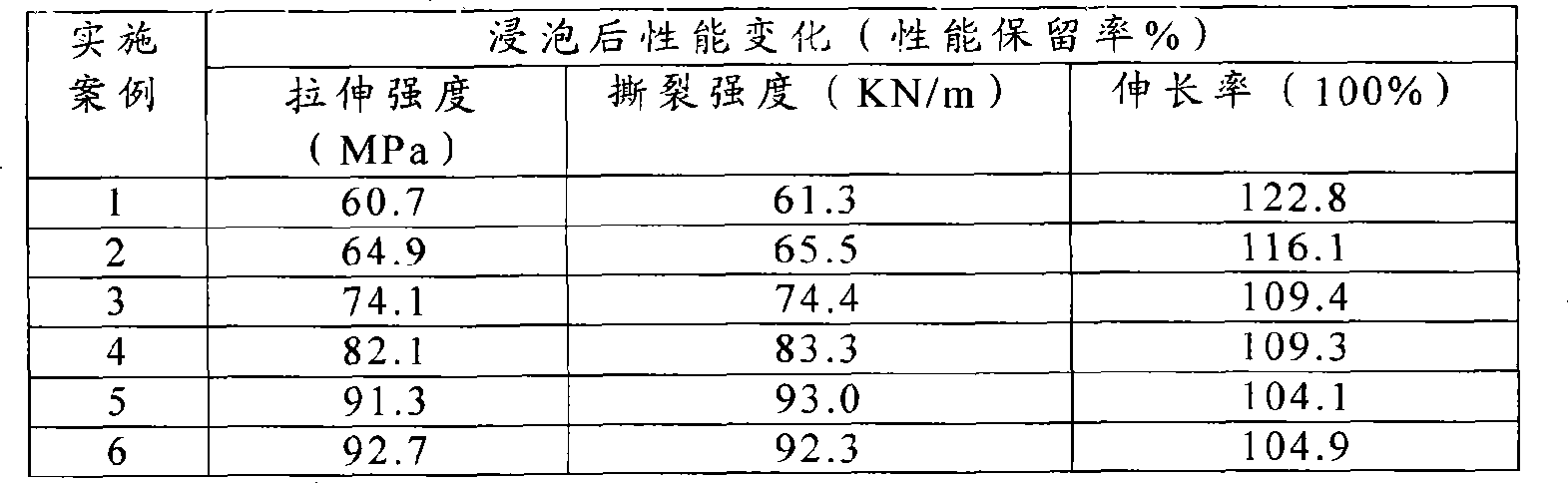

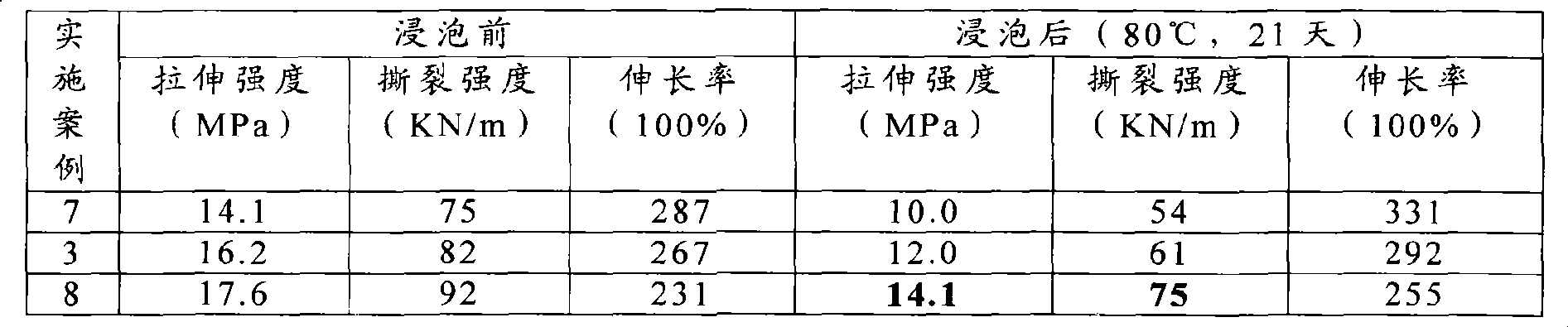

[0042] According to the method specified in GB / T 1690-1992, soak the polyurea coating in water at 80°C for 21 days, take out the sample, place it at room temperature for 30 minutes, wipe off the liquid on the surface of the sample with filter paper, and perform mechanical tests on the sample. Performance Testing.

[0043] Take the average value of three samples as the measurement result.

[0044] The mass units of various substances in the following examples are Kg; MDI-50 wherein is 50% 4,4'-diphenylmethane diisocyanate and 50% 2,4'-diphenyl Composition of methyl methane diisocyanate.

[0045] Example 1:

[0046] Synthesize 54.5 parts of MDI-50 and 45.5 parts of polyoxypropylene ether glycol 210 according to the process of the present invention to obtain a prepolymer with an NCO% of 14.5%, which is component A. The R component is composed of 10 parts of J...

Embodiment 2

[0048] Synthesize 49.5 parts of MDI-50 and 50.5 parts of polyoxypropylene ether glycol 220 according to the process of the present invention to obtain a prepolymer with an NCO% of 14.5%, which is component A. The R component is composed of 10 parts of JEFFAMINE T-5000, 64 parts of JEFFAMINE D-2000, 25 parts of diethyltoluenediamine (DETDA), 0.5 part of Irganox 1076 and 0.5 part of Tinuvin 328, and the ratio of A and R components is 1: 1 (volume ratio), spray to form polyurea flexible material.

Embodiment 3

[0050] Synthesize 54.5 parts of MDI-50 and 45.5 parts of polytetrahydrofuran polyol PolyTHF1000 according to the process of the present invention to obtain a prepolymer with an NCO% of 14.5%, which is component A. The R component is composed of 10 parts of JEFFAMINET-5000, 64 parts of JEFFAMINE D-2000, 25 parts of diethyltoluenediamine (DETDA), 0.5 part of Irganox1076 and 0.5 part of Tinuvin 328, A and R components are 1:1 ( volume ratio), spraying to form polyurea flexible material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com